Preliminary Comparison of Ammonia- and Natural Gas-Fueled Micro-Gas Turbine Systems in Heat-Driven CHP for a Small Residential Community

Abstract

1. Introduction

2. Materials and Methods

2.1. District Heating Load—Heating Demand

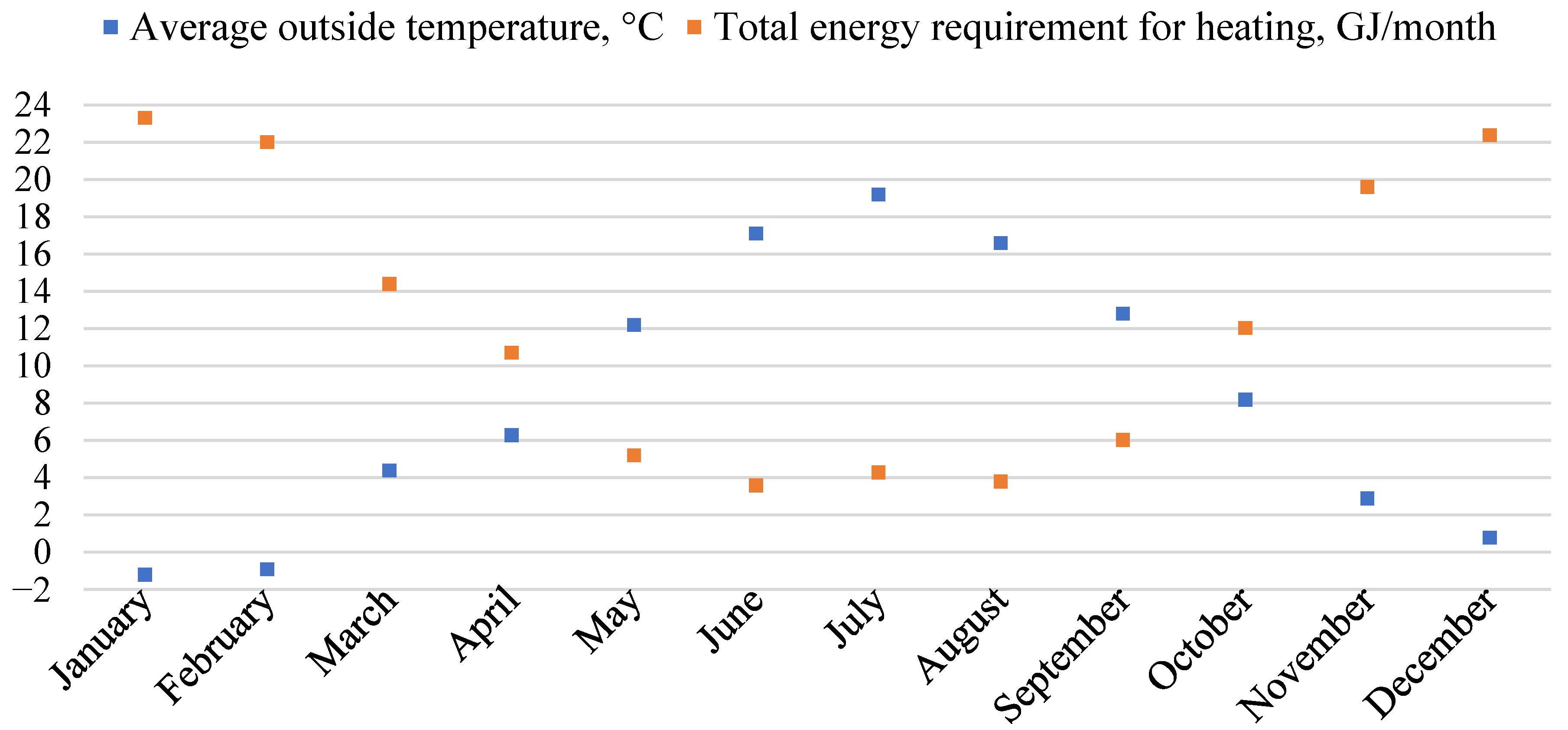

- Monthly heat demand: calculated based on average outside temperature for each month at a specified location. It is plotted in Figure 2 where the total energy requirement for the heating of the building monthly is shown versus the average outside temperature in the respective month.

- Thermal power: from a set of heat demands at corresponding temperatures, a linear regression characteristic was used to estimate the relationship between the instantaneous heating demand as a variable dependent on the outside temperature.

- Annual demand assessment: from the established relationship, the annual heat demand was derived at an hourly timestep for the building. The annual temperature data for Warsaw was sourced from the ASHRAE IWEC. Final heat demand values were adjusted to account for the CHP system covering 15 buildings within a residential community.

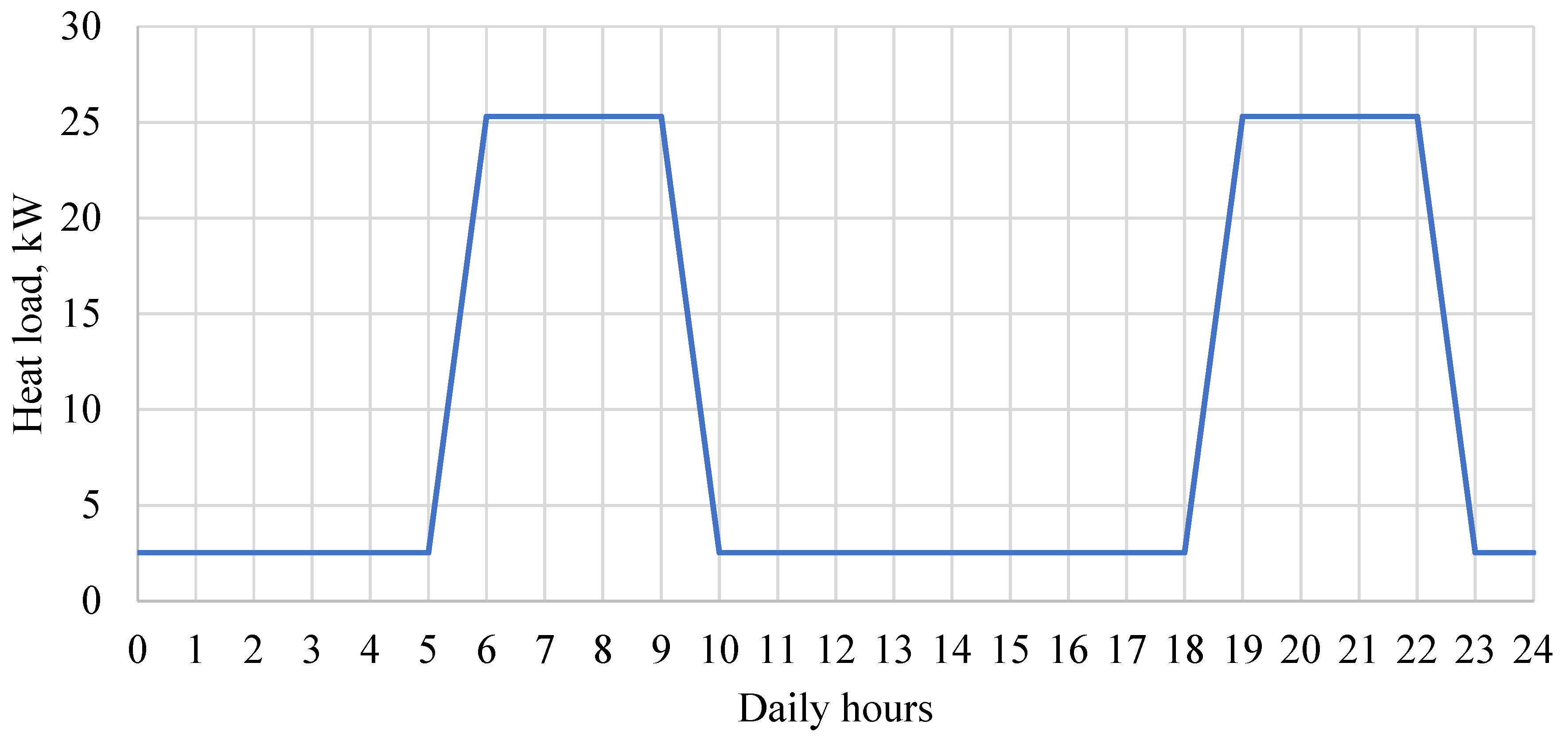

2.2. District Heating Load—Domestic Hot Water Demand

2.3. Total District Heating Load

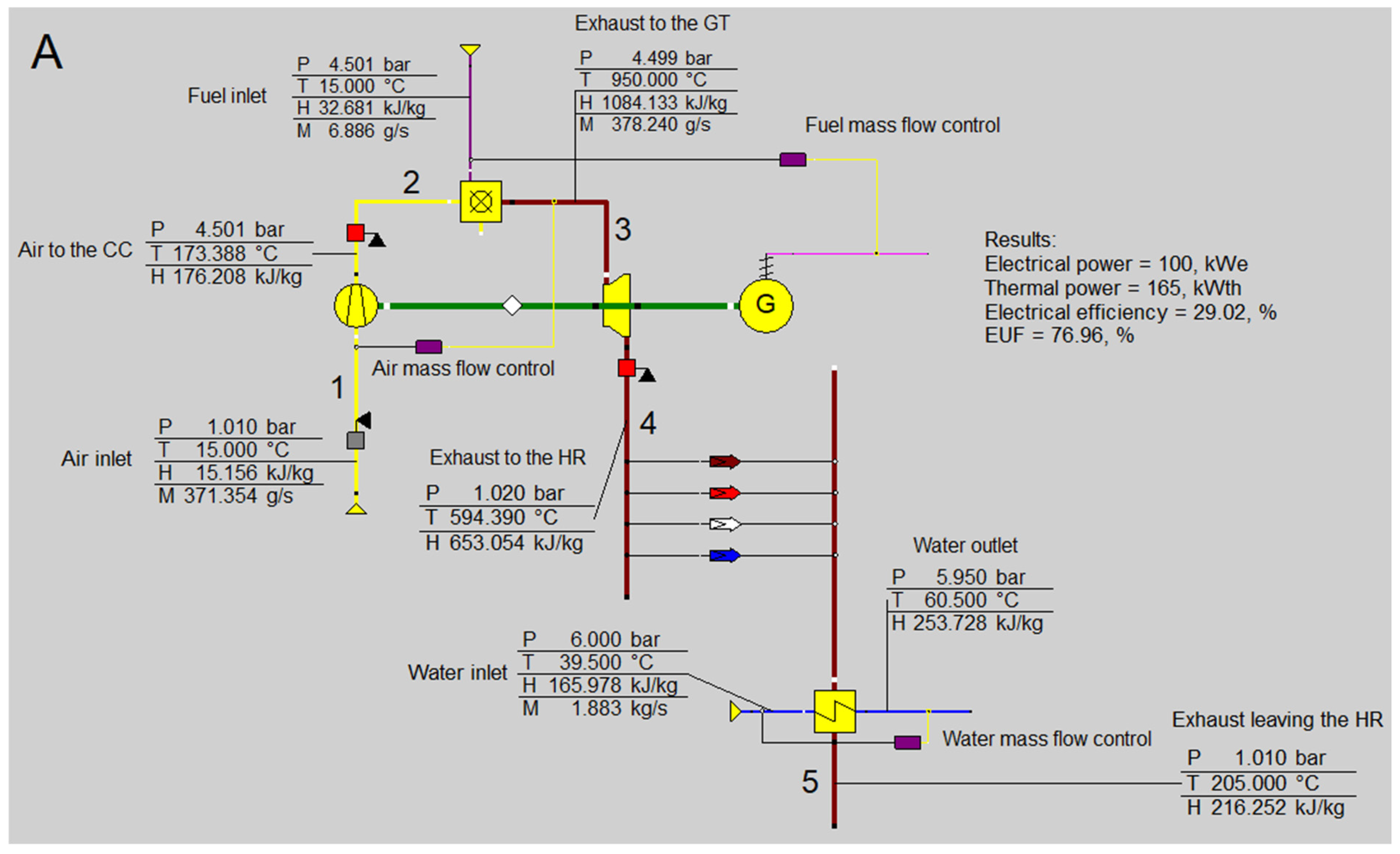

2.4. Plant Model—On-Design

- The combustion chamber pressure was based on typical values for similar micro-gas turbines (such as Ansaldo AE-T100NG).

- Internal efficiencies reflect a highly efficient scenario; as such the conditions should be treated as theoretical. The values are listed in Table 6.

- The study is set in a system-level perspective where the complete combustion of fuel is assumed. This approach is consistent with other studies of such type [31]. Combustion inefficiencies and trace exhaust components are neglected.

- The composition of the natural gas is taken as pure methane, reflecting a high-quality fuel for a baseline comparison with ammonia.

- The exhaust temperature after the HR was determined using a thermal power output of 165 kWth, corresponding to 100 kWe electrical power; a ratio between electrical and thermal power is based on Ansaldo AE-T100NG specifications.

- To offset the 5% heat loss from transportation, the CHP unit’s HR inlet and outlet temperatures were adjusted by 0.5 °C, resulting in 39.5 °C/60.5 °C to ensure that building entry and exit temperatures align with the requirements, maintained consistently year-round.

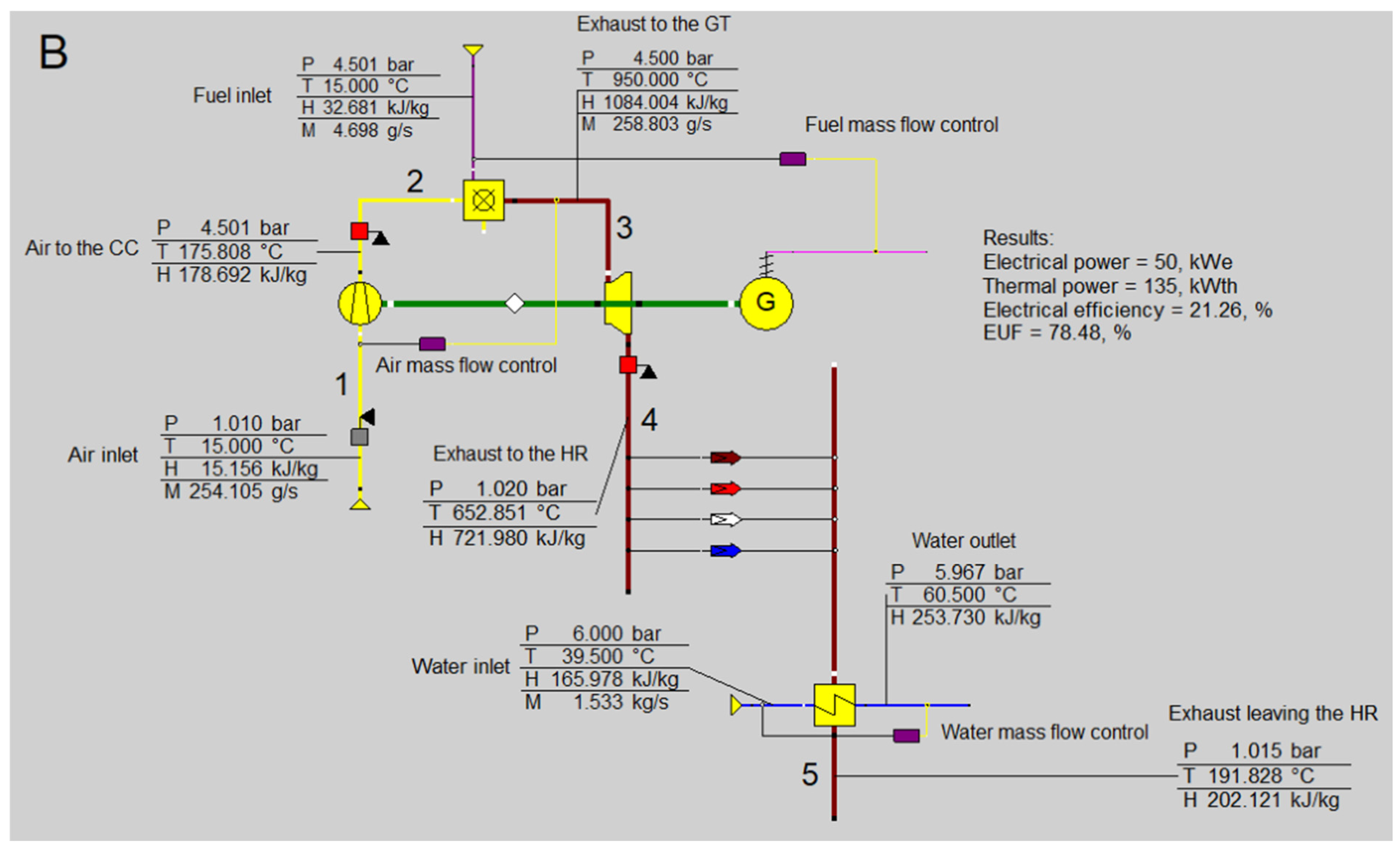

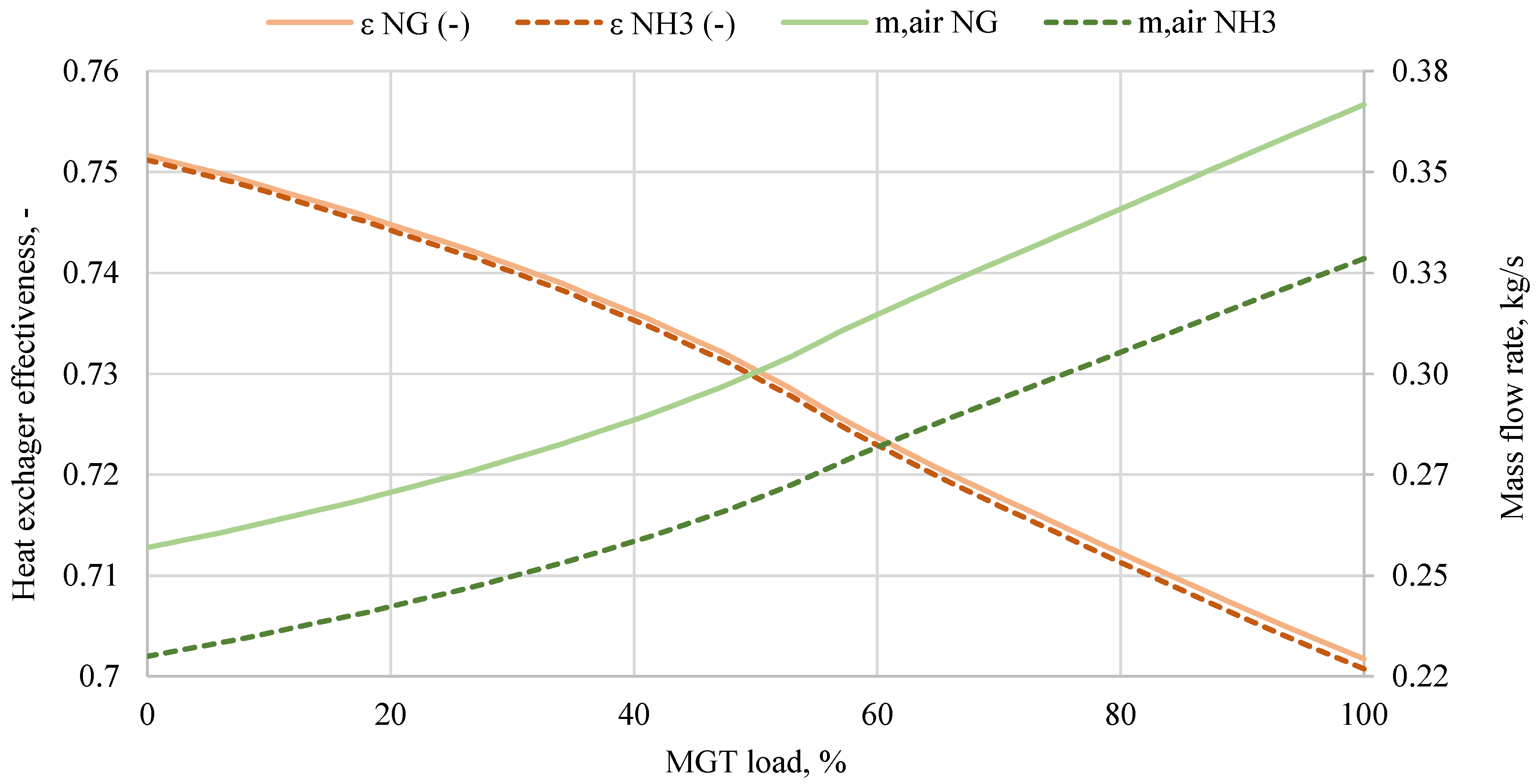

2.5. Plant Model—Off-Design

- Compressor: internal efficiency as a function of the mass flow rate of air.

- Gas turbine: internal efficiency as a function of the mass flow rate of exhaust gases.

- Heat recovery exchanger: the UA parameter (product of heat transfer coefficient and area) as a function of the mass flow rate of exhaust gases.

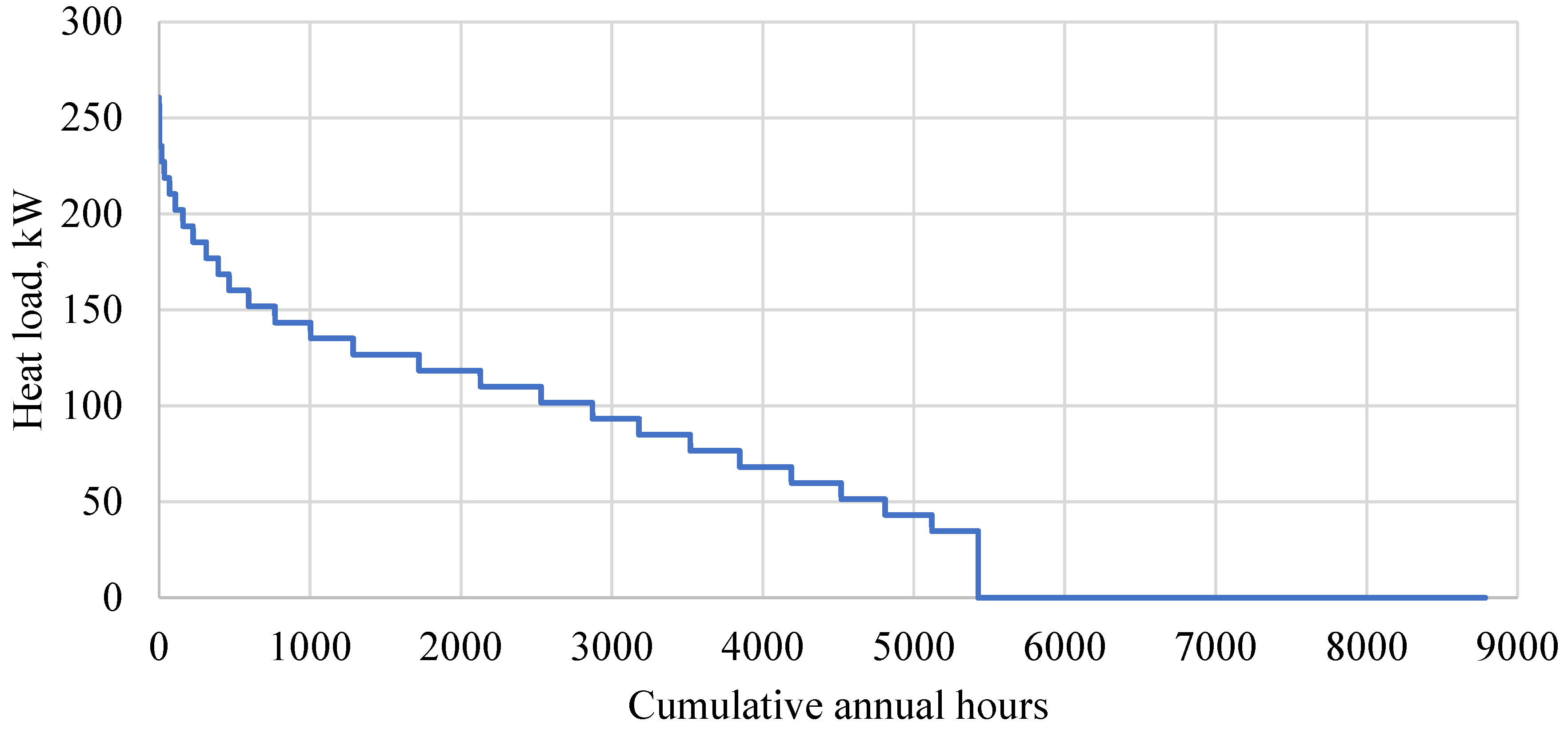

- The minimum operational load of the MGT is set at 50% of its electrical power capacity (50 kWe).

- Air inlet conditions, pressure after the compressor, exhaust temperature after the combustion chamber, pressure after the turbine, exhaust temperature after the HR, and water temperatures before and after the HR remain constant. The model iterates over mass flow rates of air, fuel and water towards solving mass and energy balances to match the required electrical energy, considering the altered performance of the equipment.

- When the heat demand exceeds the system’s heat output capacity, the MGT operates at its maximum capacity to fulfil as much of the heating requirement as possible.

- If the required heat falls within the operational range (between the maximum and minimum capacities), the MGT adjusts its output to match the actual demand.

- When the heat demand is below the system’s minimum capacity, the MGT operates at its minimal threshold.

- The MGT is only activated when the outside temperature drops below a threshold of 12 °C. This is based on the rationale that during warmer periods the heat demand significantly decreases as only the domestic hot water demand must be delivered. During these warmer periods, it is assumed that the heat requirements are met by an alternative heat source, such as a boiler or a heat pump, to avoid the unnecessary operation of the MGT and the consequent generation of excess heat.

3. Results

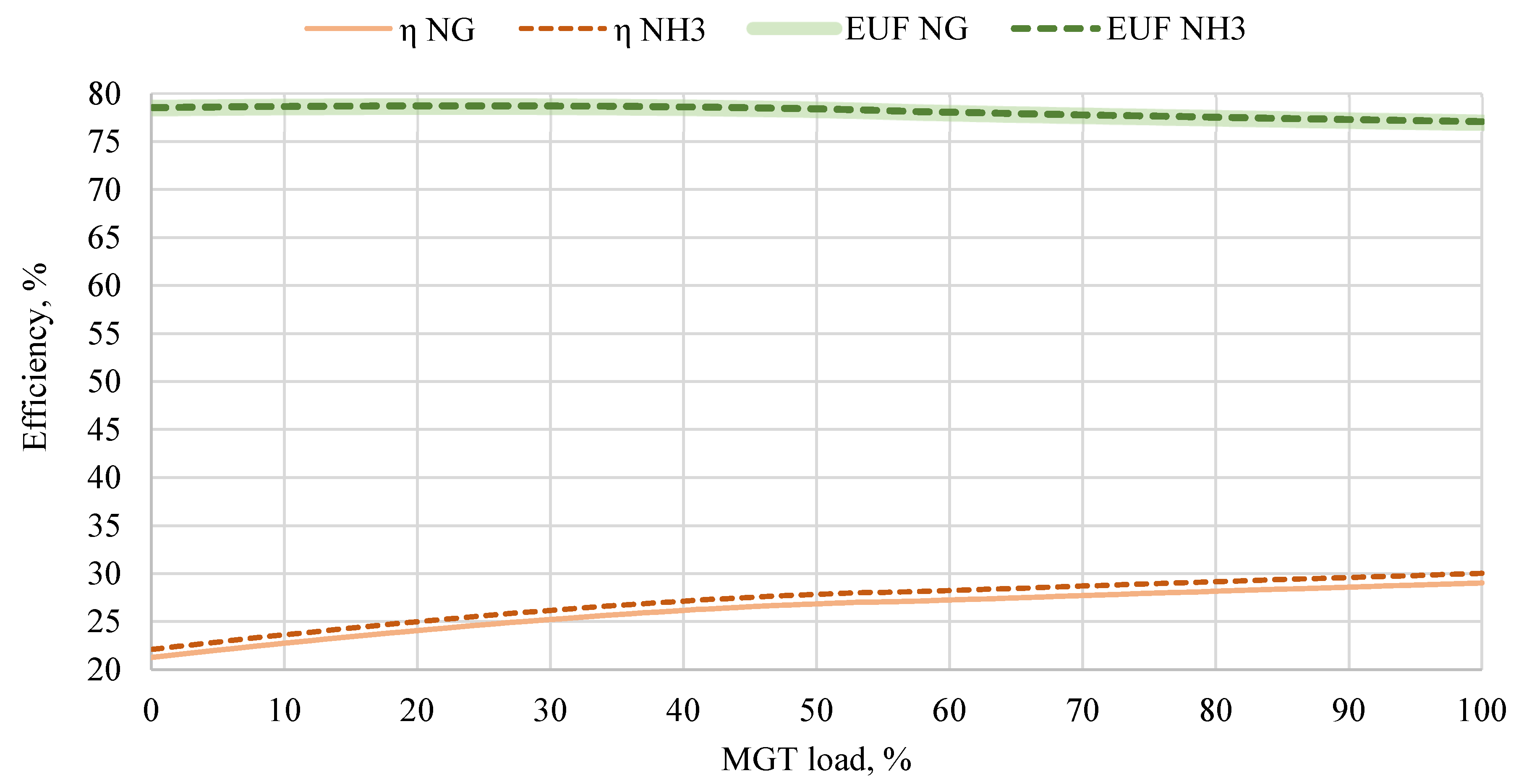

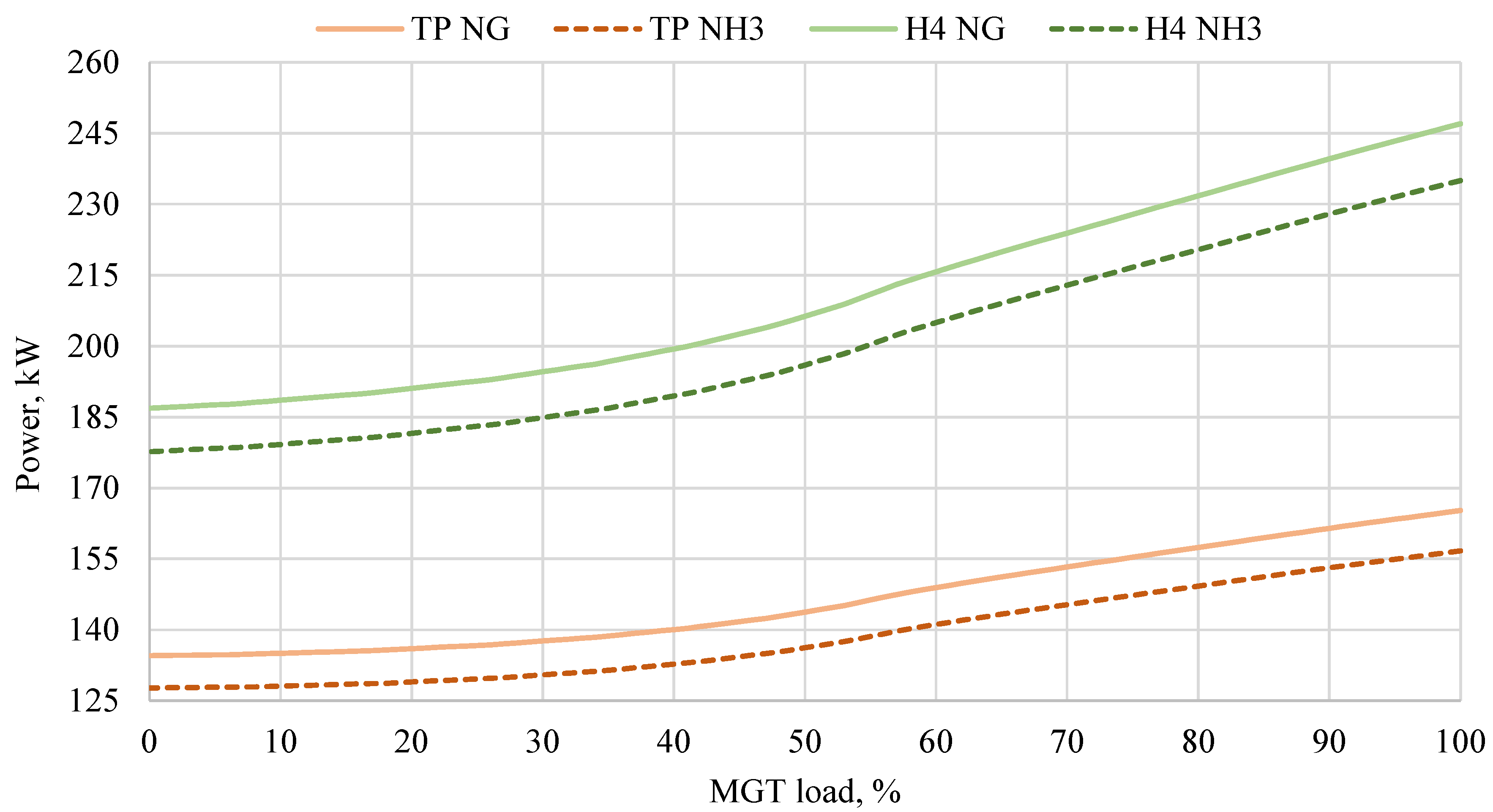

3.1. Partial Load Off-Design Characteristics

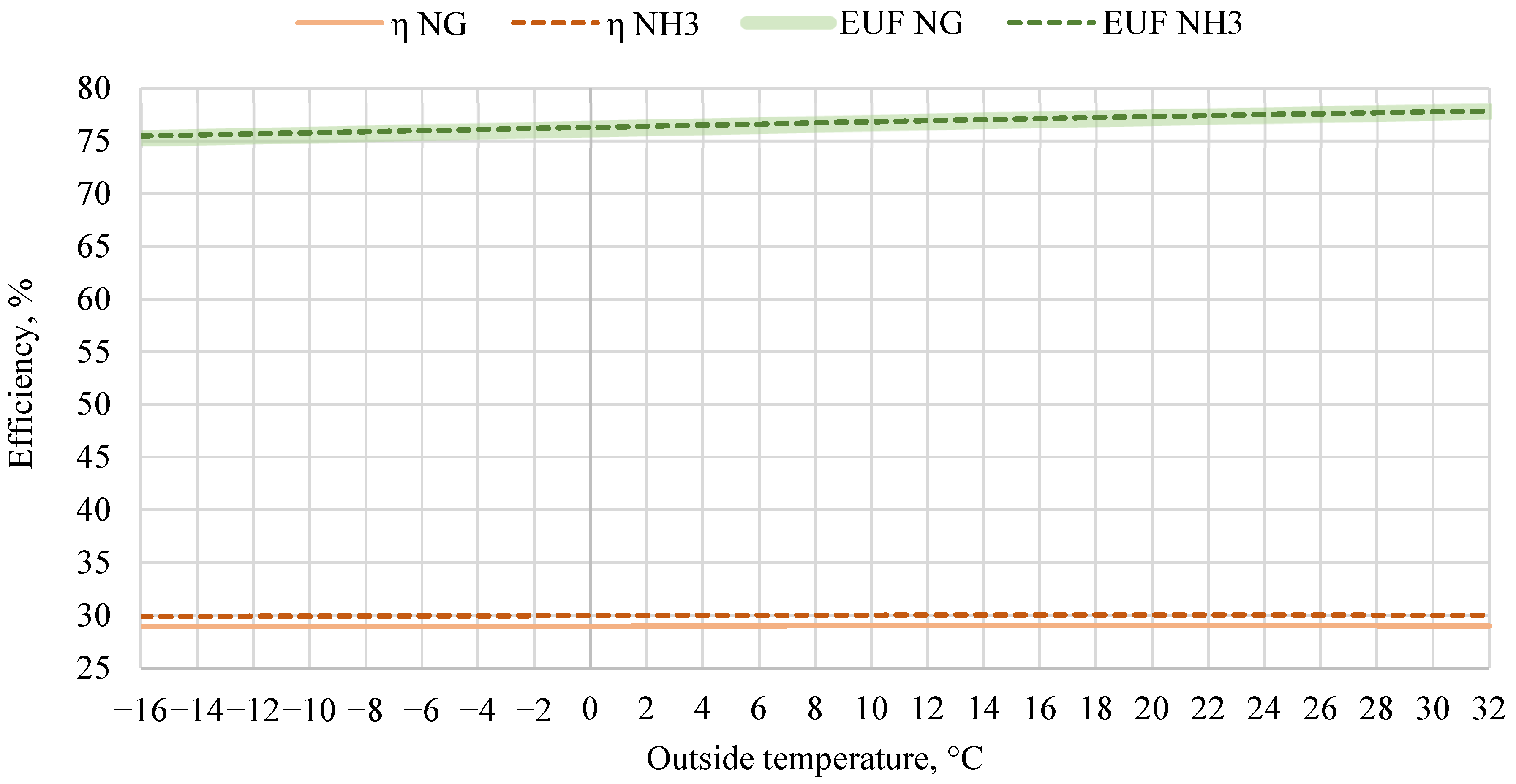

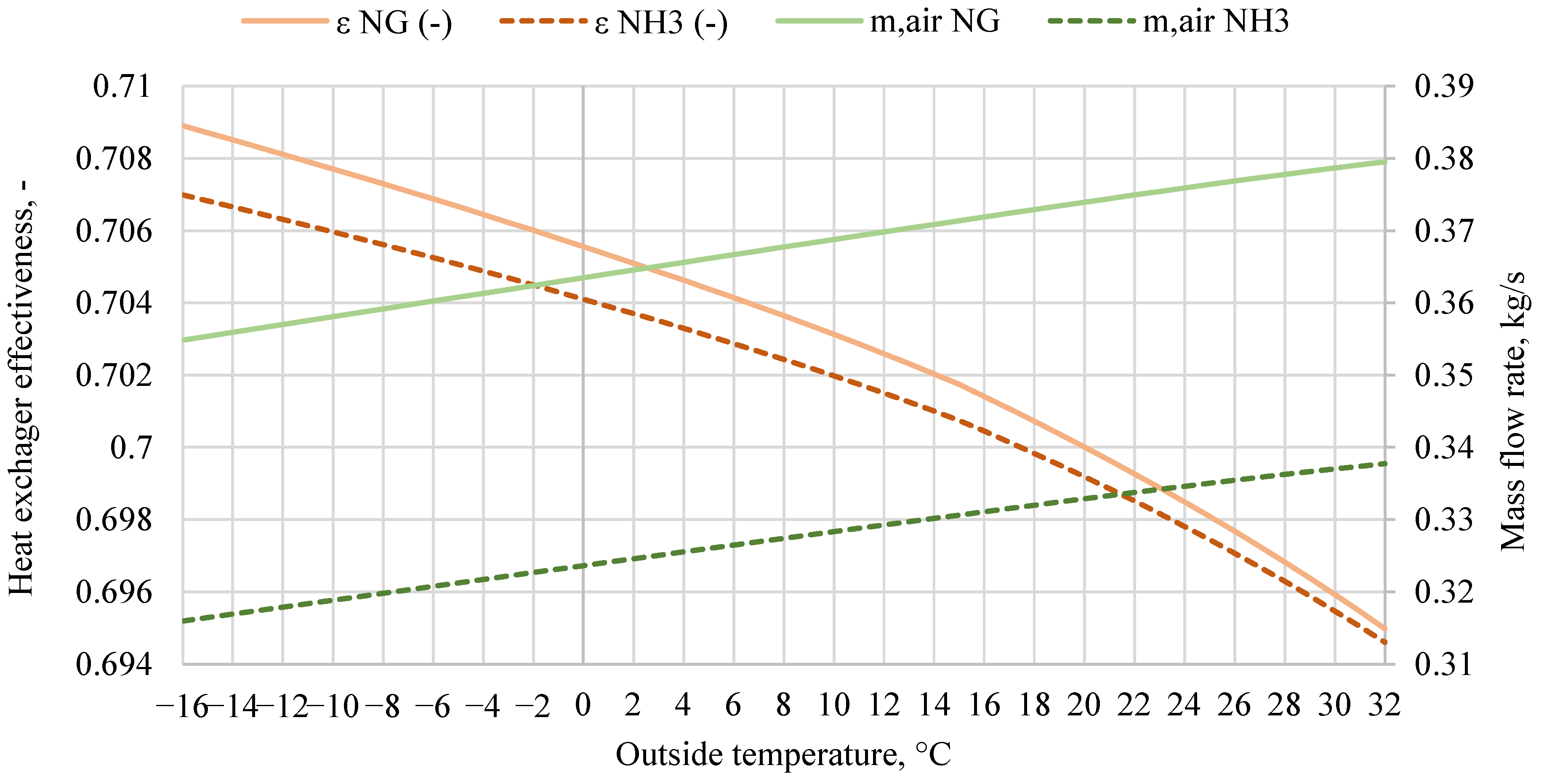

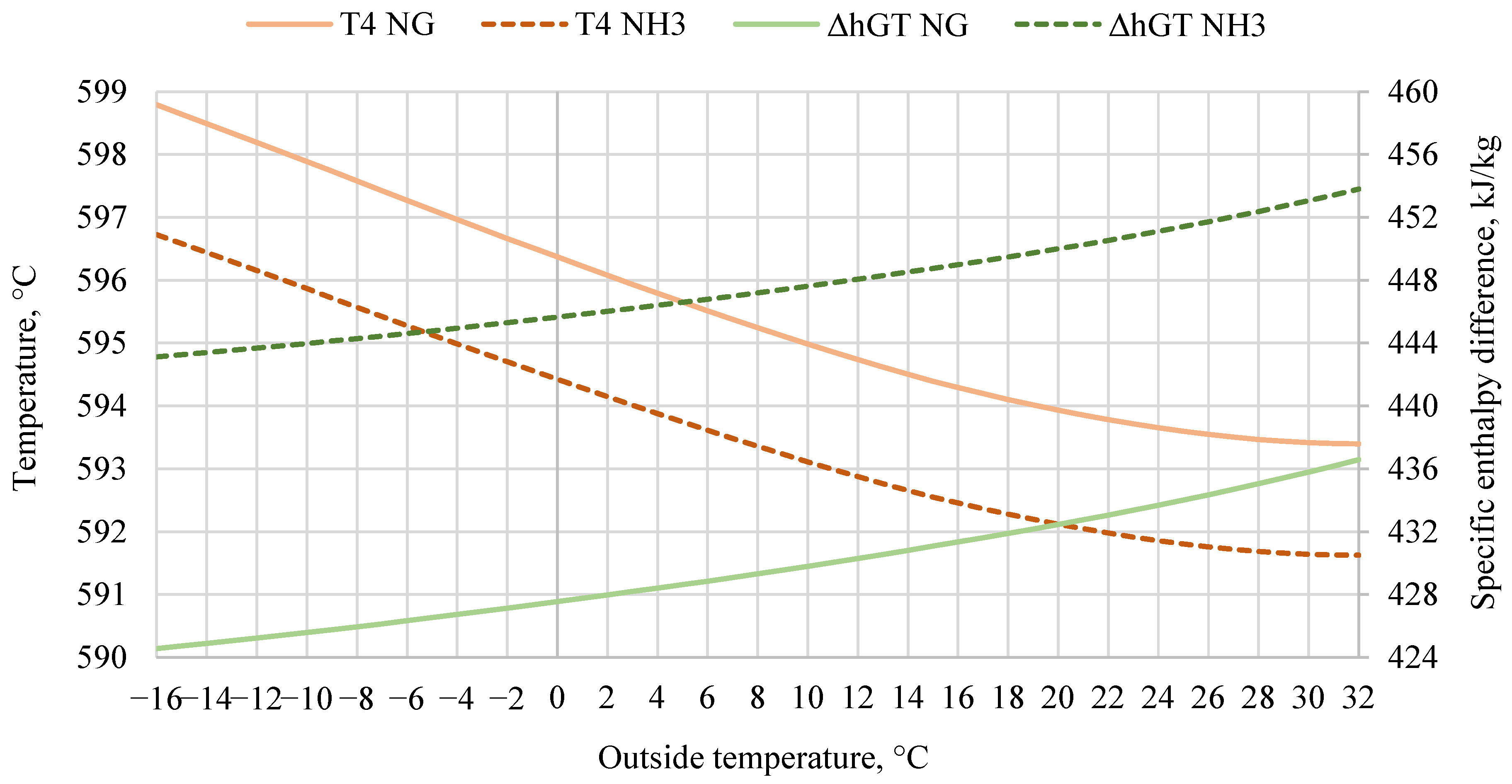

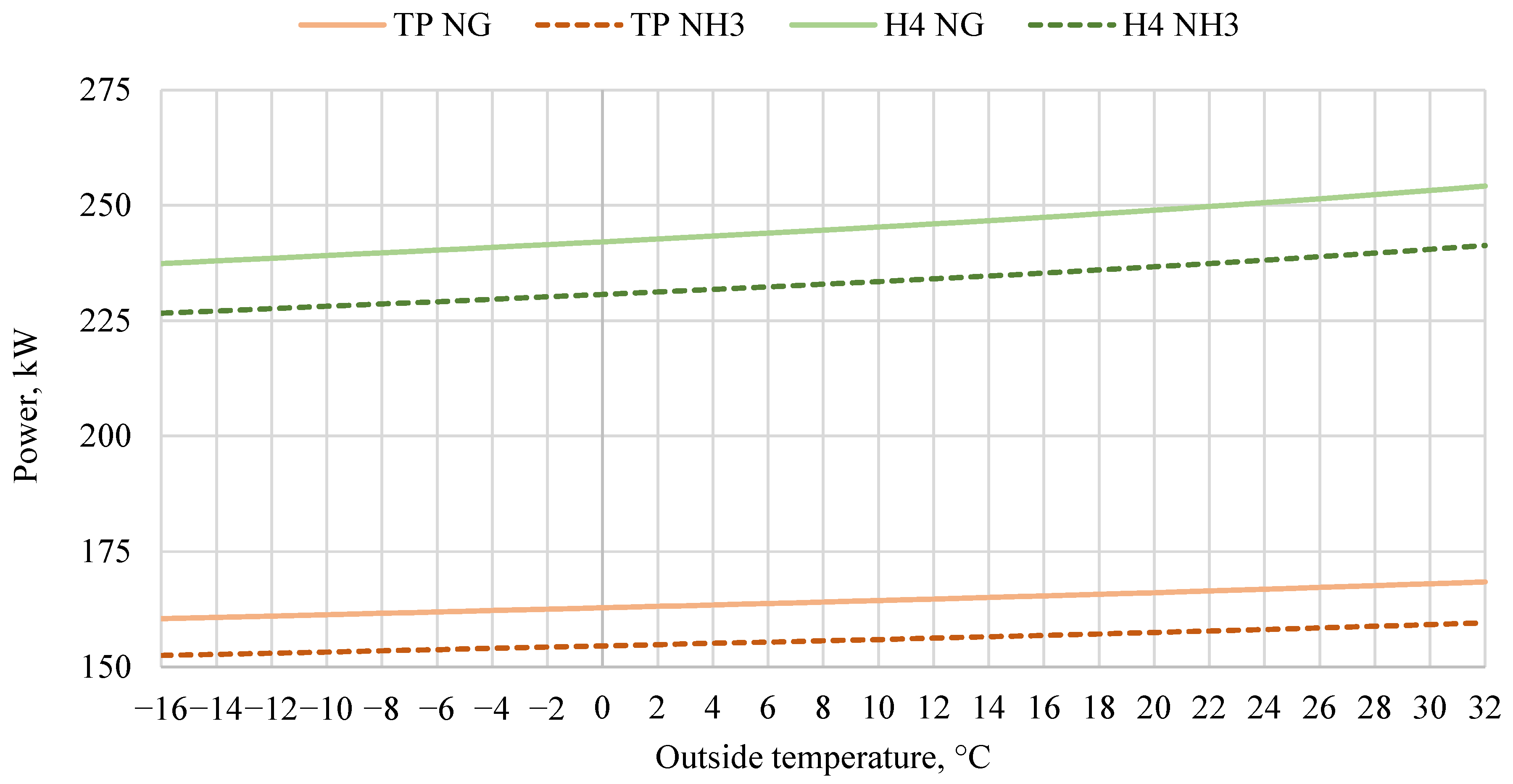

3.2. Varying Outside Temperature Off-Design Characteristics

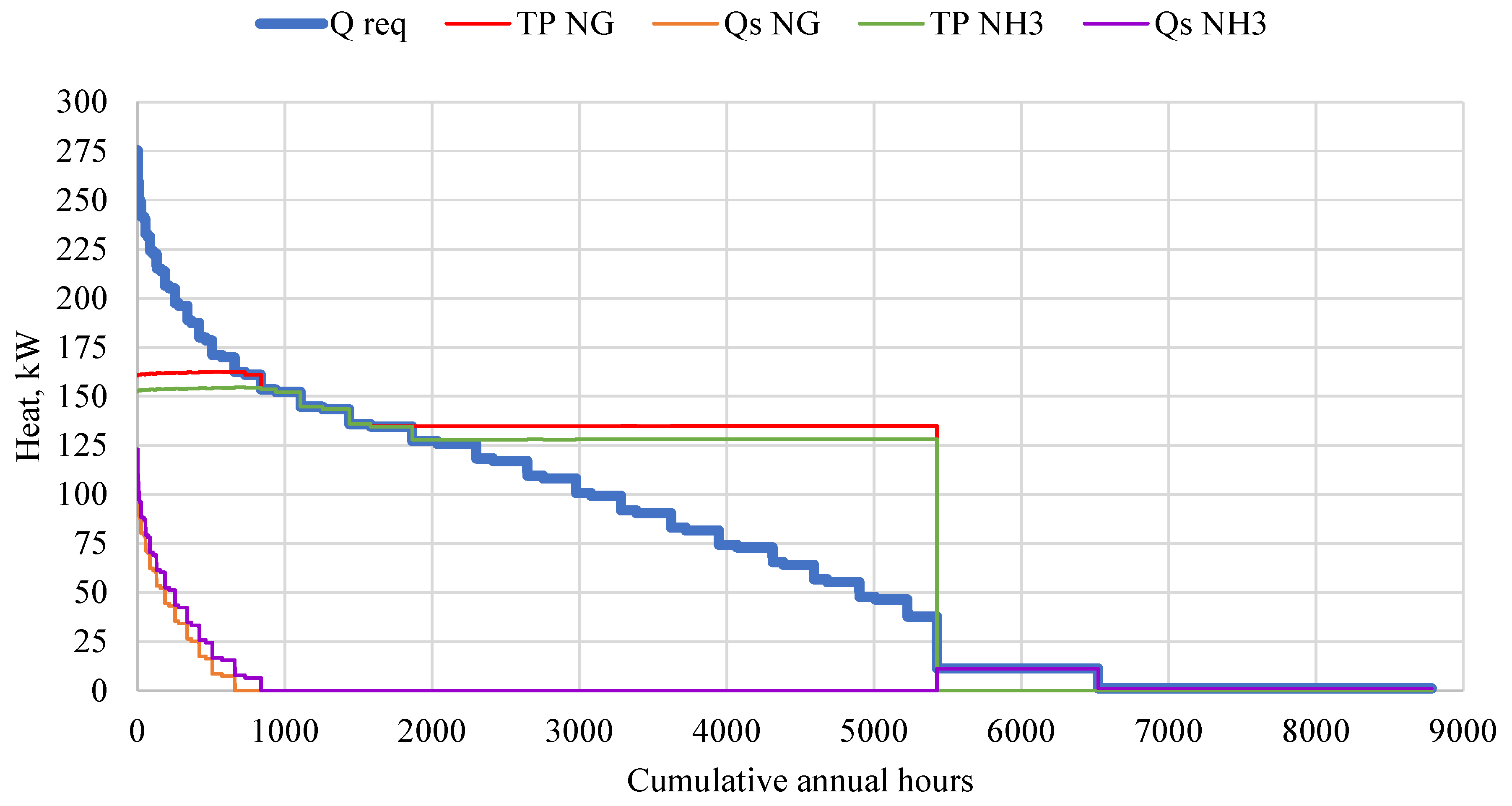

3.3. District Heating Load Results

3.4. Deviation from the Real-World Performance

4. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| Cmin | heat capacity rate (smaller one between two fluids), expressed in kW/K. |

| CC | combustion chamber. |

| EUF | energy utilization factor, expressed in %. |

| GT | gas turbine. |

| LDC | load duration curve. |

| h | specific enthalpy, expressed in kJ/kg. |

| H | enthalpy, expressed in kW. |

| fhl | heat losses factor, expressed in non-dimensional scale. |

| HR | heat recovery heat exchanger. |

| kWe | kilowatt in regard to electrical power. |

| LHV | lower heating value, expressed in kJ/kg. |

| P | pressure, expressed in bar. |

| Pel | electrical power, expressed in kW. |

| Q˙HE | actual heat transfer rate in the heat exchanger, expressed in kW. |

| Q˙DHW | domestic hot water demand of an analyzed building, expressed in kW. |

| Q˙H | heating demand of an analyzed building, expressed in kW. |

| Q˙load | heat load required to be produced in a CHP unit at given hour, expressed in kW. |

| Q˙MAX,HE | maximum heat transfer rate in the heat exchanger, expressed in kW. |

| QTload | integrated value of annual heat demand, expressed in GJ. |

| T | temperature, expressed in °C. |

| Tc,in | inlet temperature of cold fluid, expressed in °C. |

| Th,in | inlet temperature of hot fluid, expressed in °C. |

| TP | thermal power, expressed in kW. |

| mass flow rate, expressed in kg/s. | |

| φ | humidity, expressed in %. |

| electrical efficiency, expressed in %. | |

| specific enthalpy difference across the gas turbine, expressed in kJ/kg. |

References

- IEA. Combined Heat and Power; IEA: Paris, France, 2008; Available online: https://www.iea.org/reports/combined-heat-and-power (accessed on 27 July 2025).

- Breeze, P. Chapter 3—Combined Heat and Power Principles and Technologies. In Combined Heat and Power; Academic Press: Cambridge, MA, USA, 2018; pp. 21–32. ISBN 978-0-12-812908-1. Available online: https://www.sciencedirect.com/science/article/pii/B9780128129081000031 (accessed on 27 July 2025).

- Rezaei, M.; Sameti, M.; Nasiri, F. Biomass-fuelled combined heat and power: Integration in district heating and thermal-energy storage. Clean Energy 2021, 5, 44–56. [Google Scholar] [CrossRef]

- Castro, R. Combined Heat and Power. In Electricity Production from Renewables; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Wu, D.W.; Wang, R.Z. Combined cooling, heating and power: A review. Prog. Energy Combust. Sci. 2006, 32, 459–495. [Google Scholar] [CrossRef]

- Mago, P.J.; Chamra, L.M.; Hueffed, A. A review on energy, economical, and environmental benefits of the use of CHP systems for small commercial buildings for the North American climate. Int. J. Energy Res. 2009, 33, 1252–1265. [Google Scholar] [CrossRef]

- Wang, H.-C.; Jiao, W.-L.; Lahdelma, R.; Zou, P.-H. Techno-economic analysis of a coal-fired CHP based combined heating system with gas-fired boilers for peak load compensation. Energy Policy 2011, 39, 7950–7962. [Google Scholar] [CrossRef]

- Wijesekara, D.; Kularathna, L.; Abesundara, P.; Lankathilaka, U.; Muhandiram, I.; Amarasinghe, P.; Abesinghe, S.; Galpaya, C.; Koswattage, K. Comparative Energy and Environmental Analysis of Combined Cycle CHP Combustion Operations via Simulation for Biomass and Industrial Materials Derived from Waste. Energies 2025, 18, 3062. [Google Scholar] [CrossRef]

- Huang, Y.; McIlveen-Wright, D.R.; Rezvani, S.; Huang, M.J.; Wang, Y.D.; Roskilly, A.P.; Hewitt, N.J. Comparative techno-economic analysis of biomass fuelled combined heat and power for commercial buildings. Appl. Energy 2013, 112, 518–525. [Google Scholar] [CrossRef]

- Perrone, D.; Castiglione, T.; Morrone, P.; Pantano, F.; Bova, S. Numerical and experimental assessment of a micro-combined cooling, heating, and power (CCHP) system based on biomass gasification. Appl. Therm. Eng. 2023, 219, 119600. [Google Scholar] [CrossRef]

- Algieri, A.; Morrone, P.; Bova, S. Techno-Economic Analysis of Biofuel, Solar and Wind Multi-Source Small-Scale CHP Systems. Energies 2020, 13, 3002. [Google Scholar] [CrossRef]

- IEA. Net Zero by 2050; IEA: Paris, France, 2021; Available online: www.iea.org/reports/net-zero-by-2050 (accessed on 27 July 2025).

- Proniewicz, M.; Petela, K.; Szlęk, A. Life cycle assessment of ammonia as carbon-free fuel in internal combustion engine-driven orchard vehicle. Fuel 2025, 400, 135809. [Google Scholar] [CrossRef]

- Yu, S.; Fan, Y.; Shi, Z.; Li, J.; Zhao, X.; Zhang, T.; Chang, Z. Hydrogen-based combined heat and power systems: A review of technologies and challenges. Int. J. Hydrogen Energy 2023, 48, 34906–34929. [Google Scholar] [CrossRef]

- Moradpoor, I.; Koivunen, T.; Syri, S.; Hirvonen, J. The benefits of integrating industrial hydrogen production with district heating in Cold Climates with different building renovation levels. Energy 2024, 303, 131953. [Google Scholar] [CrossRef]

- Rieksta, M.; Zarins, E.; Bazbauers, G. Potential Role of Green Hydrogen in Decarbonization of District Heating Systems: A Review. Environ. Clim. Technol. 2023, 27, 545–558. [Google Scholar] [CrossRef]

- Proniewicz, M.; Petela, K.; Szlęk, A.; Adamczyk, W. Life Cycle Assessment of Selected Ammonia Production Technologies From the Perspective of Ammonia as a Fuel for Heavy-Duty Vehicle. J. Energy Resour. Technol. 2024, 146, 030905. [Google Scholar] [CrossRef]

- Proniewicz, M.; Petela, K.; Szlęk, A.; Przybyła, G.; Nadimi, E.; Ziółkowski, Ł.; Løvås, T.; Adamczyk, W. Energy and Exergy Assessments of a Diesel-, Biodiesel-, and Ammonia-Fueled Compression Ignition Engine. Int. J. Energy Res. 2023, 2023, 1–20. [Google Scholar] [CrossRef]

- Higher Calorific Values of Common Fuels: Reference & Data, The Engineering ToolBox. Available online: https://www.engineeringtoolbox.com/fuels-higher-calorific-values-d_169.html (accessed on 27 July 2025).

- Valera-Medina, A.; Banares-Alcantara, R. Techno-Economic Challenges of Green Ammonia as an Energy Vector; Academic Press: Cambridge, MA, USA, 2020; ISBN 978-0-12-820560-0. [Google Scholar] [CrossRef]

- Chehade, G.; Dincer, I. Progress in green ammonia production as potential carbon-free fuel. Fuel 2021, 299, 120845. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Murtaza, S.Z.M.; Al-Othman, A.; Alami, A.H.; Singh, K.; Olabi, A.G. Ammonia: A versatile candidate for the use in energy storage systems. Renew. Energy 2022, 194, 955–977. [Google Scholar] [CrossRef]

- Salmon, N.; Bañares-Alcántara, R. Green ammonia as a spatial energy vector: A review. Sustain. Energy Fuels 2021, 5, 2814–2839. [Google Scholar] [CrossRef]

- Boero, A.; Mercier, A.; Mounaïm-Rousselle, C.; Valera-Medina, A.; Ramirez, A.D. Environmental assessment of road transport fueled by ammonia from a life cycle perspective. J. Clean. Prod. 2023, 390, 136150. [Google Scholar] [CrossRef]

- Frattini, D.; Cinti, G.; Bidini, G.; Desideri, U.; Cioffi, R.; Jannelli, E. A system approach in energy evaluation of different renewable energies sources integration in ammonia production plants. Renew. Energy 2016, 99, 472–482. [Google Scholar] [CrossRef]

- Duong, P.A.; Ryu, B.; Jung, J.; Kang, H. Thermal Evaluation of a Novel Integrated System Based on Solid Oxide Fuel Cells and Combined Heat and Power Production Using Ammonia as Fuel. Appl. Sci. 2022, 12, 6287. [Google Scholar] [CrossRef]

- Bounitsis, G.L.; Charitopoulos, V.M. The value of ammonia towards integrated power and heat system decarbonisation. Sustain. Energy Fuels 2024, 8, 2914–2940. [Google Scholar] [CrossRef]

- Sachajdak, A.; Kalina, J.; Adamczyk, W.; Przybyła, G. Performance assessment of using ammonia-fired internal combustion engine cogeneration modules in district heating. Int. J. Hydrogen Energy 2025, 144, 1383–1395. [Google Scholar] [CrossRef]

- Eyisse, E.F.; Nadimi, E.; Wu, D. Ammonia Combustion: Internal Combustion Engines and Gas Turbines. Energies 2024, 18, 29. [Google Scholar] [CrossRef]

- Langella, G.; Sorrentino, G.; Sabia, P.; Ariemma, G.B.; Amoresano, A.; Iodice, P. Ammonia as a Fuel for Gas Turbines: Perspectives and Challenges. J. Phys. Conf. Ser. 2023, 2648, 012009. [Google Scholar] [CrossRef]

- Bonasio, V.; Ravelli, S. Performance Analysis of an Ammonia-Fueled Micro Gas Turbine. Energies 2022, 15, 3874. [Google Scholar] [CrossRef]

- Iki, N.; Kurata, O.; Matsunuma, T.; Inoue, T.; Tsujimura, T.; Furutani, H.; Kobayashi, H.; Hayakawa, A.; Arakawa, Y.; Ichikawa, A. Micro Gas Turbine Firing Ammonia. In Volume 8: Microturbines, Turbochargers and Small Turbomachines; Steam Turbines; American Society of Mechanical Engineers: Seoul, Republic of Korea, 2016. [Google Scholar] [CrossRef]

- Kuta, K.; Przybyła, G.; Kurzydym, D.; Żmudka, Z. Experimental and numerical investigation of dual-fuel CI ammonia engine emissions and after-treatment with V2O5/SiO2–TiO2 SCR. Fuel 2023, 334, 126523. [Google Scholar] [CrossRef]

- Kurata, O.; Iki, N.; Matsunuma, T.; Inoue, T.; Tsujimura, T.; Furutani, H.; Kobayashi, H.; Hayakawa, A. Performances and emission characteristics of NH3–air and NH3CH4–air combustion gas-turbine power generations. Proc. Combust. Inst. 2017, 36, 3351–3359. [Google Scholar] [CrossRef]

- PN-EN ISO 6946:2017-10; Komponenty Budowlane i Elementy Budynku—Opór Cieplny i Współczynnik Przenikania Ciepła—Metody Obliczania [Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods]. Polish Committee for Standardization (PKN): Warsaw, Poland, 2020.

- PN-EN ISO 13790:2009; Energetyczne Właściwości Użytkowe Budynków—Obliczanie Zużycia Energii na Potrzeby Ogrzewania i Chłodzenia [Energy Performance of Buildings—Calculation of Energy Consumption for Heating and Cooling]. Polish Committee for Standardization (PKN): Warsaw, Poland, 2009.

- Specific Heat Capacity of Water: Temperature-Dependent Data and Calculator, The Engineering ToolBox. Available online: https://www.engineeringtoolbox.com/specific-heat-capacity-water-d_660.html (accessed on 27 July 2025).

- Water Density, Specific Weight and Thermal Expansion Coefficients - Temperature and Pressure Dependence, The Engineering ToolBox. Available online: https://www.engineeringtoolbox.com/water-density-specific-weight-d_595.html (accessed on 27 July 2025).

- Szargut, J. Termodynamika Techniczna (Applied Thermodynamics), 5th ed.; Silesian University of Technology (Politechnika Śląska): Gliwice, Poland, 2010; ISBN 978-83-7335-667-2. [Google Scholar]

- Cengel, Y.; Ghajar, A. Heat and Mass Transfer: Fundamentals and Applications, 5th ed.; McGraw-Hill Professional: New York, NY, USA, 2014; ISBN 978-0-07-339818-1. [Google Scholar]

- Valera-Medina, A.; Xiao, H.; Owen-Jones, M.; David, W.I.F.; Bowen, P.J. Ammonia for power. Prog. Energy Combust. Sci. 2018, 69, 63–102. [Google Scholar] [CrossRef]

- Pashchenko, D. Ammonia fired gas turbines: Recent advances and future perspectives. Energy 2024, 290, 130275. [Google Scholar] [CrossRef]

- Jung, Y.; Pyo, Y.; Jang, J.; Woo, Y.; Ko, A.; Kim, G.; Shin, Y.; Cho, C. Nitrous oxide in diesel aftertreatment systems including DOC, DPF and urea-SCR. Fuel 2022, 310, 122453. [Google Scholar] [CrossRef]

- Liang, Z.; Ma, X.; Lin, H.; Tang, Y. The energy consumption and environmental impacts of SCR technology in China. Appl. Energy 2011, 88, 1120–1129. [Google Scholar] [CrossRef]

- Birolini, A. Reliability Engineering, Theory and Practice; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 978-3-662-54208-8. [Google Scholar] [CrossRef]

- Capstone Turbine Corporation. MicroTurbine Applications for the Offshore Oil and Gas Indsutry. U.S. Environmental Protection Agency. Available online: https://www.epa.gov/sites/default/files/2017-07/documents/neworleans5_2008.pdf (accessed on 27 July 2025).

- DEF and SCR Maintenance Tips from the Diesel and DEF Experts, Mansfield Service Partners. Available online: https://msp.energy/def-and-scr-maintenance-tips-from-the-diesel-and-def-experts/ (accessed on 16 July 2025).

| Fuel | LHV, MJ/L |

|---|---|

| Liquified hydrogen (1 bar, −253 °C) | 8.5 |

| Liquified ammonia (1 bar, −34 °C) | 12.7 |

| Liquified natural gas (1 bar, −161 °C) | 20.8 |

| Study | Scope | Technology | Fuel | Major Conclusions |

|---|---|---|---|---|

| Wijesekara et al. [8] | Energy-environmental analysis of combined CHP cycle | Combined CHP cycle | Solid biomass (waste briquettes) | Optimal feedstock composition defined; further benefits could be achieved through advancing combustion refinement and emission control. |

| Huang et al. [9] | Techno-economic analysis of CHP for commercial buildings | ORC and gasification | Solid biomass (willow chips, miscanthus) | Performance comparable to fossil-fuel CHP; results strongly depend on feedstock moisture content. |

| Perrone et al. [10] | Experimental and numerical analysis of a micro-CCHP | Internal combustion engine fed by gasified biomass | Solid biomass (wood) | Technical feasibility and economic profitability demonstrated; performance dependent on feedstock composition and operating settings. |

| Algieri et al. [11] | Techno-economic analysis of small-scale CHP for a 40-home residential community | ORC coupled with wind turbine, PV, and auxiliary boiler | Waste cooking oil for ORC, wind, solar | Efficient and economically justified system demonstrated; results sensitive to the chosen optimization objective. |

| Moradpoor et al. [15] | Techno-economic analysis of integrating electrolysis waste-heat into district heating grid | Electrolyzers coupled with heat recovery | Electricity (renewable, for electrolysis) | Small economic gains, but primary energy reduction achieved due to alternative heat supply; hydrogen safety issues highlighted. |

| Duong et al. [26] | Thermodynamic modelling of a cascade system | SOFC + gas turbine + steam/Kalina/organic Rankine cycles | Ammonia | High energy (60.4%) and exergy (57.3%) efficiencies achieved; future research focused on economic and sustainability aspects suggested. |

| Bounitsis and Charitopoulos [27] | Techno-economic analysis of Great Britain’s national power and heat system | Mix of commercial generation and storage technologies | Mix: renewable and fossil sources, including ammonia | Ammonia’s potential confirmed; further model validation required. |

| Sachajdak et al. [28] | Techno-economic analysis of ammonia-fired engine for CHP coupled with district heat | Internal combustion engine | Ammonia | Technical feasibility demonstrated; profitability sensitive to market conditions. |

| Description | Specification |

|---|---|

| Number of apartments | 6 |

| Building dimensions (width × length) | 12 m × 9 m |

| Building height (foundation to rooftop) | 15.4 m |

| Roof type | Gable roof |

| Building layers | Default for modern residential building |

| Radiator supply/return temperatures | 60 °C/40 °C |

| Parameter | Value | Unit |

|---|---|---|

| Water consumption per resident | 40 | L/day |

| Number of apartments in the building | 6 | - |

| Residents per apartment | 2.5 | - |

| Water consumption per building | 600 | L/day |

| Inlet/outlet water temperature | 60/50 | °C |

| Average water temperature (AT) | 55 | °C |

| Specific heat capacity at AT [37] | 4.19 | kJ/(kg·K) |

| Density at AT [38] | 0.9857 | g/cm3 |

| Coefficient for constant DHW load | 25.00% | - |

| Point | Modelling Assumptions |

|---|---|

| Air inlet | P = 1.01 bar T = 15 °C φ = 60% Mass flow rate calculated iteratively from the energy balance of the combustion chamber to achieve an exhaust temperature of 950 °C. |

| Air to the CC | P = 4.501 bar Other parameters dependent on the mass and energy balance of the compressor. |

| Fuel inlet | Fuel pressure is dependent on the pressure present in the combustion chamber. T = 15 °C Mass flow rate iteratively calculated from the energy balance of the gas turbine, ensuring generator power of 100 kW. |

| Exhaust gases to the GT | Pressure drop in the CC equals 0.002 bar. Other parameters result from the mass and energy balance of the combustion chamber, with air mass flow adjusted for an exhaust temperature of 950 °C. |

| Exhaust gases to the HR | P = 1.02 bar Temperature determined from the energy balance of the gas turbine. |

| Exhaust gases after the HR | Hot side pressure drop is equal to 0.01 bar. T = 205 °C |

| Water inlet | P = 6 bar T = 39.5 °C Mass flow rate of water dependent on the energy balance of the HR, considering ΔT = 21 K |

| Water outlet | Cold side pressure drop equals 0.05 bar. T = 60.5 °C |

| Compressor | Isentropic efficiency is equal to 0.96. Mechanical efficiency is equal to 0.99. |

| Gas turbine | Isentropic efficiency is equal to 0.965. Mechanical efficiency is equal to 0.99. |

| Generator | Generator efficiency is equal to 0.99. |

| NG | NH3 | Unit | |

|---|---|---|---|

| Electrical energy produced by the MGT | 353,823.9 | 369,176.0 | kWh |

| Heat produced by the MGT | 2743.0 | 2632.0 | GJ |

| Heat produced by a peak-reserve heat source | 136.9 | 160.8 | GJ |

| Excess heat produced by the MGT | 632.4 | 545.3 | GJ |

| Heat required by the system | 2247.5 | 2247.5 | GJ |

| Fuel consumed in the MGT | 103,563.2 | 273,261.8 | kg |

| Fuel LHV | 50,015 | 18,673 | kJ/kg |

| Electrical efficiency of the MGT | 24.59 | 26.05 | % |

| EUF of the MGT | 77.55 | 77.63 | % |

| Effective EUF | 65.34 | 66.94 | % |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Proniewicz, M.; Petela, K.; Mounaïm-Rousselle, C.; Bothien, M.R.; Gruber, A.; Fan, Y.; Lee, M.; Szlęk, A. Preliminary Comparison of Ammonia- and Natural Gas-Fueled Micro-Gas Turbine Systems in Heat-Driven CHP for a Small Residential Community. Energies 2025, 18, 4103. https://doi.org/10.3390/en18154103

Proniewicz M, Petela K, Mounaïm-Rousselle C, Bothien MR, Gruber A, Fan Y, Lee M, Szlęk A. Preliminary Comparison of Ammonia- and Natural Gas-Fueled Micro-Gas Turbine Systems in Heat-Driven CHP for a Small Residential Community. Energies. 2025; 18(15):4103. https://doi.org/10.3390/en18154103

Chicago/Turabian StyleProniewicz, Mateusz, Karolina Petela, Christine Mounaïm-Rousselle, Mirko R. Bothien, Andrea Gruber, Yong Fan, Minhyeok Lee, and Andrzej Szlęk. 2025. "Preliminary Comparison of Ammonia- and Natural Gas-Fueled Micro-Gas Turbine Systems in Heat-Driven CHP for a Small Residential Community" Energies 18, no. 15: 4103. https://doi.org/10.3390/en18154103

APA StyleProniewicz, M., Petela, K., Mounaïm-Rousselle, C., Bothien, M. R., Gruber, A., Fan, Y., Lee, M., & Szlęk, A. (2025). Preliminary Comparison of Ammonia- and Natural Gas-Fueled Micro-Gas Turbine Systems in Heat-Driven CHP for a Small Residential Community. Energies, 18(15), 4103. https://doi.org/10.3390/en18154103