5.1. Example Scenarios and Parameter Settings

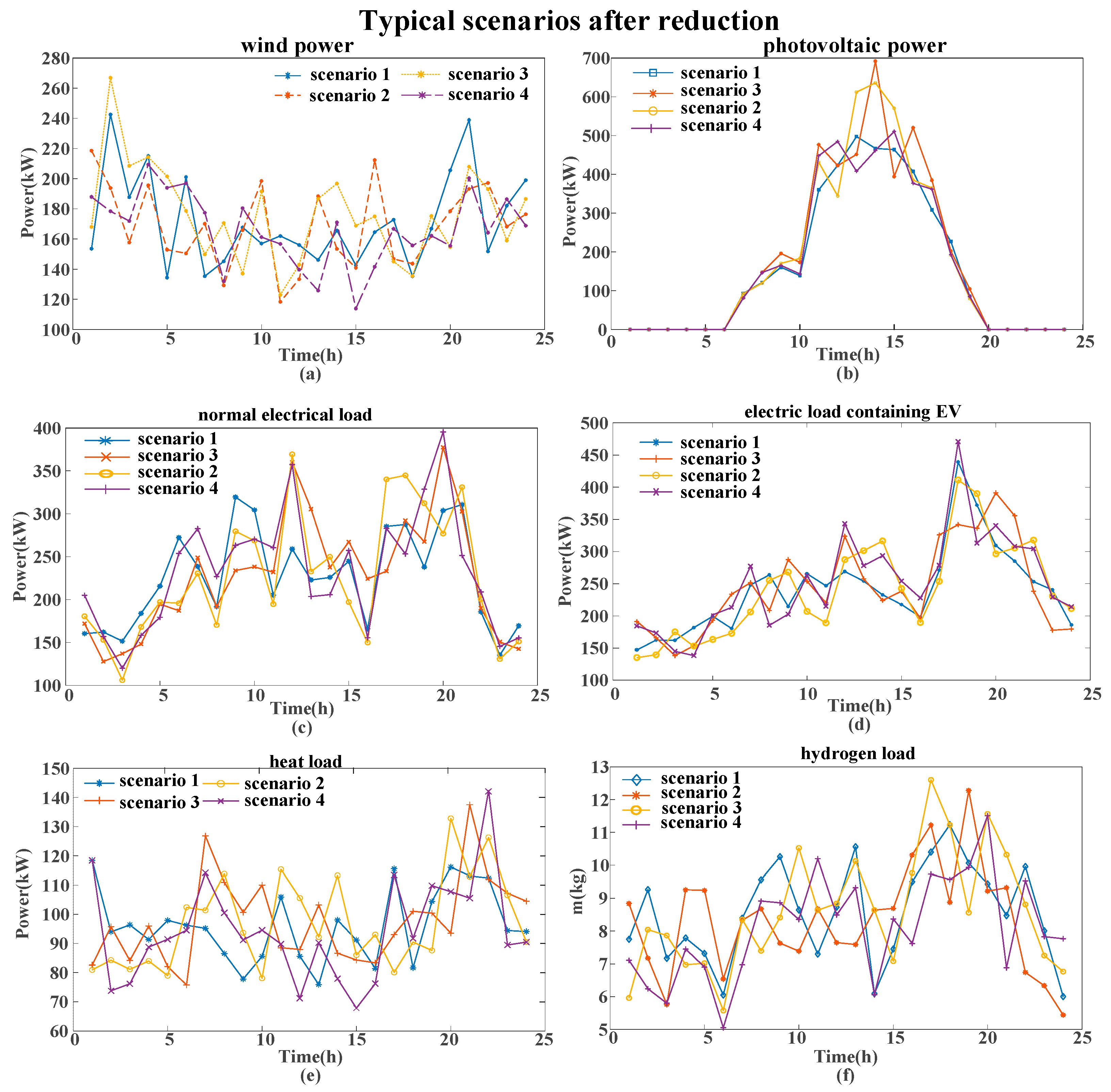

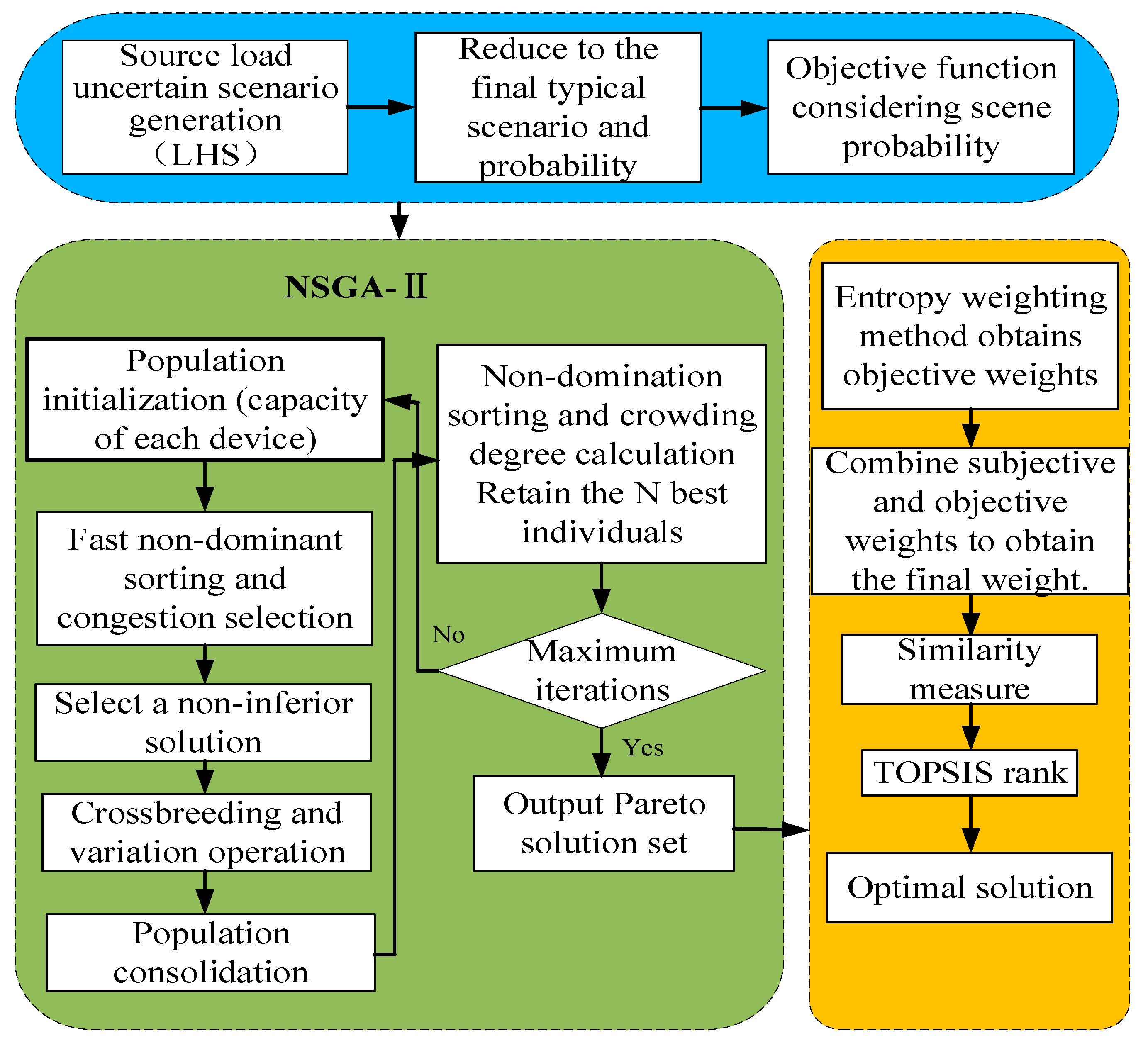

The capacity optimization analysis in this study is based on forecasted data for PV generation, wind WT generation, and electrical/thermal loads for a typical day in 2024. These data were sourced from a hydrogen-integrated demonstration project in Jiangsu Province, China. It is important to acknowledge that the use of forecasted data, as opposed to measured operational data, represents a limitation of this study. Future research will focus on validating the model with actual historical operational data from this and similar projects as such data becomes available. First, the source load forecast data is processed using LHS and EDR. The initial number of generated scenarios is set to 1000, with four typical scenarios selected. Second, the parameters for each device within the system are provided in

Table 2 [

16,

26].

This study assumes that 15 EV charging sessions occur daily within the park’s coverage area. Each session is characterized by a charging power of 7 kW and a battery capacity of 40 kWh, which corresponds to the typical capabilities of mainstream private electric vehicles and is supported by charging behavior studies [

27]. A charging service fee of 0.8 yuan per kWh is applied, and the total charging revenue is derived from both this service fee and time-of-use electricity rates. For hydrogen sourced from outside the park, coal gasification-based hydrogen production is used as a reference. The associated carbon emissions are estimated to be approximately 19 kg CO

2 per kilogram of hydrogen produced, which aligns with lifecycle assessment findings in the literature [

14,

28]. The total unit cost of hydrogen, including production and transportation fees, is estimated at approximately 17.02 yuan per kilogram, based on comprehensive cost analyses of the hydrogen industry chain [

29]. To validate the effectiveness of the research presented in this paper, four case were designed for the system. The specific factors considered in each case are outlined in

Table 3.

5.2. System Capacity Configuration Results and Operational Analysis

The capacity allocation results for the four scenarios, calculated based on the objective function and constraints outlined earlier, are presented in

Table 4.

These capacity scales fall entirely within the commercially available range for industrial applications. EL and FC of this scale are widely supplied by numerous global manufacturers, including Cummins, Siemens, and Huawei. HST with capacities in the hundreds of kilograms are standard components in industrial gas supply systems, posing no significant technical challenges. With ongoing breakthroughs and advancements in hydrogen-related technologies, the economic viability of IES equipped with hydrogen storage is expected to improve substantially in the future.

The system performance indicators obtained from testing with the configurations outlined above are presented in

Table 5.

Compared to relying exclusively on purchased hydrogen, integrating hydrogen production from clean energy sources within the system effectively manages both costs and carbon emissions. A detailed comparison of the results is presented in

Table 6.

Analysis of

Table 5 and

Table 6 indicates that the cost of purchasing hydrogen from external sources represents a significant proportion of the daily total cost, and the production of externally sourced hydrogen results in substantial carbon emissions. Compared to a system that relies solely on purchased hydrogen, integrating clean energy into the system for chemical production reduces the quantity of hydrogen purchased by 9.8%.

A sensitivity analysis was conducted to evaluate the robustness of the optimization results with respect to the number of typical scenarios. The complete model (Case 4) was re-optimized using 3 and 5 typical scenarios, respectively. The results were then compared with those obtained from the base case, which used 4 scenarios. The key findings are summarized in

Table 7.

The analysis indicates that using three scenarios leads to significant errors in capacity estimation: the EL capacity is overestimated by 36.8%, while the FC and EB capacities are underestimated by 23.5% and 25.0%, respectively. This suggests that three scenarios are insufficient to capture the source-load uncertainty adequately. In contrast, using five scenarios results in only minor deviations, with all equipment capacities differing by less than 5% from the base case, and key devices such as EL and FC varying by less than 3%. These findings suggest that four scenarios provide an optimal balance between modeling accuracy and computational efficiency.

To further assess the effectiveness of case 4, this study performed system test runs for all four cases, utilizing the configuration results described above along with the system’s recent load forecast data. The results of these simulations are presented in

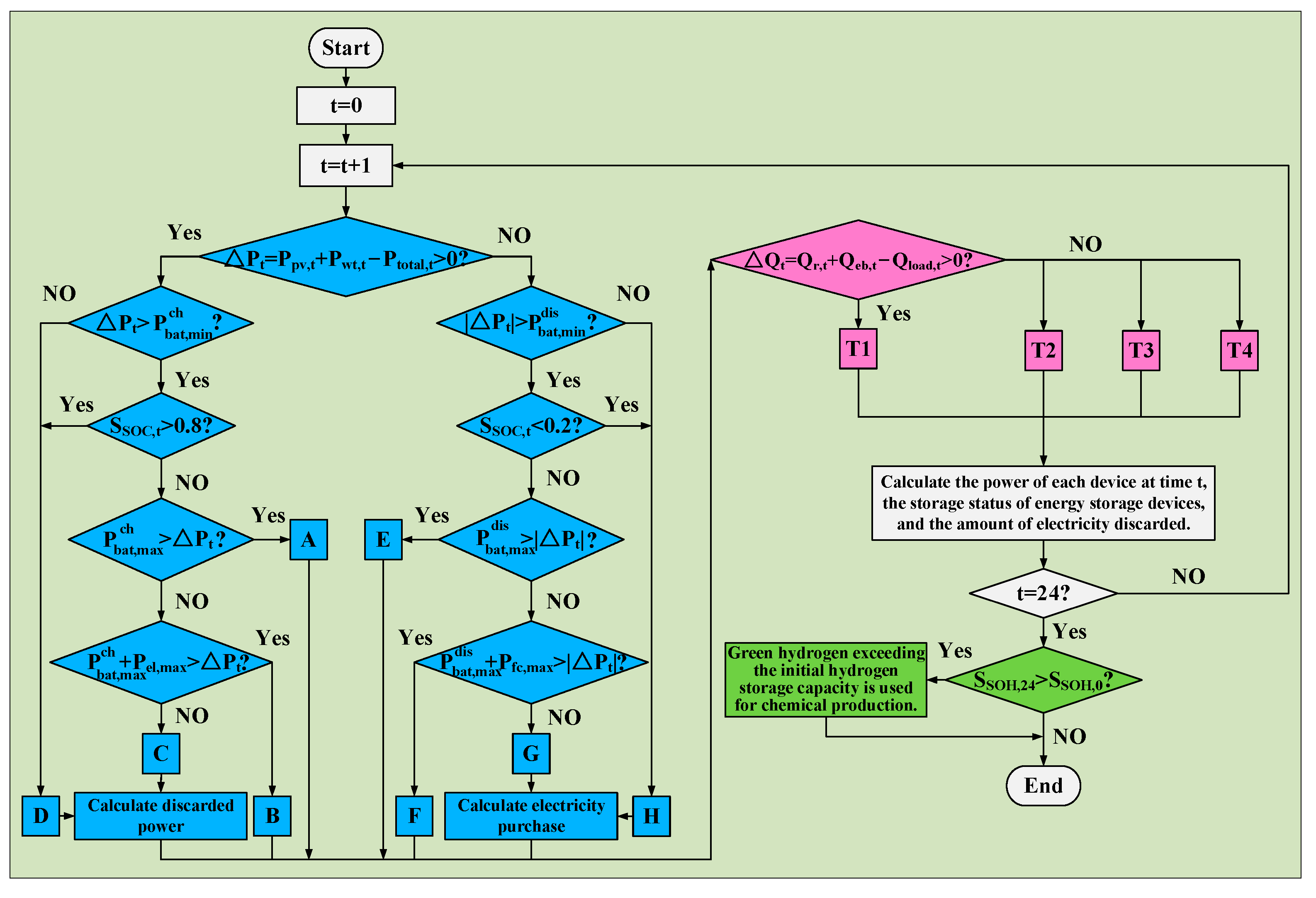

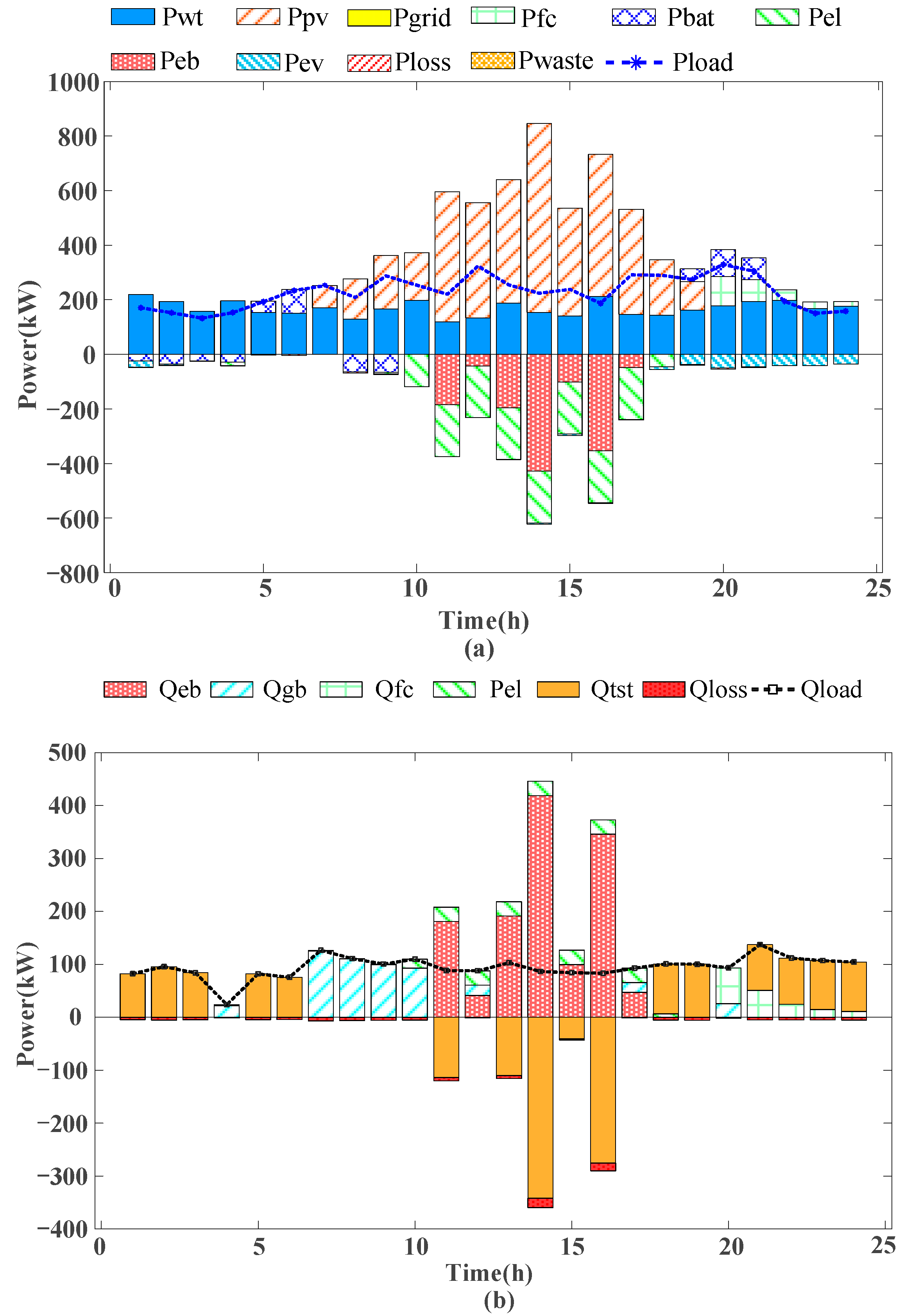

Figure 5.

Based on the planning and operational results presented in

Table 4 and

Figure 5, it is evident that Case 1 does not incorporate the utilization of waste heat from the hydrogen energy subsystem. As a result, the system relies entirely on EB, TST, and GB for heating. Between 1:00 AM and 7:00 AM, the system faces a thermal energy shortage, and the clean energy available is insufficient to activate the EB. Consequently, the system prioritizes the activation of the TST for heating. At 4:00 AM, the TST has not yet reached its safe operating lower limit, preventing its activation; therefore, the system resorts to starting the GB for heating. By 7:00 AM, the TST has fully discharged to its energy storage lower limit, and the GB supplements the remaining heat load.

Between 10:00 AM and 5:00 PM, the PV system operates, reaching its peak clean energy output. Once the BAT is fully charged, the system prioritizes activating the EL for hydrogen production. Any remaining surplus power is directed to the EB for heating. After fulfilling the thermal load demand, the excess heat is stored in the TST.

Between 8:00 PM and 10:00 PM, the evening peak and EV charging peak overlap. Despite the BAT discharging at maximum capacity, it is insufficient to meet the electrical load demand, prompting the system to activate the FC to compensate for the power deficit. However, Case 1 does not account for significant disturbances, leading to the need for additional power purchase from the grid at 8:00 PM. Since the TST was charged during the day, it is able to meet the thermal load demand of the industrial park during the night.

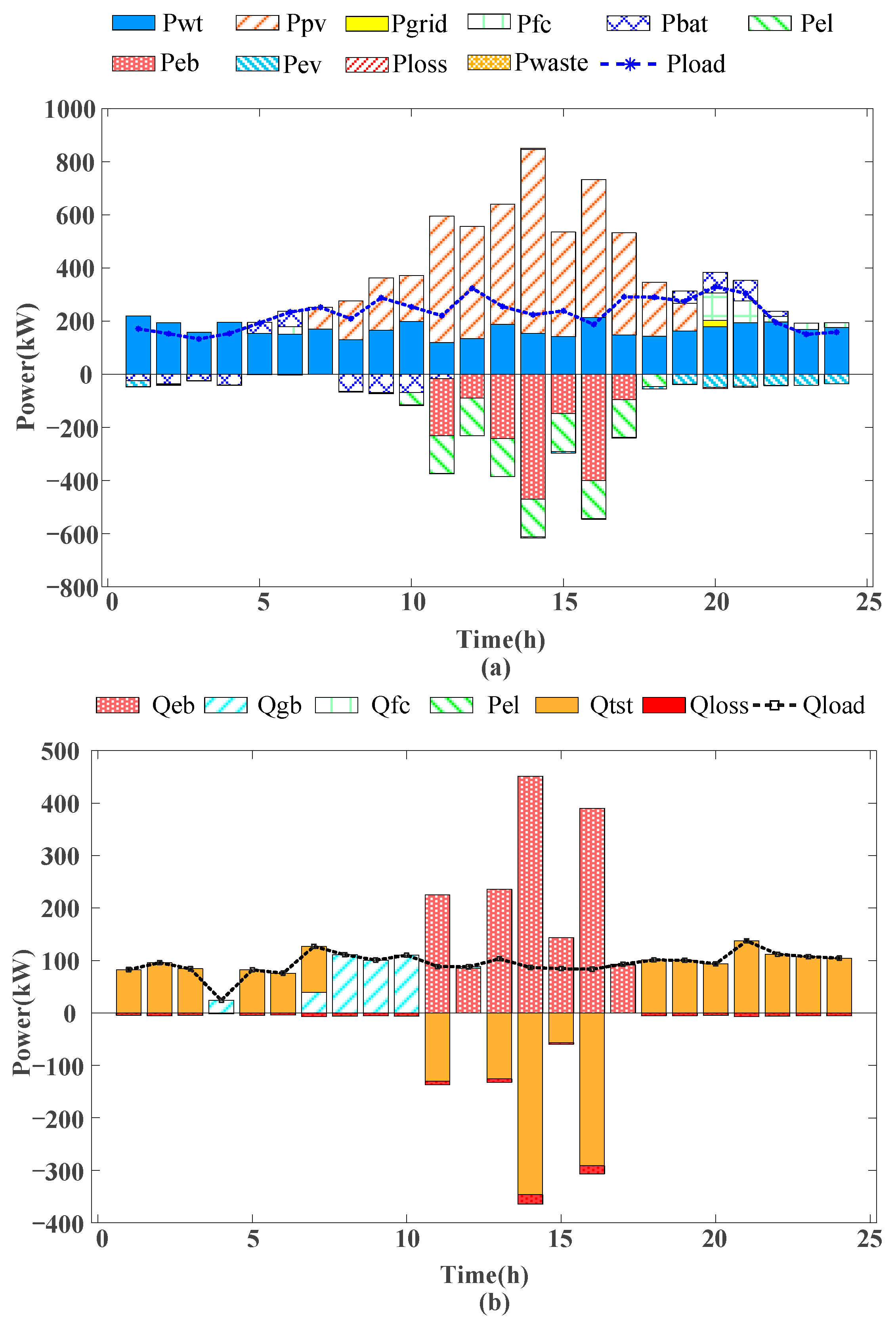

The analysis of Case 4, in conjunction with

Table 4 and

Figure 6, reveals several key insights into the system’s energy management. From an electrical energy perspective, Case 4 utilizes larger-capacity EL, enabling the storage of more energy as hydrogen during periods of peak clean energy output. This design increases the system’s energy storage capacity and facilitates more efficient utilization of renewable energy.

In terms of thermal energy, Case 4 incorporates the use of waste heat from the hydrogen energy subsystem. Specifically, from 10:00 to 17:00, the thermal load is supplied by both the EL and the EB. From 20:00 to 24:00, when clean energy and BAT are insufficient to meet the electrical load demand, the FC is activated. This ensures the regulation of the electricity supply and facilitates the recovery of waste heat for system heating, thereby enhancing overall energy efficiency.

5.3. System Configuration and Performance Analysis Under Different Cases

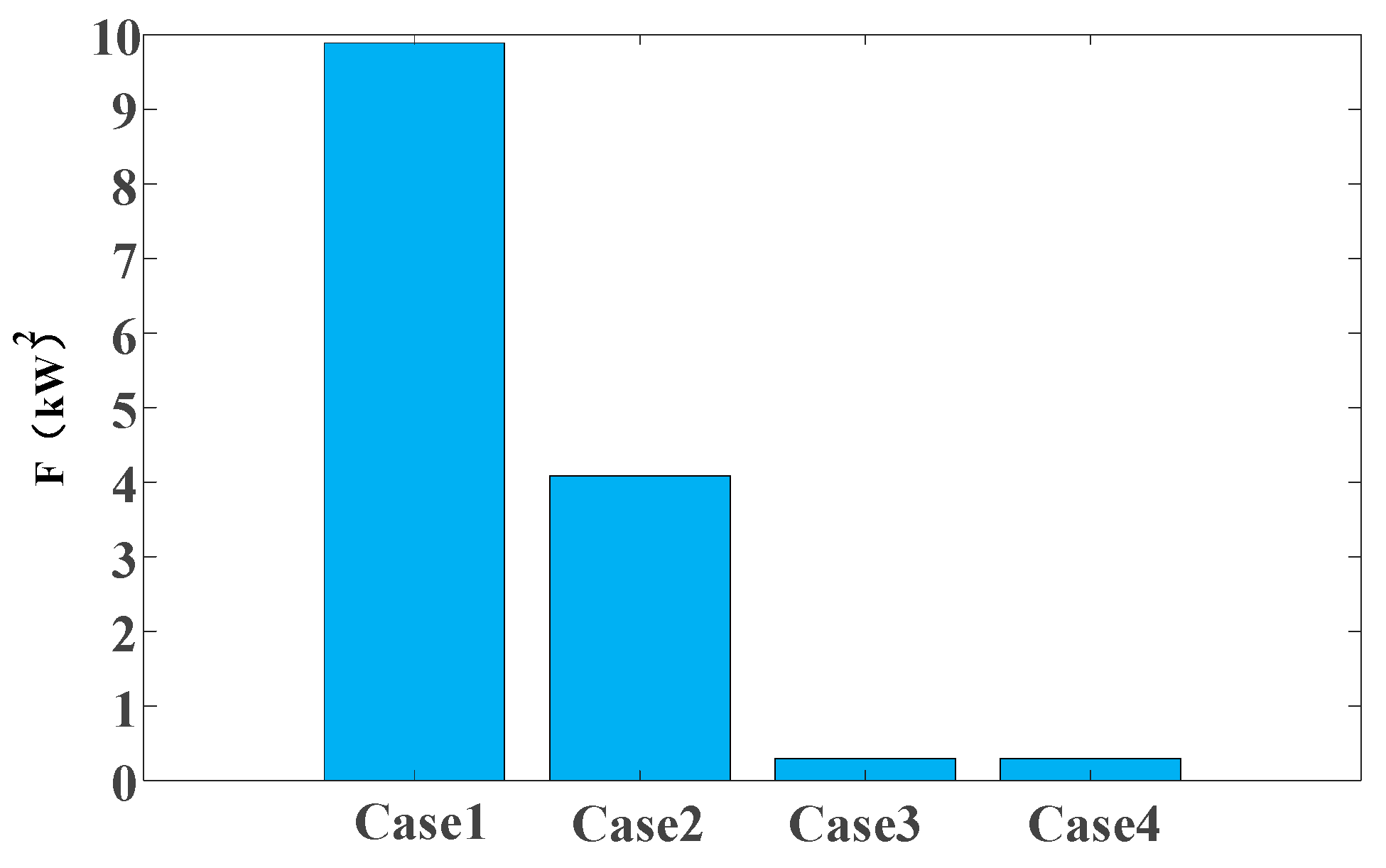

We analyzed the system configuration results in conjunction with

Table 3,

Table 4,

Table 5 and

Table 6. Compared to Case 1, Case 2 incorporates waste heat recovery from the hydrogen energy subsystem and increases the capacity of the existing FC for electrothermal regulation. The expanded capacity of the FC leads to a higher consumption of hydrogen, which in turn reduces the available capacity for hydrogen energy storage. Moreover, the use of hydrogen energy storage for thermal regulation significantly decreases the required capacity of TST and GB, effectively controlling costs and reducing the system’s daily overall cost by 9.74%. Additionally, by prioritizing waste heat for heating, the system reduces its dependence on gas-fired heating, resulting in a 6.98% reduction in carbon emissions. The increased FC capacity also contributes to a reduction in the system’s load variance by 58.6%.

Case 3 considers the inclusion of EV charging access based on Case 2. However, the random nature of EV charging will affect the system’s original load. As a result, the system requires enhanced disturbance resistance, leading to a significant increase in the equipment capacity of the hydrogen energy subsystem. With this configuration, the system largely eliminates the need to purchase electricity from the grid, while the flexible adjustment capabilities of the hydrogen energy subsystem further reduce the system’s load variance. Nevertheless, the high cost of hydrogen energy storage increases both procurement and maintenance expenses, indicating that the economic efficiency of this system requires further optimization.

Case 4 builds upon Case 3 by utilizing hydrogen produced from clean energy within the system for chemical production in the industrial park. In contrast to a system that relies entirely on externally purchased hydrogen, this approach diversifies the consumption channels for hydrogen storage, thereby enhancing the flexibility of hydrogen storage regulation. The system is equipped with higher-capacity EL, while the HSTs are smaller, further reducing both procurement and operational costs. Through the energy management strategies outlined in this paper, it is ensured that the electric heat storage system achieves full charging and discharging within a day, while the hydrogen storage system maintains a specified storage level to ensure that the initial and final states are equal throughout the cycle. This configuration is advantageous for the long-term, stable operation of the system.

Figure 7 shows the load variance under different cases.

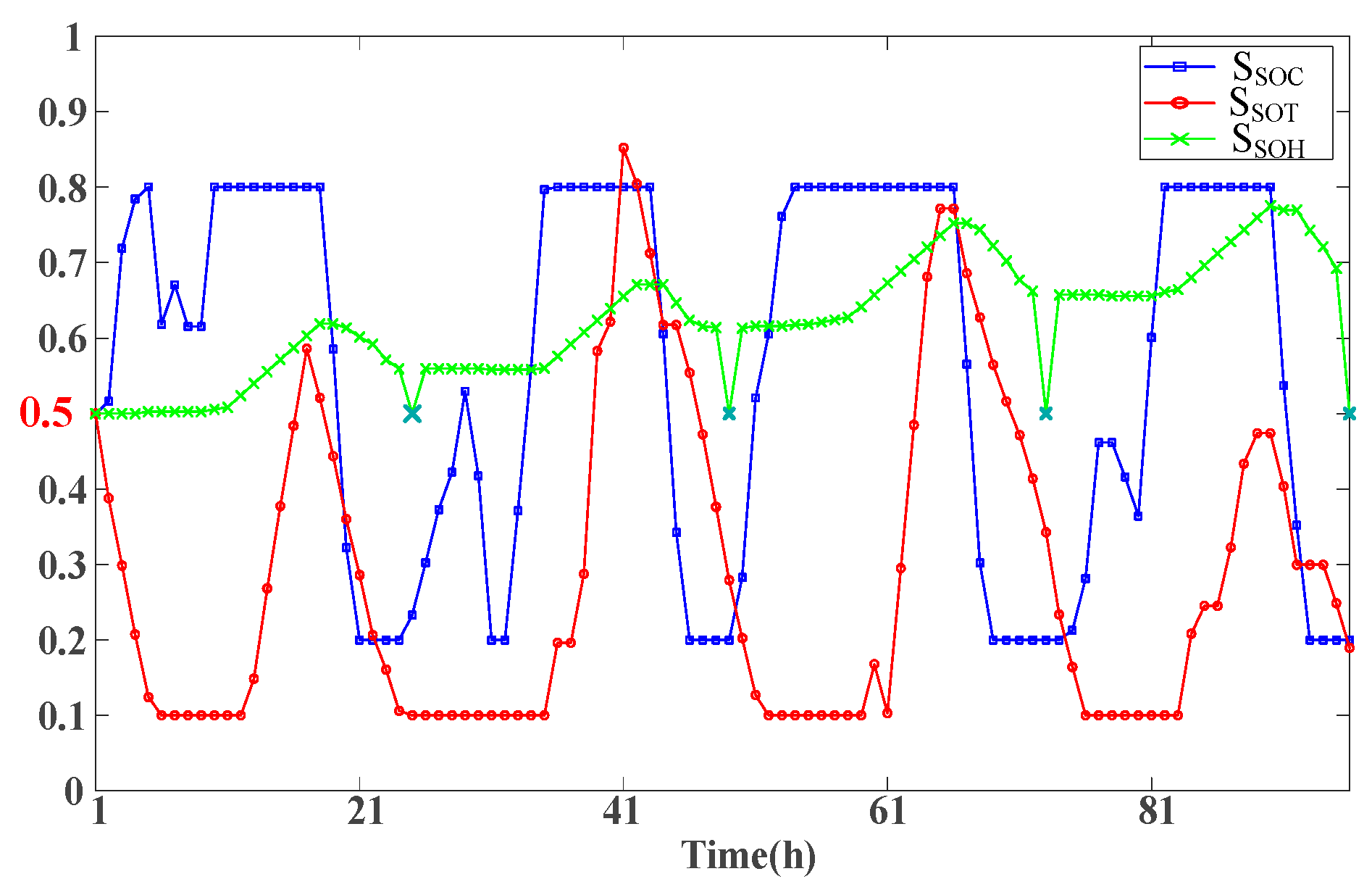

Figure 8 shows the storage status of energy storage equipment under case 4.

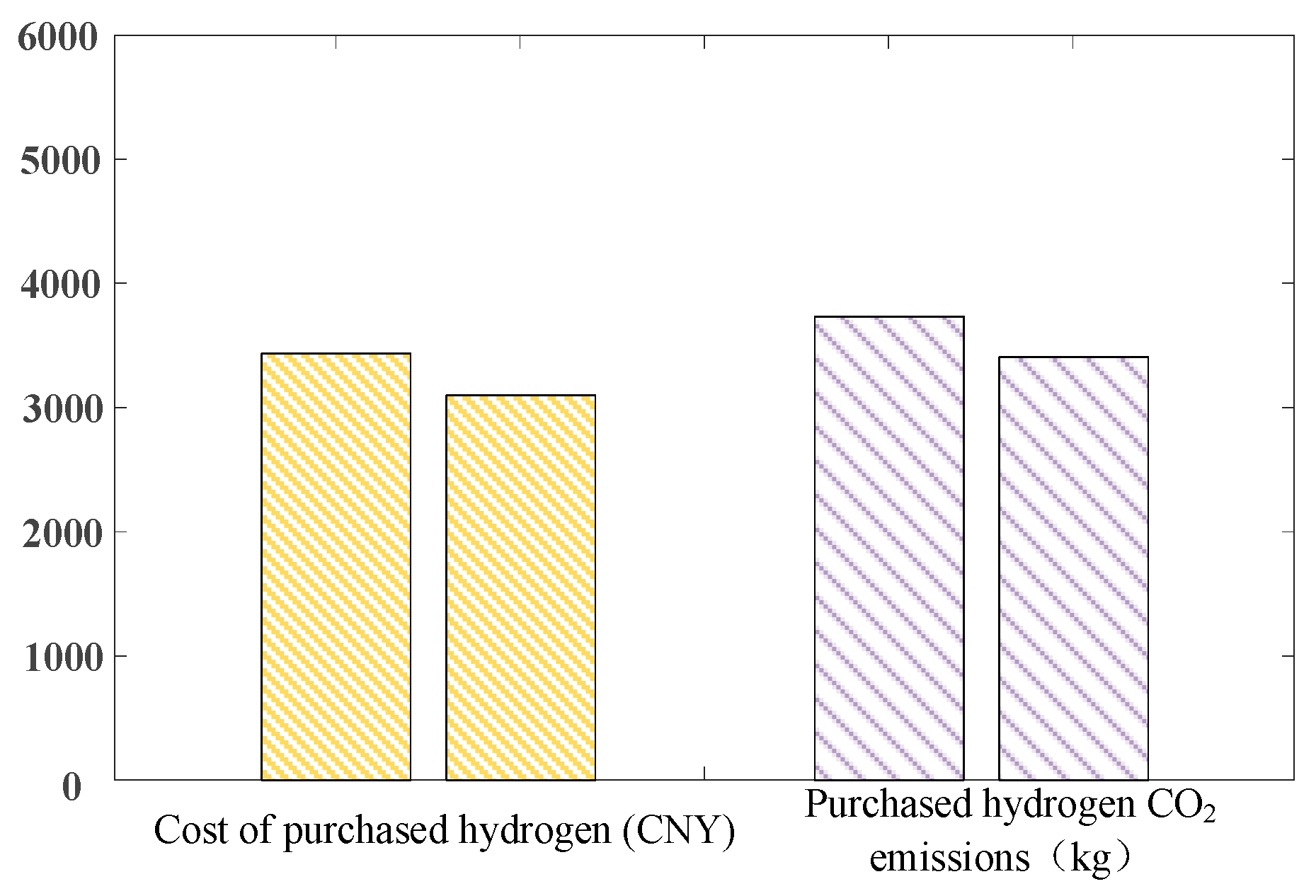

5.4. Consideration of the Cost–Benefit Analysis of Hydrogenation Production

As presented in

Table 6, the cost of purchased hydrogen for chemical production in the industrial park constitutes a significant portion of the total cost. Utilizing surplus hydrogen from the HST at the end of the cycle for chemical production can reduce the reliance on externally purchased hydrogen. In comparison to Case 3, which solely depends on externally sourced hydrogen, the reduced capacity of the hydrogen energy subsystem has led to a 9.72% reduction in procurement and maintenance costs. The internal utilization of surplus hydrogen has also resulted in a 9.8% decrease in external hydrogen procurement costs. However, since excess clean energy is primarily stored as hydrogen, the heat output of the EB is diminished, and the system’s thermal load is increasingly met by the GB. This shift results in higher carbon emissions during operation. Despite this, when accounting for the total carbon emissions associated with the production of externally purchased hydrogen, the overall carbon emissions are still reduced by 6.93%. A comparison of the costs and carbon emissions associated with relying solely on externally purchased hydrogen is presented in

Figure 9.

A comparison with recent international studies on hydrogen-based IES highlights a significant advancement in our work. While many studies focus on the use of hydrogen for renewable energy storage and grid balancing [

30,

31], our model explicitly incorporates the carbon emissions associated with hydrogen production. This enables a more comprehensive environmental assessment and reveals that the primary benefit of on-site green hydrogen production lies not only in energy storage but also in the displacement of high-carbon, externally sourced hydrogen. This finding underscores the pivotal role of hydrogen-based IES in driving deep decarbonization and in reducing the carbon intensity of industrial feedstocks.

However, the realization of decarbonization potential currently faces economic challenges due to the high upfront costs of EL and the relatively low cost of carbon-intensive alternatives. Supportive policies could significantly improve both the economic feasibility and environmental impact of the proposed integrated system. For example, a carbon emissions trading scheme would increase the operational costs of grid power and natural gas, thereby enhancing the economic advantages of clean energy, waste heat recovery, and on-site green hydrogen production. Higher carbon prices, in particular, would substantially improve the return on investment for EL and FC systems. Additionally, subsidies for green hydrogen production—whether in the form of investment or production subsidies—could shorten payback periods and mitigate initial capital risks, helping to close the cost gap and facilitating large-scale deployment. These policy mechanisms are critical for achieving deep decarbonization within the industrial sector.