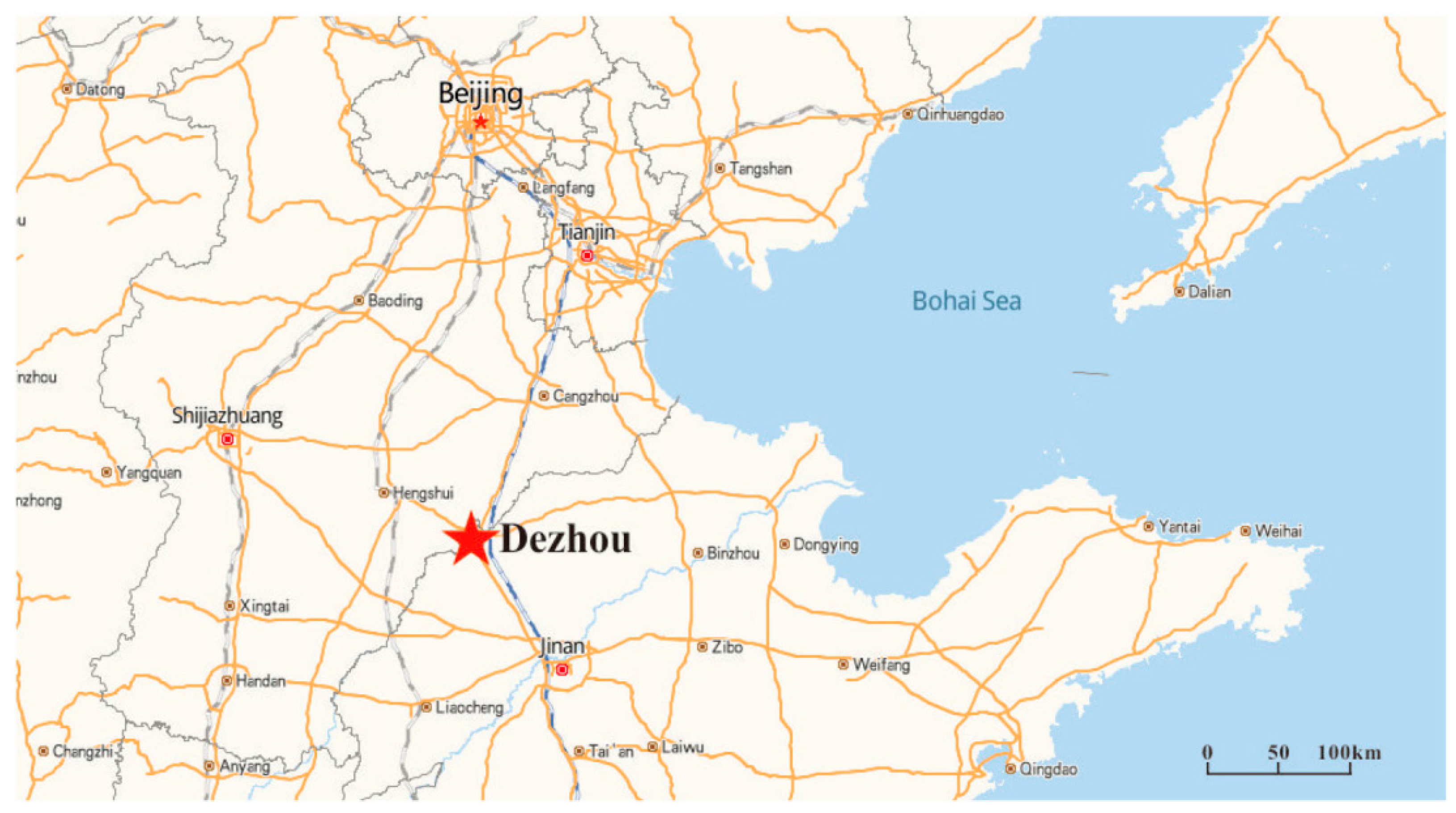

Figure 1.

Study area location.

Figure 1.

Study area location.

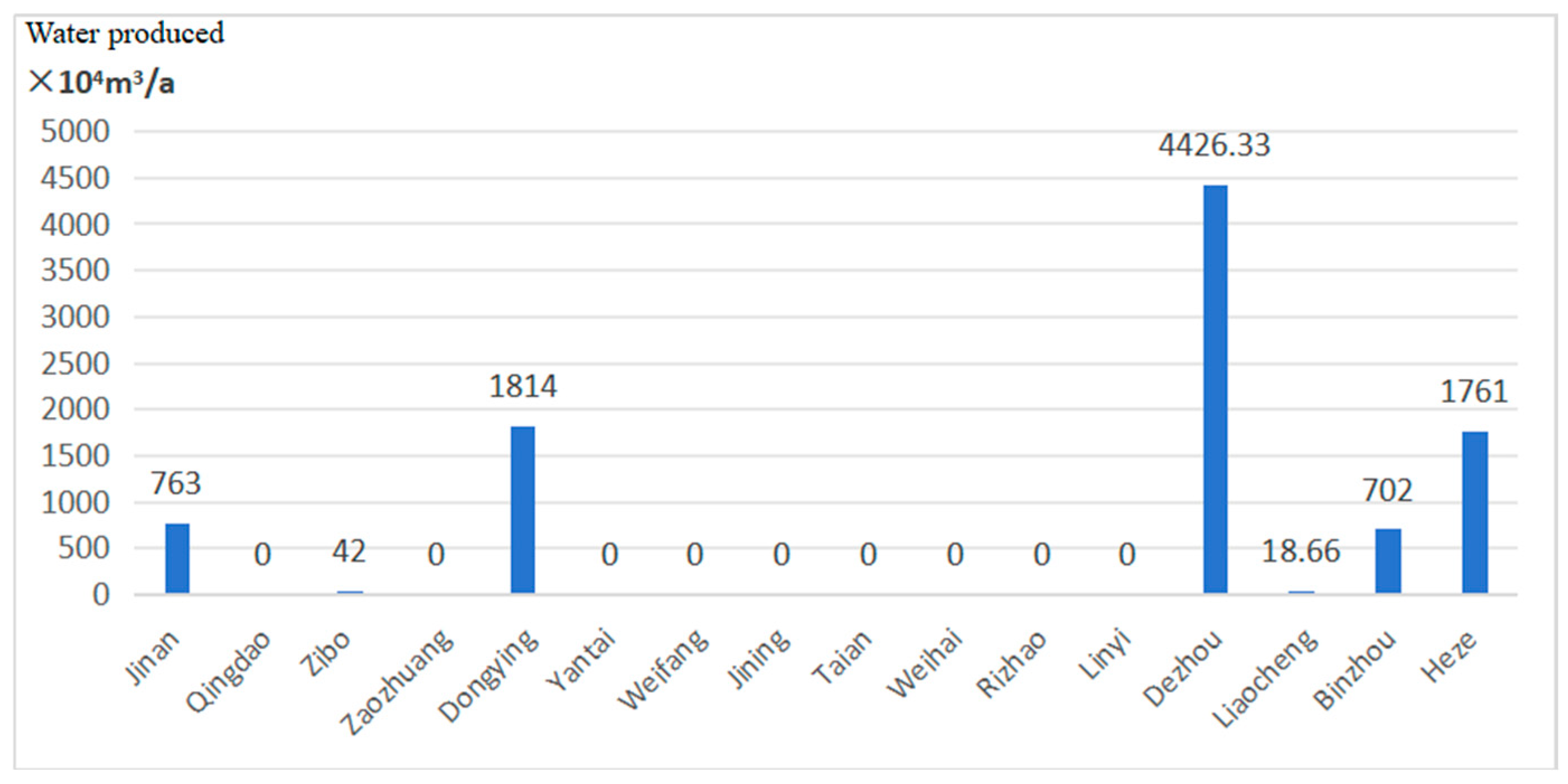

Figure 2.

Statistical chart of geothermal water produced in all cities of Shandong Province.

Figure 2.

Statistical chart of geothermal water produced in all cities of Shandong Province.

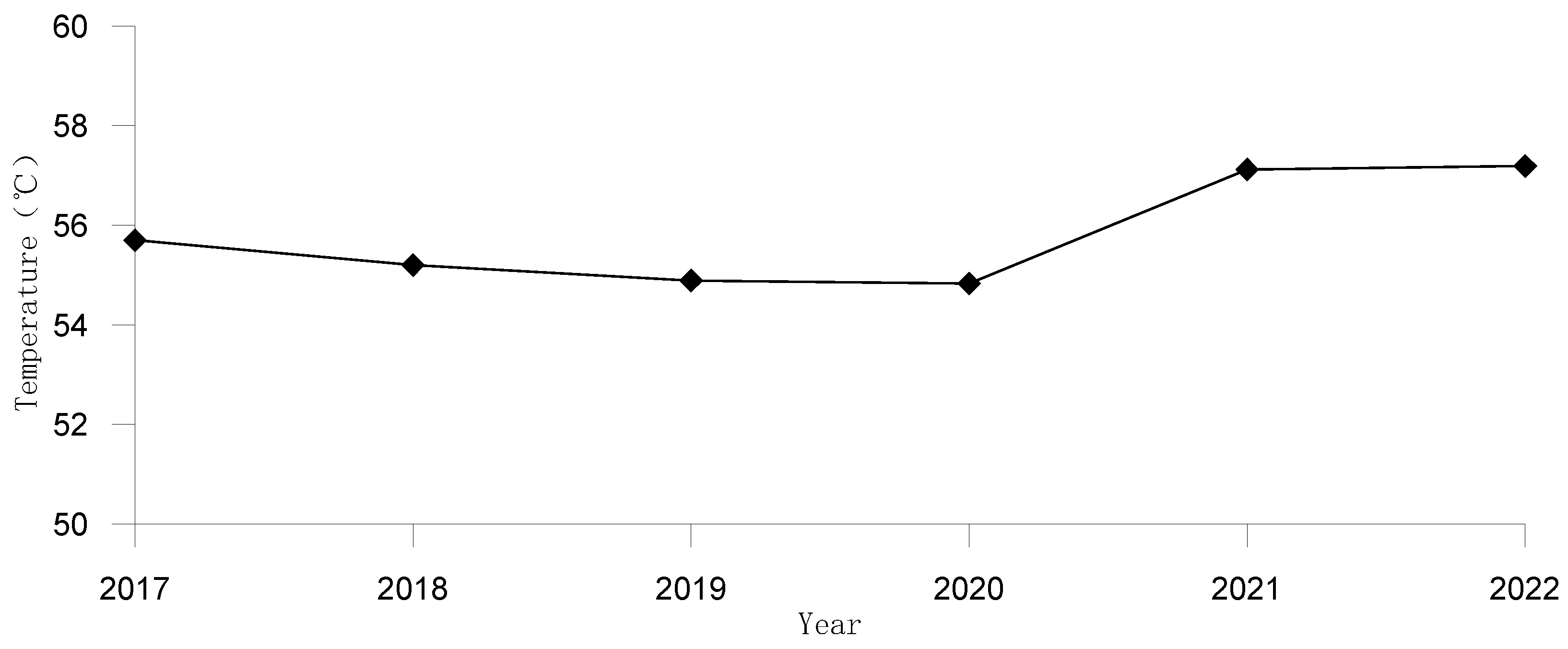

Figure 3.

Temperature change curve of wellhead of mining well in Decheng District.

Figure 3.

Temperature change curve of wellhead of mining well in Decheng District.

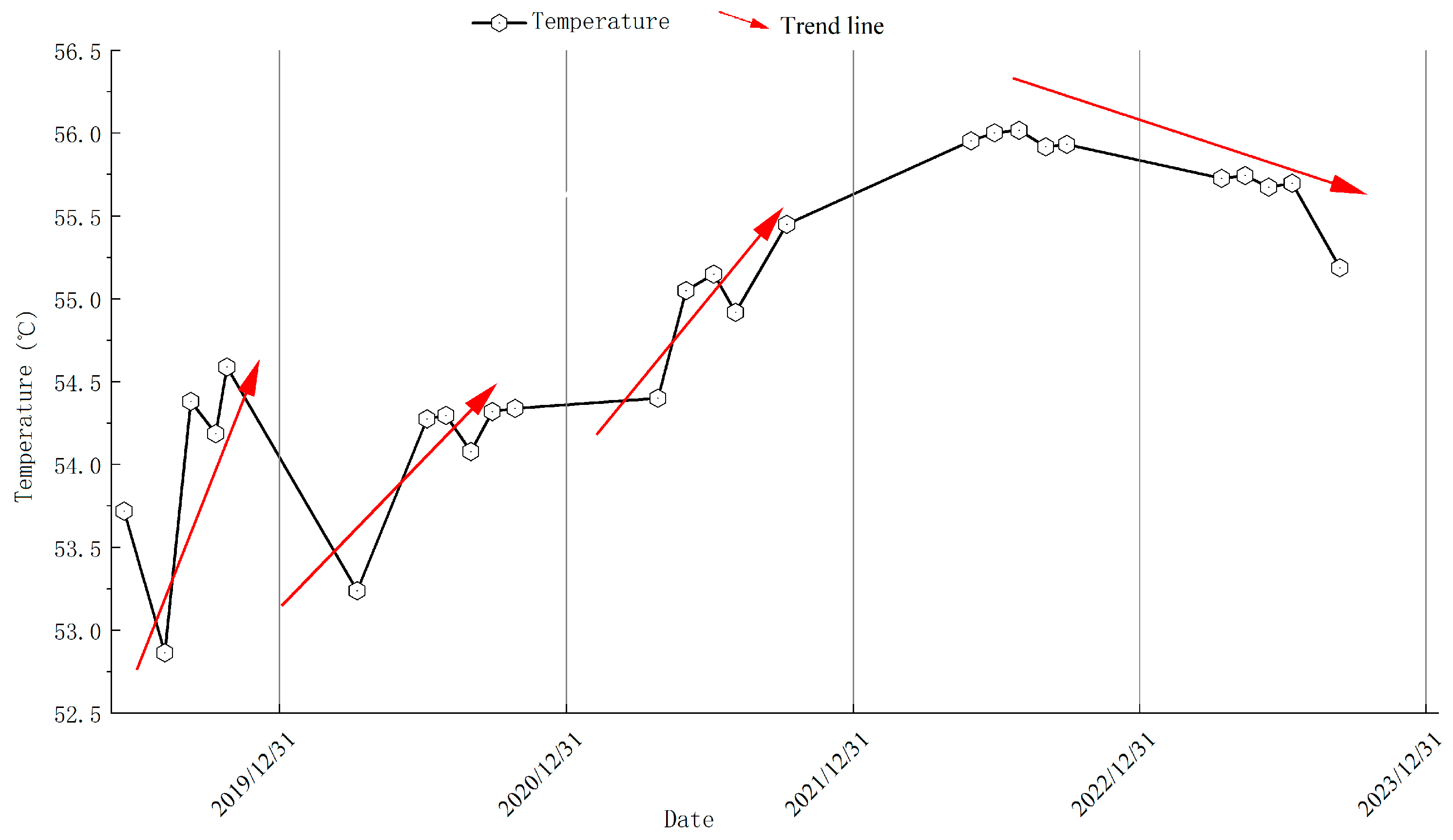

Figure 4.

Change curve of average temperature of water intake section of mining well over the years.

Figure 4.

Change curve of average temperature of water intake section of mining well over the years.

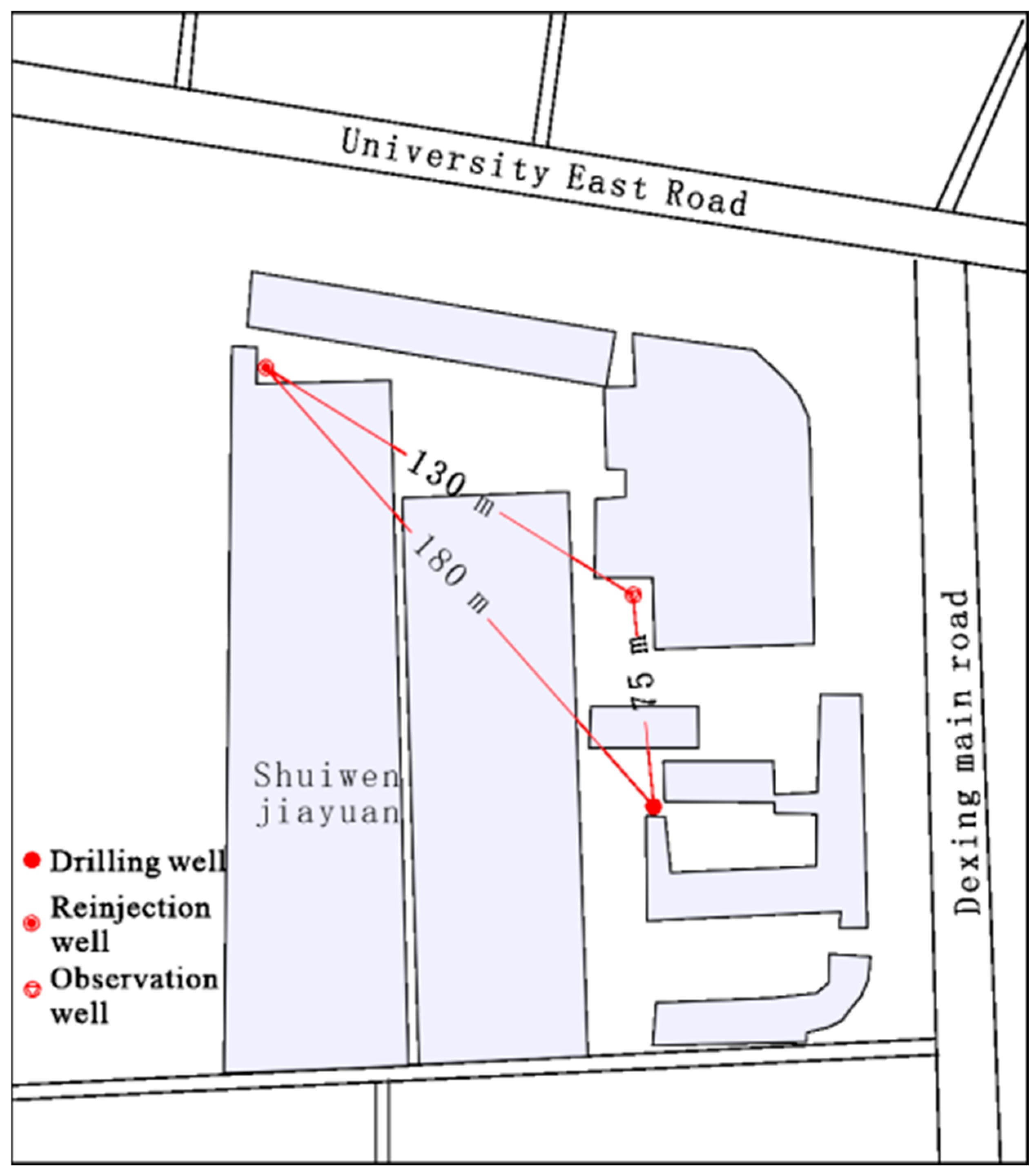

Figure 5.

Relative position diagram of geothermal wells in the Hydrological Home, Decheng District, Dezhou City.

Figure 5.

Relative position diagram of geothermal wells in the Hydrological Home, Decheng District, Dezhou City.

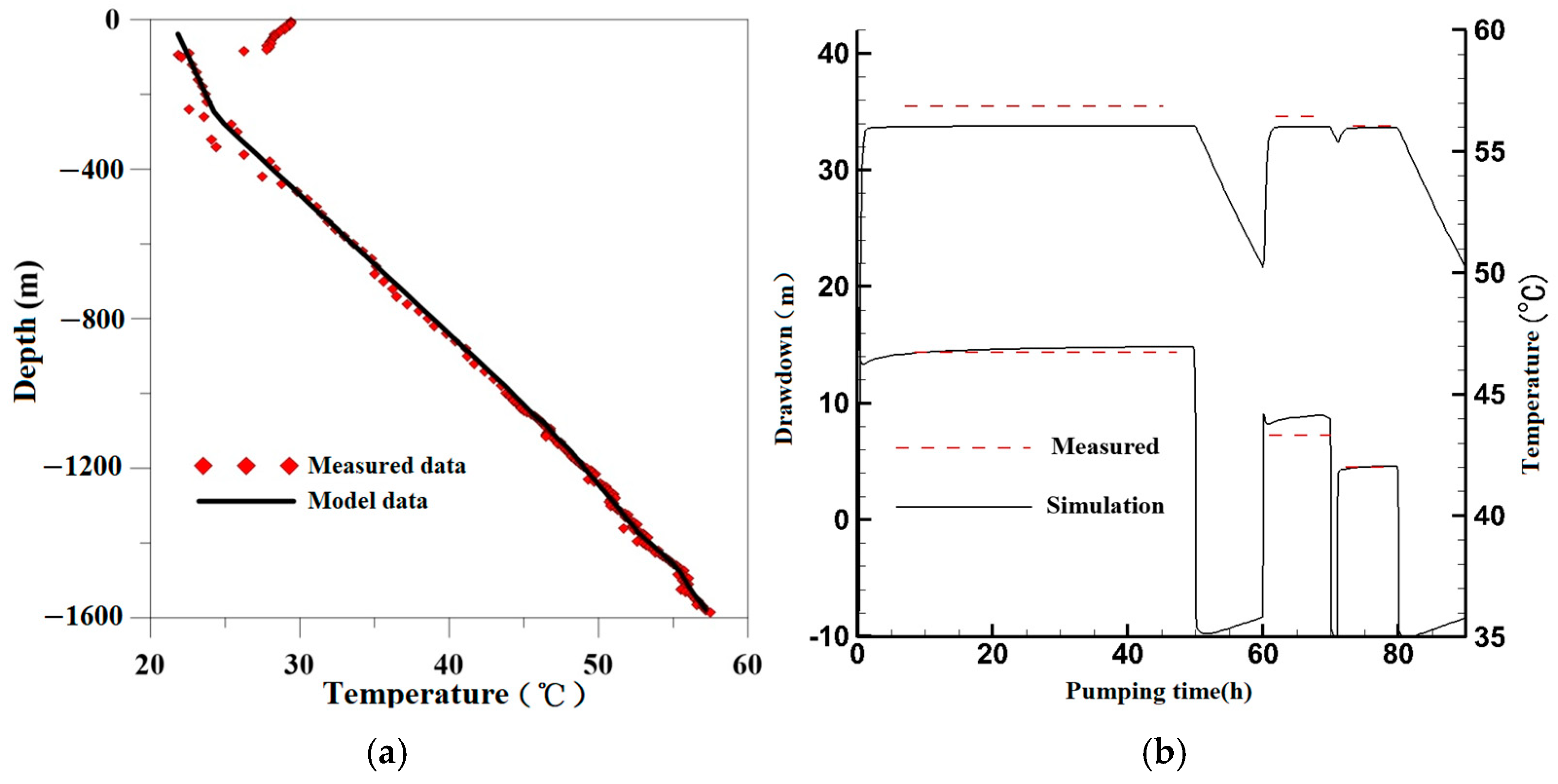

Figure 6.

Comparison of measured values and simulated correction results (a). Comparison of measured and simulated values of ground temperature, (b). Fitting effect of simulated and measured values of reduced depth and effluent temperature).

Figure 6.

Comparison of measured values and simulated correction results (a). Comparison of measured and simulated values of ground temperature, (b). Fitting effect of simulated and measured values of reduced depth and effluent temperature).

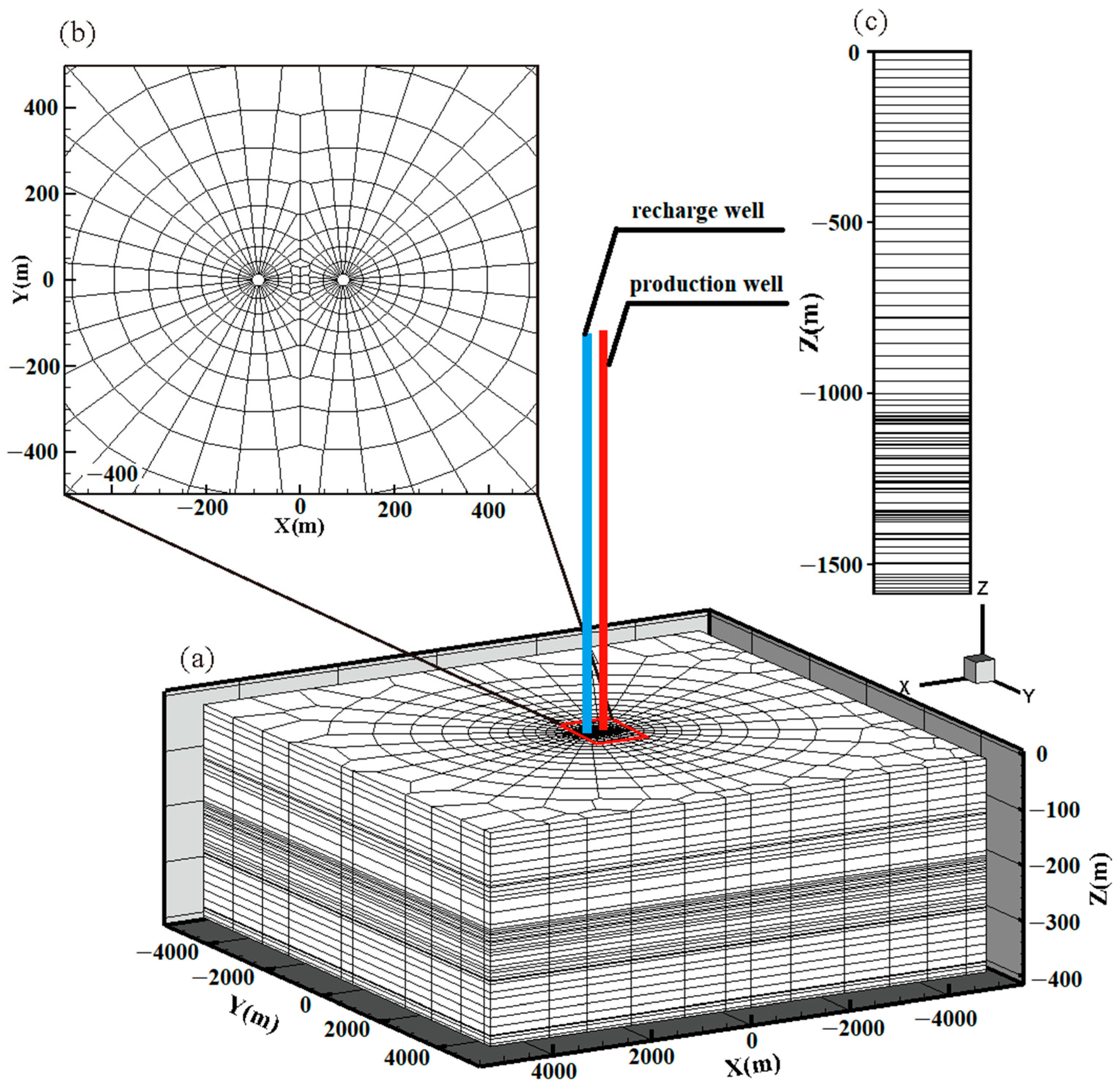

Figure 7.

(a) Schematic diagram of grid section of the well mining model (length: width: height: 1:1:10); (b) cryptosection of the near-well (c) vertical section of the shaft.

Figure 7.

(a) Schematic diagram of grid section of the well mining model (length: width: height: 1:1:10); (b) cryptosection of the near-well (c) vertical section of the shaft.

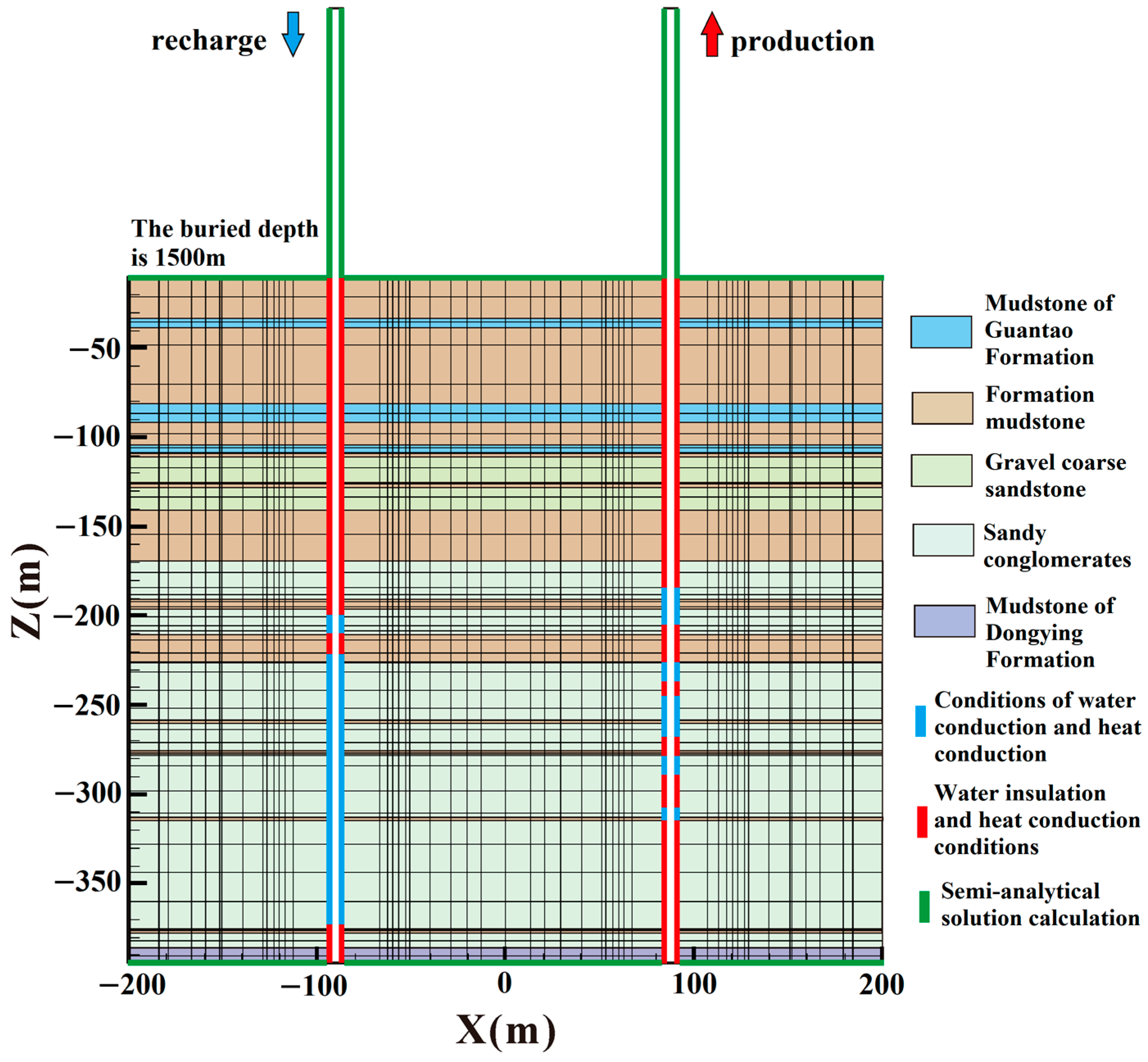

Figure 8.

Schematic diagram of the boundary conditions and lithology setting of the well mining model.

Figure 8.

Schematic diagram of the boundary conditions and lithology setting of the well mining model.

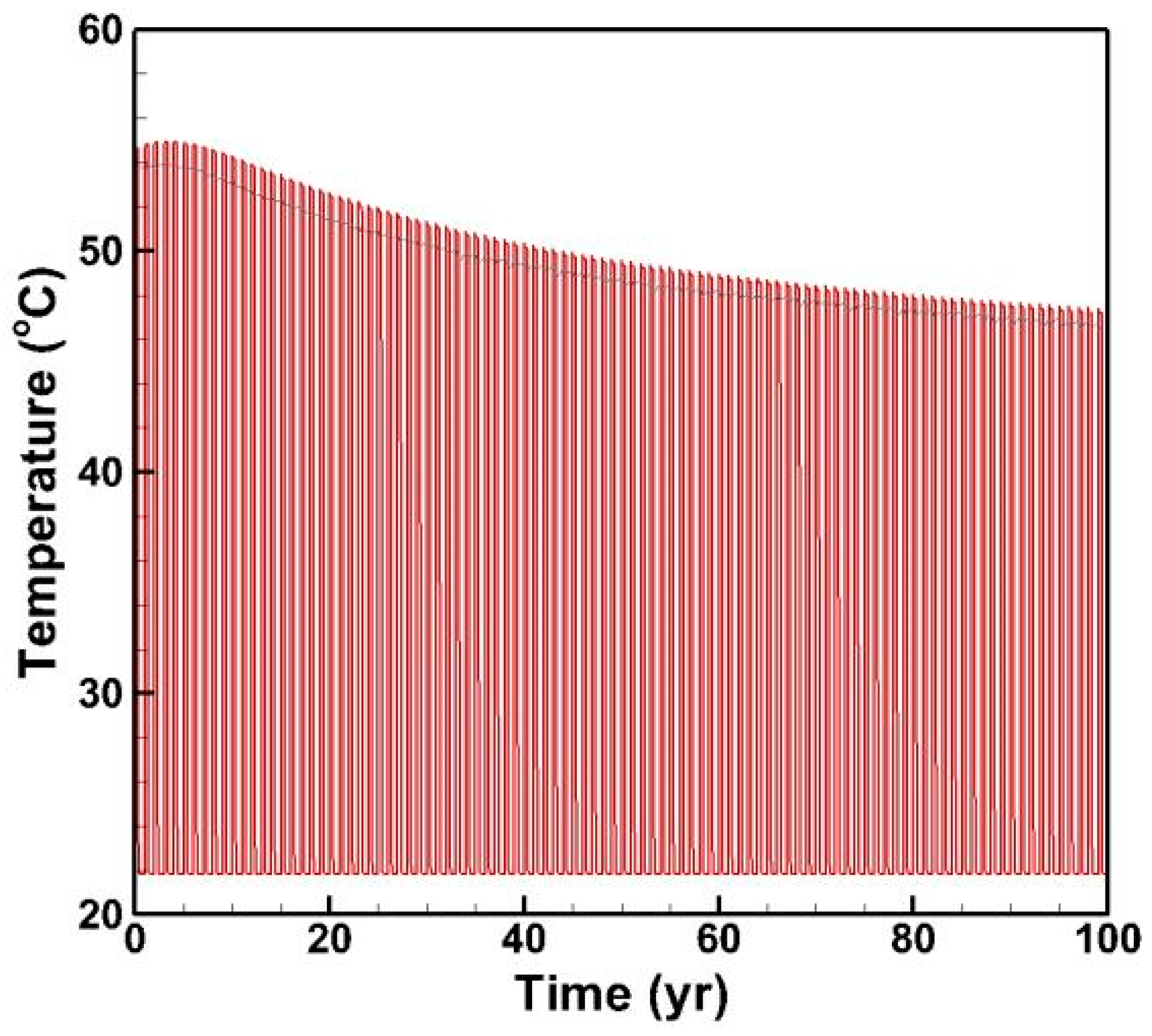

Figure 9.

Evolution of production wellhead temperature in different years.

Figure 9.

Evolution of production wellhead temperature in different years.

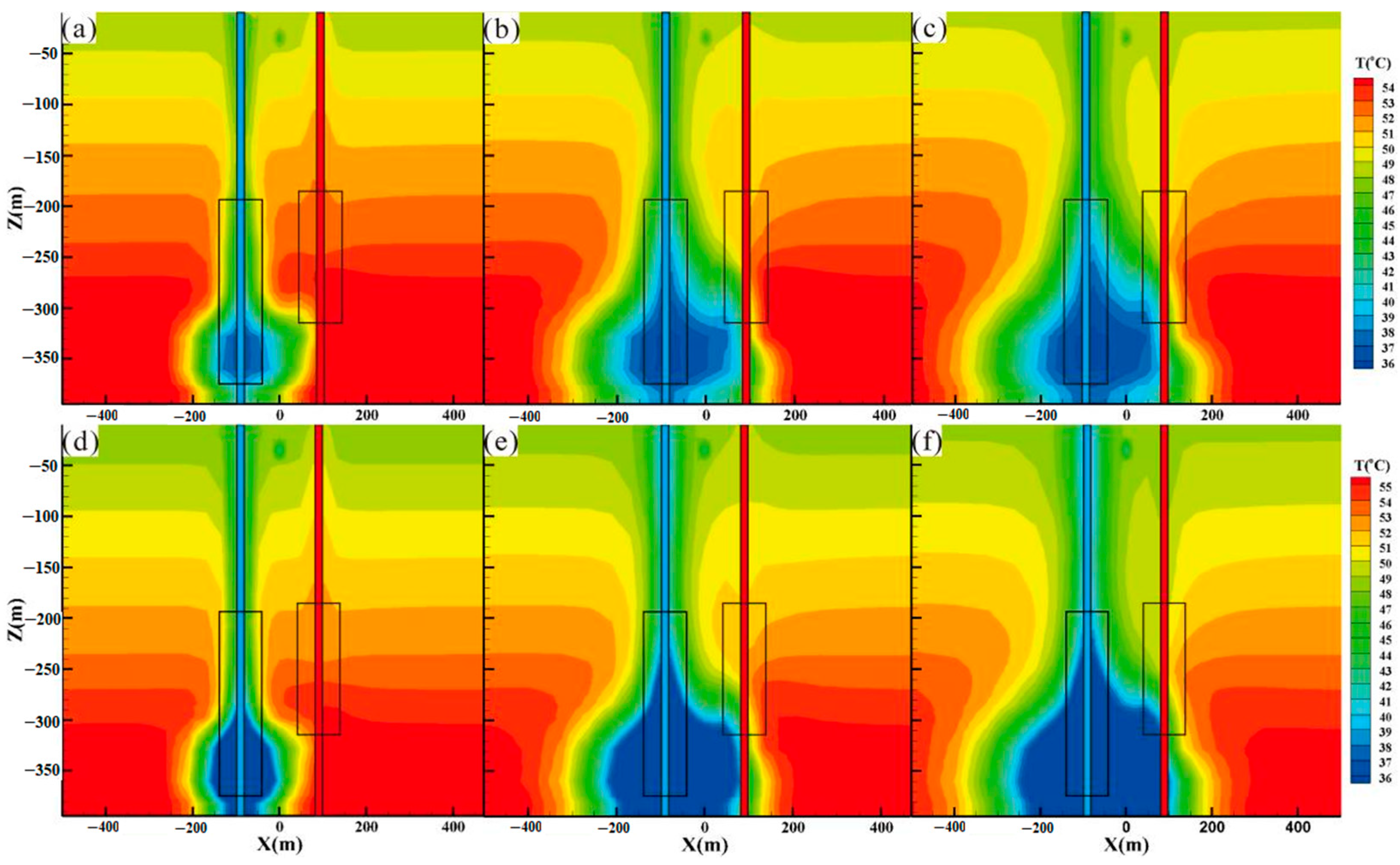

Figure 10.

Base case and simulation results in Scheme 1. (a–c) Temperature distribution at the 10th, 50th, and 100th year of Basic Case.; (d–f) Temperature distribution at the 10th, 50th, and 100th year of Low Temperature Recharge Case.

Figure 10.

Base case and simulation results in Scheme 1. (a–c) Temperature distribution at the 10th, 50th, and 100th year of Basic Case.; (d–f) Temperature distribution at the 10th, 50th, and 100th year of Low Temperature Recharge Case.

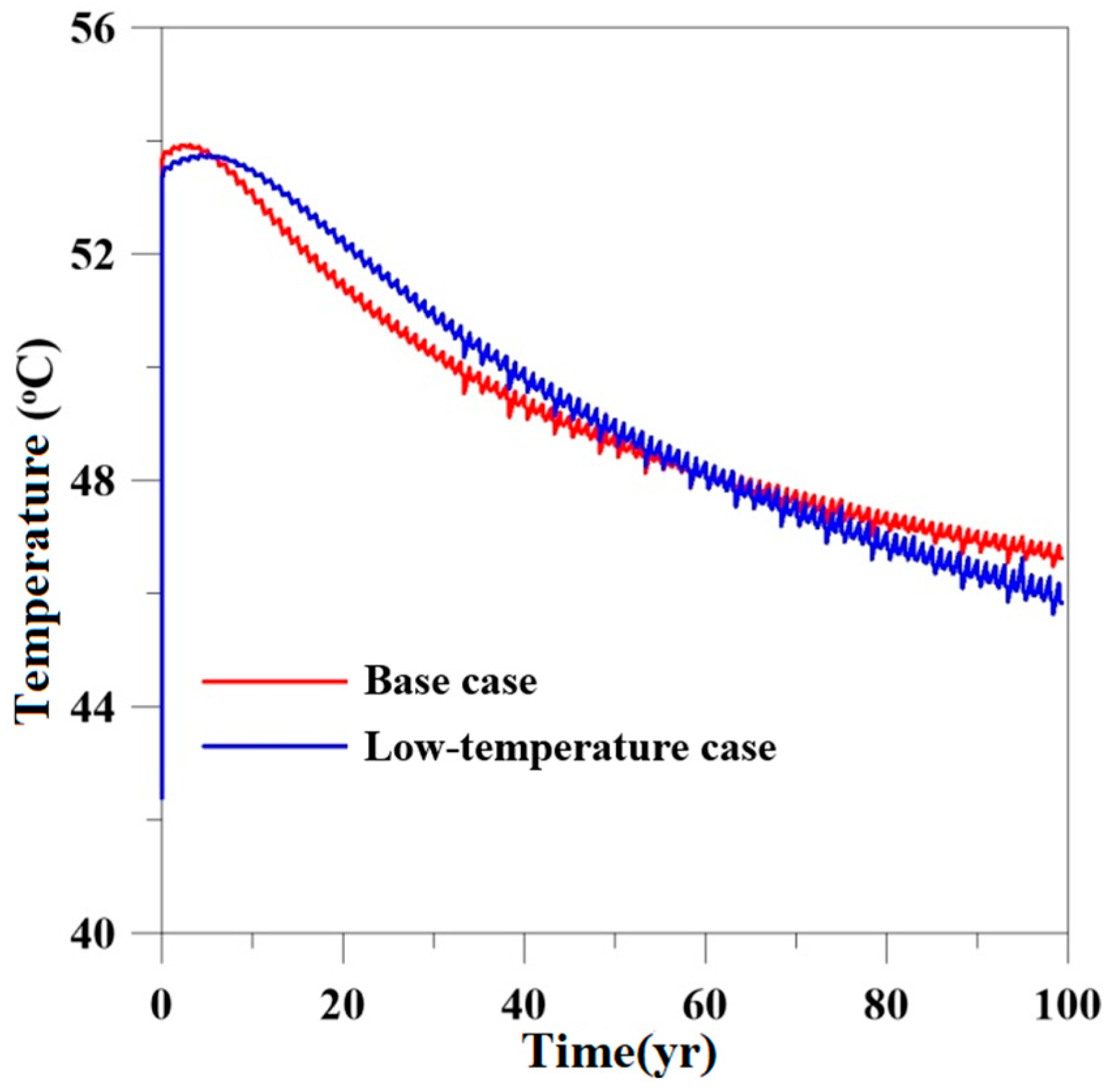

Figure 11.

Comparison of effluent temperature evolution with temperature of base case (Scheme 1).

Figure 11.

Comparison of effluent temperature evolution with temperature of base case (Scheme 1).

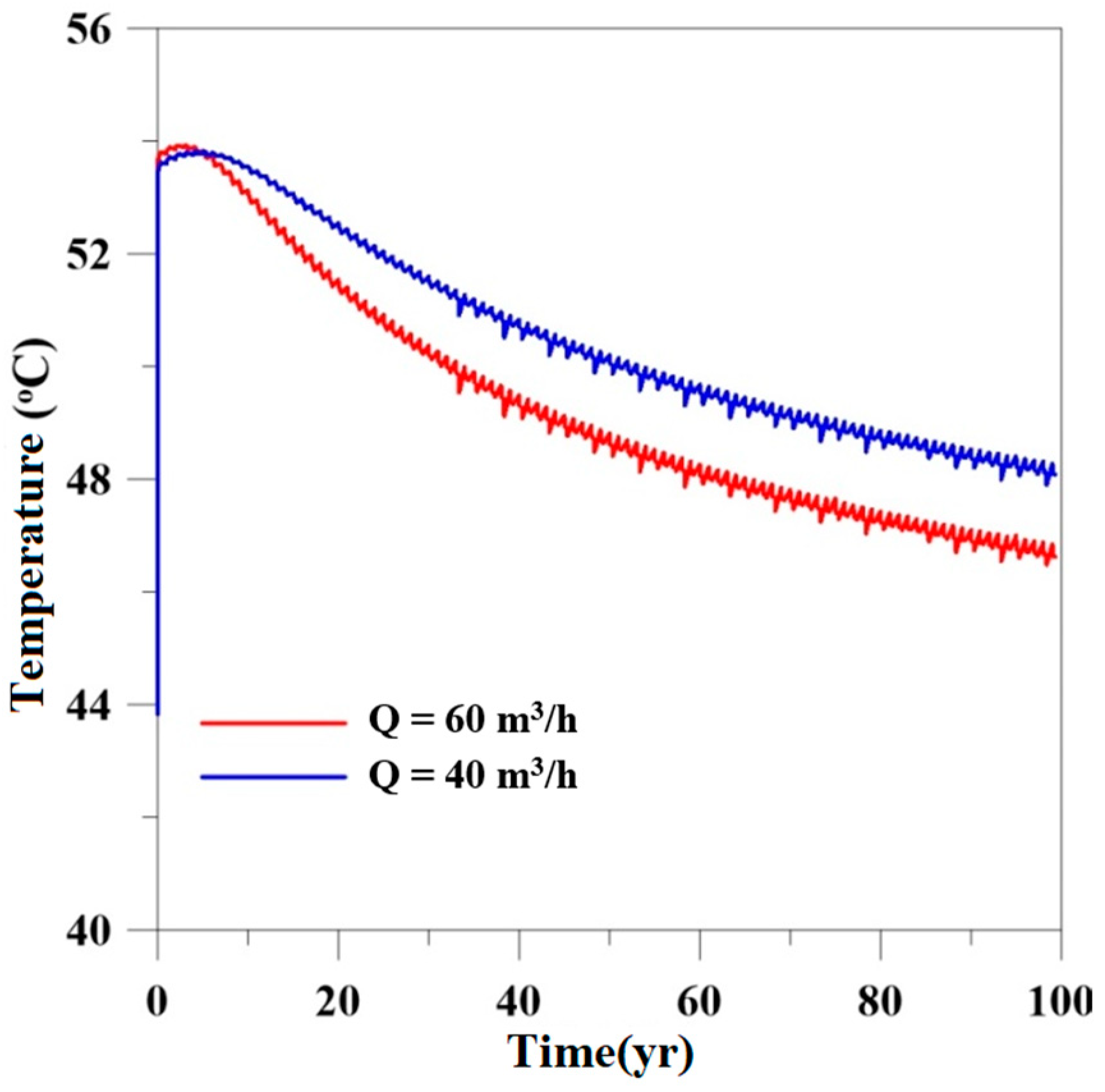

Figure 12.

Temperature evolution of outflow under different scenarios of different flow rate.

Figure 12.

Temperature evolution of outflow under different scenarios of different flow rate.

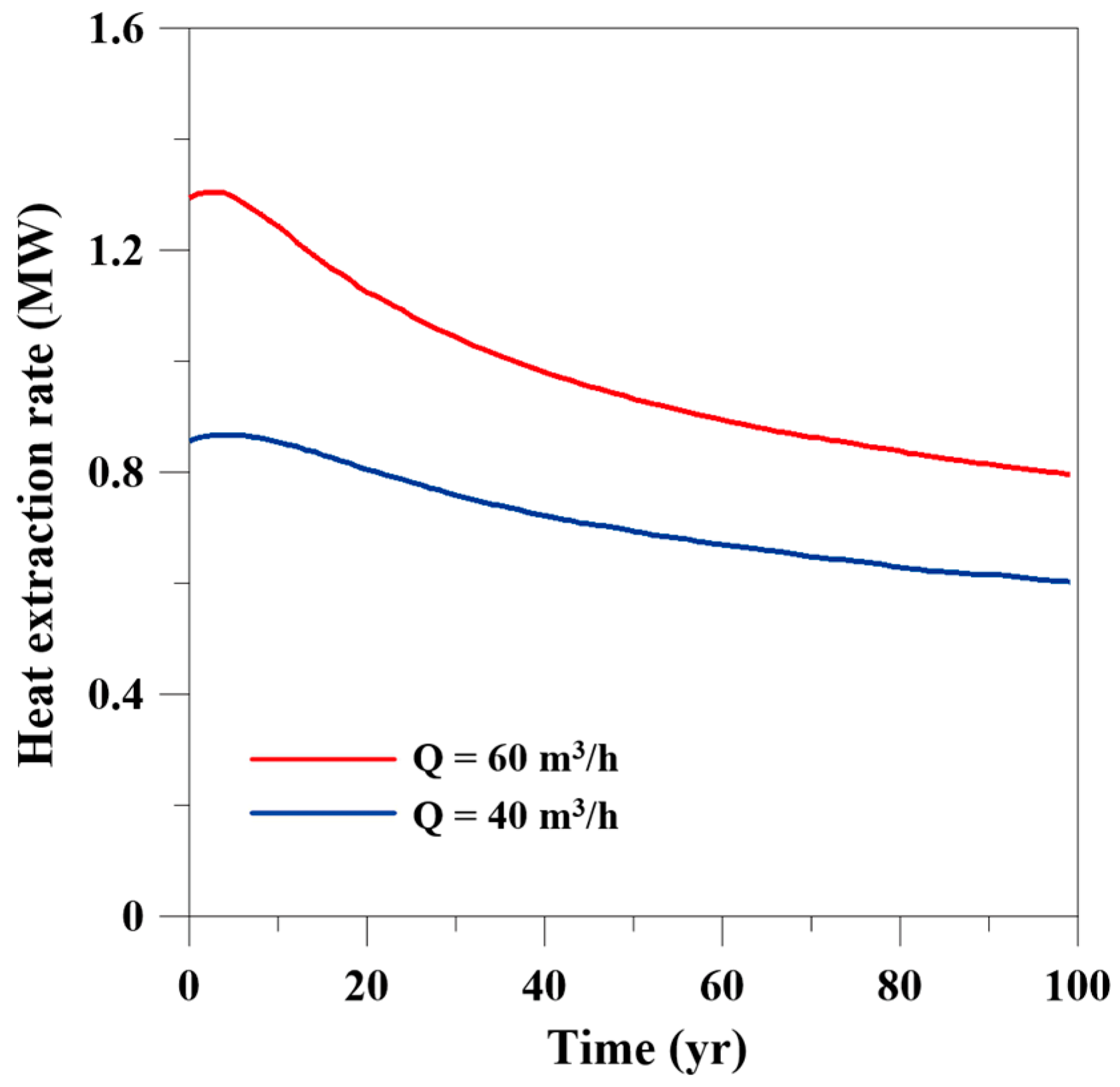

Figure 13.

Evolution of the heat extraction rate under different flux scenarios within 100 years.

Figure 13.

Evolution of the heat extraction rate under different flux scenarios within 100 years.

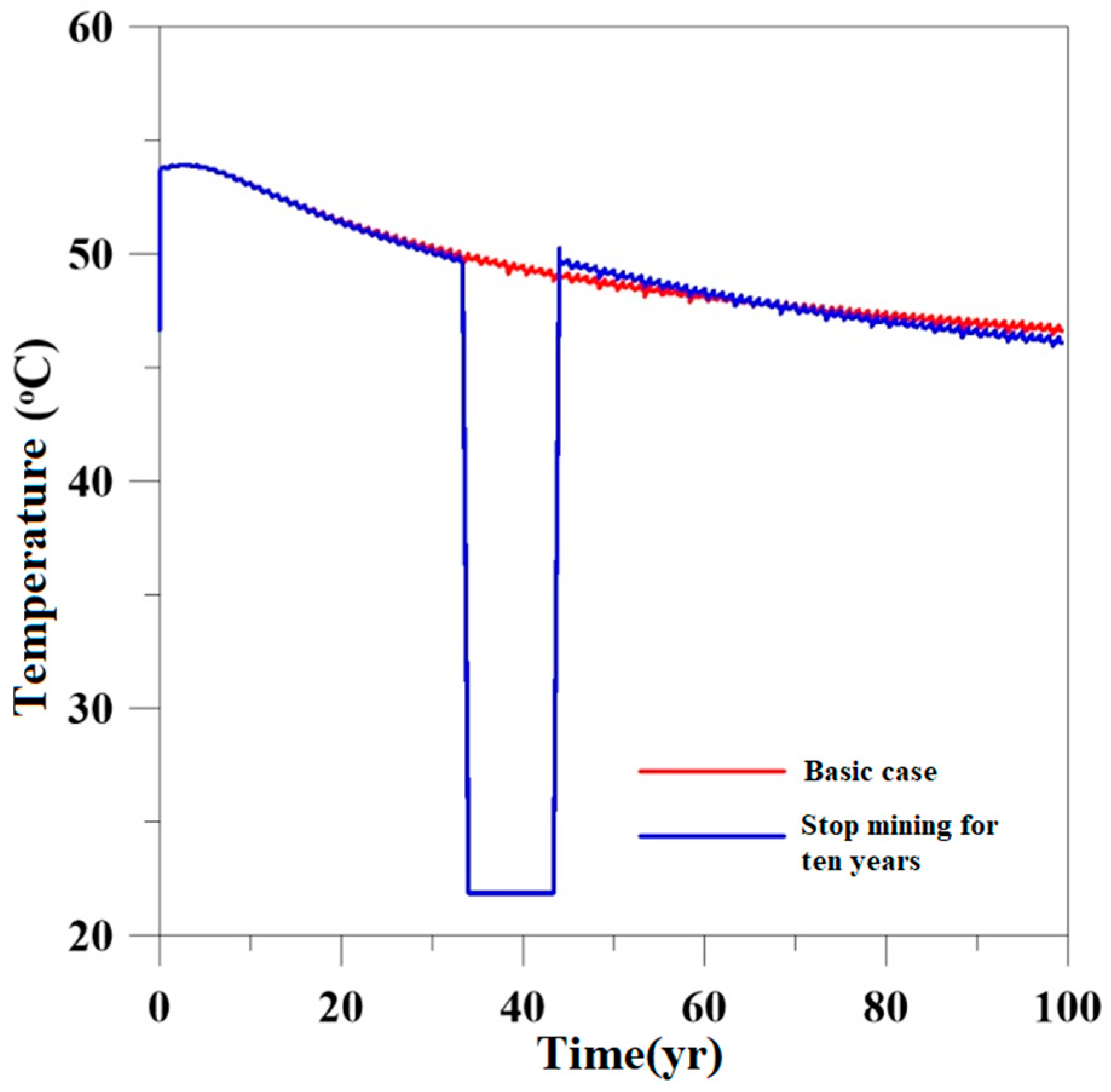

Figure 14.

The evolution of outflow temperature in Scenario 3.

Figure 14.

The evolution of outflow temperature in Scenario 3.

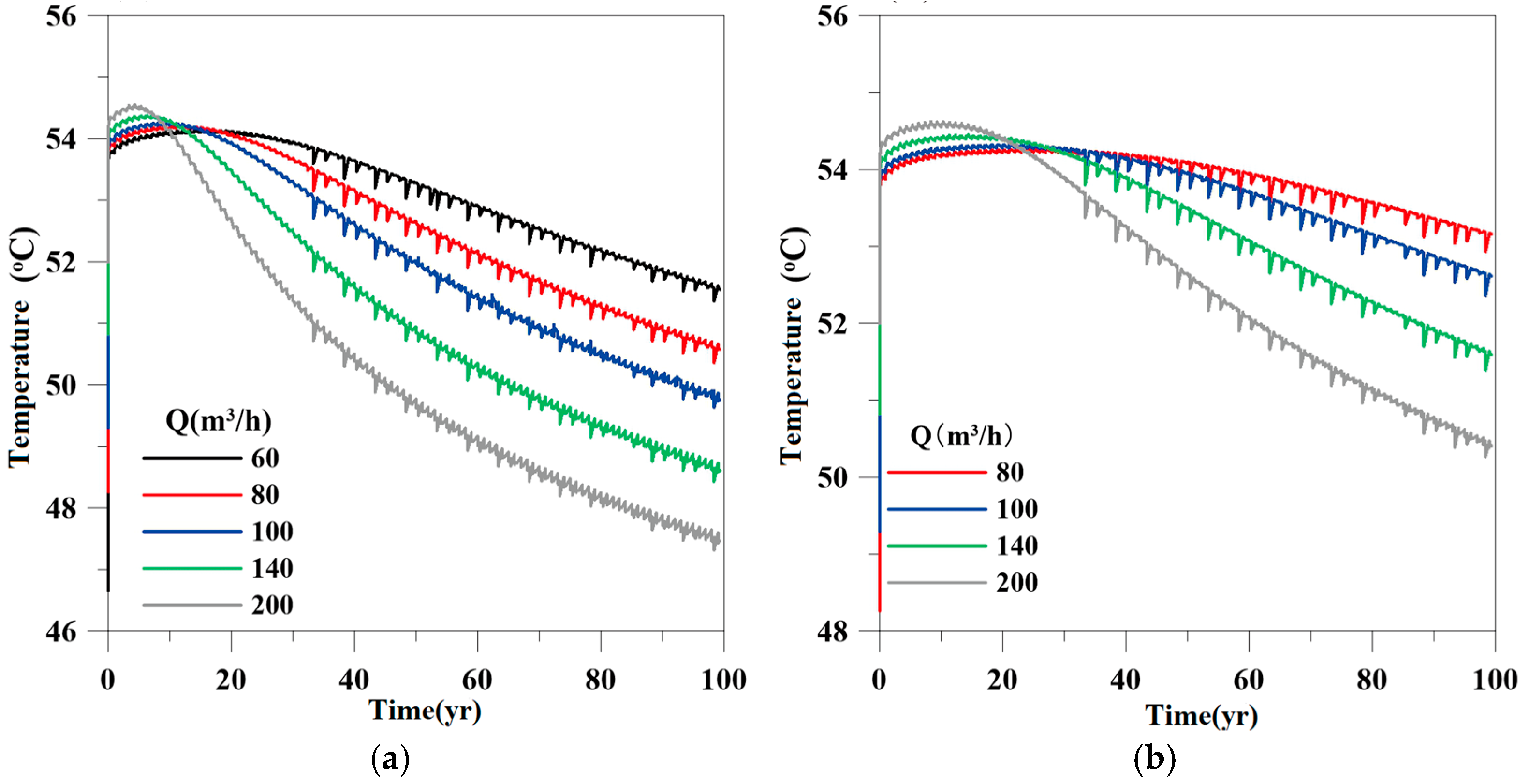

Figure 15.

Evolution curve of water outlet temperature over time with well spacings of 400 m (a) and 600 m (b).

Figure 15.

Evolution curve of water outlet temperature over time with well spacings of 400 m (a) and 600 m (b).

Table 1.

List of main thermal storage characteristics in Dezhou City, Shandong Province, China.

Table 1.

List of main thermal storage characteristics in Dezhou City, Shandong Province, China.

| Lithology | Distribution Characteristics | Outflow Temperature | Total Dissolved Solid | Discharge Rate (m3/d) | Hydrochemical Type |

|---|

| Pavilion pottery group | Except for partial loss in the southern mountain front area and regional structure and base fluctuation, the overall distribution pattern is shallow, thin, deep, and thick | 45~65 °C | 6~10 g/L | 70~120 | Cl-Na |

| Dongying group | It is mainly distributed in Wucheng–Xiajin and Dezhou–Lingcheng plain lines in the Linqing Depression, and in Yucheng and Linyi in the Jiyang Depression, while the rest of the area is missing | 60~70 °C | 10~15 g/L | 30~60 | Cl-Na, Cl·SO4-Na |

| The Cambrian–Ordovician carbonate thermal reservoir | It is mainly distributed in the Ningjin bulge, Luxi uplift, Gucheng–Wucheng bulge, Gaotang bulge, and other areas | 60~100 °C | from 1~2 g to more than 10 g/L | 50~60 | from HCO3-Ca·Na to HCO3·SO4-Ca·Na and Cl-Na |

Table 2.

Statistics of well spacing of 46 pairs of mining and recharge projects in Decheng District.

Table 2.

Statistics of well spacing of 46 pairs of mining and recharge projects in Decheng District.

| Well Spacing (m) | Quantity | Total | Proportion |

|---|

| <100 | 11 | 29 | 63.00% |

| 100–150 | 6 |

| 150–200 | 12 |

| 200–300 | 8 | 13 | 28.30% |

| 300–400 | 5 |

| >400 | 4 | 4 | 8.70% |

Table 3.

Multi-field coupled program for geothermal engineering.

Table 3.

Multi-field coupled program for geothermal engineering.

| Program | Multi-Field Coupling Function | Numerical Method |

|---|

| COMSOL | THMC | finite element |

| FALCON | THMC | finite element |

| FEHM | THMC | finite element |

| FEFLOW | TH | finite element |

| Fluent | THM | finite volume |

| GEOFRAC | THM | Boundary element |

| GEOS | HM | finite element + Limited volume |

| GPRS | TH | finite volume |

| MRST | TH | finite volume |

| NUFT | THC | finite volume |

| OpenGeoSys | THMC | finite element |

| SHEMAT | THC | finite difference |

| STOMP | THMC | finite volume |

| TOUGHREACT | THC | finite volume |

| THOUGH-FLAC | THM | finite volume |

Table 4.

Formation sequences exposed by the recharge wells.

Table 4.

Formation sequences exposed by the recharge wells.

| Formation | Bottom Depth (m) | Thickness (m) | Lithologic Character |

|---|

| Q | 260 | 260 | Clay, siltstone, fine sandstone |

| Nm | 1150 | 890 | Mudstone, fine sandstone interbedded |

| Ng | Upper | 1319 | 169 | Mudstone, with a thin layer of fine sandstone |

| Lower | 1536 | 217 | Including gravel coarse sandstone, conglomerate, thin layer mudstone |

| Ed | 1544.5 (Unpenetrated) | 8.5 | mudstone |

Table 5.

Calculation results of thermal reservoir parameters.

Table 5.

Calculation results of thermal reservoir parameters.

| Parameter | The MAX Drawdown | The Medium Drawown | The MIN Drawdown |

|---|

| Flux (m3/h) | 92.24 | 78.74 | 66.89 |

| Drawdown (m) | 14.38 | 7.23 | 4.49 |

| Hydraulic conductivity (m/d) | 0.90 | 1.44 | 1.88 |

| Permeability (Darcy) | 0.53 | 0.85 | 1.11 |

| Radius of influence (m) | 136.54 | 86.86 | 61.62 |

Table 6.

Lithological thermal conductivity correction values for different strata.

Table 6.

Lithological thermal conductivity correction values for different strata.

| Formation | Lithology | Thermal Conductivity W/(m·°C) |

|---|

| Q | Unconsolidated formation | 3.7 |

| N2m | Mudstone | 2.0 |

| Fine sandstone | 1.25 |

| N1g | Mudstone | 2.0 |

| Fine sandstone | 1.7 |

| Gravel coarse sandstone | 2.0 |

| Glutenite | 2.1 |

| E3d | Mudstone | 2.2 |

Table 7.

The permeability of each lithology is corrected and positive.

Table 7.

The permeability of each lithology is corrected and positive.

| Formation | Lithology | Permeability (×10−12 m2) |

|---|

| Ng | Mudstone | 0.057 |

| Fine sandstone | 1.5 |

| Gravel coarse sandstone | 1.9 |

| Glutenite | 2.3 |

| Ed | Mudstone | 0.052 |

Table 8.

Key hydrogeology and thermal property parameters setting of different lithology.

Table 8.

Key hydrogeology and thermal property parameters setting of different lithology.

| Formation | Lithology | Density (kg/m3) | Permeability (×10−12 m2) | Thermal Conductivity (W/m/°C) | Specific Heat Capacity (J/kg·°C) |

|---|

| Q | unconsolidated formation | 2232 | 0.23 | 3.7 | 919 |

| N | Nm | mudstone | 1968 | 0.057 | 2.0 | 934 |

| Fine sandstone | 1850 | 1.31 | 1.25 | 958 |

| Ng | Mudstone | 1968 | 0.057 | 2.0 | 934 |

| Fine sandstone | 1850 | 1.5 | 1.8 | 909 |

| Gravel coarse sandstone | 2000 | 1.9 | 2.0 | 909 |

| glutenite | 2000 | 2.3 | 2.1 | 909 |

| E | Ed | Mudstone | 1968 | 0.052 | 2.2 | 909 |

Table 9.

Recharge data over the years.

Table 9.

Recharge data over the years.

| Production and Recharge Test | Days (d) | Production Flux (m3/h) | Injection Flux (m3/h) | Recharge Water Temperature (°C) | Outflow Temperature (°C) |

|---|

| 2017 | 132 | 70.78 | 52.82 | 40 | 55.67 |

| 2018 | 115 | 64.15 | 54.84 | 34.1 | 54.9 |

| 2019 | 130 | 63.33 | 62.47 | 34.1 | 54.3 |

| 2020 | 145 | 64.41 | 60.69 | 34.12 | 54.23 |

| 2021 | 149 | 58.27 | 58.08 | 33.10 | 56.89 |

| 2022 | 137 | 64.79 | 65.52 | 32.56 | 56.31 |

| Base case | 130 | 60 | 60 | 35 | |

Table 10.

List of effluent temperature changes in the two schemes.

Table 10.

List of effluent temperature changes in the two schemes.

| Time | Basic Case (Q = 60 m3/h, T = 35 °C) | Low Temperature Recharge Case (Q = 33.5 m3/h, T = 20 °C) |

|---|

| Outflow Temperature (°C) | Temperature Drop (°C) | Outlet Temperature (°C) | Temperature Drop (°C) |

|---|

| First year | 53.9 | 0.0 | 53.5 | 0.0 |

| The 50th year | 48.6 | 5.3 | 48.9 | 4.6 |

| The 100th year | 46.6 | 7.3 | 45.8 | 7.7 |

Table 11.

Results of the outflow temperature under different flux scenarios.

Table 11.

Results of the outflow temperature under different flux scenarios.

| Time | Base Case (60 m3/h) | Flux of 40 m3/h |

|---|

| Outlet Temperature (°C) | Temperature Drop (°C) | Outlet Temperature (°C) | Temperature Drop (°C) |

|---|

| First year | 53.9 | 0.0 | 53.8 | 0.0 |

| The 50th year | 48.6 | 5.3 | 50.1 | 3.7 |

| The 100th year | 46.6 | 7.3 | 48.2 | 5.6 |

Table 12.

Changes in heat extraction efficiency of different mining and recharge volumes.

Table 12.

Changes in heat extraction efficiency of different mining and recharge volumes.

| Time | Q = 60 m3/h (Base Case) | Q = 40 m3/h |

|---|

| Heat Extraction Rate (MW) | Decreasing Amplitude (MW) | Heat Extraction Rate (MW) | Decreasing Amplitude (MW) |

|---|

| First year | 1.3 | 0.0 | 0.87 | 0.0 |

| The 50th year | 0.9 | 0.4 | 0.7 | 0.17 |

| The 100th year | 0.8 | 0.5 | 0.6 | 0.27 |

Table 13.

Variation in effluent temperature at different mining rates at well spacing 400 m.

Table 13.

Variation in effluent temperature at different mining rates at well spacing 400 m.

| | Flow

(m3/h) | 60 | 80 | 100 | 140 | 200 |

|---|

| Time | | Temperature °C | Reduced °C | Temperature °C | Reduced °C | Temperature °C | Reduced °C | Temperature °C | Reduced °C | Temperature °C | Reduced °C |

|---|

| First year | 53.8 | 0.0 | 53.9 | 0.0 | 54.0 | 0.0 | 54.1 | 0.0 | 54.3 | 0.0 |

| The 50th year | 53.3 | 0.5 | 52.6 | 1.3 | 52.0 | 2.0 | 50.9 | 3.2 | 49.7 | 4.6 |

| The 100th year | 51.6 | 2.2 | 50.6 | 3.3 | 49.8 | 4.2 | 48.6 | 5.5 | 47.5 | 6.8 |

Table 14.

Variation in effluent temperature at different mining rates with well spacing of 600 m.

Table 14.

Variation in effluent temperature at different mining rates with well spacing of 600 m.

| | Flow

(m3/h) | 80 | 100 | 140 | 200 | 260 |

|---|

| Time | | Temperature °C | Reduced °C | Temperature °C | Reduced °C | Temperature °C | Reduced °C | Temperature °C | Reduced °C | Temperature °C | Reduced °C |

|---|

| First year | 53.9 | 0.0 | 54.0 | 0.0 | 54.1 | 0.0 | 54.3 | 0.0 | 54.5 | 0.0 |

| The 50th year | 54.1 | −0.2 | 54.0 | 0.0 | 53.5 | 0.6 | 52.7 | 1.6 | 51.9 | 2.6 |

| The 100th year | 53.2 | 0.7 | 52.6 | 1.4 | 51.6 | 2.5 | 50.4 | 3.9 | 49.6 | 4.9 |