Polarization and Depolarization Current Characteristics of Cables at Different Water Immersion Stages

Abstract

1. Introduction

2. Sample Preparation and Platform Setup

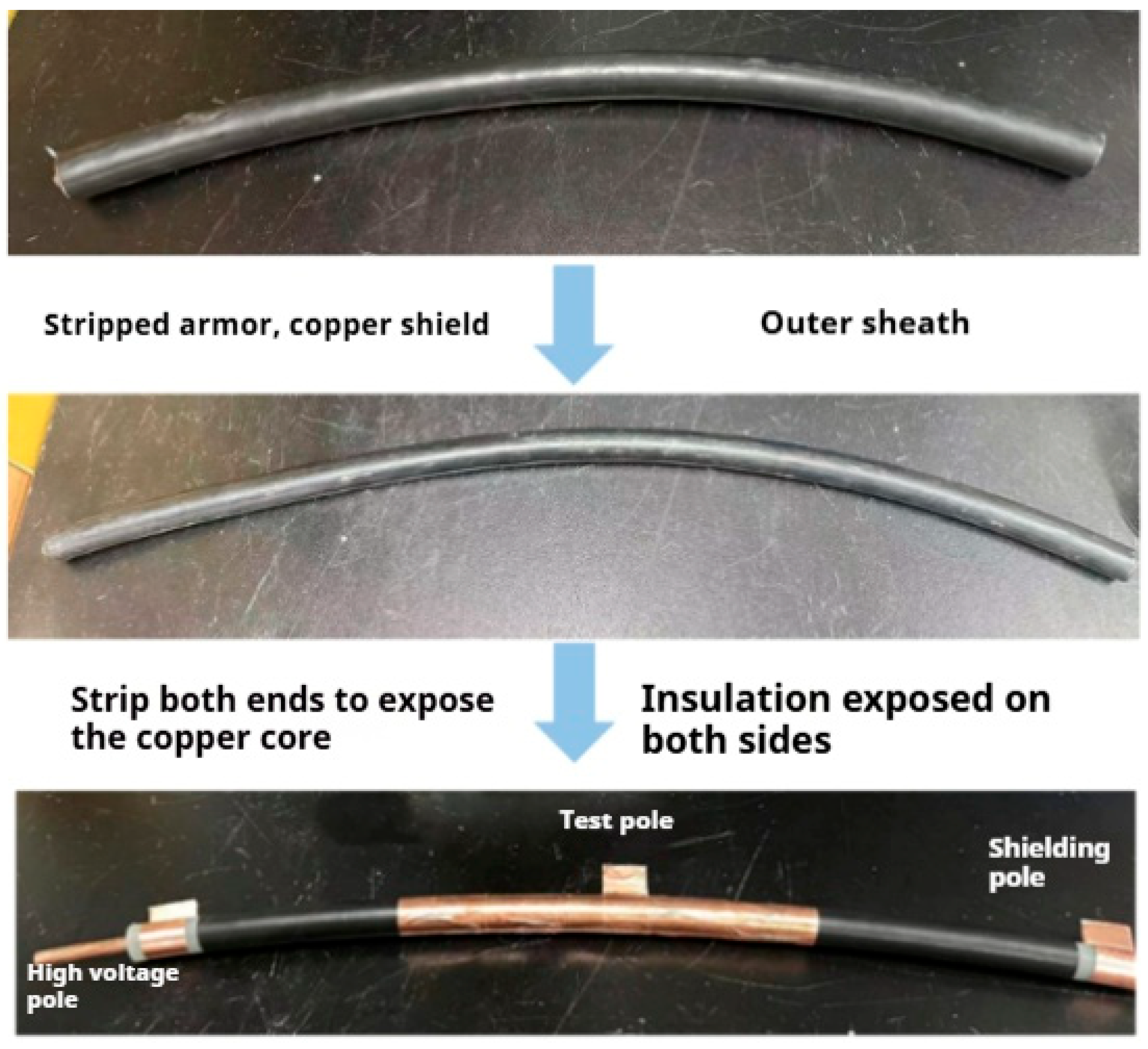

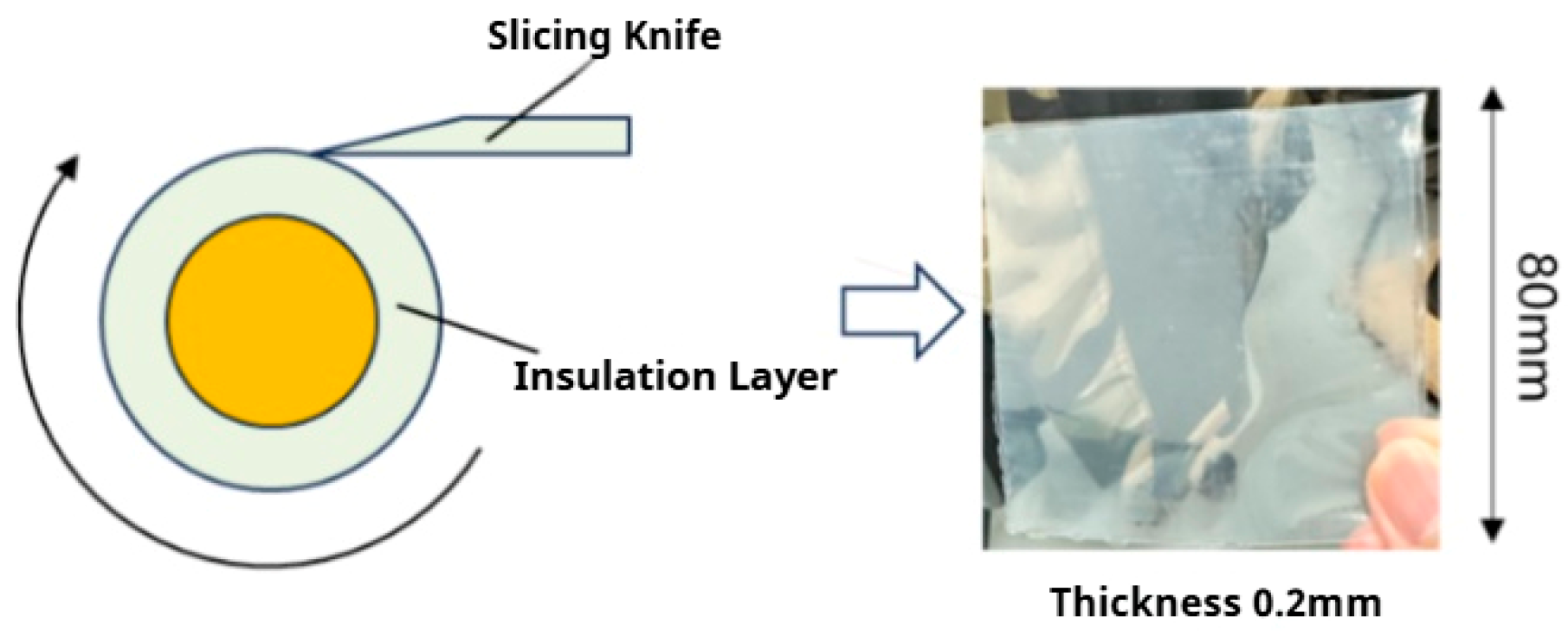

2.1. Test Specimen Preparation

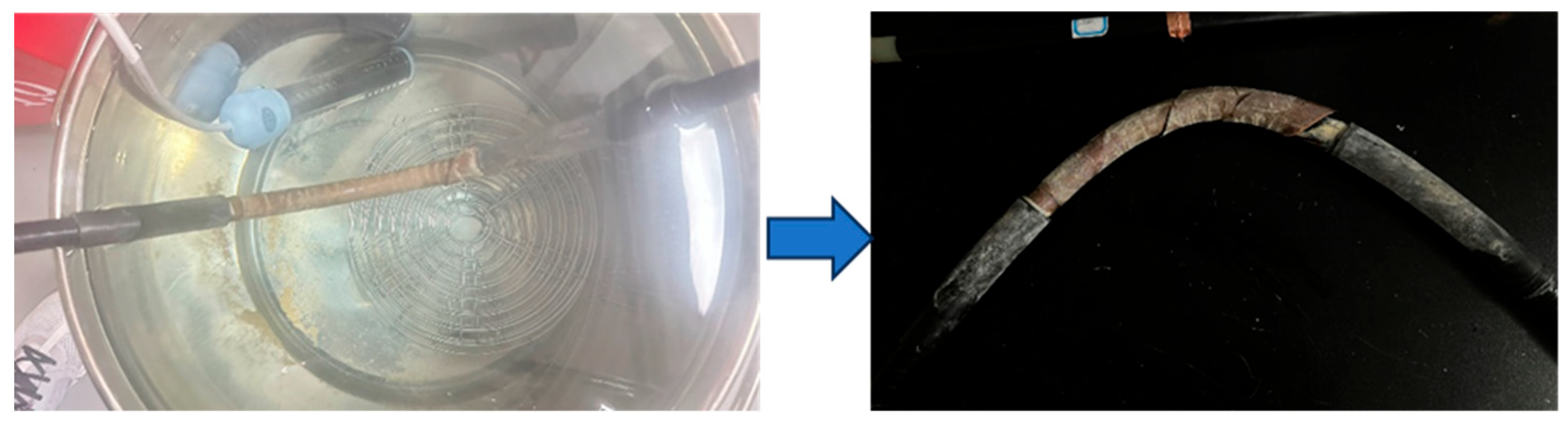

2.2. Water Immersion Test Design

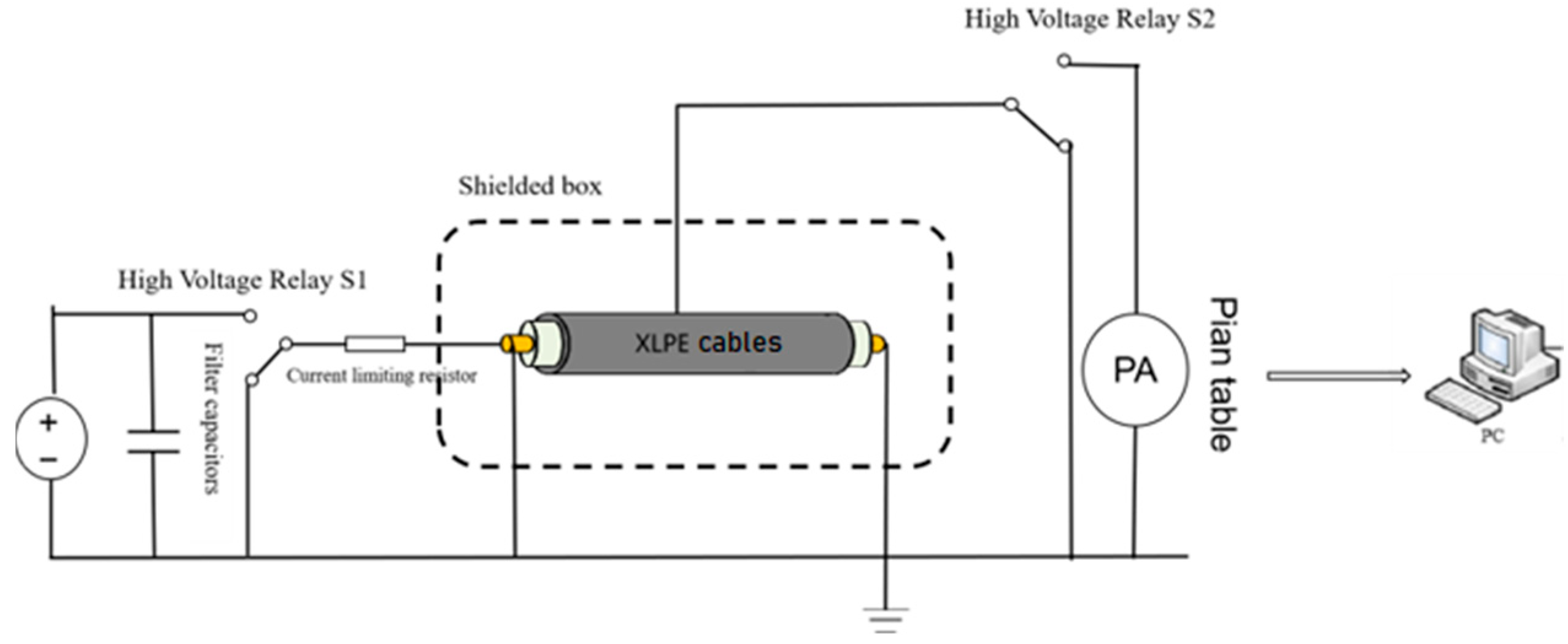

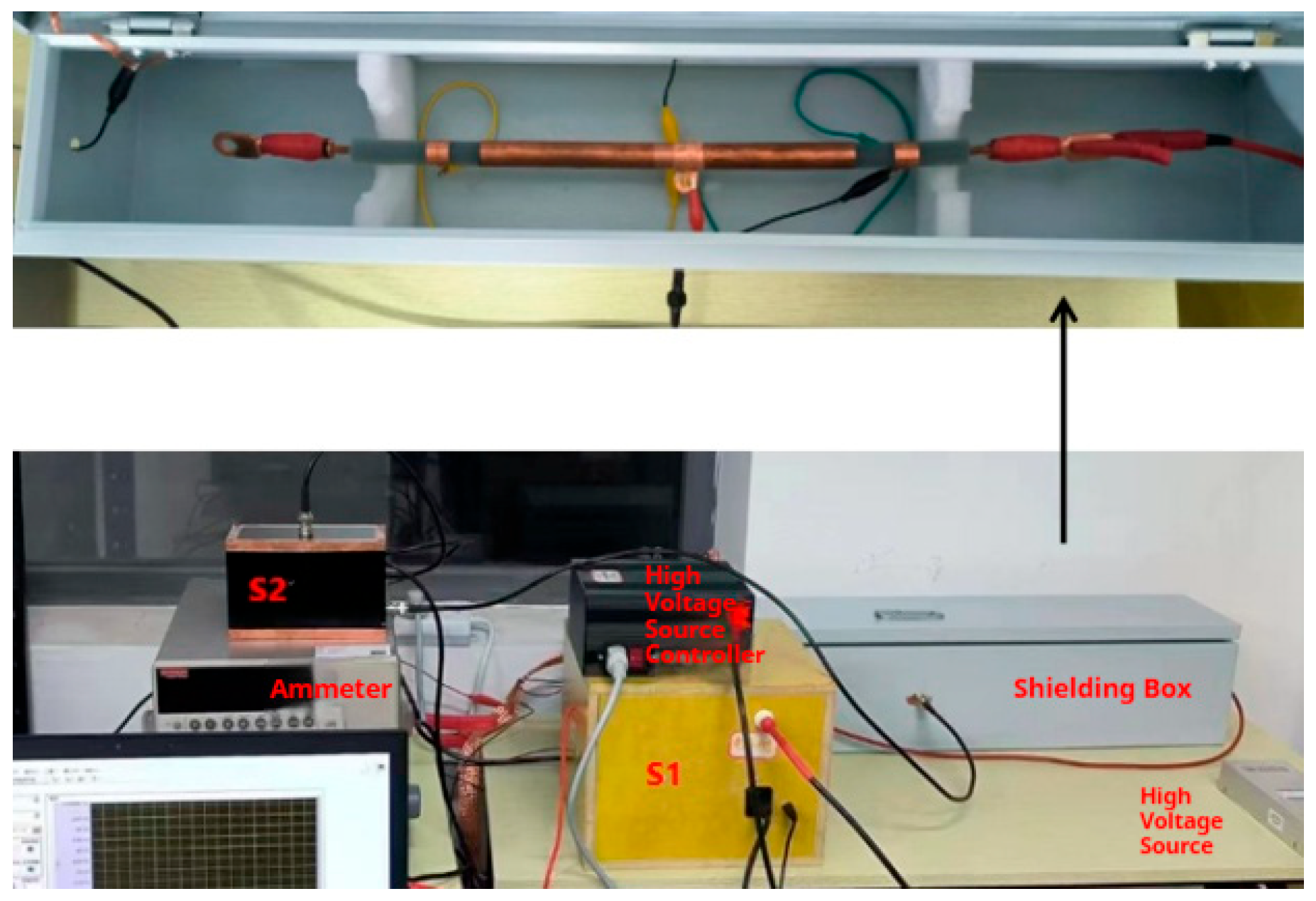

2.3. Polarization and Depolarization Current Measurement Platform

3. Research on Immersion State Assessment Method Based on Polarization/Depolarization Current

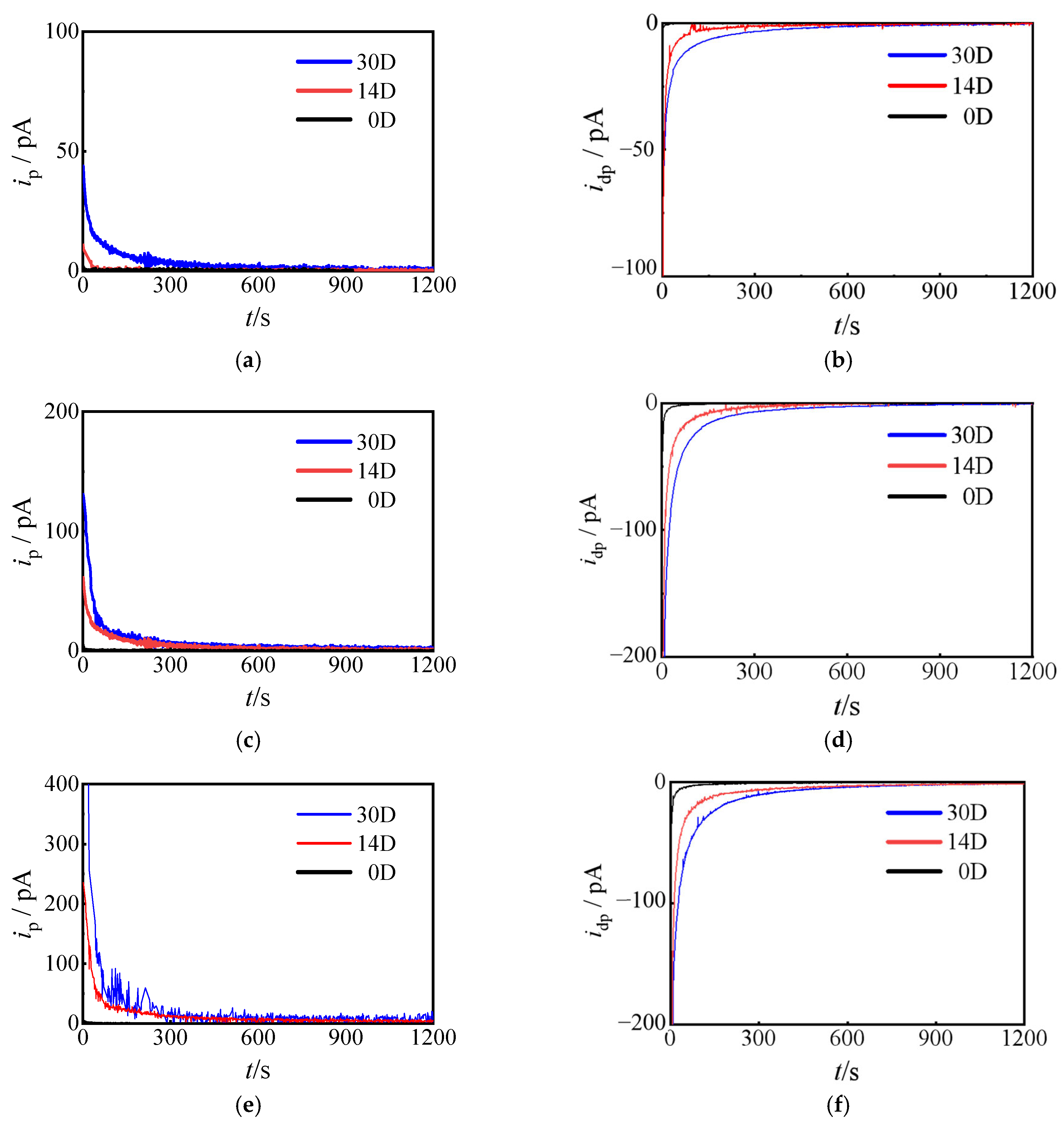

3.1. The Influence of Test Voltage and Immersion Time on PDC Testing

3.2. The Conductivity and Charge Mobility of Water-Immersed Cables

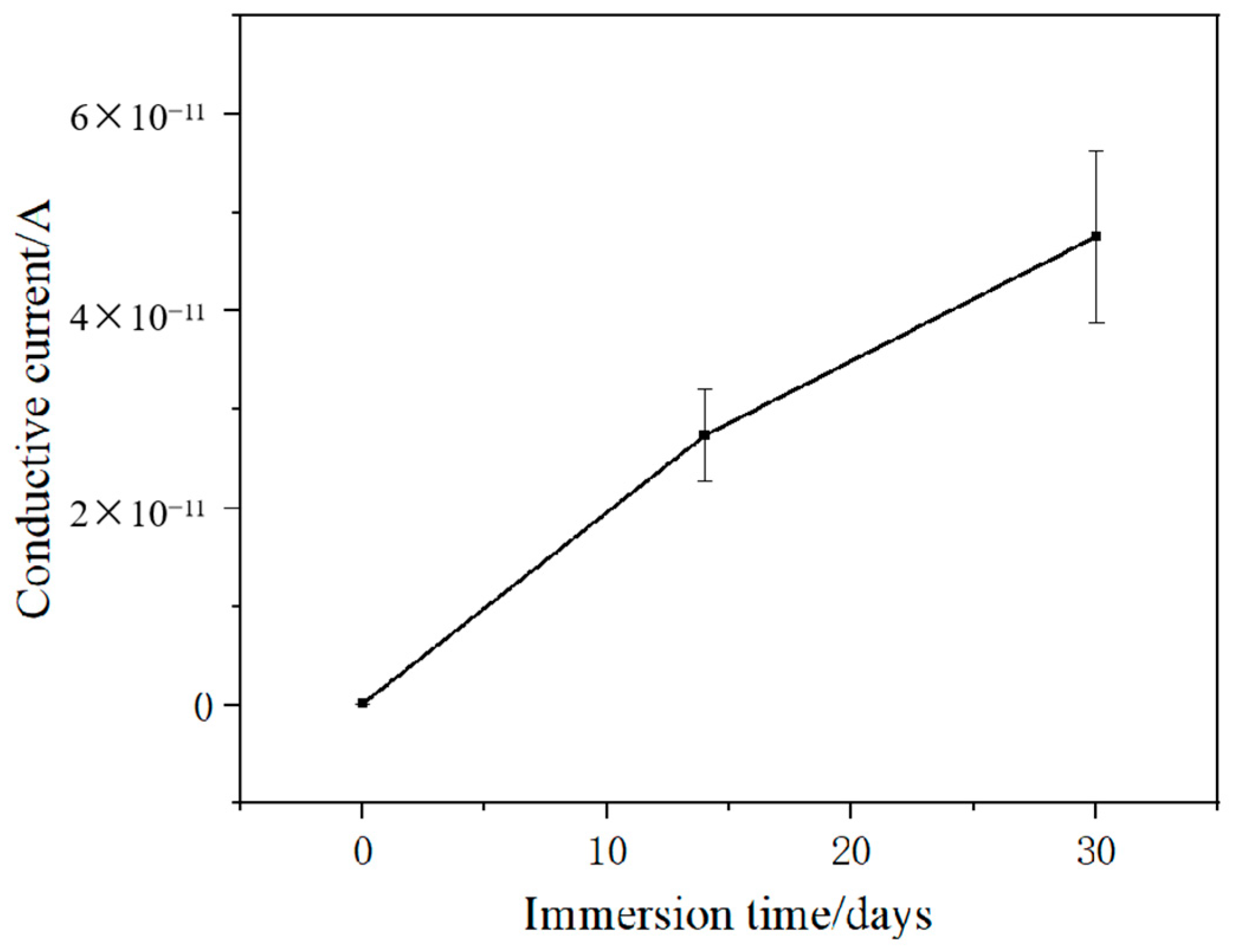

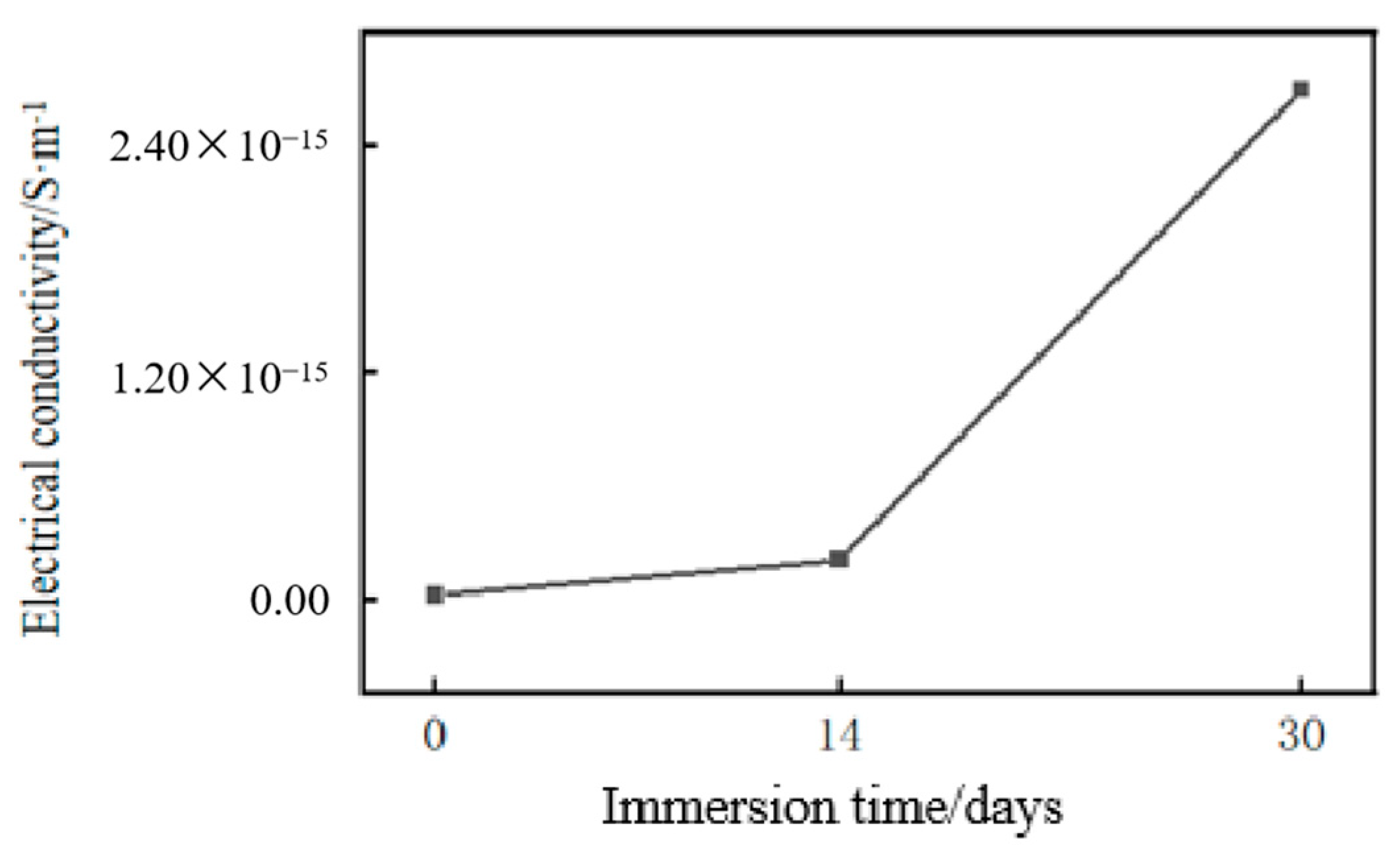

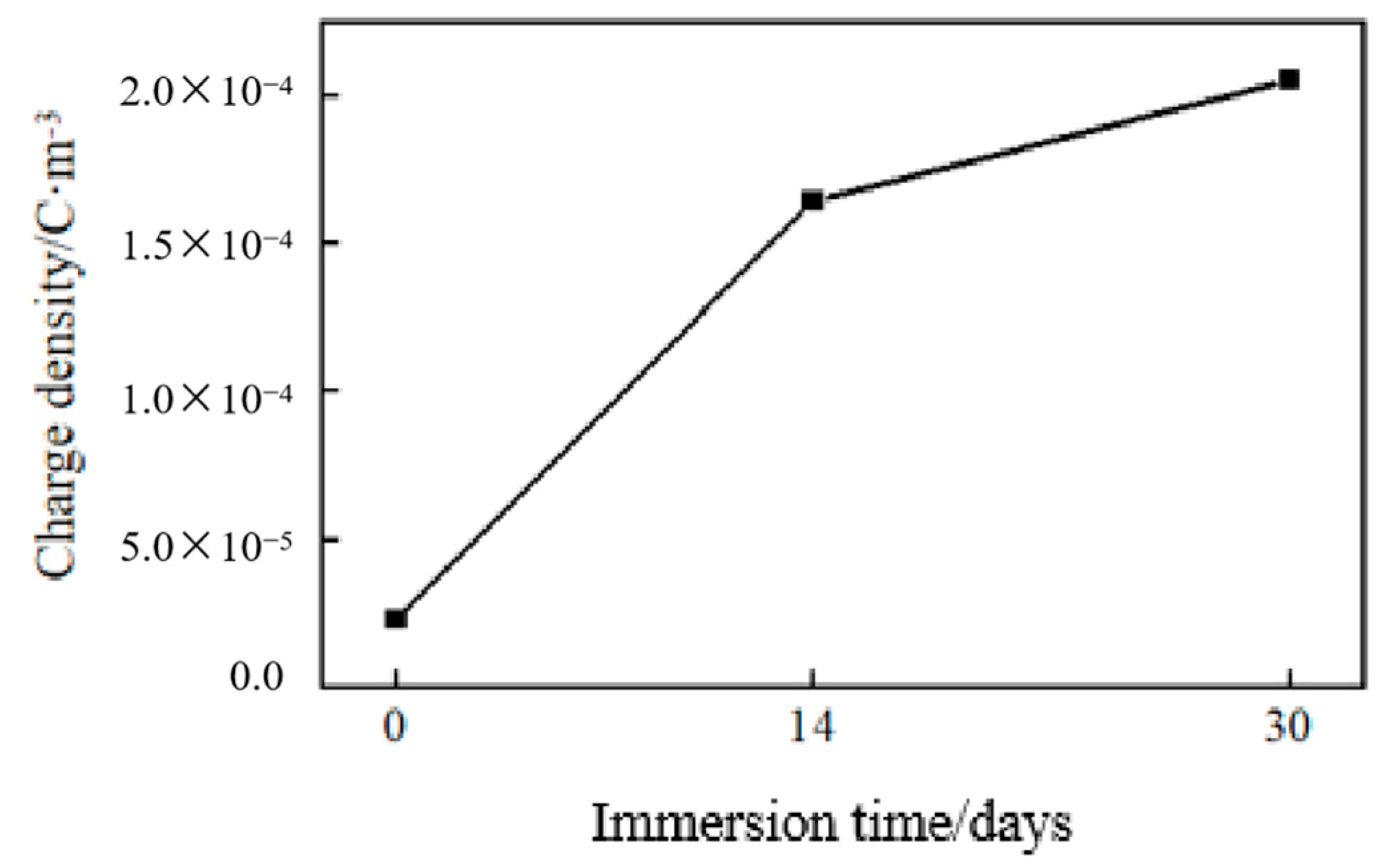

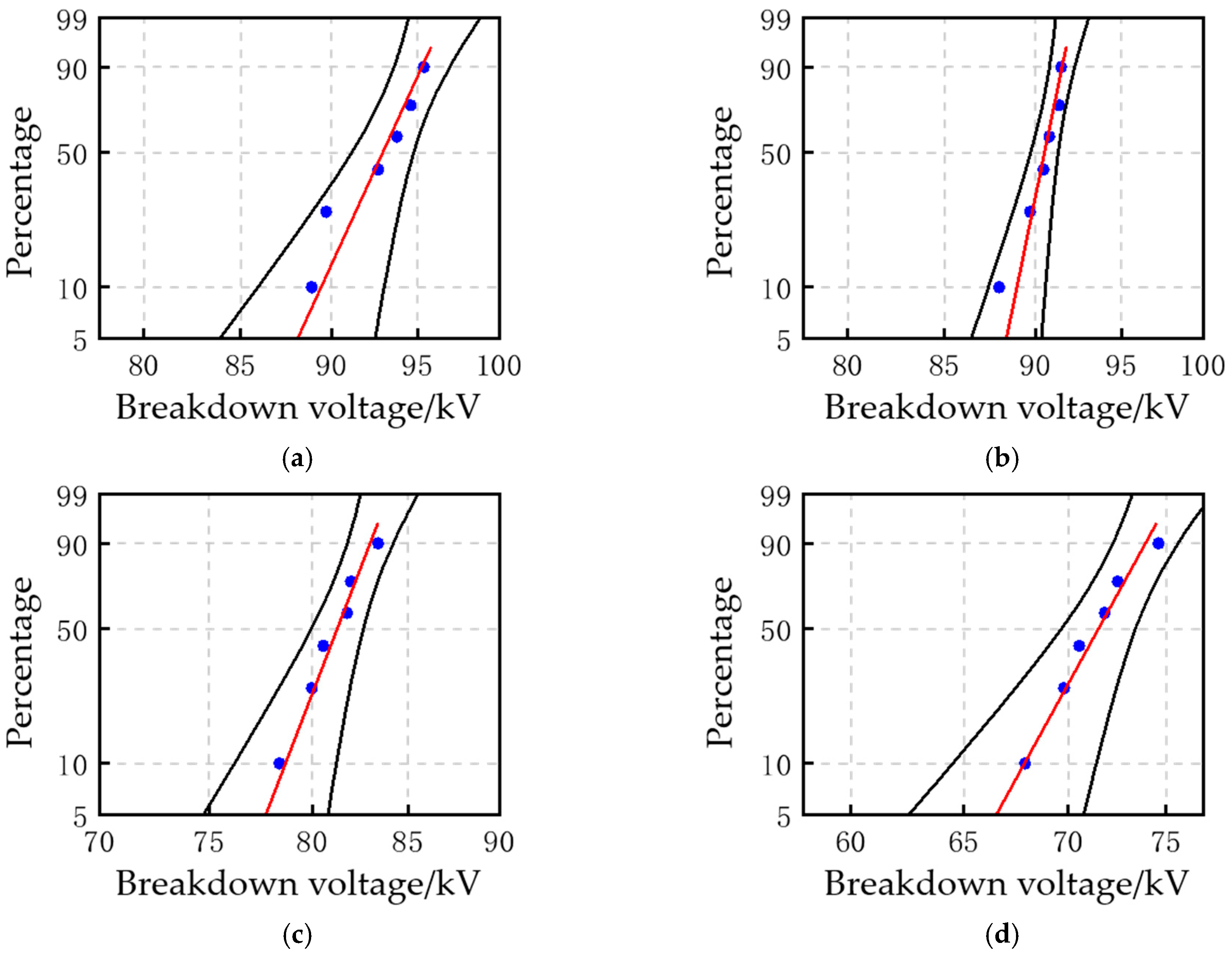

3.3. Analysis of the Correlation Between Submerged Cable Parameters and Immersion Time

4. Study on Water Immersion Characteristics of XLPE Cable Insulation Slices

4.1. The Variation Pattern of Water Absorption in Submerged XLPE Samples

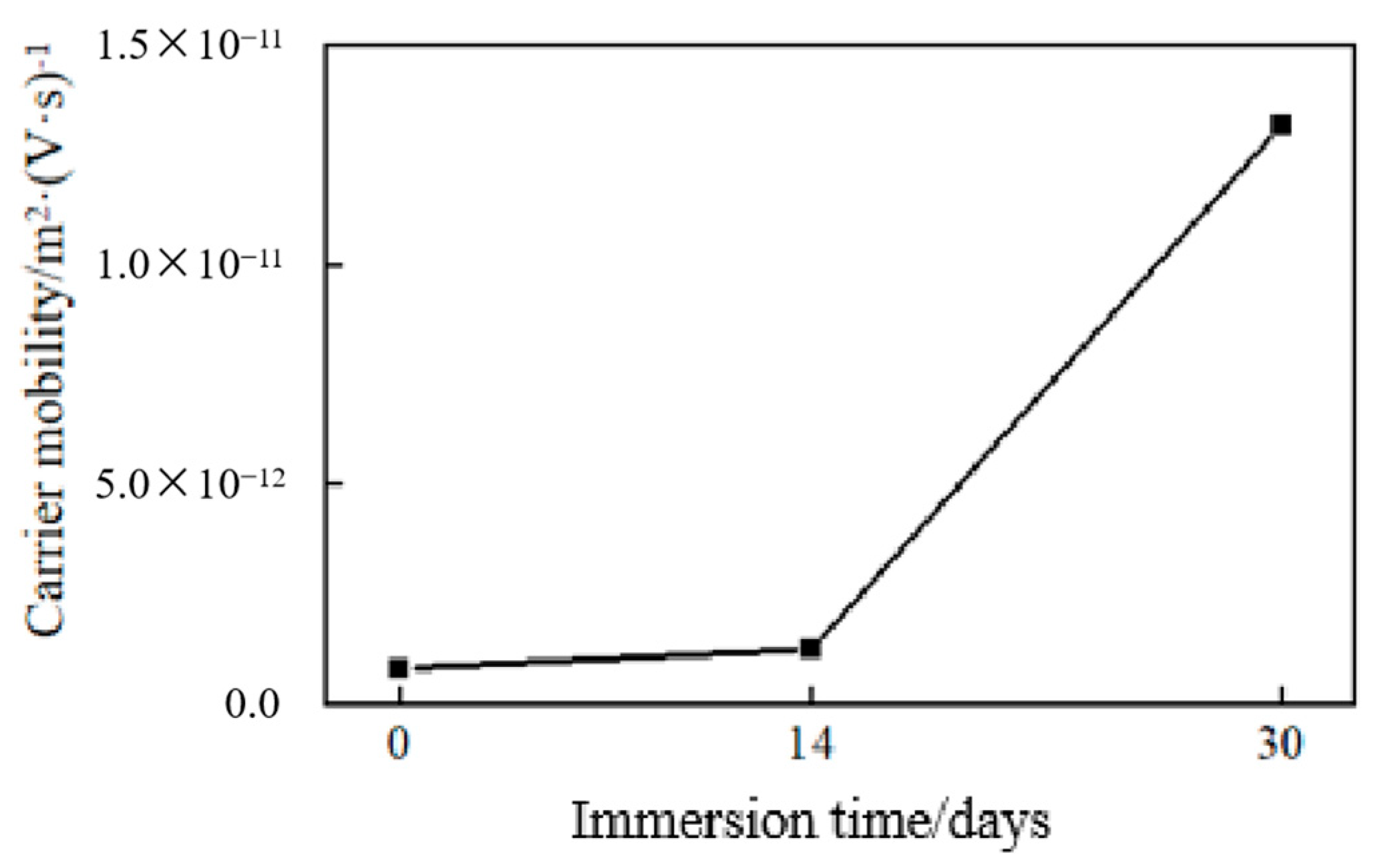

4.2. The Variation Pattern of Conductivity in Water-Immersed XLPE Samples

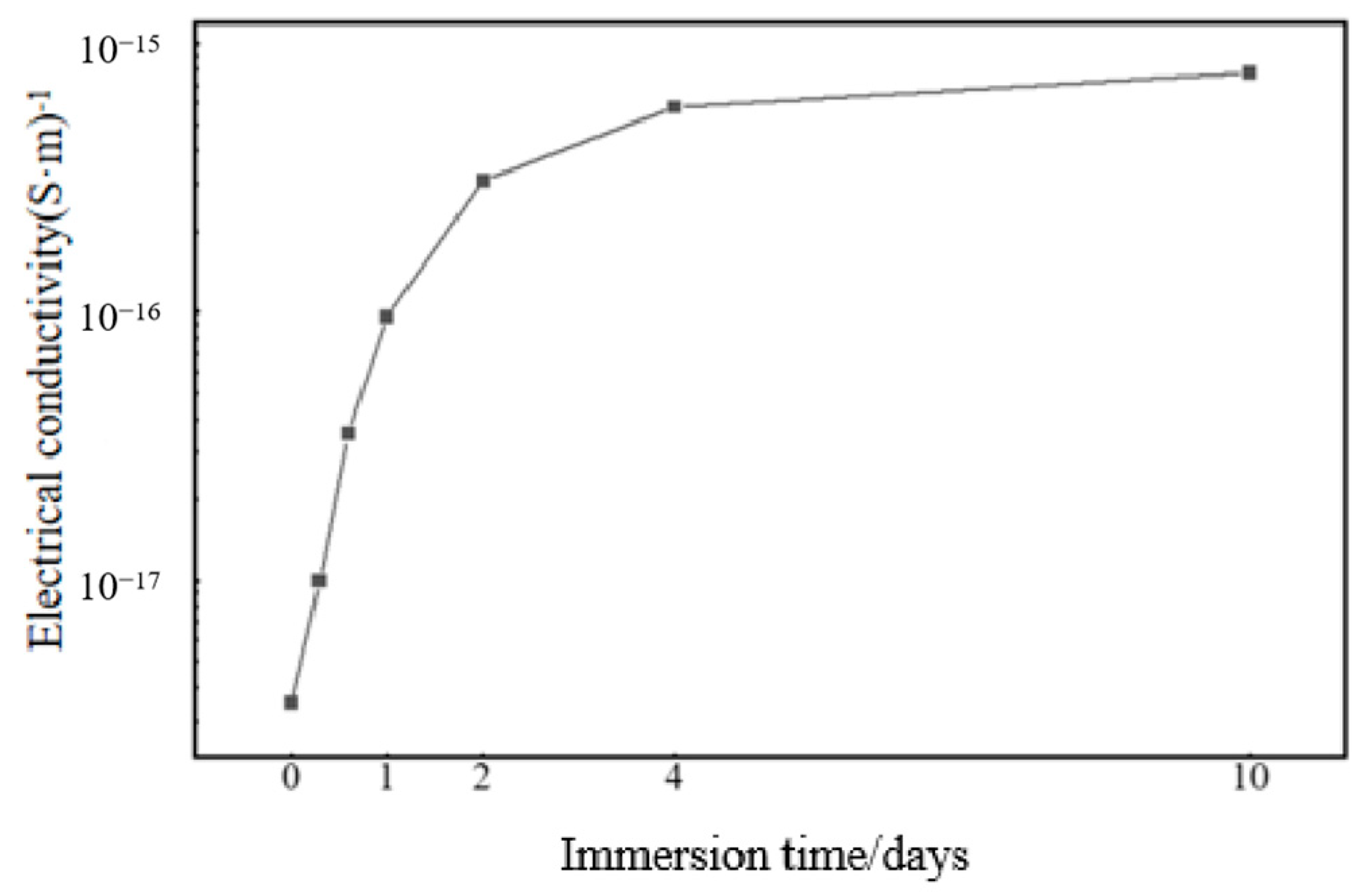

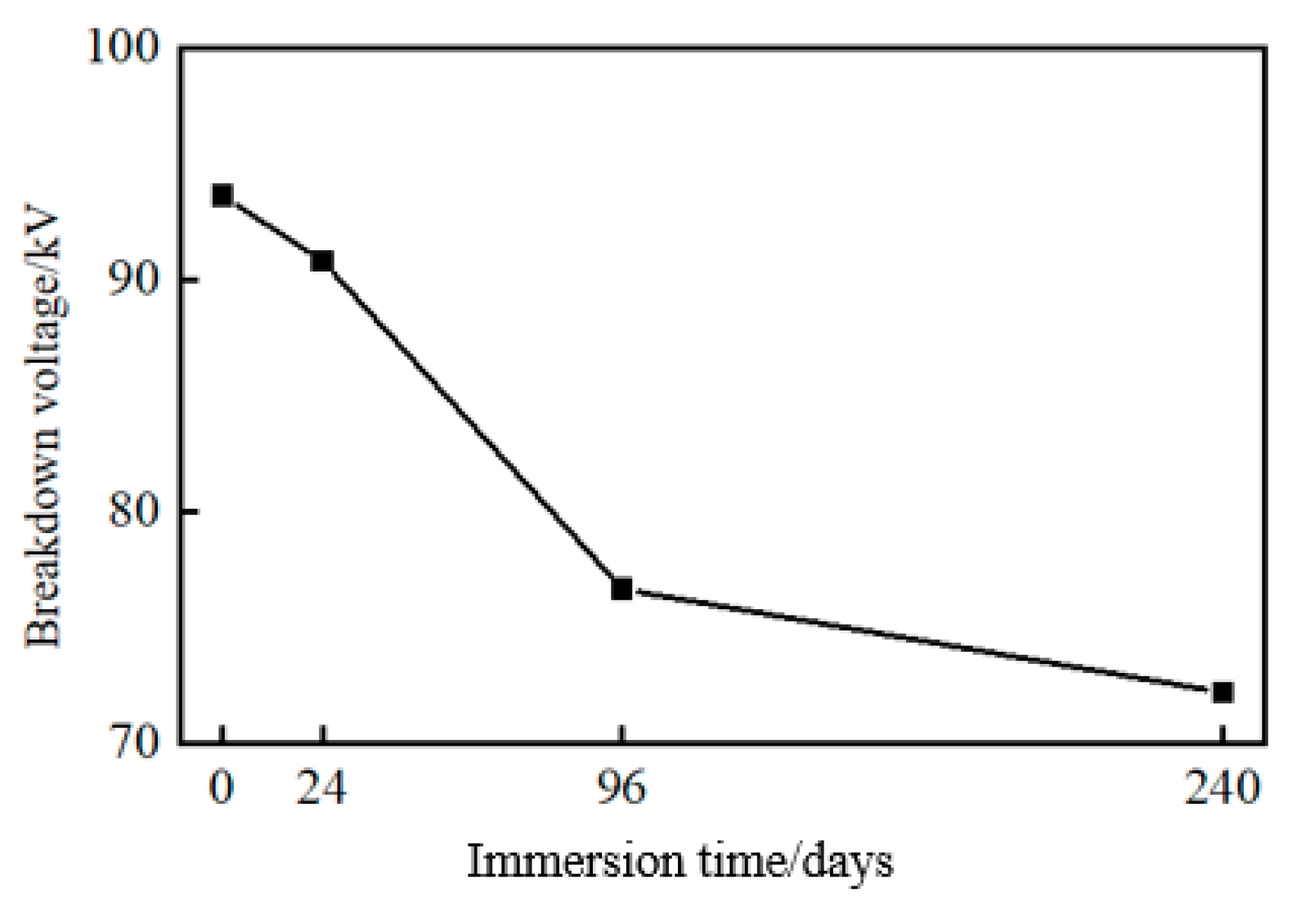

4.3. The Variation Pattern of Breakdown Voltage in Water-Immersed XLPE Samples

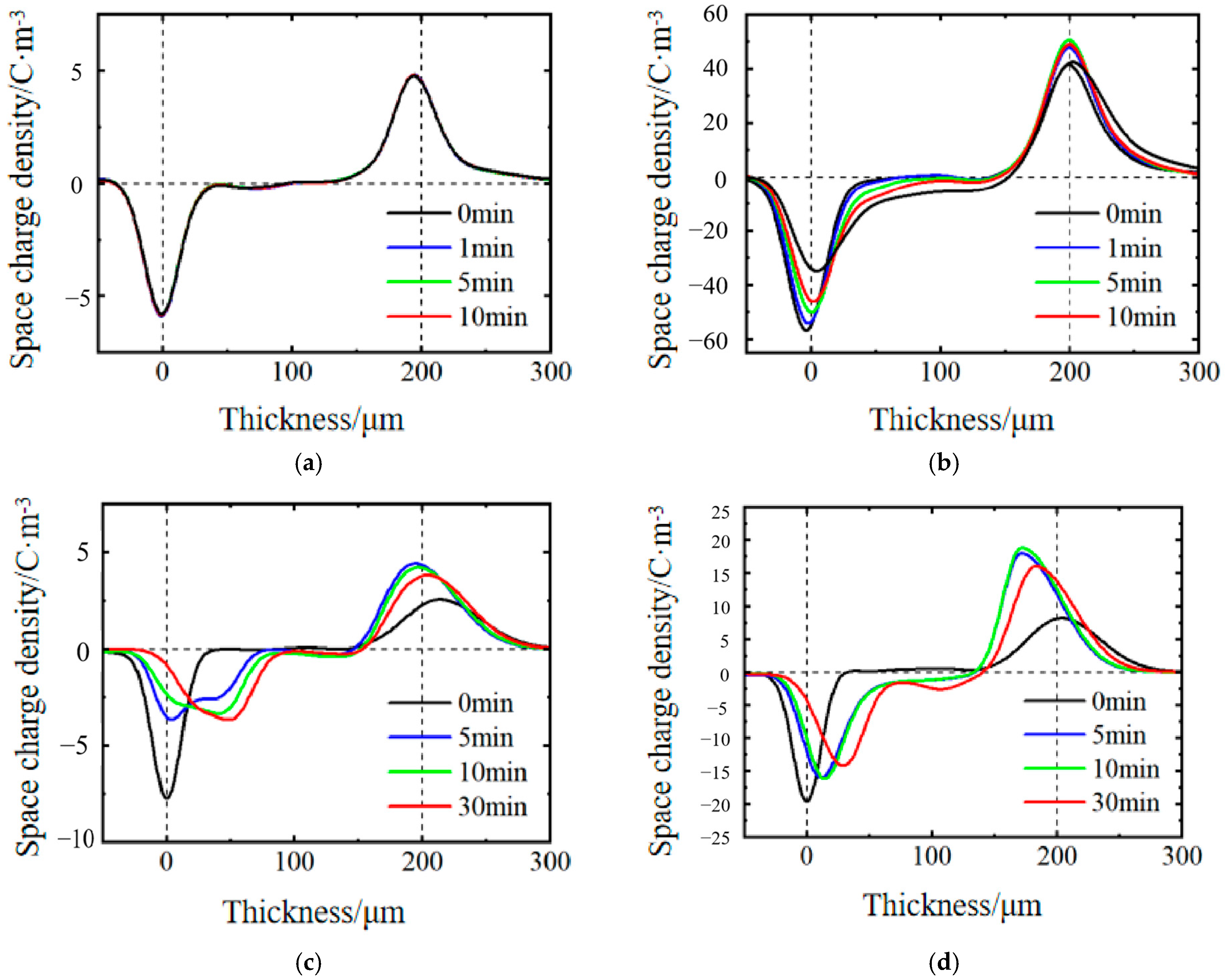

4.4. The Variation Pattern of Space Charge in Water-Immersed XLPE Samples

5. Conclusions

- From the sliced sample experiment, it can be seen that during the initial immersion period (within 24 h), water rapidly penetrates through the surface pores, and conductivity increases by nearly an order of magnitude. After immersion for 96 h, it approaches saturation and the increase in conductivity slows down. The decay rate of polarization/depolarization currents in water-immersed cables significantly decreases with increasing immersion time, approaching saturation after 96 h of immersion.

- DC conductivity of the cable insulation increases markedly with rising moisture content. Both the insulation conductivity and charge mobility exhibit a strong positive correlation with immersion time, serving as key indicators for assessing the degree of water ingress.

- With prolonged immersion, the amount of accumulated space charge within the cable insulation increases, accompanied by heightened electric field distortion and a significant reduction in breakdown voltage. This phenomenon is likely attributable to moisture substantially enhancing charge mobility inside the insulation, thereby accelerating the likelihood of insulation degradation and failure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Zhao, J.; Liu, R.; Chen, Z.; Zhang, Y. Key technologies analysis and prospects of HV/EHV power cables. High Volt. Eng. 2014, 40, 2593–2612. [Google Scholar]

- Raman, V.; Drissi-Habti, M. Numerical simulation analysis as a tool to identify areas of weakness in a turbine wind-blade and solutions for their reinforcement. Comp. Part B Eng. 2016, 103, 23–39. [Google Scholar] [CrossRef]

- Drissi-Habti, R.M. Numerical simulation of a resistant structural bonding in wind-turbine blade through the use of composite cord stitching. Comp. Part B Eng. 2019, 176, 107094. [Google Scholar]

- Drissi-Habti, M.; Raj-Jiyoti, D.; Vijayaraghavan, S.; Fouad, E.-C. Numerical Simulation for Void Coalescence (Water Treeing) in XLPE Insulation of Submarine Composite Power Cables. Energies 2020, 13, 5472. [Google Scholar] [CrossRef]

- Nie, Y.; Zhao, X.; Li, S. Research progress on condition monitoring and insulation diagnosis of XLPE cables. High Volt. Eng. 2020, 46, 1361–1371. [Google Scholar]

- Ye, D. Initiation Characteristics of Electrical Trees and Partial Discharge Analysis of XLPE Cables. Ph.D. Thesis, Chongqing University, Chong Qing, China, 2009. [Google Scholar]

- Heizmarm, T.; Zaengl, W.S. A novel diagnostic method for buriedpolymer-insulated medium-voltage cables. In Proceedings of the 8th International Symposium on High Voltage Engineering (ISH), Yokohama, Japan, 23–27 August 1993. [Google Scholar]

- Kuschel, M.; Kalkner, W. Relevance of the charging period to the dielectricresponse based diagnosis ofPE/XLPE cables. In Proceedings of the 1999 Eleventh International Symposium on High Voltage Engineering, London, UK, 23–27 August 1999; Volume 5, pp. 94–97. [Google Scholar] [CrossRef]

- Oyegoke, B.; Lyall, D.B.J. Condition assessment of XLPE cableinsulation using short-time polarisation and depolarisation current measurements. IET Sci. Meas. Technol. 2008, 2, 25–31. [Google Scholar] [CrossRef]

- Zhou, K.; Chen, Z.; Yin, Y.; Li, T. Research progress on water tree aging and diagnostic techniques of XLPE cables. Insul. Mater. 2019, 52, 7–14. [Google Scholar]

- Zhang, F.; Zhou, K.; Xie, M.; Zhao, S.; Huang, M.; He, M. Study on nonlinear dielectric response of water-treed XLPE cables. Insul. Mater. 2018, 51, 51–56. [Google Scholar]

- Yang, F.; Shen, Y.; Wang, Y.; Zhao, A.; Zhang, X.; Deng, J.; Zhang, G. Determination of thermal aging degree of XLPE cables based on polarization and depolarization current method. High Volt. Eng. 2016, 42, 496–503. [Google Scholar]

- Cai, G.; Liu, X.; Pu, J.; Zhou, K.; Huang, M. Insulation diagnosis of water tree aged cables based on PDC method. Insul. Mater. 2016, 49, 61–64, 71. [Google Scholar]

- Lei, Y.; Jiang, S.; Zhou, K.; Huang, H.; Li, C. Non-destructive detection of cross-linked polyethylene cable insulation based on polarization-depolarization current method. High Volt. Eng. 2015, 41, 2643–2649. [Google Scholar]

- Ye, G. Study on Time-Frequency Domain Dielectric Characteristics of Water Tree Aging in XLPE Cable Insulation. Ph.D. Thesis, Harbin University of Science and Technology, Harbin, China, 2016. [Google Scholar]

- Werelius, P. Development and Application of High Voltage Dielectric Spectroscopy for Diagnosis of Medium Voltage XLPE Cables. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2001. [Google Scholar]

- Ringsberg, J.W.; Li, Z.; McCormick, R.; Fagan, N.; Stewart, G.; Marwood, T. Structural Integrity Analysis of Marine Dynamic Cables: Water Trees and Fatigue. J. Offshore Mech. Arct. Eng. 2025, 147, 1–13. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhou, Y.J. Application of distributed partial discharge online monitoring technology in 500 kV XLPE power cable lines in Shanghai. High Volt. Eng. 2015, 41, 1249–1256. [Google Scholar]

- Rao, X.; Zhou, K.; Li, M.; Xie, M.; Chen, Z.; Liu, L. Parameter identification of extended Debye equivalent circuit based on depolarization current of power cable insulation. High Volt. Eng. 2020, 46, 1037–1043. [Google Scholar]

- Li, K.; Huo, W.; Wang, J.; Zhang, Y.; Zhou, K.; Zhu, L. Diagnosis method for local aging types of cables based on time-varying characteristics of PDC branch parameters. High Volt. Eng. 2025, 51, 1–10. [Google Scholar]

- Wang, W.; Chen, M.; Yin, H.; Li, Y. Comprehensive evaluation for ageing condition of XLPE cable based on radar chart of multidimensional dielectric parameters. Insul. Mater. 2024, 57, 72–79. [Google Scholar]

- Zhou, H.; Jiang, Y.; Kang, H.; Sun, L.; Xia, W.; Zhang, H.; Xiong, J.; Lv, Z. Combined analysis of space charge and current in different ageing stages of XLPE. Insul. Mater. 2025, 58, 87–98. [Google Scholar]

| Immersion Time/Days | 0 | 14 | 30 |

|---|---|---|---|

| Conductive current value/A | 1.45 × 10−13 | 2.74 × 10−11 | 4.76 × 10−11 |

| Immersion Time/Days | 0 | 14 | 30 |

|---|---|---|---|

| DC Conductivity/S·m−1 | 1.86 × 10−17 | 2.04 × 10−16 | 2.70 × 10−15 |

| Immersion Time/Days | 0 | 14 | 30 |

|---|---|---|---|

| Charge mobility/m2·(V·s)−1 | 8.19 × 10−13 | 5.59 × 10−12 | 2.18 × 10−11 |

| Pearson Correlation Coefficient (r) | p-Value | Significance Judgment | |

|---|---|---|---|

| Conductivity | 0.91 | 0.027 | Significant |

| Charge density | 0.94 | 0.11 | not significant |

| Charge mobility | 0.96 | 0.017 | Significant |

| Immersion Time/h | Weight Before Immersion/g | Weight After Immersion/g | Water Absorption/g | Relative Water Absorption |

|---|---|---|---|---|

| 4 | 0.9206 | 0.9207 | 0.0001 | 0.01% |

| 8 | 0.9977 | 0.9983 | 0.0006 | 0.06% |

| 12 | 0.9204 | 0.9214 | 0.001 | 0.11% |

| 24 | 1.0123 | 1.0134 | 0.0011 | 0.11% |

| 48 | 0.8934 | 0.8946 | 0.0012 | 0.13% |

| 96 | 0.942 | 0.9434 | 0.0014 | 0.15% |

| 240 | 1.0648 | 1.0666 | 0.0017 | 0.16% |

| Pearson Correlation Coefficient (r) | p-Value | Significance Judgment | |

|---|---|---|---|

| Conductivity | 0.87 | 0.06 | Significant |

| Breakdown voltage | −0.92 | 0.035 | Significant |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, Y.; Qu, J.; Shang, Y.; Ma, J.; Chen, J.; Xiong, J.; Lv, Z. Polarization and Depolarization Current Characteristics of Cables at Different Water Immersion Stages. Energies 2025, 18, 5094. https://doi.org/10.3390/en18195094

Jiao Y, Qu J, Shang Y, Ma J, Chen J, Xiong J, Lv Z. Polarization and Depolarization Current Characteristics of Cables at Different Water Immersion Stages. Energies. 2025; 18(19):5094. https://doi.org/10.3390/en18195094

Chicago/Turabian StyleJiao, Yuyang, Jingjiang Qu, Yingqiang Shang, Jingyue Ma, Jiren Chen, Jun Xiong, and Zepeng Lv. 2025. "Polarization and Depolarization Current Characteristics of Cables at Different Water Immersion Stages" Energies 18, no. 19: 5094. https://doi.org/10.3390/en18195094

APA StyleJiao, Y., Qu, J., Shang, Y., Ma, J., Chen, J., Xiong, J., & Lv, Z. (2025). Polarization and Depolarization Current Characteristics of Cables at Different Water Immersion Stages. Energies, 18(19), 5094. https://doi.org/10.3390/en18195094