Evaluation of Maintenance and Modernization of Road Lighting Systems Using Energy Performance Indicators

Abstract

1. Introduction

2. Materials and Methods

2.1. Definition of Energy Performance Indicators

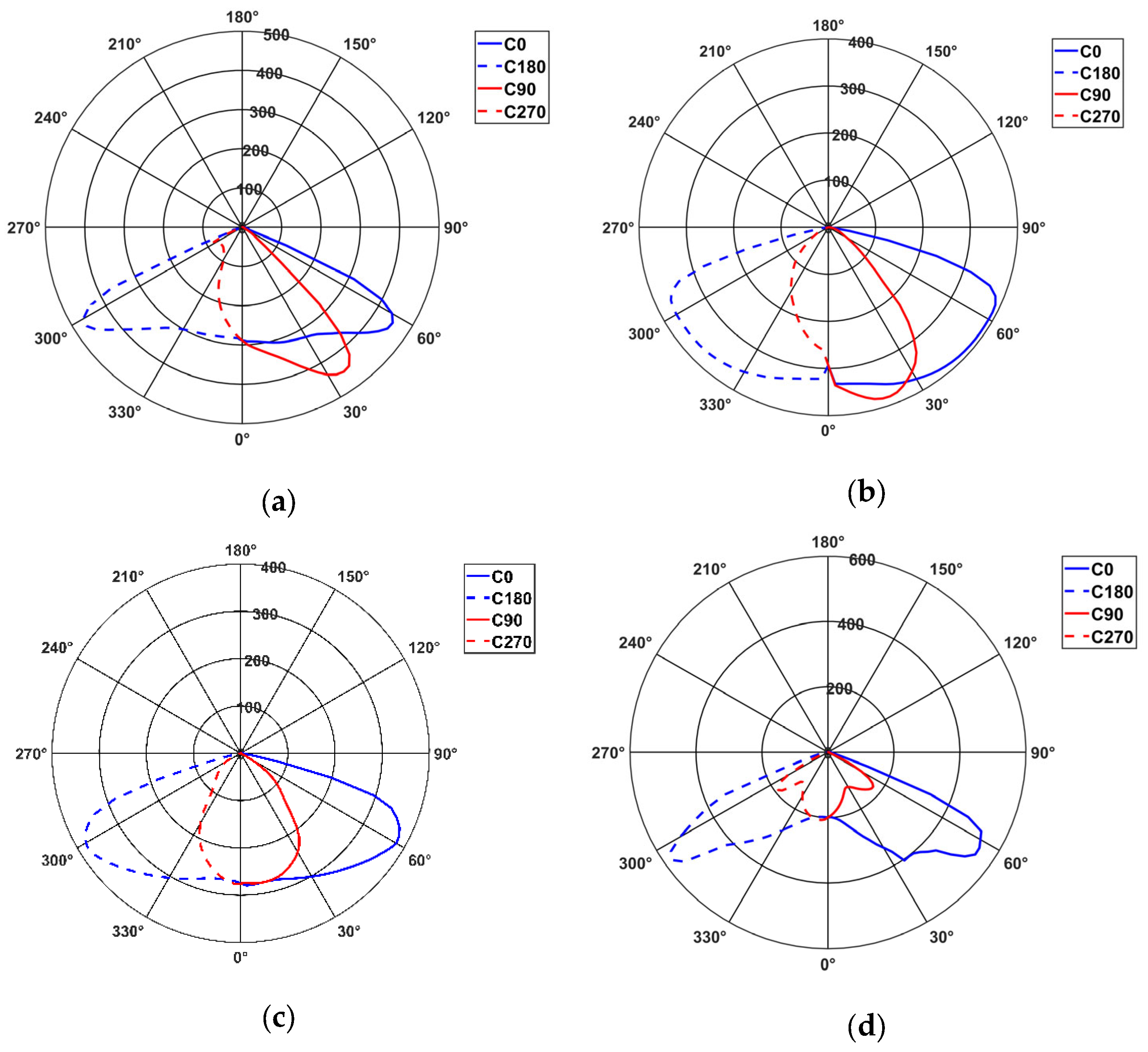

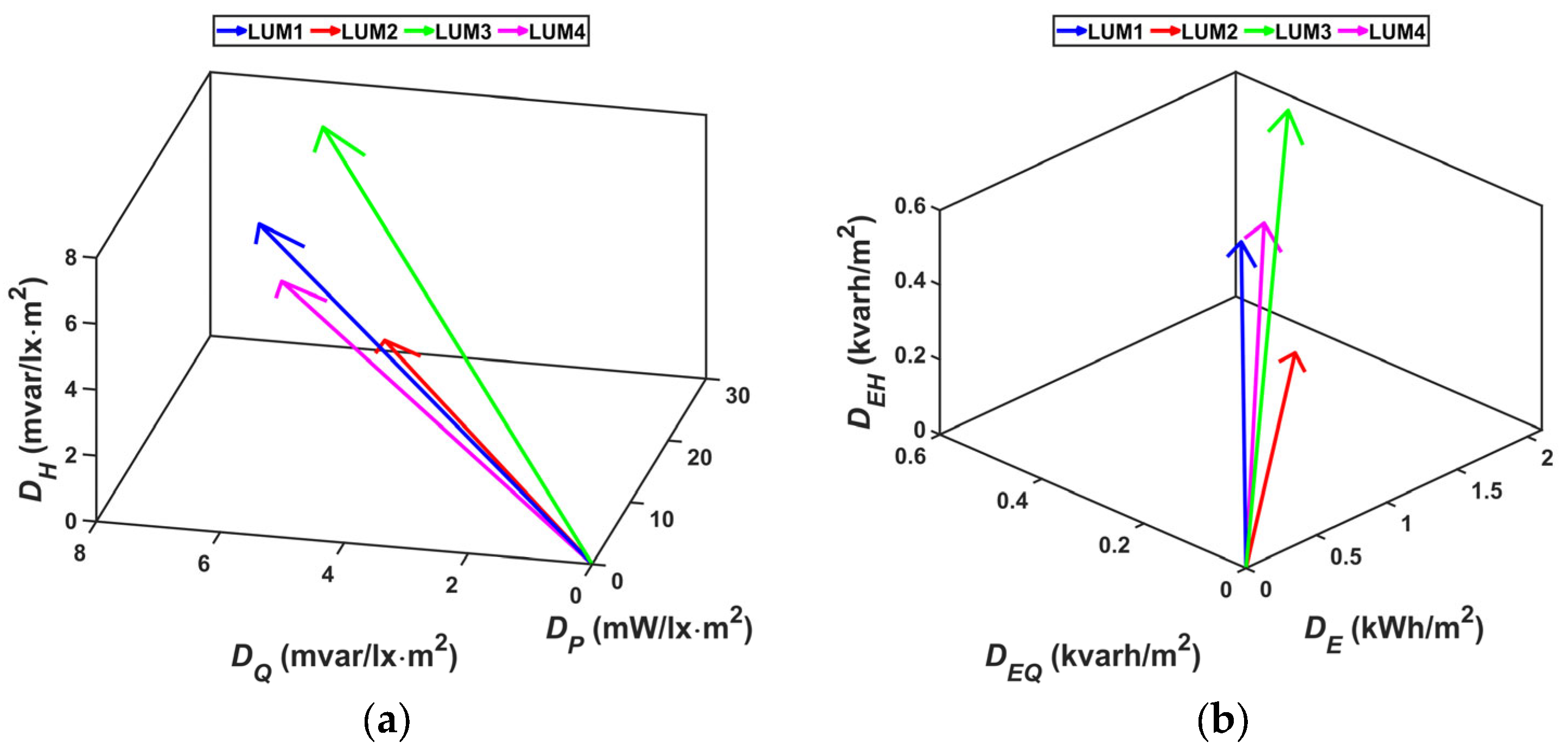

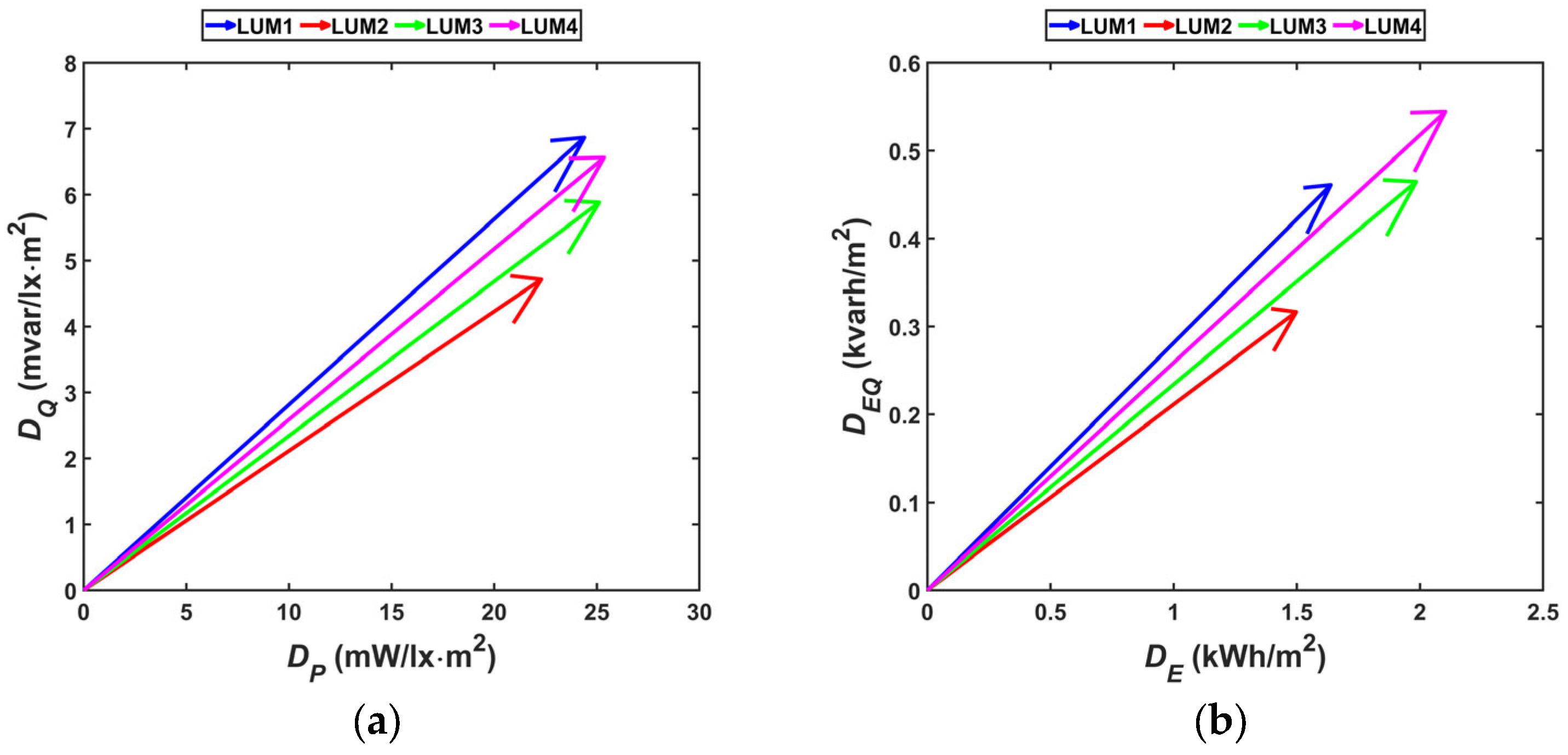

2.2. Characteristics of the Selected Road Luminaires

3. Results of the Lighting Parameters Calculation on the Road

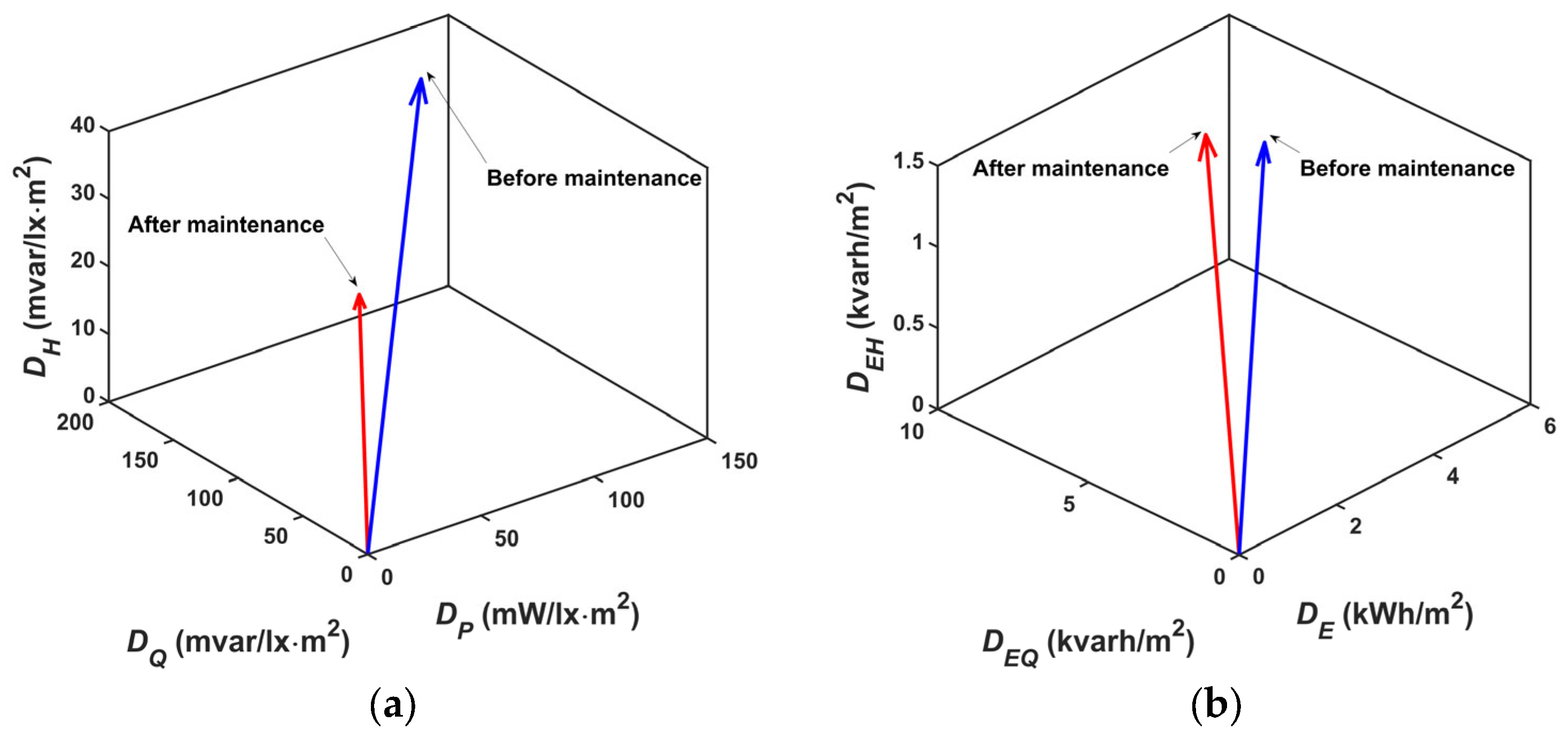

4. Use of Energy Performance Indicators to Compare the Electrical Energy Consumption of a Luminaire Before and After Maintenance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Silva, J.; Mendes, J.F.G.; Silva, L.T. Assessment of energy efficiency in street lighting design. WIT Trans. Ecol. Environ. 2010, 129, 705–715. [Google Scholar] [CrossRef]

- Boyce, P.R.; Fotios, S.; Richards, M. Road lighting and energy savings. Light. Res. Technol. 2009, 41, 245–260. [Google Scholar] [CrossRef]

- Kyba, C.C.M.; Hänel, A.; Hölker, F. Redefining efficiency for outdoor lighting. Energy Environ. Sci. 2014, 7, 1806. [Google Scholar] [CrossRef]

- Gutierrez-Escolar, A.; Castillo-Martinez, A.; Gomez-Pulido, J.M.; Escolar-Gutierrez, A.; Castillo-Martinez, A.; Gomez-Pulido, J.M.; Gutierrez-Martinez, J.M.; González-Seco, E.P.D.; Stapic, Z. A review of energy efficiency label of street lighting systems. Energy Effic. 2017, 10, 265–282. [Google Scholar] [CrossRef]

- Campisi, D.; Gitto, S.; Morea, D. Economic feasibility of energy improvements in street lighting systems in Rome. J. Clean. Prod. 2018, 175, 190–198. [Google Scholar] [CrossRef]

- Kostic, M.; Djokic, L. Recommendation for energy efficient and visually acceptable street lighting. Energy 2009, 34, 1565–1572. [Google Scholar] [CrossRef]

- Beccali, M.; Bonomolo, M.; Ciulla, G.; Galatioto, A.; Lo Brano, V. Improvement of energy efficiency and quality of street lighting in South Italy as an action of Sustainable Energy Action Plans. The case study of Comiso (RG). Energy 2015, 92, 394–408. [Google Scholar] [CrossRef]

- Djuretic, A.; Kostic, M. Actual energy savings when replacing high-pressure sodium with LED luminaires in street lighting. Energy 2018, 157, 367–378. [Google Scholar] [CrossRef]

- Zima, K.; Ciepłucha, W. Efficiency Analysis of Roadway Lighting Replacement in a Selected Polish Municipality. Appl. Sci. 2023, 13, 3257. [Google Scholar] [CrossRef]

- Vizzari, D.; Bahrani, N.; Fulco, G. Coexistence of Energy Harvesting Roads and Intelligent Transportation Systems (ITS). Infrastructures 2023, 8, 14. [Google Scholar] [CrossRef]

- Mou, K.; Ji, X.; Liu, J.; Zhou, H.; Tian, H.; Li, X.; Liu, H. Using piezoelectric technology to harvest energy from pavement: A review. J. Traffic Transp. Eng. 2025, 12, 68–86. [Google Scholar] [CrossRef]

- De Fazio, R.; De Giorgi, M.; Cafagna, D.; Del-Valle-Soto, C.; Visconti, P. Energy Harvesting Technologies and Devices from Vehicular Transit and Natural Sources on Roads for a Sustainable Transport: State-of-the-Art Analysis and Commercial Solutions. Energies 2023, 16, 3016. [Google Scholar] [CrossRef]

- Ren, J.; Li, Y.; Liu, H.; Li, K.; Hao, D.; Wang, Z. Analysis of Light Obstruction from Street Lighting in Road Scenes. Remote Sens. 2023, 15, 5655. [Google Scholar] [CrossRef]

- Mączka, M.; Hałdaś, G.; Pawłowski, S. QCL Active Area Modeling with a View to Being Applied to Chemical Substance Detection Systems. Sensors 2023, 23, 389. [Google Scholar] [CrossRef]

- Mączka, M.; Hałdaś, G. Voltage-Controlled and Injector Layer Thickness-Dependent Tuning of Quantum Cascade Laser for Terahertz Spectroscopy. ACS Appl. Mater. Interfaces 2025, 17, 26032–26044. [Google Scholar] [CrossRef]

- Khan, M.F.; Reddy, S.; Swanson, A.G. Replacement of HPS Luminaires with LED Luminaires for the Lighting Requirements of an Outdoor Electrical Substation. In Proceedings of the IEEE Sustainable Smart Lighting World Conference & Expo (LS18), Mumbai, India, 8–10 June 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Padmasali, A.N.; Lokesh, J.; Kini, S.G. An Experimental Investigation on the Role of LEDs on the Lifetime Performance of Consumer LED Luminaires. IEEE Access 2022, 10, 131765–131771. [Google Scholar] [CrossRef]

- Padmasali, A.N.; Lokesh, J.; Kini, S.G. Design of Test Method for Analysis and Estimation of LED Luminaire Lifetime Performance Under Cycle Based Realistic Operating Conditions. IEEE Access 2024, 12, 87944–87953. [Google Scholar] [CrossRef]

- Chiradeja, P.; Yoomak, S.; Ngaopitakkul, A. Economic Analysis of Improving the Energy Efficiency of Nanogrid Solar Road Lighting Using Adaptive Lighting Control. IEEE Access 2020, 8, 202623–202638. [Google Scholar] [CrossRef]

- Fryc, I.; Listowski, M.; Martinsons, C.; Fan, J.; Czyżewski, D. A Paradox of LED Road Lighting: Reducing Light Pollution Is Not Always Linked to Energy Savings. Energies 2024, 17, 5727. [Google Scholar] [CrossRef]

- Yovchev, M.; Tsankov, P.; Stoyanov, I. Measurement and Analysis of Photometric Characteristics and Efficacy of LED Luminaires for Indoor, Industrial and Street Lighting with and without an Optical System. In Proceedings of the 2023 Eight Junior Conference on Lighting (Lighting), Sozopol, Bulgaria, 23–25 September 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Jamaludin, M.H. Study of LED Retrofit Lamps in HSPV Luminaires Based on Photometric Method for Road Lighting. Pertanika J. Sci. Technol. 2024, 32, 1187–1201. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Majumder, S.; Roy, S. Modelling of the effects of luminaire installation geometries and other factors on road illumination system photometric parameters and energy efficiency. World J. Eng. 2023, 22, 674–688. [Google Scholar] [CrossRef]

- Rofaie, N.; Phoong, S.; Mutalib, M. Light-Emitting Diode (LED) versus High-Pressure Sodium Vapour (HPSV) Efficiency: A Data Envelopment Analysis Approach with Undesirable Output. Energies 2022, 15, 4589. [Google Scholar] [CrossRef]

- Gordic, D.; Vukasinovic, V.; Kovacevic, Z.; Josijevic, M.; Zivkovic, D. Assessing the Techno-Economic Effects of Replacing Energy-Inefficient Street Lighting with LED Corn Bulbs. Energies 2021, 14, 3755. [Google Scholar] [CrossRef]

- Orzáez, M.J.H.; de Andrés Díaz, J.R. Comparative study of energy-efficiency and conservation systems for ceramic metal-halide discharge lamps. Energy 2013, 52, 258–264. [Google Scholar] [CrossRef]

- Orzáez, M.J.H.; Róchaz Sola, J.; Gago-Calderon, A. Electrical consequences of large-scale replacement of metal-halide by LED luminaires. Light. Res. Technol. 2016, 50, 282–293. [Google Scholar] [CrossRef]

- Wantuch, A. The influence of LED light sources on the deterioration of the quality of electricity. Przegląd Elektrotechniczny 2024, 1, 308–311. [Google Scholar]

- Kovács, A.; Bátai, R.; Csanád Csáji, B.; Dudás, P.; Háy, B.; Pedone, G.; Révész, T.; Váncza, J. Intelligent control for energy-positive street lighting. Energy 2016, 114, 40–51. [Google Scholar] [CrossRef]

- Yoomak, S.; Ngaopitakkul, A. Optimisation of quality and energy efficiency of LED luminaires in roadway lighting systems on different road surfaces. Sustain. Cities Soc. 2018, 38, 333–347. [Google Scholar] [CrossRef]

- Al Irsyad, M.I.; Nepal, R. A survey based approach to estimating the benefits of energy efficiency improvements in street lighting systems in Indonesia. Renew. Sustain. Energy Rev. 2016, 58, 1569–1577. [Google Scholar] [CrossRef]

- Rabaza, O.; Peña-García, A.; Pérez-Ocón, F.; Gómez-Lorente, D. A simple method for designing efficient public lighting, based on new parameter relationships. Expert Syst. Appl. 2013, 40, 7305–7315. [Google Scholar] [CrossRef]

- Pizzuti, S.; Annunziato, M.; Moretti, F. Smart street lighting management. Energy Effic. 2013, 6, 607–616. [Google Scholar] [CrossRef]

- Radulovic, D.; Skok, S.; Kirincic, V. Energy efficiency public lighting management in the cities. Energy 2011, 36, 1908–1915. [Google Scholar] [CrossRef]

- Raffaele Carli, R.; Dotoli, M.; Pellegrino, R. A decision-making tool for energy efficiency optimization of street lighting. Comput. Oper. Res. 2018, 96, 222–234. [Google Scholar] [CrossRef]

- Lobăo, J.A.; TDevezas, T.; Catalăo, J.P.S. Energy efficiency of lighting installations: Software application and experimental validation. Energy Rep. 2015, 1, 110–115. [Google Scholar] [CrossRef]

- Shahzad, G.; Yang, H.; Waheed Ahmad, A.; Lee, C. Energy-Efficient Intelligent Street Lighting System Using Traffic-Adaptive Control. IEEE Sens. J. 2016, 16, 5397–5405. [Google Scholar] [CrossRef]

- Kurkowski, M.; Popławski, T.; Zajkowski, M.; Kurkowski, B.; Szota, M. Effective Control of Road Luminaires—A Case Study on an Example of a Selected City in Poland. Energies 2022, 15, 5378. [Google Scholar] [CrossRef]

- Beccali, M.; Bonomolo, M.; Leccese, F.; Lista, D.; Salvadoni, G. On the impact of safety requirements, energy prices and investment costs in street lighting refurbishment design. Energy 2018, 165, 739–759. [Google Scholar] [CrossRef]

- EN 13201-1:2014; Light and Lighting. Road Lighting—Part 1: Guidelines on Selection of Lighting Class. European Union: Brussels, Belgium, 2014. Available online: https://wiedza.pkn.pl/web/guest/wyszukiwarka-norm (accessed on 2 June 2025).

- EN 13201-2:2015; Light and Lighting. Road Lighting—Part 2: Performance Requirements. European Union: Brussels, Belgium, 2015. Available online: https://wiedza.pkn.pl/web/guest/wyszukiwarka-norm (accessed on 2 June 2025).

- EN 13201-3:2015; Light and Lighting. Road Lighting—Part 3: Calculation of Performance. European Union: Brussels, Belgium, 2015. Available online: https://wiedza.pkn.pl/web/guest/wyszukiwarka-norm (accessed on 2 June 2025).

- EN 13201-5:2015; Light and Lighting. Road Lighting—Part 5: Energy Performance Indicators. European Union: Brussels, Belgium, 2015. Available online: https://wiedza.pkn.pl/web/guest/wyszukiwarka-norm (accessed on 2 June 2025).

- Lecce, F.; Salvadoni, G.; Rocca, M. Critical analysis of the energy performance indicators for road lighting systems in historical towns of central Italy. Energy 2017, 138, 616–628. [Google Scholar] [CrossRef]

- Pracki, P. A proposal to classify road lighting energy efficiency. Light. Res. Technol. 2011, 43, 271–280. [Google Scholar] [CrossRef]

- Sikora, R.; Markiewicz, P.; Pabjańczyk, W. Computing Active Power Losses Using a Mathematical Model of a Regulated Street Luminaire. Energies 2018, 11, 1386. [Google Scholar] [CrossRef]

- Pires, D.F.; Antunes, C.H.; Martins, A.G. NSGA-II with local search for a multi-objective reactive power compensation problem. Electr. Power Energy Syst. 2012, 43, 313–324. [Google Scholar] [CrossRef]

- Czyżewski, D. Oprawy oświetlenia drogowego ze źródłami światła typu LED. Przegląd Elektrotechniczny 2009, 85, 283–288. [Google Scholar]

- Czyżewski, D.; Fryc, I. The Influence of Luminaire Photometric Intensity Curve Measurements Quality on Road Lighting Design Parameters. Energies 2020, 13, 3301. [Google Scholar] [CrossRef]

- Sikora, R.; Markiewicz, P. A new approach to calculating energy performance indicators of road lighting. Sustain. Cities Soc. 2021, 75, 103232. [Google Scholar] [CrossRef]

- Du, W.; Cheng, H.; Wang, L.; Feng, D.; Wang, X. Measurement and Analysis Method of Light Intensity Distribution for Street Lamps. J. Phys. Conf. Ser. 2022, 2173, 012069. [Google Scholar] [CrossRef]

- Tomczuk, P.; Chrzanowicz, M.; Jaskowski, P.; Budzynski, M. Evaluation of Street Lighting Efficiency Using a Mobile Measurement System. Energies 2021, 14, 3872. [Google Scholar] [CrossRef]

- Tähkämö, L.; Halonen, L. Life cycle assessment of road lighting luminaires—Comparison of light-emitting diode and high-pressure sodium technologies. J. Clean. Prod. 2015, 93, 234–242. [Google Scholar] [CrossRef]

- Tähkämö, L.; Räsänen, R.; Halonen, L. Life cycle cost comparison of high-pressure sodium and light-emitting diode luminaires in street lighting. Int. J. Life Cycle Assess. 2016, 21, 137–145. [Google Scholar] [CrossRef]

- Jägerbrand, A.K. New Framework of Sustainable Indicators for Outdoor LED (Light Emitting Diodes) Lighting and SSL (Solid State Lighting). Sustainability 2015, 7, 1028–1063. [Google Scholar] [CrossRef]

- Hamas, I.; Abdullah, A.; Hakim, D. Performance analysis of Light Emitting Diode, High Sodium Pressure and Metal Halide Lights. J. Phys. Conf. Ser. 2019, 1402, 033083. [Google Scholar] [CrossRef]

- Sikora, R.; Markiewicz, P. Assessment of Colorimetric Parameters for HPS Lamp with Electromagnetic Control Gear and Electronic Ballast. Energies 2020, 13, 2909. [Google Scholar] [CrossRef]

- Sikora, R.; Markiewicz, P. Analysis of Electric Power Quantities of Road LED Luminaires under Sinusoidal and Non-Sinusoidal Conditions. Energies 2019, 12, 1109. [Google Scholar] [CrossRef]

- IEEE Std. 1459-2010; Definitions for the Measurement of Electric Power Quantities Under Sinusoidal, Nonsinusoidal, Balanced or Unbalanced Conditions. IEEE: New York, NY, USA, 2010. Available online: https://ieeexplore.ieee.org/document/5439063 (accessed on 2 June 2025).

| Luminaire | ΦS (lm) | ΦLUM (lm) | η (−) |

|---|---|---|---|

| HPS 100 W—Before maintenance | 8562 | 3339 | 0.39 |

| HPS 100 W—After maintenance | 11,113 | 6779 | 0.61 |

| Difference | 22.96% | 50.75% | 36.07% |

| Luminaire | P (W) | Q (var) | I (A) | PFD | PFDD | THDI (%) | η (lm/W) | Tanφ |

|---|---|---|---|---|---|---|---|---|

| HPS 100 W—Before maintenance | 123.64 | 177.81 | 0.95 | 0.57 | 0.56 | 14.31 | 27.00 | 1.44 |

| HPS 100 W—After maintenance | 129.82 | 238.86 | 1.19 | 0.48 | 0.47 | 9.99 | 52.22 | 1.84 |

| Difference | 4.76% | 25.56% | 19.63% | −19.54% | −18.89% | −43.28% | 48.30% | 21.74% |

| Luminaires | ΦLUM (lm) | P (W) | Q (var) | I (mA) | PFD | PFDD | THDI (%) | η (lm/W) | Tanφ (−) |

|---|---|---|---|---|---|---|---|---|---|

| LUM1 | 6987 | 43.77 | 12.32 | 200.72 | 0.962 | 0.946 | 18.08 | 159.63 | 0.28 |

| LUM2 | 5484 | 40.01 | 8.46 | 178.36 | 0.978 | 0.975 | 7.17 | 137.07 | 0.21 |

| LUM3 | 7674 | 53.03 | 12.42 | 245.54 | 0.974 | 0.936 | 29.23 | 144.71 | 0.23 |

| LUM4 | 9428 | 56.20 | 14.55 | 253.52 | 0.968 | 0.963 | 10.39 | 167.76 | 0.26 |

| The Geometric Parameter | Value |

|---|---|

| width of the roadway (m) | 5 |

| number of lanes | 2 |

| pole spacing (m) | 19.00 |

| mounting height (m) | 8.50 |

| overhang (m) | 0.65 |

| overhang slope (°) | 10.00 |

| overhang length (m) | 1.00 |

| arrangement | one-sided at the top |

| Luminaire | Values Required Following the Standard for the Assumed Lighting Class | Lm (cd/m2) | Uo | UI | fTI (%) | EAVG (lx) |

|---|---|---|---|---|---|---|

| ≥0.75 | ≥0.40 | ≥0.60 | ≤15 | |||

| Before maintenance | Observer 1 | 0.43 | 0.61 | 0.78 | 3 | 8.80 |

| Observer 2 | 0.41 | 0.61 | 0.65 | 3 | ||

| Fulfilled or not | no | no | yes | yes | ||

| After maintenance | Observer 1 | 0.94 | 0.55 | 0.72 | 5 | 17 |

| Observer 2 | 0.89 | 0.54 | 0.69 | 6 | ||

| Fulfilled or not | yes | yes | yes | yes |

| Luminaire | Values Required Following the Standard for the Assumed Lighting Class | Lm (cd/m2) | Uo | UI | fTI (%) | EAVG (lx) |

|---|---|---|---|---|---|---|

| ≥0.75 | ≥0.40 | ≥0.60 | ≤15 | |||

| LUM1 | Observer 1 | 0.94 | 0.66 | 0.84 | 1 | 17 |

| Observer 2 | 0.89 | 0.67 | 0.72 | 1 | ||

| LUM2 | Observer 1 | 1.14 | 0.66 | 0.95 | 5 | 17 |

| Observer 2 | 1.05 | 0.67 | 0.95 | 6 | ||

| LUM3 | Observer 1 | 1.38 | 0.60 | 0.96 | 5 | 20 |

| Observer 2 | 1.27 | 0.61 | 0.96 | 7 | ||

| LED4 | Observer 1 | 1.46 | 0.50 | 0.74 | 4 | 21 |

| Observer 2 | 1.36 | 0.51 | 0.75 | 5 |

| Luminaire | Voltage | Current | ||||||

|---|---|---|---|---|---|---|---|---|

| V (V) | V1 (V) | VH (V) | THDV (%) | I (A) | I1 (A) | IH (A) | ||

| HPS 100 W—Before maintenance | 229.85 | 229.60 | 10.72 | 1.95 | 0.96 | 0.95 | 0.14 | |

| HPS 100 W—After maintenance | 230.40 | 230.36 | 4.29 | 1.89 | 1.19 | 1.18 | 0.12 | |

| LUM1 | 230.46 | 230.37 | 6.44 | 2.76 | 0.201 | 0.197 | 0.04 | |

| LUM2 | 230.03 | 229.96 | 5.67 | 2.32 | 0.178 | 0.178 | 0.01 | |

| LUM3 | 231.34 | 231.28 | 5.27 | 2.26 | 0.25 | 0.24 | 0.07 | |

| LED 3 | 230.28 | 230.21 | 5.68 | 2.31 | 0.253 | 0.252 | 0.03 | |

| Luminaire | Apparent Power Decomposition | |||||

|---|---|---|---|---|---|---|

| S (VA) | S1 (VA) | DI (VAr) | DV (VAr) | SH (VA) | SN (VA) | |

| HPS 100 W—Before maintenance | 218.91 | 217.26 | 31.11 | 10.14 | 1.45 | 32.75 |

| HPS 100 W—After maintenance | 273.30 | 272.08 | 27.23 | 5.07 | 0.51 | 27.70 |

| LUM1 | 46.26 | 45.49 | 8.30 | 1.27 | 0.23 | 8.40 |

| LUM2 | 41.03 | 40.88 | 3.30 | 1.01 | 0.08 | 3.45 |

| LUM3 | 56.67 | 54.48 | 16.02 | 1.24 | 0.36 | 16.07 |

| LED 3 | 58.38 | 58.04 | 6.10 | 1.43 | 0.15 | 6.27 |

| Indicator | Before Maintenance | After Maintenance | Difference (%) |

|---|---|---|---|

| DP (mW/lx·m2) | 147.76 | 80.36 | 45.61 ↓ |

| DQ (mvar/lx·m2) | 212.57 | 147.81 | 30.46 ↓ |

| DH (mvar/lx·m2) | 37.21 | 16.86 | 54.69 ↓ |

| DT (mV·A/lx·m2) | 261.54 | 169.08 | 35.35 ↓ |

| DPQT (mV·A/lx·m2) | 258.88 | 168.24 | 35.01 ↓ |

| DE (kWh/m2) | 5.17 | 5.40 | 4.45 ↑ |

| DEQ (kvarh/m2) | 7.39 | 9.93 | 34.37 ↑ |

| DEH (kvarh/m2) | 1.36 | 1.15 | 15.44 ↓ |

| DTE (kV·A/m2) | 9.10 | 11.36 | 24.84 ↑ |

| DPQTE (kV·A/m2) | 9.00 | 11.30 | 25.56 ↑ |

| Indicator | LUM1 | LUM2 | LUM3 | LUM4 |

|---|---|---|---|---|

| DP (mW/lx·m2) | 27.10 | 24.77 | 27.91 | 28.17 |

| DQ (mvar/lx·m2) | 7.63 | 5.24 | 6.54 | 7.29 |

| DH (mvar/lx·m2) | 5.14 | 2.04 | 8.43 | 3.06 |

| DT (mV·A/lx·m2) | 28.62 | 25.40 | 29.88 | 29.26 |

| DPQT (mV·A/lx·m2) | 28.16 | 25.32 | 28.67 | 29.10 |

| DE (kWh/m2) | 1.82 | 1.66 | 2.20 | 2.34 |

| DEQ (kvarh/m2) | 0.51 | 0.35 | 0.52 | 0.61 |

| DEH (kvarh/m2) | 0.35 | 0.14 | 0.67 | 0.25 |

| DTE (kV·A/m2) | 1.92 | 1.71 | 2.36 | 2.43 |

| DPQTE (kV·A/m2) | 1.89 | 1.70 | 2.26 | 2.41 |

| Indicator | Before Maintenance—LUM2 | After Maintenance—LUM2 |

|---|---|---|

| DP (mW/lx·m2) | 496.53% | 224.42% |

| DQ (mvar/lx·m2) | 3956.68% | 2720.80% |

| DH (mvar/lx·m2) | 1724.02% | 726.47% |

| DT (mV·A/lx·m2) | 929.69% | 565.67% |

| DPQT (mV·A/lx·m2) | 922.43% | 564.45% |

| DE (kWh/m2) | 211.45% | 225.30% |

| DEQ (kvarh/m2) | 2011.43% | 2737.14% |

| DEH (kvarh/m2) | 871.43% | 721.43% |

| DTE (kV·A/m2) | 432.16% | 564.33% |

| DPQTE (kV·A/m2) | 429.41% | 564.71% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikora, R.; Markiewicz, P.; Korzeniewska, E. Evaluation of Maintenance and Modernization of Road Lighting Systems Using Energy Performance Indicators. Energies 2025, 18, 4328. https://doi.org/10.3390/en18164328

Sikora R, Markiewicz P, Korzeniewska E. Evaluation of Maintenance and Modernization of Road Lighting Systems Using Energy Performance Indicators. Energies. 2025; 18(16):4328. https://doi.org/10.3390/en18164328

Chicago/Turabian StyleSikora, Roman, Przemysław Markiewicz, and Ewa Korzeniewska. 2025. "Evaluation of Maintenance and Modernization of Road Lighting Systems Using Energy Performance Indicators" Energies 18, no. 16: 4328. https://doi.org/10.3390/en18164328

APA StyleSikora, R., Markiewicz, P., & Korzeniewska, E. (2025). Evaluation of Maintenance and Modernization of Road Lighting Systems Using Energy Performance Indicators. Energies, 18(16), 4328. https://doi.org/10.3390/en18164328