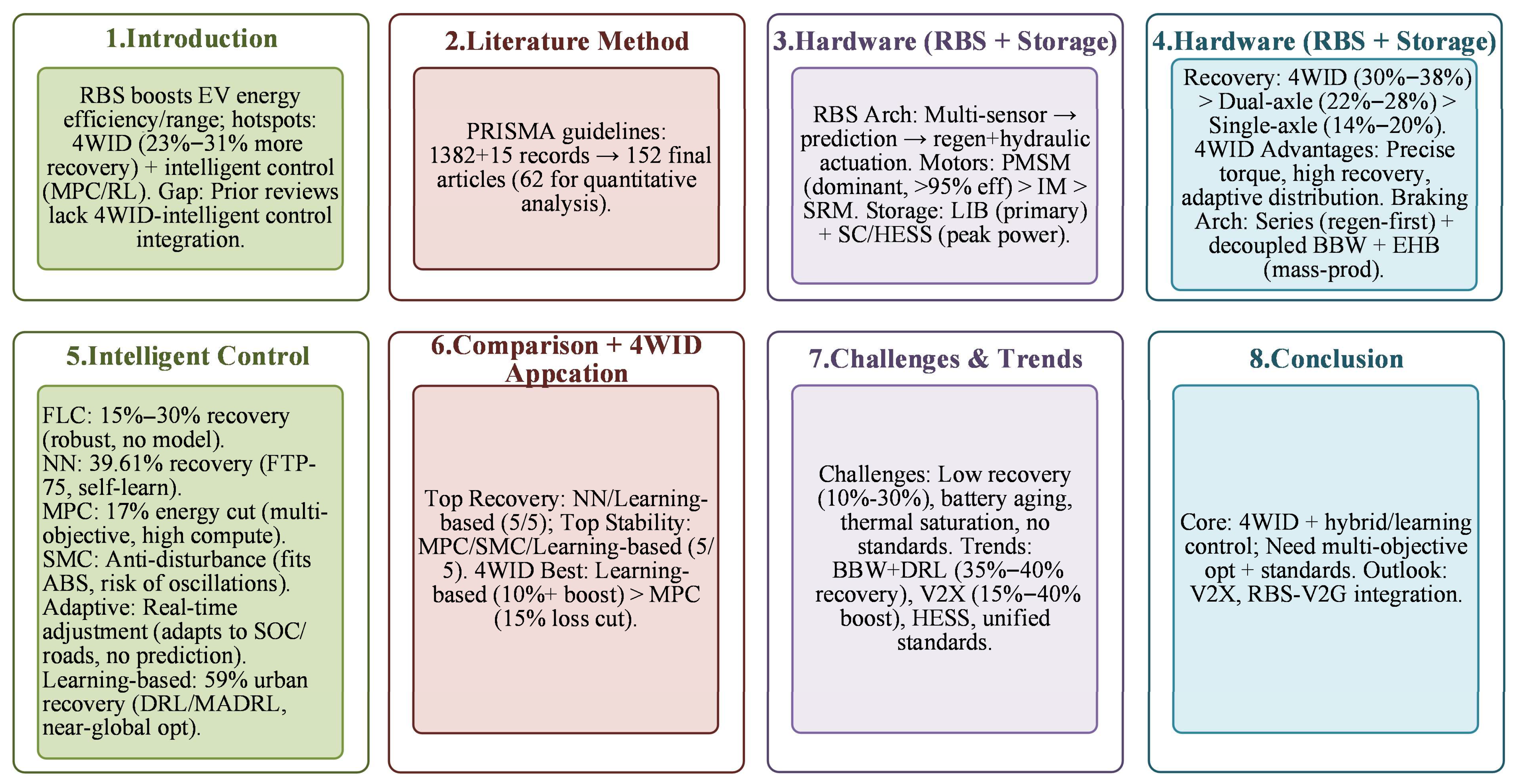

System Integration to Intelligent Control: State of the Art and Future Trends of Electric Vehicle Regenerative Braking Systems

Abstract

1. Introduction

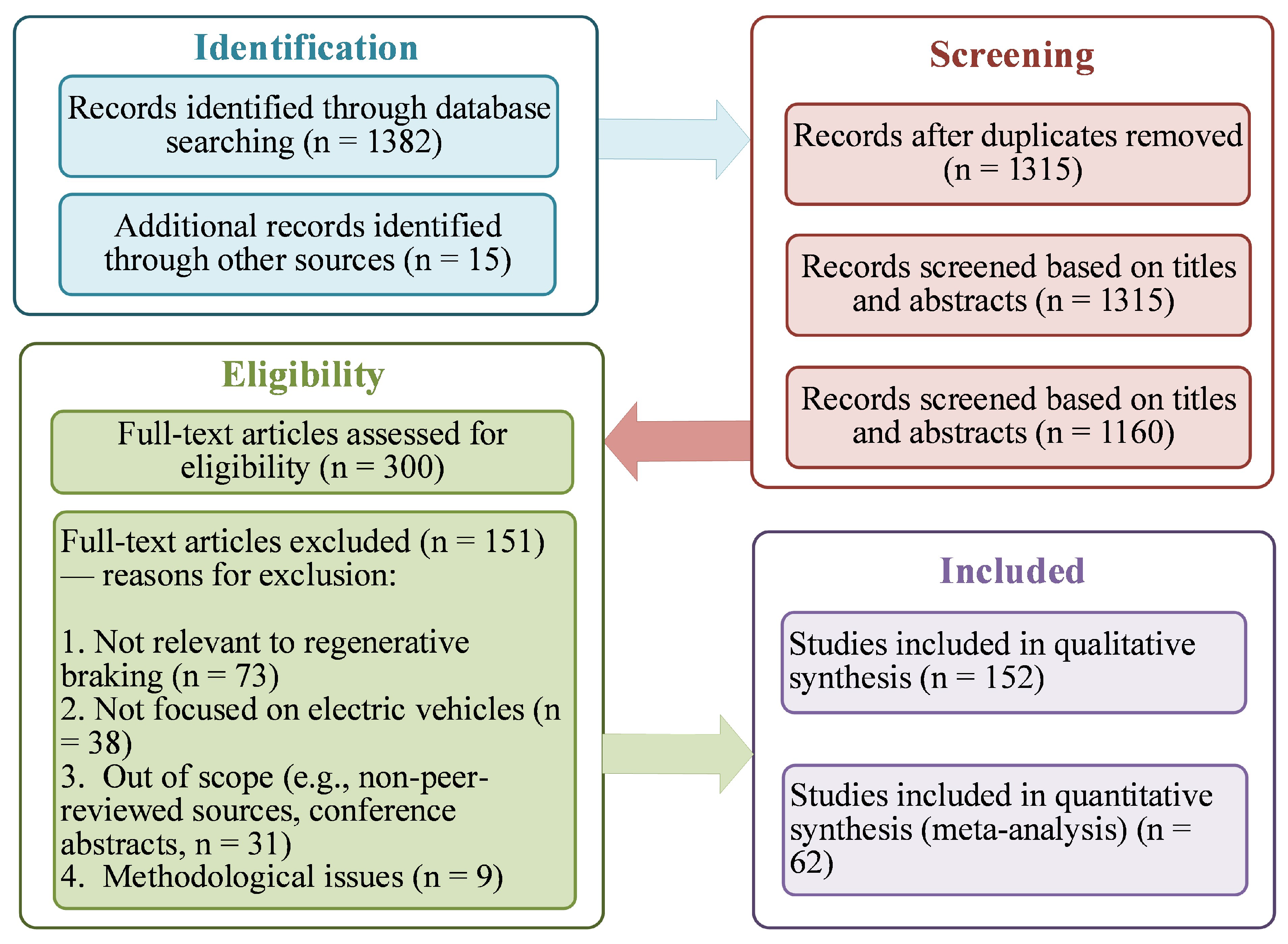

2. Literature Selection and Data Extraction Methodology

- Identification of Studies.

- Screening of Articles.

- Eligibility Assessment.

- Final Inclusion.

- Data Extraction and Synthesis.

3. RBS and Power Storage Technologies for EVs

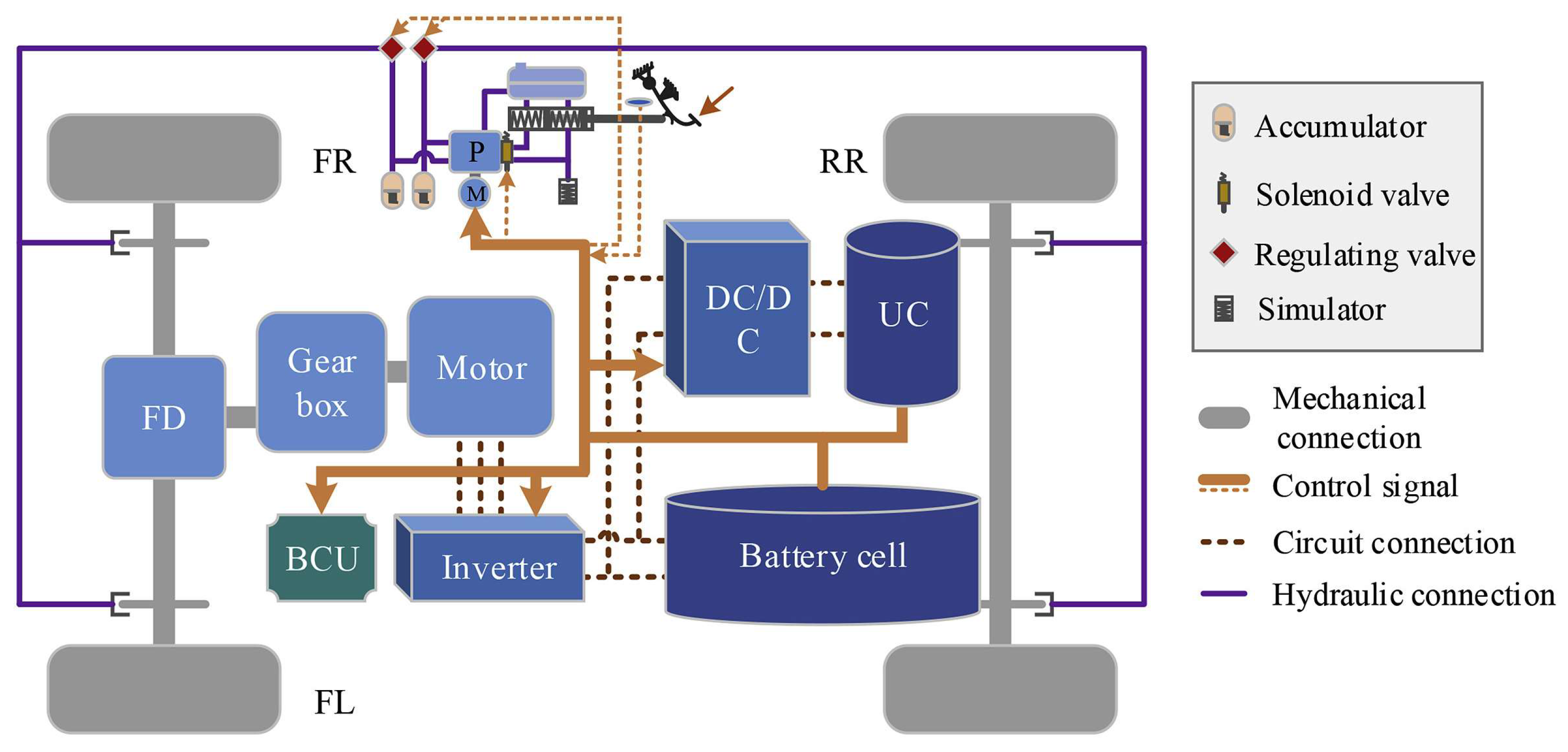

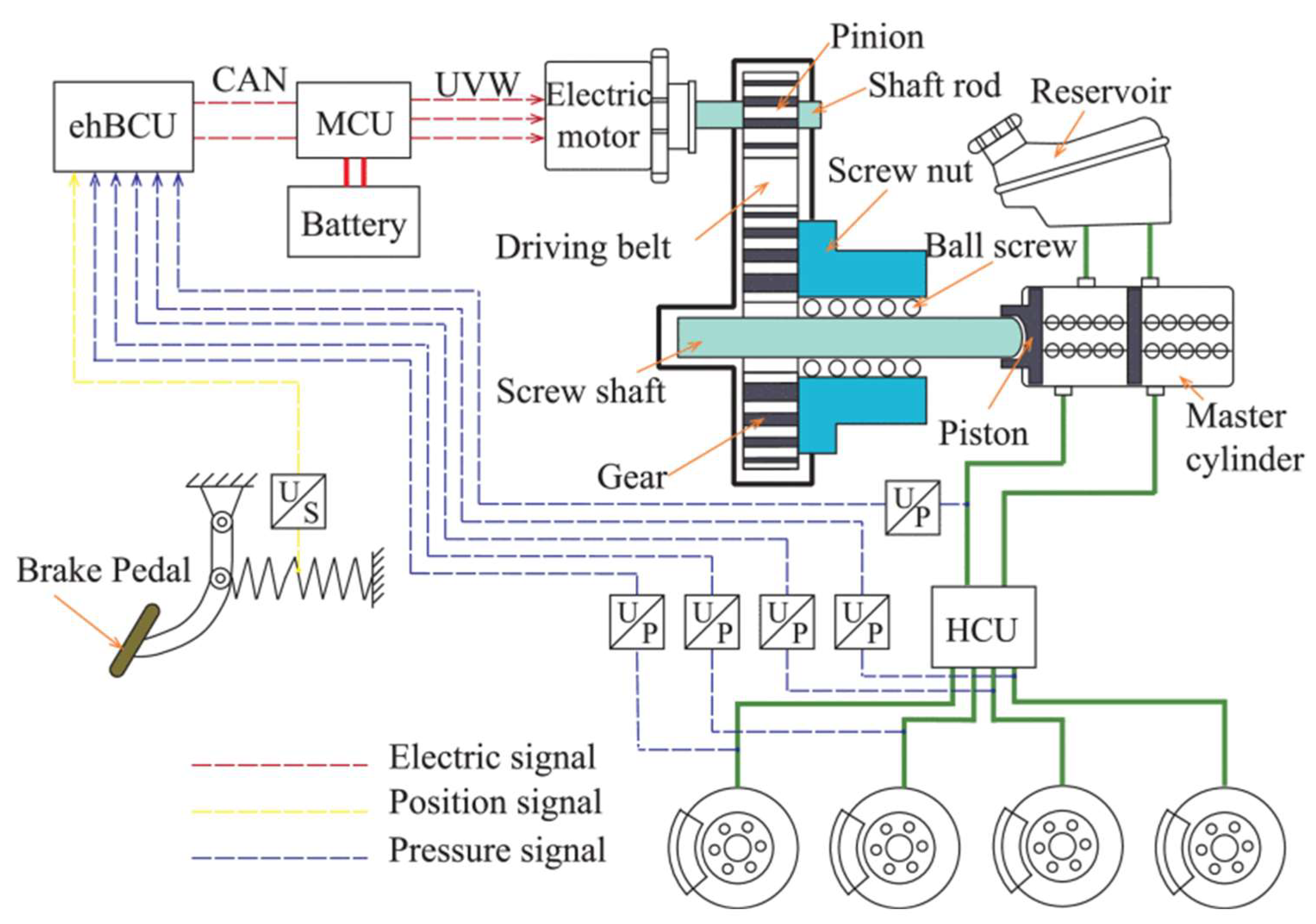

3.1. Control System Architecture of RBS in EVs

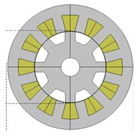

3.2. Comparison of Common Motor Types

- Brushed Direct-Current motor.

- Induction motor.

- Permanent-Magnet Synchronous Motor.

- Switched Reluctance Motor.

3.3. Energy-Storage Units

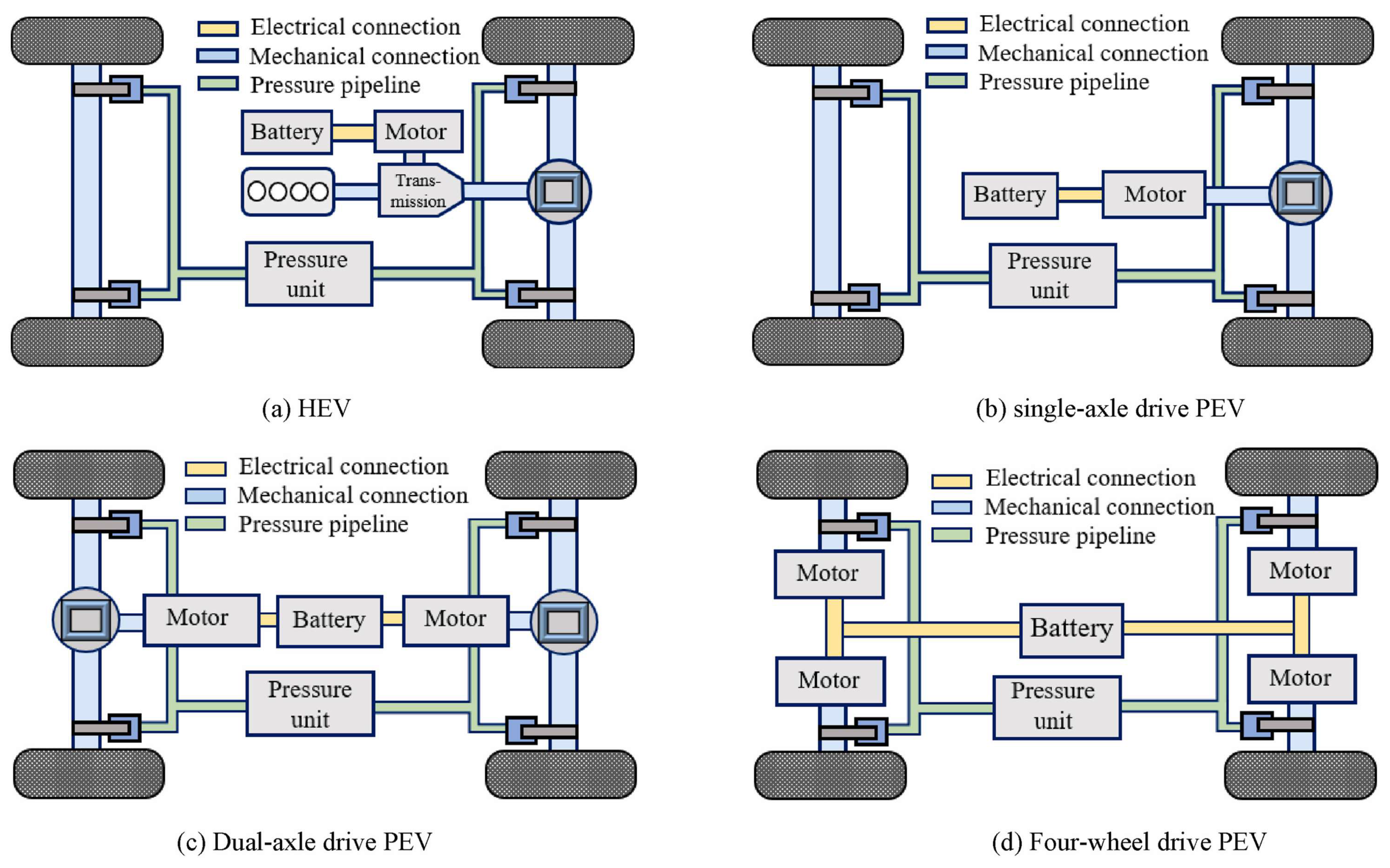

4. Analysis of the RBS and Four-Wheel Independent Drive Architecture

4.1. RBS Characteristics of Different Drive Configurations

- Single-axle-drive EVs

- Dual-axle-drive EVs

- Four-wheel independent drive (4WID) EVs

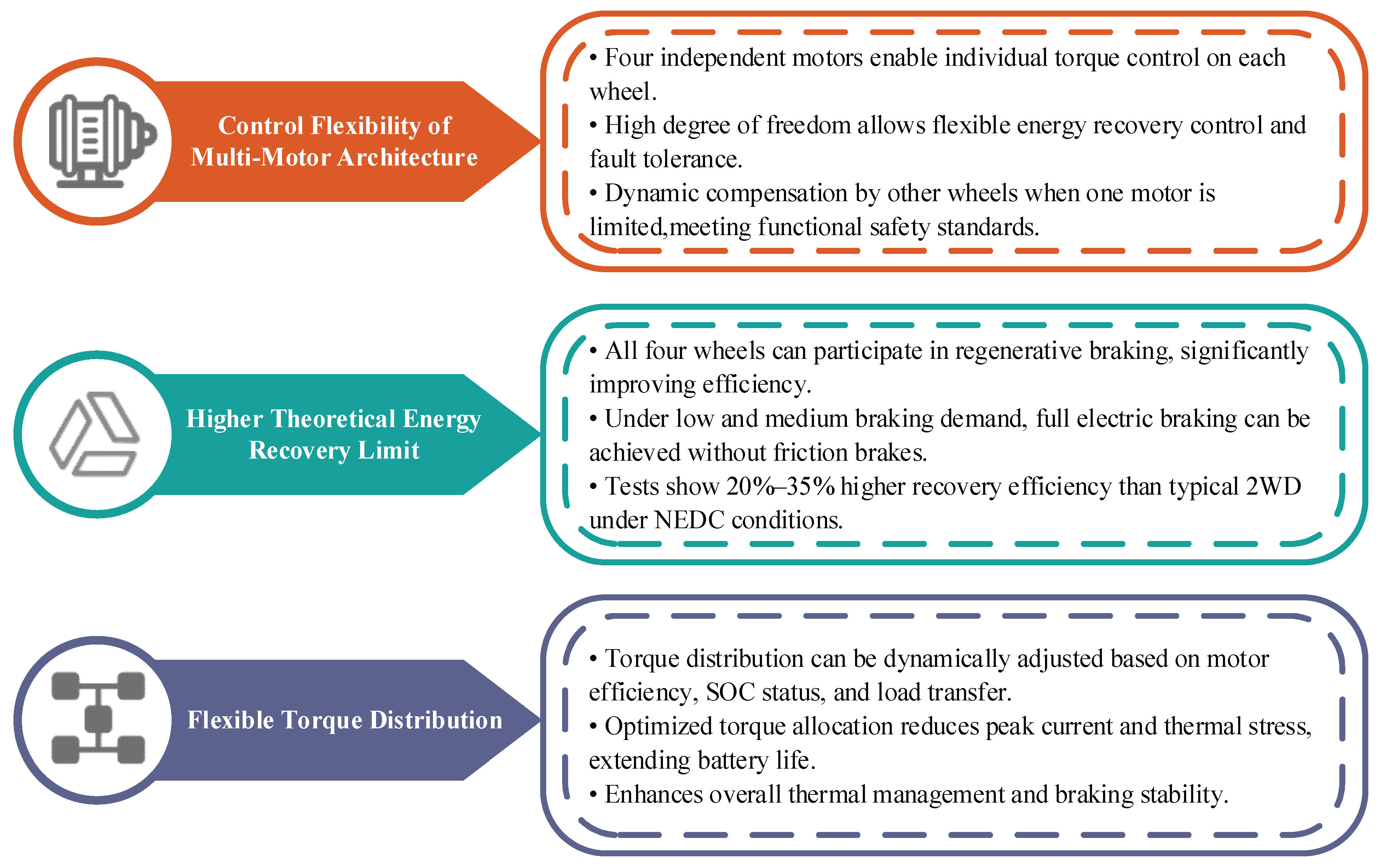

4.2. Distinct Advantages of the 4WID Architecture for Regenerative Braking

- Expanded control authority afforded by the multi-motor topology

- 2.

- Higher theoretical energy-recovery ceiling

- 3.

- Adaptive torque-distribution capability

4.3. Composite Braking-System Architectures

- System architecture has shifted from a parallel to a predominantly series layout.

- Pedal design has moved from direct mechanical coupling to an electronically decoupled interface.

- Actuation hardware has progressed from a conventional hydraulic circuit to brake-by-wire devices—most commonly the electro-hydraulic brake (EHB) and, in research settings, the electro-mechanical brake (EMB) [48].

- Architectural perspective

- Pedal interface

- Actuator technology

4.4. Traditional Control Strategies for RBS in EVs

5. Intelligent Control Strategies for RB Energy Recovery in EVs

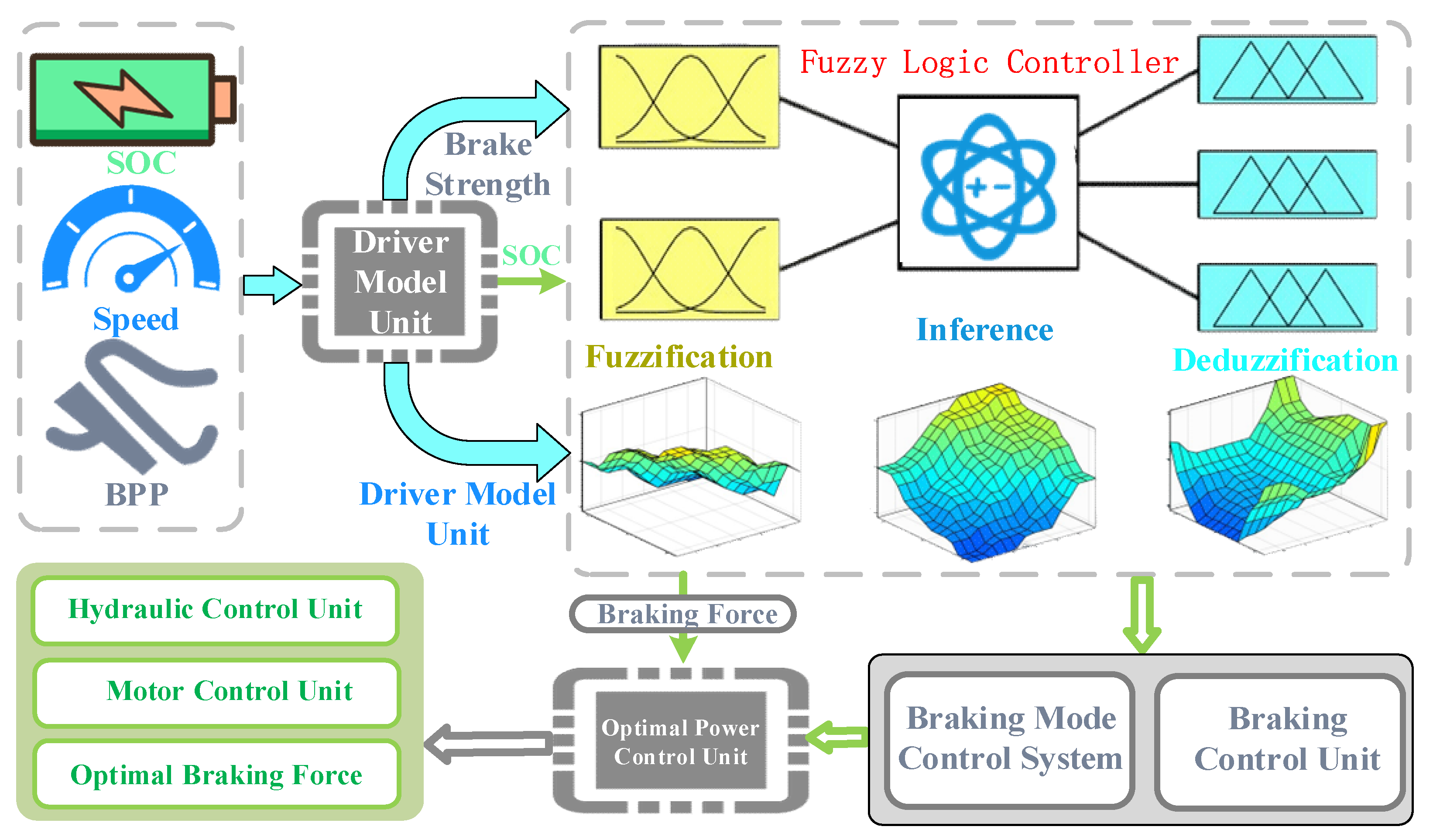

5.1. Fuzzy Logic Control (FLC) Method

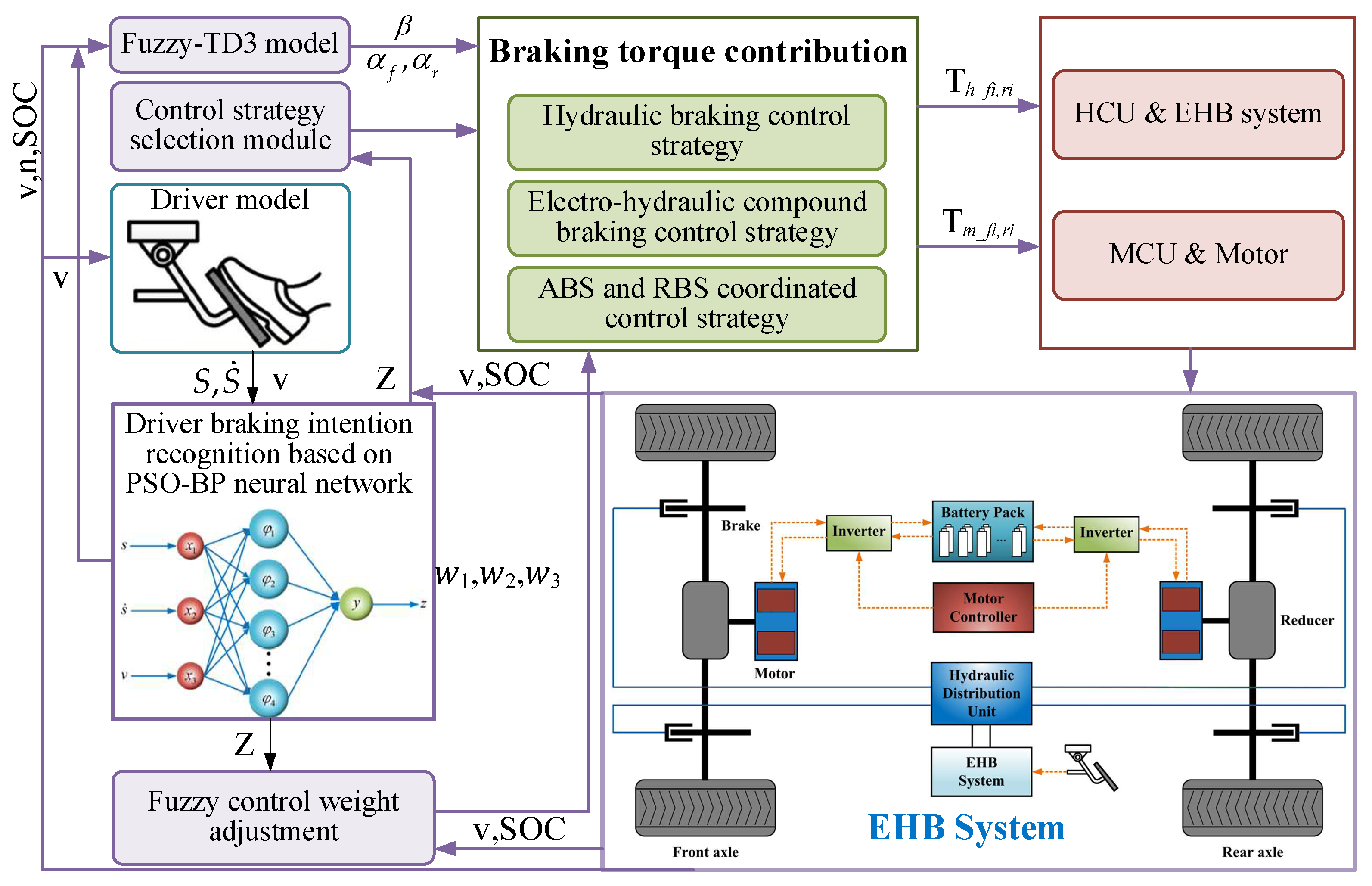

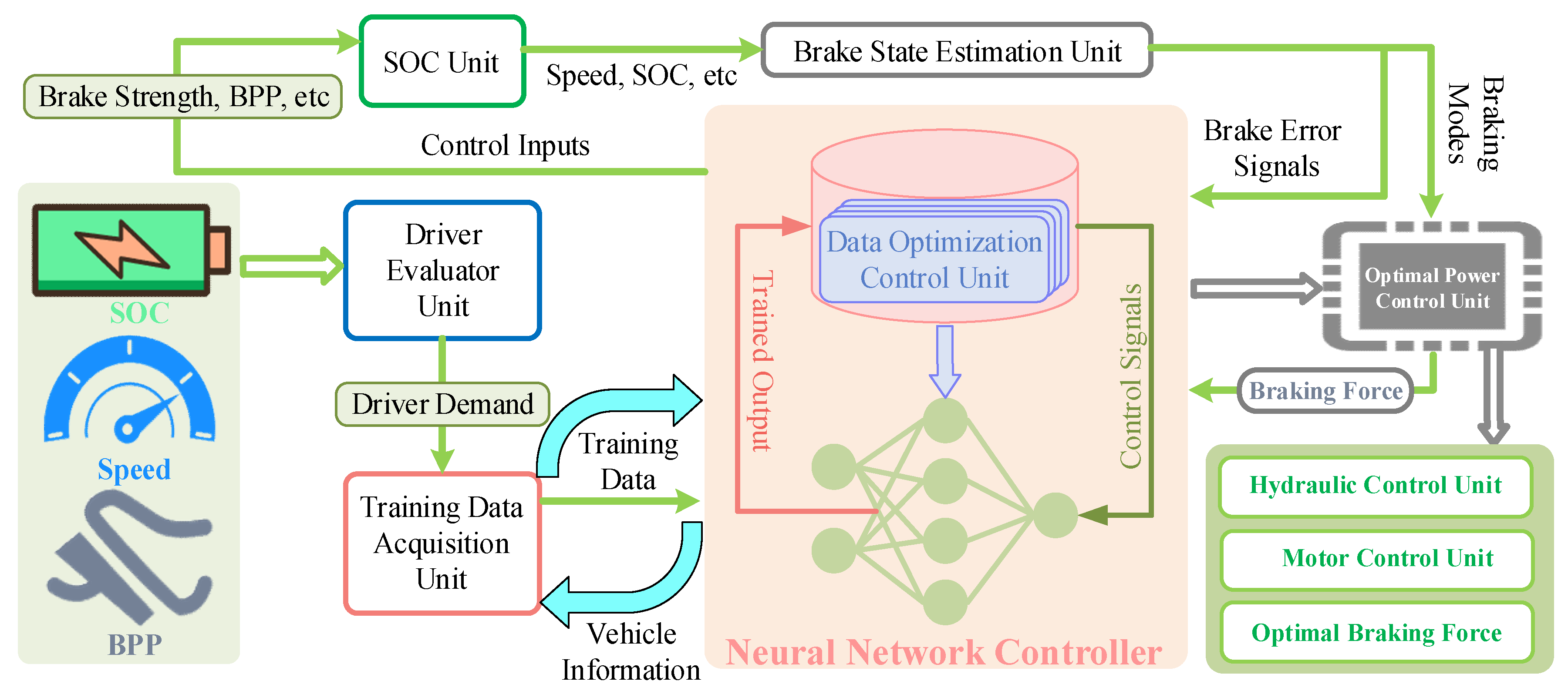

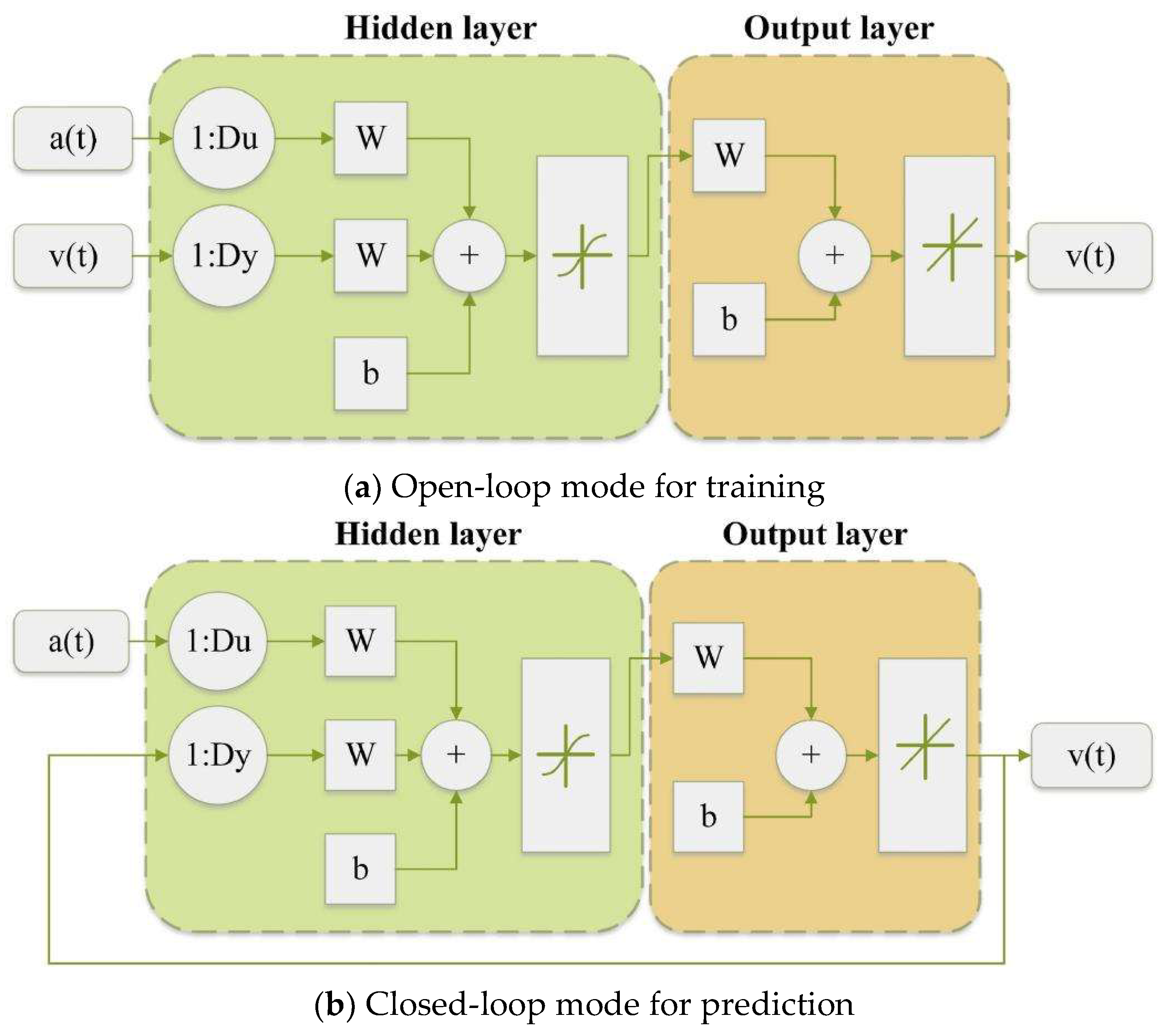

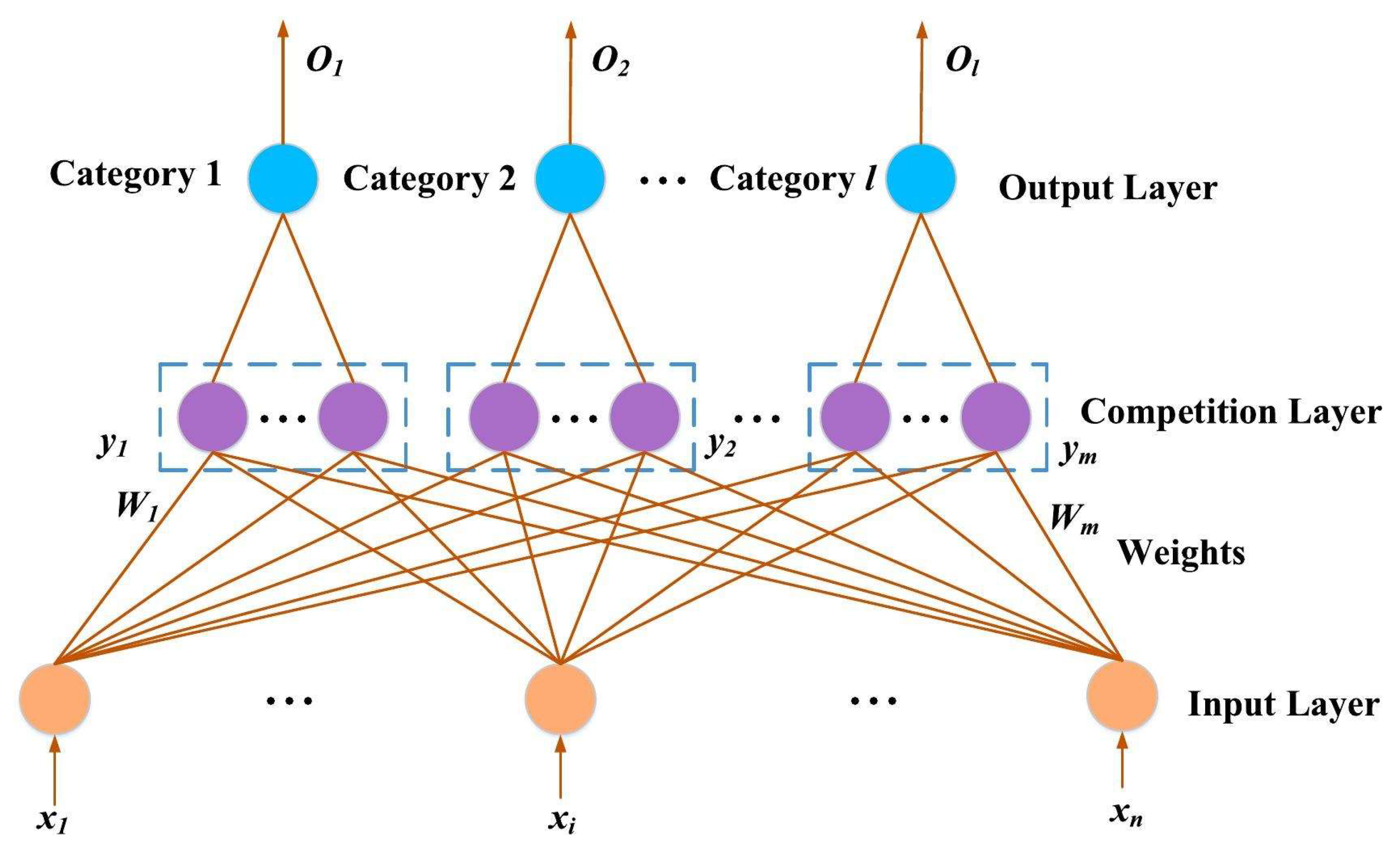

5.2. Neural Network Control Method

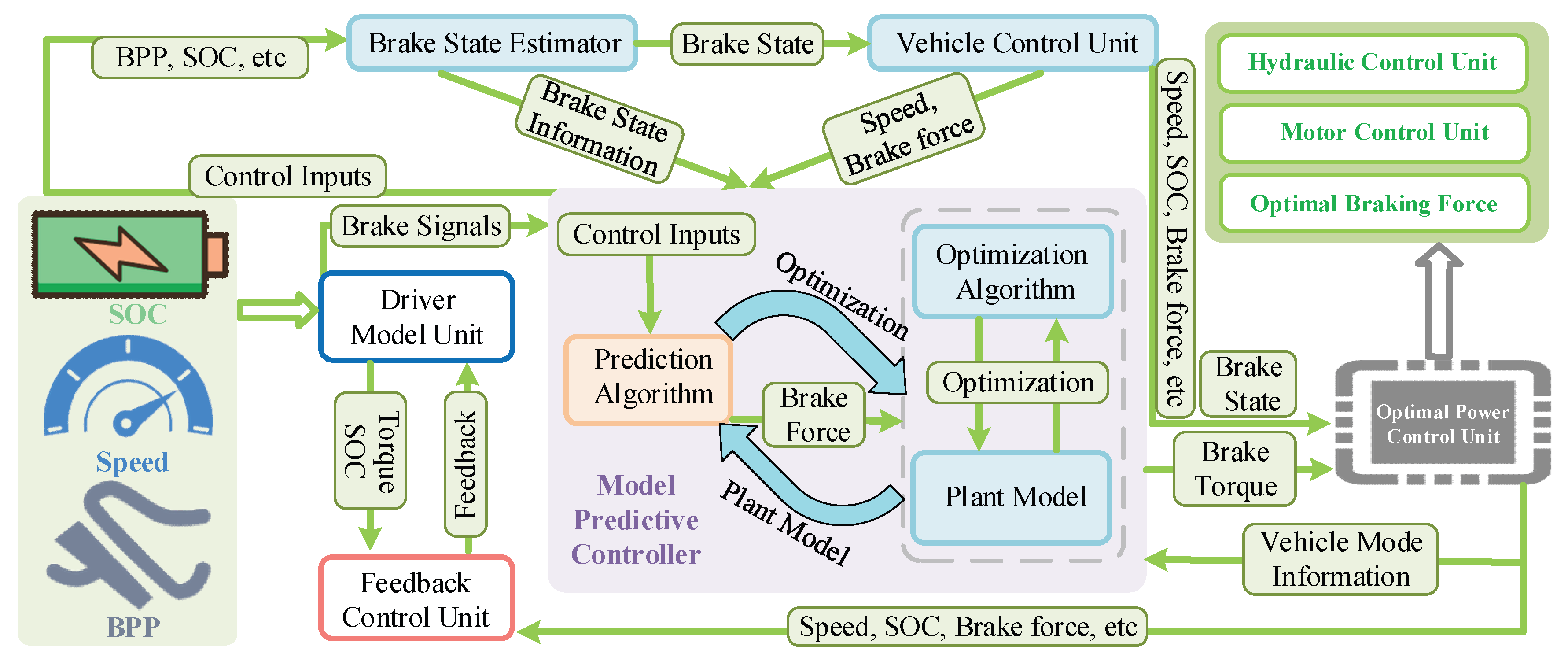

5.3. Model Predictive Control Method

5.4. Sliding Mode Control Method

5.5. Adaptive Control Method

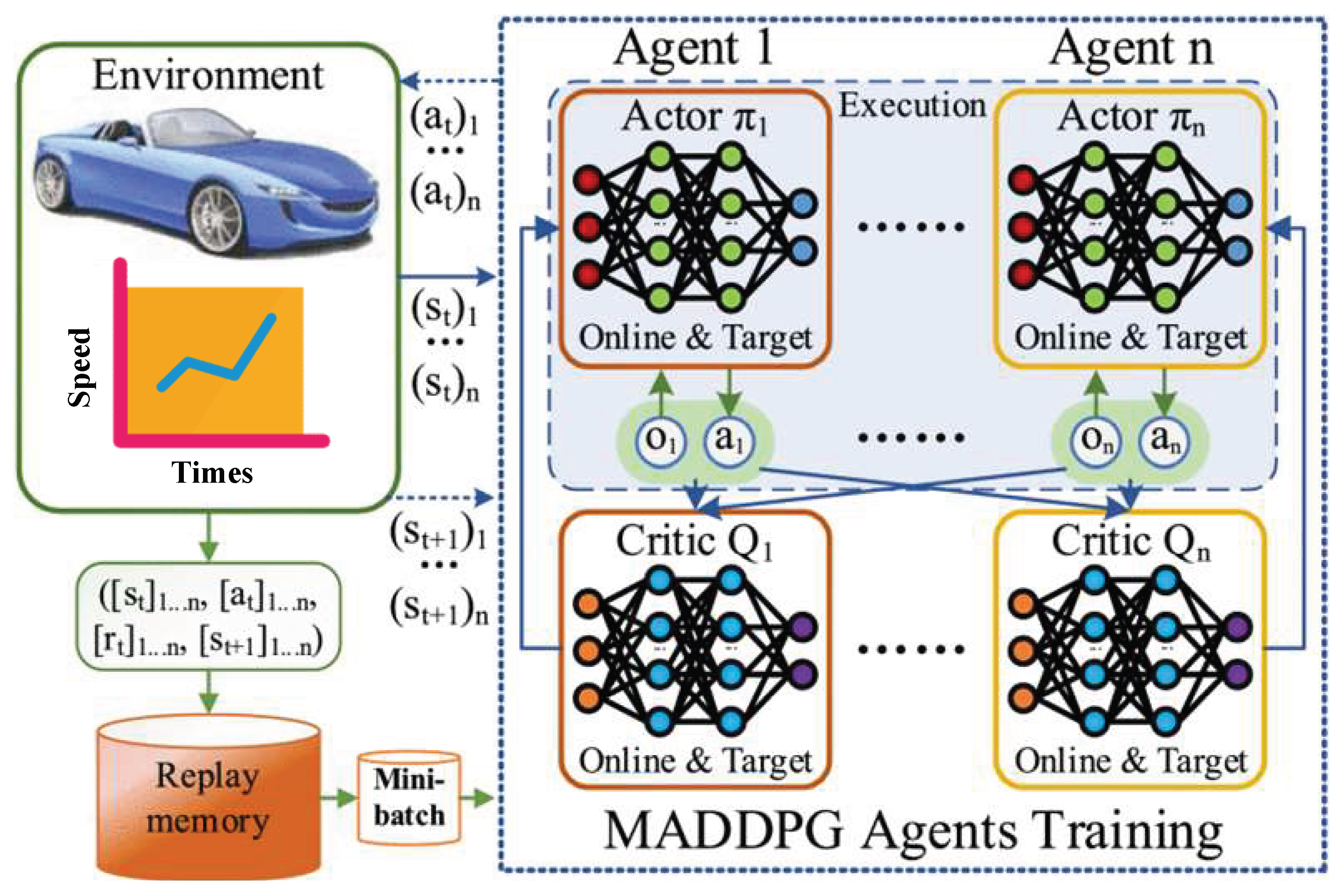

5.6. Learning-Based Control Methods

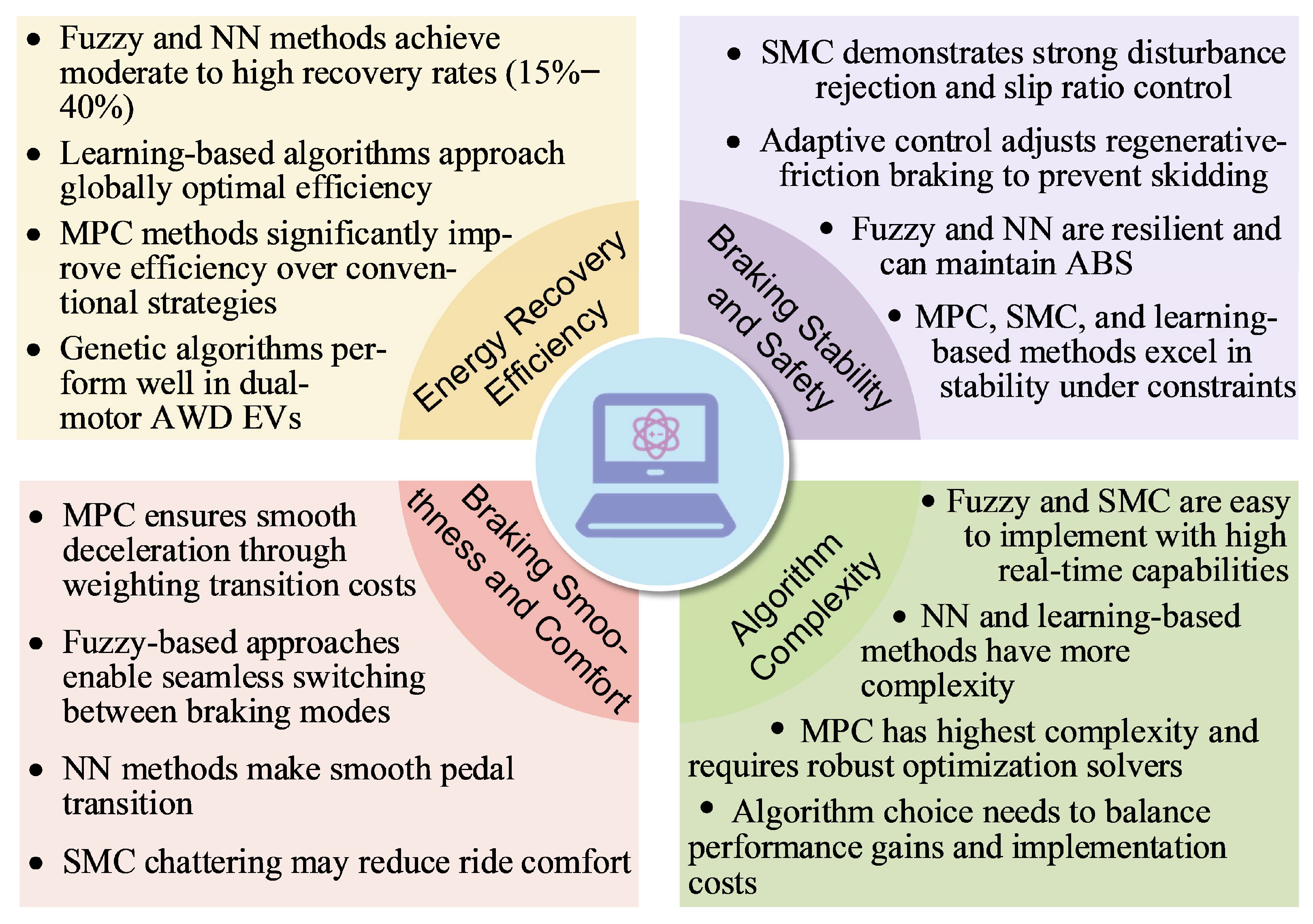

6. Comparison of Intelligent Methods and Their Application in 4WID EVs

6.1. Overview and Comparison of Intelligent RB Control Strategies

- Fuzzy Logic Control.

- 2.

- Artificial Neural Network Control.

- 3.

- Model Predictive Control.

- 4.

- Sliding Mode Control.

- 5.

- Adaptive Control.

- 6.

- Learning-based Control.

- Energy Recovery Efficiency:

- 2.

- Braking Stability:

- 3.

- Computational Cost:

6.2. Application of Intelligent Algorithms in RB Energy Recovery of 4WID EVs

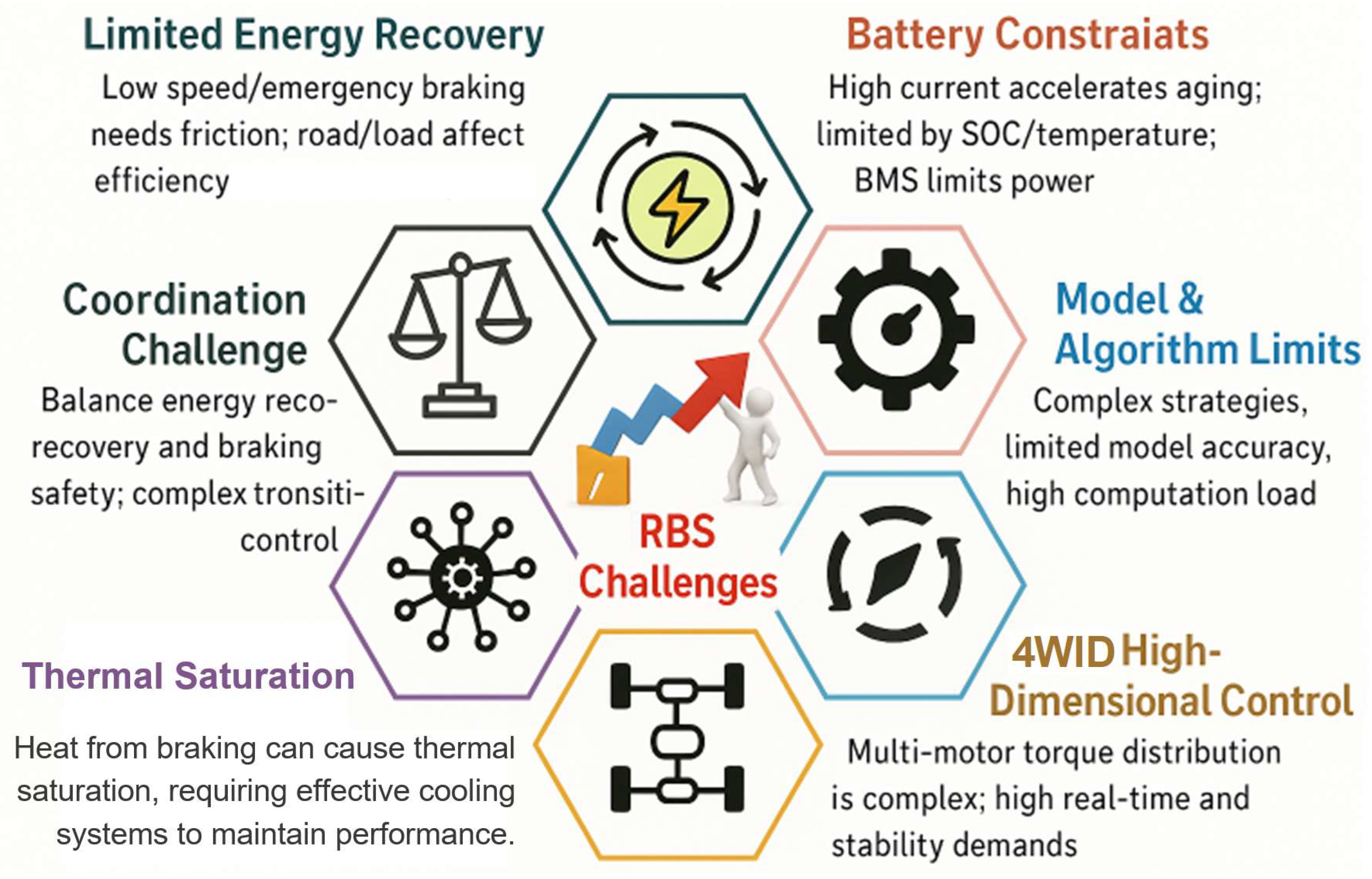

7. Challenges and Development Trends of RBS in EVs

7.1. Current Key Challenges

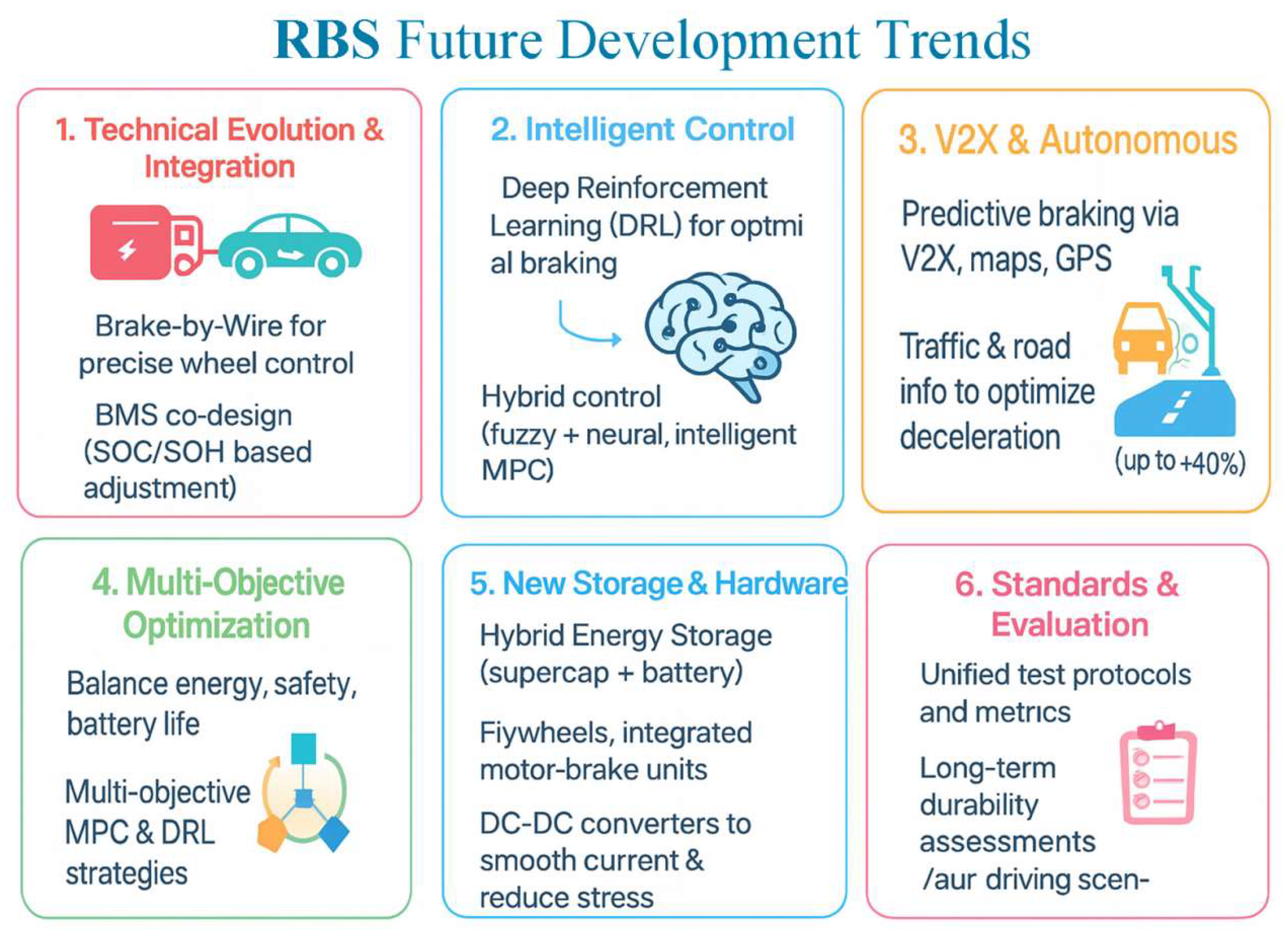

7.2. Future Development Trends

- Brake-by-Wire Technology.

- Control Algorithms Evolving from Empirical Rules to Artificial Intelligence.

- Integration of Vehicle-to-Everything (V2X) and Autonomous Driving.

- Multi-Objective Optimization Frameworks.

- Hardware Advancements.

- Standardized Testing and Technology Maturity.

8. Conclusions and Outlook

- Highly Integrated System Architecture is Fundamental to Enhancing Efficiency.

- 2.

- High-Power-Density Motors and Hybrid Energy Storage Systems Define the Recovery Potential.

- 3.

- 4WID Architectures Significantly Enhance Energy Recovery and Dynamic Control.

- 4.

- Intelligent Control Algorithms Are Diversifying Toward Hybrid and Learning-Based Methods.

- 5.

- Multi-Objective Optimization and Standardization Remain Critical Challenges.

- System-Level Collaborative Design Across the Entire Lifecycle.

- 2.

- Safety and Explainability in Intelligent Algorithm Deployment.

- 3.

- Vehicle-to-Road Collaboration and Context Prediction.

- 4.

- Hybrid Energy Storage and High-Reliability Integration of Power Electronics.

- 5.

- Unified Evaluation Systems and Standards.

- 6.

- Vehicle-to-Grid (V2G) Integration and Broader Ecosystem Interaction.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, C.; Sun, T.; Wang, W.; Li, Y.; Zhang, Y.; Zha, M. Regenerative Braking System Development and Perspectives for Electric Vehicles: An Overview. Renew. Sustain. Energy Rev. 2024, 198, 114389. [Google Scholar] [CrossRef]

- Chidambaram, R.K.; Chatterjee, D.; Barman, B.; Das, P.P.; Taler, D.; Taler, J.; Sobota, T. Effect of Regenerative Braking on Battery Life. Energies 2023, 16, 5303. [Google Scholar] [CrossRef]

- Aljohani, T.M.; Ebrahim, A.; Mohammed, O. Real-Time Metadata-Driven Routing Optimization for Electric Vehicle Energy Consumption Minimization Using Deep Reinforcement Learning and Markov Chain Model. Electr. Power Syst. Res. 2021, 192, 106962. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, J.; Zhang, J.; Li, T.; Chen, H. Research on Online Energy Management Strategy for Hybrid Energy Storage Electric Vehicles under Adaptive Cruising Conditions. Sustainability 2025, 17, 3232. [Google Scholar] [CrossRef]

- Cao, Y.; Yao, M.; Sun, X. An Overview of Modelling and Energy Management Strategies for Hybrid Electric Vehicles. Appl. Sci. 2023, 13, 5947. [Google Scholar] [CrossRef]

- Saiteja, P.; Ashok, B.; Wagh, A.S.; Farrag, M.E. Critical Review on Optimal Regenerative Braking Control System Architecture, Calibration Parameters and Development Challenges for EVs. Int. J. Energy Res. 2022, 46, 20146–20179. [Google Scholar] [CrossRef]

- Ma, Z.; Sun, D. Energy Recovery Strategy Based on Ideal Braking Force Distribution for Regenerative Braking System of a Four-Wheel Drive Electric Vehicle. IEEE Access 2020, 8, 136234–136242. [Google Scholar] [CrossRef]

- Xu, S.; Li, J.; Zhang, X.; Song, J.; Zeng, X. Research on Composite Braking Control Strategy of Four-Wheel-Drive Electric Vehicles with Multiple Motors Based on Braking Energy Recovery Optimization. IEEE Access 2023, 11, 110151–110163. [Google Scholar] [CrossRef]

- Pan, G.; Duan, Y. Research on Control of Electromechanical Composite Anti-Lock Braking System of Four-Wheel Hub Electric Vehicle Based on Improved Integral Sliding Mode. J. Mech. Sci. Technol. 2025, 39, 1035–1046. [Google Scholar] [CrossRef]

- Tang, Q.; Yang, Y.; Luo, C.; Yang, Z.; Fu, C. A Novel Electro-Hydraulic Compound Braking System Coordinated Control Strategy for a Four-Wheel-Drive Pure Electric Vehicle Driven by Dual Motors. Energy 2022, 241, 122750. [Google Scholar] [CrossRef]

- Gupta, G.; Sudeep, R.; Ashok, B.; Vignesh, R.; Kannan, C.; Kavitha, C.; Alroobaea, R.; Alsafyani, M.; AboRas, K.M.; Emara, A. Intelligent Regenerative Braking Control with Novel Friction Coefficient Estimation Strategy for Improving the Performance Characteristics of Hybrid Electric Vehicle. IEEE Access 2024, 12, 110361–110384. [Google Scholar] [CrossRef]

- Wei, H.; Fan, L.; Ai, Q.; Zhao, W.; Huang, T.; Zhang, Y. Optimal Energy Allocation Strategy for Electric Vehicles Based on the Real-Time Model Predictive Control Technology. Sustain. Energy Technol. Assess. 2022, 50, 101797. [Google Scholar] [CrossRef]

- Peng, Z.; He, Z. Optimization of Regenerative Braking Control Strategy for Dual-Motor Electric Vehicles Based on Deep Reinforcement Learning. IEEE Trans. Intell. Transp. Syst. 2025, 26, 10954–10967. [Google Scholar] [CrossRef]

- Szumska, E.M. Regenerative Braking Systems in Electric Vehicles: A Comprehensive Review of Design, Control Strategies, and Efficiency Challenges. Energies 2025, 18, 2422. [Google Scholar] [CrossRef]

- Vodovozov, V.; Raud, Z.; Petlenkov, E. Review on Braking Energy Management in Electric Vehicles. Energies 2021, 14, 4477. [Google Scholar] [CrossRef]

- Hang, P.; Chen, X. Towards Autonomous Driving: Review and Perspectives on Configuration and Control of Four-Wheel Independent Drive/Steering Electric Vehicles. Actuators 2021, 10, 184. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, R.; Ding, R.; Liu, B.; Liu, W.; Sun, D.; Guo, Z. Research Progress and Future Prospects of Brake-by-Wire Technology for New Energy Vehicles. Energies 2025, 18, 2702. [Google Scholar] [CrossRef]

- Hamada, A.T.; Orhan, M.F. An Overview of Regenerative Braking Systems. J. Energy Storage 2022, 52, 105033. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, F.; Zhang, X.; Cui, S. Research on the Efficiency Optimization Control of the Regenerative Braking System of Hybrid Electrical Vehicle Based on Electrical Variable Transmission. IEEE Access 2019, 7, 116823–116834. [Google Scholar] [CrossRef]

- Huang, C.C.; Lin, C.L. Coherent Wireless Power Charging and Data Transfer for Electric Vehicles; Bentham Science Publishers: Sharjah, United Arab Emirates, 2022; ISBN 978-1-68108-946-1. [Google Scholar]

- Kumar, K.; Devanshu, A.; Dwivedi, S.K. Electric Vehicle Propulsion Drives and Charging Systems; CRC Press: Boca Raton, FL, USA, 2024; ISBN 978-1-040-03242-8. [Google Scholar]

- Pakstys, S. Modelling, Control and Testing Methodology of Hybrid Powertrains with Recycled Permanent Magnet-Based Electric Machines. Master’s Thesis, Politecnico di Torino, Turin, Italy, 2022. [Google Scholar]

- Arora, S.; Abkenar, A.T.; Jayasinghe, S.G.; Tammi, K. Heavy-Duty Electric Vehicles: From Concept to Reality; Butterworth-Heinemann: Oxford, UK, 2021; ISBN 978-0-12-818127-0. [Google Scholar]

- Liu, F.; Zhang, D.; Mohammed, S.; Calvi, A. A PMSM Fuzzy Logic Regenerative Braking Control Strategy for Electric Vehicles. J. Intell. Fuzzy Syst. 2021, 41, 4873–4881. [Google Scholar] [CrossRef]

- Usman, A.; Saxena, A. Technical Roadmaps of Electric Motor Technology for next Generation Electric Vehicles. Machines 2025, 13, 156. [Google Scholar] [CrossRef]

- Su, Q. Overview of Motor Technologies for Electric Vehicles. Bachelor’s Thesis, Lappeenranta–Lahti University of Technology LUT, Lappeenranta, Finland, 2024. [Google Scholar]

- Maschio, G.; Tacca, A. Thermal Design and Control of a Wound Rotor Synchronous Motor for Heavy-Duty Electric Vehicles. Master’s Thesis, Politecnico di Milano, Milano, Italy, 2024. [Google Scholar]

- Lu, D.; Ouyang, M.; Gu, J.; Li, J. Instantaneous Optimal Regenerative Braking Control for a Permanent-Magnet Synchronous Motor in a Four-Wheel-Drive Electric Vehicle. Proc. Inst. Mech. Eng. D J. Automob. Eng. 2014, 228, 894–908. [Google Scholar] [CrossRef]

- Muniraj, R.; Karuppiah, N.; Nisha, P.V.; Chandran, M.B.; Jarin, T.; Akkara, S. A Comparative Analysis on Supercapacitor Based HEV. In AIP Conference Proceedings; AIP Publishing LLC: Chennai, India, 2023; p. 20064. [Google Scholar]

- Kolte, A.; Festa, G.; Ciampi, F.; Meissner, D.; Rossi, M. Exploring Corporate Venture Capital Investments in Clean Energy—A Focus on the Asia-Pacific Region. Appl. Energy 2023, 334, 120677. [Google Scholar] [CrossRef]

- Yu, X.; Zhu, L.; Wang, Y.; Filev, D.; Yao, X. Internal Combustion Engine Calibration Using Optimization Algorithms. Appl. Energy 2022, 305, 117894. [Google Scholar] [CrossRef]

- Tarascon, J.-M.; Armand, M. Issues and Challenges Facing Rechargeable Lithium Batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef]

- Huang, C.; Zhao, X.; Hao, Y.; Yang, Y.; Qian, Y.; Chang, G.; Zhang, Y.; Tang, Q.; Hu, A.; Chen, X. Selection Criteria for Electrical Double Layer Structure Regulators Enabling Stable Zn Metal Anodes. Energy Environ. Sci. 2023, 16, 1721–1731. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Muk Cho, H.; Masjuki, H.H.; Kalam, M.A.; Farooq, M.; Soudagar, M.E.M.; Gul, M.; Afzal, A.; Ahmed, W.; Raza, A.; et al. Effect of Primary and Secondary Alcohols as Oxygenated Additives on the Performance and Emission Characteristics of Diesel Engine. Energy Rep. 2021, 7, 1116–1124. [Google Scholar] [CrossRef]

- Zhao, W.; Wu, G.; Wang, C.; Yu, L.; Li, Y. Energy Transfer and Utilization Efficiency of Regenerative Braking with Hybrid Energy Storage System. J. Power Sources 2019, 427, 174–183. [Google Scholar] [CrossRef]

- Koleti, U.R.; Rajan, A.; Tan, C.; Moharana, S.; Dinh, T.Q.; Marco, J. A Study on the Influence of Lithium Plating on Battery Degradation. Energies 2020, 13, 3458. [Google Scholar] [CrossRef]

- Naseem, H.; Seok, J.-K. Recent Advances in Bidirectional Converters and Regenerative Braking Systems in Electric Vehicles. Actuators 2025, 14, 347. [Google Scholar] [CrossRef]

- He, R.; Xie, Y. Research on the Synchronization Control Strategy of Regenerative Braking of Distributed Drive Electric Vehicles. World Electr. Veh. J. 2024, 15, 512. [Google Scholar] [CrossRef]

- Wang, F.; Wu, T.; Xu, X.; Cai, Y.; Ni, Y.-Q. Regenerative Brake Torque Compensation Control for Dual-Motor PHEV Considering Backlash and Hydraulic Brake Nonlinearity. J. Vib. Control 2023, 30, 4719–4735. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, X.; Jiao, Y.; Wei, L.; He, J.; Zeng, X. Research on the Multi-Mode Composite Braking Control Strategy of Electric Wheel-Drive Multi-Axle Heavy-Duty Vehicles. World Electr. Veh. J. 2024, 15, 83. [Google Scholar] [CrossRef]

- Xing, C.; Zhu, Y.; Wang, J.; Wang, W.; Lin, Y. Regenerative Braking Control Strategy of Vehicle with In-Wheel Motor Drive System Confronting Converter Fault. IEEE/ASME Trans. Mechatron. 2024, 29, 4353–4364. [Google Scholar] [CrossRef]

- Zhao, X.; Xiong, L.; Zhuo, G.; Tian, W.; Li, J.; Shu, Q.; Zhao, X.; Xu, G. A Review of One-Box Electro-Hydraulic Braking System: Architecture, Control, and Application. Sustainability 2024, 16, 1049. [Google Scholar] [CrossRef]

- Feng, B.; Xu, H.; Wang, A.; Gao, L.; Bi, Y.; Zhang, X. A Comprehensive Review of Energy Regeneration and Conversion Technologies Based on Mechanical–Electric–Hydraulic Hybrid Energy Storage Systems in Vehicles. Appl. Sci. 2023, 13, 4152. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q. Optimized Composite Braking Energy Recovery Control for Plug-in Hybrid Electric Vehicle with a 3-Speed Dedicated Hybrid Transmission. Int. J. Automot. Technol. 2025, 1–22. [Google Scholar] [CrossRef]

- Boerboom, M. Electric Vehicle Blended Braking Maximizing Energy Recovery While Maintaining Vehicle Stability and Maneuverability. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2012. [Google Scholar]

- Hosseini, S.M.; Soleymani, M.; Kelouwani, S.; Amamou, A.A. Energy Recovery and Energy Harvesting in Electric and Fuel Cell Vehicles, a Review of Recent Advances. IEEE Access 2023, 11, 83107–83135. [Google Scholar] [CrossRef]

- Nadeau, J.; Micheau, P.; Boisvert, M. Collaborative Control of a Dual Electro-Hydraulic Regenerative Brake System for a Rear-Wheel-Drive Electric Vehicle. Proc. Inst. Mech. Eng. D J. Automob. Eng. 2018, 233, 1035–1046. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, T.; Zhang, H.; Yang, J.; Zhang, Z.; Meng, Z. Research on Braking Efficiency of Master-Slave Electro-Hydraulic Hybrid Electric Vehicle. Electronics 2022, 11, 1918. [Google Scholar] [CrossRef]

- Wu, T.; Wang, F.; Ye, P. Regenerative Braking Strategy of Dual-Motor EV Considering Energy Recovery and Brake Stability. World Electr. Veh. J. 2023, 14, 19. [Google Scholar] [CrossRef]

- Shi, Q.; He, L. A Model Predictive Control Approach for Electro-Hydraulic Braking by Wire. IEEE Trans. Ind. Inform. 2023, 19, 1380–1388. [Google Scholar] [CrossRef]

- Basrah, M.S. Integration of Anti-Lock Braking System and Regenerative Braking for Hybrid/Electric Vehicles. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2017. [Google Scholar]

- He, Q.; Yang, Y.; Luo, C.; Zhai, J.; Luo, R.; Fu, C. Energy Recovery Strategy Optimization of Dual-Motor Drive Electric Vehicle Based on Braking Safety and Efficient Recovery. Energy 2022, 248, 123543. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, X.; Liu, J.; Zhu, F.; Chen, H.; Cao, D. Hierarchical Coordinated Control Strategy for Regenerative Braking Energy Recuperation with an Electrobooster. Proc. Inst. Mech. Eng. D J. Automob. Eng. 2022, 238, 1249–1262. [Google Scholar] [CrossRef]

- Mei, P.; Yang, S.; Xu, B.; Sun, K. A Fuzzy Sliding-Mode Control for Regenerative Braking System of Electric Vehicle. In Proceedings of the 2021 7th International Conference on Control, Automation and Robotics (ICCAR), Singapore, 23–26 April 2021; pp. 397–401. [Google Scholar]

- Mei, P.; Karimi, H.R.; Yang, S.; Xu, B.; Huang, C. An Adaptive Fuzzy Sliding-Mode Control for Regenerative Braking System of Electric Vehicles. Int. J. Adapt. Control Signal Process. 2022, 36, 391–410. [Google Scholar] [CrossRef]

- Wen, H.H.; Chen, W.; Hui, J. A Single-Pedal Regenerative Braking Control Strategy of Accelerator Pedal for Electric Vehicles Based on Adaptive Fuzzy Control Algorithm. Energy Procedia 2018, 152, 624–629. [Google Scholar] [CrossRef]

- Li, P.; Jiao, X.; Li, Y. Adaptive Real-Time Energy Management Control Strategy Based on Fuzzy Inference System for Plug-in Hybrid Electric Vehicles. Control Eng. Pract. 2021, 107, 104703. [Google Scholar] [CrossRef]

- Tang, J.; Zuo, Y. Braking Intention Recognition Method Based on the Fuzzy Neural Network. Wireless Commun. Mobile Comput. 2022, 2022, 2503311. [Google Scholar] [CrossRef]

- Karabacak, Y.; Yaşar, A.; Sarıtaş, İ. Regenerative Braking Control of Brushless DC Motors with Type 2 Fuzzy Logic Controller. Int. J. Fuzzy Syst. 2023, 25, 2722–2732. [Google Scholar] [CrossRef]

- Aswathi, E.R.; Prathibha, P.K.; Nair, J.R. Regenerative Braking of BLDC Motor Using Fuzzy Control for Electric Vehicles. In Proceedings of the 2018 Second International Conference on Inventive Communication and Computational Technologies (ICICCT), Coimbatore, India, 20–21 April 2018; pp. 1661–1665. [Google Scholar]

- Nian, X.; Peng, F.; Zhang, H. Regenerative Braking System of Electric Vehicle Driven by Brushless DC Motor. IEEE Trans. Ind. Electron. 2014, 61, 5798–5808. [Google Scholar] [CrossRef]

- Huynh, Q.-V.; Dat, L.V.; Le, K.-T. An Intelligent Regenerative Braking Strategy for Power-Split Hybrid Electric Vehicle. Int. J. Mech. Eng. Appl. 2020, 8, 27. [Google Scholar] [CrossRef]

- Favilli, T.; Pugi, L.; Berzi, L.; Pierini, M.; Tobia, N. Regenerative Fuzzy Brake Blending Strategy on Benchmark Electric Vehicle: The FIAT 500e. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar]

- Chen, Y.-C.; Chang, Y.-C.; Cheng, J.-F.; Yu, W.-C.; Lin, C.-L. Regenerative Braking-Driving Control System. In Proceedings of the 2018 13th IEEE Conference on Industrial Electronics and Applications (ICIEA), Wuhan, China, 31 May–2 June 2018; pp. 887–892. [Google Scholar]

- Hamid, J.; Sheeba, R.; Sofiya, S. Energy Harvesting through Regenerative Braking Using Hybrid Storage System in Electric Vehicles. In Proceedings of the 2019 IEEE International Conference on Intelligent Techniques in Control, Optimization and Signal Processing (INCOS), Tamilnadu, India, 11–13 April 2019; pp. 1–6. [Google Scholar]

- Angundjaja, C.Y.; Wang, Y.; Jiang, W. Power Management for Connected EVs Using a Fuzzy Logic Controller and Artificial Neural Network. Appl. Sci. 2021, 12, 52. [Google Scholar] [CrossRef]

- Cai, M.; Wang, X.; Sheng, Y.; Jing, P. Hierarchical Fuzzy Energy Management and Braking Strategy of Parallel Hybrid Vehicle. In Proceedings of the 2018 Chinese Automation Congress (CAC), Xi’an, China, 30 November–2 December 2018; pp. 3254–3259. [Google Scholar]

- Ning, X.; Wang, J.; Yin, Y.; Shangguan, J.; Bao, N.; Li, N. Regenerative Braking Algorithm for Parallel Hydraulic Hybrid Vehicles Based on Fuzzy Q-Learning. Energies 2023, 16, 1895. [Google Scholar] [CrossRef]

- Chen, Z.; Ding, R.; Zhou, Q.; Wang, R.; Zhao, B.; Liao, Y. Research on Coordinated Control of Electro-Hydraulic Composite Braking for an Electric Vehicle Based on the Fuzzy-TD3 Deep Reinforcement Learning Algorithm. Control Eng. Pract. 2025, 157, 106248. [Google Scholar] [CrossRef]

- Liu, H.; Lei, Y.; Fu, Y.; Li, X. An Optimal Slip Ratio-Based Revised Regenerative Braking Control Strategy of Range-Extended Electric Vehicle. Energies 2020, 13, 1526. [Google Scholar] [CrossRef]

- Subramaniyam, K.V.; Subramanian, S.C. Electrified Vehicle Wheel Slip Control Using Responsiveness of Regenerative Braking. IEEE Trans. Veh. Technol. 2021, 70, 3208–3217. [Google Scholar] [CrossRef]

- Peng, H.; Wang, W.; Xiang, C.; Li, L.; Wang, X. Torque Coordinated Control of Four In-Wheel Motor Independent-Drive Vehicles with Consideration of the Safety and Economy. IEEE Trans. Veh. Technol. 2019, 68, 9604–9618. [Google Scholar] [CrossRef]

- Zheng, Z.; Liang, C.; Lv, H.; Zhang, K.; Zhang, W. Research on Composite Braking Mode Switching Strategy Based on Fuzzy Algorithm. Adv. Theor. Simul. 2023, 6, 2200789. [Google Scholar] [CrossRef]

- Gao, H.; Gao, Y.; Ehsani, M. A Neural Network Based SRM Drive Control Strategy for Regenerative Braking in EV and HEV. In Proceedings of the IEMDC 2001. IEEE International Electric Machines and Drives Conference (cat. No.01ex485), Cambridge, MA, USA, 17–20 June 2001; pp. 571–575. [Google Scholar]

- Zhang, Y.; Wang, W.; Xiang, C.; Yang, C.; Peng, H.; Wei, C. A Swarm Intelligence-Based Predictive Regenerative Braking Control Strategy for Hybrid Electric Vehicle. Veh. Syst. Dyn. 2022, 60, 973–997. [Google Scholar] [CrossRef]

- He, H.; Wang, C.; Jia, H.; Cui, X. An Intelligent Braking System Composed Single-Pedal and Multi-Objective Optimization Neural Network Braking Control Strategies for Electric Vehicle. Appl. Energy 2020, 259, 114172. [Google Scholar] [CrossRef]

- Won, H.; Li, S. Analysis of Neural Network Vector Control for IPM Machine in Electric Vehicles. In Proceedings of the 2016 IEEE Power and Energy Society General Meeting (PESGM), Boston, MA, USA, 17–21 July 2016; pp. 1–5. [Google Scholar]

- Cao, J.; Cao, B.; Xu, P.; Bai, Z. Regenerative-Braking Sliding Mode Control of Electric Vehicle Based on Neural Network Identification. In Proceedings of the 2008 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Xi’an, China, 2–5 July 2008; pp. 1219–1224. [Google Scholar]

- Rezk, M.; Abuzied, H. Artificial Neural Networks: A Promising Tool for Regenerative Braking Control in Electric Vehicles. Eur. J. Eng. Technol. Res. 2023, 8, 49–58. [Google Scholar] [CrossRef]

- Shijil, P.; Sindhu, M.R. Braking Control Strategies Based on Single-Pedal Regenerative Braking and Neural Network for Electric Vehicles. In Proceedings of the 2021 IEEE International Power and Renewable Energy Conference (IPRECON), Kollam, India, 24–26 September 2021; pp. 1–7. [Google Scholar]

- Indu, K.; Aswatha Kumar, M. Design and Performance Analysis of Braking System in an Electric Vehicle Using Adaptive Neural Networks. Sustain. Energy Grids Netw. 2023, 36, 101215. [Google Scholar] [CrossRef]

- Wang, M.; Yu, H.; Dong, G.; Huang, M. Dual-Mode Adaptive Cruise Control Strategy Based on Model Predictive Control and Neural Network for Pure Electric Vehicles. In Proceedings of the 2019 5th International Conference on Transportation Information and Safety (ICTIS), Liverpool, UK, 14–17 July 2019; pp. 1220–1225. [Google Scholar]

- Xing, Y.; Lv, C. Dynamic State Estimation for the Advanced Brake System of Electric Vehicles by Using Deep Recurrent Neural Networks. IEEE Trans. Ind. Electron. 2020, 67, 9536–9547. [Google Scholar] [CrossRef]

- Wu, Z.; Kang, C.; Li, B.; Ruan, J.; Zheng, X. Dynamic Modeling, Simulation, and Optimization of Vehicle Electronic Stability Program Algorithm Based on Back Propagation Neural Network and PID Algorithm. Actuators 2024, 13, 100. [Google Scholar] [CrossRef]

- Cheng, C.-H.; Ye, J.-X. GA-Based Neural Network for Energy Recovery System of the Electric Motorcycle. Expert Syst. Appl. 2011, 38, 3034–3039. [Google Scholar] [CrossRef]

- Gounis, K.; Bassiliades, N. Intelligent Momentary Assisted Control for Autonomous Emergency Braking. Simul. Modell. Pract. Theory 2022, 115, 102450. [Google Scholar] [CrossRef]

- Vodovozov, V.; Aksjonov, A.; Petlenkov, E.; Raud, Z. Neural Network-Based Model Reference Control of Braking Electric Vehicles. Energies 2021, 14, 2373. [Google Scholar] [CrossRef]

- Ning, X.; Wang, Z.; Lin, Y.; Yin, Y.; Wang, J.; Hong, Y. Optimization of Regenerative Braking Control Strategy in Single-Pedal Mode Based on Electro-Mechanical Braking. IEEE Access 2024, 12, 170994–171014. [Google Scholar] [CrossRef]

- Shetty, S.S.; Karabasoglu, O. Regenerative Braking Control Strategy for Hybrid and Electric Vehicles Using Artificial Neural Networks. In Proceedings of the Engineering Applications of Neural Networks, Sofia, Bulgaria, 5–7 September 2014; Mladenov, V., Jayne, C., Iliadis, L., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 103–112. [Google Scholar]

- Li, W.; Xu, H.; Liu, X.; Wang, Y.; Zhu, Y.; Lin, X.; Wang, Z.; Zhang, Y. Regenerative Braking Control Strategy for Pure Electric Vehicles Based on Fuzzy Neural Network. Ain Shams Eng. J. 2024, 15, 102430. [Google Scholar] [CrossRef]

- Valladolid, J.D.; Macas, J. A Proposed Strategy for the Optimal Control of Regenerative Braking in Electric Vehicle Based on Driving Style. In Proceedings of the 2023 IEEE Vehicle Power and Propulsion Conference (VPPC), Milan, Italy, 24–27 October 2023; pp. 1–5. [Google Scholar]

- Wagner, D.; Steinsträter, M.; Förth, M.; Stohwasser, M.; Hoffmann, J.; Lienkamp, M. Battery Independent Regenerative Braking Using Model Predictive Control with Auxiliary Power Consumers. Forsch. Ingenieurwes. 2019, 83, 843–852. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Z.; Zhang, L.; Dorrell, D.G. Braking/Steering Coordination Control for in-Wheel Motor Drive Electric Vehicles Based on Nonlinear Model Predictive Control. Mech. Mach. Theory 2019, 142, 103586. [Google Scholar] [CrossRef]

- Caiazzo, B.; Coppola, A.; Petrillo, A.; Santini, S. Distributed Nonlinear Model Predictive Control for Connected Autonomous Electric Vehicles Platoon with Distance-Dependent Air Drag Formulation. Energies 2021, 14, 5122. [Google Scholar] [CrossRef]

- Du, Y.; Qin, C.; You, S.; Xia, H. Efficient Coordinated Control of Regenerative Braking with Pneumatic Anti-Lock Braking for Hybrid Electric Vehicle. Sci. China Technol. Sci. 2017, 60, 399–411. [Google Scholar] [CrossRef]

- Pan, C.; Huang, A.; Wang, J.; Chen, L.; Liang, J.; Zhou, W.; Wang, L.; Yang, J. Energy-Optimal Adaptive Cruise Control Strategy for Electric Vehicles Based on Model Predictive Control. Energy 2022, 241, 122793. [Google Scholar] [CrossRef]

- Kumar, N.S. Increasing the Cruise Range and Reducing the Capital Cost of Electric Vehicles by Integrating Auxiliary Unit with the Traction Drive. Int. J. Veh. Technol. 2016, 2016, 7617692. [Google Scholar] [CrossRef]

- Zhao, H.; Ren, B.; Chen, H.; Deng, W. Model Predictive Control Allocation for Stability Improvement of Four-Wheel Drive Electric Vehicles in Critical Driving Condition. IET Control Theory Appl. 2015, 9, 2688–2696. [Google Scholar] [CrossRef]

- Yu, K.; Mukai, M.; Kawabe, T. Model Predictive Control of a Power-Split Hybrid Electric Vehicle System. Artif. Life Rob. 2012, 17, 221–226. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Yang, C.; Yan, B.; Marina Martinez, C. Model Predictive Control-Based Efficient Energy Recovery Control Strategy for Regenerative Braking System of Hybrid Electric Bus. Energy Convers. Manag. 2016, 111, 299–314. [Google Scholar] [CrossRef]

- Huang, X.; Wang, J. Model Predictive Regenerative Braking Control for Lightweight Electric Vehicles with In-Wheel Motors. Proc. Inst. Mech. Eng. D J. Automob. Eng. 2012, 226, 1220–1232. [Google Scholar] [CrossRef]

- Nadeau, J.; Micheau, P.; Boisvert, M. Model-Based Predictive Control Applied to a Dual Regenerative and Hydraulic Brake System. In Proceedings of the 2015 IEEE Vehicle Power and Propulsion Conference (VPPC), Montreal, QC, Canada, 19–22 October 2015; pp. 1–5. [Google Scholar]

- He, H.; Lu, B.; Xiong, R.; Peng, J. The Regenerative Braking Control Based on the Prediction of Braking Intention for Electric Vehicles. Researchgate 2018, 21–25. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Qin, D.; Fu, C.; Cong, Z. Regenerative Braking Control Method Based on Predictive Optimization for Four-Wheel Drive Pure Electric Vehicle. IEEE Access 2021, 9, 1394–1406. [Google Scholar] [CrossRef]

- Xu, W.; Chen, H.; Zhao, H.; Ren, B. Torque Optimization Control for Electric Vehicles with Four In-Wheel Motors Equipped with Regenerative Braking System. Mechatronics 2019, 57, 95–108. [Google Scholar] [CrossRef]

- Basrah, M.S.; Siampis, E.; Velenis, E.; Cao, D.; Longo, S. Wheel Slip Control with Torque Blending Using Linear and Nonlinear Model Predictive Control. Veh. Syst. Dyn. 2017, 55, 1665–1685. [Google Scholar] [CrossRef]

- He, L.; Ye, W.; He, Z.; Song, K.; Shi, Q. A Combining Sliding Mode Control Approach for Electric Motor Anti-Lock Braking System of Battery Electric Vehicle. Control Eng. Pract. 2020, 102, 104520. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, S.; Liu, J.; Wu, Q.; Li, L.; Liang, H. A Novel Braking Control Strategy for Hybrid Electric Buses Based on Vehicle Mass and Road Slope Estimation. Chin. J. Mech. Eng. 2022, 35, 150. [Google Scholar] [CrossRef]

- Zhang, L.; Cai, X. Control Strategy of Regenerative Braking System in Electric Vehicles. Energy Procedia 2018, 152, 496–501. [Google Scholar] [CrossRef]

- Venkatesh, A.; Kumar, S.P.; Kiran, S.S.; Gurucharan, K. Cyber-Physical Systems for Hybrid Braking Control Techniques in Hybrid Electric Vehicles. Int. J. Inf. Technol. 2024, 1–17. [Google Scholar] [CrossRef]

- Rajendran, S.; Spurgeon, S.; Tsampardoukas, G.; Hampson, R. Intelligent Sliding Mode Scheme for Regenerative Braking Control. IFAC-Pap. 2018, 51, 334–339. [Google Scholar] [CrossRef]

- Guo, J.; Jian, X.; Lin, G. Performance Evaluation of an Anti-Lock Braking System for Electric Vehicles with a Fuzzy Sliding Mode Controller. Energies 2014, 7, 6459–6476. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, H.; Zhen, C. Regenerative Braking Control under Sliding Braking Condition of Electric Vehicles with Switched Reluctance Motor Drive System. Energy 2021, 230, 120901. [Google Scholar] [CrossRef]

- Geraee, S.; Mohammadbagherpoor, H.; Shafiei, M.; Valizadeh, M.; Montazeri, F.; Feyzi, M.R. Regenerative Braking of Electric Vehicle Using a Modified Direct Torque Control and Adaptive Control Theory. Comput. Electr. Eng. 2018, 69, 85–97. [Google Scholar] [CrossRef]

- Arun Kumar, U.; Ravichandran, C.S.; Rajan Babu, W. Adaptive Neuro-Fuzzy and PID-Based Regenerative System for E-Vehicles. In Proceedings of the Soft Computing for Security Applications, TamilNadu, India, 17–18 April 2023; Ranganathan, G., Fernando, X., Piramuthu, S., Eds.; Springer Nature: Singapore, 2023; pp. 379–389. [Google Scholar]

- Kubaisi, R. Adaptive Regenerative Braking in Electric Vehicles. Ph.D. Thesis, Karlsruhe Institute of Technology, Karlsruhe, Germany, 2018. [Google Scholar]

- Akhila, M.; Ratnan, P. Brushless DC Motor Drive with Regenerative Braking Using Adaptive Neuro Based Fuzzy Inference System. In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016; pp. 748–751. [Google Scholar]

- Han, J.; Park, Y.; Park, Y. Cooperative Regenerative Braking Control for Front-Wheel-Drive Hybrid Electric Vehicle Based on Adaptive Regenerative Brake Torque Optimization Using under-Steer Index. Int. J. Automot. Technol. 2014, 15, 989–1000. [Google Scholar] [CrossRef]

- Singh, K.V.; Bansal, H.O.; Singh, D. Development of an Adaptive Neuro-Fuzzy Inference System–Based Equivalent Consumption Minimisation Strategy to Improve Fuel Economy in Hybrid Electric Vehicles. IET Electr. Syst. Transp. 2021, 11, 171–185. [Google Scholar] [CrossRef]

- Sun, D.; Zhang, J.; He, C.; Han, J. Dual-Mode Regenerative Braking Control Strategy of Electric Vehicle Based on Active Disturbance Rejection Control. Proc. Inst. Mech. Eng. D J. Automob. Eng. 2021, 235, 1483–1496. [Google Scholar] [CrossRef]

- Arslan, M.; Ahmad, I.; Azeem, M.K.; Liaquat, M. Dual-Stage Adaptive Control of Hybrid Energy Storage System for Electric Vehicle Application. J. Energy Storage 2021, 43, 103165. [Google Scholar] [CrossRef]

- Guo, H.-Q.; Liu, C.-Z.; Yong, J.-W.; Cheng, X.-Q.; Muhammad, F. Model Predictive Iterative Learning Control for Energy Management of Plug-In Hybrid Electric Vehicle. IEEE Access 2019, 7, 71323–71334. [Google Scholar] [CrossRef]

- Wu, J.; Liu, H.; Ren, X.; Nie, S.; Qin, Y.; Han, L. A Multi-Objective Optimization Approach for Regenerative Braking Control in Electric Vehicles Using MPE-SAC Algorithm. Energy 2025, 318, 134586. [Google Scholar] [CrossRef]

- Yin, Y.; Zhang, L.; Zhan, S.; Ma, Y.; Ma, S. A Novel State Energy Spatialization Regenerative Braking Control Strategy Based on Q- Learning Algorithm for a Super-Mild Hybrid Electric Vehicle. Int. J. Green Energy 2021, 18, 1263–1276. [Google Scholar] [CrossRef]

- Qiu, M.; Yu, W.; Wang, L.; Zhang, B.; Zhao, H. A Regenerative Braking Control Strategy for ICVs Considering the Coupling Effect of Driving Conditions and Driving Styles. IEEE Trans. Veh. Technol. 2023, 72, 7195–7210. [Google Scholar] [CrossRef]

- Li, L.; Zhang, T.; Lu, L.; Zhang, H.; Yang, J.; Zhang, Z. An Energy Active Regulation Management Strategy Based on Driving Mode Recognition for Electro-Hydraulic Hybrid Vehicles. Energy 2023, 285, 129548. [Google Scholar] [CrossRef]

- Si, S.; Yang, B.; Gao, B.; Hou, X.; Zhao, B.; Zhang, T. Energy Management Strategy of Flywheel Hybrid Electric Vehicle Based on Driving Condition Recognition. Appl. Therm. Eng. 2025, 272, 126445. [Google Scholar] [CrossRef]

- Prasanth, B.; Paul, R.; Kaliyaperumal, D.; Kannan, R.; Venkata Pavan Kumar, Y.; Kalyan Chakravarthi, M.; Venkatesan, N. Maximizing Regenerative Braking Energy Harnessing in Electric Vehicles Using Machine Learning Techniques. Electronics 2023, 12, 1119. [Google Scholar] [CrossRef]

- Gan, J.; Li, S.; Lin, X.; Tang, X. Multi-Agent Deep Reinforcement Learning-Based Multi-Objective Cooperative Control Strategy for Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2024, 73, 11123–11135. [Google Scholar] [CrossRef]

- Min, K.; Sim, G.; Ahn, S.; Sunwoo, M.; Jo, K. Vehicle Deceleration Prediction Model to Reflect Individual Driver Characteristics by Online Parameter Learning for Autonomous Regenerative Braking of Electric Vehicles. Sensors 2019, 19, 4171. [Google Scholar] [CrossRef] [PubMed]

- Weiwei, Y.; Denghao, L.U.O.; Wenming, Z. Regenerative Braking Strategy Based on Deep Reinforcement Learning for an Electric Mining Truck. Chin. J. Eng. 2024, 46, 503–513. [Google Scholar] [CrossRef]

- Maia, R.; Mendes, J.; Araújo, R.; Silva, M.; Nunes, U. Regenerative Braking System Modeling by Fuzzy Q-Learning. Eng. Appl. Artif. Intell. 2020, 93, 103712. [Google Scholar] [CrossRef]

- Li, C.; Zhang, L.; Lian, S.; Liu, M. Research on Regenerative Braking Control of Electric Vehicles Based on Game Theory Optimization. Sci. Prog. 2024, 107, 368504241247404. [Google Scholar] [CrossRef]

- Wu, C.; Ruan, J.; Cui, H.; Zhang, B.; Li, T.; Zhang, K. The Application of Machine Learning Based Energy Management Strategy in Multi-Mode Plug-in Hybrid Electric Vehicle, Part I: Twin Delayed Deep Deterministic Policy Gradient Algorithm Design for Hybrid Mode. Energy 2023, 262, 125084. [Google Scholar] [CrossRef]

- Min, K.; Sim, G.; Ahn, S.; Park, I.; Yoo, S.; Youn, J. Multi-Level Deceleration Planning Based on Reinforcement Learning Algorithm for Autonomous Regenerative Braking of EV. World Electr. Veh. J. 2019, 10, 57. [Google Scholar] [CrossRef]

- Xu, Z. Research on Regenerative Braking Strategy for Pure Electric Vehicles Based on Deep Reinforcement Learning Algorithms. In Proceedings of the International Conference on Physics, Photonics, and Optical Engineering (ICPPOE 2024), Singapore, 8–10 November 2024; Volume 13552, pp. 256–262. [Google Scholar]

- Yin, Z.; Ma, X.; Su, R.; Huang, Z.; Zhang, C. Regenerative Braking of Electric Vehicles Based on Fuzzy Control Strategy. Processes 2023, 11, 2985. [Google Scholar] [CrossRef]

- Li, Y. Particle Swarm Optimization Based Neural Network Automatic Controller for Stability Steering Control of Four-Wheel Drive Electric Vehicle. Front. Mech. Eng. 2024, 10, 1378175. [Google Scholar] [CrossRef]

- Jamil, H.; Naqvi, S.S.A.; Iqbal, N.; Khan, M.A.; Qayyum, F.; Muhammad, F.; Khan, S.; Kim, D.-H. Analysis on the Driving and Braking Control Logic Algorithm for Mobility Energy Efficiency in Electric Vehicle. Smart Grids Energy 2024, 9, 12. [Google Scholar] [CrossRef]

- Boopathi, S. Study on Integrated Neural Networks and Fuzzy Logic Control for Autonomous Electric Vehicles. In Computational Intelligent Techniques in Mechatronics; Wiley: Hoboken, NJ, USA, 2024; pp. 347–380. ISBN 978-1-394-17543-7. [Google Scholar]

- Zheng, Z.; Wang, S.; Zhao, X.; Yu, Q.; Zhang, H.; Lv, Y.; Tian, J. Adaptive Model Predictive Control of Four-Wheel Drive Intelligent Electric Vehicles Based on Stability Probability under Extreme Braking Conditions. IEEE Trans. Intell. Veh. 2024, 1–13. [Google Scholar] [CrossRef]

- Sun, T.; Wong, P.-K.; Wang, X. Back Propagation Neural Network-Based Fault Diagnosis and Fault Tolerant Control of Distributed Drive Electric Vehicles Based on Sliding Mode Control-Based Direct Yaw Moment Control. Vehicles 2024, 6, 93–119. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, L.; Ding, X.; Zhang, Z.; Li, S.; Gu, L. Integrated Active Suspension and Anti-Lock Braking Control for Four-Wheel-Independent-Drive Electric Vehicles. Chin. J. Mech. Eng. 2024, 37, 20. [Google Scholar] [CrossRef]

- Liu, S.; Li, Z.; Ji, H.; Wang, L.; Hou, Z. A Novel Anti-Saturation Model-Free Adaptive Control Algorithm and Its Application in the Electric Vehicle Braking Energy Recovery System. Symmetry 2022, 14, 580. [Google Scholar] [CrossRef]

- Debella, H.A.; Atnaw, S.M.; Ancha, V.R.; Debella, H.A.; Atnaw, S.M.; Ancha, V.R. A Comprehensive Review on Hybrid and Electric Vehicle Energy Control and Management Strategies. In The Dynamics of Vehicles–Basics, Simulation and Autonomous Systems; IntechOpen: London, UK, 2023; ISBN 978-1-83768-096-2. [Google Scholar]

- Bhurse, S.S.; Bhole, A.A. A Review of Regenerative Braking in Electric Vehicles. In Proceedings of the 2018 International Conference on Computation of Power, Energy, Information and Communication (ICCPEIC), Chennai, India, 28–29 March 2018; pp. 363–367. [Google Scholar]

- Guozhong, H.; Wenzhao, L.; Xuehong, G.; Lingyun, X.; Yan, W.; Honglei, D. Advancing the Regenerative Braking Systems of New Energy Vehicles: A Comprehensive State-of-the-Art Review. Int. J. Energy Res. 2025, 2025, 3460776. [Google Scholar] [CrossRef]

- Suanpang, P.; Jamjuntr, P. Optimization Regenerative Braking in Electric Vehicles Using Q-Learning for Improving Decision-Making in Smart Cities. Decis. Mak. 2025, 8, 182–216. [Google Scholar]

- Pardhi, S.; Chakraborty, S.; Tran, D.-D.; El Baghdadi, M.; Wilkins, S.; Hegazy, O. A Review of Fuel Cell Powertrains for Long-Haul Heavy-Duty Vehicles: Technology, Hydrogen, Energy and Thermal Management Solutions. Energies 2022, 15, 9557. [Google Scholar] [CrossRef]

- Chengqun, Q.; Wan, X.; Wang, N.; Cao, S.; Ji, X.; Wu, K.; Hu, Y.; Meng, M. A Novel Regenerative Braking Energy Recuperation System for Electric Vehicles Based on Driving Style. Energy 2023, 283, 129055. [Google Scholar] [CrossRef]

- Pielecha, I.; Cieślik, W.; Szałek, A. Energy Recovery Potential through Regenerative Braking for a Hybrid Electric Vehicle in a Urban Conditions. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 12013. [Google Scholar] [CrossRef]

- ISO 26262:2018; Road Vehicles—Functional Safety. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 15118; Road Vehicles—Vehicle to Grid Communication Interface. International Organization for Standardization (ISO): Geneva, Switzerland, 2019.

- Santos, J.B.; Francisco, A.M.B.; Cabrita, C.; Monteiro, J.; Pacheco, A.; Cardoso, P.J.S. Development and Implementation of a Smart Charging System for Electric Vehicles Based on the ISO 15118 Standard. Energies 2024, 17, 3045. [Google Scholar] [CrossRef]

| Reference | Focus | Gap | Novelty/Contribution |

|---|---|---|---|

| Szumska, E. M. (2025) [14]. | General EV RBS design, efficiency issues, conventional control | Does not explicitly address 4WID integration or advanced AI algorithms | Provides a comprehensive synthesis of EV RBS design and efficiency challenges, highlighting key structural and control issues. |

| Vodovozov, V. et al. (2021) [15]. | Energy allocation, braking force distribution, hardware limits | Limited discussion on intelligent control and 4WID synergies | Contributes detailed insights into braking energy allocation and system-level management approaches in EVs. |

| Hang, P. et al. (2021) [16]. | Chassis architecture and control perspectives | Does not comprehensively link RBS with intelligent control strategies | Explores 4WID/4WIS vehicle configurations and their control implications for autonomous driving. |

| Saiteja, P. et al. (2022) [6]. | Calibration, architecture, system-level challenges | No 4WID-specific integration, limited discussion of AI/learning control | Highlights critical aspects of system architecture, calibration methods, and implementation challenges in RBS. |

| Chen, Z. et al. (2025) [17]. | BBW hardware and prospects | Touches on RBS but not integrated with 4WID and AI-based control | Maps the state of the art in brake-by-wire technology for new energy vehicles, setting foundation for integration with RBS. |

| Hamada & Orhan (2022) [18] | Energy-storage devices (flywheels, supercapacitors, hybrid storage) | Lacks in-depth application on 4WID EVs | Discusses the various types of energy-storage devices, providing foundational insights for 4WID integration. |

| Our review | Systematic comparison of six intelligent control methods (fuzzy, NN, MPC, SMC, adaptive, learning-based) + hardware advances + evaluation framework | —— | First integrative review explicitly connecting 4WID with intelligent RBS control, proposes closed-loop roadmap with DRL, hierarchical MPC, predictive energy management |

| Brushed DC | IM | PMSM | SRM | |

|---|---|---|---|---|

| Motor structure diagram |  |  |  |  |

| Power density | 2.5 | 3.5 | 5.0 | 3.5 |

| Efficiency | 2.5 | 3.5 | 5.0 | 3.5 |

| Weight | 2.0 | 4.0 | 4.5 | 5.0 |

| Controllability | 5.0 | 5.0 | 5.0 | 3.0 |

| Reliability | 3.0 | 5.0 | 5.0 | 4.5 |

| Technology maturity | 5.0 | 5.0 | 5.0 | 4.0 |

| Cost | 4.0 | 5.0 | 3.0 | 4.0 |

| Total | 24.0 | 31.0 | 32.5 | 28.0 |

| Indicator | Lithium-Ion Battery (LIB) | Supercapacitor (SC) | Flywheel Energy-Storage System (FESS) | Hybrid Energy-Storage System (HESS) |

|---|---|---|---|---|

| Energy density (Wh kg−1) | 150–250 | 5–10 | 20–80 | Depends on combination (between individual units) |

| Power density (W kg−1) | 250–700 | 500–10,000 | 500–1500 | Comprehensive result (composite) |

| Cycle life (cycles) | ≈2000–3000 | ≥100,000 | ≈20,000 | Determined by the shortest-lifespan component |

| Storage efficiency (%) | ≈90–95 | ≥95 | ≈90–95 | High; strategy-dependent |

| Dimension | Type | Features | Advantages | Limitations |

|---|---|---|---|---|

| Braking architecture | Parallel | Fixed regenerative and friction braking ratio | Simple, retains conventional layout | Low recovery efficiency; lacks dynamic adjustment |

| Series | Regen-first strategy; dynamic friction braking | Higher recovery efficiency; consistent pedal feel | Complex control; limited dynamic stability | |

| Pedal-coupling method | Coupled | Mechanical linkage | Simple, intuitive | Low control freedom |

| Decoupled | Brake-by-wire with simulator | Flexible torque allocation, better control | More complex, higher cost | |

| Friction-brake actuator | Hydraulic | Vacuum booster and hydraulic system | Low cost, redundancy | Engine-dependent, not suitable for pure EVs |

| EHB | Motor-driven pump + electro-hydraulic valves | Fast response, integrates easily | Moderate cost, hydraulic components needed | |

| EMB | Direct motor drive, no hydraulics | Ultrafast response, fully by-wire | Still under development, no mechanical backup |

| Algorithm Category | Recovery Efficiency | Stability | Smoothness | Real-Time | Implementation Complexity | Computational Cost | Scalability |

|---|---|---|---|---|---|---|---|

| FLC | 4 | 4 | 4 | 5 | 5 | 5 | 4 |

| ANN | 5 | 4 | 4 | 5 | 3 | 3 | 3 |

| MPC | 3 | 5 | 5 | 2 | 2 | 4 | 3 |

| SMC | 4 | 5 | 3 | 5 | 4 | 4 | 4 |

| Adaptive | 4 | 4 | 4 | 5 | 3 | 4 | 4 |

| Learning | 5 | 5 | 4 | 5 | 1 | 2 | 3 |

| Algorithm Type | Main Advantages | Performance Improvement | References |

|---|---|---|---|

| Model Predictive Control | Handles non-linearity and uncertainty | Energy recovery improved by 9.8% | [137] |

| Neural Network Control | Prediction and self-learning capability | Energy recovery improved by 2.4% | [138] |

| Model Predictive Control | Global optimization, adaptive to conditions | Energy loss reduction by 15% | [141] |

| Sliding Mode Control | Robust, disturbance-resistant | Energy recovery increased by 2.8% | [142] |

| Adaptive Control | Real-time adjustment of control parameters | Efficiency improved by 6.2% | [139] |

| Learning-based Control | Continuous self-optimization | Energy recovery increased by 10%+ | [145] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, B.; Yu, W.; Wu, Z.; Yang, A.; Wei, J. System Integration to Intelligent Control: State of the Art and Future Trends of Electric Vehicle Regenerative Braking Systems. Energies 2025, 18, 5109. https://doi.org/10.3390/en18195109

Huang B, Yu W, Wu Z, Yang A, Wei J. System Integration to Intelligent Control: State of the Art and Future Trends of Electric Vehicle Regenerative Braking Systems. Energies. 2025; 18(19):5109. https://doi.org/10.3390/en18195109

Chicago/Turabian StyleHuang, Bin, Wenbin Yu, Zhuang Wu, Ansheng Yang, and Jinyu Wei. 2025. "System Integration to Intelligent Control: State of the Art and Future Trends of Electric Vehicle Regenerative Braking Systems" Energies 18, no. 19: 5109. https://doi.org/10.3390/en18195109

APA StyleHuang, B., Yu, W., Wu, Z., Yang, A., & Wei, J. (2025). System Integration to Intelligent Control: State of the Art and Future Trends of Electric Vehicle Regenerative Braking Systems. Energies, 18(19), 5109. https://doi.org/10.3390/en18195109