Advanced Nuclear Reactors—Challenges Related to the Reprocessing of Spent Nuclear Fuel

Abstract

1. Introduction

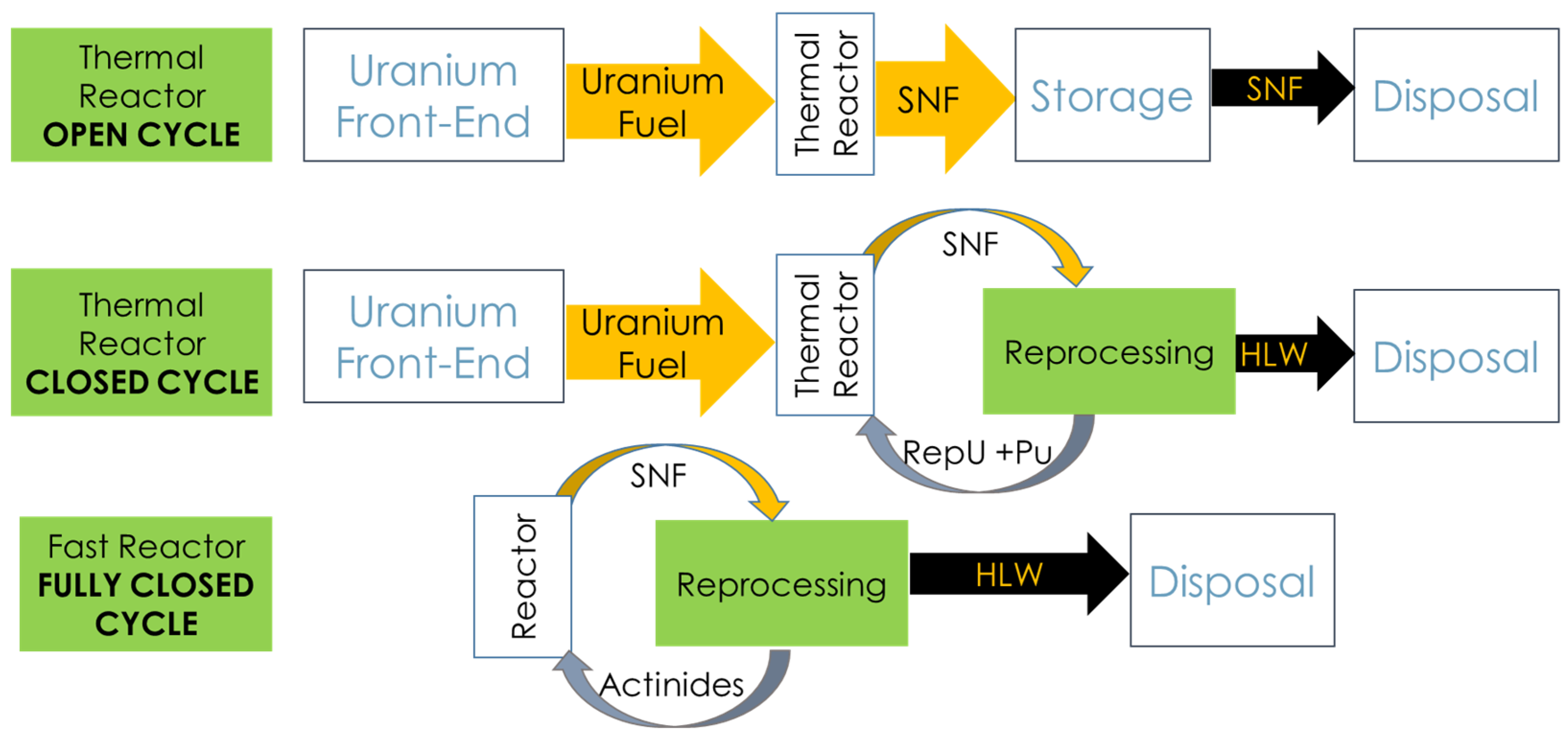

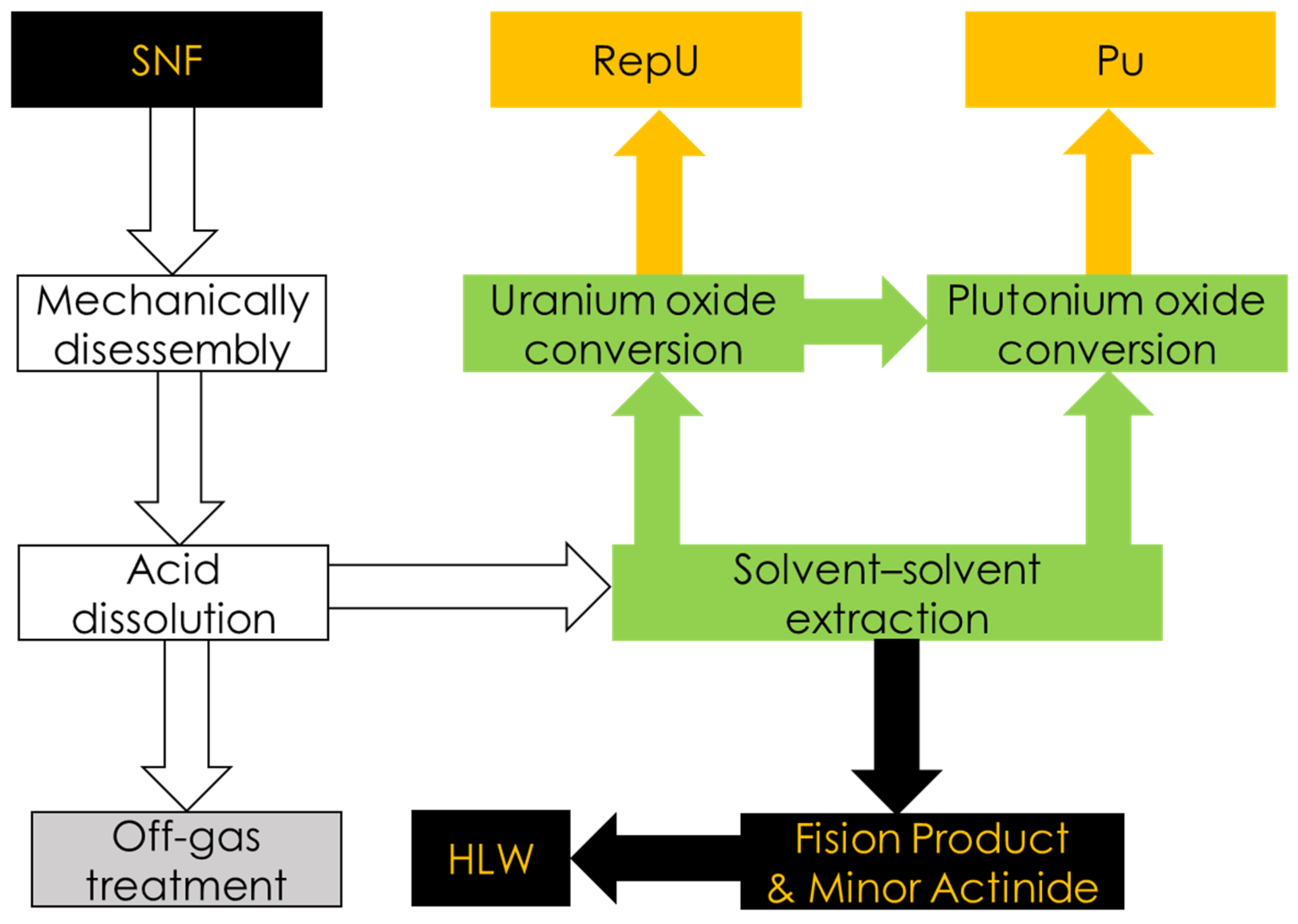

2. Spent Fuel Reprocessing—State of the Art

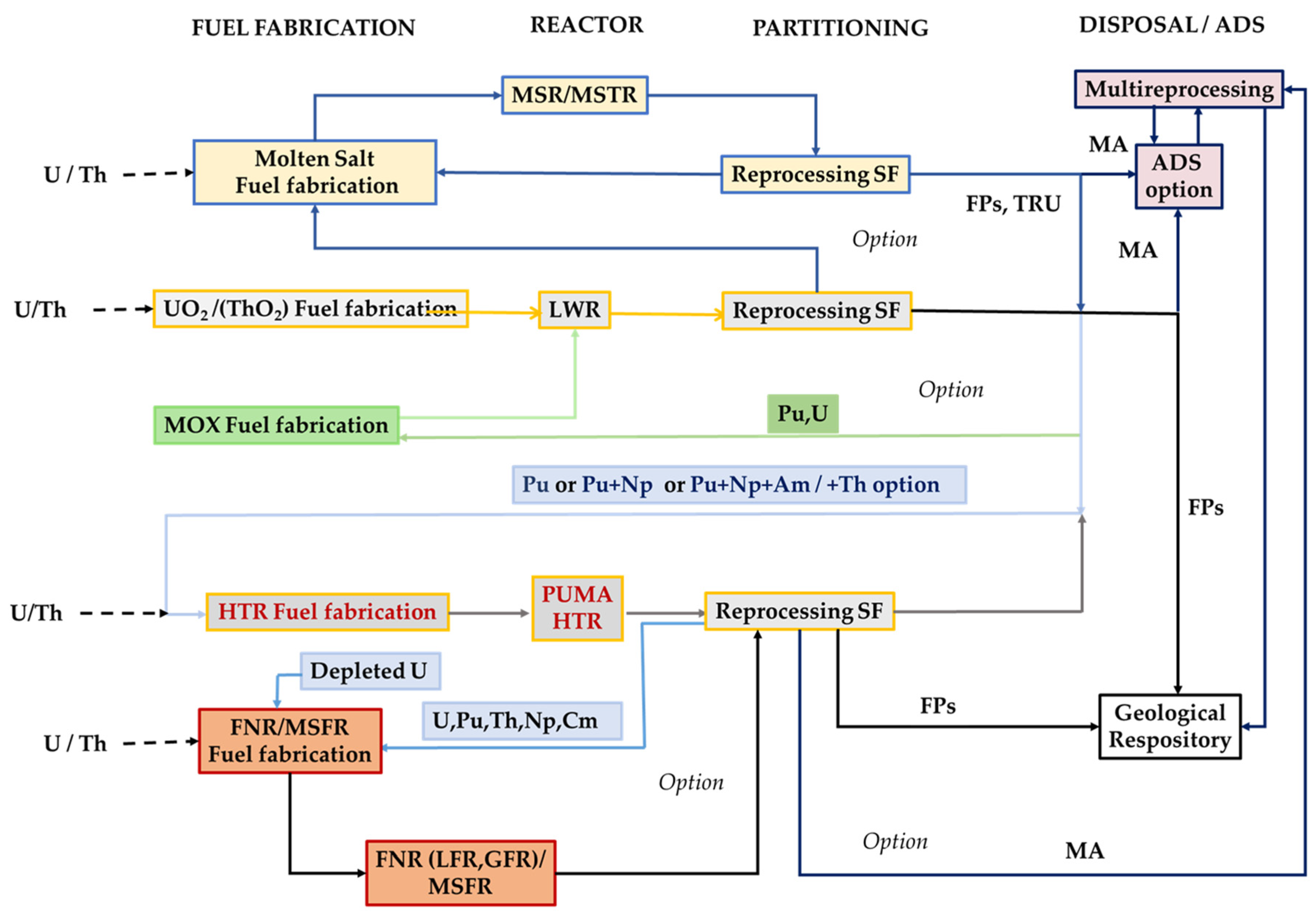

3. Gen IV Reactors—Advanced Fuel Cycle—Perspectives

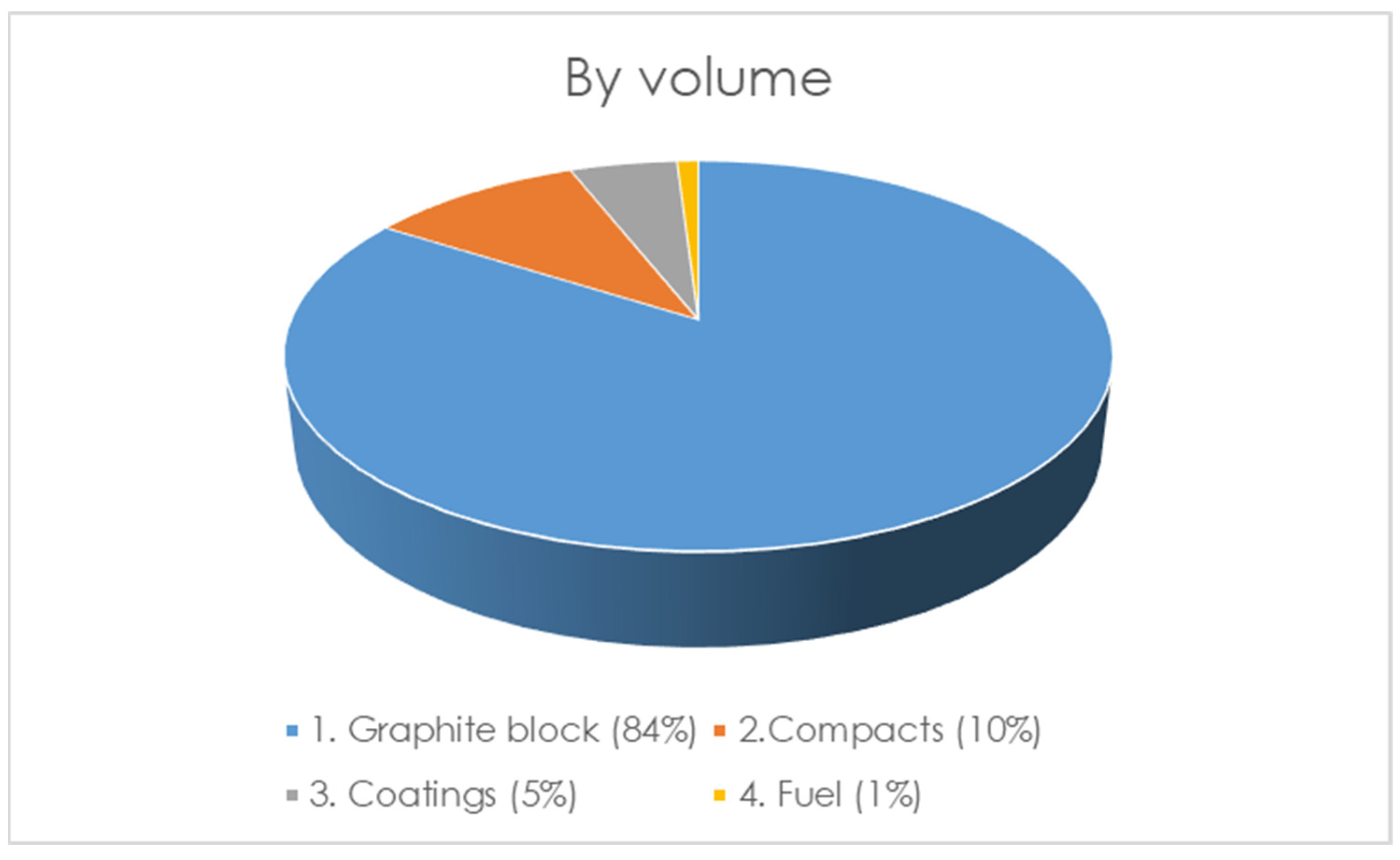

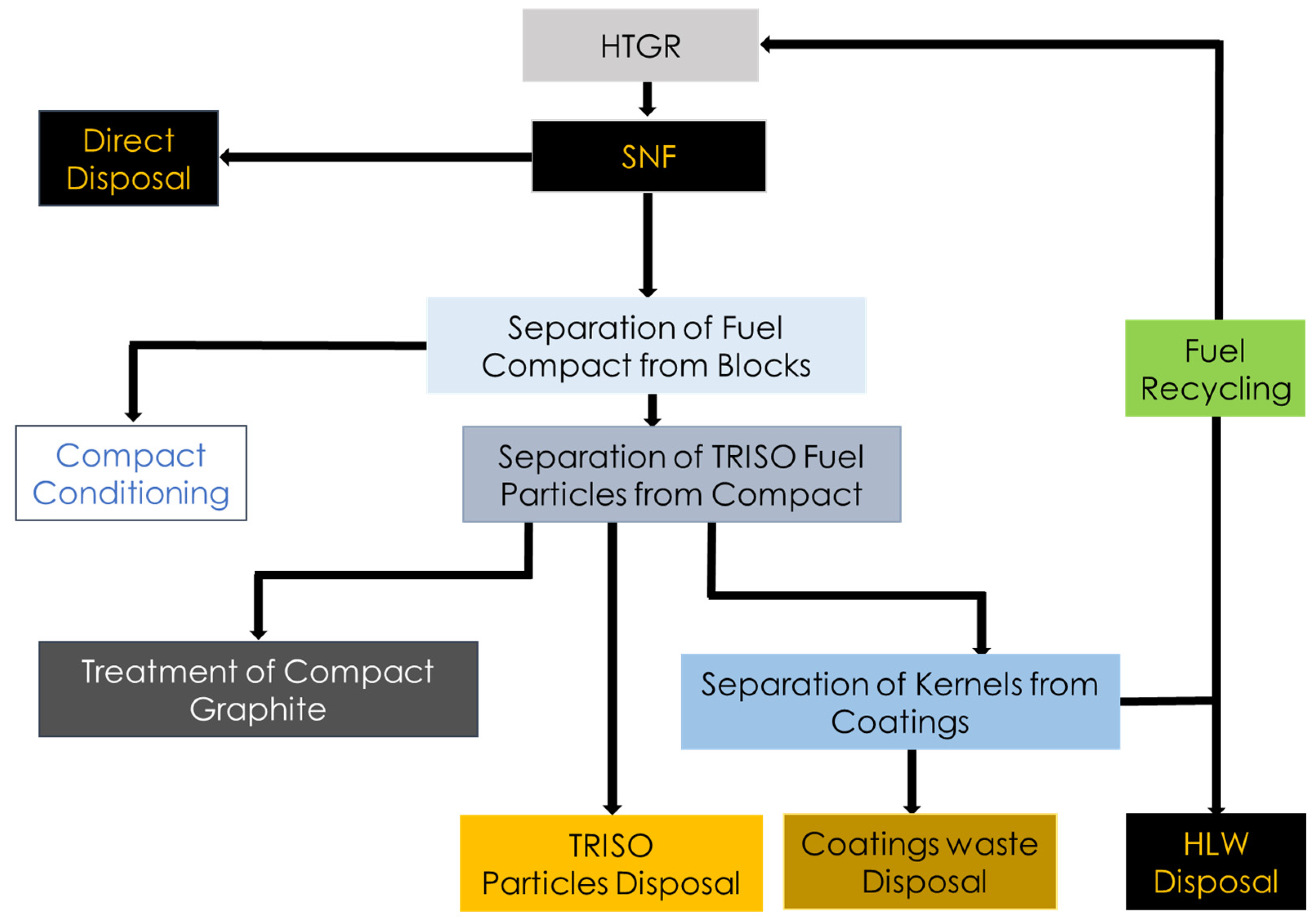

3.1. High Temperature Reactors

3.2. Lead Cooled Fast Reactors

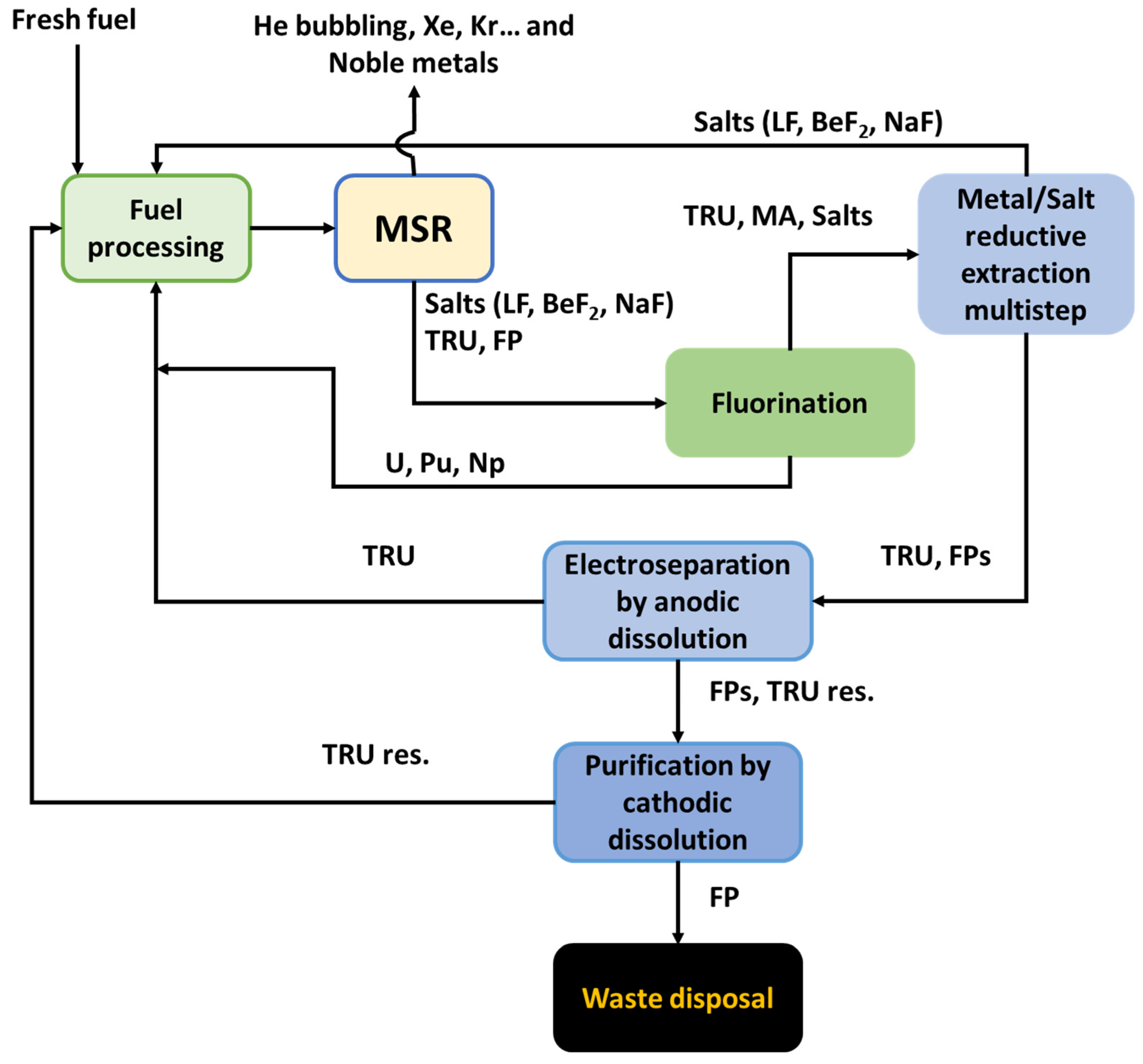

3.3. Molten Salt Reactors

3.4. Accelerator-Driven System

3.5. Thorium Cycle

- (1)

- Aqueous reprocessing (THOREX process) adapted from the PUREX process; THOREX uses tributyl phosphate in nitric acid to extract 233U from irradiated ThO2. However, ThO2’s low solubility in HNO3 complicates dissolution, often requiring fluoride additives or high-temperature treatment. The presence of 232U and its gamma-emitting daughters necessitates shielded facilities and remote operations [76].

- (2)

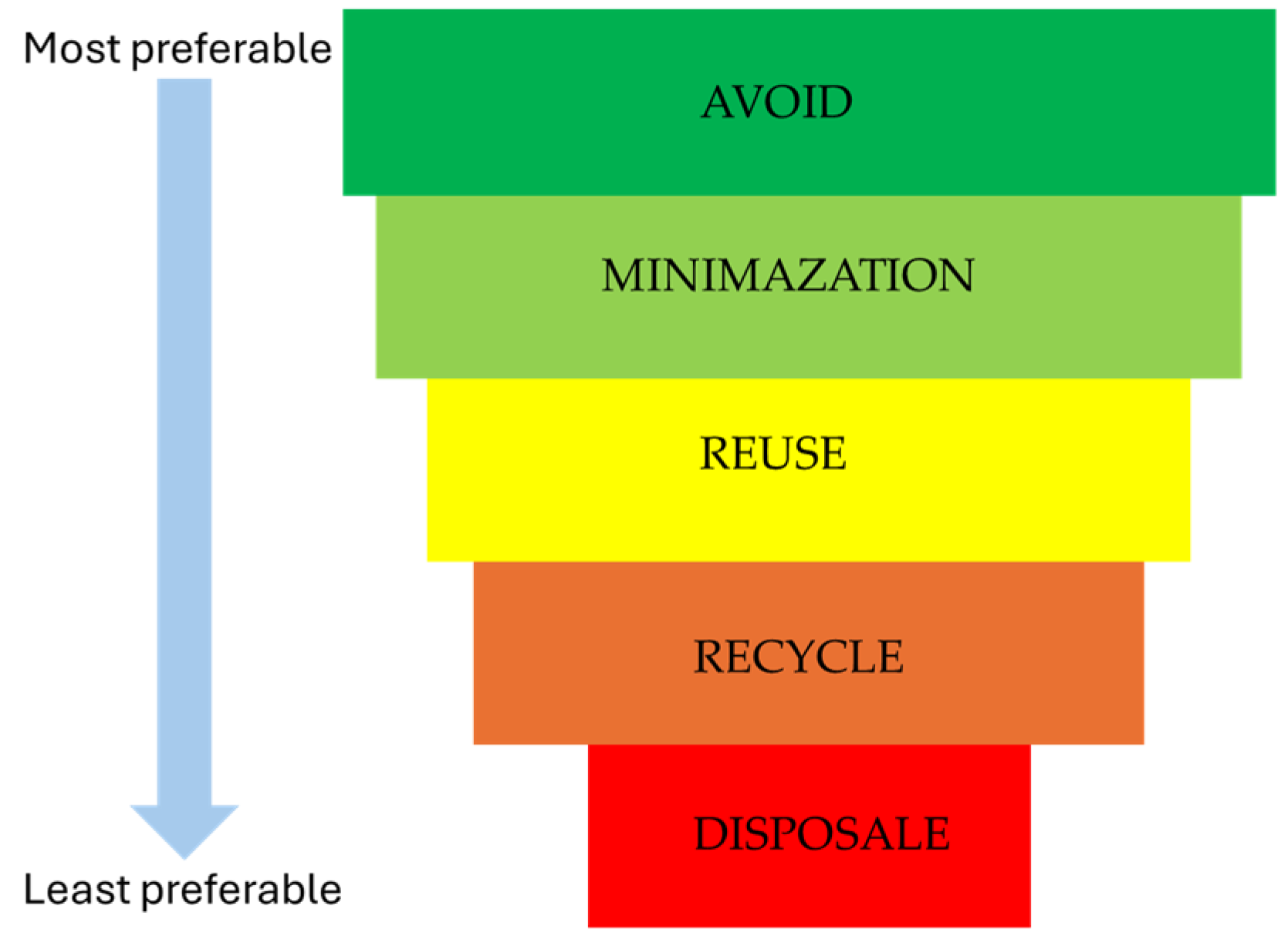

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADSs | Accelerator-Driven Systems |

| COEX | Co-Extraction of Uranium And Plutonium Process |

| ELFR | European Lead-Cooled Fast Reactor |

| ELSY | European Lead-Cooled System (ELSY) |

| FLINAK | Molten Salt LiF–NaF–KF |

| FNR | Fast Neutron Reactor |

| FPs | Fission Products |

| FVM | Fluoride Volatility Method |

| GCFR | Gas-Cooled Fast Reactors |

| HLW | High-Level Waste |

| HTGR | High-Temperature Gas-Cooled Reactors |

| IV Gen | Generation IV |

| LBE | Lead–Bismuth Eutectic Coolants |

| LEADER | Lead-Cooled European Advanced DEmonstration Reactor |

| LFRs | Lead-Cooled Fast Reactors |

| LLW | Low-Level Waste |

| LWR | Light Water Reactor |

| MAs | Minor Actinides |

| MOX | Mixed UO2 and PuO2 Fuel |

| MSR | Molten-Salt Reactor |

| MSRE | The Molten-Salt Reactor Experiment |

| MSTR | Molten-Salt Transmutation Reactor |

| P&T | Partitioning and Transmutation |

| PUREX | Plutonium Uranium Reduction Extraction |

| PWR | Pressurized Water Reactor |

| RepU | Reprocessed Uranium |

| SMR | Small Modular Reactor |

| SNF | Spent Nuclear Fuel |

| THOREX | Thorium Extraction Process |

| TRISO | Tri-structural ISOtropic (HTR fuel) |

| TRUs | Transuranic Elements |

| TRL | Technology Readiness Level |

| UREX | Uranium and Technetium Extraction Process |

| USA | United States of America |

References

- IAEA Nuclear Safety. Security Glossary: Terminology Used in Nuclear Safety, Nuclear Security, Radiation Protection and Emergency Preparedness and Response, 1st ed.; Non-Serial Publication; International Atomic Energy Agency: Vienna, Austria, 2022; ISBN 978-92-0-141822-7. [Google Scholar]

- Poinssot, C.; Boullis, B.; Bourg, S. Role of Recycling in Advanced Nuclear Fuel Cycles. In Reprocessing and Recycling of Spent Nuclear Fuel; Elsevier: Amsterdam, The Netherlands, 2015; pp. 27–48. ISBN 978-1-78242-212-9. [Google Scholar]

- Processing of Used Nuclear Fuel—World Nuclear Association. Available online: https://world-nuclear.org/information-library/nuclear-fuel-cycle/fuel-recycling/processing-of-used-nuclear-fuel (accessed on 29 June 2025).

- Wiech, J. Paliwo Jądrowe Wielokrotnego Użycia. Francja Wie, Jak Wykorzystać „Odpady z Elektrowni”. Available online: https://energetyka24.com/atom/analizy-i-komentarze/paliwo-jadrowe-wielokrotnego-uzycia-francja-wie-jak-wykorzystac-odpady-z-elektrowni (accessed on 29 June 2025).

- Nuclear Energy Agency, OECD. Accelerator-Driven Systems (ADS) and Fast Reactor (FR) in Advanced Nuclear Fuel Cycles: A Comparative Study; Nuclear Development, Nuclear Energy Agency, OECD, Eds.; OECD: Paris, France, 2002; ISBN 978-92-64-18482-4. [Google Scholar]

- Kiegiel, K.; Chmielewski, A.G. TRISO Fuel Management—Challenges Related to the Reprocessing of Spent TRISO Fuel; Institute of Nuclear Chemistry and Technology: Warsaw, Poland, 2014; pp. 68–71. [Google Scholar]

- Waste Framework Directive—European Commission. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en (accessed on 29 June 2025).

- Kim, T.; Boing, L.; Halsey, W.; Dixon, B. Nuclear Waste Attributes of SMRs Scheduled for Near-Term Deployment; ANL/NSE-22/98-Rev.1; Argonne National Laboratory: Lemont, IL, USA, 2022.

- IAEA. Development of Advanced Reprocessing Technologies. Available online: https://www.iaea.org/sites/default/files/gc/gc52inf-3-att4_en.pdf (accessed on 3 May 2025).

- Lanham, W.B.; Runion, T.C. PUREX Process for Plutonium and Uranium Recovery; ORNL-479(Del.), 4165457; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1949.

- Baron, P.; Cornet, S.M.; Collins, E.D.; DeAngelis, G.; Del Cul, G.; Fedorov, Y.; Glatz, J.P.; Ignatiev, V.; Inoue, T.; Khaperskaya, A.; et al. A Review of Separation Processes Proposed for Advanced Fuel Cycles Based on Technology Readiness Level Assessments. Prog. Nucl. Energy 2019, 117, 103091. [Google Scholar] [CrossRef]

- Bascone, D.; Angeli, P.; Fraga, E.S. Optimal Design of a COEX Process for Spent Nuclear Fuel Reprocessing Using Small Channels. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2018; Volume 44, pp. 2365–2370. ISBN 978-0-444-64241-7. [Google Scholar]

- Uchiyama, G.; Mineo, H.; Hotoku, S.; Asakura, T.; Kamei, K.; Watanabe, M.; Nakano, Y.; Kimura, S.; Fujine, S. PARC Process for an Advanced PUREX Process. Prog. Nucl. Energy 2000, 37, 151–156. [Google Scholar] [CrossRef]

- Kumari, I.; Kumar, B.V.R.; Khanna, A. A Review on UREX Processes for Nuclear Spent Fuel Reprocessing. Nucl. Eng. Des. 2020, 358, 110410. [Google Scholar] [CrossRef]

- Kiegiel, K.; Chmielewska-Śmietanko, D.; Herdzik-Koniecko, I.; Miśkiewicz, A.; Smoliński, T.; Rogowski, M.; Ntang, A.; Rotich, N.K.; Madaj, K.; Chmielewski, A.G. The Future of Nuclear Energy: Key Chemical Aspects of Systems for Developing Generation III+, Generation IV, and Small Modular Reactors. Energies 2025, 18, 622. [Google Scholar] [CrossRef]

- Geist, A.; Adnet, J.-M.; Bourg, S.; Ekberg, C.; Galán, H.; Guilbaud, P.; Miguirditchian, M.; Modolo, G.; Rhodes, C.; Taylor, R. An Overview of Solvent Extraction Processes Developed in Europe for Advanced Nuclear Fuel Recycling, Part 1—Heterogeneous Recycling. Sep. Sci. Technol. 2021, 56, 1866–1881. [Google Scholar] [CrossRef]

- Lyseid Authen, T.; Adnet, J.-M.; Bourg, S.; Carrott, M.; Ekberg, C.; Galán, H.; Geist, A.; Guilbaud, P.; Miguirditchian, M.; Modolo, G.; et al. An Overview of Solvent Extraction Processes Developed in Europe for Advanced Nuclear Fuel Recycling, Part 2—Homogeneous Recycling. Sep. Sci. Technol. 2022, 57, 1724–1744. [Google Scholar] [CrossRef]

- OECD. Actinide and Fission Product Partitioning and Transmutation: Eleventh Information Exchange Meeting. In Proceedings of the 11th Information Exchange Meeting on Actinide and Fission Product Partitioning and Transmutation (P&T), San Francisco, CA, USA, 1–4 November 2010; Nuclear Science. OECD: Paris, France, 2012. ISBN 978-92-64-99174-3. [Google Scholar]

- Gschneidner, K.A., Jr.; Eyring, L.; Choppin, G.R.; Lander, G.H. Volume 18: Lanthanides/Actinides: Chemistry. In Handbook on the Physics and Chemistry of Rare Earths; North-Holland: Amsterdam, The Netherlands, 1994; ISBN 978-0-444-81724-2. [Google Scholar]

- Kolarik, Z. Complexation and Separation of Lanthanides(III) and Actinides(III) by Heterocyclic N-Donors in Solutions. Chem. Rev. 2008, 108, 4208–4252. [Google Scholar] [CrossRef]

- Moyer, B.A. (Ed.) Ion Exchange and Solvent Extraction: A Series of Advances; CRC Press: Boca Raton, FL, USA, 2009; Volume 19, ISBN 978-0-429-13734-1. [Google Scholar]

- Panak, P.J.; Geist, A. Complexation and Extraction of Trivalent Actinides and Lanthanides by Triazinylpyridine N-Donor Ligands. Chem. Rev. 2013, 113, 1199–1236. [Google Scholar] [CrossRef]

- Ekberg, C.; Fermvik, A.; Retegan, T.; Skarnemark, G.; Foreman, M.R.S.; Hudson, M.J.; Englund, S.; Nilsson, M. An Overview and Historical Look Back at the Solvent Extraction Using Nitrogen Donor Ligands to Extract and Separate An(III) from Ln(III). Radiochim. Acta 2008, 96, 225–233. [Google Scholar] [CrossRef]

- Kania, M.J.; Nabielek, H.; Nickel, H. Coated Particle Fuels for High-Temperature Reactors. In Materials Science and Technology; Cahn, R.W., Haasen, P., Kramer, E.J., Eds.; Wiley: Hoboken, NJ, USA, 2015; pp. 1–183. ISBN 978-3-527-31395-2. [Google Scholar]

- Fukaya, Y.; Nishihara, T. Reduction on High Level Radioactive Waste Volume and Geological Repository Footprint with High Burn-up and High Thermal Efficiency of HTGR. Nucl. Eng. Des. 2016, 307, 188–196. [Google Scholar] [CrossRef]

- Geelhood, K.J. TRISO Fuel: Properties and Failure Modes; PNNL-31427; Pacific Northwest National Laboratory: Richland, WA, USA, 2021.

- Forsberg, C.W. Roadmap of Graphite Moderator and Graphite-Matrix TRISO Fuel Management Options. Nucl. Technol. 2024, 210, 1623–1638. [Google Scholar] [CrossRef]

- IAEA. Considerations for the Back End of the Fuel Cycle of Small Modular Reactors: Proceedings of a Technical Meeting, 1st ed.; IAEA TECDOC Series; International Atomic Energy Agency: Vienna, Austria, 2024; ISBN 978-92-0-156023-0. [Google Scholar]

- Rodriguez, C.; Baxter, A.; McEachern, D.; Fikani, M.; Venneri, F. Deep-Burn: Making Nuclear Waste Transmutation Practical. Nucl. Eng. Des. 2003, 222, 299–317. [Google Scholar] [CrossRef]

- Fukaya, Y.; Goto, M.; Ohashi, H.; Nishihara, T.; Tsubata, Y.; Matsumura, T. Optimization of Disposal Method and Scenario to Reduce High Level Waste Volume and Repository Footprint for HTGR. Ann. Nucl. Energy 2018, 116, 224–234. [Google Scholar] [CrossRef]

- IAEA. Processing of Irradiated Graphite to Meet Acceptance Criteria Got Waste Disposal: Results of a Coordinated Research Project; IAEA TECDOC Series; International Atomic Energy Agency: Vienna, Austria, 2016; ISBN 978-92-0-104016-9. [Google Scholar]

- Kiegiel, K.; Herdzik-Koniecko, I.; Fuks, L.; Zakrzewska-Kołtuniewicz, G. Management of Radioactive Waste from HTGR Reactors Including Spent TRISO Fuel—State of the Art. Energies 2022, 15, 1099. [Google Scholar] [CrossRef]

- Masson, M.; Grandjean, S.; Lacquement, J.; Bourg, S.; Delauzun, J.M.; Lacombe, J. Block-Type HTGR Spent Fuel Processing: CEA Investigation Program and Initial Results. Nucl. Eng. Des. 2006, 236, 516–525. [Google Scholar] [CrossRef]

- Tian, L.; Wen, M.; Li, L.; Chen, J. Disintegration of Graphite Matrix from the Simulative High Temperature Gas-Cooled Reactor Fuel Element by Electrochemical Method. Electrochim. Acta 2009, 54, 7313–7317. [Google Scholar] [CrossRef]

- Tian, L.; Wen, M.; Chen, J. Analysis of Electrochemical Disintegration Process of Graphite Matrix. Electrochim. Acta 2010, 56, 985–989. [Google Scholar] [CrossRef]

- Tian, L.; Wen, M.; Chen, J. Studies on Disintegrating Spherical Fuel Elements of High Temperature Gas-Cooled Reactor by a Electrochemical Method. J. Nucl. Mater. 2013, 432, 113–119. [Google Scholar] [CrossRef]

- Chen, X.; Lu, Z.; Zhao, H.; Liu, B.; Zhu, J.; Tang, C. The Electric Current Effect on Electrochemical Deconsolidation of Spherical Fuel Elements. Sci. Technol. Nucl. Install. 2017, 2017, 2126876. [Google Scholar] [CrossRef]

- Arm, S.; Hall, G.; Lumetta, G.; Wells, B. Plan for Developing TRISO Fuel Processing Technologies; PNNL-32969, 1874375; Pacific Northwest National Laboratory (PNNL): Richland, WA, USA, 2022.

- Arm, S.; Davidson, S.; Hall, G.; Iedema, M.; Jivelekas, A.; Lumetta, G.; Pratt, R.; Taubman, M. Feasibility of Pulsed Current Technology for Removing Bulk Carbon from TRISO-Based Fuels; PNNL-34412, 1985916; Pacific Northwest National Laboratory (PNNL): Richland, WA, USA, 2023.

- Zhu, L.; Duan, W.; Xu, J.; Zhu, Y. Uranium Extraction from TRISO-Coated Fuel Particles Using Supercritical CO2 Containing Tri-n-Butyl Phosphate. J. Hazard. Mater. 2012, 241–242, 456–462. [Google Scholar] [CrossRef]

- Pierce, R.A. Low Temperature Chemical Processing of Graphite-Clad Nuclear Fuels. U.S. Patent 9793019, 17 October 2017. [Google Scholar]

- Del Cul, G.D. TRISO-Coated Fuel Processing to Support High Temperature Gas-Cooled Reactors; ORNL/TM-2002/156, 814326; Oak Ridge National Lab.(ORNL): Oak Ridge, TN, USA, 2002.

- Fredrickson, G.L.; Yoo, T.S. Review—Nuclear Fuels and Reprocessing Technologies: A U.S. Perspective; INL/EXT-20-59106; Idaho National Laboratory: Idaho Falls, ID, USA, 2021.

- Forsberg, C.; Peterson, P.F. Spent Nuclear Fuel and Graphite Management for Salt-Cooled Reactors: Storage, Safeguards, and Repository Disposal. Nucl. Technol. 2015, 191, 113–121. [Google Scholar] [CrossRef]

- Fütterer, M.A.; von der Weid, F.; Kilchmann, P. A High Voltage Head-End Process for Waste Minimization and Reprocessing of Coated Particle Fuel for High Temperature Reactors. In Proceedings of the 2010 International Congress on Advances in Nuclear Power Plants, San Diego, CA, USA, 13 June 2010. [Google Scholar]

- Fütterer, M.A.; Hoppe, P.; Singer, J.; Hansjoachim, B. European Atomic Energy Community Euratom. Head-End Process for the Reprocessing of Reactor Core Material. U.S. Patent 8498371, 30 July 2013. [Google Scholar]

- Fukaya, Y.; Goto, M.; Hirofumi Ohashi, A. Feasibility Study on Reprocessing of HTGR Spent Fuel by Existing PUREX Plant and Technology. Ann. Nucl. Energy 2023, 181, 109534. [Google Scholar] [CrossRef]

- Rose, A.; Phillips, W.C.; Hoover, R.O.; Woods, M.E. An Assessment of Applying Pyroprocessing Technology to Advanced Pebble-Type Fuels; ANL/CFCT-23/6 Rev. 1; Argonne National Laboratory (ANL): Argonne, IL, USA, 2023.

- Guittonneau, F.; Abdelouas, A.; Grambow, B.; Huclier, S. The Effect of High Power Ultrasound on an Aqueous Suspension of Graphite. Ultrason. Sonochem. 2010, 17, 391–398. [Google Scholar] [CrossRef]

- Guittonneau, F.; Abdelouas, A.; Grambow, B. HTR Fuel Waste Management: TRISO Separation and Acid-Graphite Intercalation Compounds Preparation. J. Nucl. Mater. 2010, 407, 71–77. [Google Scholar] [CrossRef]

- Ekberg, C.; Retegan, T.; De Visser Tynova, E.; Sarsfield, M.; Wallenius, J. Fuel Fabrication and Reprocessing Issues: The ASGARD Project. EPJ Nucl. Sci. Technol. 2020, 6, 34. [Google Scholar] [CrossRef]

- Guittonneau, F.; Abdelouas, A.; Grambow, B.; Dialinas, M.; Cellier, F. New Methods for HTR Fuel Waste Management. In Proceedings of the Fourth International Topical Meeting on High Temperature Reactor Technology, Washington, DC, USA, 28 September–1 October 2008; ASME: Washington, DC, USA, 2008; Volume 2, pp. 709–713. [Google Scholar]

- Zhang, G.; Wen, M.; Wang, S.; Chen, J.; Wang, J. Insights into Electrochemical Behavior and Anodic Oxidation Processing of Graphite Matrix in Aqueous Solutions of Sodium Nitrate. J. Appl. Electrochem. 2016, 46, 1163–1176. [Google Scholar] [CrossRef]

- Paris, J.; Costes, J.-R. Method for Treating Contaminated Nuclear Graphite. Austria Patent ATE358534T1, 15 April 2017. [Google Scholar]

- Vasudevamurthy, G.; Nelson, A.T. Uranium Carbide Properties for Advanced Fuel Modeling—A Review. J. Nucl. Mater. 2022, 558, 153145. [Google Scholar] [CrossRef]

- Shepherd, J.S.; Fairweather, M.; Hanson, B.C.; Heggs, P.J. Mathematical Model of the Oxidation of a Uranium Carbide Fuel Pellet Including an Adherent Product Layer. Appl. Math. Model. 2017, 45, 784–801. [Google Scholar] [CrossRef][Green Version]

- Salvatores, M.; Palmiotti, G. Radioactive Waste Partitioning and Transmutation within Advanced Fuel Cycles: Achievements and Challenges. Prog. Part. Nucl. Phys. 2011, 66, 144–166. [Google Scholar] [CrossRef]

- Toshinsky, G.I.; Dedul, A.V.; Komlev, O.G.; Kondaurov, A.V.; Petrochenko, V.V. Lead-Bismuth and Lead as Coolants for Fast Reactors. World J. Nucl. Sci. Technol. 2020, 10, 65–75. [Google Scholar] [CrossRef]

- Loewen, E. Investigation of Polonium Removal Systems for Lead-Bismuth Cooled Fbrs. Prog. Nucl. Energy 2005, 47, 586–595. [Google Scholar] [CrossRef]

- Agbevanu, K.T.; Debrah, S.K.; Arthur, E.M.; Shitsi, E. Liquid Metal Cooled Fast Reactor Thermal Hydraulic Research Development: A Review. Heliyon 2023, 9, e16580. [Google Scholar] [CrossRef] [PubMed]

- Adamov, E. Closed Nuclear Fuel Cycle with Fast Reactors; Elsevier: Amsterdam, The Netherlands, 2022; ISBN 978-0-323-99308-1. [Google Scholar]

- Stanisz, P.; Oettingen, M.; Cetnar, J. Monte Carlo Modeling of Lead-Cooled Fast Reactor in Adiabatic Equilibrium State. Nucl. Eng. Des. 2016, 301, 341–352. [Google Scholar] [CrossRef]

- Alemberti, A.; Carlsson, J.; Malambu, E.; Orden, A.; Struwe, D.; Agostini, P.; Monti, S. European Lead Fast Reactor—ELSY. Nucl. Eng. Des. 2011, 241, 3470–3480. [Google Scholar] [CrossRef]

- Alemberti, A.; Mansani, L.; Frogheri, M. The ELFR Industrial Plant and ALFRED Demonstrator. In Proceedings of the 4th Conference on Heavy Liquid-Metal Coolants in Nuclear Technologies (HLMC-2013), Obninsk, Russia, 22–27 September 2013. [Google Scholar]

- Cinotti, L.; Nucleare, A.; Fazio, C.; Knebel, J.; Monti, S.; Abderrahim, A.; Smith, C.; Suh, K. LFR “Lead-Cooled Fast Reactor”; Lawrence Livermore National Lab. (LLNL): Livermore, CA, USA, 2006.

- Yang, K.; Kardoulaki, E.; Zhao, D.; Broussard, A.; Metzger, K.; White, J.T.; Sivack, M.R.; Mcclellan, K.J.; Lahoda, E.J.; Lian, J. Uranium Nitride (UN) Pellets with Controllable Microstructure and Phase—Fabrication by Spark Plasma Sintering and Their Thermal-Mechanical and Oxidation Properties. J. Nucl. Mater. 2021, 557, 153272. [Google Scholar] [CrossRef]

- Jones, S.; Boxall, C.; Maher, C.; Taylor, R. A Review of the Reprocessability of Uranium Nitride Based Fuels. Prog. Nucl. Energy 2023, 165, 104917. [Google Scholar] [CrossRef]

- Ekberg, C.; Ribeiro Costa, D.; Hedberg, M.; Jolkkonen, M. Nitride Fuel for Gen IV Nuclear Power Systems. J. Radioanal. Nucl. Chem. 2018, 318, 1713–1725. [Google Scholar] [CrossRef]

- Satoh, T.; Iwai, T.; Arai, Y. Electrolysis of Burnup-Simulated Uranium Nitride Fuels in LiCl-KCl Eutectic Melts. J. Nucl. Sci. Technol. 2009, 46, 557–563. [Google Scholar] [CrossRef][Green Version]

- Arai, Y.; Minato, K. Fabrication and Electrochemical Behavior of Nitride Fuel for Future Applications. J. Nucl. Mater. 2005, 344, 180–185. [Google Scholar] [CrossRef]

- Takano, H.; Akie, H.; Osugi, T.; Ogawa, T. A Concept of Nitride Fuel Actinide Recycle System Based on Pyrochemical Reprocessing. Prog. Nucl. Energy 1998, 32, 373–380. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, L.; Zhang, Y.; Li, S. Advancements and Development Trends in Lead-Cooled Fast Reactor Core Design. Processes 2025, 13, 1773. [Google Scholar] [CrossRef]

- Fuel Cycle & Sustainability|Westinghouse Nuclear. Available online: https://westinghousenuclear.com/energy-systems/lead-cooled-fast-reactor/fuel-cycle-sustainability/ (accessed on 29 June 2025).

- Tulackova, R.; Chuchvalcova-Bimova, K.; Precek, M.; Marecek, M.; Uhlir, J. Development of Pyrochemical Reprocessing of the Spent Nuclear Fuel and Prospects of Closed Fuel Cycle. At. Indones. 2012, 33, 47–59. [Google Scholar] [CrossRef]

- Nakajima, T.; Groult, H. Fluorinated Materials for Energy Conversion, 1st ed.; Elsevier: Amsterdam, The Netherlands; San Diego, CA, USA; Oxford, UK, 2005; ISBN 978-0-08-044472-7. [Google Scholar]

- Rodrigues, D.; Durán-Klie, G.; Delpech, S. Pyrochemical Reprocessing of Molten Salt Fast Reactor Fuel: Focus on the Reductive Extraction Step. Nukleonika 2015, 60, 907–914. [Google Scholar] [CrossRef]

- Uhlíř, J. Chemistry and Technology of Molten Salt Reactors—History and Perspectives. J. Nucl. Mater. 2007, 360, 6–11. [Google Scholar] [CrossRef]

- Malmbeck, R.; Nourry, C.; Ougier, M.; Souček, P.; Glatz, J.P.; Kato, T.; Koyama, T. Advanced Fuel Cycle Options. Energy Procedia 2011, 7, 93–102. [Google Scholar] [CrossRef][Green Version]

- Lopatkin, A.V.; Tret’yakov, I.T.; Larionov, I.A.; Tuktarov, M.A.; Zayko, I.V.; Klimenko, D.S. Engineering and Physical Design of a Molten Salt Reactor for Transmutation of Np, Am, and Cm from Spent VVER Fuel. At. Energy 2025, 137, 295–300. [Google Scholar] [CrossRef]

- Holcomb, D. Promise and Challenges of Molten Salt Reactors [Slides]. In Proceedings of the SAMOSAFER Final Meeting, Avignon, France, 29 November 2023. [Google Scholar]

- IAEA. Status of Molten Salt Reactor Technology, 1st ed.; Technical Reports Series; International Atomic Energy Agency: Vienna, Austria, 2024; ISBN 978-92-0-140522-7. [Google Scholar]

- Holcomb, D.E. Development Principles for Thermal-Spectrum Molten-Salt Breeder Reactors; U.S. Department of Energy National Laboratory Operated by Battelle Energy Alliance, LLC: Idaho Falls, ID, USA, 2023.

- Delpech, S.; Merle-Lucotte, E.; Heuer, D.; Allibert, M.; Ghetta, V.; Le-Brun, C.; Doligez, X.; Picard, G. Reactor Physic and Reprocessing Scheme for Innovative Molten Salt Reactor System. J. Fluor. Chem. 2009, 130, 11–17. [Google Scholar] [CrossRef]

- Mirza, M.; Abdulaziz, R.; Maskell, W.C.; Wilcock, S.; Jones, A.H.; Woodall, S.; Jackson, A.; Shearing, P.R.; Brett, D.J.L. Electrochemical Processing in Molten Salts—A Nuclear Perspective. Energy Environ. Sci. 2023, 16, 952–982. [Google Scholar] [CrossRef]

- LaPlante, P.; Dasgupta, B.; Pan, Y.-M.; Adams, G. Storage Transportation of Molten Salt Reactor Wastes: Identification of Technical Information Needs Safety Implications for Safety Review Guidance; U.S. Nuclear Regulatory Commission Office of Nuclear Regulatory Research: Rockville, MD, USA, 2024; pp. 1–48.

- Carlson, K.; Gardner, L.; Moon, J.; Riley, B.; Amoroso, J.; Chidambaram, D. Molten Salt Reactors and Electrochemical Reprocessing: Synthesis and Chemical Durability of Potential Waste Forms for Metal and Salt Waste Streams. Int. Mater. Rev. 2021, 66, 339–363. [Google Scholar] [CrossRef]

- Becker, B.; Fratoni, M.; Greenspan, E. Transmutation Performance of Molten Salt Versus Solid Fuel Reactors. In Proceedings of the 15th International Conference on Nuclear Engineering, ICONE15, Nagoya, Japan, 22 April 2007. [Google Scholar]

- Sunde, J. “Material Corrosion in Molten Salt Reactors” Physics 241, Stanford University, Winter 2017. Available online: http://large.stanford.edu/courses/2017/ph241/sunde1/ (accessed on 20 July 2025).

- Hombourger, B.; Pautz, A.; Krepel, J.; Mikityuk, K. Fuel Cycle Analysis of a Molten Salt Reactor for Breed-and-Burn Mode—15524; Societe Francaise d’Energie Nucleaire—SFEN: Paris, France, 2025. [Google Scholar]

- Igunma, T.O.; Aderamo, A.T.; Chukwuemeka, O.H. Advanced Corrosion-Resistant Materials for Enhanced Nuclear Fuel Performance: A Conceptual Review of Innovations in Fuel Cladding against Molten Salt Degradation. Open Access Res. J. Eng. Technol. 2024, 7, 16–30. [Google Scholar] [CrossRef]

- Arm, S.; Holcomb, D.; Howard, R.; Riley, B. Status of Fast Spectrum Molten Salt Reactor Waste Management Practice; PNNL-30739, 1761520; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2020.

- Midgley, E.; Fisher, M. Molten Salt Reactor Technology Development Continues as Countries Work towards Net Zero; IAEA: Vienna, Austria, 2024. [Google Scholar]

- Oigawa, H.; Tsujimoto, K.; Nishihara, K.; Sugawara, T.; Kurata, Y.; Takei, H.; Saito, S.; Sasa, T.; Obayashi, H. Role of ADS in the Back-End of the Fuel Cycle Strategies and Associated Design Activities: The Case of Japan. J. Nucl. Mater. 2011, 415, 229–236. [Google Scholar] [CrossRef]

- Romanello, V.; Salvatores, M.; Schwenk-Ferrero, A.; Gabrielli, F.; Maschek, W.; Vezzoni, B. Comparative Study of Fast Critical Burner Reactors and Subcritical Accelerator Driven Systems and the Impact on Transuranics Inventory in a Regional Fuel Cycle. Nucl. Eng. Des. 2011, 241, 433–443. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Thorium Fuel Cycle—Potential Benefits and Challenges; TECDOC Series; International Atomic Energy Agency: Vienna, Austria, 2005; ISBN 92-0-103405-9. [Google Scholar]

- OECD Nuclear Energy Agency (NEA). Perspectives on the Use of Thorium in the Nuclear Fuel Cycle—Extended Summary; OECD Publishing: Paris, France, 2024. [Google Scholar]

- Naumov, V.S. Conceptual Potential of a Pyroelectrochemical Technology for the Thorium Engagement in the Fast Neutron Fuel Cycle. Nucl. Energy Technol. 2019, 5, 17–22. [Google Scholar] [CrossRef]

- Greneche, D.; Chhor, M. 8—Development of the Thorium Fuel Cycle. In Nuclear Fuel Cycle Science and Engineering; Crossland, I., Ed.; Woodhead Publishing Series in Energy; Woodhead Publishing: Sawston, UK, 2012; pp. 177–202. ISBN 978-0-85709-073-7. [Google Scholar]

- International Atomic Energy Agency. Experiences and Trends of Manufacturing Technology of Advanced Nuclear Fuels; International Atomic Energy Agency: Vienna, Austria, 2012; pp. 1–124. [Google Scholar]

- International Atomic Energy Agency. High Temperature Gas Cooled Reactor Fuels and Materials; International Atomic Energy Agency: Vienna, Austria, 2010. [Google Scholar]

- Bomboni, E.; Cerullo, N.; Lomonaco, G. Assessment of LWR-HTR-GCFR Integrated Cycle. Sci. Technol. Nucl. Install. 2009, 2009, 193594. [Google Scholar] [CrossRef]

- Taylor, R.; Bodel, W.; Stamford, L.; Butler, G. A Review of Environmental and Economic Implications of Closing the Nuclear Fuel Cycle—Part One: Wastes and Environmental Impacts. Energies 2022, 15, 1433. [Google Scholar] [CrossRef]

- Kuijper, J.C.; Somers, J.; Bomboni, E.; Bernnat, W.; Domanska, J.G.; Girardi, E.; Hossain, K.; Jonnet, J.; Kim, Y.; Kloosterman, J.L.; et al. Plutonium and Minor Actinide Management in Thermal High-Temperature Gas-Cooled Reactors; European Commission, Euratom: Brussels, Belgium, 2010.

- International Atomic Energy Agency. Spent Fuel Reprocessing Options; TECDOC Series (CD-ROM); International Atomic Energy Agency: Vienna, Auatria, 2009; ISBN 978-92-0-150309-1. [Google Scholar]

| Utilization | |||||

|---|---|---|---|---|---|

| Technology | Block-Compact Deconsolidation | Pyrolytic Carbon Removal | Silicon Carbide Removal | TRL [38] | References |

| Acoustical | No | Yes | Yes | 1 | [49] |

| Acid intercalation | Yes | No | No | 2 | [50] |

| Thermal shock | Yes | Yes | Yes | 1 | [51] |

| Pressure water jet | Yes | Partially removed | Partially removed | 1 | [52] |

| Hot chlorine gas | No | Yes | Yes | 1 | [33] |

| Pyrometallurgical method | No | Yes | Yes | 1 | [48] |

| Combustion | No | Yes | No | 3 | [33,40,41] |

| Electrolytic Constant current | Yes | No | No | 2 | [35,36,37,53] |

| Electrolytic pulsed current | Yes | Yes | Yes | 2 | [32,38,44,45,53,54] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiegiel, K.; Smoliński, T.; Herdzik-Koniecko, I. Advanced Nuclear Reactors—Challenges Related to the Reprocessing of Spent Nuclear Fuel. Energies 2025, 18, 4080. https://doi.org/10.3390/en18154080

Kiegiel K, Smoliński T, Herdzik-Koniecko I. Advanced Nuclear Reactors—Challenges Related to the Reprocessing of Spent Nuclear Fuel. Energies. 2025; 18(15):4080. https://doi.org/10.3390/en18154080

Chicago/Turabian StyleKiegiel, Katarzyna, Tomasz Smoliński, and Irena Herdzik-Koniecko. 2025. "Advanced Nuclear Reactors—Challenges Related to the Reprocessing of Spent Nuclear Fuel" Energies 18, no. 15: 4080. https://doi.org/10.3390/en18154080

APA StyleKiegiel, K., Smoliński, T., & Herdzik-Koniecko, I. (2025). Advanced Nuclear Reactors—Challenges Related to the Reprocessing of Spent Nuclear Fuel. Energies, 18(15), 4080. https://doi.org/10.3390/en18154080