4.1. Overview of Model Predictive Control Theory

Model predictive control (MPC), also termed receding horizon control, dynamic matrix control, or generalized predictive control, is a feedback control strategy grounded in predictive models [

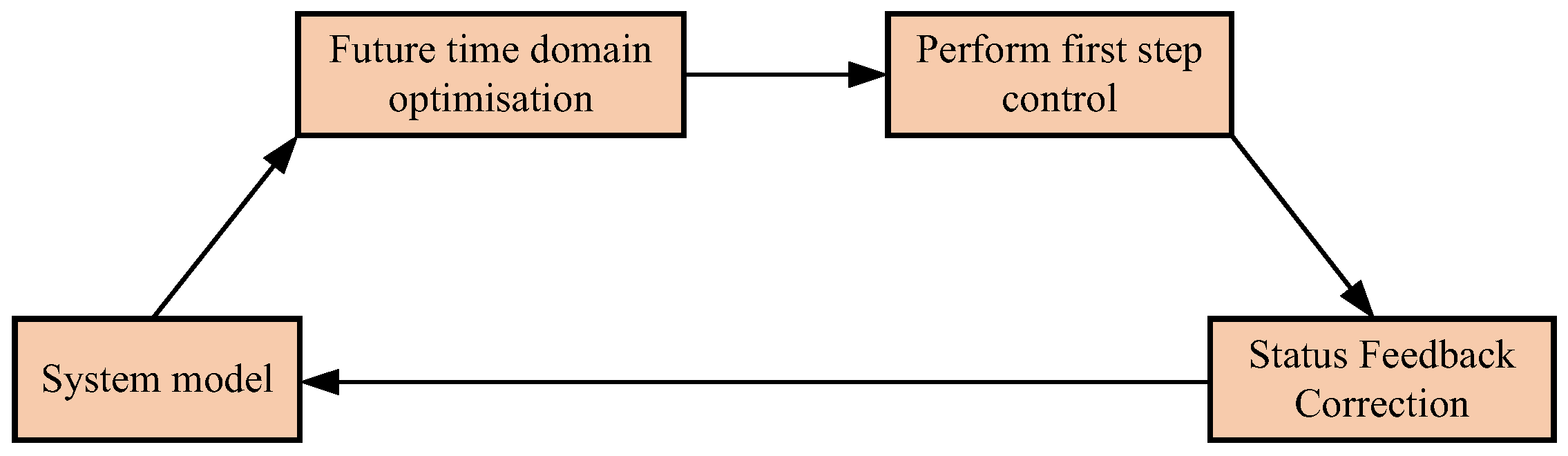

32]. A rolling optimization approach is employed to approximate global optimality with local solutions, while feedback correction based on real-time system states ensures enhanced control performance, robustness, and stability. At each sampling instant, the future system states and outputs are predicted using the predictive model, and an open-loop optimal control problem over a finite horizon is solved. Subsequently, the predictive model is iteratively refined via feedback correction using actual system outputs, forming a closed-loop control optimization process. The first component of the derived optimal control sequence is then applied to the system. This optimization cycle is repeated at subsequent sampling instants, achieving continuous system regulation. As a feedforward-feedback composite control strategy based on dynamic models, MPC’s core mechanism lies in its ability to achieve optimal control under multi-objective constraints through online rolling optimization and closed-loop correction, as illustrated in

Figure 1.

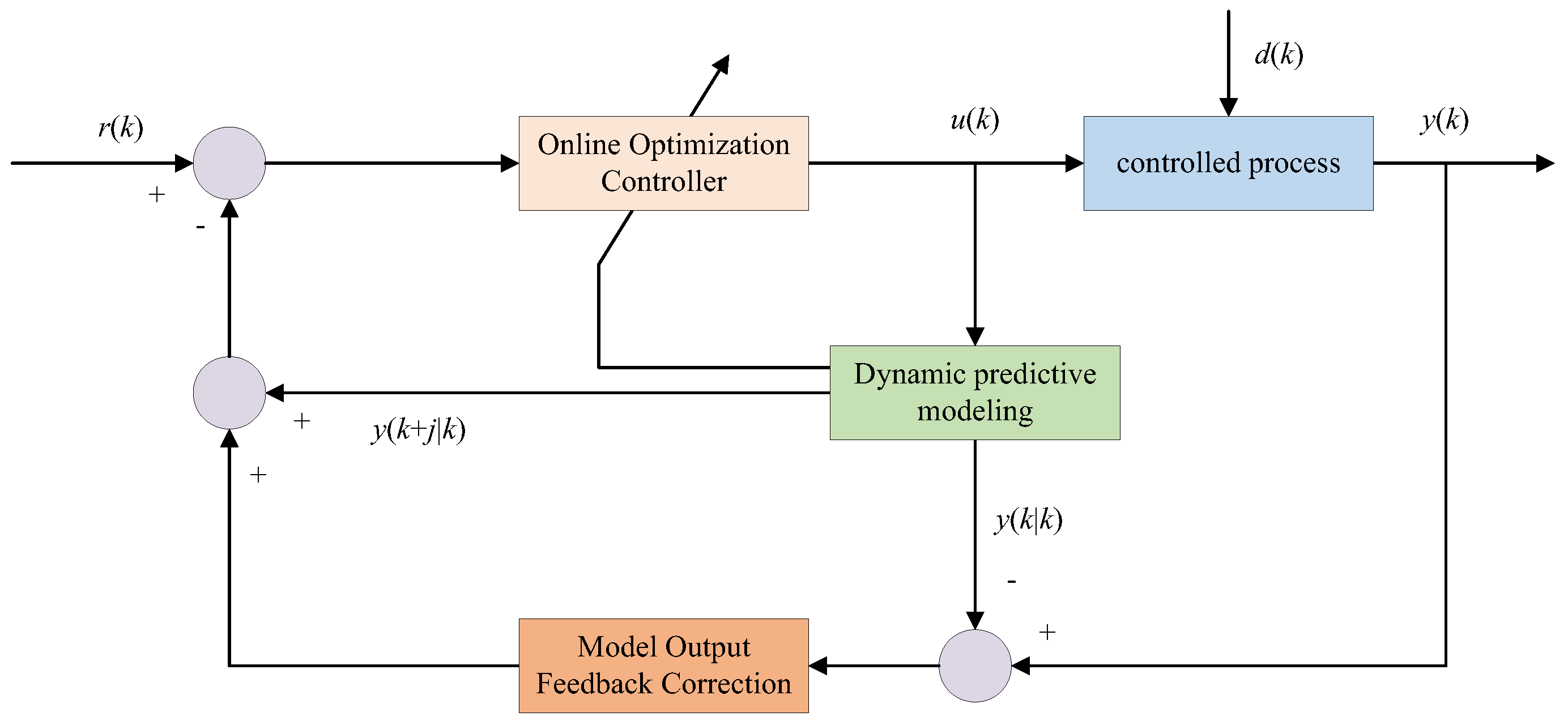

The MPC methodology constructs a state-space model or discrete transfer function to predict the dynamic response trajectory of a controlled object within a finite horizon. A convex optimization problem is solved online to minimize the objective function, generating an optimal control sequence that satisfies input/output constraints (control flowchart shown in

Figure 2). A typical MPC cycle comprises three core stages: (1) model prediction, (2) online optimization, and (3) implementation of the first-step control action. By continuously updating the rolling horizon with real-time system state feedback, MPC effectively mitigates model mismatch and external disturbances, making it particularly advantageous in complex industrial processes, intelligent transportation systems, and robotic motion control.

Compared with conventional control strategies, MPC exhibits unique strengths in handling multivariate coupled systems, explicit constraint enforcement, and nonlinear dynamic optimization. Its multi-input multi-output (MIMO) architecture inherently coordinates synergistic actions among multiple actuators, while its ability to integrate process constraints directly into a quadratic programming framework guarantees optimal system operation within safety boundaries. For nonlinear time-varying systems, dynamic linearization can be achieved through sequential quadratic programming (SQP) or nonlinear MPC; however, the resultant exponential growth in computational complexity remains a bottleneck in practical engineering applications. Furthermore, the sensitivity of control performance to model accuracy necessitates online parameter estimation via system identification techniques, imposing stricter robustness requirements on control algorithms.

Current MPC technologies have demonstrated significant success in chemical process optimization, autonomous vehicle trajectory tracking, spacecraft attitude control, and building energy management. For instance, in continuous catalytic cracking units, MPC can coordinate temperature-pressure-flow multivariate systems to increase product yield by 3–5%. In autonomous driving, its rolling optimization capability enables effective obstacle avoidance and path planning under sudden disturbances. With advancements in edge computing hardware and distributed optimization algorithms, computational latency in MPC is progressively being alleviated. Future research will focus on data-driven model construction, distributed MPC architecture design, and the engineering application of quantum optimization algorithms. These breakthroughs are expected to drive deeper integration of MPC into complex systems such as smart manufacturing and smart cities.

As an advanced control strategy, MPC’s essence lies in its online solution of finite-horizon optimization problems to achieve effective control of dynamic systems. For discrete-time domains, the mathematical equation of MPC is expressed in Equation (19).

where,

y denotes the system output variables, typically including hydropower generation, PV output, and bus voltage;

r represents the reference trajectory, generally corresponding to the dispatch schedule in hydro-PV complementary systems;

u signifies the control variables, often comprising turbine guide vane openings and PV inverter commands issued by the dispatch centre in such systems.

Np denotes the prediction horizon (in steps), typically set to 24 steps (equivalent to 24 h), while

Nc is the control horizon (in steps), usually defined as

Nc =

Np/2. The objective function

J comprises two components. The term

minimizes the tracking error between the system output y and reference trajectory

r, with the weighting matrix

Q regulating the priority of different output variables; the term

penalizes the magnitude of control increments Δ

u to ensure input smoothness and avoid abrupt actuator actions, where the weighting matrix

R balances control energy consumption and tracking performance.

First, this composite objective function design embodies the trade-off between dynamic performance and robustness inherent in MPC. Second, constraints encapsulate both system dynamics and physical limitations. The state equation x(t + k + 1) = f(x(t + k), u(t + k) governs system evolution, whose form depends on model complexity (linear or nonlinear). Input constraints umin ≤ u ≤ umax directly reflect actuator physical limits (e.g., valve openings or motor torque boundaries), while increment constraints Δumin ≤ Δu ≤ Δumax restrict control input rates to prevent instability or mechanical wear caused by abrupt changes. The explicit handling of these constraints distinguishes MPC from conventional control methods. In practical applications, solving this optimization problem faces several challenges, listed as follows:

Prediction Horizon Selection: The prediction horizon Nt must balance computational efficiency with control performance. While extended horizons enhance accuracy (typically Nc = Np/2), they escalate problem dimensionality, compromising real-time capability.

Nonlinear System Optimization: Non-convexity in nonlinear systems often necessitates sequential quadratic programming (SQP) or real-time iteration algorithms.

Weight Matrix Tuning: The calibration of Q and R requires iterative simulation or experimentation to ensure closed-loop stability and response speed.

Constraint Conflict Resolution: Infeasible scenarios due to conflicting constraints demand slack variables or priority-based constraint relaxation to enhance algorithmic robustness. Furthermore, MPC’s rolling optimization mechanism mandates state estimation updates and optimization re-solving at each sampling interval, imposing stringent requirements on computational hardware and real-time algorithms. To address this, explicit MPC or simplified linear time-invariant (LTI) models are often adopted in engineering practice to reduce complexity. Simultaneously, robust MPC or adaptive MPC frameworks can be integrated with online model updates or disturbance observers to mitigate model mismatch and external perturbations.

In summary, MPC achieves effective control of complex dynamic systems through multi-objective optimization and constraint handling. Its theoretical flexibility and engineering adaptability have enabled widespread applications in process control, robotic motion planning, and autonomous driving. Future research should focus on high-efficiency solvers, data-driven model identification, and integration with learning-based MPC to address higher-dimensional and highly uncertain control scenarios.

4.2. Rolling Optimization Mechanism for Collaborative System Modeling

Considering the rolling optimization requirements of hydro-photovoltaic collaborative systems, the hydro-power output

Ph(

t) model is expressed in Equation (20).

where,

represents the hydro-power output (kW or MW) at time

t, with typical reference values ranging from 0.2 to 50 MW. This parameter can be obtained through real-time monitoring via the SCADA system.

η denotes the comprehensive efficiency of the hydro turbine generator unit, typically ranging from 0.2 to 50 MW, which can be acquired from the technical specifications of the generator unit. ρ indicates water density (kg/m

3) with conventional reference values between 0.2 and 50 MW. g represents the gravitational acceleration constant (9.81 m/s

2).

Q(

t), the real-time discharge flow (m

3/s), is jointly regulated by guide vane opening

α(

t) ∈ [0.2, 0.9] and reservoir capacity constraints

Vmin ≤

V(

t) ≤

Vmax.

H(

t) represents the net hydraulic head (dynamic water head) at time

t, defined as the elevation difference between upstream and downstream water levels (m). Typical values range from 15 m to 300 m, measurable through water level sensor calculations.

For the rolling optimization requirements of hydro-photovoltaic collaborative systems, the photovoltaic output

model is expressed in Equation (21).

where,

denotes the output power (kW) of the photovoltaic array at time

t, typically ranging from 0 to rated capacity. This parameter can be measured through inverter output monitoring.

represents the tilted irradiance (W/m

2) at time

t, with conventional values between 0~1300 W/m

2, obtainable through pyranometer measurements or PV GIS database.

A indicates the total area of the photovoltaic array (m

2), derived from engineering design parameters.

signifies the photovoltaic conversion efficiency, typically ranging from 0.15~0.22, which can be obtained from technical specifications of photovoltaic modules.

refers to the solar panel temperature (°C) at time

t, generally varying between −20~70 °C, measurable through temperature sensors or predictable via weather forecasting models.

4.3. Multi-Objective Optimization Framework for Hydro-Photovoltaic Complementary Systems

The multi-objective optimization framework for hydro-photovoltaic complementary systems is designed to harmonize the integrated performance of the system across four dimensions: economic efficiency, environmental sustainability, operational stability, and equipment degradation. The mathematical expression of this multi-objective vector optimization problem is represented by Equations (22) and (23).

where

T is defined as the transition matrix;

τ denotes the optimization variable;

J1 represents the total operational cost, encompassing joint expenses of hydropower, photovoltaics, grid interactions, and battery storage (where

are denoted as the costs of hydropower, photovoltaics, grid transactions, and battery systems, respectively);

J2 quantifies the total carbon emissions of the system, considering only contributions from hydro-power and grid sources (with photovoltaic emissions assumed negligible,

is defined as the hydropower emission coefficient,

indicates hydropower-related emissions,

represents the grid emission coefficient, and

corresponds to grid-related emissions), whose Equation (21) is expressed through weighted coefficients;

J3 is modeled as a power fluctuation penalty term, calculated based on the difference in total power between consecutive time intervals (where

(

t) denotes the power fluctuation deviation at time

t);

J4 characterizes battery degradation, expressed as the accumulated product of absolute charging/discharging power and aging coefficients (where

represent the aging coefficient and absolute charging power, respectively, while

correspond to the aging coefficient and absolute discharging power), reflecting the negative correlation between battery lifespan and charge/discharge intensity.

The feasible solution region of the system is jointly determined by trade-offs among multiple objectives and constraint conditions in practical optimization. Economic efficiency (J1) and environmental sustainability (J2) are often contradictory; for instance, reducing carbon emissions may require increased reliance on clean energy, thereby elevating operational costs. Operational stability (J3) and equipment degradation (J4) are mutually constrained, as frequent power adjustments to suppress fluctuations may accelerate battery aging. Inequality constraints g(u) ≤ 0 and equality constraints h(u) = 0 are required to ensure power balance, equipment capacity limits (e.g., maximum hydro-power/photovoltaic outputs), and operational boundaries (e.g., battery charge/discharge rate thresholds). The multi-objective optimization problem is addressed using Pareto optimal solution generation methods (e.g., NSGA-II) or scalarization via weighted coefficients. Weight selection must align with system priorities and scenario-specific requirements. While the refined modeling of power fluctuations and battery degradation enhances long-term system reliability and cost-effectiveness, the inherent non-linearity increases computational complexity. To mitigate this, intelligent optimization algorithms (e.g., meta-heuristics) or convex relaxation strategies are recommended to improve solving efficiency.

The decision variable

u, which is defined as the core parameter governing the energy dispatch strategy across time intervals is expressed in Equation (24).

The decision variable u is structured as a column vector comprising five sub-vectors, corresponding to the hydropower output Phyd,t, photovoltaic output Ppv,t, grid interaction power Pgrid,t, battery charging power Pch,t, and discharging power Pdis,t across time intervals t = 1,2, …, T. This architecture is designed to address the multi-energy coordination requirements of the system, where hydropower and photovoltaics serve as renewable energy sources, grid interaction power characterizes external energy exchange, and battery charge/discharge power is utilized to mitigate fluctuations and enable energy time-shifting. Each sub-variable is required to be continuously optimized temporally to achieve dynamic supply-demand balance and accommodate multi-objective optimization demands.

The design of decision variables must rigorously integrate the inter-dependencies between physical constraints and optimization objectives. Regarding technical limitations, hydro-power and photovoltaic power are constrained by natural resource availability (e.g., water flow, solar irradiance) and equipment capacity limits. Grid interaction power is governed by grid connection protocols, including power limits and electricity pricing mechanisms. Battery charge/discharge power is subject to mutual exclusivity constraints (Pch,t, Pdis,t = 0) to prevent efficiency losses from simultaneous charging and discharging. For dynamic inter-variable coupling, increasing photovoltaic power may reduce J2 (carbon emissions) but could intensify power fluctuations, thereby elevating battery regulation frequency and exacerbating J3 (stability penalty) and J4 (degradation cost). Temporal horizon selection requires that the period T is optimized to balance prediction accuracy and computational complexity. Short-term optimization might overlook long-term economic efficiency, whereas long-term optimization necessitates addressing uncertainties in renewable energy forecasts.

These characteristics collectively render the feasible domain high-dimensional and non-convex. To address this, intelligent optimization algorithms (e.g., evolutionary strategies) or hierarchical solving frameworks are employed for efficient solution identification. Equation (25) formulates the multi-objective optimization model of the hydro-photovoltaic system, incorporating rigorous mathematical constraints.

The multi-objective optimization model for hydro-PV complementary systems achieves economic and environmental operational objectives through rigorously constructed mathematical constraints. Within the inequality constraint component

g(

u) ≤ 0, the system’s physical boundaries and operational rules are enforced across multiple dimensions. The real-time hydro-power output

is constrained by the upper and lower bounds to ensure hydro units operate within rated capacity ranges, thereby preventing equipment overload or inefficient operating conditions. The total reservoir water volume

imposes hard constraints reflecting water resource limitations, requiring available water to be rationally allocated throughout the scheduling cycle. The energy storage system’s state of charge (

) must be maintained within a secure operational interval to prevent battery over-charging or over-discharging, consequently extending service life. The upper and lower bounds of selling power

and purchasing power

are governed by generation limitations under extreme weather conditions and the economic boundaries of grid-interactive power

, respectively, ensuring system stability during external environmental fluctuations. These inequality constraints collectively define the feasible operational region of the system, guaranteeing physical feasibility for multi-objective optimization. The mathematical formulation of the power balance equation is expressed in Equation (26).

The equality constraint h(u) = 0 inherently reinforces the internal correlations of the system from the perspectives of energy conservation and dynamic equilibrium. The power balance equation requires that the combined output from multiple energy sources, including hydro, photovoltaic, storage, and the grid, matches the load demand in real time, thereby avoiding power deficits or surpluses. The dynamic state-of-charge (SOC) equation for the battery quantifies the variation pattern of the energy storage status, providing a dynamic model foundation for cross-period energy scheduling. Chyd denotes the hydro generation cost function (¥/MWh), which is determined by the quadratic function , αgrid represents the carbon emission intensity of grid power (kgCO2/MWh); ηch/dis indicates the battery charging/discharging efficiency; Ebat is the rated battery capacity (MWh); Wtotal signifies the total available reservoir water volume (MWh); and Δt is the time interval (h).

The quadratic growth characteristic of cost with respect to power output necessitates that generation revenue and marginal cost must be balanced during optimization. Conversely, the incorporation of grid electricity carbon emission intensity Chyd highlights the model’s consideration for low-carbon objectives. The time interval Δt, serving as a discretization parameter, transforms the continuous dynamic problem into a sequential optimization problem. Collectively, these equality constraints and variable definitions constitute the mathematical core of the system’s multi-objective optimization, establishing the theoretical framework for solving the economic-environmental dual-objective Pareto front.

The multi-objective optimization model for hydro-PV complementary systems requires the reconciliation of conflicting objectives, including economy, environmental sustainability, and operational stability, through mathematical methods. To address dimensional disparities among objective functions (e.g., cost, carbon emissions), normalization processing is applied to

J1,

J2,

J3, and

J4. A linear transformation maps each objective value to the [0, 1] interval, eliminating dimensional influences and providing a comparable basis for multi-objective trade-offs. The expression for the normalization process is expressed in Equation (27).

The weighted aggregation method, by incorporating preference weights

wi, converts the multi-objective problem into a single-objective optimization problem, i.e., it is expressed in Equation (28).

Should the actual objective be the minimization of the sum of squared weights, this may implicitly impose a constraint on the uniformity of weight distribution, thereby preventing any single objective from exerting excessive dominance. Moreover, the setting of weights must be integrated with the prioritization of the hydro cost function Chyd and the carbon emission intensity Cgdd. For instance, under low-carbon policy directives, a higher weight may be assigned to the carbon emission reduction target. These methodologies are required to be solved in coordination with the previously established constraints (e.g., the power balance equation and the SOC dynamic equation) to ensure that the optimization outcomes simultaneously satisfy physical feasibility and multi-objective equilibrium.

A comparison of the solution algorithms (e.g., NSGA-II, MOEA/D, weighted particle swarm optimization, and robust optimization) is presented in

Table 8.

In the Pareto front solution, algorithm selection directly influences optimization efficiency and the quality of the solution set. NSGA-II efficiently handles high-dimensional objective spaces through non-dominated sorting and crowding distance mechanisms, rendering it suitable for the multi-objective characteristics of hydro-PV systems with a five-star applicability rating in

Table 8 [

33]. Note: Performance rating symbols: ★ (filled star) denotes superior effectiveness (★ quantity ∝ performance level); conversely, ☆ (unfilled star) indicates inferior effectiveness (☆ quantity ∝ performance degradation). Its advantage lies in its strong global search capability, enabling the generation of uniformly distributed Pareto solution sets that support decision-makers in selecting optimal trade-off solutions based on real-time requirements. In contrast, MOEA/D (multi-Objective evolutionary algorithm based on decomposition) transforms the multi-objective optimization problem (MOP) into a set of single-objective subproblems through decomposition strategies, approximating the Pareto front via collaboration among subproblems. MOEA/D handles strongly coupled problems through objective function decomposition, exhibiting slightly lower applicability (four stars), but potentially outperforming others when significant interactions exist between objectives. Weighted particle swarm optimization (three stars) is suitable for real-time control scenarios but struggles to guarantee solution set diversity and convergence. Robust optimization (four stars) accommodates prediction uncertainties (e.g., PV output fluctuations) at the expense of computational efficiency. Collectively, NSGA-II and MOEA/D are more appropriate for long-term scheduling optimization, while scenarios with high real-time requirements may incorporate particle swarm algorithms for local adjustments. Algorithm selection must further consider model complexity factors, such as the discretization step size Δt in the SOC dynamic equation and computational resource constraints, to achieve a balance between optimization accuracy and efficiency. These methodologies provide critical technical support for translating theoretical models of hydro-PV complementary systems into practical applications.

4.4. Feedback Correction Strategy for Hydro-PV Complementary Systems

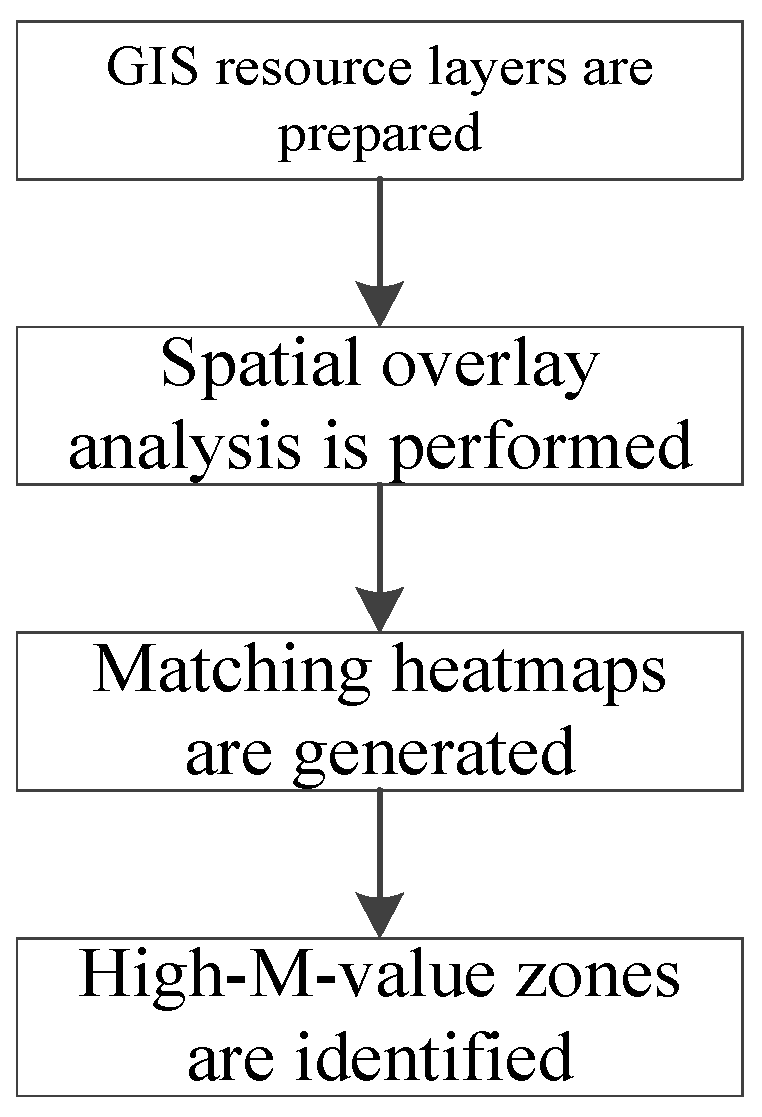

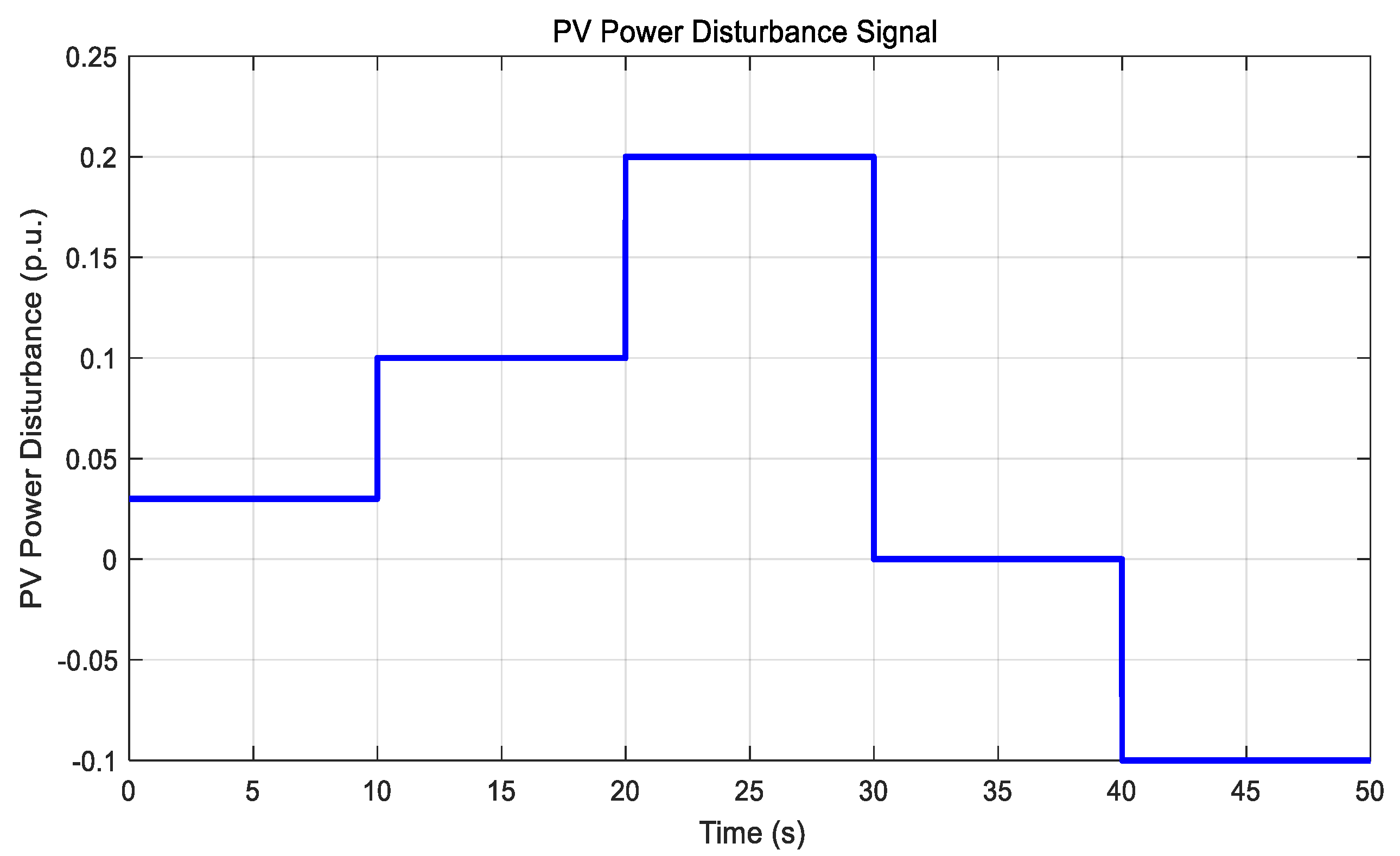

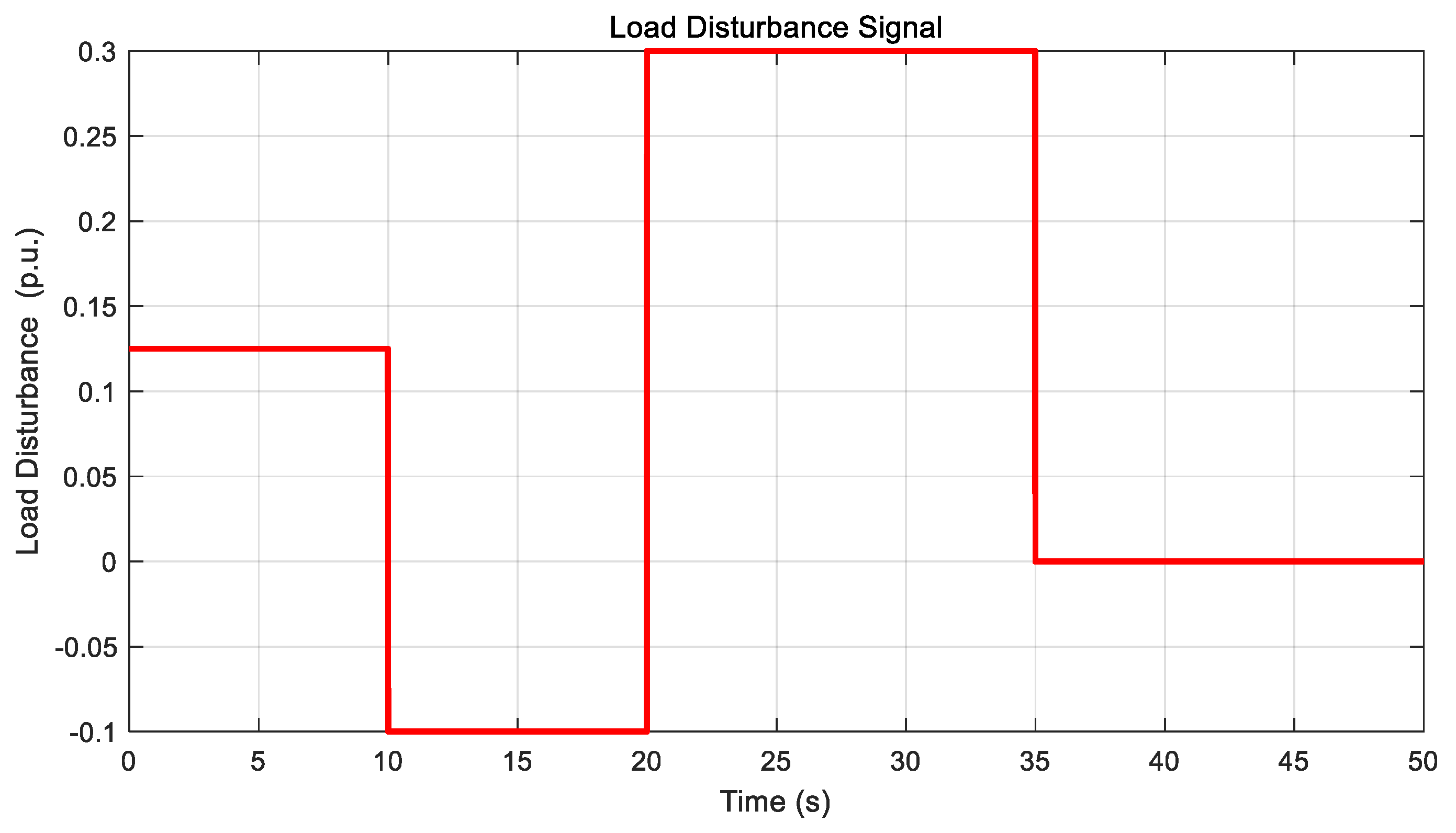

The unique design of hydro-PV complementary systems significantly enhances uncertainty resilience through the integration of multi-timescale feedback mechanisms, anti-disturbance strategies, and advanced data assimilation techniques. As detailed in

Table 9, the multi-timescale feedback design implements hierarchical correction for disturbances across different temporal dimensions. At the 15-min level, real-time PV output is compared with the forecasted values. Fluctuations caused by cloud occlusion are mitigated through dynamic adjustment of the inverter clipping coefficient M

max to limit power overshoot and ensure equipment safety.

At the hourly level, dydro-regulation deviations (e.g., unit efficiency model errors or water flow variations) are addressed by refining hydro unit efficiency models via parameter identification algorithms, thereby improving output accuracy.

At the daily level, accumulated reservoir water level errors (e.g., from precipitation forecast deviations or evaporation losses) are corrected through updates to input parameters of inflow prediction models, optimizing long-term water dispatch schedules.

This hierarchical mechanism achieves full-cycle coverage from second-scale disturbances to long-term trends, effectively balancing system responsiveness with global optimization requirements.

Regarding anti-disturbance mechanisms, a closed-loop control strategy is employed for abrupt scenarios such as irradiation plunges;

is expressed in Equation (29).

where

represents the forecasted PV generation power, while

denotes the measured PV generation power. The hydro regulation gain

Kp (typical value: 0.5 MW/%) enables hydropower output to be dynamically adjusted, facilitating rapid compensation for PV power deficits and maintaining power balance.

Data assimilation techniques are implemented through the ensemble Kalman filter (EnKF), which integrates real-time observational data (e.g., reservoir inflow rates, PV output) with model predictions. This process iteratively updates the state estimation vector

xi, significantly reducing prediction uncertainty. The data assimilation is expressed in Equation (30).

where

denotes the optimal state estimate after data assimilation. This analysis field integrates model predictions with actual observational data, representing the most accurate estimation of the system’s current state.

signifies the prior forecast result generated by the model based on historical data or the previous state, constituting the state estimate before real-time observations are incorporated.

Kt represents the Kalman gain matrix that quantifies the weighting ratio between observational data and model predictions. Its magnitude is governed by both models’ forecast error covariance and observation error covariance, determining the degree of observational corrections to the final analysis.

yt corresponds to actual measured values (e.g., reservoir inflow rates, PV output)—physical quantities acquired in real time for model prediction correction.

H denotes the observation operator, which may be a linear or nonlinear function mapping state variables to the observation space, serving to extract observable quantities from the model-predicted state. Typical control effects are presented in

Table 10.

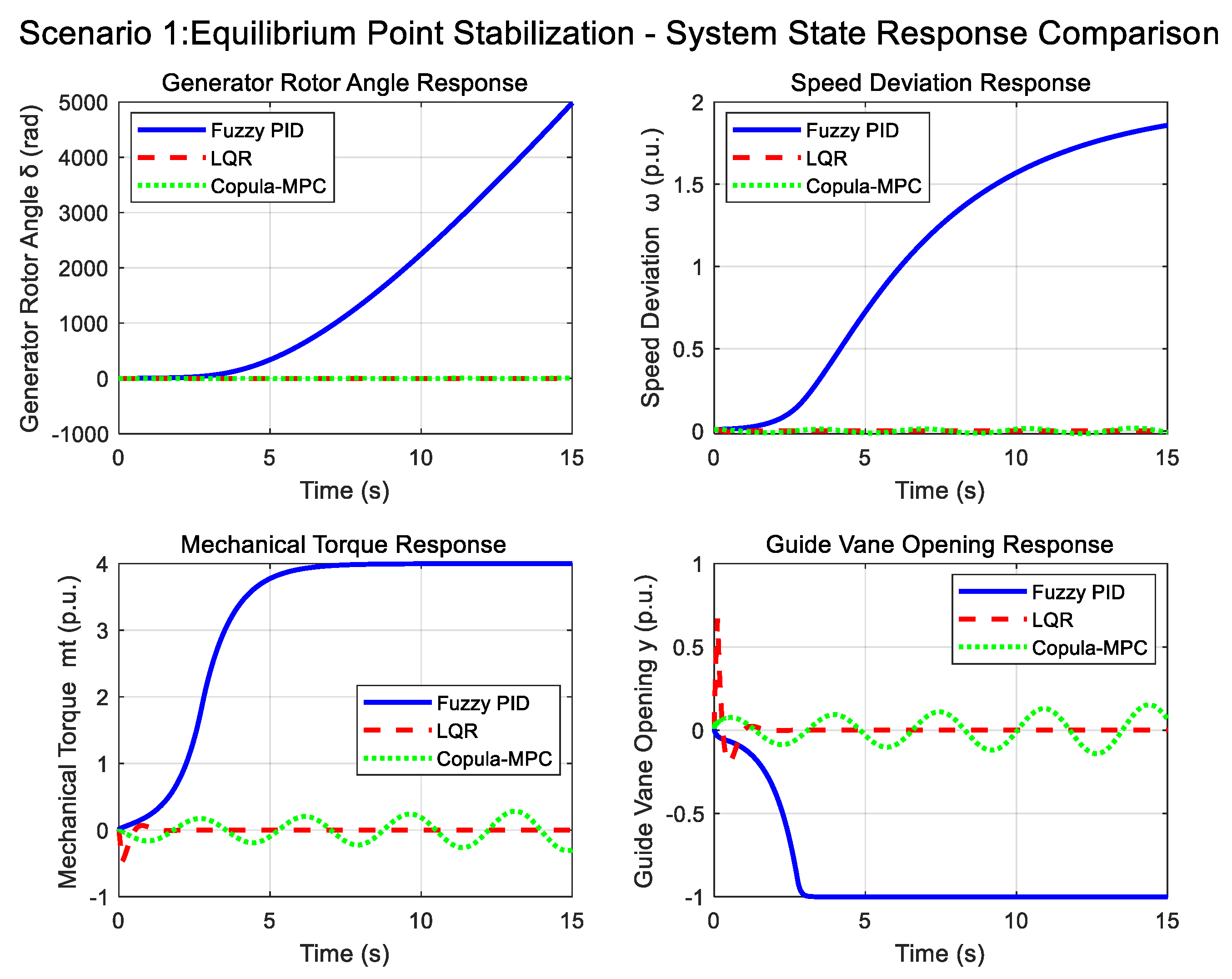

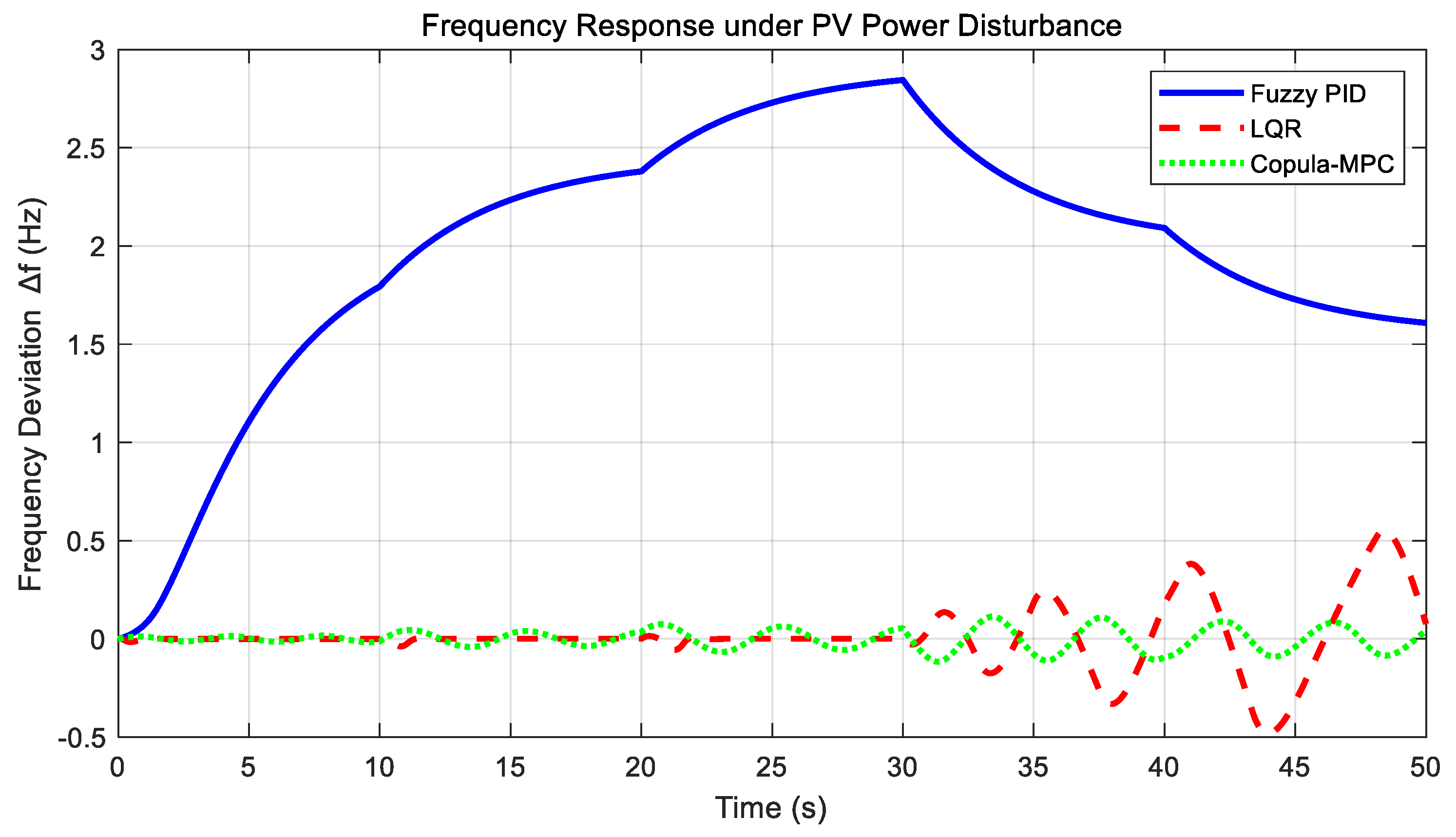

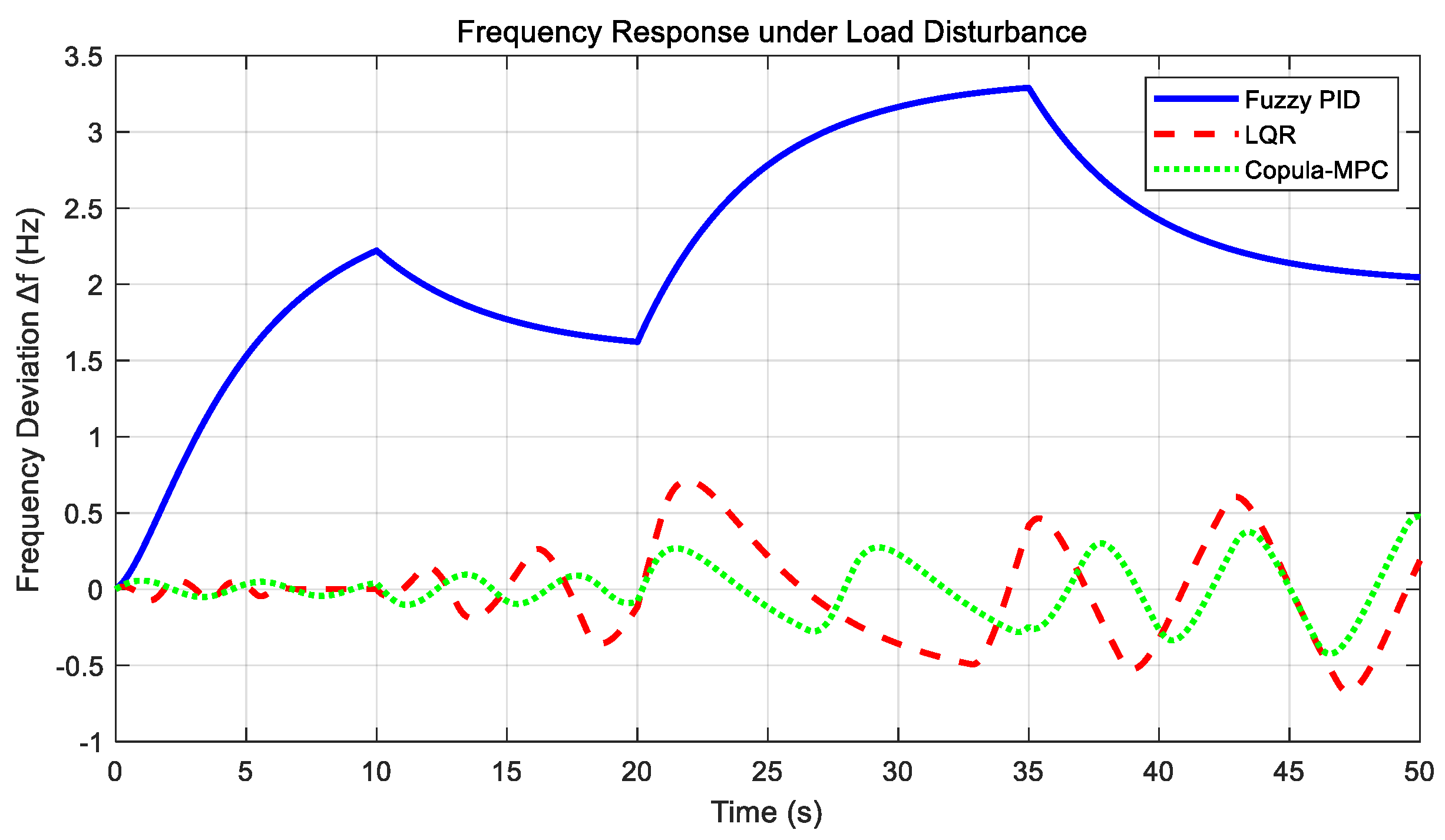

Analysis of

Table 10 reveals that MPC implementation reduces system fluctuation rates by 43.8%, 46.4%, and 43.9% under PV cloud occlusion, load surge, and unit failure scenarios, respectively, thereby verifying the effectiveness of the aforementioned strategies. The optimized design of the Kalman gain

Ki enables adaptive adjustment of weighting between observational data and model predictions, particularly excelling in scenarios involving significant nonlinearities such as reservoir inflow prediction. These techniques not only enhance system robustness but also provide real-time dynamic support for multi-objective optimization models (e.g., Pareto solution sets generated by NSGA-II), ensuring operational feasibility of theoretical optimization outcomes in practical implementations.