Advancements in Environmentally Friendly Lubricant Technologies: Towards Sustainable Performance and Efficiency

Abstract

1. Introduction

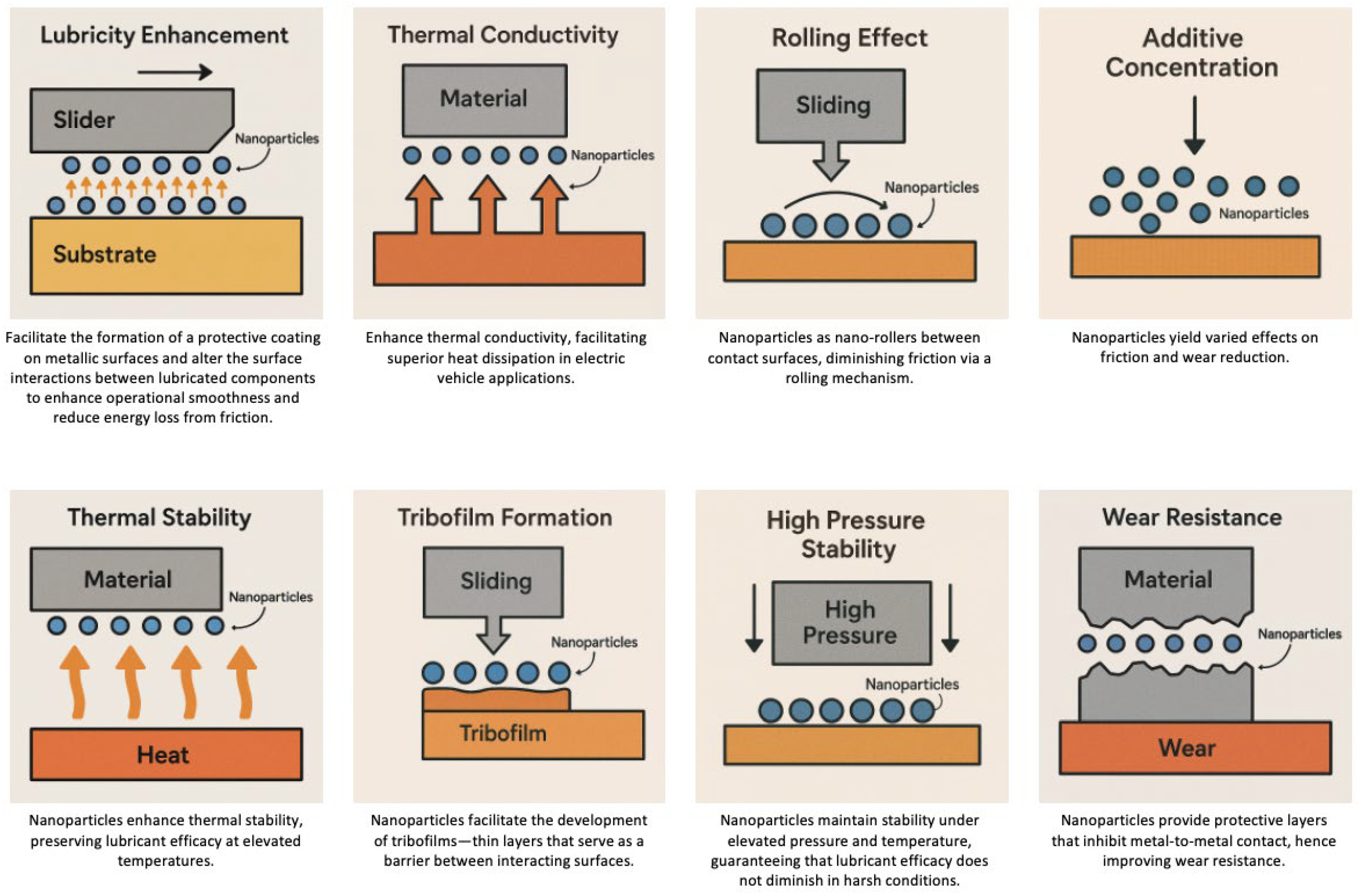

2. Nanolubricants

2.1. Key Parameters Influencing the Tribological Performance of Nanolubricants

2.2. Mechanisms of Nanoparticle Action in Tribological Systems

2.3. Examples of Nanoparticles Used in Lubricating Fluids

| Nanoparticle | Average Particle Size, nm | Base Oil, Nano-Additive Concentration | Way to Improve Dispersion | Results | References |

|---|---|---|---|---|---|

| TiO2 | 10 | commercial engine oil, 0.05 to 0.50 wt% | oleic acid (surface modifier), magnetic stirring | 0.25 wt% (optimal concentration); rolling effect. ↓ COF, ↓ power losses, ↑ anti-wear performance | [14] |

| TiO2 | 5 | low-viscosity base oil, 0.10 to 0.50 wt% | oleic acid (surface modifier), ultrasonic homogenization | 0.35 wt% (optimal concentration), adsorbed tribofilm, polishing and mending effects; ↓ COF | [23] |

| Al2O3 | 8–12 | commercial engine oil, 0.05 to 0.5 wt% | oleic acid (surface modifier), magnetic stirring | 0.25 wt% (optimal concentration); formation of self-laminating protective layers; ↓ COF, ↓ power losses, ↑ anti-wear performance | [14] |

| SiO2 | 18–35 | engine oil, 0.25 to 1.00 wt% | silane coupling agent, magnetic stirring, and then ultrasonic homogenization | surface modification improved the physicochemical properties and stability of the lubricant | [22] |

| CNTs | size and length: 2 and 8 (single-walled CNTs); 20 and 8 (multi-walled CNTs) | commercial engine oil, 0.1 to 2.0 wt% | mechanical mixing and then ultrasonic homogenization | accumulation of CNTs on the surface; ↓ COF, ↓ wear scar diameter, kinematic viscosity increased with concentration; multi-walled CNTs yielded more favorable results | [36] |

| ZnO + CNTs (hybrid formulation with different mass ratios) | ZnO: 40, CNTs: 20 (outer diameter) and 5–20 (length) | commercial engine oil, 0.25 to 1.0 wt% | oleic acid (surfactant), ultrasonic homogenization | synergistic effect (particularly at 0.25 wt%); ↓ COF, ↓ wear volume | [31] |

| Chemically modified Graphene + CNTs (hybrid formulation with different mass ratios) | n-Hexadecane, 0.1 to 2.0 wt% | ultrasonic homogenization | 0.3 wt% (optimal concentration); some CNTs were put into the interlayer of graphene; ↓ COF, ↓ wear of the friction surfaces | [3] | |

| Graphene oxide | white oil, 0.02 to 0.12 wt% | dodecanethiol (surface modifier) and two-component gelators, magnetic stirring and then ultrasonic homogenization | stable dispersion for over a year; two kinds of protective layers: tribochemical reaction film and physical adsorption film; ↓ COF, ↓ wear scar diameter | [34] | |

| Nanographite | ~50 | engine oil, 0.3 wt% | surfactant, ultrasonic homogenization | superior tribological and thermophysical properties, improving engine performance | [37] |

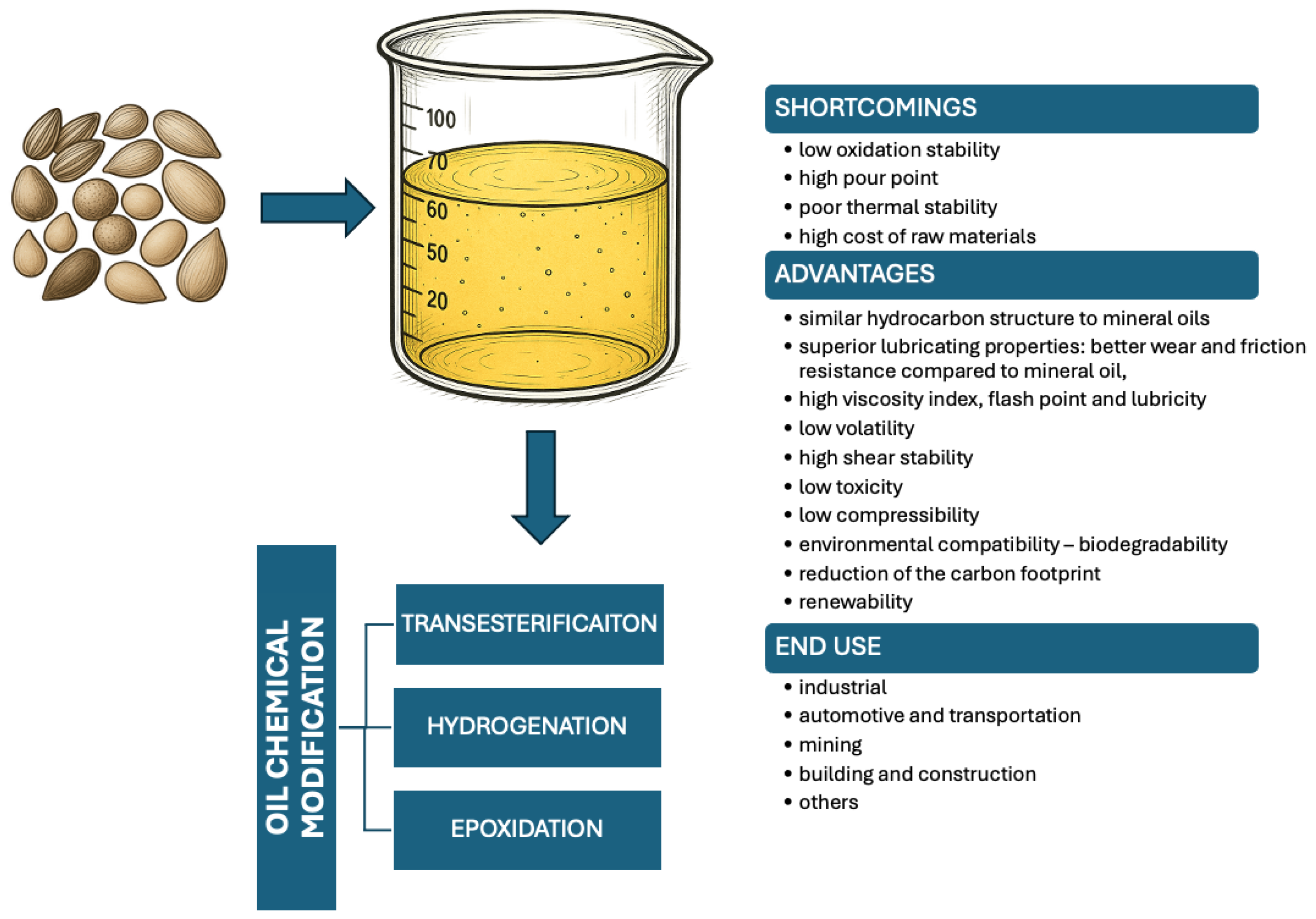

3. Biolubricants

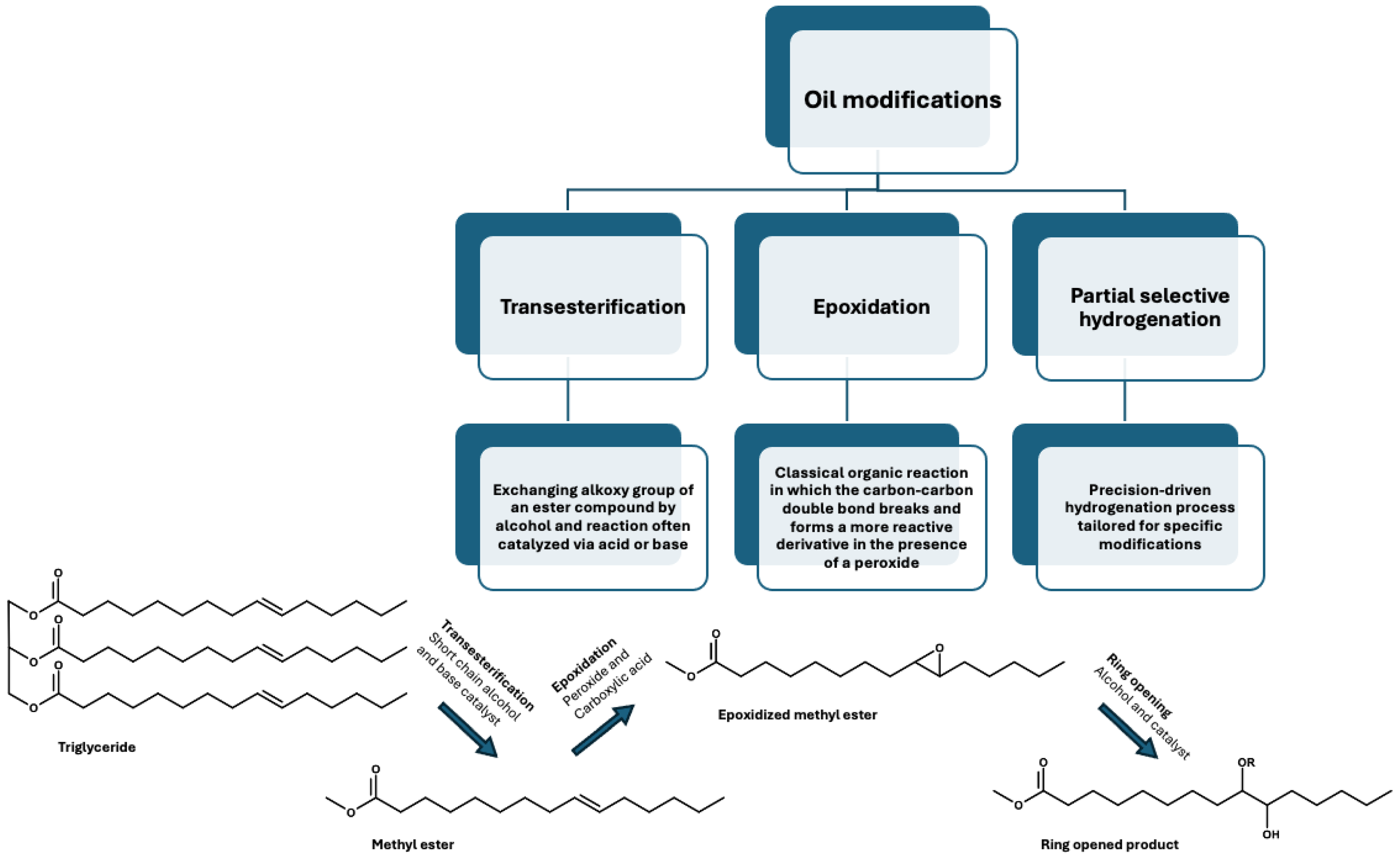

3.1. Vegetable Oils

| Vegetable Oil | Characteristics | Applications | References |

|---|---|---|---|

| Edible oils | |||

| Canola | Rich in oleic acid, offers good biodegradability and lubricity, moderate oxidative stability. Chemical modifications like double bond hydrogenation, epoxidation, and incorporation of antioxidant additives are applied to enhance stability. | Grease, diesel fuel substitutes, biodegradable grease | [38,98] |

| Coconut | Rich in medium-chain saturated fatty acids, primarily lauric acid. High oxidative stability and low viscosity—suitable for high-temperature lubrication systems. Poor low-temperature properties limit its standalone use. To improve performance, transesterification and epoxidation are applied. | Gas engine oil | [38,98] |

| Grapeseed | High proportion of linoleic acid—good lubricity but leads to low oxidative stability. Chemical modifications like epoxidation and subsequent ring-opening reactions are used to enhance thermal and oxidative performance. | Diesel fuel substitutes, automotive lubricants | [61,99] |

| Olive | High oleic acid content—high oxidative stability and lubricity. Limited cold-flow behavior. Typically, chemically modified via esterification and epoxidation to improve its performance under a broader temperature range. | Automotive lubricants | [38,98,100] |

| Palm | Abundant and cost-effective. Contains both saturated and unsaturated fatty acids—a balance of oxidative stability and lubricity. Frequently modified via epoxidation, transesterification, and branching reactions to yield biolubricants with improved pour point and viscosity indices. | Grease, rolling lubricant | [38,98] |

| Rice bran | High oryzanol and tocopherol content—natural antioxidant properties. It has been used in biolubricant formulations after undergoing transesterification and epoxidation, enhancing its viscosity and wear-resistance properties. | Cutting fluid | [38] |

| Sesame | Contains sesamol and sesamin, natural antioxidants that increase its oxidative resistance. Cold-flow properties are suboptimal. Modifications such as blending with synthetic esters or epoxidation are commonly used to improve its overall performance | Biodiesel, soap, cosmetics, lubricants | [101] |

| Soybean | One of the most studied oils for biolubricant development due to its availability and high content of unsaturated fatty acids. Chemically modified via epoxidation, maleation, and hydroxylation to enhance oxidative stability, viscosity index, and tribological properties. | Plasticizers, hydraulic oil, printing inks, pesticides, disinfectants | [98] |

| Sunflower | High linoleic acid content—good lubricity but low oxidative stability. Chemical alterations like epoxidation and esterification are employed to overcome this limitation, creating biolubricants suitable for general-purpose lubrication. | Grease, diesel fuel substitutes | [98,102] |

| Non-edible oils | |||

| Castor | Unique due to the presence of ricinoleic acid—imparts hydroxyl functionality directly in the triglyceride structure. Excellent lubricity and polarity. Its derivatives, such as estolides and polyesters, are widely used in biolubricant formulations without needing drastic modifications | Gear lubricants, greaces, fuel, and biodiesel | [98,103] |

| Cottonseed | Blend of saturated and unsaturated fatty acids. It is a by-product of cotton farming, making it cost-effective. High linoleic acid content requires epoxidation or blending to improve oxidative stability and cold-flow behavior. | Synthetic resins, inks, pastes, metal soaps, waxes, insecticides | [104,105] |

| Jatropha | Suitable for industrial biolubricant applications. It undergoes extensive modifications such as transesterification, epoxidation, and polymerization to develop high-performance lubricants, especially for heavy-duty applications. | Biodiesel, producing soap, and biocides | [106,107] |

| Karanja | Good saponification value and fatty acid composition. Modified via processes like transesterification and esterification to enhance viscosity, oxidation stability, and biodegradability. | Biodiesel, automotive lubricant | [78,108] |

| Neem | Antimicrobial properties and unsaturated fatty acid content. Despite being underutilized, it has potential in specialty biolubricants, especially where anti-corrosive and antifungal properties are desired. It is typically subjected to epoxidation and subsequent modifications. | Machining mild steel | [109] |

3.2. Waste Materials

| Waste Feedstock | Source | Performance Indicators | Environmental Benefit | Processing Challenges | Ref. |

|---|---|---|---|---|---|

| Waste Cooking Oil (WCO) | Households, restaurants | COF ↓ to 0.02, VI ↑ to 150+ | Circular economy, prevents improper disposal | Requires purification, multi-step synthesis | [53,116,117,122] |

| Cashew Nutshell Liquid (CNSL) | Agro-industrial waste | WSD ↓, excellent pressure resistance | High value from waste | Toxicity control, reactive handling | [119] |

| BSF Larvae Oil | Bioconverted organic waste | Comparable to SAE 15W-40 | Sustainable insect farming | Public acceptance, oil extraction yield | [117,120] |

| Residual Fatty Acids (RFAs) | Vegetable oil refining | Low COF, high oxidative resistance | Reduction in industrial waste | Highly variable composition | [62] |

3.3. Other Biomaterials Considered for Biolubricant Applications

3.4. Applications, Environmental Impact, and Economic Considerations of Biolubricants

4. Nano-Biolubricants

5. AI Involvement in Ecological Lubricants Development

| AI Technique | Application Area | Input Variables | Predicted Outcomes | Advantages | Ref. |

|---|---|---|---|---|---|

| ANN | Biolubricant formulation | Oil type, NP concentration, load, speed | COF, WSD, VI | High accuracy, handles nonlinearity | [120,143] |

| GA | Optimization of blends | Blend ratios, modifier type | Minimum friction, max viscosity | Global optimum search | [117,120,145] |

| ANN-GWO | BSF oil nano-biolubricant | Temp, time, NP dose | COF, wear loss | Hybrid model improves convergence | [117,120,143] |

| Random Forest | Nano-additive screening | Material properties, tribological history | Additive ranking | Robust, interpretable | [143] |

| SVM | Tribofilm prediction | Surface data, oil chemistry | Film thickness, durability | Effective with small datasets | [143] |

6. Conclusions

Funding

Conflicts of Interest

References

- Elhaseeb, D.M.A.; Kamal, M.; Ali, A. A Review of the Tribological Properties of Nanoparticles Dispersed in Bio-Lubricants. J. Eng. Tribol. 2022, 237, 27–52. [Google Scholar] [CrossRef]

- Nugroho, A.; Kozin, M.; Mamat, R.; Bo, Z.; Ghazali, M.F.; Kamil, M.P.; Puranto, P.; Fitriani, D.A.; Azahra, S.A.; Suwondo, K.P.; et al. Enhancing Tribological Performance of Electric Vehicle Lubricants: Nanoparticle-Enriched Palm Oil Biolubricants for Wear Resistance. Heliyon 2024, 10, e39742. [Google Scholar] [CrossRef] [PubMed]

- Hou, F.; Zhang, G.; Lu, S.; Qi, J.; Li, Y. Design of Intercalated Graphene/CNTs Nanocomposite Lubricants with Load-Bearing and Their Intelligent Electric Current-Controlled Friction Performance. Diam. Relat. Mater. 2025, 151, 111832. [Google Scholar] [CrossRef]

- Wang, P.; Liang, H.; Jiang, L.; Qian, L. Effect of Nanoscale Surface Roughness on Sliding Friction and Wear in Mixed Lubrication. Wear 2023, 530–531, 204995. [Google Scholar] [CrossRef]

- Hamnas, A.; Unnikrishnan, G. Bio-Lubricants from Vegetable Oils: Characterization, Modifications, Applications and Challenges–Review. Renew. Sustain. Energy Rev. 2023, 182, 113413. [Google Scholar] [CrossRef]

- Silva-Alvarez, D.F.; Dominguez-Lopez, I.; Vidales Hurtado, M.A.; Gutierrez-Antonio, C.; Flores-Garay, K.A.; Garcia-Garcia, A.L. A Review on the Menagerie of Green Fluids and Nanoparticles to Develop Sustainable Biolubricant Technologies. Environ. Technol. Innov. 2024, 33, 103532. [Google Scholar] [CrossRef]

- Nugroho, A.; Kozin, M.; Bo, Z.; Mamat, R.; Ghazali, M.F.; Kamil, M.P.; Puranto, P.; Fitriani, D.A.; Azahra, S.A.; Suwondo, K.P.; et al. Recent Advances in Harnessing Biolubricants to Enhance Tribological Performance and Environmental Responsibility–Bibliometric Review (2015–2024). Clean. Eng. Technol. 2024, 23, 100821. [Google Scholar] [CrossRef]

- Aroor, G.; Ali, M.; Shetty, A.R.; Rai, R.; Ganesha, H.; Navada, M.K. From Chemistry to Performance: How Nano Additives Are Transforming Bio-Lubricants for Enhanced Tribological Applications. J. Mol. Liq. 2025, 425, 127242. [Google Scholar] [CrossRef]

- Malik, M.; Kalam, M.A.; Mujtaba, M.A.; Almomani, F. A Review of Recent Advances in the Synthesis of Environmentally Friendly, Sustainable, and Nontoxic Bio-Lubricants: Recommendations for the Future Implementations. Environ. Technol. Innov. 2023, 32, 103366. [Google Scholar] [CrossRef]

- Darminesh, S.P.; Azwadi, N.; Sidik, C.; Lit, T.; Asako, Y.; Naja, G.; Mamat, R. Recent Development on Biodegradable Nanolubricant: A Review. Int. Commun. Heat Mass. Transf. 2017, 86, 159–165. [Google Scholar] [CrossRef]

- Uppar, R.; Dinesha, P.; Kumar, S. Characterization of Bio-Lubricants with Nanoparticles Additives. Energy Sources, Part A Recover. Util. Environ. Eff. 2024, 46, 3684–3706. [Google Scholar] [CrossRef]

- Abud, Z.; Abud, A.; Takhakh, A.M.; Al-waily, M. Materials Today: Proceedings A Review of Use of Nanoparticle Additives in Lubricants to Improve Its Tribological Properties. Mater. Today Proc. 2022, 52, 1442–1450. [Google Scholar] [CrossRef]

- Thampi, A.D.; Prasanth, M.A.; Anandu, A.P.; Sneha, E.; Sasidharan, B.; Rani, S. The Effect of Nanoparticle Additives on the Tribological Properties of Various Lubricating Oils–Review. Mater. Today Proc. 2021, 47, 4919–4924. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Hou, X.; Mai, L.; Cai, Q.; Turkson, R.F.; Chen, B. Improving the Tribological Characteristics of Piston Ring Assembly in Automotive Engines Using Al2O3 and TiO2 Nanomaterials as Nano-Lubricant Additives. Tribol. Int. 2016, 103, 540–554. [Google Scholar] [CrossRef]

- Wang, X.; Song, Y.; Li, C.; Zhang, Y.; Ali, H.M.; Sharma, S.; Li, R.; Yang, M.; Gao, T.; Liu, M.; et al. Nanofluids Application in Machining: A Comprehensive Review. Int. J. Adv. Manuf. Technol. 2024, 131, 3113–3164. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufti, R.A.; Zahid, R. Tribological Performance of Nanoparticles as Lubricating Oil Additives. J. Nanoparticle Res. 2016, 18, 223–248. [Google Scholar] [CrossRef]

- Pawar, R.V.; Hulwan, D.B.; Mandale, M.B. Recent Advancements in Synthesis, Rheological Characterization, and Tribological Performance of Vegetable Oil-Based Lubricants Enhanced with Nanoparticles for Sustainable Lubrication. J. Clean. Prod. 2022, 378, 134454. [Google Scholar] [CrossRef]

- Raina, A.; Haq, M.; Anand, A.; Sudhanraj, J. Lubrication Characteristics of Oils Containing Nanoadditives: Influencing Parameters, Market Scenario and Advancements. J. Inst. Eng. Ser. D 2021, 102, 575–587. [Google Scholar] [CrossRef]

- Liu, X.; Xu, N.; Li, W.; Zhang, M.; Chen, L.; Lou, W.; Wang, X. Exploring the Effect of Nanoparticle Size on the Tribological Properties of SiO2/Polyalkylene Glycol Nanofluid under Different Lubrication Conditions. Tribol. Int. 2017, 109, 467–472. [Google Scholar] [CrossRef]

- Mekuye, B.; Abera, B. Nanomaterials: An Overview of Synthesis, Classification, Characterization, and Applications. Nano Sel. 2023, 4, 486–501. [Google Scholar] [CrossRef]

- Malahotra, B.D.; Ali, M.A. Nanomaterials in Biosensors: Fundamentals and Applications. In Nanomaterials for Biosensors; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–74. ISBN 9789896540821. [Google Scholar]

- Piri, H.; Renzi, M.; Bietresato, M. Enhancing Performance and Sustainability of Engine Lubricants and Biolubricants by Dispersing SiO2 Nanoparticles Coated with KH570-Silane Coupling Agent. Appl. Sci. 2024, 14, 7943–7962. [Google Scholar] [CrossRef]

- Liñeira, J.M.; Mariño, F.; López, E.R.; Gonçalves, D.E.P.; Seabra, J.H.O.; Fernández, J. Tribological Enhancement of Potential Electric Vehicle Lubricants Using Coated TiO2 Nanoparticles as Additives. J. Mol. Liq. 2023, 371, 121097. [Google Scholar] [CrossRef]

- Zulhanafi, P.; Syahrullail, S.; Faizin, Z.N. Tribological Performance of Trimethylolpropane Ester Bio-Lubricant Enhanced by Graphene Oxide Nanoparticles and Oleic Acid as a Surfactant. Tribol. Int. 2023, 183, 108398. [Google Scholar] [CrossRef]

- Duan, Z.; Wang, S.; Li, C.; Wang, Z.; Bian, P. Tribological and Micro-Milling Performance of Surfactant-Free Microwave Plasma-Modified Al2O3 Nanoparticles Biodegradable Lubricants. J. Clean. Prod. 2025, 493, 144969. [Google Scholar] [CrossRef]

- Jason, Y.; How, H.G.; Teoh, Y.H.; Chuah, H. A Study on the Tribological Performance of Nanolubricants. Processes 2020, 8, 1372. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, S. 2D Nanomaterials as Lubricant Additive: A Review. Mater. Des. 2017, 135, 319–332. [Google Scholar] [CrossRef]

- Karthikeyan, K.M.B.; Vijayanand, J.; Arun, K.; Rao, V.S. Thermophysical and Wear Properties of Eco-Friendly Nano Lubricants. Mater. Today Proc. 2020, 39, 285–291. [Google Scholar] [CrossRef]

- Koshy, C.P.; Rajendrakumar, P.K.; Thottackkad, M.V. Evaluation of the Tribological and Thermo-Physical Properties of Coconut Oil Added with MoS2 Nanoparticles at Elevated Temperatures. Wear 2015, 330–331, 288–308. [Google Scholar] [CrossRef]

- Yadav, A.; Singh, Y.; Negi, P. A Review on the Characterization of Bio Based Lubricants from Vegetable Oils and Role of Nanoparticles as Additives. Mater. Today Proc. 2021, 46, 10513–10517. [Google Scholar] [CrossRef]

- Vardhaman, B.S.A.; Amarnath, M.; Ramkumar, J.; Mondal, K. Enhanced Tribological Performances of Zinc Oxide/MWCNTs Hybrid Nanomaterials as the Effective Lubricant Additive in Engine Oil. Mater. Chem. Phys. 2020, 253, 123447. [Google Scholar] [CrossRef]

- Ismail, N.A.; Zulkifli, N.W.M.; Chowdhury, Z.Z.; Johan, M.R. Functionalization of Graphene-Based Materials: Effective Approach for Enhancement of Tribological Performance as Lubricant Additives. Diam. Relat. Mater. 2021, 115, 108357. [Google Scholar] [CrossRef]

- Karacan, I.; Erdogan, G. The Influence of Thermal Stabilization Stage on the Molecular Structure of Polyacrylonitrile Fibers Prior to the Carbonization Stage. Fibers Polym. 2012, 13, 295–302. [Google Scholar] [CrossRef]

- Xia, Y.; Cheng, X.; Wang, Y.; Xie, Y.; Ding, Z.; Hu, X.; Xu, X.; Zhang, R. Synergistic Lubrication Mechanism and Dispersion Behavior of Dodecanethiol-Modified Graphene Oxide Nanolubricant. J. Ind. Eng. Chem. 2024, 145, 477–490. [Google Scholar] [CrossRef]

- Liñeira, J.M.; López, E.R.; García, F.; Fernández, J. Tribological Synergies among Chemical-Modified Graphene Oxide Nanomaterials and a Phosphonium Ionic Liquid as Additives of a Biolubricant. J. Mol. Liq. 2021, 336, 116885. [Google Scholar] [CrossRef]

- Kumar, N.; Goyal, P. Experimental Study of Carbon Nanotubes to Enhance Tribological Characteristics of Lubricating Engine Oil SAE10W40. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1225, 012052. [Google Scholar] [CrossRef]

- Prakash, J.; Singh, S.; Nandi, T.; Kumar, S. Development of Graphitic Lubricant Nanoparticles Based Nanolubricant for Automotive Applications: Thermophysical and Tribological Properties Followed by IC Engine Performance. Powder Technol. 2021, 387, 31–47. [Google Scholar] [CrossRef]

- Akanksha, M.; Sumanth, P.; Akhil, U.; Radhika, N.; Ravichandran, M. The Modification and Adoption of Biolubricants as Alternatives in the Automotive Industry. Environ. Sci. Pollut. Res. 2025, 32, 1043–1072. [Google Scholar] [CrossRef] [PubMed]

- Ho, C.K.; Mcauley, K.B.; Peppley, B.A. Biolubricants through Renewable Hydrocarbons: A Perspective for New Opportunities. Renew. Sustain. Energy Rev. 2019, 113, 109261. [Google Scholar] [CrossRef]

- Panchal, T.M.; Patel, A.; Chauhan, D.D.; Thomas, M.; Patel, J. V A Methodological Review on Bio-Lubricants from Vegetable Oil Based Resources. Renew. Sustain. Energy Rev. 2017, 70, 65–70. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Mariod, A.A.; Aroua, M.K.; Rahman, S.M.A.; Soudagar, M.E.M.; Fattah, I.M.R. Current State and Perspectives on Transesterification of Triglycerides for Biodiesel Production. Catalysts 2021, 11, 1121–1158. [Google Scholar] [CrossRef]

- Appiah, G.; Tulashie, S.K.; Akpari, E.E.A.; Rene, E.R.; Dodoo, D. Biolubricant Production via Esterification and Transesterification Processes: Current Updates and Perspectives. Int. J. Energy Res. 2022, 46, 3860–3890. [Google Scholar] [CrossRef]

- Attia, N.K.; El-Mekkawi, S.A.; Elardy, O.A.; Abdelkader, E.A. Chemical and Rheological Assessment of Produced Biolubricants from Different Vegetable Oils. Fuel 2020, 271, 117578. [Google Scholar] [CrossRef]

- Nie, J.; Shen, J.; Shim, Y.Y.; Tse, T.J.; Reaney, M.J.T. Synthesis of Trimethylolpropane Esters by Base-Catalyzed Transesterification. Eur. J. Lipid Sci. Technol. 2020, 122, 1900207. [Google Scholar] [CrossRef]

- Kim, H.; Choi, N.; Kim, Y.; Kim, H.R.; Lee, J.; Kim, I.H. Immobilized Lipase-Catalyzed Esterification for Synthesis of Trimethylolpropane Triester as a Biolubricant. Renew. Energy 2019, 130, 489–494. [Google Scholar] [CrossRef]

- Kamyab, B.; Beims, R.F.; Chio, C.; Qin, W.; Chambers, D.W.; Xu, C.C. Synthesis of TMP Esters as a Biolubricant from Canola Oil via a Two-Step Transesterification–Transesterification Process. Can. J. Chem. Eng. 2024, 102, 35–52. [Google Scholar] [CrossRef]

- Berman, D. Plant-Based Oils for Sustainable Lubrication Solutions—Review. Lubricants 2024, 12, 300. [Google Scholar] [CrossRef]

- Wilkanowicz, S.I.; Kao, P.K.; Saud, K.T.; Wilińska, I.; Ciesińska, W. Electrohydrodynamic Processing in Biodiesel Production from Waste Cooking Oil. Fuel 2024, 373, 132289–132299. [Google Scholar] [CrossRef]

- Wilkanowicz, S.I.; Hollingsworth, N.R.; Saud, K.; Kadiyala, U.; Larson, R.G. Immobilization of Calcium Oxide onto Polyacrylonitrile (PAN) Fibers as a Heterogeneous Catalyst for Biodiesel Production. Fuel Process. Technol. 2020, 197, 106214. [Google Scholar] [CrossRef]

- Wilkanowicz, S.; Wilińska, I.; Ciesińska, W.; Gierlotka, S.; Kao, P.K. Electrospinning for Catalyst Immobilization in Waste Polylactide Processing. Chem. Eng. Res. Des. 2025, 218, 729–742. [Google Scholar] [CrossRef]

- Moser, B.R.; Kenar, J.A.; Cermak, S.C.; Doll, K.M. A Review of Fatty Epoxide Ring Opening Reactions: Chemistry, Recent Advances, and Applications. J. Am. Chem. Soc. 2022, 99, 801–842. [Google Scholar] [CrossRef]

- Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H. A Review on the Chemistry, Production, and Technological Potential of Bio-Based Lubricants. Renew. Sustain. Energy Rev. 2018, 82, 80–102. [Google Scholar] [CrossRef]

- Joshi, J.R.; Bhanderi, K.K.; Karve, M.; Patel, J.V. Chemical Modification of Waste Cooking Oil for the Bio Lubricant Production through Epoxidation Process. Biomass Convers. Biorefinery 2025, 15, 2739–2756. [Google Scholar] [CrossRef]

- Védrine, J.C. Recent Developments and Prospectives of Acid-Base and Redox Catalytic Processes by Metal Oxides. Appl. Catal. A Gen. 2019, 575, 170–179. [Google Scholar] [CrossRef]

- Leveneur, S.; Pinchard, M.; Rimbault, A.; Safdari, M.; Meyer, T. Parameters a Ff Ecting Thermal Risk through a Kinetic Model under Adiabatic Condition: Application to Liquid-Liquid Reaction System. Thermochim. Acta 2018, 666, 10–17. [Google Scholar] [CrossRef]

- Salih, N.; Salimon, J. A Review on Eco-Friendly Green Biolubricants from Renewable and Sustainable Plant Oil Sources. Biointerface Res. Appl. Chem. 2021, 11, 13303–13327. [Google Scholar] [CrossRef]

- Mehdi, S.; Asghari, A.; Ghobadian, B.; Soufi, M.D. Conversion of Pistacia Atlantica Mutica Oil to Trimethylolpropane Fatty Acid Triester as a Sustainable Lubricant. Biomass Convers. Biorefinery 2020, 10, 139–148. [Google Scholar] [CrossRef]

- Sharma, S.; Kundu, A.; Basu, S.; Shetti, N.P.; Aminabhavi, T.M. Sustainable Environmental Management and Related Biofuel Technologies. J. Environ. Manag. 2020, 273, 111096. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Cruz, M.C.; Meza-Gordillo, R.; Domínguez, Z.; Rosales-Quintero, A.; Abud-Archila, M.; Ayora-Talavera, T.; Villalobos-Maldonado, J.J. Optimization and Characterization of in Situ Epoxidation of Chicken Fat with Peracetic Acid. Fuel 2021, 285, 119127. [Google Scholar] [CrossRef]

- Bashiri, S.; Ghobadian, B.; Dehghani, M.; Gorjian, S. Chemical Modification of Sunflower Waste Cooking Oil for Biolubricant Production through Epoxidation Reaction. Mater. Sci. Energy Technol. 2021, 4, 119–127. [Google Scholar] [CrossRef]

- Leang, J.; Walvekar, R.; Chun, K.; Khalid, M. Biolubricants from Waste Cooking Oil: A Review of Extraction Technologies, Conversion Techniques, and Performance Enhancement Using Natural Antioxidants. J. Environ. Manag. 2025, 375, 124267. [Google Scholar] [CrossRef]

- de Melo Neta, M.M.F.; de Oliveira Tavares, P.; Ribeiro Filho, P.R.C.F.; Cavalcante, C.L.; de Luna, F.M.T. Lubricants Basestock Oil Obtained from Residual Fatty Acids: Evaluation of Tribological Properties and Thermo-Oxidative Stability. J. Braz. Soc. Mech. Sci. Eng. 2025, 47, 65–77. [Google Scholar] [CrossRef]

- Melo, L.N.; Barbosa, G.E.G.S.; Meneghetti, M.R.; Bortoluzzi, J.H. Alkoxide-Catalyzed Synthesis and Characterization of Acylglycerol-Estolide Biolubricants From Neat Castor Oil. Eur. J. Lipid Sci. Technol. 2025, 127, e202400125. [Google Scholar] [CrossRef]

- Naik, E.; Ngomade, S.B.L.; Bhonsle, A.K.; Singh, R.K.; Sinha, A.K.; Atray, N. Synthesis and Characterization of Eco-Friendly Biolubricant from Brassica Carinata Oil: Parameter Optimizations Using Response Surface Methodology. Biomass Convers. Biorefinery 2025, 1, 1–21. [Google Scholar] [CrossRef]

- Sharma, B.K.; Rashid, U.; Anwar, F.; Erhan, S.Z. Lubricant Properties of Moringa Oil Using Thermal and Tribological Techniques. J. Therm. Anal. Calorim. 2009, 96, 999–1008. [Google Scholar] [CrossRef]

- Tan, C.P.; Man, Y.B.C.; Selamat, J.; Yusoff, M.S.A. Comparative Studies of Oxidative Stability of Edible Oils by Differential Scanning Calorimetry and Oxidative Stability Index Methods. Food Chem. 2002, 76, 385–389. [Google Scholar] [CrossRef]

- Encinar, J.M.; Nogales-Delgado, S.; Sánchez, N.; González, J.F. Biolubricants from Rapeseed and Castor Oil Transesterification by Using Titanium Isopropoxide as a Catalyst: Production and Characterization. Catalysts 2020, 10, 366–378. [Google Scholar] [CrossRef]

- Symoniuk, E.; Ratusz, K.; Krygier, K. Evaluation of the Oxidative Stability of Cold-Pressed Rapeseed Oil by Rancimat and Pressure Differential Scanning Calorimetry Measurements. Eur. J. Lipid Sci. Technol. 2019, 121, 1800017. [Google Scholar] [CrossRef]

- Jayadas, N.H.; Nair, K.P. Coconut Oil as Base Oil for Industrial Lubricants-Evaluation and Modification of Thermal, Oxidative and Low Temperature Properties. Tribol. Int. 2006, 39, 873–878. [Google Scholar] [CrossRef]

- Lee, C.T.; Lee, M.B.; Chong, W.W.F.; Ng, J.H.; Wong, K.J.; Chong, C.T. Boundary Lubricity of Vegetable-Oil-Derived Trimethylolpropane (TMP) Ester. Lubricants 2022, 10, 346–369. [Google Scholar] [CrossRef]

- Bolonio, D.; García-Martínez, M.J.; Ortega, M.F.; Lapuerta, M.; Rodríguez-Fernández, J.; Canoira, L. Fatty Acid Ethyl Esters (FAEEs) Obtained from Grapeseed Oil: A Fully Renewable Biofuel. Renew. Energy 2019, 132, 278–283. [Google Scholar] [CrossRef]

- Singh, G.; Mohapatra, S.K.; Ragit, S.S.; Kundu, K. Optimization of Biodiesel Production from Grape Seed Oil Using Taguchi’s Orthogonal Array. Energy Sources Part. A Recover. Util. Environ. Eff. 2018, 40, 2144–2153. [Google Scholar] [CrossRef]

- Wan Nik, W.B.; Ani, F.N.; Masjuki, H.H. Thermal Stability Evaluation of Palm Oil as Energy Transport Media. Energy Convers. Manag. 2005, 46, 2198–2215. [Google Scholar] [CrossRef]

- Md Alias, M.A.; Bin Abdollah, M.F.; Amiruddin, H. Tribological Properties of Palm Oil Blended with Zinc Dioctyldithiophosphate. Mater. Res. Express 2018, 5, 085505. [Google Scholar] [CrossRef]

- Joseph, T.N.; Chijioke, E.O.; Okwudili, C.N. Equilibrium, Kinetics and Thermodynamics of the Bleaching of Palm Oil Using Activated Nando Clay. J. Eng. Res. Rep. 2018, 1, 1–13. [Google Scholar] [CrossRef]

- Nor, N.M.; Salih, N.; Salimon, J. Optimization and Lubrication Properties of Malaysian Crude Palm Oil Fatty Acids Based Neopentyl Glycol Diester Green Biolubricant. Renew. Energy 2022, 200, 942–956. [Google Scholar] [CrossRef]

- Ali, M.A.; Islam, M.A.; Othman, N.H.; Noor, A.; Ibrahim, M. Effect of Rice Bran Oil Addition on the Oxidative Degradation and Fatty Acid Composition of Soybean Oil During Heating. Acta Sci. Pol. Technol. Aliment. 2019, 18, 427–438. [Google Scholar]

- Edla, S.; Thampi, A.D.; Prasannakumar, P.; Rani, S. Evaluation of Physicochemical, Tribological and Oxidative Stability Properties of Chemically Modified Rice Bran and Karanja Oils as Viable Lubricant Base Stocks for Industrial Applications. Tribol. Int. 2022, 173, 107631. [Google Scholar] [CrossRef]

- Thampi, A.D.; John, A.R.; Arif, M.M.; Rani, S. Evaluation of the Tribological Properties and Oxidative Stability of Epoxidized and Ring Opened Products of Pure Rice Bran Oil. J. Eng. Tribol. 2020, 235, 1093–1100. [Google Scholar] [CrossRef]

- Saydut, A.; Duz, M.Z.; Kaya, C.; Kafadar, A.B.; Hamamci, C. Transesterified Sesame (Sesamum indicum L.) Seed Oil as a Biodiesel Fuel. Bioresour. Technol. 2008, 99, 6656–6660. [Google Scholar] [CrossRef] [PubMed]

- Reeves, C.J.; Menezes, P.L.; Jen, T.C.; Lovell, M.R. The Influence of Fatty Acids on Tribological and Thermal Properties of Natural Oils as Sustainable Biolubricants. Tribol. Int. 2015, 90, 123–134. [Google Scholar] [CrossRef]

- Dodos, G.S.; Zannikos, F.; Lois, E. Utilization of Sesame Oil for the Production of Bio-Based Fuels and Lubricants. In Proceedings of the 3rd International CEMEPE&SECOTOX Conference, Athens, Greece, 19–24 June 2011; pp. 623–628. [Google Scholar]

- Menkiti, M.C.; Ocholi, O.; Oyoh, K.B.; Onukwuli, O.D. Synthesis and Tribological Evaluation of Sesame Oil-Based Trimethylolpropane Ester. J. Chinese Adv. Mater. Soc. 2015, 3, 71–88. [Google Scholar] [CrossRef]

- Adhvaryu, A.; Erhan, S.Z. Epoxidized Soybean Oil as a Potential Source of High-Temperature Lubricants. Ind. Crop. Prod. 2002, 15, 247–254. [Google Scholar] [CrossRef]

- López-Beceiro, J.; Artiaga, R.; Gracia, C.; Tarrío-Saavedra, J.; Naya, S.; Mier, J.L. Comparison of Olive, Corn, Soybean and Sunflower Oils by PDSC. J. Therm. Anal. Calorim. 2011, 104, 169–175. [Google Scholar] [CrossRef]

- Lotfy, H.R.; Mukakalisa, C.; Raidron, C. Analysis of Different Namibian Traditional Oils against Commercial Sunflower and Olive Oils. African J. Food Sci. 2015, 9, 372–379. [Google Scholar] [CrossRef]

- Obanla, O.R.; Mohammed, F.U.; Alebiosu, O.S.; Ojewumi, M.E.; Oladimeji, T.E.; Babatunde, D.E. Study on the Lubricating Properties of Castor (Ricinus communis) and Hydroxylated Rubber (Hevea brasiliensis) Seed Oil. ACS Omega 2021, 6, 28471–28476. [Google Scholar] [CrossRef]

- Jedrzejczyk, M.A.; Bosch, S.V.D.; Aelst, J.V.; Aelst, K.V.; Kouris, P.D.; Moalin, M.; Haenen, G.R.M.M.; Boot, M.D.; Hensen, E.J.M.; Lagrain, B.; et al. Lignin-Based Additives for Improved Thermo-Oxidative Stability of Biolubricants. ACS Sustain. Chem. Eng. 2021, 9, 12548–12559. [Google Scholar] [CrossRef]

- He, C.; Yan, Y.; Li, S.; Zhang, L.; Zhao, X.; Deng, Z.; Zhang, X. Modification of Cottonseed Oil with Lipases and Ionic Liquid Catalysts to Prepare Highly Branched Lubricant with Low Pour Point and High Viscosity. Biochem. Eng. J. 2023, 192, 108815. [Google Scholar] [CrossRef]

- Arbain, N.; Salimon, J.; Salih, N. Optimization for Epoxidation of Malaysian Jatropha Curcas Oil Based Trimethylolpropane Ester Biolubricant. Appl. Sci. Eng. Prog. 2022, 15, 5552–5563. [Google Scholar] [CrossRef]

- Aransiola, E.; Betiku, E.; Ikhuomoregbe, D.; Ojumu, T. Production of Biodiesel from Crude Neem Oil Feedstock and Its Emissions from Internal Combustion Engines. African J. Biotechnol. 2012, 11, 6178–6186. [Google Scholar] [CrossRef]

- Ibrahim, E.; Ahmed, S.; Abir, S.S.H.; Taylor, K.; Padilla-Gainza, V.M.; Lozano, K. Centrifugally Spun Alginate-Poly(Lactic Acid) Microbeads: A Promising Carrier for Drug Delivery and Tissue Engineering. Int. J. Biol. Macromol. 2022, 220, 671–682. [Google Scholar] [CrossRef] [PubMed]

- Suresha, B.; Hemanth, G.; Rakesh, A.; Adarsh, K.M. Tribological Behaviour of Neem Oil with and without Graphene Nanoplatelets Using Four-Ball Tester. Adv. Tribol. 2020, 2020, 1984931. [Google Scholar] [CrossRef]

- Goes, Q.; Ana, A.; Araújo, L.; José, S.; Porto, I.; Ronaldo, S.; Santos, G. Study of the Stability and Physicochemical Behavior of a Novel Biolubricant Based on Castor Oil Used in Cutting Operations. Biomass Convers. Biorefinery 2025, 1, 1–15. [Google Scholar] [CrossRef]

- Degaga, Y.A.; Kassahun, S.K.; Tiruneh, S.N. Green Synthesis and Characterization of Bifunctional CaO-Sulfated SnO2 Catalyst for Epoxidation of Brassica Carinata Seed Oil: Towards Eco-Friendly Biolubricants. Biomass Convers. Biorefinery 2025, 1–15. [Google Scholar] [CrossRef]

- Afifah, A.N.; Syahrullail, S.; Azlee, W.; Izyan, N.; Rohah, A.M. Rheological, Thermal and Tribological Assessment of Palm Stearin-Based Biolubricants in Boundary Lubrication Regime. Fuel 2025, 388, 134567. [Google Scholar] [CrossRef]

- Attanatho, L.; Suemanotham, A.; Thanmongkhon, Y.; Sisuthog, W.; Natewong, P.; Reubroycharoen, P.; Kaewmala, S.; Prasongthum, N. Hydrothermal Synthesis of Calcium Methoxide Nano-Catalyst for Palm Oil Based Biolubricant Production. Mol. Catal. 2025, 578, 115010. [Google Scholar] [CrossRef]

- Agarwal, M.; Maheshwari, K.; Pal, N. Synthesis of Bio-Based Lubricants. In Multifunctional Bio-Based Lubricants: Synthesis, Properties and Applications; IOP Publishing Ltd.: Bristol, UK, 2023; pp. 1–21. ISBN 9780750334358. [Google Scholar]

- Silva, T.F.; Melo Neta, M.M.F.D.; Ribeiro Filho, P.R.C.F.; Luna, F.M.T.D.; Cavalcante, C.L. Tribological Characteristics of Biolubricant Obtained by Transesterification of Grape Seed Oil. Lubricants 2024, 12, 459–473. [Google Scholar] [CrossRef]

- García, J.M.; Seller, S.; Pérez-Camino, M.C. Influence of Fruit Ripening on Olive Oil Quality. J. Agric. Food Chem. 1996, 44, 3516–3520. [Google Scholar] [CrossRef]

- Elkhaleefa, A.; Shigidi, I. Optimization of Sesame Oil Extraction Process Conditions. Adv. Chem. Eng. Sci. 2015, 5, 305–310. [Google Scholar] [CrossRef]

- Griffin, E. Diesel Fuen from Vegetable Oils: Status and Opportunities. Biomass Bioenergy 1993, 4, 227–242. [Google Scholar]

- Patel, V.R.; Dumancas, G.G.; Viswanath, L.C.K.; Maples, R.; Subong, B.J.J. Castor Oil: Properties, Uses, and Optimization of Processing Parameters in Commercial Production. Lipid Insights 2016, 9, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Durak, E.; Karaosmanoǧlu, F. Using of Cottonseed Oil as an Environmentally Accepted Lubricant Additive. Energy Sources 2010, 26, 611–625. [Google Scholar] [CrossRef]

- Riaz, T.; Iqbal, M.W.; Mahmood, S.; Yasmin, I.; Leghari, A.A.; Rehman, A.; Mushtaq, A.; Ali, K.; Azam, M.; Bilal, M. Cottonseed Oil: A Review of Extraction Techniques, Physicochemical, Functional, and Nutritional Properties. Crit. Rev. Food Sci. Nutr. 2023, 63, 1219–1237. [Google Scholar] [CrossRef] [PubMed]

- Shanker, C.; Dhyani, S.K. Insect Pests of Jatropha curcas L. and the Potential for Their Management [10]. Curr. Sci. 2006, 91, 162–163. [Google Scholar]

- Koh, M.Y.; Idaty, T.; Ghazi, M. A Review of Biodiesel Production from Jatropha curcas L. Oil. Renew. Sustain. Energy Rev. 2011, 15, 2240–2251. [Google Scholar] [CrossRef]

- Sneha, E.; Revikumar, A.; singh, J.Y.; Thampi, A.D.; Rani, S. Viscosity Prediction of Pongamia Pinnata (Karanja) Oil by Molecular Dynamics Simulation Using GAFF and OPLS Force Field. J. Mol. Graph. Model. 2020, 101, 107764. [Google Scholar] [CrossRef]

- Ekengwu, I.E.; Okoli, I.G.; Okafor, O.C.; Ezenwa, O.N.; Ogu, J.C. Lubricity Potentials of Azadirachta Indica (Neem) Oil and Cyperus Esculentus (Tiger Nut) Oil Extracts and Their Blends in Machining of Mild Steel Material. Heliyon 2025, 11, e42059. [Google Scholar] [CrossRef]

- Avilés, M.D.; Mostaza, P.; Bermúdez, M.D.; Carrión-Vilches, F.J. Epoxidized Vegetable Lubricant Enhanced by Ionic Liquid. Wear 2025, 564–565, 205740. [Google Scholar] [CrossRef]

- Avilés, M.D.; Caparros, T.; Mostaza, P.; Bermúdez, M.D.; Carrión-Vilches, F.J. Novel Vegetable Biolubricants Containing Ionic Liquid. Tribol. Int. 2025, 202, 110255. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L.; Lovell, M.R.; Jen, T.C. The Size Effect of Boron Nitride Particles on the Tribological Performance of Biolubricants for Energy Conservation and Sustainability. Tribol. Lett. 2013, 51, 437–452. [Google Scholar] [CrossRef]

- Reeves, C.J.; Siddaiah, A.; Menezes, P.L. Friction and Wear Behavior of Environmentally Friendly Ionic Liquids for Sustainability of Biolubricants. J. Tribol. 2019, 141, 051604. [Google Scholar] [CrossRef]

- Gao, X.; Zhu, H.; Shen, Z.; Ou, S.; Pan, T.; Duan, Y.; Liang, X.; Ji, W.; Xie, Q.; Nie, Y. Transesterification of Methyl Oleate for Biolubricant Production over K2CO3/Activated Carbon Catalyst under Conventional and Microwave Heating. Catal. Today 2025, 447, 115157. [Google Scholar] [CrossRef]

- de Brito, D.H.A.; Schuller, A.P.D.; Cavalcante, I.M.; Rocha, N.R.C.; Moreira, D.R.; Maier, M.E.; Petzhold, C.L.; Ricardo, N.M.P.S. Synthesis, Characterization and Application of Polyesters from Diglycerol and Triglycerol as Lubricants and Additives. JAOCS, J. Am. Oil Chem. Soc. 2024, 102, 71–82. [Google Scholar] [CrossRef]

- Alvarez, P.; Contreras, J.C.; Nogales-delgado, S. Biodiesel and Biolubricant Production from Waste Cooking Oil: Transesterification Reactor Modeling. Appl. Sci. 2025, 15, 575–601. [Google Scholar] [CrossRef]

- Riayatsyah, T.; Silitonga, A.; Kalam, M.A. Results in Engineering Optimisation of Trimethylolpropane Ester Synthesis from Waste Cooking Oil Methyl Ester by Response Surface Methodology, and Its Physicochemical Properties and Tribological Characteristics. Results Eng. 2025, 25, 104055. [Google Scholar] [CrossRef]

- Biju, G.; Marimuthu, P.; Thampi, A.D.; Sasidharan, B.; Santhakumari, R. Property Evaluation of Multi-Staged Chemically Modified Used Coconut Oil for Bio-Lubricant Applications. Biomass Convers. Biorefinery 2025. [Google Scholar] [CrossRef]

- Li, T.; Ma, J.; Li, G.; Chen, X. High-Performance and Promising Biolubricants from Agro-Waste Cashew Nut Shell Liquid. Ind. Lubr. Tribol. 2025, 77, 698–707. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Milano, J.; Atiqah, N.; Aziz, M.; Nurulita, B.; Sebayang, A.R.; Mahlia, T.M.I.; Kalam, M.A.; Fattah, I.M.R.; Sebayang, A.H.; et al. Results in Engineering ANN-GWO Optimization of Biolubricants from Black Soldier Fly: A Value-Added Approach to Animal Waste Conversion. Results Eng. 2025, 25, 104437. [Google Scholar] [CrossRef]

- Oliveira, A.; Barros, A.; Almeida, G.E.P.; Rodrigues, F.A.M.; Rocha, W.S.; Dias, F.S.; Uchoa, A.F.J.; Ricardo, M.P.S. Optimization of Biolubricant Synthesis Using Heterogeneous Catalysis: A Response Surface Methodology Approach. Ind. Eng. Chem. Res. 2025, 64, 1393–1404. [Google Scholar] [CrossRef]

- Singh, N.; Porwal, J.; Porwal, S.K. Exploring the Sustainable Impact and Performance Evaluation of Garlic Oil Additive in WCO for Biolubricant Formulations. J. Brazilian Soc. Mech. Sci. Eng. 2025, 47, 105–117. [Google Scholar] [CrossRef]

- Reséndiz-Calderón, C.D.; Soriano-Vargas, O.; Cao-Romero-Gallegos, J.A.; Campos-Silva, I.; Farfan-Cabrera, L.I. Tribological Performance of Borided Tool Steel with Minimum Bio-Lubrication for Sheet Metal Forming Applications. Wear 2025, 566–567, 205748. [Google Scholar] [CrossRef]

- Levy, H.; Rodriguez, T.; de Albuquerque, T.; Sant Ana, H.; Feitosa, F.; Rocha, M. Biosynthesis of Biolubricant Catalyzed by Lipase B from C Andida Antarctica Immobilized on Nanocomposite of Cashew Apple Bagasse Lignin. Renew. Energy 2025, 243, 122452. [Google Scholar] [CrossRef]

- Gebreyes, D.; Alemea, M.; Robi, A.; Abera, W.; Tenkolu, G. Heliyon Synthesis, Characterization, and Optimization of Antimicrobial Biolubricant Derived from Ocimum Lamiifolium and Lactic Acid. Heliyon 2025, 11, e38972. [Google Scholar] [CrossRef] [PubMed]

- Loo, D.; Teoh, Y.; How, H.; Le, T.; Nguyen, H.; Rashid, T.; Pottmaier, D.; Sher, F. Effect of Nanoparticles Additives on Tribological Behaviour of Advanced Biofuels. Fuel 2023, 334, 126798. [Google Scholar] [CrossRef]

- Özakın, B.; Gültekin, K.; Yurdgülü, H.İ. Improvement of Oxidation Stability, Hydrolytic Stability and Tribological Properties of Kaolin Particles Doped Bio-Based Green Palm Oil. Colloids Surf. A Physicochem. Eng. Asp. 2025, 712, 136441. [Google Scholar] [CrossRef]

- Uniyal, P.; Gaur, P.; Yadav, J.; Khan, T.; Ahmed, O.S. A Review on the Effect of Metal Oxide Nanoparticles on Tribological Properties of Biolubricants. ACS Omega 2024, 9, 12436–12456. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Zhang, Y.; Ding, W.; An, Q.; Liu, B.; Li, H.N.; Said, Z.; Sharma, S.; Li, R.; et al. Comparative Assessment of Force, Temperature, and Wheel Wear in Sustainable Grinding Aerospace Alloy Using Biolubricant. Front. Mech. Eng. 2023, 18, 3–36. [Google Scholar] [CrossRef]

- Yıldız, G.; Gürel, A.E.; Cingiz, Z.; Ağbulut, Ü. Energy, Exergy, Environmental, and Economic (4E) Analyses of the Usability of Various Nano-Sized Particles Added Lubricant in a Heat Pump System. Heliyon 2024, 10, e37691. [Google Scholar] [CrossRef]

- Nugroho, A.; Mamat, R.; Xiaoxia, J.; Bo, Z.; Jamlos, M.F.; Ghazali, M.F. Performance Enhancement and Optimization of Residential Air Conditioning System in Response to the Novel FAl2O3-POE Nanolubricant Adoption. Heliyon 2023, 9, e20333. [Google Scholar] [CrossRef]

- Aljuwayhel, N.F.; Ali, N.; Ebrahim, S.A.; Bahman, A.M. Experimental Investigation of Thermophysical Properties, Tribological Properties and Dispersion Stability of Nanodiamond-Based Nanolubricant for Air Conditioning Systems. Int. J. Refrig. 2023, 145, 325–337. [Google Scholar] [CrossRef]

- Fernando, D.; Pico, M.; Rosa, L.; Hernandez, O.S.; Pedone, E.; Filho, B. International Journal of Heat and Mass Transfer Experimental Study on Thermal and Tribological Performance of Diamond Nanolubricants Applied to a Refrigeration System Using R32. Int. J. Heat Mass. Transf. 2020, 152, 119493. [Google Scholar] [CrossRef]

- Xie, M.; Xu, D.; Shen, J.; Zhang, C. Achieving the Good Thermal-Stability and Lubricity via a Dihydroxy Biolubricant from the Agro-Waste of Codonopsis Pilosula. Renew. Energy 2024, 221, 119867. [Google Scholar] [CrossRef]

- Han, T.; Zhang, C.; Luo, J. Macroscale Superlubricity Enabled by Hydrated Alkali Metal Ions. Langmuir 2018, 34, 11281–11291. [Google Scholar] [CrossRef]

- Tang, Q.; Wu, Q.Y.; Gu, L. Ultra−fast and Stable Dispersion of Graphene Oxide in Lubricant Oil toward Excellent Tribological Property. Tribol. Int. 2024, 192, 109214. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Guan, B.W.; Liang, S.W.; Liu, Q.X.; Li, Y.Q.; Fu, S.Y. Frictional and Wear Behaviors of Short Carbon Fiber Reinforced Polyetherimide Composites in an Oil Lubricant Environment. Wear 2024, 542–543, 205275. [Google Scholar] [CrossRef]

- Kamal Kamarulzaman, M.; Hisham, S.; Kadirgama, K.; Ramasamy, D.; Samykano, M.; Saidur, R.; Yusaf, T. Improving the Thermophysical Properties of Hybrid Nanocellulose-Copper (II) Oxide (CNC-CuO) as a Lubricant Additives: A Novel Nanolubricant for Tribology Application. Fuel 2023, 332, 126229. [Google Scholar] [CrossRef]

- Kumar, D.S.; Garg, H.C.; Kumar, G. Tribological Analysis of Blended Vegetable Oils Containing CuO Nanoparticles as an Additive. Mater. Today Proc. 2022, 51, 1259–1265. [Google Scholar] [CrossRef]

- Kamarapu, S.; Amarnath, M.; Tiwari, S. Nanoenhanced Biolubricant for Improving Lubrication in Roller Bearing Steel-Steel Contact Surfaces-a Comparative Tribological Study. Diam. Relat. Mater. 2025, 154, 112160. [Google Scholar] [CrossRef]

- Hamnas, A.; Unnikrishnan, G. Green Lubrication: Mustard Oil-Based Bio-Lubricant Enhanced with Waste Eggshell-Derived CaO Nanoparticles for Sustainable and Eco-Friendly Industrial Solutions. J. Clean. Prod. 2024, 453, 142184. [Google Scholar] [CrossRef]

- Khan, Z.A.; Saeed, A.; Gregory, O.; Ghafoor, A. Biodiesel Performance within Internal Combustion Engine Fuel System-A Review. Tribol. Ind. 2016, 38, 197–213. [Google Scholar]

- Bhaumik, S.; Mathew, B.R.; Datta, S. Computational Intelligence-Based Design of Lubricant with Vegetable Oil Blend and Various Nano Friction Modi Fi Ers. Fuel 2019, 241, 733–743. [Google Scholar] [CrossRef]

- Marian, M.; Tremmel, S. Current Trends and Applications of Machine Learning in Tribology—A Review. Lubricants 2021, 9, 86–128. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Marian, M.; Profito, F.J.; Aragon, N.; Shah, R. The Use of Artificial Intelligence in Tribology—A Perspective. Lubricants 2021, 9, 2. [Google Scholar] [CrossRef]

- Sebayang, A.H.; Kusumo, F.; Milano, J.; Shamsuddin, A.H.; Silitonga, A.S.; Ideris, F.; Siswantoro, J.; Veza, I.; Mofijur, M.; Reen Chia, S. Optimization of Biodiesel Production from Rice Bran Oil by Ultrasound and Infrared Radiation Using ANN-GWO. Fuel 2023, 346, 128404. [Google Scholar] [CrossRef]

- Alremali, F.A.M.; Yaylacı, E.K.; Uluer, İ. Optimization of Proportional-Integral Controllers of Grid-Connected Wind Energy Conversion System Using Grey Wolf Optimizer Based on Artificial Neural Network for Power Quality Improvement. Adv. Sci. Technol.Res. J. 2022, 16, 295–305. [Google Scholar] [CrossRef] [PubMed]

- Gul, M.; Zulkifli, N.W.M.; Kalam, M.A.; Masjuki, H.H.; Mujtaba, M.A.; Yousuf, S.; Bashir, M.N.; Ahmed, W.; Yusoff, M.N.A.M.; Noor, S.; et al. RSM and Artificial Neural Networking Based Production Optimization of Sustainable Cotton Bio-Lubricant and Evaluation of Its Lubricity & Tribological Properties. Energy Rep. 2021, 7, 830–839. [Google Scholar] [CrossRef]

| Vegetable Oil | Modification | Biolubricant | Viscosity of Pure Oil (cSt) | Viscosity of Modified Oil (cSt) | Viscosity Index | Pour Point of Modified Oil (°C) | Flash Point of Modified Oil (°C) | Oxidation Onset Temperature (°C) | Oxidation Induction Time (min) | Reference | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 °C | 100 °C | 40 °C | 100 °C | Pure Oil | Modified Oil | Pure Oil | Modified Oil | Pure Oil | Modified Oil | ||||||

| Edible oils | |||||||||||||||

| Canola | Two-stage transesterification | Canola FAME biolubricant (AV 0.39 mg KOH/g) | 34.9 | 8.1 | 10.04 | 4.09 | 219 | 377 | −10 | 222 | 164 339 | ND | 60.28–67.05, 3.4 h, 37.41 (140 °C) | 0.94 (h) | [61,65,66,67,68] |

| Two-stage transesterification | Canola TMP ester | 154.50 | 18.03 | 121 | −9 | 98 | 401 | ND | |||||||

| Coconut | Two-stage transesterification | Coconut TMP ester | 27.6 | 5.9 | 12.87 | 4.12 | 166 | 259 | 7 | 140 | 241,257 | 345 | 44.86 (140 °C) | ND | [66,69,70] |

| Grapeseed | Transesterification | FAEE | 26.92 | ND | 4.32 | ND | ND | ND | −8 | ND | ND | ND | 7.53 (140 °C) | 2.01 h | [71,72] |

| Olive | Two-stage transesterification | Canola TMP ester | ND | ND | 72.29 | 13.85 | ND | 199 | -8 | 116 | 178.65–192.28 377 | 384 | 13.94 (140 °C) | ND | |

| Palm | Hydrolysis | CPOFAs | ND | ND | 52.9 | 9.2 | ND | 130 | 10 | 240 | 179 | ND | 14 (RPVOT) 82.36 (140°C) | ND | [73,74,75,76] |

| Hydrolysis + esterification | CPOFAs-NPG diester | 50.1 | 15.5 | 190 | 7 | 245 | ND | ND | |||||||

| Enzymatic esterification | HO-PME:TMP triester | 43.7 | 9.3 | 203 | −37 | ND | ND | 41 (RPVOT) | |||||||

| Enzymatic esterification | HO-PME:TMP triester | 46.2 | 9.5 | 195 | −48 | ND | ND | ND | |||||||

| Two-stage transesterification | Palm TMP ester | 22.95 | 5.54 | 188 | 11 | 152 | 362 | ND | |||||||

| Rice bran | Epoxidation + ring opening | Epoxidized RBO Ring opened RBO | 41.13 | 5.19 | 89.28 174.8 | ND | ND | ND | −4 −7 | ND | ND | ND | 10.11 (RPVOT) | ND | [77,78,79] |

| Two-stage transesterification | Rice bran TMP ester | 32.25 | 4.55 | ND | −6 | ND | ND | 14.21 (RPVOT) | |||||||

| Epoxidation | Epoxidized rice bran oil | 93.51 | 14.94 | ND | −3 | ND | ND | 22.47 | |||||||

| Sesame | Transesterification | SEOTMPE | 25.78 | ND | 35.43 | 7.93 | ND | 206 | −12 | ND | 246 370 | ND | 69.55 (140 °C) | 378 (110 °C) | [66,69,80,81,82,83] |

| Soybean | Epoxidation + transesterification+ oxirane ring opening (hydroxylation) + acetylation | Crude | 32.93 | 8.06 | ND | ND | 233.608 | 230 | −9 | 177 | 371 173.1 | ND | 20 (140 °C) | ND | [43,66,81,84,85] |

| SOY1 (epoxidized) | ND | ND | 147 | −12 | 183 | ND | ND | ||||||||

| SOY2 (tranesterified) | ND | ND | 153 | −9 | 186 | ND | ND | ||||||||

| SOY3 (oxirane ring opened) | ND | ND | 183 | −15 | 83 | ND | ND | ||||||||

| SOY4 (acetylated) | ND | ND | 194 | −21 | 192 | 350 | ND | ||||||||

| Two-stage transesterification | EDGE | 21.30 | 6.31 | 281 | −5 | ND | 200 | ND | |||||||

| Sunflower | Transesterification | EDGE | 36.8 | 8.5 | 11.24 | 3.35 | 218 | 196 | −4 | ND | 165.81 342 | 200 | 1.1 h 19.96 (140 °C) | ND | [43,65,66,85,86] |

| Non-edible oils | |||||||||||||||

| Castor | Two-stage transesterification | Castor FAME biolubricant (AV 0.45 mg KHO/g) | 281.8 | 72.53 | 208.25 | 26.74 | 321 | 163 | −16 | 271 | ND | ND | ND | ND | [67,87,88] |

| Esterification + epoxidation + oxirane ring opening | COFA | 130.7 | 12.76 | 83 | −24 | ND | ND | 0.31 h | |||||||

| 2E1H | 28.25 | 5.03 | 104 | −3.9 | ND | ND | 3.6 h | ||||||||

| E2E1H | 57.49 | 7.79 | 99 | −36 | ND | ND | 4.3 h | ||||||||

| BIOWAT | 472.78 | 62.25 | 51 | −9 | ND | 251.5-297.1 | 3.27 h | ||||||||

| BIOBUT | 23.53 | 8.12 | 97 | −48 | ND | 233-265.7 | 4.22 h | ||||||||

| Cottonseed | Hydrolysis + esterification + ring opening and branching | Crude (AV 5.88 mg/g) | 34.3 | 8.0 | 32.55 | 7.25 | 216 | 197 | −3 | 320 | 343 159 | 370.01 303.11 | 1.9 h | 13 | [61,65,89] |

| Isodecyl ester (esterified, AV 1.02 mg/g) | 8.74 | 2.75 | 175 | −59 | ND | ND | ND | ||||||||

| Epoxide isodecyl ester (AV 10.64 mg/g) | 22.56 | 4.77 | 136 | 10 | ND | ND | ND | ||||||||

| Nonyl branched isodecyl ester (ring opening and branching, AV 0.65 mg/g) | 200.3 | 23 | 141 | −47 | 254 | 310.11 | 21 | ||||||||

| Jatropha | Transesterification | EDGE | 34.6 | 8.0 | 14.60 | 4.73 | 213 | 311 | −12 | ND | 322 169 | 200 | 2.6 h | ND | [43,65,90] |

| Esterification | TMPJO | 51 | 8.3 | 136 | −6.5 | ND | ND | ND | |||||||

| Esterification + epoxidation | ETMPJO | 160 | 21.6 | 160 | −2.1 | ND | ND | ND | |||||||

| Karanja | Two-stage transesterification | Karanja TMP ester | 43.39 | 6.93 | 33.33 | 4.76 | 117.176 | ND | 3 | ND | ND | ND | 13.4 (RPVOT) | 19.32 (RPVOT) | [61,78] |

| Epoxidation | Epoxidized Karanja oil | 78.79 | 10.17 | ND | 5 | ND | ND | 21.17 (RPVOT) | |||||||

| Neem | Epoxidation | Epoxidized neem oil | 54.37 | 10.39 | 78.51 | 11.3 | 134 | 135 | ND | 239 | ND | ND | ND | ND | [91,92,93] |

| Feedstock | Key Properties | Main Limitations | Chemical Modifications | Reference |

|---|---|---|---|---|

| Canola oil | Moderate VI, good film strength | Low oxidation resistance | Epoxidation, antioxidant addition | [67,68,69,70] |

| Soybean oil | Good lubricity | Prone to oxidation | TMP esters, hydroxylation | [83,84,85,86,87] |

| Castor oil | High VI, strong polarity | High viscosity | Estolide formation | [88,89,90] |

| Palm oil | Balanced fatty acid profile | Requires thermal stability boost | Transesterification | [75,76,77,78] |

| BSF larvae oil | High oxidative stability, unique lipids | Processing complexity | ANN-GWO optimized blending | [116,117,118] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilińska, I.; Wilkanowicz, S. Advancements in Environmentally Friendly Lubricant Technologies: Towards Sustainable Performance and Efficiency. Energies 2025, 18, 4006. https://doi.org/10.3390/en18154006

Wilińska I, Wilkanowicz S. Advancements in Environmentally Friendly Lubricant Technologies: Towards Sustainable Performance and Efficiency. Energies. 2025; 18(15):4006. https://doi.org/10.3390/en18154006

Chicago/Turabian StyleWilińska, Iwona, and Sabina Wilkanowicz. 2025. "Advancements in Environmentally Friendly Lubricant Technologies: Towards Sustainable Performance and Efficiency" Energies 18, no. 15: 4006. https://doi.org/10.3390/en18154006

APA StyleWilińska, I., & Wilkanowicz, S. (2025). Advancements in Environmentally Friendly Lubricant Technologies: Towards Sustainable Performance and Efficiency. Energies, 18(15), 4006. https://doi.org/10.3390/en18154006