A Review of Marine Dual-Fuel Engine New Combustion Technology: Turbulent Jet-Controlled Premixed-Diffusion Multi-Mode Combustion

Abstract

1. Introduction

- (1)

- The high-velocity turbulent jets ejected from the pre-chamber significantly enhance the mixing of the main fuel (typically injected into the main chamber) with air, thereby improving the overall combustion rate and potentially increasing engine thermal efficiency.

- (2)

- The physical separation afforded by the pre-chamber design allows for independent control over the combustion characteristics of the small amount of ignition fuel and the bulk of the main fuel combusting in the main chamber, minimizing mutual interference.

- (3)

- Utilizing a pre-chamber ignition system can enable a significantly higher substitution rate of the main fuel compared to main-chamber micro-pilot diesel ignition. This increased substitution of fossil liquid fuel often leads to a reduction in engine-out emissions, including PM, SOx, and CO2.

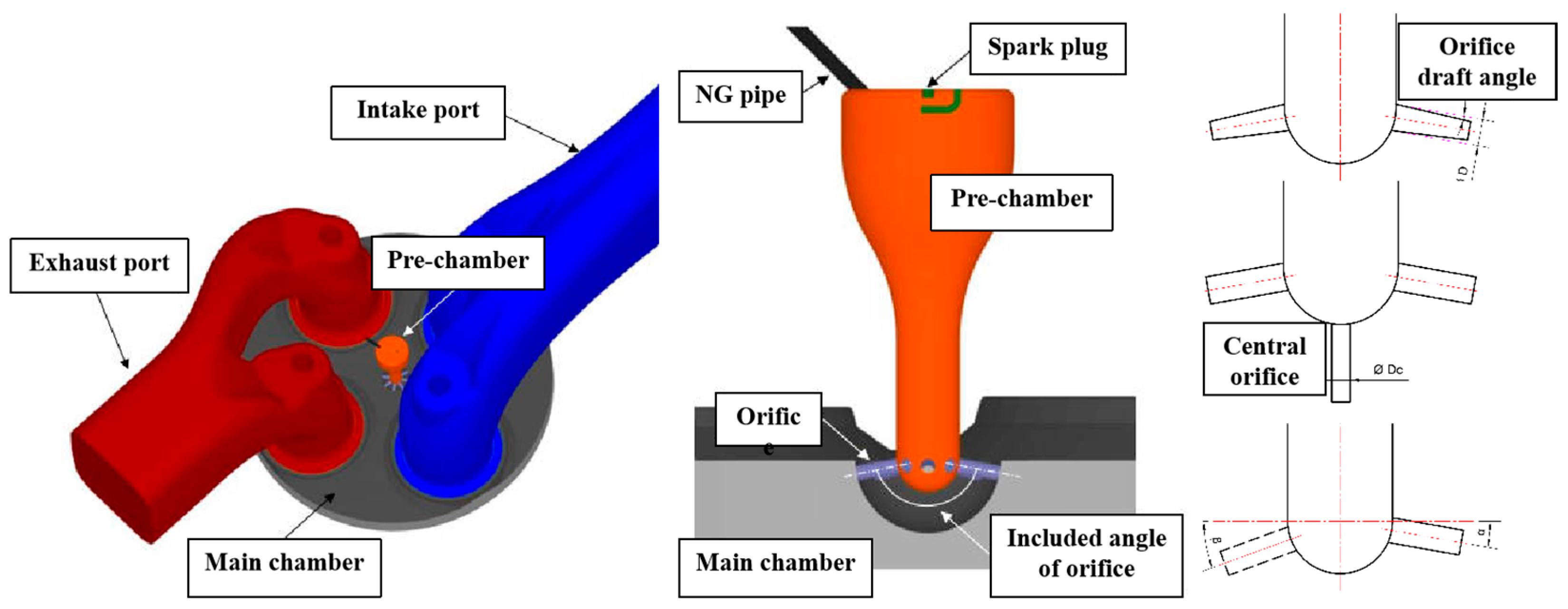

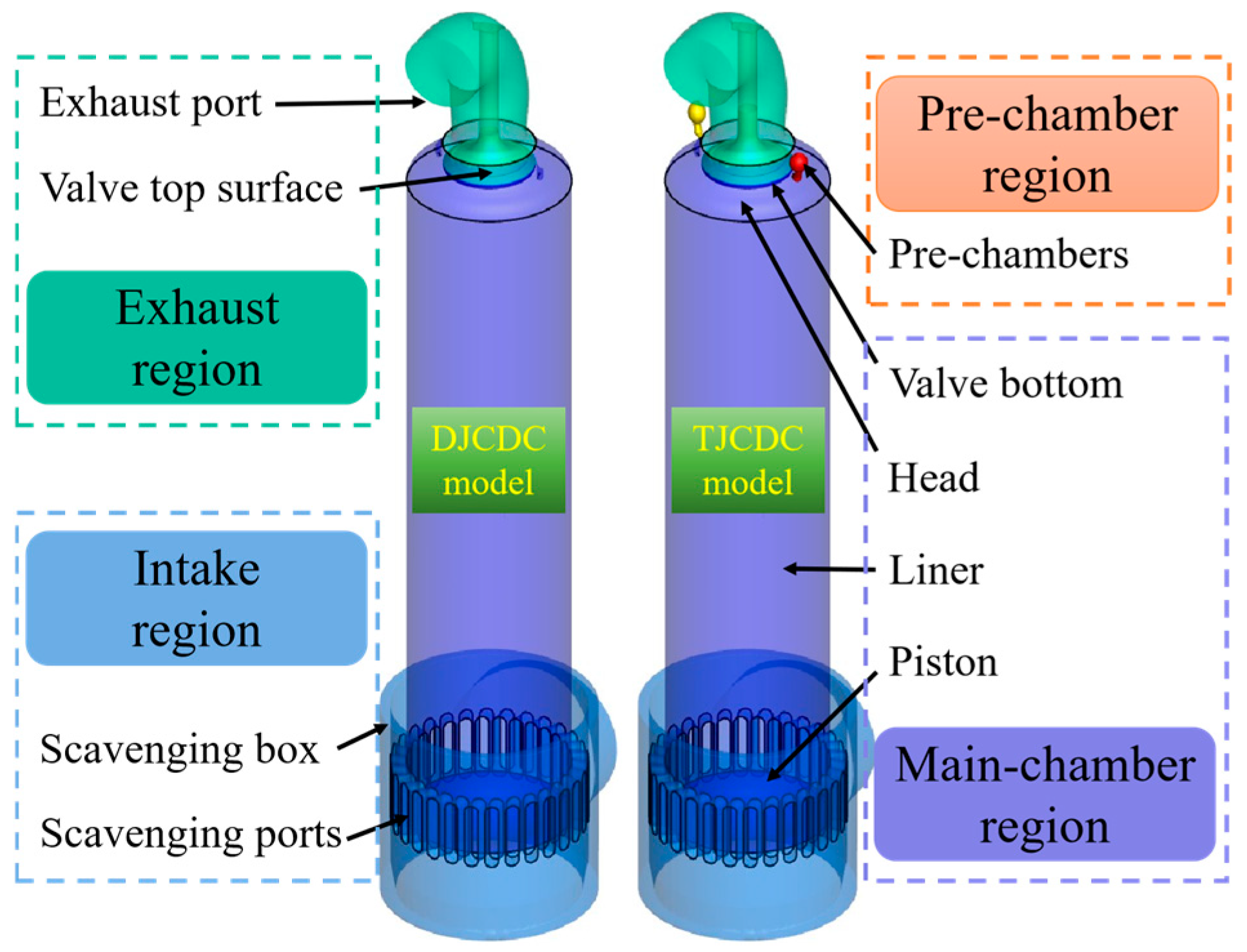

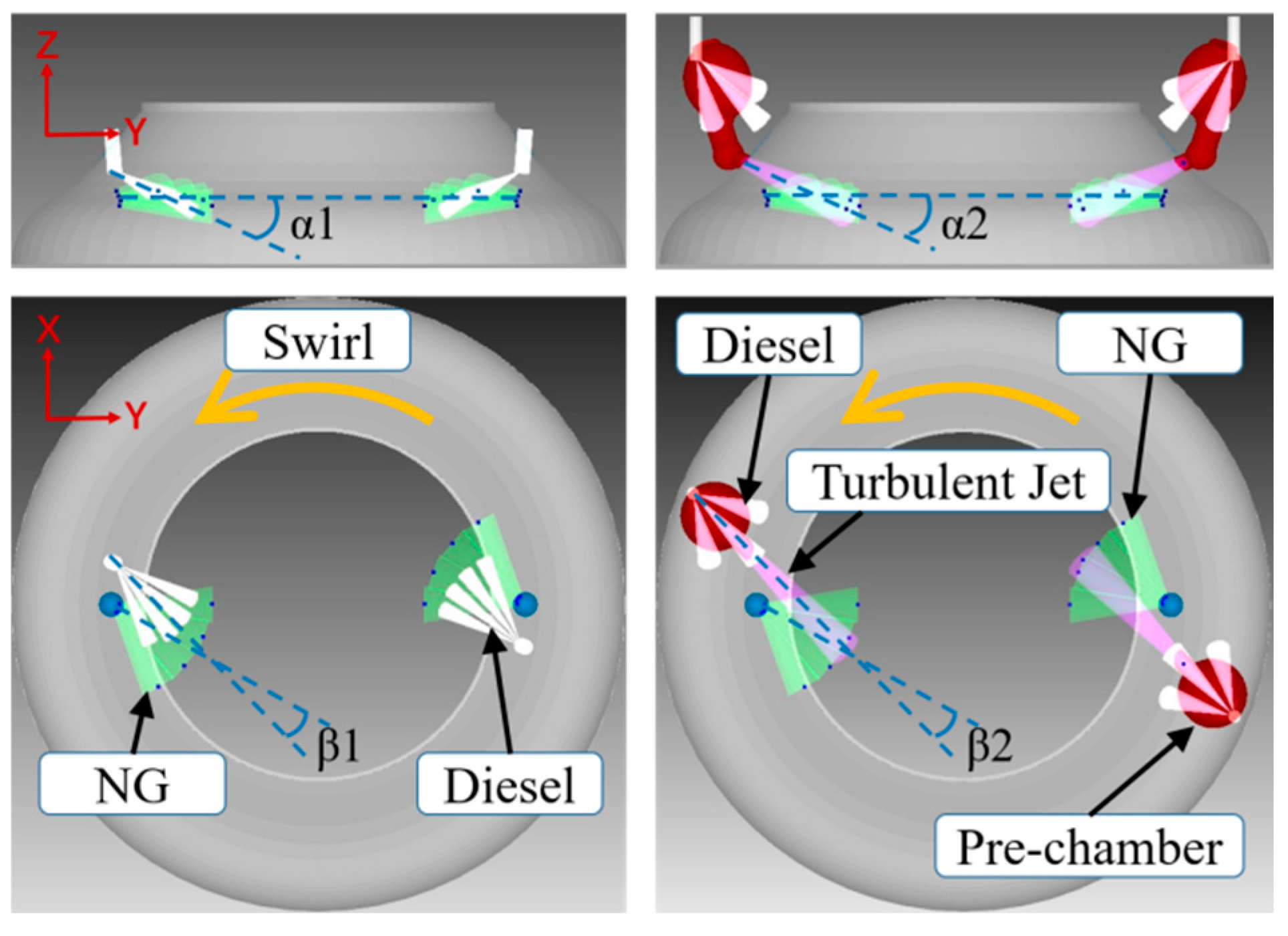

2. Turbulent Jet-Controlled Diffusion Combustion (TJCDC) Mode

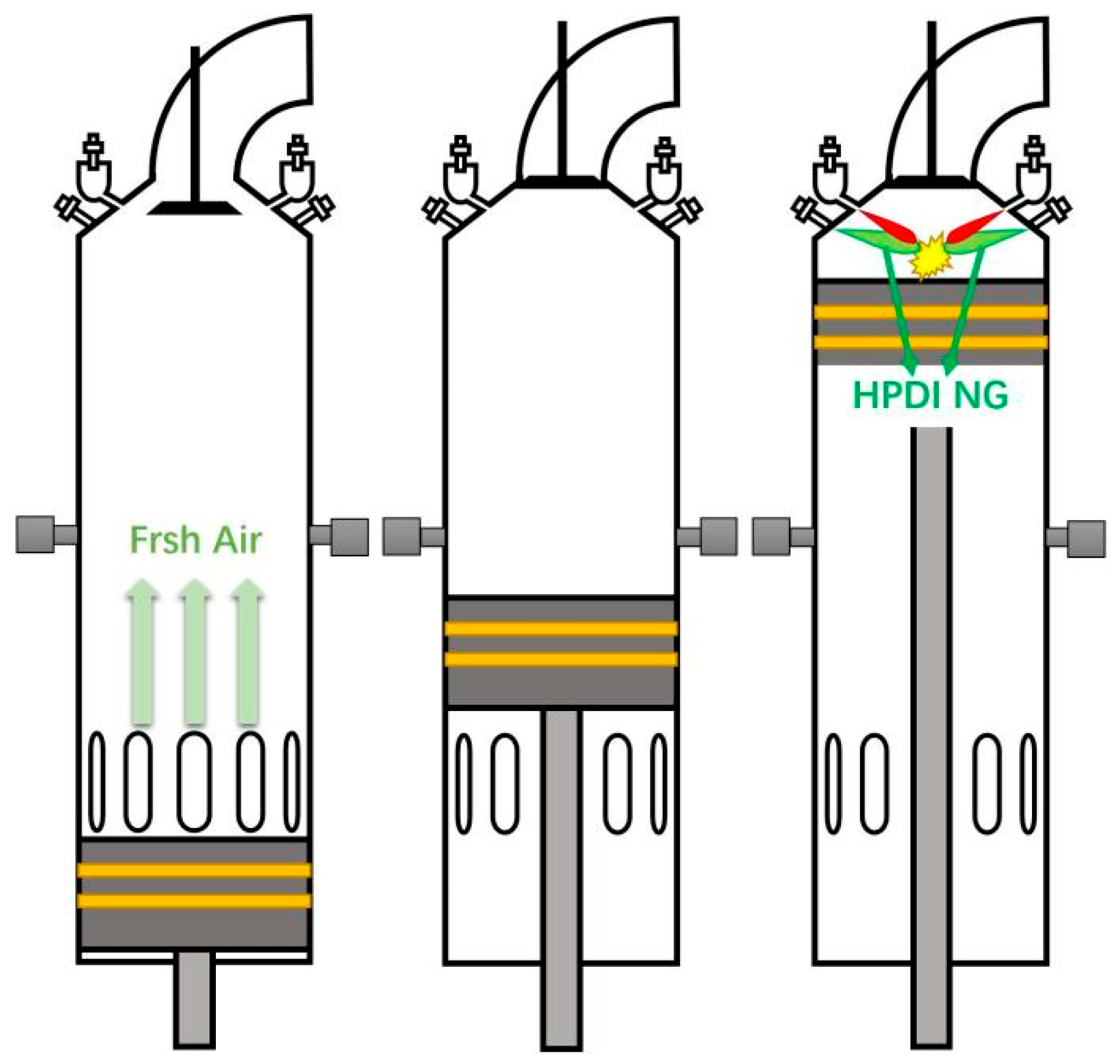

2.1. Operating Process of the TJCDC Mode

2.2. Combustion and Emission Characteristics of the TJCDC Mode

2.2.1. Combustion Characteristics of the TJCDC Mode

2.2.2. Emission Characteristics of the TJCDC Mode

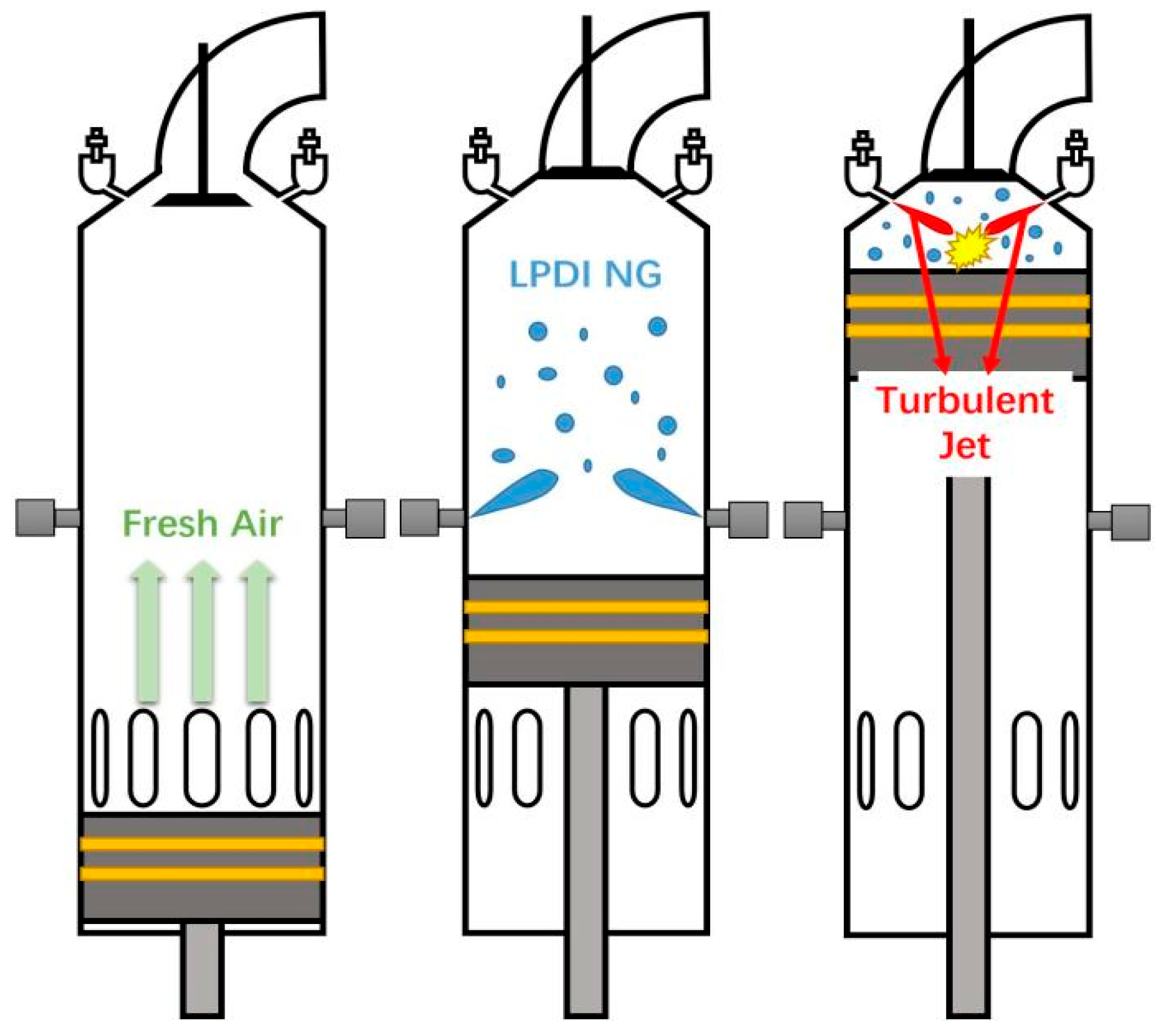

3. Turbulent Jet-Controlled Premixed Combustion (TJCPC) Mode Study

3.1. Operating Process of the TJCPC Mode

3.2. Combustion and Emission Characteristics of the TJCPC Mode

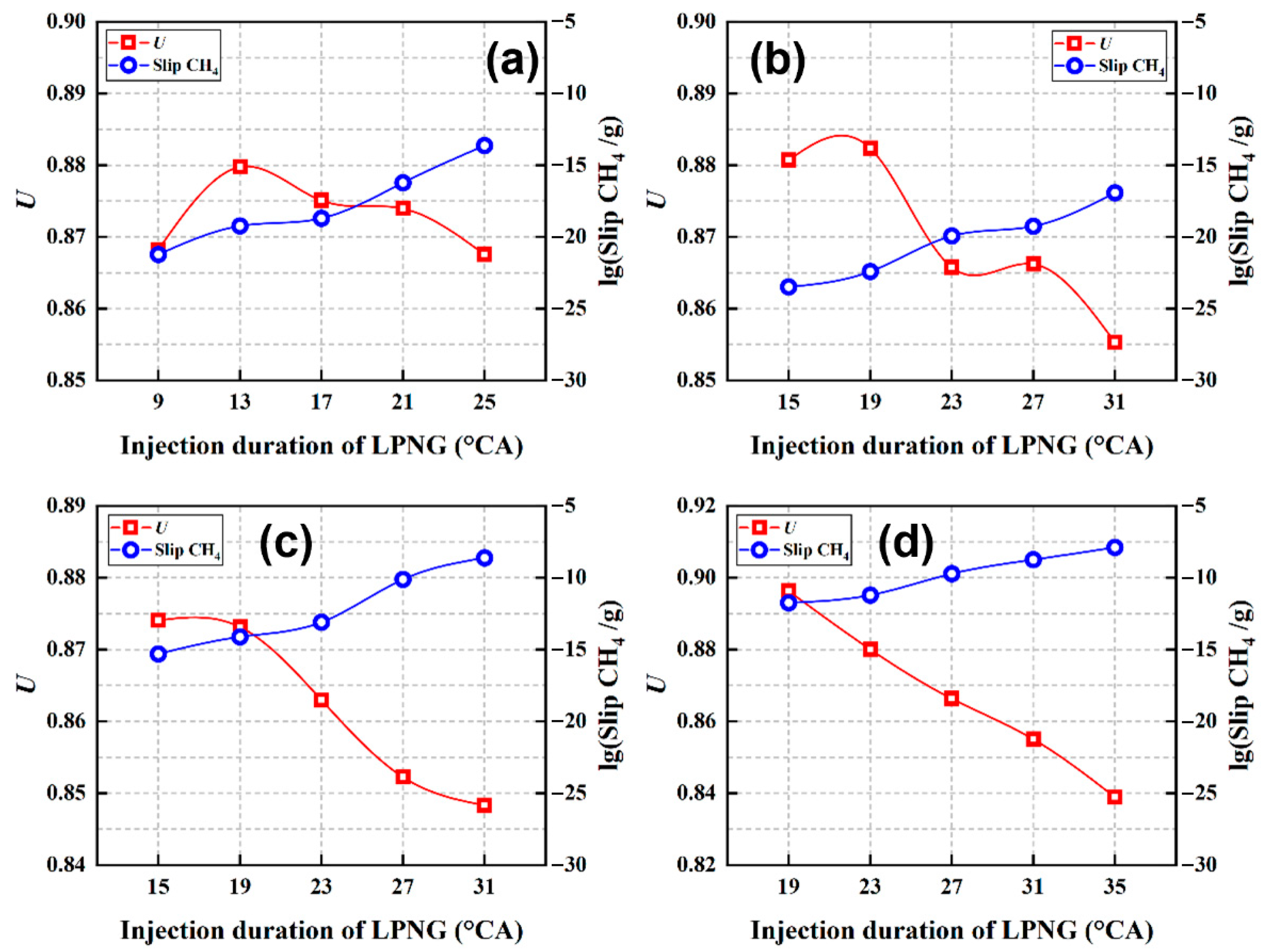

3.2.1. Influence of Natural Gas Injection Parameters on Premixing Performance

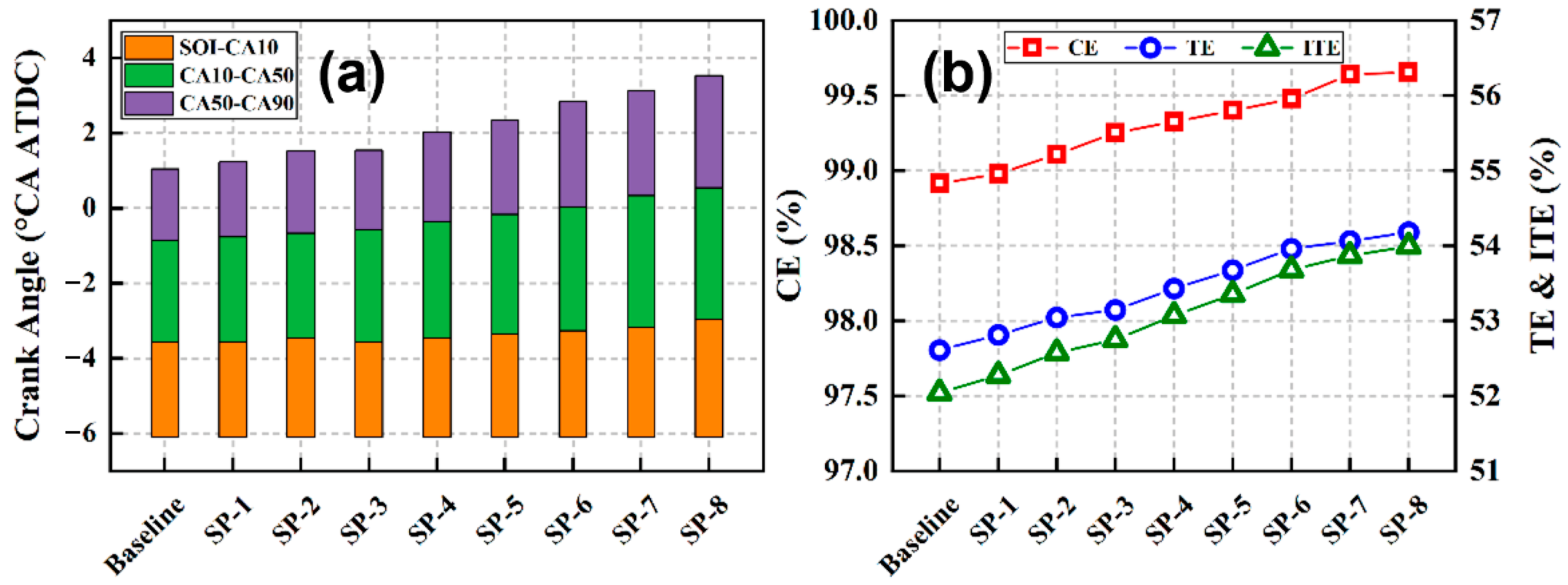

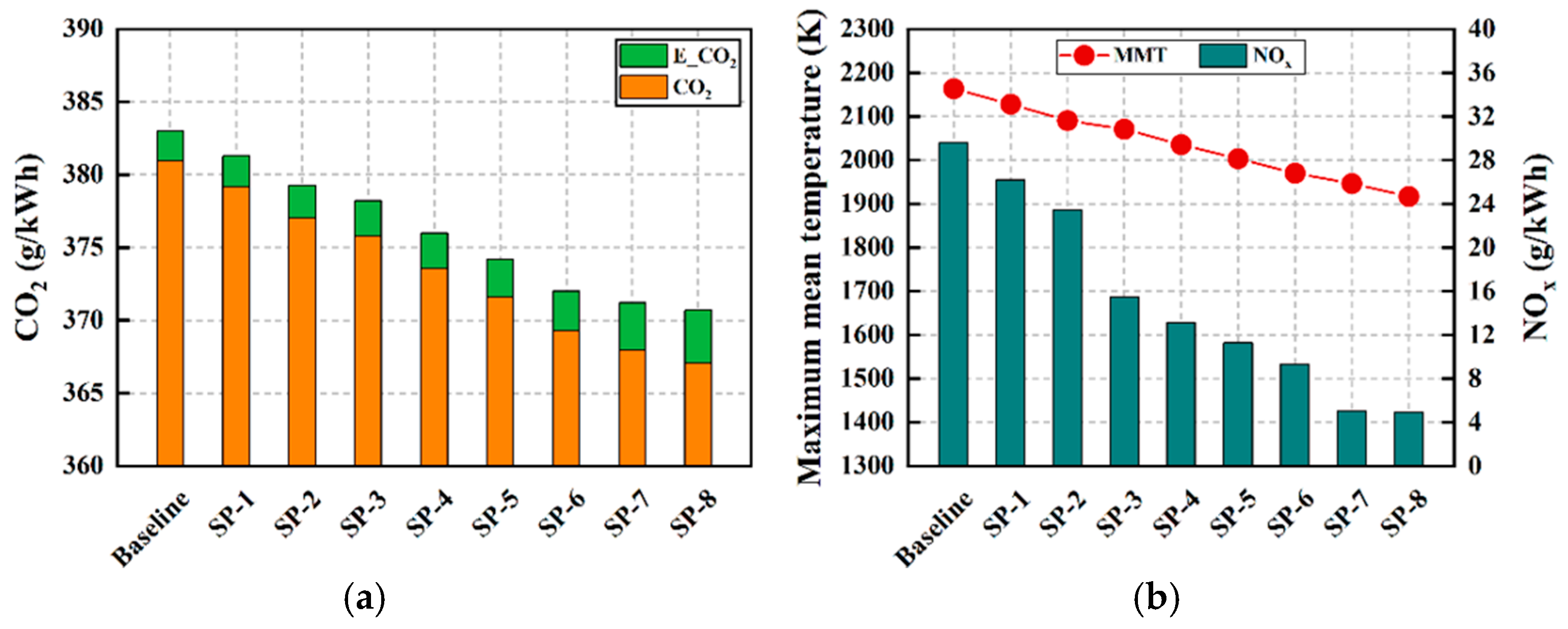

3.2.2. Effect of Excess Air Ratio Under High Compression Ratio

3.3. Future Research Directions and Recommendations

- (1)

- Injector Packaging: The integration of pre-chamber injectors within the confined space of an engine chamber poses a significant challenge that needs to be addressed in retrofit scenarios;

- (2)

- Cooling: Pre-chamber systems may generate considerable heat, requiring effective cooling solutions to prevent overheating and maintain component integrity;

- (3)

- Maintenance: The addition of pre-chamber systems could increase maintenance complexity and frequency, necessitating the development of robust maintenance procedures;

- (4)

- Combustion Noise: The turbulent jets and combustion processes might increase engine noise levels, thus requiring strategies to manage acoustic emissions.

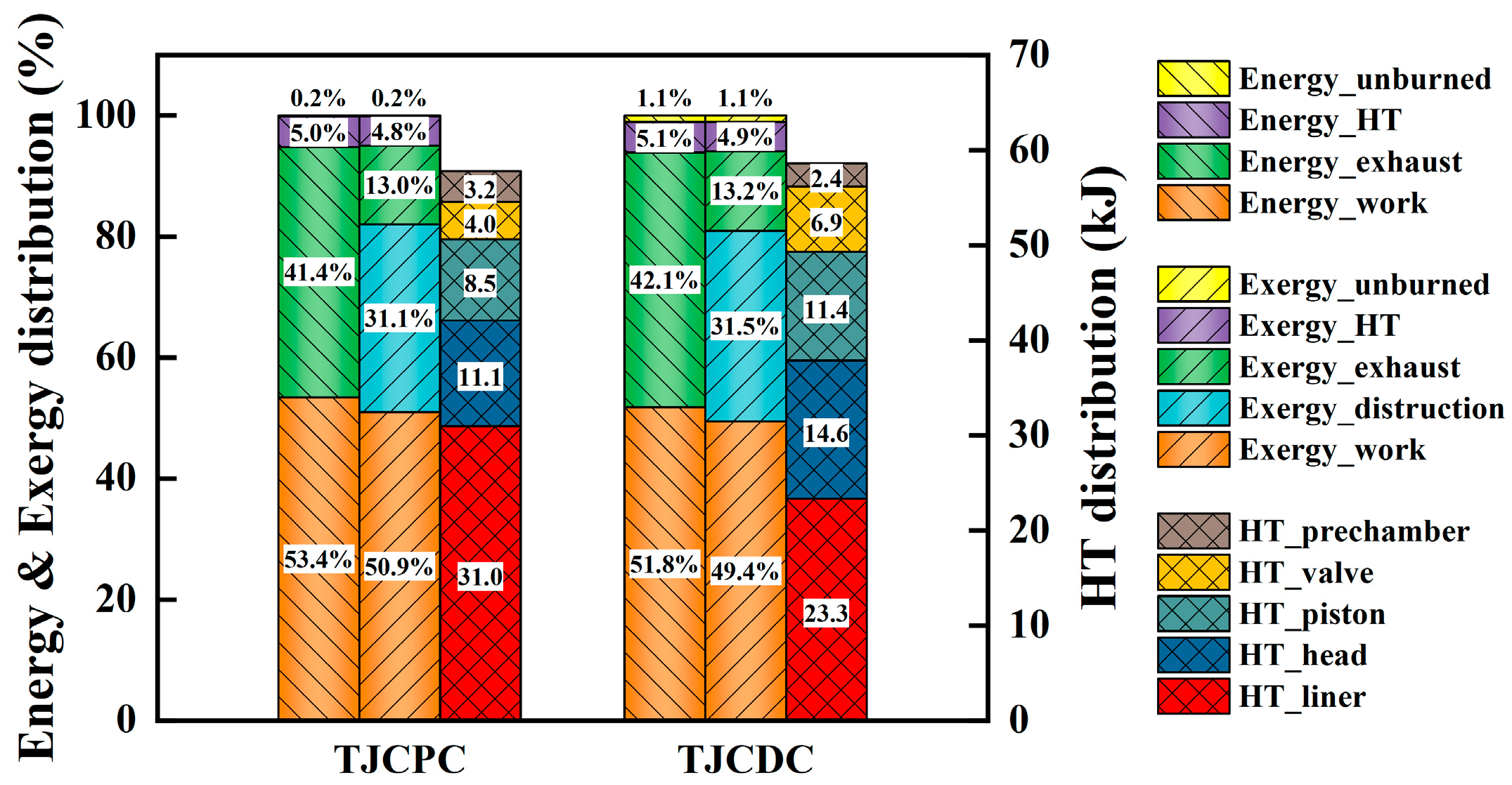

4. Comparative Summary of Combustion Modes

5. Conclusions and Outlook

Funding

Conflicts of Interest

Nomenclature

| 3D | Three-dimensional |

| ATDC | After Top Dead Center |

| CA | Crank angle |

| CA10 | Crankshaft angle for 10% combustion |

| CA50 | Crankshaft angle for 50% combustion |

| CA90 | Crankshaft angle for 90% combustion |

| CE | Combustion Efficiency |

| CH4 | Methane |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| DJCDC | Diesel Jet-Controlled Diffusion Combustion |

| ECA | Emission Control Areas |

| EGR | Exhaust gas recirculation |

| EISFC | Equivalent Indicated Specific Fuel Consumption |

| GHG | Greenhouse gases |

| HPDI | High-pressure direct injection |

| IMO | International Maritime Organization |

| ITE | Indicated thermal efficiency |

| LHV | Lower heating value |

| LNG | Liquefied natural gas |

| LPG | Liquefied petroleum gas |

| LPDI | Low-pressure direct injection |

| LPNG | Low-pressure natural gas |

| MMT | Maximum mean temperature |

| NOx | Nitrogen oxides |

| PC | Pre-combustion chamber |

| PC-MCC | Pre-chamber-Enabled Mixing-Controlled Combustion |

| PI-HPDI | Pre-chamber-Ignited High-Pressure Direct Injection |

| PM | Particulate matter |

| SCR | Selective catalytic reduction |

| SOI | Start of injection |

| SOx | Sulfur Oxides |

| TDC | Top Dead Center |

| TE | Thermodynamic efficiency |

| TJCDC | Turbulent Jet-Controlled Diffusion Combustion |

| TJCPC | Turbulent Jet-Controlled Premixed Combustion |

| TJC-PDMC | Turbulent Jet-Controlled Premixed-Diffusion Multi-Mode Combustion |

References

- Anika, O.C.; Nnabuife, S.G.; Bello, A.; Okoroafor, E.R.; Kuang, B.; Villa, R. Prospects of low and zero-carbon renewable fuels in 1.5-degree net zero emission actualisation by 2050: A critical review. Carbon Capture Sci. Technol. 2022, 5, 100072. [Google Scholar]

- Miola, A.; Ciuffo, B. Estimating air emissions from ships: Meta-analysis of modelling approaches and available data sources. Atmos. Environ. 2011, 45, 2242–2251. [Google Scholar] [CrossRef]

- Deng, J.; Wang, X.; Wei, Z.; Wang, L.; Chen, Z. A review of NOx and SOx emission reduction technologies for marine diesel engines and the potential evaluation of liquefied natural gas fuelled vessels. Sci. Total Environ. 2020, 766, 144319. [Google Scholar] [CrossRef] [PubMed]

- Ni, P.; Wang, X.; Li, H. A review on regulations, current status, effects and reduction strategies of emissions for marine diesel engines. Fuel 2020, 279, 118477. [Google Scholar] [CrossRef]

- Shi, H.; Welch, C.; Erhard, J.; Ye, P.; Chu, H.; Dreizler, A.; Böhm, B. Experimental study on early flame dynamics in an optically accessible hydrogen-fueled spark ignition engine. Front. Energy 2025. [Google Scholar] [CrossRef]

- Ithnin, A.M.; Noge, H.; Abdul Kadir, H.; Jazair, W. An overview of utilizing water-in-diesel emulsion fuel in diesel engine and its potential research study. J. Energy Inst. 2014, 87, 273–288. [Google Scholar] [CrossRef]

- Mayer, S.; Sjöholm, J.; Ishibashi, R.; Fukushima, T.; Kondo, M.; Kjemtrump, N. NOx reduction to tier III levels on MAN B&W LGI low-speed engines by water addition to either methanol or conventional diesel fuel oil. In Proceedings of the CIMAC Congress, Vancouver, BC, Canada, 10–14 June 2019. [Google Scholar]

- Ji, W.; Li, A.; Lu, X.; Huang, Z.; Zhu, L. Numerical study on NOx and ISFC co-optimization for a low-speed two-stroke engine via Miller cycle, EGR, intake air humidification, and injection strategy implementation. Appl. Therm. Eng. 2019, 153, 398–408. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, H.; Wang, H.; Zou, X.; Yao, M. A Numerical Study on Combustion and Emission Characteristics of Marine Engine Through Miller Cycle Coupled with EGR and Water Emulsified Fuel; SAE Technical Paper; SAE: Warrendale, PA, USA, 2016; ISSN 0148-7191. [Google Scholar]

- Hountalas, D.T.; Mavropoulos, G.C.; Zannis, T.C. Comparative Evaluation of EGR, Intake Water Injection and Fuel/Water Emulsion as NOx Reduction Techniques for Heavy Duty Diesel Engines. In In-Cylinder Diesel Particulate and NOx Control; Society of Automotive Engineers: Warrendale, PA, USA, 2007. [Google Scholar]

- Hountalas, D.T.; Mavropoulos, G.C.; Zannis, T.; Mamalis, S. Use of Water Emulsion and Intake Water Injection as NOx Reduction Techniques for Heavy Duty Diesel Engines; SAE Technical Paper; SAE: Warrendale, PA, USA, 2006; ISSN 0148-7191. [Google Scholar]

- Lu, T.; Lu, Z.; Shi, L.; Wang, T.; Wang, H. Improving the fuel/air mixing and combustion process in a low-speed two-stroke engine by the IFA strategy under EGR atmosphere. Fuel 2021, 302, 121200. [Google Scholar] [CrossRef]

- Al-Qurashi, K.; Lueking, A.D.; Boehman, A.L. The deconvolution of the thermal, dilution, and chemical effects of exhaust gas recirculation (EGR) on the reactivity of engine and flame soot. Combust. Flame 2011, 158, 1696–1704. [Google Scholar] [CrossRef]

- Raptotasios, S.I.; Sakellaridis, N.F.; Papagiannakis, R.G.; Hountalas, D.T. Application of a multi-zone combustion model to investigate the NOx reduction potential of two-stroke marine diesel engines using EGR. Appl. Energy 2015, 157, 814–823. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, S.; Feng, Y.; Zhu, Y. EGR modeling and fuzzy evaluation of Low-Speed Two-Stroke marine diesel engines. Sci. Total Environ. 2020, 706, 135444. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Tang, X.; Shi, L.; Ni, X.; Hu, Z.; Deng, K. Experimental investigation of the influences of Miller cycle combined with EGR on performance, energy and exergy characteristics of a four-stroke marine regulated two-stage turbocharged diesel engine. Fuel 2021, 300, 120940. [Google Scholar] [CrossRef]

- Zhu, L.; Li, B.; Li, A.; Ji, W.; Huang, Z. Effects of fuel reforming on large-bore low-speed two-stroke dual fuel marine engine combined with EGR and injection strategy. Int. J. Hydrogen Energy 2020, 45, 29505–29517. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, C.; Liu, D.; Zhu, Y.; Feng, Y. Experimental investigation of the high-pressure SCR reactor impact on a marine two-stroke diesel engine. Fuel 2023, 335, 127064. [Google Scholar] [CrossRef]

- Zhu, Y.; Xia, C.; Shreka, M.; Wang, Z.; Yuan, L.; Zhou, S.; Feng, Y.; Hou, Q.; Ahmed, S.A. Combustion and emission characteristics for a marine low-speed diesel engine with high-pressure SCR system. Environ. Sci. Pollut. Res. Int. 2020, 27, 12851–12865. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Yan, H.; Li, T.; Zhu, Y.; Zhou, W. Relation Analysis on Emission Control and Economic Cost of SCR system for Marine Diesels. Sci. Total Environ. 2021, 788, 147856. [Google Scholar] [CrossRef] [PubMed]

- Seyam, S.; Dincer, I.; Agelin-Chaab, M. A comprehensive assessment of a new hybrid combined marine engine using alternative fuel blends. Energy 2023, 283, 128488. [Google Scholar] [CrossRef]

- Noor, C.M.; Noor, M.M.; Mamat, R. Biodiesel as alternative fuel for marine diesel engine applications: A review. Renew. Sustain. Energy Rev. 2018, 94, 127–142. [Google Scholar] [CrossRef]

- Gabiña, G.; Martin, L.; Basurko, O.C.; Clemente, M.; Aldekoa, S.; Uriondo, Z. Waste oil-based alternative fuels for marine diesel engines. Fuel Process. Technol. 2016, 153, 28–36. [Google Scholar] [CrossRef]

- Shi, H.; Liu, Z.; Mashruk, S.; Alnajideen, M.; Alnasif, A.; Liu, J.; Valera-Medina, A. Modeling and optimization of ammonia/hydrogen/air premixed swirling flames for NOx emission control: A hybrid machine learning strategy. Energy 2025, 330, 136735. [Google Scholar] [CrossRef]

- Zarrinkolah, M.T.; Hosseini, V. Methane slip reduction of conventional dual-fuel natural gas diesel engine using direct fuel injection management and alternative combustion modes. Fuel 2023, 331, 125775. [Google Scholar] [CrossRef]

- Yao, S.; Li, C.; Wei, Y. Design and optimization of a zero carbon emission system integrated with the utilization of marine engine waste heat and LNG cold energy for LNG-powered ships. Appl. Therm. Eng. 2023, 231, 120976. [Google Scholar] [CrossRef]

- Ortega, N.; Fontalvo, V.M.; Guerrero, F.; Toledo, M.; Amador, G. Dynamic response of the performance and emissions of an LPG diesel dual-fuel engine with water injection. Appl. Therm. Eng. 2023, 228, 120543. [Google Scholar] [CrossRef]

- Sun, W.; Jiang, M.; Guo, L.; Zhang, H.; Jia, Z.; Qin, Z.; Zeng, W.; Lin, S.; Zhu, G.; Ji, S.; et al. Numerical study of injection strategies for marine methanol/diesel direct dual fuel stratification engine. J. Clean. Prod. 2023, 421, 138505. [Google Scholar] [CrossRef]

- Troberg, M.; Delneri, D. Tier III emission roadmap for marine engine application. MTZ Worldw. 2010, 71, 12–17. [Google Scholar] [CrossRef]

- Gulcan, H.E. Effect of methane injection strategy on combustion, exergetic performance, and enviro-economic analyses in a diesel/methane CRDI engine. Appl. Therm. Eng. Des. Process. Equip. Econ. 2024, 243, 122654. [Google Scholar] [CrossRef]

- Hassan, S.S.M.; Mohamed, N.R.G.; Saad, M.M.A.; Salem, A.M.; Ibrahim, Y.H.; Elshakour, A.A.; Fathy, M.A. A novel non-woven fabric sandwich filter with activated carbon/polypyrrole nanocomposite for the removal of CO, SO2 and NOx emitted from gasoline engines. Fuel 2025, 401, 135838. [Google Scholar] [CrossRef]

- Hall, C.; Kassa, M. Advances in combustion control for natural gas–diesel dual fuel compression ignition engines in automotive applications: A review. Renew. Sustain. Energy Rev. 2021, 148, 111291. [Google Scholar] [CrossRef]

- Hao, C.; He, J.; Zhong, X. Engine combustion and emission fuelled with natural gas: A review. J. Energy Inst. 2018, 92, 1123–1136. [Google Scholar]

- Schinas, O.; Butler, M. Feasibility and commercial considerations of LNG-fueled ships. Ocean. Eng. 2016, 122, 84–96. [Google Scholar] [CrossRef]

- Banawan, A.; El Gohary, M.M.; Sadek, I. Environmental and economical benefits of changing from marine diesel oil to natural-gas fuel for short-voyage high-power passenger ships. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2010, 224, 103–113. [Google Scholar] [CrossRef]

- Alvarez, C.E.C.; Couto, G.E.; Roso, V.R.; Thiriet, A.B.; Valle, R.M. A review of prechamber ignition systems as lean combustion technology for SI engines. Appl. Therm. Eng. 2018, 128, 107–120. [Google Scholar] [CrossRef]

- Frasci, E.; Rosa, R.N.; Moreno, B.P.; Arsie, I.; Jannelli, E. Impact of prechamber design and air–fuel ratio on combustion and fuel consumption in a SI engine equipped with a passive TJI. Fuel 2023, 345, 128265. [Google Scholar] [CrossRef]

- Hua, J.; Zhou, L.; Gao, Q.; Feng, Z.; Wei, H. Influence of pre-chamber structure and injection parameters on engine performance and combustion characteristics in a turbulent jet ignition (TJI) engine. Fuel 2021, 283, 119236. [Google Scholar] [CrossRef]

- Zhou, L.; Zhong, L.; Liu, Z.; Wei, H. Toward highly-efficient combustion of ammonia–hydrogen engine: Prechamber turbulent jet ignition. Fuel 2023, 352, 129009. [Google Scholar] [CrossRef]

- Zhou, L.; Ding, Y.; Li, A.Q.; Song, Y.; Liu, Z.; Wei, H. Experimental study of gasoline engine with EGR dilution based on reactivity controlled turbulent jet ignition (RCTJI). Fuel 2023, 331, 125744. [Google Scholar] [CrossRef]

- Wu, X.; Feng, Y.; Gao, Y.; Xia, C.; Zhu, Y.; Shreka, M.; Ming, P. Numerical simulation of lean premixed combustion characteristics and emissions of natural gas-ammonia dual-fuel marine engine with the pre-chamber ignition system. Fuel 2023, 343, 127990. [Google Scholar] [CrossRef]

- Sharma, P.; Tang, Q.; Marquez, M.E.; Cenker, E.; Turner, J.; Magnotti, G. Active and passive prechamber assisted engine combustion: Simultaneous 50kHz formaldehyde PLIF and OH* visualization. Combust. Flame 2023, 256, 112989. [Google Scholar] [CrossRef]

- Wu, X.; Feng, Y.; Xu, G.; Zhu, Y.; Ming, P.; Dai, L. Numerical investigations on charge motion and combustion of natural gas-enhanced ammonia in marine pre-chamber lean-burn engine with dual—Fuel combustion system. Int. J. Hydrogen Energy 2023, 48, 11476–11492. [Google Scholar] [CrossRef]

- Jun, Z.; Bo, L.; Lei, C.; Weiyao, W.; Long, W.; Tian, J.; Liyan, F.; Baoguo, D. Research on the Characteristics of Enrichment Fuel Injection Process in the Pre-Chamber of a Marine Gas Engine; SAE Report; SAE: Warrendale, PA, USA, 2015. [Google Scholar]

- Wang, M.; Leng, X.; He, Z.; Wei, S.; Chen, L.; Jin, Y. A Numerical Study on the Effects of the Orifice Geometry Between Pre- and Main Chamber for a Natural Gas Engine; SAE Technical Paper; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Leng, X.; Deng, Y.; He, D.; Wei, S.; He, Z.; Wang, Q.; Long, W.; Zhu, S. A preliminary numerical study on the use of methanol as a Mono-Fuel for a large bore marine engine. Fuel 2022, 310, 122309. [Google Scholar] [CrossRef]

- Leng, X.; Huang, H.; Ge, Q.; He, Z.; Zhang, Y.; Wang, Q.; He, D.; Long, W. Effects of hydrogen enrichment on the combustion and emission characteristics of a turbulent jet ignited medium speed natural gas engine: A numerical study. Fuel 2021, 290, 119966. [Google Scholar] [CrossRef]

- Li, B.; Cao, J.; Tian, L.; Fan, L.; Xiao, G.; Long, W. Numerical Research on the Effects of Pre-Chamber Orifice Scheme on the Performance in a Large-Bore Natural Gas Engine; SAE Report; SAE: Warrendale, PA, USA, 2023. [Google Scholar]

- Xiong, Q.; Wan, Z.; Liu, L.; Zhao, B. Numerical analysis of combustion process and pressure oscillation phenomena in low-pressure injection natural gas/diesel dual fuel low speed marine engine. Therm. Sci. Eng. Prog. 2023, 42, 101913. [Google Scholar] [CrossRef]

- Liu, L.; Wu, Y.; Wang, Y. Numerical investigation on knock characteristics and mechanism of large-bore natural gas dual-fuel marine engine. Fuel A J. Fuel Sci. 2022, 310, 122298. [Google Scholar] [CrossRef]

- Altinkurt, M.D.; Merts, M.; Tunér, M.; Turkcan, A. Effects of split diesel injection strategies on combustion, knocking, cyclic variations and emissions of a natural gas-diesel dual fuel medium speed engine. Fuel 2023, 347, 128517. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, L.; Liu, B.; Cao, E.; Xiong, Q. Investigation of rapid flame front controlled knock combustion and its suppression in natural gas dual-fuel marine engine. Energy 2023, 279, 128078. [Google Scholar] [CrossRef]

- Badr, O.; Alsayed, N.; Manaf, M. A parametric study on the lean misfiring and knocking limits of gas-fueled spark ignition engines. Appl. Therm. Eng. 1998, 18, 579–594. [Google Scholar] [CrossRef]

- MAN Energy Solutions. ME-GA–The Latest Dual-Fuel MAN B&W Two-Stroke Engine; MAN Energy Solutions: Singapore, 2022. [Google Scholar]

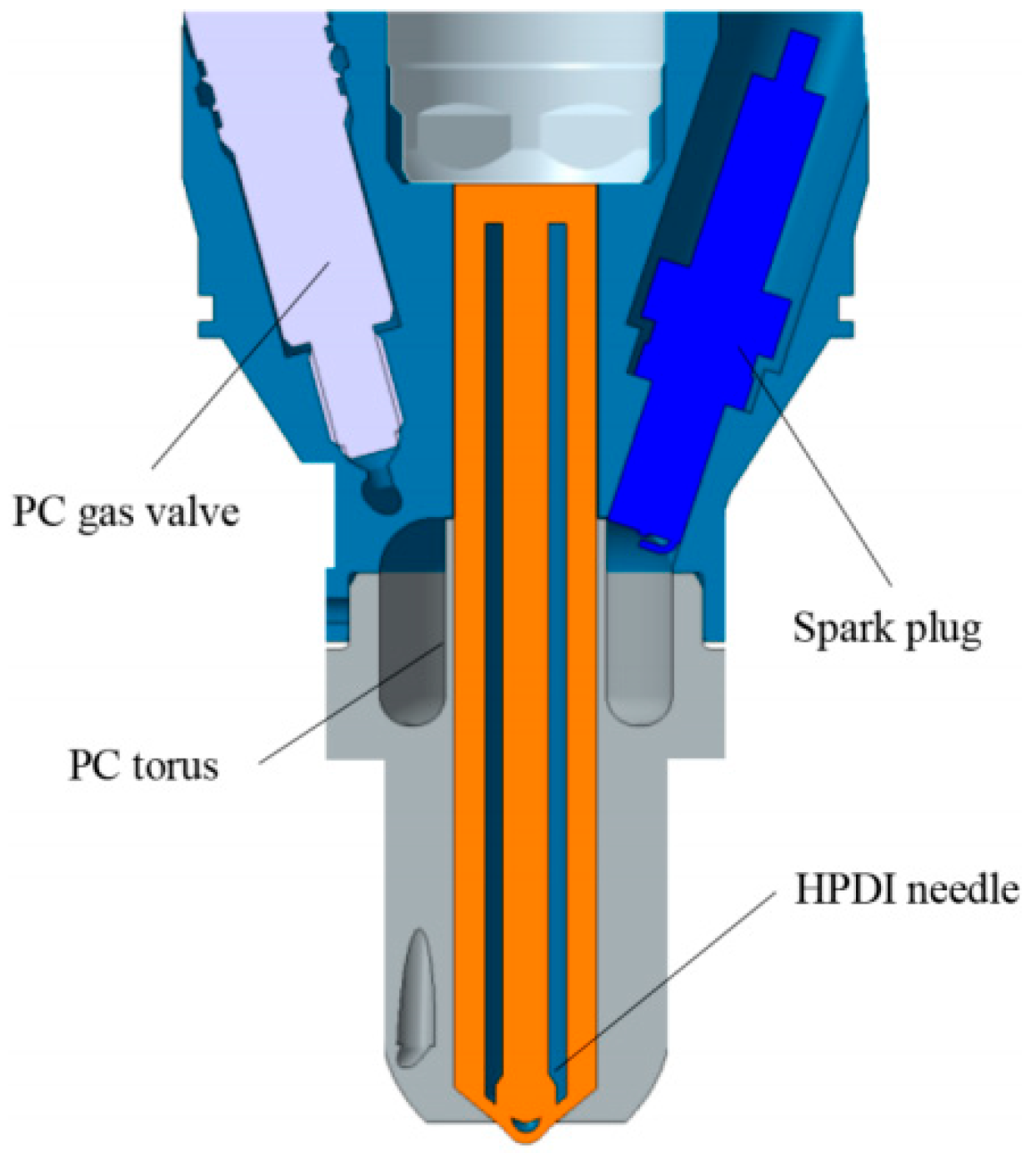

- Kammel, G.; Mair, F.; Zelenka, J.; Lackner, M.; Wimmer, A.; Kogler, G.; Brow, E. Simulation Based Predesign and Experimental Validation of a Prechamber Ignited HPDI Gas Combustion Concept; SAE Report; SAE: Warrendale, PA, USA, 2019. [Google Scholar]

- Zelenka, J.; Kammel, G.; Wimmer, A.; Brow, E.; Huschenbett, M. Analysis of a Prechamber Ignited HPDI Gas Combustion Concept; SAE Technical Papers; SAE: Warrendale, PA, USA, 2020. [Google Scholar]

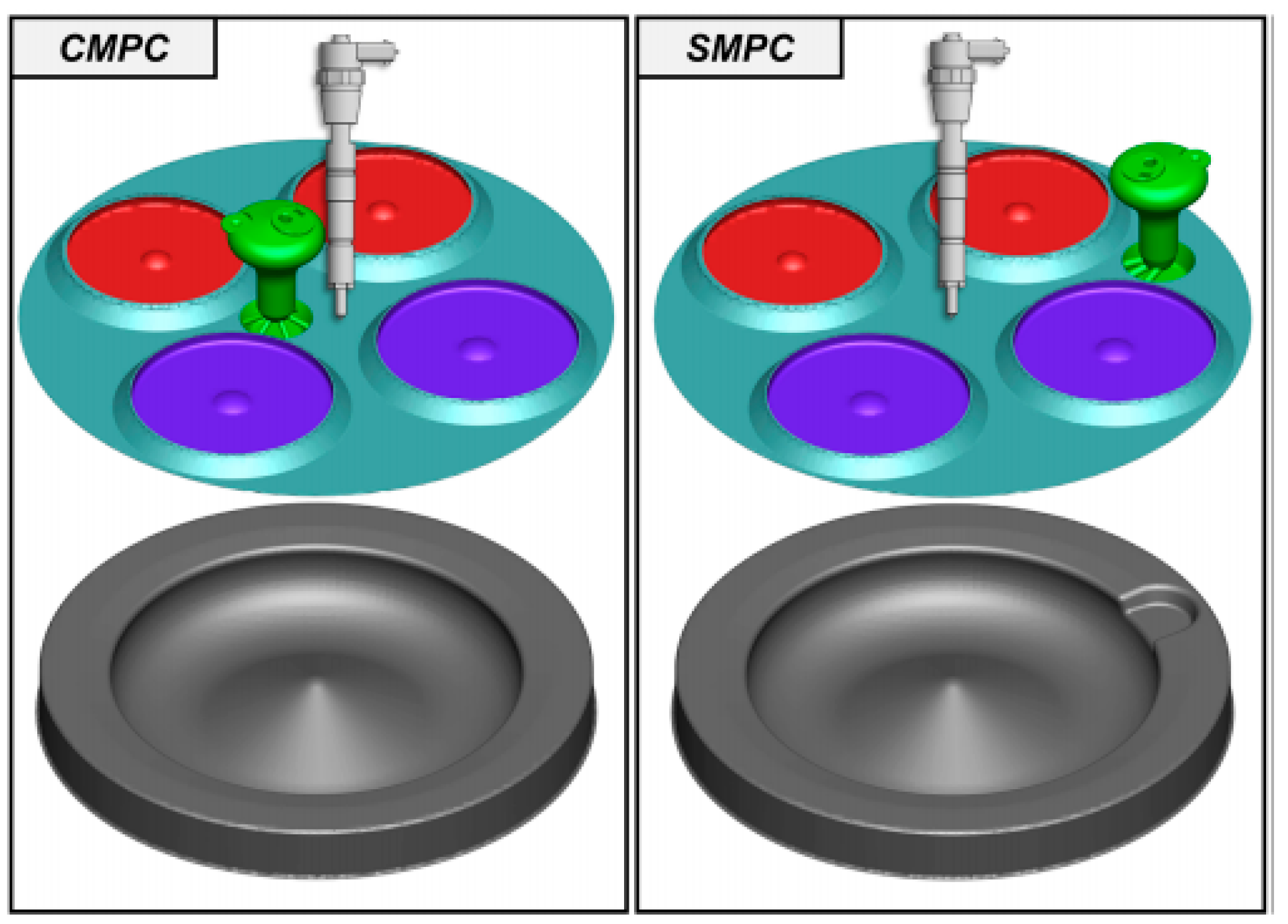

- Nsaif, O.; Kokjohn, S.; Hessel, R.; Dempsey, A. Reducing Methane Emissions from Lean Burn Natural Gas Engines with Prechamber Ignited Mixing-Controlled Combustion. J. Eng. Gas Turbines Power 2024, 146, 061023. [Google Scholar] [CrossRef]

- Dempsey, A.B.; Zeman, J.; Wall, M. A system to enable mixing controlled combustion with high octane fuels using a prechamber and high-pressure direct injector. Front. Mech. Eng. 2021, 7, 637665. [Google Scholar] [CrossRef]

- Dempsey, A.; Chowdhury, M.; Kokjohn, S.; Zeman, J. Prechamber Enabled Mixing Controlled Combustion—A Fuel Agnostic Technology for Future Low Carbon Heavy-Duty Engines; SAE Report; SAE: Warrendale, PA, USA, 2022. [Google Scholar]

- Zeman, J.; Yan, Z.; Bunce, M.; Dempsey, A. Assessment of design and location of an active prechamber igniter to enable mixing-controlled combustion of ethanol in heavy-duty engines. Int. J. Engine Res. 2023, 24, 4226–4250. [Google Scholar] [CrossRef]

- Zeman, J.; Dempsey, A. Characterization of Flex-Fuel Prechamber Enabled Mixing-Controlled Combustion with Gasoline/Ethanol Blends at High Load. J. Eng. Gas Turbines Power 2024, 146, 081015. [Google Scholar] [CrossRef]

- Vera-Tudela, W.; Schneider, B.; Wüthrich, S.; Herrmann, K. Study on the ignitability of a high-pressure direct-injected methane jet using a diesel pilot, a glow-plug, and a pre-chamber. Int. J. Engine Res. 2023, 24, 360–372. [Google Scholar] [CrossRef]

- Vera-Tudela, W.; Schneider, B.; Wüthrich, S.; Herrmann, K. Study on the ignitability of a high-pressure direct-injected methane jet using a scavenged pre-chamber under a wide range of conditions. Int. J. Engine Res. 2023, 24, 1603–1616. [Google Scholar] [CrossRef]

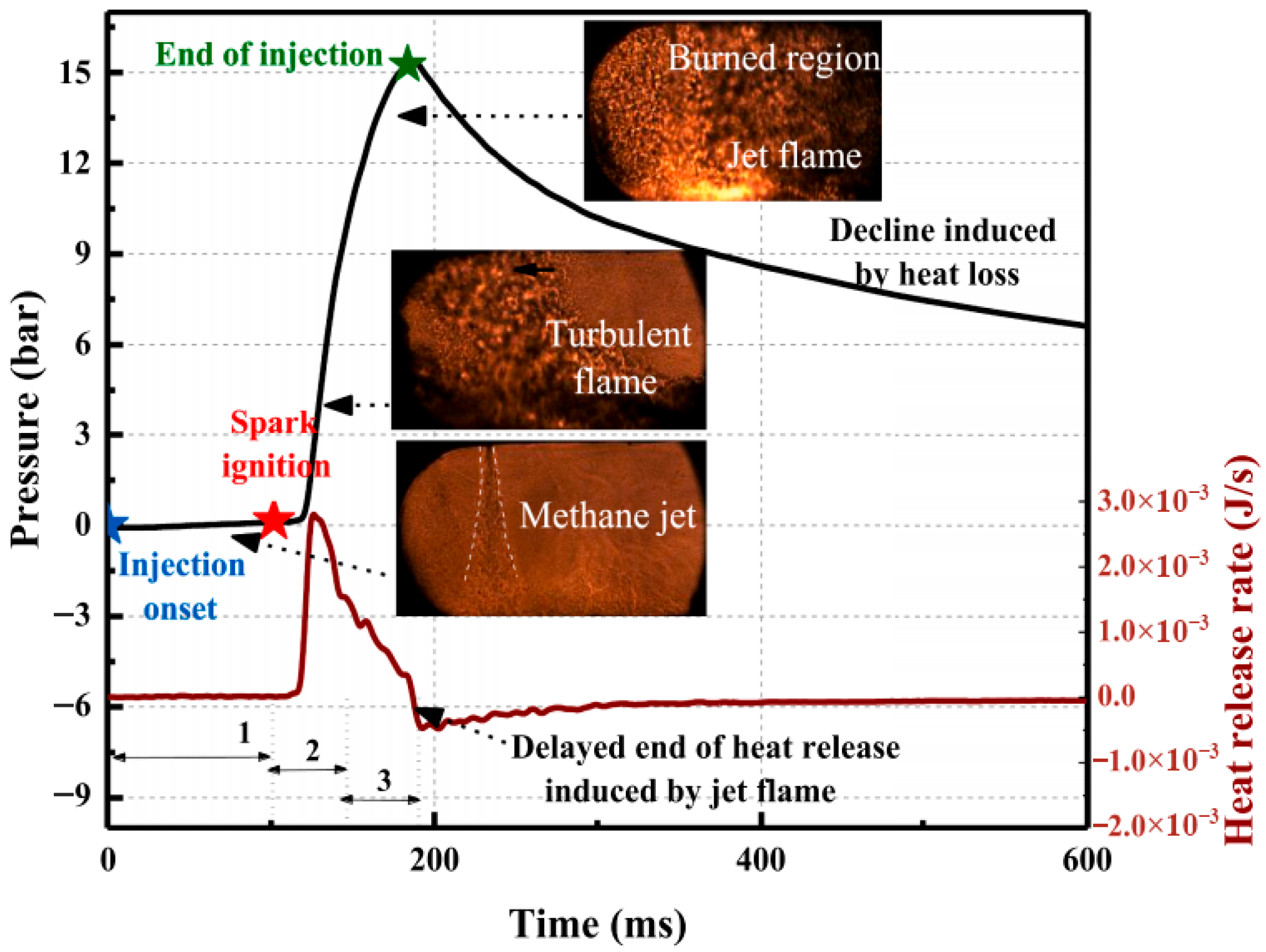

- Zhong, L.; Zhao, W.; Wei, H.; Zhou, L. Experimental observation of the TJI-initiated HPDI gas combustion: Vertically crossed flame jet and methane jet. Appl. Energy Combust. Sci. 2023, 16, 100207. [Google Scholar] [CrossRef]

- Zhong, L.; Wei, H.; Liu, Z.; Zhou, L. Fundamental Experiment of Ignition and Flame Development in Turbulent Jet Ignition Ignited Methane Jet Flame. Combust. Sci. Technol. 2025, 197, 683–704. [Google Scholar] [CrossRef]

| Mode | DJCDC | TJCDC |

| Ignition delay (°CA) | 5.43 | 4.63 |

| Combustion duration (°CA) | 20.8 | 21.1 |

| Indicated thermal efficiency | 52.8% | 52.9% |

| NOx (g/kWh) | 13.19 | 13.94 |

| CO2 (g/kWh) | 416.0 | 412.3 |

| Parameters | Value |

|---|---|

| Engine Model | 4T50ME-GI |

| Cylinder Bore (mm) | 500 |

| Stroke (mm) | 2885 |

| Connecting Rod Length (mm) | 2200 |

| Geometric Compression Ratio | 18.14 |

| Number of Cylinders | 4 |

| Number of Pre-Combustion Chambers | - |

| Pilot Fuel Injector | 2 |

| Natural Gas Injection Valve | 2 |

| Natural Gas Injection Mode | High-pressure direct injection |

| Pilot Fuel Maximum Percentage (%) | 11.3 |

| Rated Speed (r/min) | 123 |

| Rated Power (kW) | 7080 |

| Nox Emission Standard | Meets Tier II |

| Load | Injection Timing (°CA ATDC) | Injection Duration (°CA) |

|---|---|---|

| 25% | −120 | 13 |

| 50% | −123 | 19 |

| 75% | −131 | 23 |

| 100% | −121 | 27 |

| Scheme | Baseline | SP-1 | SP-2 | SP-3 | SP-4 | SP-5 | SP-6 | SP-7 | SP-8 |

|---|---|---|---|---|---|---|---|---|---|

| Scavenging pressure (bar) | 1.60 | 1.65 | 1.70 | 1.75 | 1.80 | 1.85 | 1.90 | 1.95 | 2.00 |

| λ | 1.97 | 2.04 | 2.11 | 2.17 | 2.24 | 2.30 | 2.37 | 2.43 | 2.50 |

| Parameters | TJCPC Mode | TJCDC Mode |

|---|---|---|

| CA10 (°CA ATDC) | 5.7 | 2.4 |

| CA50 (°CA ATDC) | 8.8 | 9.2 |

| CA10-CA90 (°CA) | 5.3 | 16.2 |

| CE (%) | 99.82 | 98.95 |

| ITE (%) | 53.39 | 51.79 |

| EISFC (g/kWh) | 158.65 | 163.55 |

| NOx (g/kWh) | 1.66 | 17.48 |

| CO2 (g/kWh) | 371.2 | 381.3 |

| Unburned CH4 (g/kWh) | 0.11 | 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, J.; Liu, Z.; Shi, H.; Dong, D.; Kang, S.; Bu, L. A Review of Marine Dual-Fuel Engine New Combustion Technology: Turbulent Jet-Controlled Premixed-Diffusion Multi-Mode Combustion. Energies 2025, 18, 3903. https://doi.org/10.3390/en18153903

Cao J, Liu Z, Shi H, Dong D, Kang S, Bu L. A Review of Marine Dual-Fuel Engine New Combustion Technology: Turbulent Jet-Controlled Premixed-Diffusion Multi-Mode Combustion. Energies. 2025; 18(15):3903. https://doi.org/10.3390/en18153903

Chicago/Turabian StyleCao, Jianlin, Zebang Liu, Hao Shi, Dongsheng Dong, Shuping Kang, and Lingxu Bu. 2025. "A Review of Marine Dual-Fuel Engine New Combustion Technology: Turbulent Jet-Controlled Premixed-Diffusion Multi-Mode Combustion" Energies 18, no. 15: 3903. https://doi.org/10.3390/en18153903

APA StyleCao, J., Liu, Z., Shi, H., Dong, D., Kang, S., & Bu, L. (2025). A Review of Marine Dual-Fuel Engine New Combustion Technology: Turbulent Jet-Controlled Premixed-Diffusion Multi-Mode Combustion. Energies, 18(15), 3903. https://doi.org/10.3390/en18153903