Numerical Analysis of Heat Transfer in a Double-Pipe Heat Exchanger for an LPG Fuel Supply System

Abstract

1. Introduction

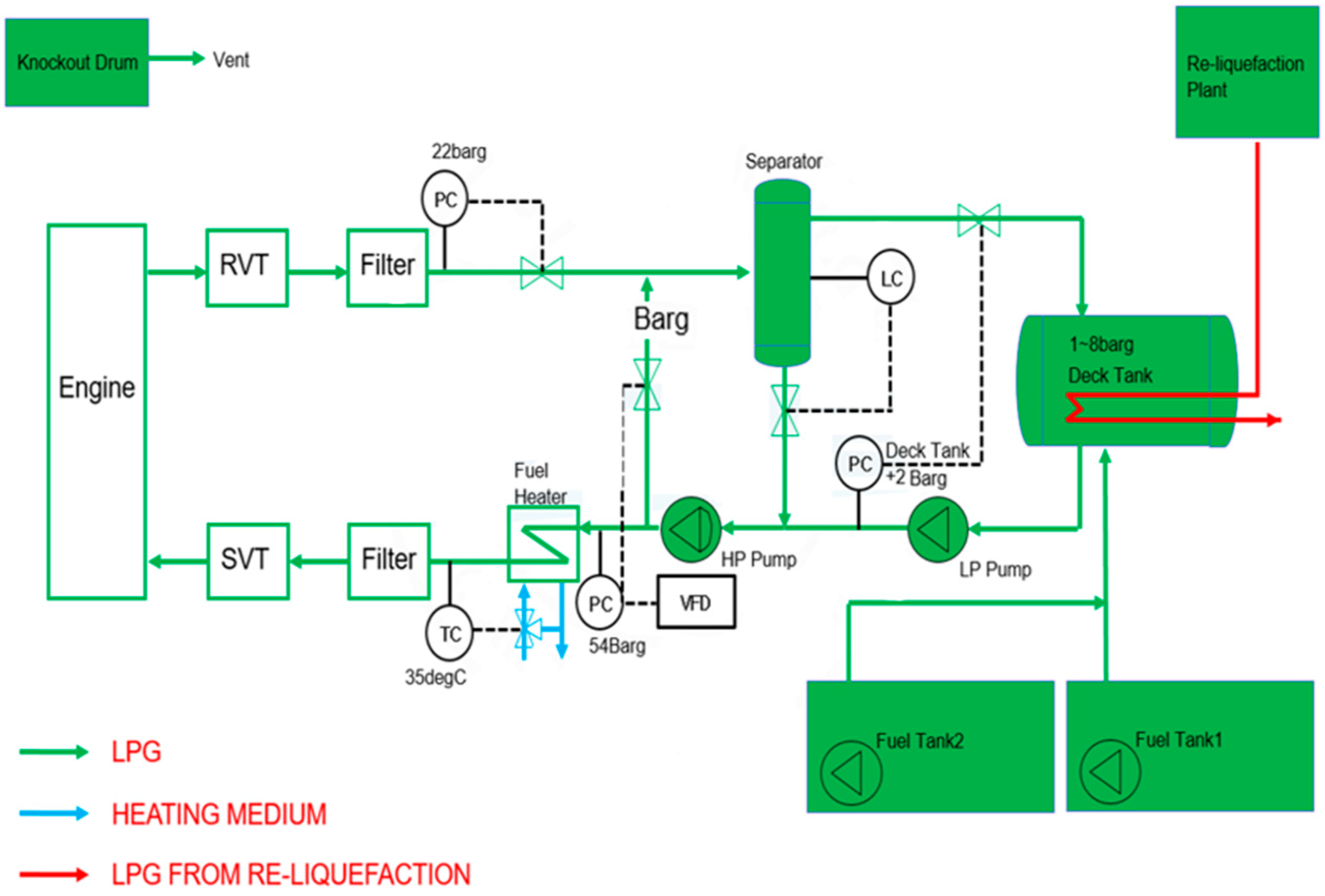

2. Background

3. Numerical Analysis

3.1. Governing Equation

3.2. Numerical Conditions

4. Results

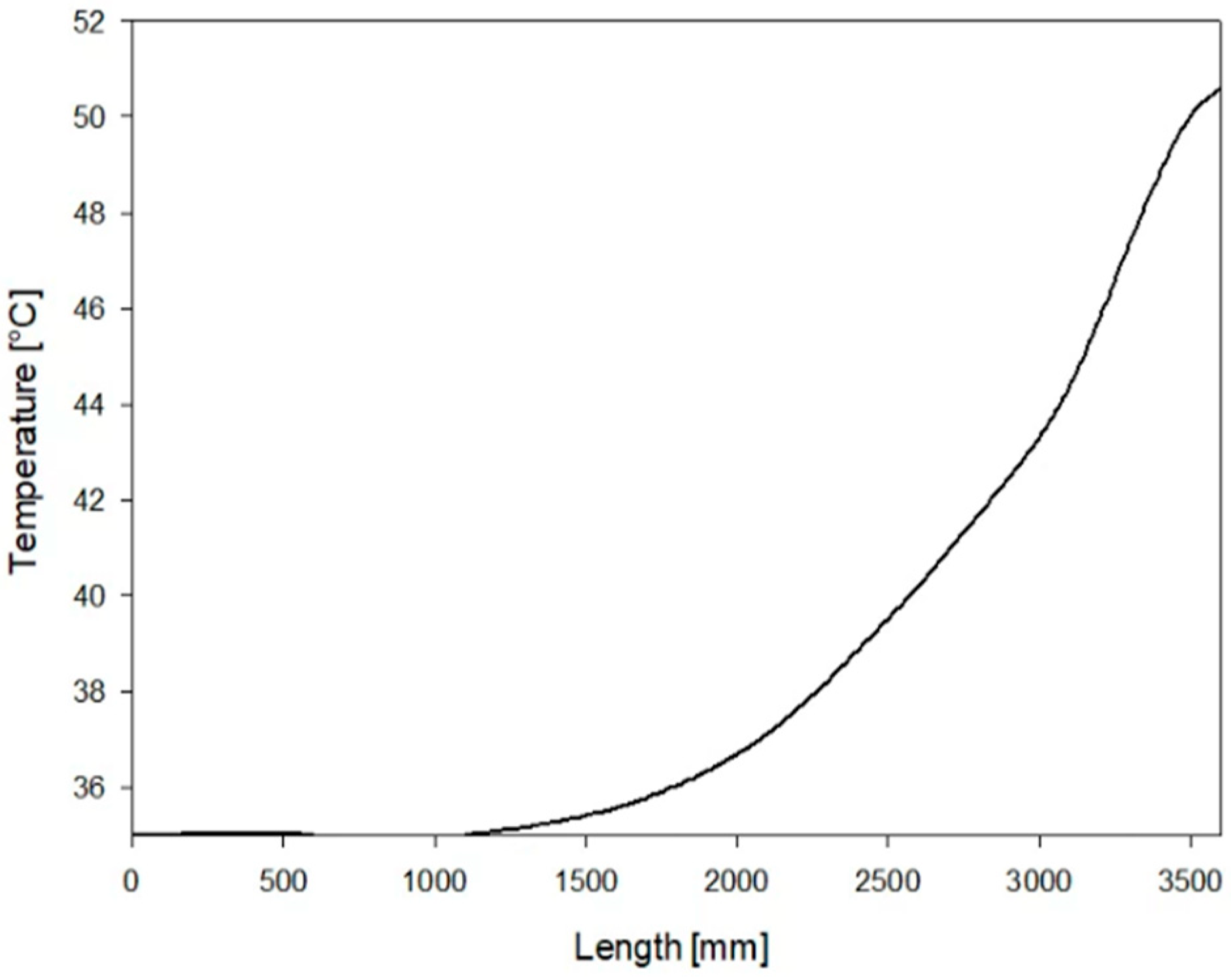

4.1. Numerical Validation Study

4.2. Parametric Study

4.2.1. Effects of the Turbulence Model

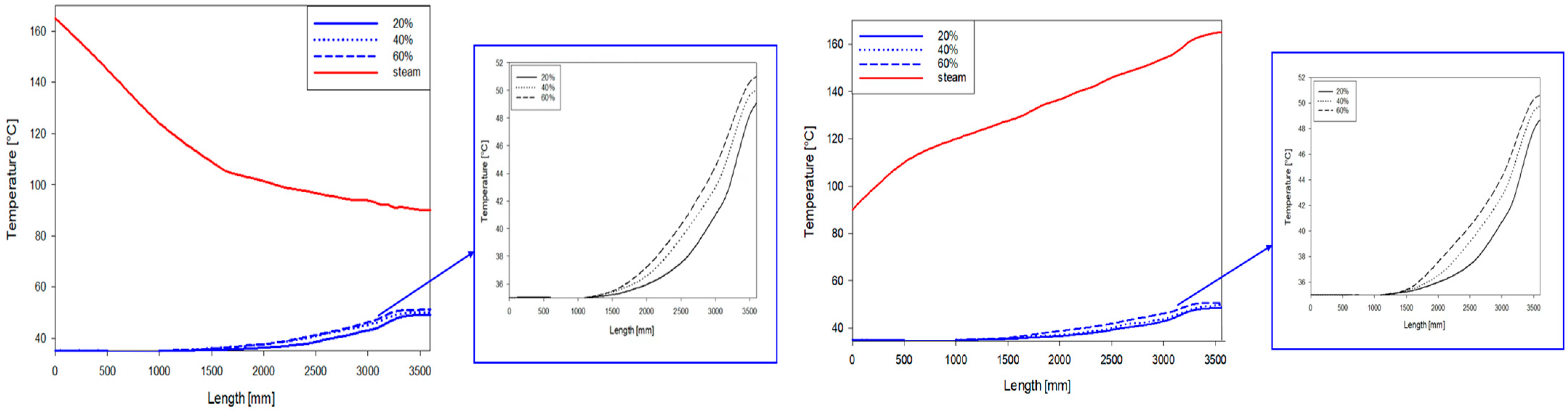

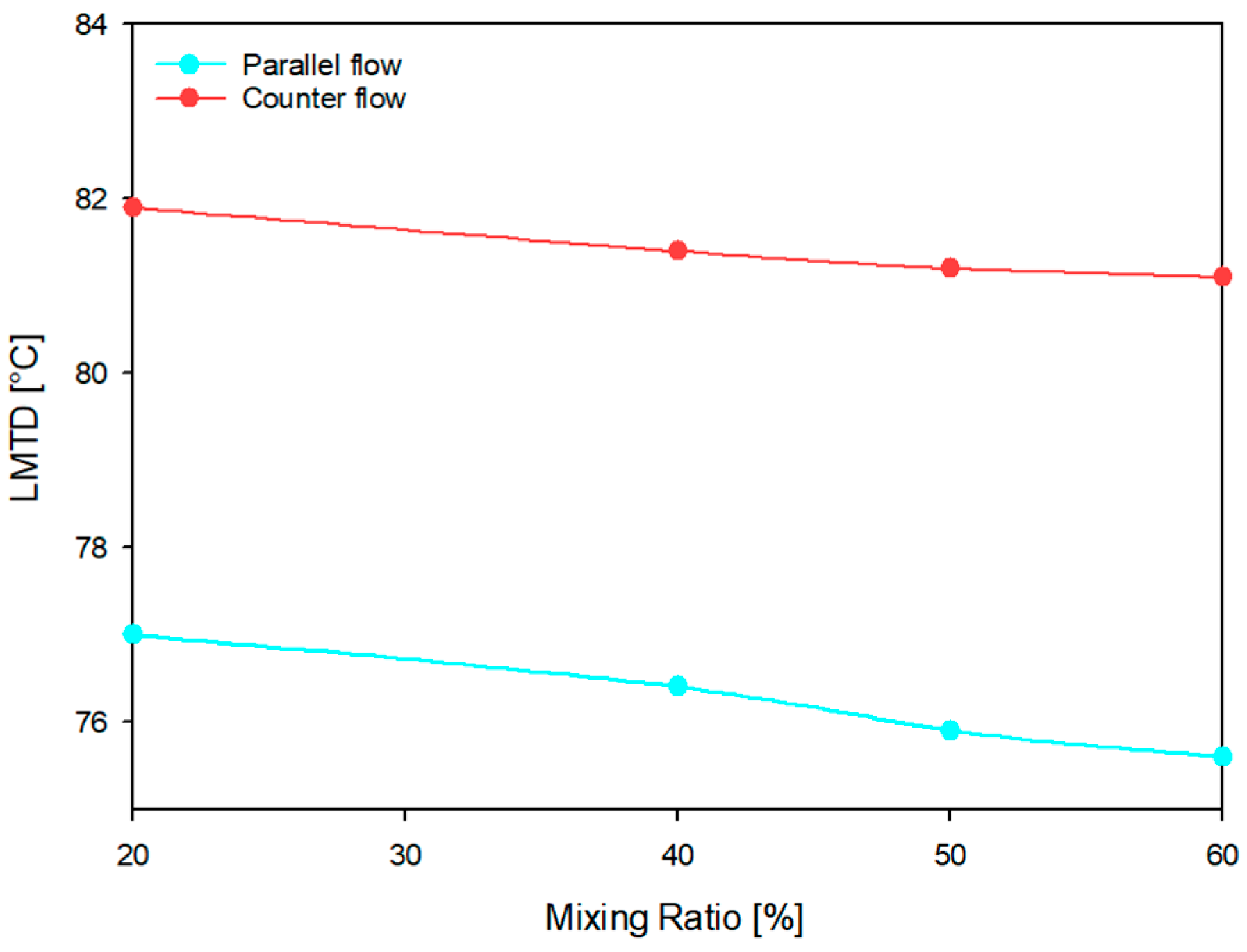

4.2.2. Effect of the Glycol–Water Mixing Ratio and Flow Direction

4.3. Application

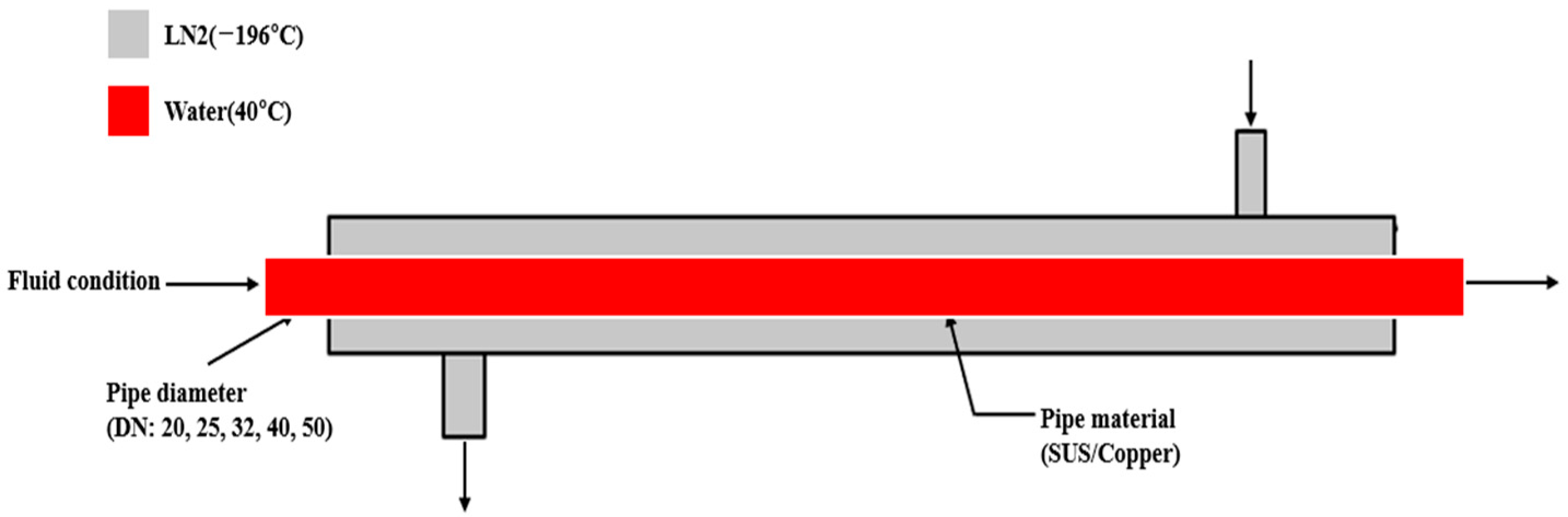

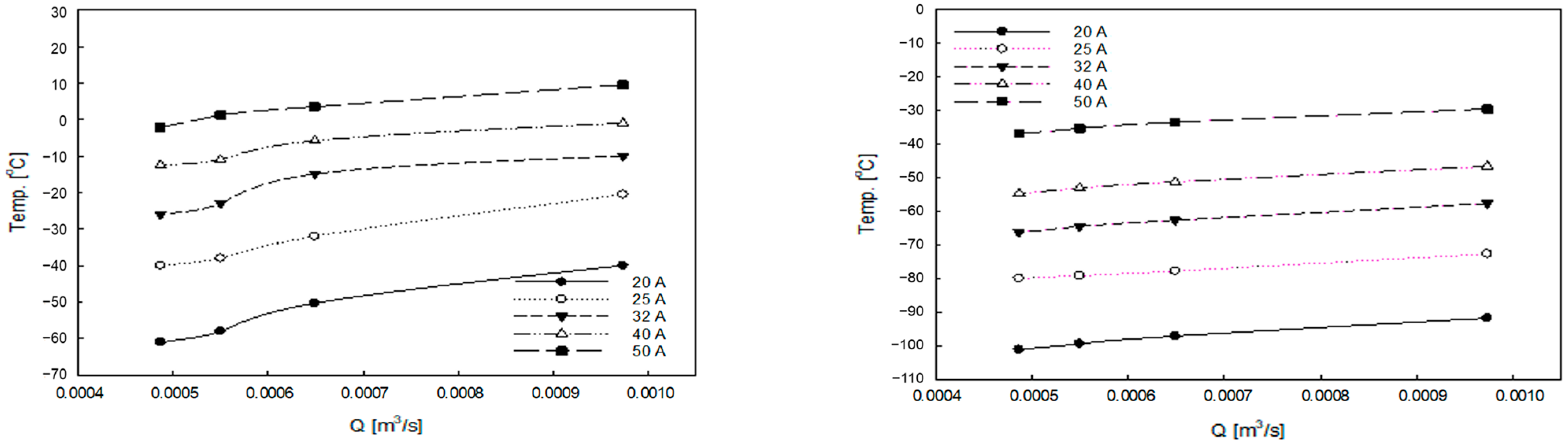

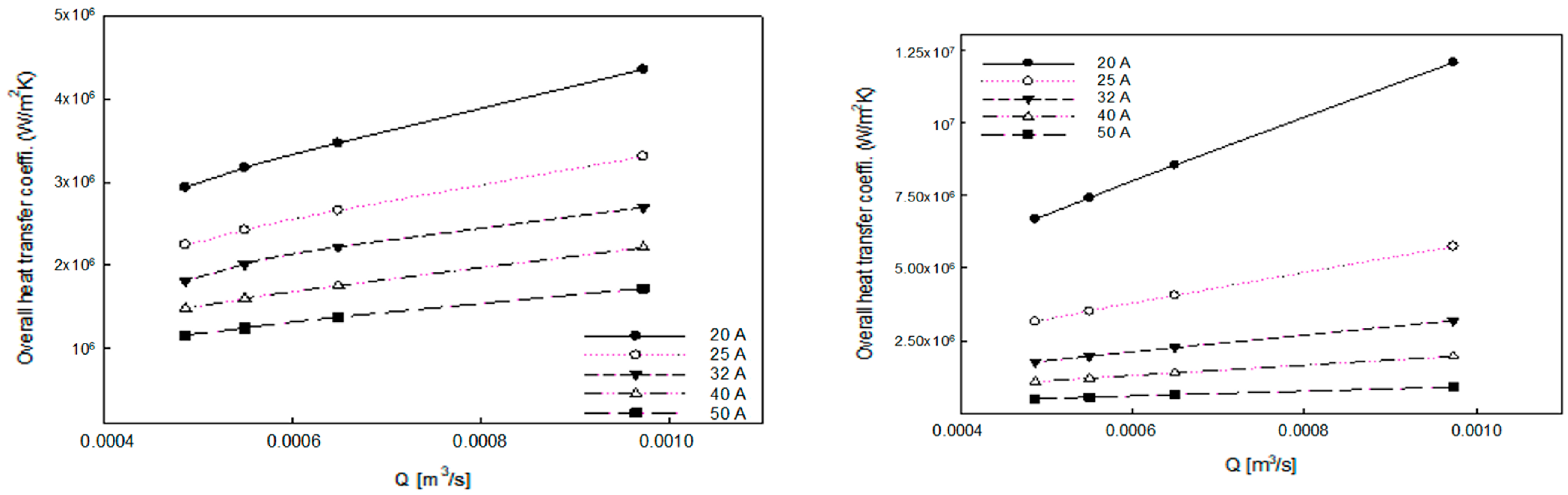

4.3.1. The Effect of Geometry and Fluid Condition

4.3.2. The Effect of Pipe Material

5. Concluding Remarks

- A numerical validation analysis was performed to verify the reliability of the numerical methodology with the numerical parameters included steam 90 kg/h, 6 bar(g), and 165 °C, and the glycol–water (ethylene glycol 50%) used a flow rate of 6500 kg/h, a pressure of 1.8 to 5 bar(g), and an inlet temperature of 35 °C. The numerical results showed a deviation of ±2% from the experimental results under parallel-flow conditions, confirming that the numerical method employed is both reasonable and reliable, as it demonstrates good agreement with the experimental data.

- In the comparison of temperature results using different turbulence models (k-ε and k-ω), both models produced nearly identical results under consistent conditions. Under the reference condition of 50% glycol and parallel flow, the k-ε turbulence model predicted a glycol–water outlet temperature of 50.6 °C, closely matching the experimental value. This indicates that the k-ε model more effectively predicts bulk flow characteristics and provides a better representation of heat transfer behavior.

- Analysis of the effect of the mixing ratio of ethylene glycol (EG) to water on the heat transfer performance (UA value) revealed that changes in the glycol–water outlet temperature were directly correlated with variations in the UA value. As the glycol ratio increased by 20%, the UA value decreased by an average of 11% in parallel flow and 13% in counter flow. Additionally, the glycol–water outlet temperature was found to be approximately 0.6% higher in parallel flow compared to counter flow, suggesting slightly improved heat transfer performance in parallel-flow configurations under the same operating conditions.

- The heat transfer performance of a double-pipe heat exchanger (DPHE) in an LPG fuel supply system was evaluated by examining geometry, pipe material, and fluid conditions. Copper pipes outperformed stainless steel, yielding lower outlet temperatures due to their higher thermal conductivity and more compact dimensions. These results underscore the critical importance of material selection and flow rate optimization, as both factors significantly influence heat exchanger effectiveness and overall thermal efficiency in of the heat exchanger applications.

- This study offers significant contributions to the engineering design of double-pipe heat exchanger systems for LPG fuel supply applications. Future research should incorporate long-term operational variables to further improve the model’s applicability, thereby reinforcing its potential as a versatile and practical tool for the design and development of advanced fuel supply systems.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Heat transfer area | Diameter of inner pipe [] | ||

| H | Enthalpy [J] | Radius of inner tube [mm] | |

| Heat transfer coefficient, [] | Radius of outer tube [mm] | ||

| Reynolds number (dimensionless) | Temperature of hot fluid [] | ||

| Pressure [bar] | Temperature of cold fluid [] | ||

| Heat flux [] | Thickness of heat transfer path inside and outside the surface [] | ||

| Temperature [] | Energy dissipation rate [] | ||

| Overall heat transfer | Turbulence kinetic energy [] | ||

| Internal energy | Density [] | ||

| Logarithmic mean temperature [] | Shear stress [] | ||

| Pipe thickness [] | |||

| Diameter of outer pipe [] |

References

- Kim, B.-I.; Kim, K.-T.; Islam, S. Development of strength evaluation methodology for independent IMO type C tank with LH2 carriers. J. Ocean Eng. Technol. 2024, 38, 87–102. [Google Scholar] [CrossRef]

- DNV. Maritime Forecast to 2050: Energy Transition Outlook. 2023. Available online: https://www.dnv.com/publications/maritime-forecast-to-2050-edition-2023/ (accessed on 31 July 2025).

- Kim, S.-J.; Park, S.-J. Riser configuration design for a 15-MW floating offshore wind turbine integrated with a green hydrogen facility. J. Ocean Eng. Technol. 2024, 38, 137–147. [Google Scholar] [CrossRef]

- Nam, T.; Yu, T.; Lim, Y. Thermodynamic modeling and analysis of boil-off gas generation and self-pressurization in liquefied carbon dioxide tanks. J. Ocean Eng. Technol. 2024, 38, 257–268. [Google Scholar] [CrossRef]

- Lee, H.-Y. A Study on the Rule and Design of the LPG Hybrid Electric Propulsion System for Small Vessels, Korea Maritime and Ocean University. 2023. Available online: http://repository.kmou.ac.kr/handle/2014.oak/13205 (accessed on 31 July 2025).

- Lee, S.-W.; Jeong, S.-Y.; Choi, S.-W. Frost behavior in ambient air vaporizer. J. Korean Soc. Mar. Eng. 2021, 45, 17–20. [Google Scholar] [CrossRef]

- Kang, D.-H. A Study on the Commercialization Possibility of LPG Engines for Medium-Sized Vessels in South Korea, Korea Maritime and Ocean University. 2023. Available online: http://kmou.dcollection.net/common/orgview/200000670640 (accessed on 31 July 2025).

- Heo, J.-W.; Choi, Y.-H.; Kim, S.-H.; Lee, S.-H.; Choi, H.-Y.; Yoo, D.-I.; Lee, Y.-W. Predicting heat transfer performance in a complex heat exchanger for LNG FGSS development. J. Korean Soc. Mar. Eng. 2023, 47, 52–58. [Google Scholar] [CrossRef]

- Han, S.H.; Kim, H.S.; Han, B.U.; Lee, D.J. A study on the fuel supply system of LPG propulsion VLGC ME-LGIP engine. Bull. Soc. Na-Val Archit. Korea 2019, 56, 10–14. [Google Scholar]

- Choi, A.; Lee, S.; Shin, I.H.; Choi, S. Study on simulation of cooling water through concentric double pipe heat exchanger. Trans. Korean Hydrog. New Energy Soc. 2023, 34, 741–747. [Google Scholar] [CrossRef]

- Park, C.; Kwon, H.; Ali, E.; Seo, J.; Lee, B.; Kim, I.; Kim, S.; Park, H. Numerical analysis study on the flow properties of shell-tube heat exchanger with different baffle angle. J. Comput. fluids Eng. 2023, 28, 80–87. [Google Scholar] [CrossRef]

- Mai, V.T.; Mai, T.L.; Yoon, H.K. Numerical Investigation of Motion Response of the Tanker at Varying Vertical Center of Gravities. J. Ocean Eng. Technol. 2024, 38, 1–9. [Google Scholar] [CrossRef]

- Kim, J.-B.; Min, E.-H.; Koo, W. Experimental and numerical study on the characteristics of free surface waves by the movement of a circular cylinder-shaped submerged body in a single fluid layer. J. Ocean Eng. Technol. 2023, 37, 89–98. [Google Scholar] [CrossRef]

- Lee, S.-W.; Choi, S.-W. Fin and temperature effect of frost in ambient air vaporizer. J. Ocean Eng. Technol. 2022, 36, 211–216. [Google Scholar] [CrossRef]

- Mozley, J.M. Predicting dynamics of concentric pipe heat exchangers. Ind. Eng. Chem. 1956, 48, 1035–1041. [Google Scholar] [CrossRef]

- Cohen, W.C.; Johnson, E.F. Dynamic characteristics of double-pipe heat exchangers. Ind. Eng. Chem. 1956, 48, 1031–1034. [Google Scholar] [CrossRef]

- Aicher, T.; Kim, W. Experimental investigation of the influence of the cross flow in the nozzle region on the shell-side heat transfer in double-pipe heat exchangers. Int. Commun. Heat Mass Transf. 1998, 25, 43–58. [Google Scholar] [CrossRef]

- Dezfoli, A.R.A.; Mehrabian, M.A. The overall heat transfer characteristics of a double-pipe heat exchanger. Heat Transf. Res. 2009, 40, 555–570. [Google Scholar] [CrossRef]

- Moradi, M.; Etemad, S.G.; Moheb, A. Laminar flow heat transfer of a pseudoplastic fluid through a double pipe heat ex-changer. Iran. J. Chem. Eng. 2006, 3, 13–19. [Google Scholar]

- Naphon, P. Heat transfer and pressure drop in the horizontal double pipes with and without twisted tape insert. Int. Commun. Heat Mass Transf. 2006, 33, 166–175. [Google Scholar] [CrossRef]

- Choudhari, S.S.; Taji, S. Experimental studies on effect of coil wire insert on heat transfer enhancement and friction factor of double pipe heat exchanger. Int. J. Comput. Eng. Res. 2013, 3, 32–39. [Google Scholar]

- Zhang, L.; Guo, H.; Wu, J.; Du, W. Compound heat transfer enhancement for shell side of double-pipe heat exchanger by helical fins and vortex generators. Heat Mass Transf. 2012, 48, 1113–1124. [Google Scholar] [CrossRef]

- Braga, C.; Saboya, F. Turbulent heat transfer, pressure drop and fin efficiency in annular regions with continuous longitudinal rectangular fins. Exp. Therm. Fluid Sci. 1999, 20, 55–65. [Google Scholar] [CrossRef]

- Zamzamian, A.; Oskouie, S.N.; Doosthoseini, A.; Joneidi, A.; Pazouki, M. Experimental investigation of forced convective heat transfer coefficient in nanofluids of Al2O3/EG and CuO/EG in a double pipe and plate heat exchangers under turbulent flow. Exp. Therm. Fluid Sci. 2011, 35, 495–502. [Google Scholar] [CrossRef]

- Prasad, P.D.; Gupta, A.; Deepak, K. Investigation of trapezoidal-cut twisted tape insert in a double pipe u-tube heat exchanger using Al2O3/water nanofluid. Procedia Mater. Sci. 2015, 10, 50–63. [Google Scholar] [CrossRef]

- Han, K.-Y.; Lim, H.-G.; Lee, J.-W. Performance analysis of a constant-speed LPG engine. J. Adv. Mar. Eng. Technol. (JAMET) 2024, 48, 63–71. [Google Scholar] [CrossRef]

- Marzouk, S.; Almehmadi, F.A.; Aljabr, A.; Alam, T.; Singh, T.; Khargotra, R. Effects of extended pin fins on the hydrothermal performance of double pipe heat exchanger. Therm. Sci. Eng. Prog. 2024, 55, 102915. [Google Scholar] [CrossRef]

- Alkalibi, A.; Alahmadi, Y.H.; Tlili, I. Performance Analysis of an Extended-Surface Double-Pipe Heat Exchanger for Heat Recovery from Hot Exhaust Gas Using Water and Nanofluids. Results Eng. 2025, 27, 106140. [Google Scholar] [CrossRef]

- Kavitha, R.; Algani, Y.M.A.; Kulkarni, K.; Gupta, M. Heat transfer enhancement in a double pipe heat exchanger with copper oxide nanofluid: An experimental study. Mater. Today: Proc. 2022, 56, 3446–3449. [Google Scholar] [CrossRef]

- Venkatesh, B.; Khan, M.; Alabduallah, B.; Kiran, A.; Babu, J.C.; Bhargavi, B.; Alhayan, F. Design Optimization of Counter-Flow Double-Pipe Heat Exchanger Using Hybrid Optimization Algorithm. Processes 2023, 11, 1674. [Google Scholar] [CrossRef]

- Esfandyari, M.; Delouei, A.A.; Jalai, A. Optimization of ultrasonic-excited double-pipe heat exchanger with machine learning and PSO. Int. Commun. Heat Mass Transf. 2023, 147, 106985. [Google Scholar] [CrossRef]

- Gabir, M.M.; Albayati, I.M.; Hatami, M.; Alkhafaji, D. An experimental investigation of the convective heat transfer augmentation in U-bend double pipe heat exchanger using water-MgO-Cmc fluid. Sci. Rep. 2024, 14, 1–13. [Google Scholar] [CrossRef]

- Jeong, J.-Y.; Nam, S.-C.; Kang, Y.-T. A Numerical analysis on the heat transfer and pressure drop characteristics of welding type plate heat exchangers. J. Adv. Mar. Eng. Technol. 2008, 32, 676–682. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An introduction to computational fluid dynamics: The finite volume method; Longman Scientific & Technical Publisher: Harlow, UK, 1995. [Google Scholar]

- Gemicioğlu, B.; DemirCan, T. Experimental analysis of the effects of using different water-ethylene glycol mixture rates on heat transfer performance in a heat exchanger. J. Eng. Archit. Fac. Eskiseh. Osman. Univ. 2021, 29, 145–157. [Google Scholar] [CrossRef]

- Sridhar, K.; Bicha, K. Comparative analysis of parallel and counter flow heat exchangers. Sci. Eng. Technol. Res. 2017, 6, 0638–0644. [Google Scholar]

- Lenhart, T.; Eckhardt, K.; Fohrer, N.; Frede, H.-G. Comparison of two different approaches of sensitivity analysis. Phys. Chem. Earth Parts A/B/C 2002, 27, 645–654. [Google Scholar] [CrossRef]

| Property | LPG | LNG | Unit |

|---|---|---|---|

| Liquefaction Temperature (at atmospheric pressure) | −42 | −162 | °C |

| Boiling Point | −42 | −162 | °C |

| Density (liquid) | 500–580 | 430–470 | |

| Density (gas, 15 °C) | 1.898 | 0.66 | |

| Liquid Volume Ratio | 1/250 | 1/600 | - |

| Storage conditions | |||

| Storage Pressure (at 20 °C) | 7 | Atmospheric | bar |

| Storage Pressure (at 45 °C) | 18 | Atmospheric | bar |

| Storage Temperature Range | −42 to 45 | −162 to −157 | °C |

| Environmental Impact | |||

| Reduction (vs. HFO) | 15–20 | 20–25 | % |

| Reduction (vs. HFO) | 90–95 | 95–100 | % |

| Reduction (vs. HFO) | 10–20 | 80–90 | % |

| Inner Pipe (Glycol–Water) | Outer Pipe (Steam) | |

|---|---|---|

| DN (A) | 80 | 125 |

| Pressure (bar) | 1.8~5 | 6 |

| In () | 35 | 165 |

| Out () | 49.5 | 90 |

| Required Flow Rate () | 6500 | 90 |

| Setting Temperature () | 35 | 40 |

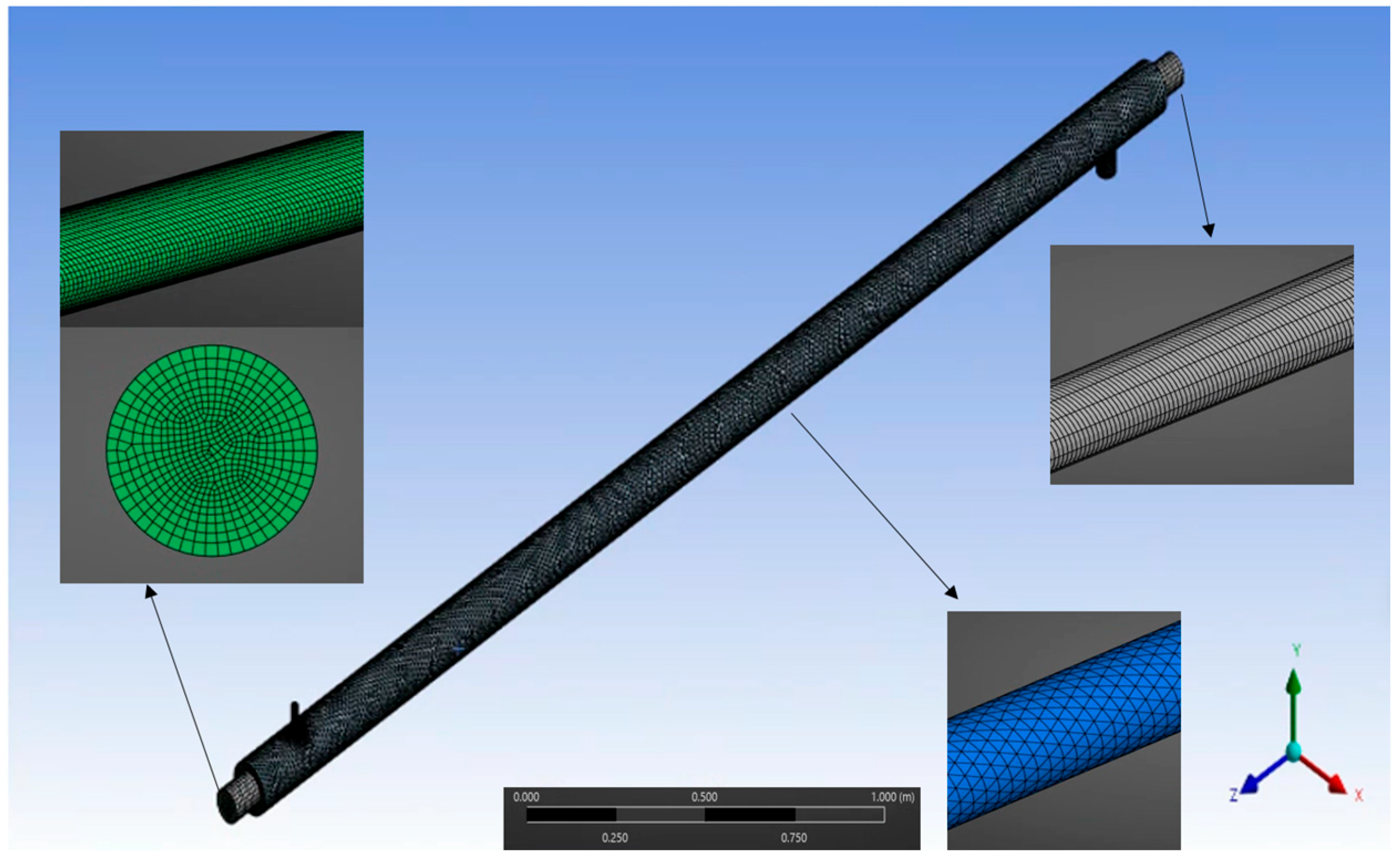

| Dimension | Description |

|---|---|

| Reynolds number, (Re) | 7200–20,000 |

| Inner pipe wall thickness [mm] | 5.5 |

| Outer pipe wall thickness [mm] | 6.6 |

| Inner pipe diameter [mm] | 78.1 |

| Outer pipe diameter [mm] | 139.8 |

| Total length [mm] | 3600 |

| Fluids Properties | Ethylene Glycol (50%) + Fresh Water (50%) | Steam |

|---|---|---|

| Density ) | 1044 | 0.4981 |

| Thermal conductivity () | 0.393 | 0.0302 |

| Temperature inlet () | 35 | 165 |

| Temperature outlet () | 49.5 | 90 |

| Viscosity () | 2.987 | 1.479 × 10−5 |

| Mass flow rate () | 1.805 | 0.025 |

| Specific heat transfer capacity () | 3.690 | 1.977 |

| Mixing ratio (%) | Ethylene glycol | 20 | 40 | 50 | 60 |

| Fresh water | 80 | 60 | 50 | 40 | |

| Density ) | 1022 | 1033 | 1044 | 1069 | |

| Specific heat () | 4 | 3.82 | 3.82 | 3.56 | |

| Thermal conductivity () | 0.491 | 0.433 | 0.399 | 0.354 | |

| Viscosity () | 1.42 | 2.26 | 2.98 | 3.73 | |

| Case. No | Total Number of Nodes | Total Number of Element | Differences Value of for Outlet Temperature (%) |

|---|---|---|---|

| 1 | 101,040 | 328,732 | 2.44 |

| 2 | 192,272 | 486,543 | 0.49 |

| 3 | 260,158 | 622,103 | 0.10 |

| 4 | 342,018 | 782,733 | Under 0.01 |

| Mixing ratio (%) | Ethylene glycol | 50 |

| Fresh water | 50 | |

| Flow rate () | 6500 | |

| Experimental result () | 49.5 | |

| Numerical result () | 50.6 | |

| Error (%) | 2 | |

| Parallel flow | Mixing ratio (%) | Ethylene glycol | 50 |

| Fresh water | 50 | ||

| Glycol–water inlet temperature () | 35 | ||

| k-ε model | Glycol–water outlet temperature () | 51.7 | |

| k-ε model | Glycol–water outlet temperature () | 50.6 | |

| Parallel Flow | ||||

|---|---|---|---|---|

| Mixing Ratio (%) | GW Inlet (°C) | k-ω Model | k-ε Model | |

| Ethylene Glycol | Fresh Water | GW Outlet (°C) | GW Outlet (°C) | |

| 20 | 80 | 35 | 50.0 | 49.1 |

| 40 | 60 | 50.9 | 50.0 | |

| 50 | 50 | 51.7 | 50.6 | |

| 60 | 40 | 49.8 | 51.0 | |

| Counter Flow | ||||

| Mixing ratio (%) | GW Inlet (°C) | k-ωmodel | k-εModel | |

| Ethylene glycol | Fresh water | GW Outlet (°C) | GW Outlet (°C) | |

| 20 | 80 | 35 | 50.0 | 48.7 |

| 40 | 60 | 51.1 | 49.8 | |

| 50 | 50 | 51.2 | 50.3 | |

| 60 | 40 | 49.2 | 50.6 | |

| Parallel Flow | ||||||

|---|---|---|---|---|---|---|

| Mixing Ratio (%) | UA (kw/°C) | GW Inlet (°C) | GW Outlet (°C) | Steam Inlet (°C) | Steam Outlet (°C) | |

| Ethylene Glycol | Fresh Water | |||||

| 20 | 80 | 1.3786 | 35 | 49.1 | 165 | 90 |

| 40 | 60 | 1.1952 | 50.0 | |||

| 50 | 50 | 1.2318 | 50.6 | |||

| 60 | 40 | 1.2701 | 51.0 | |||

| Counter Flow | ||||||

| Mixing ratio (%) | UA (kW/°C) | GW Inlet (°C) | GW Outlet (°C) | Steam Inlet (°C) | Steam Outlet (°C) | |

| Ethylene glycol | Fresh water | |||||

| 20 | 80 | 1.3495 | 35 | 48.7 | 165 | 90 |

| 40 | 60 | 1.1601 | 49.8 | |||

| 50 | 50 | 1.2136 | 50.3 | |||

| 60 | 40 | 1.2359 | 50.6 | |||

| Material | SUS 304 KS D 3576 | ||||

|---|---|---|---|---|---|

| DN (A) | 20 | 25 | 32 | 40 | 50 |

| OD () | 27.2 | 34.0 | 42.7 | 48.6 | 60.5 |

| WT ( | 1.65 | 1.65 | 1.65 | 1.65 | 1.65 |

| ID ( | 23.9 | 30.7 | 39.4 | 45.3 | 57.2 |

| Material | “L” TYPE KS D 5301 | ||||

| DN (A) | 20 | 25 | 32 | 40 | 50 |

| OD () | 22.2 | 28.5 | 34.9 | 41.2 | 53.9 |

| WT ( | 1.14 | 1.27 | 1.40 | 1.52 | 1.78 |

| ID ( | 19.9 | 26.0 | 32.1 | 38.2 | 50.4 |

| Parameter | Present Study DPHE | Kennedy Tank Hairpin DPHE | Alfa Laval DPHE |

|---|---|---|---|

| Configuration | Single inner pipe + outer pipe compact design | U-shaped hairpin, single inner/outer pipe | Straight concentric tube configuration |

| Flow arrangement | Parallel/Counter | Counter | Counter |

| Material | Copper (Cu)/SUS | SS304, SS316L | Copper alloy, SS316L |

| Design standards | Custom (marine LPG application) | ASME VIII, TEMA, API 650 | ASME BPE (hygienic), ASME VIII upon request |

| Design temperature range | −200~300 °C | −50~450 °C | −253~800 °C |

| Maintenance requirements | Medium (regular cleaning and inspection required) | Low (simple structure) | Low (modular design) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Kim, Y.; Choi, A.; Choi, S. Numerical Analysis of Heat Transfer in a Double-Pipe Heat Exchanger for an LPG Fuel Supply System. Energies 2025, 18, 4179. https://doi.org/10.3390/en18154179

Lee S, Kim Y, Choi A, Choi S. Numerical Analysis of Heat Transfer in a Double-Pipe Heat Exchanger for an LPG Fuel Supply System. Energies. 2025; 18(15):4179. https://doi.org/10.3390/en18154179

Chicago/Turabian StyleLee, Seongwoo, Younghun Kim, Ancheol Choi, and Sungwoong Choi. 2025. "Numerical Analysis of Heat Transfer in a Double-Pipe Heat Exchanger for an LPG Fuel Supply System" Energies 18, no. 15: 4179. https://doi.org/10.3390/en18154179

APA StyleLee, S., Kim, Y., Choi, A., & Choi, S. (2025). Numerical Analysis of Heat Transfer in a Double-Pipe Heat Exchanger for an LPG Fuel Supply System. Energies, 18(15), 4179. https://doi.org/10.3390/en18154179