1. Introduction

Since the industrial revolution, there has been a continuous increase in greenhouse gas emissions that have led to a rise in the global average temperature, with increasingly dramatic consequences for the environment. Much of the emissions are associated with energy production. Detailed in

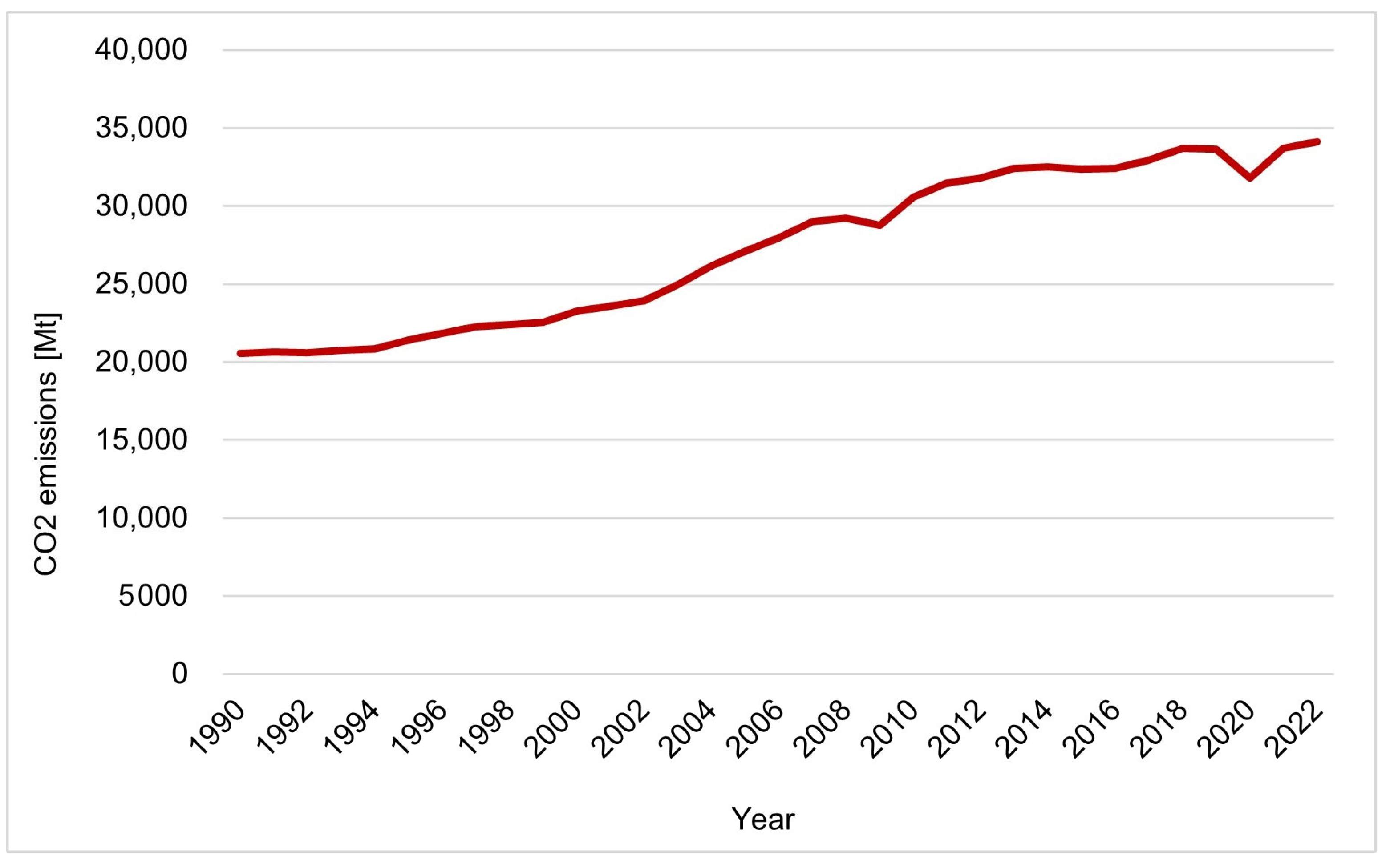

Figure 1 is the trend in global carbon dioxide emissions related to fuel use between 1990 and 2022 according to IEA data [

1]: after a slight decline in 2009, due to the economic crisis, and a more pronounced decline in 2020 due to the pandemic, emissions have returned to growth, reaching nearly 35,000 megatons in 2022.

For this reason, international strategies that aim to combat climate change through decarbonization processes have been defined over the years. The European Union, in particular, in accordance with the Paris Agreement, is committed, through its Green Deal initiatives, to cutting greenhouse gas emissions by at least 55% below pre-industrial levels by 2030 and achieving the goal of climate neutrality, or zero net carbon emissions, by 2050 [

2].

In order to achieve the set goals, more and more is being invested in the construction of new renewable energy generation facilities. As reported in [

3], 2024 was the year of the largest increase in global renewable energy capacity to date, with the addition of 585 GW of renewables, expanding the renewable energy stock by 15.1%. The fastest growth was seen in solar and wind power plants: solar power accounted for more than 75% of renewable additions, with a record 452 GW added during the year, while wind power contributed 113 GW. These renewable sources, however, are highly random, which poses major challenges for the optimal management of the energy obtained from them. Indeed, it often happens that energy is produced at instants when users do not need it or simply cannot be fed into the grid due to local congestion problems, resulting in the need to resort to curtailment. In addition, the presence of distributed generation from non-programmable sources can result in the reversal of power flows in grid branches, affecting the sensitivity and selectivity of protections [

4], as well as the voltage, transmission and distribution losses, and temperature of transformers. In mitigating these phenomena, Power-to-Gas technologies can help [

5], complementing the classical battery storage technologies typically employed. Among the various Power-to-Gas technologies available, the focus in recent years has particularly been on Power-to-Hydrogen plants, mainly because of the many uses of hydrogen, which, in addition to being an excellent fuel, can also be used as a raw material for various production processes (in refining, glass production, ceramics, steel and more).

In the recent study reported in [

6], the authors proposed and analysed possible distributed generation systems for power supply on the island of Rum, an island in Scotland not connected to the national grid that currently has a power supply system consisting of two hydroelectric generators, a backup diesel generator, and a battery storage system with an integrated inverter. The authors proposed several cases, including one in which a hydrogen production and storage subsystem flanks the classic battery storage system, and another case in which a hydrogen system replaces the batteries entirely, in both cases providing for the installation of wind and photovoltaic renewable sources to replace the current diesel generator, thus reducing the environmental impact.

The hydrogen storage considered consists of a PEM electrolyser, a compressed hydrogen tank, and a diesel generator converted to hydrogen. The electrolyser was chosen such that the maximum excess production for each scenario is converted to hydrogen. An economic analysis was conducted for each case considered, considering the capital expenditures (CAPEX), expected operating and maintenance costs (OPEX) and replacement costs associated with the various system components, based on their typical life cycle, considering a 20-year time window. For each case, the total life cycle cost (TLCC) and the levelized cost of energy (LCOE) were calculated.

The results obtained by the authors showed that the proposed hydrogen system can represent a sustainable solution even from an economic point of view, despite the current high investment expenses, leading to a completely renewable energy mix to meet the electricity demand of the considered island, with a lower LCOE than that of the current energy system. In addition, the TLCC of the case where the hydrogen storage system entirely replaces battery storage was found to be 13% lower than that of the case where both forms of storage are present, as the battery system incurs higher operating expenses due to its replacement, which must occur every 10 years. From this, the authors concluded that hydrogen generation and storage can be an economical means of stand-alone clean energy storage for island power systems.

The presence of power-to-hydrogen plants, however, can also be very useful for grid-connected systems. This is the case of the Terni medium-voltage distribution grid. A case study was conducted in [

7], where the authors proposed the installation of hydrogen systems consisting of fuel cells, electrolysers and compressed hydrogen storage. The aim was to enhance the energy performance of the distribution grid and facilitate the integration of distributed generation. Through an optimisation algorithm, the optimal size and placement of such systems were identified, achieving a high rate of self-consumed excess renewable energy of 38.7% and a decrease in reverse energy flows of 14.8%. The sizing problem was solved through an optimisation procedure based on the micro genetic algorithm, which is adequate for solving problems with complex and nonlinear data, setting as the goal the identification of the minimum sizes of the fuel cell, electrolyser and hydrogen storage system such that a specific Key Performance Indicator value can be achieved. The problem of location, on the other hand, has been solved by means of Key Selection Indicators, which are indicators related to the efficient operation of hydrogen systems that enable the selection of the most suitable energy districts to host them.

In [

8], the authors showed the impact that a Power-to-Gas plant can have on two electrical systems, one rural and one semi-urban, for different penetration rates of renewable sources. The plant considered consists of an alkaline electrolyser, a tank and a methanation unit to which hydrogen can be sent for the production of synthetic natural gas. To determine the network node where the plant should be installed and the size of the plant, the authors applied the Simulated Annealing method, considering the minimisation of reverse power flows, overvoltages and overcurrents as objective functions. The results achieved are significant, with a reduction in reverse power flows in the range of 78–100%, depending on the network topology and penetration of renewable sources, alleviating or eliminating overcurrent and/or overvoltage problems. However, the study did not consider the investment costs during the plant design phase, nor other local uses of hydrogen besides methanation.

In a case study reported in [

9], instead, reverse power flows generated by a grid-connected photovoltaic system were fully converted to hydrogen to power a fleet of fuel cell vehicles, leading, however, to the hydrogen produced having a higher storage size than the sizes obtained in cases where the electrolyser operates more continuously due to other electricity supplies.

Sizing power-to-hydrogen plants to maximise the energy yield from renewable sources, as proposed in [

6,

9], could therefore be uneconomical. For this reason, it would be better to use optimisation studies, as performed in [

7,

10]. In the latter paper, in particular, a linear mathematical model of an energy hub was employed, which allows great flexibility in modelling with a low computational time. The model was developed in the MATLAB R2023b environment to determine the optimal size of the components of two storage systems, one hydrogen and one battery, such as to minimise the curtailment of renewable energy, which is necessary in some cases to avoid the emergence of congestion in the transmission grid. In addition, the sizes of the two systems were optimised in order to find the most economical solution.

The adoption of energy systems of this type, based on the energy hub concept, is widespread in the literature because they allow for a number of advantages: first, the reliability of the energy supply can be increased because it is no longer completely dependent on a single grid; second, such a system allows, through linear equations, the optimisation of the supply itself according to certain criteria such as, for example, the cost, emissions and availability of the various carriers; and, finally, it allows, as in this case, to facilitate the integration of non-programmable renewable energy sources due to the presence of conversion and storage elements [

11,

12,

13].

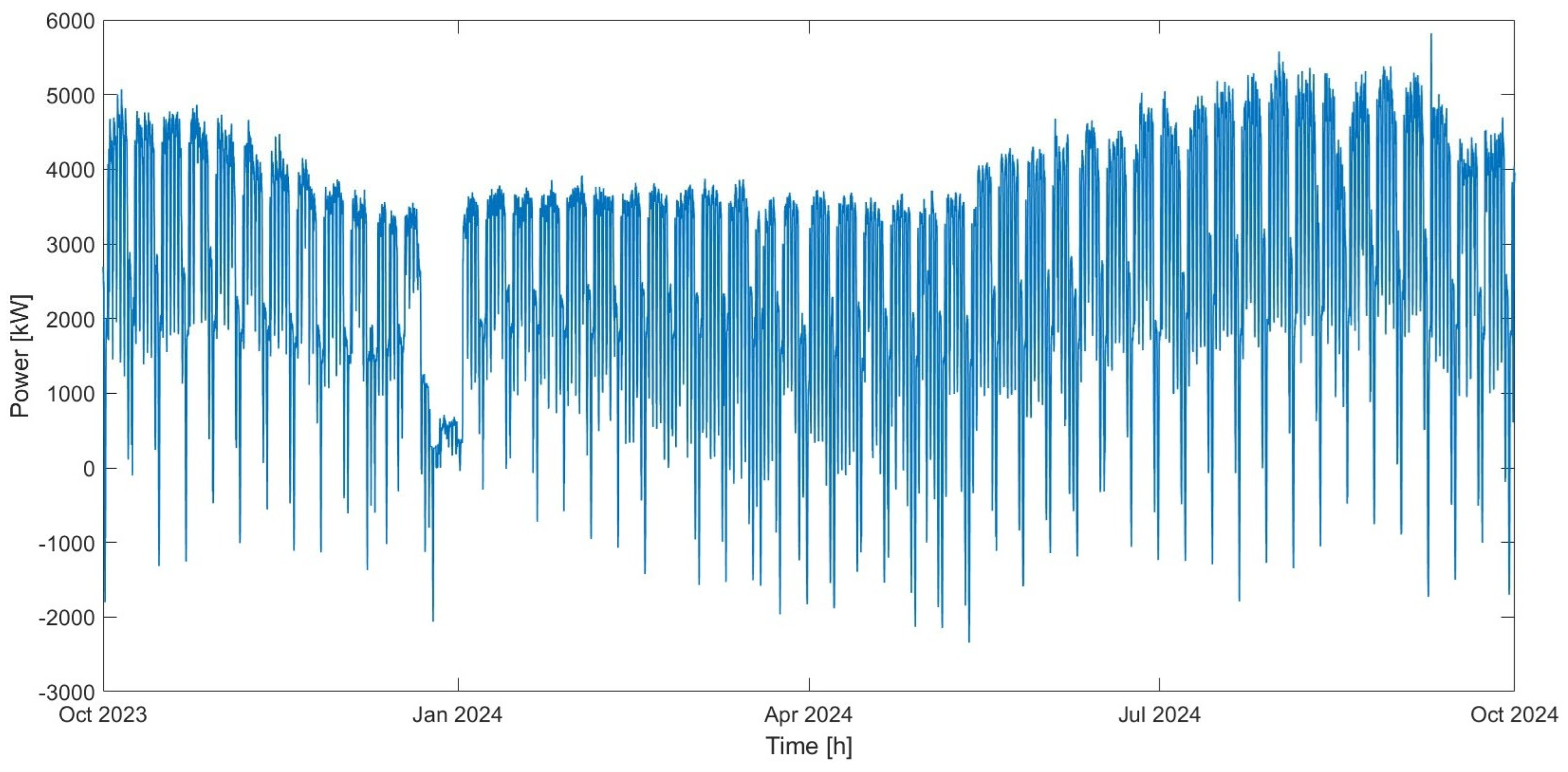

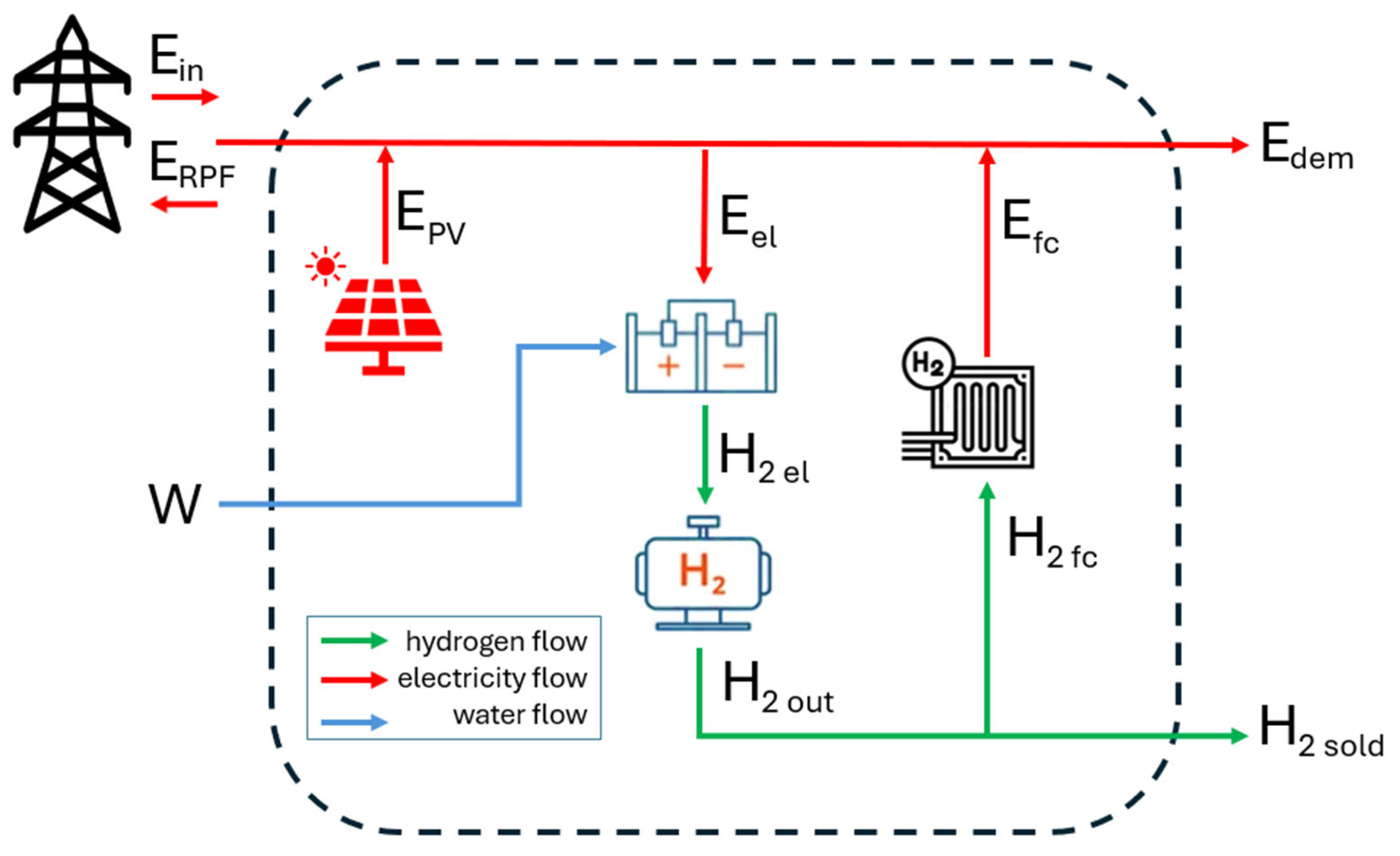

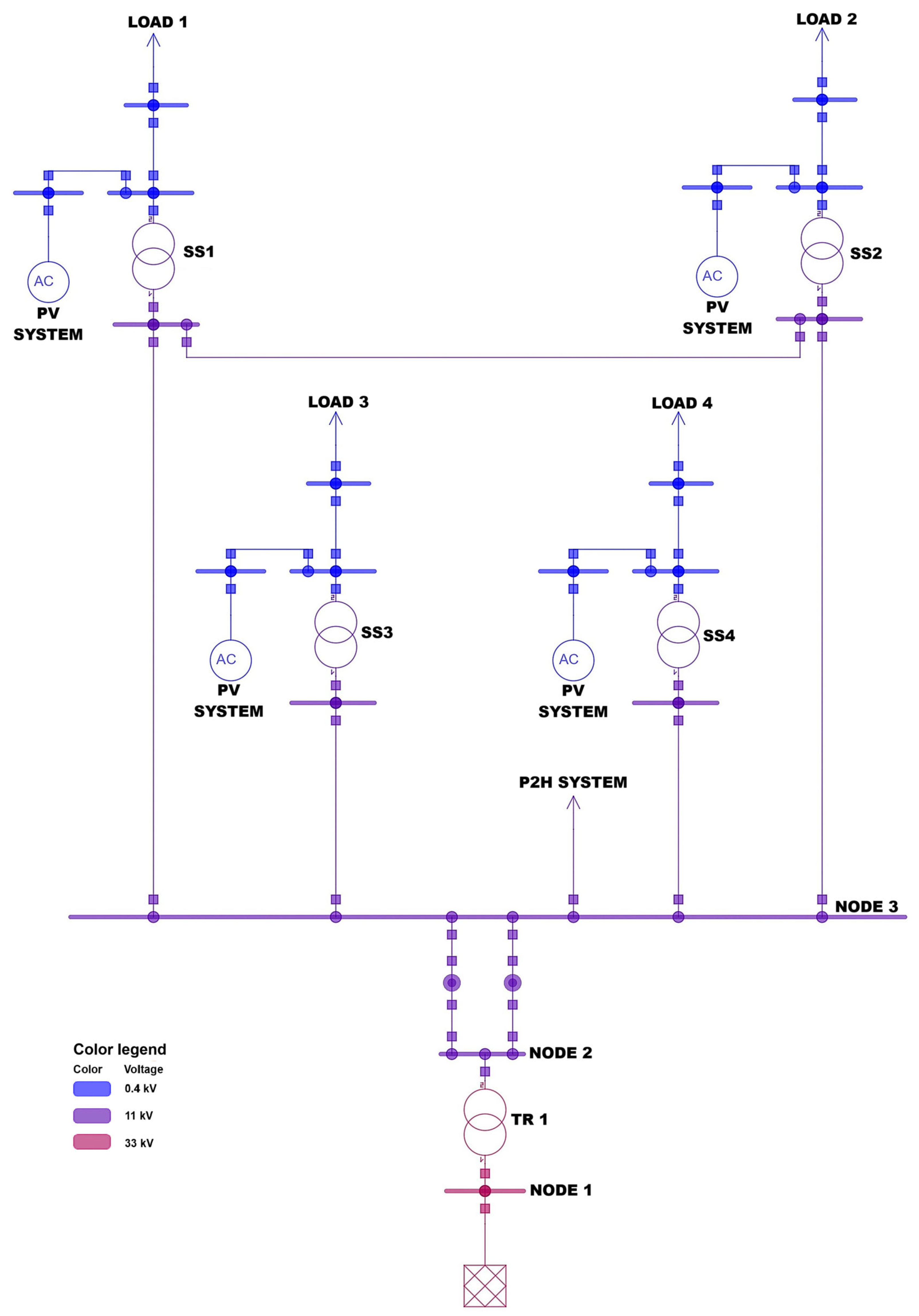

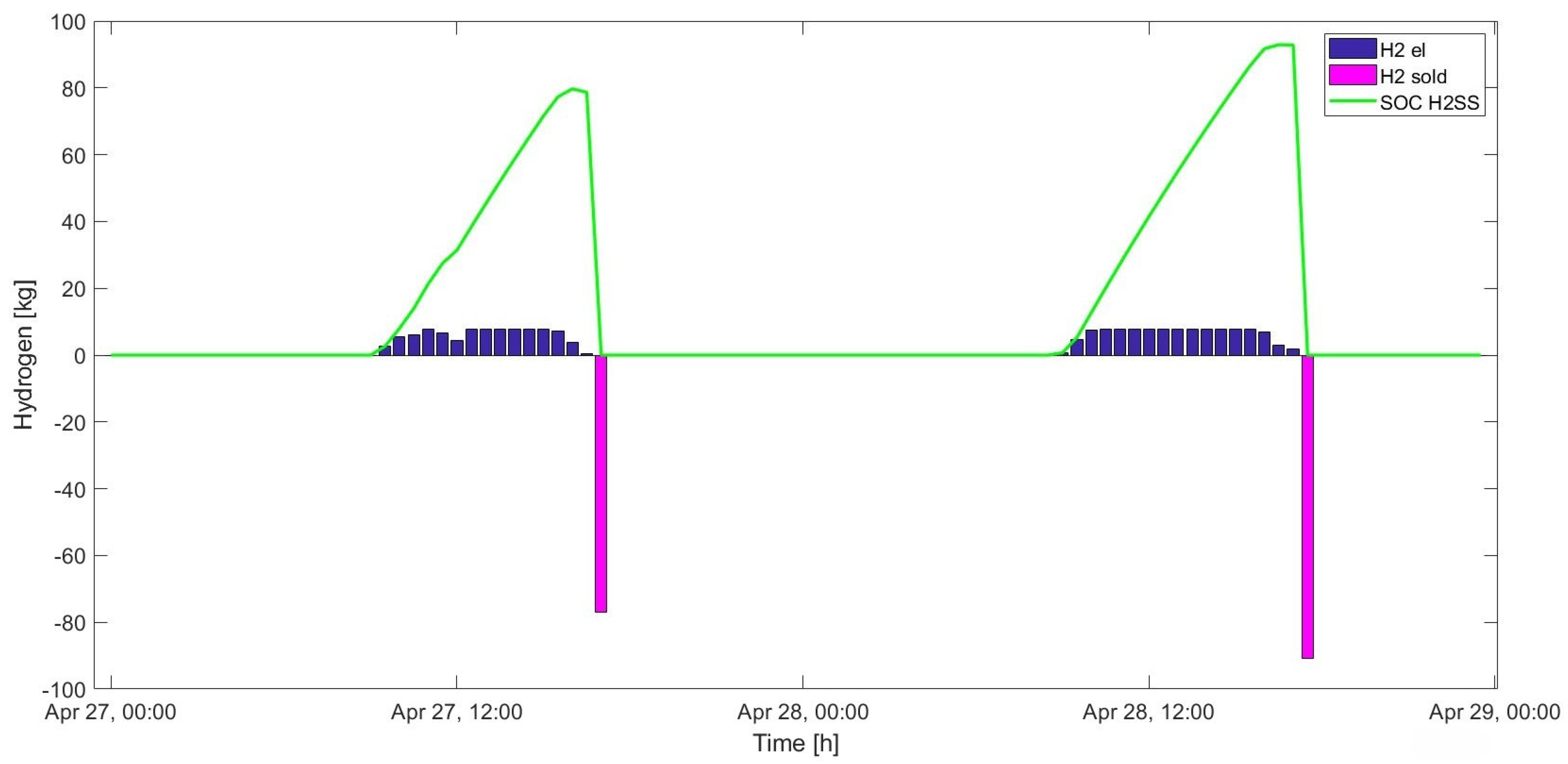

In the study presented in this paper, the same mathematical model proposed in [

10] has been adopted, incorporating aspects such as the operational flexibility of the electrolysers and the possibility of selling the hydrogen produced. Specifically, the network under study is a medium-voltage industrial distribution network located in Malta that is subjected to reverse power flows deriving from the photovoltaic plants connected to it. To minimise the reverse energy flow, the installation of a Power-to-Hydrogen plant consisting of a PEM electrolyser, a gaseous hydrogen storage system and a fuel cell has been considered. Compared to studies found in the literature, this article proposes a sizing algorithm for the Power-to-Hydrogen system that not only minimises reverse power flows but also limits investment costs, while considering the revenues obtained from the sale of the hydrogen produced and the excess energy generated by photovoltaic systems. The study presented in this article also evaluates the benefits to the grid in terms of losses and voltage profiles, through load flow calculations performed using time series of real load and generation data from existing photovoltaic plants connected to the grid and the load profile of the Power-to-Hydrogen plant obtained from the optimisation algorithm. Below, in

Section 2, the methodology and data used are presented in detail, both for the optimisation study and for the impact assessment on the grid;

Section 3 presents the results obtained; finally,

Section 4 discusses the results and conclusions.

4. Discussion of Results and Conclusions

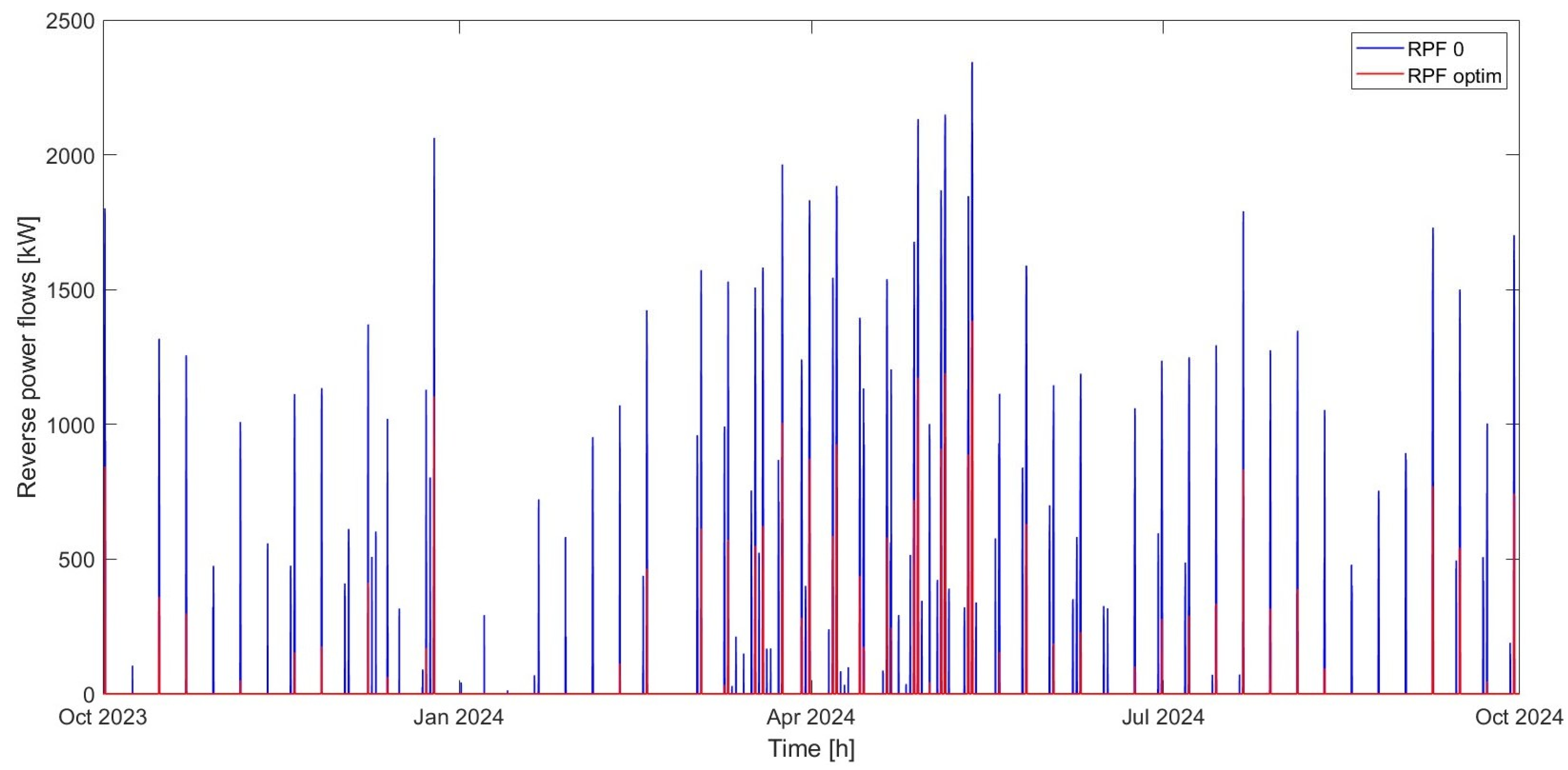

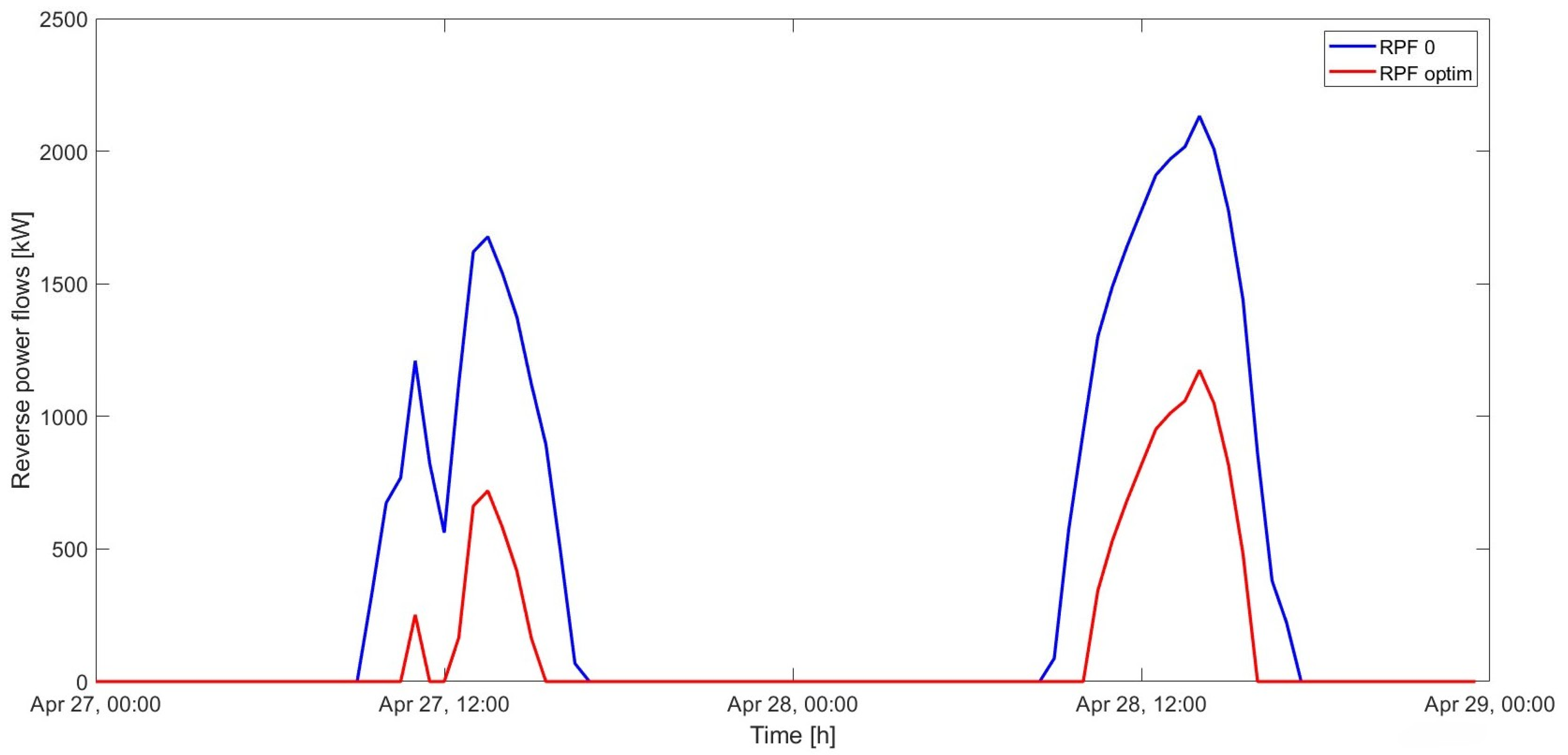

The increase in the installation of electricity generation plants using non-programmable renewable sources is causing a significant challenge for the proper management of networks, including reverse power flows, which can lead to voltage increases, transformer overheating, and malfunctions in line protection systems. This study shares the findings from a case study conducted on a 11 kV medium-voltage industrial grid in Malta, which will be subject to the expansion of the photovoltaic plants currently installed. After evaluating the reverse power flows that will occur because of these expansions, this study proposes an optimal sizing method for a Power-to-Hydrogen plant that will exploit the excess energy produced by photovoltaic plants to produce green hydrogen, while also providing support to the grid.

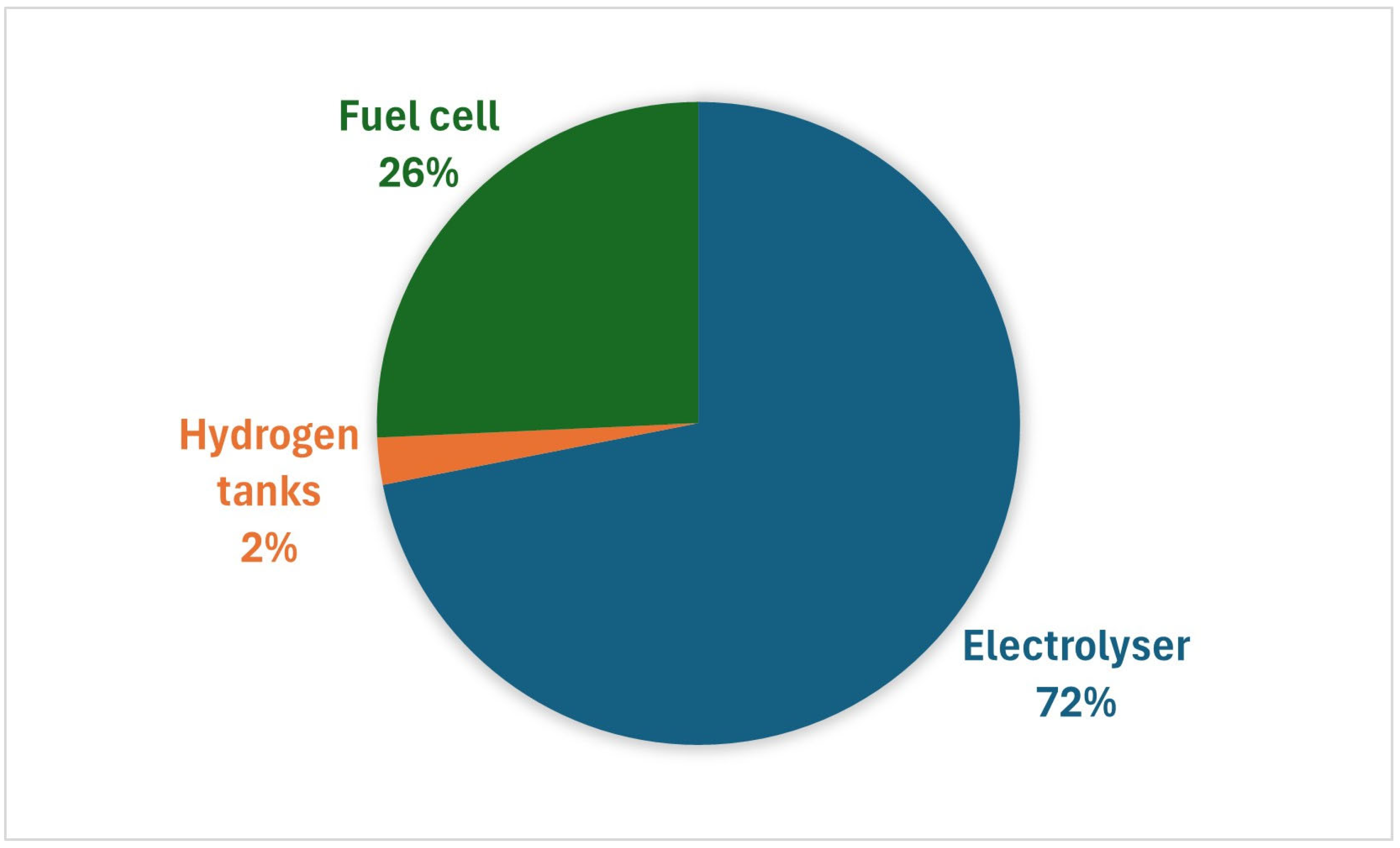

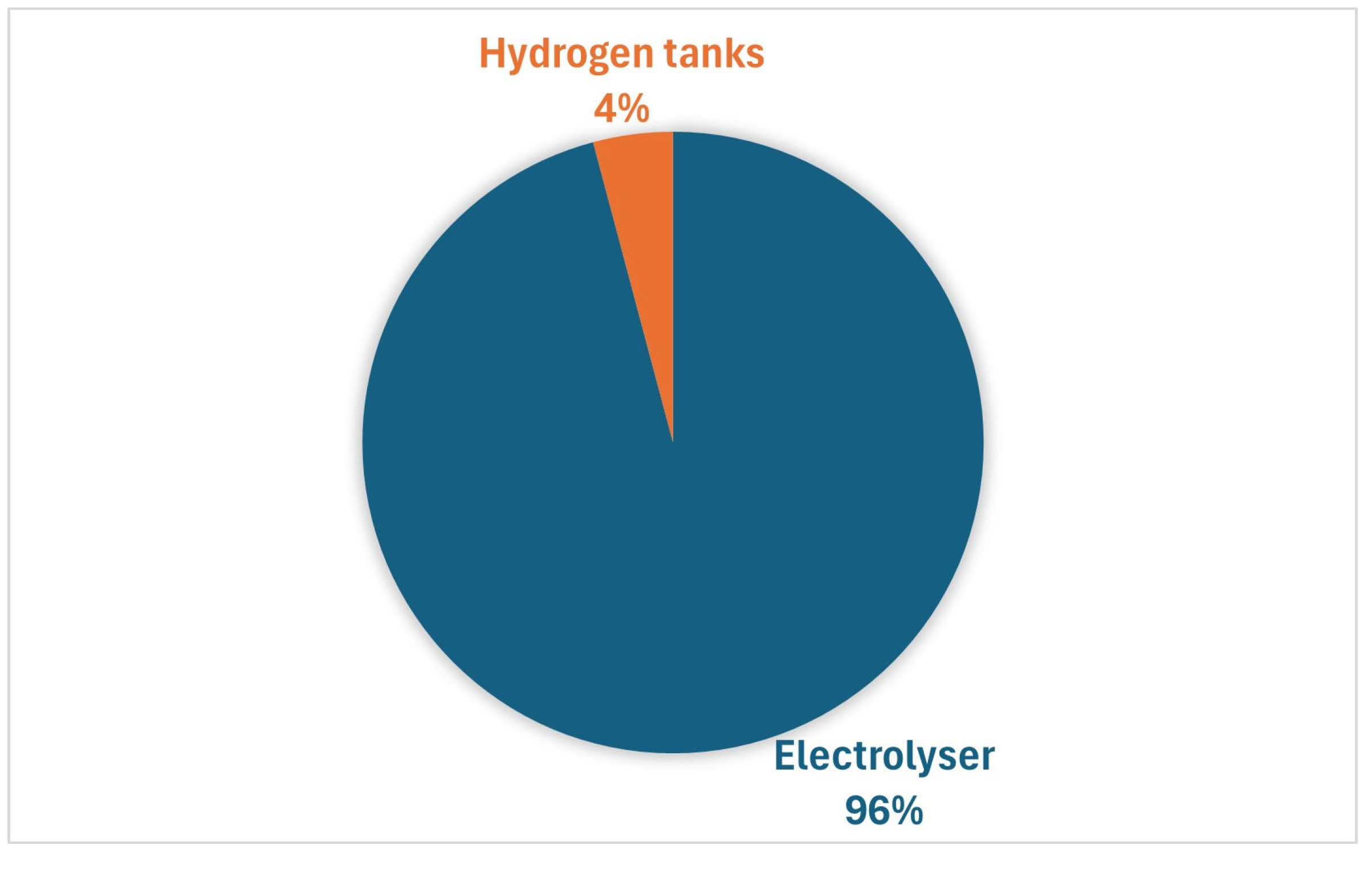

The plant was initially sized by solving a single-objective optimisation problem, which aims to minimise reverse power flows. This solution allows the excess energy to be totally converted into hydrogen, but involves excessive expenditure, especially for the installation of the fuel cell, which will only provide 0.04% of the energy required on site by users. Its integration is therefore not very convenient, both from a technical and economic point of view. The Power-to-Hydrogen system was therefore redesigned using a multi-objective optimisation code, with the aim of finding a technical–economic compromise. Both optimisation problems were solved in MATLAB.

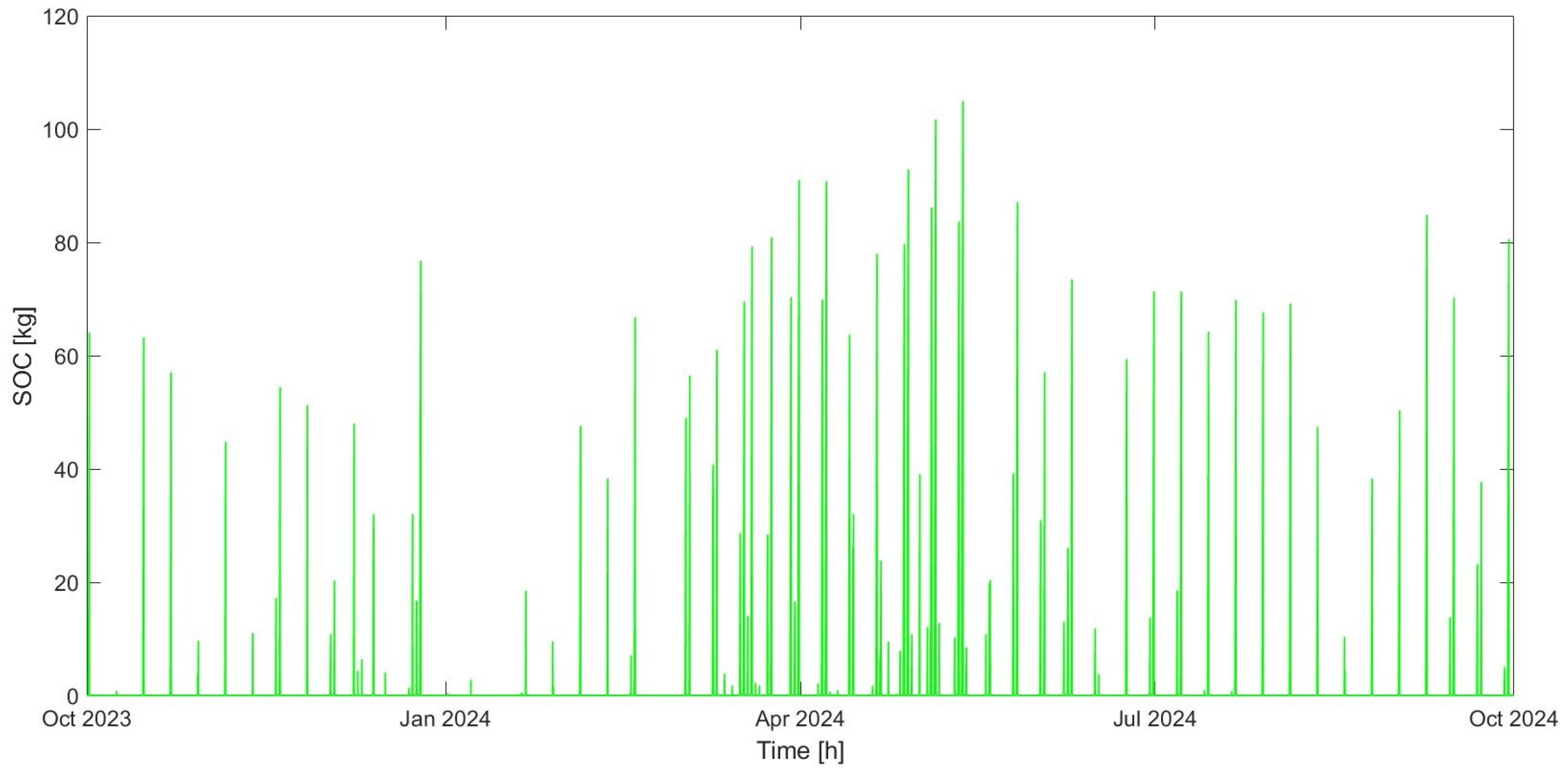

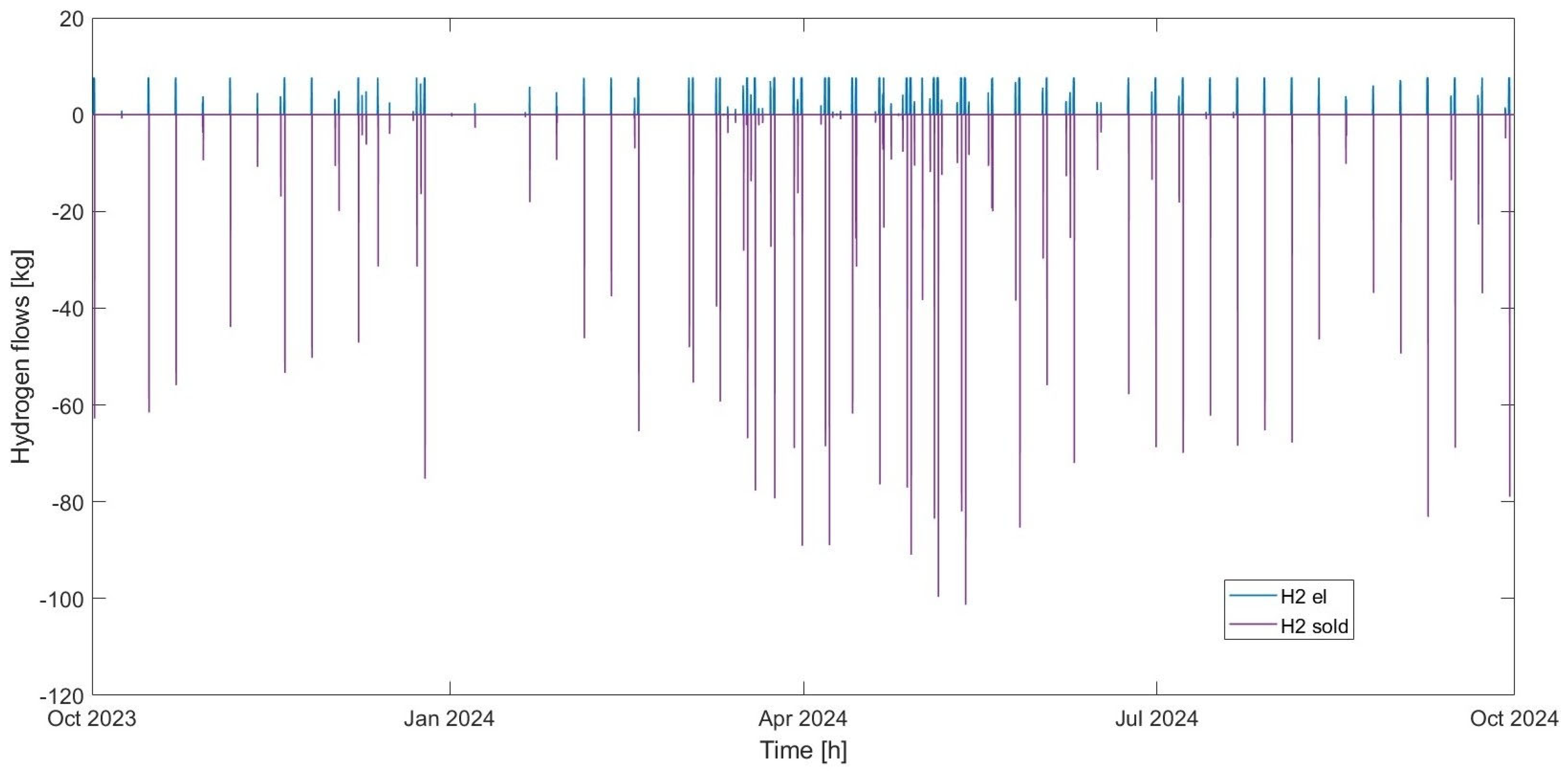

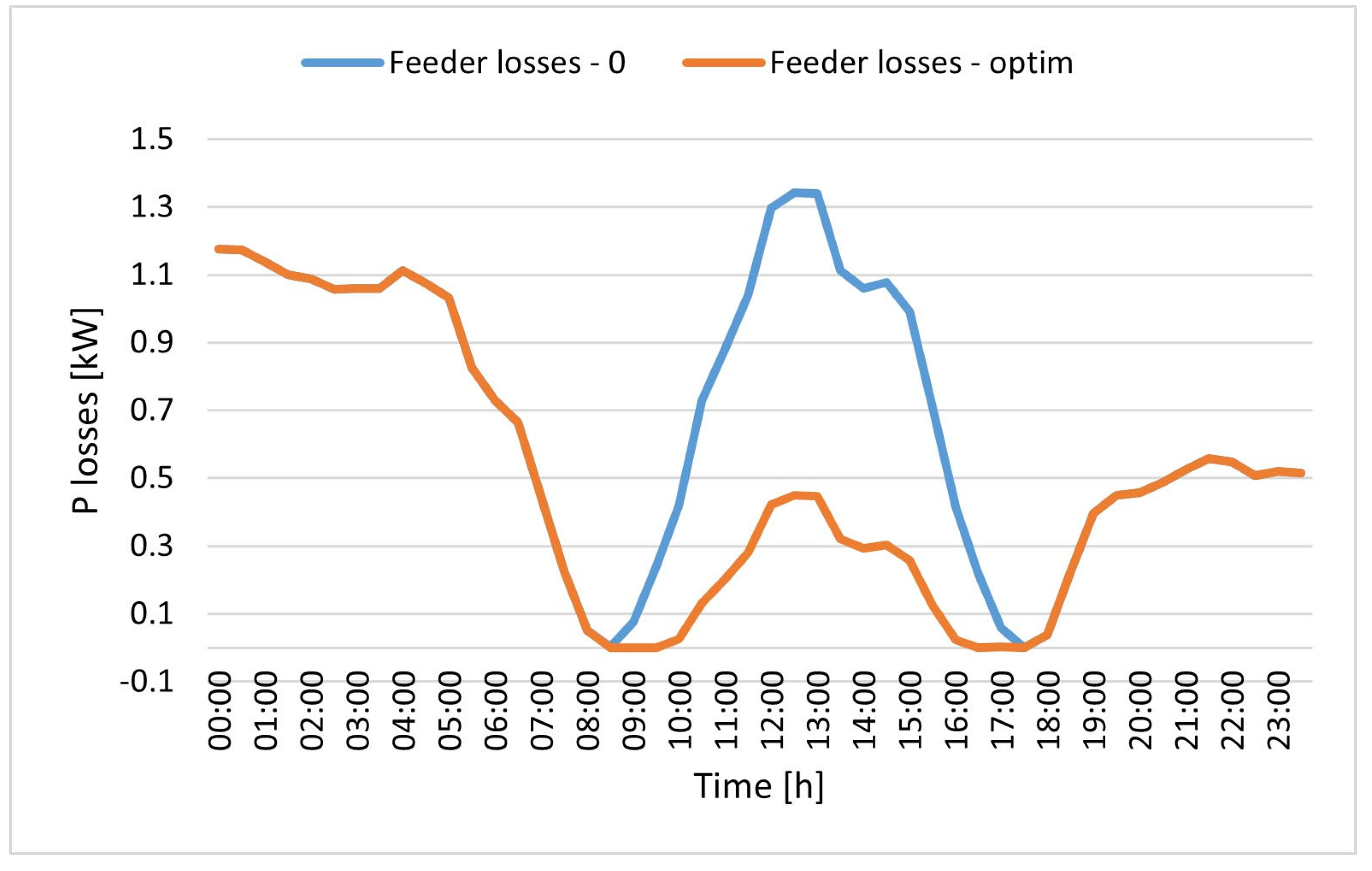

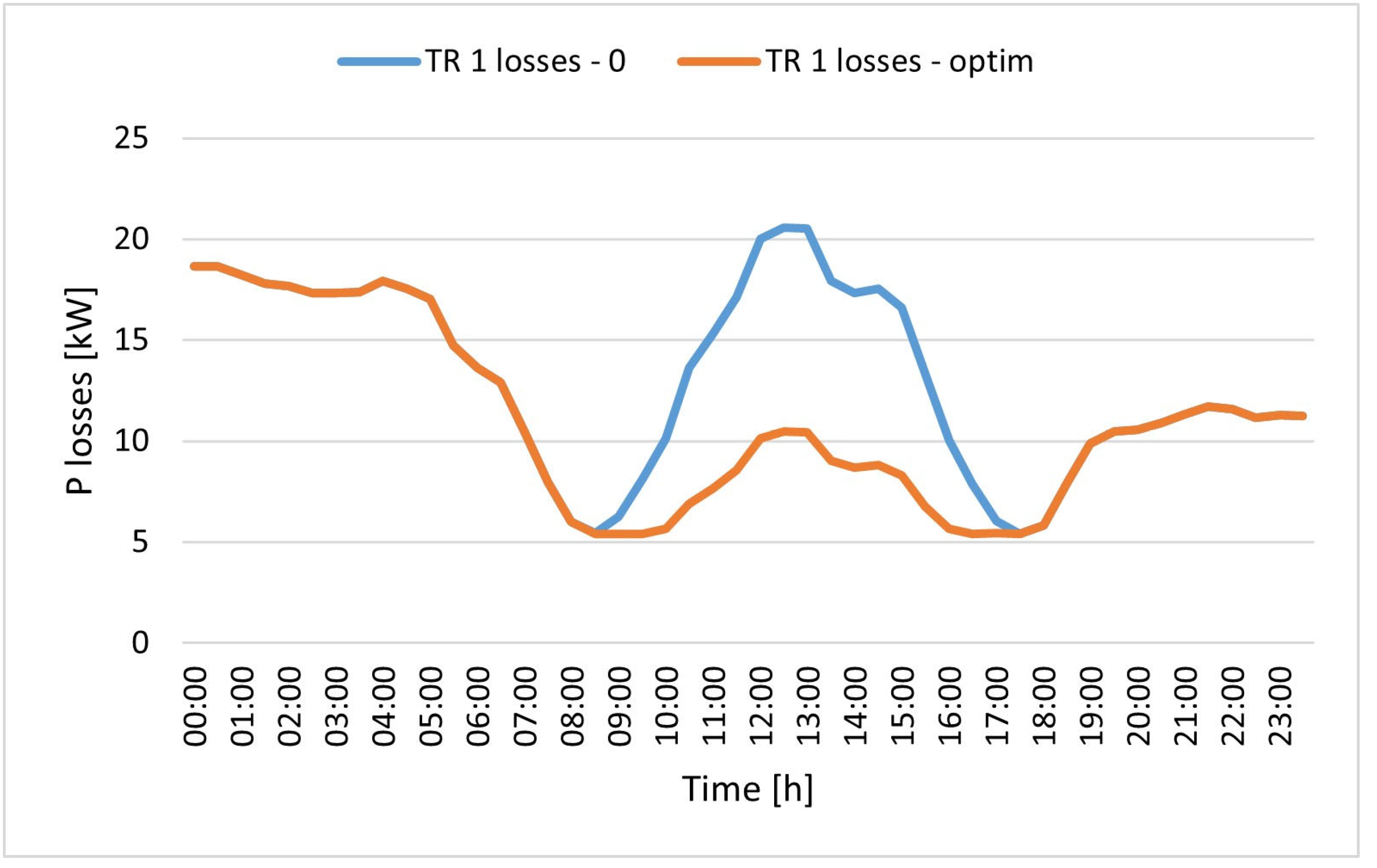

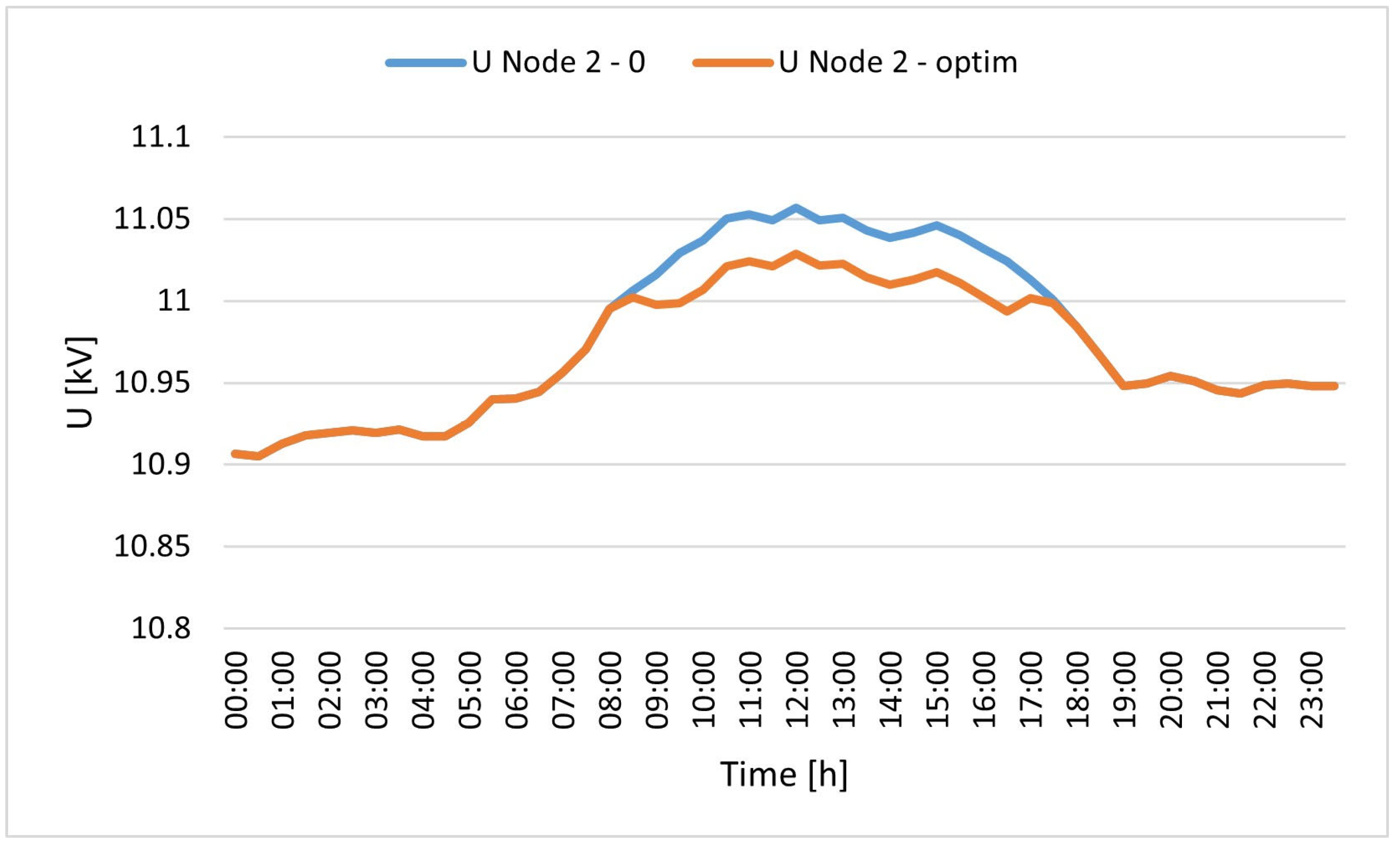

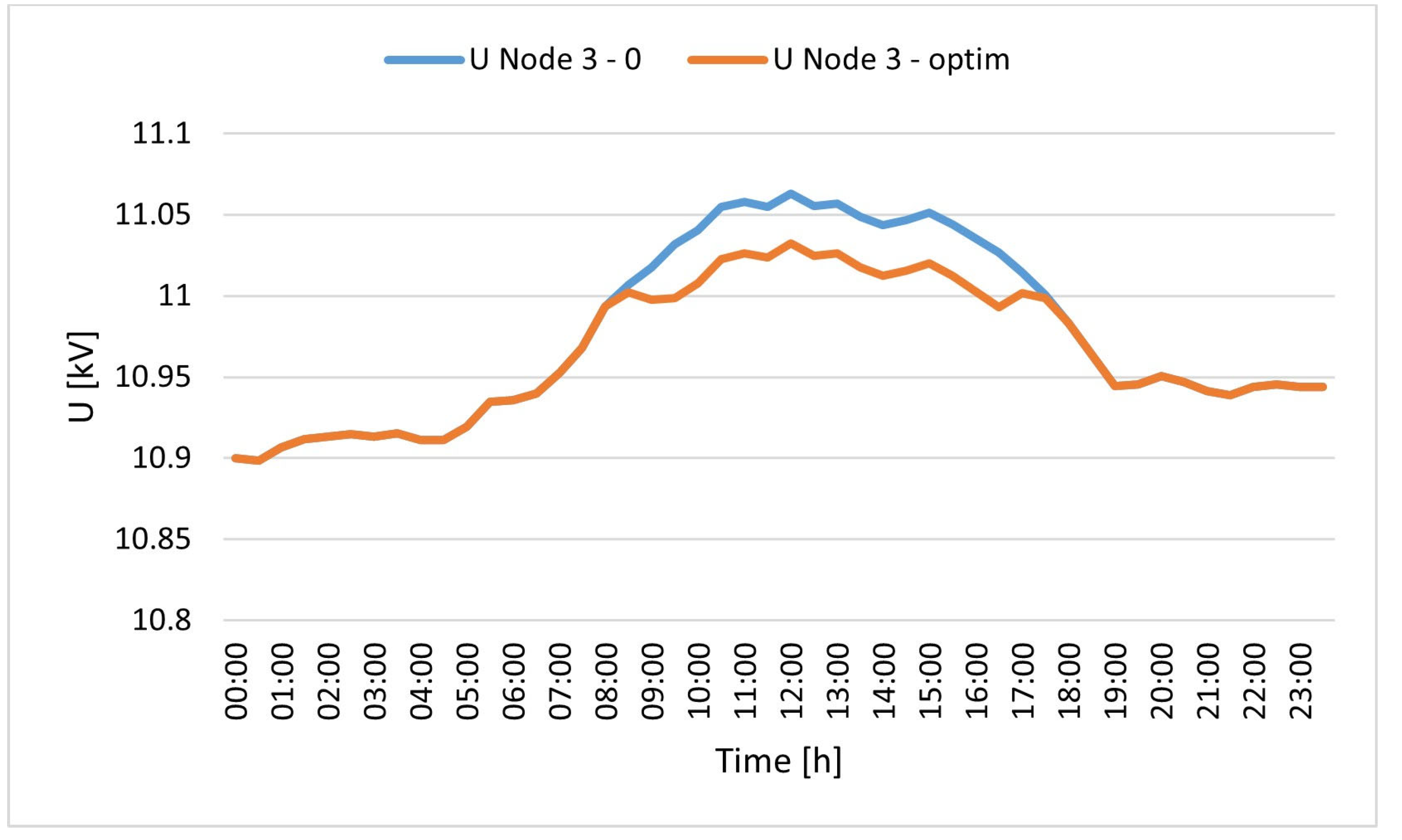

The optimal solution consists of installing a 737 kW electrolysis system and a 105 kg hydrogen storage system, without any fuel cells. The hydrogen produced, amounting to over 4 tons per year, is then sold in its entirety, while reverse power flows are reduced by 81.61% compared to the scenario without an electrolysis plant. The percentage reduction in annual reverse power flows achieved is within the range of 78–100% found in similar case studies in the literature. Additional benefits to the electrical grid resulting from the installation of the plant were evaluated using NEPLAN software, which performed load flow calculations. The results obtained showed that the presence of the electrolysis plant reduces energy losses in the feeders supplying the 11 kV industrial grid by over 29% and losses in the upstream transformer by over 17% during the day when reverse power flow values are at their highest.

This study has thus provided an alternative to traditional battery storage systems, which have already been evaluated in previous studies, offering a twofold benefit: supporting the electricity grid and producing a fuel with zero environmental impact that can be used in various sectors, thereby increasing the energy independence of the island of Malta.