Insights into the Effect of Confinement on Swirling Flow by PIV

Abstract

1. Introduction

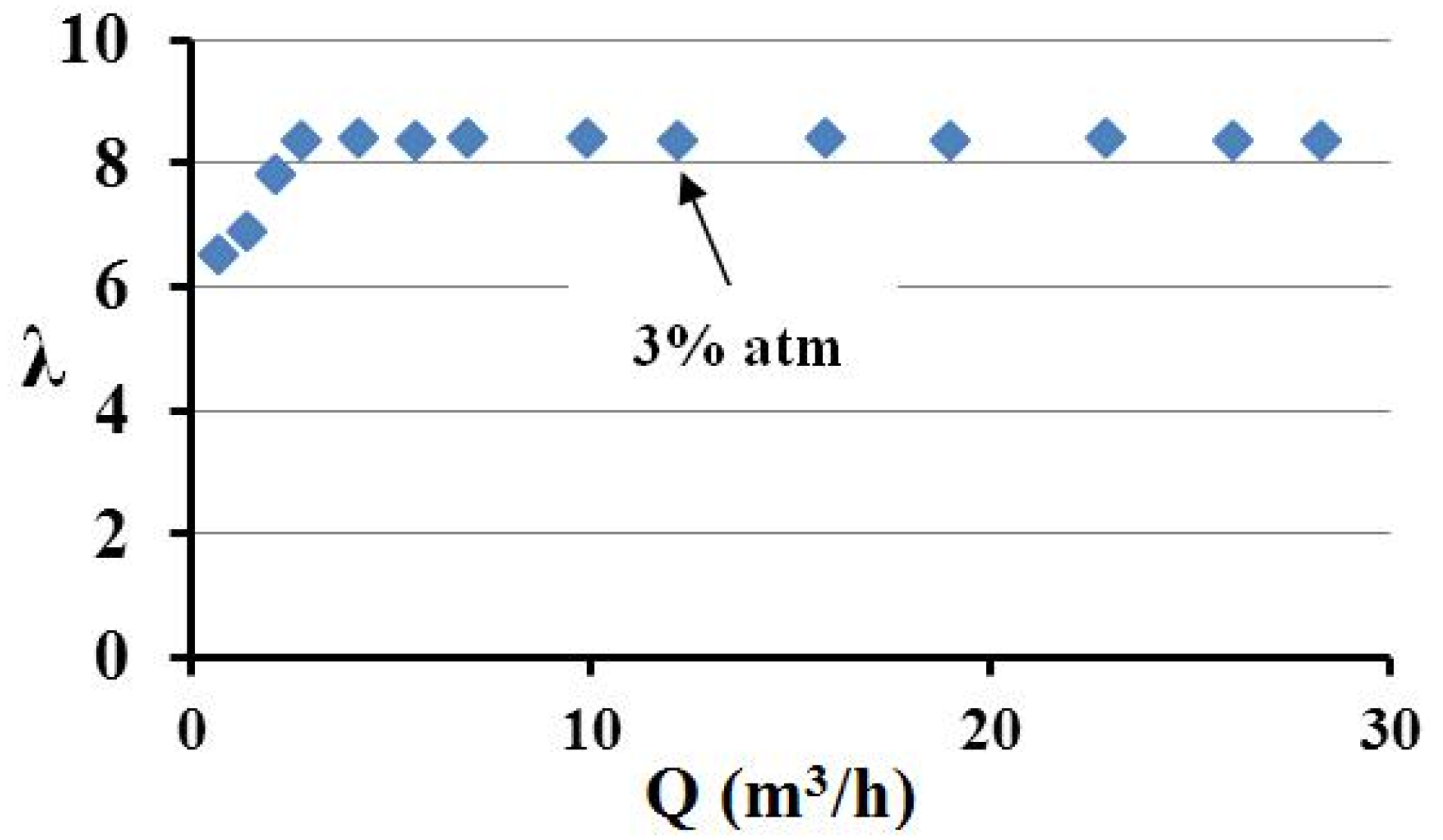

2. Experimental Setup

3. Results and Discussion

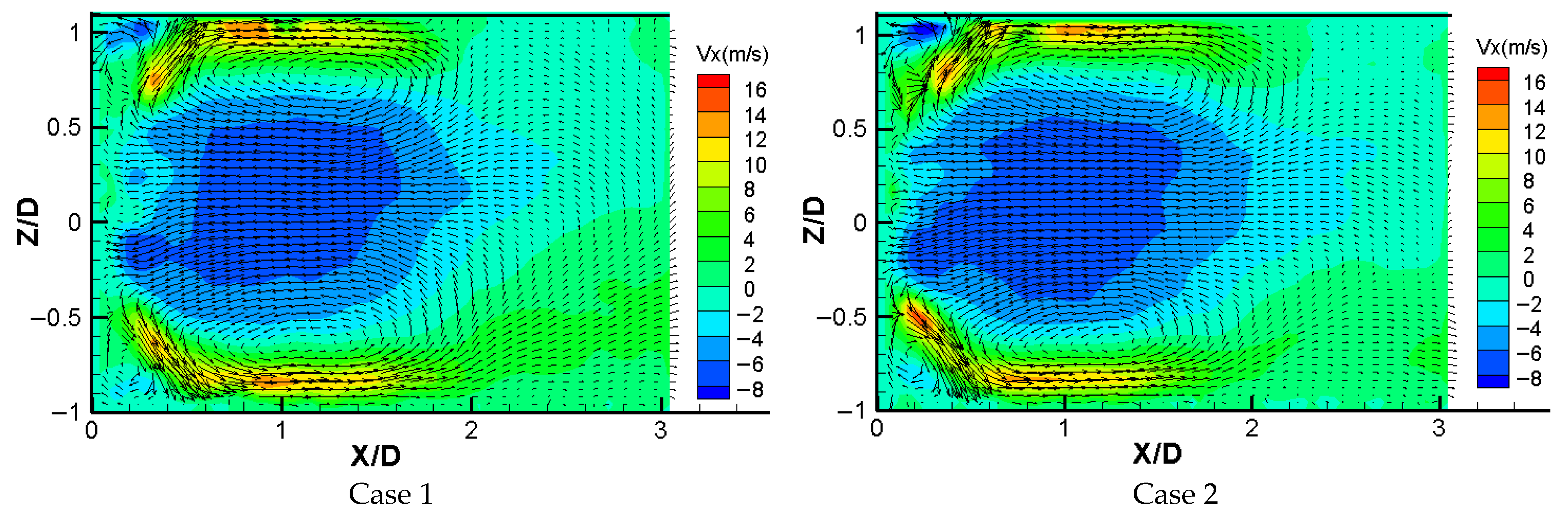

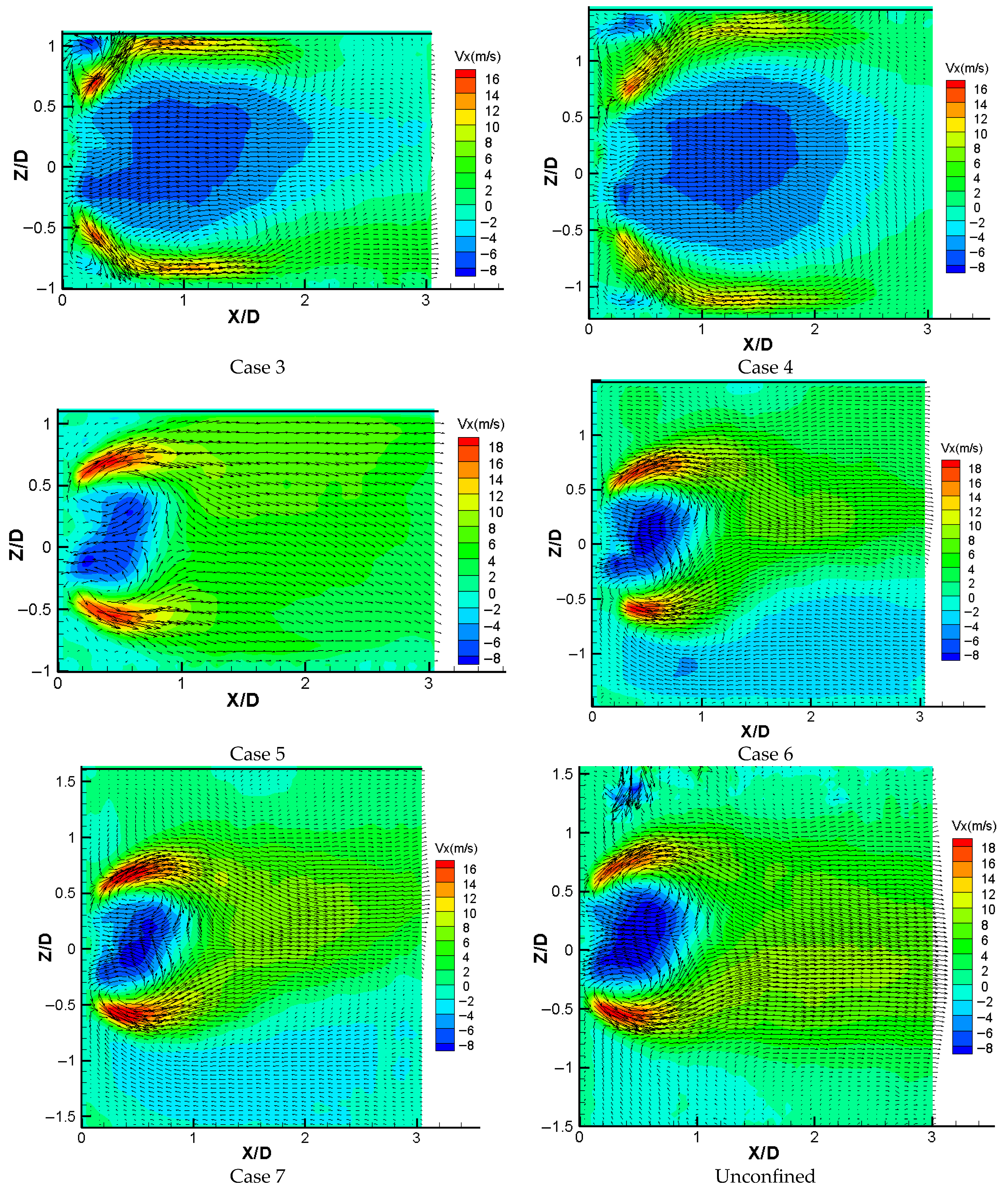

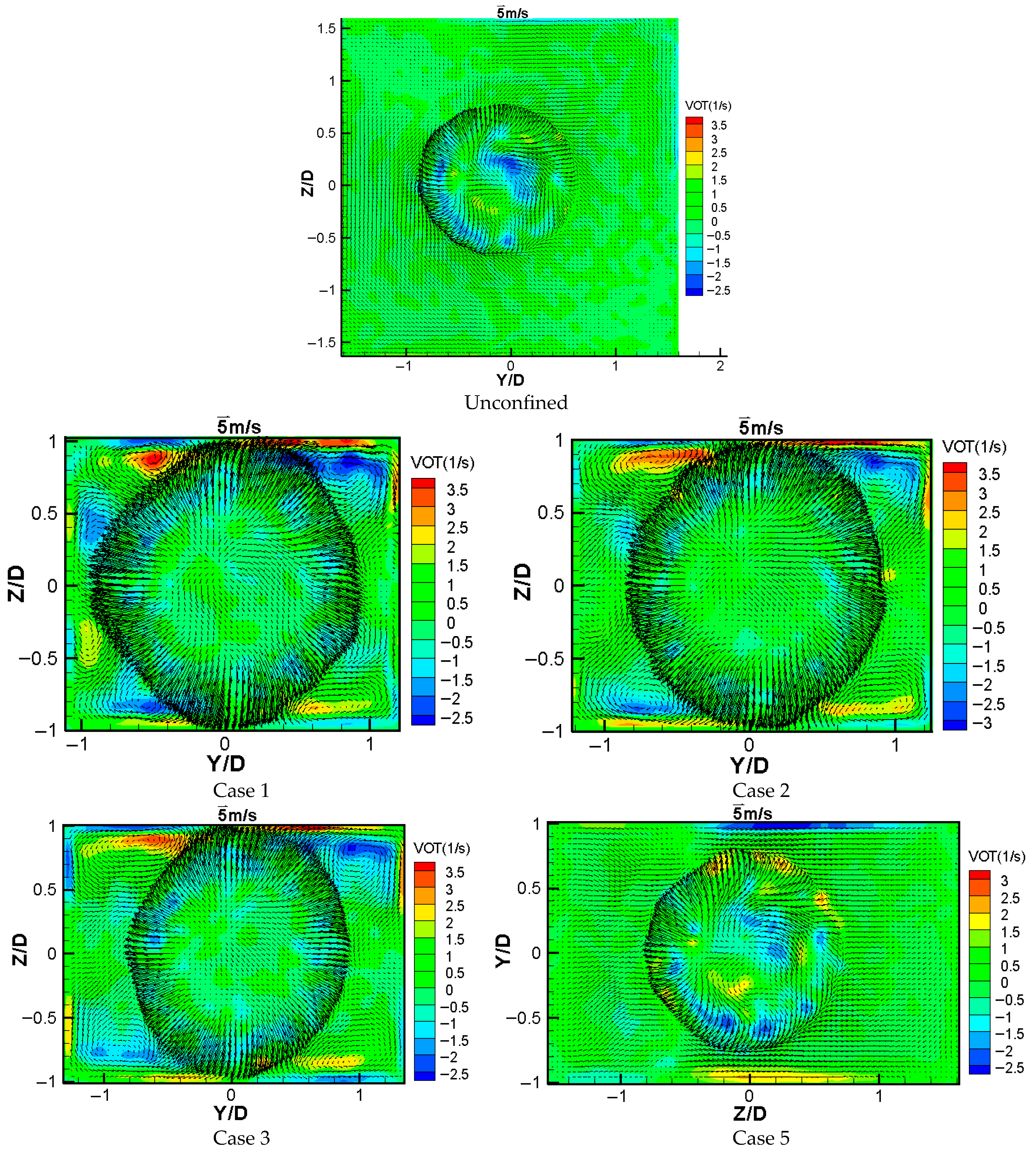

3.1. Axial Velocity Contour

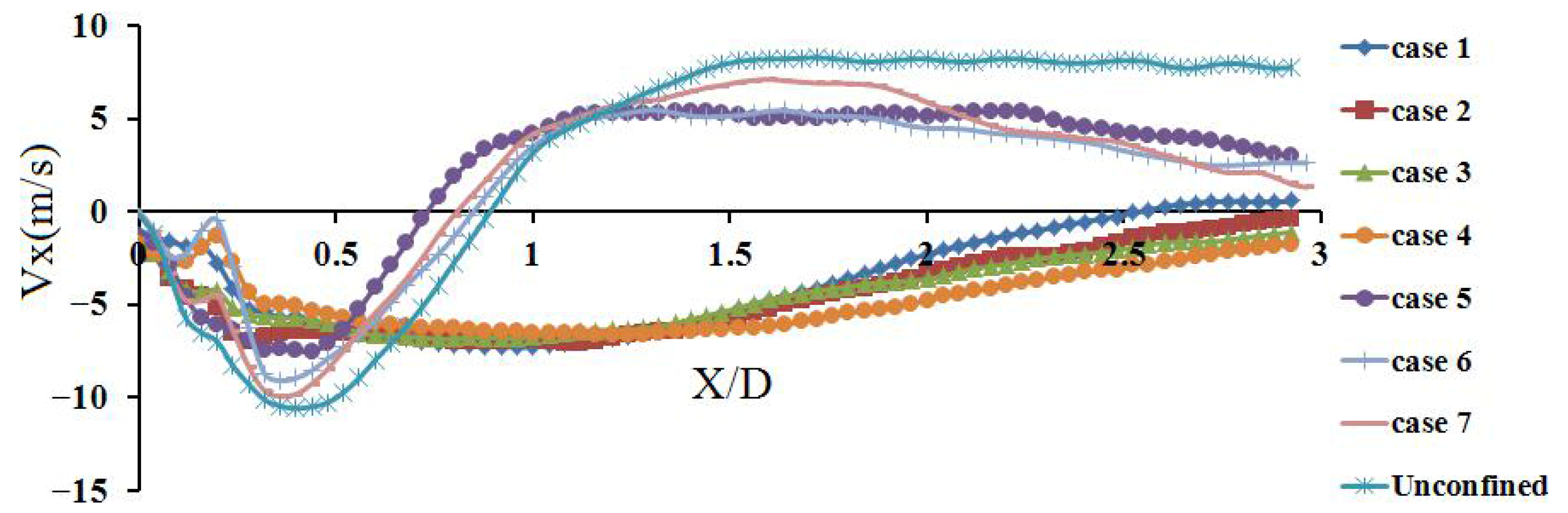

3.2. Centerline Axial Velocity Distribution

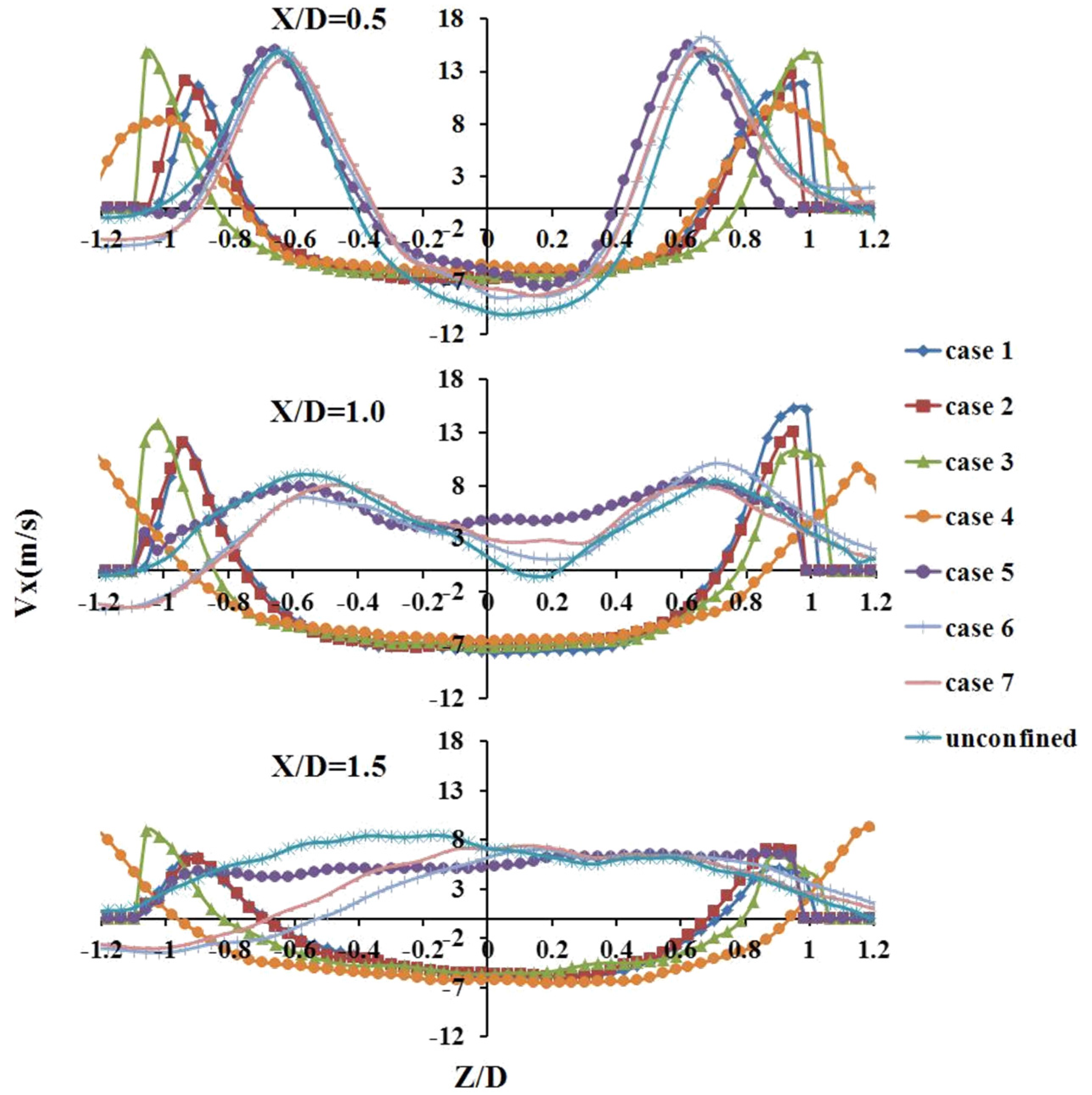

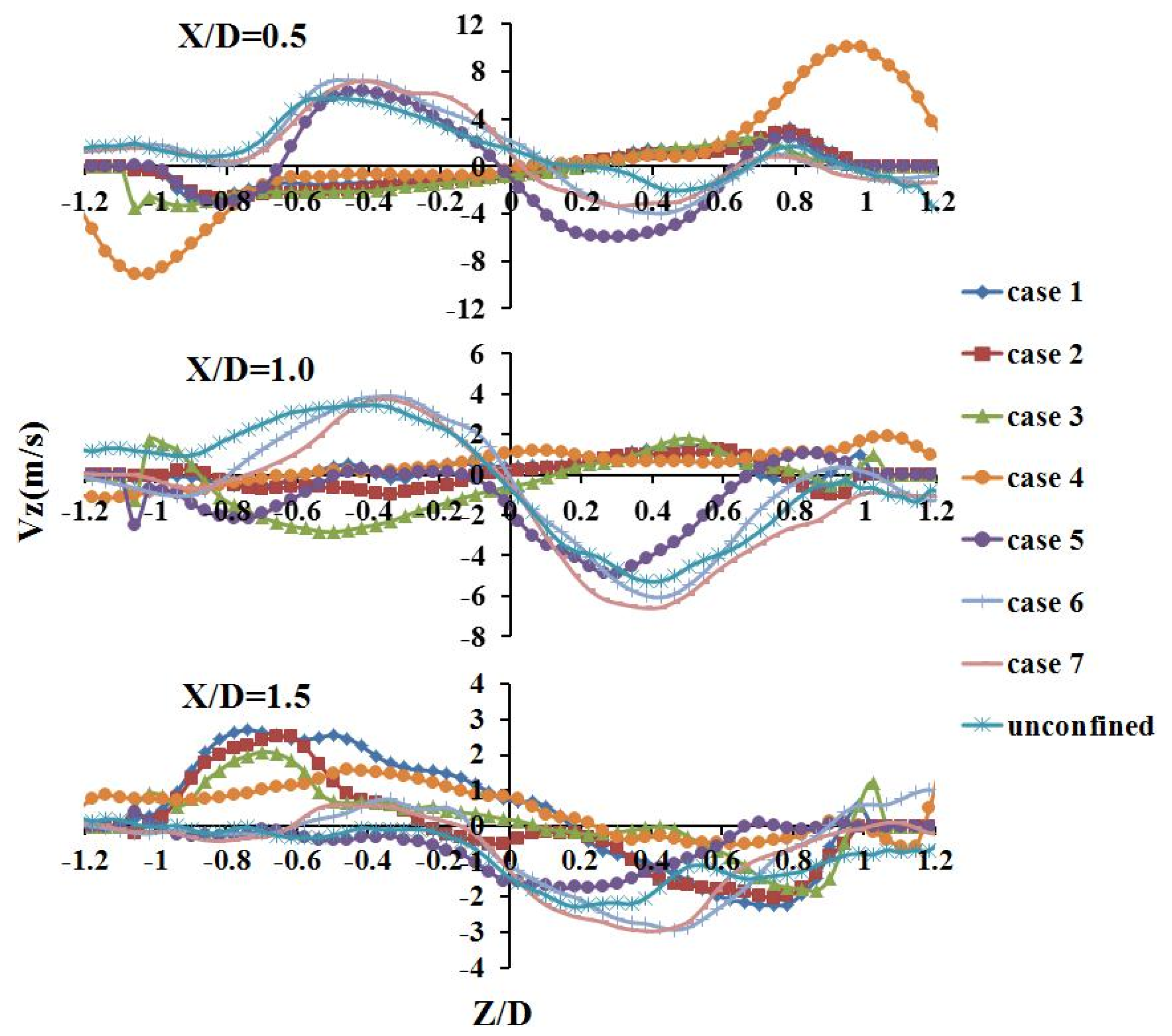

3.3. Velocity Distribution

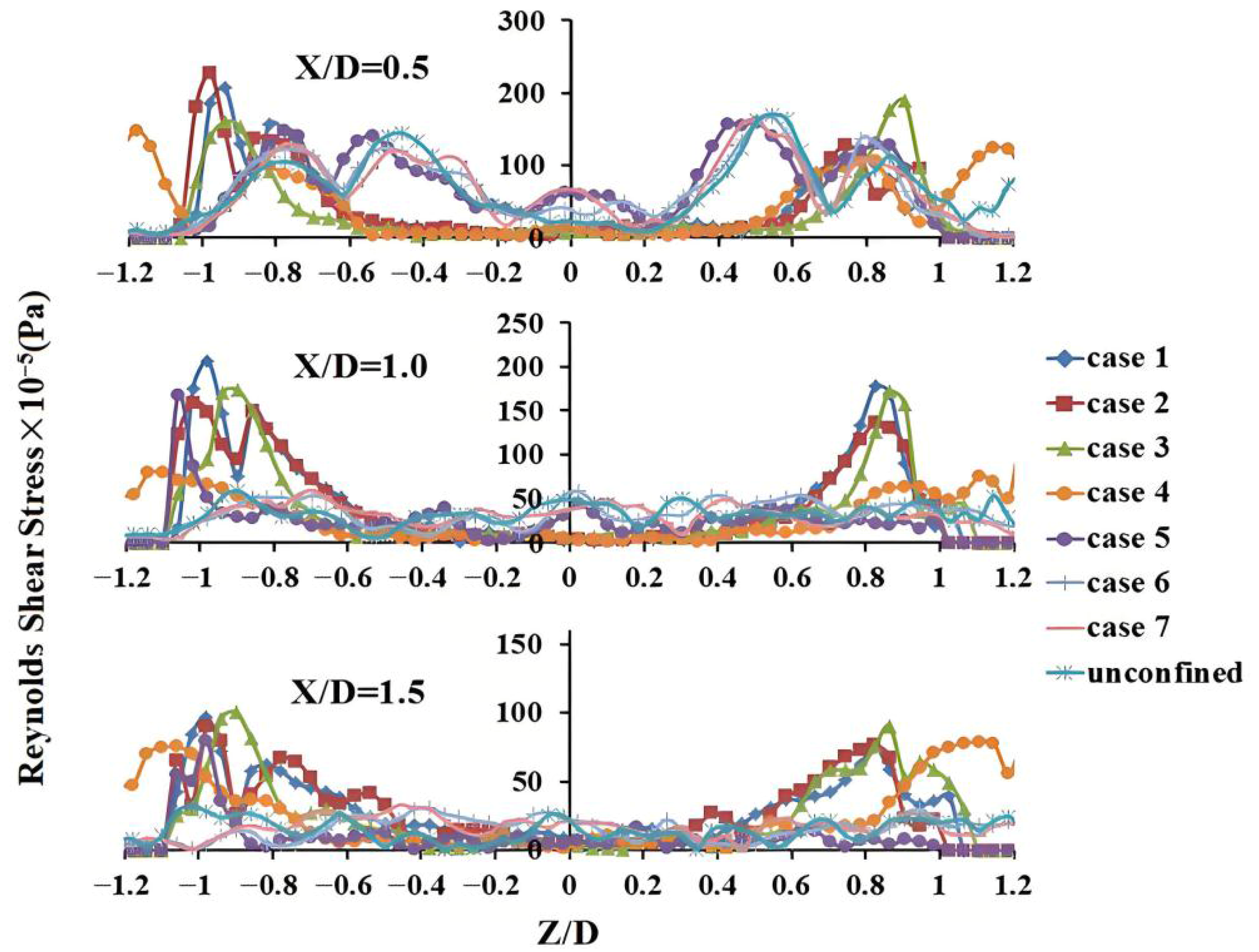

3.4. Reynolds Shear Stress Distribution

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Beer, J.M.; Chigier, N.A. Combustion Aerodynamics; Applied Science Publisher Ltd.: London, UK, 1972. [Google Scholar]

- Mongia, H.; Al-Roub, M.; Danis, A.; Elliott-Lewis, D.; Johnson, A.; Vise, S.; Jeng, S.-M.; McDonell, V.; Samuelsen, G. Swirl cup modeling. I. In Proceedings of the 37th Joint Propulsion Conference and Exhibit, Salt Lake City, UT, USA, 8–11 July 2001. [Google Scholar]

- Ahmed, S.A.; Nejad, A.S. Velocity measurements in a research combustor part 1: Isothermal swirling flow. Exp. Therm. Fluid Sci. 1992, 5, 162–174. [Google Scholar] [CrossRef]

- Thundil Karuppa Raj, R.; Ganesan, V. Study on the effect of various parameters on flow development behind vane swirlers. Int. J. Therm. Sci. 2008, 47, 1204–1225. [Google Scholar] [CrossRef]

- Yadav, N.P.; Kushari, A. Effect of swirl on the turbulent behaviour of a dump combustor flow. J. Aerosp. Eng. 2010, 224, 705–717. [Google Scholar] [CrossRef]

- Wu, Y.; Carlsson, C.; Szasz, R.; Peng, L.; Fuchs, L.; Bai, X.S. Effect of geometrical contraction on vortex breakdown of swirling turbulent flow in a model combustor. Fuel 2016, 170, 210–225. [Google Scholar] [CrossRef]

- Tang, C.W.; Yao, Q.; Jin, W.; Li, J.Z.; Yan, Y.S.; Yuan, L. Effect of swirler geometry on the outlet temperature profile performance of a model gas turbine combustor. Appl. Therm. Eng. 2025, 260, 124946. [Google Scholar] [CrossRef]

- Chun, B.; Mousavi, S.M.; Lee, J.; Lee, B.J.; Faroughi, S.A. On the effects of fractal geometry on reacting and nonreacting flows in a low-swirl burner: A numerical study with large-eddy simulation. Case Stud. Therm. Eng. 2023, 49, 103385. [Google Scholar] [CrossRef]

- Eldrainy, Y.A.; Saqr, K.M.; Aly, H.S.; Lazim, T.M.; Jaafar, M.N.M. Large eddy simulation and preliminary modeling of the flow downstream a variable geometry swirler for gas turbine combustors. Int. Commun. Heat Mass Transf. 2011, 38, 1104–1109. [Google Scholar] [CrossRef]

- Bourgouin, J.F.; Moec, J.; Durox, D.; Schuller, T.; Candel, S. Sensitivity of swirling flows to small changes in the swirler geometry. Comptes Rendus Mec. 2013, 341, 211–219. [Google Scholar] [CrossRef]

- Cai, J.; Fu, Y.; Flohre, N.M.; Jeng, S.M. Experimental study on coherent structures of a counter-rotating multi-swirler Cup. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cincinnati, OH, USA, 8–11 July 2007. [Google Scholar]

- Kao, Y.H.; Tambe, S.B.; Jeng, S.M. Aerodynamics of linearly arranged rad-rad swirlers, effect of number of swirlers and alignment. In Proceedings of the ASME Turbo Expo 2013, San Antonio, TX, USA, 3–7 June 2013; Volume 1A. [Google Scholar]

- Mondal, S.; Datta, A.; Sarkar, A. Influence of side wall expansion angle and swirl generator on flow pattern in a model combustor calculated with k-ε model. Int. J. Therm. Sci. 2004, 43, 901–914. [Google Scholar] [CrossRef]

- Huo, W.; Lin, Y.; Zhang, C.; Sung, C.J. Effect of boundary conditions on downstream vorticity from counter-rotating swirlers. Chin. J. Aeronaut. 2015, 28, 34–43. [Google Scholar] [CrossRef]

- Wang, D.; Huang, Y.; Zhang, H. Spray characteristics of different regions downstream of a swirl cup. Chin. J. Aeronaut. 2024, 37, 124–143. [Google Scholar] [CrossRef]

- Li, T.; Wu, Y.; Wang, Y.; Song, G.; Cui, J.; Gao, Q.; Wang, G.; Wu, X. POD and DMD analysis of dynamic flow structures in the recirculation region of an unconfined swirl cup. Exp. Therm. Fluid Sci. 2025, 160, 111306. [Google Scholar]

- Beltagui, S.A.; Maccallum, N.R.L. Aerodynamics of Vane-Swirled Flames in Furnaces. J. Inst. Fuel 1976, 49, 183–193. [Google Scholar]

- Beltagui, S.A.; Maccallum, N.R.L. Aerodynamics of Swirling Flames-Vane Generated Type. In Proceedings of the 1st European Symposium on Combustion, Sheffield, UK, 16–21 September 1973; pp. 559–564. [Google Scholar]

- Herff, S.; Pausch, K.; Loosen, S.; Schroder, W. Impact of non-sysmmetric confinement on the flame dynamics of a lean-premixed swirl flame. Combust. Flame 2022, 235, 111701. [Google Scholar]

- Khalil, A.E.E.; Brooks, J.M.; Gupta, A.K. Impact of confinement on flowfield of swirl flow burners. Fuel 2016, 184, 1–9. [Google Scholar] [CrossRef]

- Archer, S.; Gupta, A. The role of confinement on flow dynamics under fuel lean combustion conditions. In Proceedings of the 2nd International Energy Conversion Engineering Conference, Providence, RI, USA, 19 August 2004. [Google Scholar]

- Archer, S. Morphology of Unconfined and Confined Swirling Flows Under Non-Reacting and Combustion Conditions. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2005. [Google Scholar]

- Santhosh, R.; Pattanshetti, A.; Yadav, R. Confinement effect on recirculation structures in isothermal coaxial swirling jet. Exp. Therm. Fluid Sci. 2024, 155, 111208. [Google Scholar] [CrossRef]

- Nogenmyr, K.J.; Cao, H.J.; Chan, C.K.; Cheng, R.K. Effect of confinement on premixed turbulent swirling flame useing large eddy simulation. Combust. Theory Model 2013, 17, 1003–1019. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, L.; Shang, M.; Li, J.; Rinoshika, A. Tomographic particle image velocimetry measurement on three-dimensional swirling flow in dual-stage counter-rotating swirler. Chin. J. Aeronaut. 2024, 37, 7–20. [Google Scholar] [CrossRef]

- Cai, J.; Fu, Y.; Elkady, A.; Jeng, S.; Mongia, H. Swirl cup modeling part 4: Effect of confinement on flow characteristics. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 2003. [Google Scholar]

- Fu, Y.; Cai, J.; Jeng, S.M.; Mongia, H. Characteristics of the swirling flow generated by a counter-rotating swirler. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cincinnati, OH, USA, 8–11 July 2007. [Google Scholar]

- Fu, Y.; Jeng, S.M.; Tacina, R. Confinement effects on the swirling flow generated by a helical axial swirler. In Proceedings of the 44th AIAA Aerospace Sciences Meeting &Exhibit, Reno, NV, USA, 9–12 January 2006. [Google Scholar]

- Fujisawa, N.; Yamagata, T.; Abe, A.; Maxey, M.R. Characterization of swirling-flow behavior in complex pipeline using bubble trajectory method with stereo particle tracking/image velocimetry. Flow Meas. Instrum. 2022, 85, 102159. [Google Scholar] [CrossRef]

- Tang, C.; Li, J.; Feng, J.; Yao, Q.; Yuan, L.; Jin, W. Imaging diagnostics and PIV measurements of flame propagation and flow structure during ignition process in a three-sector RQL combustor. Aerosp. Sci. Technol. 2024, 152, 109361. [Google Scholar] [CrossRef]

- Chen, F.; Liu, H. Particle image velocimetry for combustion measurements: Applications and developments. Chin. J. Aeronaut. 2018, 31, 1407–1427. [Google Scholar] [CrossRef]

- Temme, J.E.; Allison, P.M.; Driscoll, J.F. Combustion instability of a lean premixed prevaporized gas turbine combustor studied using phase-averaged PIV. Combust. Flame 2014, 161, 958–970. [Google Scholar] [CrossRef]

- Gupta, A.K.; Lilley, D.G.; Syred, N. Swirl Flows; Abacus Press: Tunbridge Wells, UK, 1984; p. 475. [Google Scholar]

- Brazhenko, V.; Mochalin, I.; Cai, J. DIY-PIV system for Poiseuille flow investigation in undergraduate fluid mechanics course. Int. J. Mech. Eng. Educ. 2025, 53, 373–390. [Google Scholar] [CrossRef]

- Lefebvre, A.H.; Ballal, D.R. Gas Turbine Combustion: Alternative Fuels and Emissions, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2010; pp. 123–125. [Google Scholar]

| Case | Confinement Ratio | Y/D | Z/D | Y/Z | X/D |

|---|---|---|---|---|---|

| 1 | 5.09 | 2 | 2 | 1 | 3 |

| 2 | 6.37 | 2.5 | 2 | 1.25 | 3 |

| 3 | 7.64 | 3 | 2 | 1.5 | 3 |

| 4 | 7.96 | 2.5 | 2.5 | 1 | 3 |

| 5 | 8.92 | 3.5 | 2 | 1.75 | 3 |

| 6 | 11.46 | 3 | 3 | 1 | 3 |

| 7 | 15.61 | 3.5 | 3.5 | 1 | 3 |

| 8 | Unconfined | / | / | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Zhang, C.; Xue, X.; Zheng, S.; Yao, M. Insights into the Effect of Confinement on Swirling Flow by PIV. Energies 2025, 18, 5155. https://doi.org/10.3390/en18195155

Liu T, Zhang C, Xue X, Zheng S, Yao M. Insights into the Effect of Confinement on Swirling Flow by PIV. Energies. 2025; 18(19):5155. https://doi.org/10.3390/en18195155

Chicago/Turabian StyleLiu, Tao, Chi Zhang, Xin Xue, Shun Zheng, and Muwei Yao. 2025. "Insights into the Effect of Confinement on Swirling Flow by PIV" Energies 18, no. 19: 5155. https://doi.org/10.3390/en18195155

APA StyleLiu, T., Zhang, C., Xue, X., Zheng, S., & Yao, M. (2025). Insights into the Effect of Confinement on Swirling Flow by PIV. Energies, 18(19), 5155. https://doi.org/10.3390/en18195155