Research on Energy-Saving Control of Automotive PEMFC Thermal Management System Based on Optimal Operating Temperature Tracking

Abstract

1. Introduction

- (1)

- Departing from fixed-temperature targets prevalent in existing studies, we experimentally establish the dynamic relationship between PEMFC output power and OOT, deriving the stack’s optimal thermal trajectory. This approach resolves the suboptimal efficiency of conventional fixed-temperature control under dynamic loads and enables precision thermal regulation across power levels.

- (2)

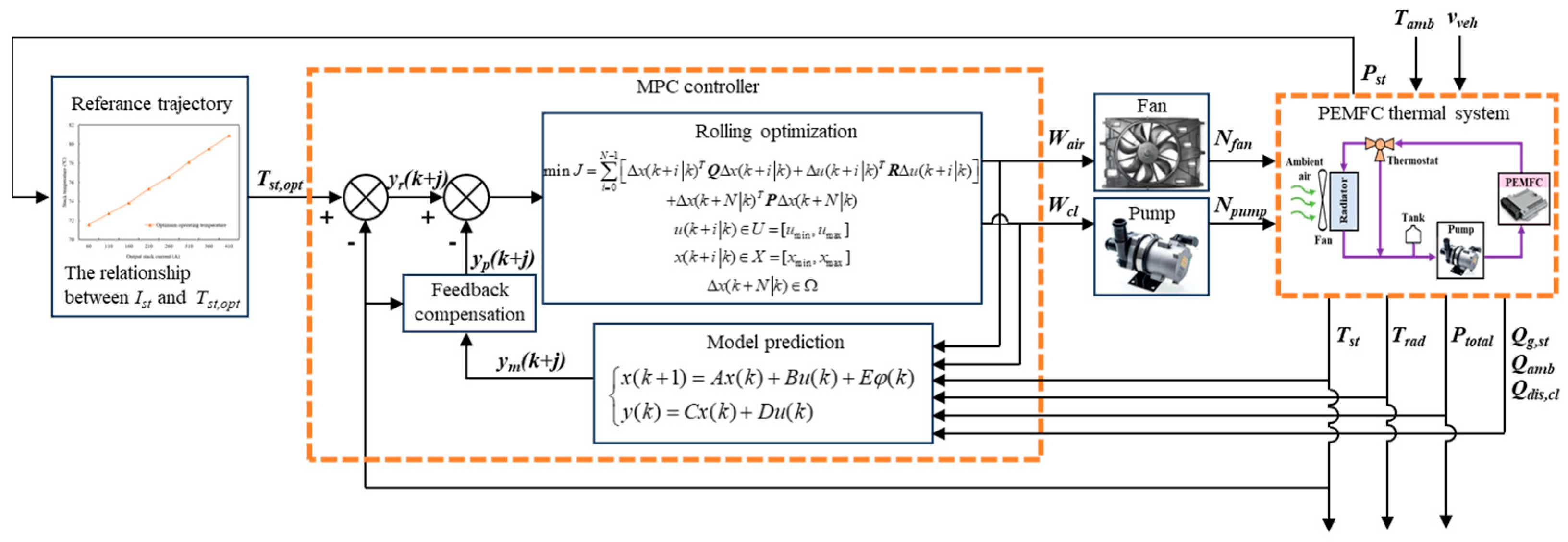

- A model-adaptive model predictive control (MPC) framework is designed. Addressing the time-delay and nonlinear characteristics of the TMS, we develop a full-power-range temperature prediction model through linearization and discretization, enabling real-time model switching under varying load conditions.

- (3)

- The MPC cost function incorporates not only the deviation between actual temperature and OOT plus TMS parasitic power, but also dynamic actuator constraints. This integration prevents mechanical degradation caused by aggressive speed modulation of fans and pumps.

2. Systems Modeling

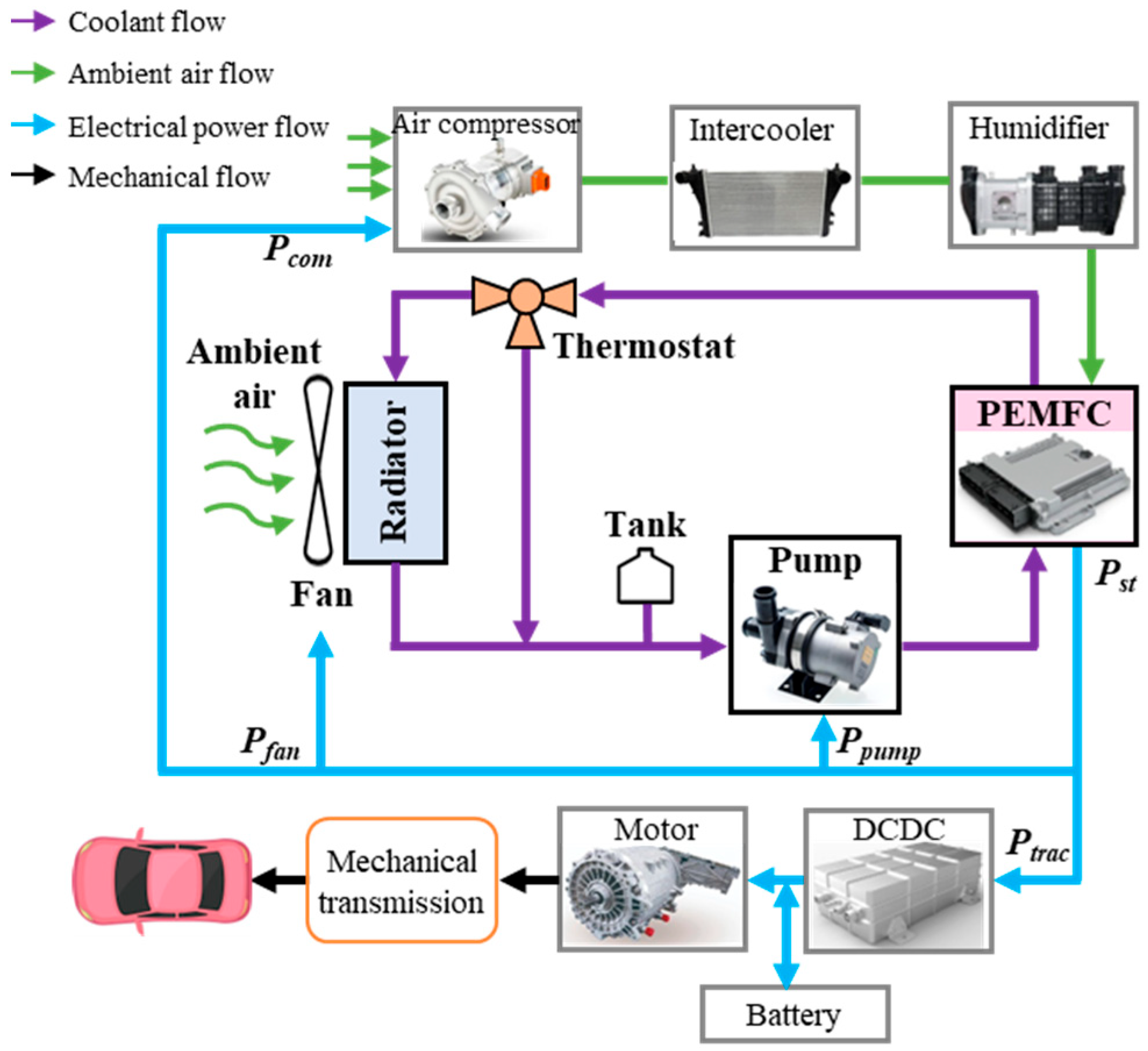

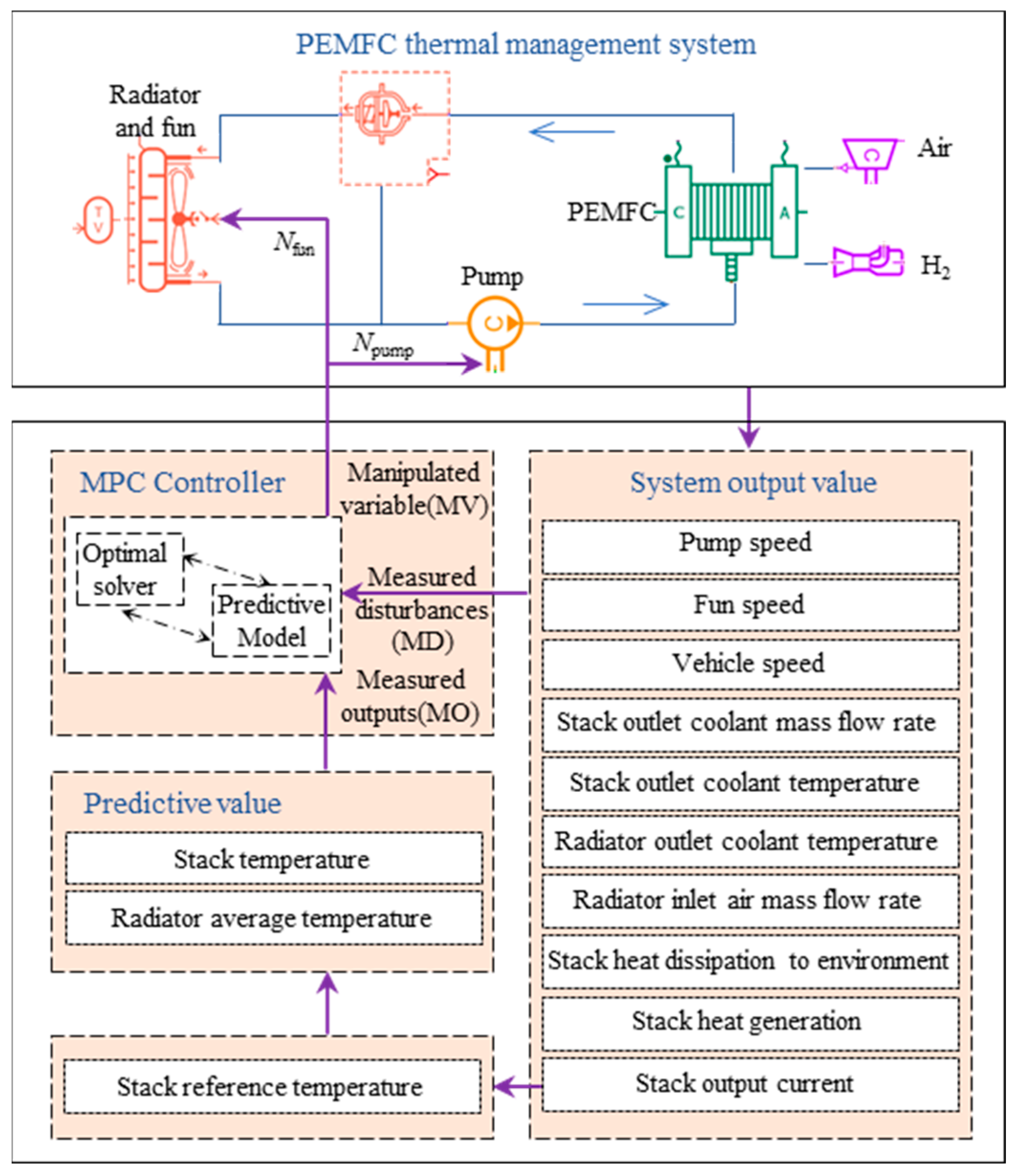

2.1. PEMFC Thermal Management System

2.2. PEMFC Thermal Management System Modeling

2.2.1. PEMFC Thermoelectric Coupling Model

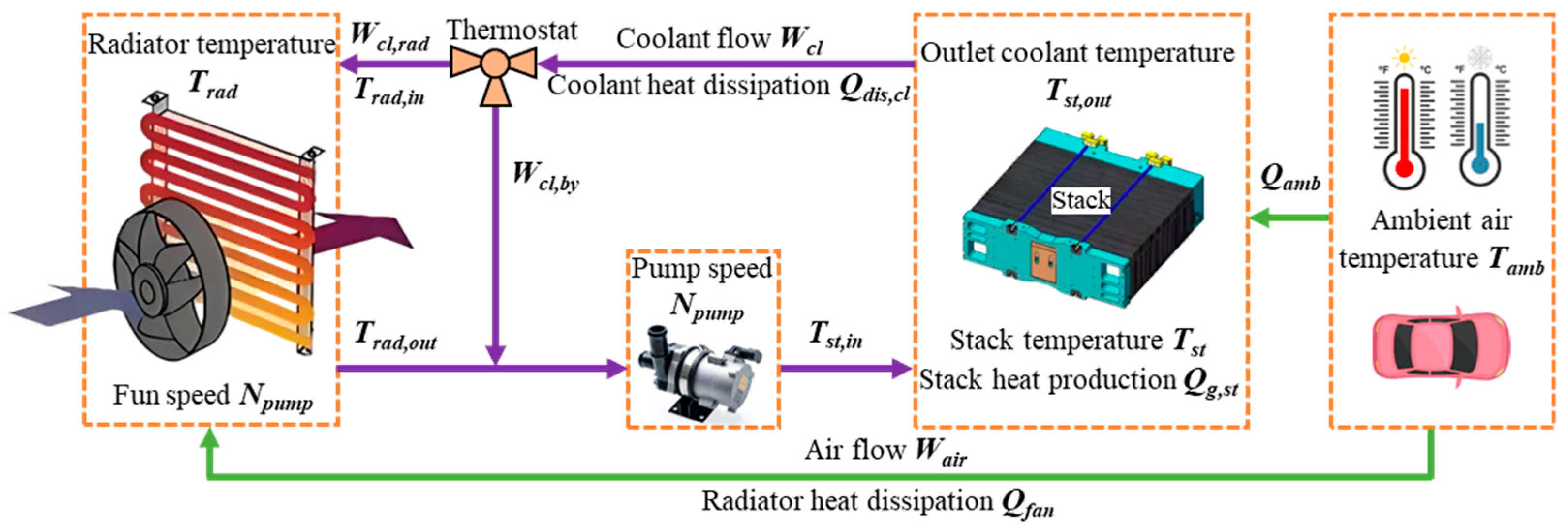

2.2.2. Radiator Heat Transfer Model

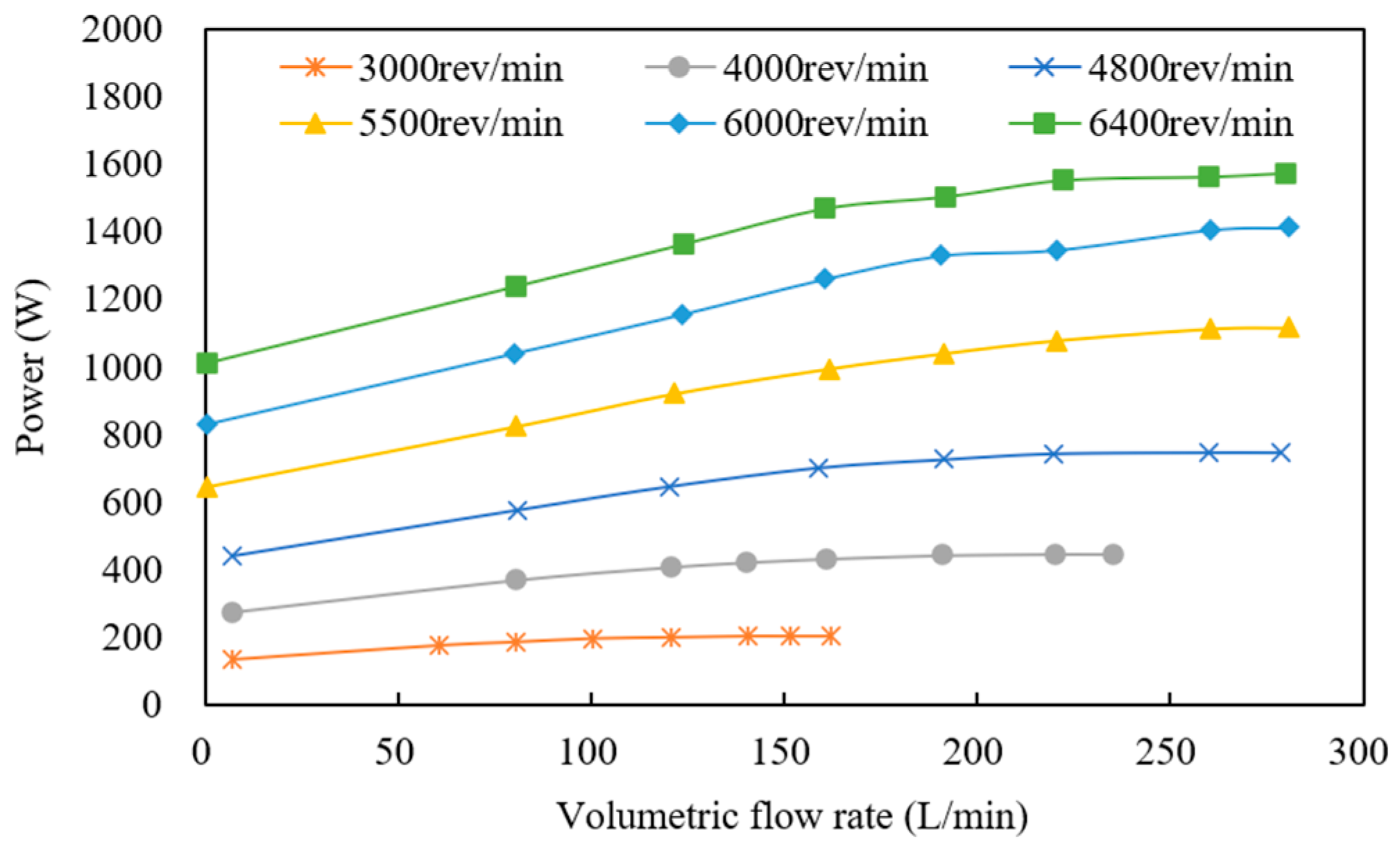

2.2.3. Pump and Fan Model

2.2.4. Thermostat Model

3. PEMFC Model Validation

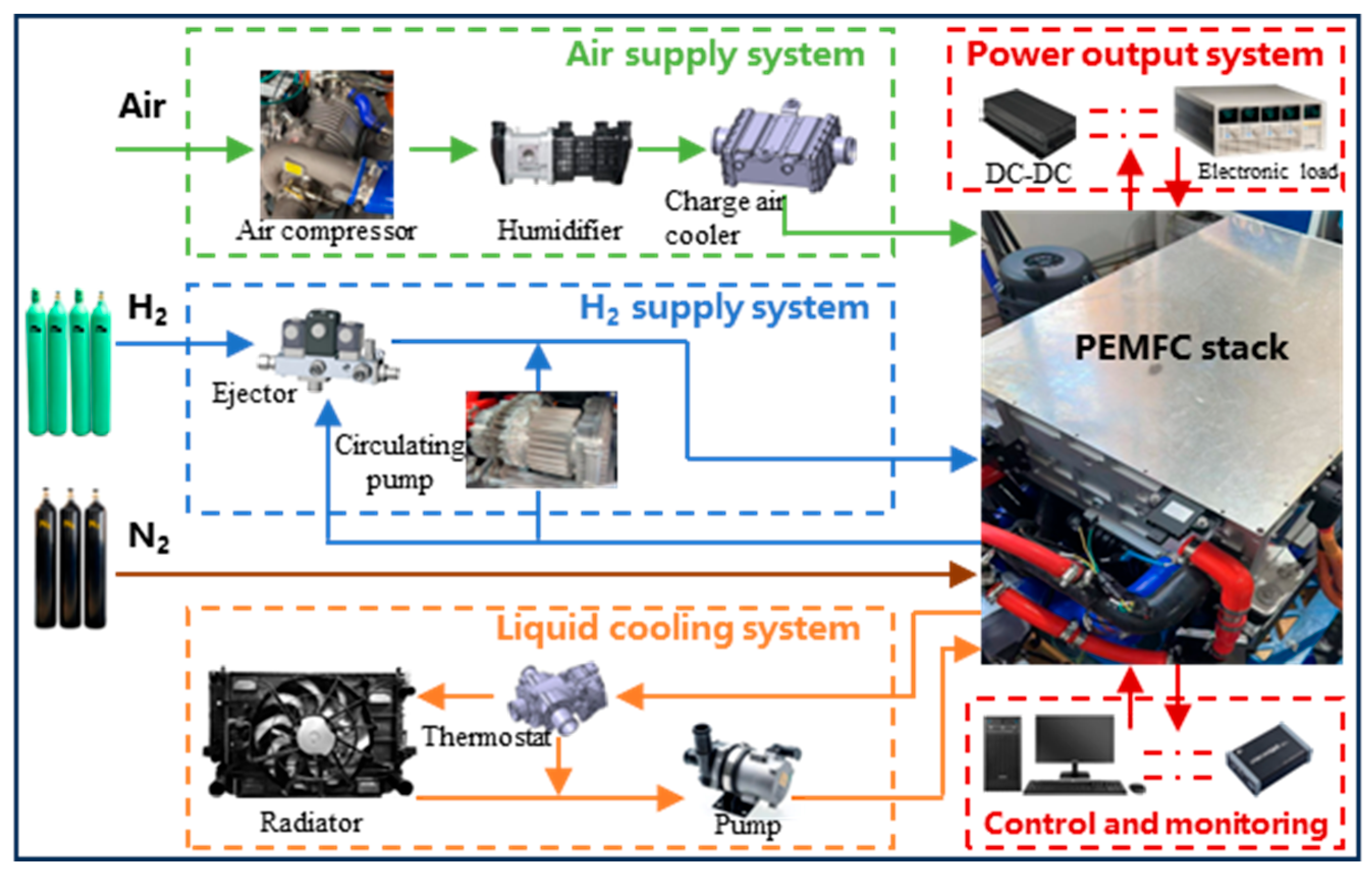

3.1. PEMFC Experimental Platform

3.2. Model Validation

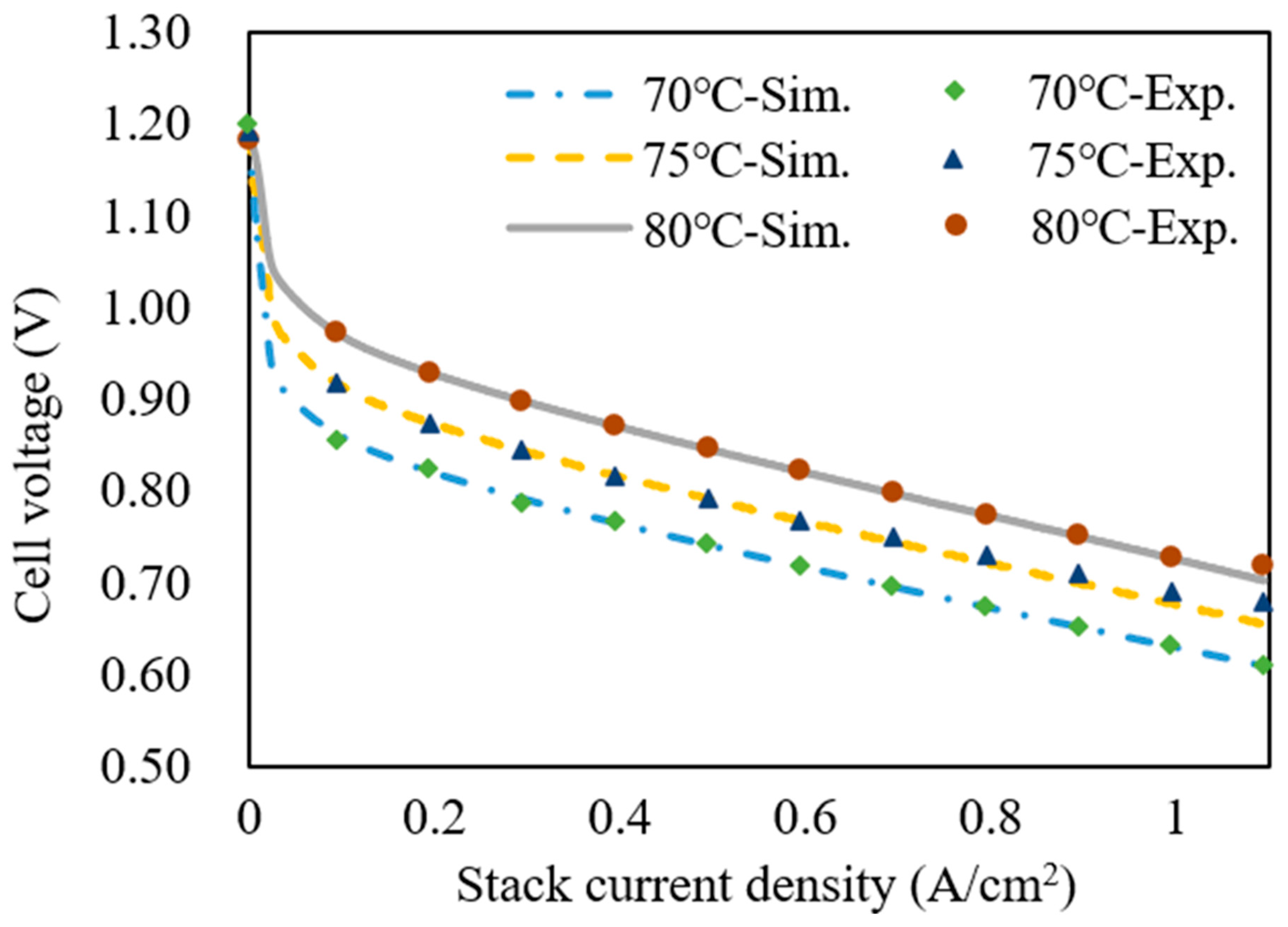

3.2.1. PEMFC Voltage Model

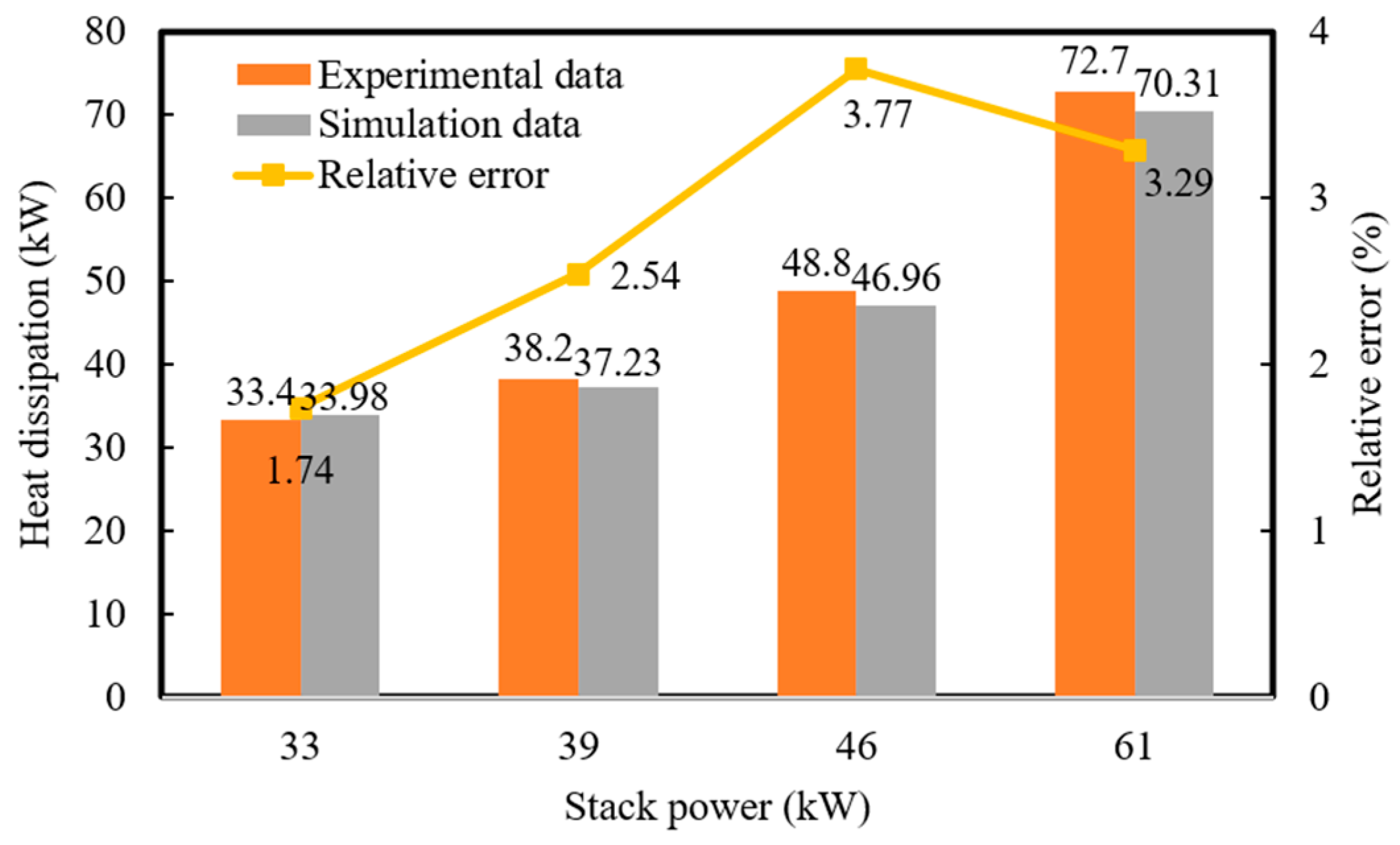

3.2.2. PEMFC Heat Generation Model

3.3. Experiment on the OOT of PEMFC

4. PEMFC Thermal Management MPC Controller Design

4.1. MPC Controller Design

4.1.1. Model Prediction

4.1.2. Rolling Optimization

- (1)

- Design of the state weight matrix Q.

- (2)

- Design of the control weight matrix R.

- (3)

- Dynamic adjustment strategy of weight coefficients.

4.2. Simulation Platform

4.2.1. Co-Simulation Operation Model

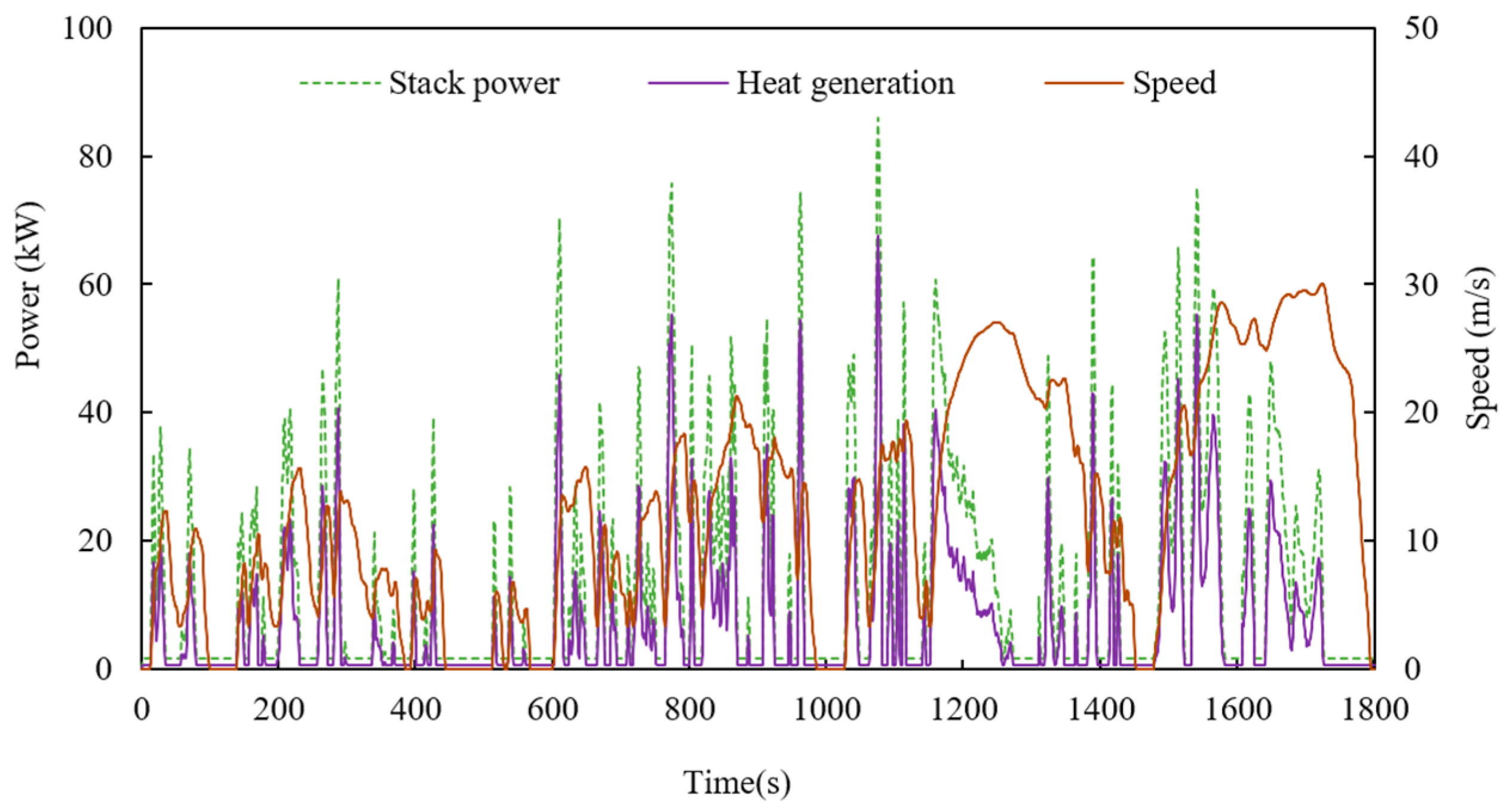

4.2.2. Testing Cycle

5. Results and Discussions

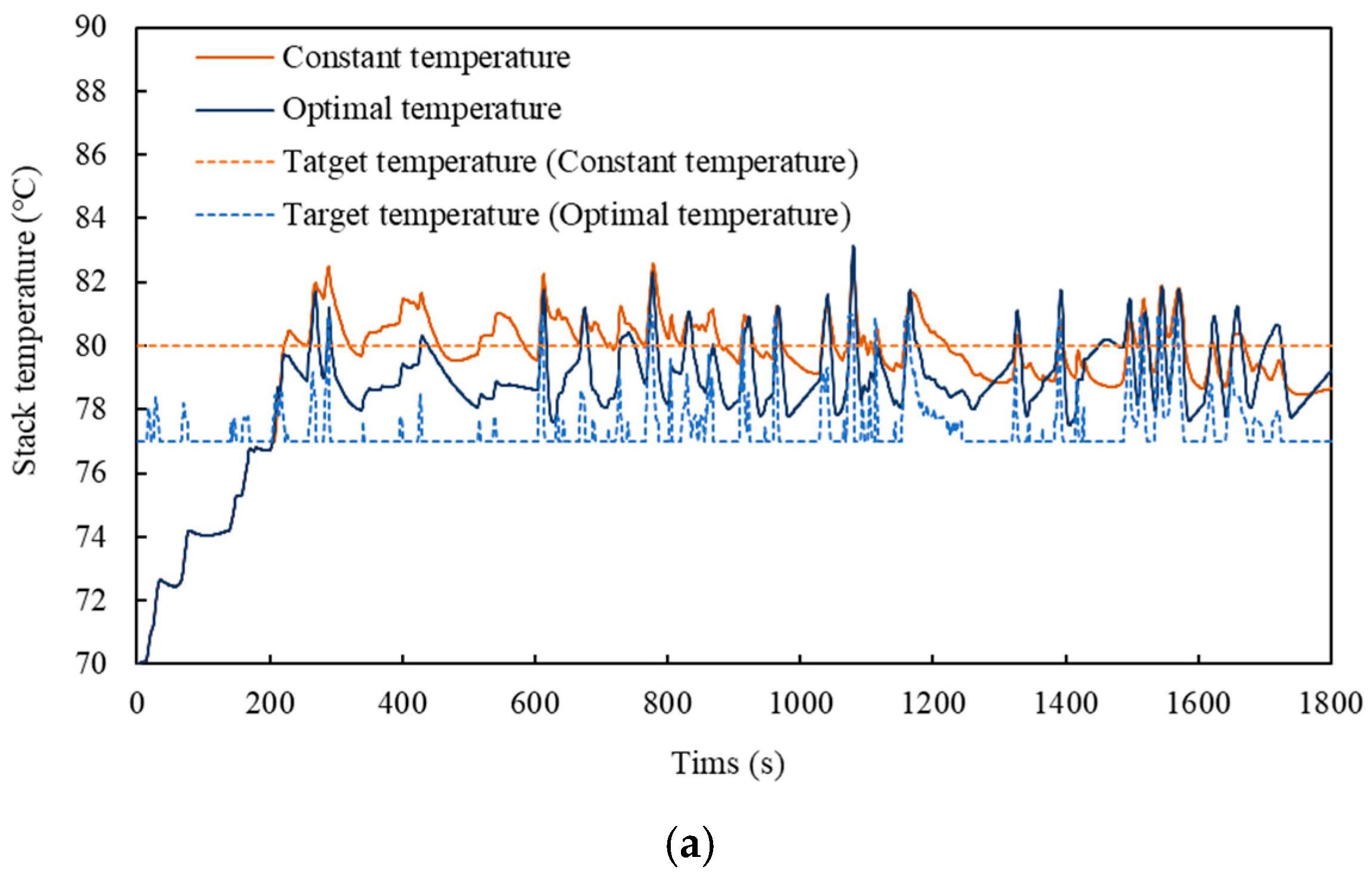

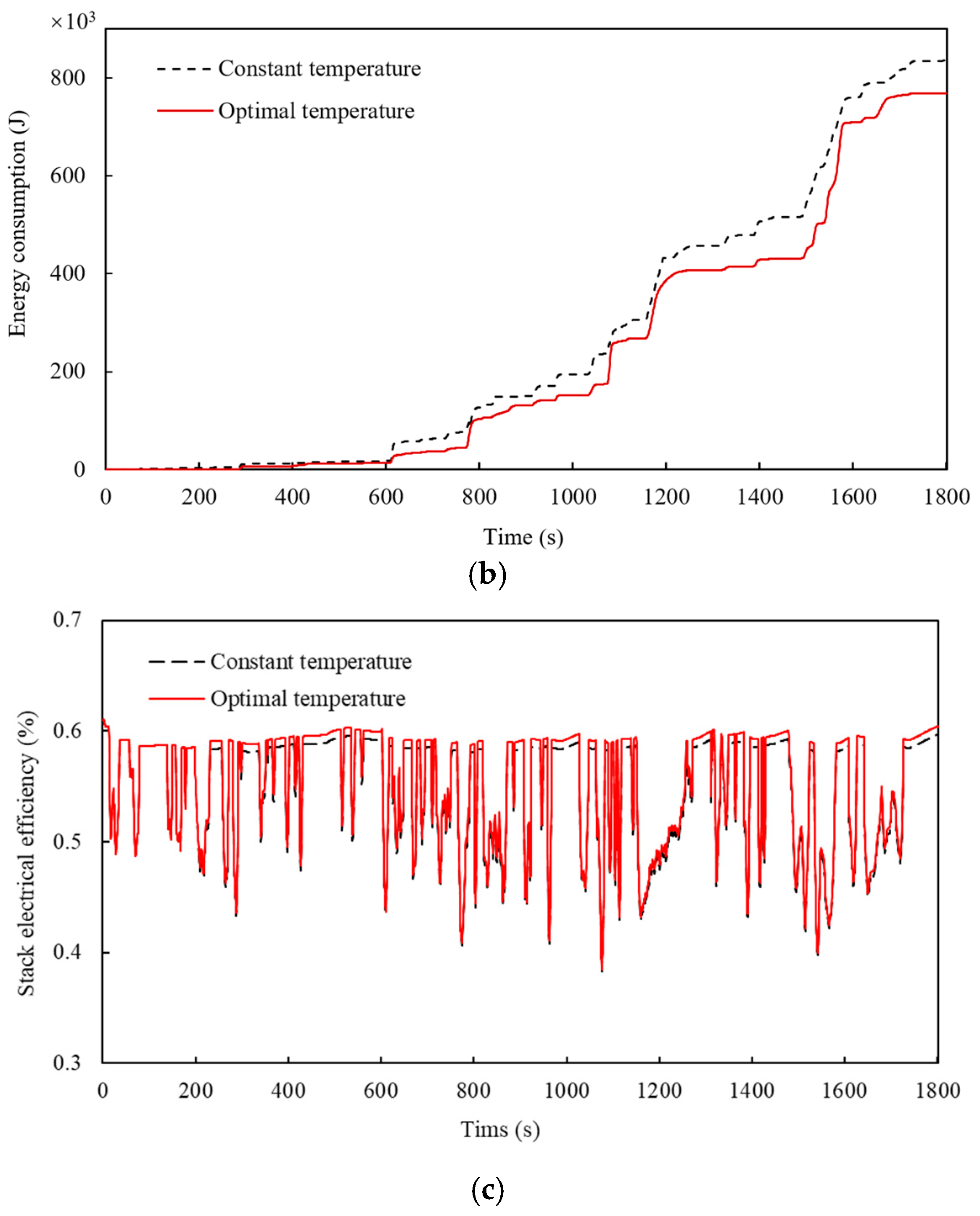

5.1. The Impact of the OOT Tracking Method on PEMFC Systems

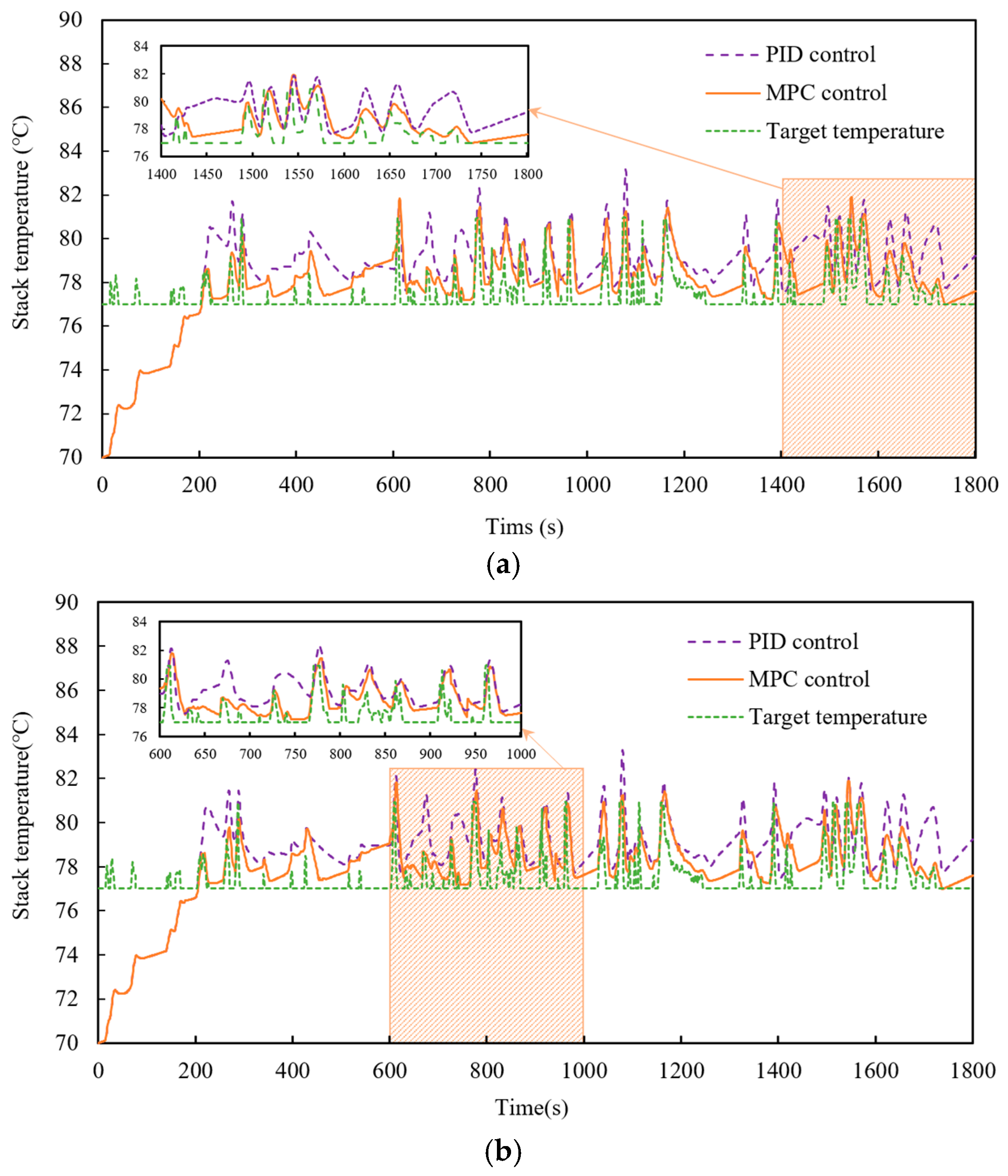

5.2. Control Performance of MPC Based on OOT Tracking

5.2.1. Tracking Performance of the OOT

5.2.2. Energy Consumption Performance of TMS

6. Conclusions

- (1)

- In the model validation results, the deviation between experimental data and simulation results of the developed PEMFC and TMS models is within 4%. This indicates that the proposed models possess high accuracy and can effectively support simulation studies.

- (2)

- The relationship between the output power of the PEMFC and its OOT was experimentally determined. The OOT corresponding to each output power level was subsequently adopted as the reference trajectory for the controller. In PID control, using the OOT as the reference trajectory (instead of maintaining a constant temperature setpoint) yields a 1.15% improvement in the average efficiency of the PEMFC and a 7.97% reduction in TMS energy consumption.

- (3)

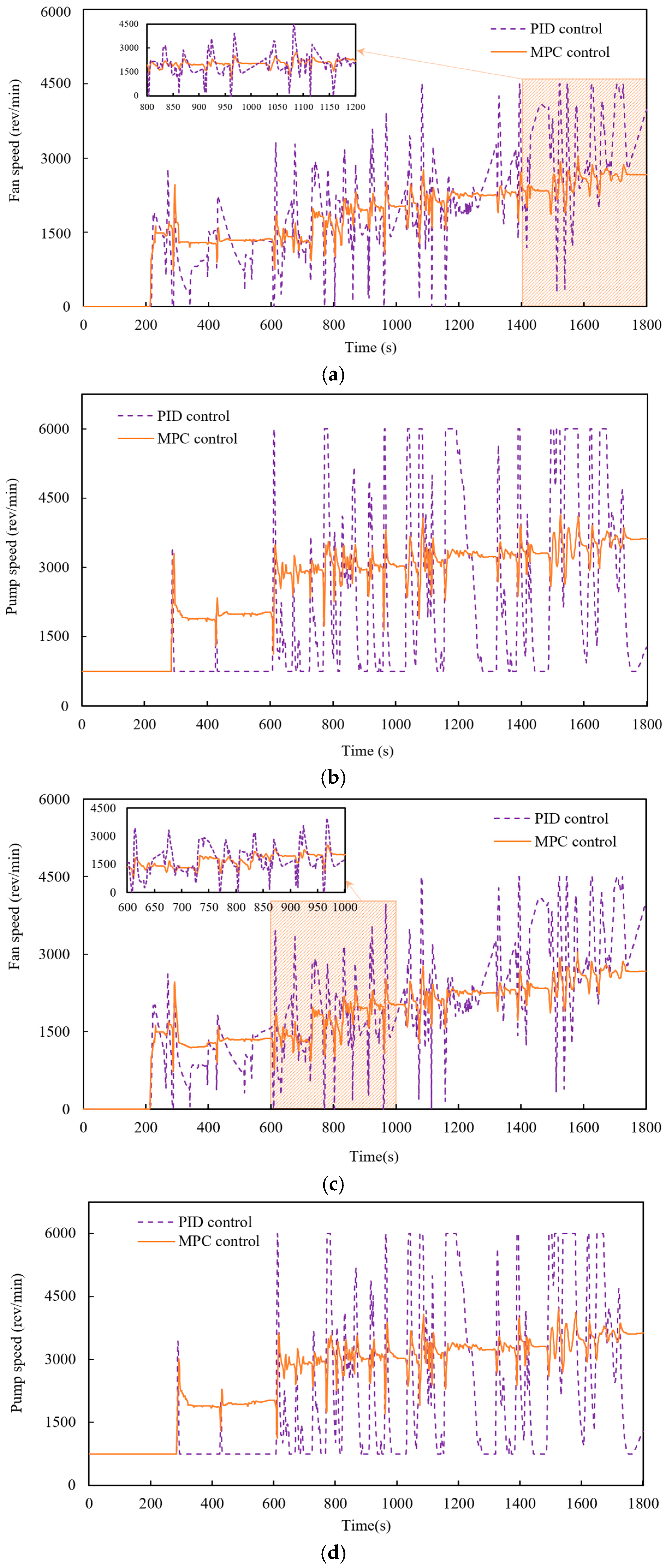

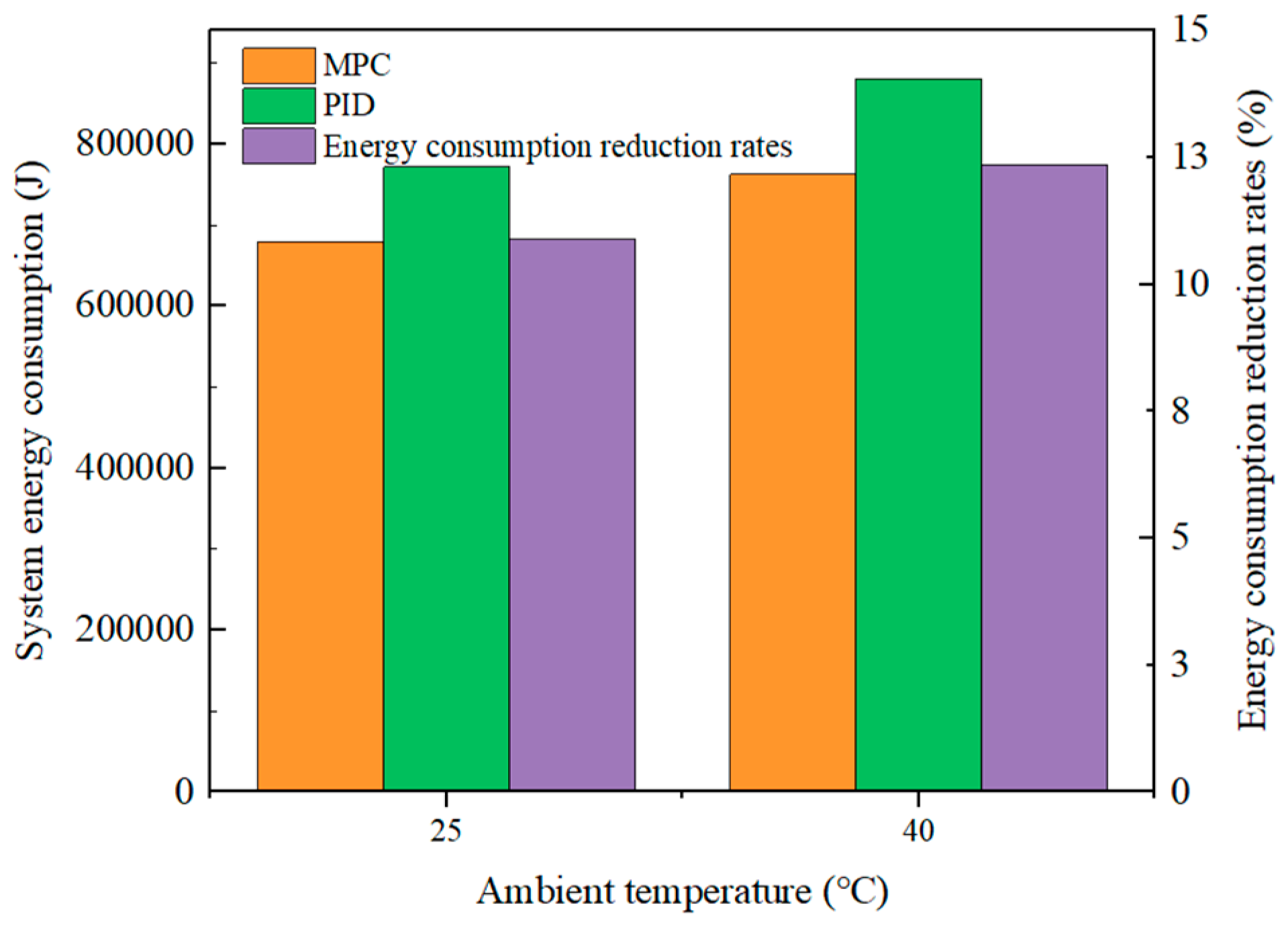

- A model-adaptive MPC strategy for OOT tracking is proposed, integrating TMS energy consumption into the objective function to enable multi-objective optimization. Simulation results under the WLTC show that the MPC controller reduces OOT tracking error by more than 33% compared to the PID controller. At 25 °C and 40 °C ambient temperatures, MPC reduces fan speed fluctuations by 37.4% and 32.7%, pump speed fluctuations by 32.3% and 24.2%, and TMS energy consumption by 10.8% and 12.4%, respectively, relative to PID control. Overall, the OOT-tracking-based MPC strategy exhibits higher accuracy and efficiency in regulating fan and pump speeds while achieving lower energy consumption.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Nomenclature | ||

| C | specific heat capacity | J/(kg·K) |

| M | mass | kg |

| T | temperature | K |

| Q | heat transfer rate | W |

| U | voltage | V |

| I | current | A |

| E | energy | J |

| q | thermal power per unit time | W |

| W | mass flow rate | kg/s |

| R | thermal resistance | K/W |

| m | molar mass | g/mol |

| V | volume | m3 |

| N | speed | rev/min |

| P | power | W |

| t | time | s |

| H | head | m |

| x | status variable | |

| u | input variable | |

| Greek letters | ||

| ρ | density | kg/m3 |

| η | efficiency | % |

| κ | opening degree | |

| φ | disturbance variable | |

| Subscripts | ||

| st | stack | |

| gen | heat generation | |

| dis | heat dissipation | |

| theo | heat dissipation | |

| elec | electrical | |

| amb | ambient | |

| cl | coolant | |

| rad | radiator | |

| in | inlet | |

| out | outlet | |

| tv | thermostat | |

| op | operating point | |

| Acronyms | ||

| FCV | fuel cell vehicle | |

| MPC | model predictive control | |

| PEMFC | proton exchange membrane fuel cell | |

| OOT | optimal operating temperature | |

| TMS | thermal management system | |

References

- Jia, C.; Liu, W.; He, H.; Chau, K. Health-conscious energy management for fuel cell vehicles: An integrated thermal management strategy for cabin and energy source systems. Energy 2025, 333, 137330–137341. [Google Scholar] [CrossRef]

- Jia, C.; Liu, W.; He, H.; Chau, K. Superior energy management for fuel cell vehicles guided by improved DDPG algorithm: Integrating driving intention speed prediction and health-aware control. Appl. Energy 2025, 394, 126195–126206. [Google Scholar] [CrossRef]

- Lu, D.; Yi, F.; Hu, D.; Li, J.; Yang, Q.; Wang, J. Online optimization of energy management strategy for FCV control parameters considering dual power source lifespan decay synergy. Appl. Energy 2023, 348, 121516–121528. [Google Scholar] [CrossRef]

- Jia, C.; Liu, W.; He, H.; Chau, K. Deep reinforcement learning-based energy management strategy for fuel cell buses integrating future road information and cabin comfort control. Energy Convers. Manag. 2024, 321, 119032–119043. [Google Scholar] [CrossRef]

- Li, K.; Zhou, J.; Jia, C.; Yi, F.; Zhang, C. Energy sources durability energy management for fuel cell hybrid electric bus based on deep reinforcement learning considering future terrain information. Int. J. Hydrogen Energy 2024, 52, 821–833. [Google Scholar] [CrossRef]

- Liso, V.; Nielsen, M.; Kaer, S.; Mortensen, H.H. Thermal modeling and temperature control of a PEM fuel cell system for forklift applications. Int. J. Hydrogen Energy 2014, 39, 8410–8420. [Google Scholar] [CrossRef]

- Saygili, Y.; Eroglu, I.; Kincal, S. Model based temperature controller development for water cooled PEM fuel cell systems. Int. J. Hydrogen Energy 2015, 40, 615–622. [Google Scholar] [CrossRef]

- Ahn, J.W.; Choe, S.Y. Coolant controls of a PEM fuel cell system. J. Power Sources 2008, 179, 252–264. [Google Scholar] [CrossRef]

- Chen, J.H.; He, P.; Cai, S.J.; He, Z.-H.; Zhu, H.-N.; Yu, Z.-Y.; Yang, L.-Z.; Tao, W.-Q. Modeling and temperature control of a water-cooled PEMFC system using intelligent algorithms. Appl. Energy 2024, 372, 123790–123809. [Google Scholar] [CrossRef]

- Cheng, S.; Fang, C.; Xu, L.; Li, J.; Ouyang, M. Model-based temperature regulation of a PEM fuel cell system on a city bus. Int. J. Hydrogen Energy 2015, 40, 13566–13575. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, Y.; Xu, S. Temperature sensitivity characteristics of PEM fuel cell and output performance improvement based on optimal active temperature control. Int. J. Heat Mass Transf. 2023, 206, 123966–123980. [Google Scholar] [CrossRef]

- Han, J.; Yu, S.; Yi, S. Advanced thermal management of automotive fuel cells using a model reference adaptive control algorithm. Int. J. Hydrogen Energy 2017, 42, 4328–4341. [Google Scholar] [CrossRef]

- Song, D.; Wu, Q.; Zeng, X.; Qian, Q.; Yang, D. Feedback-linearization decoupling based coordinated control of air supply and thermal management for vehicular fuel cell system. Energy 2024, 305, 132347–132364. [Google Scholar] [CrossRef]

- Yan, C.; Chen, J.; Liu, H.; Lu, H. Model-based fault tolerant control for the thermal management of PEMFC systems. IEEE Trans. Ind. Electron 2019, 67, 2875–2884. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.; Fang, Y.; Li, W.; Ding, Y.; Wan, Z.; Wang, X.; Tu, Z. Temperature and humidity management of PEM fuel cell power system using multi-input and multi-output fuzzy method. Appl. Therm. Eng. 2022, 203, 117865–117874. [Google Scholar] [CrossRef]

- Xu, D.; Yan, W.; Ji, N. RBF neural network based adaptive constrained PID control of a solid oxide fuel cell. In Proceedings of the 2016 Chinese Control and Decision Conference (CCDC), Yinchuan, China, 28–30 May 2016; pp. 3986–3991. [Google Scholar]

- Xu, J.H.; Yan, H.Z.; Ding, Q.; Zhu, K.-Q.; Yang, Y.-R.; Wang, Y.-L.; Huang, T.-M.; Chen, X.; Wan, Z.-M.; Wang, X.-D. Sparrow search algorithm applied to temperature control in PEM fuel cell systems. Int. J. Hydrogen Energy 2022, 47, 39973–39986. [Google Scholar] [CrossRef]

- Baroud, Z.; Benmiloud, M.; Benalia, A.; Ocampo-Martinez, C. Novel hybrid fuzzy-PID control scheme for air supply in PEM fuel-cell-based systems. Int. J. Hydrogen Energy 2017, 42, 10435–10447. [Google Scholar] [CrossRef]

- Chen, X.; Feng, W.; You, S.; Hu, Y.; Wan, Y.; Zhao, B. Dual temperature parameter control of PEMFC stack based on improved differential evolution algorithm. Renew. Energy 2025, 241, 122319–122332. [Google Scholar] [CrossRef]

- Cao, J.H.; Yin, C.; Wang, R.K.; Li, R.; Liu, R.; Tang, H. Dynamic thermal management of proton exchange membrane fuel cell vehicle system using the tube-based model predictive control. Int. J. Hydrogen Energy 2024, 70, 493–509. [Google Scholar] [CrossRef]

- Tümer, B.; Yıldız, D.Ş.; Arkun, Y. Water and thermal management in PEM fuel cells using feasible humidity plots and model predictive controllers. Comput. Chem. Eng. 2025, 192, 108905–108917. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Zhang, C.Z.; Fan, R.J.; Deng, C.; Wan, S.; Chaoui, H. Energy management strategy for fuel cell vehicles via soft actor-critic-based deep reinforcement learning considering powertrain thermal and durability characteristics. Energy Convers. Manag. 2023, 283, 116921–116938. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuan, W.W.; Wang, Y.X.; Ou, K.; Huang, Y.; Xuan, D. Enhanced deep reinforcement learning-based thermal management strategy for PEMFC considering coolant system parasitic power. Int. J. Hydrogen Energy 2025, 146, 149919–149932. [Google Scholar] [CrossRef]

- Lin, Y.H.; Huang, Y.H. Integrated thermal and energy management systems using particle swarm optimization for energy optimization in electric vehicles. Case Stud. Therm. Eng. 2025, 71, 106136–106157. [Google Scholar] [CrossRef]

- Ju, F.; Jiang, Y.H.; Zhuang, W.H.; Li, B.; Dai, J. Integrated optimization of energy management and thermal control strategies for fuel-cell heavy truck. Int. J. Hydrogen Energy 2025, 145, 928–941. [Google Scholar] [CrossRef]

- Jiang, K.; Tian, Z.; Wen, T.; Song, K.; Hillmansen, S.; Ochieng, W.Y. Collaborative optimization strategy of hydrogen fuel cell train energy and thermal management system based on deep reinforcement learning. Appl. Energy 2025, 393, 2318–2335. [Google Scholar] [CrossRef]

- Lin, Y.; Lee, M.; Hung, Y. A thermal management control using particle swarm optimization for hybrid electric energy system of electric vehicles. Results Eng. 2024, 21, 101717–101734. [Google Scholar] [CrossRef]

- De Schepper, P.; Danilov, V.A.; Denayer, J.F.M. Cathode flow field design for nitric oxide/hydrogen fuel cell in cogeneration of hydroxylamine and electricity. Energy Res. 2016, 40, 1355–1366. [Google Scholar] [CrossRef]

- Luo, X.; Chung, H.S. An Improved MPC-based energy management strategy for hydrogen fuel cell EVs featuring dual-motor coupling powertrain. Energy Convers. Manag. X 2025, 26, 100975–100994. [Google Scholar] [CrossRef]

- Xie, R.; Ma, R.; Pu, S.; Xu, L.; Zhao, D.; Huangfu, Y. Prognostic for fuel cell based on particle filter and recurrent neural network fusion structure. Energy AI 2020, 2, 100017–100027. [Google Scholar] [CrossRef]

- Qing, H.Y.; Feng, Y.; Zhang, C.Z.; Gao, J.; Chen, H.; Hao, D.; Yu, P.; Simonovic, M. Parallel structure-based decentralized model predictive control of vehicle PEMFC anode circulation system. Energy 2025, 324, 135767–135779. [Google Scholar] [CrossRef]

- Deng, Z.; Chen, M.; Wang, H.; Chen, Q. Performance-oriented model learning and model predictive control for PEMFC air supply system. Int. J. Hydrogen Energy 2024, 64, 339–348. [Google Scholar] [CrossRef]

- Zhu, Y.; Zou, J.; Li, S.; Peng, C.; Xie, Y. Nonlinear model predictive control of PEMFC anode hydrogen circulation system based on dynamic coupling analysis. Int. J. Hydrogen Energy 2023, 48, 2385–2400. [Google Scholar] [CrossRef]

- Chen, F.X.; Zhang, J.Y.; Pei, Y.W.; Chi, X.; Zhang, H.; Wang, Y. Real-time pressure-flow coordinated control based on adaptive switching algorithm of PEMFC durability test bench. Int. J. Hydrogen Energy 2024, 141, 598–614. [Google Scholar] [CrossRef]

- Hu, H.; Ou, K.; Yuan, W.W. Fused multi-model predictive control with adaptive compensation for proton exchange membrane fuel cell air supply system. Energy 2023, 284, 128459–128477. [Google Scholar] [CrossRef]

- He, H.W.; Quan, S.W.; Wang, Y.X. Hydrogen circulation system model predictive control for polymer electrolyte membrane fuel cell-based electric vehicle application. Int. J. Hydrogen Energy 2020, 45, 20382–20390. [Google Scholar] [CrossRef]

- Zo, W.J.; Kim, Y.B. Temperature control for a 5 kW water-cooled PEM fuel cell system for a household application. IEEE Access 2019, 7, 144826–144835. [Google Scholar] [CrossRef]

- Masoudi, Y.; Azad, N.L. MPC-based battery thermal management controller for plug-in hybrid electric vehicles. In Proceedings of the 2017 American Control Conference (ACC), Seattle, WA, USA, 24–26 May 2017; pp. 4365–4370. [Google Scholar]

- Chen, X.; Fang, Y.; Liu, Q.; He, L.; Zhao, Y.; Huang, T.; Wan, Z.; Wang, X. Temperature and voltage dynamic control of PEMFC Stack using MPC method. Energy Rep. 2022, 8, 798–808. [Google Scholar] [CrossRef]

- Yuan, X.H.; Wu, G.; Zhou, J.G.; Xiong, X.; Wang, Y.-P. MPC-based thermal management for water-cooled proton exchange membrane fuel cells. Energy Rep. 2022, 8, 338–348. [Google Scholar] [CrossRef]

- Zhang, R.; Jia, Y.; Zhang, T.; Fan, Z. Research on modeling and control of PEMFC cooling system. Appl. Therm. Eng. 2024, 241, 122303–122313. [Google Scholar] [CrossRef]

- Yang, L.; Nik-Ghazali, N.N.; Ali, M.A.H.; Chong, W.T.; Yang, Z.; Liu, H. A review on thermal management in proton exchange membrane fuel cells: Temperature distribution and control. Renew. Sustain. Energy Rev. 2023, 187, 113737–113756. [Google Scholar] [CrossRef]

- Yu, X.; Zhou, B.; Sobiesiak, A. Water and thermal management for Ballard PEM fuel cell stack. J. Power Sources 2005, 147, 184–195. [Google Scholar] [CrossRef]

| Component | Description | Specification |

|---|---|---|

| Fuel cell stack | Maximum output power | 87 kW |

| Cells | 290 | |

| Cells active area | 282 cm2 | |

| Oxidant composition | 0.21 | |

| Radiator | Frontal area | 0.38 m2 |

| Maximum heat dissipation | 120 kW | |

| Radiator fan | Diameter dimension | 384 mm |

| Temperature sensor | Type | Type T thermocouple |

| Precision | ±0.5 °C |

| Parameter | Value |

|---|---|

| Cathode air inlet pressure | 155 kPa |

| Cathode hydrogen inlet pressure | 150 kPa |

| Ambient temperature | 20 °C |

| Stack operating temperature | 70 °C/75 °C/80 °C |

| Electric current density | 0/0.1/0.2/0.3/0.4/0.5/0.6/0.7/0.8/0.9/1.0/1.1 A/cm2 |

| Operating Temperature | MAE | MaxAE |

|---|---|---|

| 70 °C | 0.0024 V | 0.0103 V |

| 75 °C | 0.0032 V | 0.0135 V |

| 80 °C | 0.0026 V | 0.0117 V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Q.; Xiong, S.; Sun, B.; Chen, P.; Chen, H.; Zhu, S. Research on Energy-Saving Control of Automotive PEMFC Thermal Management System Based on Optimal Operating Temperature Tracking. Energies 2025, 18, 4100. https://doi.org/10.3390/en18154100

Jiang Q, Xiong S, Sun B, Chen P, Chen H, Zhu S. Research on Energy-Saving Control of Automotive PEMFC Thermal Management System Based on Optimal Operating Temperature Tracking. Energies. 2025; 18(15):4100. https://doi.org/10.3390/en18154100

Chicago/Turabian StyleJiang, Qi, Shusheng Xiong, Baoquan Sun, Ping Chen, Huipeng Chen, and Shaopeng Zhu. 2025. "Research on Energy-Saving Control of Automotive PEMFC Thermal Management System Based on Optimal Operating Temperature Tracking" Energies 18, no. 15: 4100. https://doi.org/10.3390/en18154100

APA StyleJiang, Q., Xiong, S., Sun, B., Chen, P., Chen, H., & Zhu, S. (2025). Research on Energy-Saving Control of Automotive PEMFC Thermal Management System Based on Optimal Operating Temperature Tracking. Energies, 18(15), 4100. https://doi.org/10.3390/en18154100