Study on the Influence of Inducer Structure Change on Pump Cavitation Characteristics

Abstract

1. Introduction

2. Numerical Simulation Methods

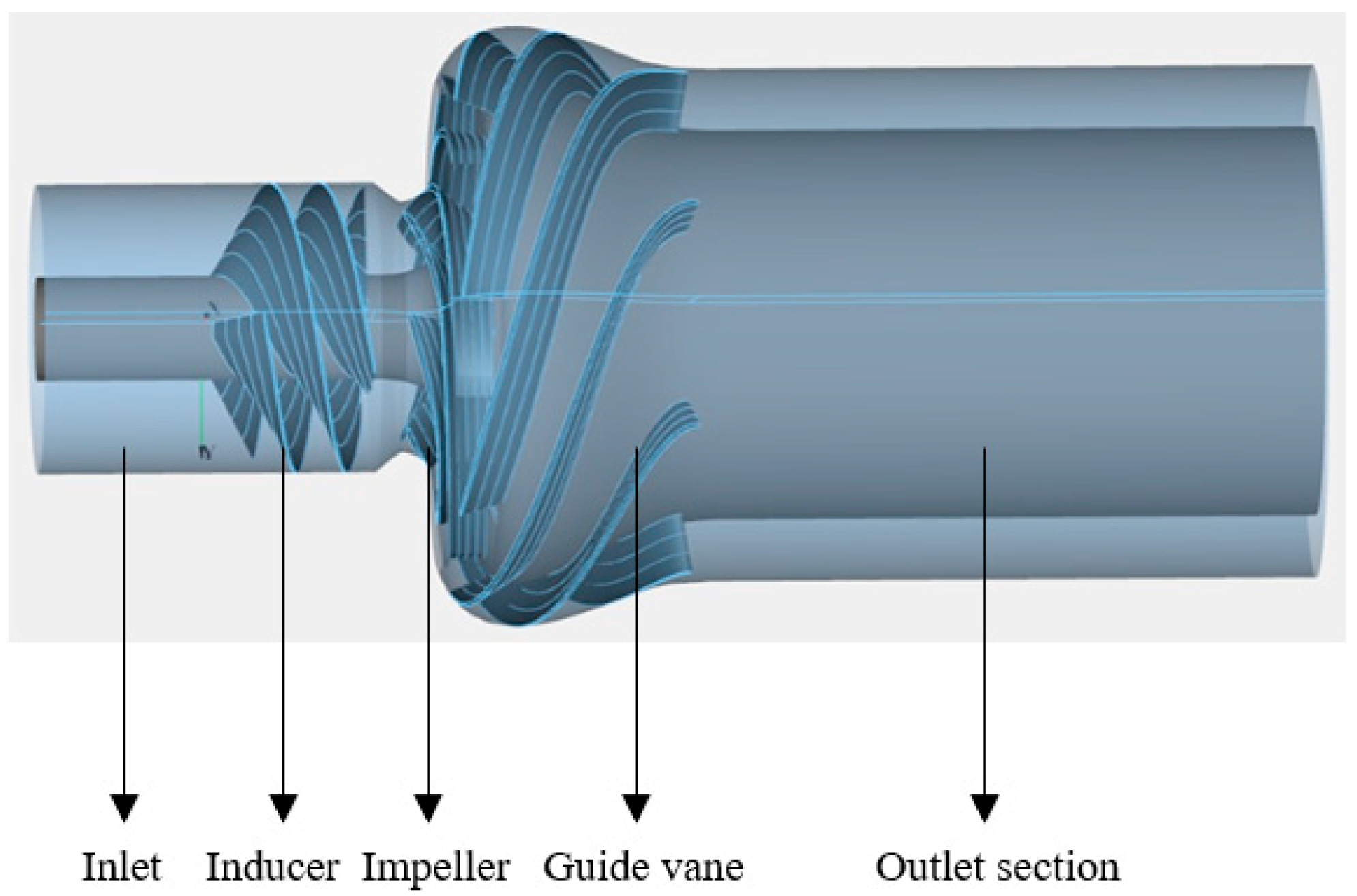

2.1. Study Subjects

2.2. Orthogonal Experimental Design

2.3. Mesh Model

3. Results and Analysis

3.1. Comparison of Cavitation Results of Inducers with Different Structures

3.2. Effect of Inducer Blade Number on Cavitation Performance

3.3. Study on the Influence of Inducer Geometric Parameters on Cavitation Performance and Cavitation Process

4. Conclusions

- Employing a dual-bladed inducer effectively lowers the critical cavitation margin and suppresses local low-pressure zones without compromising the pump head or efficiency. During the commissioning of and under low-flow conditions in LNG pumps, it is therefore advisable to adopt this two-blade design, supplemented by online NPSH monitoring and automated blade clearance adjustment, to extend the startup life and reduce the risk of unplanned downtime.

- Optimizing the ratio of the inlet angle to the outlet angle can smoothly guide the fluid at the inlet and achieve sufficient kinetic energy to pressure energy conversion at the outlet, thereby slowing down the initiation of cavitation; during the assembly and on-site commissioning stages, the impeller geometry accuracy should be strictly controlled and, combined with a variable frequency speed regulation strategy, the speed should be gradually increased to prevent early cavitation and improve operational stability.

- By reasonably adjusting the blade wrap angle, the fluid contact time along the blade surface can be extended, the pressure gradient can become smoother, and the initiation of cavitation can be inhibited; at the same time, a surface finish and edge transition treatment must be ensured. Under different LNG composition and temperature conditions, a wrap angle–NPSH relationship database can be established with the help of online vibration and sonar monitoring to achieve dynamic operating condition adjustments that take into account both the efficiency and cavitation risks.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, H.; Wan, X.; Jing, H. Analysis on the current status and localization of LNG cryogenic submersible pumps in my country. Gen. Mach. 2014, 54–56. [Google Scholar]

- Huang, J.; Chen, B.; Huang, X. Research on configuration and control system of LNG cryogenic submersible pump test platform. Petrochem. Equip. Technol. 2018, 39, 26–30. [Google Scholar]

- Luo, Z.; Ren, Y.; Chen, S.; Feng, C.; Ge, J. Structure and design analysis of LNG cryogenic submersible pumps. Cryog. Supercond. 2012, 40, 13–16. [Google Scholar]

- Pan, Z.; Guan, X. Theory and design of pump inducer. Trans. Chin. Soc. Agric. Mach. 2000, 31, 45–47. [Google Scholar]

- Zhang, T.; Guan, X.; Liu, H. Development of hydraulic design software for inducer based on AutoCAD2000. Pump Technol. 2002, 22–25. [Google Scholar]

- Wang, J.; Hu, J.; He, Y.; Zhu, B. Design of centrifugal pump inducer. Fluid Mach. 2005, 33, 20–22. [Google Scholar]

- Kong, F.; Zhang, H.; Zhang, X.; Wang, Z. Design on variable-pitch inducer based on numerical simulation for cavitation flow. J. Drain. Irrig. Mach. Eng. 2010, 28, 12–17. [Google Scholar]

- Wang, X.; Wang, G.; Shi, S.; Wu, Q. Cavitation flow characteristics of liquid hydrogen inside inducer. J. Drain. Irrig. Mach. Eng. 2013, 31, 558–564. [Google Scholar]

- Wang, W.; Chen, H.; Li, Y.; Du, Y. Matching of inducer and centrifugal wheel of high-speed centrifugal pump. J. Drain. Irrig. Mach. Eng. 2015, 33, 301–305. [Google Scholar]

- Li, X.; Li, J.; Wang, J.; Zhang, W.; Zhao, H. Cavitation performance of inducer with spiral stator blades. J. Beijing Univ. Aeronaut. Astronaut. 2016, 2654–2661. [Google Scholar]

- Sun, Q.; Jiang, J.; Zhang, S.; Chen, Q. Effect of variable pitch inducer on cavitation performance of high-speed centrifugal pump. J. Drain. Irrig. Mach. Eng. 2017, 35, 856–862. [Google Scholar]

- Parikh, T.; Mansour, M.; Thévenin, D. Maximizing the performance of pump inducers using CFD-based multi-objective optimization. Struct. Multidiscip. Optim. 2022, 65, 9. [Google Scholar] [CrossRef]

- Xu, Z.; Kong, F.; Zhang, H.; Zhang, K.; Wang, J.; Qiu, N. Research on Visualization of Inducer Cavitation of High-Speed Centrifugal Pump in Low Flow Conditions. J. Mar. Sci. Eng. 2021, 9, 1240. [Google Scholar] [CrossRef]

- Ehsan, D.; Amelie, D.; Moises, S.; Mohamed, K.; Farid, B. Study on the pump cavitation characteristic through novel independent rotation of inducer and centrifugal impeller in co-rotation and counter-rotation modes. Phys. Fluids 2024, 36, 015120. [Google Scholar] [CrossRef]

- Yang, Z.; Cao, P.; Zhang, J.; Gao, S.; Song, X.; Zhu, R. Research on Energy Loss of Optimization of Inducer–Impeller Axial Fit Dimensions Based on Wave-Piercing Theory. Water 2024, 16, 1385. [Google Scholar] [CrossRef]

- Coutier-Delgosha, O.; Caignaert, G.; Bois, G.; Leroux, J.-B. Influence of the blade number on inducer cavitating behavior. J. Fluids Eng. 2012, 134. [Google Scholar] [CrossRef]

- Coutier-Delgosha, O.; Morel, P.; Fortes-Patella, R.; Reboud, J. Numericalsimulation of turbopump inducer cavitating behavior. Int. J. Rotating Mach. 2014, 2005, 135–142. [Google Scholar] [CrossRef]

- Pasini, A.; Hadavandi, R.; Valentini, D.; Pace, G.; D’AGostino, L. Dynamics of the blade channel of an inducer under cavitation-induced instabilities. In Proceedings of the International Symposium on Transport Phenomena and Dynamics of Rotating Machinery, Maui, HI, USA, 16–21 December 2017. [Google Scholar]

- Xu, X. Research on Low Temperature Cavitation Characteristics of LNG Submersible Pump. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2020. Available online: https://d.wanfangdata.com.cn/thesis/ChhUaGVzaXNOZXdTMjAyNDA5MjAxNTE3MjUSCUQwMjAzNjUxMRoIampoc2hzM2c%3D (accessed on 15 July 2025).

- Schnerr, G.H.; Sauer, J. Physical and numerical modeling of unsteady cavitation dynamics. In Proceedings of the Fourth International Conference on Multiphase Flow, New Orleans, LA, USA, 21 May–1 June 2001; pp. 1–8. [Google Scholar]

- Cao, J.; Luo, Y.; Shi, Y.; Liu, X.; Xu, D.; Wang, Y.; Zhai, L.; Wang, Z. A review of hydro-turbine unit rotor system dynamic behavior: Multi-field coupling of a three-dimensional model. Phys. Fluids 2024, 36, 121304. [Google Scholar] [CrossRef]

- Lu, Y.; Xin, L.; Hu, N.; Zhu, Z.; Xia, W. Influences of floating ice on the water entry process of slender body on the cavity evolution and hydrodynamic characteristic. Phys. Fluids 2025, 37, 042103. [Google Scholar] [CrossRef]

- Long, Y.; Wu, Z.; Zhang, M.; Xu, Y. Research on the transient flow and vortex structure evolution mechanism of reactor coolant pump under non-uniform inflow. Ann. Nucl. Energy 2025, 217, 111346. [Google Scholar] [CrossRef]

- Long, Y.; Xu, Y.; Guo, X.; Zhang, M. Analysis of internal flow excitation characteristics of reactor coolant pump based on, P.O.D. Ann. Nucl. Energy 2025, 216, 111286. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, N.; Zheng, F.; Gad, M.; Gao, B. Experimental investigation on the effect of the rotor-stator matching mode on velocity pulsation in the centrifugal pump with a vaned diffuser. Nucl. Eng. Technol. 2024. [Google Scholar] [CrossRef]

- Li, D.; Zhang, N.; Jiang, J.; Gao, B.; Alubokin, A.A.; Zhou, W.; Shi, J. Numerical investigation on the unsteady vortical structure and pressure pulsations of a centrifugal pump with the vaned diffuser. Int. J. Heat Fluid Flow 2022, 98, 109050. [Google Scholar] [CrossRef]

- Wang, W.; Liu, S.; Pei, J.; Sun, J.; Sun, Q. Efficiency improvement and pressure pulsation reduction of volute centrifugal pump through diffuser design optimization. J. Energy Storage 2024, 102, 114184. [Google Scholar] [CrossRef]

| Physical Parameters | Liquid | Gas |

|---|---|---|

| Temperature | −163 °C | −163 °C |

| Molar mass (g/mol) | 17.0246 | 16.0436 |

| Pressure (MPa) | 0.084 | 0.084 |

| Density (kg/m3) | 442.2 | 1.6598 |

| Dynamic viscosity (Pa s) | 13.56 | 43.45 |

| Factors | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Number of blades, Z | 2 | 3 | — |

| Inlet angle, | +2° | −2° | ±0° |

| Outlet angle, | +2° | −2° | ±0° |

| Blade wrap angle, φ | +5° | −5° | ±0° |

| Sample | Z | |||

|---|---|---|---|---|

| 1 | 2 | ±0° | ±0° | ±0° |

| 2 | 2 | −2° | +2° | −5° |

| 3 | 2 | +2° | −2° | +5° |

| 4 | 2 | ±0° | +2° | +5° |

| 5 | 2 | −2° | −2° | ±0° |

| 6 | 2 | +2° | ±0° | −5° |

| 7 | 3 | ±0° | −2° | −5° |

| 8 | 3 | −2° | ±0° | +5° |

| 9 | 3 | +2° | +2° | ±0° |

| Flow-Through Parts | Number of Elements | Number of Nodes | Minimum Mesh Quality | Average Mesh Quality |

|---|---|---|---|---|

| Inlet section | 106,307 | 20,850 | 0.313 | 0.837 |

| Inducer | 1,213,646 | 224,119 | 0.178 | 0.834 |

| Impeller | 387,883 | 76,157 | 0.231 | 0.833 |

| Guide vane | 771,208 | 150,428 | 0.212 | 0.834 |

| Outlet section | 666,537 | 129,193 | 0.254 | 0.837 |

| Test | Head H/m | Efficiency η/% | Critical Cavitation Margin NPSHr/m |

|---|---|---|---|

| 1 | 184.400 | 83.40 | 35.95 |

| 2 | 184.873 | 83.47 | 29.04 |

| 3 | 182.139 | 83.60 | 35.96 |

| 4 | 183.661 | 82.95 | 35.03 |

| 5 | 183.529 | 83.17 | 31.35 |

| 6 | 185.226 | 83.26 | 30.19 |

| 7 | 185.669 | 82.02 | 44.03 |

| 8 | 184.494 | 81.50 | 44.25 |

| 9 | 184.224 | 81.78 | 46.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Song, W.; Lin, X.; Zhao, Y.; Lu, Y. Study on the Influence of Inducer Structure Change on Pump Cavitation Characteristics. Energies 2025, 18, 4059. https://doi.org/10.3390/en18154059

Wang Z, Song W, Lin X, Zhao Y, Lu Y. Study on the Influence of Inducer Structure Change on Pump Cavitation Characteristics. Energies. 2025; 18(15):4059. https://doi.org/10.3390/en18154059

Chicago/Turabian StyleWang, Zhengwei, Wei Song, Xuanyi Lin, Yun Zhao, and Yonggang Lu. 2025. "Study on the Influence of Inducer Structure Change on Pump Cavitation Characteristics" Energies 18, no. 15: 4059. https://doi.org/10.3390/en18154059

APA StyleWang, Z., Song, W., Lin, X., Zhao, Y., & Lu, Y. (2025). Study on the Influence of Inducer Structure Change on Pump Cavitation Characteristics. Energies, 18(15), 4059. https://doi.org/10.3390/en18154059