Experimental Investigation into the Mechanisms of Liquid-Phase Damage in Shale Oil Reservoirs: A Case Study from the Leijia Area

Abstract

1. Introduction

2. Samples and Methods

2.1. Experimental Samples

2.2. Fracturing Fluid System

2.3. Equipments

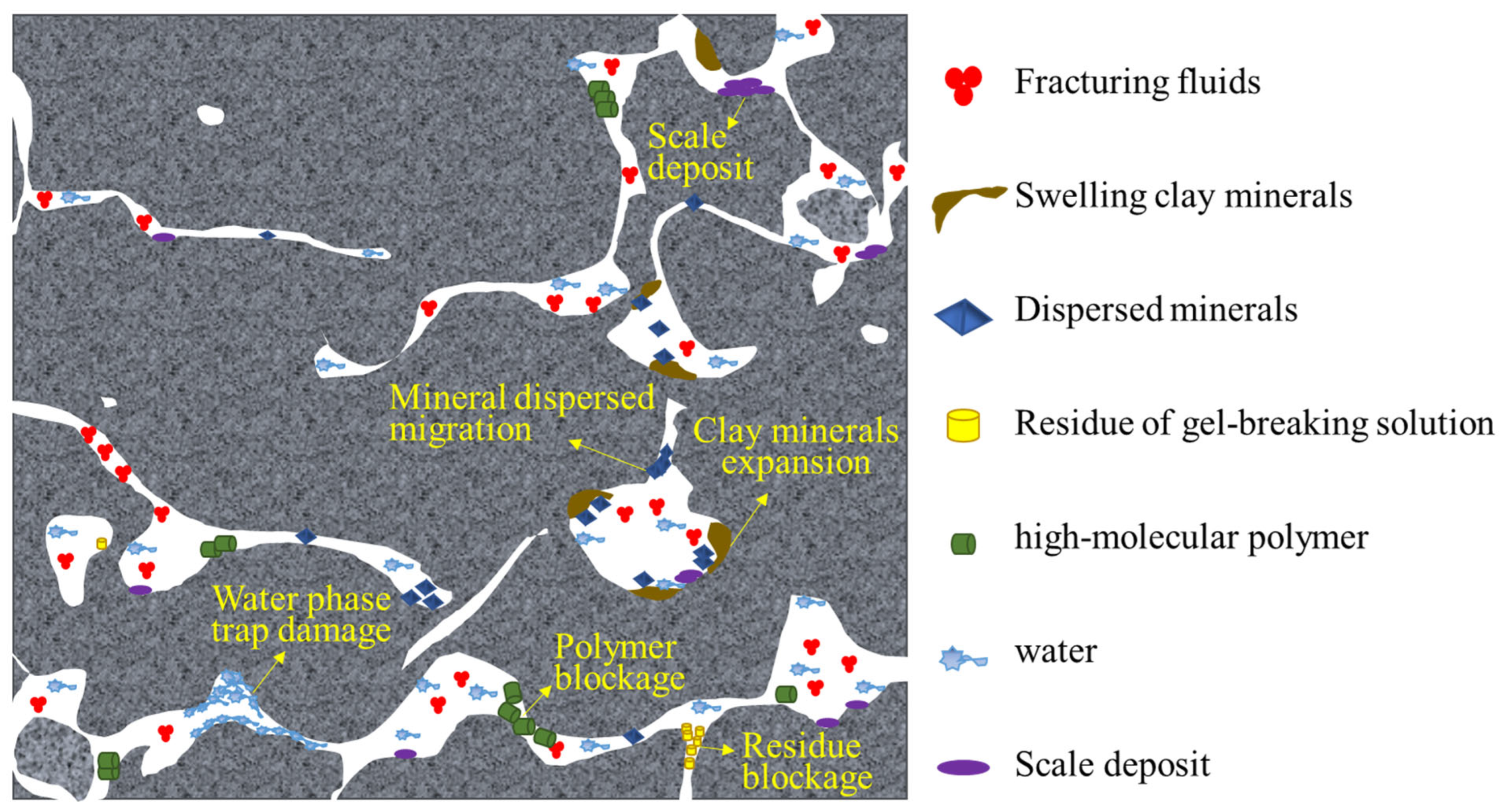

2.4. Potential Damage Mechanisms

- (1)

- Compatibility-Induced Damage Between Fracturing Fluid and Reservoir Minerals

- (2)

- Water Phase Trapping Damage

- (3)

- Reservoir Damage Caused by Fracturing Fluid Thickeners

- (4)

- Incompatibility Between Fracturing Fluids and Formation Fluids

2.5. Experimental Methods

3. Results and Discussions

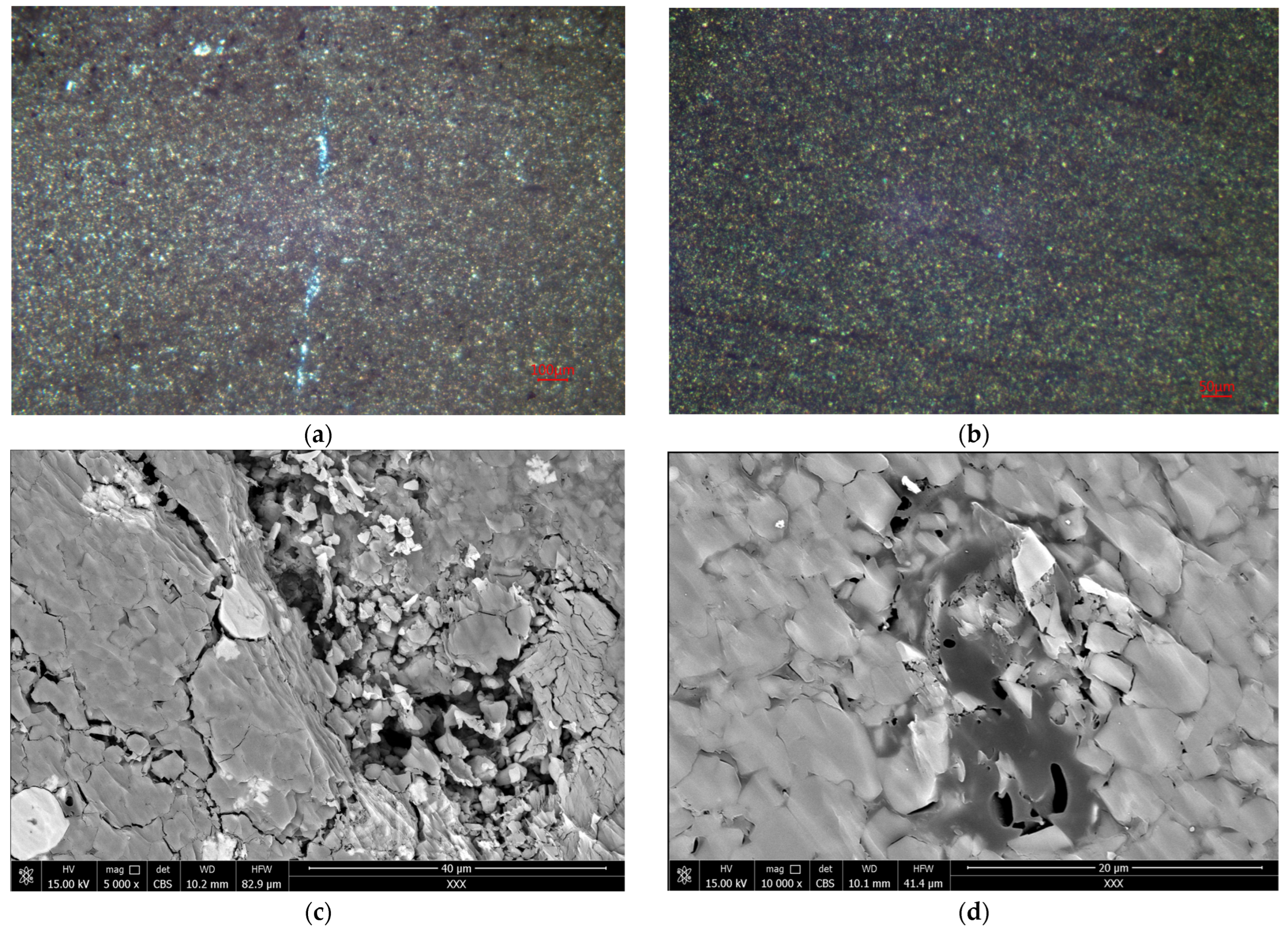

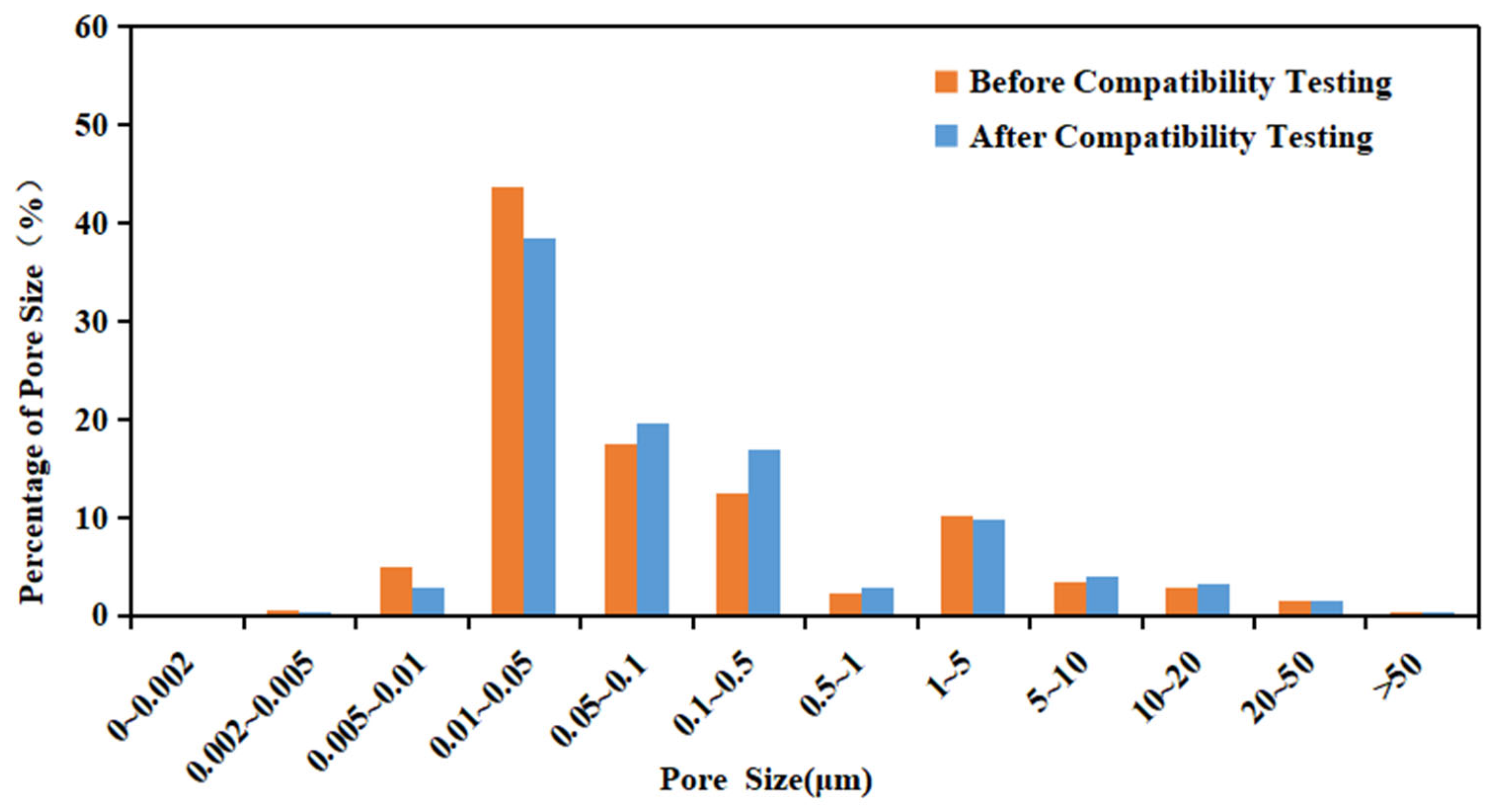

3.1. Compatibility Between Fracturing Fluid and Reservoir Minerals

- (1)

- The experimental core was washed of oil and salt, dried to a constant weight, and then the basic parameters such as the core length and diameter were measured. The porosity and permeability of the core were tested.

- (2)

- The experimental core was evacuated and saturated with formation water under pressure. The T2 spectrum distribution of the core before the experiment was tested using a nuclear magnetic resonance instrument.

- (3)

- The base fluid of the fracturing fluid was prepared according to the fracturing fluid system formula (without adding thickener), and was left to stand for 24 h and then finely filtered for later use.

- (4)

- The initial permeability K1 of the experimental core was measured in the forward direction using formation water under a certain flow rate.

- (5)

- The finely filtered base fluid of the fracturing fluid was used to displace 10–12 PV in the reverse direction. The reaction was carried out at the reservoir temperature (90 °C) for 24 h.

- (6)

- The formation water was used to backflow in the forward direction under a constant flow rate to test the permeability K2 of the core after backflowing formation water, and the permeability damage rate Ir of the core was calculated.

- (7)

- The T2 spectrum distribution of the core after dynamic damage was tested using a nuclear magnetic resonance instrument. The microscopic structural characteristics such as the pore structure and mineral occurrence of the core after the experiment were observed using a field emission scanning electron microscope.

3.1.1. Experimental Results

3.1.2. Evaluation and Analysis

3.2. Water Phase Trapping

- (1)

- The experimental core was washed of oil and salt, dried to a constant weight, and then the basic parameters such as the core length and diameter were measured. The porosity and permeability of the core were also tested.

- (2)

- The experimental core was initially saturated with water by capillary self-attraction, then vacuumed and pressurized to saturate with kerosene.

- (3)

- Under a certain flow rate, the initial permeability K1 was measured by forward kerosene flow. The initial water saturation Sw1 of the core was also tested by nuclear magnetic resonance.

- (4)

- The experimental core was displaced with 1–2 PV of the base fluid of the fracturing fluid in the reverse direction and was left to fully saturate for 1 h at the reservoir temperature (90 °C).

- (5)

- Under a constant speed, the core was forwardly backflushed with kerosene to test the oil phase permeability K2. The water saturation Sw2 of the core after water lock damage was tested by nuclear magnetic resonance. The permeability damage rate Ik of the core was calculated.

3.2.1. Experimental Results

3.2.2. Evaluation and Analysis

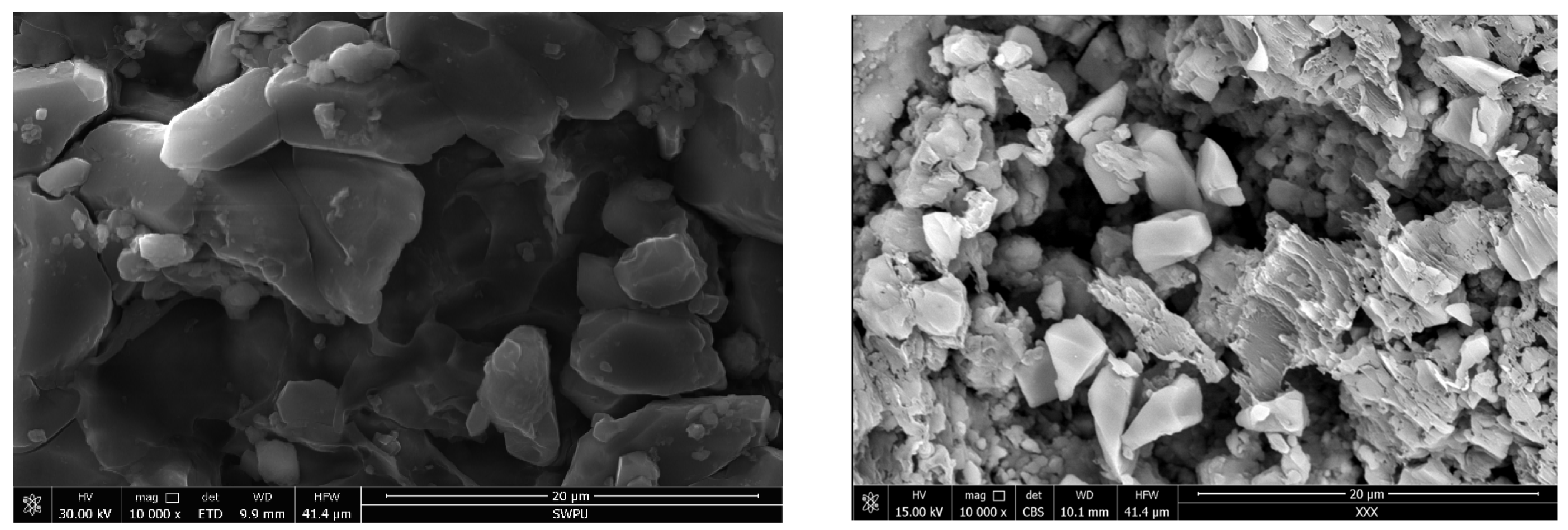

3.3. Polymer Adsorption and Retention Damage

- (1)

- The experimental core was washed of oil and salt, dried to a constant weight, and then the basic parameters such as core length and diameter were measured. The porosity and permeability of the core were tested.

- (2)

- The guar gum fracturing fluid system was prepared according to the formula and then broken down. The broken-down fracturing fluid was centrifuged using a high-speed centrifuge, and the clear broken-down fluid at the top was reserved for later use.

- (3)

- The experimental core was evacuated and pressurized to be saturated with formation water.

- (4)

- Under a certain flow rate, the initial permeability K1 was measured in the forward direction using formation water. The T2 spectrum distribution of the core was tested using a nuclear magnetic resonance instrument.

- (5)

- The core was displaced in the reverse direction with 1–2 PV of the broken-down fracturing fluid, and then left to stand for 2 h at the reservoir temperature (90 °C).

- (6)

- The core was tested for natural flowback permeability K2 in the forward direction using formation water. During the flowback process, the water phase was collected for ESEM environmental scanning electron microscopy observation, and the natural permeability recovery rate Ik was calculated.

- (7)

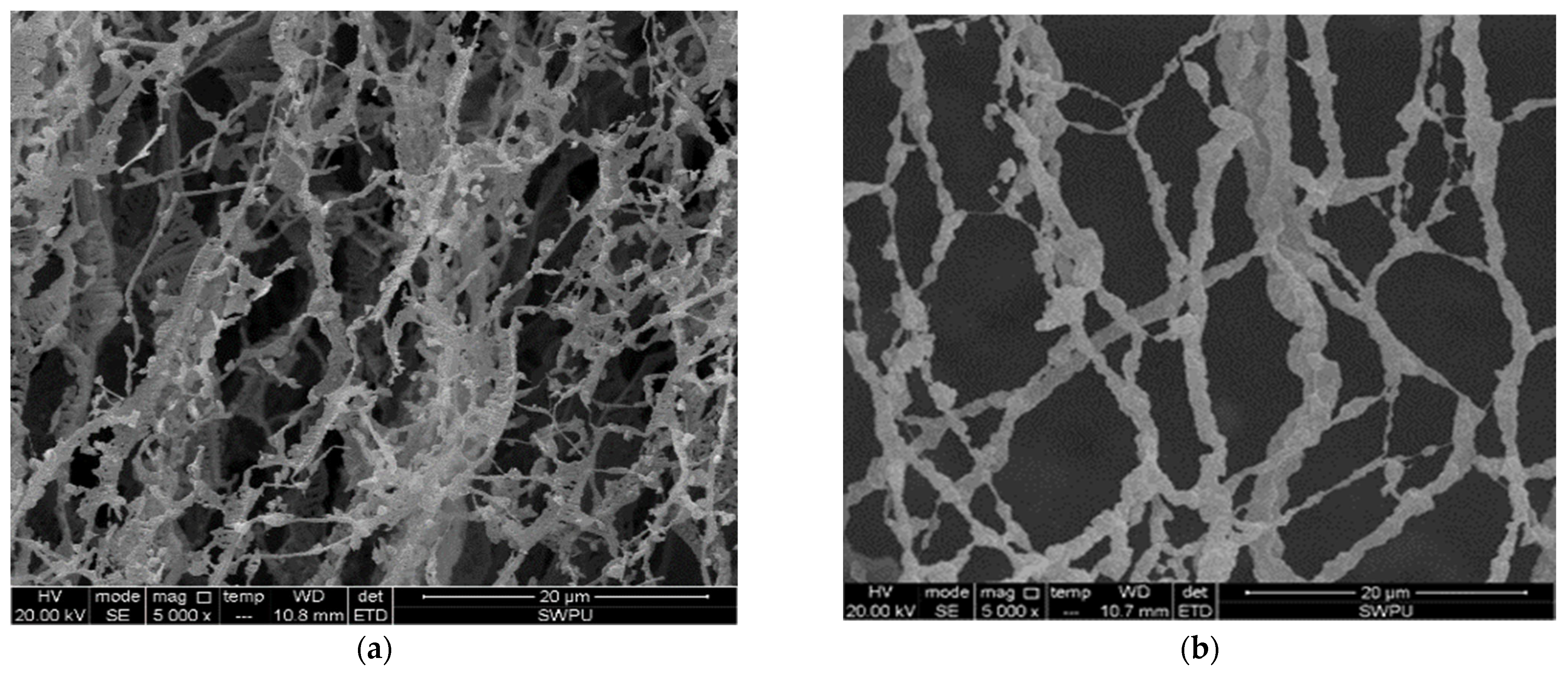

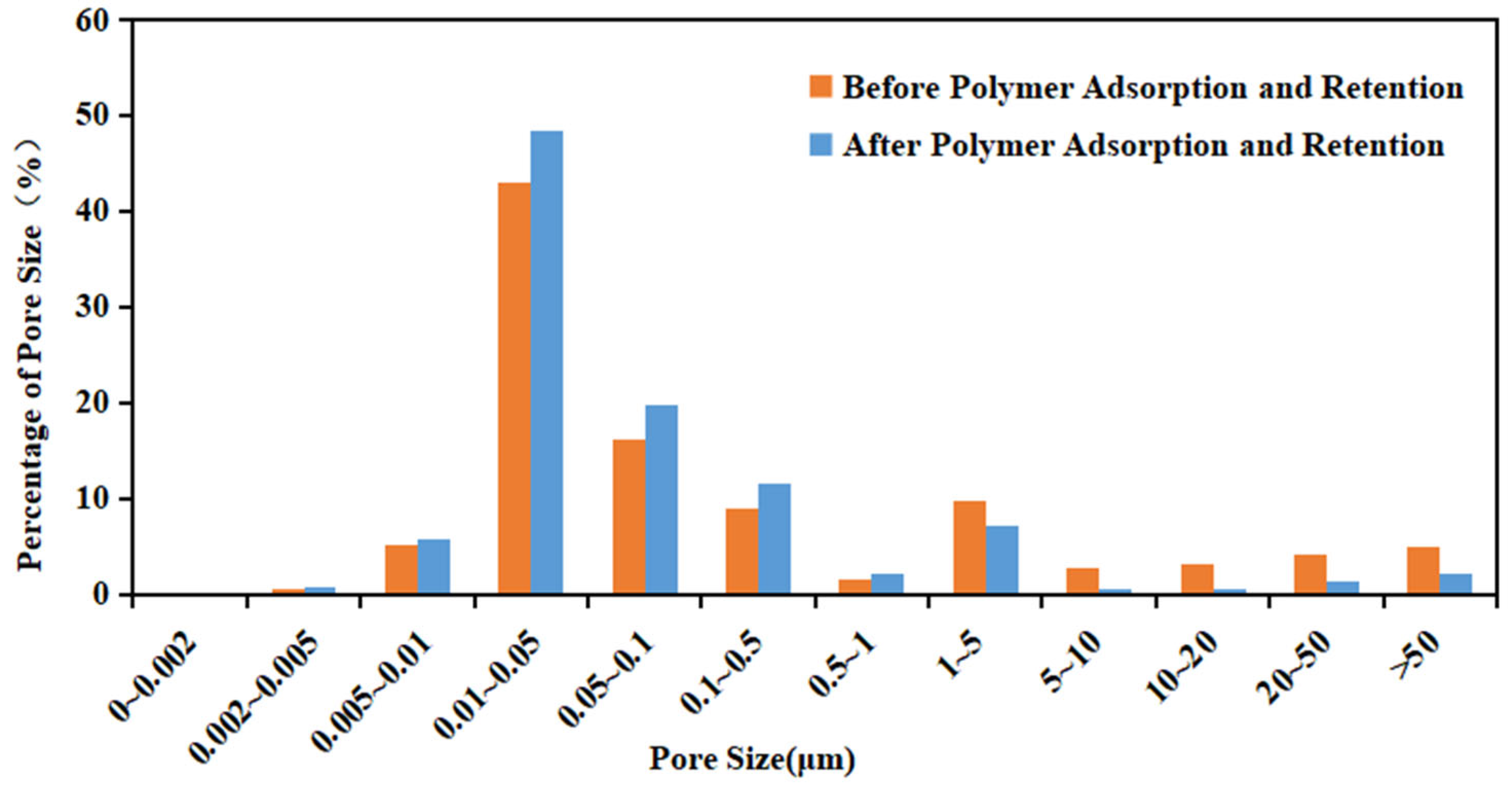

- The T2 spectrum distribution of the core after polymer damage was tested using nuclear magnetic resonance. The microscopic structural characteristics of the core after the experiment were observed using a scanning electron microscope.

3.3.1. Experimental Results

3.3.2. Evaluation and Analysis

4. Suggestions

- (1)

- Enhance the gel-breaking performance of the fracturing fluid to ensure thorough hydration and gel breaking, thereby reducing the viscous resistance during fluid flow within the formation.

- (2)

- Incorporate highly effective flowback agents in the fluid system to reduce oil–water interfacial tension. Given that the reservoir pore throats are predominantly micro- and nano-scale and that bound water potential is significant, the selection of flowback agents must be optimized specifically for the reservoir characteristics of the study area.

- (3)

- Promote rapid gel breaking of the fracturing fluid and employ small-diameter nozzles post-fracturing to utilize residual pressure for forced fracture fluid flowback, minimizing fluid retention time in the reservoir.

- (4)

- Utilize auxiliary flowback methods such as liquid nitrogen or CO2 injection to enhance fluid removal from the fractures.

- (5)

- Apply interfacial modification techniques to alter the wettability of the rock surface by adjusting surface energy or morphology, thereby mitigating the degree of water-phase blockage damage.

- (6)

- Adopt low-residue or residue-free, easily breakable, and low-polymer concentration water-based fracturing fluid systems, such as clean fracturing fluids or low-concentration polymer fluids, to further reduce formation damage.

5. Conclusions

- (1)

- Based on relevant petroleum and natural gas industry standards and the geological characteristics of shale oil reservoirs, an effective experimental evaluation method for assessing fracturing fluid damage to shale oil reservoirs was developed. This method enables the identification and quantification of different damage mechanisms caused by fracturing fluids, thereby providing valuable guidance for the design and optimization of fracturing fluid systems.

- (2)

- Experimental evaluation results indicate that the primary damage mechanisms of fracturing fluids to the shale oil reservoir in the Leijia area are water-phase blockage and polymer adsorption retention. It is recommended to adopt water-based fracturing fluid systems with low or zero residue, easy gel breaking, and low polymer concentration; to select highly efficient flowback agents; and to apply interfacial modification technologies to alter reservoir wettability. These measures effectively improve fracturing fluid performance and protect the shale oil reservoir.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kuang, L.; Hou, L.; Yang, Z.; Wu, S. Key parameters and methods of lacustrine shale oil reservoir characterization. Acta Pet. Sin. 2021, 42, 1–14. [Google Scholar]

- Zou, C.; Yang, Z.; Cui, J.; Zhu, R.; Hou, L.; Tao, S.; Yuan, X.; Wu, S.; Lin, S.; Wang, L.; et al. Formation mechanism, geological characteristics and development strategy of nonmarine shale oil in China. Pet. Explor. Dev. 2013, 40, 14–26. [Google Scholar] [CrossRef]

- Jin, Z.J.; Bai, Z.R.; Gao, B.; Li, M. Has China ushered in the shale oil and gas revolution? Oil Gas Geol. 2019, 40, 451–458. [Google Scholar]

- Li, Q.; Zhao, D.; Yin, J.; Zhou, X.; Li, Y.; Chi, P.; Han, Y.; Ansari, U.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-bearing Sediment in Northern South China Sea by Horizontal Wellbore: Evolution and Mechanism. Nat. Resour. Res. 2023, 32, 1595–1620. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Xu, N.; Wang, Y.; Bai, B. Settling behavior and mechanism analysis of kaolinite as a fracture proppant of hydrocarbon reservoirs in CO2 fracturing fluid. Colloids Surf. A Physicochem. Eng. Asp. 2023, 724, 137463. [Google Scholar] [CrossRef]

- Jinsheng, S.; Chengyuan, X.; Yili, K.; Jie, Z. Research Progress and Development Recommendations Covering Damage Mechanisms and Protection Technologies for Tight/Shale Oil and Gas Reservoirs. Pet. Drill. Tech. 2020, 48, 1–9. [Google Scholar]

- Bennion, D.B. An overview of formation damage mechanisms causing a reduction in the productivity and injectivity of oil and gas producing formations. J. Can. Pet. Technol. 2002, 44, 29–36. [Google Scholar] [CrossRef]

- Civan, F. Reservoir Formation Damage, 2nd ed.; Gulf Professional Publishing: London, UK, 2015. [Google Scholar]

- Luo, X.; Nguyen, Q.; Di Carlo, D. Experimental study on the formation damage caused by gas fracturing fluids. J. Pet. Sci. Eng. 2020, 192, 107254. [Google Scholar] [CrossRef]

- Wang, J.; Huang, Y.; Zhang, Y. Study of Fracturing Fluid on Gel Breaking Performance and Damage to fracture conductivity. J. Pet. Sci. Eng. 2020, 193, 107443. [Google Scholar] [CrossRef]

- Cheng, B.; Li, J.; Li, J. Pore-scale formation damage caused by fracturing fluids in low-permeability sandy conglomerate reservoirs. J. Pet. Sci. Eng. 2021, 208, 109301. [Google Scholar] [CrossRef]

- Al-Ameri, A.; Gamadi, T.; Ispas, I. Evaluation of the near fracture face formation damage caused by the spontaneously imbibed fracturing fluid in unconventional gas reservoirs. J. Pet. Sci. Eng. 2018, 171, 23–36. [Google Scholar] [CrossRef]

- Luo, X.; Jiang, G.; Yang, L. Experimental investigation of formation damage during drilling of ultradeep fractured carbonate reservoir. Geomech. Energy Environ. 2023, 33, 100437. [Google Scholar] [CrossRef]

- Yin, L.; Zhao, F.; Tang, H. Reseach on the characteristics of the dense oil reservoir in the shale 4 menber of the Shahejie Formation in Leijia area. Contrib. Geol. Miner. Resour. Res. 2020, 35, 178–186. [Google Scholar]

- Wang, Y.; Wang, S.; Li, J. The hydrocarbon expulsion efficiency of medium-low mature source rocks and tight-shale oil potential in the Es4, Leijia area in West Depression, Liaohe Basin. Oil Gas Geol. 2019, 40, 810–821. [Google Scholar]

- SY/T 5107-2016; The Evaluation Measurement for Properties of Water-Based Fracturing Fluids. National Energy Administration: Beijing, China, 2016.

- Xu, T. Technology for Protecting Oil and Gas Layers; Petroleum Industry Press: Beijing, China, 2010. [Google Scholar]

- Wang, B.; Liu, B.; Yang, J.; Bai, L.; Li, S. Compatibility characteristics of fracturing fluid and shale oil reservoir: A case study of the first member of Qingshankou Formation, northern Songliao Basin, Northeast China. J. Pet. Sci. Eng. 2022, 211, 110161. [Google Scholar] [CrossRef]

- Tang, H.; Lv, J.; Lv, D. Study on mechanism of gas and liquid interaction in complex perforation. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2009, 31, 91–94. [Google Scholar]

- Tan, J.; Hu, C.; Lyu, Q.; Feng, G.; Chen, S. Experimental investigation on the effects of different fracturing fluids on shale surface morphology. J. Pet. Sci. Eng. 2022, 212, 110356. [Google Scholar] [CrossRef]

- Guo, J.; Li, Y.; Wang, S. Hydrogen bond inhibition method: Reducing the adsorption damage of guar fracturing fluid to sandstone reservoirs. Nat. Gas Ind. 2019, 39, 57–62. [Google Scholar]

- Cao, Y.; Qu, Z.; Guo, T.; Huaru, X.; Gong, D. Experimental Study on Damage Mechanism of Water-based Fracturing Fluid to Reservoir. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2016, 31, 87–92. [Google Scholar]

- Guo, J.; He, C. Microscopic mechanism of the damage caused by gelout process of fracturing fluid. Acta Pet. Sin. 2012, 33, 1018. [Google Scholar]

- Shao, J.; You, L.; Kang, Y.; Chen, M.; Tian, J. Salinity of flowback fracturing fluid in shale reservoir and its reservoir damage: Experimental and field study. J. Pet. Sci. Eng. 2022, 211, 110217. [Google Scholar] [CrossRef]

- Shao, J.; You, L.; Jia, N.; Kang, Y.; Chen, M. Investigation of induced change in pore structure by the reaction of shale with fracturing fluid. Gas Sci. Eng. 2023, 110, 204860. [Google Scholar] [CrossRef]

- Gong, C. Research on the Geological Characteristics of the Reservoir and the Damage Mechanism of Fracturing Fluid in the Shahejie Formation of the G94 Fault Block in Jidong Oilfield. Ph.D. Thesis, Southwest Petroleum University, Chengdu, China, 2016. [Google Scholar]

- SY/T 5358-2010; Formation Damage Evaluation by Flow Test. National Energy Administration: Beijing, China, 2010.

- SY/T 6540-2021; Lab Testing Method of Drilling and Completion Fluid Damaging Oil Formation. National Energy Administration: Beijing, China, 2021.

- Behr, A.; Mtchedlishvili, G.; Friedel, T.; Haefner, F. Consideration of damaged zone in a tight gas reservoir model with a hydraulically fractured well. SPE Prod. Opertions 2006, 21, 206–211. [Google Scholar] [CrossRef]

- Zhang, X. Researching on the Use of New Type Surfactant to Weaken Water Blocking and Jiamin Effect. Ph.D. Thesis, Ocean Universty of China, Qingdao, China, 2013. [Google Scholar]

- Yang, Y.; Cai, M.; Chu, Y.; Wang, A. Effect of wettability on fracturing fluid microscale flow in shale oil reservoirs. Int. J. Hydrog. Energy 2024, 67, 500–505. [Google Scholar] [CrossRef]

- Lu, L.; Li, J.; Zhang, X.; Li, Y.; Ma, F. Effects of Clay Minerals and External Pressures on Imbibition in Shales. Energies 2021, 14, 7528. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Liang, L.; Xiong, J. Experimental study on the damage of organic-rich shale during water-shale interaction. J. Nat. Gas Sci. Eng. 2020, 74, 103103. [Google Scholar] [CrossRef]

- Cheng, Y.; Brown, K.M.; Prud’homme, R.K. Characterization and intermolecular interactions of hydroxypropyl guar solutions. Biomacromolecules 2002, 3, 456–461. [Google Scholar] [CrossRef]

- Guo, B. The role of formation damage in hydraulic fracturing shale gas wells. In Proceedings of the SPE Eastern Regional Meeting, Columbus, OH, USA, 17–19 August 2011; pp. 1–13. [Google Scholar]

| Dolomite | Quartz | Feldspar | Mordenite | Clay Minerals | Clay Mineral Content (%) | |

|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | (%) | I | I/S |

| 32.81 | 19.3 | 11.2 | 6.4 | 18.5 | 24.1 | 71.2 |

| Breaker Time (min) | Apparent Viscosity of Base Fluid (mPa·s) | Viscosity of Crosslinked Fluid (mPa·s) | Viscosity After Gel Break (mPa·s) | Interfacial Tension (mN/m) | Residue Content (mg/L) |

|---|---|---|---|---|---|

| 120 | 56.2 | 73.9 | 4.3 | 6.09 | 206.3 |

| No. | Identified Issues | Proposed Improvements and Optimization Measures |

|---|---|---|

| 1 | Dense matrix leading to poor displacement efficiency | Apply backpressure to enhance permeability of tight cores; use pulse decay method for permeability measurement |

| 2 | Difficulty in saturating core samples with formation fluids | Employ vacuum extraction with molecular pumps and pressure-assisted saturation techniques |

| 3 | Absence of initial water saturation conditions | Establish initial water saturation using capillary imbibition; apply vacuum and pressurized saturation methods for oil saturation |

| 4 | Limited evaluation parameters and insufficient understanding of damage mechanisms | Utilize environmental scanning electron microscopy (ESEM) and nuclear magnetic resonance (NMR) to characterize mineral and pore structure alterations before and after fluid exposure, thus enhancing understanding of damage mechanisms |

| No. | Well ID | Well Depth (m) | Formation Interval | KW1 (mD) | KW2 (mD) | Ir (%) |

|---|---|---|---|---|---|---|

| 1 | Lei 88-59-85 | 3508.50 | Shahejie Formation Member 4 | 17.377 | 15.625 | 89.92 |

| 2 | Lei 88-59-85 | 3496.57 | Shahejie Formation Member 4 | 1.927 | 1.586 | 82.30 |

| 3 | Lei 88-59-85 | 3495.57 | Shahejie Formation Member 4 | 1.531 | 1.380 | 90.11 |

| 4 | Lei 88-59-85 | 3484.18 | Shahejie Formation Member 4 | 0.932 | 0.792 | 84.98 |

| No. | Well ID | Well Depth (m) | Formation Interval | K1 (mD) | Sw1 (%) | K2 (mD) | Sw2 (%) | Ik (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | Lei 88 | 3487.18 | Shahejie Formation Member 4 | 1.985 | 52.16 | 1.037 | 62.32 | 52.24 |

| 2 | Lei 88 | 3498.70 | Shahejie Formation Member 4 | 3.211 | 49.88 | 1.930 | 53.42 | 60.11 |

| 3 | Lei 88 | 3498.57 | Shahejie Formation Member 4 | 3.014 | 40.29 | 1.782 | 50.25 | 59.12 |

| 4 | Lei 96 | 3080.02 | Shahejie Formation Member 4 | 0.676 | 42.76 | 0.320 | 52.65 | 47.34 |

| No. | Well ID | Well Depth (m) | Formation Interval | K1 (mD) | K2 (mD) | Ik (%) |

|---|---|---|---|---|---|---|

| 1 | Lei 88-59-85 | 3497.67 | Shahejie Formation Member 4 | 1.113 | 0.732 | 65.75 |

| 2 | Lei 96 | 3124.60 | Shahejie Formation | 0.920 | 0.698 | 75.87 |

| 3 | Lei 88-59-85 | 3500.37 | Shahejie Formation | 0.684 | 0.405 | 59.23 |

| 4 | Lei 88-59-85 | 3508.50 | Shahejie Formation | 1.289 | 0.863 | 66.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, T.; Ma, C.; Li, Y.; Zhao, F.; Wang, X.; Xu, J. Experimental Investigation into the Mechanisms of Liquid-Phase Damage in Shale Oil Reservoirs: A Case Study from the Leijia Area. Energies 2025, 18, 3990. https://doi.org/10.3390/en18153990

Gu T, Ma C, Li Y, Zhao F, Wang X, Xu J. Experimental Investigation into the Mechanisms of Liquid-Phase Damage in Shale Oil Reservoirs: A Case Study from the Leijia Area. Energies. 2025; 18(15):3990. https://doi.org/10.3390/en18153990

Chicago/Turabian StyleGu, Tuan, Chenglong Ma, Yugang Li, Feng Zhao, Xiaoxiang Wang, and Jinze Xu. 2025. "Experimental Investigation into the Mechanisms of Liquid-Phase Damage in Shale Oil Reservoirs: A Case Study from the Leijia Area" Energies 18, no. 15: 3990. https://doi.org/10.3390/en18153990

APA StyleGu, T., Ma, C., Li, Y., Zhao, F., Wang, X., & Xu, J. (2025). Experimental Investigation into the Mechanisms of Liquid-Phase Damage in Shale Oil Reservoirs: A Case Study from the Leijia Area. Energies, 18(15), 3990. https://doi.org/10.3390/en18153990