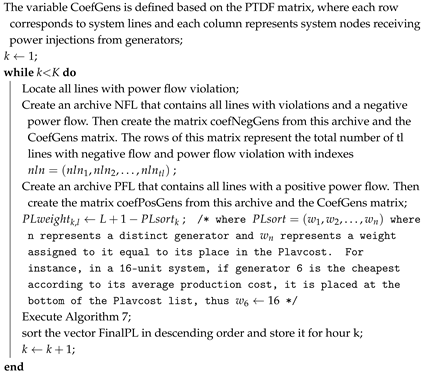

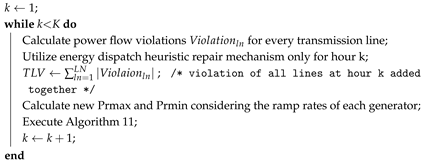

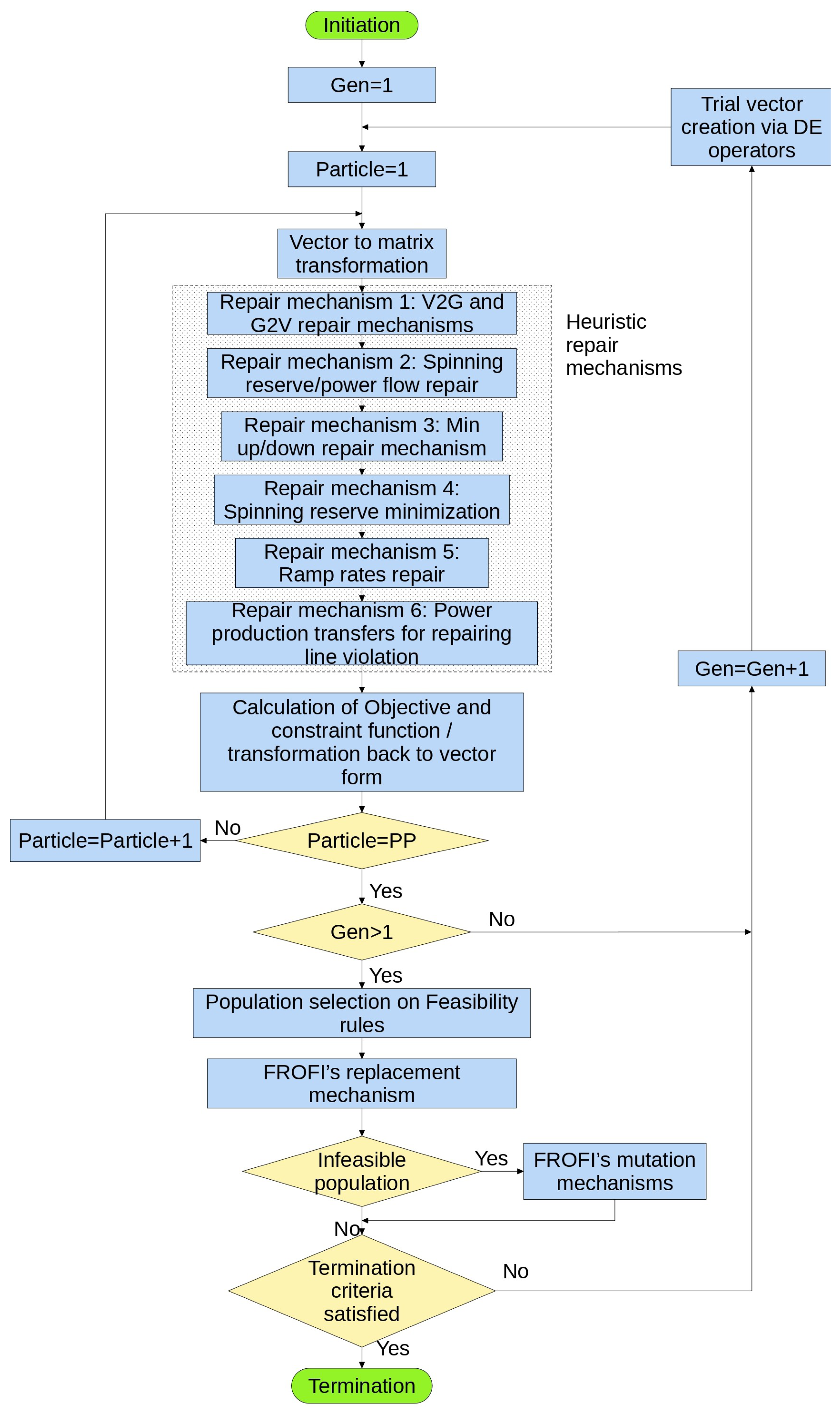

This work aims to introduce a novel method for solving the Transmission-Constrained Unit Commitment Problem (TCUCP) and investigates the integration of electric vehicles (EVs) as both flexible loads and power sources. Specifically, it examines EVs in the Grid-to-Vehicle (G2V) operation, where they function as adjustable loads, and the Vehicle-to-Grid (V2G) operation, where they inject power back into the electric grid. The problem is solved via a Differential Evolution (DE) variant that belongs to the family of evolutionary inspired algorithms.

1.1. Literature Review

The growing adoption of EVs in national fleets due to their significant advantages has raised legitimate concerns about the impact of uncoordinated charging on the power grid. The unscheduled charging of EVs can cause significant load peaks in daily electricity demand. This can lead to multiple consecutive or heightened existing peaks [

1], resulting in increased electricity production costs. Other concerns include voltage dips, fluctuations, phase imbalances, and higher total harmonic distortion (THD). Such loads can also shorten the lifespan of power grid components like transformers and transmission lines, mainly due to excessive power loading from simultaneous EV charging at maximum capacity.

Several strategies have been proposed to mitigate the aforementioned problems while taking advantage of the existence of the EVs connected to the grid. All these strategies have in common the load management of the EVs. According to [

2] the load management of EVs can be categorized as decentralized coordination and centralized coordination. Under centralized coordination, the following operations can be present: (1) the G2V operation, where EV load is handled as a flexible load under Demand-Side Management controls, and (2) the V2G operation, which involves EVs supplying electric power to the power grid. The coordinated charging strategy takes advantage of the flexibility of the EVs as a load in order to create a charging schedule that doesn’t hinder the smooth operation of the power grid. In addition, the stored energy of these EVs can be used for load management, power quality control, and power regulation [

3].

In decentralized coordination, EV owners control their charging schedules, while EV aggregators incentivize beneficial charging for an independent system operator (ISO) through demand response programs (DRP). These programs use price signalling, reduced or increased pricing and tariffs to encourage charging during off-peak hours or times advantageous to the power network [

4]. A DRP integrated with TCUCP reduces costs compared with uncoordinated charging [

5]. DRPs can be utilized to prevent transformer saturation [

6] and manage EVs to update daily demand curves [

7]. Several DRPs with EVs approaches have been proposed. A DRP approach, strictly for residential complexes that considers the profitability of the V2G operation by comparing electricity price and multiple discharge costs is proposed by [

8]. A decentralized approach using blockchain for secure smart charging is proposed in [

9]. Furthermore Vehicle-to-Vehicle (V2V) operation can be fund under decentralized charging approaches such as in [

10] where EVs coordinate with each other to facilitate V2G and V2V operation without relying on a centralized control system. In [

11] a DRP is combined with frequency control in a system with high wind penetration. A decentralized approach to handling small EV fleets at the distribution network level via a DRP is proposed in [

12]. Another price signal approach is proposed by [

13] for type 3 charging (fast charging) in the day-ahead market. A DRP approach considering environmental constraints is suggested in [

14]. The literature proves that the DRP is a very flexible management tool, however it might not operate as planed due to the customers risk aversion [

15] leading to the need for direct load control and load shedding. In this section of the literature review, additional optimization approaches can be considered, such as energy management systems for individual vehicles. The presence of such vehicles in future fleets, especially those using hydrogen fuel cells, can help reduce the stress on the power grid by reducing the number of plug-in electric vehicles. Smart energy management systems that integrate both batteries and hydrogen fuel cells will be essential for improving driving efficiency. In [

16], a real-time energy management system for fuel cell vehicles is proposed, combining GPS data with information from the vehicle’s DC bus system to regulate hydrogen consumption. In [

17], an energy management system is enhanced by a reinforcement learning algorithm that leverages trip history data to predict hydrogen consumption needs, aiming to optimize both travel efficiency and cabin environment control. In decentralized coordination charger deployment problems such as [

18] can be integrated into energy management problems.

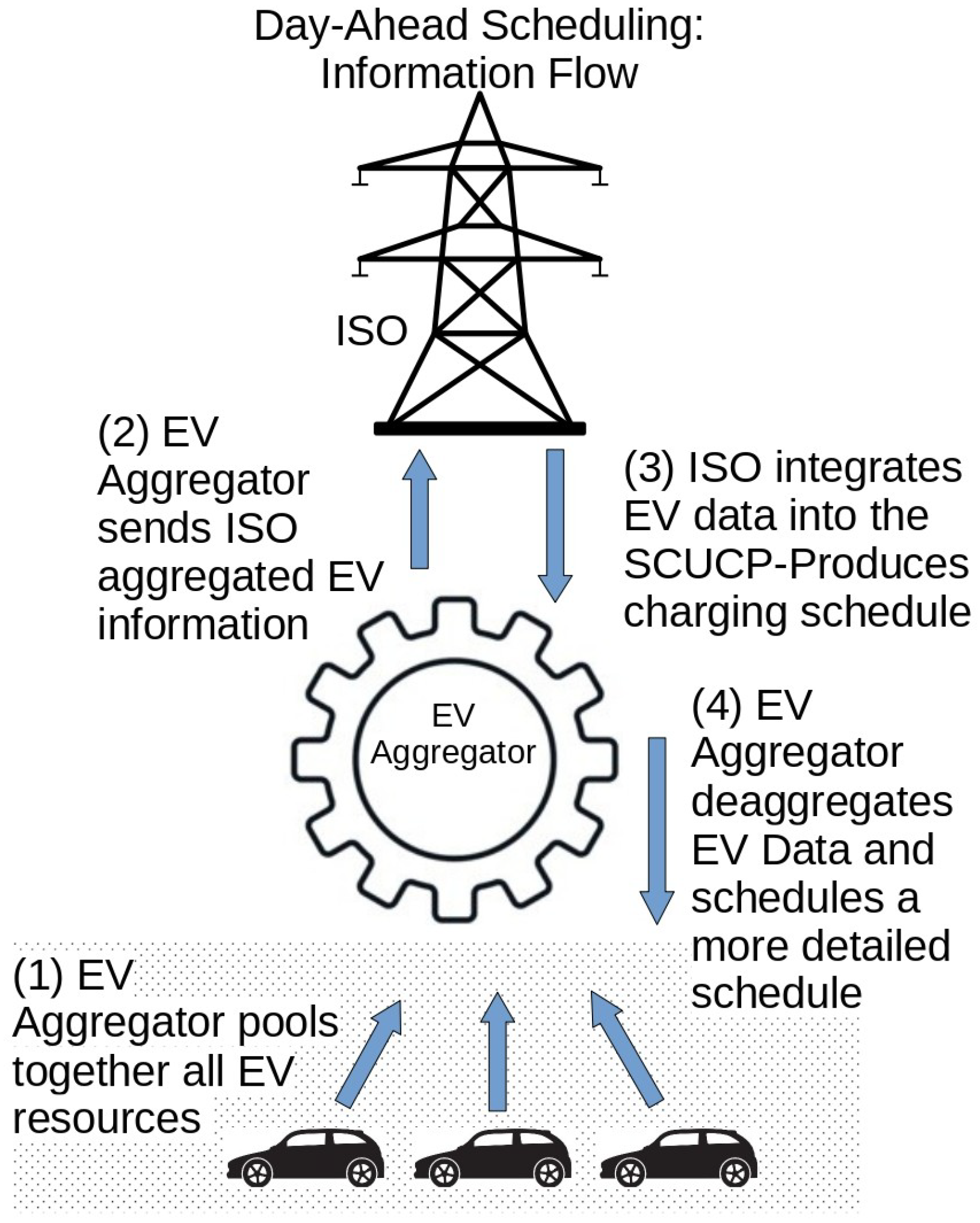

In centralized coordination, accountability for the EV charging lies mainly on the ISO, which, in cooperation with the EV aggregator, organizes the charging of the EV fleet attached to the system. The EV aggregator consolidates EV information, such as identification parameters, battery state of charge (SoC), customer priority profiles, and travel patterns. The EV data are processed for the creation of an effective charging schedule. The centralized coordinated charging schedule management may be a product of optimization from both the DSO and the aggregators, as depicted in

Figure 1.

The centralized coordination problem may see a plethora of variations. For instance in [

19], two different formulations of solving the centralized coordination problem are proposed. The first approach focuses on maximizing economic benefits by minimizing battery degradation and charging costs, while the second aims to reduce peak load and flatten the load curve by minimizing load deviations. Minimization of load deviation is also performed by [

20] who also regulates EV charging power to stabilize voltage levels. In [

21], three types of optimization are considered: (a) minimizing transmission line power loss and load variance, (b) minimizing charging cost for the EV owner, (c) maximizing aggregator profits. In [

22], one of the EV charging criteria is customer satisfaction. Multi-objective optimization is employed by [

23] to achieve economic benefits for charging station owners and EV users, as well as technological advantages for the power grid. Another criterion of centralized coordination is minimization of PV curtailment, as proposed by [

24]. A distinct multi-objective algorithm is proposed by [

25] to optimize electric vehicle (EV) load and enhance the voltage profile of the test system within an optimal power flow (OPF) optimization framework. Finally, the integration of EV charging scheduling into the UCP has been proposed as a means to facilitate the EV load management [

26]. We refer to [

27] for a part of the centralized coordination. This enables the establishment of realistic usage expectations and enhances the integration of the EV’s battery capacity across various energy markets, including day-ahead and regulation markets.

Table 1 summarizes the main contributions of previous studies on centralized and decentralized charging coordination.

The TCUCP is a complex, nonlinear optimization problem solvable by deterministic or stochastic algorithms. Integrating EVs as flexible loads, especially in V2G mode, adds nonlinearities via battery degradation formulations, heightening optimization complexity, necessitating the use of more advanced and suitable computational tools such as stochastic algorithms.

Optimization algorithms can be categorized into deterministic and stochastic algorithms. The deterministic optimization algorithms utilize linear algebra and gradient methods in order to reach optimum solutions in an efficient manner. Stochastic algorithms or meta-heuristic algorithms utilize randomness in order to reach global near optimal solutions while managing to escape local optimal points by adopting nature inspired strategies.

Numerous deterministic algorithms have been employed in the literature to solve the UCP incorporating EVs, often utilizing various linearization techniques. Madzharov et al. [

26] propose a MILP formulation that integrates EV charging into the UCP through load aggregation. However, the model excludes transmission constraints and V2G capabilities. The formulation focuses on optimizing valley-filling to achieve cost-efficient generation, without considering EVs as a potential energy source.

In [

28], an MILP formulation is presented that engages in V2G operation, optimizing a 48 h UCP for greater flexibility than traditional 24 h schedules. This extended period better utilizes EV capacity to meet demand. However, EVs are evenly distributed across buses, preventing vehicle movement between them. Another deterministic formulation is proposed in [

29], where a two-stage optimization approach was employed using Benders decomposition. In this formulation, EVs are modeled as a distributed battery storage system, where each network node represents a location at which stored energy can be injected into the power grid. Ref. [

30] employs a second-order cone programming algorithm for TCUCP in distribution networks (DN), integrating natural gas, district heating, and EV constraints.

Stochastic algorithms have been employed in prior literature to address the TCUCP and the UCP incorporating EVs. In [

31,

32], a binary symmetric Particle Swarm Optimization (PSO) combined with a self-adaptive Differential Evolution algorithm is proposed to solve the UCP involving EVs. The two meta-heuristic algorithms were paired to determine the commitment schedule of the generators and their respective power generation, as well as the EV charging/discharging schedule. In their work, three constraint-handling mechanisms were used as suggested by [

33]. DE has been utilized in [

34] in order to reach near-optimal solutions to the optimal power flow problem, proving the versatility of the method. In [

19], a Genetic Algorithm (GA) was utilized to minimize the charging cost of EVs aimed at charging cost reduction and battery degradation. A bat algorithm was used in [

35] to solve the TCUCP with EVs while considering emission constraints in order to absorb considerable discharging energy from the EVs. A multi-objective optimization based on a Grey wolf algorithm that maximizes profits for the EV aggregator while minimizing the operating costs of the system by integrating the EV charging and discharging within the OPF is suggested in [

36]. Meta-heuristic algorithms have proven highly effective in solving a wide range of optimization problems, particularly in energy applications [

37].

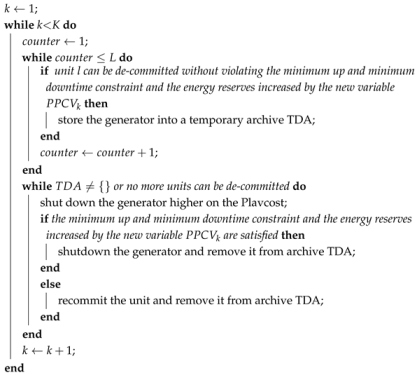

Recent research has focused on improving meta-heuristic solvers for the UCP using specialized constraint handling algorithms (heuristic repair mechanisms) that led to improvements such as decreased convergence speed, reduced standard deviation, smaller convergence rates, and improved solutions. These gains are achieved by incorporating logical analyses of the real-world problem, which effectively create a filtering mechanism that guides the particles or agents of the meta-heuristic algorithm toward near-optimal global solutions. However, these methods have been successfully applied only to the UCP.

A prominent example of the application of heuristic methods is presented in [

33], where a quantum binary Particle Swarm Optimization (PSO) algorithm is employed to solve the UCP. This approach has been adapted and extended in several subsequent studies. Three heuristic mechanisms were employed: the first addresses the minimum up and downtime constraints; the second ensures compliance with spinning reserve requirements by maintaining a sufficient number of generators in operation; and the third de-commits generator units to minimize the number of active generators, thereby reducing operational costs. These mechanisms were also integrated in the work of [

27,

38] who also introduced new mechanisms that repair the energy dispatch problem and the transmission line power flow violation. In [

39] a hybrid optimization algorithm is employed that utilized a GA algorithm to solve the UCP using a priority list to initiate generators. Ref. [

40] proposed a unit de-commitment and re-commitment module that is utilized in order to reduce voltage violation in a node. The module operates by manipulating the state of the generators, beginning from the closest ones to the furthest, until a result with no violation is obtained. A Lagrangian relaxation algorithm was proposed in [

41] that utilized a spinning reserve handling technique to solve the UCP. Ref. [

42] solves the UCP by including the reserve reduction heuristic repair mechanism in order to reduce the standard deviation of the solutions. On the operation of heuristic repair mechanisms rely other works such as [

43], where the UCP with renewable energy production is solved via a PSO algorithm. In their work, the following three repair mechanisms are utilized: the Spinning reserve constraints repair mechanism, the minimum up/downtime repair mechanism, and the de-commitment of excess units repair mechanism. The same mechanisms are used in [

44] where a priority list is integrated in the same mechanisms. A relevance matrix-inspired heuristic is introduced in [

45] that increases the operational speed of their algorithm. Finally, a profit-based UCP is solved in [

46] with the aid of the unit de-commitment repair mechanism and the ramp rate repair mechanism.

1.2. Motivation

As highlighted in the literature, most studies employing heuristic mechanisms primarily address the UCP. This focus arises from the fact that many widely used heuristics are effective at guiding solutions toward global optima in the UCP. However, when these heuristics are applied to the TCUCP, they often lead to solutions with transmission constraint violations, hindering convergence and compromising solution feasibility.

One commonly used heuristic involves the commitment of generators based on a priority list to ensure sufficient power reserve. While effective in the UCP, this approach can be problematic in the TCUCP. Specifically, when a generator essential for balancing the power network is ranked low on the priority list, it may not be committed, resulting in unaddressed transmission constraints. Consequently, the reliance on static priority-based commitment can impede the ability of the algorithm to maintain grid reliability under transmission constraints.

Another widely used heuristic is the enforcement of minimum up and minimum downtime constraints. Although this mechanism does not directly exacerbate power flow violations, it can hinder the optimization algorithm’s ability to find feasible schedules in the TCUCP. In particular, the inability to deactivate a generator at a specific hour, due to its minimum up time requirement, may prevent the mitigation of line overloads, thereby obstructing convergence to a feasible solution that satisfies both unit and transmission constraints.

A third popular heuristic is the de-commitment of generators to reduce excess reserve capacity. This approach is often employed to accelerate convergence in meta-heuristic algorithms by minimizing the number of active units. Typically, generators with lower capacity, often placed at the end of the priority list, are deactivated. While this strategy is effective in reducing operational costs and is frequently used to obtain cost-optimal schedules in the UCP, it poses significant challenges for the TCUCP. These smaller units often play a crucial role in reducing transmission violations. Their removal can destabilize power flow across the network, leading to severe violations of transmission constraints and undermining the performance of the optimization algorithm.

In many research studies, electric vehicles (EVs) are modeled as static loads or sources connected to fixed buses within the power network, without accounting for their mobility between different locations. This simplification is common across the referenced literature, including [

5], where aggregated EV fleets are represented as virtual power plants centralized at a single node. Such approaches overlook the dynamic nature of EVs and their potential to impact multiple nodes within the network as they travel. However, only a limited number of works explore the possibility that EVs can move and connect to different buses over a 24 h period, thereby influencing multiple buses as they travel throughout the day. Additionally, while much of the literature posits that V2G operations can consistently reduce the system’s start-up, commitment, and unit commitment scheduling costs, some studies argue that EVs are less competitive compared with large-scale generators, especially when the system operator is required to replenish the energy utilized during V2G operations within the same 24 h period. This highlights the need for a tool that can optimize TCUCP while integrating EVs with V2G capabilities, accounting for complex nonlinearities such as battery degradation costs.

1.3. Contribution

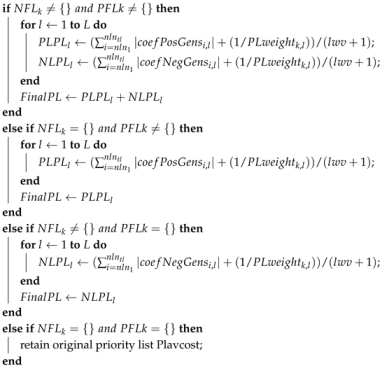

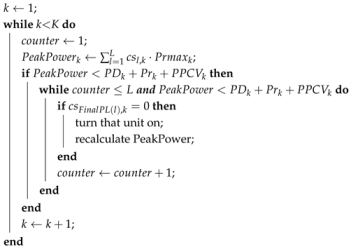

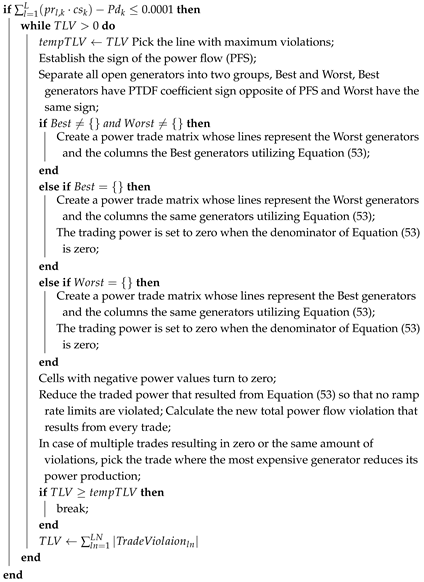

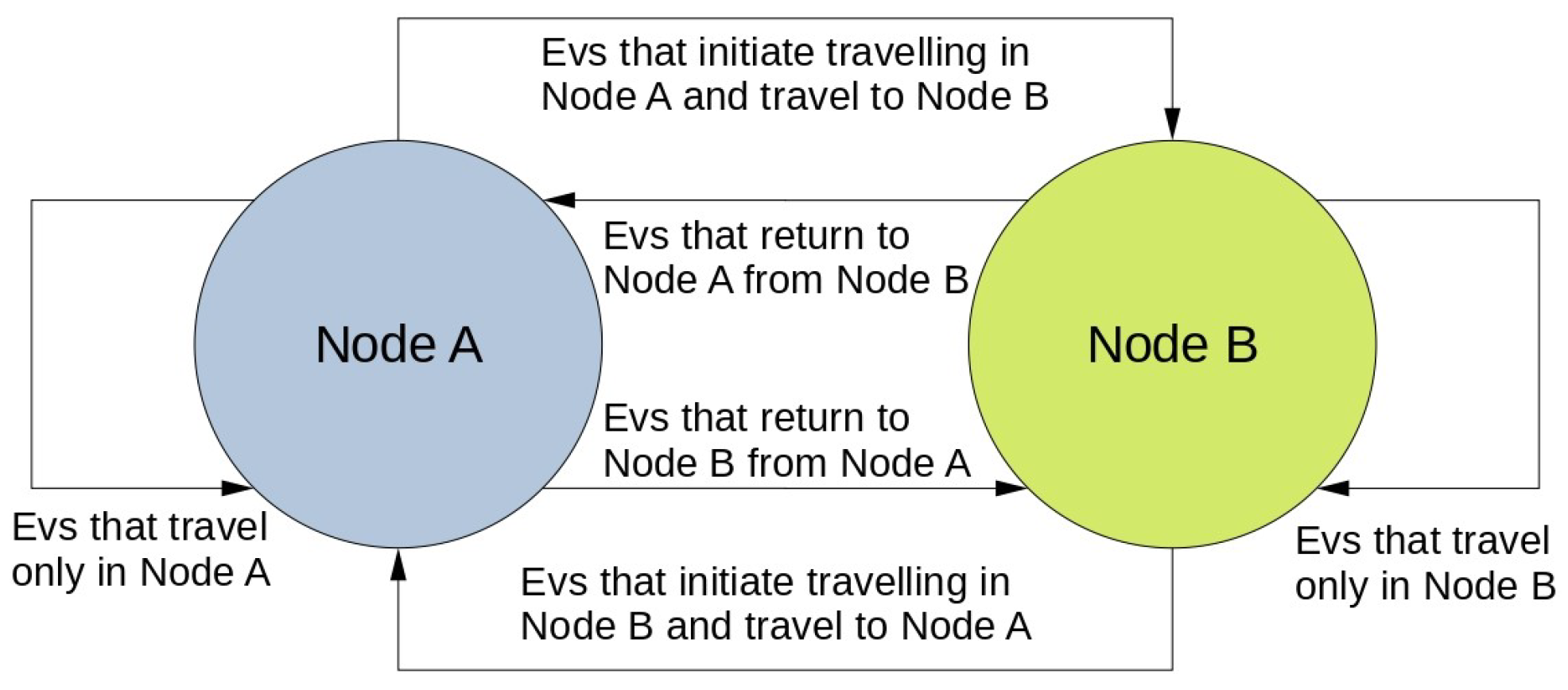

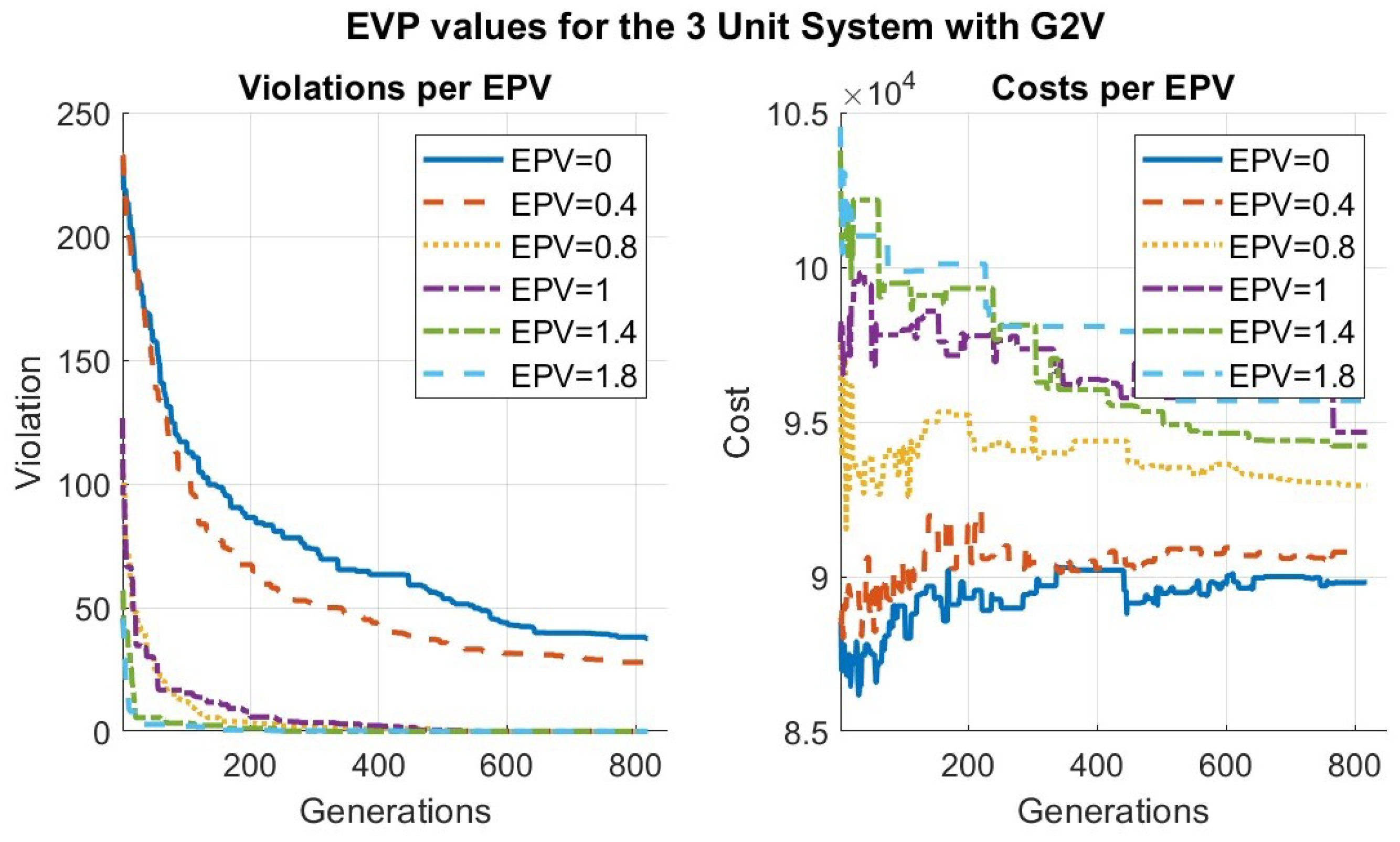

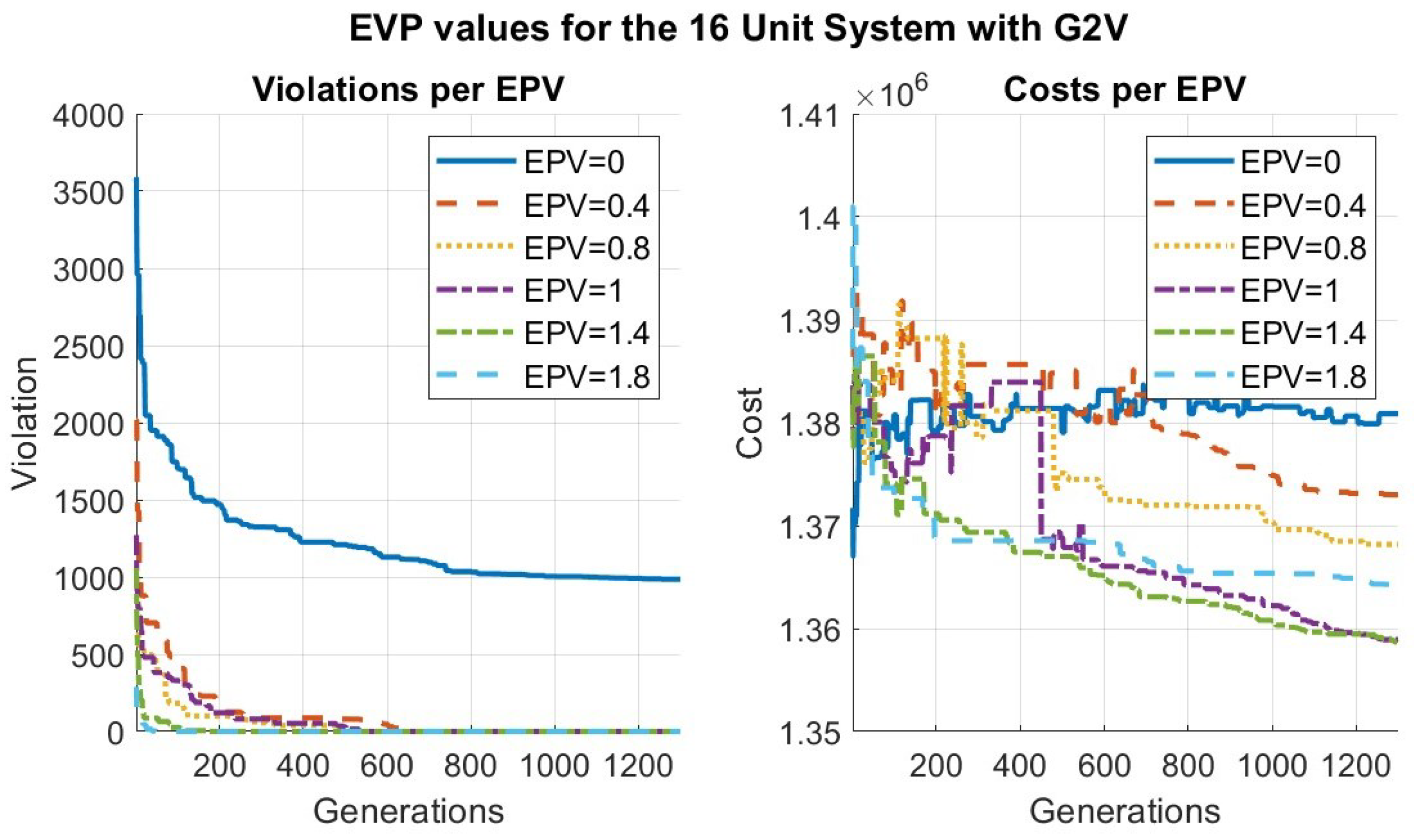

This work presents a novel formulation of integrating electric vehicles in the TCUCP, representing the coordinated charging and discharging of a large EV fleet. The fleet of EVs belongs to a large urban environment where the EVs travel within the day. The formulation accounts for the daily movement of EVs within two nodes (buses) that supply the city with power, allowing charging or discharging whenever vehicles are available. This is a complex problem solved via a variant of Differential Evolution. The algorithm is enhanced by a series of heuristic repair mechanisms that lead the solution to the feasible region by following problem-specific rules. Each repair mechanism handles a discrete set of constraints of the problem, repairing the variables of the problem so that both the constraint violation and the operational cost are reduced. This work incorporates several heuristic mechanisms previously used in the literature for the simpler UCP, adapted and updated here to accommodate transmission constraints. In addition to those heuristics that include the ramp-rate repair mechanism, the minimum up and downtime repair mechanism, the energy dispatch repair mechanism, and the minimization of reserve repair mechanism, three novel mechanisms are introduced. Two of them are assigned to the transmission power flow constraints, and a third one that handles the charging and discharging of EVs.

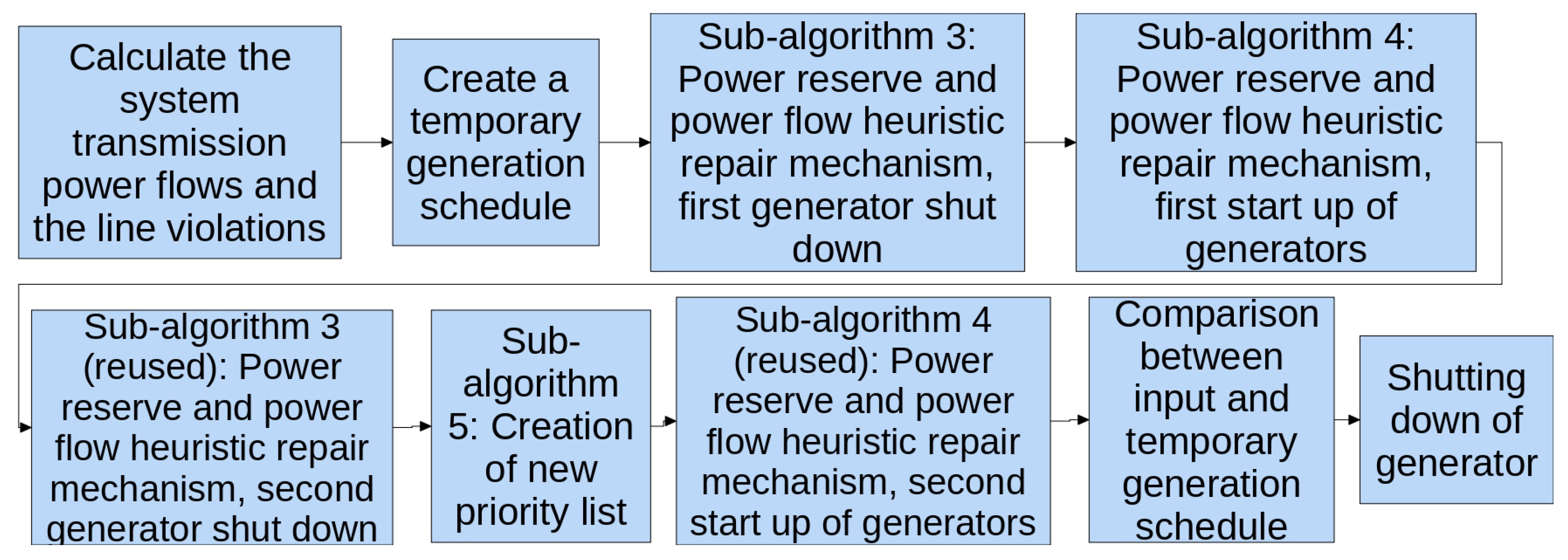

The transmission constraints are handled by two heuristic repair mechanisms. These heuristics utilize information from the PTDF matrix to identify the nodes (buses) that have the greatest impact on the overloaded transmission lines. By appropriately adjusting load and generation at these key nodes, either increasing or decreasing them, the power flow violations can be effectively mitigated. The approach is further enhanced with the use of priority lists, which guide the search toward feasible solutions more efficiently, despite the NP-hard nature of the problem. Although many meta-heuristic algorithms over the years have incorporated priority lists, none have successfully solved the Unit Commitment Problem (UCP) while accounting for transmission constraints.

The first transmission repair algorithm builds upon the average production priority list proposed in [

38], which has been updated and expanded to incorporate power grid data using Power Transfer Distribution Factors (PTDFs). This enhancement enables the algorithm to systematically commit generators to resolve violations on transmission lines where power flow exceeds specified limits. The priority list determines the most cost-effective generator commitments until both energy reserve and dispatch constraints are met. Power Transfer Distribution Factors dictate the power flow within the transmission system. Each line’s power flow is determined by the PTDF values associated with each node (bus). By adjusting the demand or production at each node, the algorithm alters power flows across transmission lines. The second mechanism serves as a constraint handling mechanism, adjusting the production of committed generators based on PTDF information to minimize transmission violations without undoing previous repair efforts. A third proposed mechanism focuses on managing EV charging. By incorporating PTDFs, this mechanism adjusts EV loads at each node to mitigate transmission line violations effectively.

In addition to these contributions, the unit de-commitment constraint handling technique, aimed at minimizing reserve capacity, is enhanced by introducing a new variable into the optimization model. This variable defines the maximum acceptable level of reserve in the final solution, allowing the DE mechanisms to set the total number of operational generators in the system. Furthermore, all repair mechanisms, mainly the constraint handling techniques of minimum up to minimum downtime, unit de-commitment and energy dispatch constraints, are suggested mainly in [

33,

38] and numerous other literature works, which are utilized in this work, are appropriately modified and expanded so as to retain their original purpose and not hinder the optimization process that engages with power grid constraints.

The proposed optimization method solves all sub-problems of the TCUCP and EVs in a single DE convergence. The proposed method, despite aiming to optimize the operation of electrical generators, can be utilized for any available production method, including renewable energy sources. Thus, the primary objective of this work is to develop an effective heuristic mechanism that integrates power grid information to support an evolutionary-inspired algorithm in solving complex optimization problems, specifically the TCUCP. The proposed method for solving the TCUCP with EVs is evaluated utilizing a small, intermediate, and large test system, demonstrating the robustness of the proposed meta-heuristic algorithm.

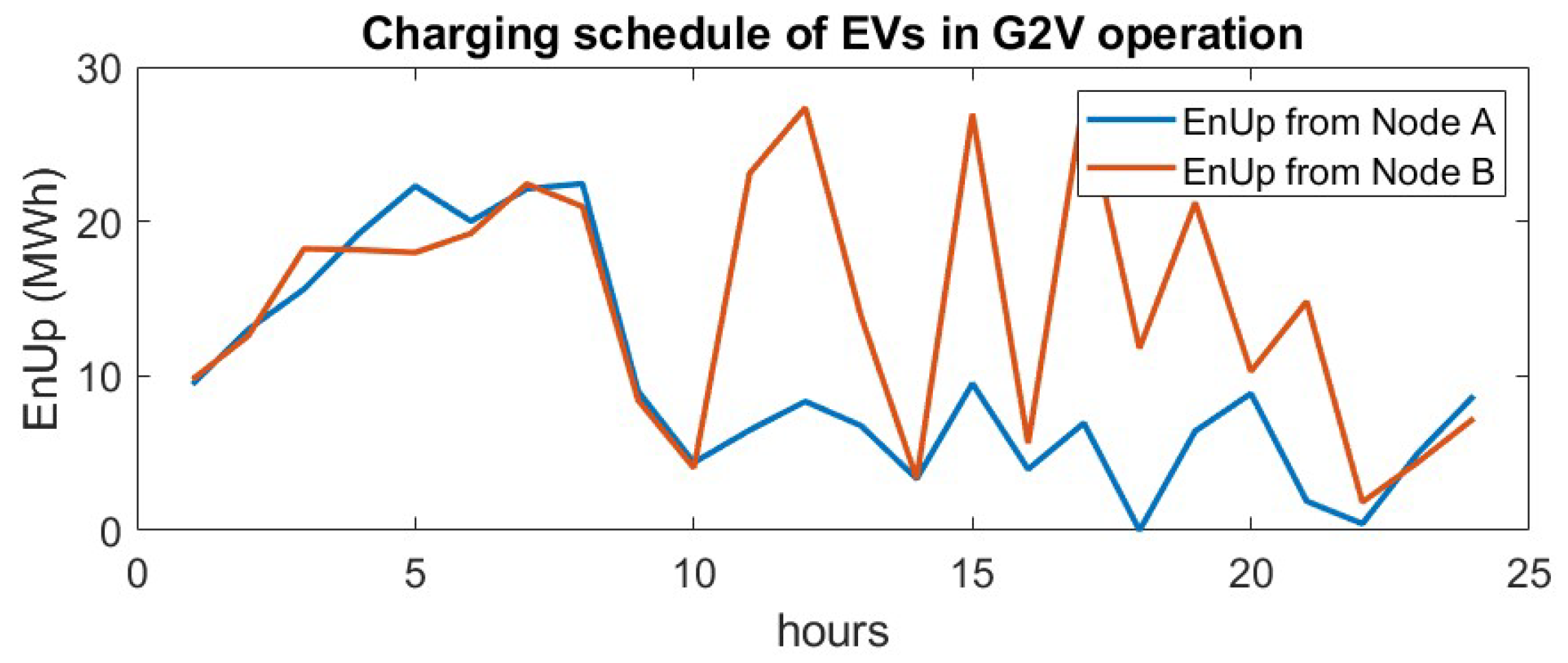

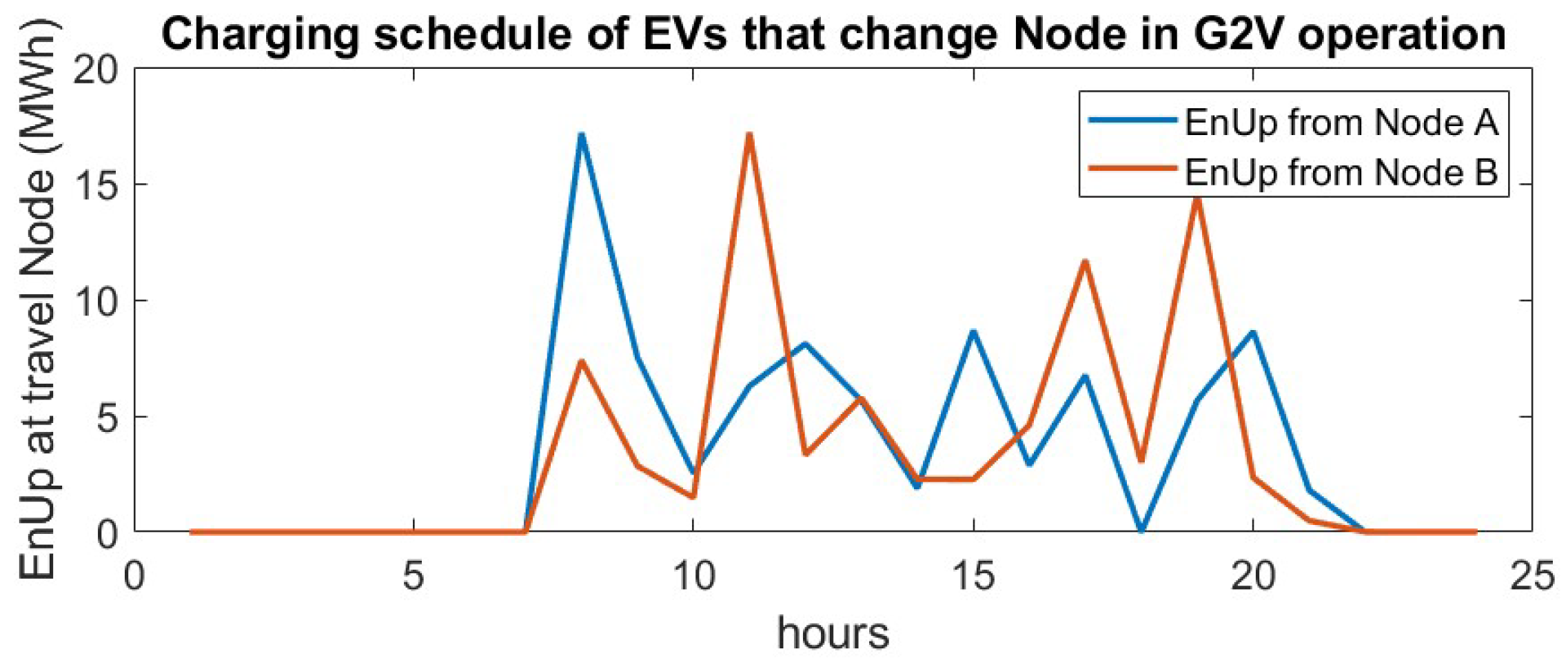

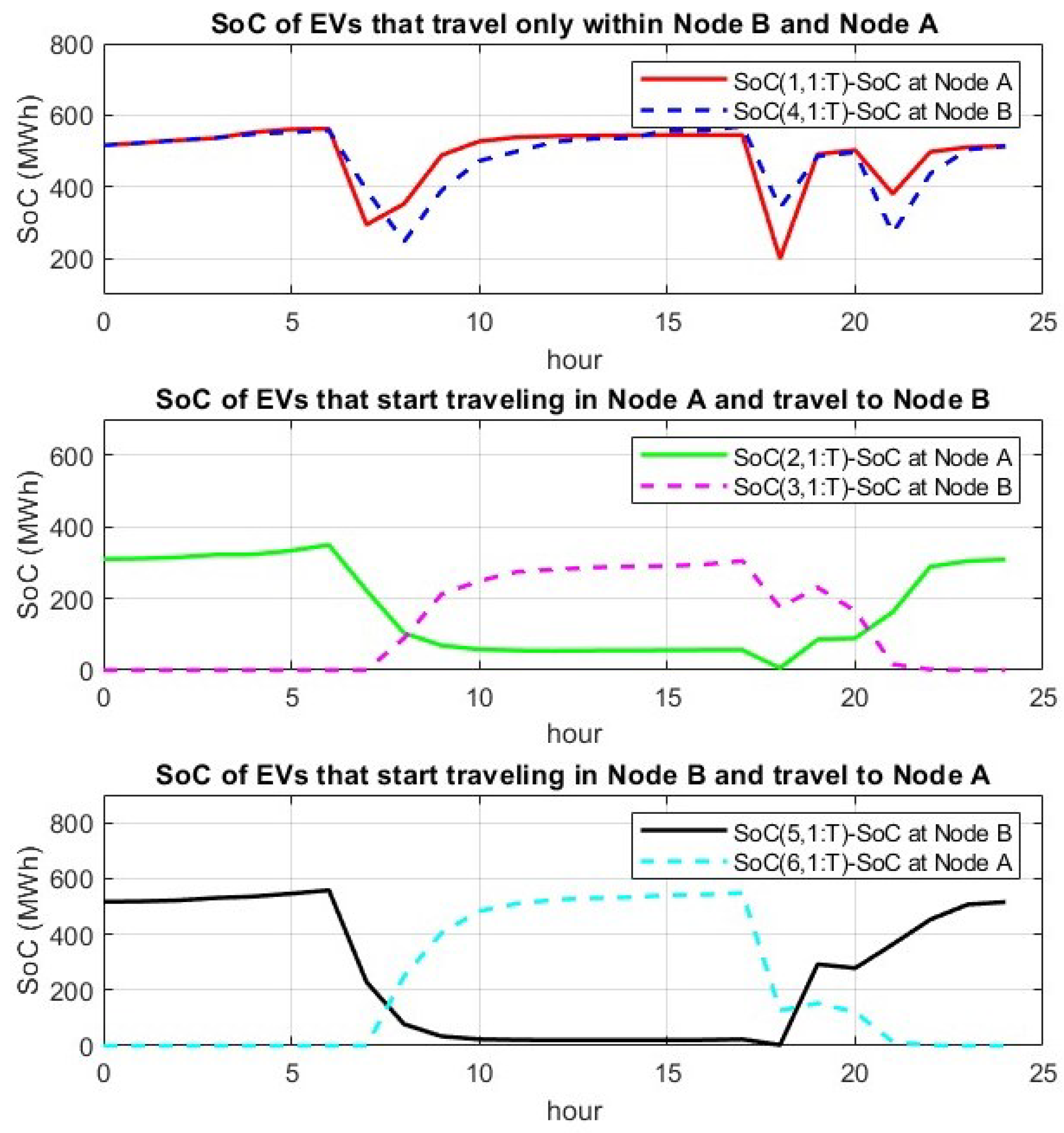

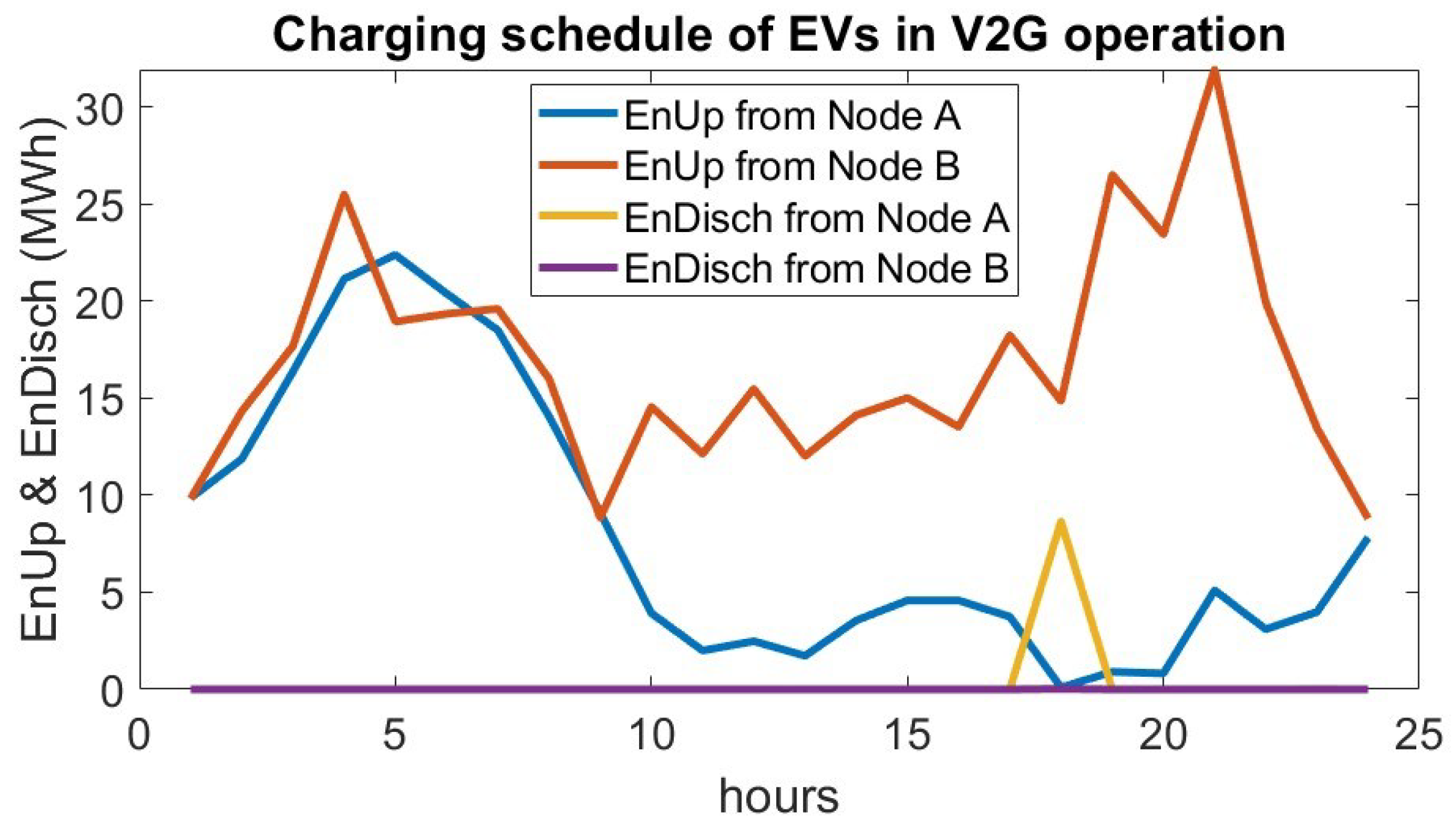

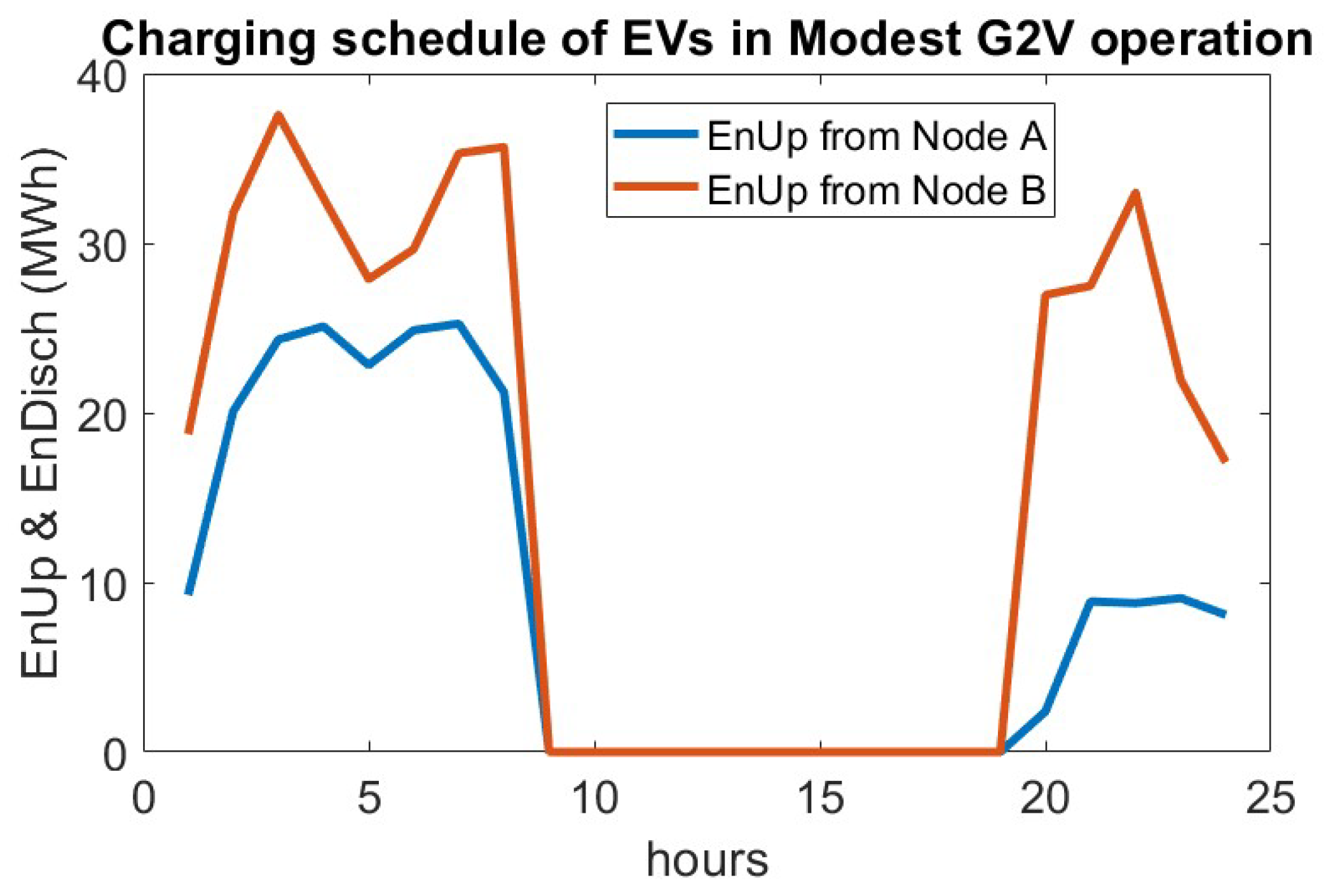

The EV formulation models a large urban area with two power nodes, allowing EVs to alternate their charging locations between the nodes over the course of the day. The charging of the EVs is coordinated and heavily constrained. This ensures that no negative effects such as power flow violations and peak loads affect the power grid and the energy production. To reduce the potential strain on the power network, each EV is restricted to a maximum charging rate of 3 kWh, which is considered as Level 1 charging [

47]. Given the large number of vehicles, the charging process is managed in groups rather than individually, with the SoC of each group representing the average SoC of all vehicles within that group. It is further assumed that the SoC within each group is homogeneous. When a group of aggregated vehicles is combined with another group, it is assumed that the vehicles mix, and the new group’s SoC represents the average SoC of the combined vehicles. This approach allows for an estimation of vehicle movement throughout the day, which is essential because vehicles may change charging nodes as their schedule progresses. Previous studies have either considered EVs as part of the day-ahead demand without accounting for power network constraints or have modeled the entire fleet as charging at a single node. Additionally, some studies have assumed fixed EV populations at each node. In contrast, this work presents a formulation that accounts for spatial variability in the load.

The UCP primarily addresses the scheduling and operational cost of various network elements that impact the overall system cost in day-ahead planning and market operation. For this reason, the UCP typically uses a time resolution of one hour, aligning with the hourly scheduling intervals of the day-ahead market. One of the elements of the system can be considered to be EVs and their load, which could be optimized. In general, EVs are connected to the distribution system. However, in this work, all EVs and distribution system loads are aggregated into the system’s Nodes (buses) without causing significant differences in the total analysis.

The power production system interacts with EVs through two operations: G2V, where EVs are treated as flexible loads, and V2G, where EVs serve as power sources. The V2G operation accounts for battery degradation costs, a critical factor in many EV charging optimization models, as demonstrated by [

48]. This consideration introduces significant nonlinearity into the optimization system.