Dual-Level Electric Submersible Pump (ESP) Failure Classification: A Novel Comprehensive Classification Bridging Failure Modes and Root Cause Analysis

Abstract

1. Introduction

2. Methodology

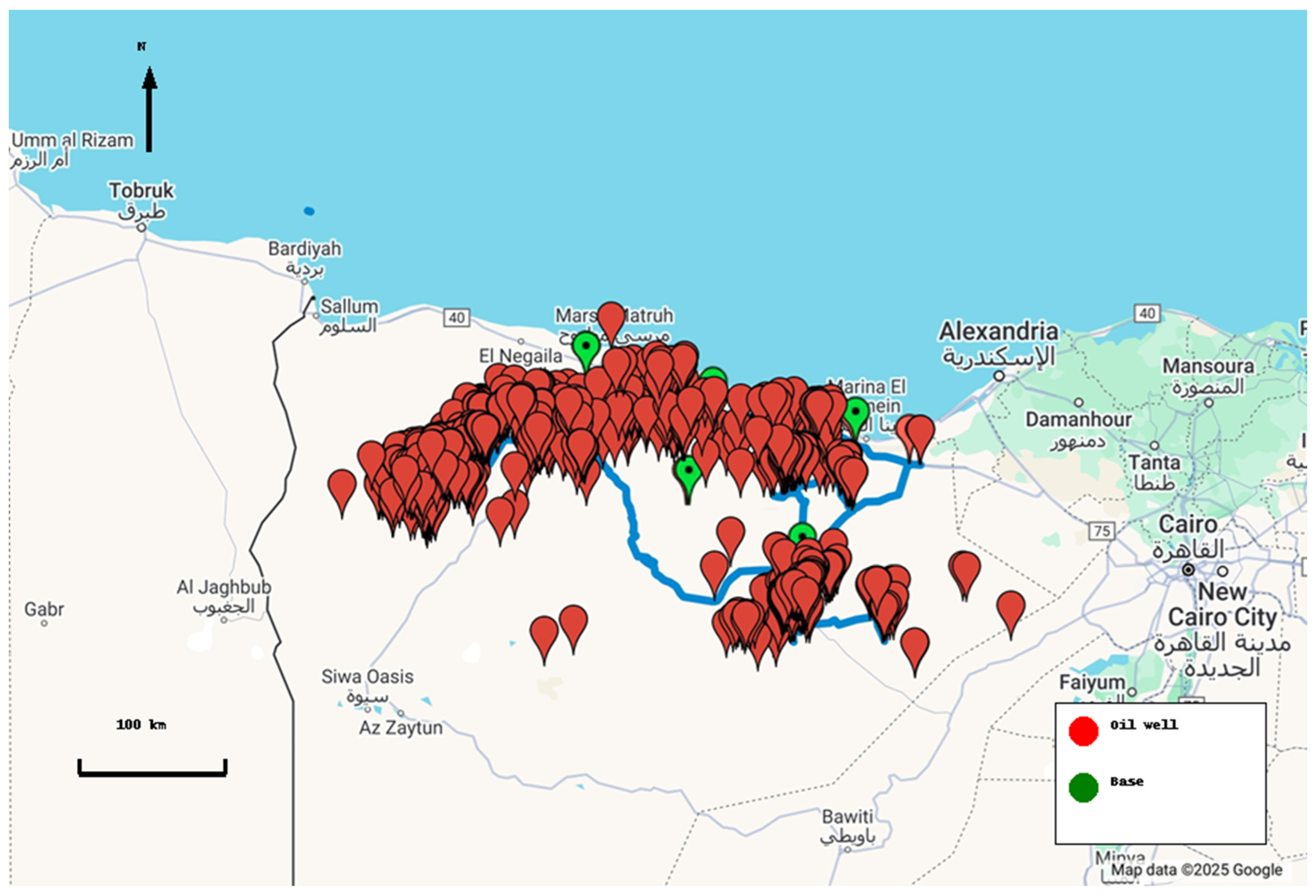

- Quantitative Data: Field data from over 4000 ESP installations in Egypt’s Western Desert, spanning 10 years of recorded parameters, were collected from an ESP team, engineering databases, workover records, and failure investigation reports (DIFA). These data provide a reliable and diverse foundation for identifying failure patterns and trends.

- Qualitative Data: A thorough literature review was conducted to identify gaps and inconsistencies in existing ESP failure classifications. The literature review highlighted the mix up between failure modes and root causes and led to the development of a structured framework that clearly distinguishes between failure modes and root causes.

- Field Data: Failure records from ESP installations, including failure modes, root causes, operational conditions, and troubleshooting logs were extracted from engineering databases and database systems.

- Literature Data: Existing classifications and failure descriptors from academic and industry sources were reviewed to identify gaps and inconsistencies.

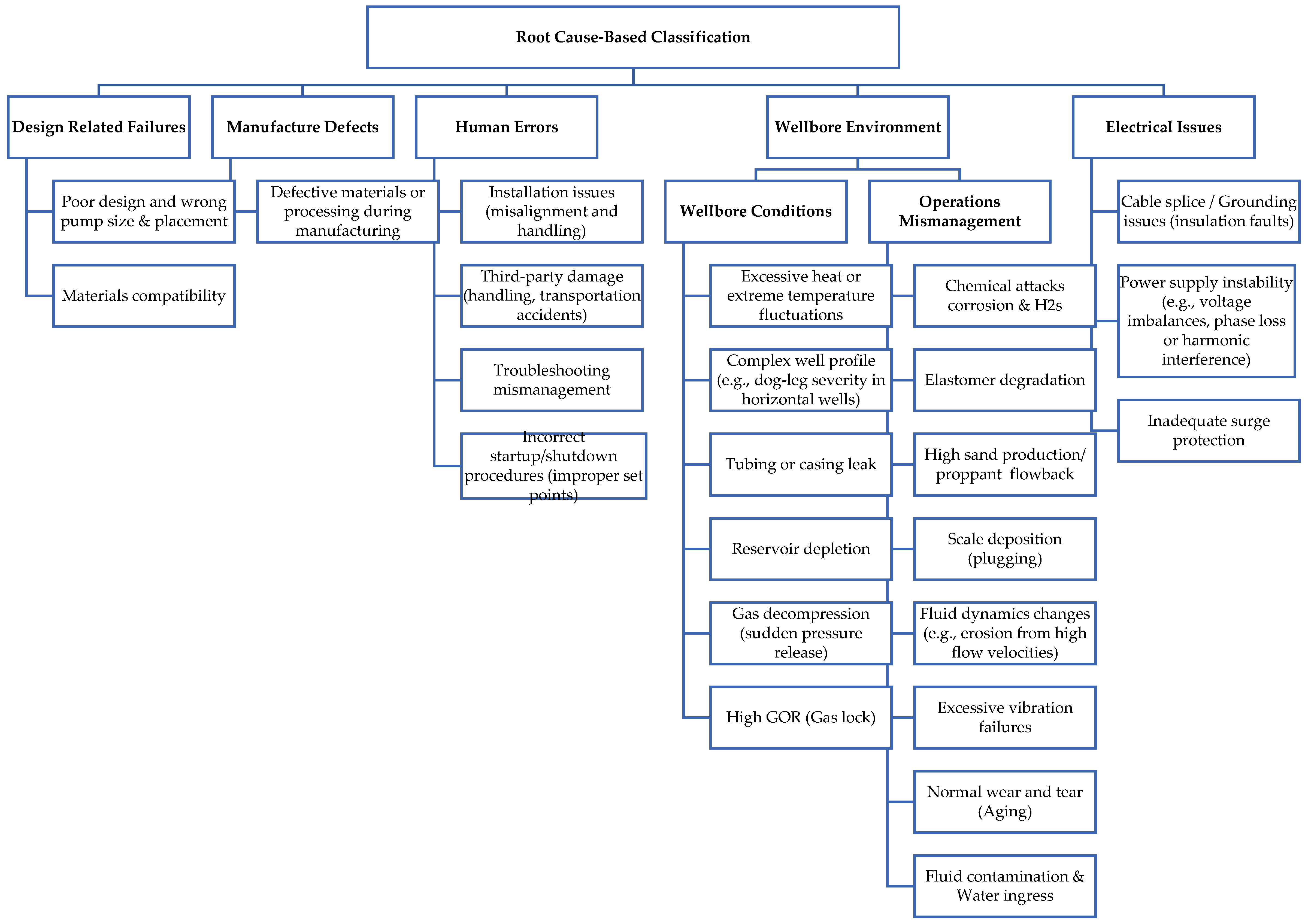

- Root Causes (leftmost box) serve as the fundamental sources of failures; these causes may be directly causing the failure, or multiple interrelated factors may be contributing to a failure.

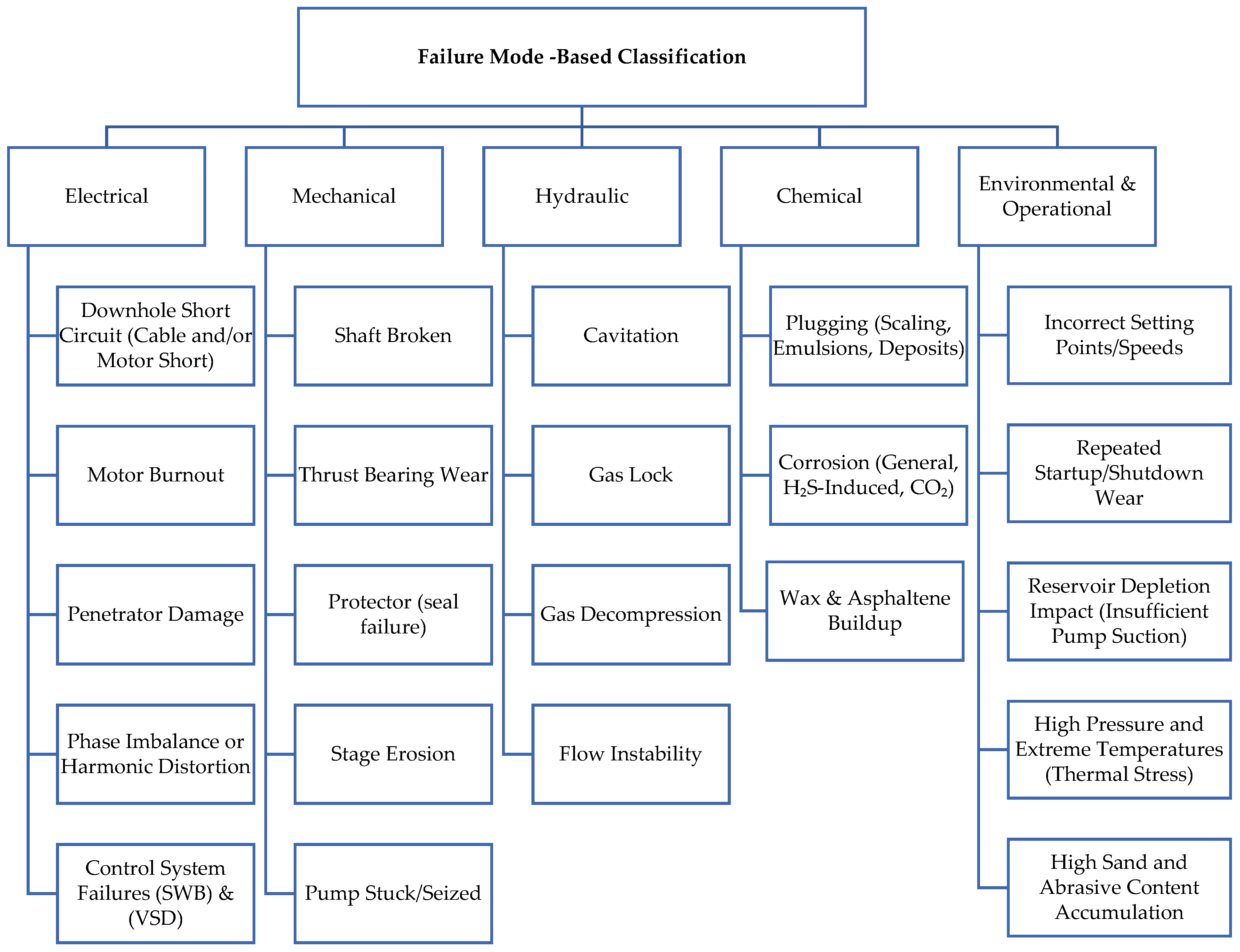

- Failure Categories include the following:

- Chemical Failures (e.g., corrosion, chemical attacks).

- Mechanical Failures (e.g., stuck pump, broken shaft).

- Electrical Failures (e.g., power surges, cable short circuits).

- Hydraulic Failures (e.g., fluid pressure issues, seal degradation).

- Environmental Failures (e.g., extreme temperatures, high sand and abrasive content).

- Operational Failures (e.g., human errors, repeated startup/shutdown).

- Pump Down Notification—Identify an issue requiring investigation.

- Data Collection—Gather relevant operational data and obtain a failure potential from history.

- Failure Event Decision:

- Pump Up? → System resumes normal operation.

- Pump Down? → Failure event occurred.

- 4

- Failure Analysis:

- Step 1: Identify the failure mode.

- Step 2: Determine the root cause.

- 5

- Documentation and Action—Findings are recorded in a report and used as input for modeling to improve system reliability.

3. Discussion

4. Conclusions

- The proposed two-step classification system provides a holistic view of ESP failures by integrating interconnected subsystems. It encompasses previous literature classifications, enhances diagnostic accuracy, eliminates confusion, and supports efficient troubleshooting and root cause identification. The framework also standardizes knowledge transfer, enabling personnel to better anticipate, detect, and manage failures.

- The two-step classification system includes five failure modes and five main root cause categories, with some root causes contributing to different types of failures. This makes the framework general and applicable to various environments beyond the Western Desert case history. It can be extended to offshore operations and unconventional reservoirs with appropriate contextual validation.

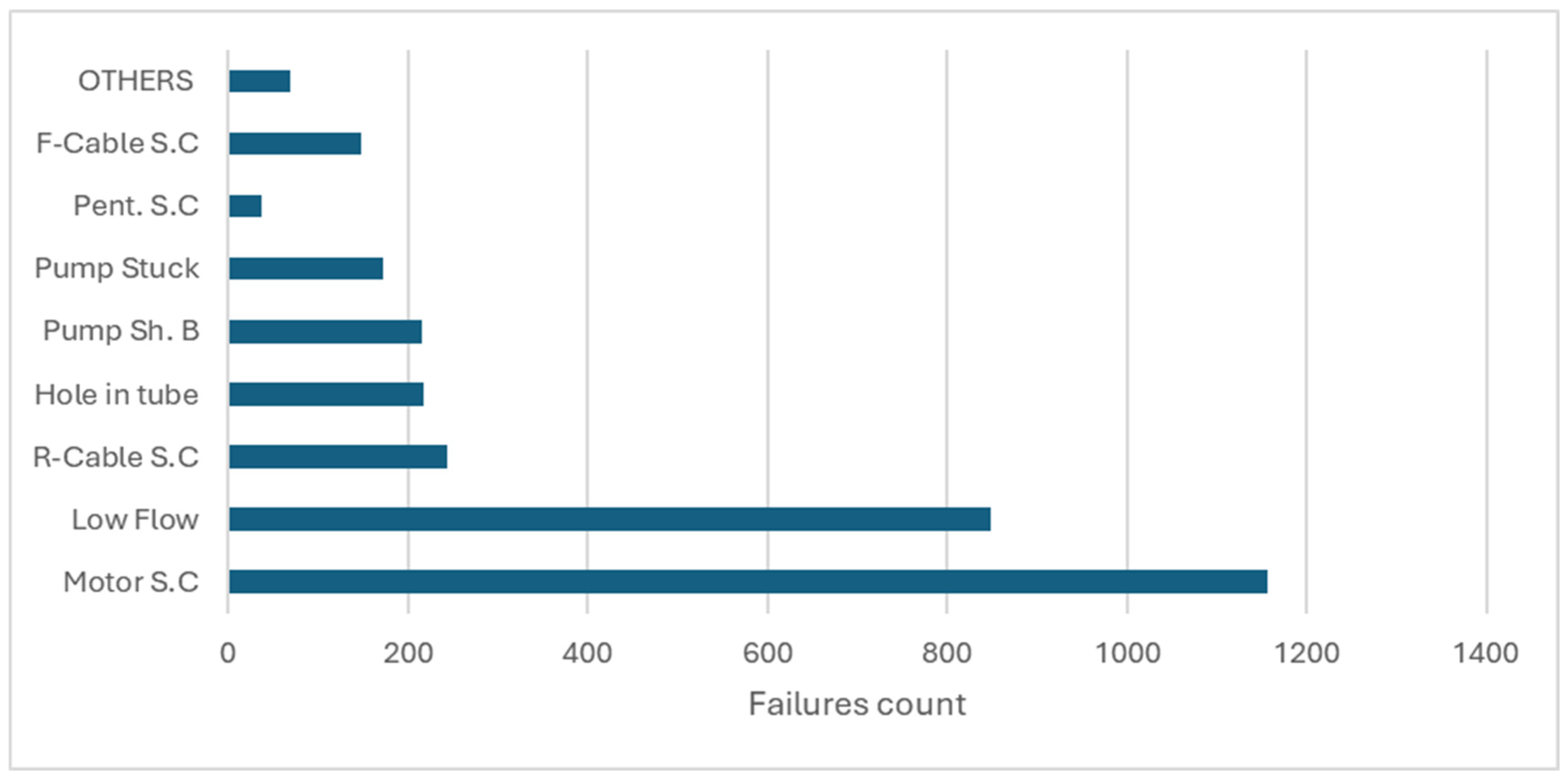

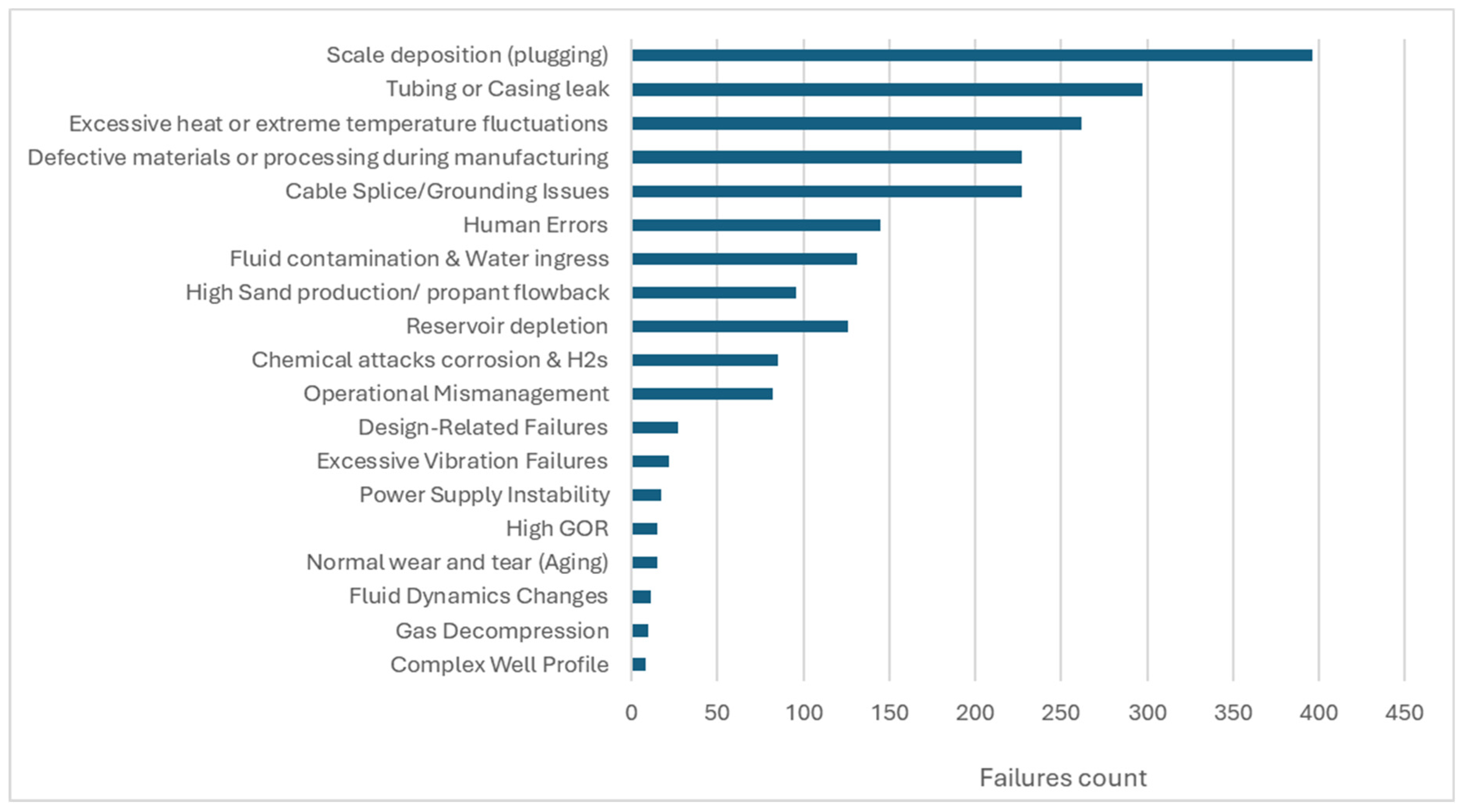

- The two-step classification was applied to a large dataset from the Western Desert, comprising over 4000 failure events from more than 350 wells over a 10-year monitoring period. Several benefits were observed, including improved failure analysis and more targeted remediation strategies.

- The case history reveals that failure modes are rarely caused by a single root cause but are often the result of multiple contributing factors. A detailed root cause analysis, combined with proactive maintenance and operational improvements, is crucial to addressing these failures effectively.

- Applying the two-step classification revealed that issues with chemical injection practices in the case history led to a significant number of failures. This was identified as a prominent root cause, and remedial actions are currently underway to address the problem based on the case study.

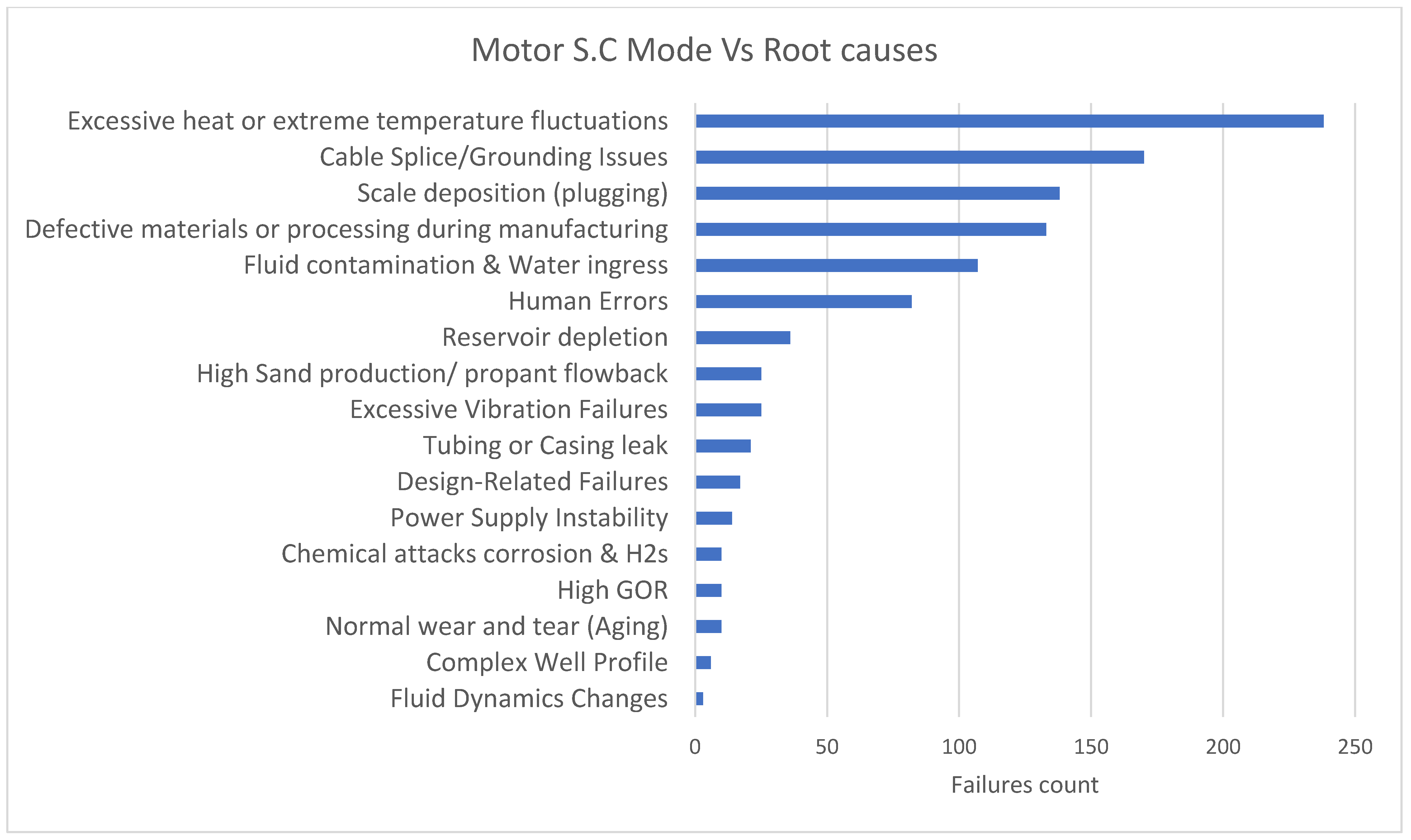

- Based on the findings of the case study, the motor short circuit was identified as a major failure mode, primarily driven by excessive heat and temperature fluctuations. These thermal stresses emerged as the dominant contributing root cause, leading to motor insulation degradation and eventual burnout.

- Some failure modes are complicated and require deep analysis. For example, motor short circuits should be accompanied by (DIFA) to better understand the root causes and enable effective remedial actions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| API | American Petroleum Institute |

| BPD | Barrel Per Day |

| CAPEX | Capital Expenditure |

| CNNs | Convolution Neural Networks |

| CO2 | Carbon Dioxide |

| DAE | Denoising Autoencoders |

| DIFA | Dismantle, Inspection, and Failure Analysis |

| DHSH | Downhole Short |

| EGPC | Egyptian General Petroleum Corporation |

| EPF | Early Production Facility |

| ESPs | Electrical Submersible Pumps |

| F-Cable | Flat Cable |

| FRAC | Fracture Stimulation |

| GOR | Gas/Oil Ratio |

| G.S.Sh. B | Gas Separator Shaft broken |

| H2S | Hydrogen Sulfide |

| IFMRC | Integrated Failure Modes and Root Cause |

| ISO | International Organization for Standardization |

| LPRO | Low Production |

| LSTM | Long Short-Term Memory |

| MLE | Motor Lead Extension |

| MTBF | Mean Time Between Failures |

| NORM | Naturally Occurring Radioactive Material |

| OHTL | Overhead Tower Line |

| OPEX | Operating Expenditure |

| PCA | Principal Component Analysis |

| PCP | Progressive Cavity Pump |

| POFF | Production Off |

| PSI | Pound Per Square Inch |

| QC | Quality Control |

| RCA | Root Cause Analysis |

| RCFC | Root Cause-Based Failure Classification |

| R-Cable | Round Cable |

| S.C | Short Circuit |

| Sh. B | Shaft Broken |

| SRP | Sucker Rod Pump |

| SWB | Switch Board |

| TBG | Tubing |

| VSD | Variable Speed Drive |

| WAG | Water Alternating Gas |

Appendix A. Failure Mode Classification

| Category | Subcategory | Description | Examples | Application/Importance |

|---|---|---|---|---|

| Electrical Failures | Downhole short circuit and grounding issues. | Insulation breakdown leading to short circuits. These failures typically happen in critical components such as the motor windings, power cables round to flat splices or round to round splices, motor lead extensions (MLE), or penetrators. They can have severe operational consequences, leading to shutdowns, workovers, or early equipment replacements. | In a study by on offshore wells in Saudi Arabia, 50% of the electrical failures were caused by downhole short circuits in the motor lead extension (MLE) beneath the packer. The extreme environmental conditions, including high salinity and high temperatures, contributed to cable degradation and short circuits. Poor grounding leads to electrical faults or damage. | Production Downtime: Short circuits cause immediate ESP shutdown, halting production and necessitating costly workovers. Power cable is often the single most costly component of the ESP system. When it has been correctly matched to the operating environment and handled with care it can provide years of service and often may be fit for re-use even though other mechanical components of the ESP system may have failed |

| Motor Burnt | Overheating of motor windings causing permanent damage or leading to short circuits. | Excessive current drawing, poor cooling, elevated temperatures, or harmonic interference. | Impacts motor lifespan, requiring frequent replacements or workovers. | |

| Control System Failures (SWB) and (VSD) | Failures related to the control systems that manage the operation of the ESP. This includes issues with variable frequency drives (VFDs), programmable logic controllers (PLCs), and other electronic control components such as fuse blown. | VFD malfunctions, PLC programming errors, and sensor failures. | Equipment Damage: Prolonged electrical faults can damage the motor and associated equipment, reducing the lifespan of ESP components. Safety Risks: Short circuits in gas-producing wells pose significant fire and explosion hazards, making prevention and detection critical. | |

| Penetrator Damage | Physical damage to electrical penetrators in wellbore or corrosion can cause short circuits. | Cracked penetrator seals, water ingress in cables. | Essential to ensure electrical integrity and prevent hazardous leaks. | |

| Phase Imbalance/Harmonic Distortion | Failures due to electrical noise or interference that affects the control systems and communication within the ESP system. This can lead to erratic operation or failure of sensitive electronic components. Voltage imbalance across phases, harmonic interference from power supply affecting motor performance. | Interference from nearby power lines, electrical noise from variable frequency drives (VFDs), and voltage spikes causing control system malfunctions. Erratic Voltage spikes/drops causing motor stalling and electrical failures. | Ensure smooth motor operation and protect against premature burnout. Essential for ensuring stable power delivery to ESPs. Use of Sinusoidal VSD Units: Variable Speed Drives (VSDs) with clean sinusoidal output prevent voltage spikes and harmonics that could compromise electrical insulation. | |

| Mechanical Failures | Shaft Broken | Breakage or bending or cracks of the shaft caused by fatigue wear, misalignment, or excessive stress and vibrations. It occurs at any point across shaft in (pump, intake, seal or motor). | Shaft failure from operational fatigue. Excessive vibration, misalignment, or corrosion. | Ensures mechanical integrity and avoids disruptions to the pump’s performance. |

| Thrust Bearing Wear | Wear, corrosion, or inadequate lubrication leads to bearing seizure, causing rotational issues. | Metal fatigue, improper lubrication Bearing seizure resulting in pump breakdown. Overloading or underloading leads to thrust bearing failure. Up thrust and down thrust conditions. | Critical for withstanding axial forces from the pump stages. Critical for the smooth operation of the rotating components to minimize downtime. | |

| Protector/Seal Failure | Seal leakage or breakdown caused by extreme pressure, fluid incompatibility, or thermal stress. | Seal failure under high pressure leading to fluid intrusion/leaks. | Essential for preventing contamination and maintaining the system’s pressure balance. Protects motor components from wellbore fluids, enhancing durability. | |

| Pump Stuck/Seized | Mechanical locking of the pump, preventing movement. | Foreign object intrusion, scaling deposits like Sand deposits causing pump impeller seizure. | Requires immediate intervention to restore operations. Essential to maintain continuous flow and prevent shutdowns. | |

| Stage erosion (Impeller Wear/Damage) | Abrasive particles in the fluid (like sand) cause wear on pump components, including impellers and diffusers. | Loss of hydraulic efficiency and Impeller vane damage. Impeller eroded by sand-laden fluid. | Continuous erosion degrades ESP performance and increases the frequency of workovers. | |

| Coupling Failure | Damage to couplings connecting motor shafts and pump shafts, often due to misalignment or torque overload. | Coupling shearing under excessive torque. | Ensures proper power transmission from motor to pump. | |

| Hydraulic Failures | Cavitation | Occurs when localized pressure within the pump drops below the vapor pressure of the fluid, causing vapor bubbles to form. When bubbles collapse, they damage pump components. | Pitting on pump surfaces. Rapid impeller wear | Critical for pump longevity; cavitation can result in severe mechanical erosion if not detected early. |

| Gas Lock | Happens when excessive free gas accumulates in the pump, disrupting the fluid flow. The motor experiences underload due to reduced liquid intake. | ESP motor current drops abruptly Insufficient fluid lift | Reduces efficiency and leads to pump shutdown. Horizontal wells are particularly prone to gas lock issues. | |

| Gas Decompression | Damage caused by sudden gas pressure release. | Rapid pressure drops causing explosive effect on cable. | Prevents sudden mechanical/electrical failures. | |

| Flow Instability | Fluctuations in flow rate impacting pump performance. | Slug flow, rapid flow velocity changes. | Maintains steady operation for optimal performance. | |

| Chemical | Plugging (Scaling) | Deposition of minerals like calcium carbonate, barium sulfate, or iron sulfide on pump surfaces due to changes in temperature or pressure. Blockages from scaling, emulsions, or wax deposits. | Scale buildup, Blocked impellers and tubing Reduced fluid flow and efficiency | Scale inhibitors, acidizing, or mechanical cleaning. Ensures continuous flow and prevents system downtime. |

| Corrosion | Degradation of metallic components due to chemical reactions with well fluids containing water, oxygen, CO2, or H2S. Sulfide stress cracking (SSC) and hydrogen embrittlement caused by H2S exposure, especially in sour wells. | Failure of motor seals and cables. Catastrophic failure of seals and pump shafts. Corrosion pits in casings and tubing. | Use of corrosion-resistant materials, chemical inhibitors, or cathodic protection. Non-metallic seals and use of H2S-resistant materials. | |

| Wax and Asphaltene Buildup | Accumulation of wax and asphaltenes restrict flow. Formation of stable emulsions or wax deposits within the ESP or tubing, blocking fluid flow. | Formation of deposits in tubing or pump. Asphaltene precipitation. Impeller clogging Reduced flow efficiency | Reduces flow interruptions and maintains system efficiency. Use of demulsifies or wax inhibitors. | |

| Environmental and Operational | High Sand and Abrasives | Sand or solid particles like proppants back flow causing wear and erosion of pump internals. | Erosion of impellers due to sand-laden fluids. | Important for selecting suitable materials and design modifications to manage abrasive environments. |

| High Pressure and Extreme Temperatures | Extreme well conditions impact the fluid’s properties and can lead to seal degradation, fluid leaks, and pressure imbalances. Failures from continuous operation in high or low temperatures beyond design specs. | - Seal failure under pressure - Lubricant breakdown at high temperatures Thermal degradation of electrical insulation or including seals, bearings. | Ensuring ESP components are rated for specific well conditions is essential to prevent premature failures. studies indicate that for every 10 °C increase in temperature, the rate of material degradation can double, leading to reduced lifespan of components [38]. | |

| Incorrect Setting Points and Operating Speeds | Running the ESP at improper speeds or Operation outside the optimal range, leading to inefficiency. Improper surge protections cause electrical failure. | Operating at sub-optimal conditions affecting performance. | Vital for maximizing pump efficiency and preventing damage. | |

| Repeated Startup/Shutdown Wear | Wear caused by frequent cycling of the pump. | Excessive startups lead to mechanical stress. | Minimizes mechanical fatigue and extends equipment life. |

Appendix B. Root Cause-Based Failure Classification

| Root Cause | Description | Examples | Application/Importance |

|---|---|---|---|

| Design-Related Failures | Failures originating from flaws or limitations in the initial design of the ESP system. | Inadequate material selection leads to premature corrosion. Poor design and wrong pump size and placement Suboptimal Pump Sizing Incorrect pump selection for well conditions, leading to inefficient operation and excessive wear. selecting pumps incompatible with well fluids or operational range. Material Incompatibility: Mismatch between materials and well environment (e.g., high salinity or corrosivity). | Highlights the importance of robust design processes and material selection to avoid inherent weaknesses. |

| Manufacturing Defects | Failures caused by errors during the manufacturing process, including material defects or assembly errors. | Motor winding faults cause short circuits. Poor welds result in mechanical failures. Defective materials or processing during manufacturing Quality Control Issues: Insufficient QA during production. Welding or Assembly Defects: Inadequate joint strength or misaligned assemblies. | Emphasizes the need for stringent quality control during manufacturing to prevent latent defects. |

| Human errors | Failures resulting from improper installation practices or alignment issues caused by mistake from by operators, rig crew., technicians, or engineers during any phase of the ESP lifecycle. Including surveillance teams that monitor pump performance. | Installation Errors: Misalignment of the pump causing excessive vibration and mechanical wear. Incorrect wiring during installation causing electrical faults. Troubleshooting mismanagement: Excessive start and stop or (incorrect set points) start pump while having back spin causing shaft broken issue. Monitoring System Neglect: Inaccurate data interpretation or failure to respond to alerts. Third-Party Damage (Handling Accidents): 1. Transportation Damage: Dropped equipment causing internal misalignments or cracks. 2. Forklift/Crane Damage: Dents or electrical faults caused by mishandling during loading/unloading. 3. Storage Damage: Exposure to moisture or extreme temperatures due to improper storage. 4. Packaging Errors: Inadequate padding during shipping leading to component micro-damage. 5. Accidental Collisions: Damage to equipment during on-site installation from careless handling. | Critical for ensuring that proper installation procedures are followed to avoid early-life failures. Stresses the need for proper training, oversight, and protocols to minimize the risk of human error. |

| Wellbore environment | Wellbore conditions Failures caused by external environmental factors such as extreme temperatures, pressures, abrasive particles, or corrosive fluids. | Thermal Degradation: High operating temperatures, either due to poor cooling or Excessive Heat or Extreme Fluctuations: Causes component degradation (motor and seal failures) Complex Well Profile: Dog-leg severity leads to mechanical stress. Reservoir Depletion: Impacts pump efficiency. Pressure Surges: Beyond just decompression, transient pressure spikes can cause component damage Gas Decompression: Sudden pressure drop causing equipment stress. Gas Interference: High gas-to-liquid Triggers gas lock or cavitation within the pump, stopping flow. Or operating the pump at incorrect speeds causing cavitation or gas lock. High pressure surges (gas decompression) Tubing or Casing Leak: Causes pressure imbalance and Inadequate Cooling: Insufficient fluid flow or incorrect operating conditions causing the motor to overheat. | Focuses on the need to consider environmental conditions in the selection and design of ESPs to prevent damage. Emphasizes the need to understand and manage the fluid dynamics to prevent hydraulic failures. |

| Operations Mismanagement Failures due to incorrect operation, including running the pump outside its designed specifications. | Chemical attacks Reactions between injected chemicals and formation fluids or the materials in ESP components. H2S Exposure (Sour Gas): Hydrogen sulfide in well fluids causes rapid corrosion of metallic components, particularly in sour gas wells. Microbiologically Influenced Corrosion (MIC) Corrosion caused by sulfate-reducing bacteria (SRB) and other microbes present in the water phase. Pitting corrosion on pump surfaces - Biofilm formation blocking fluid paths. Elastomer Degradation Breakdown of elastomeric components (such as seals) due to chemical exposure or temperature changes. Fluid Instability: Wax build-up or emulsions causing flow disruptions. Fluid Incompatibility: Changes in fluid chemistry can destabilize operations. - Scale Deposition (Plugging): Reduces flow and efficiency. - High Sand Production/Proppant Flowback: Causes erosion and blockage. Fluid Dynamics Changes: Erosion due to high flow velocity Rapid Startup/Shutdown Cycles: Contributing to wear. Excessive Vibration Failures: Component fatigue and misalignment. Bolt and Fastener Failure Loose or sheared bolts due to vibration or thermal expansion. Wear Ring Damage: Damage to wear rings, leading to increased internal leakage between pump stages. Wear rings eroded from fluid abrasion. Normal Wear and Tear (Aging): Long-term mechanical degradation, and natural deterioration of components over time. Fluid Contamination and Water Ingress: Causes motor and seal failures. | Reinforces the importance of adhering to operational parameters for reliable performance. Focuses on environmental monitoring and operational adjustments to optimize ESP performance. Highlights the importance of selecting materials resistant to specific chemical environments. Chemical Incompatibility - Seal swelling or degradation - Plugging injection lines Chemical compatibility testing before injection programs. Seal failure due to high H2S exposure. Important for sealing integrity and fluid containment. Vibration Fatigue: Loosening of bolts and fasteners, shaft misalignment leading to vibration, and bearing damage due to excessive vibration. Biocide treatments and water quality management. - Fastener loosening due to excessive vibration. Maintains secure assembly of components. Important for sustaining pump efficiency and reducing bypass losses. | |

| Electrical Power Issues | Failures caused by power supply problems, including voltage fluctuations, phase imbalance, or electrical faults. | Inadequate Surge Protection: Lack of protection from voltage spikes leads to motor burnout. Power Supply Instability: Voltage imbalances, phase loss affecting system stability. Grounding Issues: Poor or faulty grounding can cause power disruptions. Control System Failures: Malfunction of VSDs or sensors affecting motor control. | Highlights the necessity of stable and clean power supply for maintaining the integrity of electrical components. |

Appendix C. Crosswalk Between API RP 11S1 Code and IFMRC Framework

| API Code | API Description | Mapped IFMRC Category | Mapped IFMRC Description |

|---|---|---|---|

| LPRO | Low Production | Operational—Reservoir Impact | Reservoir depletion or low drawdown |

| POFF | Production Off | Electrical/Operational | Power failure, VSD/SWB trip, or shut-in condition |

| RSIH | Resize (Increase Production) | Not a failure—Operational Change | - |

| RSDH | Resize (Decrease Production) | Not a failure—Operational Change | - |

| DHSH | Downhole Short | Electrical—Downhole Short Circuit | Cable or motor insulation breakdown |

| LPUM | Locked Pump | Mechanical—Pump Stuck/Seized | Debris, gas lock, or mechanical jamming |

| LOAM | Drawing Low Amps | Electrical—Control System Failure | Faulty VSD setting or underload trip condition |

| HIAM | Drawing High Amps | Electrical—Motor Burnout | High load, phase imbalance, or motor overheating |

| HITB | Hole in Tubing | Root Cause—Wellbore Environment | Mechanical damage or corrosion leading to leakage |

| CSRP | Casing Repair Required | Root Cause—Wellbore Environment | Casing deformation, collapse, or corrosion |

| WKOV | Workover | Not a failure | - |

| STIM | Stimulation Required | Not a failure—Reservoir Enhancement | - |

| LOGG | Logging Well Required | Not a failure—Diagnostic Action | - |

| COVT | Converting Well | Not a failure—Strategic Reuse | - |

| TEST | Testing Well | Not a failure—Diagnostic Action | - |

| TSPN | Temporary Suspending Well | Not a failure—Operational Pause | - |

| ABAN | Abandoning Well | Not a failure—Lifecycle Conclusion | - |

| OTH1–5 | Other (1–5) | Various | - |

| 7000 | Splice Failure | Electrical—Cable Fault | Splice or termination failure |

| 7010 | Cable Failure | Electrical—Cable Fault | Jacket abrasion, crush, or thermal degradation |

| 7020 | Motor Flat Failure | Electrical—Motor Burnout | Electrical insulation breakdown, winding failure |

| 7030 | Pigtail Failure | Electrical—Connector Fault | Improper torque, contact loss, or corrosion |

| 7040 | Tubing Failure | Root Cause—Wellbore Environment | Corrosion, scaling, or mechanical stress failure |

| 7070 | No Failure, Equip. Changed | Not a failure | - |

| 7080 | Unknown | Insufficient data for failure classification | - |

| 7090 | Other Failures | Insufficient data for failure classification |

References

- Rensburg, N.J.v. Artificial Intelligence Can Reduce ESP Failures. J. Pet. Technol. 2019, 71, 16–17. [Google Scholar] [CrossRef]

- Sabaa, A.; Abu El Ela, M.; El-Banbi, A.H.; Sayyouh, M.H.M. Artificial Neural Network Model to Predict Production Rate of Electrical Submersible Pump Wells. SPE Prod. Oper. 2023, 38, 63–72. [Google Scholar] [CrossRef]

- Skoko, I.; Lusic, Z.; Pusic, D. Commercial and strategic aspects of the offshore vessels market. Sci. J. Marit. Univ. Szc. 2020, 62, 18–25. [Google Scholar] [CrossRef]

- Pastre, L.F.; Fastovets, A. The Evolution of ESP Technology in the North Sea: A Reliability Study Based on Historical Data and Survival Analysis. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 16–18 October 2017. [Google Scholar]

- Vorgutti, S.G.V.; Dixon, D. Artificial Lift Market Global Opportunity Analysis and Industry Forecast, 2022–2029. Available online: https://exactitudeconsultancy.com/reports/4718/artificial-lift-market/ (accessed on 15 January 2025).

- Del Pino, J.J.; Martin, J.L.; Vargas, H.; Maldonado, J.S.; Rubiano, E.; Núñez, W.; Sánchez, L.M.; Prada, J.; Gómez, S.; Sarkis, N.; et al. Installation of Electric Submersible Pump as Artificial Lift Method in Low Flow Rate Wells, a Case History. In Proceedings of the SPE Electric Submersible Pump Symposium, The Woodlands, TX, USA, 24–28 April 2017. [Google Scholar]

- Ratcliff, D.E.; Gomez, C.; Cetkovic, I.; Madogwe, O. Maximizing Oil Production and Increasing ESP Run Life in a Brownfield Using Real-Time ESP Monitoring and Optimization Software: Rockies Field Case Study. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Michael Nirtl, H.H. Sophisticated ESP Sensor Data Analysis and Failure Classification. Master’s Thesis, Petroleum and Geothermal Energy Recovery, University of Leoben, Leoben, Austria, 2017. [Google Scholar]

- Alhanati, F.J.S.; Francisco, A.; Sandeep, S.; Solanki, S.C.; Zahacy, T.A.; Todd, Z. ESP Failures: Can We Talk the Same Language? In Proceedings of the SPE Gulf Coast Section Electric Submersible Pump Workshop, Houston, TX, USA, 25–27 April 2001. [Google Scholar] [CrossRef]

- Sawaryn, S.J.; Grames, K.N.; Whelehan, O.P. The Analysis and Prediction of Electric Submersible Pump Failures in the Milne Point Field, Alaska. SPE Prod. Facil. 2002, 17, 53–61. [Google Scholar] [CrossRef]

- Lapi, S.G.; Arisman, B.; Johnson, M.E. Artificial Lift Performance Enhancements by applying Root Cause Failure Analysis. In Proceedings of the International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 10–12 December 2014. [Google Scholar]

- Mubarak, H.A.; Khan, F.A.; Oskay, M.M. ESP Failures/Analysis/Solutions in Divided Zone—Case Study. In Proceedings of the Middle East Oil Show, Manama, Bahrain, 9–12 June 2003. [Google Scholar]

- Marra, F.; Girard, C. Advanced Electric Submersible Pumps—Added Value for Offshore Fields. In Proceedings of the SPE Electric Submersible Pump Symposium, The Woodlands, TX, USA, 24–28 April 2017. [Google Scholar]

- Alamu, O.A.; Pandya, D.A.; Warner, O.; Debacker, I. ESP Data Analytics: Use of Deep Autoencoders for Intelligent Surveillance of Electric Submersible Pumps. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2020. [Google Scholar]

- Chad Bremner, G.H.; Kosmala, A.; Nicholson, B. Evolving Technologies: Electrical Submersible Pumps. SLB Artif. Lift 2024, 1. Available online: https://www.slb.com/-/media/files/oilfield-review/p30-43-2 (accessed on 15 April 2025).

- Song, Y.; Jun, S.; Nguyen, T.C.; Wang, J. Experimental data-driven model development for ESP failure diagnosis based on the principal component analysis. J. Pet. Explor. Prod. Technol. 2024, 14, 1521–1537. [Google Scholar] [CrossRef]

- AlBallam, S.; Karami, H.; Devegowda, D. A Data-Based Reliability Analysis of ESP Failures in Oil Production Wells. J. Energy Power Technol. 2022, 4, 1–29. [Google Scholar] [CrossRef]

- ISO 14224:2016; Petroleum, Petrochemical and Natural Gas Industries—Collection and Exchange of Reliability and Maintenance Data for Equipment. ISO: Geneva, Switzerland, 2016.

- API RP 11S1; Recommended Practice for the Operation, Maintenance, and Troubleshooting of Electric Submersible Pumps. API: Washington, DC, USA, 2017.

- Lea, J.F.; Power, W.J. ESP teardown inspection. Part 6—Here’s what wear and damaging conditions can do. Pet. Eng. Int. 1984, 56, 6413627. [Google Scholar]

- Gupta, S.; Saputelli, L.; Nikolaou, M. Applying Big Data Analytics to Detect, Diagnose, and Prevent Impending Failures in Electric Submersible Pumps. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016. [Google Scholar]

- Gupta, S.; Nikolaou, M.; Saputelli, L.; Bravo, C. ESP Health Monitoring KPI: A Real-Time Predictive Analytics Application. In Proceedings of the SPE Intelligent Energy International Conference and Exhibition, Aberdeen, UK, 6–8 September 2016. [Google Scholar]

- Kalu-Ulu, T.C.; Andrawus, J.A.; George, I.P. Modelling System Failures of Electric Submersible Pumps in Sand Producing Wells. In Proceedings of the Nigeria Annual International Conference and Exhibition, Abuja, Nigeria, 30 July–3 August 2011. [Google Scholar]

- Saptadi, S.; Widodo, A.; Athaillah, M.; Ayyasyi, M. Implementation of machine learning methods in predicting failures in electrical submersible pump machines. Multidiscip. Sci. J. 2024, 7, 2025137. [Google Scholar] [CrossRef]

- Abdalla, R.; Nikolaev, D.; Gönzi, D.; Manasipov, R.; Schweiger, A.; Stundner, M. Deep Insight into Electrical Submersible Pump Maintenance: A Predictive Approach with Deep Learning. In Proceedings of the SPE Offshore Europe Conference & Exhibition, Aberdeen, UK, 2–5 September 2023. [Google Scholar]

- Mello, L.H.S.; Oliveira-Santos, T.; Varejão, F.M.; Ribeiro, M.P.; Rodrigues, A.L. Ensemble of metric learners for improving electrical submersible pump fault diagnosis. J. Pet. Sci. Eng. 2022, 218, 110875. [Google Scholar] [CrossRef]

- Takacs, G. Electrical Submersible Pumps Manual: Design, Operations, and Maintenance; Gulf Professional Publishing: Houston, TX, USA, 2017. [Google Scholar]

- Thomson, W.T.; Leonard, R.A.; Milne, A.J.; Penman, J. Failure identification of offshore induction motor systems using on-condition monitoring. Reliab. Eng. 1984, 9, 49–64. [Google Scholar] [CrossRef]

- Borling, D.C.; Sviderskiy, S.V.; Gorlanov, S.F. Best Practices & Innovations for Improved ESP Performance; Mature Field Case History; TNK-BP Company, Russian Federation. In Proceedings of the SPE Russian Oil and Gas Conference and Exhibition, Moscow, Russia, 26–28 October 2010. [Google Scholar]

- Barrios Castellanos, M.; Serpa, A.L.; Biazussi, J.L.; Monte Verde, W.; do Socorro Dias Arrifano Sassim, N. Fault identification using a chain of decision trees in an electrical submersible pump operating in a liquid-gas flow. J. Pet. Sci. Eng. 2020, 184, 106490. [Google Scholar] [CrossRef]

- Patri, O.P.; Panangadan, A.V.; Chelmis, C.; McKee, R.G.; Prasanna, V.K. Predicting Failures from Oilfield Sensor Data using Time Series Shapelets. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar]

- Chen, J.R.; Li, W.; Yang, P.H.; Chen, B.Q.; Li, S. Prediction and classification of faults in electric submersible pumps. AIP Adv. 2022, 12, 045215. [Google Scholar] [CrossRef]

- Kimery, D.W.; Saponja, J.C.; Chachula, R.C.; Jensen, C. Breaking the 800 Psi ESP PIP Barrier: How A Proven Flow-Conditioning Technology can Dramatically Improve ESP Performance in Horizontal Wells. In Proceedings of the SPE Electric Submersible Pump Symposium, The Woodlands, TX, USA, 24–28 April 2017; p. D051S014R002. [Google Scholar]

- Fakher, S.; Khlaifat, A.; Hossain, M.E.; Nameer, H. Rigorous review of electrical submersible pump failure mechanisms and their mitigation measures. J. Pet. Explor. Prod. Technol. 2021, 11, 3799–3814. [Google Scholar] [CrossRef]

- Kannaujia, V.; Bhore, S.P.; Goyal, H.S. Failure Analysis of Submersible Pumps—A Review. In Recent Advances in Industrial Machines and Mechanisms; Springer Nature Singapore: Singapore, 2024; pp. 393–410. [Google Scholar]

- EGPC. ESP Failure Classification; EGPC: Cairo, Egypt, 2021. [Google Scholar]

- Google LLC. Google Maps [Online]. (2025). Available online: https://www.google.com/maps (accessed on 15 April 2025).

- Xiao, J.J.; Lastra, R.A.; Roth, B.A.; Lee, W. Material Overview for Electrical Submersible Pumps: Part I—Metallic and Ceramic Materials. SPE Prod. Oper. 2020, 35, 001–008. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobhy, M.A.; Hegazy, G.M.; El-Banbi, A.H. Dual-Level Electric Submersible Pump (ESP) Failure Classification: A Novel Comprehensive Classification Bridging Failure Modes and Root Cause Analysis. Energies 2025, 18, 3943. https://doi.org/10.3390/en18153943

Sobhy MA, Hegazy GM, El-Banbi AH. Dual-Level Electric Submersible Pump (ESP) Failure Classification: A Novel Comprehensive Classification Bridging Failure Modes and Root Cause Analysis. Energies. 2025; 18(15):3943. https://doi.org/10.3390/en18153943

Chicago/Turabian StyleSobhy, Mostafa A., Gehad M. Hegazy, and Ahmed H. El-Banbi. 2025. "Dual-Level Electric Submersible Pump (ESP) Failure Classification: A Novel Comprehensive Classification Bridging Failure Modes and Root Cause Analysis" Energies 18, no. 15: 3943. https://doi.org/10.3390/en18153943

APA StyleSobhy, M. A., Hegazy, G. M., & El-Banbi, A. H. (2025). Dual-Level Electric Submersible Pump (ESP) Failure Classification: A Novel Comprehensive Classification Bridging Failure Modes and Root Cause Analysis. Energies, 18(15), 3943. https://doi.org/10.3390/en18153943