1. Introduction

The distribution of energy resources in China shows a significant regional imbalance, with the western region having abundant energy but limited demand, while the eastern region has huge energy demand but relatively scarce resources. The use of a high-voltage direct current (HVDC) system, with its high efficiency and low loss transmission characteristics, has successfully transported the abundant energy in the west to the areas with strong demand in the east at a large scale, effectively alleviating the mismatch between energy distribution and demand. Now, China has established a “system of UHV transmission projects straights”, which not only greatly facilitates the widespread consumption of clean energy, but also strongly guarantees China’s energy security for crosses 19 and 20.

However, with the expansion of power system construction, the environment in which transmission lines are located is becoming more complex and diversified, and transmission lines are facing the notable contamination challenge of pollution (e.g., industrial dust, bird droppings, algae) [

1]. In addition, currently, extreme climate events are intensifying globally, and ultra-rapid wetting of the pollution layer, caused by complex meteorological conditions such as large temperature differences, heavy rainfall, and short-term dense fog, frequently occurs. In mountainous areas with high humidity and micrometeorological environments, transmission lines are facing new challenges. Algae attached to the surface of a large number of insulators are becoming a new source of external insulation contamination. Field tests conducted using ultraviolet corona imaging on three towers of the ±800 kV Qishaoo HVDC transmission line demonstrated that compared to insulator strings with mild algae contamination exhibiting a discharge frequency of 1.3 times/min, heavily and severely contaminated insulator strings showed significantly increased discharge frequencies of 2.8 times/min and 4.5 times/min, respectively. Since the current insulation configurations in mountainous areas are generally designed according to the light contamination zone, these algae attachment phenomena pose a serious threat to the safe operation and maintenance of transmission lines. On the one hand, algae attachment accelerates pollution accumulation and increases its degree of attachment by enhancing hydrophilicity and surface roughness, coupled with water absorption and water retention of algae, resulting in partial discharges of insulators under low-ambient humidity conditions [

2,

3,

4,

5]. On the other hand, the current lack of countermeasures for algae management on the surface of transmission lines also leads to an increase in the number of outages for cleaning, while algae on the surface of insulators break easily under external forces, leading to an increased risk of accidents caused by hand-slip or foot-slip accidents by O&M personnel, which greatly affects the safety and efficiency of maintenance work [

6,

7,

8,

9,

10].

The process of pollution flashover is generally divided into four stages as follows: surface accumulation of pollution, surface wetting, local discharge, and local arc development until flashover [

11,

12]. Among these, wetting is a necessary condition for insulator flashover, and algae attached to the insulator surface greatly affect the insulator wetting characteristics, thus increasing the probability of pollution flashover accidents. In addition, according to the Obennaus pollution flashover model, whether the surface arc can continue to develop and eventually penetrate the leakage distance of the insulator (i.e., cause a complete flashover) depends on the energy balance during the arc development process; that is, whether the sum of the arc partial voltage drop and the residual pollution layer voltage drop is less than the total voltage, and the conductivity of the pollution layer is the key factor affecting this process [

11,

12,

13]. The surface conductivity of the insulator surface is, in turn, affected by the dissolution of soluble salts in the contamination layer [

14,

15]. Before the contaminated layer on the insulator surface reaches saturation wetting, the higher the degree of wetting of the contaminated layer, the lower the pollution flashover voltage of the insulator with the same level of contamination. However, when the insulator surface is saturated with wetting, the pollution flashover voltage of the insulator string does not increase significantly, and even decreases, due to the loss of the dissolved contaminated layer. Therefore, it is of great significance to study the contamination wetting characteristics of algae-covered insulators and the saturated water absorption of the contamination layer on the insulator surface after wetting, in order to reveal the influence of algae on the contamination layer wetting characteristics and the flashover characteristics of the insulator surface [

16,

17,

18,

19,

20,

21,

22].

To this end, this paper first proposes a method for measuring insulator surface water absorption based on surface conductivity, and then takes porcelain insulators for station lines in an Enshi 500 kV substation as the test material to study the influence of algae attachment on the saturated water absorption of insulators, as well as the influence on the loss of pollution soluble salts. The test results provide a reference for studying the flashover process of insulators in foggy environments, bridging the gap between biological contamination and electrical insulation failure, thus addressing an emerging issue driven by climate change and ecological shifts in grid environments [

23,

24].

2. Test Methods

This study aims to investigate the influence of green algae growth and adhesion on the surface wetting characteristics and soluble salt loss properties of porcelain insulators by measuring the following two key indicators: saturated water absorption and the residual rate of soluble salts in the contamination layer. The surface conditions of the porcelain insulators were categorized as clean or algae-covered, leading to four experimental series, measuring the following: (1) the effect of green algae adhesion on saturated water absorption under varying parameters, and (2) the influence of green algae adhesion on the loss characteristics of soluble salts.

The test samples were selected from the porcelain insulators used in the Enshi 500 kV substation. To eliminate interference from the inherent contamination components (both soluble and insoluble) in the algae contamination layer and algal cells, all samples underwent a decontamination pretreatment with deionized water. The specific procedure was as follows: first, the insulator surfaces were rinsed with deionized water at a rate of 5 mL/cm

2, and the rinsing solution was collected. Then, the algae-covered insulators were immersed in deionized water for 12 h and subsequently air-dried. Finally, the rinsing process was repeated, and the rinsing solution was collected again. The major elemental contents in the rinsing solution before and after treatment were analyzed via ICP spectroscopy (

Table 1). The results confirmed that the concentrations of major soluble salt cation elements (e.g., Na

+, K

+, Ca

2+, Mg

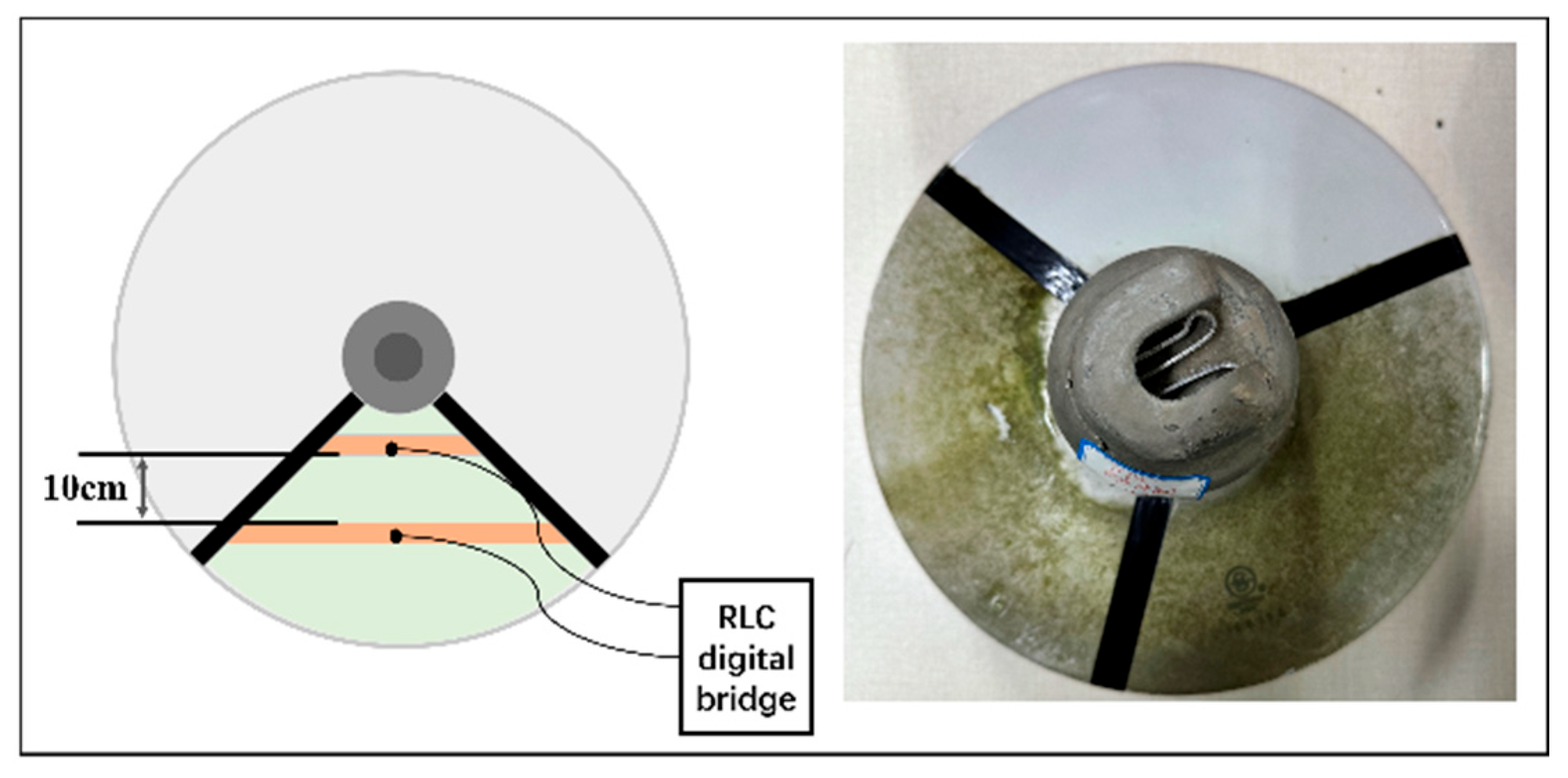

2+) were below 0.005 mg/L, indicating negligible contamination interference from the algae layer itself. The treated algae-covered samples were labeled as “algae-coated samples,” while the thoroughly cleaned insulators of the same model were labeled as “blank samples.” On both algae-coated and blank samples, approximately 120° fan-shaped test areas were demarcated using insulating tape, with copper-conductive tape applied radially at 10 cm intervals as electrodes (

Figure 1).

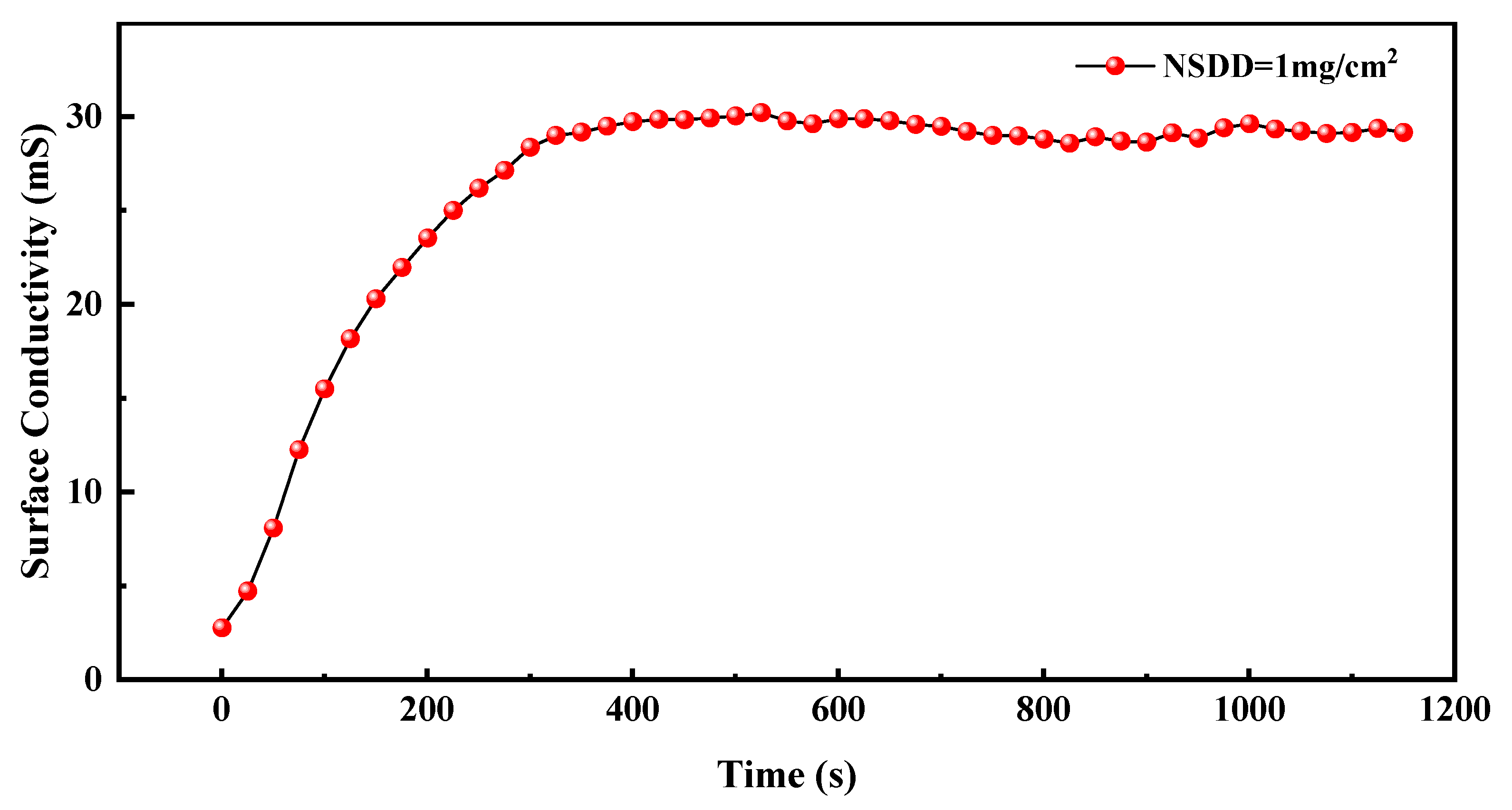

Because the saturated moisture after the contamination of the layer of water absorption by the insulator is very low, it is difficult to use the weighing method to directly measure the surface contaminated layer of water absorption. For this reason, this study proposes a method to measure the water absorption of the insulator surface based on surface conductivity.

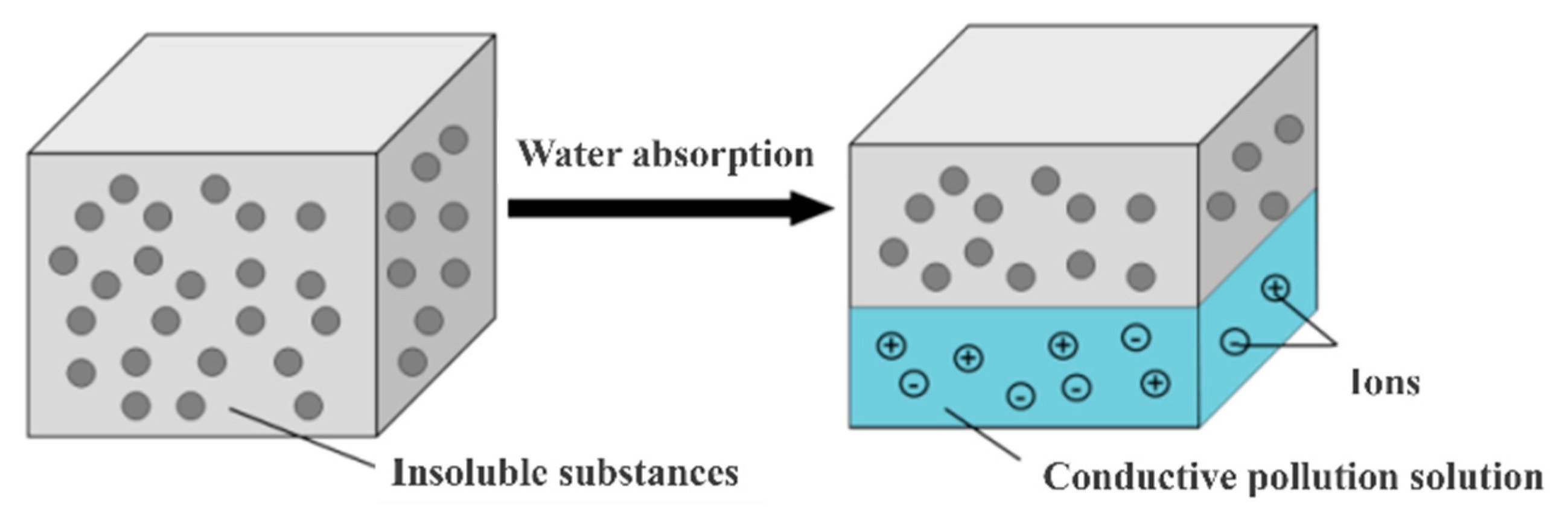

First, a NaCl solution with a specific conductivity is configured, and then, after the NaCl solution is converted into salt mist with the same conductivity using an ultrasonic atomizer, it is introduced into an artificial fog chamber to provide a wetting condition for the contamination layer. Then, an insulating specimen coated only with an insoluble substance (kaolin) is placed into the artificial fog chamber to be wetted. Tests conducted via the two-electrode method using an RLC bridge demonstrated that an increase in moisture exposure time caused the salt spray particles to adhere, and the conductivity of the contamination layer surface increased with the formation of a water film. A high-precision digital bridge was utilized to measure the change in surface conductivity during the wetting process. Since the volume conductivity of the contaminated layer solution is the same as that of the salt spray solution, the amount of water attached to the contaminated layer on the insulating surface can be calculated according to the relationship between the surface conductivity of the contaminated layer and its volume conductivity. A schematic diagram of the insulator contamination layer wetting process is shown in

Figure 2.

During the humidification process, the surface resistance of the contamination layer is measured and recorded using an RLC bridge.

where

R is the measured surface resistance and f is the shape factor of the insulator surface. As shown in Equation (2), the measured conductivity can be corrected for temperature.

where

K20 is the corrected surface conductivity below 20 °C;

Kt is the surface conductivity measured at a temperature of

t °C; and

kt denotes the temperature coefficient [

18]. The relationship between the surface conductivity and the salt spray conductivity is

where

K denotes the surface conductivity;

h denotes the thickness of the water film after wetting; and

σ denotes the conductivity of the salt spray. On the other hand, water absorption

mwater is calculated as

where

ρwater is water density and

S is the surface area (1 cm

2).

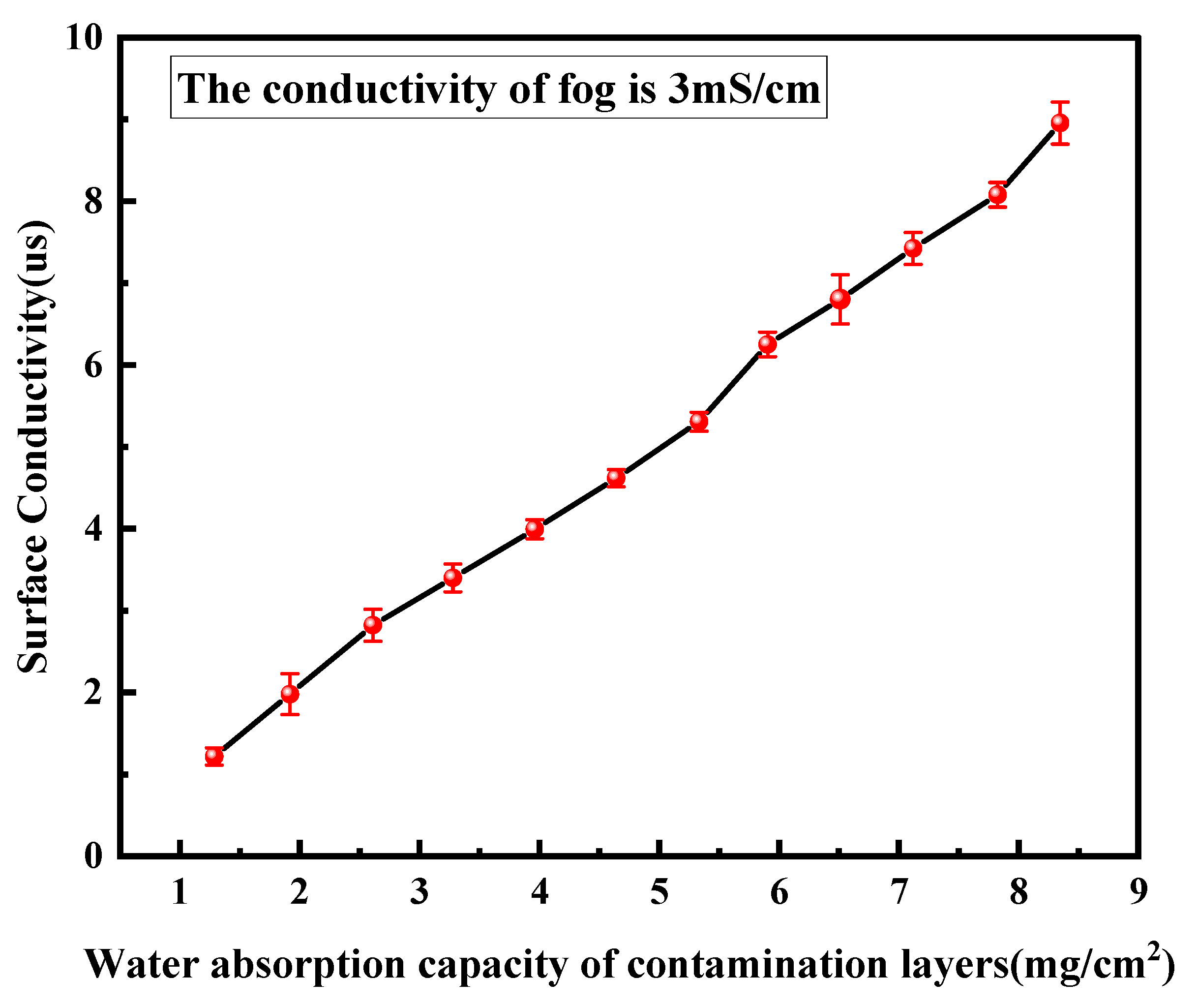

Figure 3 shows the relationship between surface conductivity and water absorption.

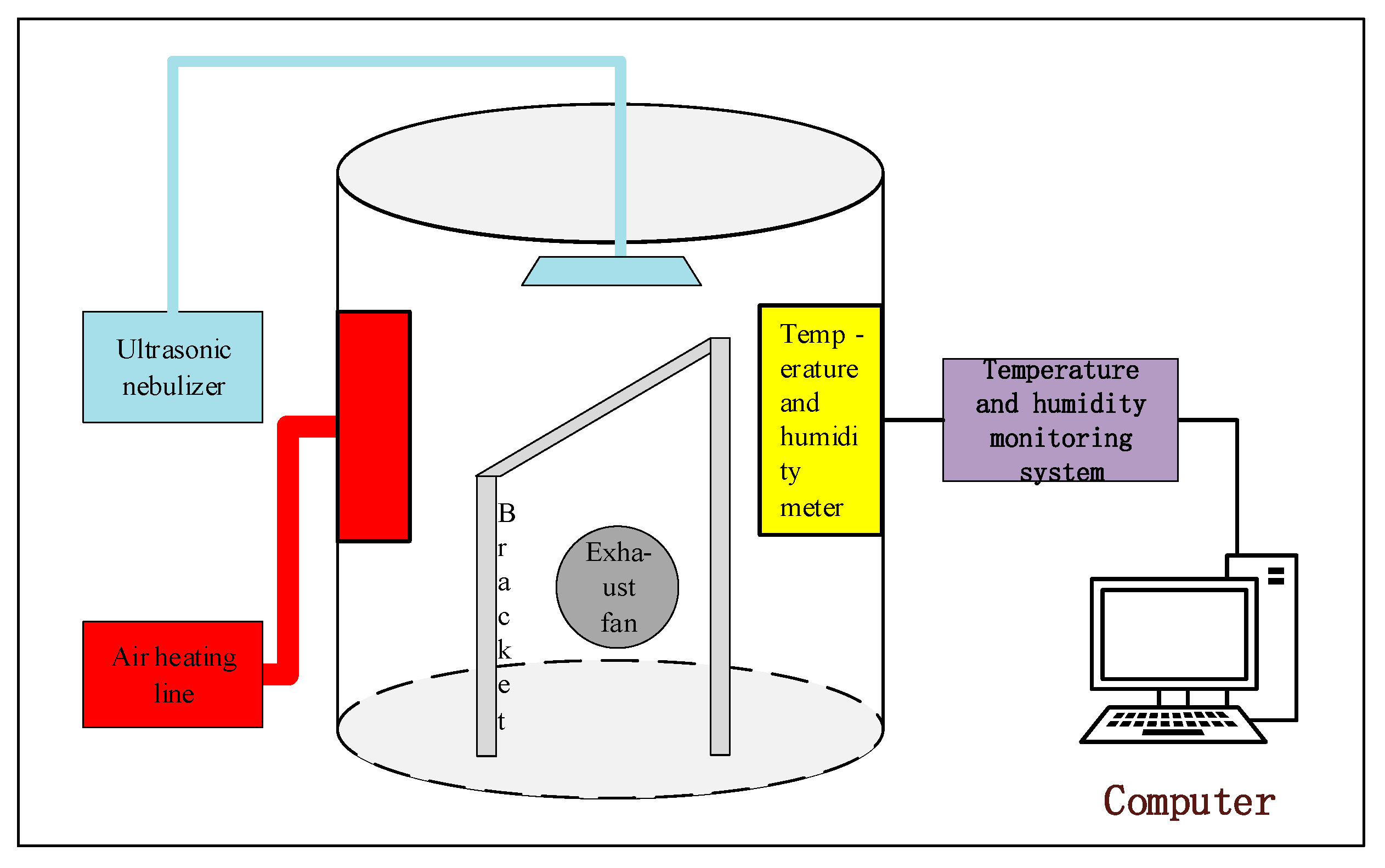

The test platform is mainly composed of a small fog chamber, an ultrasonic nebulizer, and an RLC bridge, in which an air heating line, an exhaust fan, and a temperature and humidity meter are mainly used for control and detection of environmental parameters, such as temperature and fog concentration, inside the artificial fog chamber, as shown in

Figure 4. A test tilt-adjustable bracket was placed inside the fog chamber. Before the test, we controlled the humidity of the artificial fog chamber to 93%RH, and the average fog water settling rate in the fog chamber was measured by gravimetric sampling using a fog cup, which measured 0.245 mg/cm

2·min (±0.02 mg/cm

2), and the uniformity was verified by measuring the conductivity at four locations in the artificial fog chamber (deviation < 5%). In addition, the spray distance (40 cm) was optimized to ensure that droplet sizes (10–20 μm) adhered to IEC 60,507 for artificial pollution tests.

The specific experimental procedure was as follows: first, an artificial contamination layer containing only kaolin was applied to the sample surfaces using the solid-layer method. The samples were then placed in a drying oven and dried at 40 °C for 3 h to completely dry the contamination layer [

25,

26]. For testing, the test specimen was moved into an artificial fog chamber, and the spray position and angle were adjusted so that the vertical distance from the surface of the test specimen to the sprayer was 40 cm. A NaCl solution with a specific conductivity was prepared at 20 °C and then added to the ultrasonic nebulizer, and the salt mist was sprayed into the fog chamber. During the wetting process, the surface conductivity trend was measured and recorded by an RLC bridge.

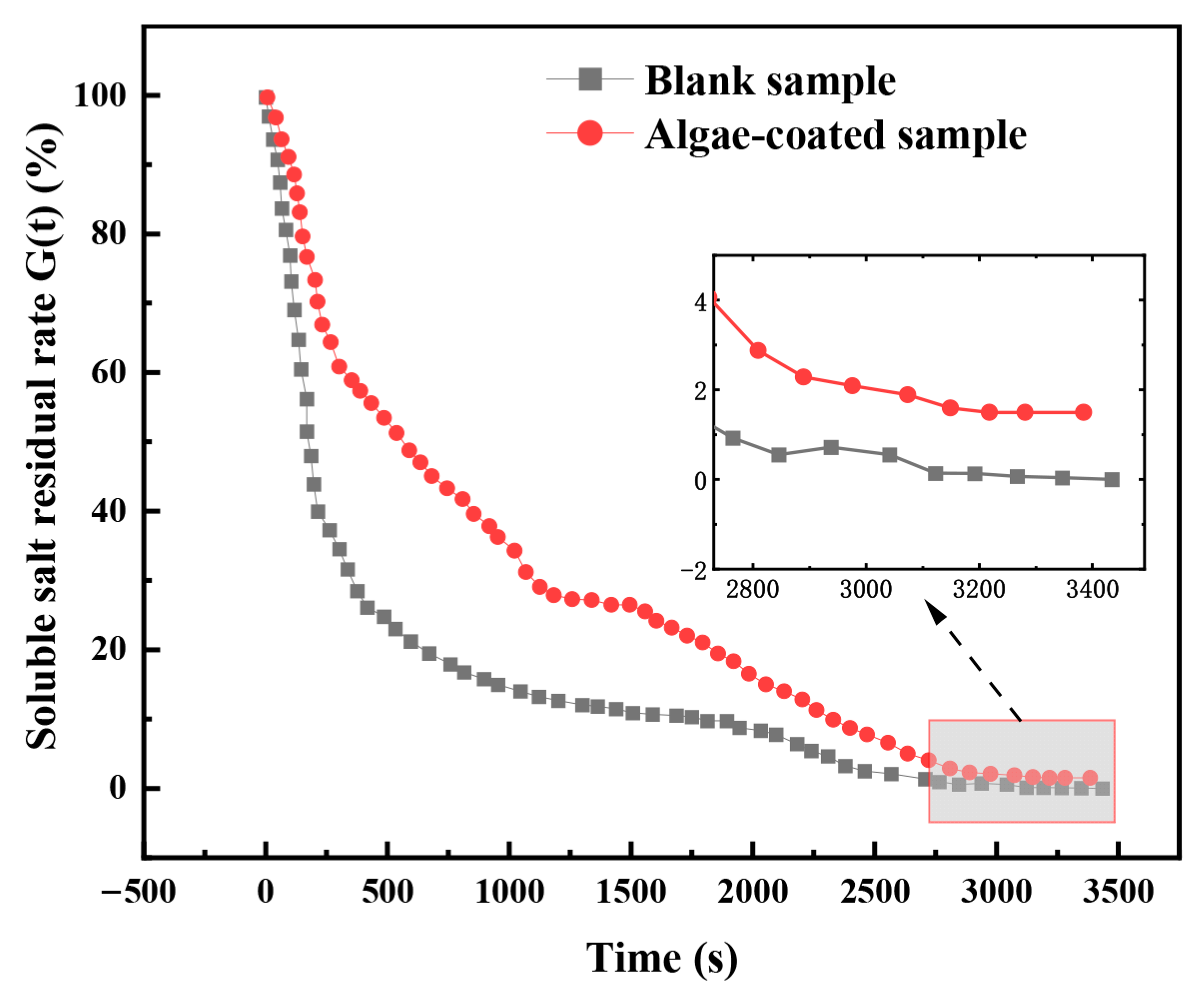

In the experiment investigating the influence of green algae adhesion on soluble salt loss characteristics, artificial contamination with NaCl and kaolin was first applied to both algae-coated samples and blank samples using the solid-layer method. The contamination was proportionally prepared according to the test area dimensions to achieve an equivalent salt deposit density (ESDD) of 0.5 mg/cm2 and a non-soluble deposit density (NSDD) of 1 mg/cm2 in the test areas. In addition, due to insulator contamination in the wet conditions of the loss of a slow process, in order to avoid insulators being in the artificial fog chamber in the wet time for too long, before the test, an equal amount of deionized water was sprayed on to the surface of the blank samples and the samples that were algae-coated with a spray can in order to accelerate the wetting. After the insulator was wetted, it was placed horizontally into the artificial fog chamber, and then the clean fog generated only by deionized water was passed into the artificial fog chamber. Due to the existence of the insulator umbrella, itself at an angle of inclination, the soluble salts were constantly dissolved and lost through the edge. During the test, a cotton swab was dipped into the edge of the insulator test area and dissolved into 10 mL of deionized water to determine the conductivity, which was recorded every 60 s.

Conductivity–time curves were fitted to the conductivity recorded at each discrete time.

The integration of the curve yields a total loss soluble salt conductivity–time curve as follows:

where

F(

t) is the conductivity corresponding to the total amount of soluble salts lost from the insulator surface dissolved into 10 mL of water up to the moment t, and

F(∞) is the conductivity corresponding to the dissolution of all the soluble salts on the insulator surface dissolved into 10 mL of water. Since the amount of pollution solution sampled each time is very small, dissolving it into 10 mL of deionized water does not lead to the phenomenon in which the dissolution of soluble salts reaches saturation, and the conductivity of the test solution is proportional to the number of soluble salts in the pollution solution.

In order to eliminate the interference of intracellular salt release after algae cell rupture, the soluble salt residual rate G(t) of artificial pollution and algae pollution was compared and analyzed.

For algae-coated samples,

In order to ensure the accuracy of the test, in the above tests, five test samples were selected to repeat the test, fit the data after the test, remove the curve with the largest dispersion, and then take the average of the valid data at each sampling point to fit the final curve.

5. Conclusions

This study presents a method for analyzing the water absorption of contamination layers on insulator surfaces based on surface conductivity. Using this method, the wetting characteristics of artificial and algae-induced pollution were compared, and the algae’s roles in inhibiting salt dissolution and enhancing water retention were quantitatively assessed.

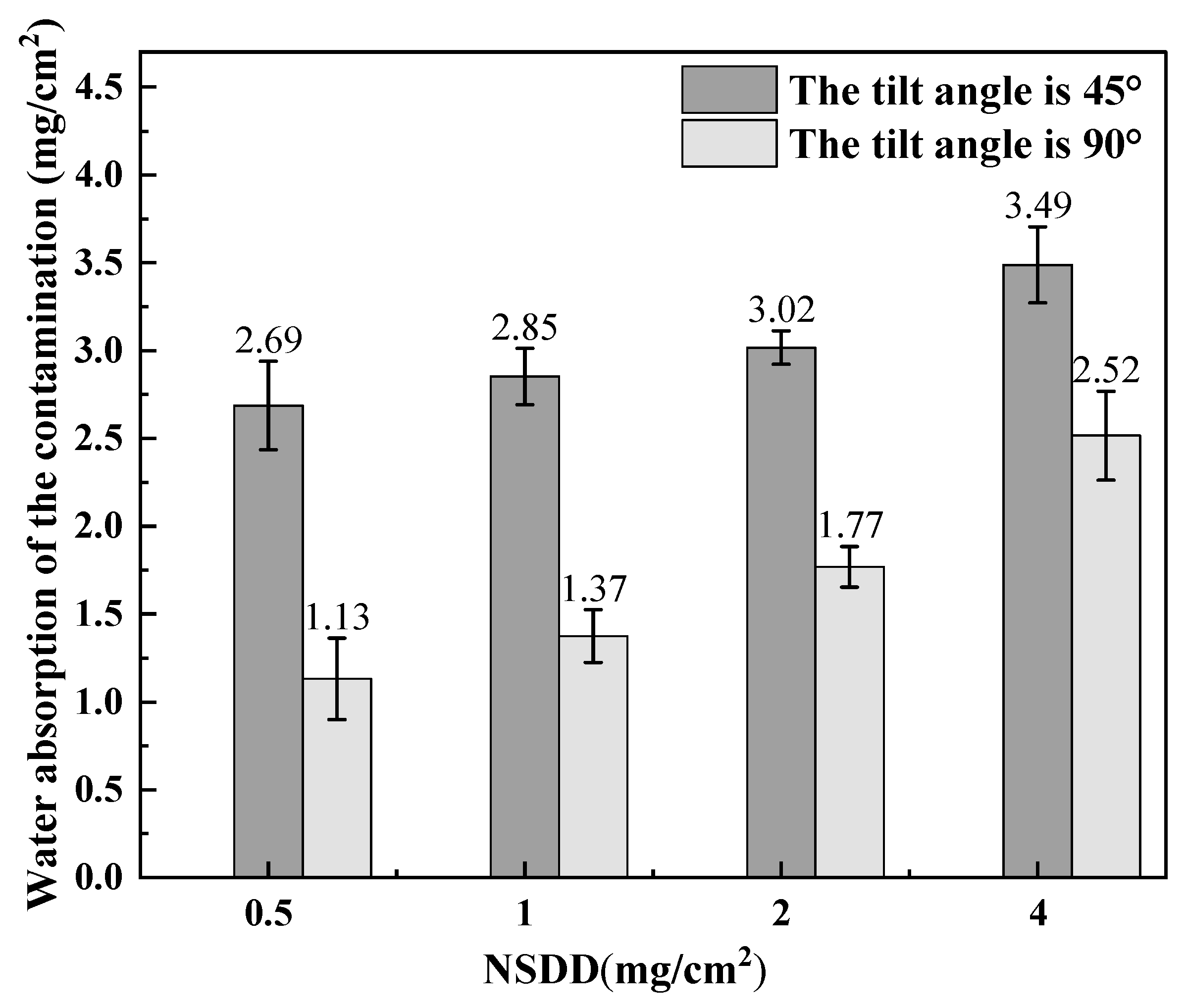

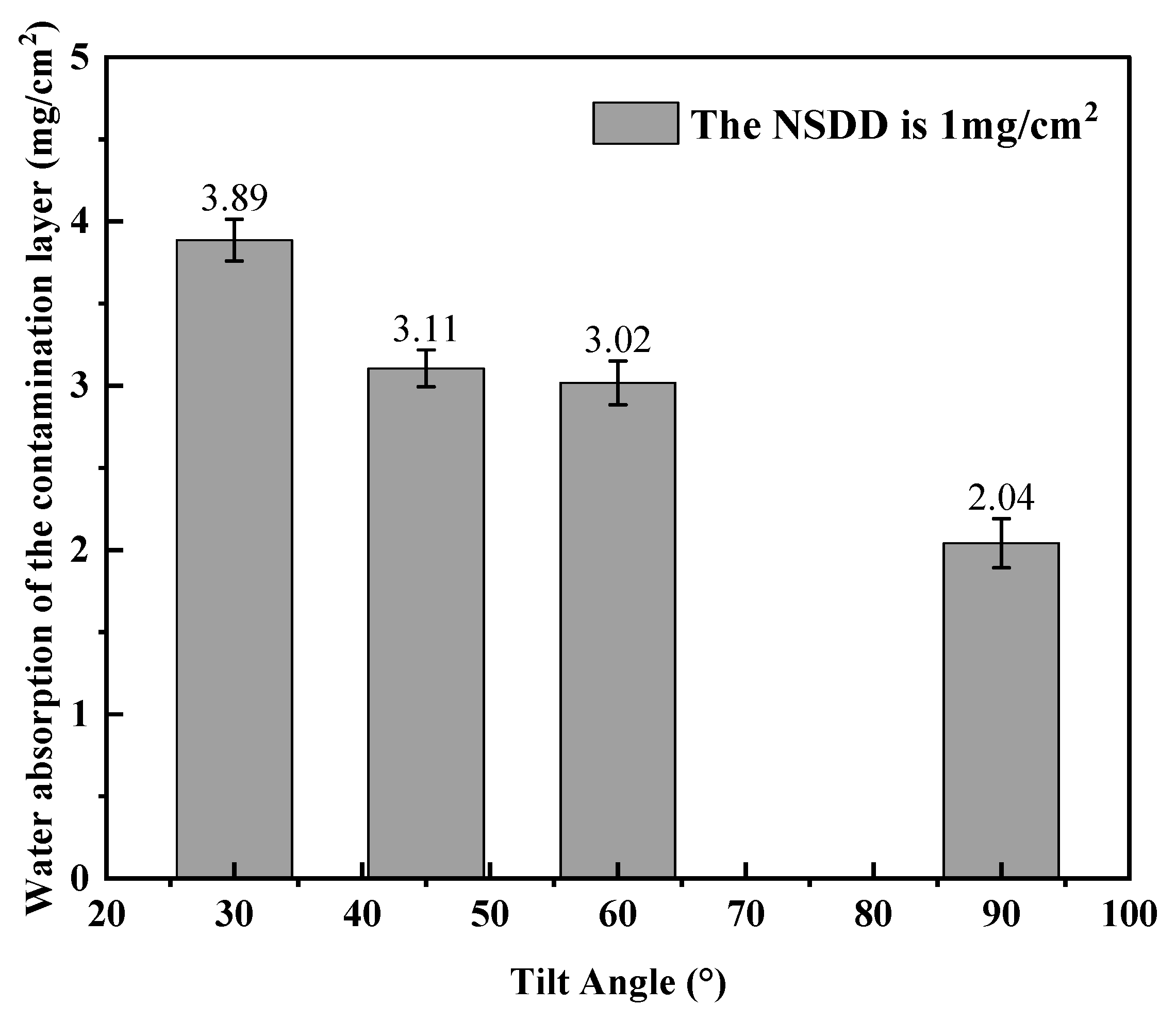

The test results show that for samples without algae, both NSDD and tilt angle influence saturated water absorption. For vertically aligned specimens, the saturated water absorption ranges from 1.68 to 2.7 mg/cm2, and is strongly affected by NSDD. However, when tilted (e.g., at 45°), the absorption becomes largely independent of NSDD, ranging narrowly between 3.04 and 3.42 mg/cm2.

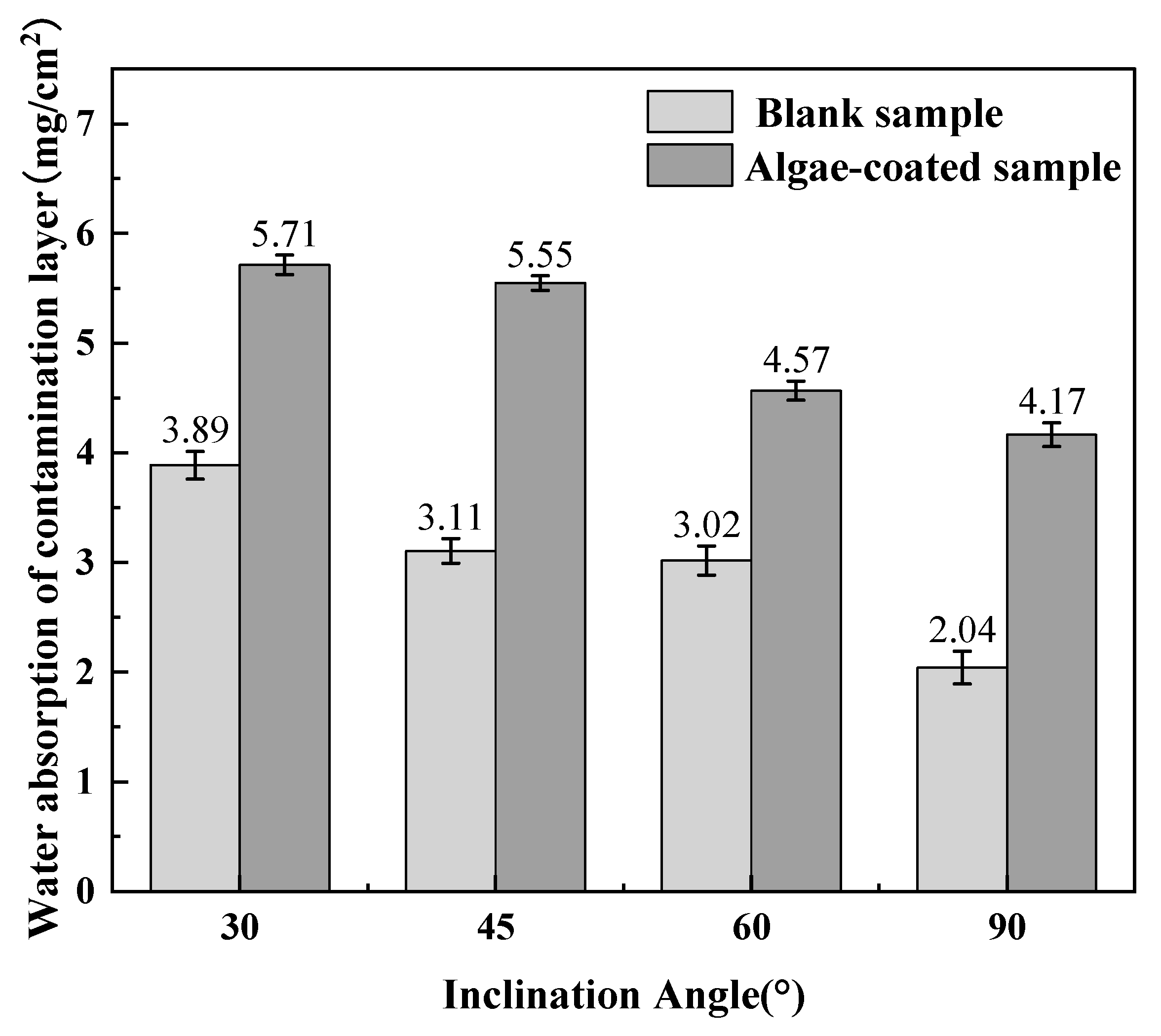

Algae contamination was found to reduce the soluble salt loss rate by 40% by increasing surface roughness. Artificially polluted surfaces reached a 20% residual salt rate in 500 s, whereas algae-contaminated surfaces required 2000 s. Across all tilt angles, algae-coated samples exhibited consistently higher saturated water absorption than clean samples. As the tilt angle increased from 30° to 90°, the saturated water absorption in blank samples decreased by 47.37%, compared to 27.88% in algae-coated samples, indicating greater sensitivity to tilt in non-algae-contaminated surfaces.

This study highlights the significant impact of algae on the wetting behavior of porcelain insulators under rapid-wetting conditions. However, our results are limited to UHVDC-grade porcelain insulators in artificial fog environments. Future work will examine behavior under medium- and low-humidity conditions and extend the analysis to composite insulator materials with hydrophobicity.