1. Introduction

1.1. Introduction

Global environmental and energy challenges are becoming increasingly severe, prompting governments to explore sustainable industrial development strategies that balance energy conservation with environmental protection for the coming decades. Fuel-powered vehicles are a major cause of CO

2 emissions and remain a critical concern among all major sources of this gas. Energy-related carbon dioxide emissions from the transport sector are estimated at more than 900 million tons, accounting for about 10 per cent of the country’s total emissions (IEA, 2023) [

1]. The road transport sector, in particular, accounts for more than 70 per cent of total transport sector carbon emissions [

1]. Concurrently with the ongoing expansion of the automotive market, conventionally fueled vehicles maintain their preeminence in the consumer market. Thus, reducing gasoline consumption in passenger vehicles necessitates advancements in fuel efficiency and thermal engine performance.

Low-temperature combustion (LTC) strategies have been identified as a potential avenue for enhancing fuel thermal efficiency. A growing body of research has demonstrated the efficacy of applying LTC strategies, such as homogeneous Charge Compression Ignition (HCCI), Premixed Charge Compression Ignition (PCCI), and Reactivity Controlled Compression Ignition (RCCI), in production-grade light-duty diesel engines, in conjunction with select alternative fuels. This approach has been shown to result in a substantial extension of the engine load range and a notable reduction in HC and CO emissions compared with conventional diesel combustion. Under conditions of similar fuel cetane number, conventional combustion exhibits steep pressure rise rate and heat release rate, whereas LTC strategies demonstrate substantially moderated profiles, particularly at low loads. Among the various strategies employed, HCCI has been demonstrated to exhibit superior performance in mitigating HC/CO emissions. It has been demonstrated that all LTC modes enhance brake thermal efficiency (BTE), with PCCI achieving optimal BTE performance [

2].

New-energy vehicles (NEVs), categorized into battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs), offer a potential solution to the energy problem. Pure electric vehicles allow for emission-free driving, but their energy source is not necessarily emission-free. Coal-fired power plants are responsible for approximately 70% of China’s total power generation [

3]. Additionally, BEVs face unresolved challenges, including limited driving range and battery recycling issues [

4]. To meet carbon peak and neutrality targets, hybrid powertrains are paired with thermal efficiency improvements in hybrid engines—a solution that works for the automotive industry.

At present, the majority of commercial hybrid engines are adapted from conventional fuel engines, resulting in suboptimal thermal efficiency. Consequently, enhancing the indicated thermal efficiency (ITE) of hybrid-dedicated gasoline engines has become a matter of pressing research priority. It is evident from an analysis of industry practices that the combination of high-compression-ratio, high-efficiency engines with electrification has the potential to achieve a substantial reduction in fuel consumption. This is particularly significant in addressing the technical limitations currently experienced with BEVs. Hybrid powertrains have the potential to be the next technological focal point beyond the traditional internal combustion engine and future pure electric technologies.

1.2. Ways to Improve Brake-Specific Fuel Consumption

The efficiency of an internal combustion engine can be enhanced through three approaches: improving combustion efficiency, cycle thermal efficiency, and mechanical efficiency. The optimization of combustion efficiency is contingent upon the enhancement in fuel–air mixing, thereby ensuring complete combustion and maximum heat conversion, with turbocharged lean combustion being one effective method. Increasing the compression ratio (CR) and specific heat ratio directly enhances cycle thermal efficiency, where supercharging or turbocharging contributes by increasing the intake air quantity and consequently the mixture’s specific heat ratio. Mechanical efficiency improvement primarily relies on reducing friction between moving components, though this is largely constrained by material properties.

The Otto cycle [

5] is often used as a theoretical basis for SI engines, and the thermal efficiency of this cycle is expressed as

Thermal efficiency is determined by both the compression ratio and the specific heat ratio of the working fluid. The aforementioned formula represents the maximum theoretical thermal efficiency achievable under ideal Otto cycle conditions, where the working fluid absorbs all heat at the top dead center. This relationship reveals two primary approaches to enhancing engine thermal efficiency: increasing the specific heat ratio of the in-cylinder mixture (through lean combustion techniques and higher excess air ratios) and increasing the compression ratio. However, while the theoretical efficiency improves with higher compression ratios at constant specific heat ratios, practical operation introduces various losses—including heat transfer losses, pumping losses, exhaust losses, dissociation losses, non-isochoric losses, mechanical losses, etc. These losses together make the actual thermal efficiency lower than the theoretical value of the Otto cycle.

Table 1 [

6,

7,

8,

9,

10] shows the high-efficiency engine models and technological routes developed by mainstream engine R&D organizations and enterprises in recent years. It is not difficult to find that in addition to technologies such as reducing accessory power consumption and friction losses, the vast majority of high-efficiency engines improve thermal efficiency by increasing the compression ratio, which typically reaches 13 or more.

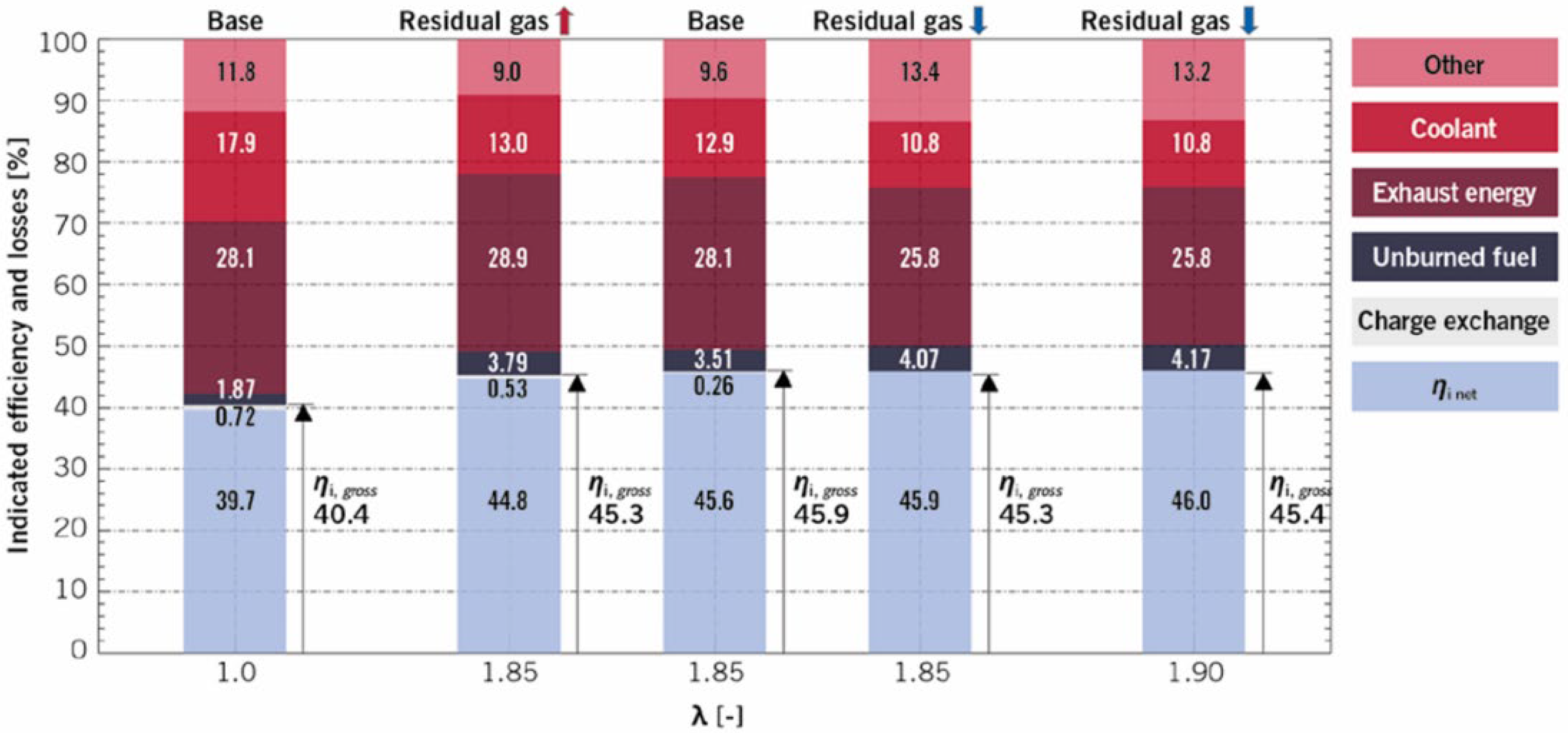

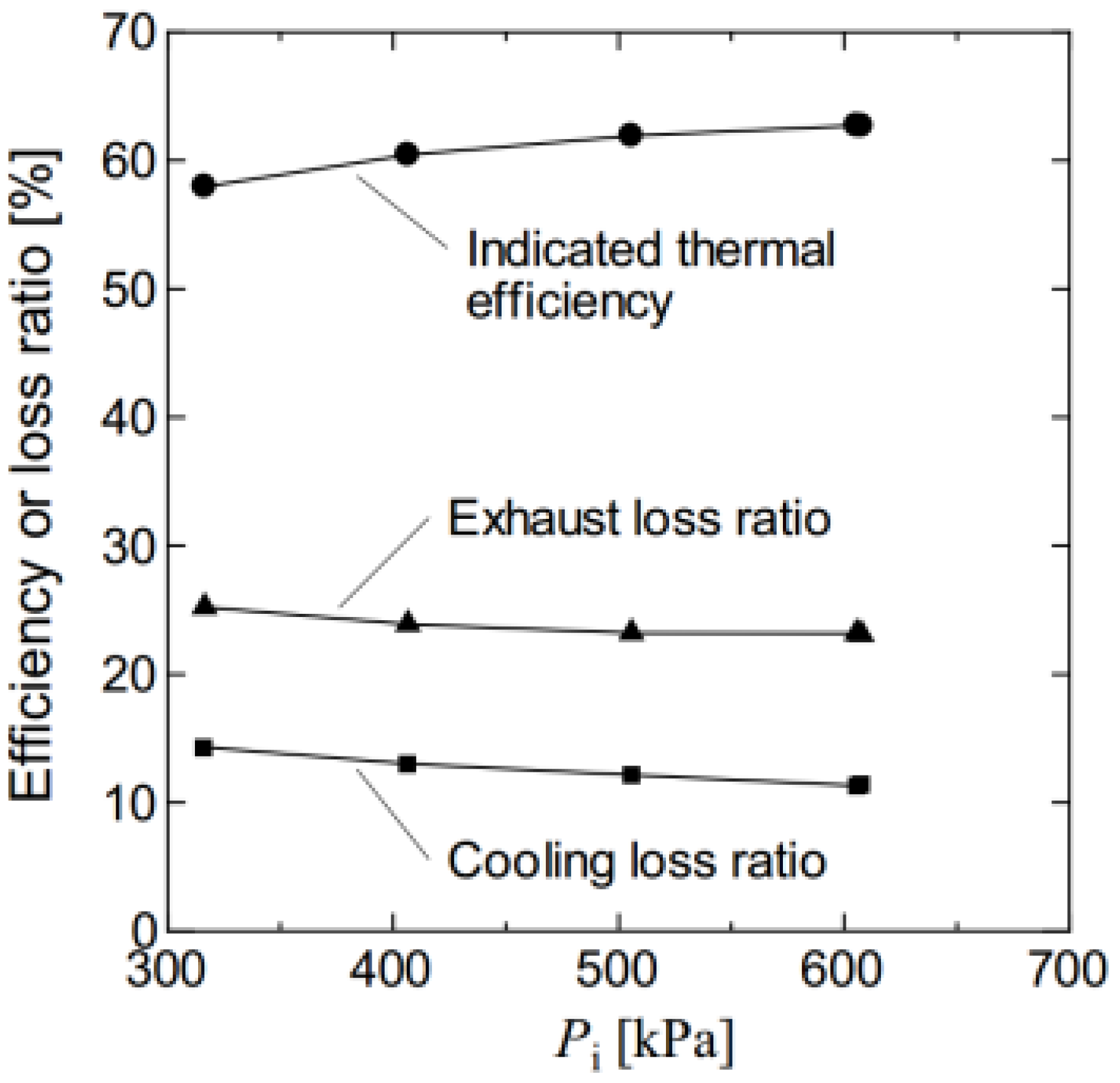

From an energy distribution perspective,

Figure 1 illustrates the impact of the compression ratio on energy utilization. In the diagram, IMEP (Indicated Mean Effective Pressure) is defined as the mean effective pressure calculated by integrating the actual combustion pressure curve within the cylinder. It reflects the actual indicated work performed by the working fluid on the piston. QMEP (Quasi-Mean Effective Pressure) refers to the theoretical mean effective pressure equivalent to the work that would be performed on the piston by the combustion enthalpy released from the complete combustion of the fuel. Increasing the compression ratio can reduce exhaust losses—the unavailable energy determined by Carnot cycle limitations and ambient temperature conditions. The larger the compression ratio is, the larger the ratio of the volume at the lower stop point to the volume at the upper stop point is, and since the specific heat ratio is greater than 1, the lower the temperature at the end of expansion is, the closer to the ambient temperature it is; therefore, the smaller the minimum of the heat that may be emitted from the cold source is, and the greater the efficiency that may be obtained. However, the final exhaust temperature is also affected by many other factors, and the above theory is based more on the assumption of equal capacity within the Otto cycle. The purpose of high-compression-ratio research is to reduce the direct energy loss in the Otto cycle equation, at least ensure that the rest of the loss distribution is unchanged, or increase the percentage of indicated work, so as to increase the compression ratio to obtain greater efficiency.

For hybrid engine research, the primary goal is to enhance the thermal efficiency of the engine, and the most direct way is to improve and optimize the combustion system, adopting a higher-CR design or using a charging system.

1.3. Definition of High Compression Ratio

According to internal combustion engine theory, the compression ratio (CR) is defined as the ratio between the cylinder volume at bottom dead center (BDC) and the volume at top dead center (TDC). This critical design parameter is determined by several factors, including combustion chamber volume, piston crown geometry, bore-to-stroke ratio, and cylinder head gasket thickness. Since the invention of gasoline engines, compression ratios have shown a continuous upward trend, making “high compression ratio” a relative concept. Conventional passenger car engines typically operate with CRs ranging from 9:1 to 12:1, while modern hybrid-dedicated engines can achieve significantly higher ratios of 15:1 to 16:1 or more.

2. Method

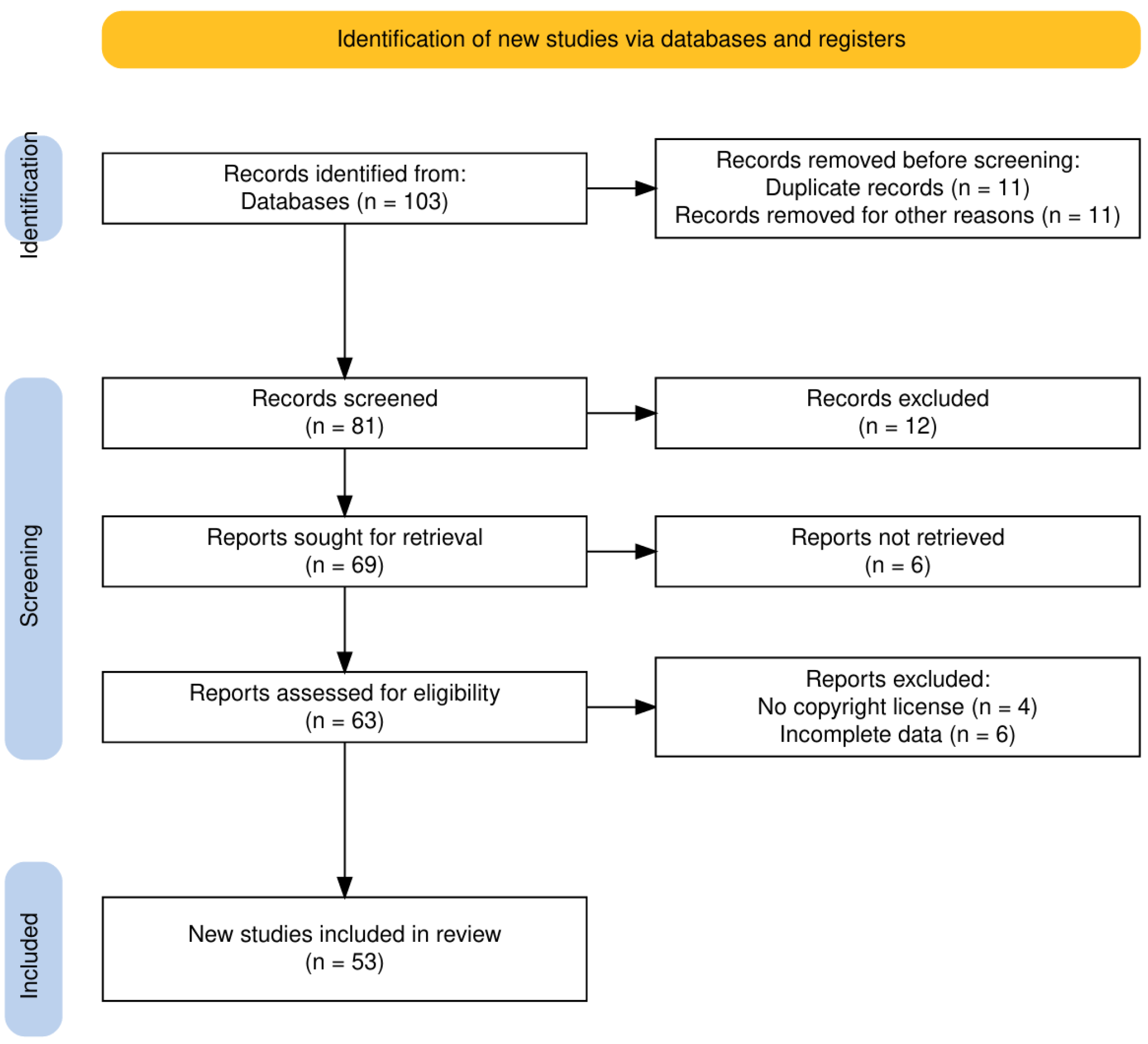

A systematic literature search was conducted using core keywords including “high compression ratio”, “dedicated hybrid gasoline engine”, and their semantic variants across academic databases (Web of Science, Engineering Village, and CNKI). After deduplication, a three-tiered screening protocol was implemented:

- (1)

Title/abstract screening: Exclusion of publications with low thematic relevance;

- (2)

Full-text preliminary review: Removal of studies presenting unclear data or incomplete methodological descriptions;

- (3)

Quality assessment: The quality of the chosen articles was evaluated in order to ascertain the robustness of the methodology.

This initial process identified 35 core publications. Following thematic categorization and gap analysis, 18 additional pivotal studies (including recent empirical research and authoritative reviews) were incorporated to address knowledge voids. The final analytical corpus comprised 53 rigorously selected references, with the screening workflow detailed in

Figure 2.

3. Problems Arising from High Compression Ratio

The increase in the CR gives rise to two fundamental challenges. Firstly, it is evident that higher compression ratios engender a number of detrimental effects, including an augmented propensity to knock, a heightened incidence of heat transfer losses, and elevated friction losses. Secondly, it is imperative to consider the impact of increasing the CR on the system’s theoretical thermal efficiency; i.e., the effect of increasing the CR on the theoretical thermal efficiency of the gains decreases with the increase in compression ratio [

11,

12,

13,

14,

15]. For instance, increasing the compression ratio to CR = 22:1 yields only 10% of the efficiency improvement achievable at CR = 4:1 and merely 40% of that at CR = 12:1. Conversely, detrimental effects such as knock intensification exhibit fundamentally different behavior—the temperature and pressure in the cylinder are important factors. During compression, the top dead center (TDC) rises nearly linearly across a wide compression-ratio range. Consequently, pursuing higher compression ratios yields progressively diminishing returns, making technological breakthroughs essential prerequisites for continued efficiency gains. Consequently, the primary research focus for high-compression-ratio gasoline engines is to maximize the compression ratio while mitigating associated negative impacts and balancing various loss mechanisms. The more prominent issues arising from increasing the compression ratio in hybrid-dedicated gasoline engines include enhanced knocking propensity, increased heat transfer losses, decrease in combustion isotropy, elevated friction losses, and augmented dissociation losses.

This study investigates methods to increase the compression ratio in hybrid gasoline engines while addressing the technical challenges inherent to high-compression-ratio operation.

3.1. Enhancement in Knock Tendency

The occurrence of engine knock is primarily caused by the autoignition of the mixture at the end of the cylinder before the flame reaches it. This results in rapid pressure and temperature spikes that generate high-frequency pressure oscillations. Hybrid engines employ higher compression ratios to enhance fuel economy; however, this simultaneously increases knock tendency and preignition risks, ultimately leading to degradation in engine performance through elevated fuel consumption, vibration, noise, and potential cylinder damage.

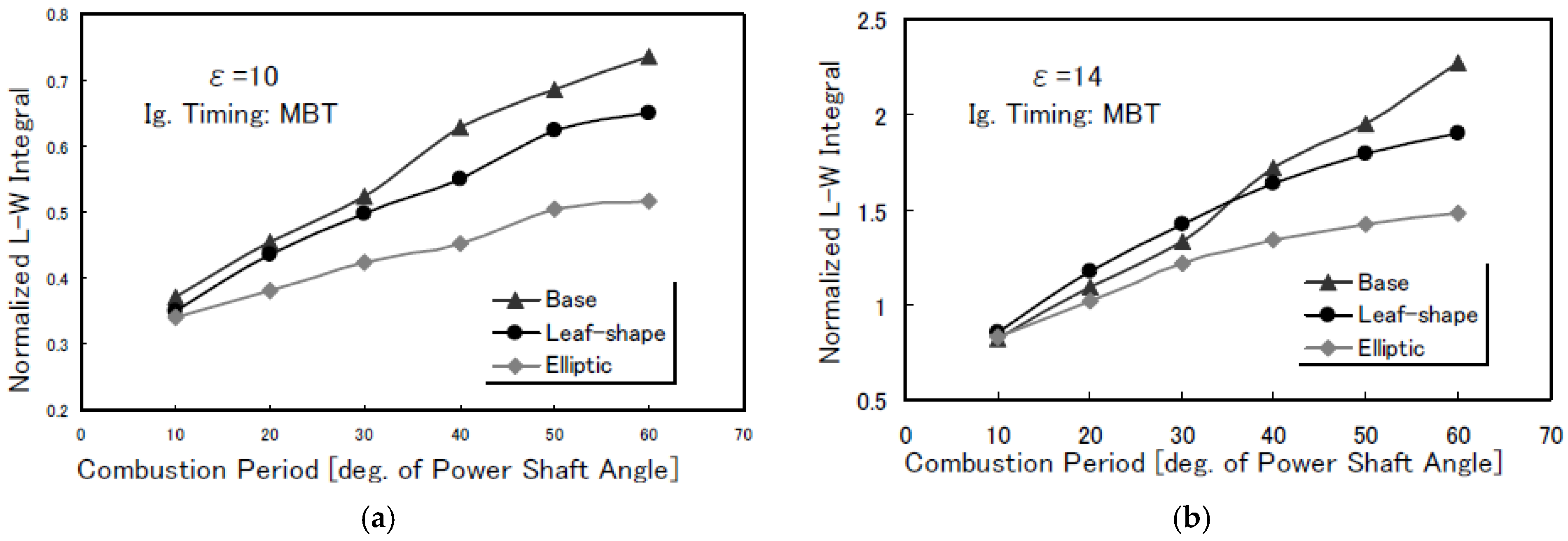

The Livengood–Wu integral model predicts spontaneous combustion timing by assuming a critical concentration of key free radicals. As illustrated in the

Figure 3, increasing the CR from 10:1 to 14:1 significantly raises the integral value. When the integral value reaches 1, it means that autoignition of the end gas occurs, so the increase in CR leads to a shorter time required for autoignition of the end mixture, and it is more likely to cause engine knocking.

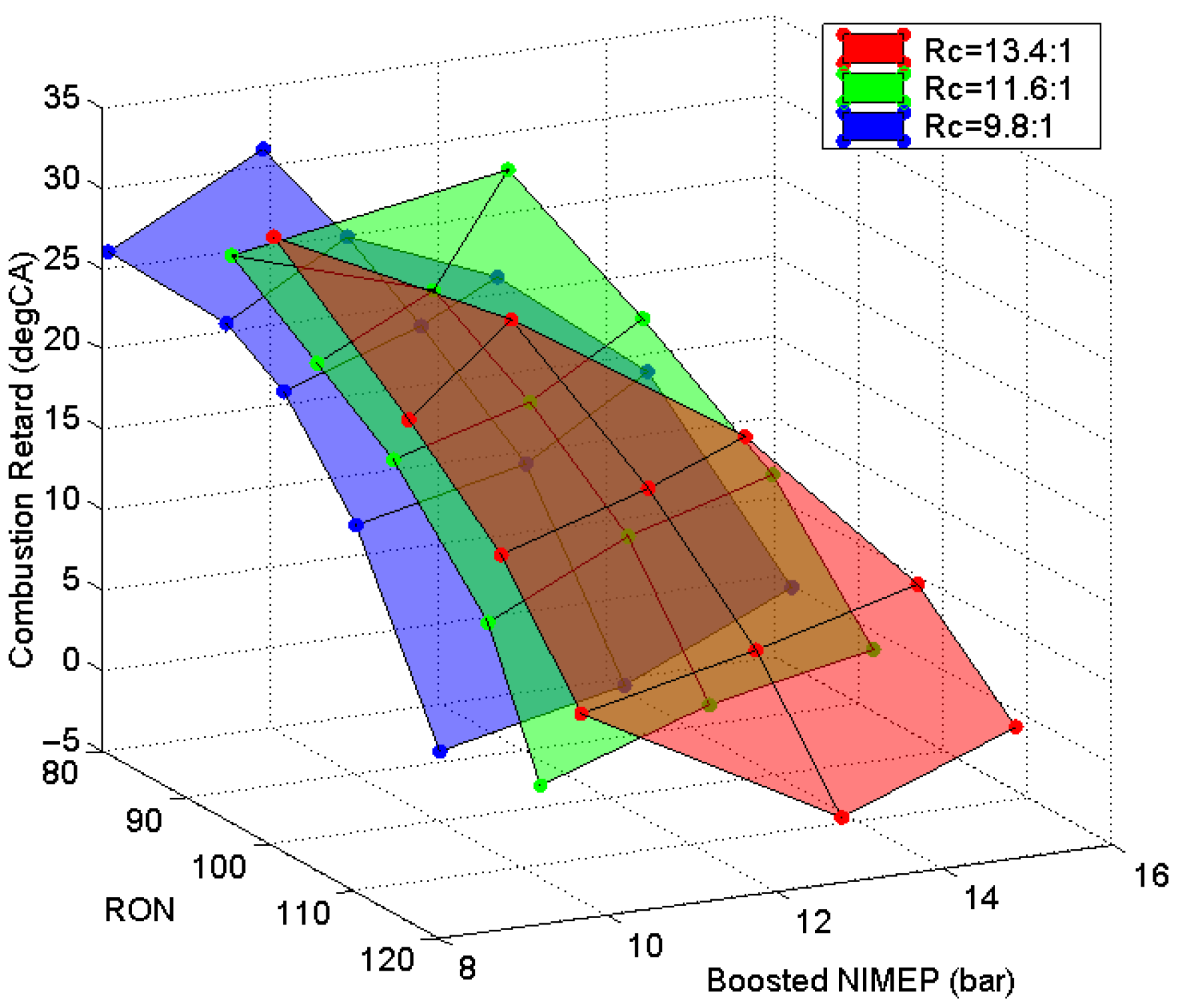

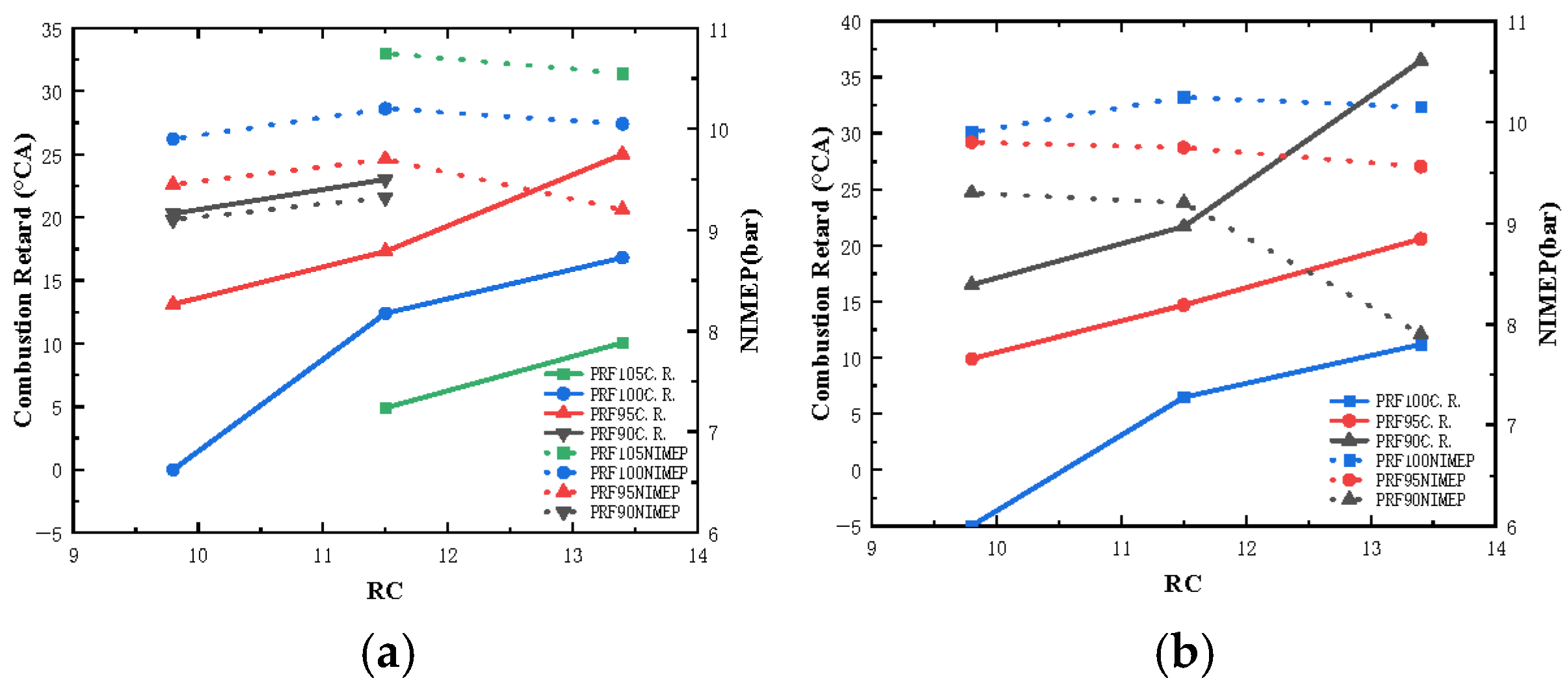

Under certain conditions, the compression ratio increases, and to avoid knocking, the ignition timing is delayed; as the compression ratio increases, the degree of delay also increases, resulting in increased exhaust losses, and cycle fluctuations increase, which is the most direct impact of the results caused by the knock, the most important factor limiting the compression ratio of gasoline engines to continue to improve. As shown in the accompanying

Figure 4, the CR increases from 9.8 to 11.6 and 13 under the naturally aspirated condition. To prevent knock from occurring, combustion is retarded at maximum output power and appears to have varying degrees of hysteresis. By increasing the compression ratio, the hysteresis degree also increases, resulting in a more pronounced IMEP loss. Consequently, the potential gain from an increased compression ratio is significantly diminished, resulting in a slight decrease in the actual NIMEP at a compression ratio of 13.4 compared with 9.8.

It has been established that high compression ratios have the potential to result in elevated compression end temperatures and pressures. This, in turn, can give rise to knock, which has been shown to initiate spontaneous combustion of the end mixture before the flame front arrives. This premature combustion interacts with the pressure wave from normal flame propagation, generating high-amplitude pressure oscillations. These oscillations may cause engine damage while adversely affecting thermal efficiency. The implementation of the conventional ignition timing retardation strategy to mitigate the intensity of the detonation has been shown to result in a substantial decline in efficiency, accompanied by an increase in exhaust loss and cycle fluctuation. Consequently, the increase in exhaust loss is recognized as the most immediate consequence of the detonation, with the latter being the predominant factor hindering the increase in the CR in gasoline engines, a matter of particular significance.

3.2. Increased Heat Transfer Losses

Heat transfer in internal combustion engines mainly occurs near the combustion end point, and the determining factors are the wall area and temperature, the combustion temperature, the heat transfer coefficient, and other parameters. Generally speaking, after the increase in compression ratio, the surface area ratio and combustion temperature are affected to a certain extent, which leads to changes in the amount of heat transfer.

Figure 5 shows a comparison at thermal equilibrium at compression ratios of 11.2 and 15, where the heat transfer losses as a percentage rise most significantly, and although the theoretical thermal efficiency increases, the indicated thermal efficiency gradually fails to benefit from the increase in compression ratio. Elevated combustion temperatures primarily drive the rise in thermal losses, with the peak combustion temperature increasing from 1450 K at a compression ratio of 10 to 1760 K at a compression ratio of 60 [

12]. Therefore, an important balancing act in the design of internal combustion engines is the need to find a suitable compromise between increasing thermal efficiency and minimizing heat losses.

3.3. Decrease in Combustion Homogeneity

The constant volume degree of heat release in gasoline engines is closely linked to exhaust losses; a poor constant volume degree results in higher exhaust losses. This degree is primarily determined by combustion phasing and combustion speed (combustion duration). In high-compression gasoline engines, combustion phasing may be retarded due to knock tendency, consequently reducing the constant volume degree of heat release. Meanwhile, combustion speed can undergo significant variations in high-compression gasoline engines as a result of changes in turbulent kinetic energy, temperature, and pressure, which in turn affects the constant volume degree.

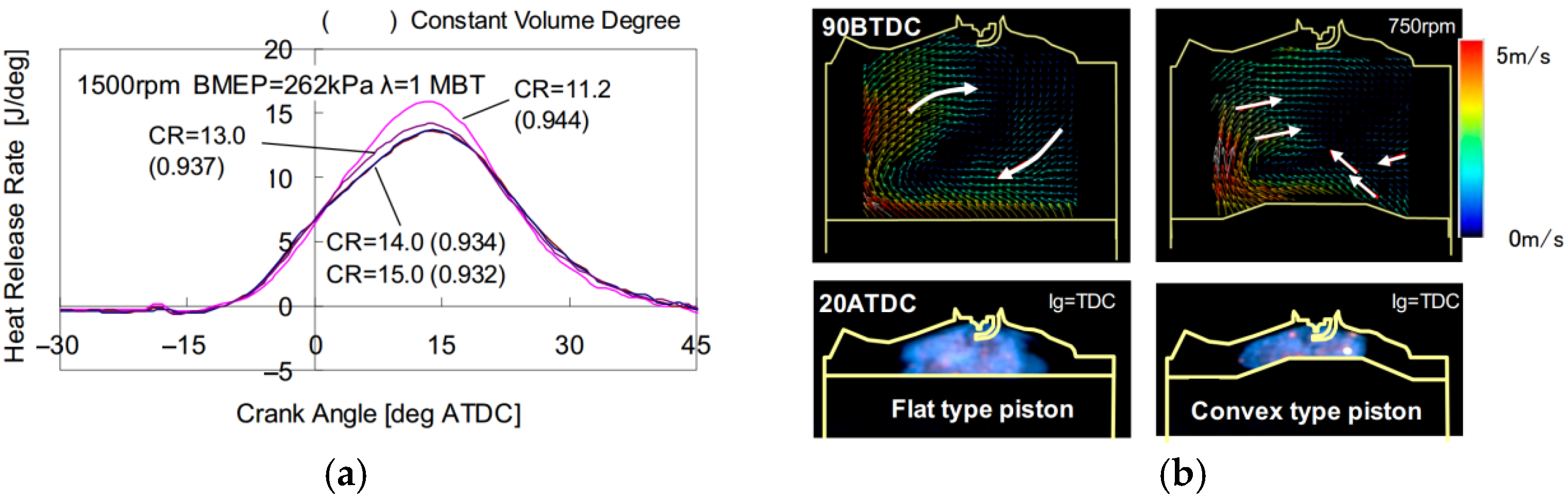

Figure 6 demonstrates these effects under knock-limited conditions at a compression ratio of 15. For an accurate comparison of compression-ratio effects on the combustion rate, the ignition timing was fixed across three tested CRs. The results show that as the CR increases from 11.2 to 15, the heat release rate decreases, while the combustion duration increases, leading to decreased combustion homogeneity. Visualization studies reveal that this is caused by two interrelated phenomena: (1) altered turbulence development due to piston crown geometry changes and (2) flame propagation interference as the piston crown moves closer to the spark plug at higher compression ratios. This proximity causes earlier flame–piston contact during the development stage, reducing the effective flame front area. Notably, isochronicity stabilizes at a compression ratio of 15 due to low-temperature reaction effects, though this phenomenon only occurs under specific boundary conditions.

3.4. Increased Dissociation Losses

Dissociation losses occur when excessively high cylinder temperatures cause combustion products to undergo pyrolysis, absorbing heat energy in the process [

19]. It has been determined that these losses cannot be fully characterized as unburned fuel losses. This is due to the fact that some dissociated products may recombine into final combustion products and release heat when temperatures decrease. Nevertheless, the phenomenon of dissociation produces effects analogous to retarded combustion phasing and should therefore be understood as a combined result of reduced isochronicity, leading to increased exhaust losses, and actual unburned losses.

3.5. Cold-Start Misfire and Increased Friction Losses

The issue of cold-start misfire remains a persistent concern in the domain of gasoline engine research, given its substantial impact on cost, durability, and reliability of aftertreatment equipment, among other factors. Despite the fact that high-compression-ratio gasoline engines experience elevated temperatures and pressures during the initiation stage, thereby facilitating the formation of the initial fire nucleus, the cold-start stage, particularly the initial combustion cycle in poor thermal atmospheres, and the precision of air–fuel ratio control cannot be assured. This is disadvantageous to the process of ignition. Moreover, due to the elevated back pressure, the current ignition system is subjected to greater demands, which in turn increases the likelihood of misfire to a certain extent. Concurrently, the high compression ratio of gasoline engines typically results in suboptimal airflow, hindering the development and propagation of the flame. This phenomenon also imposes a higher demand on the cold start, particularly during the initial cycle of combustion. Consequently, high-compression-ratio gasoline engines generally exhibit increased complexity when it comes to the cold-start process.

Friction losses occur throughout the engine’s rotating and reciprocating components. These losses exhibit positive correlation with peak cylinder pressure [

20]—a parameter that increases significantly with compression-ratio increase through both higher compression pressures and maximum combustion pressures. This inherent relationship makes friction reduction a key challenge in high-compression engine development, requiring comprehensive solutions including optimized component design and advanced friction reduction technologies.

4. Ways to Address the Negative Effects of High Compression Ratios

4.1. High-Octane Fuels

The fuel characteristic that exerts the most significant influence on the intensity of knock is the octane number, encompassing both the motor octane number (MON) and the research octane number (RON). These characteristics demonstrate a robust linear correlation across diverse fuel types. The results of an investigation into the effect of knock on different octane numbers of the basic reference fuel (PRF; an n-heptane and iso-octane mixture) and toluene reference fuel (TRF; a toluene and n-heptane mixture) at high compression ratios are shown in

Figure 7.

At low compression ratios (CR), increasing the CR requires minimal spark retardation, allowing the IMEP to benefit from higher compression and thus increase. However, at elevated CRs, significant combustion phase retardation occurs, causing the IMEP to decline. Fuels with high octane numbers exhibit reduced phase retardation during CR increase, enabling greater IMEP gains that support higher-CR operation. Consequently, optimal compression ratios correlate with fuel octane ratings.

4.2. Special Engine Construction

4.2.1. Inlet Design

The turbulent flame propagation velocity is calculated as [

21]

where

and

are the turbulent flame and laminar flame propagation speeds;

is the root-mean-square value of the turbulent dissipation speed;

a,

, and

are the model constants; and

Da is the Dummköhler number. Generally, at the end of the compression stroke, the stronger the turbulent kinetic energy is, the larger the corresponding

and

are. The level of turbulent kinetic energy remains consistent throughout the entire cylinder volume. Therefore, increasing the intake tract roll-off ratio can enhance the airflow pulsation rate at the ignition moment, thus realizing fast combustion and avoiding spontaneous combustion of the terminal gas mixture before the flame surface is reached.

For example, adjusting the lower bottom surface of the intake tract to a curved transition enhances the flow separation effect, resulting in a higher roll-off flow [

22]. Throughout the intake and compression stroke, the optimized intake tract maintains a high tumbling ratio, which not only helps to promote oil and gas mixing but also facilitates tumbling breakup at compression stroke completion, forming larger turbulent kinetic energy, increasing the flame surface propagation area in the cylinder, and making the flame propagation faster, which is more conducive to rapid consumption of the end mixture and reduction in knock.

4.2.2. Cooling System Design

Externally cooled EGR is used to re-enter the cylinder by cooling high specific heat capacity exhaust gases to produce some suppression of the flame, lowering the combustion temperature and improving the autoignition of the end mixture, as well as lowering the emissions.

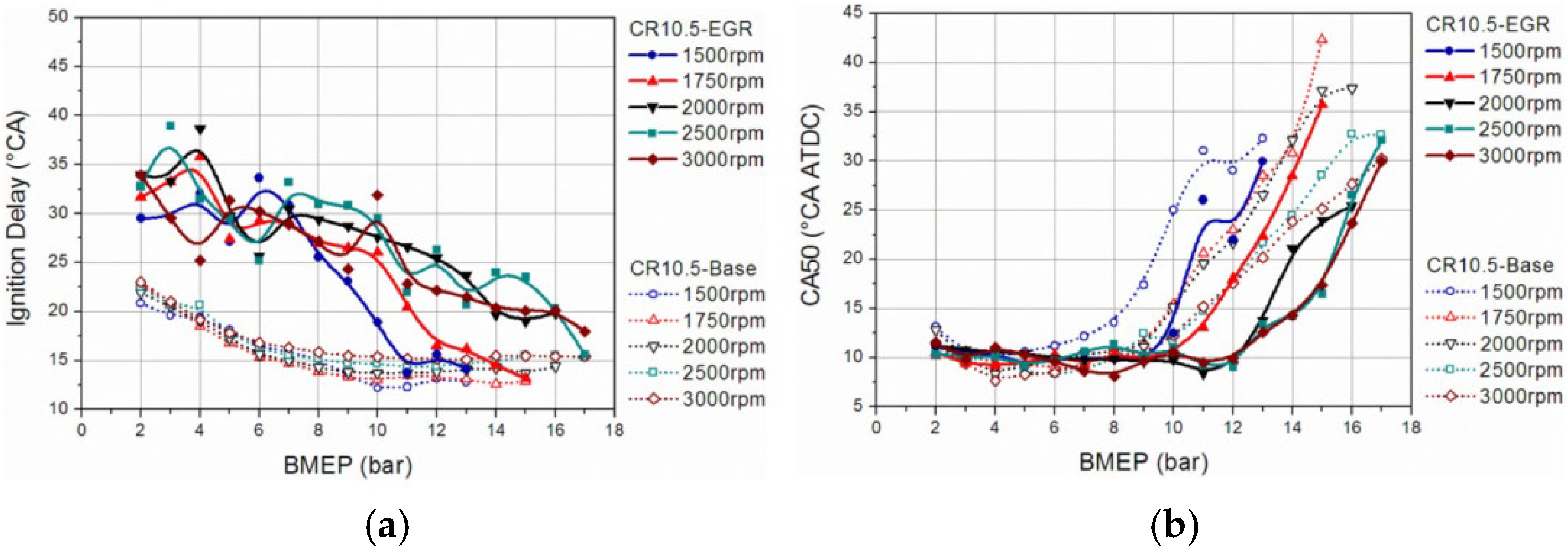

The EGR (exhaust gas recirculation) strategy is widely recognized for its benefits in high-compression-ratio gasoline engines. This strategy reduces temperatures during combustion and decreases the tendency to knock due to the introduction of additional work mass in the cylinder and increased heat capacity. This, in turn, reduces heat transfer losses. As demonstrated in

Figure 8, EGR exerts a substantial influence on both ignition lag and combustion phasing under diverse load–speed conditions. The ignition delay period serves as a critical indicator of combustion stability. As the load increases, the ignition delay gets shorter, stabilizing at approximately 15 °CA for loads exceeding 8 bar BMEP. It is notable that the introduction of EGR results in a significant extension of this delay period. Whilst higher compression ratios generally result in degradation of combustion phasing, the implementation of EGR has been demonstrated to provide compensating benefits through both knock suppression and phasing optimization. However, it should be noted that the compression ratios tested in the literature remain within the conventional range of production engines. This suggests that the effects of the exhaust gas recirculation (EGR) system are the most pronounced at extremely high compression ratios (e.g., above 15:1), and this area may be worthy of further investigation in future studies.

In addition to the use of cooling EGR to cool the mixture, some special structures can be used.

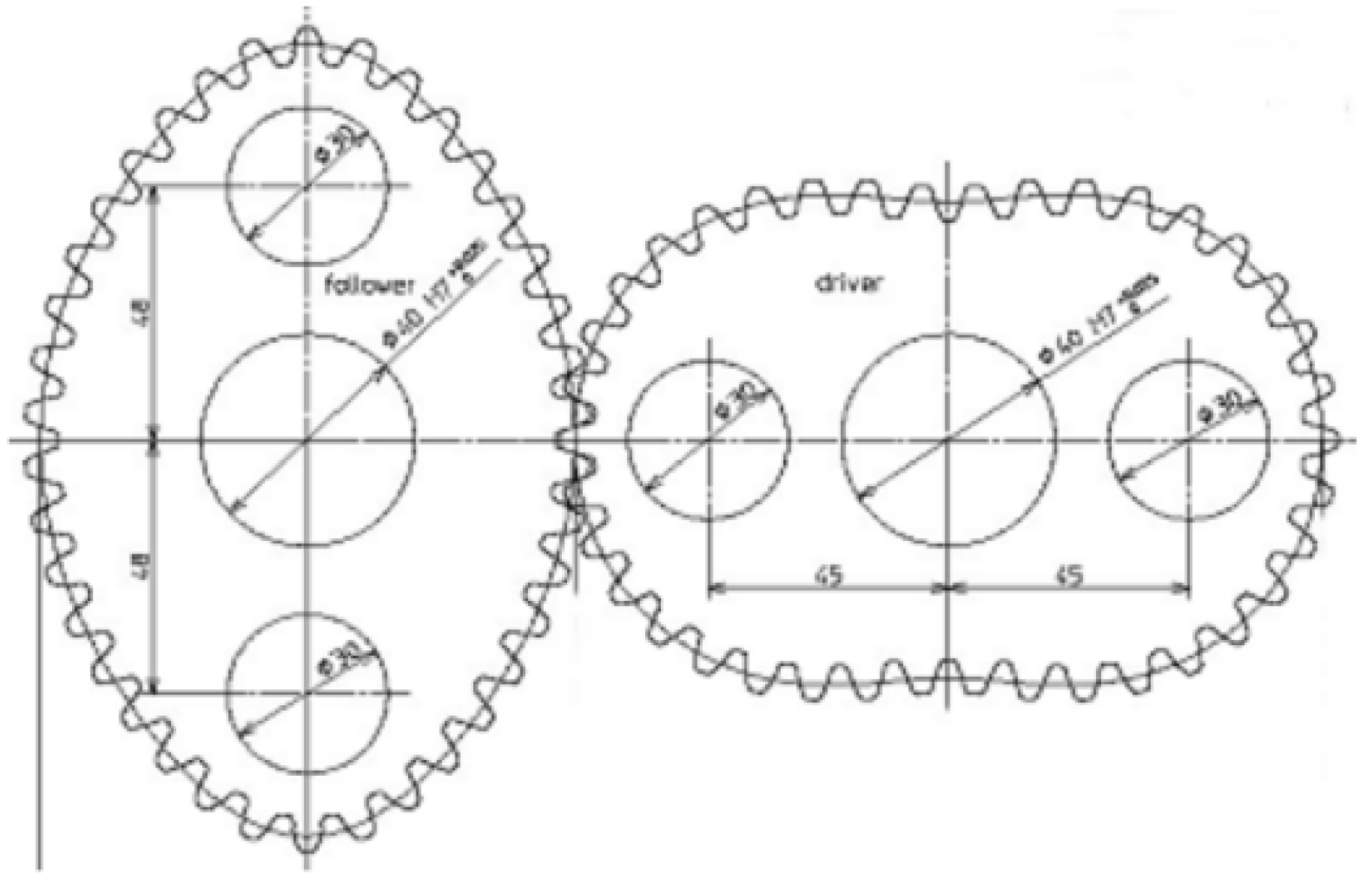

Figure 9 shows a special mechanism (a pair of blade-type gears), which is utilized to obtain a special set of piston and crankshaft angle relationships; compared with the normal crank–linkage mechanism of the piston movement law, it allows the piston to move faster near the upper stop point, so as to reduce the tendency to knock by using the rapid expansion cooling effect.

Figure 10 shows the results for a CR of 13.7. The results compare the limitations of knock on the ignition timing for the three operating conditions; the original piston trajectory is most obviously limited by knock, and the ignition timing is limited to the upper stop and cannot be advanced further. It is worth noting that although the CA ignition timing is advanced by 7°, the IMEP does not increase significantly, which indicates that the method causes some additional losses while optimizing the combustion phase. However, the final test results were still good for most conditions, with efficiency gains at all loads up to 1000 r/min, 1600 r/min, and 2000 r/min.

Hybrid engines operating with higher compression ratios, predominantly in the high-load fuel-economy zone, exhibit significant thermal loading and knock challenges. Consequently, enhanced cooling capacity is required. As demonstrated in Reference [

25], the coolant flow rate in water jackets directly influences the heat transfer coefficient of the combustion chamber walls, thereby affecting thermal dissipation performance. This relationship indicates that optimized water jacket design can effectively mitigate knock issues.

It has been demonstrated that enhancing cooling to reduce combustion chamber wall temperatures can effectively reduce end-gas temperatures and suppress knock tendency. However, excessively low wall temperatures substantially increase heat transfer losses, leading to efficiency degradation. Consequently, recent studies have investigated differential thermal management by analyzing location-specific cooling effects on knock suppression, implementing targeted cooling strategies to minimize adverse impacts on combustion stability.

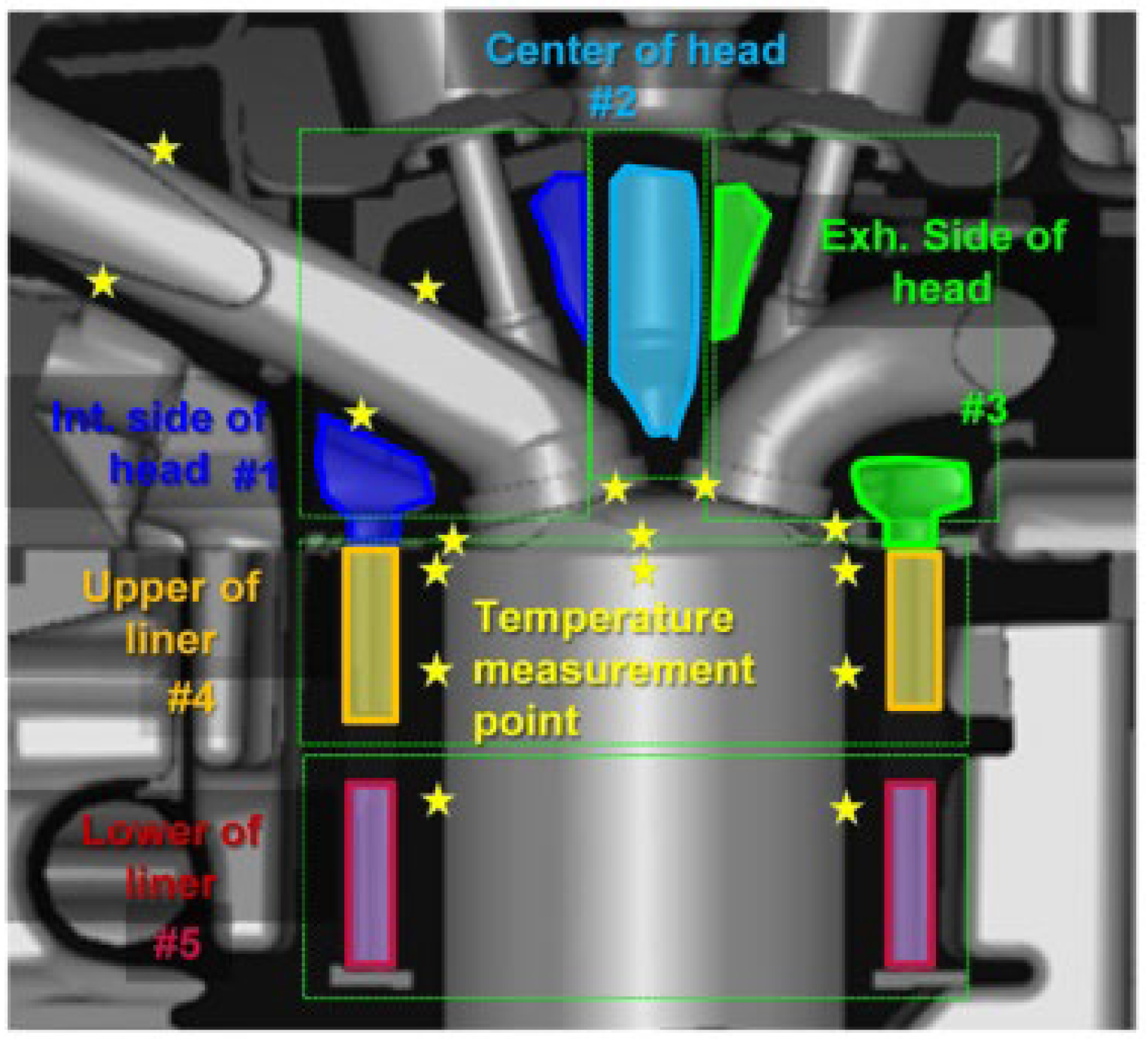

As illustrated in

Figure 11, a partitioned cooling system featuring dedicated water jackets for individual components enables precise temperature control, with comprehensive wall temperature monitoring during testing.

Figure 12 compares the knock suppression effectiveness of various cooling strategies, revealing that uniform wall temperature reduction achieves optimal knock mitigation, while the isolated cooling of the cylinder head’s intake side provides secondary benefits. The findings of the temperature measurements indicate that this secondary effect originates from significantly reduced intake runner temperatures. These temperatures are the result of the focused cooling of the cylinder head’s intake side.

4.3. Engine Strategy Design

In addition to the aforementioned search for higher octane fuels and better engine design, optimizing the engine strategy can also effectively reduce the negative effects of high compression ratios.

4.3.1. Lean Combustion

It has been demonstrated that lean combustion has the capacity to significantly reduce the in-cylinder combustion temperature. Furthermore, it has been shown to reduce heat transfer losses and enable low-temperature combustion, thereby suppressing vibration. Consequently, lean combustion can be utilized in high-compression-ratio technology. Simultaneously, the phenomenon of lean combustion has been demonstrated to have the capacity to markedly curtail engine fuel loss at minor and medium loads under conditions of pump gas loss. In conjunction with lean combustion on the cylinder, the increase in the mixture’s specific heat ratio has been shown to engender a substantial enhancement in the thermal efficiency of the engine. Firstly, as demonstrated in

Figure 13, the indicated efficiency increases steadily with enleanment, so that under stoichiometric conditions, the indicated efficiency improves from a reference value of 39.7% (λ = 1.00) to 45.4% at λ = 1.75 and finally reaches 46% at λ = 1.90. Secondly, an examination of the loss chain reveals that in the case of rarefied combustion, the observed increase in efficiency is primarily attributable to a reduction in HTR losses. Furthermore, as the excess air coefficient increases, both the ignition timing and the combustion phase are advanced, due to the weakened tendency to knock being observed until the combustion phase is optimized after the excess air coefficient exceeds 1.7. However, the combustion rate gradually slows down due to the effects of dilute combustion on the laminar flame speed and initial fire core development [

27]. Liu, Zuowen et al. [

28] found in their research that lean combustion (λ = 1.9–2.1) synergistically enables high-compression-ratio (CR = 17) operation by suppressing knock through reduced in-cylinder temperature peaks while reducing heat transfer and exhaust energy losses. This triple effect—achieved with 424 mJ ignition energy—yields a peak ITE of 50.3% at λ = 1.9 (IMEP = 10 bar). Efficiency gains diminish at higher loads (IMEP ≥ 12 bar) due to combustion instability (COV

IMEP limiting λ to 1.3–1.45), underscoring lean burn’s critical role in optimizing thermodynamic losses under knock-limited conditions.

4.3.2. Direct Water Injection (DWI)

The implementation of in-cylinder water injection (WI) has been identified as a pivotal strategy for the direct inhibition of knock. This approach has been demonstrated to play a vital role in the reduction in cylinder temperature, the effective inhibition of knock, and the increase in engine load. The following common water injection technologies are currently in use: airway WI, intake manifold WI, direct in-cylinder WI, and oil–water mixing in the form of emulsified oil injection. In comparison with alternative options, DWI has the advantages of flexible arrangement, precise control, and excellent cooling effect. It is well established that water has a significant latent heat of vaporization. When water mist is injected into the cylinder through the water injector, the atomized water droplets absorb a large amount of heat. This results in a significant reduction in the temperature of the mixture in the cylinder. The effective cooling of the mixture in the cylinder in turn reduces the combustion temperature and effectively suppress knock.

The LTC mode has garnered significant attention due to its combination of high thermal efficiency and low particulate matter/NOx emissions compared with spark ignition and CDC [

29,

30]. Among these, Homogeneous Charge Compression Ignition (HCCI) has been the most extensively studied, involving the injection of a lean pre-mixed charge into the cylinder during the intake stroke. Water injection (WI) technology is primarily used to suppress knock in SI engines [

31,

32,

33], but Christensen et al. [

34] found that it can extend combustion duration and control the combustion phase in CAI mode, though it increases CO/HC and reduces NOx. Iwashiro’s team [

35] further confirmed that direct WI increases CO/HC but improves thermal efficiency and expands engine load range. Their study investigated the effects of water-containing ethanol fuel on HCCI by achieving CAI through WI coupled with CDC cylinder direct heat recovery. G.D. Telli et al. [

36] employed full exhaust gas recirculation combined with WI in a diesel cylinder to address the issue of uncontrollable HCCI combustion. The results indicate that the indicated efficiency and combustion efficiency of a 20 vol.% water-containing ethanol mixture were slightly lower than the E95W05 baseline, but its CO, soot, and NOx emissions were significantly better than those of 30–40% high-water-content fuel mixtures.

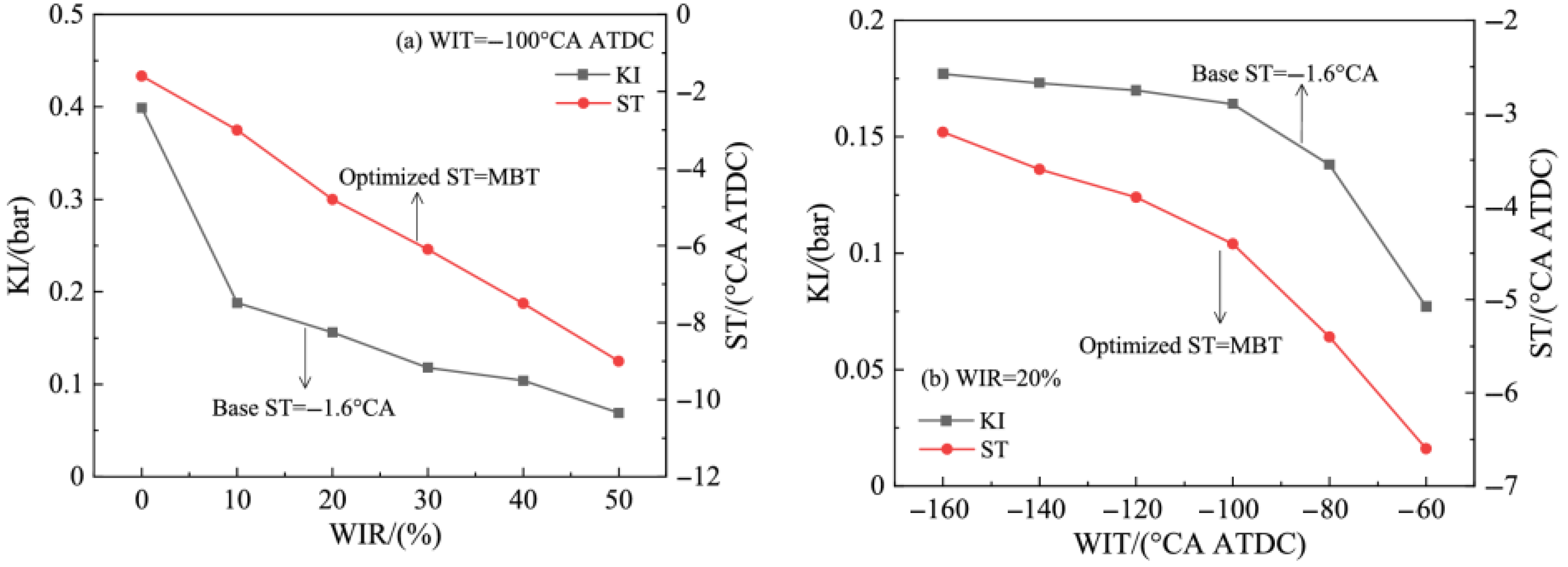

Reference [

37], a high-compression-ratio single-cylinder engine research study, shows that the cylinder WI strategy can significantly inhibit high-CR engine knocking and enhance the engine load. In addition, the optimized in-cylinder water injection strategy can still effectively suppress knock without losing fuel economy.

Figure 14 demonstrates the effects of different WI ratios and WI phases on KI.

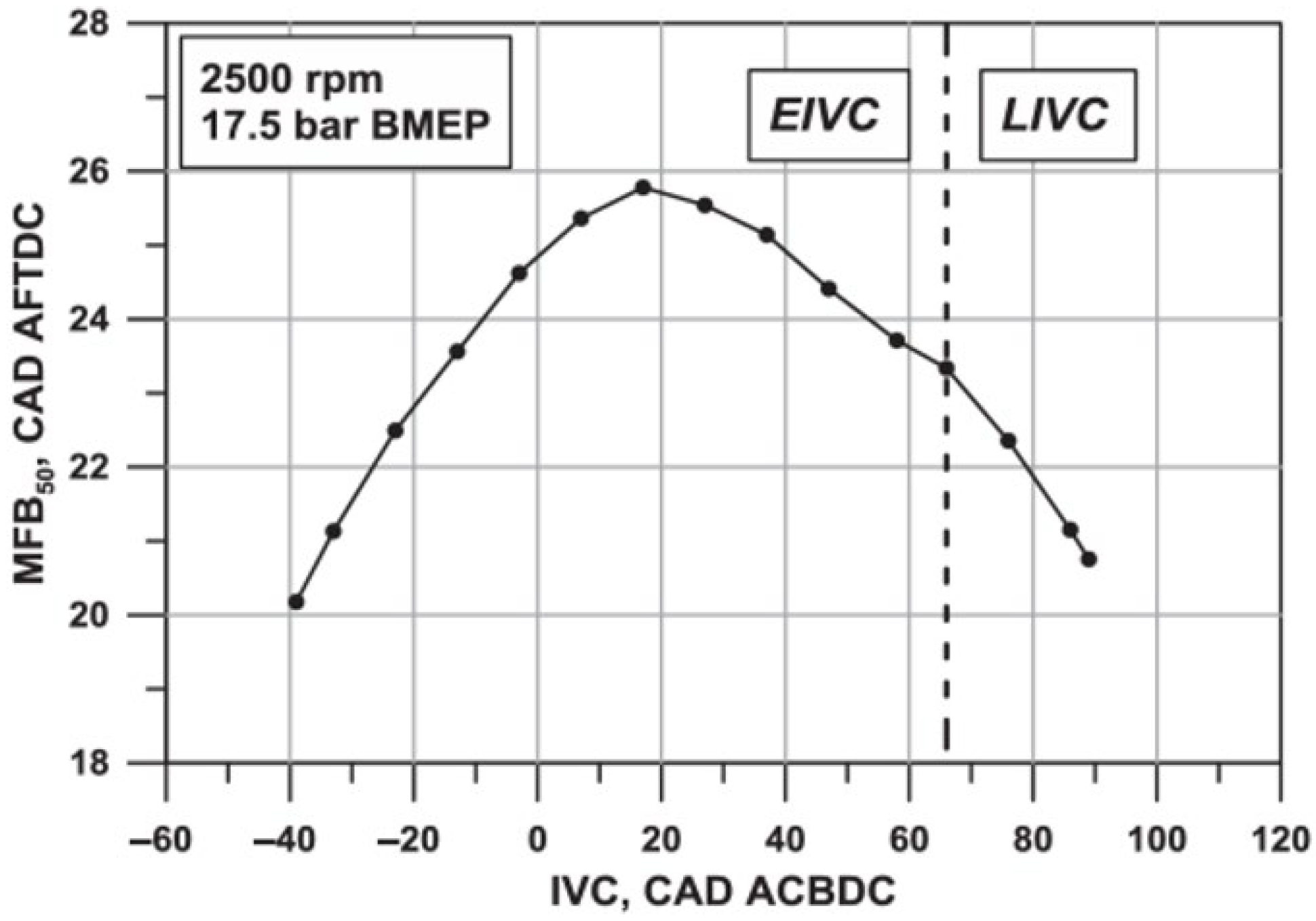

4.3.3. Valve Strategy

The strategy employed by the valve can exert a substantial influence on the alteration in in-cylinder flow and the effective compression ratio. This, in turn, has the capacity to impact the propensity to knock. A literature study compares the effects of three different valve strategies (early intake valve closing, normal intake valve closing, and late intake valve closing) on effective CR, efficiency, and tendency to knock.

Figure 15 shows three different valve profiles. The findings indicate that in comparison to the standard intake valve closing moment (illustrated by the black dotted line in

Figure 16), a certain degree of adjustment in the timing of the intake valve closing moment can mitigate the occurrence of knocking. This adjustment leads to an advancement in the combustion phase, resulting in a reduction in exhaust gas temperature and combustion thickening. Consequently, this optimizes efficiency by 1.9% and 2.4%, respectively. However, both the early and late intake valve closing strategies have the effect of increasing the boost pressure. The observed change in popping tendency of the valve strategy is primarily attributable to a reduction in the effective CR (lower compression temperature). Additionally, it is noteworthy that the decrease in airflow motion exerts a detrimental influence on the process.

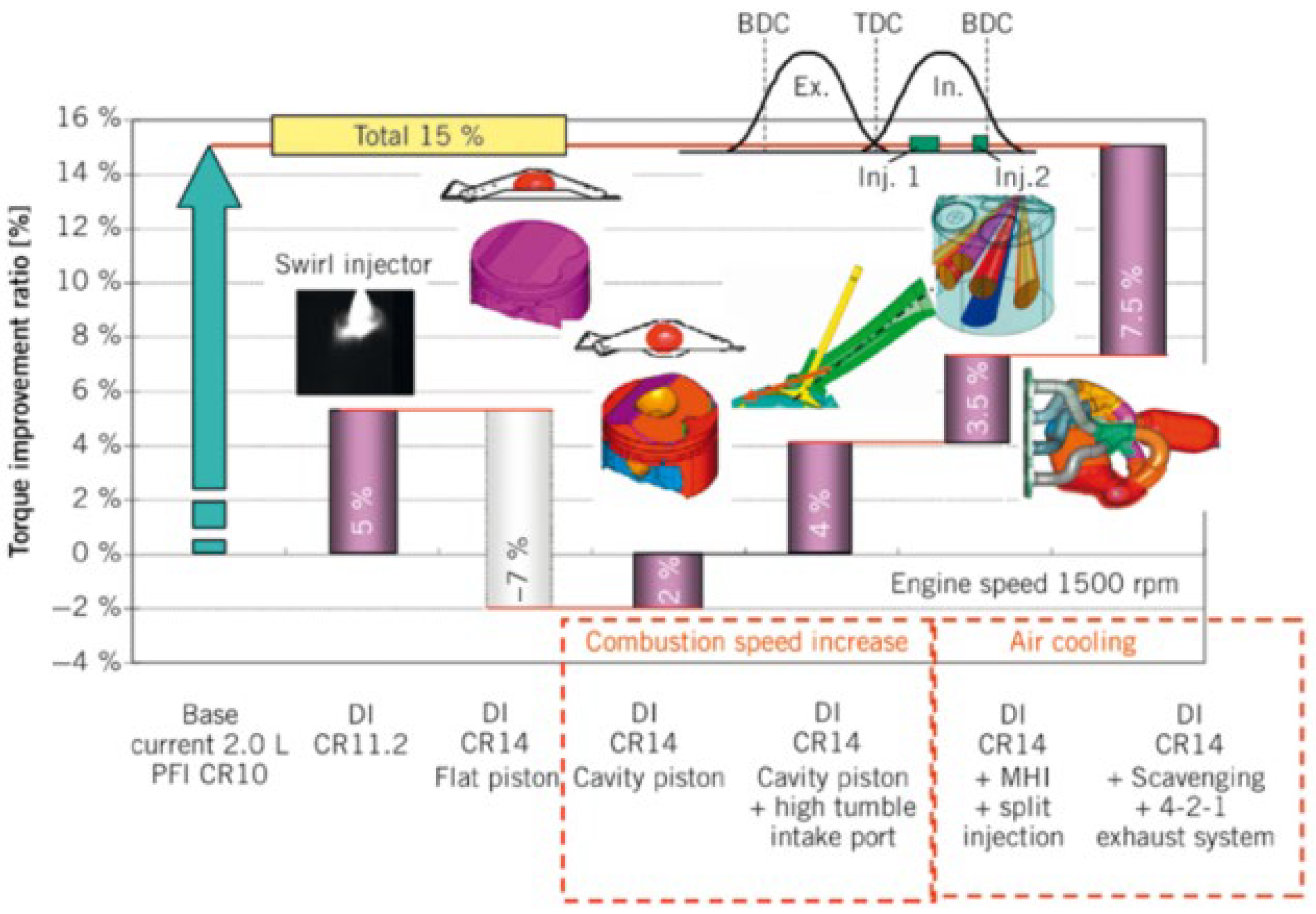

4.3.4. Rapid Combustion

The concept of fast combustion has been proposed in high-compression-ratio gasoline engines to reduce the tendency to knock [

18,

39,

40,

41,

42].

Figure 17 shows the measures adopted by Mazda Japan to solve the problem of maximum torque loss due to knock in a high-CR gasoline engine through the idea of rapid combustion. At the beginning of the project, a flat-topped piston was used; it was not conducive to flame propagation, and the combustion was slow, which resulted in a large torque loss. In order to solve this problem, a piston in the form of a dimple was used, the speed of combustion was accelerated, the combustion duration period was reduced, and the torque was increased by 2%. In order to further reduce the combustion duration, the intake channel angle and valve angle were optimized to enhance airflow movement, which, combined with cylinder bore optimization, resulted in a 2 °CA reduction in combustion duration, again increasing the torque by 4%.

4.3.5. Multi-Engine Strategy Synergy

Ferrey, P. et al. [

43] demonstrated that in a turbocharged GDI engine, implementing the Miller cycle (EIVC = −55 °CA) increases the geometric compression ratio to 13.5:1 while reducing the effective compression ratio to 10.8:1. Coupled with a high-tumble combustion system (TR = 2.5), this approach achieved 4.1% thermal efficiency improvement under WLTC conditions, extended the knock margin by 17%, and maintained the rated power output at 142 kW. Prechamber technology can synergize with other engine technologies (e.g., lean combustion or water injection) to simultaneously enhance thermal efficiency and extend the knock limit. Corrigan, D. et al. [

44], through research, compared knock characteristics between conventional spark ignition (SI) and prechamber combustion systems by using the same single-cylinder research engine and, by evaluating them, established novel knock detection methods. Detailed examination confirms greater complexity in high-frequency pressure oscillations for prechamber systems. Critically, the prechamber igniter demonstrates a significant gain in knock-limited (KL) combustion phasing compared with standard spark plugs at equivalent knock intensities. Ikeya, K. et al. [

42] found that in turbocharged GDI engines, brake thermal efficiency (BTE) reaches 39.2% at CR = 14.5:1 (2.4% higher than CR = 12.0). However, further increasing the compression ratio to 17.5:1 yields only a 0.4% additional efficiency gain due to 180% intensified knock tendency and 42% increased heat transfer losses. By adopting the Miller cycle (EIVC = −60 °CA) to reduce the effective compression ratio to 13.8:1 combined with 25% cooled EGR and high tumble flow (TR = 2.3), knock suppression and combustion phasing optimization were achieved, ultimately realizing 41.1% BTE at CR = 17.5 and overcoming the efficiency degradation limitation at high compression ratios.

4.4. Adiabatic Engines

In addition to the aforementioned methods of reducing heat transfer losses, such as exhaust gas recirculation (EGR) and rarefaction, the addition of coatings to the cylinder walls or the alteration in material properties has also been demonstrated to be an effective means of achieving this objective.

Adiabatic engines have been demonstrated to substantially augment the negative work during the compression process. The majority of the losses in heat transfer are dissipated in the form of an increase in the exhaust temperature, thereby indicating a significant limitation of the theory. However, the findings of simulation studies indicate that the application of coatings with reduced thermal conductivity and specific heat capacity can effectively mitigate heat transfer losses. This approach concomitantly increases the optimal efficiency–compression-ratio threshold, as illustrated in

Figure 17 and

Figure 18.

As demonstrated in

Figure 18, the insulated coating exhibits rapid surface temperature fluctuations. The “variable temperature” coating’s surface temperature rises during combustion and declines during exhaust/intake strokes, achieving dual benefits: the reduction in combustion heat loss and the prevention of intake air heating.

Figure 19 shows the result of using a material (VM4) with a thermal conductivity 0.001 times that of aluminum and a specific heat capacity 0.01 times that of aluminum as a coating (thickness of 1 mm). VM4 achieves three synergistic effects: (1) a reduction in combustion heat transfer loss through low thermal conductivity; (2) the precise tracking of the temperature in the cylinder variations due to minimal heat capacity; (3) a reduction in compression/exhaust stroke wall temperatures, thereby decreasing negative compression work relative to conventional adiabatic engines.

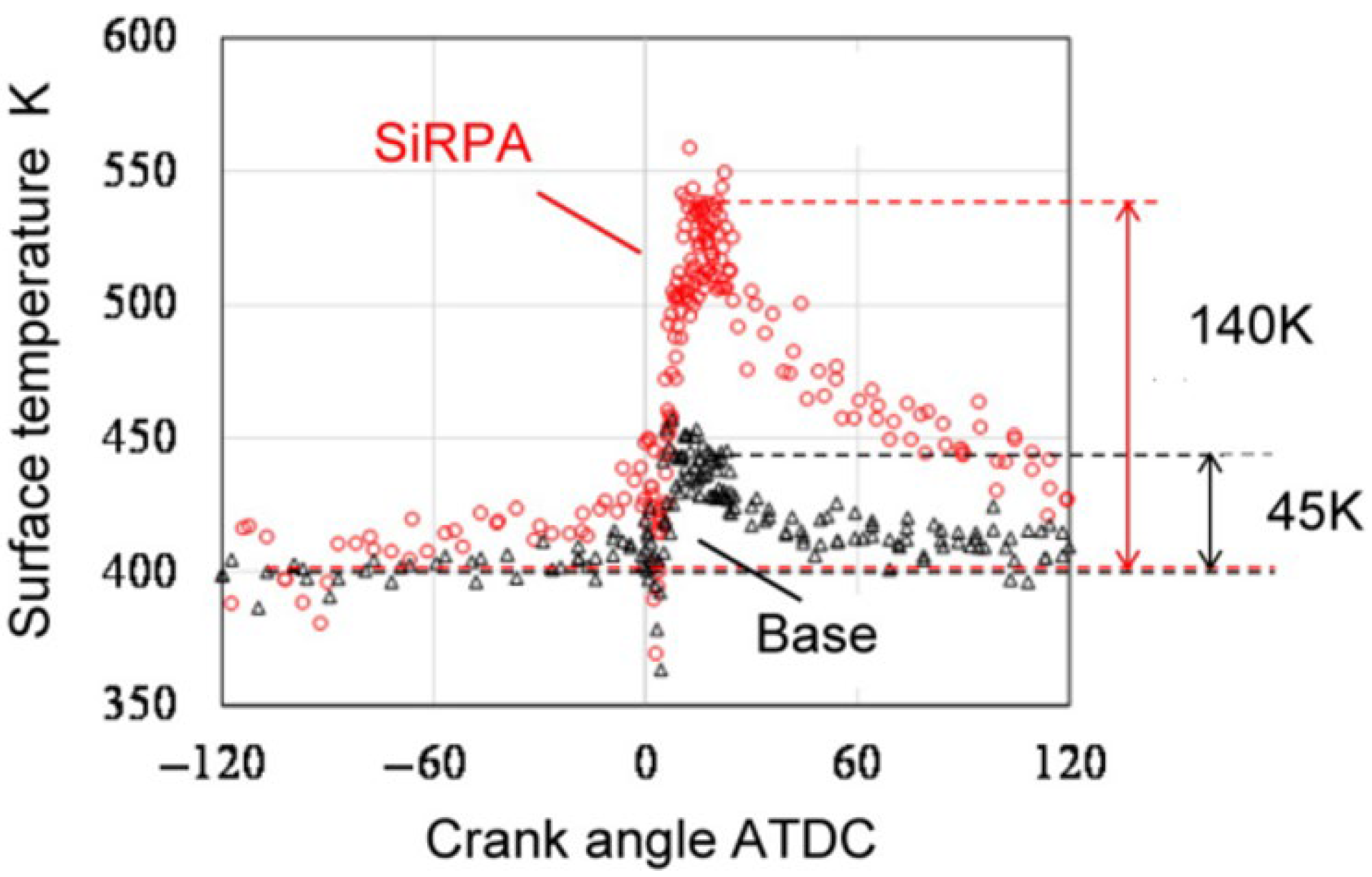

Subsequently to the initial simulation verification, Toyota Motor Corporation in Japan conducted experimental validation using silica-reinforced porous anodized aluminum (SiRPA) as the coating material. SiRPA is characterized by its ability to preserve the desired thermal properties of low conductivity and heat capacity while concurrently demonstrating superior durability.

Figure 20 compares the temporal variation in piston surface temperatures between the SiRPA-coated and uncoated (base) cases. The results demonstrate that the SiRPA coating induces a rapid temperature rise during combustion, followed by a sharp decline during the expansion stroke. A temperature fluctuation amplitude of approximately 140 K is the result of this.

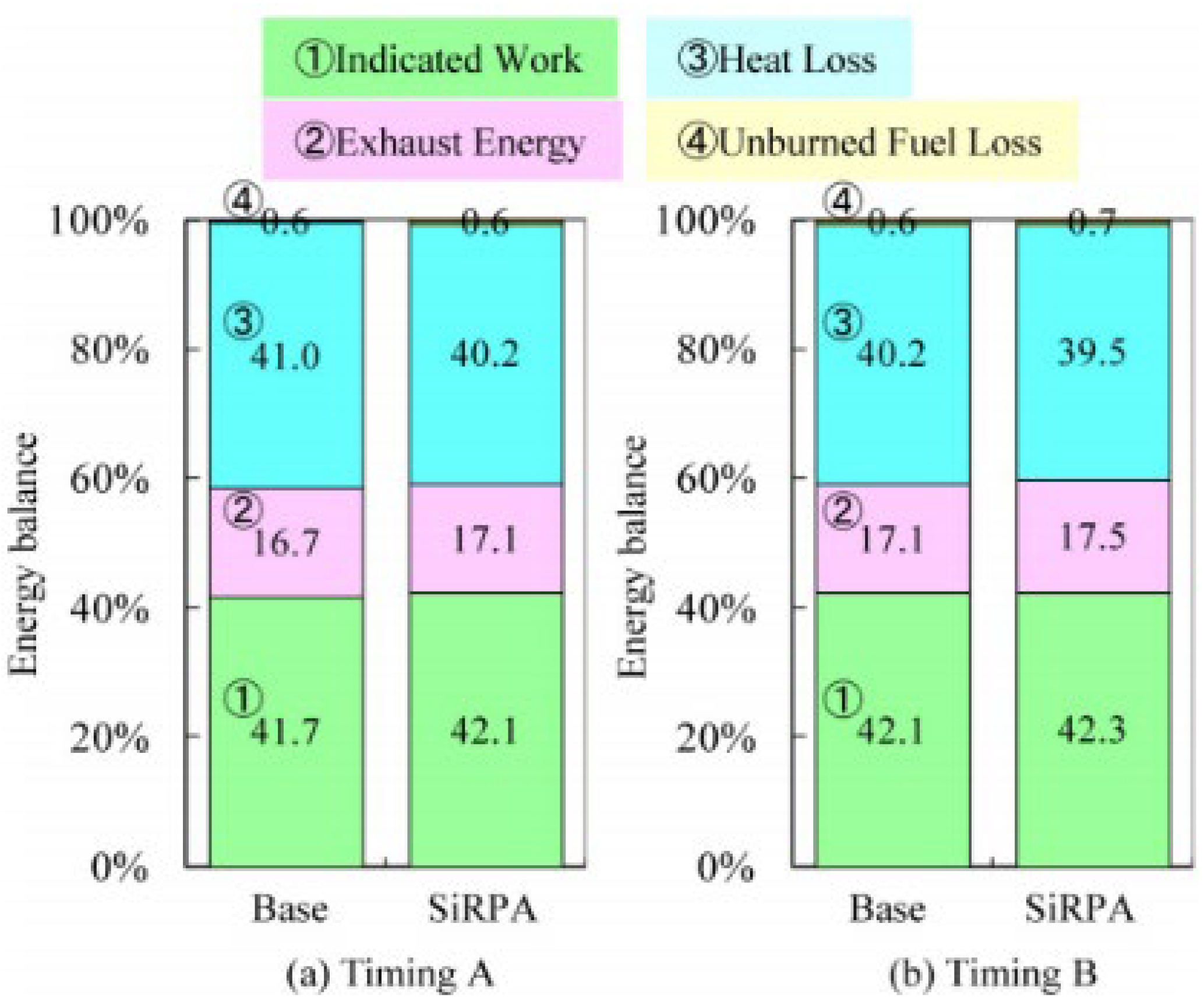

Figure 21 provides a more detailed analysis of the impact of SiRPA across different combustion phases. The findings indicate that the coating mitigates heat transfer losses during all combustion stages; however, a proportion of these savings is counterbalanced by augmented exhaust losses. Notwithstanding, the aggregate effect remains positive, and the final indicated work is still improved.

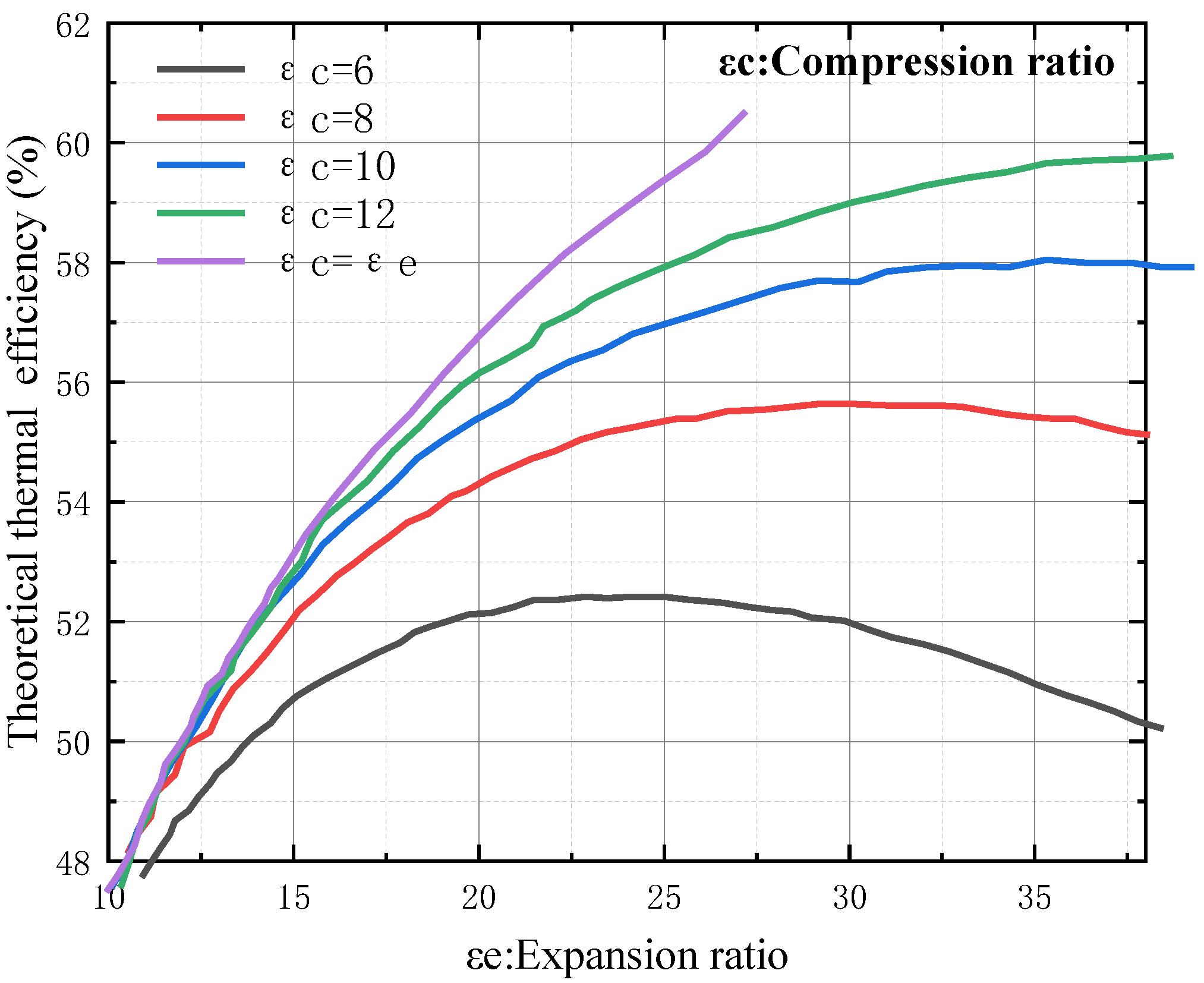

4.5. Independent Adjustment of Compression and Expansion Ratios

Furthermore, it is not a disadvantageous solution to consider the CR separately from the expansion ratio, in addition to increasing the CR. Consequently, certain studies have examined the impact of compression and expansion ratios on theoretical thermal efficiency independently. The findings of these calculations are presented in

Figure 22. The results demonstrate that when the compression ratio (ε

c) is maintained at or slightly above 10, a substantial enhancement in thermal efficiency can be achieved by solely increasing the expansion ratio (ε

e). For instance, in a real engine, even if εc is fixed at approximately 10 in order to prevent knock and other abnormal combustion phenomena, the theoretical thermal efficiency (TTE) can be improved by around 20% relative to the case of ε

c = ε

e = 10 by increasing εe alone to 25 or even higher. However, it is necessary to take into account the occurrence of both HTR losses and unburned losses and the impact of increasing the expansion-ratio peaks to approximately ε

e = 20~25, which is marginally lower than the TTE case, yet it can be enhanced by a minimum of 15% in comparison with the fundamental condition of ε

c = ε

e = 10 [

47]. The test utilizes a variable compression ratio and a variable air distribution phase in order to achieve an effective compression-ratio adjustment when the load is minimal. This is accomplished through a small clearance volume and late intake valve closing, resulting in a large expansion ratio. Consequently, the effective compression ratio is maintained at 13 for a large load. This ensures that the intake volume of the intake valve is closed normally, necessitating the use of a large clearance volume. Consequently, the expansion ratio is 13. Experimental findings indicate a 4.9% enhancement in the ITE of the load.

4.6. Cold-Start Misfire Risk Monitoring

The risk of misfire in the first cycle of the cold-start process can be controlled by using sensors such as ionic current and cylinder pressure sensors to monitor the starting process, and when a misfire occurs [

48,

49,

50], misfire make-up is carried out in the current cycle, thus avoiding a large amount of hydrocarbon emissions from a misfire in the current cycle. Meanwhile, ionic current has been widely studied as an effective and low-cost sensor [

51,

52].

4.7. Combustion System Machining Accuracy Control

The CR of the engine has a direct impact on the power, economy, and emission levels. The smaller the manufacturing tolerance of the compression ratio is, the more favorable the burst consistency control is, which also reduces the friction loss to a certain extent. By changing the manufacturing process of the engine combustion chamber curved surface, valve head, and piston end face from forging to machining, the machining accuracy was significantly improved from the original ±0.3 mm to ±0.05 mm. In addition, by grouping and assembling the axle shingles, the tolerance of the compression ratio was better controlled, and the consistency of the compression ratio of each cylinder was ensured. After improving the machining accuracy of the combustion system, the tolerance of the CR was reduced from 16.0 ± 0.7 to 16.0 ± 0.3. At the same time, machining significantly improved the surface roughness of the combustion chamber, which effectively reduced the emergence of hot spots on the surface, thus avoiding the phenomenon of premature combustion or knock in the combustion process [

22].

5. Conclusions

In order to achieve peak carbon and carbon neutrality goals, hybrid powertrains paired with more thermally efficient hybrid engines will be the next key research direction for the automotive industry. In hybrid engine systems, high-compression-ratio technology is an important means of improving the indicated thermal efficiency of gasoline engines, but its application faces many challenges.

Increasing the compression ratio induces the premature spontaneous combustion of the end-gas mixture prior to flame front arrival, generating high-frequency pressure oscillations that directly precipitate engine knocking. This phenomenon is exacerbated by elevated peak cylinder pressures, which simultaneously amplify frictional losses across engine components. To suppress knock, ignition timing retardation is typically employed; however, this strategy inherently increases exhaust energy losses and cyclic variability while potentially degrading engine performance and risking cylinder block damage—collectively establishing knocking as the primary constraint on further compression-ratio increase. Additionally, higher compression ratios increase combustion temperatures, intensifying heat transfer losses and promoting the thermal dissociation of reaction products, thereby compounding dissociation losses. In high-compression engines, the synergistic effects of knocking and retarded timing impair fuel heat release kinetics, extending combustion duration and decreasing charge homogeneity. Compounding these issues, suboptimal in-cylinder flow structures under high compression ratios impede flame kernel development and propagation while simultaneously imposing more stringent cold-start operational requirements.

In response to the problems brought about by high-compression-ratio technology, researchers have proposed a variety of optimization strategies. For example, the use of high-octane fuels, the optimization of the engine structure, the application of EGR technology, thin combustion, and in-cylinder water injection can effectively alleviate the knock problem. In terms of reducing heat transfer losses, optimization can be achieved through the use of heat-insulating materials or the independent adjustment of the compression–expansion ratio. In the case of cold-start misfires, risk-monitoring techniques have been shown to be an effective solution. Controlling combustion processing accuracy can reduce engine friction losses to some extent.

This review comprehensively analyzes the technical challenges and solutions for high-compression-ratio engines, providing foundational insights for hybrid-dedicated engine development while elucidating root causes of inherent limitations. Current strategies, however, remain predominantly confined to isolated problem solving, lacking integrated frameworks for the synergistic optimization of fuel chemistry, combustion chamber design, and control methodologies. Three critical research voids persist: (1) inadequate multiphysics coupling studies addressing knock/heat transfer/flow field interactions, (2) the absence of extreme-condition databases for ultra-high compression ratios (CR > 16), and (3) deficient cross-scale integration methodologies. Future efforts must prioritize establishing experimental databases for extreme operating regimes and developing multi-parameter cooperative control systems via digital twin platforms, thereby accelerating the market deployment of high-compression hybrid engines.

Author Contributions

Conceptualization, Z.K.; methodology, Z.K.; validation, Q.L.; formal analysis, Z.K.; investigation, Q.L.; resources, B.M. and Z.Z.; data curation, Q.L.; writing—original draft preparation, Q.L.; writing—review and editing, C.F., B.M., Z.Z. and Z.K.; visualization, Q.L.; supervision, Z.K.; project administration, Z.K.; funding acquisition, C.F. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Natural Science Foundation of Chongqing Municipality under grant CSTB2023NSCQ-LZX0169.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Baitan Ma and Zhiqiang Zhang were employed by the company Dongfeng Liuzhou Motor Compoany Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhang, S.; Xie, X.; Zhang, T.; Xie, H.; Sun, F. A study on the low-carbon transition path of China’s road transport sector under the “dual-carbon” goal. J. Environ. Sci. 2024, 44, 430–442. [Google Scholar] [CrossRef]

- Gupta, S.K.; Krishnasamy, A. A relative comparison of HCCI, PCCI, and RCCI combustion strategies: An alternative fuels perspective. Int. J. Engine Res. 2024, 25, 1078–1092. [Google Scholar] [CrossRef]

- Sammarchi, S.; Li, J.; Izikowitz, D.; Yang, Q.; Xu, D. China’s coal power decarbonization via capture and storage and biomass co-firing: A LCA case study in Inner Mongolia. Energy 2022, 261, 125158. [Google Scholar] [CrossRef]

- Golzari, R.; Zhao, H.; Hall, J.; Bassett, M.; Williams, J.; Pearson, R. Impact of intake port injection of water on boosted downsized gasoline direct injection engine combustion, efficiency and emissions. Int. J. Engine Res. 2019, 22, 295–315. [Google Scholar] [CrossRef]

- Zhou, L. Internal Combustion Mechanics; Mechanical Industry Press: Beijing, China, 2011. [Google Scholar]

- HYUNDAI MOTOR COMPANY. Development of the Kappa 1.6L GDI Engine for Hybrid Application; SAE Technical Paper 2017-01-1023; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- TOYOTA MOTOR CORPORATION. Toyota’s New 2.5L Gasoline Engine for Hybrid Vehicles; SAE Technical Paper 2018-01-0370; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- TOYOTA. TNGA Powertrain: Dynamic Force Engine Technology White Paper; Toyota Internal Publication: Toyota City, Japan, 2018; pp. 12–15. [Google Scholar]

- China Automotive Engineering Research Institute. Plug-in Hybrid Electric Vehicle Engine Certification Test Report; CAERI Report CAERI-2020-ET-005; China Automotive Engineering Research Institute: Tianjin, China, 2020. [Google Scholar]

- GAC Research Institute. Transcript of GAC GMC 2.0 Hybrid System Technology Launch [EB/OL]; GAC Research Institute: Guangzhou, China, 2021. [Google Scholar]

- Celik, M.B. Experimental determination of suitable ethanol–gasoline blend rate at high compression ratio for gasoline engine. Appl. Therm. Eng. 2008, 28, 396–404. [Google Scholar] [CrossRef]

- Cohn, D.R.; Bromberg, L.; Rabinovich, A. High Compression Ratio, Hydrogen Enhanced Gasoline Engine System. U.S. Patent 6655324B2, 2 December 2003. [Google Scholar]

- Li, T.; Gao, Y.; Wang, J.; Chen, Z. The Miller cycle effects on improvement of fuel economy in a highly boosted, high compression ratio, direct-injection gasoline engine: EIVC vs. LIVC. Energy Convers. Manag. 2014, 79, 59–65. [Google Scholar] [CrossRef]

- Costa, R.C.; Sodré, J.R. Compression ratio effects on an ethanol/gasoline fuelled engine performance. Appl. Therm. Eng. 2011, 31, 278–283. [Google Scholar] [CrossRef]

- Zhen, X.; Wang, Y.; Zhu, Y. Study of knock in a high compression ratio SI methanol engine using LES with detailed chemical kinetics. Energy Convers. Manag. 2013, 75, 523–531. [Google Scholar] [CrossRef]

- Morikawa, K.; Kaneko, M.; Moriyoshi, Y. A study on new combustion method of high compression ratio spark ignition engine. SAE Trans. 2005, 449–456. [Google Scholar] [CrossRef]

- Gerty, M.D.; Heywood, J.B. An Investigation of Gasoline Engine Knock Limited Performance and the Effects of Hydrogen Enhancement; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Yamakawa, M.; Youso, T.; Fujikawa, T. Combustion technology development for a high compression ratio SI engine. SAE Int. J. Fuels Lubr. 2012, 5, 98–105. [Google Scholar] [CrossRef]

- Liu, D.; Li, Q.; Wang, L.; Zhao, E.; Sun, C. G12V190ZLDT gas engine. Pet. Sci. Technol. Forum 2018, 36, 24–26. [Google Scholar]

- Tung, S.C.; Mcmillan, M.L. Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- Tan, Z.; Reitz, R. Modeling Ignition and Combustion in Spark Ignition Engines Using a Level Set Method. In Proceedings of the SAE 2003 World Congress & Exhibition, Detroit, MI, USA, 3–6 March 2003; SAE: Detroit, MI, USA, 2003. [Google Scholar]

- Zhang, Z.Q.; Cai, J.L. Research on knock control of dedicated hybrid engine with ultra-high compression ratio. Automot. Technol. 2024, 9, 25–31. [Google Scholar] [CrossRef]

- Lu, H.; Deng, J.; Hu, Z.; Wu, Z.; Li, L.; Yuan, F.; Xie, D.; Yuan, S.; Shen, Y. Study on Fuel Economy Improvement by Low Pressure Water Cooled EGR System on a Downsized Boosted Gasoline Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Morikawa, K.; Yoshimatsu, A.; Moriyoshi, Y.; Kuboyama, T.; Matsuura, K. A Study of High Compression Ratio SI Engine Equipped with a Variable Piston Crank Mechanism for Knocking Mitigation; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Grandin, B.; Denbratt, I. The Effect of Knock on Heat Transfer in SI Engines. In Proceedings of the SAE 2002 World Congress & Exhibition, Detroit, MI, USA, 4–7 March 2002; SAE: Detroit, MI, USA, 2002. [Google Scholar]

- Imaoka, Y.; Shouji, K.; Inoue, T. A Study of Combustion Technology for a High Compression Ratio Engine: The Influence of Combustion Chamber Wall Temperature on Knocking. SAE Int. J. Engines 2016, 9, 768–776. [Google Scholar] [CrossRef]

- Luszcz, P.; Takeuchi, K.; Pfeilmaier, P. Homogeneous lean burn engine combustion system development–Concept study. In 18. Internationales Stuttgarter Symposium; Springer Vieweg: Wiesbaden, Germany, 2018; pp. 205–223. [Google Scholar]

- Liu, Z.; Zheng, Z. The effect of ignition energy on the lean combustion limitation in high compression ratio engines. Energy 2024, 301, 131591. [Google Scholar] [CrossRef]

- Srivastava, D.K.; Agarwal, A.K.; Datta, A.; Maurya, R.K. Advances in Internal Combustion Engine Research; Springer Nature: Singapore, 2018. [Google Scholar]

- Krishnamoorthi, M.; Malayalamurthi, R.; He, Z.; Kandasamy, S. A review on low temperature combustion engines: Performance, combustion and emission characteristics. Renew. Sustain. Energy Rev. 2019, 116, 109404. [Google Scholar] [CrossRef]

- Wan, J.; Zhuang, Y.; Huang, Y.; Qian, Y.; Qian, L. A review of water injection application on spark-ignition engines. Fuel Process. Technol. 2021, 221, 106956. [Google Scholar] [CrossRef]

- Lanni, D.; Galloni, E.; Fontana, G. Numerical analysis of the effects of port water injection in a downsized SI engine at partial and full load operation. Appl. Therm. Eng. 2022, 205, 118060. [Google Scholar] [CrossRef]

- Pei, Y.; Zhang, Q.; Peng, Z.; An, Y.; Shi, H.; Qin, J.; Zhang, B.; Zhang, Z.; Gao, D. Thermal efficiency improvement of lean burn high compression ratio engine coupled with water direct injection. Energy Convers. Manag. 2022, 251, 114969. [Google Scholar] [CrossRef]

- Christensen, M.; Johansson, B. Homogeneous charge compression ignition with water injection. In Proceedings of the International Congress and Exposition, Detroit, MI, USA, 1–4 March 1999. [Google Scholar]

- Iwashiro, Y.; Tsurushima, T.; Nishijima, Y.; Asaumi, Y.; Aoyagi, Y. Fuel consumption improvement and operation range expansion in HCCI by direct water injection. In Proceedings of the SAE 2002 World Congress, Detroit, MI, USA, 4–7 March 2002. [Google Scholar]

- Telli, G.D.; Zulian, G.Y.; Lanzanova, T.D.M.; Martins, M.E.S.; Rocha, L.A.O. Investigation of the use of wet ethanol in an HCCI engine using water injection and direct exhaust heat recovery. Energy Convers. Manag. X 2023, 18, 100377. [Google Scholar] [CrossRef]

- Zhang, Q.; Pei, Y.; An, Y.; Peng, Z.; Qin, J.; Shi, H.; Zhang, B.; Zhang, Z.; Gao, D. Study of water direct injection on knock control and combustion process of a high compression ratio GDI engine. Fuel 2021, 306, 121631. [Google Scholar] [CrossRef]

- Teodosio, L.; Pirrello, D.; Berni, F.; De Bellis, V.; Lanzafame, R.; D’Adamo, A. Impact of intake valve strategies on fuel consumption and knock tendency of a spark ignition engine. Appl. Energy 2018, 216, 91–104. [Google Scholar] [CrossRef]

- Goto, T.; Isobe, R.; Yamakawa, M.; Nishida, M. The new Mazda gasoline engine Skyactiv-G. MTZ Worldw. eMagazine 2011, 72, 40–47. [Google Scholar] [CrossRef]

- Fan, M.-Q. Mazda Motor Corporation’s New Skyactiv-G Gasoline Engine. Foreign Intern. Combust. Engines 2012, 44, 11–15. [Google Scholar]

- Yamazaki, D.; Mori, A.; Murase, E. The Development of a New V6 3.5 L Turbocharged Gasoline Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Ikeya, K.; Takazawa, M.; Yamada, T.; Park, S.; Tagishi, R. Thermal efficiency enhancement of a gasoline engine. SAE Int. J. Engines 2015, 8, 1579–1586. [Google Scholar] [CrossRef]

- Ferrey, P.; Miehe, Y.; Constensou, C.; Collee, V. Potential of a Variable Compression Ratio Gasoline SI Engine with Very High Expansion Ratio and Variable Valve Actuation. SAE Int. J. Engines 2014, 7, 468–487. [Google Scholar] [CrossRef]

- Corrigan, D.J.; Di Blasio, G.; Ianniello, R.; Silvestri, N.; Breda, S.; Fontanesi, S.; Beatrice, C. Engine Knock Detection Methods for Spark Ignition and Prechamber Combustion Systems in a High-Performance Gasoline Direct Injection Engine. SAE Int. J. Engines 2022, 15, 883–897. [Google Scholar] [CrossRef]

- Wakisaka, Y.; Inayoshi, M.; Fukui, K.; Kosaka, H.; Hotta, Y.; Kawaguchi, A.; Takada, N. Reduction of heat loss and improvement of thermal efficiency by application of “temperature swing” insulation to direct-injection diesel engines. SAE Int. J. Engines 2016, 9, 1449–1459. [Google Scholar] [CrossRef]

- Fujimoto, H.; Yamamoto, H.; Fujimoto, M.; Yamashita, H. A Study on Improvement of Indicated Thermal Efficiency of ICE Using High Compression Ratio and Reduction of Cooling Loss; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Akihisa, D.; Daisaku, S. Research on Improving Thermal Efficiency Through Variable Super-High Expansion Ratio Cycle; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Chao, Y.; Chen, X.; Deng, J.; Hu, Z.; Wu, Z.; Li, L. Additional injection timing effects on first cycle during gasoline engine cold start based on ion current detection system. Appl. Energy 2018, 221, 55–66. [Google Scholar] [CrossRef]

- Fan, Q.; Bian, J.; Lu, H.; Tong, S.; Li, L. Misfire detection and re-ignition control by ion current signal feedback during cold start in two-stage direct-injection engines. Int. J. Engine Res. 2014, 15, 37–47. [Google Scholar] [CrossRef]

- Cao, Y.; Li, L. A Novel Closed Loop Control Based on Ionization Current in Combustion Cycle at Cold Start in a GDI Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Butt, R.H.; Chen, Y.; Mack, J.H.; Saxena, S.; Dibble, R.W.; Chen, J.-Y. Improving ion current of sparkplug ion sensors in HCCI combustion using sodium, potassium, and cesium acetates: Experimental and numerical modeling. Proc. Combust. Inst. 2015, 35, 3107–3115. [Google Scholar] [CrossRef]

- Gao, Z.; Wu, X.; Huang, Z.; Yoshiyama, S.; Tomita, E.; Yamazaki, K.; Higashi, T. The interdependency between the maximal pressure and ion current in a spark-ignition engine. Int. J. Engine Res. 2013, 14, 320–332. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).