Modification of Short-Channel Structures Towards Heat Transfer Intensification: CFD Modeling

Abstract

1. Introduction

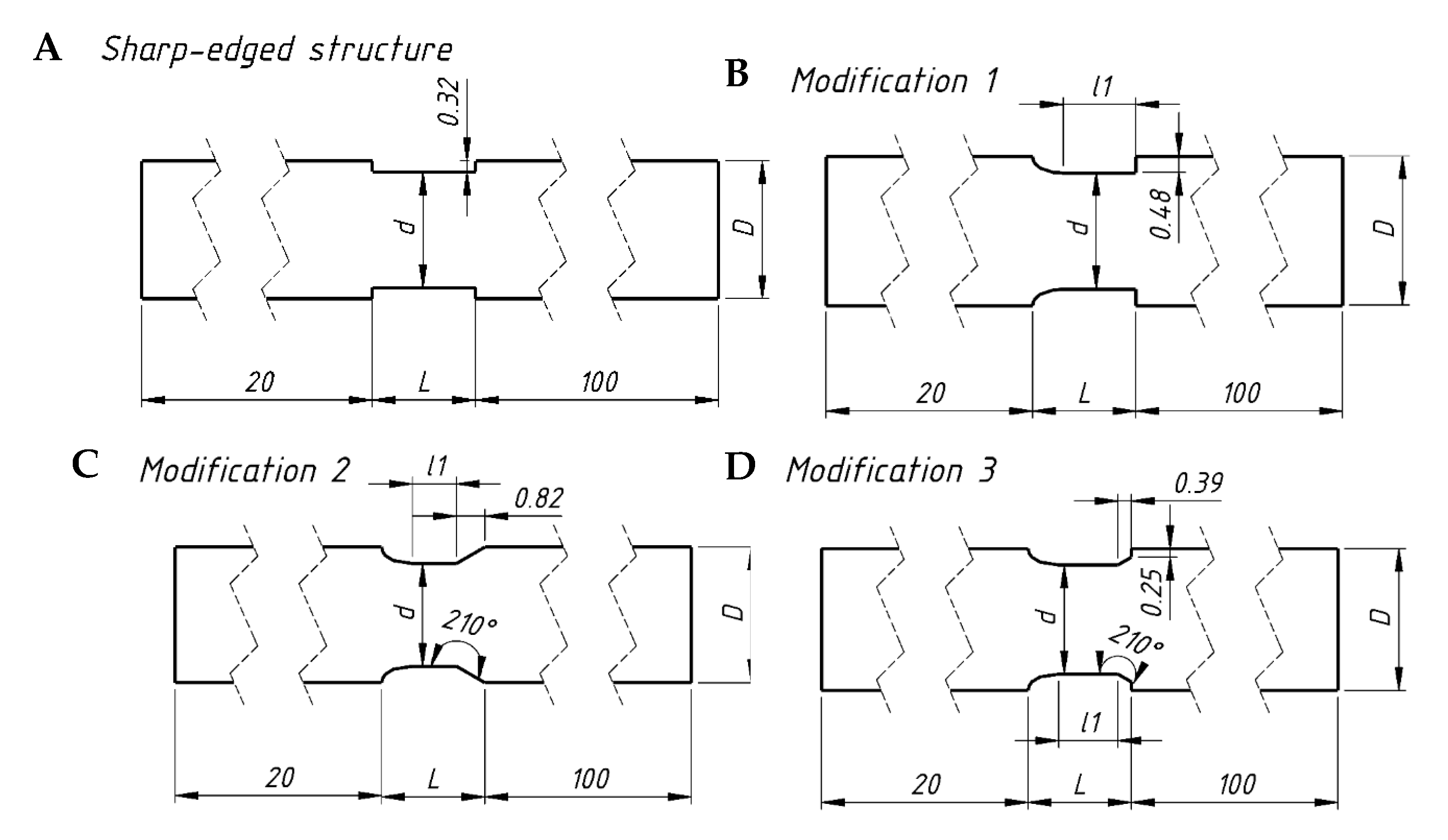

2. Modifications of the Structure Geometries

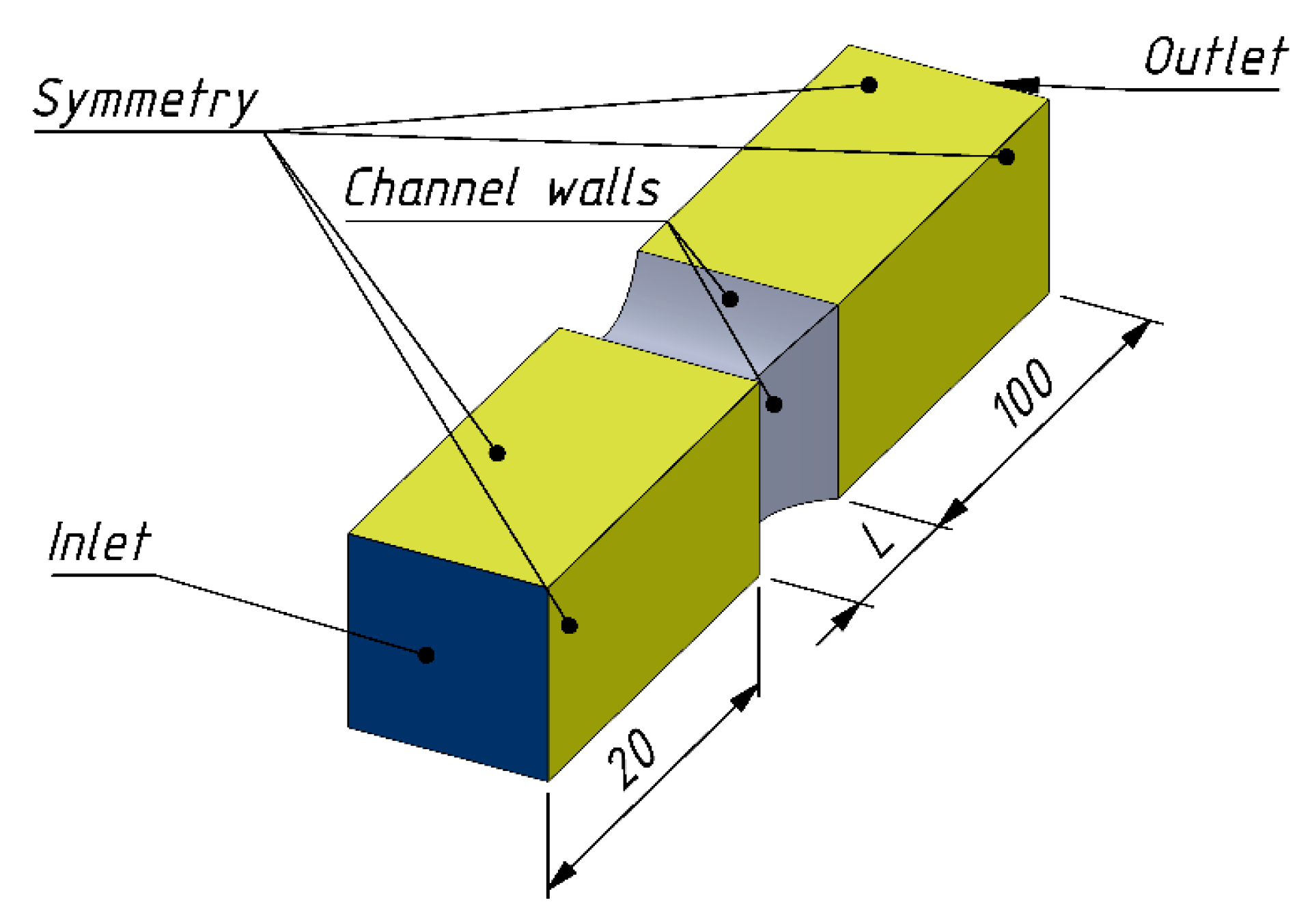

- The dimension of all the square structures (side of the square) is D = 4 mm (the distance of the channel wall axes);

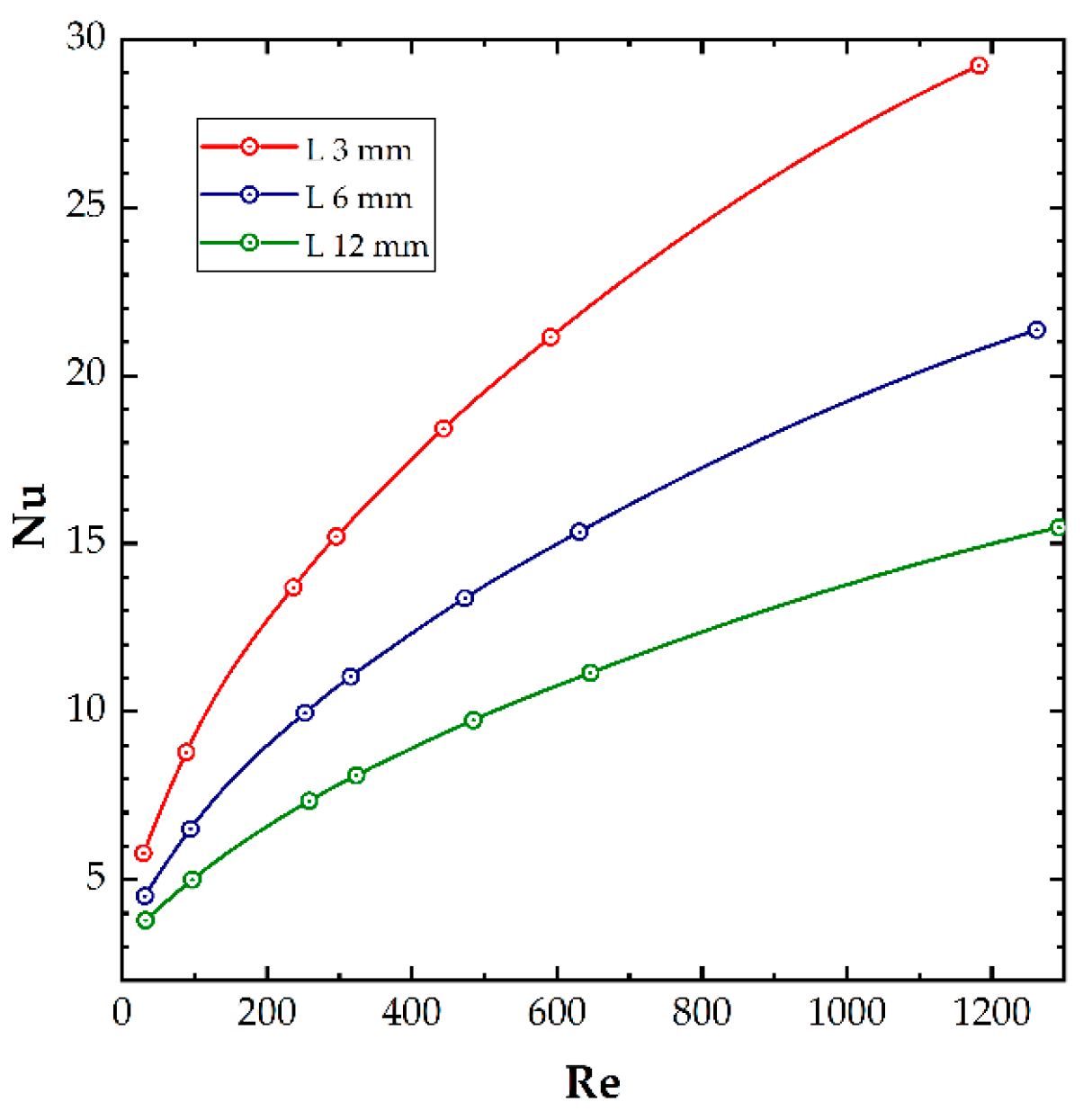

- The lengths of the structures are L = 3, 6 and 12 mm;

- All the structures, for a given channel length, have similar specific surface area.

3. Experiments

4. CFD Modeling

- –

- At inlet velocity = constant;

- –

- At inlet temperature = constant;

- –

- At channel walls, heat flux = constant;

- –

- At symmetry walls, shear stress = 0;

- –

- At outlet “pressure outlet”, static pressure = 0.

Validation of Numerical Model

5. Results and Discussion

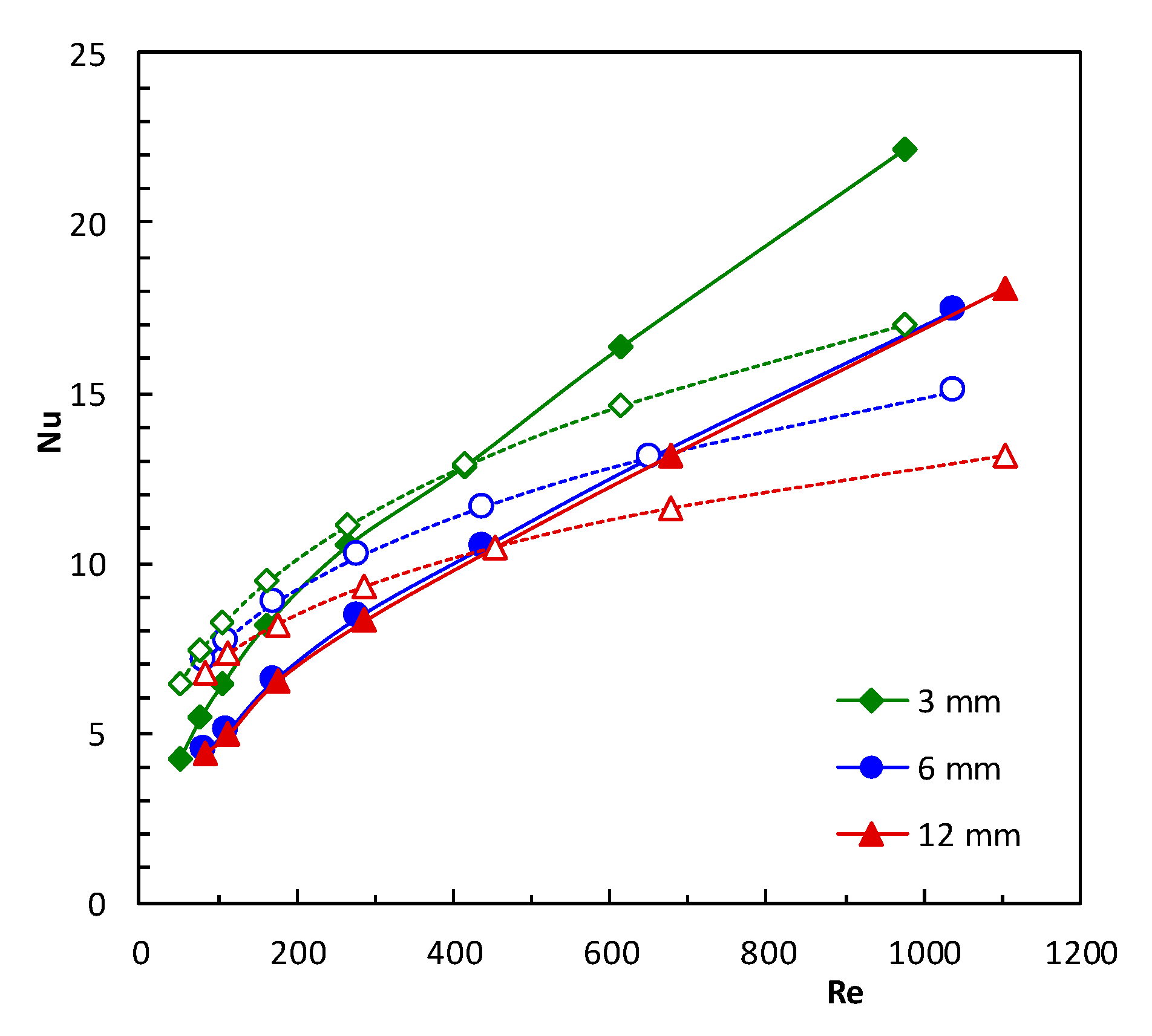

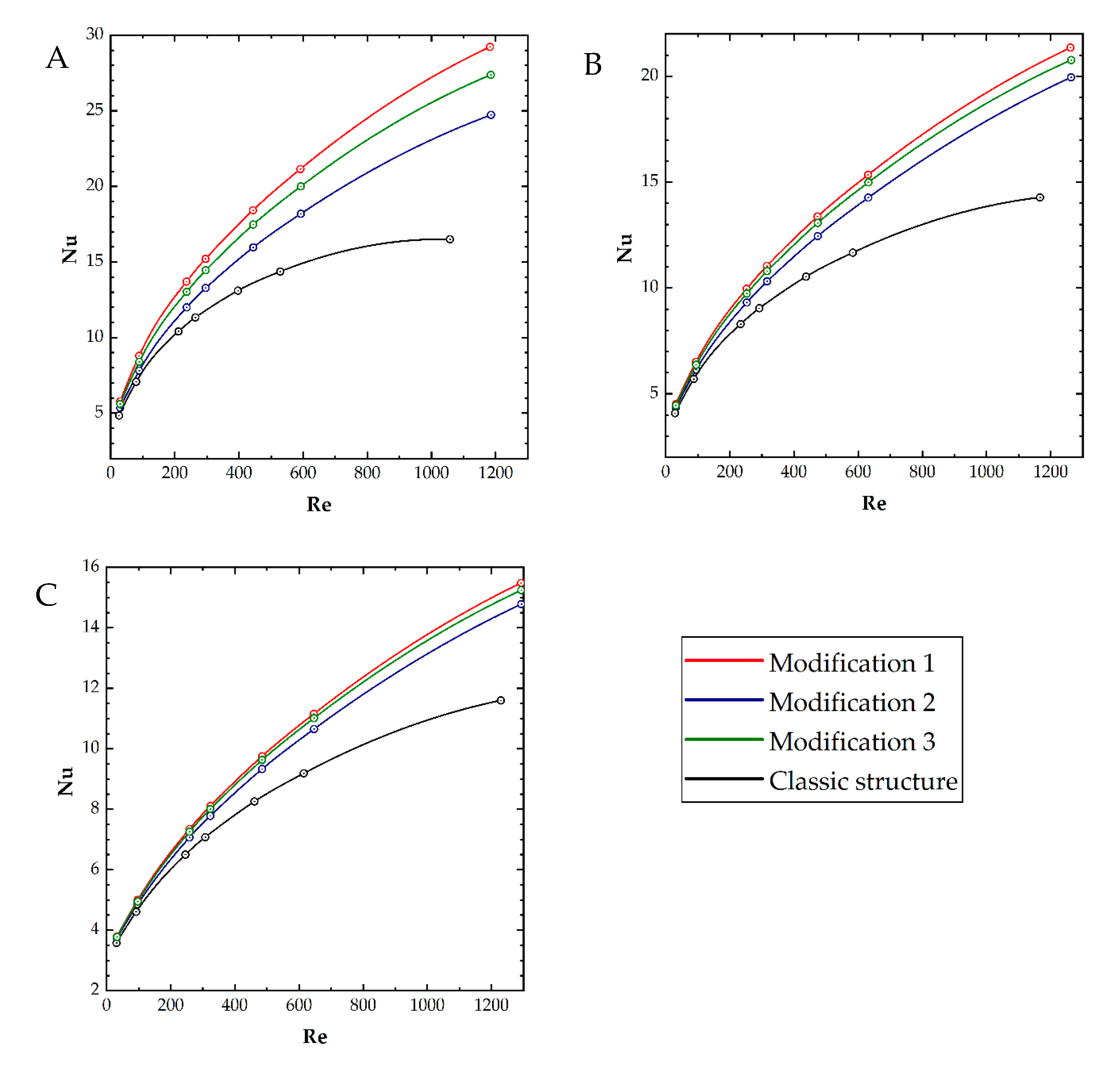

5.1. Heat Transfer

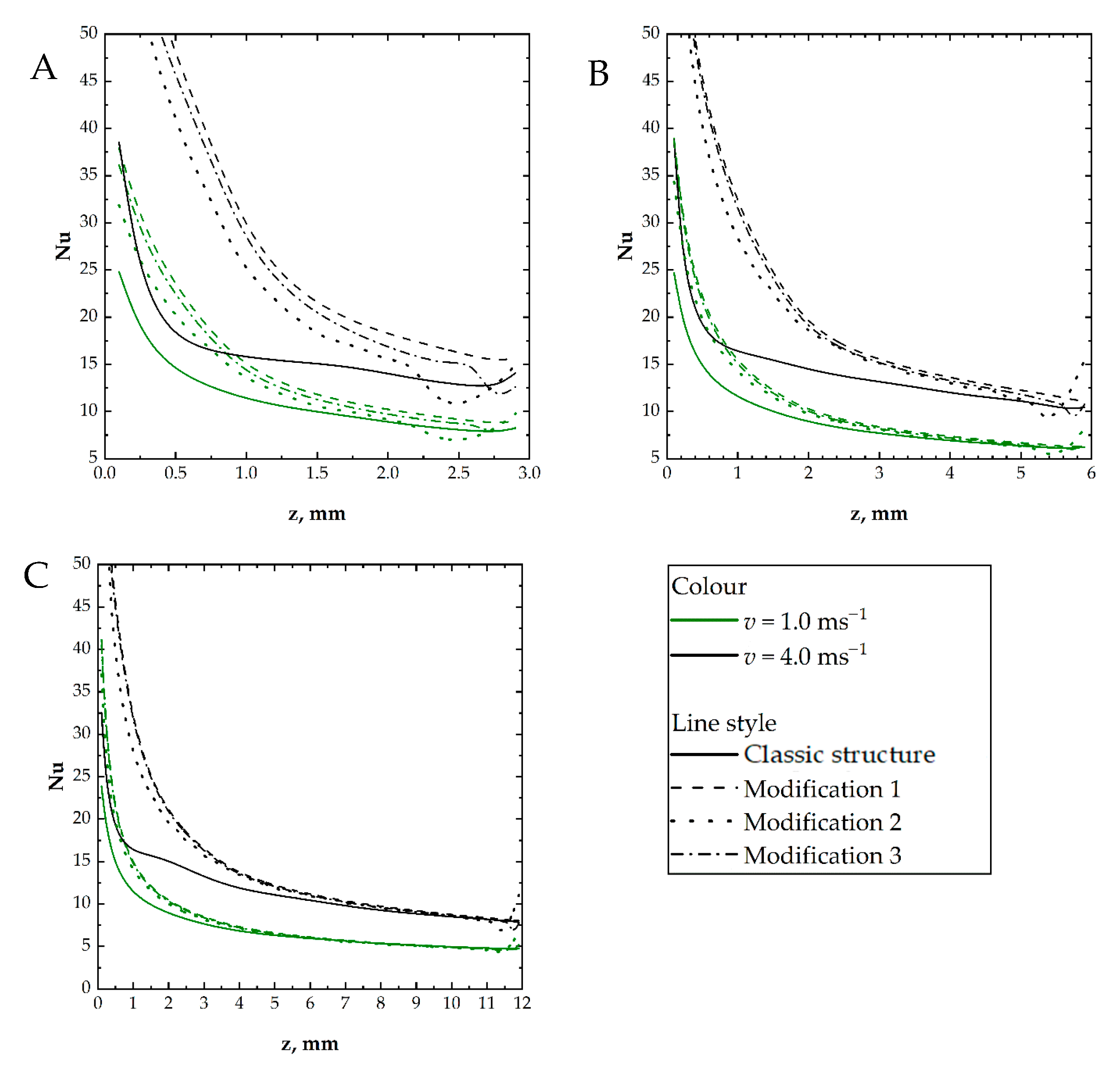

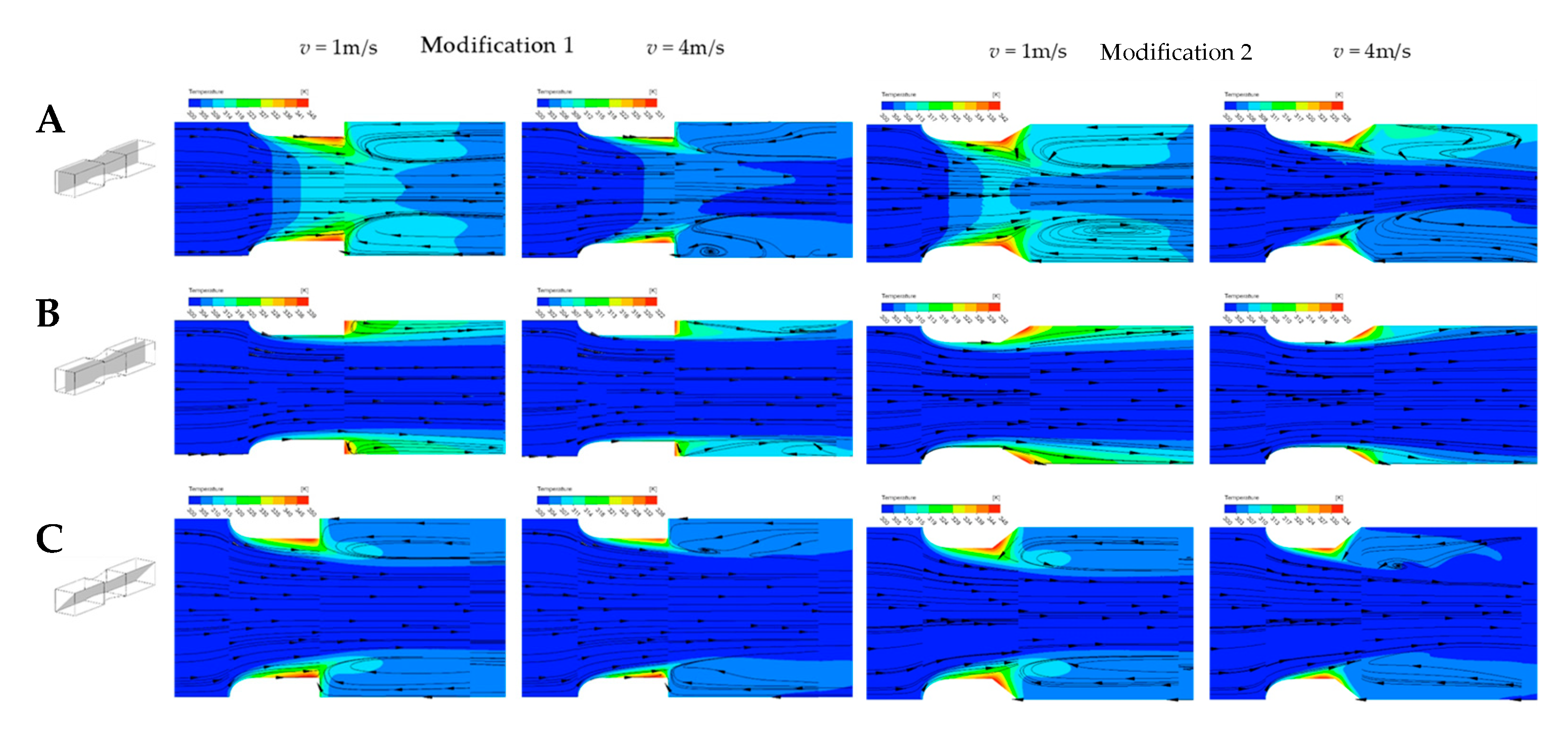

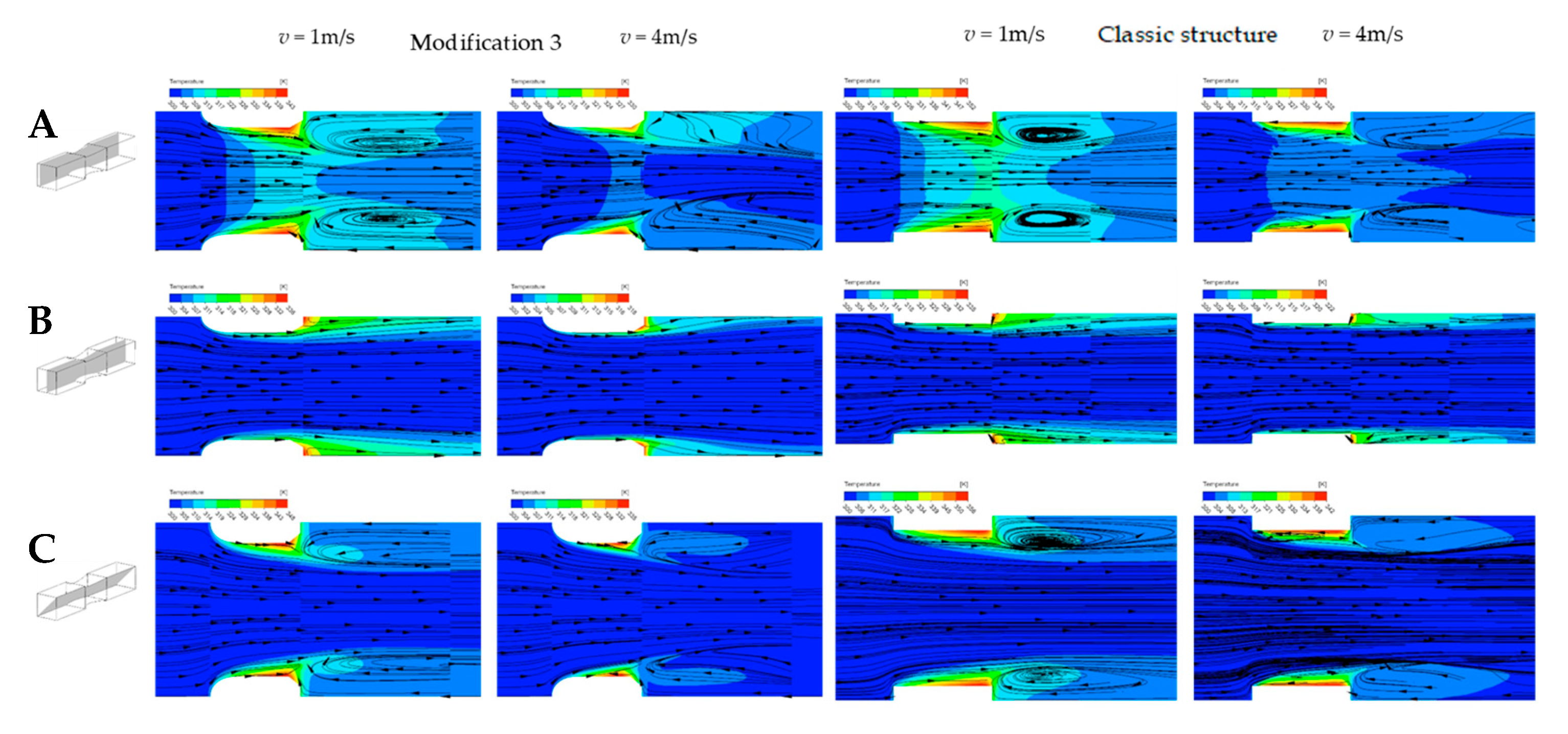

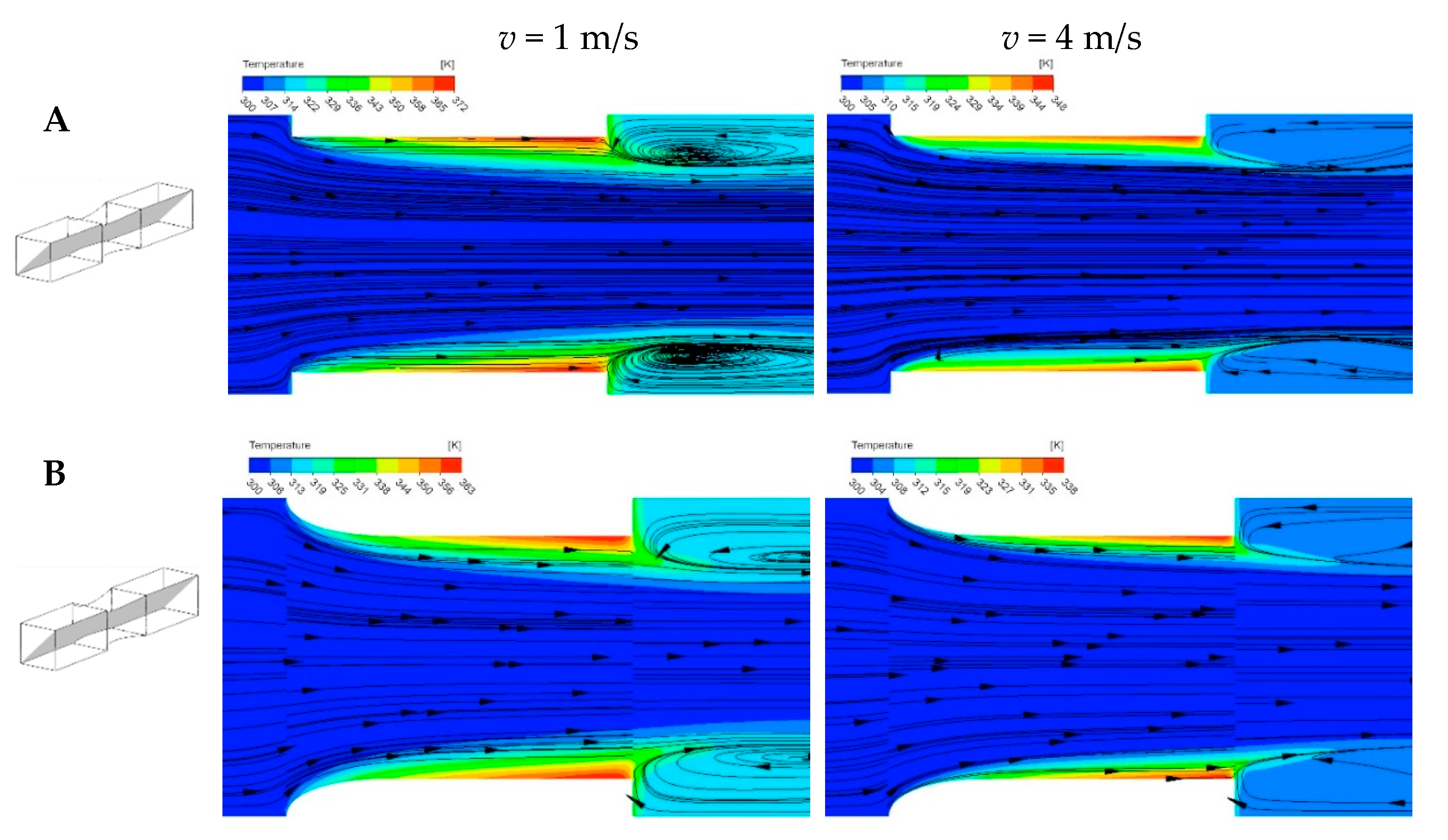

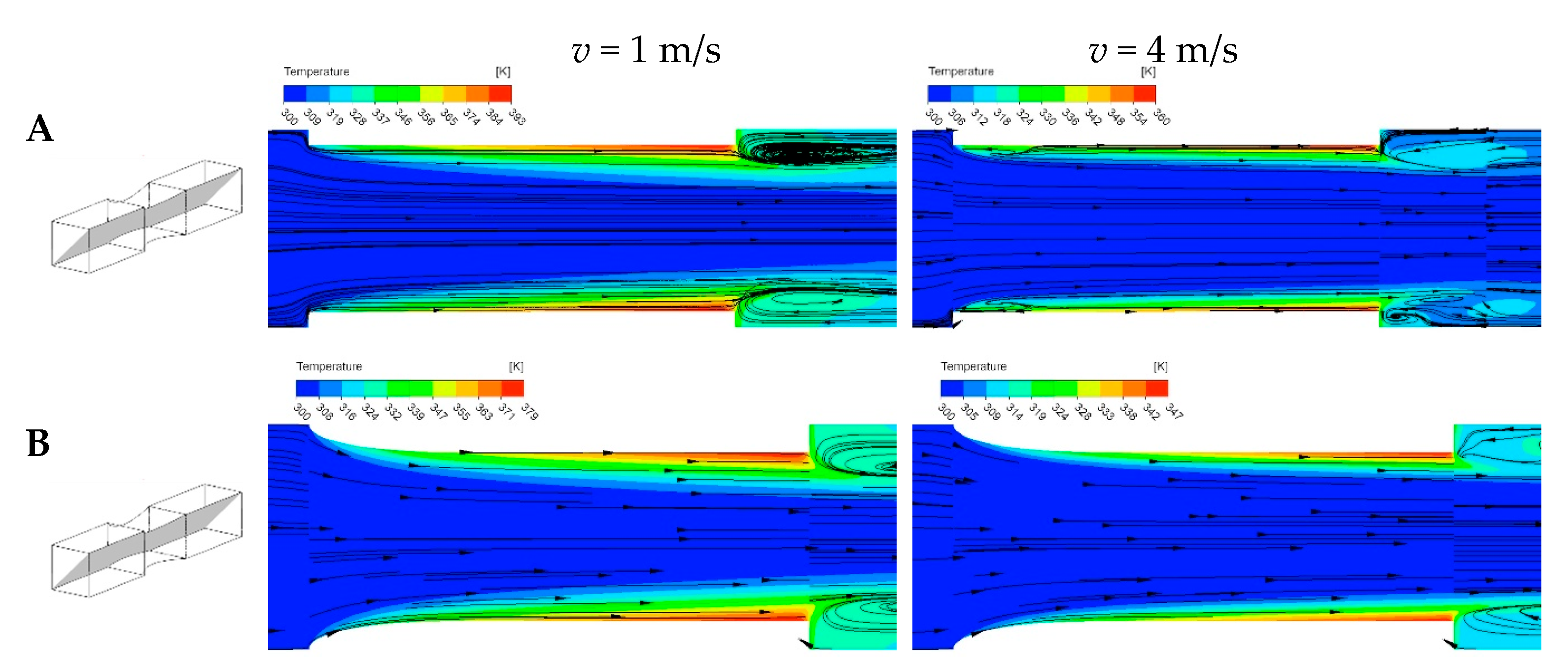

5.2. Flow and Transfer Phenomena

6. Conclusions

- The Nusselt numbers for modifications 1–3 are higher than for the classic short-channel structure. The results for the modified structures are close to each other; the most intensive heat transport is shown by modification 1, then 3, and finally 2.

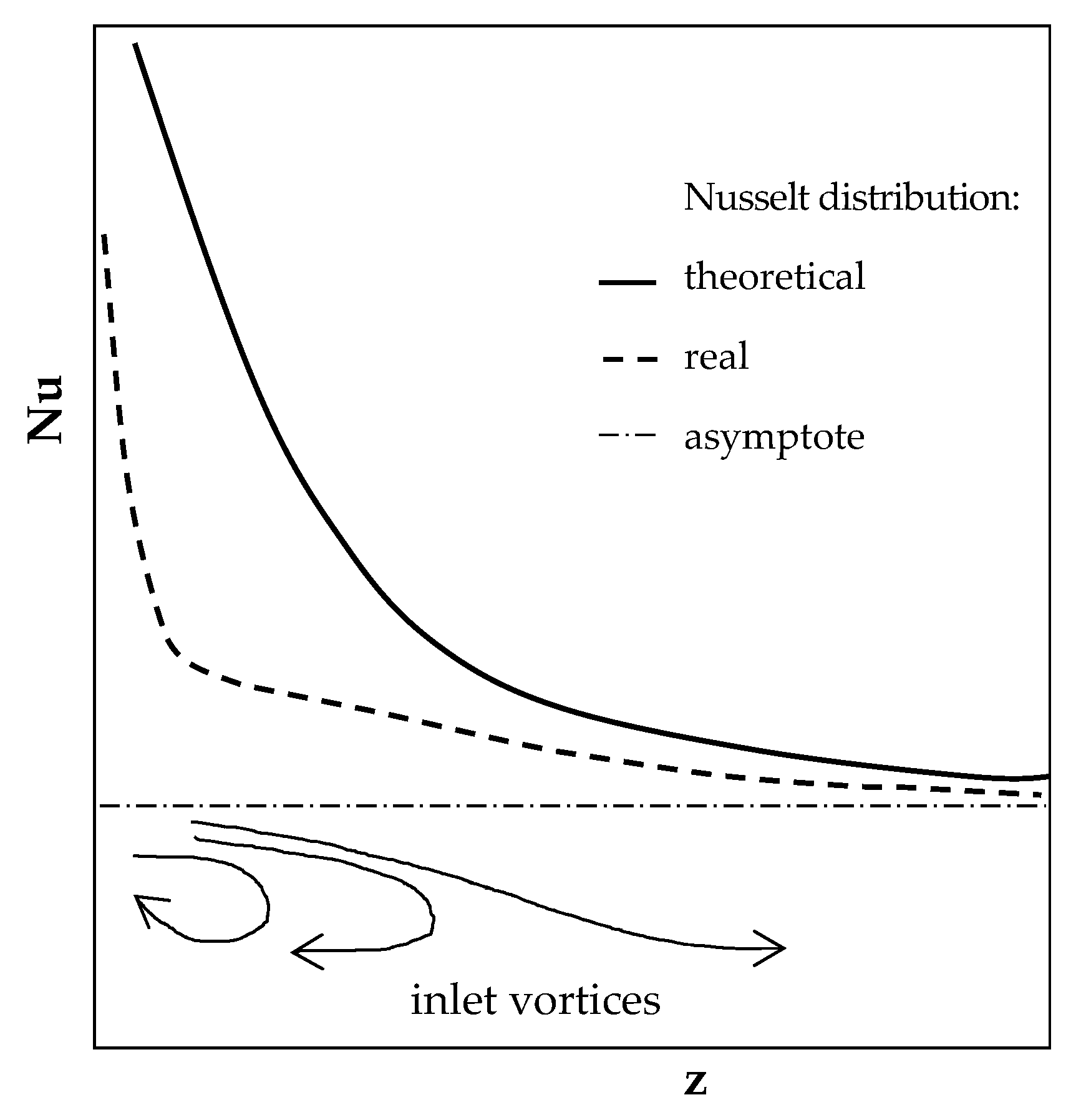

- Heat transfer is particularly intensive for the modified structures in the inlet part of the channel when compared to the classic structure. This is a result of the lack, for the modified structures, of inlet vortices that weaken heat transport in the inlet region, theoretically, transport phenomena should be the most intensive. The lack of inlet vortices is visible on the temperature and streamline maps. On the contrary, the inlet vortices are visible for the classic structure, especially for the velocity of 4 m/s. These vortices isolate the channel wall near the inlet from the main fluid flow, thus weakening the heat transfer intensity.

- Intensive outlet vortices appear in all structures, modified and classic. In the rear of the channel, the temperature gradient decreases. The outlet vortices intensify heat transfer on the back surface of the structures, where the gradient is slightly larger.

- The heat transfer intensity decreases significantly down the channel for all the structures studied.

- Modification 1 provides the smoothness streamlines, which may explain the observed highest Nu value compared to the other considered modifications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moulijn, J.A.; Kapteijn, F. Monolithic reactors in catalysis: Excellent control. Curr. Opin. Chem. Eng. 2013, 2, 346–353. [Google Scholar] [CrossRef]

- Cybulski, A.; Moulijn, J.A. Monoliths in heterogeneous catalysis. Catal. Rev. 1994, 36, 179–270. [Google Scholar] [CrossRef]

- Boger, T.; Heibel, A.K.; Sorensen, C.M. Monolithic catalysts for the chemical industry. Ind. Eng. Chem. Res. 2004, 43, 4602–4611. [Google Scholar] [CrossRef]

- Williams, J.L. Monolith structures, materials, properties and uses. Catal. Today 2001, 69, 3–9. [Google Scholar] [CrossRef]

- Shah, R.K.; London, A.L. Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical Data; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Kołodziej, A.; Łojewska, J. Short-channel structured reactor for catalytic combustion: Design and evaluation. Chem. Eng. Process. 2007, 46, 637–648. [Google Scholar] [CrossRef]

- Bennett, C.J.; Kolaczkowski, S.T.; Thomas, W.J. Determination of heterogeneous reaction kinetics and reaction rates under mass transfer controlled conditions for a monolith reactor. Process Saf. Environ. Protect. 1991, 69, 209–220. [Google Scholar]

- Hayes, R.E.; Kolaczkowski, S.T. Mass and heat transfer effects in catalytic monolith reactors. Chem. Eng. Sci. 1994, 49, 3587–3599. [Google Scholar] [CrossRef]

- Heibel, A.K.; Heiszwolf, J.J.; Kapteijn, F.; Moulijn, J.A. Influence of channel geometry on hydrodynamics and mass transfer in the monolith film flow reactor. Catal. Today 2001, 69, 153–163. [Google Scholar] [CrossRef]

- Chatre, L.; Socci, J.; Adams, S.J.; Denissenko, P.; Cherkasov, N. Design of 3D-printed structures for improved mass transfer and pressure drop in packed-bed reactors. Chem. Eng. J. 2021, 420, 129762. [Google Scholar] [CrossRef]

- Sindera, K.; Korpyś, M.; Iwaniszyn, M.; Gancarczyk, A.; Suwak, M.; Kołodziej, A. New streamlined catalytic carriers of enhanced transport properties: Experiments vs CFD. Chem. Eng. J. 2022, 450, 138297. [Google Scholar] [CrossRef]

- Korpys, M.; Iwaniszyn, M.; Sindera, K.; Suwak, M.; Gancarczyk, A.; Kolodziej, A. Flow phenomena in laminar flow through streamlined and sharp-edged short monolithic structures. Sci. Rep. 2023, 13, 15742. [Google Scholar] [CrossRef]

- Iwaniszyn, M.; Jodłowski, P.J.; Sindera, K.; Gancarczyk, A.; Korpyś, M.; Jędrzejczyk, R.J.; Kołodziej, A. Entrance effects on forced convective heat transfer in laminar flow through short hexagonal channels: Experimental and CFD study. Chem. Eng. J. 2021, 405, 126635. [Google Scholar] [CrossRef]

- Zakharov, V.P.; Zolotarskii, I.A.; Kuzmin, V.A. CFD simulation of “gauze pad–honeycomb” catalytic system. Chem. Eng. J. 2003, 91, 249–255. [Google Scholar] [CrossRef]

- Kołodziej, A.; Łojewska, J.; Ochońska, J.; Łojewski, T. Short-channel structured reactor: Experiments versus previous theoretical design. Chem. Eng. Process. 2011, 50, 869–876. [Google Scholar] [CrossRef]

- Wang, L.; Tran, T.P.; Vo, D.V.; Sakurai, M.; Kameyama, H. Design of novel Pt-structured catalyst on anodic aluminum support for voc’s catalytic combustion. Appl. Catal. A 2008, 350, 150–156. [Google Scholar] [CrossRef]

- Kolb, G.; Hessel, V. Micro-structured reactors for gas phase reactions. Chem. Eng. J. 2004, 98, 1–38. [Google Scholar] [CrossRef]

- Jiang, S.Y.; Yang, Z.R.; Zhang, J.; Duan, X.Z.; Qian, G.; Zhou, X.G. Development of a mini-channel heat exchanger reactor with arborescent structures for fast exothermic reactions. Ind. Eng. Chem. Res. 2022, 61, 14121–14131. [Google Scholar] [CrossRef]

- Schlichting, H. Boundary Layer Theory; McGraw-Hill: New York, NY, USA, 1979. [Google Scholar]

- Deepakkumar, R.; Jayavel, S. Air side performance of finned-tube heat exchanger with combination of circular and elliptical tubes. Appl. Therm. Eng. 2017, 119, 360–372. [Google Scholar] [CrossRef]

- Arani, A.A.A.; Uosofvand, H. Double-pass shell-and-tube heat exchanger performance enhancement with new combined baffle and elliptical tube bundle arrangement. Int. J. Therm. Sci. 2021, 167, 106999. [Google Scholar] [CrossRef]

- Veerraju, C.; Gopal, M.R. Heat and mass transfer studies on elliptical metal hydride tubes and tube banks. Int. J. Hydrogen Energy 2009, 34, 4340–4350. [Google Scholar] [CrossRef]

- Moser, F.; Kessler, A. Increased capacity thanks to improved geometry. Sulzer Tech. Rev. 1999, 3, 24. [Google Scholar]

- Čmelíková, T.; Valenz, L.; Lyko Vachková, E.; Rejl, F.J. Basic separation efficiency and hydraulic data of MellapakPlus 452.Y structured packing under distillation conditions. Chem. Eng. Res. Des. 2021, 172, 175–185. [Google Scholar] [CrossRef]

- Ferroni, C.; Bracconi, M.; Ambrosetti, M.; Groppi, G.; Maestri, M.; Tronconi, E. Periodic open cellular structures with streamlined elliptical struts for the intensification of mass transfer-limited catalytic reactors. Acs Eng. Au 2025, 5, 168–182. [Google Scholar] [CrossRef]

- Ferziger, J.H.; Perić, M. Computational Methods for Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Patankar, S. Numerical Heat Transfer and Fluid Flow, 1st ed.; CRC Press: Boca Raton, FL, USA, 1980. [Google Scholar]

| Type | L, m | Sv, m2/m3 | ε | dh, m | D, m | d, m | l1, m |

|---|---|---|---|---|---|---|---|

| Modif. 1 | 0.003 | 926 | 0.63 | 0.0027 | 0.004 | 0.00338 | 0.00211 |

| Modif. 2 | 924 | 0.65 | 0.0028 | 0.004 | 0.00299 | 0.00128 | |

| Modif. 3 | 924 | 0.62 | 0.0027 | 0.004 | 0.00317 | 0.00172 | |

| Classic | 1036 | 0.71 | 0.0027 | 0.004 | 0.00337 | 0.003 | |

| Classic exp. | 1021 | 0.70 | 0.0027 | ||||

| Modif. 1 | 0.006 | 868 | 0.60 | 0.0028 | 0.004 | 0.00306 | 0.00422 |

| Modif. 2 | 867 | 0.61 | 0.0028 | 0.004 | 0.00285 | 0.00339 | |

| Modif. 3 | 867 | 0.60 | 0.0028 | 0.004 | 0.00295 | 0.00383 | |

| Classic | 939 | 0.71 | 0.0030 | 0.004 | 0.00337 | 0.006 | |

| Classic exp. | 930 | 0.71 | 0.0031 | ||||

| Modif. 1 | 0.012 | 847 | 0.59 | 0.0028 | 0.004 | 0.00286 | 0.00843 |

| Modif. 2 | 847 | 0.59 | 0.0028 | 0.004 | 0.00275 | 0.00761 | |

| Modif. 3 | 847 | 0.58 | 0.0027 | 0.004 | 0.00280 | 0.00804 | |

| Classic | 891 | 0.71 | 0.0032 | 0.004 | 0.00337 | 0.012 | |

| Classic exp. | 873 | 0.70 | 0.0032 |

| Type | Velocity at Inlet, m s−1 | Reynolds Number | Temperature at Inlet, K | Heat Flux, W m−2 K−1 |

|---|---|---|---|---|

| Modif. 1 | 0.1 | 30 | 300 | 1500 |

| 0.3 | 89 | 300 | 1500 | |

| 0.8 | 237 | 300 | 1500 | |

| 1.0 | 296 | 300 | 1500 | |

| 1.5 | 444 | 300 | 1500 | |

| 2.0 | 592 | 300 | 1500 | |

| 4.0 | 1183 | 300 | 1500 | |

| Modif. 2 | 0.1 | 30 | 300 | 1500 |

| 0.3 | 89 | 300 | 1500 | |

| 0.8 | 237 | 300 | 1500 | |

| 1.0 | 296 | 300 | 1500 | |

| 1.5 | 444 | 300 | 1500 | |

| 2.0 | 593 | 300 | 1500 | |

| 4.0 | 1185 | 300 | 1500 | |

| Modif. 3 | 0.1 | 30 | 300 | 1500 |

| 0.3 | 89 | 300 | 1500 | |

| 0.8 | 237 | 300 | 1500 | |

| 1.0 | 296 | 300 | 1500 | |

| 1.5 | 444 | 300 | 1500 | |

| 2.0 | 593 | 300 | 1500 | |

| 4.0 | 1185 | 300 | 1500 | |

| Classic | 0.1 | 26 | 300 | 1500 |

| 0.3 | 79 | 300 | 1500 | |

| 0.8 | 211 | 300 | 1500 | |

| 1.0 | 264 | 300 | 1500 | |

| 1.5 | 396 | 300 | 1500 | |

| 2.0 | 529 | 300 | 1500 | |

| 4.0 | 1057 | 300 | 1500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korpyś, M.; Iwaniszyn, M.; Sindera, K.; Suwak, M.; Kołodziej, A.; Gancarczyk, A. Modification of Short-Channel Structures Towards Heat Transfer Intensification: CFD Modeling. Energies 2025, 18, 4343. https://doi.org/10.3390/en18164343

Korpyś M, Iwaniszyn M, Sindera K, Suwak M, Kołodziej A, Gancarczyk A. Modification of Short-Channel Structures Towards Heat Transfer Intensification: CFD Modeling. Energies. 2025; 18(16):4343. https://doi.org/10.3390/en18164343

Chicago/Turabian StyleKorpyś, Mateusz, Marzena Iwaniszyn, Katarzyna Sindera, Mikołaj Suwak, Andrzej Kołodziej, and Anna Gancarczyk. 2025. "Modification of Short-Channel Structures Towards Heat Transfer Intensification: CFD Modeling" Energies 18, no. 16: 4343. https://doi.org/10.3390/en18164343

APA StyleKorpyś, M., Iwaniszyn, M., Sindera, K., Suwak, M., Kołodziej, A., & Gancarczyk, A. (2025). Modification of Short-Channel Structures Towards Heat Transfer Intensification: CFD Modeling. Energies, 18(16), 4343. https://doi.org/10.3390/en18164343