Numerical Optimization of the Coil Geometry in a Large-Scale Levitation Melting Device—With Titanium as a Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Variants of the Optimized Levitator

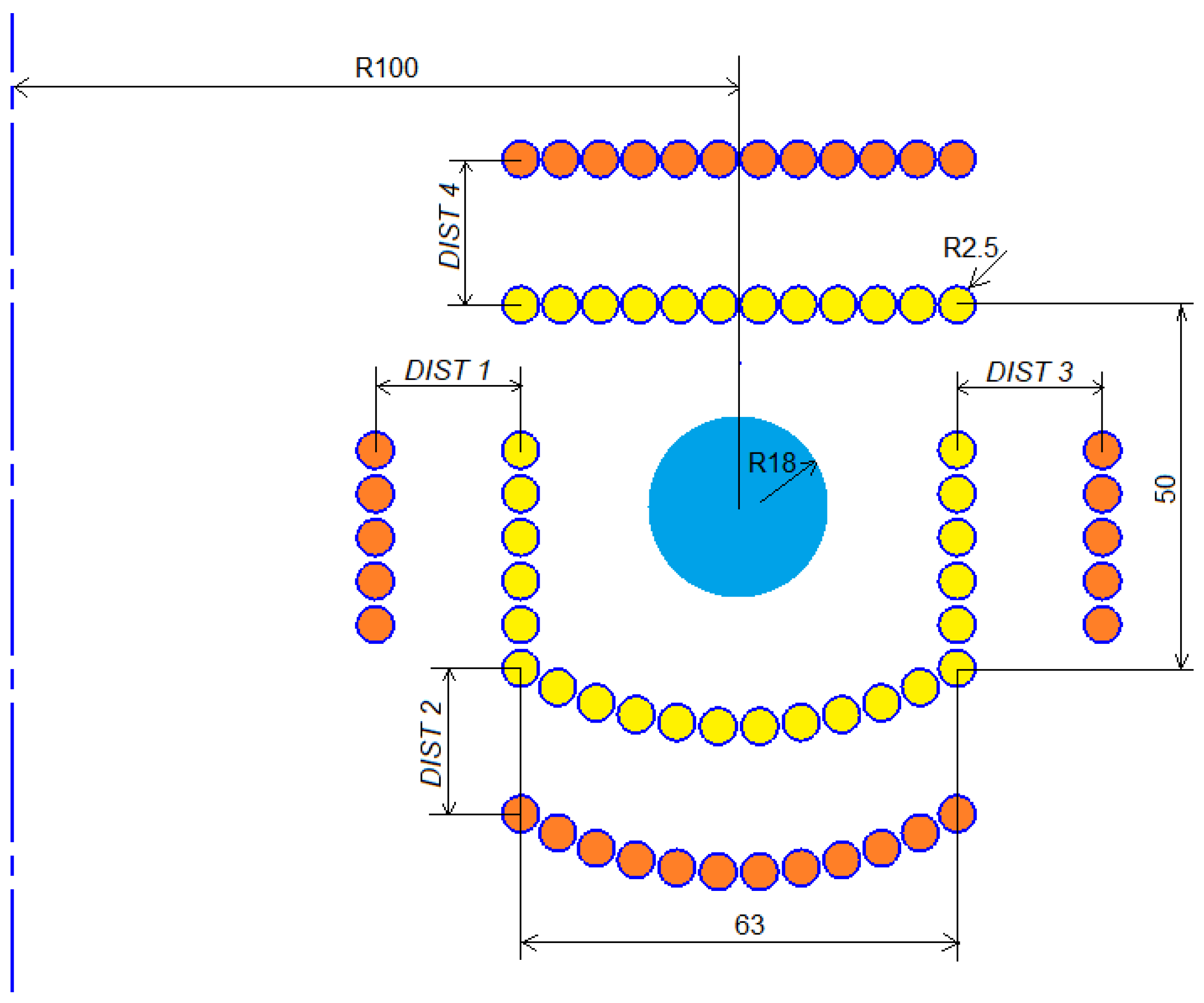

2.1.1. Levitation System with Four Rigid Coil Sections

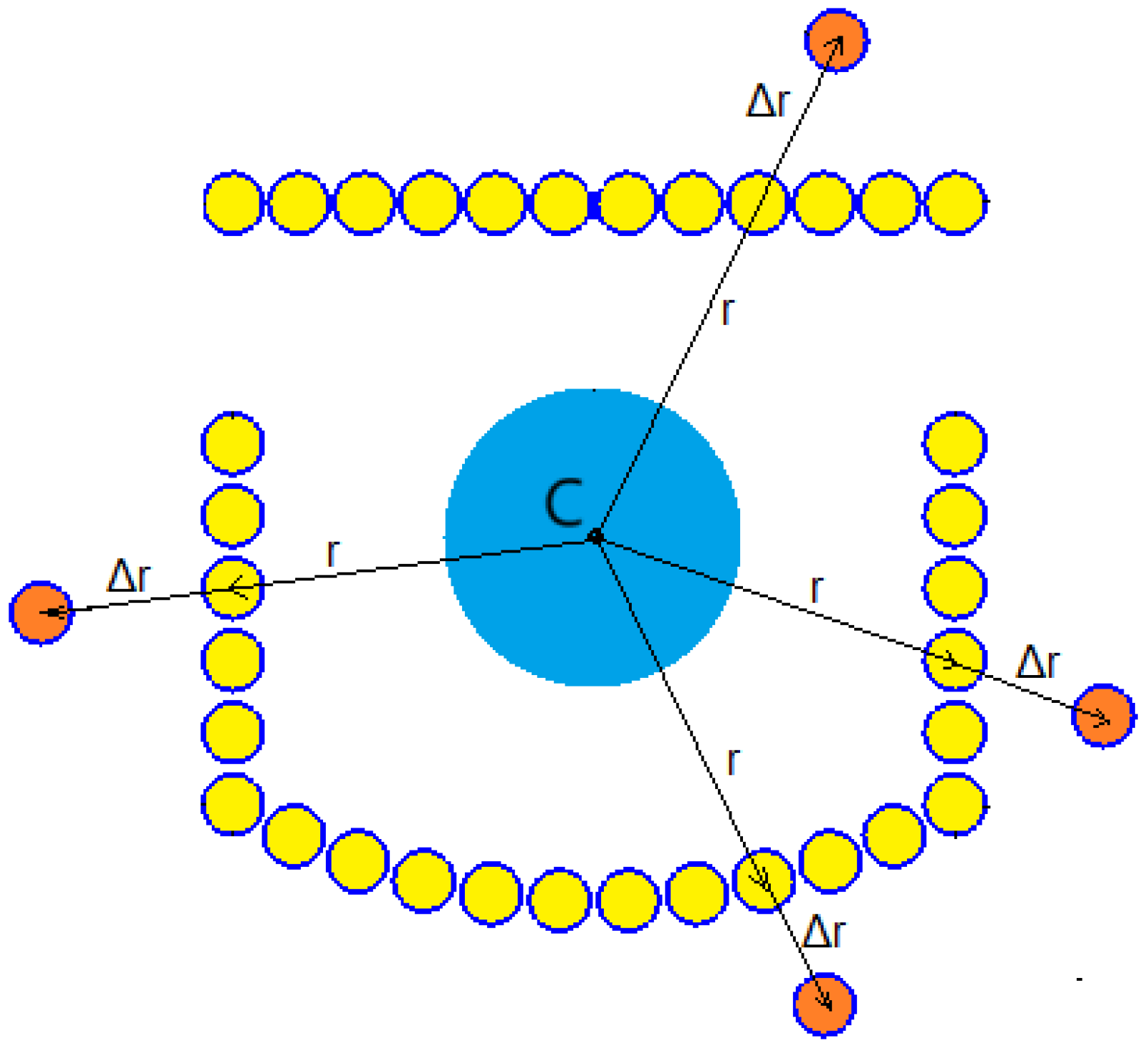

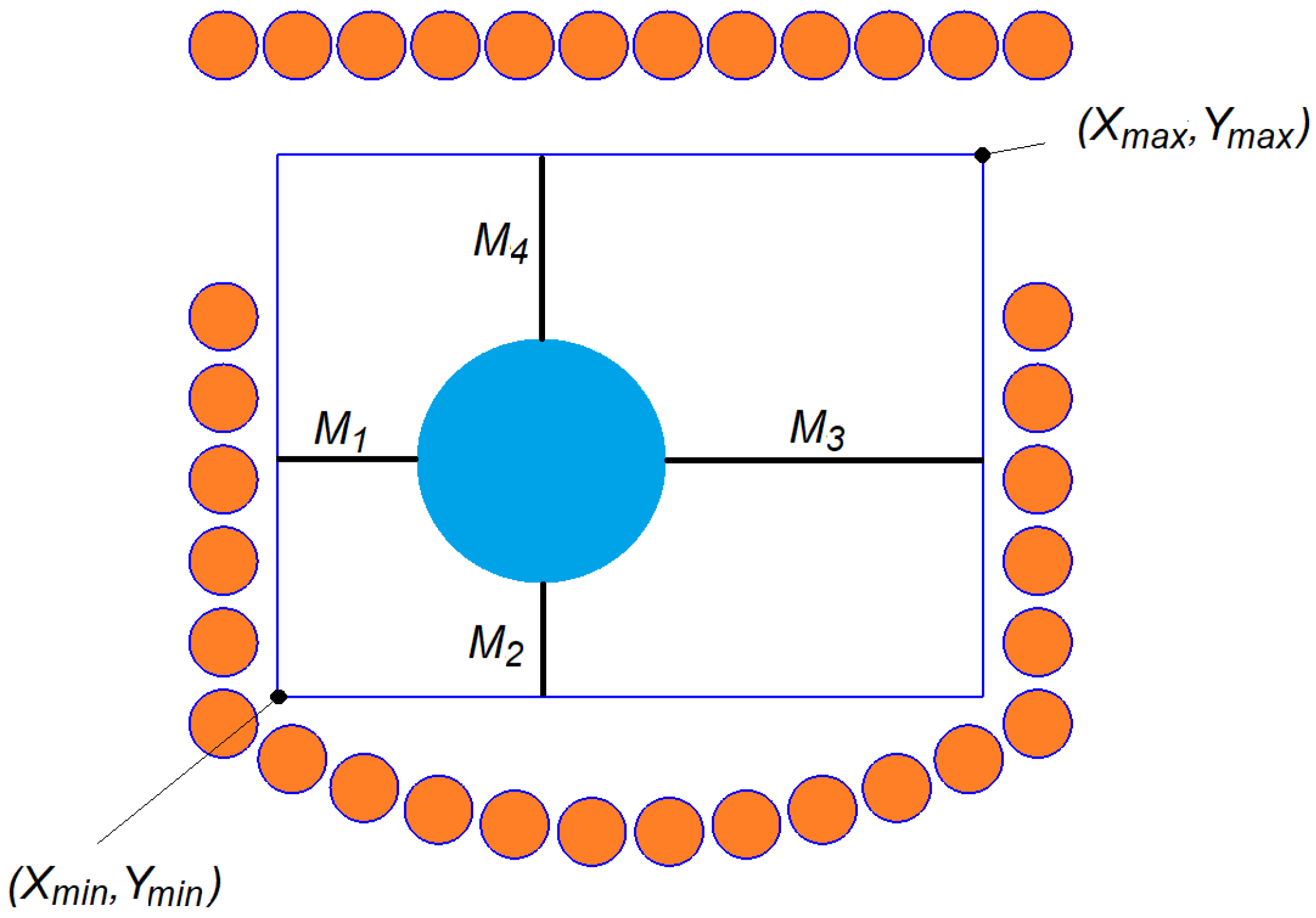

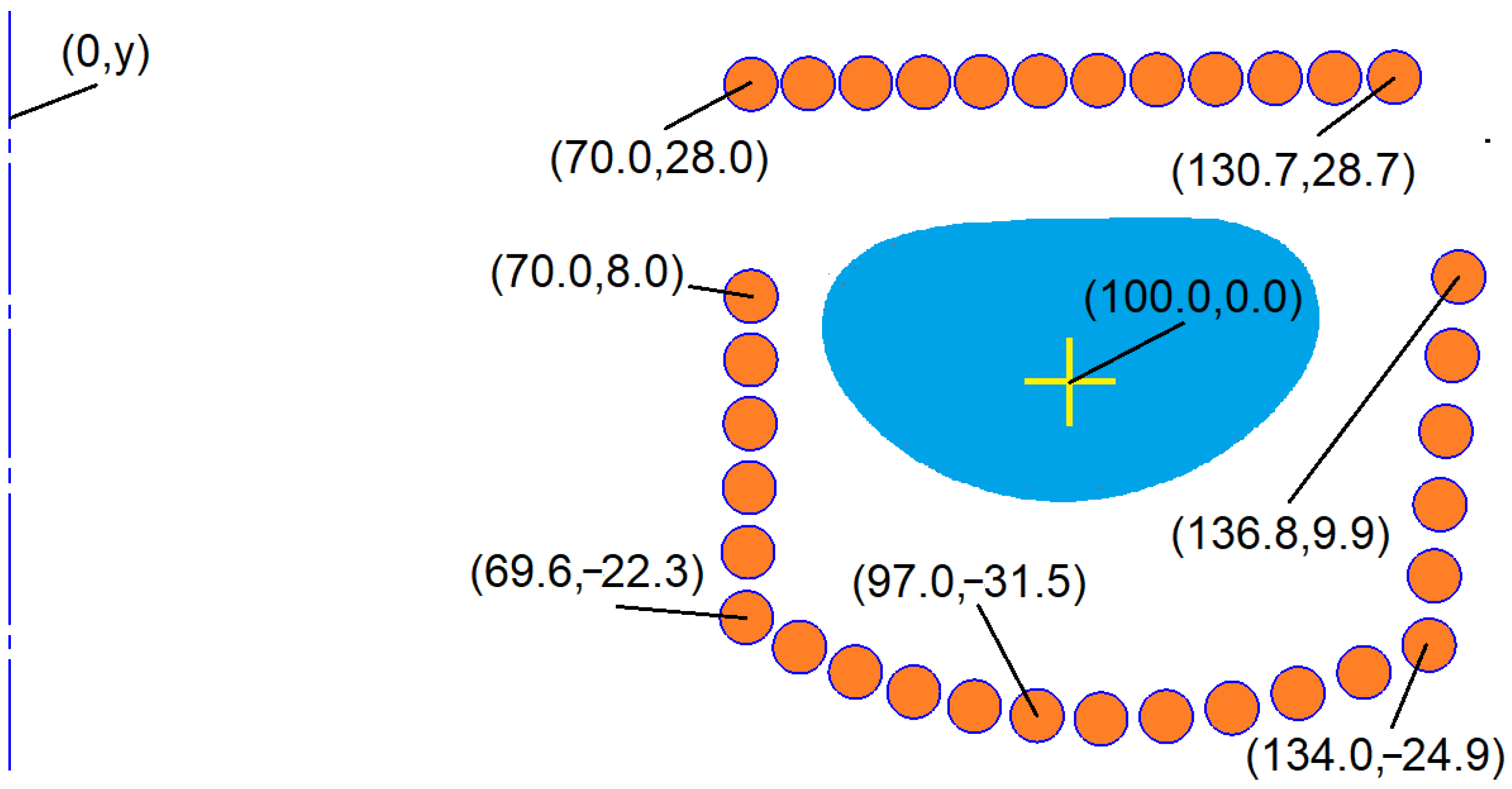

2.1.2. Levitation System with Two Coil Sections Featuring Controlled Winding Envelope

2.1.3. Levitator Application Scenario

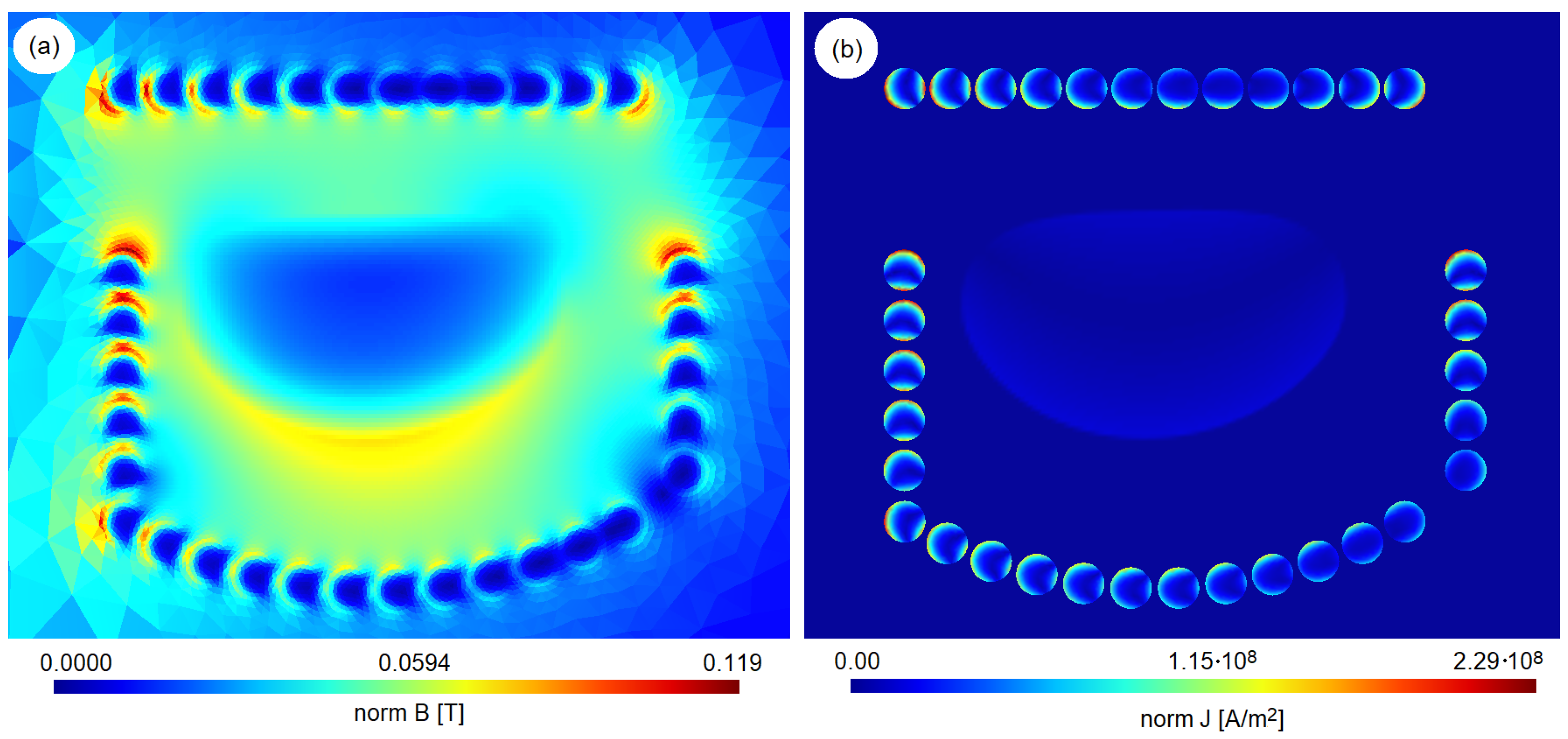

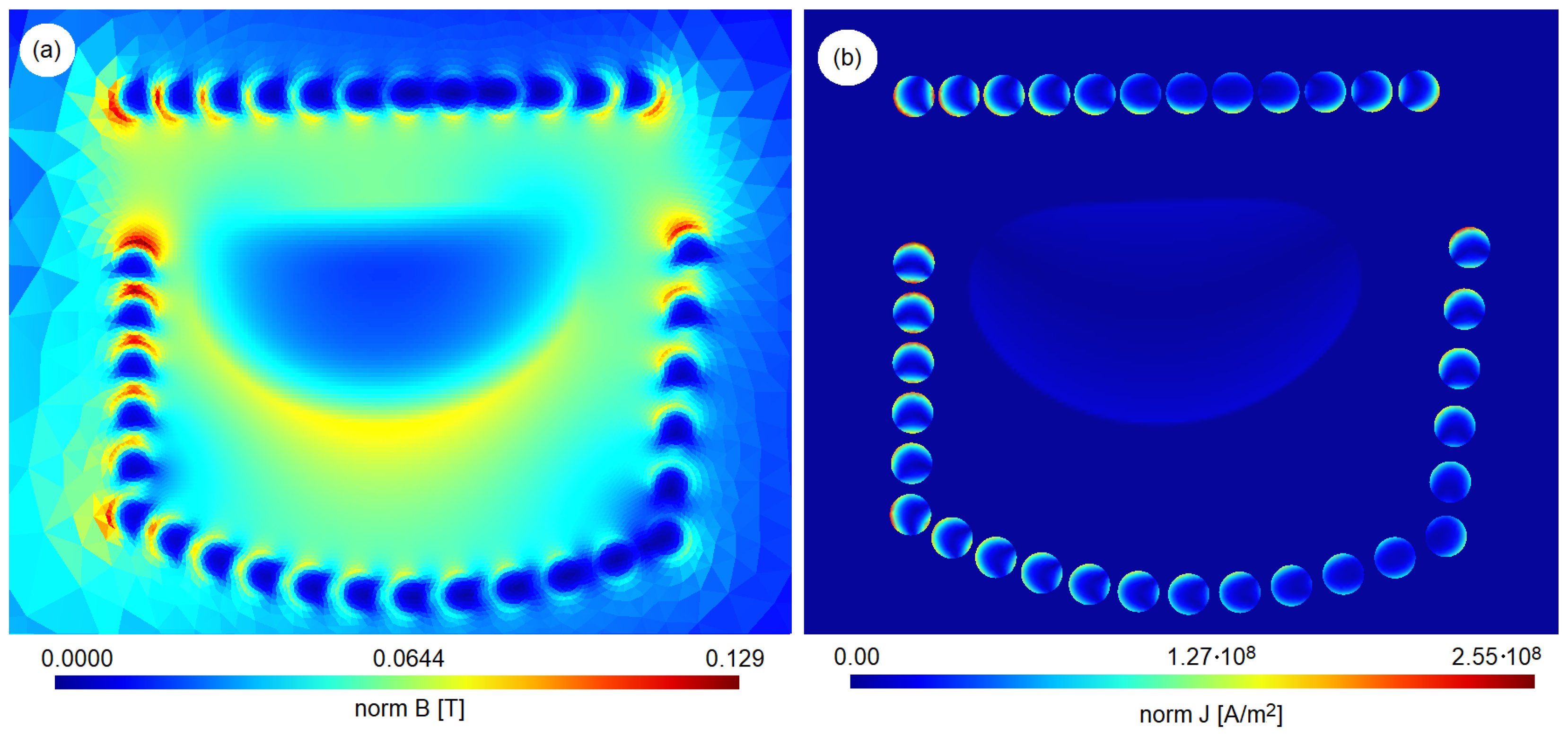

2.2. Numerical Model

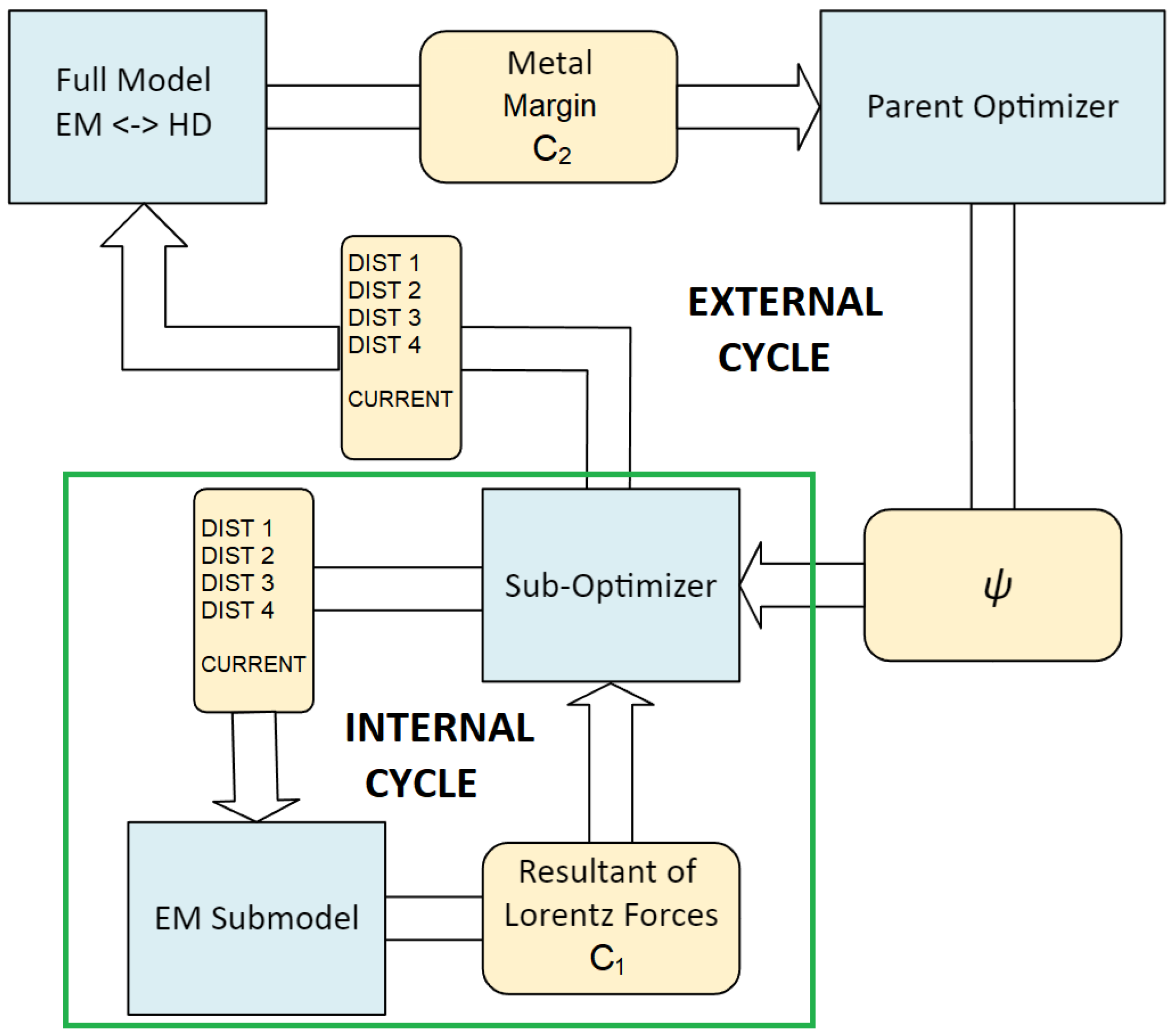

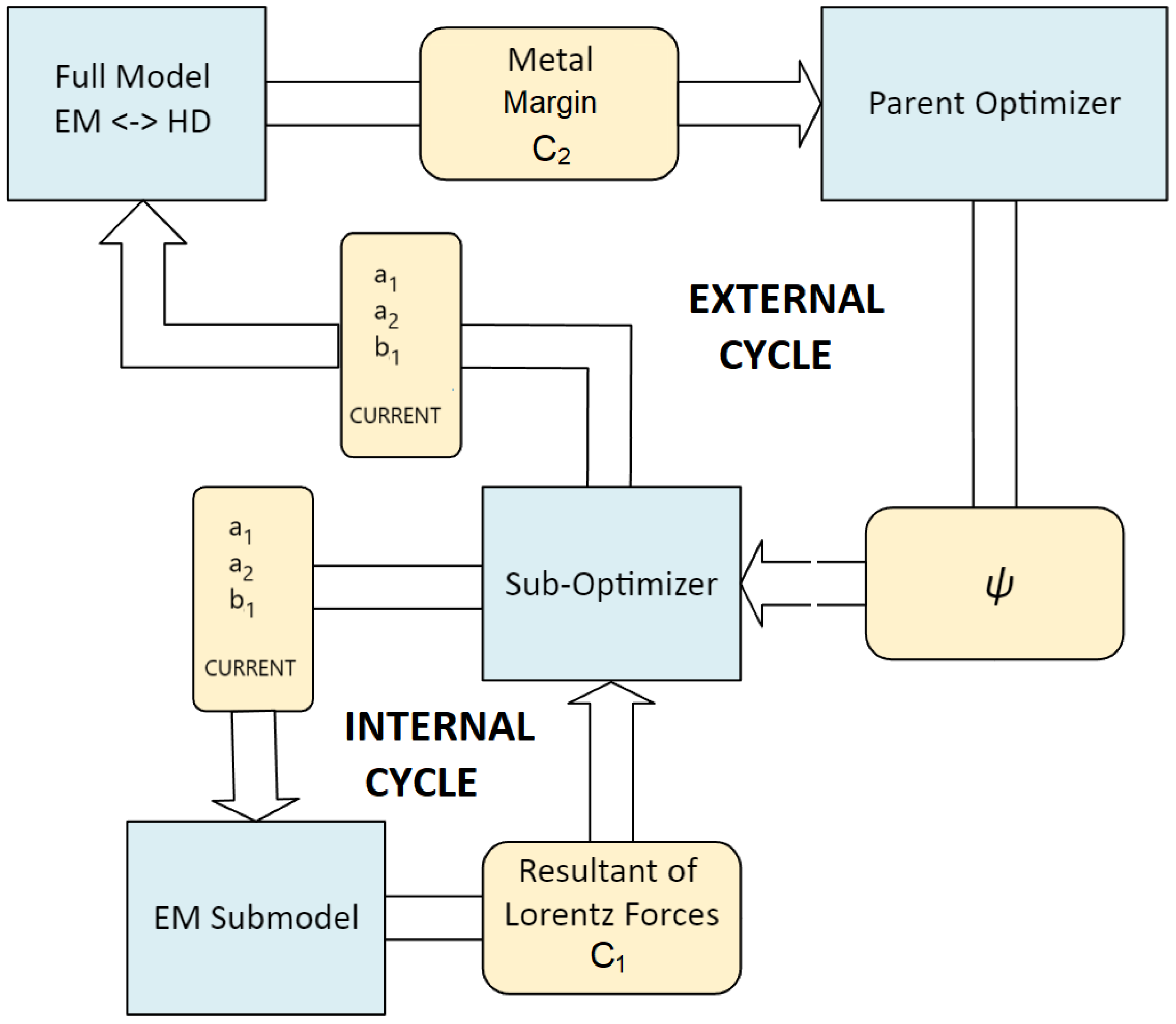

2.3. Optimization Methodology

2.3.1. Distances of Entire Rigid Coil Sections

- distance of the left section from the base position (DIST 1);

- distance of the lower section from the base position (DIST 2);

- distance of the right section from the base position (DIST 3);

- distance of the top section from the base position (DIST 4);

- current supplying all coil sections (CURRENT).

2.3.2. Smooth Winding Envelope of Two Coil Sections

- two second-degree polynomial coefficients for the lower coil section ( and );

- one first-degree polynomial coefficient for the upper coil section ();

- the current supplying the two coil sections (CURRENT).

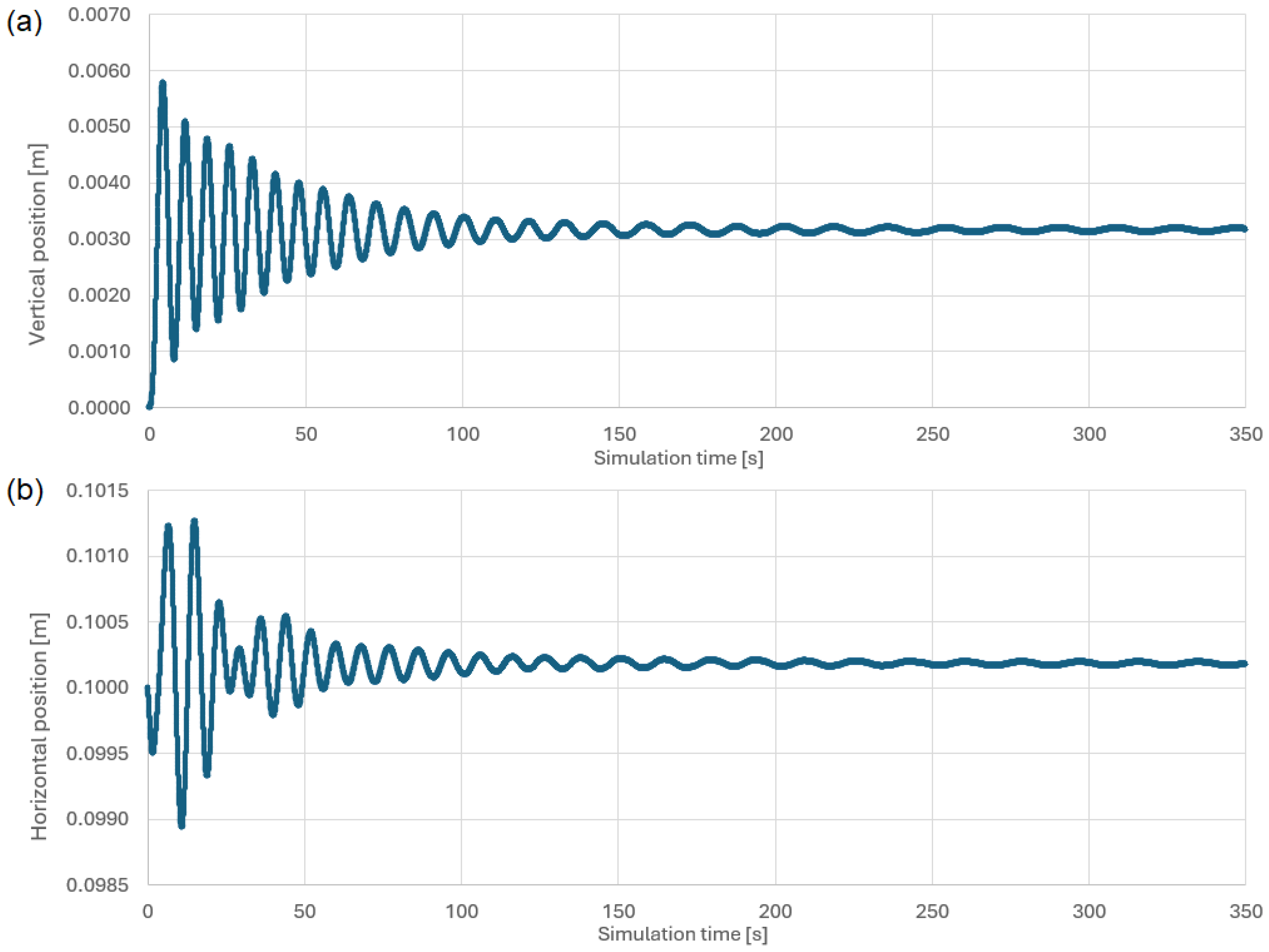

2.3.3. Validation Method

3. Results and Discussion

3.1. Optimization of Distances of All Four Coil Sections

3.2. Optimization of Smooth Winding Envelope with Two Coil Sections

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Friedrich, B.; Morscheiser, J.; Lochbichler, C. Potential of ceramic crucibles for melting of titanium-alloys and gamma-titaniumaluminide. In Proceedings of the 51st International Colloquium on Refractories, Aachen, Germany, 15–16 October 2008; pp. 229–232. [Google Scholar] [CrossRef]

- Schaffoener, S.; Aneziris, C.G.; Berek, H.; Hubalkova, J.; Rotmann, B.; Friedrich, B. Corrosion behavior of calcium zirconate refractories in contact with titanium aluminide melts. J. Eur. Ceram. Soc. 2015, 35, 1097–1106. [Google Scholar] [CrossRef]

- Schafföner, S.; Aneziris, C.G.; Berek, H.; Rotmann, B.; Friedrich, B. Investigating the corrosion resistance of calcium zirconate in contact with titanium alloy melts. J. Eur. Ceram. Soc. 2015, 35, 259–266. [Google Scholar] [CrossRef]

- Fashu, S.; Lototskyy, M.; Davids, M.W.; Pickering, L.; Linkov, V.; Tai, S.; Renheng, T.; Fangming, X.; Fursikov, P.V.; Tarasov, B.P. A review on crucibles for induction melting of titanium alloys. Mater. Des. 2020, 186. [Google Scholar] [CrossRef]

- Kamyshnykova, K.; Lapin, J. Vacuum induction melting and solidification of TiAl-based alloy in graphite crucibles. Vacuum 2018, 154, 218–226. [Google Scholar] [CrossRef]

- Song, Q.; Liang, T.; Qian, K.; Xing, W.; Zha, X.; Chen, B.; Ma, Y.; Liu, K. Corrosion resistance of calcium zirconate crucible to titanium-copper melts. J. Eur. Ceram. Soc. 2022, 42, 3321–3331. [Google Scholar] [CrossRef]

- Bulinski, P.; Smolka, J.; Golak, S.; Przylucki, R.; Blacha, L.; Bialecki, R.; Palacz, M.; Siwiec, G. Effect of turbulence modelling in numerical analysis of melting process in an induction furnace. Arch. Metall. Mater. 2015, 60, 1575–1579. [Google Scholar] [CrossRef]

- Guglielmi, M.; Baake, E.; Köppen, A.; Holzmann, E.; Herbst, S.; Maryamnegari, S.M. Induction melting in a cold crucible furnace applied to innovative high-melting temperature metals. Magnetohydrodynamics 2022, 58, 523–532. [Google Scholar] [CrossRef]

- Bojarevics, V.; Nishimura, T.; Matsuwaka, D. Development of advanced cold crucible melting of titanium alloys. Magnetohydrodynamics 2022, 58, 13–24. [Google Scholar] [CrossRef]

- Witteveen, J.P.; Vrielink, M.A.B.; van Gastel, R.; van Houselt, A.; Zandvliet, H.J.W. Containerless metal single-crystal growth via electromagnetic levitation. Rev. Sci. Instrum. 2021, 92, 105105. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, F.; Zhang, L.; Jin, Z.; Cao, G.; Qiu, Z.; Shen, H.; Huang, Y.; Jiang, S.; Sun, J. Break the superheat temperature limitation of induction skull melting technology. Appl. Therm. Eng. 2023, 220. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.; Cao, F.; Jin, Z.; Cao, G.; Shen, H.; Huang, Y.; Sun, J. Optimizing energy efficiency in induction skull melting process: Investigating the crucial impact of melting system structure. Sci. Rep. 2024, 14, 6303. [Google Scholar] [CrossRef]

- Wang, G.; Bai, Y.; Zhao, B.; Li, L.; Liu, Y.; Zhang, K.; Liu, Y.; Yu, K. Improve the performance of cold crucible used for emissivity measurement of molten metal. Case Stud. Therm. Eng. 2025, 68, 105898. [Google Scholar] [CrossRef]

- Muck, O. Verfahren und Vorrichtung zum Schmelzen, Insbesondere von Leitern u. dgl. Durch Elektrische Induktionsstroeme. German Patent 422004, 30 October 1923. [Google Scholar]

- Okress, E.C.; Wroughton, D.M.; Comenetz, G.; Brace, P.H.; Kelly, J.C.R. Electromagnetic Levitation of Solid and Molten Metals. J. Appl. Phys. 1952, 23, 545–552. [Google Scholar] [CrossRef]

- Matson, D.; Battezzati, L.; Galenko, P.; Gandin, C.A.; Gangopadhyay, A.; Henein, H.; Kelton, K.; Kolbe, M.; Valloton, J.; Vogel, S.; et al. Electromagnetic levitation containerless processing of metallic materials in microgravity: Rapid solidification. NPJ Microgravity 2023, 9, 65. [Google Scholar] [CrossRef]

- Snikeris, J.; Apsitis, A.; Pumpurs, A.; Lacis, U.; Kravchenko, S.; Silamikelis, V. Experimental observation of the vertical displacement between heating and levitation regions in an electromagnetic levitation coil. J. Phys. D Appl. Phys. 2024, 57, 095002. [Google Scholar] [CrossRef]

- Pang, X.; Zhang, G.; Yan, P.; Xiao, Z.; Wang, X. Study on the Migration Patterns of Oxygen Elements during the Refining Process of Ti-48Al Scrap under Electromagnetic Levitation. Materials 2024, 17, 3709. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, G.; Yan, P.; Pang, X.; Xiao, Z. Numerical Simulation of Electromagnetic–Thermal–Fluid Coupling for the Deformation Behavior of Titanium–Aluminum Alloy under Electromagnetic Levitation. Materials 2024, 17, 3338. [Google Scholar] [CrossRef]

- Brillo, J.; Yang, F.; Holland-Moritz, D. Transport property measurement of liquid metals and alloys using electromagnetic and electrostatic levitation. Int. J. Thermophys. 2024, 45, 17–32. [Google Scholar] [CrossRef]

- Peifer, W.A. Levitation melting. A Survey of the State-of-the-Art. JOM 1965, 17, 487–493. [Google Scholar] [CrossRef]

- Brace, P.H. Apparatus for the Magnetic Levitation and Heating of Conductive Materials. US2664496A, 29 December 1953. [Google Scholar]

- El-Kaddah, N.; Szekely, J. The electromagnetic force field, fluid flow field, and temperature profiles in levitated metal droplets. Metall. Trans. B 1983, 14, 401–410. [Google Scholar] [CrossRef]

- Sun, H.; Pehlke, R.D. Coil Design for Lower Temperature Levitation Melting of Iron Alloys. High Temp. Mater. Processes 2000, 19, 41–48. [Google Scholar] [CrossRef]

- Bojarevics, V.; Pericleous, K. Modelling electromagnetically levitated liquid metal droplets. Magnetohydrodynamics 2003, 39, 437–450. [Google Scholar]

- Royer, Z.L.; Tackes, C.; LeSar, R.; Napolitano, R.E. Coil optimization for electromagnetic levitation using a genetic like algorithm. J. Appl. Phys. 2013, 113, 214901. [Google Scholar] [CrossRef]

- Feng, L.; Shi, W.Y. The Influence of Eddy Effect of Coils on Flow and Temperature Fields of Molten Droplet in Electromagnetic Levitation Device. Metall. Mater. Trans. B. 2015, 46, 1895–1901. [Google Scholar] [CrossRef]

- Gao, L.; Shi, Z.; Li, D.; Zhang, G.; Yang, Y.; McLean, A.; Chattopadhyay, K. Applications of Electromagnetic Levitation and Development of Mathematical Models: A Review of the Last 15 Years (2000 to 2015). Metall. Mater. Trans. B. 2015, 47, 537–547. [Google Scholar] [CrossRef]

- Feng, L.; Shi, W.Y. Influence of Coil Angle Arrangement on Dynamic Deformation and Stability of Molten Droplet in Electromagnetic Levitation System. ISIJ Int. 2016, 56, 50–56. [Google Scholar] [CrossRef]

- Witteveen, J.; van Gastel, R.; van Houselt, A.; Zandvliet, H. 3D modeling of electromagnetic levitation coils. Curr. Appl. Phys. 2021, 32, 45–49. [Google Scholar] [CrossRef]

- Nie, W.; Liu, J.; Wang, L.; Zhang, T.; Liu, B.; Liu, Y.; Zhang, Y. Induction Smelting Cold Crucible with Full Suspension and Strong Stirring Capacity. CN112393588A, 23 February 2021. [Google Scholar]

- Pons, R.; Gagnoud, A.; Chaussende, D.; Budenkova, O. Design of a coil for electromagnetic levitation: Comparison of numerical models and coil realization. Magnetohydrodynamics 2022, 58, 55–64. [Google Scholar] [CrossRef]

- Nycz, B.; Przylucki, R.; Malinski, L. Comparison of Characteristics for Two Selected Inductors for Levitation Melting. In Proceedings of the 14th International Conference on Measurement, Smolenice, Slovakia, 29–31 May 2023; pp. 222–225. [Google Scholar] [CrossRef]

- Hatchavanich, N.; Sangswang, A.; Naetiladdanon, S. A Mutually Coupled Stabilization Coil Configuration for Electromagnetic Levitation Melting With Frequency Consideration. IEEE Access 2024, 12, 2025–2031. [Google Scholar] [CrossRef]

- Zorzetto, M.; Torchio, R.; Lucchini, F.; Forzan, M.; Dughiero, F. Proper Orthogonal Decomposition for Parameterized Macromodeling of a Longitudinal Electromagnetic Levitator. IEEE Trans. Magn. 2025, 61, 1–7. [Google Scholar] [CrossRef]

- Zorzetto, M.; Poggiana, G.; Dughiero, F. Frequency and Current Analysis for Aluminum Billet Lifting with a Longitudinal Electromagnetic Levitator Prototype. Energies 2025, 18, 3437. [Google Scholar] [CrossRef]

- Spitans, S.; Baake, E.; Jakovics, A.; Franz, H. Large scale electromagnetic levitation melting of metals. Int. J. Appl. Electrom. 2017, 53, S61–S66. [Google Scholar] [CrossRef]

- Spitans, S.; Franz, H.; Baake, E.; Jakovics, A. Large-scale levitation melting and casting of titanium alloys. Magnetohydrodynamics 2017, 53, 633–641. [Google Scholar] [CrossRef]

- Spitans, S.; Bauer, C.; Franz, H.; Sehring, B.; Baake, E. Investment casting with unique levitation melting technology-FastCast. In Proceedings of the Liquid Metal Processing and Casting (LMPC) Conference, Philadelphia, PA, USA, 18–21 September 2022; pp. 213–222. [Google Scholar]

- Golak, S.; Panic, B. Numerical model of large-scale levitation melting process. Arch. Metall. Mater. 2019, 64, 627–632. [Google Scholar] [CrossRef]

- Golak, S.; Wyciślik, J.; Zybała, R.; Hanusek, R. Numerical modeling and optimization of large-scale molten titanium levitation. Materials 2025, 18, 1268. [Google Scholar] [CrossRef]

- Golak, S.; Dolata, A.J. Fabrication of functionally graded composites using a homogenised low-frequency electromagnetic field. J. Compos. Mater. 2016, 50, 1751–1760. [Google Scholar] [CrossRef]

- Spitans, S.; Jakovics, A.; Baake, E.; Nacke, B. Numerical modelling of free surface dynamics of melt in an alternate electromagnetic field. Magnetohydrodynamics 2011, 47, 385–397. [Google Scholar] [CrossRef]

- Spitans, S.; Jakovics, A.; Baake, E.; Nacke, B. Numerical modeling of free surface dynamics of melt in an alternate electromagnetic field: Part I. Implementation and verification of model. Metall. Mater. Trans. B 2013, 44, 593–605. [Google Scholar] [CrossRef]

- Spitans, S.; Baake, E.; Nacke, B.; Jakovics, A. Numerical Modeling of Free Surface Dynamics of Melt in an Alternate Electromagnetic Field. Part II: Conventional Electromagnetic Levitation. Metall. Mater. Trans. B 2016, 47, 522–536. [Google Scholar] [CrossRef]

- Terekhov, T.V.; Skrigan, I.N.; Lopukh, D.B. Numerical Modeling of Electromagnetic Levitation of Metal. In Proceedings of the 2024 Conference of Young Researchers in Electrical and Electronic Engineering (ElCon), St. Petersburg, Russia, 29–31 January 2024; pp. 510–514. [Google Scholar] [CrossRef]

- Golak, S.; Geuzaine, C.; Przylucki, R.; Nycz, B.; Henrotte, F. Hybrid numerical 3D model of electromagnetic levitation of molten metal. Appl. Therm. Eng. 2025, 258, 124697. [Google Scholar] [CrossRef]

- Hirt, C.; Nichols, B. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Dular, P.; Geuzaine, C. GetDP Reference Manual: The Documentation for GetDP, a General Environment for the Treatment of Discrete Problems. 2022. Available online: https://getdp.info/doc/texinfo/getdp.pdf (accessed on 1 June 2025).

- Geuzaine, C. GetDP: A general finite-element solver for the de Rham complex. In PAMM: Proceedings in Applied Mathematics and Mechanics; Wiley: Berlin, Germany, 2008; Volume 7, pp. 1010603–1010604. [Google Scholar]

- Nelder, J.A.; Mead, R. A Simplex Method for Function Minimization. Comput. J. 1965, 7, 308–313. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Density | 4110 kg/m3 |

| Electrical conductivity | 0.56 MS/m |

| Relative magnetic permeability | 1.00 |

| Dynamic viscosity | 4.42 mPa s |

| Surface tension | 1.56 N/m |

| Load mass | 2.6 kg |

| DIST 1 | DIST 2 | DIST 3 | DIST 4 | CURRENT | |

|---|---|---|---|---|---|

| 0.1 [mm] | 0.1 [mm] | 7.3 [mm] | 1.8 [mm] | 403 [A] | 4.25 [N] |

| Levitator Variant | Power Supply [W] | Joule Heat Generated in Coil [W] | Joule Heat Generated in Charge [W] | Efficiency [%] |

|---|---|---|---|---|

| 1: Four coil sections | 34,561 | 10,054 | 24,507 | 70.91 |

| 2: Two coil sections | 39,559 | 11,555 | 28,004 | 70.79 |

| CURRENT | ||||

|---|---|---|---|---|

| 0.000498 | 0.000296 | 0.002134 | 439 [A] | 4.35 [N] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golak, S.; Zybała, R. Numerical Optimization of the Coil Geometry in a Large-Scale Levitation Melting Device—With Titanium as a Case Study. Energies 2025, 18, 4162. https://doi.org/10.3390/en18154162

Golak S, Zybała R. Numerical Optimization of the Coil Geometry in a Large-Scale Levitation Melting Device—With Titanium as a Case Study. Energies. 2025; 18(15):4162. https://doi.org/10.3390/en18154162

Chicago/Turabian StyleGolak, Sławomir, and Radosław Zybała. 2025. "Numerical Optimization of the Coil Geometry in a Large-Scale Levitation Melting Device—With Titanium as a Case Study" Energies 18, no. 15: 4162. https://doi.org/10.3390/en18154162

APA StyleGolak, S., & Zybała, R. (2025). Numerical Optimization of the Coil Geometry in a Large-Scale Levitation Melting Device—With Titanium as a Case Study. Energies, 18(15), 4162. https://doi.org/10.3390/en18154162