1. Introduction

The demand for high-power-density machines is increasing to meet the needs of transportation electrification and to achieve the 2050 zero carbon goal. Due to the dominance of winding loss, technology demand forecasts predict that increased production will be required across all operating regions, so enabling scalable production is essential [

1]. Winding faults, particularly conductor faults, are a major source of machine failure [

2]. Improving manufacturing quality is necessary for automotive production [

3], as defects impact electrical, thermal, and mechanical performance, leading to increased losses, reduced lifetime, and machine failure [

4,

5].

1.1. Electromagnetic Characteristics

Different types of windings are available, such as stranded, hairpin, and edgewise. Hairpin conductors have high fill factors but suffer from high AC losses, whereas litz wire has good high-frequency performance but is complex to manufacture. These are not explored in depth at the current stage of research [

6]. Edgewise conductors are rectangular bar conductors with large cross-sectional areas (CSA) and aspect ratios.

Stranded conductors typically achieve 0.4–0.5 slot fill due to poor geometric compatibility, while edgewise conductors reach up to 0.7 due to their rectangular CSA [

7,

8,

9,

10]. Edgewise windings also have shorter end windings, leading to lower resistance and, thus, lower DC loss [

9]. At room temperature, stranded coil structures have been shown to have per unit DC resistance 2.3× higher than an edgewise coil equivalent [

11].

On the other side, AC losses, while generally lower in small conductors, also suffer from proximity losses and vary with manufacturing precision. Stranded windings have high variability, in both build method and the resulting coils, while edgewise windings have higher manufacturing precision. However, edgewise windings experience skin effect losses due to high eddy current circulation, which can be reduced by optimising the aspect ratio [

7,

9,

12,

13]. Additionally, higher AC copper losses occur at the slot opening due to the large conductor volume and high leakage flux, this can be overcome with a higher number of conductors per slot and by reducing conductor size [

14].

Due to differing loss characteristics, the AC/DC loss ratio varies considerably between the winding types. Stranded windings have AC/DC loss ratios ranging from 1.8 to 4 at 1.5 kHz operating frequency [

15,

16]. However, manufacturing variation can substantially affect this ratio. In one study, stranded coils showed AC/DC loss ratio from 3.5 to 6.3 at 1 kHz purely from manufacturing variation, leading to the rejection of one-third of the produced coils [

17].

Conversely, edgewise windings, while offering lower DC losses, experience higher AC copper losses, resulting in an AC/DC loss ratio that increases rapidly with frequency [

18]. Small edgewise conductors have been shown to have an AC/DC loss ratio of 4 at 1 kHz, whereas large edgewise conductors can have AC/DC loss ratios of up to 20 at the same frequency [

18].

In general, AC copper losses represent a smaller proportion of total losses in stranded windings compared to edgewise. In one comparative case, AC copper losses accounted for 55.5% of the total losses in a stranded winding, whereas the edgewise equivalent had 76.5% of the total loss attributed to AC losses [

11]. These impacts are summarised in

Table 1.

With stringent design, considering conductor aspect ratio and slot position, the AC/DC loss ratio of edgewise windings can be reduced to be comparable to stranded windings. However, this typically requires large numbers of conductors and complex manufacturing [

19,

20].

1.2. Thermal Characteristics

Edgewise conductors also offer high thermal conductivity due to favourable surface-area-to-volume ratios, high surface contact area, and high effective slot thermal conductivity from high fill factor. These characteristics make them ideal for thermally constrained, or cost-sensitive applications, as they can reduce the cooling requirements.

Flat-wire structures have demonstrated equivalent slot thermal conductivities of 1.4–2.83 W/mK for standard fill factors [

20,

21,

22] and up to 5.41 W/mK in compact, high-fill designs [

21,

23]. In comparison, a typical stranded winding ranges from 0.25–0.96 W/mK [

21,

24,

25], with highly compact designs achieving up to 2.1 W/mK [

21].

This improved thermal conductivity in edgewise windings allows for the use of lower conductor volume with increased thermal conductivity, reduced requirements on insulation thermal limits, or extended lifespans due to lower operating temperatures [

26].

Table 1.

Electromagnetic performance parameters for conductor types.

Table 1.

Electromagnetic performance parameters for conductor types.

| Parameter | Winding Type | Ref. |

|---|

| | Stranded | Edgewise | |

| Fill factor | 0.45–0.55 | 0.7–0.75 | [7,8,27] |

| DC loss | High | Low | [12,28] |

| AC loss | Medium | Medium-High | [29] |

1.3. Mechancial and Manufacturing Characteristics

Mechanically, stranded wires face constraints like limited end winding bend radius and susceptibility to NVH-induced degradation, such as insulation sparking [

30,

31,

32]. Edgewise conductors, are more robust and consistent with lower manufacturing variability, but are sensitive to bending and welding-induced strain, particularly from the high aspect ratio of the conductor [

33,

34,

35]. Mechanical stress in edgewise designs can impact electrical conductivity, insulation, thermal resistance, and overall reliability and mean failure time [

36].

Manufacturing processes have inherent tolerances, with manual methods showing higher variability that increases losses, faults, and labour costs [

37]. Manual stranded winding is often required for complex structures [

7,

30], but causes performance loss due to placement sensitivity, leading to issues like partial discharge and insulation failure. Stranded windings can be made via automated needle, flyer, or linear winding techniques for concentrated coils. For distributed coils, insert methods can be implemented where the coil is wound onto an insertion tool in the slot, which is later removed. This technique is used in vehicles like the BMW i-series and Tesla Model S [

38]. However, there are still challenges such as high wire stress, position variability, long end windings, and limited fill factor [

34,

39].

Edgewise windings allow more predictable, automated manufacturing due to the large CSA [

40]. Further, edgewise windings offer better robustness and scalability but have higher upfront costs and design constraints, such as slot structure and coil dimensions [

35]. Typically, it is necessary to compromise electromagnetic performance to practically manufacture the winding; for example, the slot opening must be wide enough to fit the coil. Edgewise windings have higher initial investment due to tooling but are becoming more common [

41]. These conclusions are summarised in

Table 2.

The paper will provide a comprehensive view of both stranded and edgewise winding types, as well as experimentally validating the performance. The paper structure is as follows:

Section 2 presents the baseline machine performance and simulation analysis;

Section 3 shows the motorette manufacturing and experimental results. Finally,

Section 4 concludes the research. The contribution of the paper is the development of a highly manufacturable edgewise winding structure without significant performance impact.

3. Experimental Validation

This section validates simulation results with experimental testing on motorettes. An overview of the test conditions and motorette design are provided, followed by experimental results for the coil manufacturing process, and thermal performance with DC current. DC current is used to evaluate the cooling performance between different segments and the values of DC losses can be accurately quantified during the tests.

3.1. Motorettes

Motorettes with stranded windings, and edgewise windings in PS and PT stators, are manufactured in six-slot sections, representing ¼ of the machine. The structure ensures realistic tangential heat generation; additionally, using this number of slots allows for incorporation of end winding connections. For simplicity, the stator core is aluminium and iron loss is not considered at this stage [

44]. Motorettes are chosen over a full machine to reduce costs and allow for multiple prototype variants at reduced build time [

45].

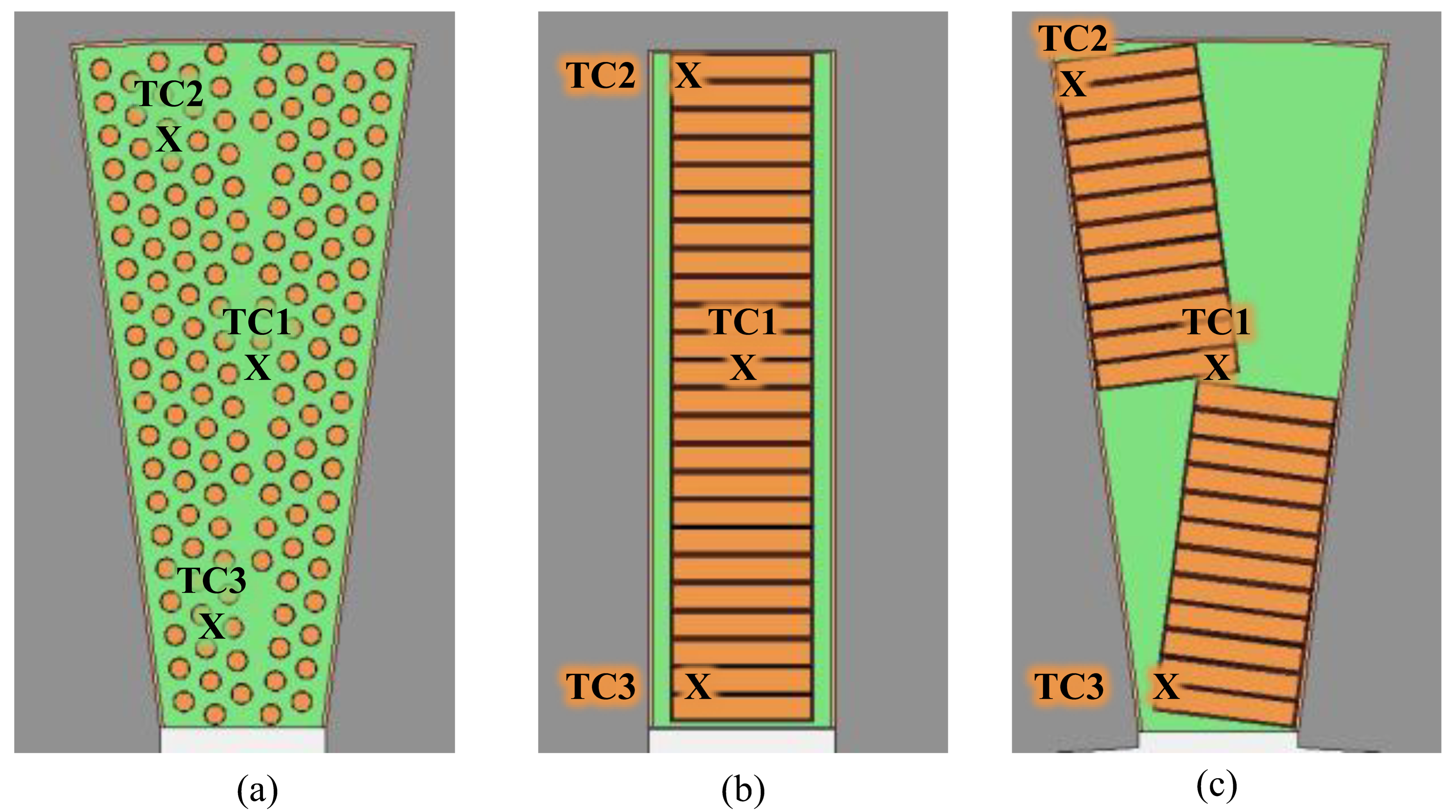

Each motorette is equipped with 15 thermocouples. The critical in-slot thermocouple arrangement is shown in

Figure 5. Thermocouple 1 (TC1) measures the hotspot temperature, while TC2 and TC3 capture temperature distribution within the slot. Thermocouples also monitor the end windings, and the same TC1–3 layout is applied through different slots and axial lengths.

3.2. Manufacturing Process Analysis

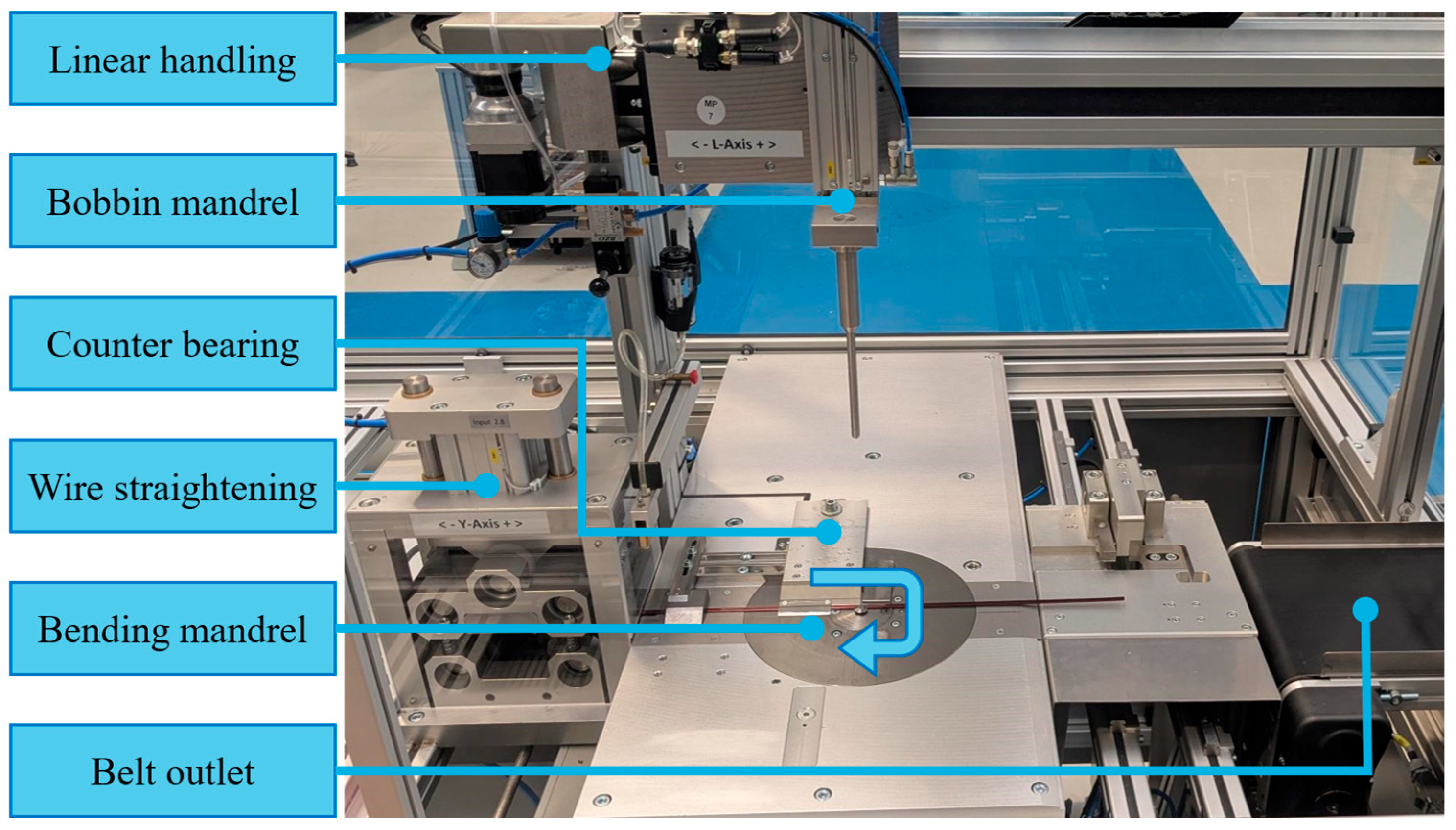

The stranded coils are manually wound for the experimental prototypes. In contrast, the manufacturing of edgewise coils reduces each layer to a series of turn angles and length projections. This process is completed using the LJU Bending Winding System (BWS), which forms part of the DER winding line at the PEMC Research Institute at the University of Nottingham. This system is shown in

Figure 6, depicting the straightened wire being fed onto the central bending mandrel.

During manufacturing, the wire is fed through the counter bearing to the specified length and the turn angle is fabricated by pushing the fed-through wire around the bending mandrel. This process of feeding the wire through and creating the turn angles around the bending mandrel is repeated layer-by-layer until the full coil structure is realised. At this point, the coil is passed to the linear handling by the bobbin mandrel and fed through to the belt outlet where the wire is cut.

Production times for each prototype are measured to assess manufacturing efficiency. Using motorette prototypes that are easy to produce is key as this facilitates the testing and validation of manufacturing processes, assembly, and parameter calibration for simulations. Further, prototyping multiple variants helps reduce material and consumption and labour requirements, improving efficiency in early-stage testing.

For mass production of full-sized machines, some adjustments would be necessary. While the fundamental manufacturing and assembly remains consistent, the stranded winding motorettes would likely be produced using automated or semi-automated techniques such as needle or flyer winding. However, the BWS or similar systems would still be employed for producing edgewise coils for mass manufacturing. Additionally, the coil assembly process would become more complex as the motorettes do not include the full, per-phase end winding layout; instead, these are modified to form continuous windings for DC excitation.

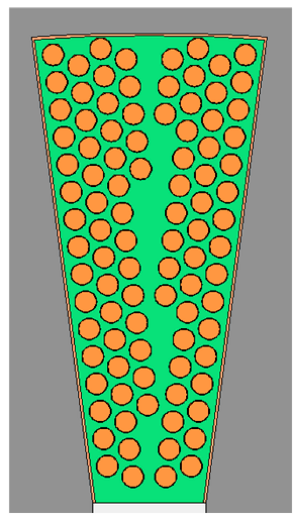

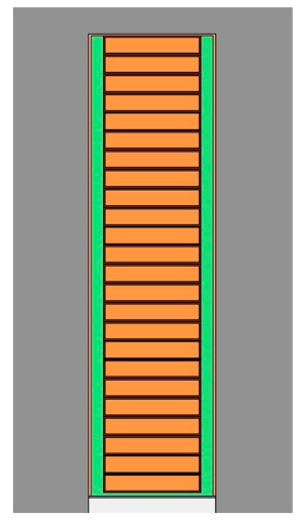

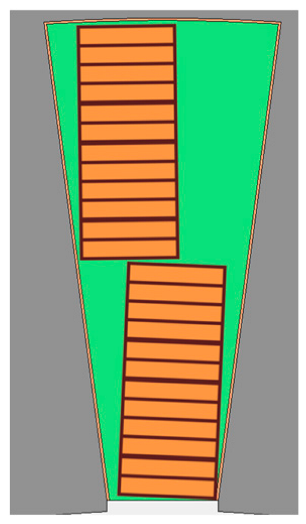

Producing edgewise coils in PS stators is more complex and time-consuming due to variable end turn lengths and angles, resulting in increased tuning for tolerance for material spring-back [

44]. The variation in dimensions is shown in

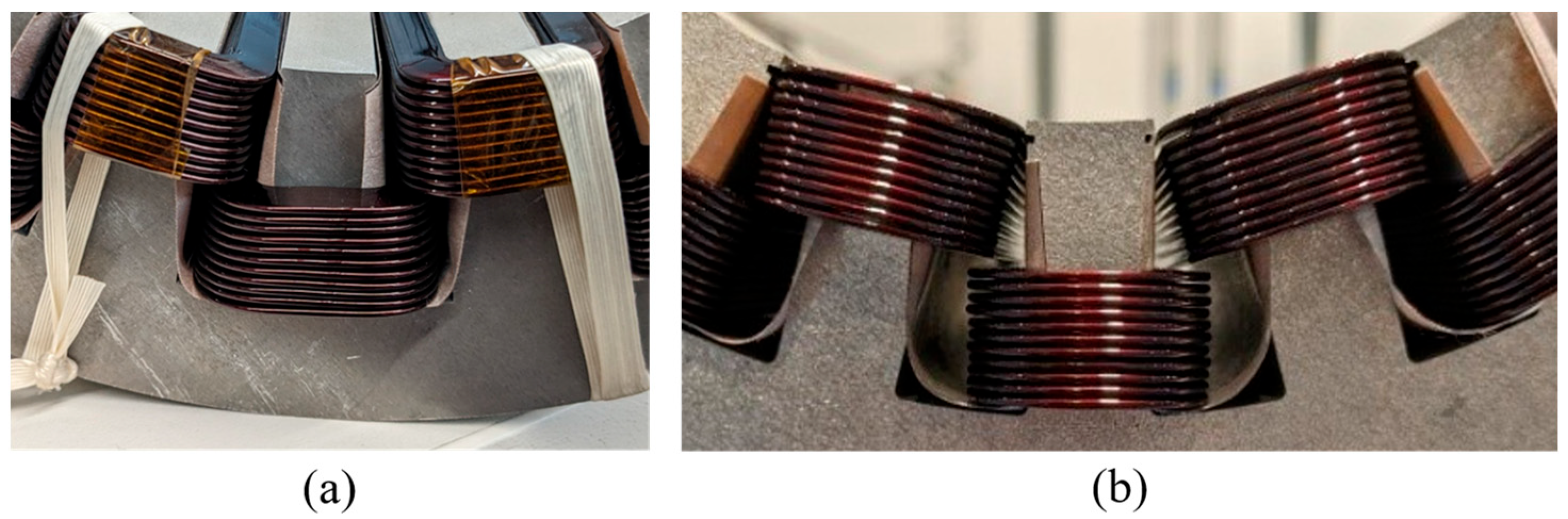

Figure 2. In contrast, PT stators allow uniform turn dimensions, reducing design and manufacturing complexity. The edgewise coil structures are shown in

Figure 7.

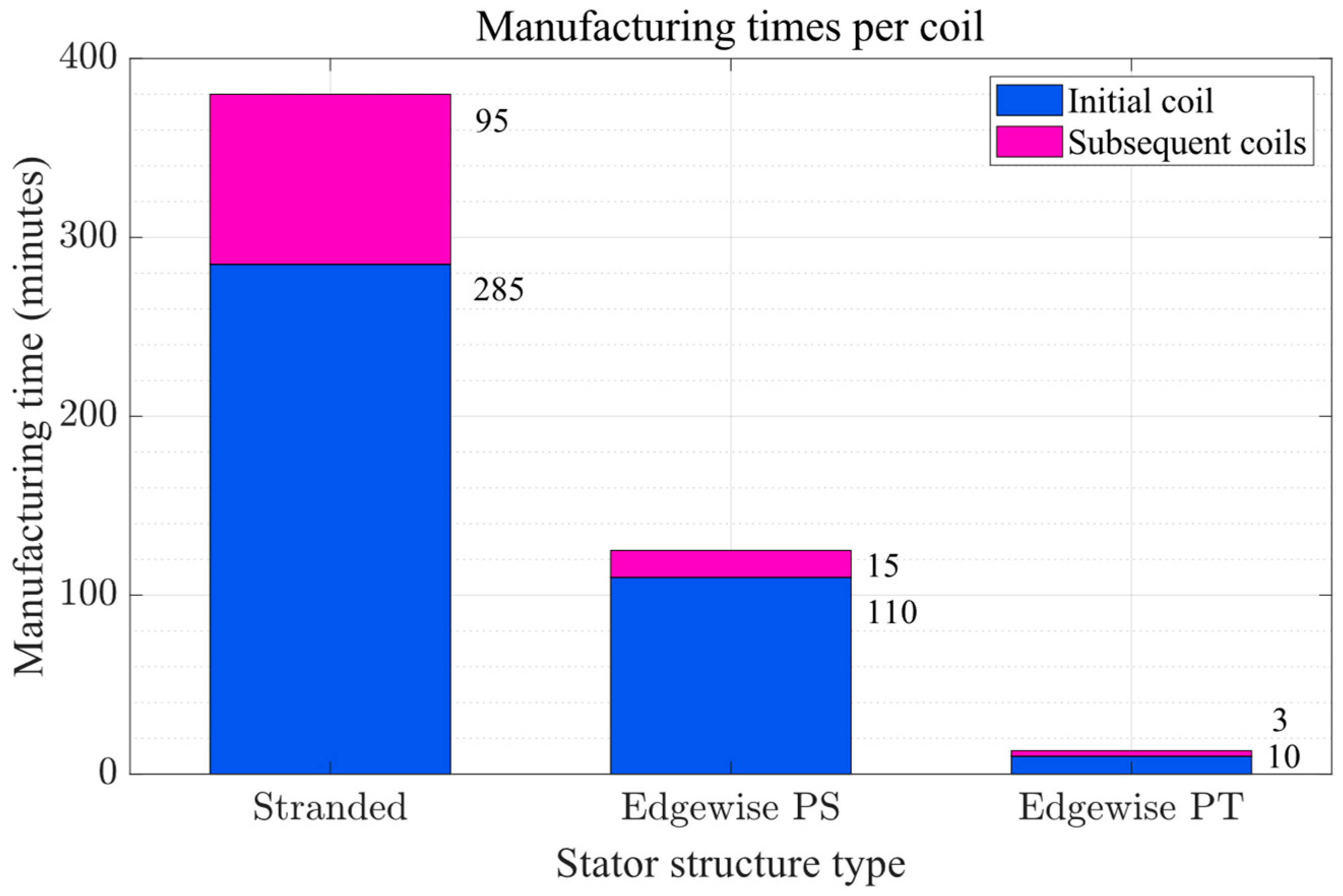

The “Initial coil” time describes the time taken to manufacture the first coil from the theoretical dimensions, and the “Subsequent coils” time reflects the average time taken to produce one additional coil with the same dimensions.

Figure 8 shows that the manually wound stranded coils take substantially longer to manufacture, both for the initial coil and subsequent coils. Compared to edgewise PS, the more time-consuming edgewise structure, the stranded coils have 2.6 times higher initial coil time and 6.3 times higher subsequent coil time. Further, it is shown that the edgewise PT coils require 91% less initial design time and 80% less build time per coil than PS coils, due to fewer variable design points and easier tolerance management. The edgewise PS windings face construction challenges from cumulative tolerance and error, and this is reflected in the fact that the initial and subsequent coil build times for edgewise PS are higher than the stranded coils, which are manually wound. The continued gap between PT and PS per coil duplicate illustrates the challenges in accounting for cumulative error. It is shown that for situations where minimising manufacturing time and expense is a priority, the use of edgewise coils in the PT stator can substantially reduce the overall coil manufacturing time.

3.3. Thermal Analysis

The DC resistance and the variation between the coils in the sample set is assessed, and the measurements are given in

Table 7. The original calculation overestimates the resistance by around 2% for the edgewise coils compared to a 24% underestimation for the stranded coil. The stranded coils calculation is an underestimation as they are required to give substantial clearance for end winding bending and the bend radii used in practice are not accurately known. Further, the overlap between conductors results in substantial variations in end winding length for stranded layouts. For the edgewise coils, the calculation method accounts analytically for the end winding bend radii that occur during manufacturing. In this case, the allowance for bend radius is slightly higher than the measured result, resulting in a smaller resistance. The measured data shows that edgewise PT coils have lower DC resistance, which is expected due to lower path length. There is variation between different sets of coils, for example, 0.6% is shown for PT coils and 6.5% for PS coils, reflecting PT coils having better manufacturing consistency and alignment with simulation.

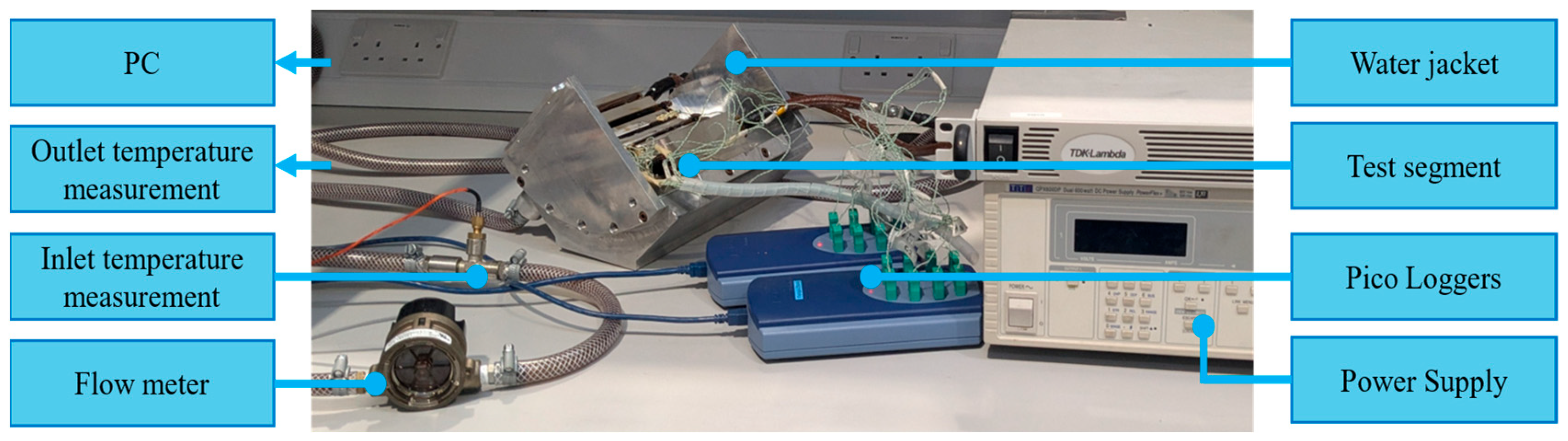

This section evaluates the thermal performance of windings with DC currents, focusing on temperature rise and distribution. The tests use a housing water jacket with controlled coolant flow and monitored temperature. DC current is supplied until reaching thermal equilibrium, which is defined as less than 1 °C temperature change over 10 min. The process is repeated at increasing currents until insulation limits are reached. Results are used to calibrate simulations and support conclusions. The test rig is shown in

Figure 9.

Table 8 presents the temperatures measured at thermocouple nodes under maximum steady-state current loading, representing the thermal limit without exceeding 180 °C. If the temperature exceeds this limit, the rig is shut down to prevent damage. Consequently, the current is increased in set intervals, and the highest interval where the system could reach thermal steady state without exceeding 180 °C is used for comparison.

For the stranded segment, the difference between the maximum and minimum temperatures (temperature variation) within the slot is 74.4 °C at a current loading of 3685 Amp-turns, representing a 42% temperature difference. This is the largest thermal variation among the tested segments. This is partly due to the lower copper-to-insulation ratio in the round wire, as insulation has much lower thermal conductivity, reducing the overall heat transfer. Additionally, the fill factor is lower, and manufacturing variability leads to uneven conductor placement and greater temperature variation [

46]. The stranded segment also shows lower temperatures in the active region at its thermal limit due to lower axial thermal conductivity compared to edgewise. As a result, different axial positions reach the insulation thermal limit at varying rates, restricting the maximum current loading factor to 3685 Amp-turns for a 180 °C thermal limit.

For the same thermal limit, 4896 Amp-turns can be applied to edgewise windings. The edgewise PS structure showed a maximum slot temperature variation of 30.7 °C at 4896 Amp-turns, equivalent to an 18.2% difference in temperature across the slot distribution, meaning that the maximum and minimum temperatures are closer to the average temperature. The reduction in variation compared to the stranded winding is due to a higher copper-to-insulation ratio, which enhances radial and tangential thermal conductivity. Edgewise PS also shows higher temperatures at the centre of the winding, reflecting improved axial thermal conductivity.

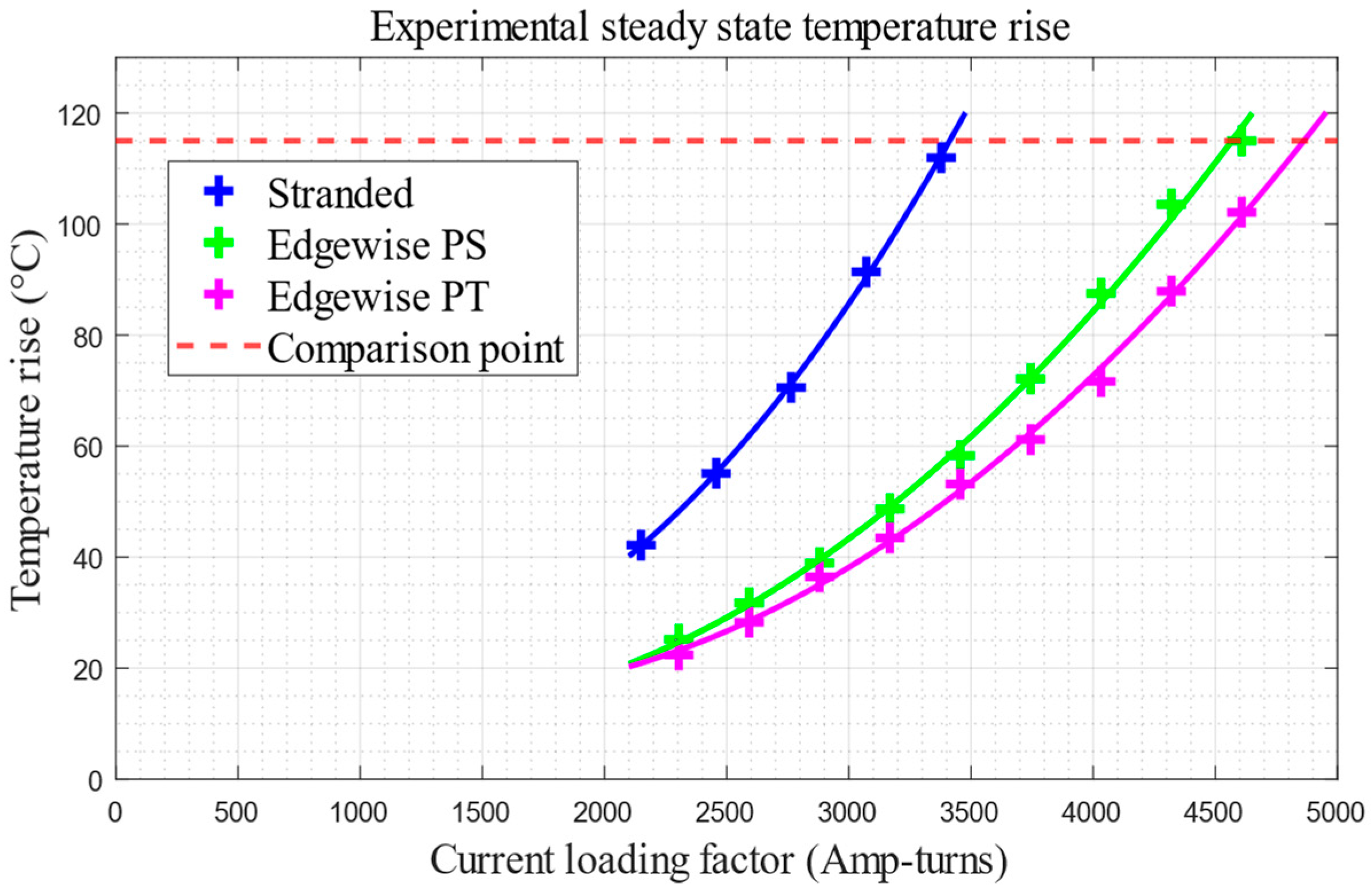

The edgewise PT structure has maximum slot temperature variation of 35.4 °C at 4896 Amp-turns, which is a 20.8% temperature shift in the slot. Although it has the same copper-to-insulation ratio as the PS structure, geometric factors like reduced contact area and more resin restrict thermal conductivity and cause greater temperature differences within the slot. The steady-state temperature rise per current loading factor operating point is shown in

Figure 10.

Overall, the edgewise segments achieve higher current loading factor than the stranded segment. Although the stranded winding has a higher number of turns per phase, the small CSA limits the current capacity due to the temperature rise. The stranded winding reaches a maximum current loading of 3685 Amp-turns, with a temperature rise of 110 °C. In comparison, edgewise windings at similar current loadings have 35 °C and 39 °C temperature increases for PS and PT, respectively. For equal temperature rise of 115 °C, the stranded winding reaches a current loading factor of 3413 Amp-turns, compared to 4570 Amp-turns for edgewise PS and 4861 Amp-turns for edgewise PT, representing an increase in current loading factor of 1157 Amp-turns and 1448 Amp-turns, respectively, compared to the stranded control motorette, corresponding to an increase of 25.3% and 42.4%. At the same current loading factor of 4608 Amp-turns for the edgewise windings with PS and PT structures, the edgewise PT windings show a 13.8 °C lower operating temperature than the PS winding, equal to a current of 51 A in the edgewise structures.

3.4. Comparison

From a manufacturing perspective, the edgewise winding structures are quicker to manufacture, with low variation in performance compared to stranded windings, which are manually wound. This leads to an increase in manufacturing efficiency and costs, with a per-coil manufacturing time reduction of 84% moving from stranded to the edgewise PS structure. Further, by considering the stator slot–tooth geometry, the manufacturing complexity of the edgewise structures can be further reduced by 80% by implementing PT stator structures to simplify the geometry of edgewise coils. This further reduces manufacturing time and complexity, resulting in reduced costs, as well as increased precision in the manufactured coils.

From an electromagnetic perspective, this increase in precision results in more predictable DC resistance characteristics, with 6.5% variation in DC resistance for edgewise PS and 0.6% variation for edgewise PT. This leads to increased confidence in DC loss performance and more predictable electromagnetic performance for edgewise PT.

The experimental validation of losses and thermal performance is used to determine key performance parameters at the thermal limit. The equivalent slot thermal conductivity for each structure is determined through calibrating an equivalent LPTN. Simulations are completed with the updated thermal conductivity and resistance parameters. These results are summarised in

Table 9.

For the current experimental set up, in which the in-slot gaps are filled with resin and the cooling is provided by a housing water jacket, the equivalent thermal conductivity of each winding structure is evaluated. The stranded winding has a moderate improvement compared to the simulation, at 0.63 W/mK. In comparison, the edgewise structures demonstrate significantly higher values than the stranded winding due to increased copper volume and a higher copper-to-insulation ratio. However, the edgewise PT structure shows a reduction in equivalent thermal conductivity relative to edgewise PS, which is due to the larger volume of resin required to fill the in-slot gaps, reducing the overall thermal conductivity.

As the edgewise windings have higher equivalent thermal conductivity, the maximum current loading achievable while remaining under the thermal limit is higher than the stranded windings. As with the pre-experimental simulations, the stranded structure achieves slightly higher current density despite having slightly lower current due to the change in turn CSA. This impacts the loss density in the slot, as is also seen with the change in current. There is a relatively small change from stranded to edgewise PS, this is due to higher slot volume for the stranded layout, which reduces the in-slot loss density, so despite the lower thermal conductivity, the dissipation area is higher, resulting in higher achievable current density. This change is further highlighted by the large increase in potential current for the edgewise PT layout. Despite the thermal conductivity being slightly lower than edgewise PS, the slot area is larger and, consequently, the maximum allowable current increases considerably, a 30% increase from the stranded winding. Consequently, the achievable torque is higher for the edgewise PT winding, 27.8% higher than stranded and 24% higher than edgewise PS.

Therefore, it is concluded that the implementation of edgewise PT winding structures can increase the manufacturability beyond that of a conventional stranded winding but also improve manufacturability compared to edgewise PS structures. Further, this edgewise PT structure allows for increased current loading while maintaining the same thermal limit, leading to higher torque production in a full machine equivalent.

4. Conclusions

High-performance electrical machines are at the core of the transportation electrification sectors to achieve the 2050 zero carbon target. Windings are key components of electrical machines, including stranded, hairpin, and edgewise windings, but are rarely reported on in terms of all the multidomain aspects. This paper has assessed edgewise windings with both PS and PT structures, from electromagnetic, thermal, and manufacturing perspectives, in comparison to stranded windings. It has been shown that with similar current loading factors, the decrease in DC losses is 53% for the edgewise windings compared to the stranded ones. For a comparable temperature rise of around 110 °C, the increase in current for the edgewise windings compared to the stranded windings results in a 50% increase in torque production when applied to the full machine. With motorettes manufactured and experimentally tested, it is shown that edgewise PS windings reduce manufacturing time per coil by 85% compared to stranded windings, and edgewise PT structures can reduce the per coil manufacturing time by a further 80%, with improved manufacturing consistency and repeatability compared to both stranded windings and edgewise PS windings. Further, the average operating temperature at the highest load operating point is 13.8 °C lower for an edgewise parallel tooth than the parallel slot equivalent, however, it has 1.9 °C higher hot spot temperatures. Calibrated simulation results show that by operating at the thermal limit condition, edgewise parallel tooth windings can achieve a torque increase of 27.8% compared to stranded windings and 24% compared to the edgewise parallel slot. Overall, this leads to a recommendation for the usage of edgewise PT coil structures for manufacturability and thermal performance.

To further improve the thermal performance, the unused slot space in the PT design offers potential for improved cooling and higher current loading, which will be explored in future work.