Application of High Efficiency and High Precision Network Algorithm in Thermal Capacity Design of Modular Permanent Magnet Fault-Tolerant Motor

Abstract

1. Introduction

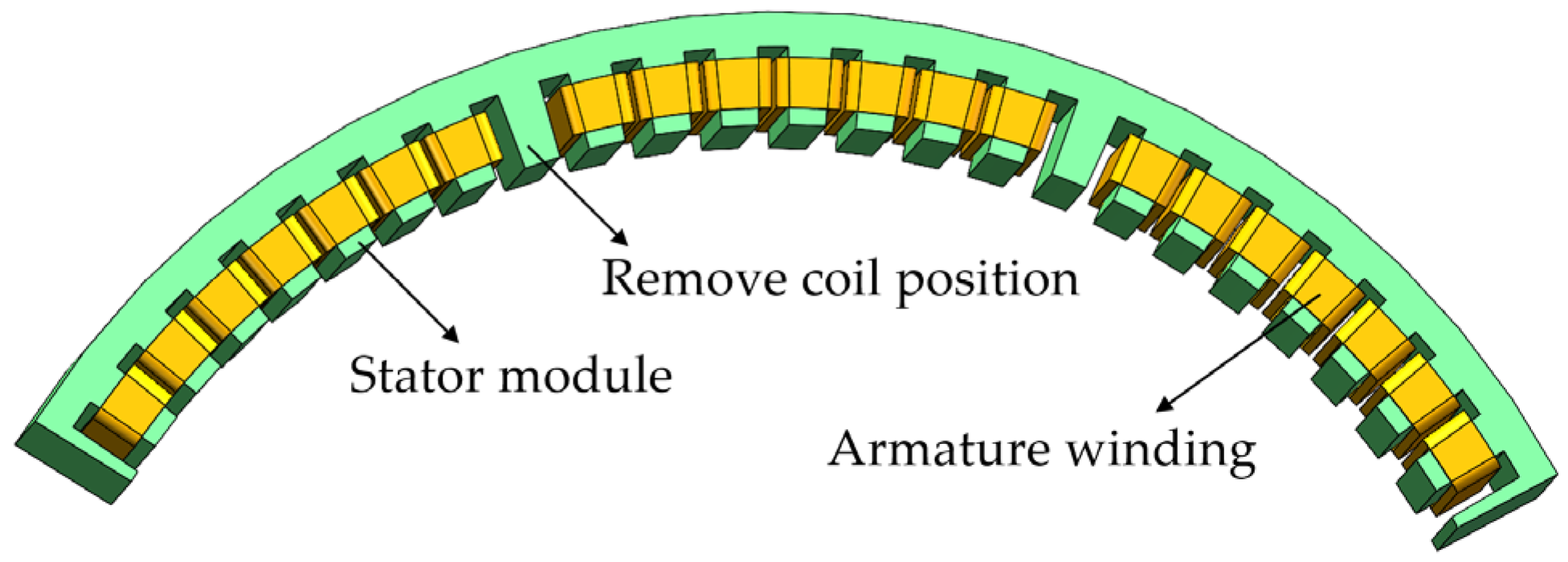

2. Performance Analysis of MFT-PMSMs

2.1. Electromagnetic Design of MFT-PMSMs

2.2. Loss Calculation of MFT-PMSM

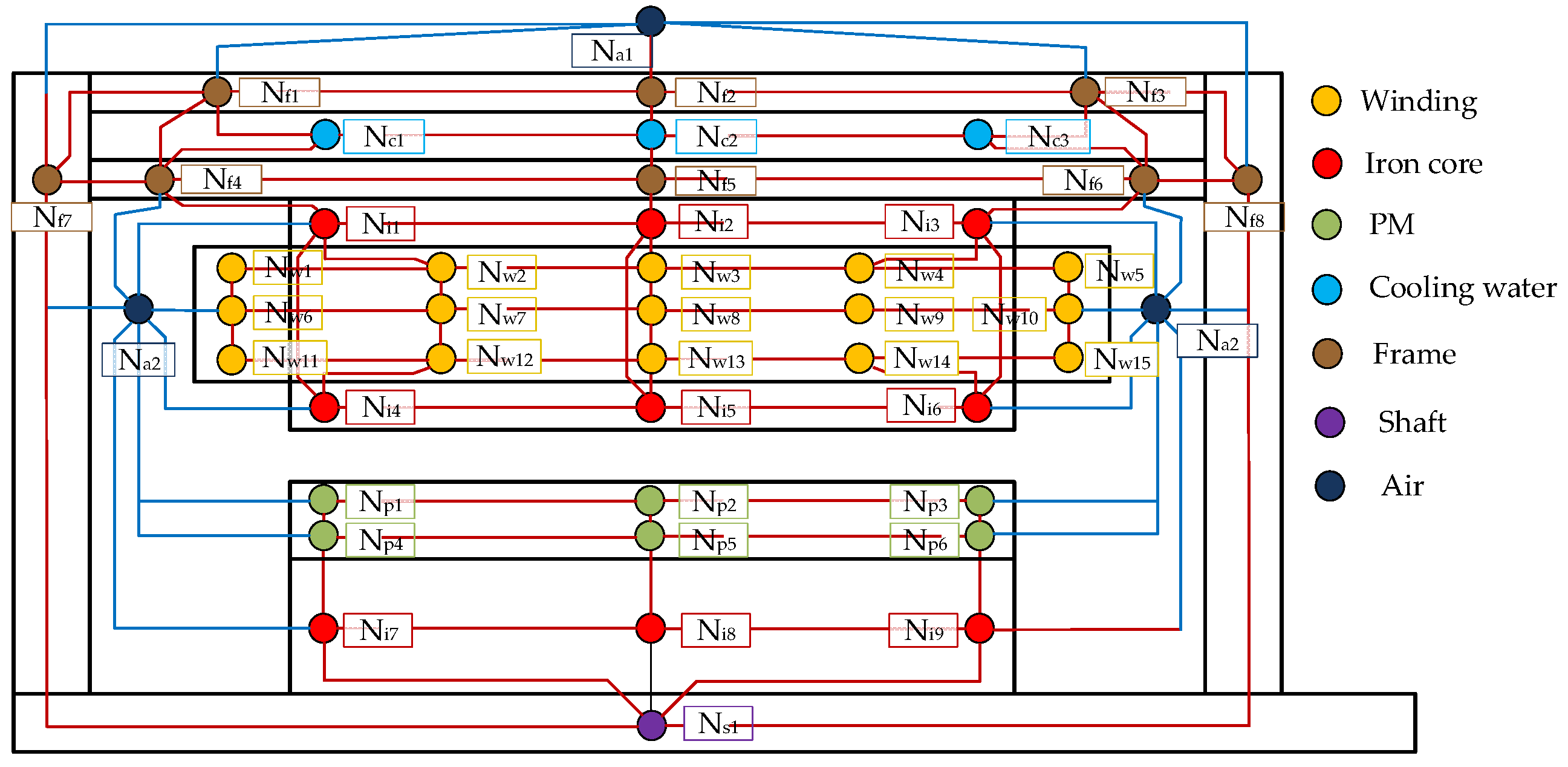

3. Thermal Network Algorithm Considering Temperature Change of Cooling Medium

3.1. Construction of Thermal Network Model

3.2. Thermal Network Parameters Calculation

3.2.1. Thermal Resistance Calculation

3.2.2. Calculation of Convective Heat Transfer Coefficient

3.3. Calculate Temperature Using Transient Heat Conduction Equation

3.4. Temperature Solution Results and Analysis

4. Fluid-Solid Coupling Temperature Simulation

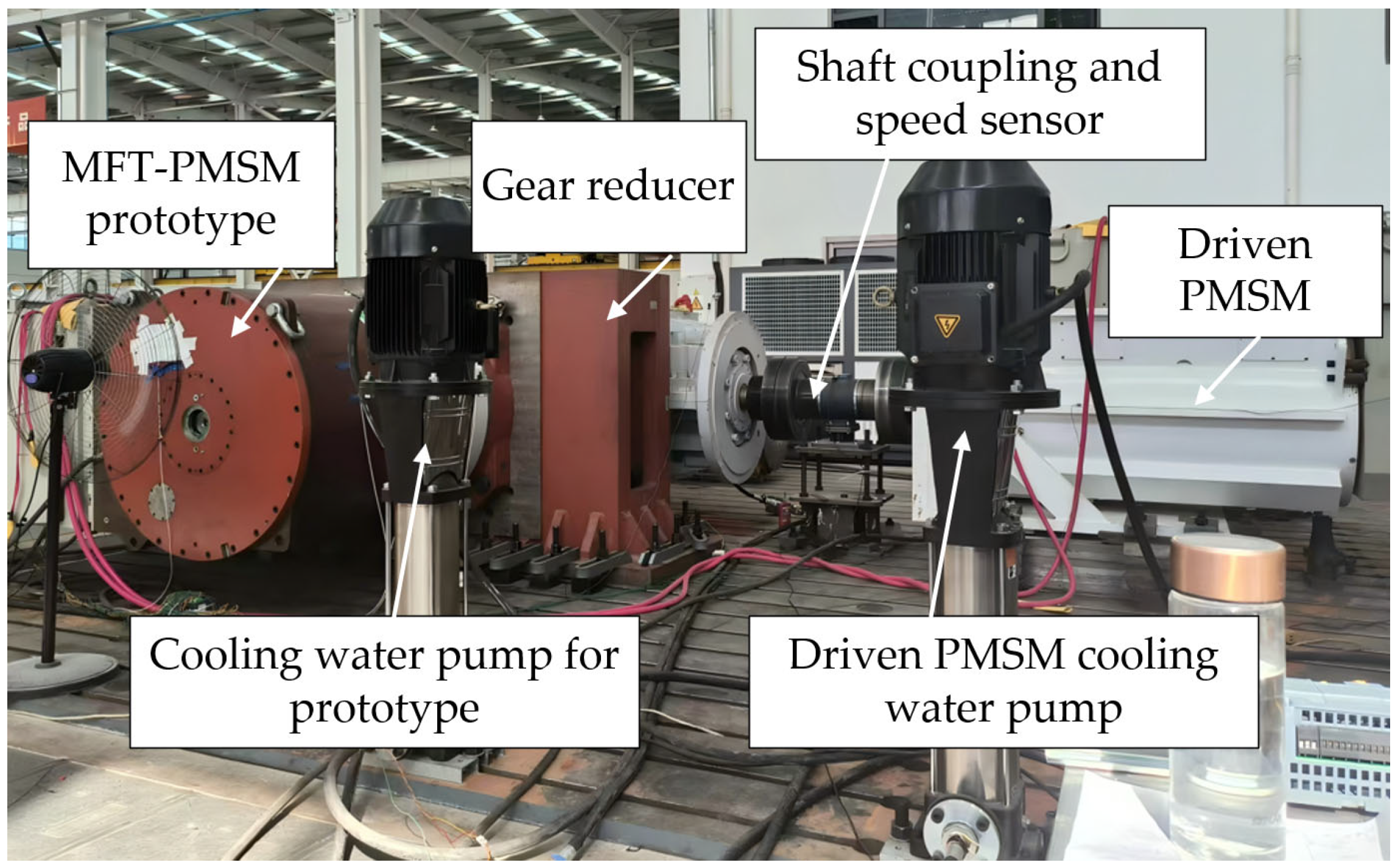

5. Experimental Verification

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, X.; Zhang, Z.; Ma, K.; Weng, X.; Bu, F. Design and Analysis of a Fault-Tolerant Permanent Magnet Steering Motor for Electric Vehicles. IEEE Trans. Energy Convers. 2025, 40, 970–983. [Google Scholar] [CrossRef]

- Tang, Y.; Chai, F.; Xie, Y.; Cai, W.; Guo, Q.; Tian, J. Investigation of Fault-Tolerant Performance and Inductance in a Modular Permanent Magnet In-Wheel Motor. IEEE Trans. Magn. 2023, 59, 1–6. [Google Scholar]

- Zhang, B.; Gan, B.; Li, Q. Analysis of a Fault-Tolerant Module-Combined Stator Permanent Magnet Synchronous Machine. IEEE Access 2020, 8, 70438–70452. [Google Scholar] [CrossRef]

- Zhang, L.; Deng, S.; Zhu, X.; Shen, D.; Chen, C.; Li, X. Multiple Operation Design and Optimization of a Five-Phase Interior Permanent Magnet Motor Considering Compound Fault Tolerance from Perspective of Flux-Intensifying Effect. IEEE Trans. Transp. Electrif. 2024, 10, 9043–9054. [Google Scholar] [CrossRef]

- Madhavan, S.; P B, R.D.; Gundabattini, E.; Mystkowski, A. Thermal Analysis and Heat Management Strategies for an Induction Motor, a Review. Energies 2022, 15, 8127. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, L.; Chai, F.; Chen, T. Thermal Modeling and Analysis of Active and End Windings of Enclosed Permanent-Magnet Synchronous In-Wheel Motor Based on Multi-Block Method. IEEE Trans. Energy Convers. 2020, 35, 85–94. [Google Scholar] [CrossRef]

- Bourgault, A.; Taqavi, O.; Li, Z.; Byczynski, G.; Kar, N.C. Advanced Lumped Parameter Thermal Network for Modeling of Cooling Solutions in Electric Vehicle Motor Applications. IEEE Trans. Magn. 2024, 60, 8205405. [Google Scholar] [CrossRef]

- Ma, Y.; Xiao, Y.; Wang, J.; Zhou, L. Multicriteria Optimal Latin Hypercube Design-Based Surrogate-Assisted Design Optimization for a Permanent-Magnet Vernier Machine. IEEE Trans. Magn. 2022, 58, 1–5. [Google Scholar] [CrossRef]

- Fasquelle, A.; Laloy, D. Water Cold Plates Cooling in a Permanent Magnet Synchronous Motor. IEEE Trans. Ind. Appl. 2017, 53, 4406–4413. [Google Scholar] [CrossRef]

- Li, B.; Yan, L.; Cao, W. An Improved LPTN Method for Determining the Maximum Winding Temperature of a U-Core Motor. Energies 2020, 13, 1566. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Y.; Gao, Y.; Hua, W.; Ni, Q.; Zhang, H. Thermal Model Approach to the YASA Machine for In-Wheel Traction Applications. Energies 2022, 15, 5431. [Google Scholar] [CrossRef]

- Li, C.; Zhang, H.; Hua, W.; Yin, H.; Zhang, K.; Su, L. Thermal Modeling and Loss Analysis of Fractional-Slot Concentrated Winding Permanent Magnet Motors for Improved Performance. IEEE Trans. Transp. Electrif. 2024, 10, 7151–7159. [Google Scholar] [CrossRef]

- Yu, S.; Zhou, Y.; Wang, Y.; Zhang, J.; Dong, Q.; Tian, J.; Chen, J.; Leng, F. Optimization Study of Cooling Channel for the Oil Cooling Air Gap Armature in a High-Temperature Superconducting Motor. Electronics 2024, 13, 97. [Google Scholar] [CrossRef]

- Hu, K.; Zhang, G.; Zhang, W. Rotor Design and Optimization of High-Speed Surface-Mounted Permanent Magnet Motor Based on the Multi-Physical Field Coupling Method. IEEE Access 2023, 11, 69614–69625. [Google Scholar] [CrossRef]

- Ai, Q.; Wei, H.; Dou, H.; Zhao, W.; Zhang, Y. Robust Rotor Temperature Estimation of Permanent Magnet Motors for Electric Vehicles. IEEE Trans. Veh. Technol. 2023, 72, 8579–8591. [Google Scholar] [CrossRef]

- Jing, H.; Chen, Z.; Wang, X.; Wang, X.; Ge, L.; Fang, G.; Xiao, D. Gradient Boosting Decision Tree for Rotor Temperature Estimation in Permanent Magnet Synchronous Motors. IEEE Trans. Power Electron. 2023, 38, 10617–10622. [Google Scholar] [CrossRef]

- Tang, P.; Zhao, Z.; Li, H. Short-Term Prediction Method of Transient Temperature Field Variation for PMSM in Electric Drive Gearbox Using Spatial-Temporal Relational Graph Convolutional Thermal Neural Network. IEEE Trans. Ind. Electron. 2024, 71, 7839–7852. [Google Scholar] [CrossRef]

- Jin, L.; Mao, Y.; Wang, X.; Lu, L.; Wang, Z. A Model-Based and Data-Driven Integrated Temperature Estimation Method for PMSM. IEEE Trans. Power Electron. 2024, 39, 8553–8561. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, B.; Feng, G. Analysis of Unwinding Stator Module Combined Permanent Magnet Synchronous Machine. IEEE Access 2020, 8, 191901–191909. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, B.; Feng, G. Research on Thermal Capacity of a High-Torque-Density Direct Drive Permanent Magnet Synchronous Machine Based on a Temperature Cycling Module. IEEE Access 2020, 8, 155721–155731. [Google Scholar] [CrossRef]

- Welty, J.; Rorrer, G.L.; Foster, D.G. Fundamentals of Momentum, Heat and Mass Transfer, 6th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014. [Google Scholar]

- Lu, Q.; Zhang, X.; Chen, Y.; Huang, X.; Ye, Y.; Zhu, Z.Q. Modeling and Investigation of Thermal Characteristics of a Water-Cooled Permanent-Magnet Linear Motor. IEEE Trans. Ind. Appl. 2015, 51, 2086–2096. [Google Scholar] [CrossRef]

- IEC60751; Industrial Platinum Resistance Thermometers and Platinum Temperature Sensors. International Electrotechnical Commission: Geneva, Switzerland, 2022.

| Parameter | Value | Unit |

|---|---|---|

| Outer diameter | 1400 | mm |

| Inner diameter | 1225 | mm |

| Axial length (Before/After module) | 590/665 | mm |

| Slots/Poles | 72/60 | |

| PM thickness | 14 | mm |

| Air-gap length | 2 | mm |

| Iron core type | 50WW470 | |

| PM materials | N38SH | |

| Operational speed | 75 | r/min |

| Maximal torque | 59,000 | Nm |

| DC Bus Voltage | 8000 | V |

| Operating Conditions | Current (A) | Electromagnetic Torque (kN/m) |

|---|---|---|

| Rated load condition | 86 | 55.2 |

| Overload condition | 129 | 78.6 |

| Single module fault condition | 86 | 36.8 |

| Operating Conditions | Loss Category | Value |

|---|---|---|

| Rated load condition | copper loss Pcu | 14,377.9 |

| stator iron loss Pfe | 11,943.6 | |

| PM eddy current loss Ppm | 630.9 | |

| Overload condition | copper loss Pcu | 31,997.8 |

| stator iron loss Pfe | 13,492.2 | |

| PM eddy current loss Ppm | 1227.6 | |

| Single module fault condition | copper loss Pcu | 9585.3 |

| stator iron loss Pfe | 7961.5 | |

| PM eddy current loss Ppm | 450.8 |

| Symbol | Physical Meaning | Corner Meaning |

|---|---|---|

| Ri_j | The thermal resistance | Unit i and unit j |

| Ai_j | Heat conduction area | Contact unit i and j |

| Li | Heat transfer axial length | unit i |

| Si_j | Thermal convection area | Contact unit i and j |

| λi | Thermal conductivity | Unit i |

| αi | Convective heat transfer coefficient | Unit i |

| hi | Heat transfer radial length | Unit i |

| Components | Node/Temperature | ||||

|---|---|---|---|---|---|

| Environment | Na1/303.15 | ||||

| Stator yoke | Ni1/328.7 | Ni2/326.2 | Ni3/328.7 | ||

| Stator tooth | Ni4/349.9 | Ni5/348.7 | Ni6/349.9 | ||

| Winding | Nw1/370.4 | Nw2/368.1 | Nw3/367.3 | Nw4/368.1 | Nw5/370.4 |

| Nw6/371.7 | Nw7/368.5 | Nw8/367.8 | Nw9/368.5 | Nw10/371.7 | |

| Nw11/373.3 | Nw12/370.5 | Nw13/368.7 | Nw14/370.5 | Nw15/373.3 | |

| Permanent Magnet | Np1/362.5 | Np2/369.4 | Np3/362.5 | ||

| Np4/364.7 | Np5/367.9 | Np6/364.7 | |||

| Rotor core | Ni7/360.1 | Ni8/362.4 | Ni9/360.1 | ||

| Components | Temperature | |||||

|---|---|---|---|---|---|---|

| Part 1 | Part 2 | Part 3 | Part 4 | Part 5 | Part 6 | |

| Cooling water | 305.4 | 306.5 | 307.7 | 309 | 310.3 | 311.5 |

| Winding | 373.3 | 374 | 374.5 | 374.9 | 375.6 | 376.3 |

| Permanent Magnet | 369.4 | 369.4 | 369.5 | 369.5 | 369.6 | 369.7 |

| Components | Node/Temperature | ||||

|---|---|---|---|---|---|

| Environment | Na1/303.3 | ||||

| Stator yoke | Ni1/378.5 | Ni2/374.8 | Ni3/378.5 | ||

| Stator tooth | Ni4/394.7 | Ni5/392.9 | Ni6/394.7 | ||

| Winding | Nw1/419.7 | Nw2/415 | Nw3/419.1 | Nw4/415 | Nw5/419.7 |

| Nw6/421.4 | Nw7/418 | Nw8/410.8 | Nw9/418 | Nw10/421.4 | |

| Nw11/422.1 | Nw12/418.4 | Nw13/411.9 | Nw14/418.4 | Nw15/422.1 | |

| Permanent Magnet | Np1/383.3 | Np2/386.4 | Np3/383.3 | ||

| Np4/386.6 | Np5/388.5 | Np6/386.6 | |||

| Rotor core | Ni7/374.1 | Ni8/375.0 | Ni9/374.1 | ||

| Components | Material | Density (kg/m3) | Specific Heat Capacity (J/kg·K) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|

| Frame | 20Mn2 | 7850 | 460 | 45 |

| Stator | DW465 | 7650 | 460 | 30 |

| Winding | Copper | 8980 | 381 | 387.6 |

| Permanent Magnet | NdFeB | 7500 | 460 | 7.6 |

| Rotor yoke | 40Cr | 7850 | 460 | 42.7 |

| Components | Fluid-Solid Coupling Analysis | Network Method | Relative Error |

|---|---|---|---|

| Winding | 371.7 | 376.3 | 1.23% |

| Permanent Magnet | 368.2 | 369.7 | 0.41% |

| Cooling water | 314.5 | 311.5 | 0.95% |

| Temperature Sensor | Position | Detected Temperature |

|---|---|---|

| S1 | Winding end, close to outlet | 381.15 K |

| S2 | Winding ends, on the radial circumference | 376.25 K |

| S3 | Winding ends, on the radial circumference | 374.45 K |

| S4 | Winding end, close to inlet | 373.55 K |

| S5 | Middle of the winding, located in stator slot | 367.75 K |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, Y.; Ma, S.; Zhang, B.; Feng, W. Application of High Efficiency and High Precision Network Algorithm in Thermal Capacity Design of Modular Permanent Magnet Fault-Tolerant Motor. Energies 2025, 18, 3967. https://doi.org/10.3390/en18153967

Yi Y, Ma S, Zhang B, Feng W. Application of High Efficiency and High Precision Network Algorithm in Thermal Capacity Design of Modular Permanent Magnet Fault-Tolerant Motor. Energies. 2025; 18(15):3967. https://doi.org/10.3390/en18153967

Chicago/Turabian StyleYi, Yunlong, Sheng Ma, Bo Zhang, and Wei Feng. 2025. "Application of High Efficiency and High Precision Network Algorithm in Thermal Capacity Design of Modular Permanent Magnet Fault-Tolerant Motor" Energies 18, no. 15: 3967. https://doi.org/10.3390/en18153967

APA StyleYi, Y., Ma, S., Zhang, B., & Feng, W. (2025). Application of High Efficiency and High Precision Network Algorithm in Thermal Capacity Design of Modular Permanent Magnet Fault-Tolerant Motor. Energies, 18(15), 3967. https://doi.org/10.3390/en18153967