Multi-Objective Optimization of 12-Pole Radial Active Magnetic Bearings with Preference-Based MOEA/D Algorithm

Abstract

1. Introduction

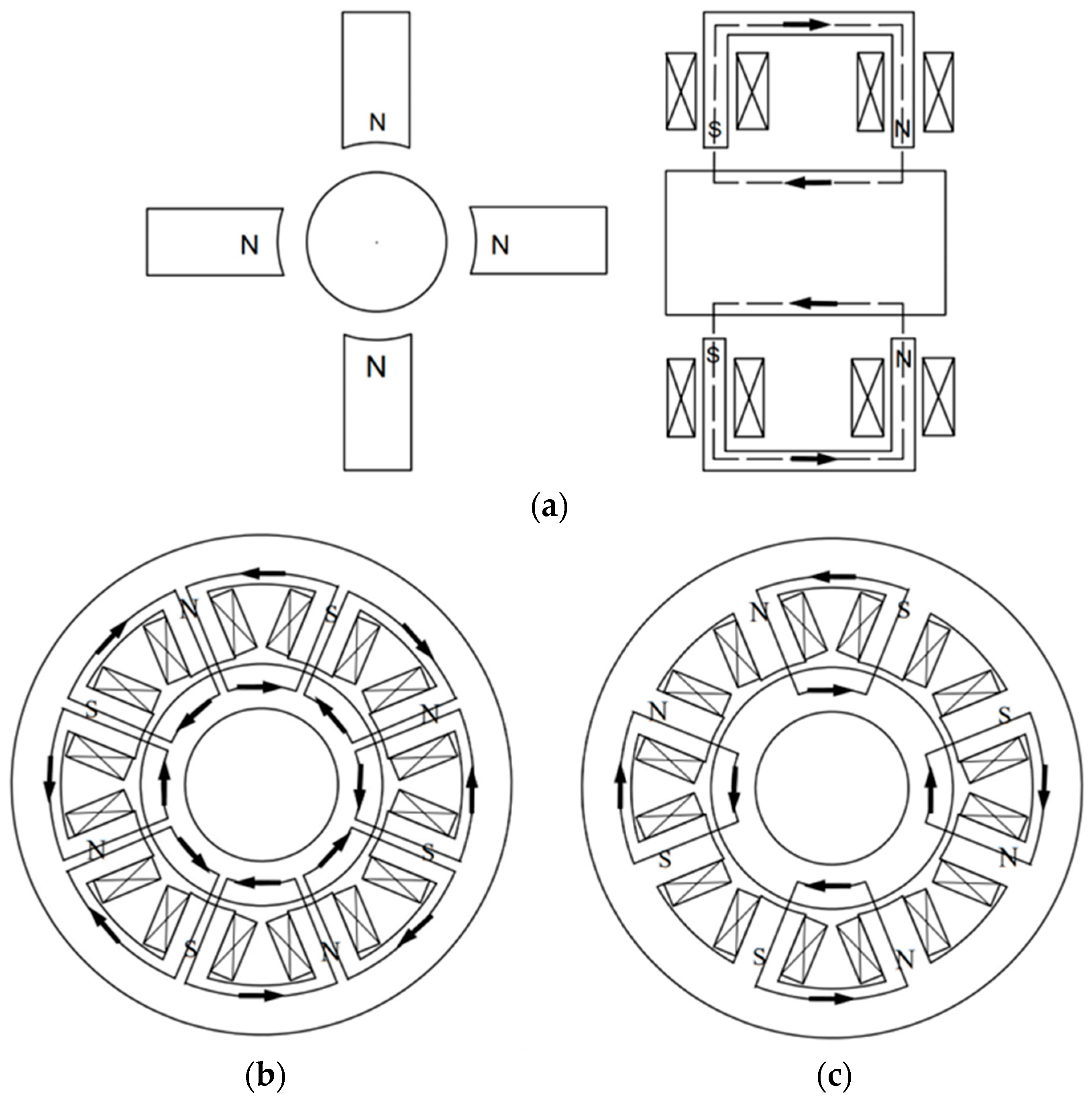

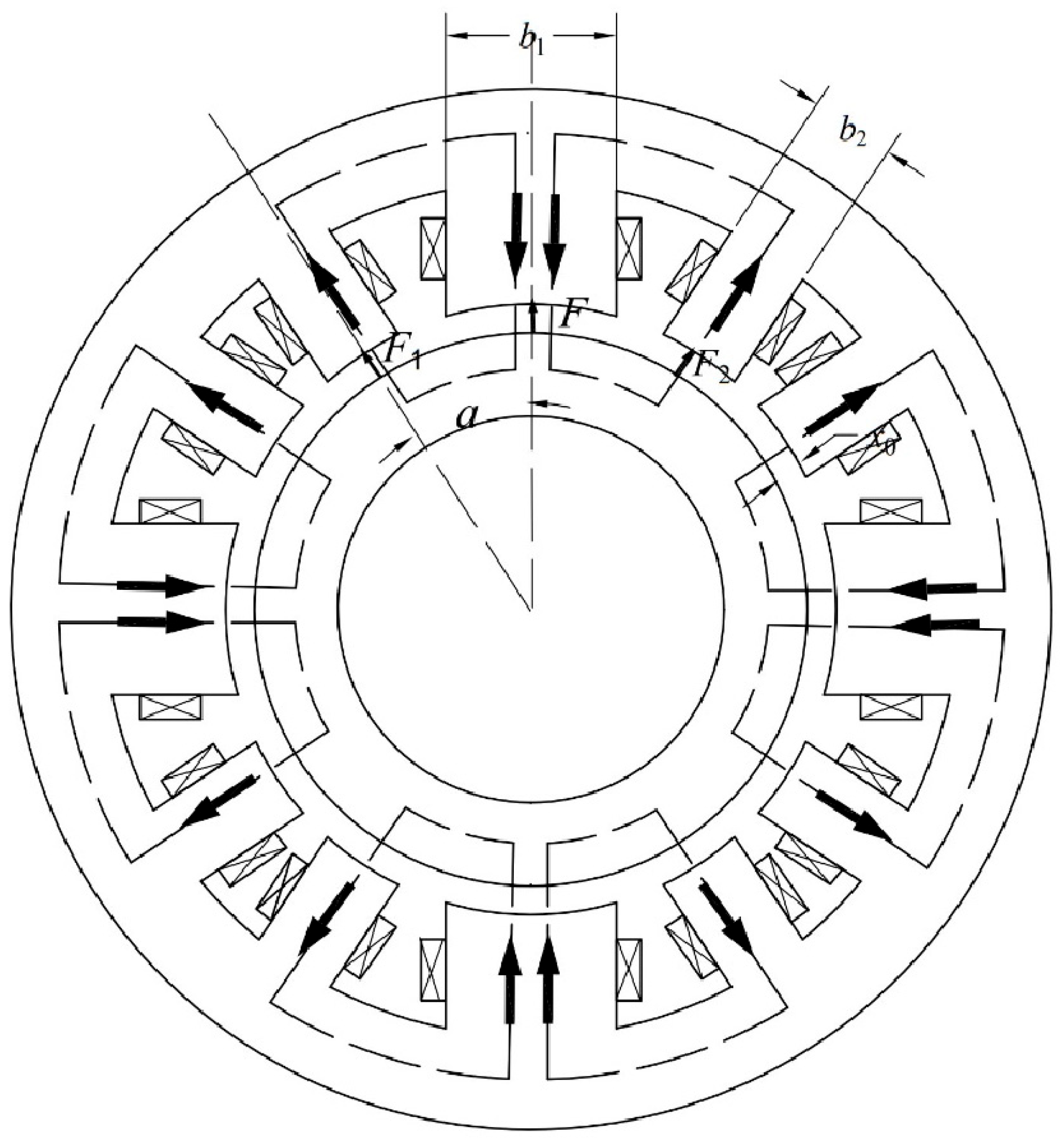

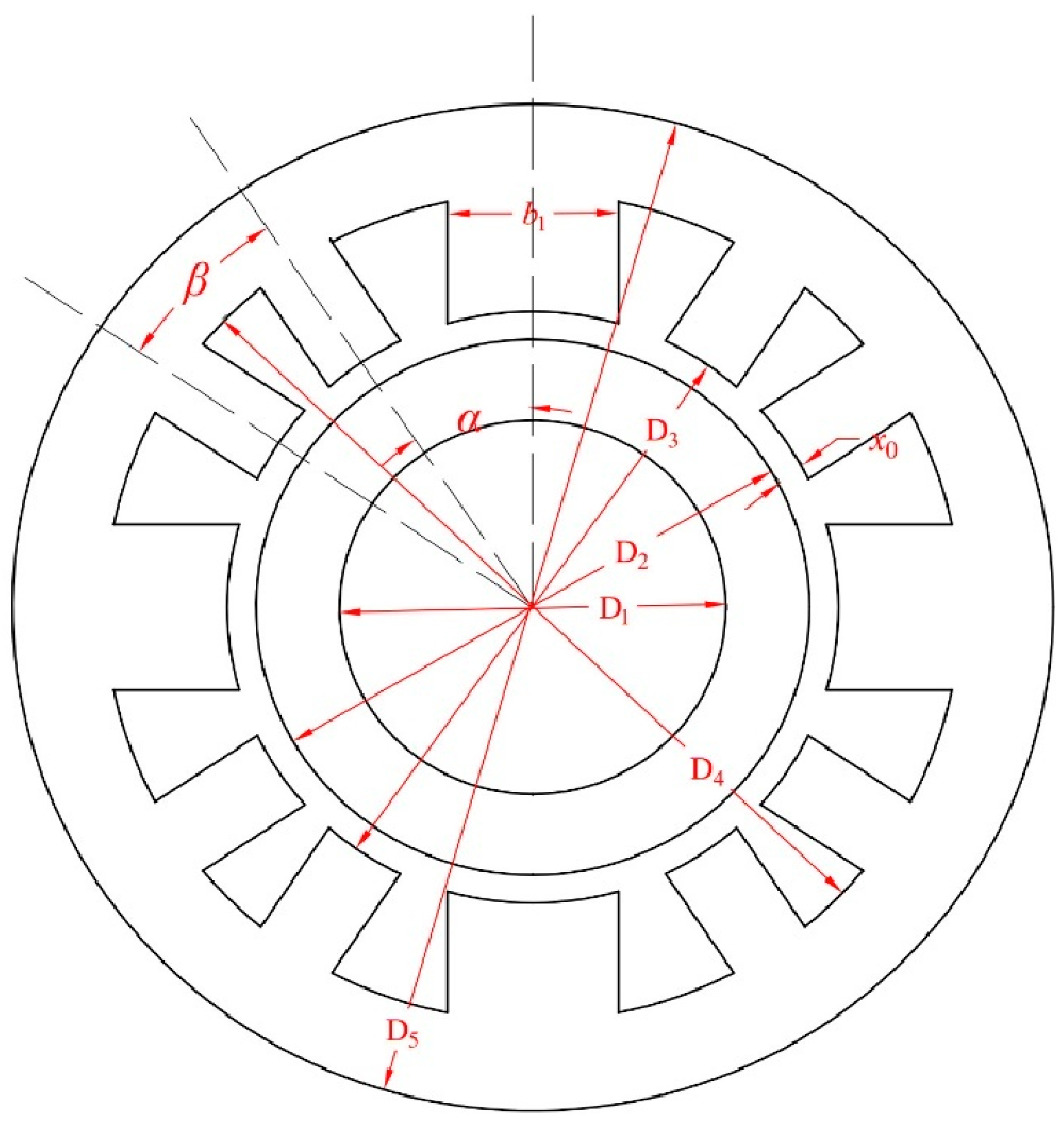

2. Structure and Mathematical Modeling of the 12-Pole RAMB

2.1. Structure of the 12-Pole RAMB

2.2. Mathematical Modeling of the 12-Pole RAMB

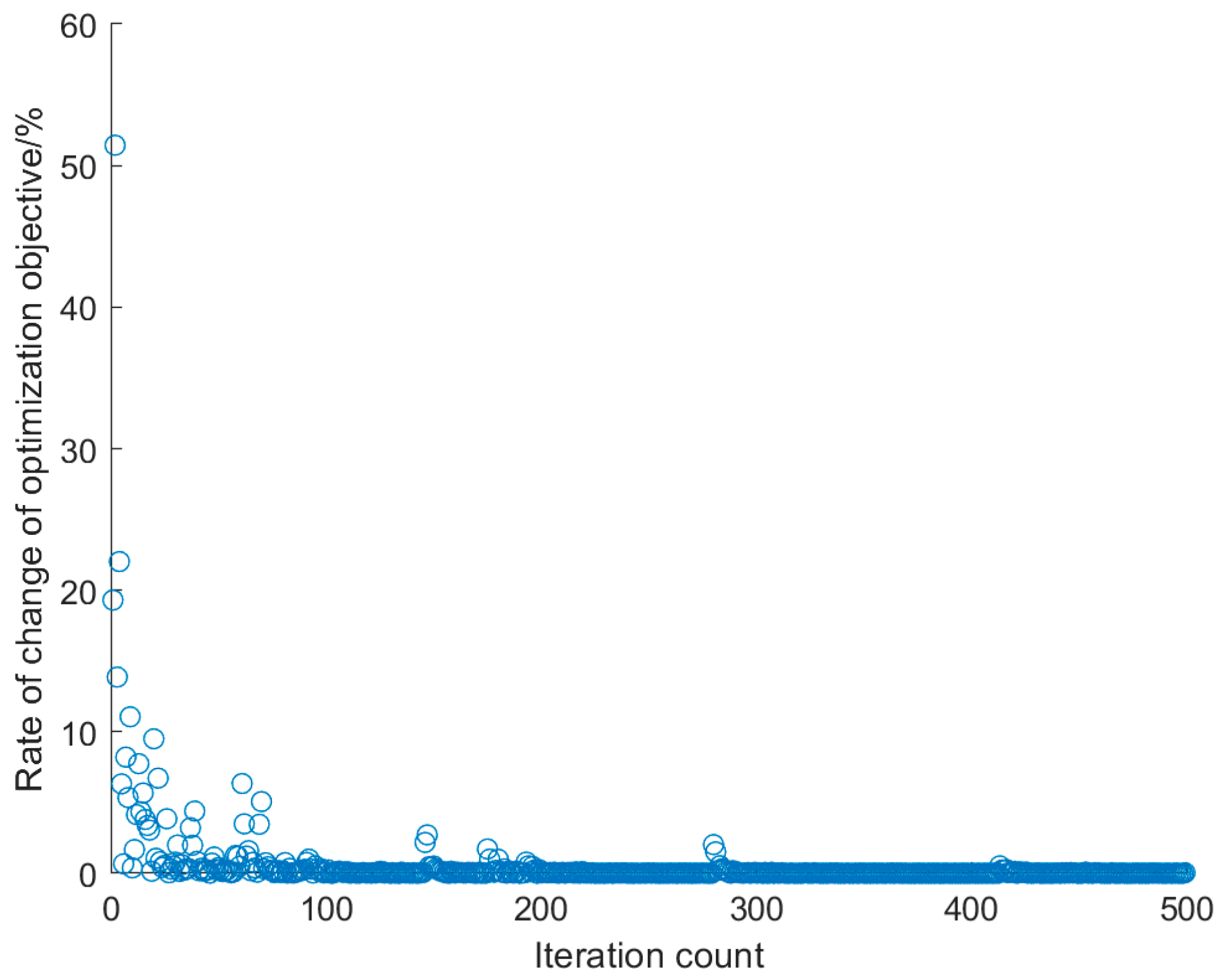

3. Optimization of RAMB Using MOEA/D

3.1. Principles, Aggregation Approach and Normalization of MOEA/D

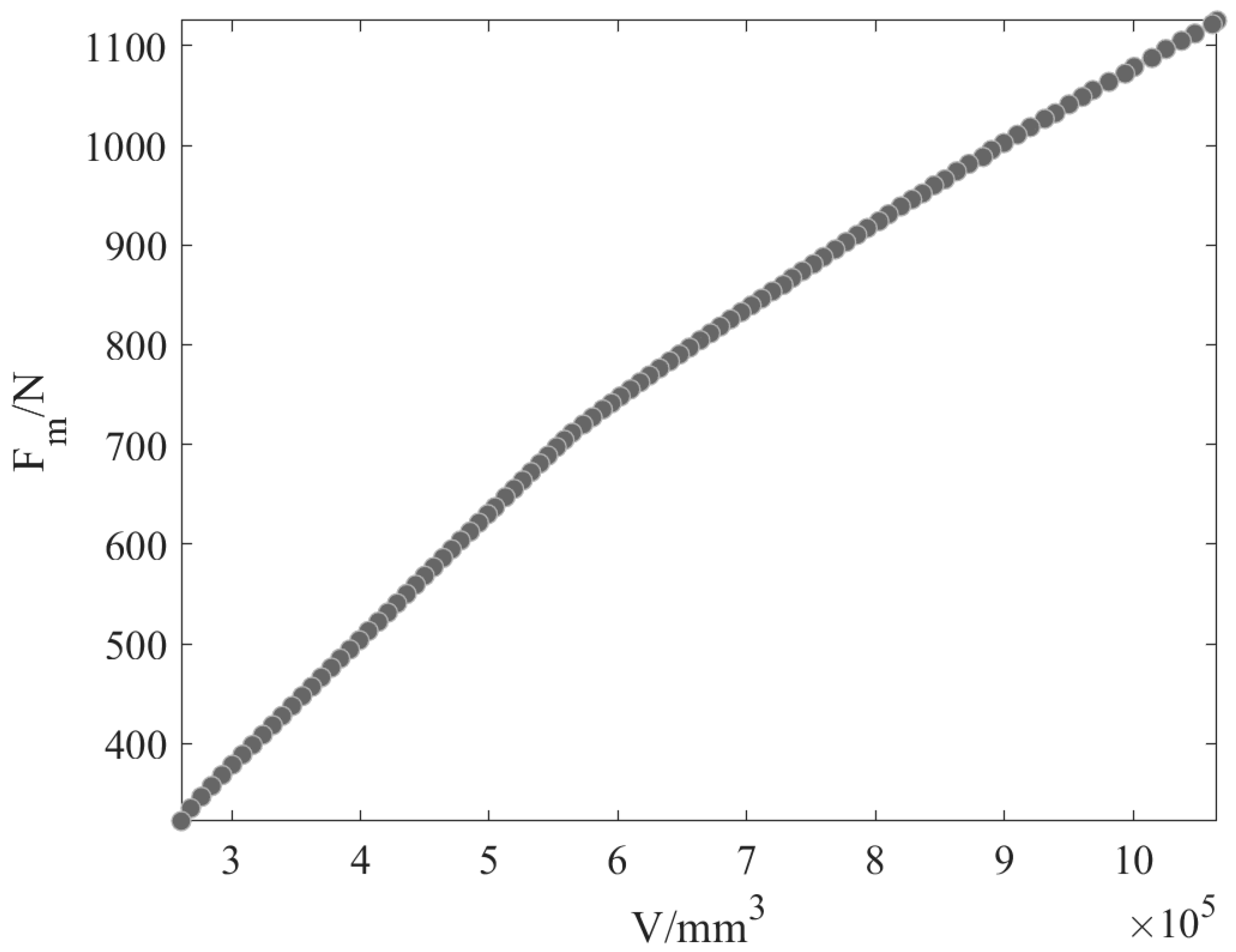

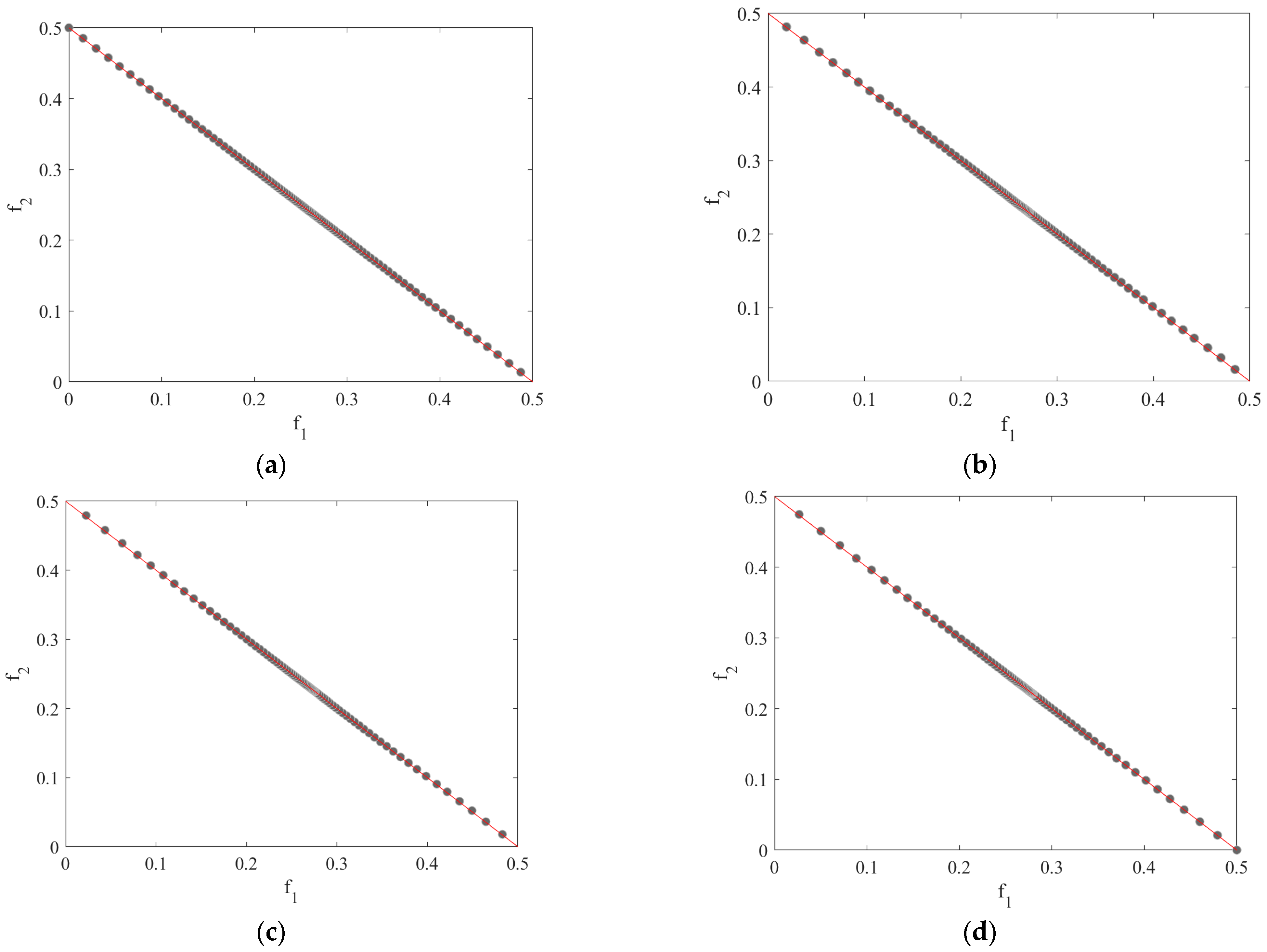

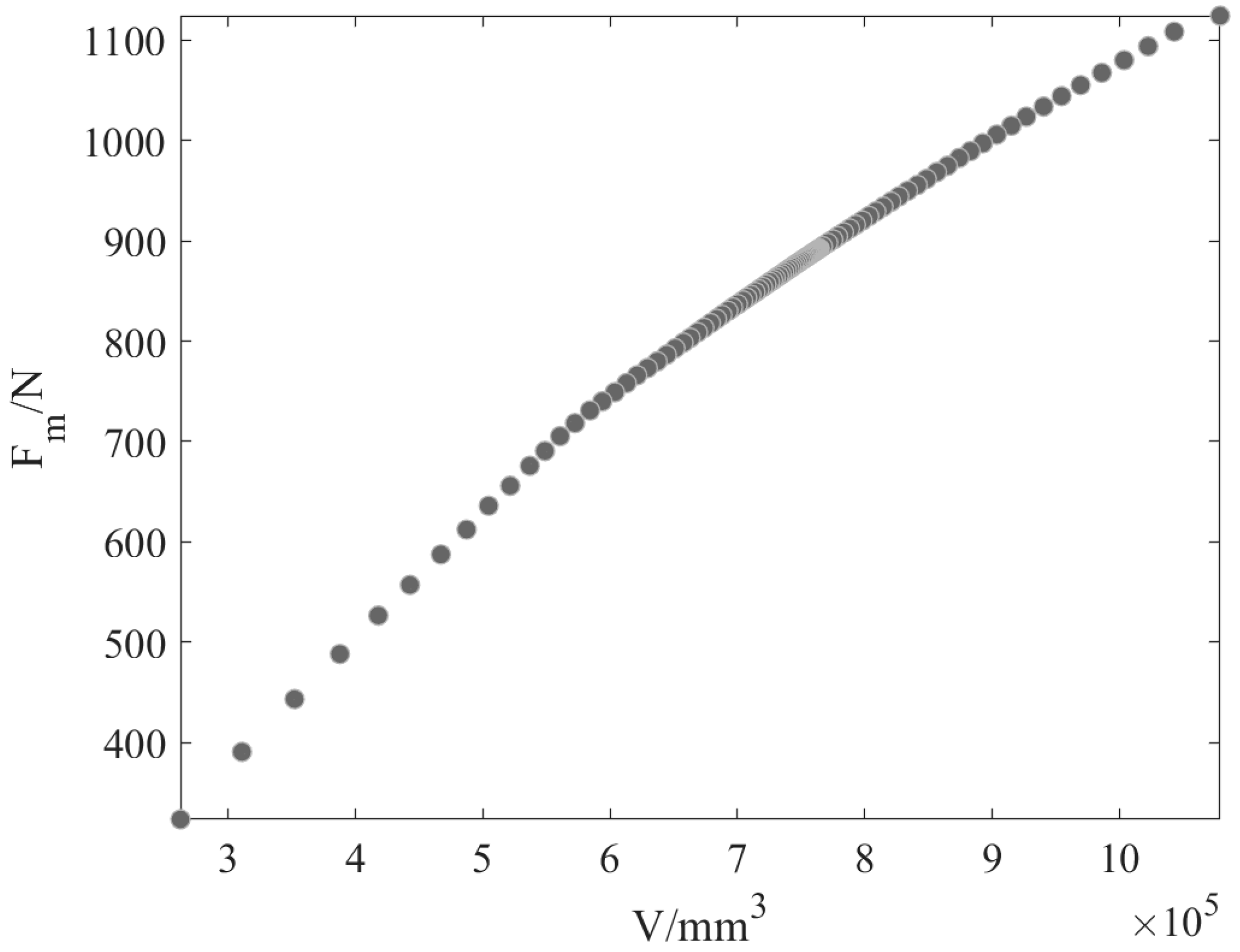

3.2. Optimization Objective, Optimization Parameters, Constraints and Results

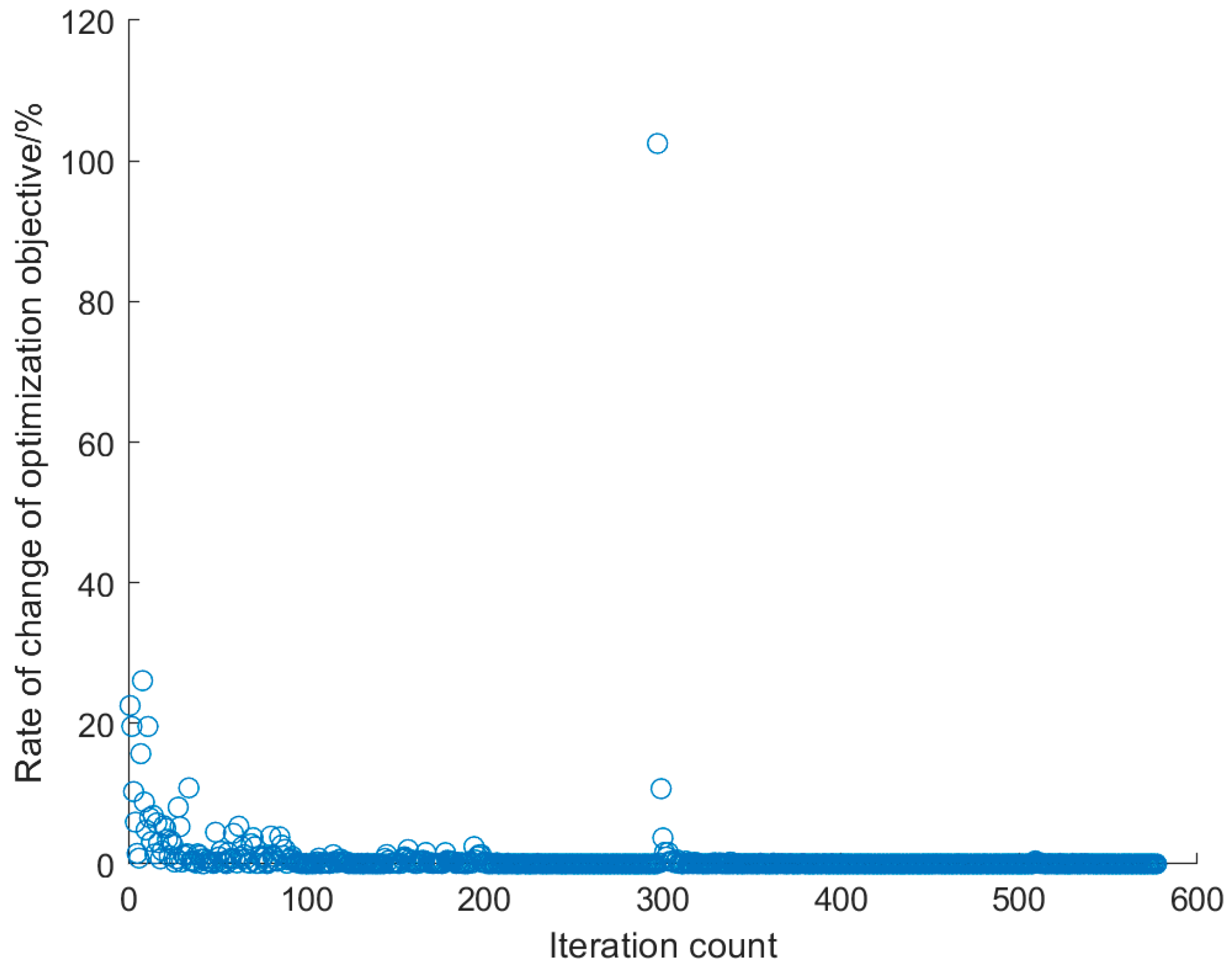

4. Optimization of RAMB Using MOEA/D-Pref

5. Optimal Design of 12-Pole RAMB

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Le, Y.; Wang, D.; Zheng, S.Q. Design and optimization of a radial magnetic bearing considering unbalanced magnetic pull effects for magnetically suspended compressor. IEEE Trans. Mechatron. 2022, 27, 5760–5770. [Google Scholar] [CrossRef]

- Zheng, S.; Wang, C. Rotor balancing for magnetically levitated TMPs integrated with vibration self-sensing of magnetic bearings. IEEE Trans. Mechatron. 2021, 26, 3031–3039. [Google Scholar] [CrossRef]

- Han, X.; Liu, G.; Le, Y.; Dong, B.T.; Zheng, S.Q. Unbalanced magnetic pull disturbance compensation of magnetic bearing systems in MSCCs. IEEE Trans. Ind. Electron. 2023, 70, 4088–4097. [Google Scholar] [CrossRef]

- Jastrzebski, R.P.; Liukkonen, O. Analysis of a segmented axial active magnetic bearing for multi-MW compressor applications. IEEE Trans. Mechatron. 2023, 28, 2799–2809. [Google Scholar] [CrossRef]

- Zhang, R.; Song, X.Y.; Cui, Z.Z.; Hao, W.; Xu, C.; Song, L.W. Distributed modeling of isolated active magnetic bearings considering magnetic leakage and material nonlinearity. Energies 2023, 16, 8023. [Google Scholar] [CrossRef]

- Moser, R.; Sandtner, J.; Bleuler, H. Optimization of repulsive passive magnetic bearings. IEEE Trans. Magn. 2006, 42, 2038–2042. [Google Scholar] [CrossRef]

- Cheng, S.B.; Olles, M.W.; Burger, A.F.; Day, S.W. Optimization of a hybrid magnetic bearing for a magnetically levitated blood pump via 3-D FEA. Mechatronics 2011, 21, 1163–1169. [Google Scholar] [CrossRef]

- Sun, Y.K.; Yin, S.J.; Yuan, Y.; Huang, Y.H. Multi-objective optimization design of magnetic bearing based on genetic particle swarm optimization. Prog. Electromagn. Res. M 2019, 81, 181–192. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.Q.; Wu, M.Y. Multi-Objective Parameter Optimization-Based Design of Six-Pole Radial Hybrid Magnetic Bearing. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 4526–4535. [Google Scholar] [CrossRef]

- Wang, Y.B.; Cao, J.W.; Chen, B.; Chen, X.; Liu, J.X.; Li, L.Y. Multi-objective Parameter Optimization Design of Radial Magnetic Levitation Bearing. In Proceedings of the 2024 27th International Conference on Electrical Machines and Systems (ICEMS), Fukuoka, Japan, 26–29 November 2024. [Google Scholar]

- Jin, Z.J.; Sun, X.D.; Chen, L.; Yang, Z.B. Robust Multi-Objective Optimization of a 3-Pole Active Magnetic Bearing Based on Combined Curves with Climbing Algorithm. IEEE Trans. Ind. Electron. 2022, 69, 5491–5501. [Google Scholar] [CrossRef]

- Zhong, W.; Palazzolo, A.; Kang, X. Multi-Objective optimization design of nonlinear magnetic bearing rotor dynamic system. J. Vib. Acoust. Trans. ASME 2017, 139, 011011. [Google Scholar] [CrossRef]

- Rao, J.S.; Tiwari, R. A pareto optimal design analysis of magnetic thrust bearings using multi-objective genetic algorithms. Int. J. Comput. Methods Eng. Sci. Mech. 2015, 16, 71–85. [Google Scholar] [CrossRef]

- Yadav, V.K.; Kumar, P.; Bhushan, G. A novel approach for design optimisation of radial active magnetic bearing. Aust. J. Mech. Eng. 2023, 21, 1461–1473. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Zhang, Q.F.; Li, H. MOEA/D: A multiobjective evolutionary algorithm based on decomposition. IEEE Trans. Evol. Comput. 2007, 11, 712–731. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Tian, Y.; Jin, Y.C. A knee point driven evolutionary algorithm for many-objective optimization. IEEE Trans. Evol. Comput. 2014, 19, 761–776. [Google Scholar] [CrossRef]

- Bozorgi, S.M.; Yazdni, S. IWOA: An improved whale optimization algorithm for optimization problems. J. Comput. Des. Eng. 2019, 6, 243–259. [Google Scholar] [CrossRef]

- Deb, K.; Jain, H. An evolutionary many-objective optimization algorithm using reference-point-based nondominated sorting approach, part I: Solving problems with box constraints. IEEE Trans. Evol. Comput. 2013, 18, 577–601. [Google Scholar] [CrossRef]

- Molina, J.; Santana, L.V.; Hernández-Díaz, A.G.; Coello, C.A.; Caballero, R. g-dominance: Reference point based dominance for multiobjective metaheuristics. Eur. J. Oper. Res. 2009, 197, 685–692. [Google Scholar] [CrossRef]

- Said, L.B.; Bechikh, S.; Ghedira, K. The r-Dominance: A New Dominance Relation for Interactive Evolutionary Multicriteria Decision Making. IEEE Trans. Evol. Comput. 2010, 14, 801–818. [Google Scholar] [CrossRef]

- Zheng, J.H.; Xie, Z.H. A Study on How to Use Angle Information to Include Decision Maker’s Preferences. Acta Electron. Sin. 2014, 42, 2239–2246. [Google Scholar]

- Mohammadi, A.; Omidvar, M.N.; Li, X.D. Reference point based multi-objective optimization through decomposition. In Proceedings of the 2012 IEEE Congress on Evolutionary Computation, Brisbane, QLD, Australia, 10–15 June 2012. [Google Scholar]

- Li, Y.; Sheng, C.; Zhang, B.; Zhao, Q.; Du, G.F. Optimization Design of Electromagnetic Bearing for Long-life Centrifugal Pump. In Proceedings of the 3rd International Conference on Mechatronics Technology and Aerospace Engineering (ICMTAE), Nanchang, China, 15–17 September 2023. [Google Scholar]

- Fang, J.; Wang, C.; Wen, T. Design and optimization of a radial hybrid magnetic bearing with separate poles for magnetically suspended inertially stabilized platform. IEEE Trans. Mechatron. 2014, 50, 8101011. [Google Scholar]

- Chang, Y.T.; Luo, W.J.; Lin, X.; She, Z.N.; Shi, Y.H. Multiparty multiobjective optimization by MOEA/D. In Proceedings of the 2022 IEEE Congress on Evolutionary Computation (CEC), Padua, Italy, 18–23 July 2022. [Google Scholar]

- Gulec, M.; Yolacan, E.; Aydin, M. Design and control of an 8-slot radial flux magnetic bearing. In Proceedings of the 2014 Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Ischia, Italy, 18–20 June 2014. [Google Scholar]

- Zhu, X.Q.; Gao, Z.H.; Du, Y.M.; Cheng, S.X.; Fang, X. A decomposition-based multi-objective optimization approach considering multiple preferences with robust performance. Appl. Soft Comput. 2018, 73, 263–282. [Google Scholar] [CrossRef]

- Stumberger, G.; Dolinar, D.; Palmer, U. Optimization of radial active magnetic bearings using the finite element technique and the differential evolution algorithm. IEEE Trans. Magn. 2020, 36, 1009–1013. [Google Scholar]

- Borozan, S.; Giannelos, S.; Aunedi, M.; Strbac, G. Option Value of EV Smart Charging Concepts in Transmission Expansion Planning under Uncertainty. In Proceedings of the 21st Mediterranean Electrotechnical Conference (MELECON), Palermo, Italy, 14–16 June 2022. [Google Scholar]

| S | Spacing |

|---|---|

| 2 | 0.0090 |

| 3 | 0.0113 |

| 4 | 0.0130 |

| 5 | 0.0145 |

| 6 | 0.0156 |

| 7 | 0.0167 |

| 8 | 0.0177 |

| Load Capacity Range | Number of Selectable Solutions by MOEA/D | Number of Selectable Solutions by MOEA/D-Pref |

|---|---|---|

| 900 N–910 N | 1 | 5 |

| 900 N–920 N | 2 | 9 |

| 900 N–930 N | 4 | 12 |

| 900 N–940 N | 5 | 14 |

| 900 N–950 N | 6 | 16 |

| Load Capacity Range | Percentage Ratio of Computational Load of MOEA/D-Pref to that of MOEA/D |

|---|---|

| 900 N–910 N | 38% |

| 900 N–920 N | 42% |

| 900 N–930 N | 64% |

| 900 N–940 N | 69% |

| 900 N–950 N | 72% |

| Parameter | Value |

|---|---|

| Rotor inner diameter/mm | 65.2 |

| Rotor outer diameter/mm | 91.2 |

| Stator inner diameter/mm | 92 |

| Stator outer diameter/mm | 160.2 |

| Axial length/mm | 60 |

| Main pole width/mm | 26 |

| Angle between centerlines of main and secondary poles/deg | 33 |

| Bias current/A | 3 |

| Maximum control current/mm | 3 |

| Maximum current density/A/mm2 | 3.5 |

| Number of turns of coil on main pole | 53 |

| Number of turns of coil on secondary pole | 43 |

| Load capacity/N | 927 |

| Volume/mm3 | 817620 mm3 |

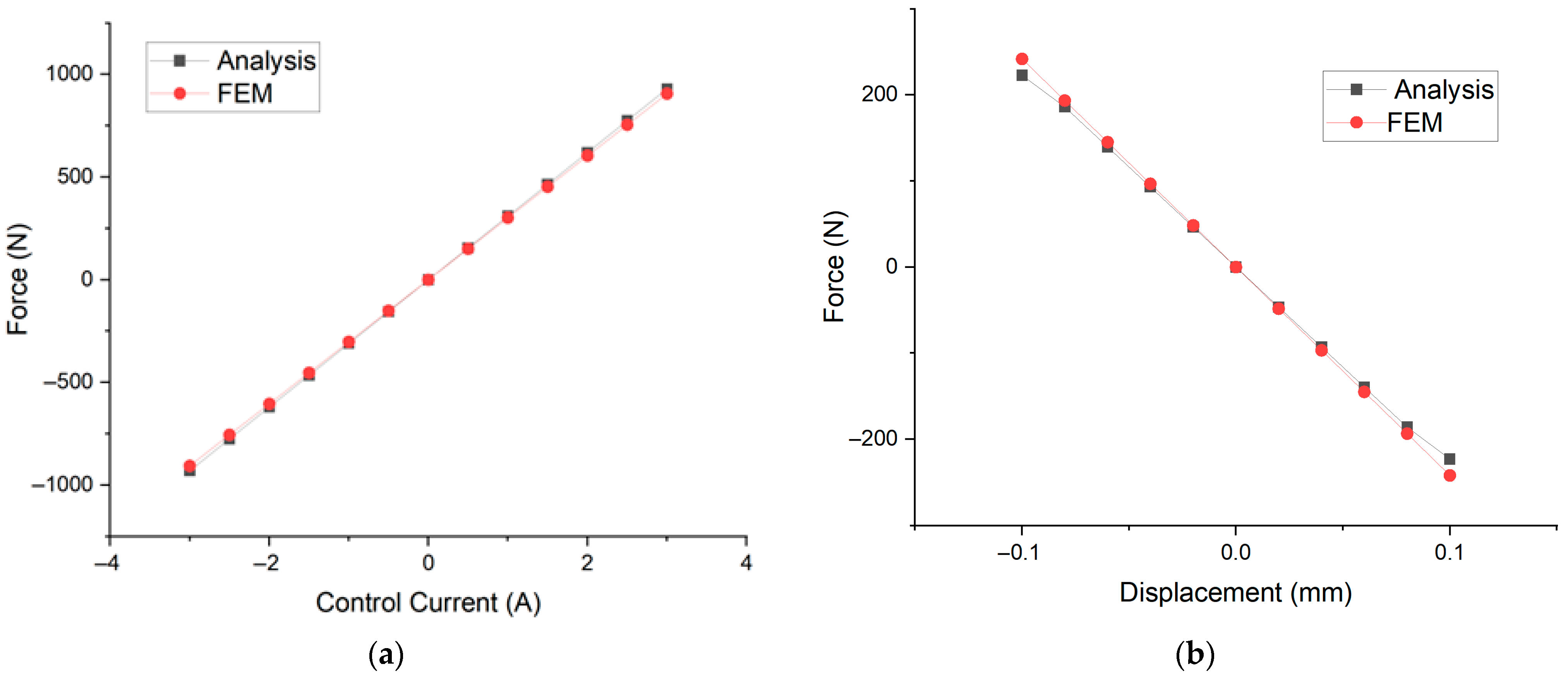

| Current stiffness coefficient/N/A | 309 N/A |

| Displacement stiffness coefficient/N/mm | −2317 N/mm |

| 1 | 2 | 3 | 4 | 5 | |

|---|---|---|---|---|---|

| B (T) | 0.4543 | 0.4461 | 0.4465 | 0.4532 | 0.4481 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wang, X.; Shen, H. Multi-Objective Optimization of 12-Pole Radial Active Magnetic Bearings with Preference-Based MOEA/D Algorithm. Energies 2025, 18, 4299. https://doi.org/10.3390/en18164299

Li X, Wang X, Shen H. Multi-Objective Optimization of 12-Pole Radial Active Magnetic Bearings with Preference-Based MOEA/D Algorithm. Energies. 2025; 18(16):4299. https://doi.org/10.3390/en18164299

Chicago/Turabian StyleLi, Xueqing, Xiaoyuan Wang, and Haoyu Shen. 2025. "Multi-Objective Optimization of 12-Pole Radial Active Magnetic Bearings with Preference-Based MOEA/D Algorithm" Energies 18, no. 16: 4299. https://doi.org/10.3390/en18164299

APA StyleLi, X., Wang, X., & Shen, H. (2025). Multi-Objective Optimization of 12-Pole Radial Active Magnetic Bearings with Preference-Based MOEA/D Algorithm. Energies, 18(16), 4299. https://doi.org/10.3390/en18164299