Achieving the Sustainable Agricultural Development Goals by Adopting the New Energy Electric Agricultural Machinery: An Analysis of Opportunities and Challenges of China

Abstract

1. Introduction

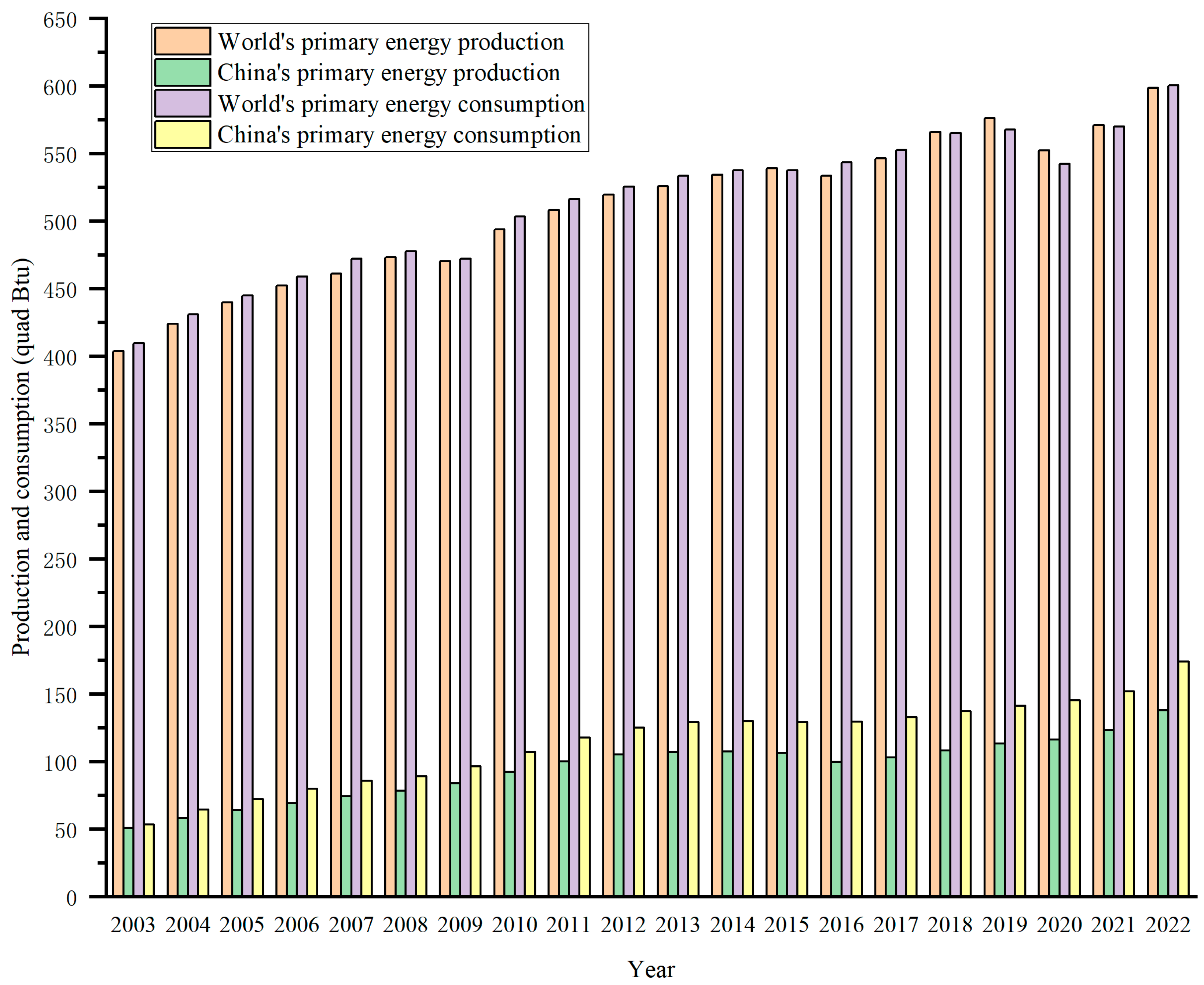

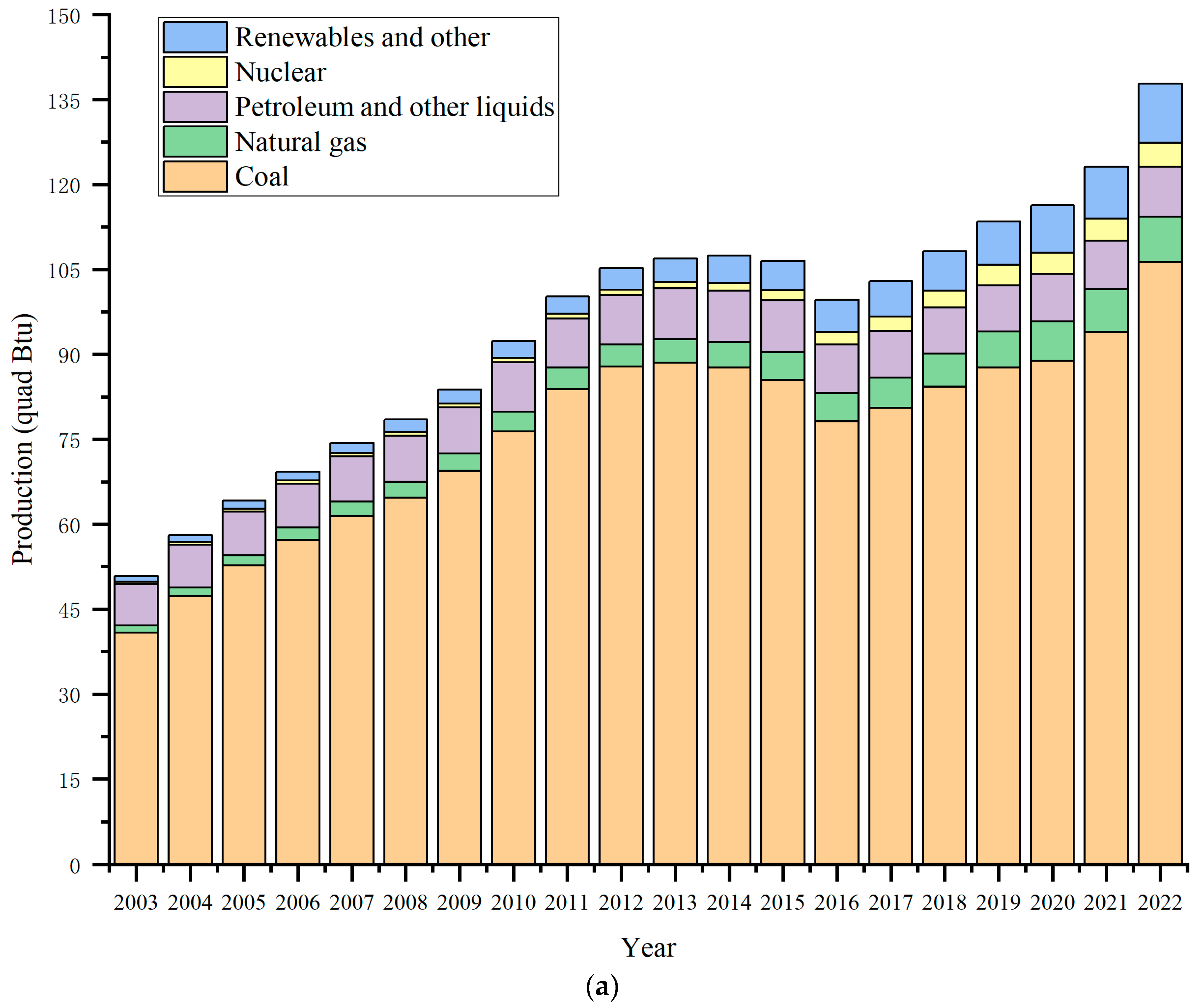

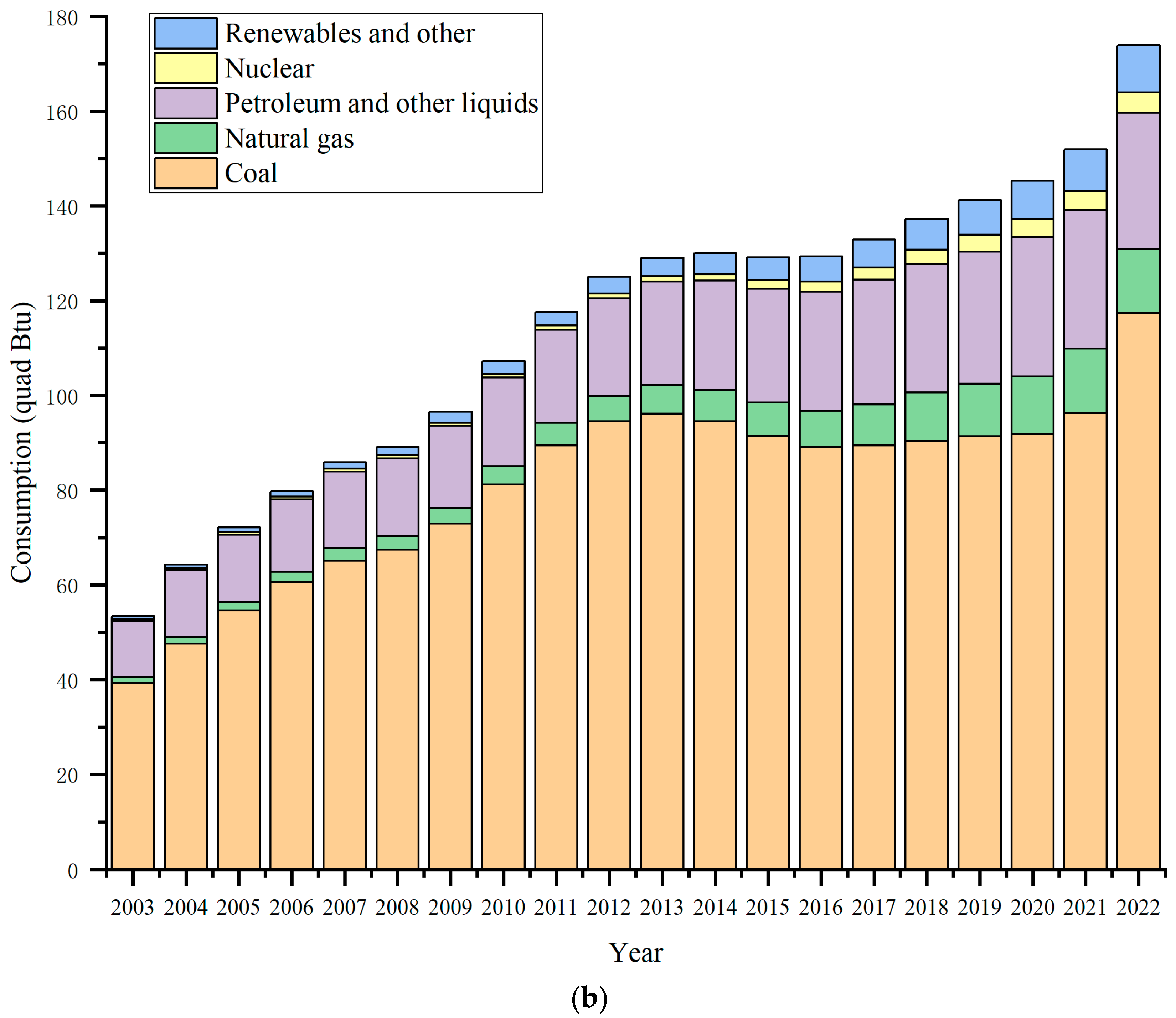

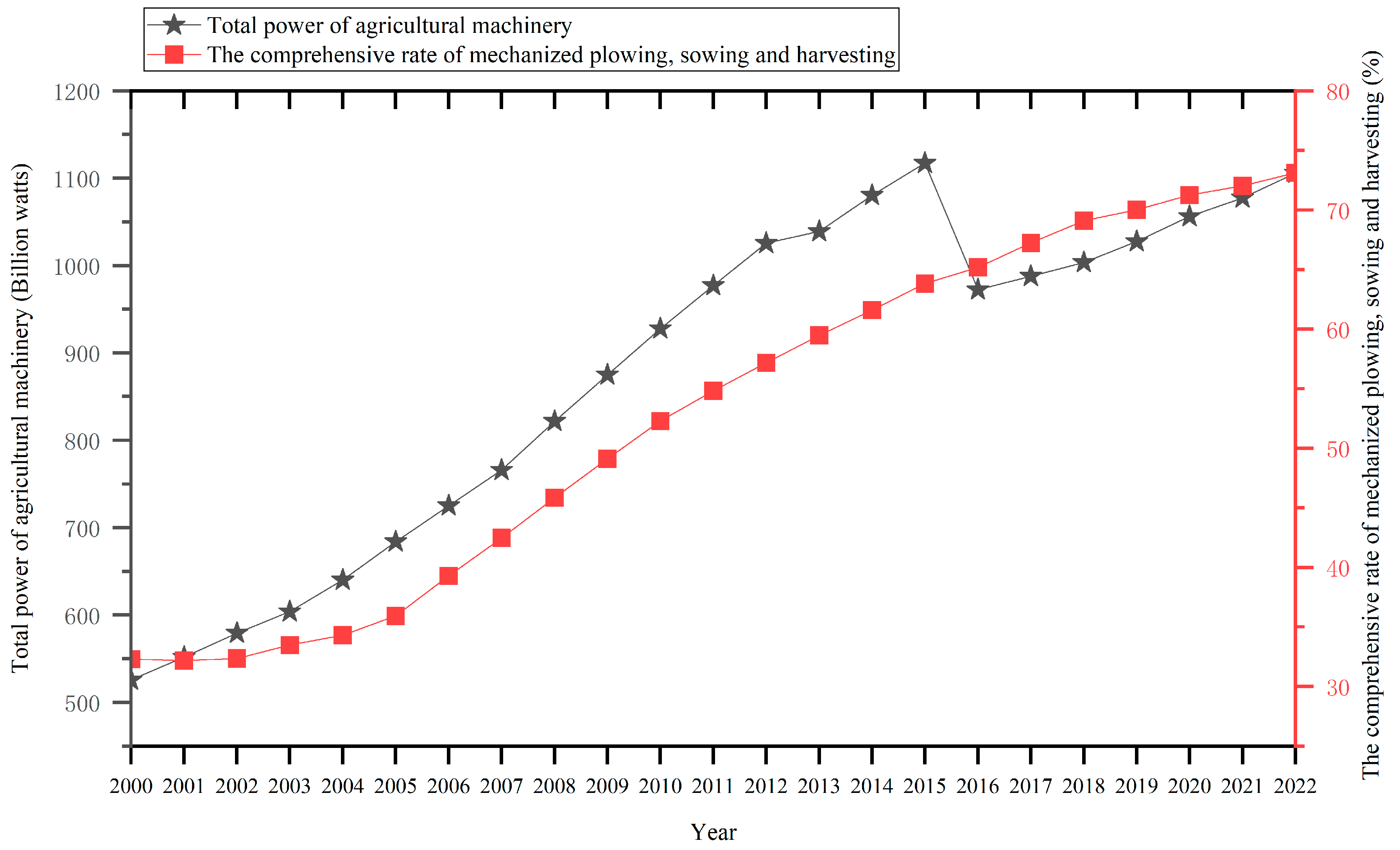

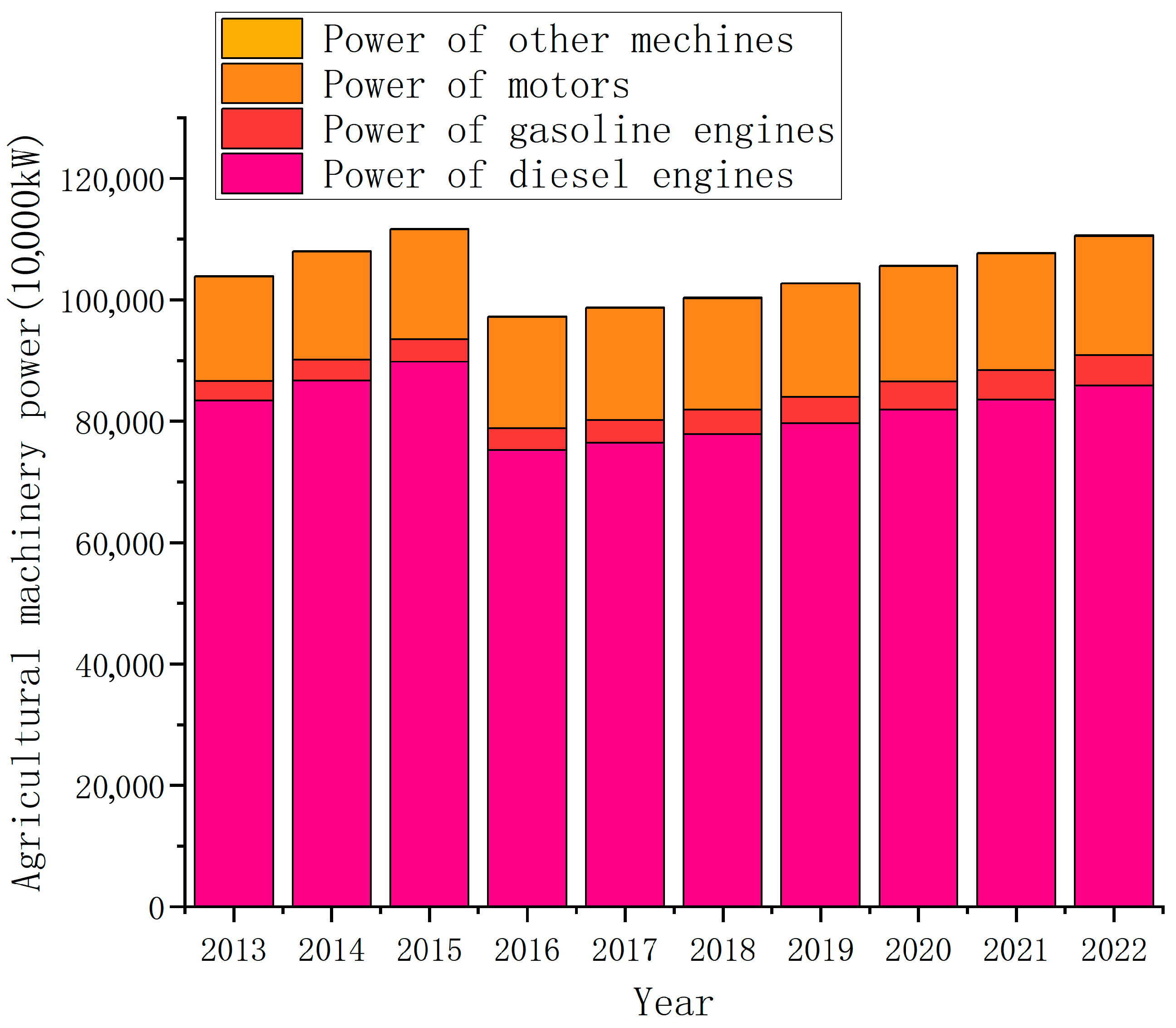

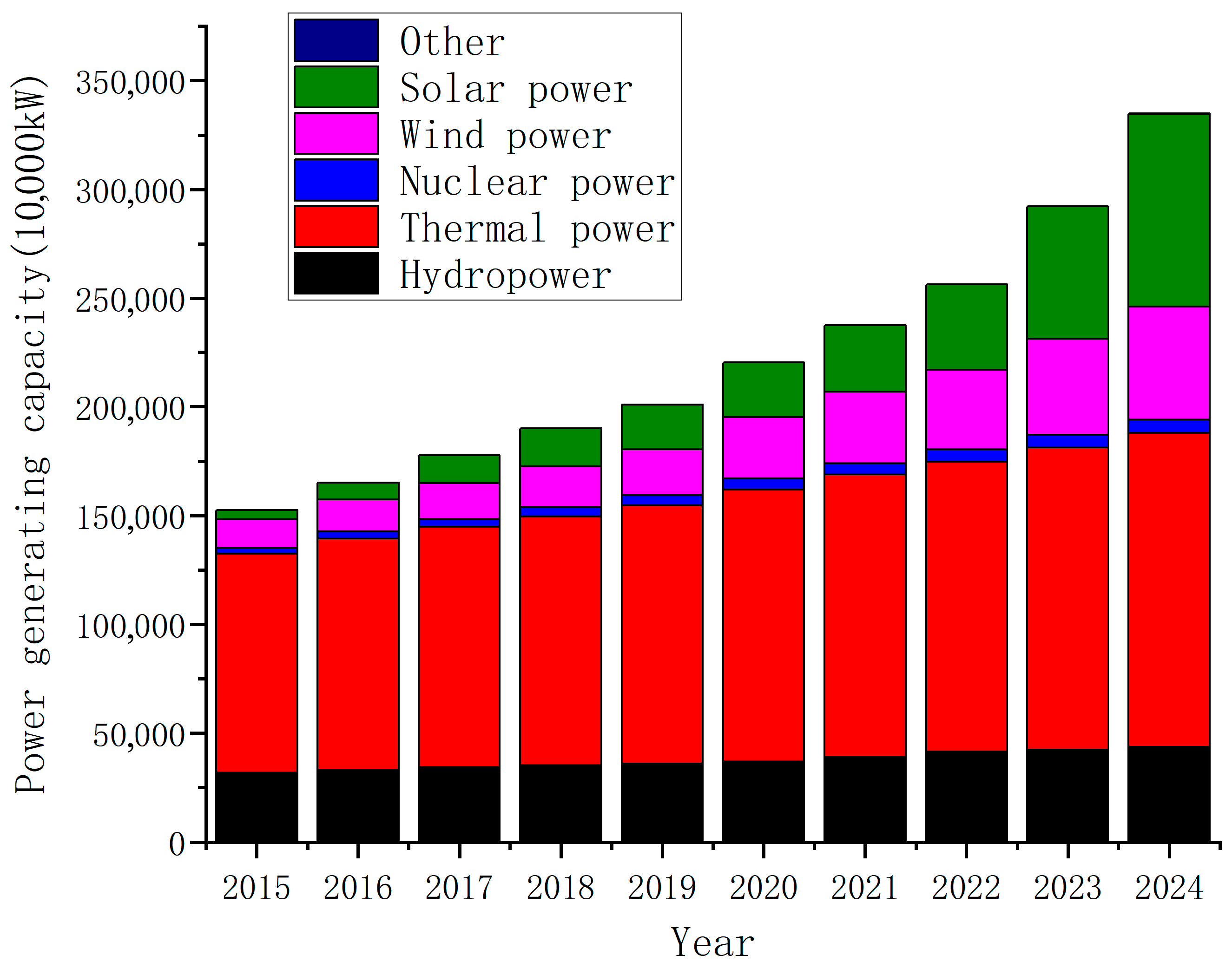

2. The Production and Consumption of Primary Energy in China

2.1. Overview of Primary Energy Production and Consumption

2.2. Structure of Primary Energy Production and Consumption

3. The Current Status of Agricultural Mechanization in China

4. The Status of New Energy Electric Agricultural Machinery in China

4.1. Definition and Classification of New Energy Electric Agricultural Machinery

4.2. The Development History of New Energy Electric Agricultural Machinery

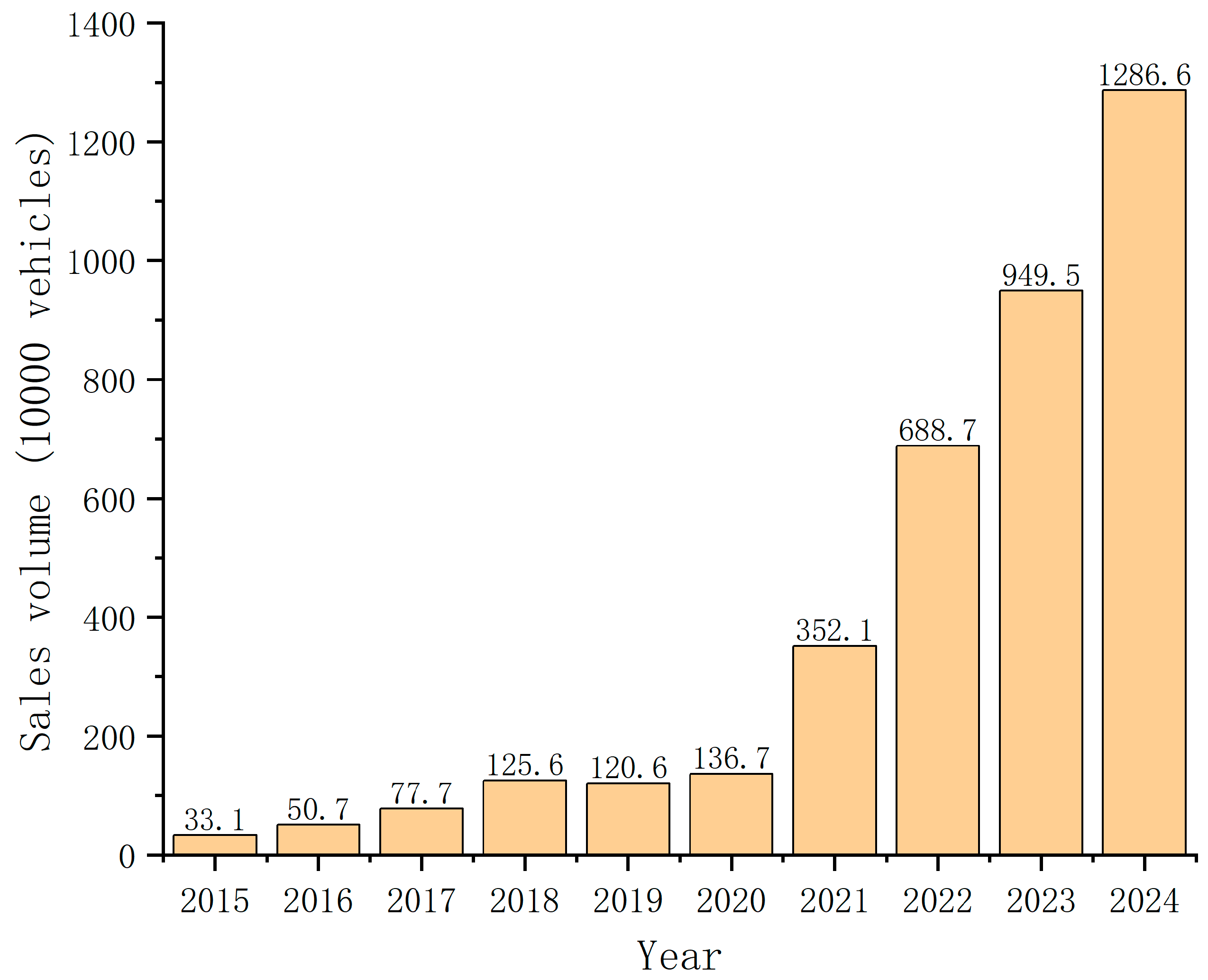

4.3. The Current Situation of New Energy Electric Agricultural Machinery

4.3.1. Electric Tractors

4.3.2. Electric Tillage Machinery

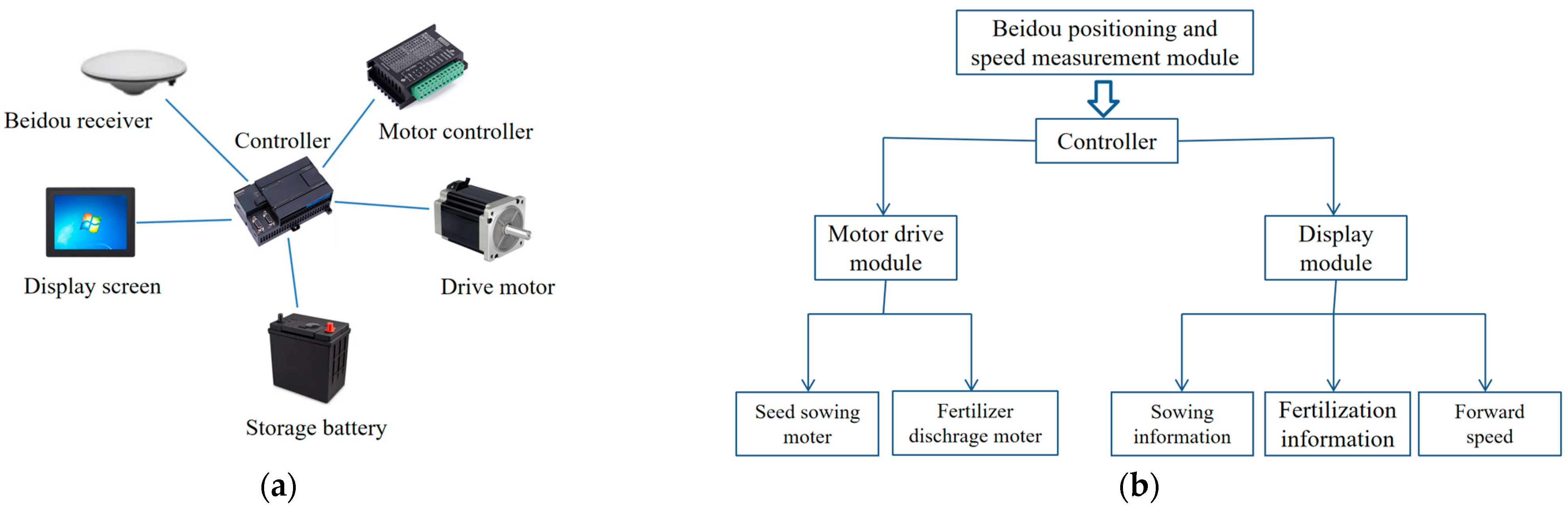

4.3.3. Electric Planting and Fertilization Machinery

4.3.4. Electric Field Management Machinery

4.3.5. Electric Harvesting Machinery

5. Challenges and Opportunities Faced by China’s Development of New Energy Electric Agricultural Machinery

5.1. Opportunities

5.2. Challenges

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Javed, M.H.; Ahmad, A.; Rehan, M.; Musharavati, F.; Nizami, A.-S.; Khan, M.I. Advancing sustainable energy: Environmental and economic assessment of plastic waste gasification for syngas and electricity generation using life cycle modeling. Sustainability 2025, 17, 1277. [Google Scholar] [CrossRef]

- Bin Abu Sofian, A.D.A.; Lim, H.R.; Munawaroh, H.S.H.; Ma, Z.; Chew, K.W.; Show, P.L. Machine learning and the renewable energy revolution: Exploring solar and wind energy solutions for a sustainable future including innovations in energy storage. Sustain. Dev. 2024, 32, 3953–3978. [Google Scholar] [CrossRef]

- Laurentiu, G.; Luis, A.; Puch, J. Energy news shocks and their propagation to renewable and fossil fuels use. Energy Econ. 2024, 130, 107289. [Google Scholar] [CrossRef]

- Yang, T.; Fang, S.; Du, A.M.; Du, Q. Navigating the nexus: Geopolitical risk, fossil energy prices, and European utility stock returns—Implications for environmental management and energy security in a conflict-ridden global landscape. J. Environ. Manag. 2024, 352, 120086. [Google Scholar] [CrossRef]

- Paravee, M.; Nuttaphong, K.; Woraphon, Y. The influence of the Ukraine-Russia conflict on renewable and fossil energy price cycles. Energy Econ. 2024, 129, 107218. [Google Scholar]

- Wang, J.; Wang, L.; Wan, H. Study on the impact of reducing fossil energy use on China’s existing economic structure under carbon neutrality goals. J. Clean. Prod. 2024, 449, 141819. [Google Scholar] [CrossRef]

- Wang, S.; Li, B.; Zhao, X.; Hu, Q.; Liu, D. Assessing fossil energy supply security in China using ecological network analysis from a supply chain perspective. Energy 2024, 288, 129772. [Google Scholar] [CrossRef]

- Zhang, Q.; Mao, X.; Lu, J.; Guo, Z.; Duman, Z.; Chen, Y.; Song, P.; Tu, K. EU-Russia energy decoupling in combination with the updated NDCs impacts on global fossil energy trade and carbon emissions. Appl. Energy 2024, 356, 122415. [Google Scholar] [CrossRef]

- Sunday, T.; Adebayo, S. Towards a sustainable future: The role of energy efficiency, renewable energy, and urbanization in limiting CO2 emissions in Sweden. Sustain. Dev. 2024, 32, 244–259. [Google Scholar]

- Gardiner, R.; Hajek, P. Interactions among energy consumption, CO2, and economic development in European Union countries. Sustain. Dev. 2020, 28, 723–740. [Google Scholar] [CrossRef]

- Hartono, D.; Indriyani, W.; Iryani, B.; Komarulzaman, A.; Nugroho, A.; Kurniawan, R. Carbon tax, energy policy, and sustainable development in Indonesia. Sustain. Dev. 2023, 31, 2332–2346. [Google Scholar] [CrossRef]

- Lohani, S.; Gurung, P.; Gautam, B.; Kafle, U.; Fulford, D.; Jeuland, M. Current status, prospects, and implications of renewable energy for achieving sustainable development goals in Nepal. Sustain. Dev. 2023, 31, 572–585. [Google Scholar] [CrossRef]

- Zastempowski, M. Analysis and modeling of innovation factors to replace fossil fuels with renewable energy sources—Evidence from European Union enterprises. Renew. Sustain. Energy Rev. 2023, 178, 113262. [Google Scholar] [CrossRef]

- Wu, G.; Zeng, M.; Peng, L.L.; Liu, X.M.; Li, B.; Duan, J.H. China׳s new energy development: Status, constraints and reforms. Renew. Sustain. Energy Rev. 2016, 53, 885–896. [Google Scholar] [CrossRef]

- Du, X. Thoughts on strategies and paths to achieve carbon peaking and carbon neutrality in China. Front. Energy 2023, 17, 324–331. [Google Scholar] [CrossRef]

- Chai, Q. Research on China’s pathways to achieve carbon peaking and carbon neutrality goals. Chin. J. Urban Environ. Stud. 2022, 10, 2250007. [Google Scholar] [CrossRef]

- Group, C. Non-fossil sources to meet 62% of India’s total energy demand by 2030. Chem. News Off. J. Indian Chem. Manuf. Assoc. 2023, 19, 73. [Google Scholar]

- Rives, K. Michigan legislation proposes 2030 coal phase-out, fossil-free energy by 2035. Platts Megawatt Dly. 2013, 14, 7–8. [Google Scholar]

- Eden, J. Denmark outlines plan to eliminate fossil fuel use by 2050. Uranium Intell. Wkly. 2010, 4, 7. [Google Scholar]

- Ahlgren, S.; Björnsson, L.; Prade, T.; Lantz, M. Biofuels from Agricultural Biomass-Land Use Change in Swedish Perspective; The Swedish Knowledge Centre for Renewable Transportation Fuels: Stockholm, Sweden, 2017; Available online: https://lup.lub.lu.se/record/32d8c0be-6d3c-4172-9a2f-5bf7e4a258c8 (accessed on 27 May 2025).

- Orach, H.; Qianling, S.; Arthur, A.A.; Twumasi, M.A.; Zhang, S. Impacts of carbon dioxide emissions on agricultural production indicators in sub-saharan african countries: New perspectives from static and dynamic panel models. Environ. Sci. Pollut. Res. 2025, 32, 1247–1271. [Google Scholar] [CrossRef]

- Iyke-Ofoedu, M.; Takon, S.; Ugwunta, D.; Ezeaku, H.; Nsofor, E.; Egbo, O. Impact of CO2 emissions embodied in the agricultural sector on carbon sequestration in South Africa: The role of environmental taxes and technological innovation. J. Clean. Prod. 2024, 444, 141210. [Google Scholar] [CrossRef]

- Xu, X.; Yang, H.; Yang, H. The threshold effect of agricultural energy consumption on agricultural carbon emissions: A comparison between relative poverty regions and other regions. Environ. Sci. Pollut. Res. 2021, 28, 55592–55602. [Google Scholar] [CrossRef]

- Azwardi, A.; Sukanto, S.; Igamo, A.; Kurniawan, A.; Ozturk, I. Carbon emissions, economic growth, forest, agricultural land and air pollution in Indonesia. Int. J. Energy Econ. Policy 2021, 11, 537–542. [Google Scholar] [CrossRef]

- Chen, P.; Li, J. Sustainable agricultural management: How to achieve carbon neutrality in agriculture-evidence from China agricultural sustainable development plan. Sustain. Dev. 2024, 32, 2846–2857. [Google Scholar] [CrossRef]

- Patthanaissaranukool, W.; Polprasert, S.; Neamhom, T. Carbon smart agriculture: Lower carbon emissions and higher economic benefits of maize production in Thailand. Int. J. Environ. Sci. Technol. 2023, 20, 6003–6014. [Google Scholar] [CrossRef]

- Guru, P.; Shrivastava, A.; Tiwari, P. Estimation of carbon emissions of agricultural machinery use in India. Oryza 2022, 59, 260–268. [Google Scholar] [CrossRef]

- Lang, J.; Tian, J.; Zhou, Y.; Li, K.; Chen, D.; Huang, Q.; Xing, X.; Zhang, Y.; Cheng, S. A high temporal-spatial resolution air pollutant emission inventory for agricultural machinery in China. J. Clean. Prod. 2018, 183, 1110–1121. [Google Scholar] [CrossRef]

- Gao, D.; Zhi, Y.; Yang, X. Assessing carbon emission reduction benefits of the electrification transition of agricultural machinery for sustainable development: A case study in China. Sustain. Energy Technol. Assess. 2024, 63, 103634. [Google Scholar] [CrossRef]

- Bessette, D.; Brainard, D.; Srivastava, A.; Lee, W.; Geurkink, S. Battery electric tractors: Small-scale organic growers’ preferences, perceptions, and concerns. Energies 2022, 15, 8648. [Google Scholar] [CrossRef]

- Kivekäs, K.; Lajunen, A. Effect of soil properties and powertrain configuration on the energy consumption of wheeled electric agricultural robots. Energies 2024, 17, 966. [Google Scholar] [CrossRef]

- Lagnelv, O.; Dhillon, S.; Larsson, G.; Nilsson, D.; Hansson, P. Cost analysis of autonomous battery electric field tractors in agriculture. Biosyst. Eng. 2021, 204, 358–376. [Google Scholar] [CrossRef]

- Shishkov, A.; Sychev, D.; Bychkov, A.; Sidorenko, N. The DET-400 tractor traction electric drive. Russ. Electr. Eng. 2014, 85, 610–612. [Google Scholar] [CrossRef]

- Zaitsev, A.; Zakharov, A.; Kobelev, A.; Makarov, A. Experience in the development and modernization of the electric machine set for the electromechanical transmission of the Belarus-3023 tractor. Russ. Electr. Eng. 2025, 96, 122–130. [Google Scholar] [CrossRef]

- Varlese, C.; Ferrara, A.; Hametner, C.; Hofmann, P. Experimental validation of a predictive energy management strategy for agricultural fuel cell electric tractors. Int. J. Hydrogen Energy 2024, 77, 1–14. [Google Scholar] [CrossRef]

- Moreda, G.; Muñoz-García, M.; Barreiro, P. High voltage electrification of tractor and agricultural machinery—A review. Energy Convers. Manag. 2016, 115, 117–131. [Google Scholar] [CrossRef]

- Williams, T.; Wilson, J.; Partington, L.; Andrews, C.; Chavula, I.; Gondwe, F.; Betts, T.; Strickland, D. Micro-electric tractors for deep bed farming and sustainable micro-grid electricity. Front. Energy Res. 2024, 12, 1384568. [Google Scholar] [CrossRef]

- Kim, W.-S.; Baek, S.-Y.; Kim, T.-J.; Kim, Y.-S.; Park, S.-U.; Choi, C.-H.; Hong, S.-J.; Kim, Y.-J. Work load analysis for determination of the reduction gear ratio for a 78 kW all wheel drive electric tractor design. Korean J. Agric. Sci. 2019, 46, 613–627. [Google Scholar] [CrossRef]

- Arjharn, W.; Koike, M.; Takigawa, T.; Yoda, A.; Hasegawa, H.; Bahalayodhin, B. Preliminary study on the applicability of an electric tractor (part 2): Effect of battery allocation on the tractive performance. J. Jpn. Soc. Agric. Mach. 2001, 63, 92–99. [Google Scholar]

- Cristea, M.; Matache, M.; Sorica, C.; Biris, S.; Cristea, R. Study on the behavior of a battery on an electric tractor prototype. INMATEH Agric. Eng. 2020, 62, 19–28. [Google Scholar] [CrossRef]

- Vogt, H.; de Melo, R.; Daher, S.; Schmuelling, B.; Antunes, F.; dos Santos, P.; Albieroet, D. Electric tractor system for family farming: Increased autonomy and economic feasibility for an energy transition. J. Energy Storage 2021, 40, 102744. [Google Scholar] [CrossRef]

- Kocakulak, T.; Thallapalli, V.; Kiyakli, A. Modeling of an electric tractor and determining energy consumption values in different duties. Eng. Perspect. 2021, 1, 79–85. [Google Scholar] [CrossRef]

- Mousazadeh, H.; Keyhani, A.; Javadi, A.; Mobli, H.; Abrinia, K.; Sharifi, A. Optimal power and energy modeling and range evaluation of a solar assist plug-in hybrid electric tractor (sapht). Trans. ASABE 2010, 53, 1025–1035. [Google Scholar] [CrossRef]

- Mocera, F. A Model-based design approach for a parallel hybrid electric tractor energy management strategy using hardware in the loop technique. Vehicles 2021, 3, 1–19. [Google Scholar] [CrossRef]

- Xia, R.; Long, Z.; Xing Khan, Y. Achieving sustainable development through economic growth, energy consumption, and agricultural productivity in China. Sustain. Dev. 2023, 31, 3428–3442. [Google Scholar] [CrossRef]

- Song, C.; Liu, Z.; Chen, H.; Zhao, T. The role of intermediate factors in china’s energy consumption from the perspective of global production chain. J. Clean. Prod. 2024, 435, 140263. [Google Scholar] [CrossRef]

- Hou, F.; Liu, Y.; Ma, Z.; Liu, C.; Zhang, S.; Yang, F.; Nie, Y. Study of the carbon neutral path in China: A literature review. Chin. J. Urban Environ. Stud. 2023, 11, 2350008. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. China Energy Data. 2024. Available online: https://www.eia.gov/international/data/country/CHN (accessed on 27 May 2025).

- China Association of Agricultural Machinery Manufacturers. China Agricultural Machinery Industry Yearbook 2001–2023; Machinery Industry Press: Beijing, China, 2024. [Google Scholar]

- Ministry of Agriculture and Rural Affairs of the People’s Republic of China. The Yearbook of Agricultural Mechanization in China 2005–2023; China Agricultural Science and Technology Press: Beijing, China, 2024. [Google Scholar]

- Liu, J. Research on the development strategies of new energy automotive industry based on car charging stations and battery management. Int. J. Smart Home 2015, 9, 213–222. [Google Scholar] [CrossRef]

- Zhang, T.; Ma, C.; Yong, C. Development Status and Trends of New Energy Vehicles in China. In Proceedings of the International Conference on Energy Science and Applied Technology, AIPC, Chongqing, China, 29–30 December 2018. [Google Scholar] [CrossRef]

- Zbek, S.; Naimolu, M. The effectiveness of renewable energy technology under the ekc hypothesis and the impact of fossil and nuclear energy investments on the UK’S ecological footprint. Energy 2025, 322, 135351. [Google Scholar]

- Ding, T.; Chen, X.; Li, Z.; Liu, H.; Zhu, C.; Zhao, T.; Zhang, Y.; Yang, J.; Zhang, H. A review of flow boiling heat transfer: Theories, new methods and emerging applications. Renew. Sustain. Energy Rev. 2025, 215, 115615. [Google Scholar] [CrossRef]

- Gao, H.; Zhu, S.; Lv, B. Development of electric tractor and key technologies. Tract. Farm Transp. 2007, 34, 4–7. [Google Scholar]

- Xu, L.; Zhang, J.; Yan, X.; Zhao, S.; Wu, Y.; Liu, M. Review of research for agricultural equipment electrification technology. Trans. Chin. Soc. Agric. Mach. 2023, 54, 1–12. [Google Scholar]

- Cheng, Q.; Xiong, Y. Low-carbon sustainable development driven by new energy vehicle pilot projects in China: Effects, mechanisms, and spatial spillovers. Sustain. Dev. 2024, 32, 979–1000. [Google Scholar] [CrossRef]

- Ren, J. New energy vehicle in china for sustainable development: Analysis of success factors and strategic implications. Transp. Res. Part D Transp. Environ. 2018, 59, 268–288. [Google Scholar] [CrossRef]

- Liu, H.; Shen, C.; Hu, L.; Chang, C.; Cao, G. Research progress and development trend of electric agricultural equipments. Trans. Chin. Soc. Agric. Eng. 2024, 40, 39–51. [Google Scholar]

- Mousazadeh, H.; Keyhani, A.; Javadi, A.; Mobli, H.; Abrinia, K.; Sharifi, A. Life-cycle assessment of a solar assist plug-in hybrid electric tractor (SAPHT) in comparison with a conventional tractor. Energy Convers. Manag. 2011, 52, 1700–1710. [Google Scholar] [CrossRef]

- Ueka, Y.; Yamashita, J.; Sato, K.; Doi, Y. Study on the development of the electric tractor: Specifications and traveling and tilling performance of a prototype electric tractor. Eng. Agric. Environ. Food 2013, 6, 160–164. [Google Scholar]

- Schmidt, J.; Cheein, F. Assessment of power consumption of electric machinery in agricultural tasks for enhancing the route planning problem. Comput. Electron. Agric. 2019, 163, 104868. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Łyp-Wrońska, K.; Gdowska, K.; Paciolla, F. Sustainability evaluation of hybrid agriculture-tractor powertrains. Sustainability 2024, 16, 1184. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. Analysis of a Parallel Hybrid Electric Tractor for Agricultural Applications. Energies 2020, 13, 3055. [Google Scholar] [CrossRef]

- Gao, H.; Wang, S.; Zhu, S. Experiment on characteristics of driving force and transmission efficiency of electric tractor. Trans. Chin. Soc. Agric. Mach. 2008, 39, 40–43, 58. [Google Scholar]

- Gao, H.; Zhu, S. Study on design theory and method for driving line of electric tractor. J. Nanjing Agric. Univ. 2009, 32, 140–145. [Google Scholar]

- Gao, H.; Zhang, Y.; Zhu, S. Development and application of electric tractor simulation system based on ADVISOR. Comput. Simul. 2009, 26, 282–285. [Google Scholar]

- Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor torque distribution strategy for different tillage modes of agricultural electric tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- Wang, B.; Qiao, M.; Chu, X.; Shang, S.; Wang, D. Design and experiment on extended-range electric caterpillar tractor. Trans. Chin. Soc. Agric. Mach. 2023, 54, 431–439. [Google Scholar]

- Chen, L.; Zhan, Q.; Wang, W.; Huang, X.; Zheng, Q. Design and experiment of electric drive system for pure electric tractor. Trans. Chin. Soc. Agric. Mach. 2018, 49, 388–394. [Google Scholar]

- Zhang, J.; Shi, M.; Liu, M.; Wang, D.; Yan, X.; Xu, L.; Wu, Y. Design method of dual-motor electric tractor drive system based on mass constraint algorithm under uncertainty using mass. Energy 2025, 322, 135140. [Google Scholar] [CrossRef]

- Zhao, Z.; Xie, B.; Wen, C.; Xing, S.; Luo, Z.; Feng, R. Transient characteristics and control methods of mode switching in electric tractor dual motor drive system. Trans. Chin. Soc. Agric. Mach. 2025, 56, 532–542. [Google Scholar]

- Wu, Z.; Xie, B.; Li, Z.; Chi, R.; Ren, Z.; Du, Y.; Inoue, E.; Mitsuoka, M.; Okayasu, T.; Hirai, Y. Modelling and verification of driving torque management for electric tractor: Dual-mode driving intention interpretation with torque demand restriction. Biosyst. Eng. 2019, 182, 65–83. [Google Scholar] [CrossRef]

- An, Y.; Wang, L.; Deng, X.; Chen, H.; Lu, Z.; Wang, T. Research on differential steering dynamics control of four-wheel independent drive electric tractor. Agriculture 2023, 13, 1758. [Google Scholar] [CrossRef]

- Deng, X.; Sun, H.; Lu, Z.; Cheng, Z.; An, Y.; Chen, H. Research on dynamic analysis and experimental study of the distributed drive electric tractor. Agriculture 2023, 13, 40. [Google Scholar] [CrossRef]

- Zhou, H.; Lu, Z.; Deng, X.; Zhang, C.; Luo, G.; Zhou, R. Study on torque distribution of traction operation of four wheel independent driven electric tractor. J. Nanjing Agric. Univ. 2018, 41, 962–970. [Google Scholar]

- Du, Y.; Sun, X.; Sun, Y.; Xiao, F.; Zhu, X.; Mao, Y.; Yan, X. Electronic pole-changing strategy and analysis for PC-DSPM motor in electric tractors. Trans. Chin. Soc. Agric. Eng. 2023, 39, 44–53. [Google Scholar]

- Li, L.; Ran, G.; Gao, Z.; Liu, Y.; Nie, J. Adaptive energy management and capacity configuration for electric tractor power supply system. Trans. Chin. Soc. Agric. Eng. 2024, 40, 82–91. [Google Scholar]

- Zhang, K.; Deng, X.; Lu, Z.; Wang, T. Research on the energy management strategy of a hybrid tractor OS-ECVT based on a dynamic programming algorithm. Agriculture 2024, 14, 1658. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, J.; Wang, X. Research on energy management model for extended-range electric rotary-tilling tractor. Trans. Chin. Soc. Agric. Mach. 2024, 55, 428–438. [Google Scholar]

- Zhao, Y.; Xu, L.; Zhao, C.; Xu, H.; Yan, X. Research on energy management strategy for hybrid tractors based on DP-MPC. Energies 2024, 17, 3924. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, B.; Zhang, J.; Xu, L.; Zhang, K. Research on power optimization for energy system of hydrogen fuel cell wheel-driven electric tractor. World Electr. Veh. J. 2024, 15, 188. [Google Scholar] [CrossRef]

- Wu, J.; Xia, C.; Sun, Y.; Han, J.; Sheng, Z. Energy management strategy of fuel cell electric tractors. J. Agric. Mech. Res. 2024, 46, 248–253. [Google Scholar]

- Yang, H.; Sun, Y.; Xia, C.; Zhang, H. Research on energy management strategy of fuel cell electric tractor based on multi-algorithm fusion and optimization. Energies 2022, 15, 6389. [Google Scholar] [CrossRef]

- Tao, W.; Chen, B.; Yang, X.; Guo, B.; Xu, W.; Ke, S.; Huang, S. Design and experimental study of tillage depth control system for electric rotary tiller based on, LADRC. Sci. Rep. 2025, 15, 1740. [Google Scholar] [CrossRef]

- Liao, G.; Du, Y.; Chen, Z.; Li, J.; Wang, S.; Li, Q. Analysis and optimization of operating parameters of pure electric rotary tillers based on discrete element method. J. Shandong Agric. Univ. (Nat. Sci. Ed.) 2024, 55, 848–858. [Google Scholar]

- Wang, J.; Wei, W.; Wang, G.; Gao, J.; Xiao, M.; Lu, Z.; Wang, G. Design and experiment of the automatic navigation system for tracked electric micro tillers. Trans. Chin. Soc. Agric. Eng. 2024, 40, 63–72. [Google Scholar]

- Xue, S.; Cai, Z.; Li, Q.; Yang, C.; Liu, W.; Li, G. Research and experiment on composite power supply system of micro-tiller based on super capacitor auxiliary energy. J. Southwest Univ. (Nat. Sci. Ed.) 2023, 45, 179–191. [Google Scholar]

- Mo, T.; Chen, J.; Zheng, Y.; Jin, Z.; Wang, L.; Zhang, M. Simulation of air-cooled heat dissipation of lithium battery pack for electric micro-tiller. J. Agric. Mech. Res. 2021, 43, 247–253. [Google Scholar]

- Jiang, Z.; Wu, D.; Guan, S.; Dou, Q.; Shen, J.; Sun, Y.; Yu, Y. Research progress on control technology of electric driving corn seeder. J. Agric. Mech. Res. 2025, 47, 257–263. [Google Scholar]

- Li, L.; Chen, F.; Liang, X.; Wang, S.; Guo, Y. Research and application analysis of vegetable mechanized seeding technology. Agric. Eng. 2025, 15, 21–25. [Google Scholar]

- Li, Y.; Li, S.; Wen, C.; Li, K. Design of an electrically driven sugarcane seeding system based on GNSS-RTK receiver and SAPSO-LADRC algorithm. Sugar Tech 2025, 27, 832–843. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, W.; Zhu, L.; Wu, C.; Ren, Z. Design and test of spoon-wheel type electric drive corn seeders. J. Chin. Agric. Mech. 2025, 46, 48–55. [Google Scholar]

- Huang, X.; Wang, X.; Meng, Z.; Ling, L.; Xiao, Y.; Wu, G.; Luo, C.; Yan, B. Corn electric drive precision seeder operating condition parameter detection system. Trans. Chin. Soc. Agric. Mach. 2025, 56, 61–71. [Google Scholar]

- Li, T.; Liu, J.; Sang, Y.; Hu, M.; Week, T. Design and experiment of electric drive wheat planter monitoring system based on beidou speed measurement. J. Chin. Agric. Mech. 2025, 47, 116–121. [Google Scholar]

- Zhang, C.; Kang, J.; Zhang, J.; Peng, Q.; Wang, X.; Zhang, N.; Niu, M. Design and experiment of electric-driven air-suction peanut precision seeder. Agric. Equip. Veh. Eng. 2024, 62, 8–13. [Google Scholar]

- Chen, L.; Chen, Y.; Zheng, Y.; Zhang, J. Design and experiment on electric fertilizer applicator. J. Mach. Des. 2013, 30, 78–82. [Google Scholar]

- Wang, J.; Li, S.; Zhang, Z.; Li, Q. Design and experiment of electrical drive side deephill-drop fertilization system for precision ricehill-direct-seeding machine. Trans. Chin. Soc. Agric. Eng. 2018, 34, 43–54. [Google Scholar]

- Ling, L.; Xiao, Y.; Huang, X.; Wu, G.; Li, L.; Yan, B.; Geng, D. Design and testing of electric drive system for maize precision seeder. Agriculture 2024, 14, 1778. [Google Scholar] [CrossRef]

- Li, Y.; Yang, D.; Tao, X.; Wang, X.; Liu, M.; Chen, X.; Jia, J. Market overview of foreign self-propelled sprayer. Agric. Eng. 2024, 14, 12–16. [Google Scholar]

- Sun, Z.; Gu, W.; Cui, L.; Cai, C.; Chen, C.; Zhou, Q.; Ding, S.; Lan, Y.; Xue, X. Research status and development trends of key technologies for intelligent plant protection equipment. J. Intell. Agric. Mech. 2024, 5, 1249. [Google Scholar]

- Liu, X.; Che, J.; Yang, X.; Hu, T.; Tian, W.; Zheng, Y. Design and test of the intra-row electric driven obstacle avoidance weeder forwolfberry. Trans. Chin. Soc. Agric. Eng. 2024, 40, 104–114. [Google Scholar]

- Lu, Y.; Yi, W.; Cheng, F.; Xiong, C.; Wang Pan Tuo, H. Design and experiment of light-weight electric Weeder for mulberry garden. J. Chin. Agric. Mech. 2020, 41, 76–81. [Google Scholar]

- Wang, J.; Gao, G.; Yan, D.; Wang, J.; Weng, W.; Chen, B. Design and experiment of electric control double row deep fertilizing weeder in paddy field. Trans. Chin. Soc. Agric. Mach. 2018, 49, 46–57. [Google Scholar]

- Hao, J.; Ai, Q.; Yuan, D.; Li, Z.; Yang, S. Design and experiment of electric self-propelled maize-peanut strip compound planting pesticide applicator. Trans. Chin. Soc. Agric. Mach. 2024, 55, 216–225. [Google Scholar]

- Lu, X.; Gong, Y.; Chen, X.; Wang, G.; Liu, D.; Zhang, X. Design and experiment of electric crawler vertical boom sprayer. J. Chin. Agric. Mech. 2021, 42, 83–91. [Google Scholar]

- Dong, Y.; Zhang, Y.; Shi, Y.; Li, J.; Wu, G. Design on the spraying system of electric agricultural unmanned aerial vehicle (UAV). Heilongjiang Agric. Sci. 2016, 6, 142–143. [Google Scholar]

- Slaven, M.; Maximilian, K.; Borger, C. Exploring the potential of electric weed control: A review. Weed Sci. J. Weed Sci. Soc. Am. 2023, 71, 403–421. [Google Scholar] [CrossRef]

- Li, H.; Peng, S.; Huang, D. Policy effect and optimization strategies of plant protection UAV subsidy system in southern China. J. China Agric. Univ. 2022, 27, 287–296. [Google Scholar]

- Sarkar, P.; Raheman, H. Design, structural analysis and development of a walk-behind type electric cabbage harvester. Int. J. Sustain. Eng. 2024, 17, 806–828. [Google Scholar] [CrossRef]

- Sarkar, P.; Raheman, H. Development and performance evaluation of an electric cabbage harvester with a precise cabbage pushing mechanism. Smart Agric. Technol. 2024, 8, 100465. [Google Scholar] [CrossRef]

- Zou, F.; Li, J.; He, X.; Ji, M.; Yang, X. Design and experiment of self-propelled water body restoration plants harvester. Trans. Chin. Soc. Agric. Mach. 2016, 47, 61–66, 82. [Google Scholar]

- Zheng, H.; Zhang, Y.; Cao Ja Huang, C.; Wang, L.; Yuan, X.; Wu, S. The Influence of the rubber tree tapped and latex production characteristics using type 4GXJ-Iof portable cordless brushless tapping knife. Chin. J. Trop. Crops 2017, 38, 1725–1735. [Google Scholar]

- Li, X.; Zhang, J.; Yun, Y.; Zhao, Y. Design and experiment on an intelligent control system for small electric leafy vegetable harvester. J. Agric. Mech. Res. 2020, 42, 83–87. [Google Scholar]

- Qu Zhe Liu Long Sun, Y.; Zhao, Y.; Wang, H.; Wang, D.; Yu, Y. Design and simulation of control system of garlic bolting harvester with electric drive. J. Agric. Mech. Res. 2021, 43, 78–84. [Google Scholar]

- Liu, Z.; Wang, E.; Mao, H.; Zuo, Z.; Peng, H.; Zhao, M.; Yu, Y.; Li, Z. Design and testing of an electric side-mounted cabbage harvester. Agriculture 2024, 14, 1741. [Google Scholar] [CrossRef]

- Chen Yong Huang, Z.; Li, Z.; Guo, W.; Zhang, J.; Wang, L.; Sun, Y.; Zhang, B. Design and experiment of self-propelled electric leek harvester. J. Agric. Mech. Res. 2025, 47, 269–275. [Google Scholar]

- Zhu, Z.; Chai, X.; Xu, L.; Quan, L.; Yuan, C.; Tian, S. Design and performance of a distributed electric drive system for a series hybrid electric combine harvester. Biosyst. Eng. 2023, 236, 160–174. [Google Scholar] [CrossRef]

- Yuan, C.; Liu, M.; He, Y.; Chen, L.; Shen, J.; Xu, L. Distributed drive control method of electric harvester based on BLF multi-constraint inversion control. Trans. Chin. Soc. Agric. Mach. 2024, 55, 212–220. [Google Scholar]

- Wang, J.; Mo, P.; Yin, B.; Huang, Y.; Zhu, Y. Simulation of the energy management strategy for six-row hybrid cotton pickers. Trans. Chin. Soc. Agric. Eng. 2024, 40, 126–134. [Google Scholar]

- Ma, S.; Mai, J.; Wang, W.; Yao, K.; Li, D. Development status and trend of new energy vehicles in China: Consumer data analysis based on internet. Int. J. Educ. Humanit. 2021, 1, 10–15. [Google Scholar] [CrossRef]

- Malik, A.; Kohli, S. Electric tractors: Survey of challenges and opportunities in India. Mater. Today Proc. 2020, 28, 2318–2324. [Google Scholar] [CrossRef]

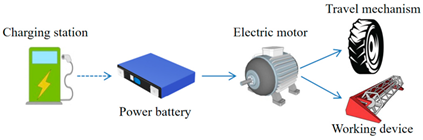

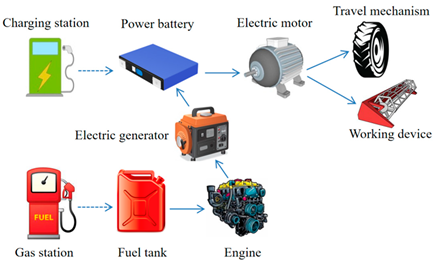

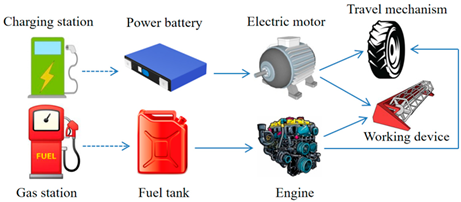

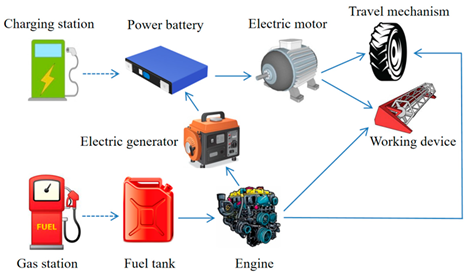

| Type | Schematic Diagram | |

|---|---|---|

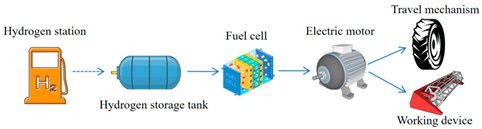

| Pure electric agricultural machinery |  | |

| Hybrid electric agricultural machinery | Series hybrid |  |

| Parallel hybrid |  | |

| Parallel–serial hybrid |  | |

| Fuel cell electric agricultural machinery | Pure fuel cell |  |

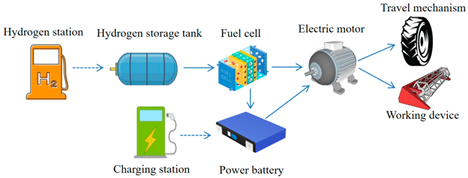

| Hybrid of fuel cell and power battery |  | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Ding, F.; Gu, F.; Wu, F.; Yu, Z.; Zhang, P.; Wang, J.; Hu, Z. Achieving the Sustainable Agricultural Development Goals by Adopting the New Energy Electric Agricultural Machinery: An Analysis of Opportunities and Challenges of China. Energies 2025, 18, 4211. https://doi.org/10.3390/en18164211

Yang H, Ding F, Gu F, Wu F, Yu Z, Zhang P, Wang J, Hu Z. Achieving the Sustainable Agricultural Development Goals by Adopting the New Energy Electric Agricultural Machinery: An Analysis of Opportunities and Challenges of China. Energies. 2025; 18(16):4211. https://doi.org/10.3390/en18164211

Chicago/Turabian StyleYang, Hongguang, Fujie Ding, Fengwei Gu, Feng Wu, Zhaoyang Yu, Peng Zhang, Jiangtao Wang, and Zhichao Hu. 2025. "Achieving the Sustainable Agricultural Development Goals by Adopting the New Energy Electric Agricultural Machinery: An Analysis of Opportunities and Challenges of China" Energies 18, no. 16: 4211. https://doi.org/10.3390/en18164211

APA StyleYang, H., Ding, F., Gu, F., Wu, F., Yu, Z., Zhang, P., Wang, J., & Hu, Z. (2025). Achieving the Sustainable Agricultural Development Goals by Adopting the New Energy Electric Agricultural Machinery: An Analysis of Opportunities and Challenges of China. Energies, 18(16), 4211. https://doi.org/10.3390/en18164211