Advancing Sustainable Propulsion Solutions for Maritime Applications: Numerical and Experimental Assessments of a Methanol HT-PEMFC System

Abstract

1. Introduction

State-of-Art and Study Contribution

2. Materials and Methods

2.1. Vessel Characterization

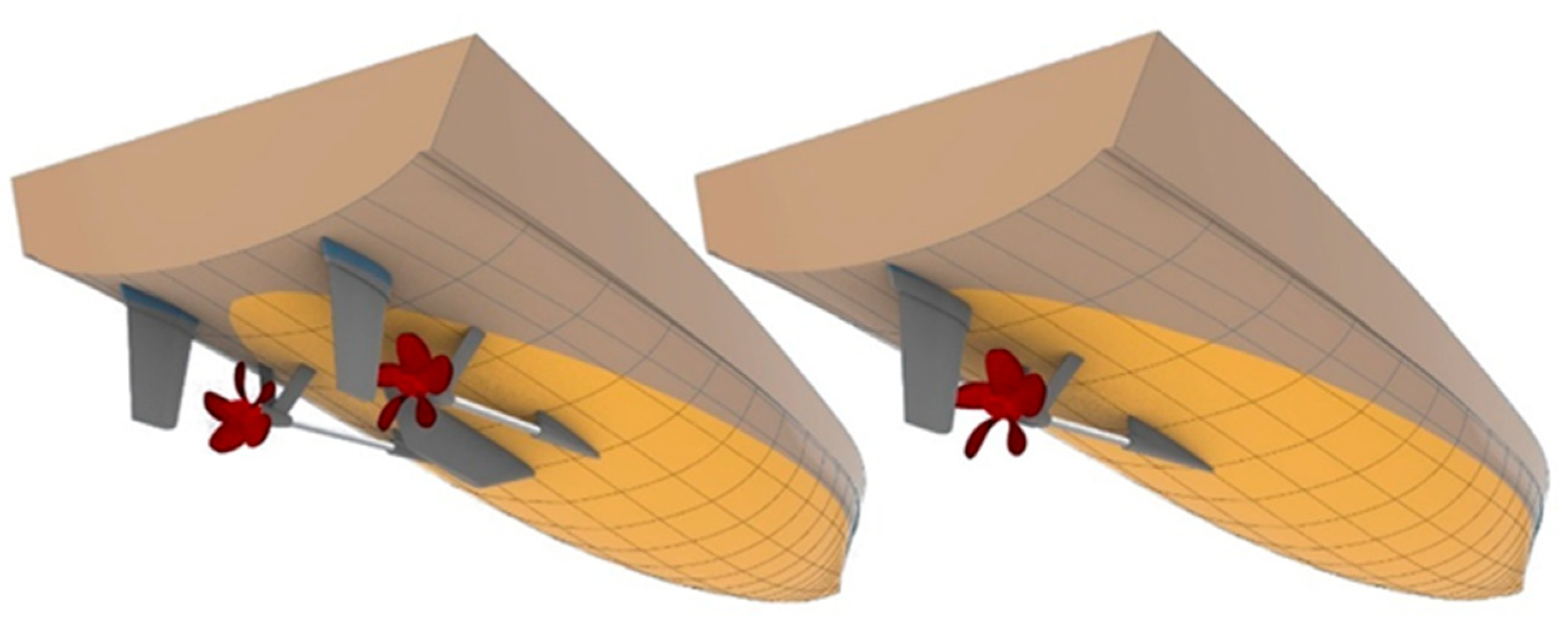

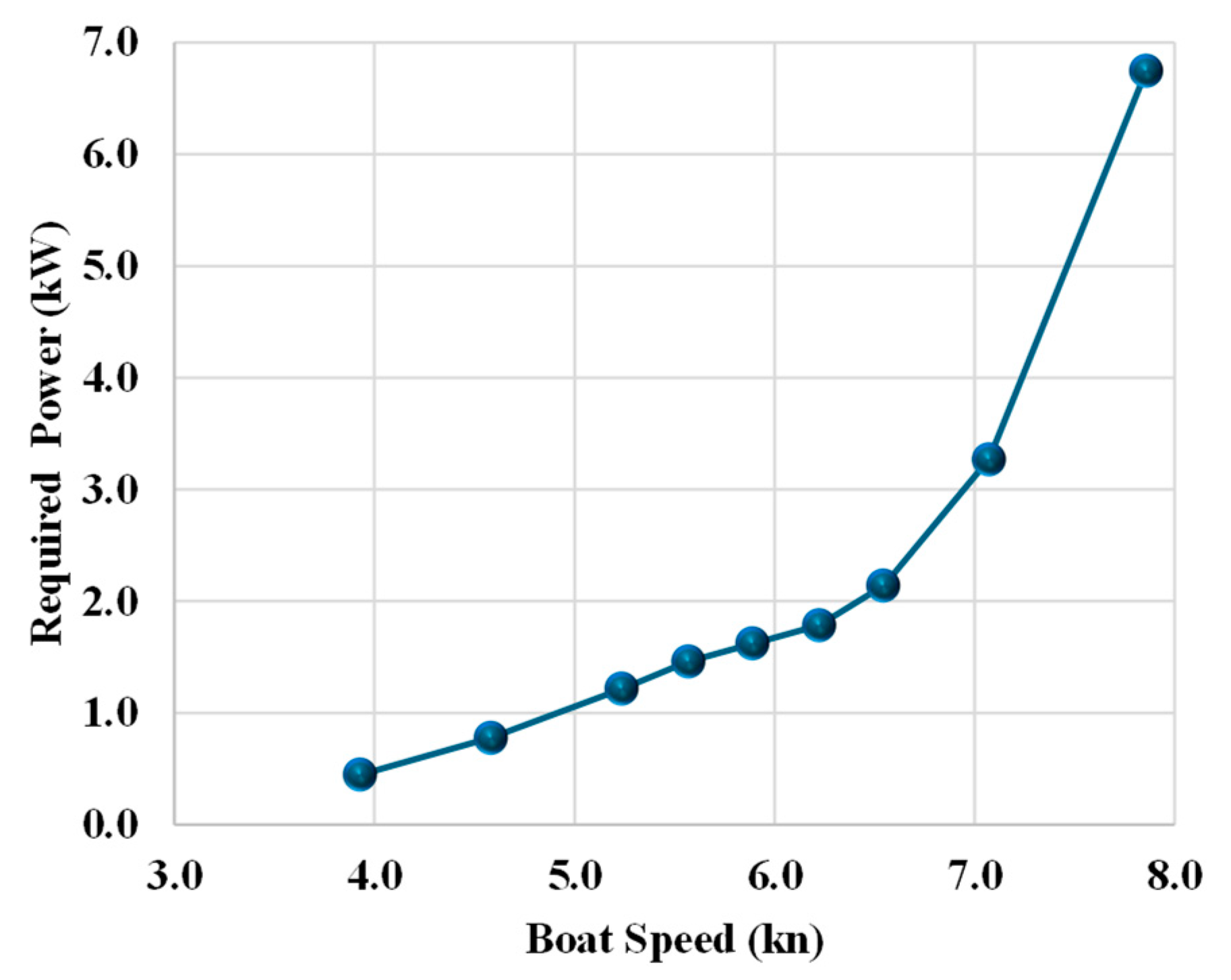

2.1.1. Hull Design and Modeling

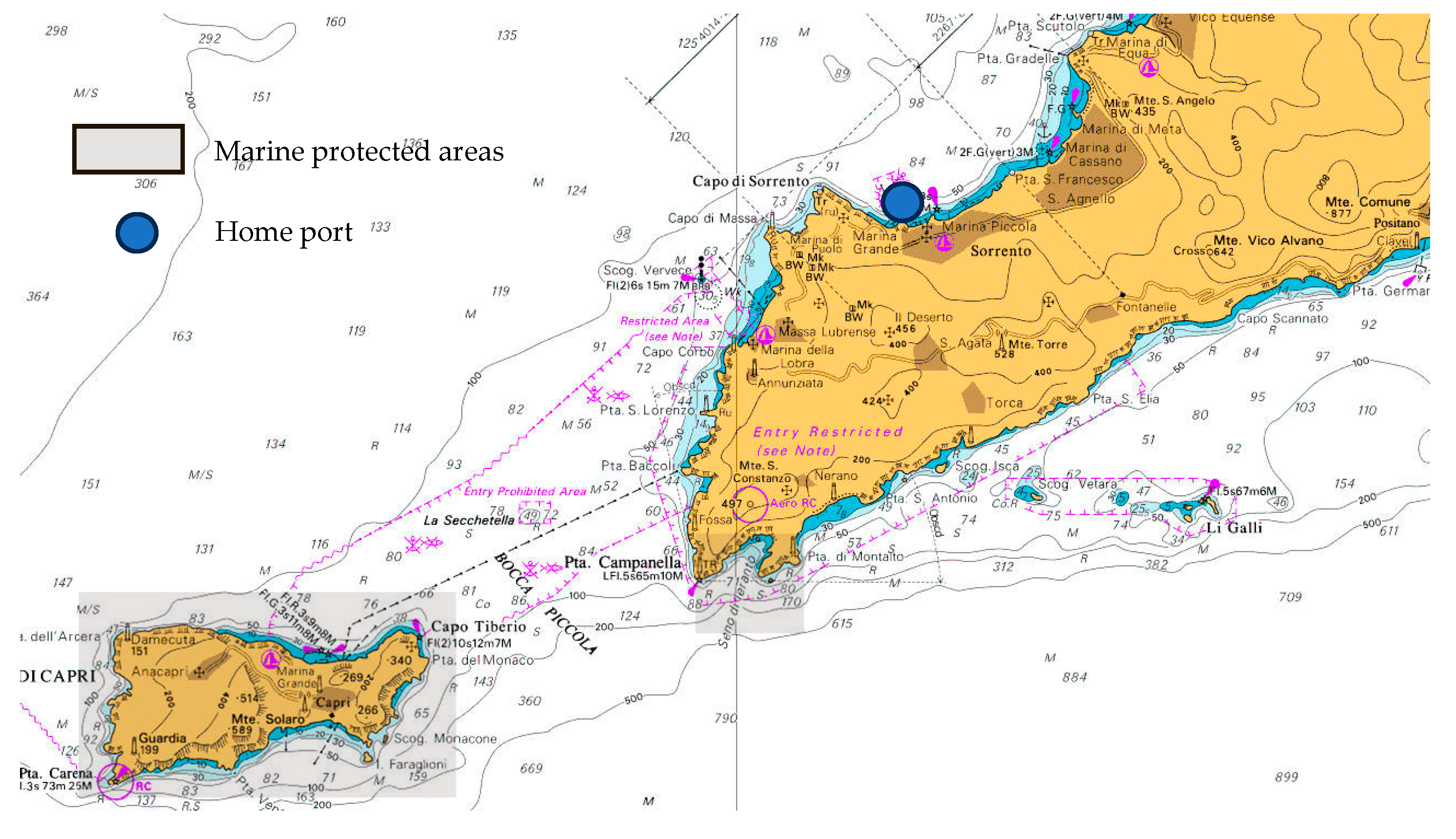

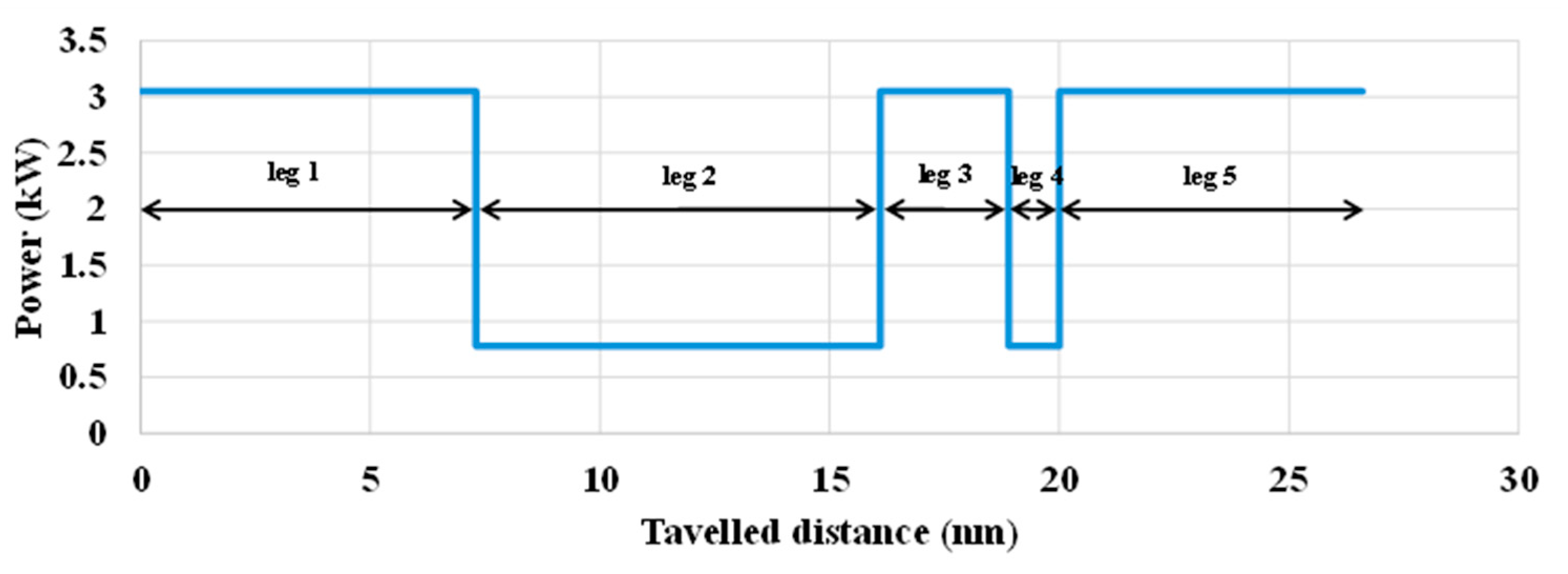

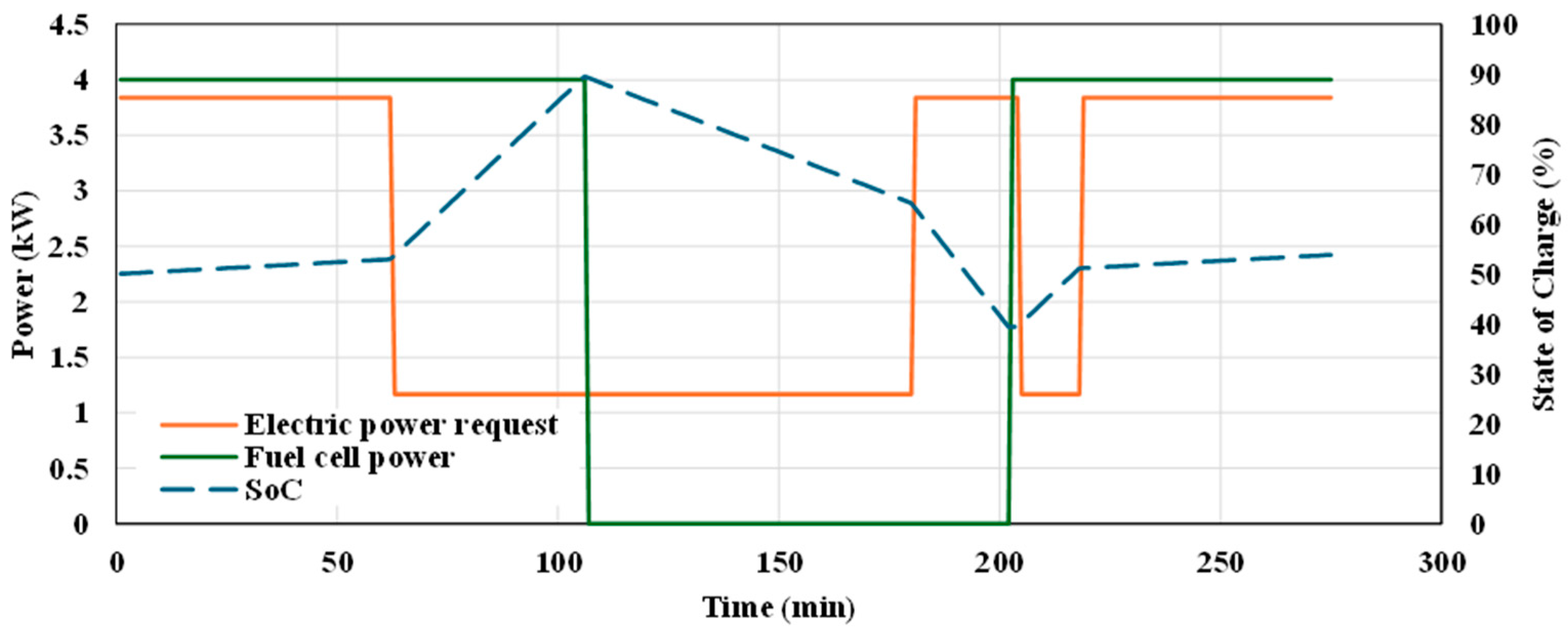

2.1.2. Vessel Mission Profile

- ●

- Leg 1: Approach to Capri: The initial leg towards Capri is powered by active fuel cells, which not only supply power to the propulsion system but also may recharge the battery (about 7 nm).

- ●

- Leg 2: Around Capri at Low Speed: The vessel navigates around the island at approximately 4.5 knots (about 9 nm).

- ●

- Leg 3: Return to Land: The return leg to port mirrors the same speed as the approach to Capri until the next entry into the P.ta Campanella protected marine area (about 1 nm).

- ●

- Leg 4: Protected Marine Area Navigation: The vessel operates at zero emissions within the protected area (about 1 nm).

- ●

- Leg 5: Return to Port: After completing the protected area navigation, the vessel returns to its home port (about 7 nm).

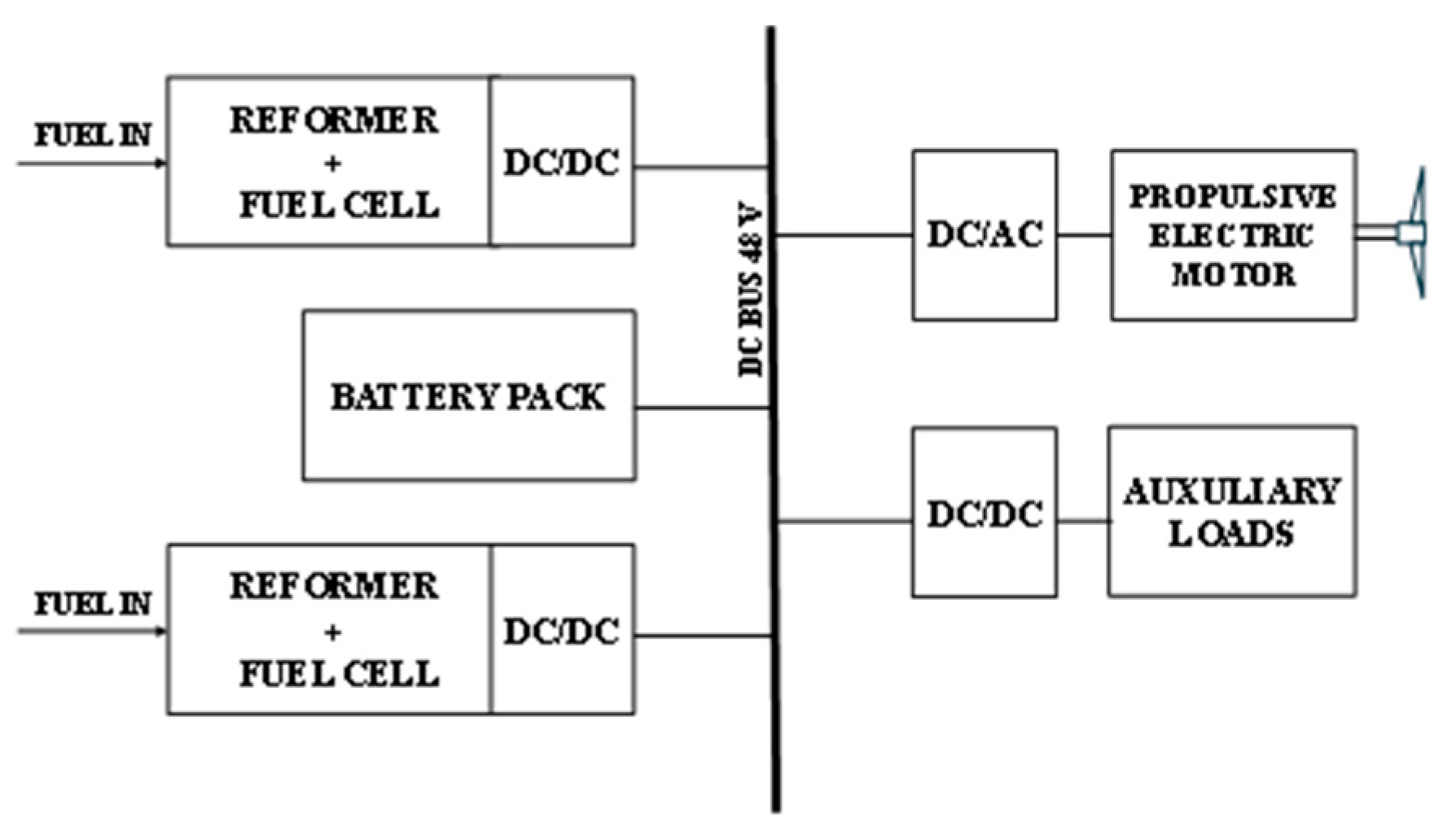

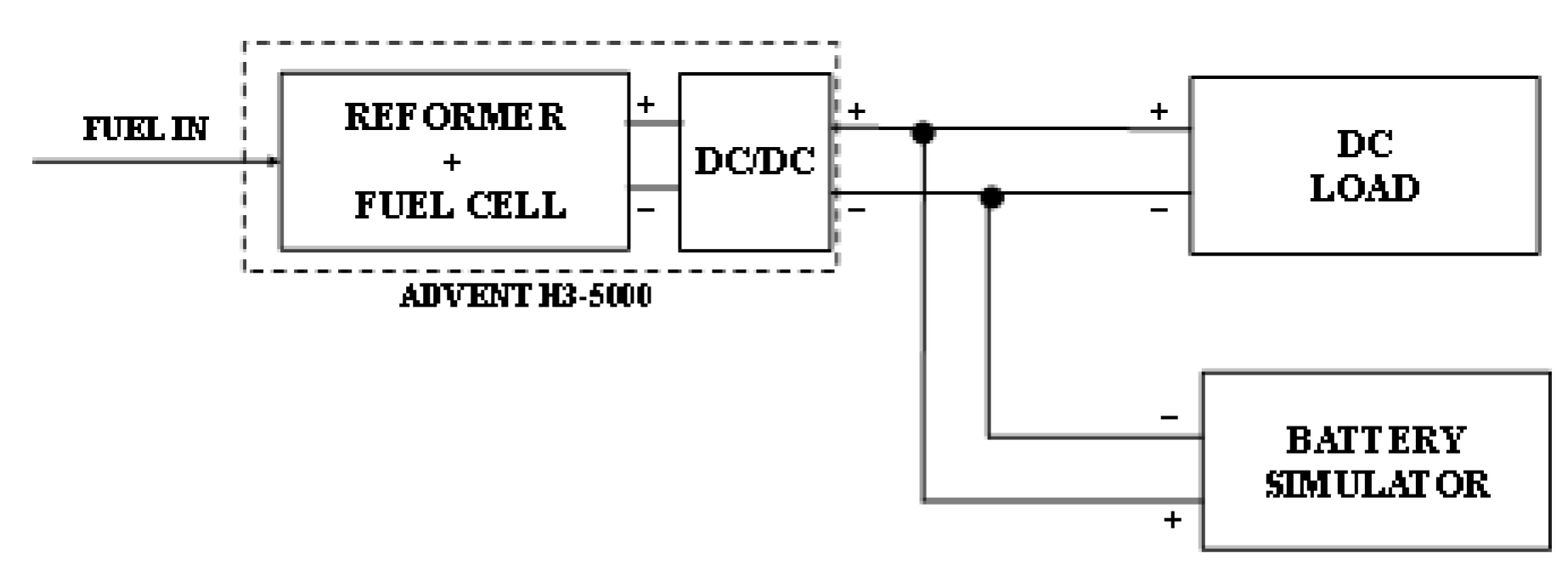

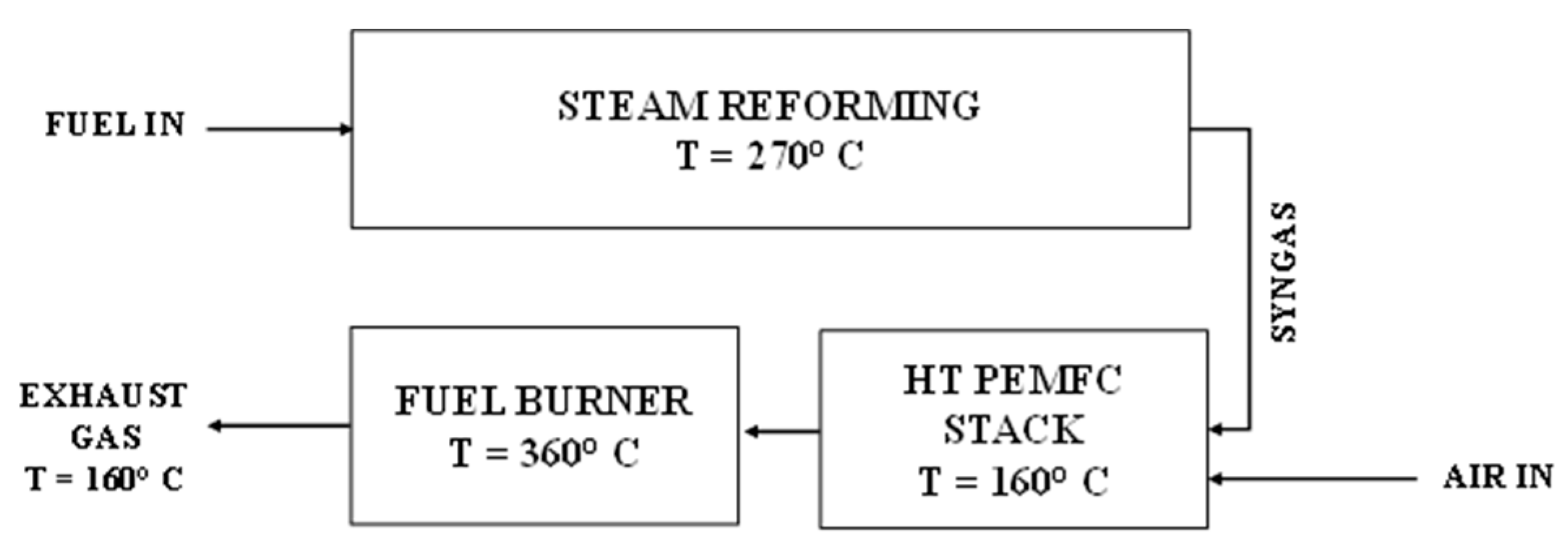

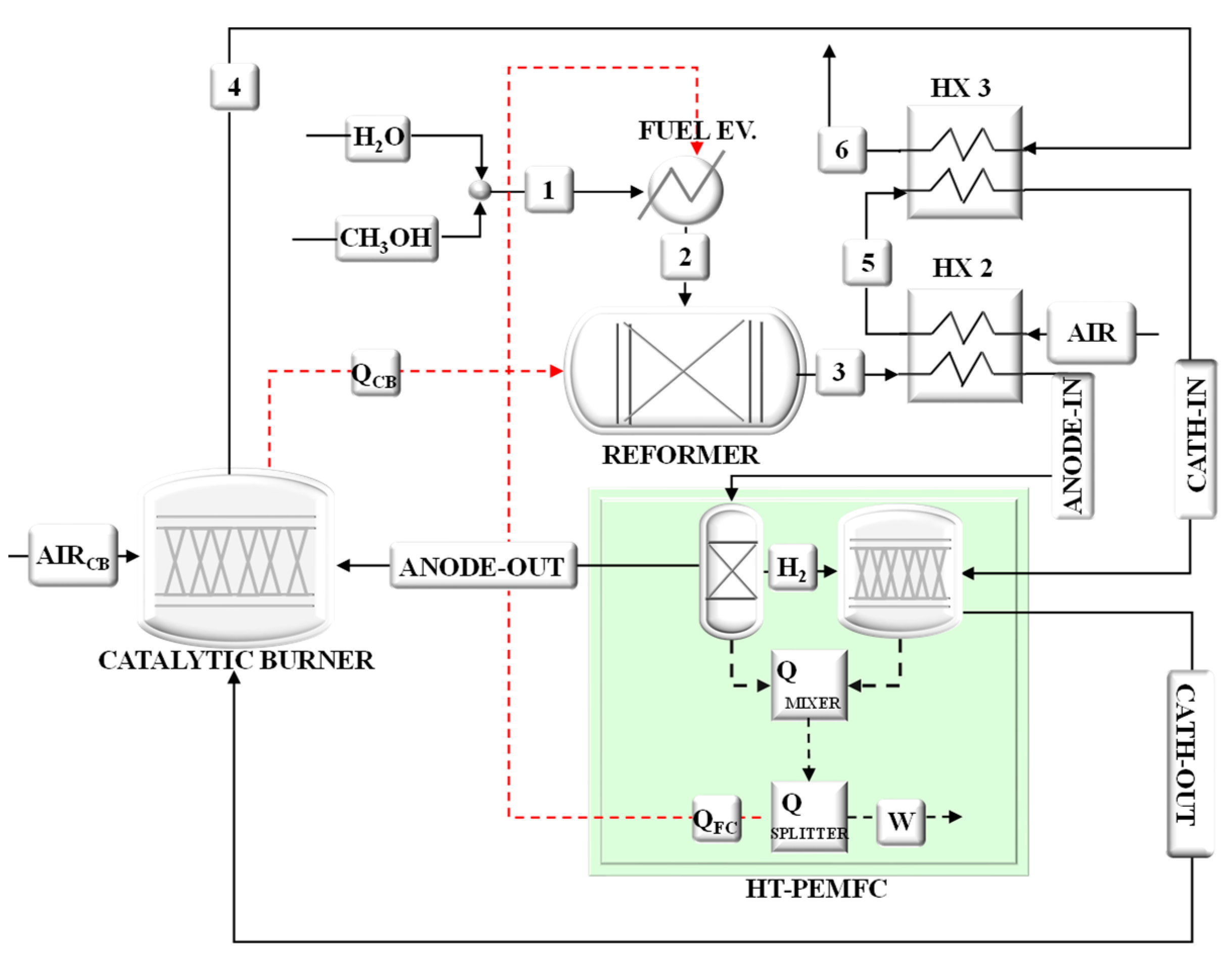

2.2. Propulsion System Characterization: HT-PEMFC System

- Reformed Methanol Fuel Cell Systems: The HT-PEMFCs are powered by syngas coming from a reformed mixture of methanol and water. The system under study, made by ADVENT A/S, was tested by the University Federico II at the CNR-STEMS laboratories in Naples, showing a nominal power output of 5 kW from the fuel cells themselves and a maximum deliverable power of 4 kW.

- Battery Pack: The lithium-ion battery pack operates as an energy buffer and allows compensation for the limited dynamic response of the fuel cells, providing propulsion power when the fuel cells cannot meet peak demand or in areas where only the battery pack is allowed as a power source [31].

- Electric Propulsion Motor with Drive: The electric motor and drive system provide propulsion power to the propeller from the fuel cells and battery electric power [32].

- Central 48 V DC Power Bus: A central bus operating at 48 V powers both the propulsion motors and auxiliary electrical loads of the ship. For the auxiliary loads, a DC/DC converter is used to reduce the voltage to 24 V.

2.2.1. HT-PEMFC Testing Activities

Start-Up Phase

Response to Load Variations

Energy Management

- ●

- SoCmax: 0.90

- ●

- SoCmin: 0.40

- ●

- Charging Power: Corresponds to a point of high efficiency in the fuel cells.

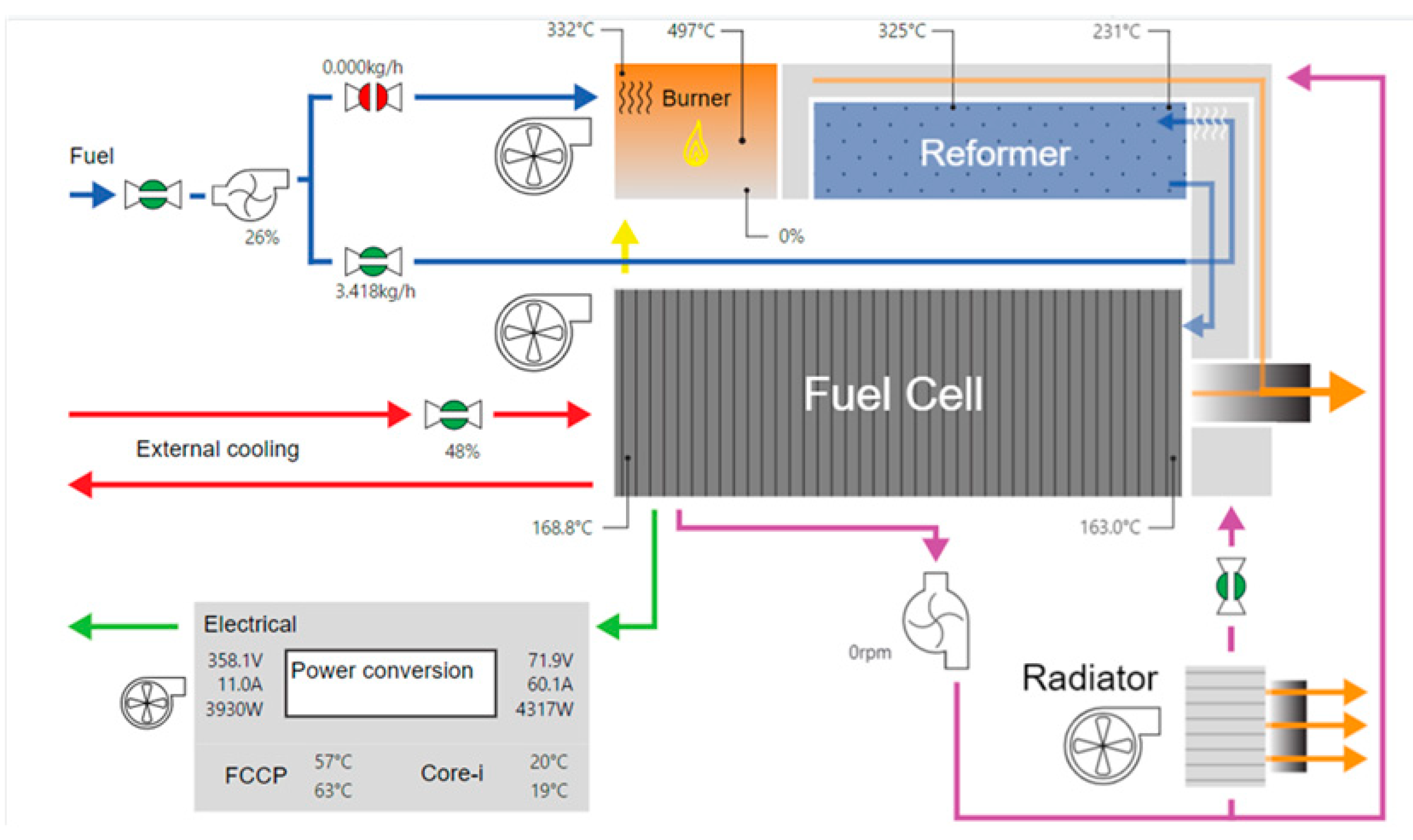

Thermal Management

2.3. HT-PEMFC System Model Development

2.3.1. Heat Exchangers

2.3.2. Reformer

2.3.3. Catalytic Burner

2.3.4. Proton Exchange Membrane Fuel Cell

3. Results

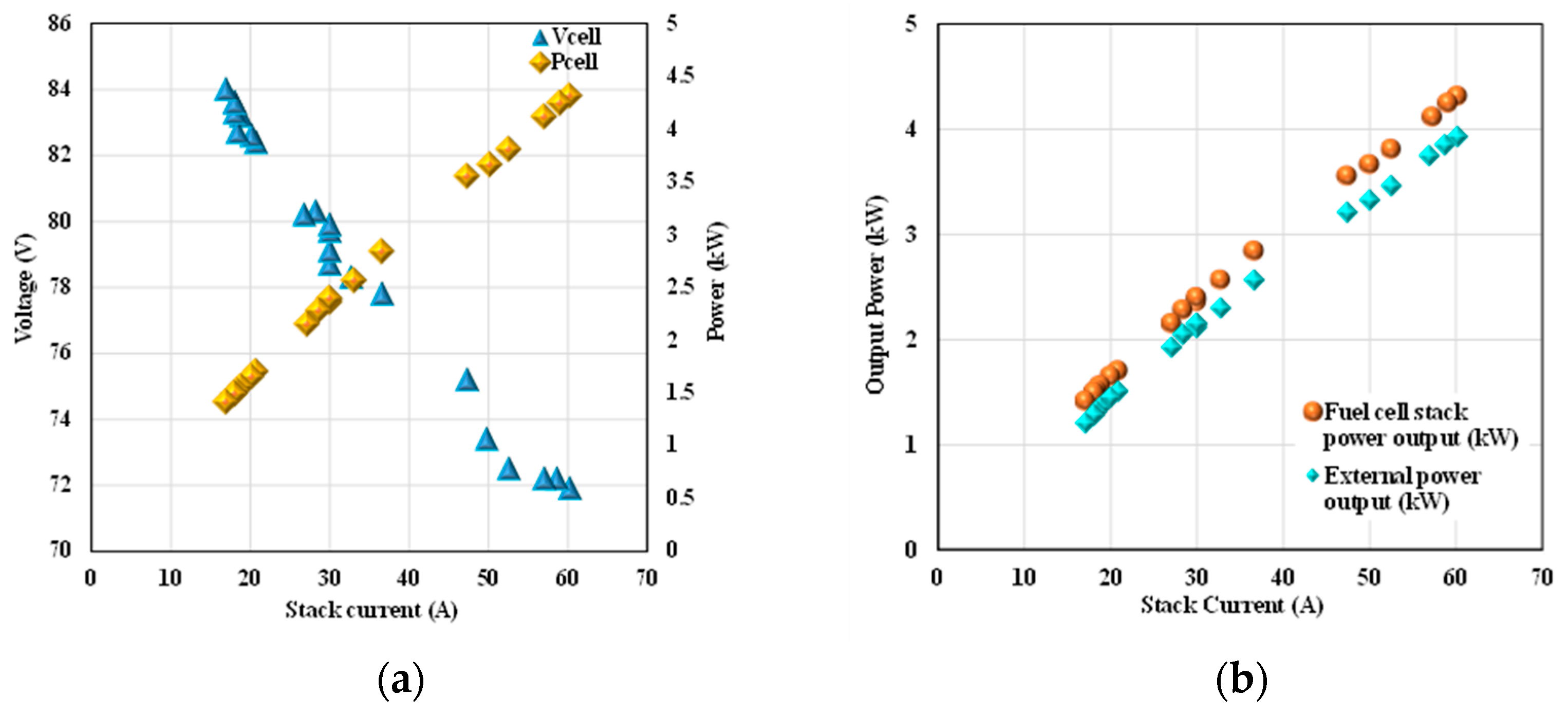

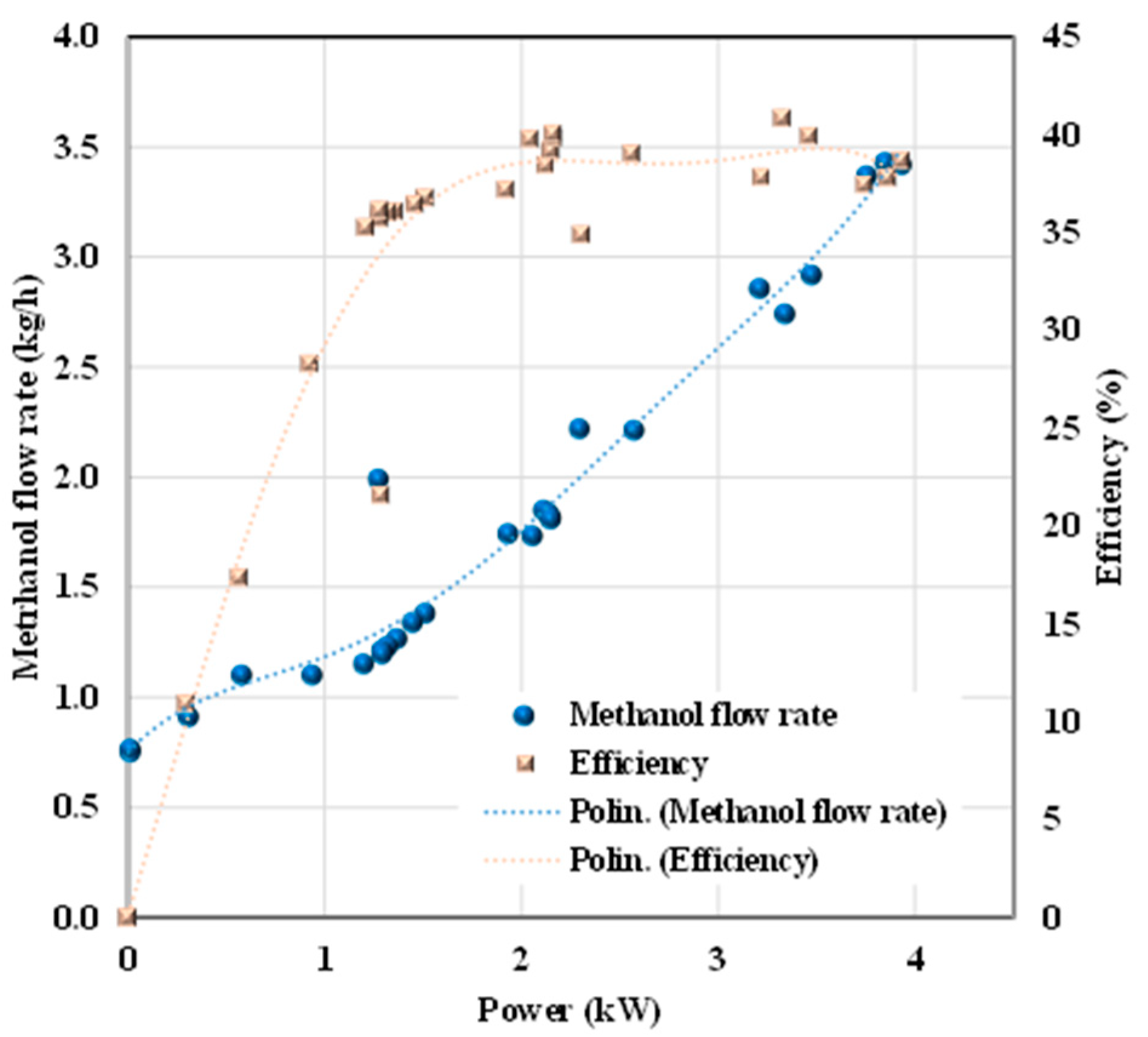

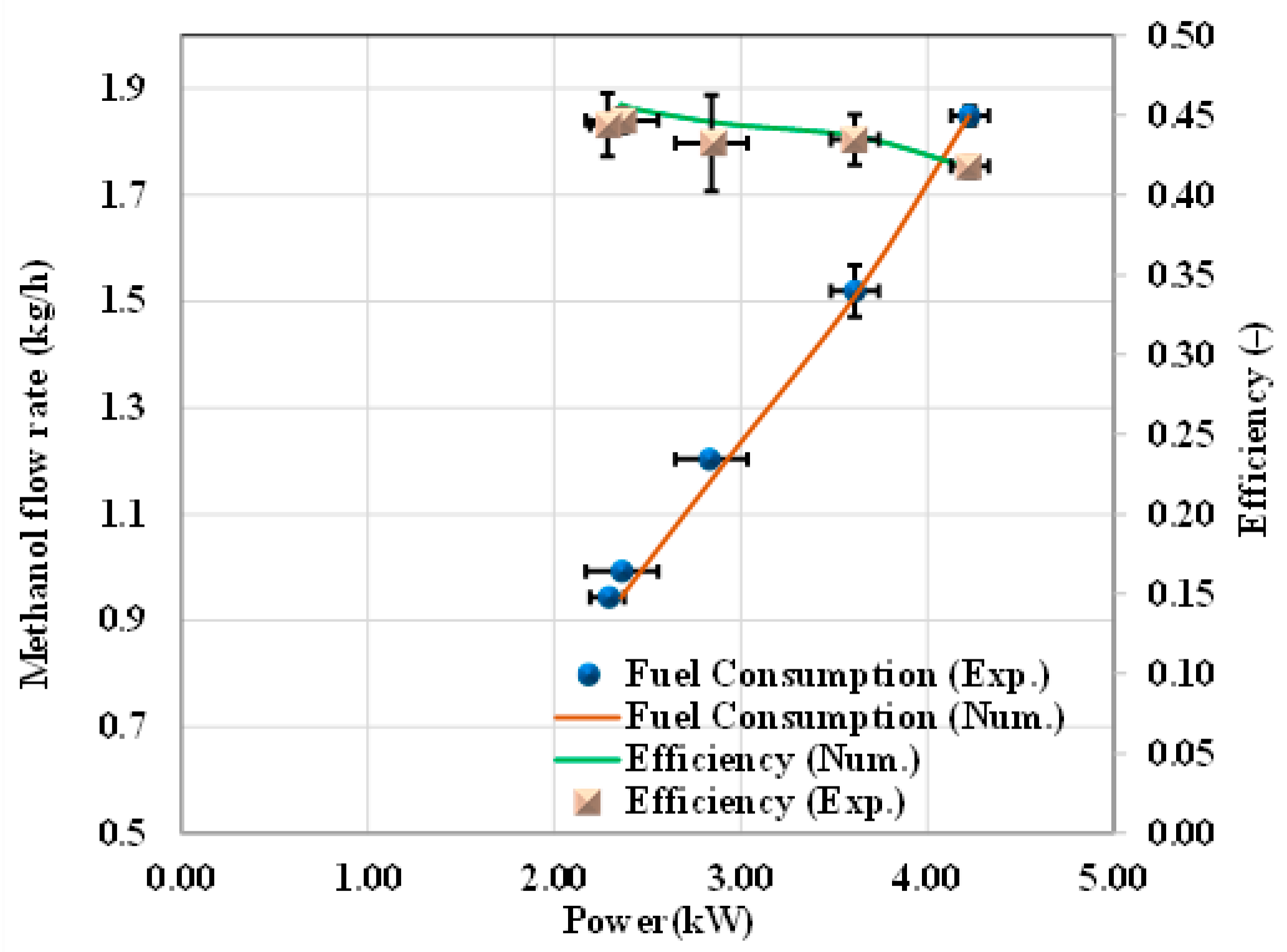

3.1. Experimental Results

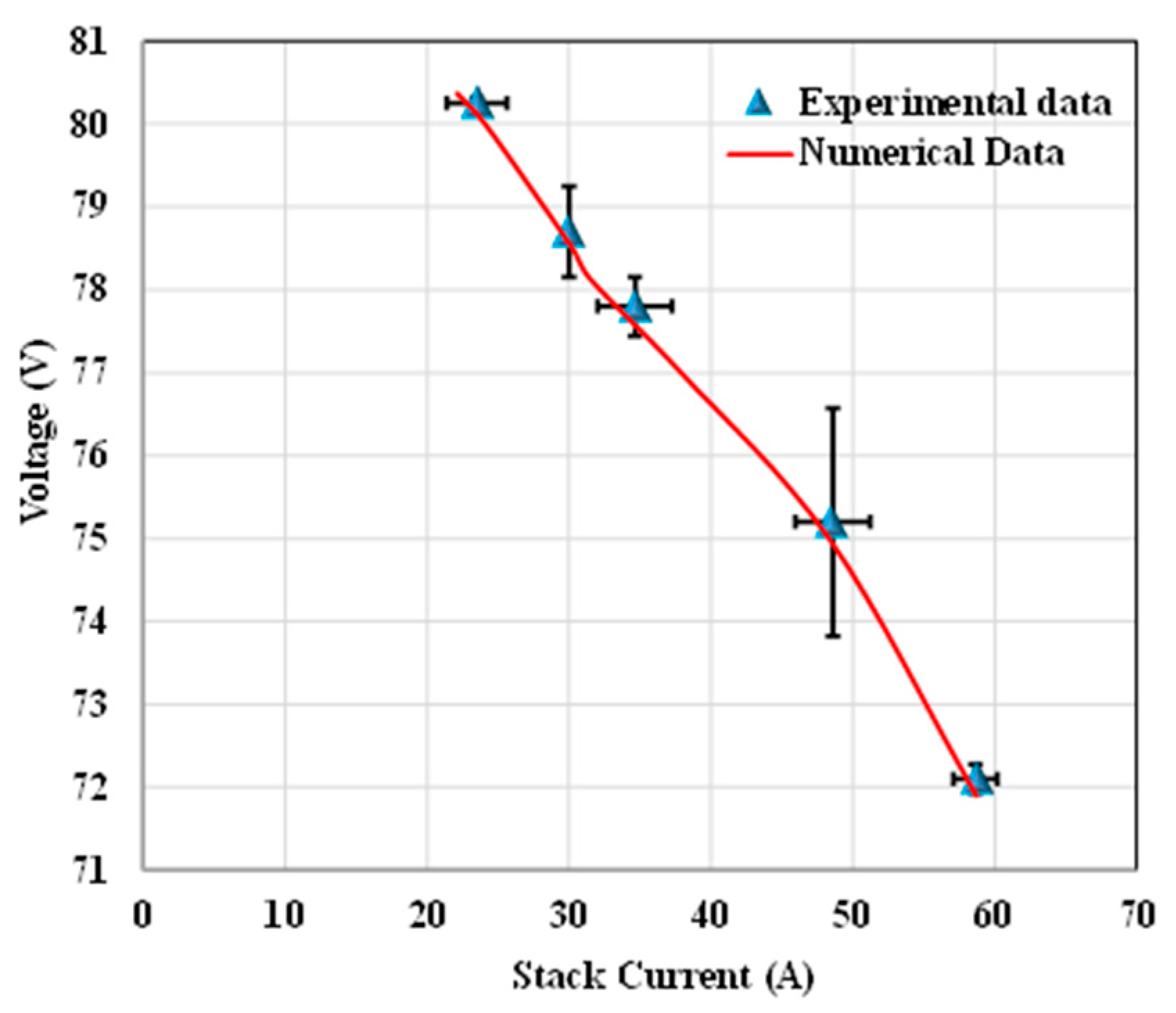

3.2. Model Identification and Validation

3.3. Energies and Mass Balances

3.4. Feasibility Assessment

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| AC | Alternate Current |

| BoP | Balance of Plant |

| BS | Battery Simulator |

| CB | Catalytic Burner |

| CFDs | Computational Fluid Dynamics |

| CR | Residual Resistance Coefficient |

| DC | Direct Current |

| FC | Fuel Cell |

| FN | Froude Number |

| HIL | Hardware-in-the-Loop |

| HT-PEMFCs | High-Temperature Polymeric Exchange Membrane Fuel Cells |

| ITTC | International Towing Tank Conference |

| Li-NMC | Lithium–Nickel–Manganese–Cobalt |

| SNMP | Simple Network Management Protocol |

| SoC | State of Charge |

| SOFCs | Solid Oxide Fuel Cells |

References

- Wang, Y.; Xiao, X.; Ji, Y. A Review of LCA Studies on Marine Alternative Fuels: Fuels, Methodology, Case Studies, and Recommendations. J. Mar. Sci. Eng. 2025, 13, 196. [Google Scholar] [CrossRef]

- Tai, T.-H.; Li, S.; Chang, Y.-C. Trends and Challenges in Maritime Energy Management; Springer Nature: Berlin/Heidelberg, Germany, 2020; Volume 197, p. 117223. [Google Scholar] [CrossRef]

- Adami, G.; Figari, M. Multi-Parametric Methodology for the Feasibility Assessment of Alternative-Fuelled Ships. J. Mar. Sci. Eng. 2024, 12, 905. [Google Scholar] [CrossRef]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transp. Res. D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Trivyza, N.L.; Rentizelas, A.; Theotokatos, G.; Boulougouris, E. Decision support methods for sustainable ship energy systems: A state-of-the-art review. Energy 2022, 239, 122288. [Google Scholar] [CrossRef]

- Ortiz-Imedio, R.; Caglayan, D.G.; Ortiz, A.; Heinrichs, H.; Robinius, M.; Stolten, D.; Ortiz, I. Power-to-Ships: Future electricity and hydrogen demands for shipping on the Atlantic coast of Europe in 2050. Energy 2021, 228, 120660. [Google Scholar] [CrossRef]

- Russo, D.; Portarapillo, M.; Turco, M.; Di Benedetto, A. Towards H2-free shipboard storage: Energetic and risk analysis of oxidative methanol steam reforming in integrated fuel cell systems. Energy 2025, 320, 135376. [Google Scholar] [CrossRef]

- Tomos, B.A.D.; Stamford, L.; Welfle, A.; Larkin, A. Decarbonising international shipping—A life cycle perspective on alternative fuel options. Energy Convers. Manag. 2024, 299, 117848. [Google Scholar] [CrossRef]

- Frasci, E.; Sementa, P.; Arsie, I.; Vaglieco, B.M. Modeling and Experimental Validation of a Pure Methanol-Fueled Small SI Engine: Impact of the Laminar Flame Speed Correlation; SAE Technical Paper 2024-24-0033. 2024. Available online: https://www.sae.org/papers/modeling-experimental-validation-a-pure-methanol-fueled-small-si-engine-impact-laminar-flame-speed-correlation-2024-24-0033 (accessed on 18 June 2025). [CrossRef]

- Qu, J.; Feng, Y.; Zhu, Y.; Wu, B.; Wu, Y.; Xiao, Z.; Zheng, S. Assessment of a methanol-fueled integrated hybrid power system of solid oxide fuel cell and low-speed two-stroke engine for maritime application. Appl. Therm. Eng. 2023, 230, 120735. [Google Scholar] [CrossRef]

- Lv, J.; Sun, Y.; Zhang, Z.; Fang, Y. Optimization of operational parameters of marine methanol dual-fuel engine based on RSM-MOPSO. Process. Saf. Environ. Prot. 2024, 191, 2634–2652. [Google Scholar] [CrossRef]

- Di Micco, S.; Cigolotti, V.; Mastropasqua, L.; Brouwer, J.; Minutillo, M. Ammonia-powered ships: Concept design and feasibility assessment of powertrain systems for a sustainable approach in maritime industry. Energy Convers. Manag. X 2024, 22, 100539. [Google Scholar] [CrossRef]

- Seyam, S.; Dincer, I.; Agelin-Chaab, M. Optimization and comparative evaluation of novel marine engines integrated with fuel cells using sustainable fuel choices. Energy 2024, 301, 131629. [Google Scholar] [CrossRef]

- Gandiglio, M.; Marocco, P.; Nieminen, A.; Santarelli, M.; Kiviaho, J. Energy and environmental performance from field operation of commercial-scale SOFC systems. Int. J. Hydrogen Energy 2024, 85, 997–1009. [Google Scholar] [CrossRef]

- Wu, Z.; Zhu, P.; Yao, J.; Tan, P.; Xu, H.; Chen, B.; Yang, F.; Zhang, Z.; Ni, M. Thermo-economic modeling and analysis of an NG-fueled SOFC-WGS-TSA-PEMFC hybrid energy conversion system for stationary electricity power generation. Energy 2020, 192, 116613. [Google Scholar] [CrossRef]

- Fu, Z.; Lu, L.; Zhang, C.; Xu, Q.; Zhang, X.; Gao, Z.; Li, J. Fuel cell and hydrogen in maritime application: A review on aspects of technology, cost and regulations. Sustain. Energy Technol. Assess. 2023, 57, 103181. [Google Scholar] [CrossRef]

- Di Micco, S.; Minutillo, M.; Forcina, A.; Cigolotti, V.; Perna, A. Feasibility analysis of an innovative naval on-board power-train system with hydrogen- based PEMFC technology. E3S Web Conf. 2021, 312, 07009. [Google Scholar] [CrossRef]

- Di Micco, S.; Mastropasqua, L.; Cigolotti, V.; Minutillo, M.; Brouwer, J. A framework for the replacement analysis of a hydrogen-based polymer electrolyte membrane fuel cell technology on board ships: A step towards decarbonization in the maritime sector. Energy Convers. Manag. 2022, 267, 115893. [Google Scholar] [CrossRef]

- Pivetta, D.; Dall’Armi, C.; Taccani, R. Multi-objective optimization of hybrid PEMFC/Li-ion battery propulsion systems for small and medium size ferries. Int. J. Hydrogen Energy 2021, 46, 35949–35960. [Google Scholar] [CrossRef]

- Cavo, M.; Gadducci, E.; Rattazzi, D.; Rivarolo, M.; Magistri, L. Dynamic analysis of PEM fuel cells and metal hydrides on a zero-emission ship: A model-based approach. Int. J. Hydrogen Energy 2021, 46, 32630–32644. [Google Scholar] [CrossRef]

- Helgason, R.; Cook, D.; Davíðsdóttir, B. An evaluation of the cost-competitiveness of maritime fuels—A comparison of heavy fuel oil and methanol (renewable and natural gas) in Iceland. Sustain. Prod. Consum. 2020, 23, 236–248. [Google Scholar] [CrossRef]

- Thaler, B.; Kanchiralla, F.M.; Posch, S.; Pirker, G.; Wimmer, A.; Brynolf, S.; Wermuth, N. Optimal design and operation of maritime energy systems based on renewable methanol and closed carbon cycles. Energy Convers. Manag. 2022, 269, 116064. [Google Scholar] [CrossRef]

- Russo, D.; De Martino, M.; Di Benedetto, A.; Portarapillo, M.; Turco, M. Oxidative Methanol Reforming for Hydrogen-fed HT-PEMFC: Applications in the Naval Sector. Chem. Eng. Trans. 2023, 99, 367–372. [Google Scholar] [CrossRef]

- E4Ships. Available online: https://www.e4ships.de/english/maritime-shipping/pa-x-ell-2/ (accessed on 18 June 2025).

- Freudenberg e-Power Systems. Available online: https://www.freudenberg.com/press-media/press-releases/detail/ship-lengths-ahead (accessed on 25 June 2025).

- Blue World Technologies. Available online: https://www.blue.world/ (accessed on 25 June 2025).

- Advent Technology. Available online: https://advent.energy/advent-technologies-a-s-5kw-fuel-cell-systems-roll-out-in-asian-market-for-telecom-sector/ (accessed on 25 June 2025).

- Sorrentino, V.; Altosole, M.; De Luca, F.; Micoli, L.; Mocerino, L.; Russo, R. Preliminary modeling of a ferry methanol fuel cell power plant by using AVL Cruise M software. In Advances in Maritime Technology and Engineering; CRC Press: Boca Raton, FL, USA, 2024; pp. 63–70. [Google Scholar]

- ITTC-Recommended Procedures and Guidelines. Available online: https://ittc.info/media/1217/75-02-02-01.pdf (accessed on 25 June 2025).

- Balsamo, F.; Capasso, C.; Coppola, T.; Micoli, L.; Russo, R.; Veneri, O. A case study on High-Temperature Fuel Cells for Hybrid electric Ship Propulsion. In Proceedings of the 2023 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Venice, Italy, 29–31 March 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Justesen, K.K.; Andreasen, S.J.; Pasupathi, S.; Pollet, B.G. Modeling and control of the output current of a Reformed Methanol Fuel Cell system. Int. J. Hydrogen Energy 2015, 40, 16521–16531. [Google Scholar] [CrossRef]

- Groene-Bootmotoren. Available online: https://groene-bootmotoren.nl/winkel/motoren/binnenmotor/water-world-10-0 (accessed on 25 June 2025).

- Clean Tech Batteries—Clean Tron. Available online: https://www.cleantron.nl/wp-content/uploads/2024/04/P4X.pdf (accessed on 25 June 2025).

- Garibaldi, D.; Bianchi, F.R.; Altosole, M.; Scamardella, F.; Balsamo, F.; Bosio, B. Plant Simulation of a Methanol Fueled HT PEM Fuel Cell for Ship Propulsion. In Proceedings of the 2024 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Naples, Italy, 26–29 November 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Thomas, S.; Jeppesen, C.; Steenberg, T.; Araya, S.S.; Vang, J.R.; Kær, S.K. New load cycling strategy for enhanced durability of high temperature proton exchange membrane fuel cell. Int. J. Hydrogen Energy 2017, 42, 27230–27240. [Google Scholar] [CrossRef]

- Thomas, S. Operational Strategies for Longer Durability of HT-PEM Fuel Cells Operating on Reformed Methanol. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 2017. [Google Scholar]

- Song, K.; Hou, T.; Jiang, J.; Grigoriev, S.A.; Fan, F.; Qin, J.; Wang, Z.; Sun, C. Thermal management of liquid-cooled proton exchange membrane fuel cell: A review. J. Power Sources 2025, 648, 237227. [Google Scholar] [CrossRef]

- Sahlin, S.L.; Andreasen, S.J.; Kær, S.K. System model development for a methanol reformed 5 kW high temperature PEM fuel cell system. Int. J. Hydrogen Energy 2015, 40, 13080–13089. [Google Scholar] [CrossRef]

- Minutillo, M.; Perna, A.; Jannelli, E. SOFC and MCFC system level modeling for hybrid plants performance prediction. Int. J. Hydrogen Energy 2014, 39, 21688–21699. [Google Scholar] [CrossRef]

- Kim, J.; Lee, S.-M.; Srinivasan, S.; Chamberlin, C.E. Modeling of Proton Exchange Membrane Fuel Cell Performance with an Empirical Equation. J. Electrochem. Soc. 1995, 142, 2670–2674. [Google Scholar] [CrossRef]

- Jannelli, E.; Minutillo, M.; Perna, A. Analyzing microcogeneration systems based on LT-PEMFC and HT-PEMFC by energy balances. Appl. Energy 2013, 108, 82–91. [Google Scholar] [CrossRef]

| Ref. | System | Scope |

|---|---|---|

| [23] | 1 kW HT-PEMFCs fed by a methanol reformer | Demonstration of a fully self-sustained system. |

| [24] | 90 kW HT-PEMFCs installed on board MS Mariella | Use of HT-PEMFCs for auxiliary power generation. |

| [25] | 500 kW HT-PEMFC system for marine application | Press release-type approval of the system from RINA for the safe use in marine environments. |

| [26] | Up to 2 MW HT-PEMFC systems | Press release—development of the system for marine applications (mainly container vessels). |

| This study | 2 × 5 kW HT-PEMFCs for marine application | Thermodynamic modeling from experimental data on the system and feasibility analysis for installation on a 10 m boat for the full power system. |

| Ship Speed (VS) | Froude Number (FN) | Residual Resistance (CR) |

|---|---|---|

| (kn) | (-) | (-) |

| 6.00 | 0.20 | |

| 7.00 | 0.24 | |

| 8.00 | 0.27 | |

| 8.50 | 0.29 | |

| 9.00 | 0.31 | |

| 9.50 | 0.32 | |

| 10.00 | 0.34 | |

| 10.80 | 0.37 | |

| 12.00 | 0.41 |

| Scale factor | 2.33 | - |

| Waterline length (LWL) | 10.00 | m |

| Wetted surface | 17.52 | m2 |

| Waterline breadth (BWL) | 1.89 | m |

| Depth (T) | 0.55 | m |

| Hull volume | 3.61 | m3 |

| Ship Speed | Froude Number (FN) | Residual Resistance (CR) | Brake Power (PB) |

|---|---|---|---|

| (kn) | (-) | (-) | (W) |

| 3.93 | 0.20 | 450 | |

| 4.58 | 0.24 | 779 | |

| 5.24 | 0.27 | 1217 | |

| 5.57 | 0.29 | 1462 | |

| 5.89 | 0.31 | 1624 | |

| 6.22 | 0.32 | 1784 | |

| 6.55 | 0.34 | 2144 | |

| 7.07 | 0.37 | 3272 | |

| 7.86 | 0.41 | 6747 |

| Cells Capacity @ 1 A Discharge | 37 Ah |

| Nominal Voltage | 51.1 V |

| Capacity | 1890 Wh |

| Peak Discharge Current | 120 A |

| Dimensions | 429 × 266 × 78 mm |

| Weight | 12.4 kg |

| Parameters | Data |

|---|---|

| Anode feeding stream | Hydrogen rich gas |

| Cathode feeding stream | Air |

| Nominal power | 5 kW |

| Number of cells | 120 |

| Number of stacks | 1 |

| Minimum H2 stoichiometry | 1.35 |

| Maximum utilization H2 | 0.74 |

| O2 stoichiometry | 2–3 |

| O2 utilization | 0.33–0.50 |

| Reformer temperature | 270 °C |

| Stack temperature | 160 °C |

| Ventilation outlet temperature | <60° |

| Fuel (v/v methanol/water) | 60/40 |

| Current change slope (load increase) | 30 mA/s |

| Current change slope (load decrease) | 60 mA/s |

| Active area | 165 cm2 |

| Exhaust temperature | 160 °C |

| (V/dec) | (Ω cm2) | |||

|---|---|---|---|---|

| 0.7407 | 0.0318 | 0.2769 | 0.097 | 0.15 |

| Flows | Mass Flow Rate (kg/h) | T (°C) | ||||

|---|---|---|---|---|---|---|

| System Power/Flows | 100% | 50% | 30% | 100% | 50% | 30% |

| CH3OH | 2.05 | 0.9 | 0.55 | 25 | 25 | 25 |

| H2O | 1.37 | 0.6 | 0.37 | 25 | 25 | 25 |

| 1 | 3.42 | 1.5 | 0.92 | 21 | 21 | 21 |

| 2 | 3.42 | 1.5 | 0.92 | 270 | 270 | 270 |

| 3 | 3.42 | 1.5 | 0.92 | 270 | 270 | 270 |

| ANODE-IN | 3.42 | 1.5 | 0.92 | 160 | 160 | 160 |

| AIR | 25.30 | 13.24 | 6.06 | 25 | 25 | 25 |

| 4 | 51.56 | 22.25 | 13.21 | 270 | 270 | 270 |

| CATH-IN | 25.30 | 5.18 | 6.06 | 160 | 160 | 160 |

| ANODEOUT | 3.05 | 1.34 | 0.82 | 160 | 160 | 160 |

| CATH-OUT | 25.66 | 5.35 | 6.16 | 160 | 160 | 160 |

| AIRCB | 22.85 | 4.14 | 5.71 | 25 | 25 | 25 |

| 5 | 25.30 | 13.24 | 6.06 | 63 | 65 | 67 |

| 6 | 51.56 | 22.25 | 13.21 | 226 | 230 | 231 |

| Item | Weight (kg) |

|---|---|

| HT-PEMFC | 2 × 65 |

| Battery pack (3 modules) | 37 |

| Electric motor | 76 |

| Fuel tank | 63.5 (70 L tank) |

| Crew + passengers | 10 × 80 |

| Ship displacement | 3698 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Micco, S.; Scamardella, F.; Altosole, M.; Arsie, I.; Minutillo, M. Advancing Sustainable Propulsion Solutions for Maritime Applications: Numerical and Experimental Assessments of a Methanol HT-PEMFC System. Energies 2025, 18, 5119. https://doi.org/10.3390/en18195119

Di Micco S, Scamardella F, Altosole M, Arsie I, Minutillo M. Advancing Sustainable Propulsion Solutions for Maritime Applications: Numerical and Experimental Assessments of a Methanol HT-PEMFC System. Energies. 2025; 18(19):5119. https://doi.org/10.3390/en18195119

Chicago/Turabian StyleDi Micco, Simona, Filippo Scamardella, Marco Altosole, Ivan Arsie, and Mariagiovanna Minutillo. 2025. "Advancing Sustainable Propulsion Solutions for Maritime Applications: Numerical and Experimental Assessments of a Methanol HT-PEMFC System" Energies 18, no. 19: 5119. https://doi.org/10.3390/en18195119

APA StyleDi Micco, S., Scamardella, F., Altosole, M., Arsie, I., & Minutillo, M. (2025). Advancing Sustainable Propulsion Solutions for Maritime Applications: Numerical and Experimental Assessments of a Methanol HT-PEMFC System. Energies, 18(19), 5119. https://doi.org/10.3390/en18195119