Energy-Efficient Induction Heating-Based Deicing System for Railway Turnouts Under Real Snowfall Conditions

Abstract

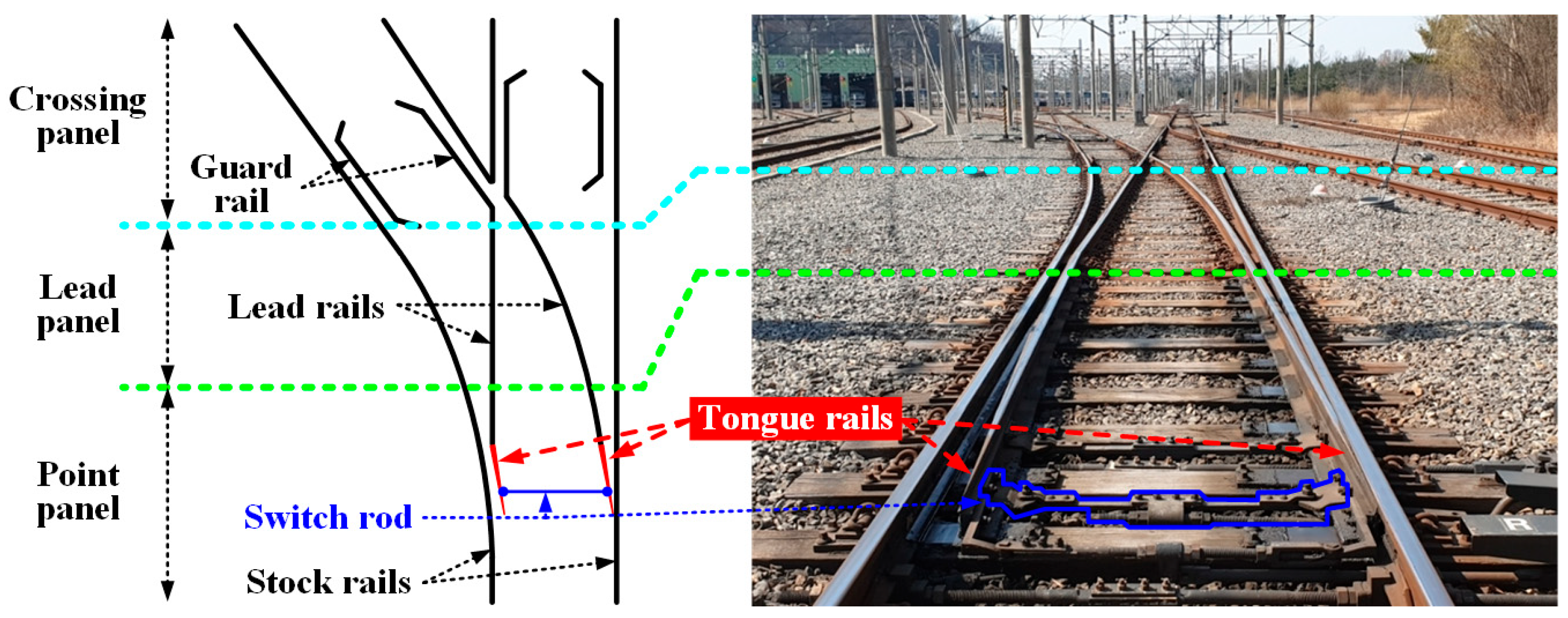

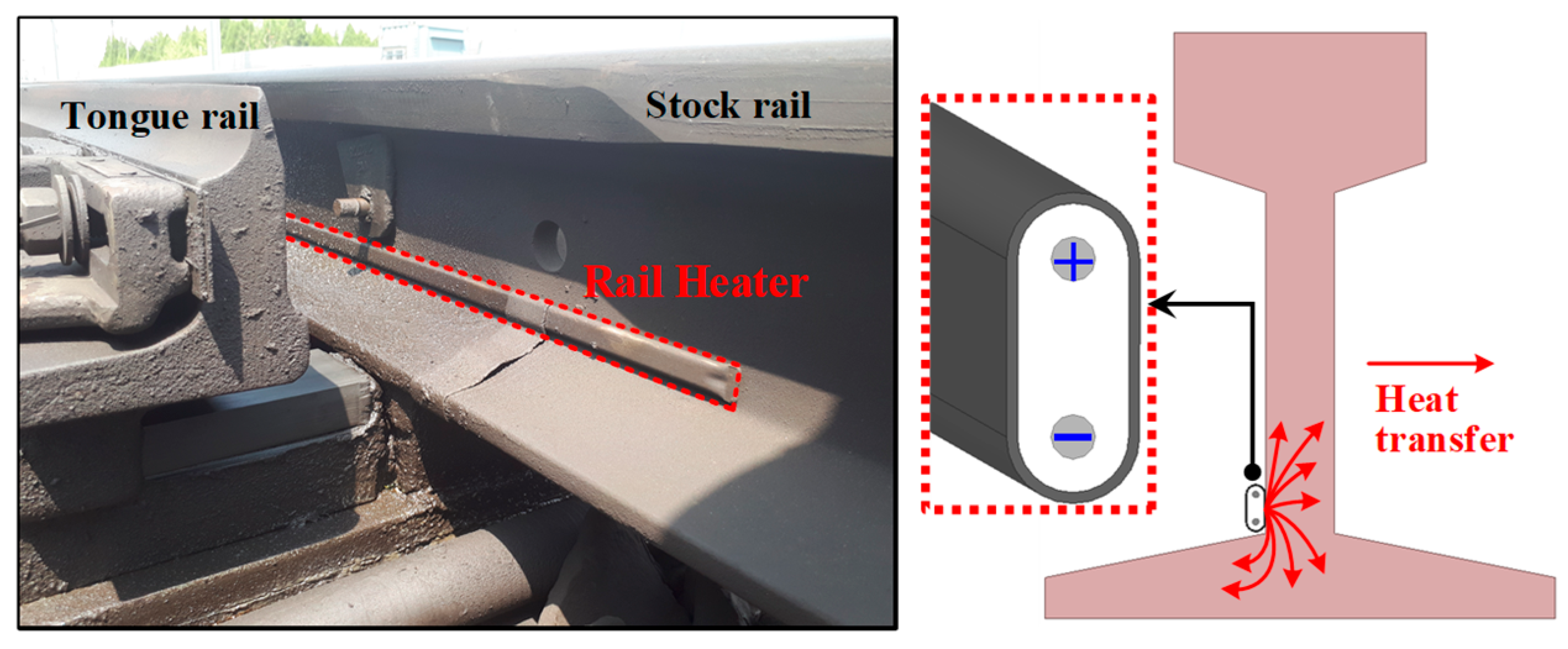

1. Introduction

- Direct replacement of the conventional RH system;

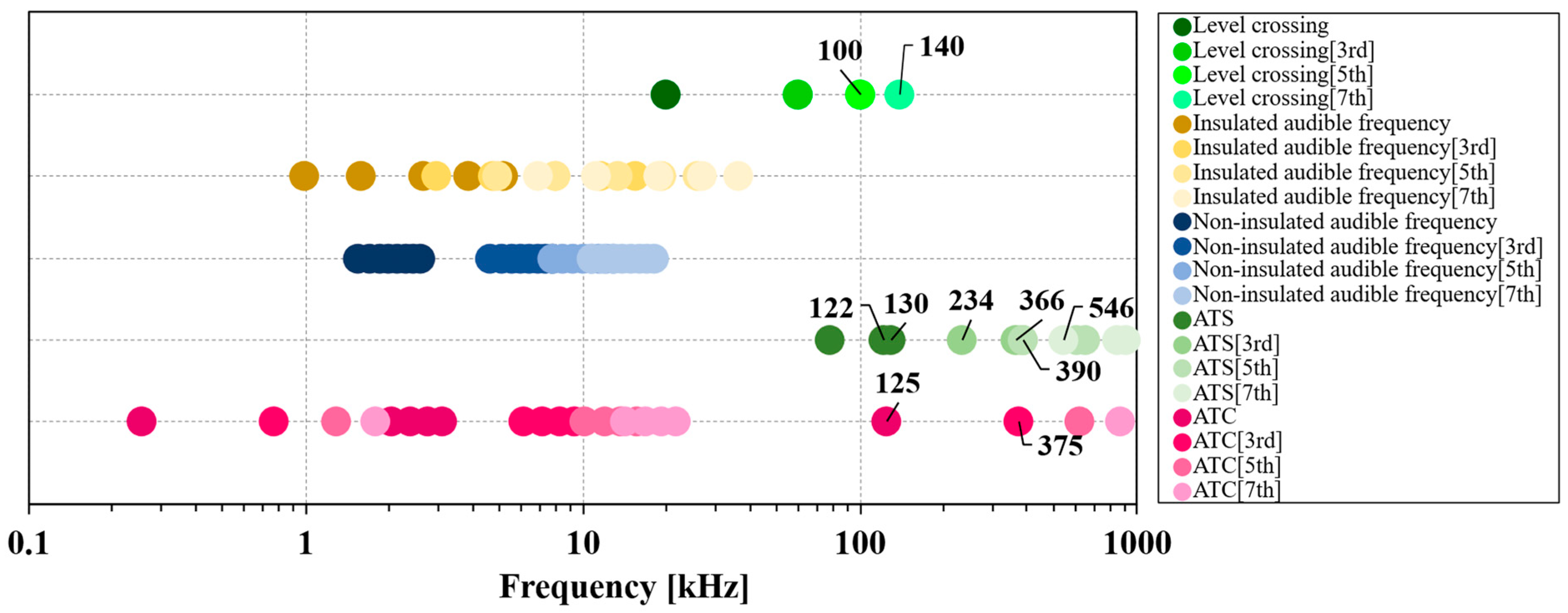

- Design consideration to avoid interference with Korean railway signal system;

- Temperature regulation of the IH coil;

- Experimental validation under an actual snowfall condition;

- Performance comparison with conventional RH systems.

2. Conceptualization

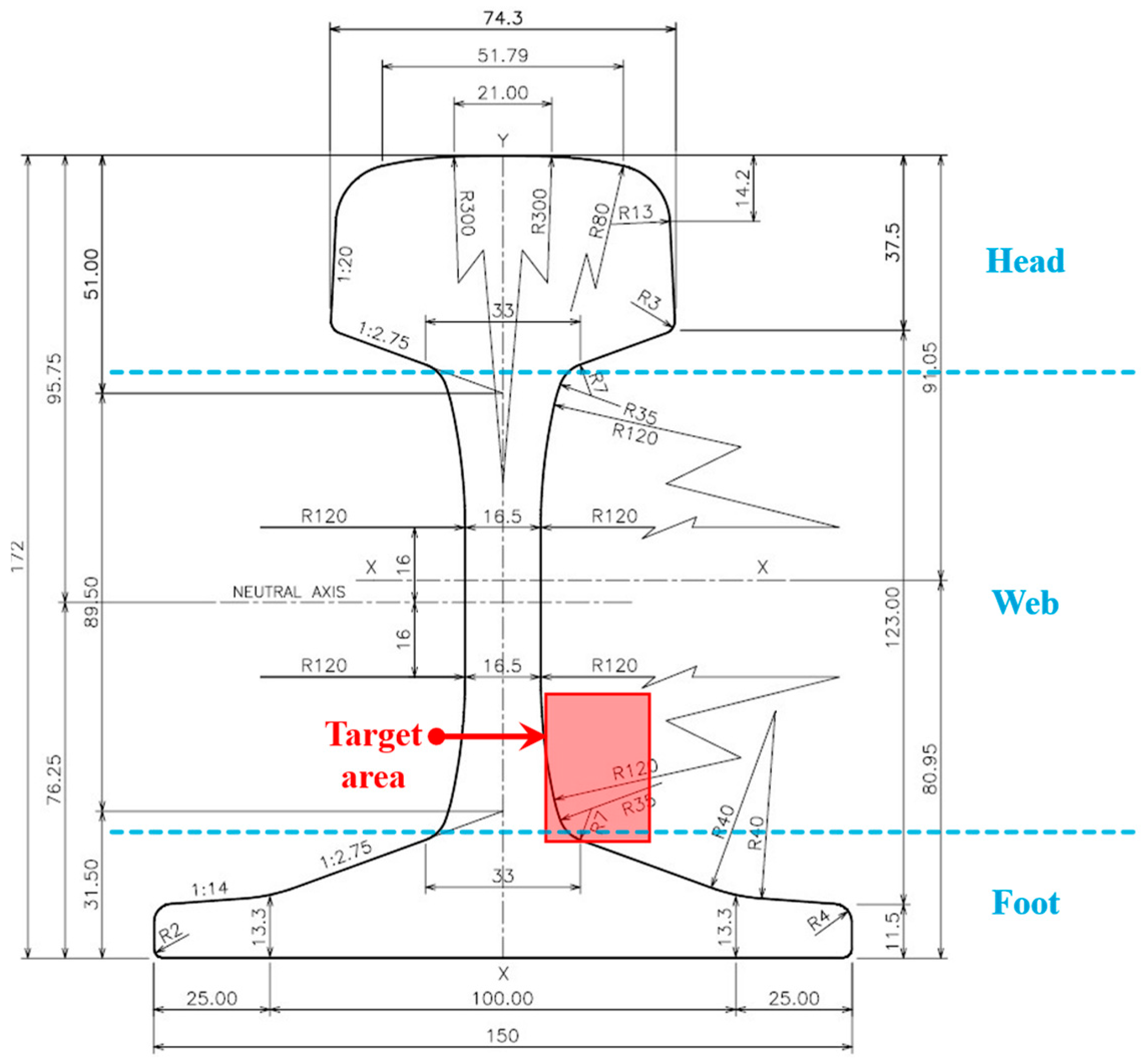

3. Design Considerations

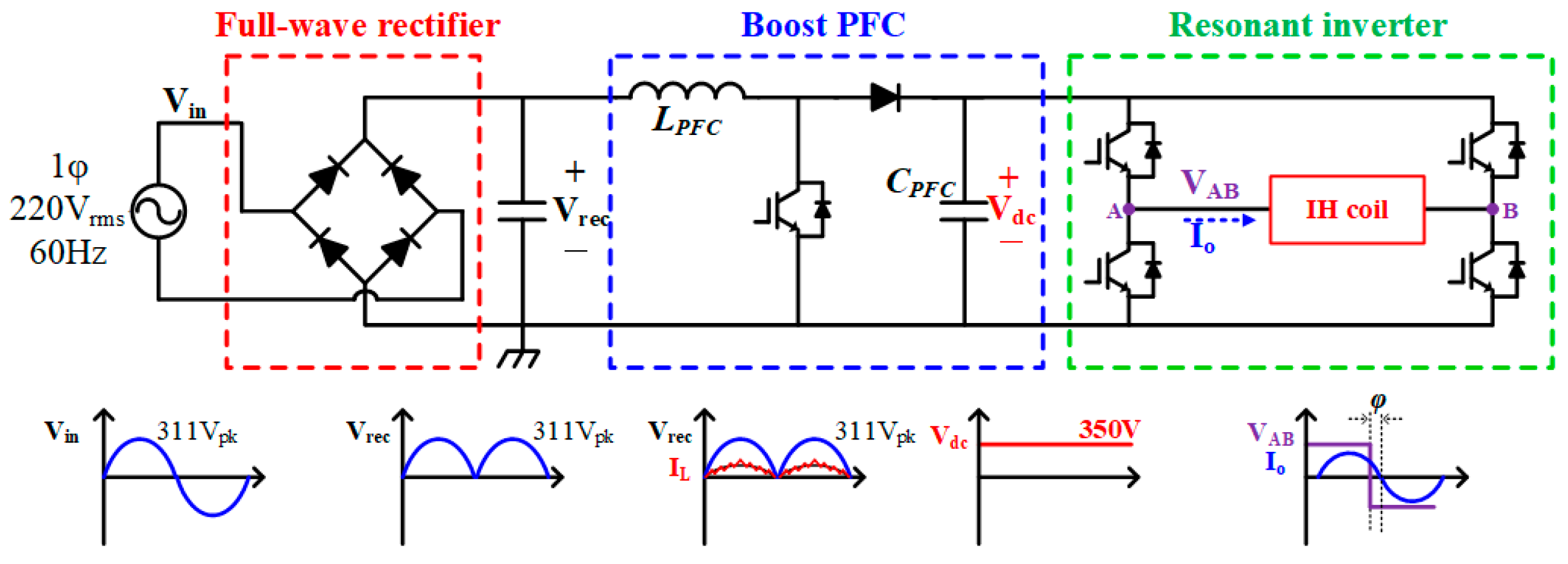

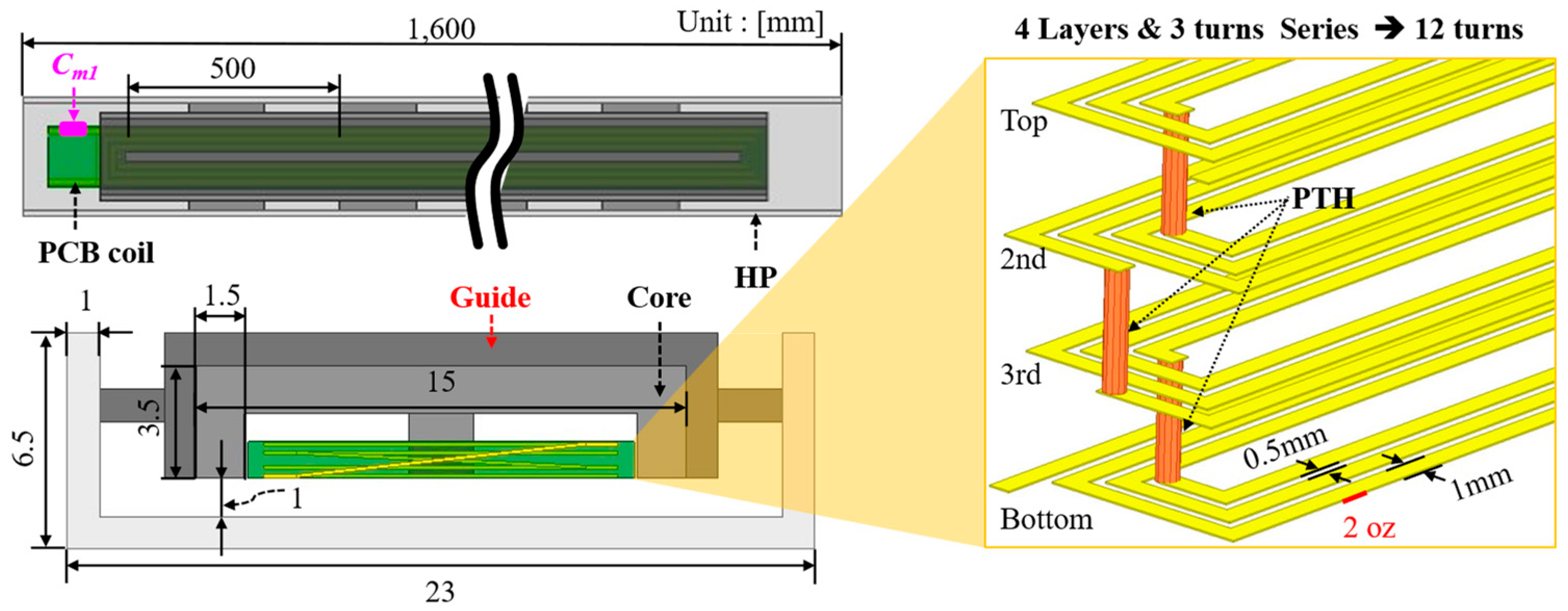

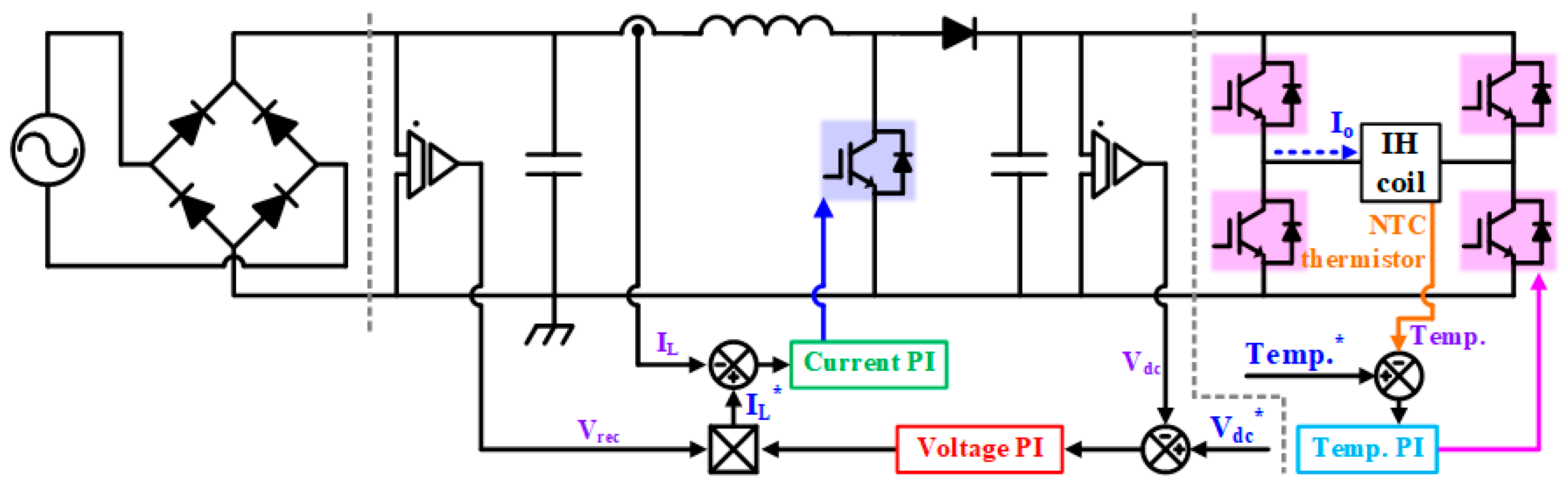

4. Design of the IH-Based Deicing System

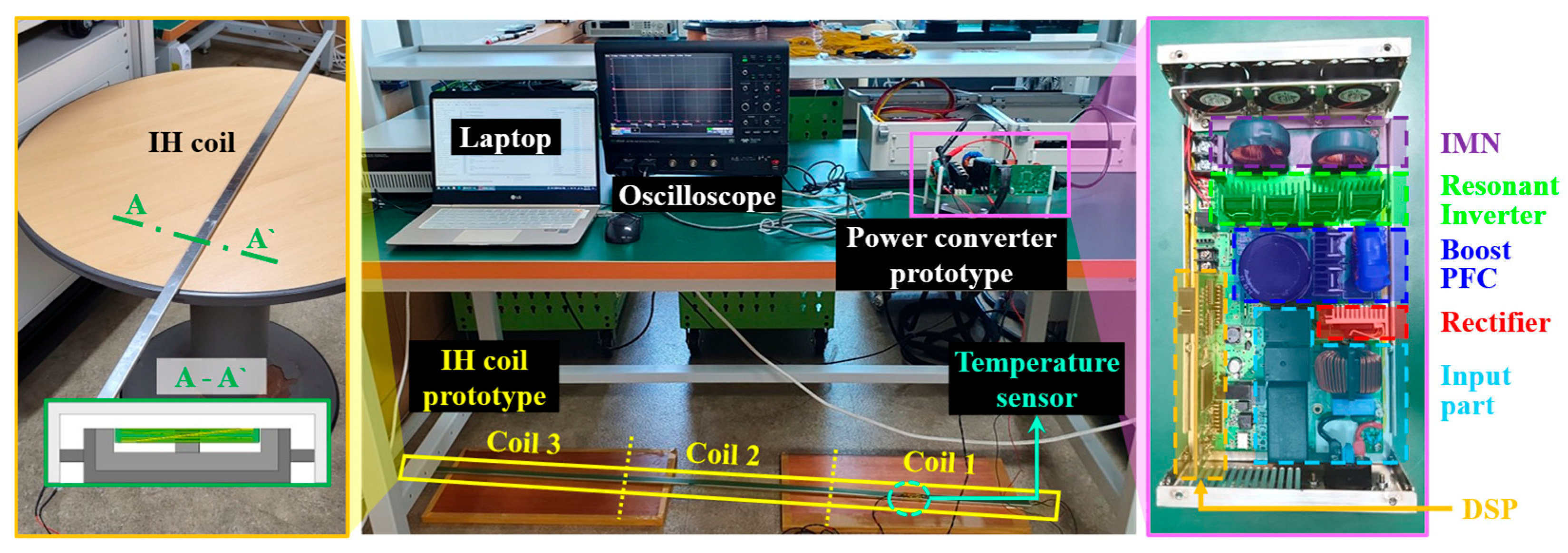

5. Experiments and Tests

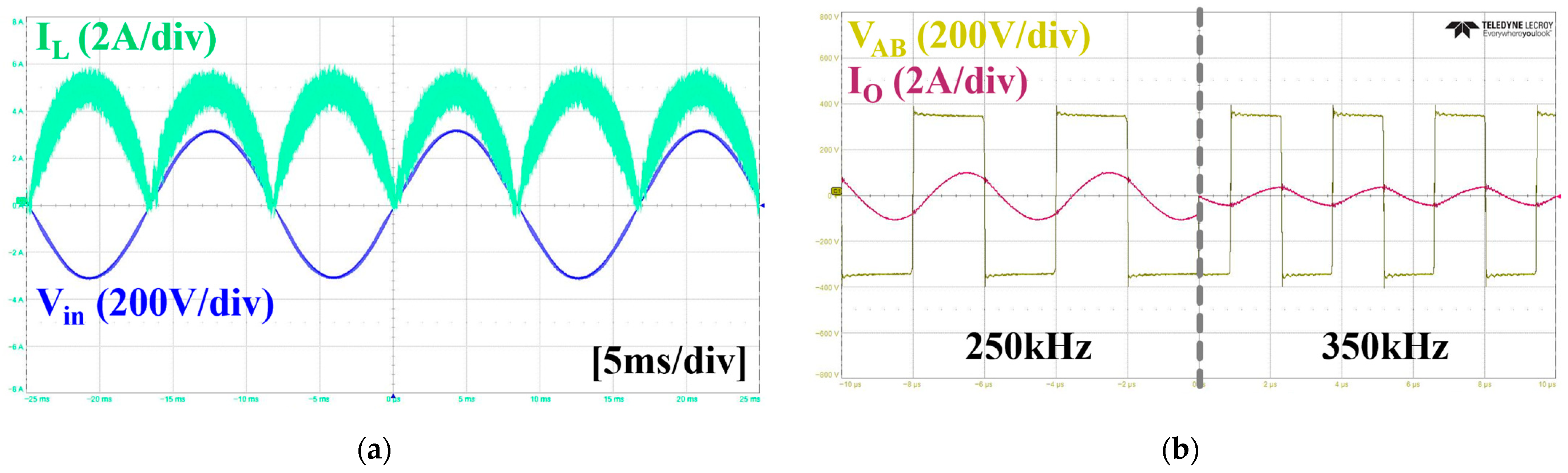

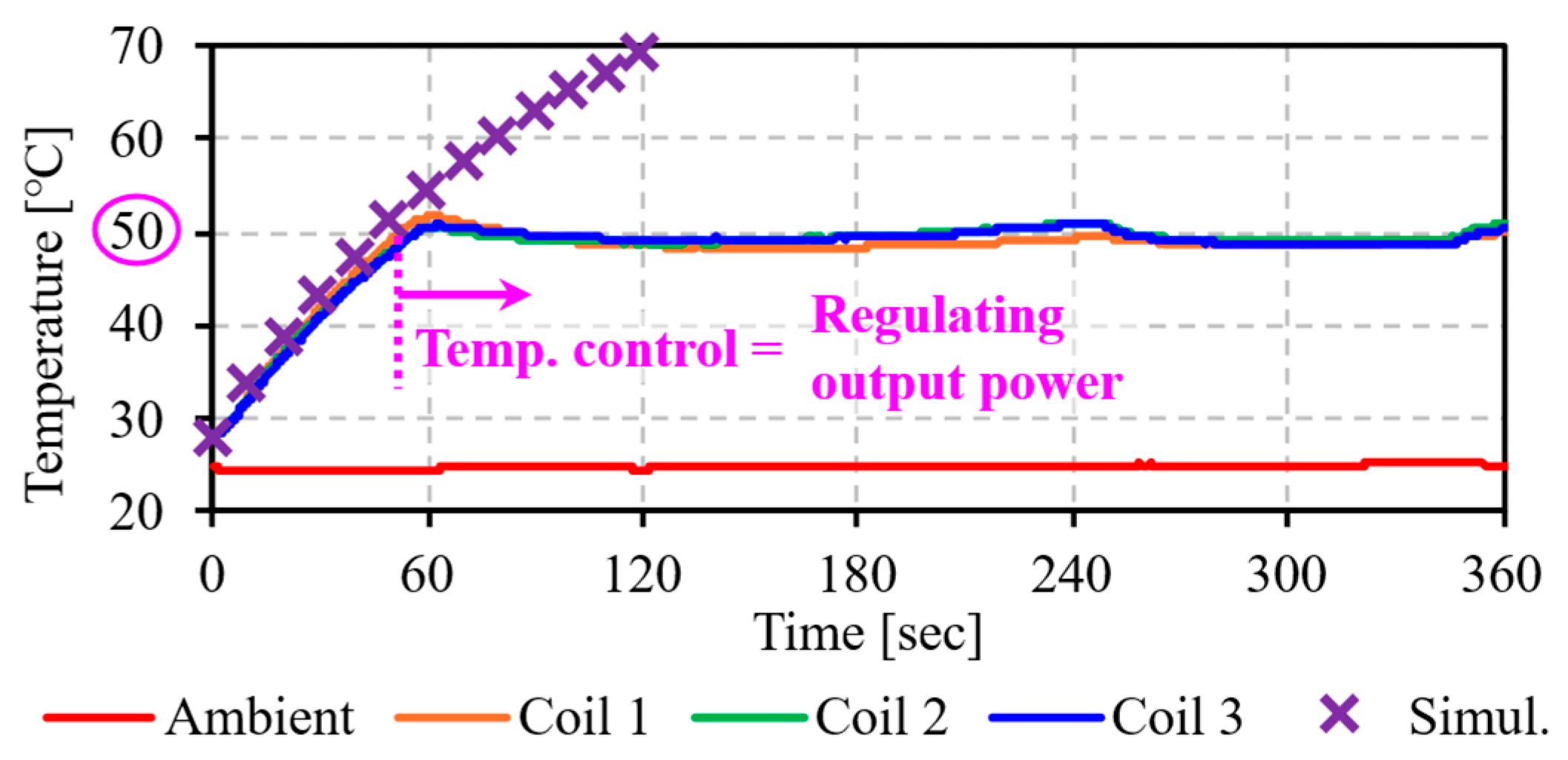

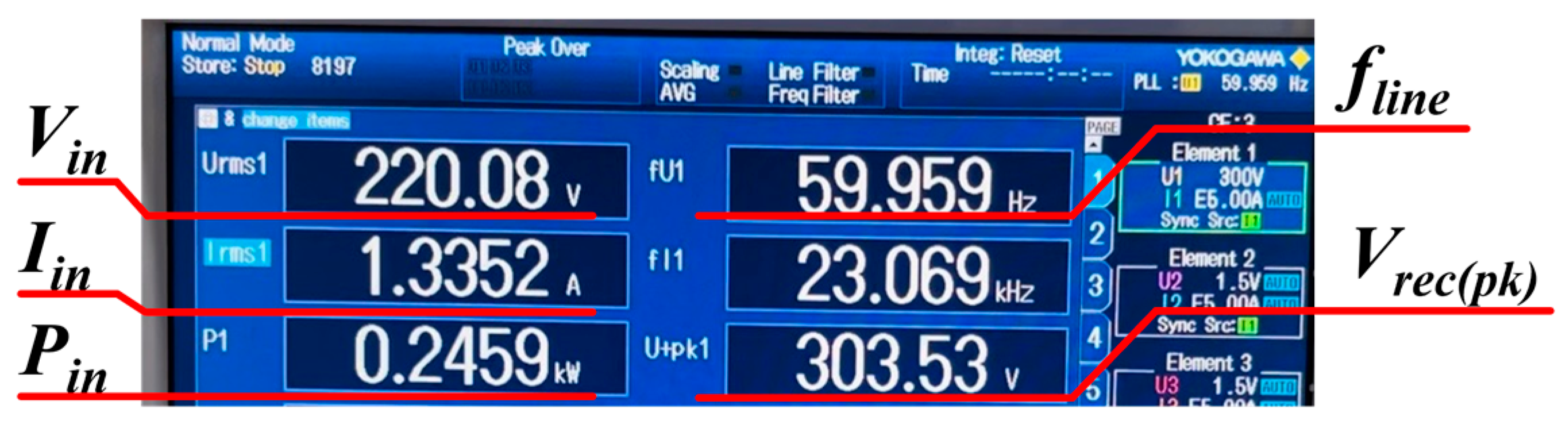

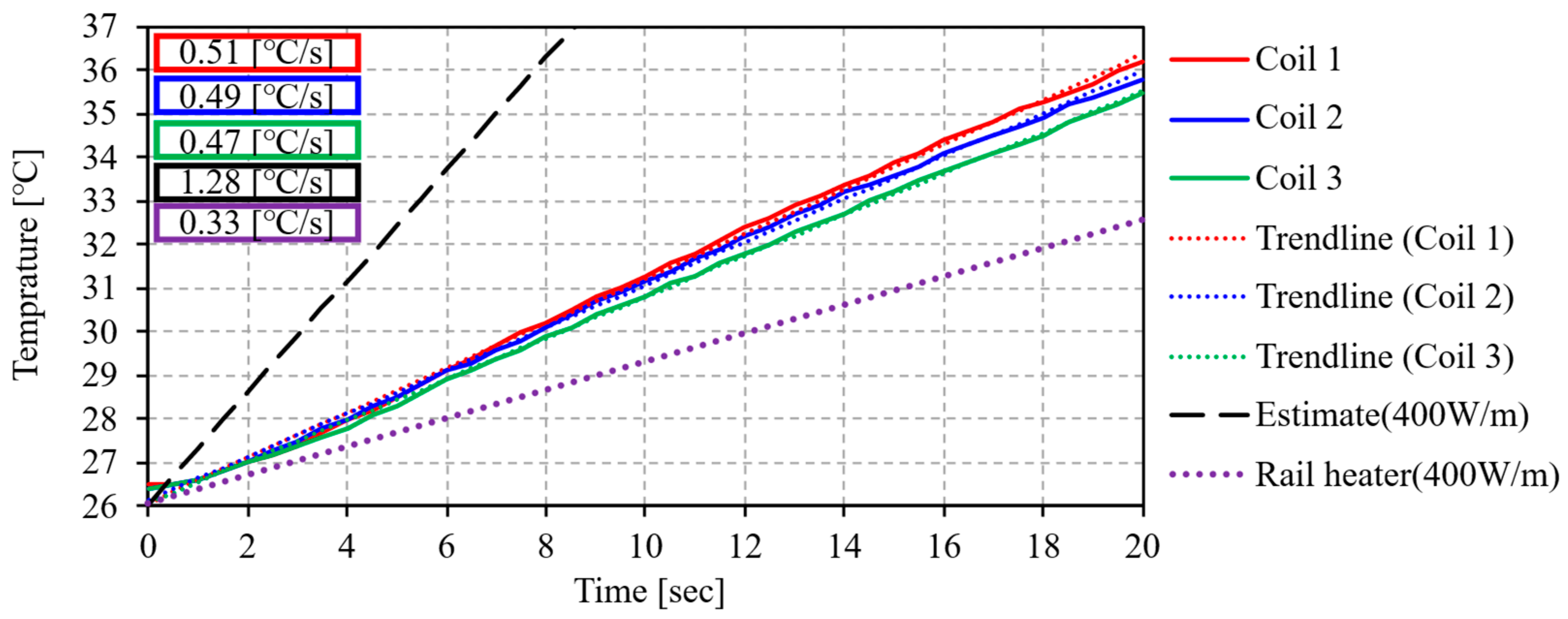

5.1. Room-Temperature Experiment

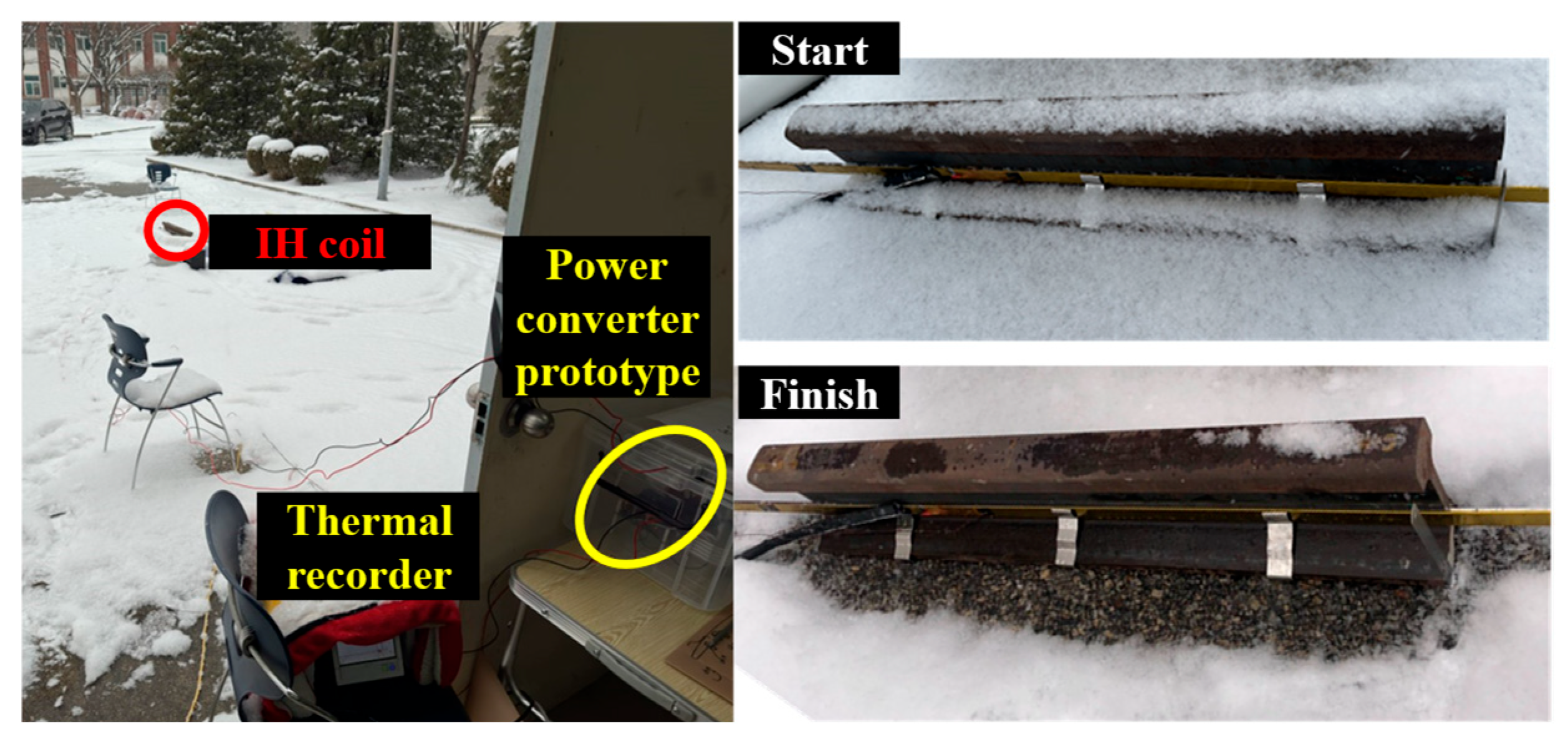

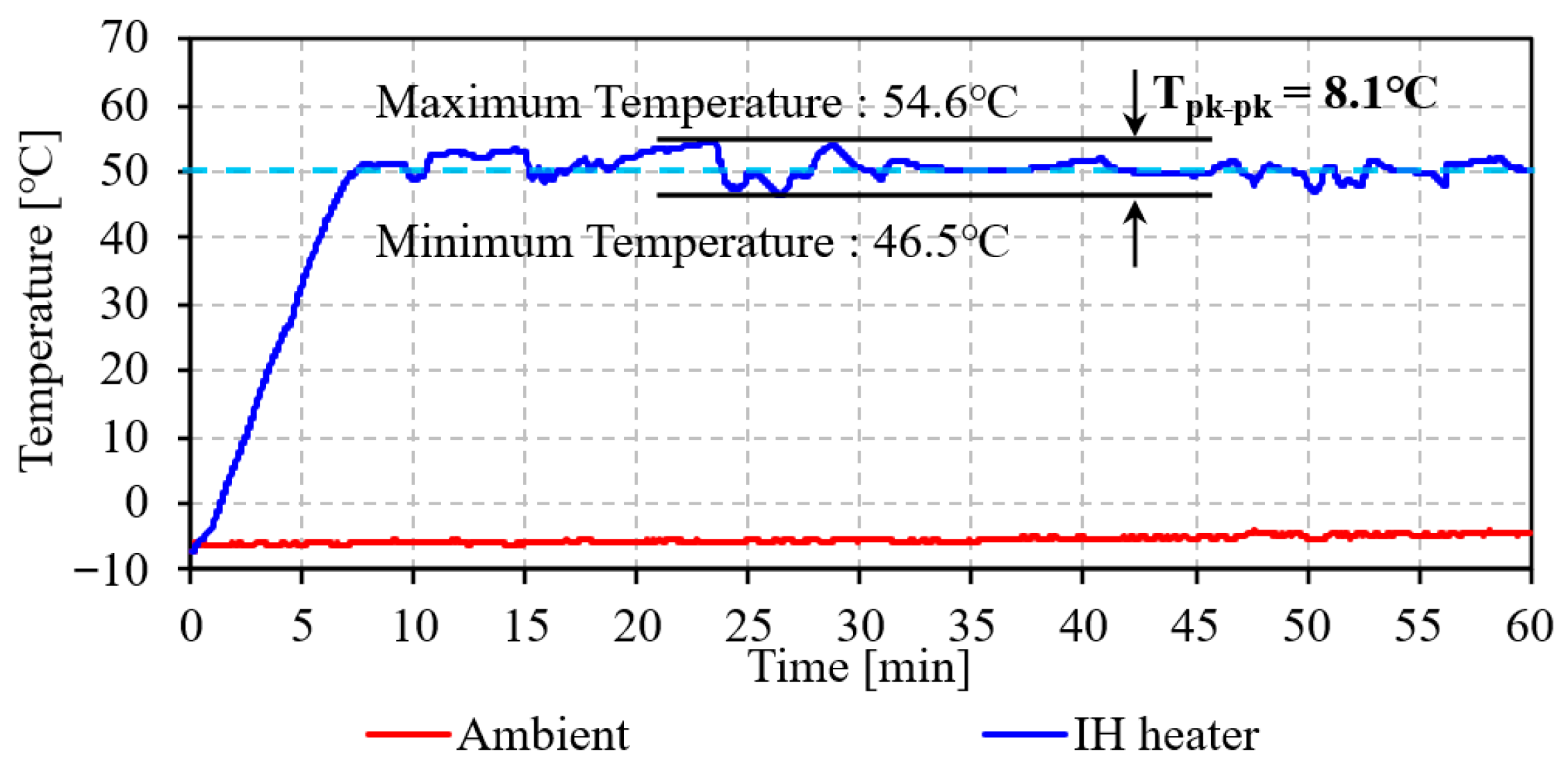

5.2. Actual Snowfall Experiment

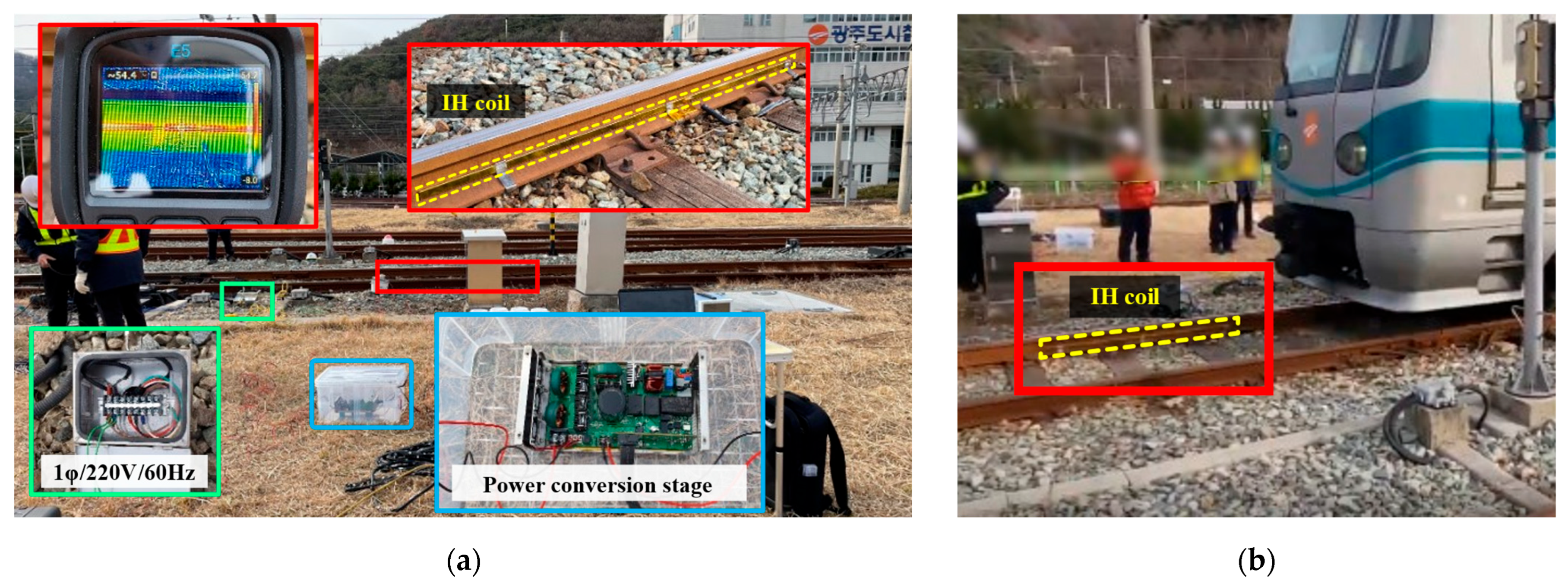

5.3. Field Application Tests

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, Y.-S.; Lee, S.-H. Trends of extreme cold events in the central regions of Korea and their influence on the heating energy demand. Weather Clim. Extrem. 2019, 24, 100199. [Google Scholar] [CrossRef]

- Huang, E.; Zhu, G.; Wang, Y.; Li, R.; Miao, Y.; Qi, X.; Wang, Q.; Jiao, Y.; Wang, Q.; Zhao, L. Long-Term Snow Cover Change in the Qilian Mountains (1986–2024): A High-Resolution Landsat-Based Analysis. Remote Sens. 2025, 17, 2497. [Google Scholar] [CrossRef]

- Quante, L.; Willner, S.N.; Middelanis, R.; Levermann, A. Regions of intensification of extreme snowfall under future warming. Sci. Rep. 2011, 11, 16621. [Google Scholar] [CrossRef] [PubMed]

- Kisilowski, J.; Kowalik, R. Mechanical Wear Contact between the Wheel and Rail on a Turnout with Variable Stiffness. Energies 2021, 14, 7520. [Google Scholar] [CrossRef]

- Loidolt, M.; Marschnig, S.; Bürgler, M.; Berghold, A.; Dornig, P.; Ossberger, U. Quality Behaviour of Turnouts: Comparison, Problem Specification and Recommendation of Measures. Appl. Sci. 2023, 13, 10665. [Google Scholar] [CrossRef]

- Loponen, T.R.; Salmenperä, P.; Luomala, H.; Nurmikolu, A. Studies of Snow-Dropping from a Train on a Turnout due to Dynamic Excitations. J. Cold Reg. Eng. 2018, 32, 04018003. [Google Scholar] [CrossRef]

- Żelazny, R.; Jabłoński, P.; Szczegielniak, T. Operation of the Prototype Device for Induction Heating of Railway Turnouts at Various Operating Frequencies. Energies 2021, 14, 476. [Google Scholar] [CrossRef]

- Flis, M. Contactless turnouts’ heating for energy consumption optimization. Arch. Electr. Eng. 2020, 69, 133–145. [Google Scholar] [CrossRef]

- Heger, J.; Kurzweil, F.; Schladitz, M.; Adam, R.; Großmann, S. Experimental Verification of an Optimized Heating System for Hollow Sleepers Containing Points Positioning Systems. In Proceedings of the 5th International Conference on Road and Rail Infrastructure—CETRA 2018, Zadar, Croatia, 17–19May 2018. [Google Scholar]

- Kaufmann, B.; Kurzweil, F.; Heger, J.; Adam, R.; Grossmann, S. Development of a Heating System for Hollow Sleepers Containing Points Positioning Systems. In Proceedings of the 3rd International Conference on Road and Rail Infrastructure—CETRA 2014, Split, Croatia, 28–30 April 2014. [Google Scholar]

- Heger, J. Inductive Railway Turnout Heating Systems—A Review of Scientific Publications. In Proceedings of the 8th International Conference on Road and Rail Infrastructure—CETRA 2024, Cavtat, Croatia, 15–17 May 2024. [Google Scholar]

- Hong, S.-Y.; Kim, D.-K.; Oh, H.-S.; Lee, J.-B.; Park, C.-B.; Lee, B.-S.; Lee, H.-W. Development of PFC Converter for Induction Heating System in Railway. In Proceedings of the 25th IEEE International Conference on Electrical Machines and Systems (ICEMS), Chiang Mai, Thailand, 29 November–2 December 2022; pp. 1–4. [Google Scholar]

- Oh, H.-S.; Kim, D.-K.; Hong, S.-M.; Ryu, S.-G.; Park, C.-B.; Lee, J.-B. Anti-icing System on Railway Turnouts using Induction Heating Technology for Energy Saving. In Proceedings of the 2022 IEEE 21st Mediterranean Electrotechnical Conference (MELECON), Palermo, Italy, 14–16 June 2022; pp. 342–347. [Google Scholar]

- Oh, H.-S.; Lee, J.-H.; Lee, S.-H.; Park, C.-B.; Lee, J.-B.; Lee, J.; Lee, H.-W. Parasitic Capacitance Analysis of PCB-type Induction Heating Coil and LCCC/S Matching Network Design for Railway Turnouts. J. Electr. Eng. Technol 2023, 18, 3311–3320. [Google Scholar]

- Szychta, E.; Szychta, L. Comparative Analysis of Effectiveness of Resistance and Induction Turnout Heating. Energies 2020, 13, 5262. [Google Scholar] [CrossRef]

- Oh, H.-S.; Park, C.-B.; Lee, S.-H.; Lee, J.-B.; Kim, T.-H.; Lee, H.-W. A Study on De-Icing for Railway Turnouts Using 250 kHz-200 W-Class Induction Heating System. AIP Adv. 2019, 9, 125229. [Google Scholar] [CrossRef]

- Kwon, H.B. Current status of affairs and preventive technology of railway damage in winter. Railw. J. 2015, 18, 26–43. [Google Scholar]

- Texas Instruments. Fundamentals of Power Factor Correction; Application Report SLYT830. Available online: https://www.ti.com/lit/an/slyt830/slyt830.pdf (accessed on 28 August 2025).

- Han, J.-K. Frequency Modulation Scheme for CCM Boost PFC Converter to Improve THD in Light-Load Condition. Electronics 2024, 13, 256. [Google Scholar] [CrossRef]

- Musumeci, S.; Bojoi, R.; Borlo, S.; Armando, E. IGBT Based Three Channel Interleaved PFC Boost Converter for Inverter Front-End Application. In Proceedings of the 2019 AEIT International Annual Conference (AEIT), Florence, Italy, 18–20 September 2019; pp. 1–6. [Google Scholar]

- Yeon, J.; Akbar, S.Q. A Reverse-Conducting IGBT Enabling High Switching Frequency up to 60 kHz for PFCs in Home Appliances. In Proceedings of the 2021 23rd European Conference on Power Electronics and Applications (EPE’21 ECCE Europe), Ghent, Belgium, 6–10 September 2021; pp. 1–9. [Google Scholar]

- TEWA Sensors LLC, (TEWA). Available online: https://www.tme.eu/Document/e292f795619d93c54d810f1cd48bfb50/TT6-100KC3L-5-AUR.PDF (accessed on 28 August 2025).

- YOKOGAWA. Available online: https://www.yokogawa.com/solutions/products-and-services/measurement/data-acquisition-products/portable-data-acquisition/touch-screen-gp10-gp20/ (accessed on 28 August 2025).

- OMEGA. Available online: https://assets.dwyeromega.com/pdf/cable-and-wire/thermocouple-and-rtd-wire-and-cable/GG_T_TC_WIRE.pdf (accessed on 28 August 2025).

- TELEDYNE FILR. Available online: https://www.flir.com/support/products/e5-xt/?vertical=condition+monitoring&segment=solutions#Overview (accessed on 28 August 2025).

- Korean Standards & Certification. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchView.do?menuId=919&topMenuId=502&upperMenuId=503&ksNo=KSCIEC60529&tmprKsNo=KSCIEC60529&reformNo=04 (accessed on 28 August 2025).

| Item | Value | Unit | Note |

|---|---|---|---|

| 800 | W | Nominal rated output power | |

| 311 | V | Maximum input voltage | |

| 5.14 | A | Maximum input current | |

| 1.54 | A | Current ripple 30% | |

| 350 | V | Output voltage | |

| 2.29 | A | Output current | |

| 10.5 | V | Voltage ripple 3% | |

| 945 | μH | ||

| 577.43 | μF | Unity power factor (PF = 1) |

| Item | Value | Unit | Note |

|---|---|---|---|

| Core | OD358 | - | High-Flux 60 μ |

| Turns | 131 | - | 0.81 φ, 3.5 A/mm2(Free convection) |

| Bmax | 0.61 | T | - |

| 3.96 | W | Core loss of PFC Inductor | |

| 1.18 | W | Coil loss of PFC Inductor | |

| 1.63 | W | IDH16G65C6 | |

| 0.51 | W | Conduction loss@100% Load | |

| 0.43 | W | Switching loss@100% Load | |

| 0.15 | W | ||

| 0.31 | W | Capacitive loss | |

| 1.40 | W | IPW60R090CFD7XKSA1 | |

| 945 | μH | Measured by IM3533, Hioki | |

| 577.43 | μF | 450UF560MBN |

| Item | Value | Unit | Note |

|---|---|---|---|

| 500 | J/kg·°C | Rail heater | |

| 0.672 | kg | ||

| 0.33 | °C/s | ||

| 460 | J/kg·°C | IH coil | |

| 0.255 | kg | ||

| 0.49 | °C/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, H.-S.; Ji, W.-Y.; Lee, H.-W.; Lee, J.-B.; Park, C.-B. Energy-Efficient Induction Heating-Based Deicing System for Railway Turnouts Under Real Snowfall Conditions. Energies 2025, 18, 5149. https://doi.org/10.3390/en18195149

Oh H-S, Ji W-Y, Lee H-W, Lee J-B, Park C-B. Energy-Efficient Induction Heating-Based Deicing System for Railway Turnouts Under Real Snowfall Conditions. Energies. 2025; 18(19):5149. https://doi.org/10.3390/en18195149

Chicago/Turabian StyleOh, Hyeong-Seok, Woo-Young Ji, Hyung-Woo Lee, Jae-Bum Lee, and Chan-Bae Park. 2025. "Energy-Efficient Induction Heating-Based Deicing System for Railway Turnouts Under Real Snowfall Conditions" Energies 18, no. 19: 5149. https://doi.org/10.3390/en18195149

APA StyleOh, H.-S., Ji, W.-Y., Lee, H.-W., Lee, J.-B., & Park, C.-B. (2025). Energy-Efficient Induction Heating-Based Deicing System for Railway Turnouts Under Real Snowfall Conditions. Energies, 18(19), 5149. https://doi.org/10.3390/en18195149