Technology for the Production of Energy Briquettes from Bean Stalks

Abstract

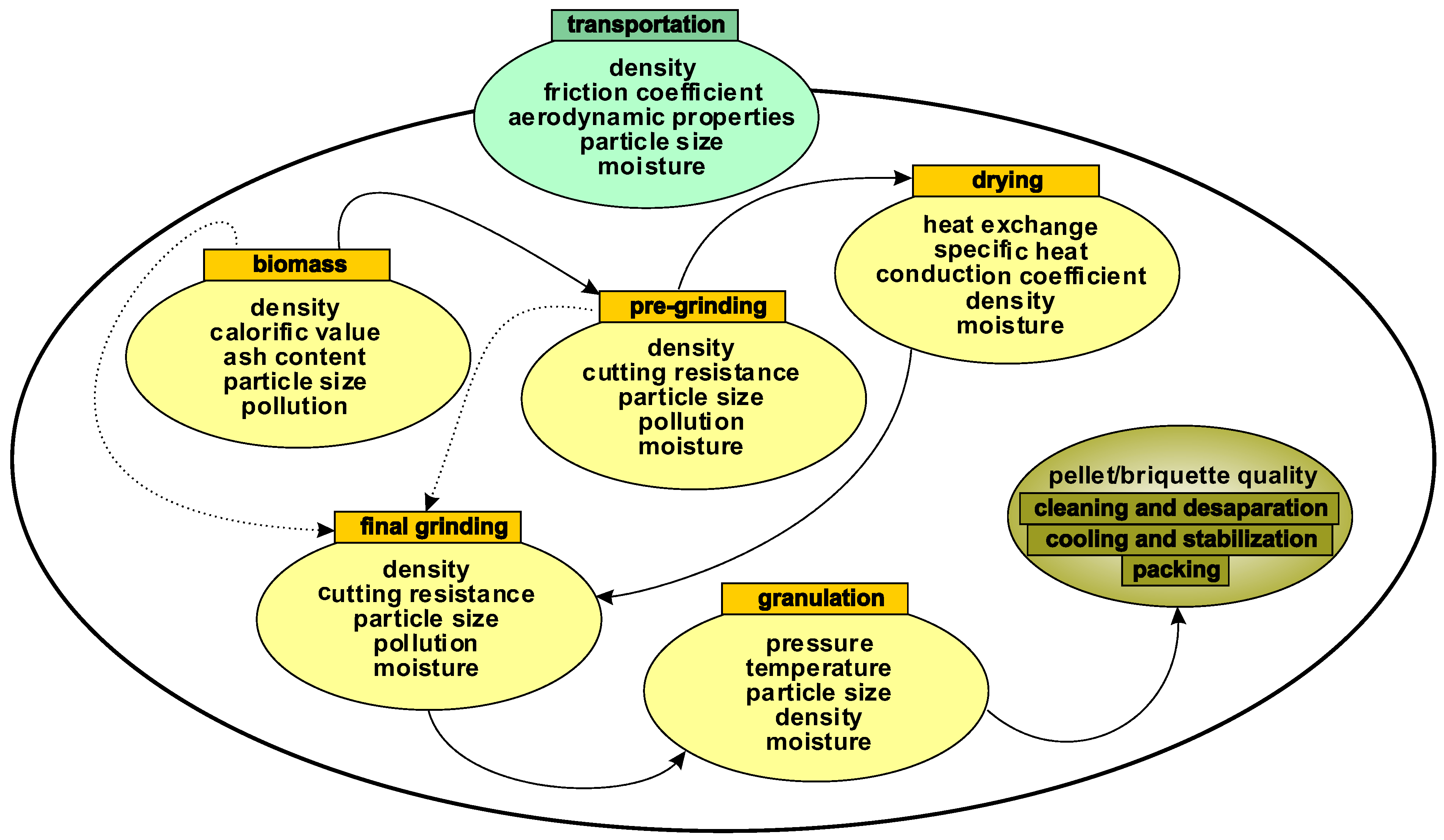

1. Introduction

- -

- ensure consistent fuel quality;

- -

- define the responsibilities and obligations of market participants to guarantee legal compliance and safety for all stakeholders;

- -

- support the harmonization of different stages along the supply chain by specifying acceptable ranges for quality indicators;

- -

- inform end users about the characteristic properties of the product.

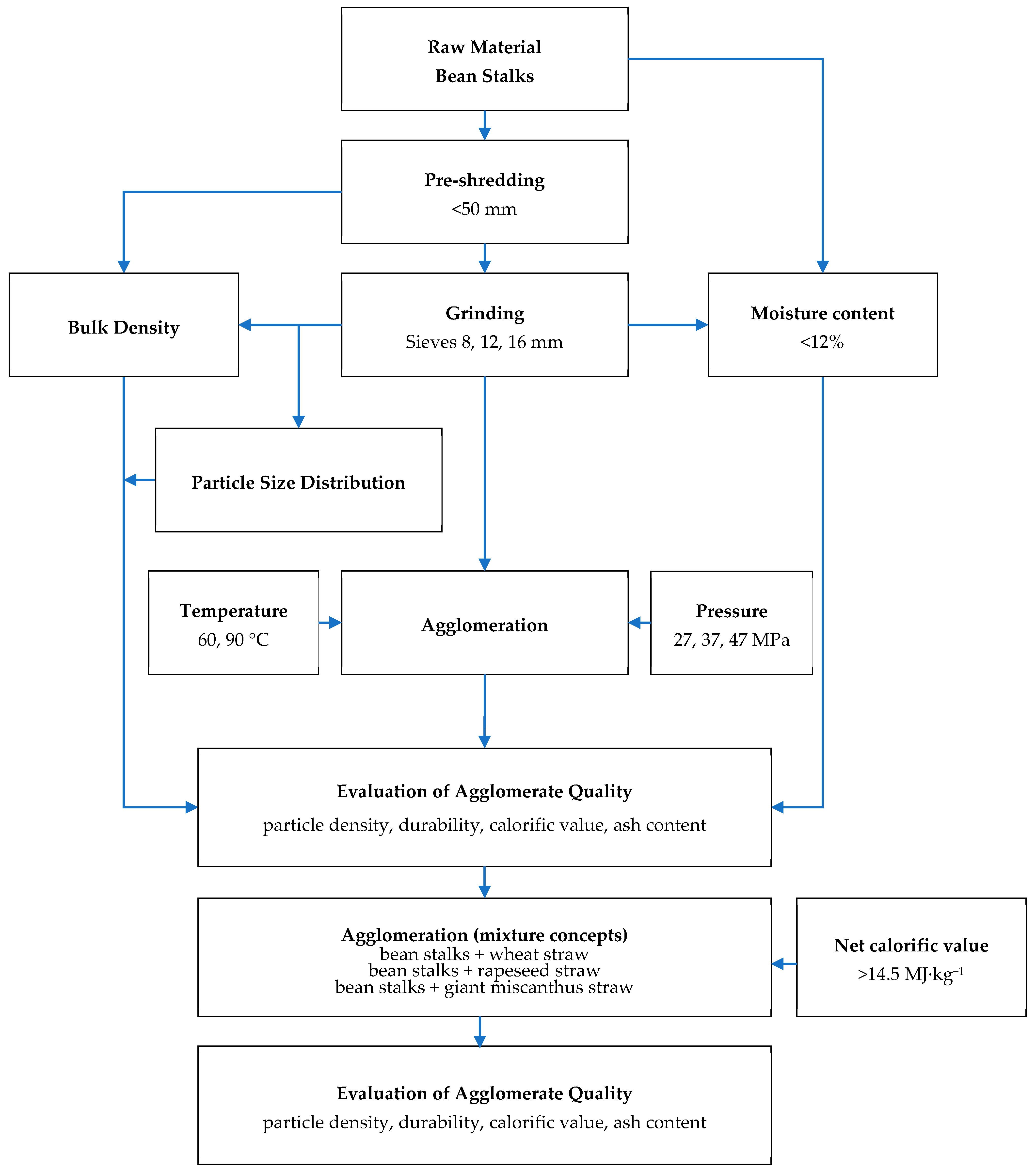

2. Materials and Methods

- Working moisture content after harvest (in baled form): 20–28%;

- Ash content: 7–10%;

- Crude fiber (cellulose + hemicellulose + lignin): 35–45%;

- Carbon content (C): 45–49%;

- Hydrogen content (H): 5.5–6.4%;

- Nitrogen content (N): 0.5–1.2%;

- Sulfur content (S): <0.1%.

- -

- without die heating—the temperature was determined solely by the heat generated during the operation of the compaction unit, reaching approximately 60 °C;

- -

- with a heating sleeve—designed to maintain the inner surface of the die at 90 °C.

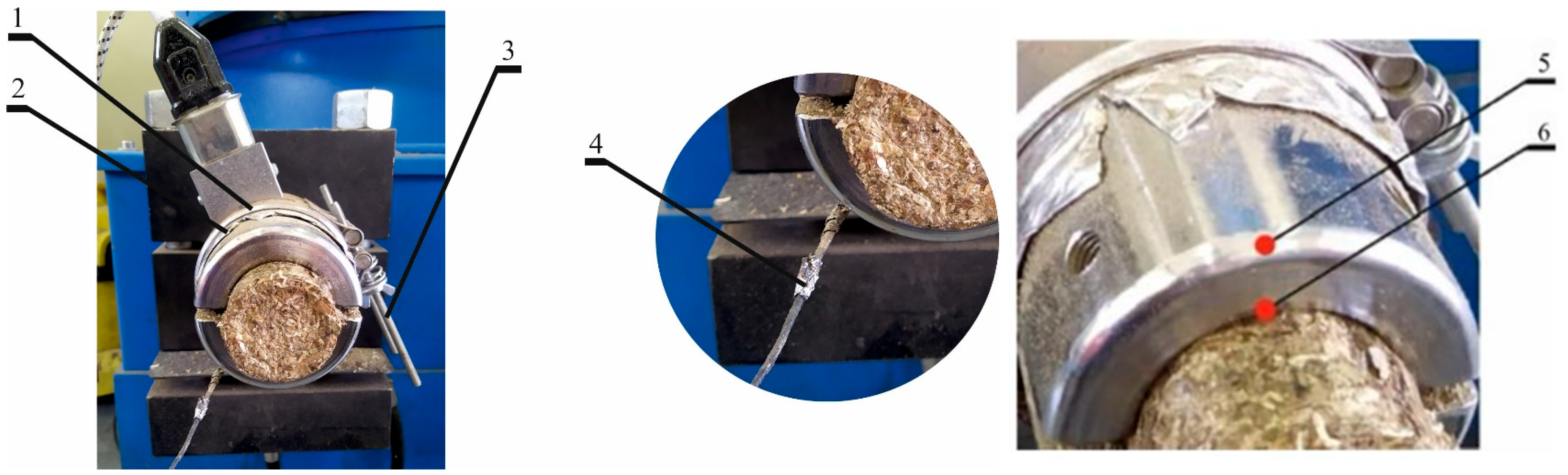

Determination of Quality Parameters of Agglomerates

3. Results and Discussions

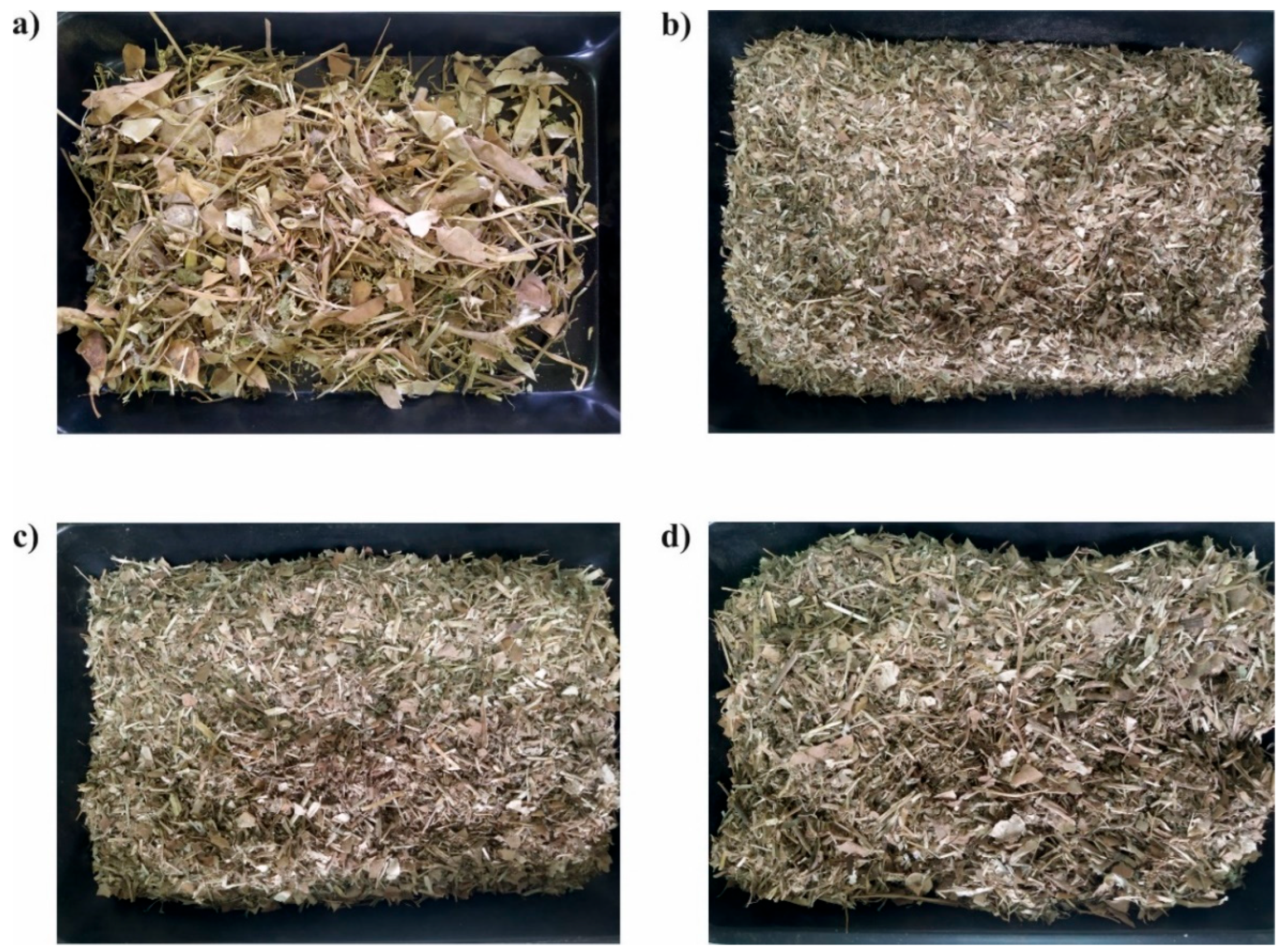

3.1. Selected Physical Properties of Bean Stalks

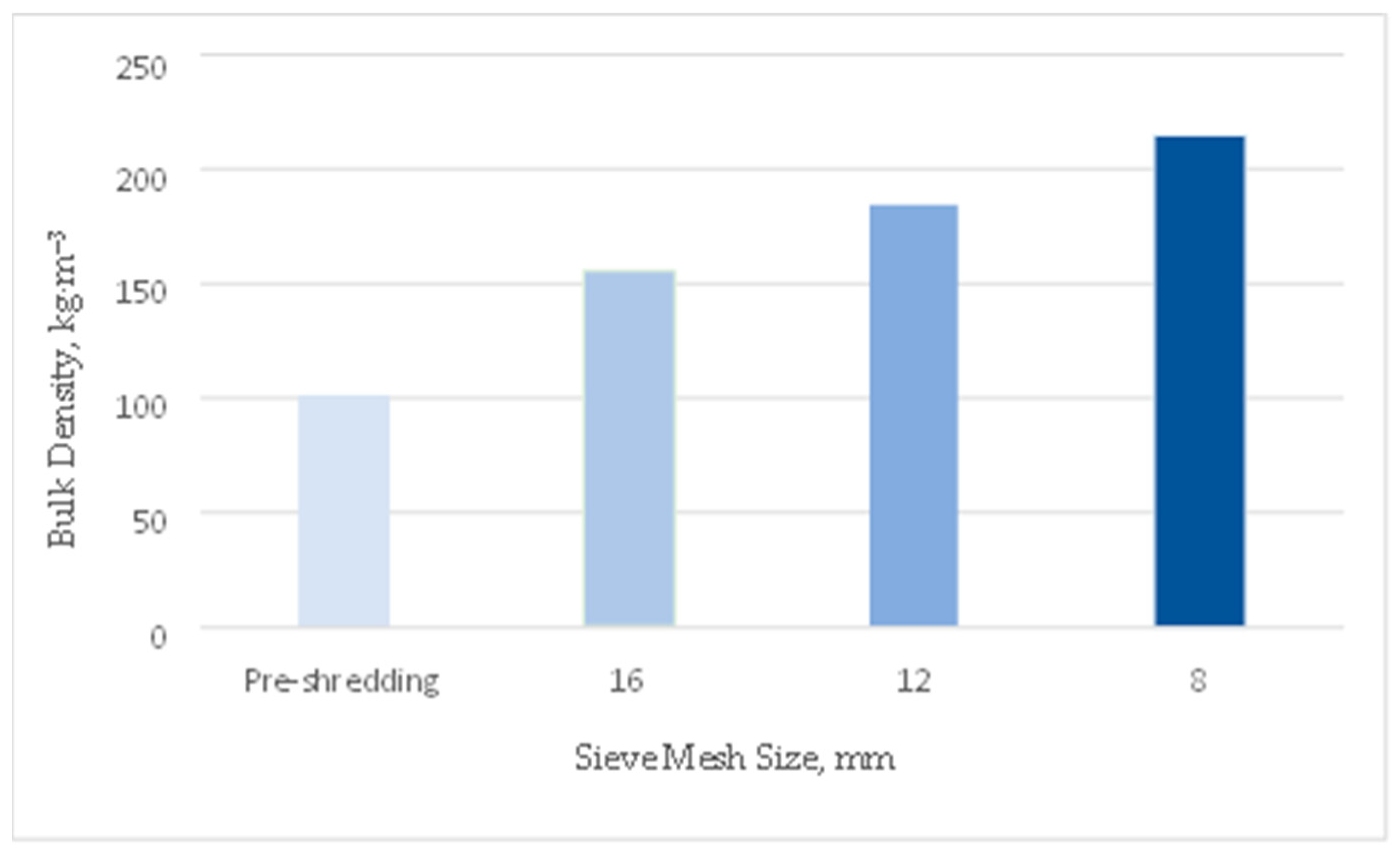

3.1.1. Bulk Density

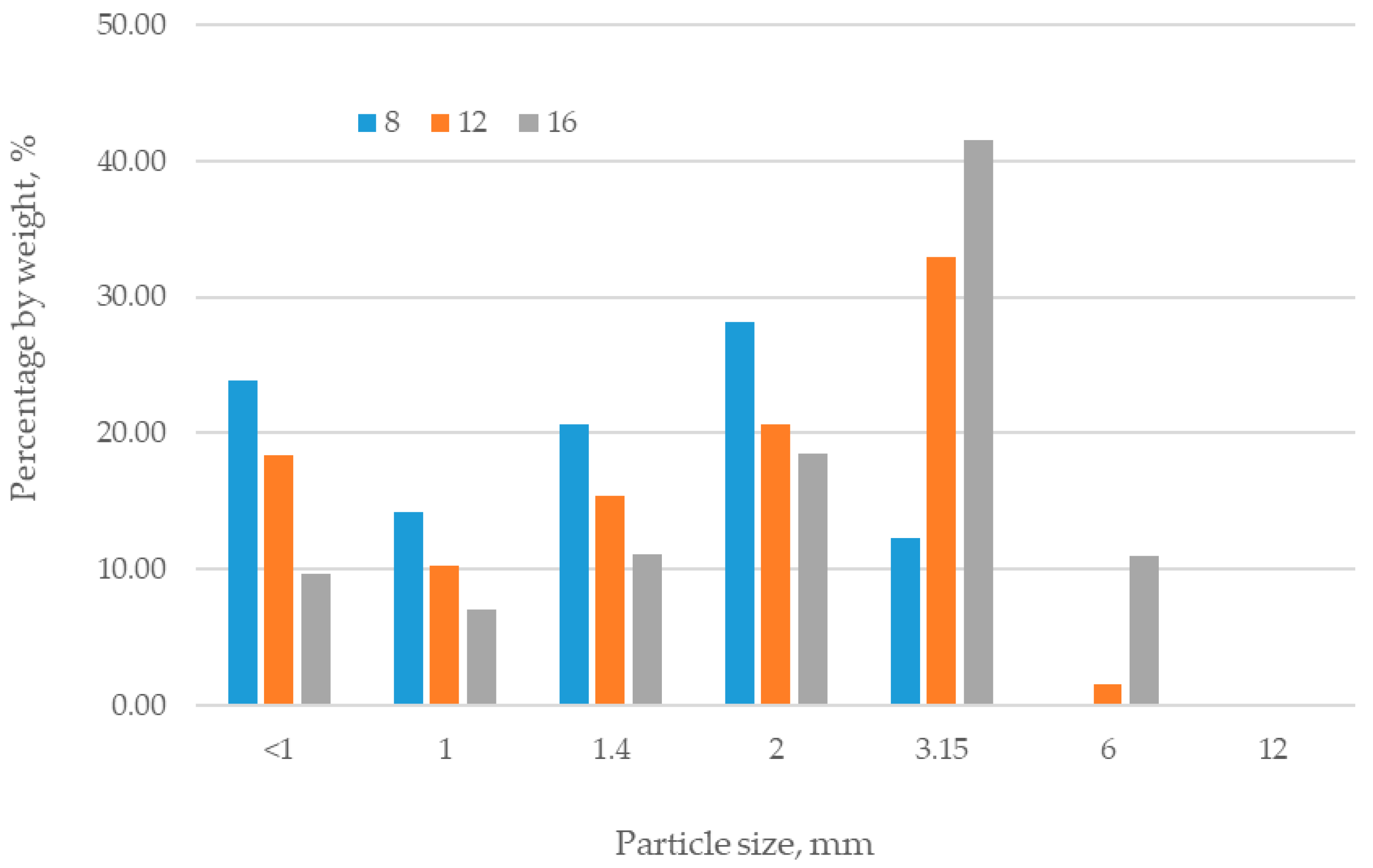

3.1.2. Particle Size Distribution

- -

- a and b—where a represents the difference in the position of the 30% mass share threshold between the 12 mm and 8 mm sieves and b refers to the analogous difference between the 16 mm and 12 mm sieves;

- -

- a* and b*—where a* represents the difference in the position of the 90% mass share threshold between the 12 mm and 8 mm sieves and b* refers to the analogous difference between the 16 mm and 12 mm sieves.

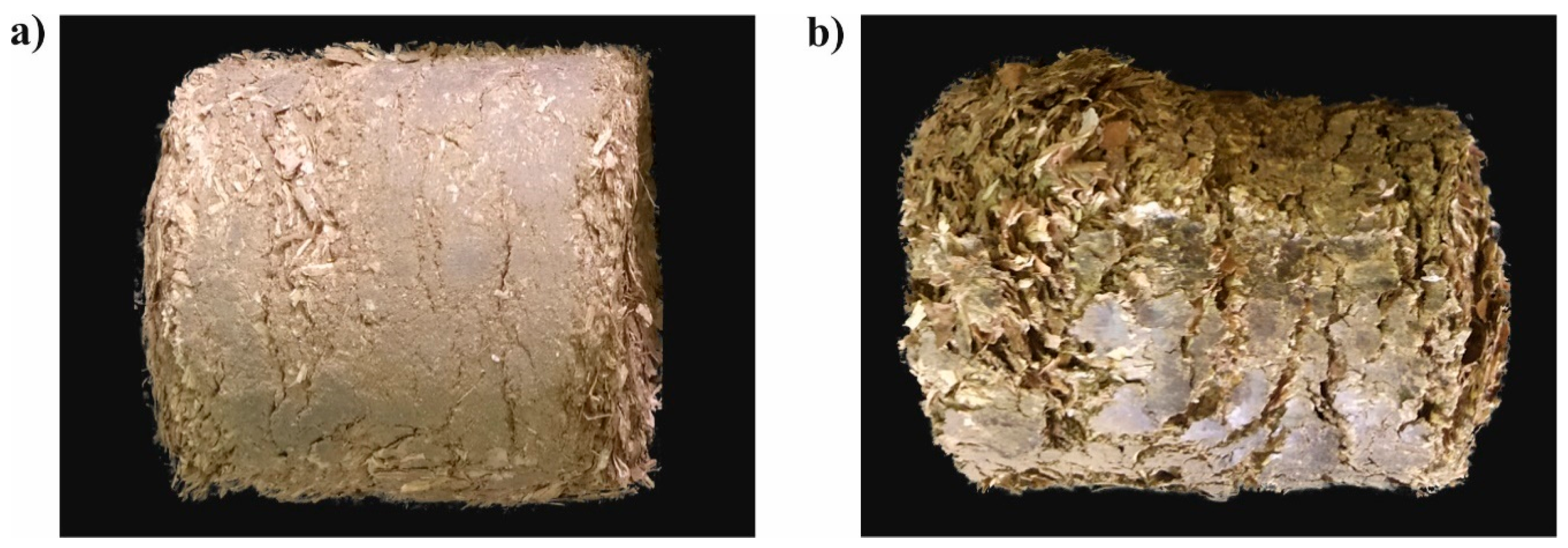

3.2. Briquette Quality Parameters

3.2.1. Moisture Content

3.2.2. Ash Content

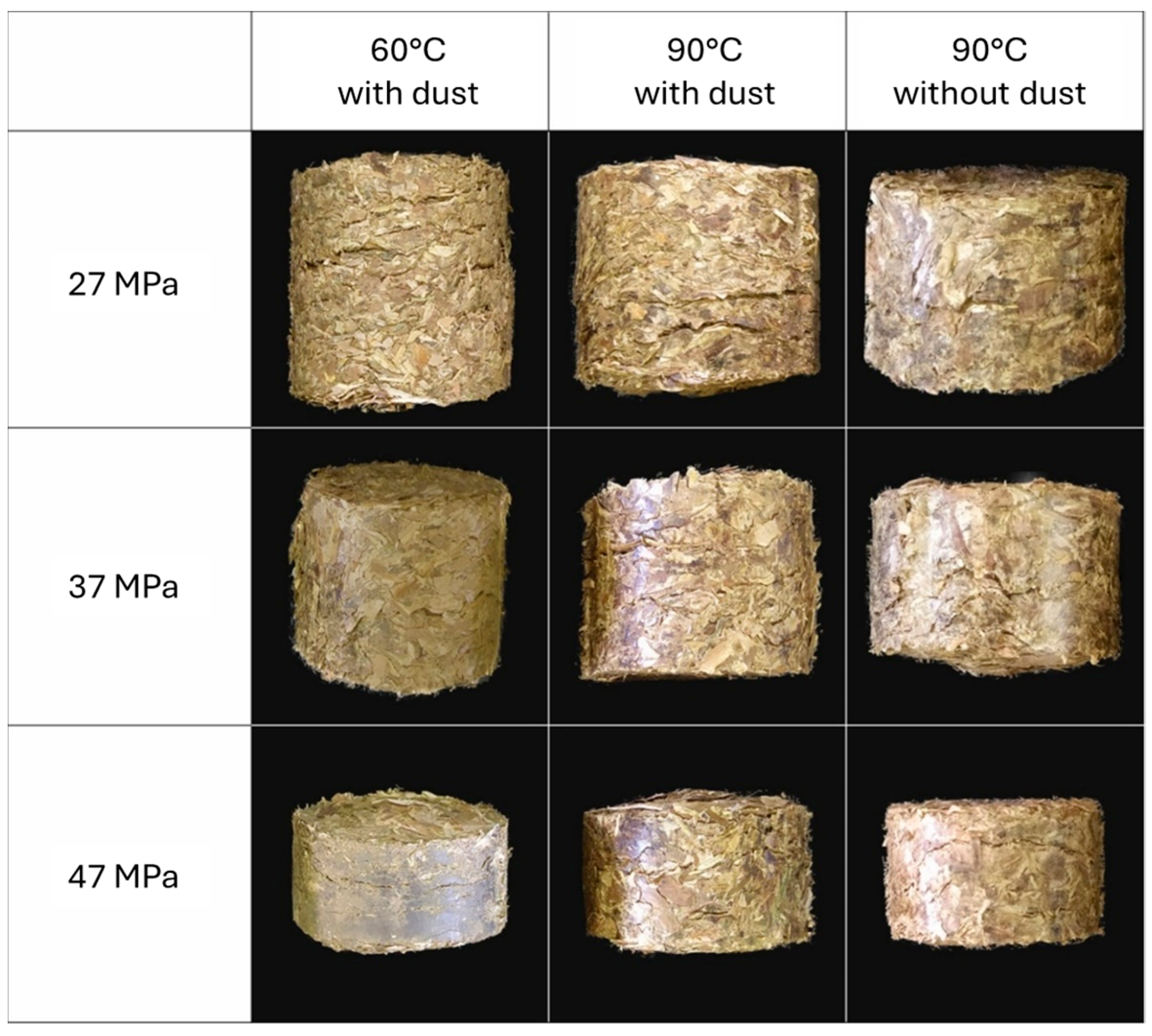

3.2.3. Particle Density (DE)

3.2.4. Calorific Value

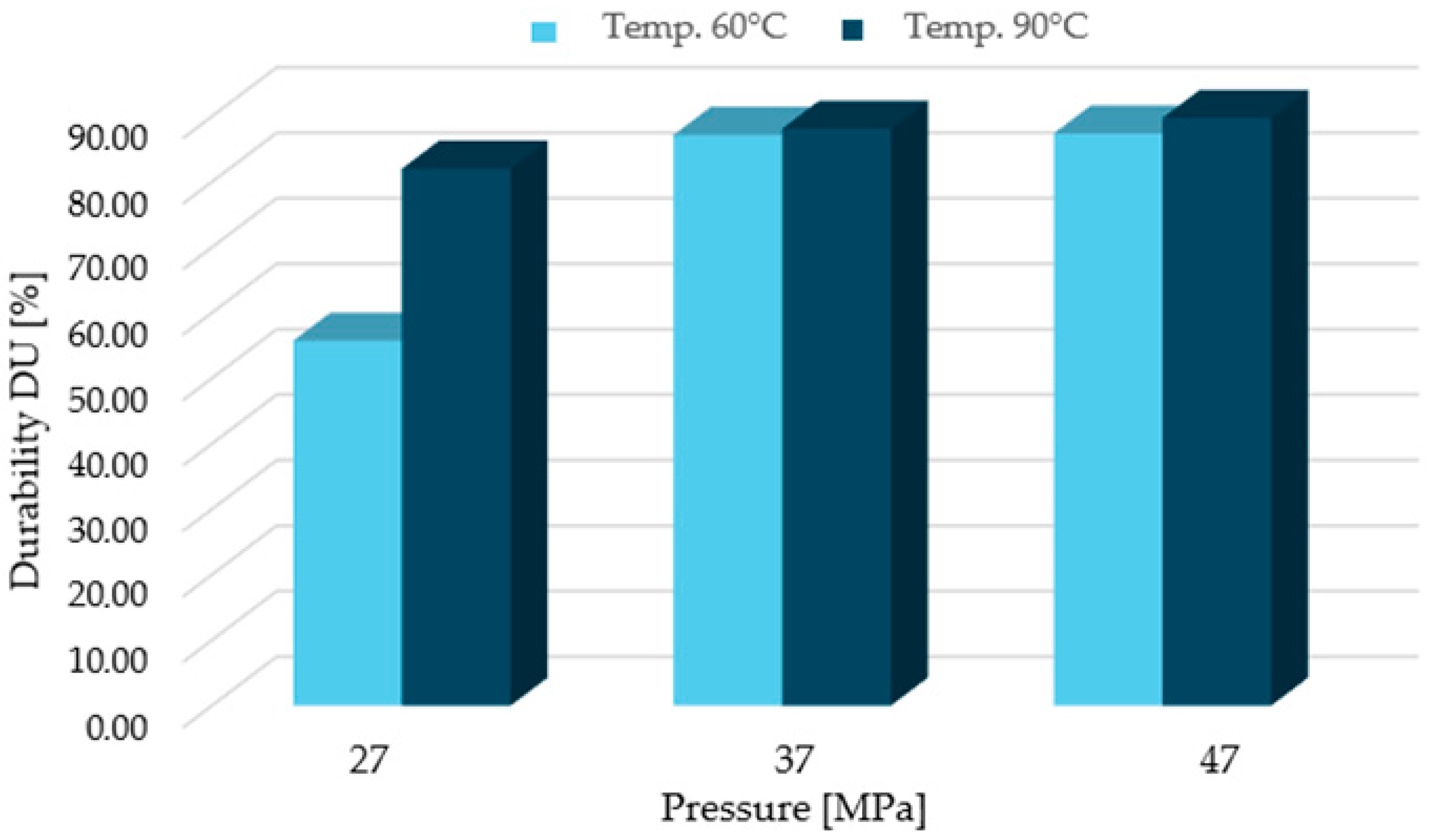

3.2.5. Durability (DU)

3.2.6. Durability of Briquettes Without the <1 mm Fraction

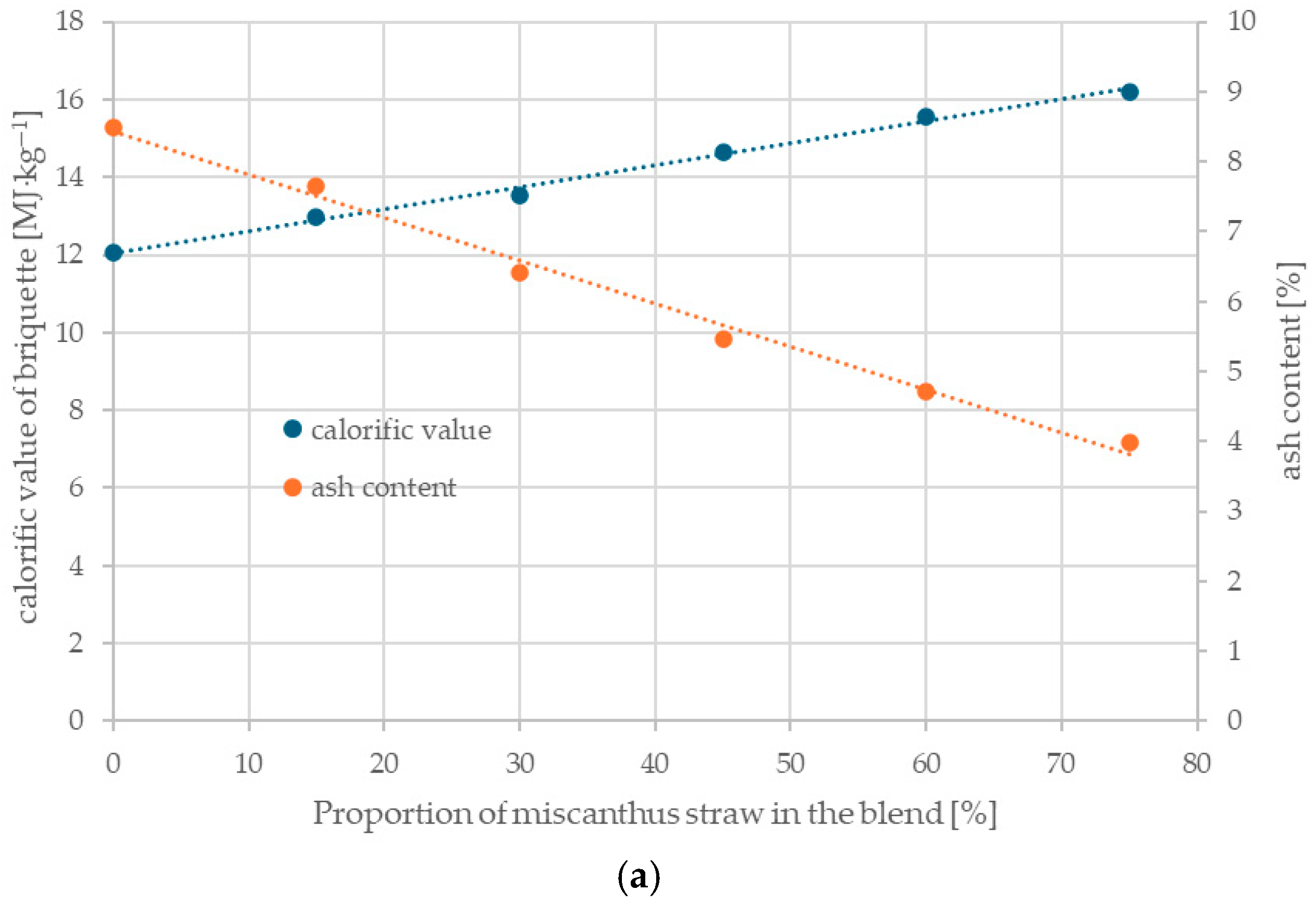

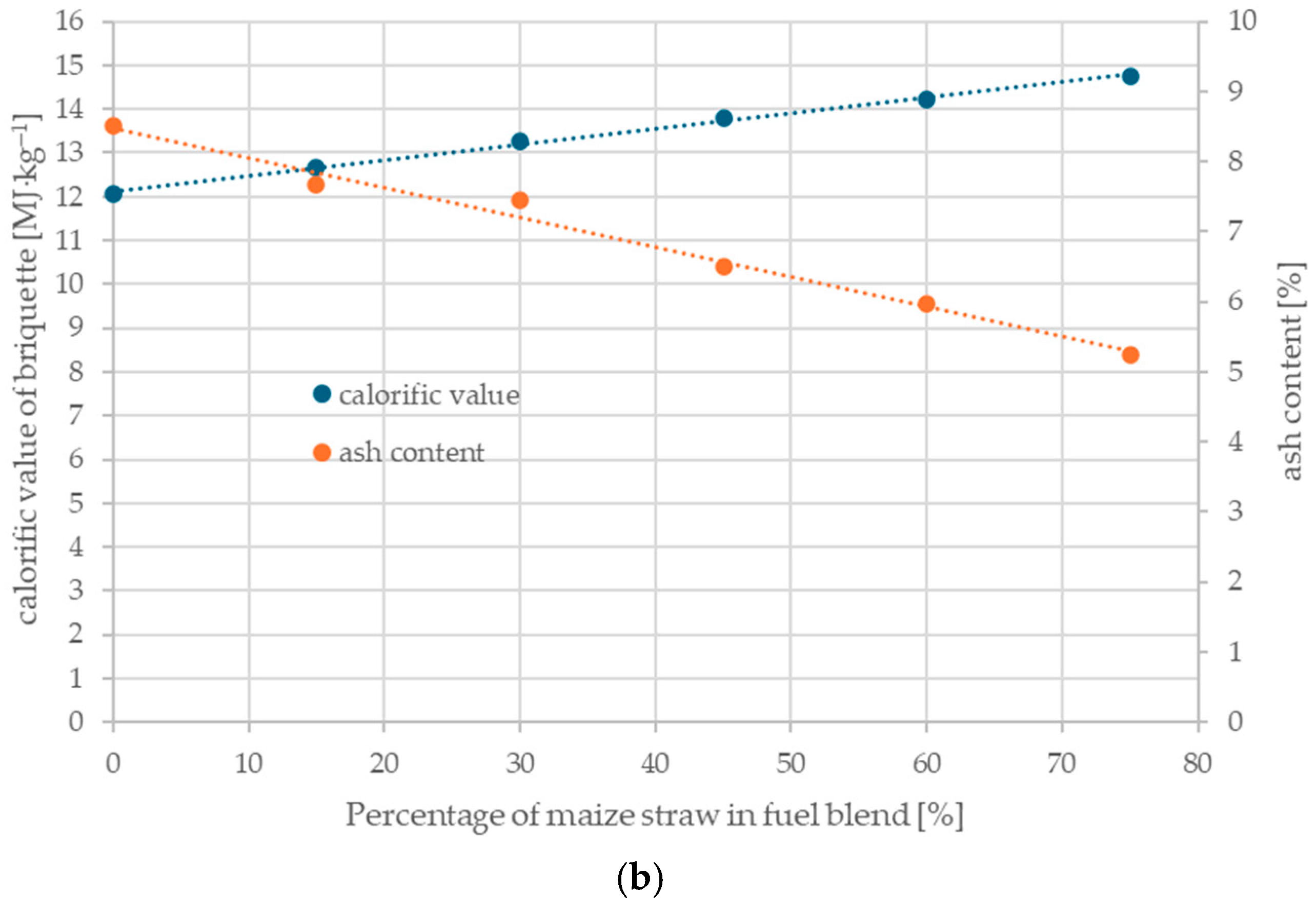

3.3. Results of the Process of Modification of Raw Material Mixtures

4. Conclusions

- The highest bulk density of shredded bean stalks was obtained for material from the 8 mm sieve fraction (215 kg·m−3), while the lowest was recorded for the 16 mm fraction (155 kg·m−3), confirming the significant influence of particle size on the technological properties of biomass.

- The ash content in the primary raw material (bean stalks) decreased from 10.5% to 8.5% after removing the dust fraction (<1 mm), indicating the potential to improve fuel quality through simple separation of mineral particles.

- The net calorific value of pure bean stalks was 11.85 MJ·kg−1. After the removal of the <1 mm fraction, it increased to 12.05 MJ·kg−1. Nevertheless, this value remains below the threshold required for Class B fuels according to PN-EN ISO 17225-7:2021.

- The highest mechanical durability of briquettes was achieved at the highest compaction pressure (47 MPa) and with larger particle sizes (8–12 mm). Additionally, raising the die temperature facilitated partial lignin vitrification, resulting in improved cohesion and hydrophobicity of the briquettes.

- Bean stalks represent a promising agricultural biomass feedstock for the production of Class B briquettes, but they require technological support in the form of additives with higher energy content.

- Tests involving bean stalks blended with complementary biomass demonstrated that as follows:

- mixtures with 30% maize straw achieved a net calorific value close to 14.6 MJ·kg−1 and ash content reduced to approximately 6.5%;

- increasing maize straw content to 45% allowed a stable calorific value of 15.1 MJ·kg−1 with ash content below 6%;

- mixtures with 30% miscanthus straw yielded a calorific value above 15.2 MJ·kg−1 and ash content below 5.5%; at 45% miscanthus, the calorific value reached 15.9 MJ·kg−1 with ash around 5%;

- mixtures containing 60–75% miscanthus achieved calorific values exceeding 16.5 MJ·kg−1 and ash contents below 4%, placing the fuel at the boundary of Class A2.

- The approach of blending locally available residual biomass streams aligns with the principles of the circular economy and decentralized energy systems. It offers practical opportunities for utilizing agricultural residues at the level of farms, municipalities, or small enterprises.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Adam, R.; Yiyang, D.; Kruggel-Emden, H.; Zeng, T.; Lenz, V. Influence of pressure and retention time on briquette volume and raw density during biomass densification with an industrial stamp briquetting machine. Renew. Energy 2024, 229, 120773. [Google Scholar] [CrossRef]

- Akande, O.M.; Olorunnisola, A.O. Potential of Briquetting as a Waste-Management Option for Handling Market-Generated Vegetable Waste in Port Harcourt, Nigeria. Recycling 2018, 3, 11. [Google Scholar] [CrossRef]

- Yub Harun, N.; Parvez, A.M.; Afzal, M.T. Process and Energy Analysis of Pelleting Agricultural and Woody Biomass Blends. Sustainability 2018, 10, 1770. [Google Scholar] [CrossRef]

- Ali, M.A.; Nasir, A.; Muneer, A.; Ali, S.; Rashid, U. Compaction characteristics of sawdust, cotton stalks, maize straw and rice straw briquettes. J. Energy Env. Carbon Credit. 2015, 5, 1–9. [Google Scholar]

- Antar, M.; Lyu, D.; Nazari, M.; Shah, A.; Zhou, X.; Smith, D.L. Biomass for a sustainable bioeconomy: An overview of world biomass production and utilization. Renew. Sustain. Energy Rev. 2021, 139, 110691. [Google Scholar] [CrossRef]

- Araque, O.; Arzola, N.; Gallego, L. Mechanical Behavior of Briquettes Made from a Mixture of Sawdust and Rice Husks for Commercialization. Resources 2022, 11, 32. [Google Scholar] [CrossRef]

- Chidiebele, E.J.U.; Okoroigwe, E.; Kadivar, M.; Anye, V.C.; Bello, A.; Ezealigo, U.; Ngasoh, F.O.; Pereira, H.; Onwualu, P.A. Characterization of Wood, Leaves, Barks, and pod wastes from Prosopis africana biomass for biofuel production. Waste Manag. Bull. 2024, 2, 172–182. [Google Scholar] [CrossRef]

- Demirbaş, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Fiszer, A. Influence of straw humidity and temperature of briquetting process on the quality of agglomerate. J. Res. Appl. Agric. Eng. 2009, 54, 68–70. [Google Scholar]

- Tomei, J.; Helliwell, R. Food versus fuel? Going beyond biofuels. Land Use Policy 2016, 56, 320–326. [Google Scholar] [CrossRef]

- Frączek, J.; Cieślikowski, B.; Francik, S.; Ślipek, Z. Wpływ stopnia rozdrobnienia pędów wierzby oraz ciśnienia aglomeracji na trwałość brykietu. Logistyka-nauka 2014, 6, 3636–3641. (In Polish) [Google Scholar]

- Fraczek, J.; Cieślikowski, B.; Ślipek, Z. Ocena jakości biopaliw stałych kompaktowanych. Część I: Wymagania jakościowe. Autobusy. 2011, 58, 161–169. (In Polish) [Google Scholar]

- He, H.; Wang, Y.; Sun, Y.; Sun, W.; Wu, K. From raw material powder to solid fuel pellet: A state-of-the-art review of biomass densification. Biomass Bioenergy 2024, 186, 107271. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Rajan, K.; Hamilton, C.; Pope, C.; Rials, T.G.; McCord, J.; Labbé, N.; André, N.O. Pilot-Scale Pelleting Tests on High-Moisture Pine, Switchgrass, and Their Blends: Impact on Pellet Physical Properties, Chemical Composition, and Heating Values. Front. Energy Res. 2022, 9, 788284. [Google Scholar] [CrossRef]

- Gil, M.V.; Oulego, P.; Casal, M.D.; Pevida, C.; Pis, J.J.; Rubiera, F. Mechanical durability and combustion characteristics of pellets from biomass blends. Bioresour. Technol. 2010, 101, 8859–8867. [Google Scholar] [CrossRef] [PubMed]

- Ha, H.; Brown, T.R.; Quinn, R.J.; Volk, T.A.; Malmsheimer, R.W.; Fortier, M.-O.P.; Frank, J.R.; Bick, S. Economic feasibility of forest biomass feedstock supply chains: Clean and dirty chips for bioenergy applications. Biofuels Bioprod. Bioref. 2022, 16, 389–402. [Google Scholar] [CrossRef]

- Jeguirim, M.; Khiari, B. Solid biofuels production and combustion at domestic scales. In Advances in Biofuels Production, Optimization and Applications; Elsevier: Amsterdam, The Netherlands, 2024; pp. 207–239. ISBN 9780323950763. [Google Scholar]

- Jasiulewicz, M. Produkcja energii z agrobiomasy w Polsce i na tle wybranych krajów Unii Europejskiej, Stowarzyszenie Ekonomistów Rolnictwa i Agrobiznesu. Rocz. Nauk. T. 2015, 17, 94–99. (In Polish) [Google Scholar]

- Hamid, A.; Muaddah, H.H.; Sharif Za’ba, A.S.; Afandy, M.D. Biomass briqmure: BBQ briquettes fuel source from cow manure. Educ. Humanit. Res. 2021, 536, 457–460. [Google Scholar]

- Ivaschuk, V.P.; Atamanyuk, V.M.; Chyzhovych, R.A.; Kiiaieva, S.S.; Duleba, V.P.; Sobechko, I.B. Research of solid fuel briquettes obtaining from brewer’s spent grain. J. Chem. Technol. 2022, 30, 216–221. [Google Scholar]

- Jha, S.; Okolie, J.A.; Nanda, S.; Dalai, A.K. A Review of Biomass Resources and Thermochemical Conversion Technologies. Chem. Eng. Technol. 2022, 45, 791–799. [Google Scholar] [CrossRef]

- Krenz, L.M.M.; Grebenteuch, S.; Zocher, K.; Rohn, S.; Pleissner, D. Valorization of faba bean (Vicia faba) by-products. Biomass Convers. Biorefinery 2024, 14, 26663–26680. [Google Scholar] [CrossRef]

- Kajda-Szczęśniak, M. Ocena jakości brykietów wykonanych w oparciu o słomę kukurydzy i polietylenu o niskiej gęstości. Arch. Gospod. Odpad. I Ochr. Sr. 2012, 14, 41–50. (In Polish) [Google Scholar]

- Study “Protein crop market in Poland”. Available online: https://www.agroberichtenbuitenland.nl/landeninformatie/polen/achtergrond/protein-crop-market-in-poland (accessed on 22 July 2025).

- Hesami, M.; Yoosefzadeh-Najafabadi, M. Trends in production, consumption, trade, and research of dry beans across the globe and Canada. Can. J. Plant Sci. 2025, 105, 1–14. [Google Scholar] [CrossRef]

- Akibode, C.S.; Maredia, M.K. Global and Regional Trends in Production, Trade and Consumption of Food Legume Crops. 2012. Available online: https://ageconsearch.umn.edu/record/136293?v=pdf (accessed on 22 July 2025). [CrossRef]

- Stelte, W.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.; Sanadi, A.R. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Marreiro, H.M.P.; Peruchi, R.S.; Lopes, R.M.B.P.; Andersen, S.L.F.; Eliziário, S.A.; Rotella, P., Jr. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies 2021, 14, 8320. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Jekayinfa, S.O.; Dittrich, C.; Obi, O.F.; Pecenka, R. Effects of Feeding Speed and Temperature on Properties of Briquettes from Poplar Wood Using a Hydraulic Briquetting Press. Resources 2023, 12, 12. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- PN-EN ISO 17225-7; Solid Biofuels—Fuel Specifications and Classes—Part 7: Graded Non-Woody Briquettes. Polish Standardization Committee: Warsaw, Poland, 2021.

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Briquetting characteristics of bean straw-maize cob blend. Biomass Bioenergy 2019, 126, 150–158. [Google Scholar] [CrossRef]

- Obidziński, S.; Kobyliński, M.; Dec, D.; Piekut, J. Badania procesu brykietowania mieszanin materiałów odpadowych pochodzenia roślinnego. Postępy Tech. Przetwórstwa Spożywczego 2015, 1, 126–130. (In Polish) [Google Scholar]

- Jasinskas, A.; Minajeva, A.; Šarauskis, E.; Romaneckas, K.; Kimbirauskienė, R.; Pedišius, N. Recycling and utilisation of faba bean harvesting and threshing waste for bioenergy. Renew. Energy 2020, 162, 257–266. [Google Scholar] [CrossRef]

- Trejo-Zamudio, D.; Gutiérrez-Antonio, C.; García-Trejo, J.F.; Feregrino-Pérez, A.A.; Toledano-Ayala, M. Production of fuel pellets from bean crop residues (Phaseolus vulgaris). IET Renew. Power Gener. 2022, 16, 2978–2987. [Google Scholar] [CrossRef]

- Petlickaitė, R.; Jasinskas, A.; Mieldažys, R.; Romaneckas, K.; Praspaliauskas, M.; Balandaitė, J. Evaluation of the processing of multi-crop plants into pelletized biofuel and its use for energy conversion. Processes 2023, 11, 421. [Google Scholar] [CrossRef]

- PN-EN ISO 17225-6; Solid Biofuels—Fuel Specifications and Classes—Part 6: Graded Non-Woody Pellets. Polish Standardization Committee: Warsaw, Poland, 2021.

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N.; Manning, D.A.C. Kinetics of maize cob and bean straw pyrolysis and combustion. Heliyon 2023, 9, e17236. [Google Scholar] [CrossRef]

- Lopez, A.; Morales, M.S. Intake and apparent digestibility of forages in llamas (Lama glama). II. clover hay (Trifolium pratense), ryegrass hay (Lolium multiflorum), beans straw (Phaseolus vulgaris) and oat straw (Avena sativa). Arch. Med. Vet. 2001, 33, 145–153. [Google Scholar] [CrossRef]

- Arija, I.; Centeno, C.; Viveros, A.; Brenes, A.; Marzo, F.; Illera, J.C.; Silvan, G. Nutritional Evaluation of Raw and Extruded Kidney Bean (Phaseolus vulgaris L. var. Pinto) in Chicken Diets. Poult. Sci. 2006, 85, 635–644. [Google Scholar] [CrossRef]

- PN-EN ISO 18134-1:2015-11; Solid Biofuels—Determination of Moisture Content—Drying Method—Part 1: Total Mois-Ture—Reference Method. ISO: Polish Standardization Committee: Warsaw, Poland, 2015.

- PN EN ISO 17828:2016; Solid biofuels—Determination of Bulk Density. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN-ISO 17831-2:2016-02; Solid Biofuels—Methods for the Determination of Mechanical Durability of Pellets and Briquettes—Part 2: Briquettes. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 18122:2016-01; Solid Biofuels—Determination of Ash Content. Polish Standardization Committee: Warsaw, Poland, 2016.

- PN-EN ISO 18125:2017-07; Solid Biofuels—Determination of Calorific Value. Polish Standardization Committee: Warsaw, Poland, 2017.

- PN-EN ISO 17225-3:2021-08; Solid Biofuels—Fuel Specifications and Classes—Part 3: Graded Wood Briquettes. Polish Standardization Committee: Warsaw, Poland, 2021.

- De Monte, C.; Arrighetti, L.; Ricci, L.; Civello, A.; Bronco, S. Agro-Waste Bean Fibers as Reinforce Materials for Polycaprolactone Composites. Compounds 2023, 3, 504–520. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Densification characteristics of corn stover and switchgrass. Trans. ASABE 2009, 52, 907–920. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. The Pellet Handbook: The Production and Thermal Utilization of Biomass Pellets; Earthscan: London, UK, 2010; ISBN 9781844076314. [Google Scholar]

- Stelte, W.; Clemons, C.; Holm, J.K.; Sanadi, A.R.; Ahrenfeldt, J.; Shang, L.; Henriksen, U. Pelletizing properties of torrefied spruce. Biomass Bioenergy 2011, 35, 4690–4698. [Google Scholar] [CrossRef]

| Parameter | Okot et al. (2019) [32] | Obidziński et al. (2015) [33] | Jasinskas et al. (2022) [34] | Trejo_Zamudio et al. (2022) [35] | Petlickaitė et al. (2022) [36] | Krenz et al. (2024) [22] | Standard PN-EN ISO 17225-7 | |

|---|---|---|---|---|---|---|---|---|

| Briquette Class A | Briquette Class B | |||||||

| Pressure (MPa) | 100–250 | 120–200 | 100–180 | 90–150 | 80–140 | 110–190 | - | - |

| Temperature (°C) | 20–80 | 70–90 | 50–90 | 60–85 | 60–100 | 70–90 | - | - |

| Moisture content (%) | 10–15 | 8–12 | 10–14 | 9–13 | 9–15 | 10–14 | M12 ≤ 12 | M15 ≤ 15 |

| Particle size (mm) | <4 | <5 | <4 | <4 | <4 | <4 | - | - |

| Density (g·cm−3) | 0.886–1.123 | 0.9–1.1 | 0.85–1.05 | 0.88–1.1 | 0.87–1.05 | 0.9–1.15 | DE0.9 ≥ 0.9 | DE0.6 ≥ 0.6 |

| Durability DU (%) | >96 | >90 | >92 | >90 | >91 | >93 | - | - |

| Net calorific value (MJ·kg−1) | 16.5–18.2 | 16.8–18.0 | 16.2–17,8 | 16.0–17.5 | 16.5–18.1 | 16.7–18.3 | Q14.5 ≥ 14.5 | Q14.5 ≥ 14.5 |

| Sample | Ash (%) | Ash (%) (After Sieving) |

|---|---|---|

| I | 10.44 | 8.63 |

| II | 11.42 | 8.49 |

| III | 9.55 | 8.33 |

| Average | 10.5 | 8.5 |

| Temperature (°C) | Fraction (mm) | Pressure (MPa) | Particle Density (kg·m−3) |

|---|---|---|---|

| 60 | 8 | 27 | 845.35 |

| 37 | 925.56 | ||

| 47 | 984.11 | ||

| 12 | 27 | 854.31 | |

| 37 | 900.88 | ||

| 47 | 913.82 | ||

| 16 | 27 | 803.97 | |

| 37 | 846.36 | ||

| 47 | 898.31 | ||

| 90 | 8 | 27 | 754.98 |

| 37 | 838.71 | ||

| 47 | 875.58 | ||

| 12 | 27 | 755.78 | |

| 37 | 831.23 | ||

| 47 | 882.32 | ||

| 16 | 27 | 849.75 | |

| 37 | 868.25 | ||

| 47 | 884.12 |

| Sample | Sample with Dust | Sample Without Dust | ||

|---|---|---|---|---|

| Gross Calorific Value | Net Calorific Value | Gross Calorific Value | Net Calorific Value | |

| MJ·kg−1 | MJ·kg−1 | MJ·kg−1 | MJ·kg−1 | |

| I | 15.11 | 11.85 | 15.42 | 12.07 |

| II | 5.12 | 11.82 | 15.40 | 12.05 |

| III | 15.14 | 11.89 | 15.41 | 12.04 |

| Average | 15.12 | 11.85 | 15.41 | 12.05 |

| Particle Size Fraction (mm) | Mechanical Durability (DU) (%) |

|---|---|

| 8 | 84.80 |

| 12 | 86.03 |

| 16 | 90.41 |

| Parameter. | Unit | Normative Value/Class | Test Result | Remarks |

|---|---|---|---|---|

| Moisture content, M | % | ≤15/A1 | 12 | Constant across all agglomerates |

| Ash content, A | % | ≤10/B | 8.5 | After removal of <1 mm fraction |

| Particle density, DE | kg·m−3 | ≥0.6/B | ≥0.85 | Average across all fractions |

| Additives | % | <5/B | - | No additives used |

| Net calorific value, Q | MJ·kg−1 | ≥14.5/ (A1, A2, B) | 12.05 | For sample after removal of <1 mm fraction |

| Durability, DU | % | –/B | >90 | For 16 mm fraction, 47 MPa pressure, 90 °C die temperature |

| Parameter | Unit | Maize Straw | Giant Miscanthus Straw |

|---|---|---|---|

| Moisture content, M | % | 12 ± 0.5 | 12 ± 0.5 |

| Ash content, A | % | 4.3 ± 0.1 | 2.2 ± 0.1 |

| Net calorific value, Q | MJ·kg−1 | 15.5 ± 0.2 | 17.6 ± 0.15 |

| Mixture Bean Stalks+ | Share of Bean Stalks [%] | Share of Additive [%] | Net Calorific Value [MJ·kg−1] |

|---|---|---|---|

| Maize straw | 29.00 | 71.00 | 14.50 |

| Miscanthus straw | 55.90 | 44.10 | 14.50 |

| Parameter | 16 mm Fraction + 27 MPa | 16 mm Fraction + 47 MPa | Change (%) |

|---|---|---|---|

| Particle density | ~850 kg/m3 | ~955 kg/m3 | ↑ +12.35% |

| Mechanical durability | ~55.8% | ~91.0% | ↑ +63.1% (rel.) |

| Structural integrity | Low, cracked | Compact, stable | Qualitative gain |

| Parameter | Before Removal | After Removal | Change (%) |

|---|---|---|---|

| Ash content | 10.50% | 8.50% | ↓ –19.0% |

| Net calorific value | 11.85 MJ/kg | 12.05 MJ/kg | ↑ +1.7% |

| Mechanical durability | ~70–74% | +3–5 pp more | ↑ ~5–7% (estimated) |

| Additive and Share | Calorific Value | Ash Content | Classification |

|---|---|---|---|

| 30% maize straw | 14.6 MJ·kg−1 | ~6.5% | B |

| 45% maize straw | 15.1 MJ·kg−1 | <6% | B |

| 30% miscanthus | >15.2 MJ·kg−1 | <5.5% | B |

| 45% miscanthus | 15.9 MJ·kg−1 | ~5% | B |

| 60–75% miscanthus | >16.5 MJ·kg−1 | <4% | A2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mudryk, K.; Frączek, J.; Leszczyńska, J.; Krotowski, M. Technology for the Production of Energy Briquettes from Bean Stalks. Energies 2025, 18, 4009. https://doi.org/10.3390/en18154009

Mudryk K, Frączek J, Leszczyńska J, Krotowski M. Technology for the Production of Energy Briquettes from Bean Stalks. Energies. 2025; 18(15):4009. https://doi.org/10.3390/en18154009

Chicago/Turabian StyleMudryk, Krzysztof, Jarosław Frączek, Joanna Leszczyńska, and Mateusz Krotowski. 2025. "Technology for the Production of Energy Briquettes from Bean Stalks" Energies 18, no. 15: 4009. https://doi.org/10.3390/en18154009

APA StyleMudryk, K., Frączek, J., Leszczyńska, J., & Krotowski, M. (2025). Technology for the Production of Energy Briquettes from Bean Stalks. Energies, 18(15), 4009. https://doi.org/10.3390/en18154009