1. Introduction

Environmental challenges, including global warming and climate change, are intensifying on a global scale. To mitigate further environmental harm, there is a pressing need for researchers and industry experts to prioritize advancements in renewable energy and energy management systems. Currently, 10% of global water usage occurs in households, with projections indicating a 20% rise over the next decade. In Canada, residents consume an average of 75 L of hot water daily, with water heating accounting for approximately 17.2% of household energy consumption [

1]. These figures underscore the importance of adopting technologies such as drain water heat recovery (DWHR) to decrease energy use associated with water heating in homes.

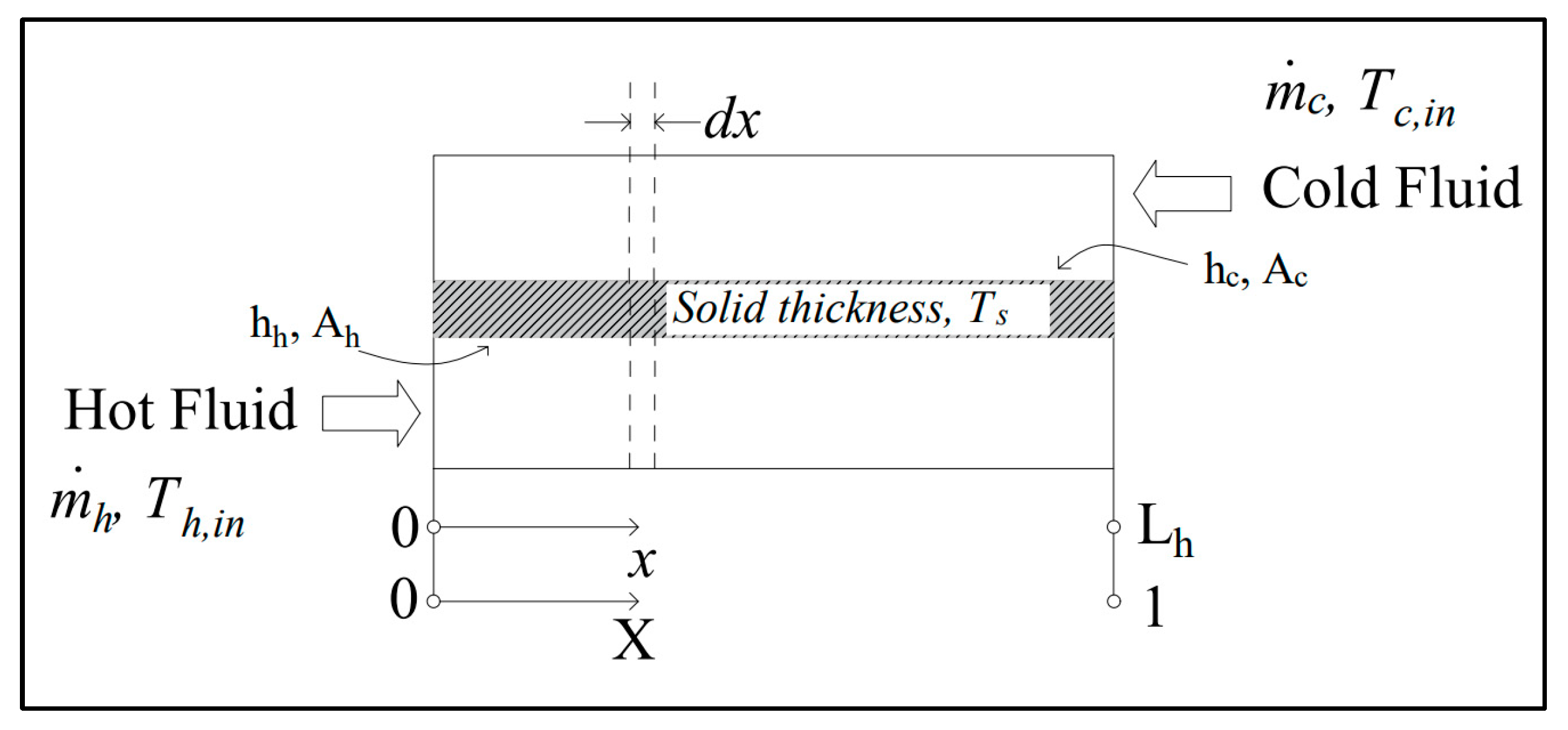

A DWHR system is an effective solution for reducing energy consumption associated with water heating by enabling heat transfer between two fluid streams. In residential applications, these systems work by transferring thermal energy from warm greywater to incoming cold freshwater. Rather than being lost, the residual heat in the greywater is used to preheat the cold water supply before it reaches the water heater, benefiting various household uses such as showers and dishwashers. DWHR systems can differ in design, orientation, size, and installation location within a building. Studies indicate that vertically oriented units tend to recover more heat compared to horizontal configurations, though their implementation may be limited by spatial constraints [

2]. Current vertical DWHR devices typically consist of either a single or multiple copper helical tubes wrapped around a central copper drainpipe. As warm greywater flows through the central pipe, it forms a thin film on its inner surface, facilitating heat transfer to the cold freshwater circulating through the outer helical coils. These vertical systems are often referred to as falling film or gravity film heat exchangers, as they operate passively without requiring additional energy input or ongoing maintenance after installation.

Extensive research has been carried out on DWHR systems operating under steady-state conditions, exploring various configurations and operational parameters. The general agreement among studies is that harnessing waste heat from drain water is a practical way to reduce energy consumption for water heating [

3,

4,

5,

6]. Findings indicate that such systems can cut energy use for water heating by up to 25% [

7,

8]. To evaluate the thermal performance of heat exchangers, the NTU-effectiveness method is commonly employed, as it calculates the ratio of actual heat transfer to the maximum possible under steady-state conditions [

9]. Zaloum et al. [

10] utilized this method to assess several residential DWHR units. After testing eight different devices, they identified that the most efficient design featured a quadruple helical pass for cold-water flow. In another study, Manouchehri and Collins [

11] highlighted that the rated performance of a DWHR system may not accurately reflect its real-world performance once installed. They developed an empirical model to predict actual device performance more precisely and validated it through experimental testing. Beentjes et al. [

12] discovered that in falling-film DWHR systems, there exists a critical flow rate below which effectiveness becomes unpredictable due to uneven wetting of the central copper pipe at low flow rates. Additionally, they observed an inverse relationship between effectiveness and flow rate. Expanding on this, Salama [

13] and Salama and Sharqawy [

14] noted that when a DWHR system operates under partially wet conditions, its effectiveness can drop by as much as 28.5%. For optimal performance, the inner surface of the drainpipe must maintain a consistent film of drain water.

The performance and heat transfer capability of a heat exchanger during the transition period before reaching steady state are critical factors. A heat exchanger operates in a transient state when disturbances occur in its inlet conditions, such as changes in temperature or flow rate, which subsequently affect outlet parameters. Until these variables stabilize, the system remains in a transient state. Research on the transient behavior of DWHR systems has been limited, with Zaloum et al. [

10] reporting only minor differences between steady-state and transient data. However, other studies have extensively investigated counter-flow heat exchangers, offering insights applicable to DWHR systems. For instance, Askar et al. [

15] examined the transient response of a cross-flow heat exchanger when subjected to changes in operating conditions, such as temperature and flow rate. Their experimental results revealed that the two fluid streams did not respond immediately or uniformly to a step change in mass flow rate. Additionally, they observed that larger step changes led to increased response times. Similar findings were reported in another study analyzing the transient thermal performance of cross-flow heat exchangers under disturbances in inlet mass flow rates [

16]. This study highlighted that the delayed response of the fluids to inlet perturbations is due to energy storage in the heat exchanger walls. Furthermore, the authors noted that the size of the device plays a key role in determining response time, as it is directly linked to the residence time of the fluids. In related work, Silaipillayarputhur [

17] demonstrated that higher mass flow rates reduce the time required to achieve steady-state conditions, as the temperature difference propagates through the heat exchanger more quickly.

Researchers have shown considerable interest in developing analytical models for heat exchangers operating under transient conditions, often employing similar methodologies that incorporate the initial and final fluid temperatures. Lachi et al. [

18] investigated the time constant of a double-pipe heat exchanger under varying flow rates. Their model for the time constant relies on the initial and final bulk temperatures of the fluids, as well as the flow rates. Similarly, Yin and Jensen [

19] formulated an analytical model to describe the transient response of counter-flow heat exchangers. They approximated the system’s behavior using an integral model that considers the initial and final temperature distributions to derive a time-dependent function. Their analysis involves two first-order ordinary differential equations to represent the time-varying temperatures of the fluid and tube wall. However, their work provides limited insight into how a step change in inlet conditions might influence the overall performance of the heat exchanger.

The Laplace transform has been widely employed in analyzing the transient performance of heat exchangers, owing to its effectiveness in solving problems within the frequency domain. Romie [

20] determined the temperature response of a counter-flow heat exchanger by applying a finite difference method to solve the governing equations and utilizing the Laplace transform to calculate the fluid exit temperatures. Similarly, Yang et al. [

21] developed an analytical model to evaluate the dynamic behavior of heat exchanger networks, relying on the Laplace transform to derive the system’s outlet temperature function in the Laplace domain. Later, Yang and Tran [

22] refined their model to address convergence challenges and provided the outlet temperature in the time domain. However, this approach to constructing heat exchanger networks is not practical for DWHR systems due to their inherent complexity. Other researchers have also used the Laplace transform to derive equations for outlet temperature distributions in counter-flow and cross-flow heat exchangers, but no such application has been extended to model DWHR systems [

23,

24].

Although the DWHR device has been proven effective at reducing energy consumption for water heating, economic and life cycle analyses are crucial for the success of the device. Zaloum et al. [

10] tested several DWHR-installed devices and found the best-performing device saved

$154.32 worth of fuel for water heating in the first year. Their simulation showed the annual savings decreasing by an average of

$5 per year for 30 years and a total savings of

$2,177.83 over the lifetime of the device. For the device studied, the payback period was under six years [

10]. Ravichandran et al. [

25] studied the influence of climatic conditions on DWHR systems, and all scenarios showed that the implementation of a DWHR system is more sustainable than the baseline system. They showed the economic savings over the lifetime of a DWHR system range from

$1960 in warm regions to

$7160 in cold regions with an electric water heater.

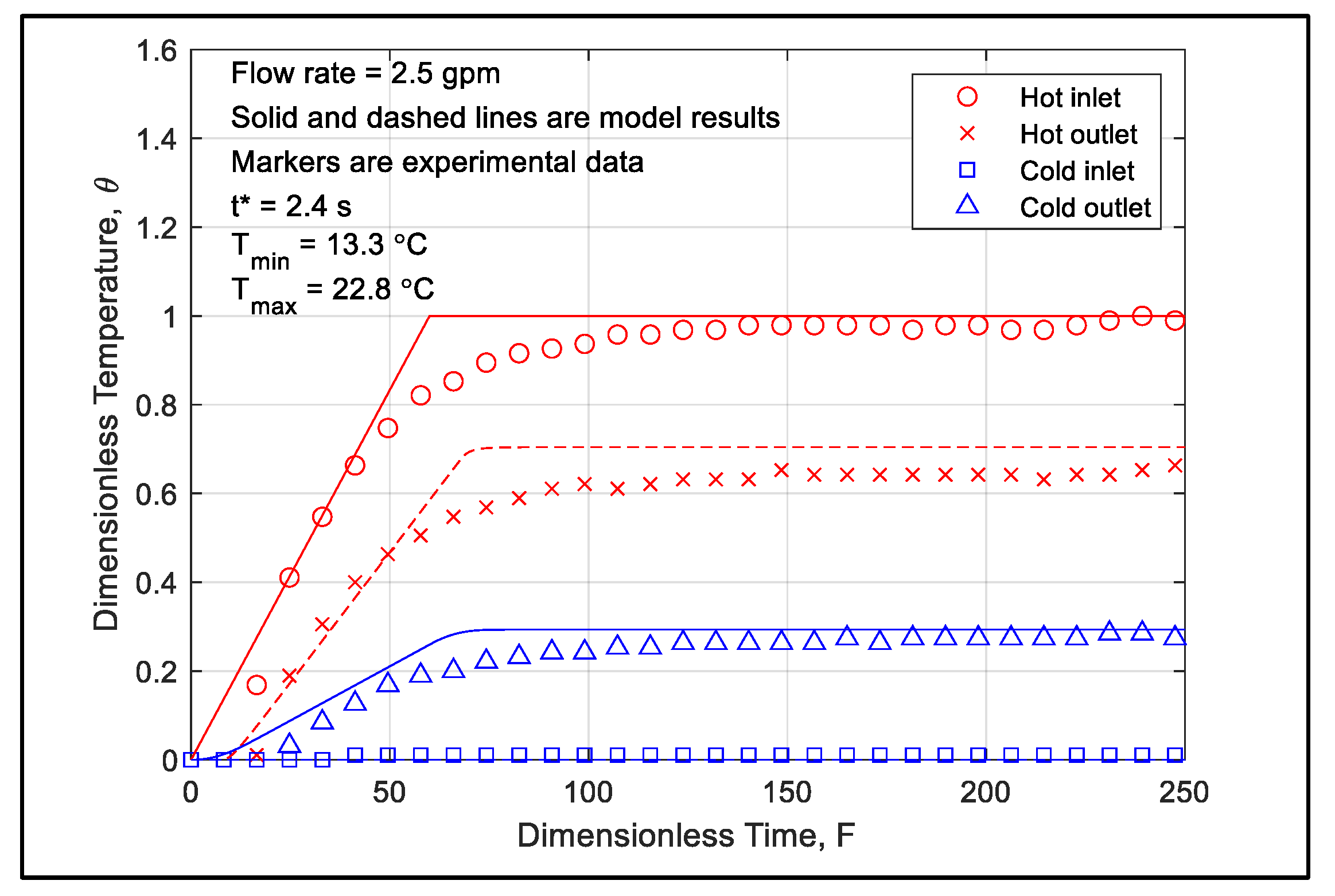

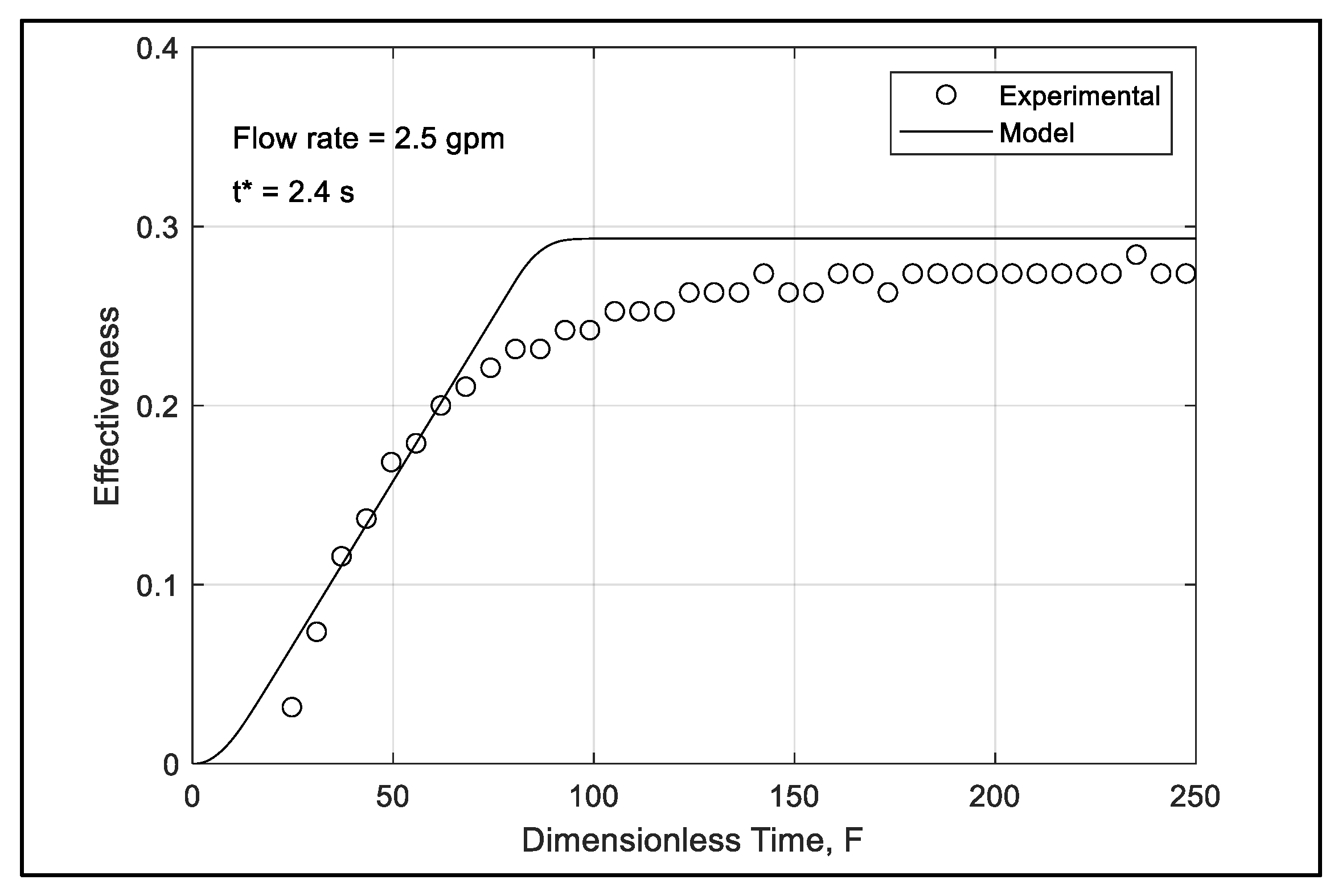

The review of existing literature reveals a lack of significant research on the transient performance of residential DWHR systems. Most studies have focused on steady-state performance, a common approach in heat exchanger evaluations. However, due to the inherently dynamic nature of water usage in residential settings, heat recovery in these systems is far from static. To address this gap, this study investigates the dynamic behavior of a residential DWHR device through both experimental and numerical methods, considering the impact of transient operating periods on overall system performance. The time-dependent variations in hot and cold-water temperatures are measured and modeled under fluctuating heat input from the water heater. A mathematical model tailored to the DWHR device as a counter-flow heat exchanger is developed and solved numerically. The analysis provides insights into the system’s effectiveness and economic advantages during transient operation.

The remainder of the paper is organized as follows:

Section 2 describes the experimental setup used for testing the DWHR system, the development and solution of the mathematical model, and the uncertainty analysis conducted to ensure result accuracy.

Section 3 provides the results and discussion, including a technical performance analysis of the DWHR under transient conditions, followed by an economic analysis that demonstrates how transient performance influences energy savings and cost-effectiveness.