1. Introduction

Energy serves as the foundational pillar and driving force for national socio-economic development, critically influencing economic security, public welfare, and social stability [

1]. However, the energy sector faces escalating challenges as climate change intensifies global sustainability pressures [

2]. Fossil fuels, the primary source of pollutants, account for the majority of global CO

2 emissions through their production and consumption [

3]. As China commits to achieving carbon peak by 2030 and carbon neutrality by 2060 [

4], the energy industry—responsible for one-third of national CO

2 emissions from coal-fired power generation in integrated energy systems—becomes pivotal for deep decarbonization. China’s energy transition is particularly challenging given its coal-dominated energy infrastructure (60% of current energy mix) [

5,

6], constrained by resource endowment characteristics of “abundant coal, limited oil, and scarce natural gas” [

7].

Carbon Capture, Utilization, and Storage (CCUS) has emerged as a pivotal technology for low-carbon retrofitting and operational flexibility enhancement of thermal power units [

8], serving as the cornerstone tool for emission reduction in coal-fired power plants. Characterized by its capacity to reconcile energy security with decarbonization imperatives, CCUS is widely recognized as a critical enabler for achieving carbon neutrality targets [

9]. Chen et al. [

10] investigated carbon capture plant energy flows, revealing peak-shaving capabilities and grid optimization roles. Sheng et al. [

11] demonstrated carbon capture integration in IESs enhances carbon reduction capabilities. Chen et al. [

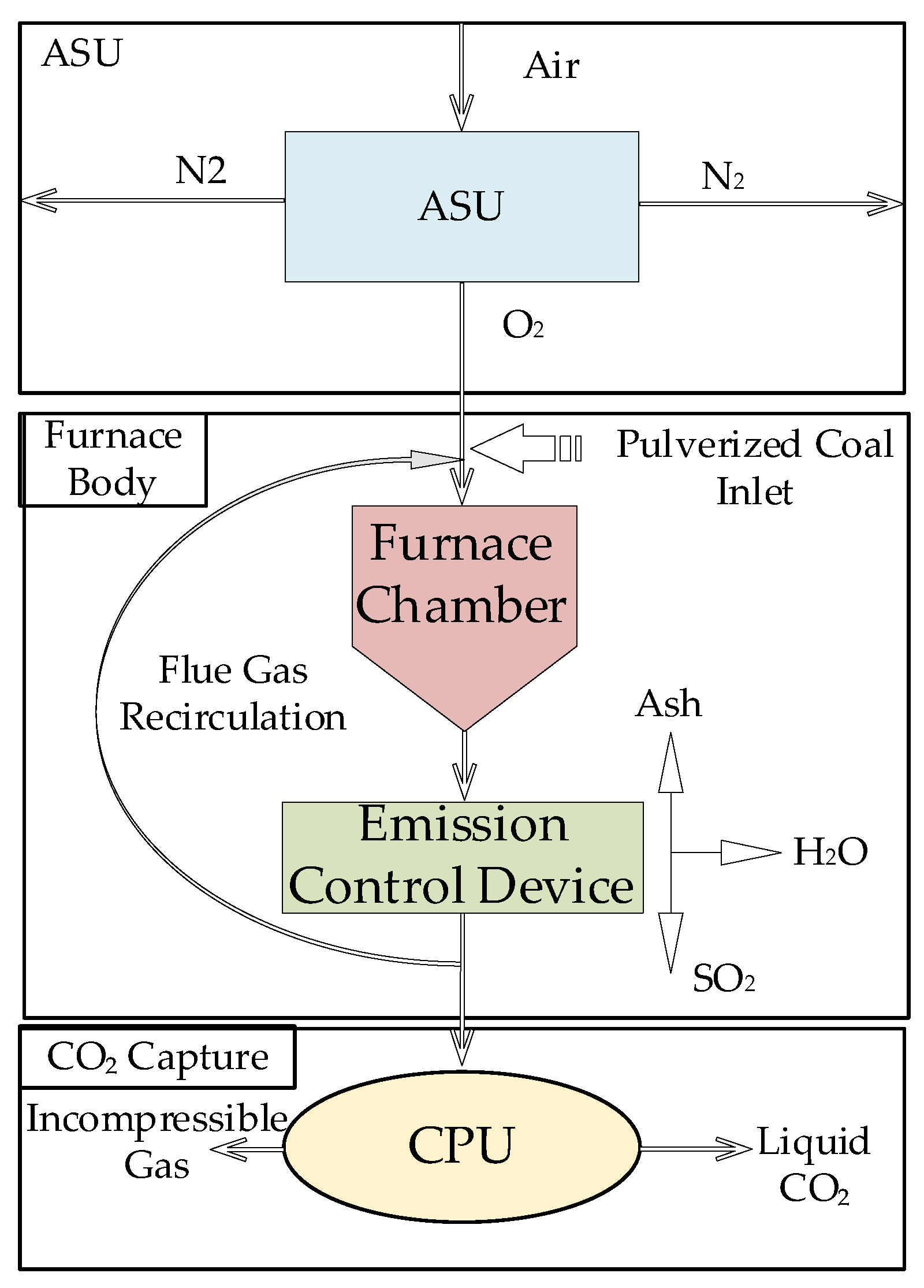

12] demonstrated P2G-CCUS integration enhances renewable utilization and emission reduction, while oxy-fuel CCS overcomes conventional CCS limitations through carbon capture. Zheng et al. [

13] systematically reviewed China’s oxy-fuel combustion R&D progress, highlighting its potential as a leading carbon-reduction solution for coal plants. Liu et al. [

14] analyzed oxy-fuel combustion principles, demonstrating superior economic-environmental performance versus air-fired systems. This literature only discusses the technology itself and does not combine it with IESs, so the CO

2 captured by CCS and the oxygen produced by the P2G process are not effectively utilized. As the core technology for carbon capture during combustion, oxy-fuel combustion technology, when compared with the other two technologies, has the following characteristics: pre-combustion capture efficiency is high, and it has good synergy in pollution control, but it requires large-scale transformation, with complex equipment and high costs; post-combustion carbon capture technology has strong adaptability and mature technology, and can directly treat tail flue gas. However, due to the low concentration of CO

2, the energy consumption for separation is extremely high, and problems such as solvent degradation and equipment corrosion are prominent, resulting in high long-term operating costs. In contrast, oxy-fuel combustion and flue gas recirculation can increase the concentration of CO

2 in the flue gas and significantly reduce the energy consumption for separation in subsequent capture, and are compatible with existing coal-fired power plants without the need to transform the main body of the boiler. Therefore, under the background of “dual carbon” goals, it has great development potential and unique competitiveness. However, existing literature focuses solely on oxy-fuel combustion technology itself without systemic integration into low-carbon integrated energy systems.

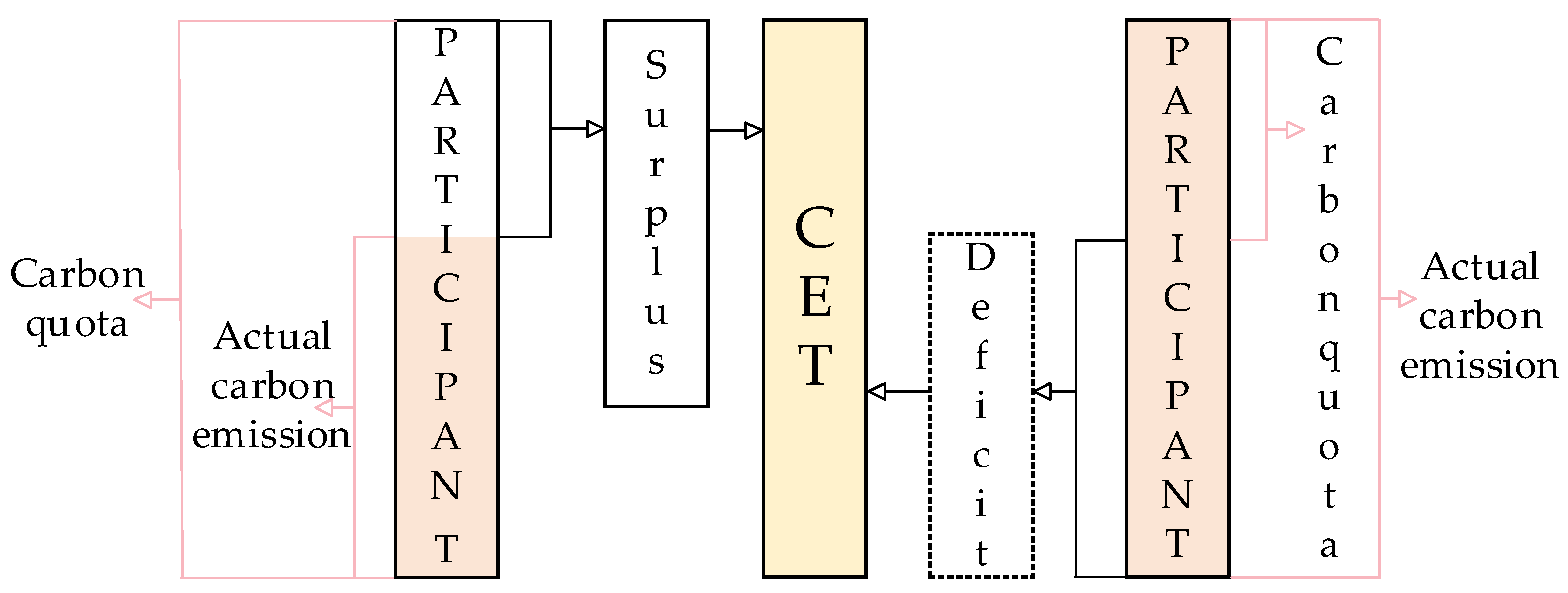

Amidst accelerating global decarbonization efforts, carbon emission trading (CET) markets have emerged as critical policy levers for accelerating low-carbon transitions in energy systems, serving as central market-driven instruments for emission mitigation. Ma et al. [

15] integrated a multi-energy complementary system into the carbon trading market and introduced a hierarchical carbon trading mechanism to guide the system in controlling carbon emissions. Tang et al. [

16] developed an IES model considering stepped carbon trading, two-stage P2G, adjustable CHP heat-to-power ratio, and load demand response. Xing et al. [

17] proposed a multi-objective optimal scheduling method for integrated energy systems with combined heat, power, and hydrogen supply considering a stepped carbon trading mechanism. Wu et al. [

18] established a two-layer carbon trading mechanism and proposed a stepped carbon price cost model. Bao et al. [

19] proposed a low-carbon operation model for multi-energy complementary integrated energy systems considering two-layer power-to-gas and demand response. Cui et al. [

20] introduced carbon capture and P2G into a multi-energy IES, building a two-layer model to analyze output and costs under demand response and carbon trading. Wang et al. [

21] introduced a carbon trading market into an IES model with green energy and analyzed stepped carbon trading’s impact on economic costs.

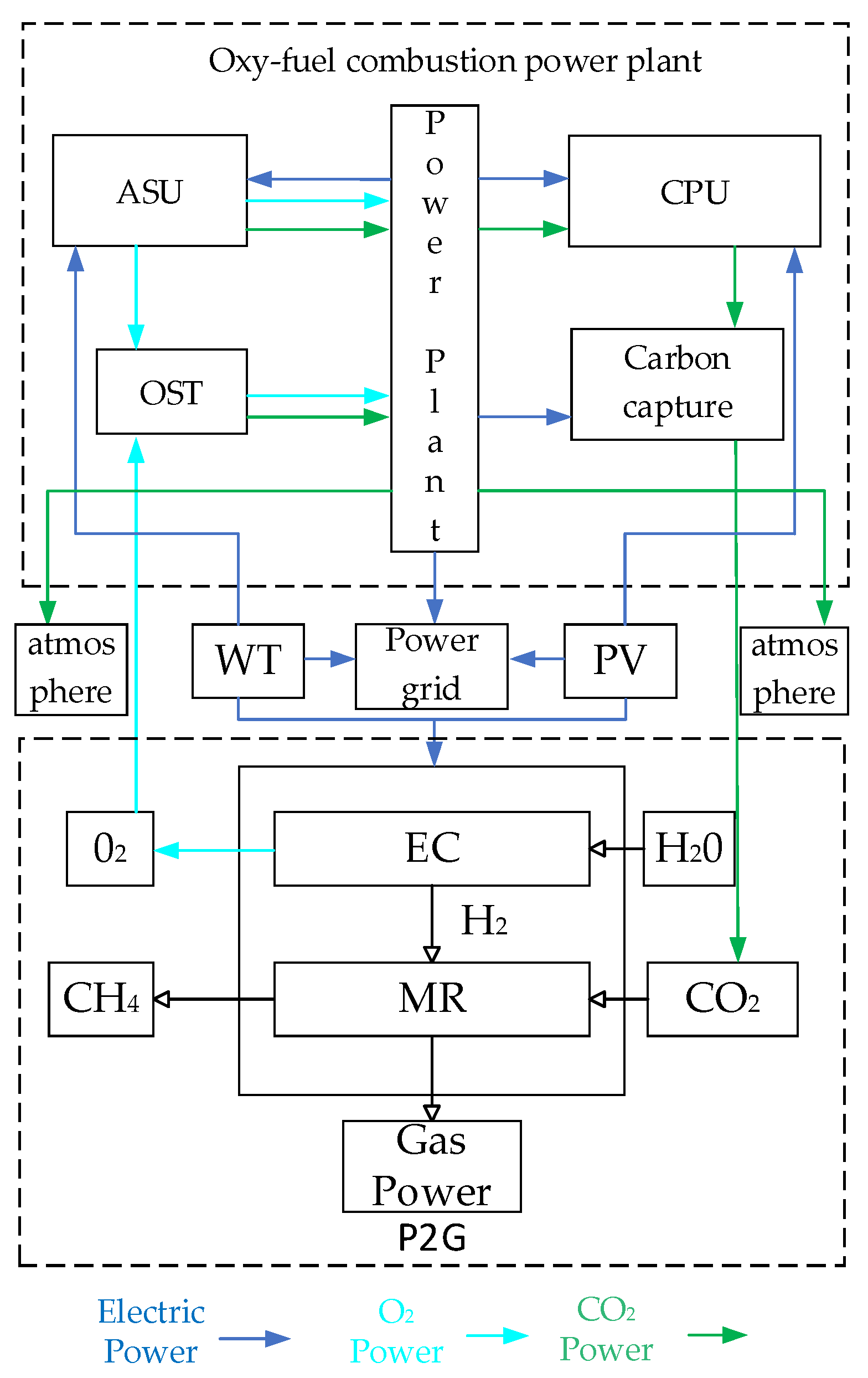

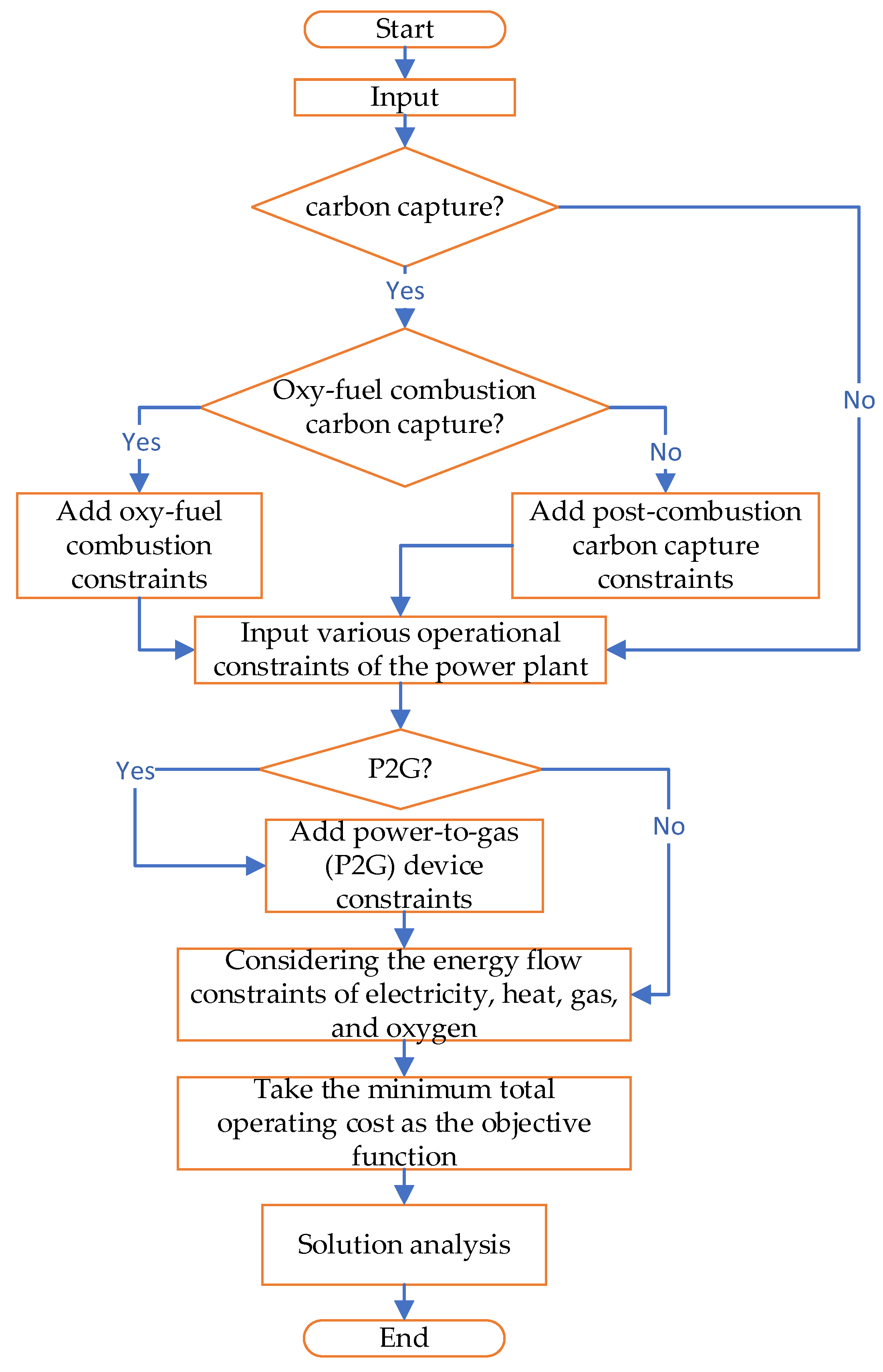

However, current market mechanisms exhibit limited interaction, with most studies employing parallel optimization models that lack carbon emission trading. Addressing this gap, this study focuses on optimizing the coordinated dispatch of oxy-fuel combustion technology and CET mechanisms. A dual-path framework is developed through technical and policy innovations: (1) Technically, an IES scheduling model integrates oxy-fuel combustion plants, two-stage P2G systems, and wind–solar co-generation; (2) policy-wise, a market mechanism embedding CET rules is formulated. This approach enables synergistic optimization of low-carbon technology deployment and market-driven emission constraints.

Building upon existing research [

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21], this study proposes an optimized scheduling model that synergistically integrates oxy-fuel carbon capture technology with carbon trading mechanisms. The mixed-integer linear programming framework is solved using MATLAB’s CPLEX solver, with comparative scenario analyses demonstrating the strategy’s effectiveness. The results validate the technical–economic superiority of coupling oxy-fuel retrofitting with CET policies for low-carbon transitions. The following is a summary of this paper’s primary contributions:

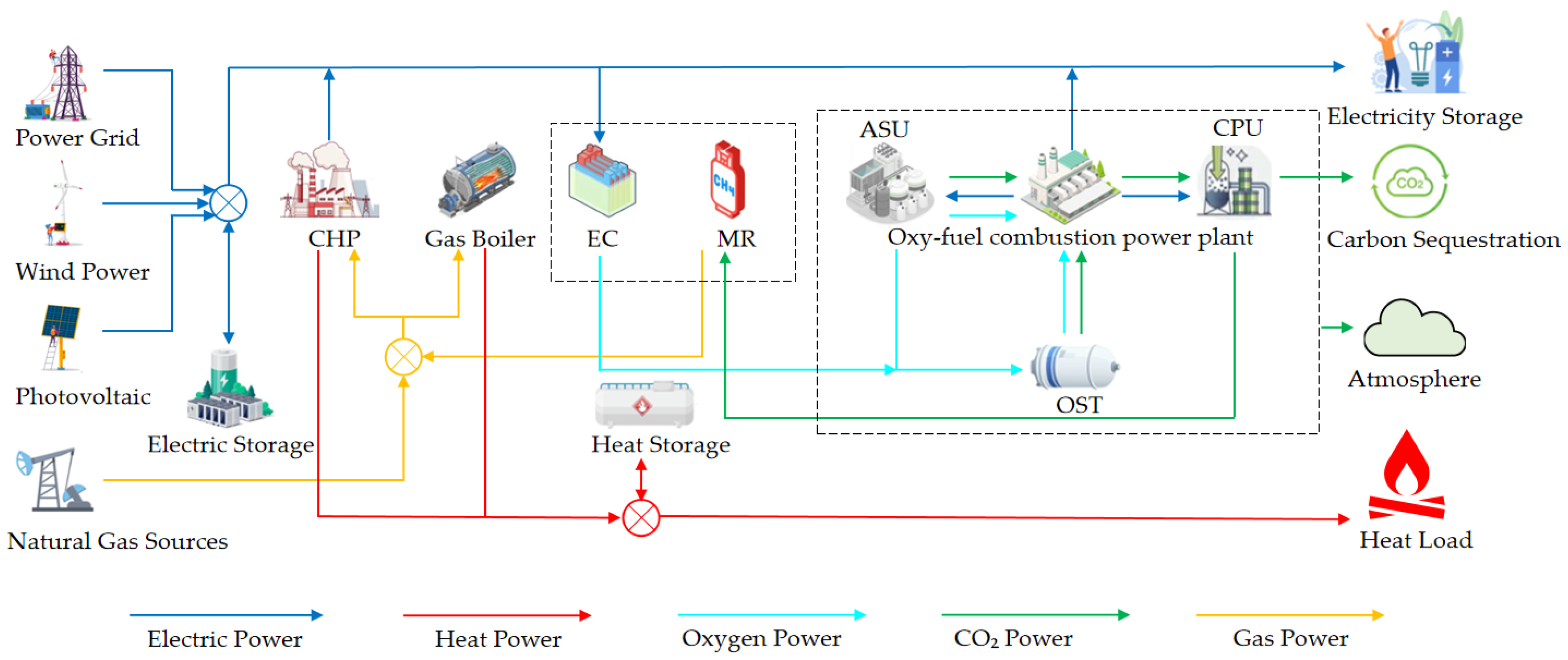

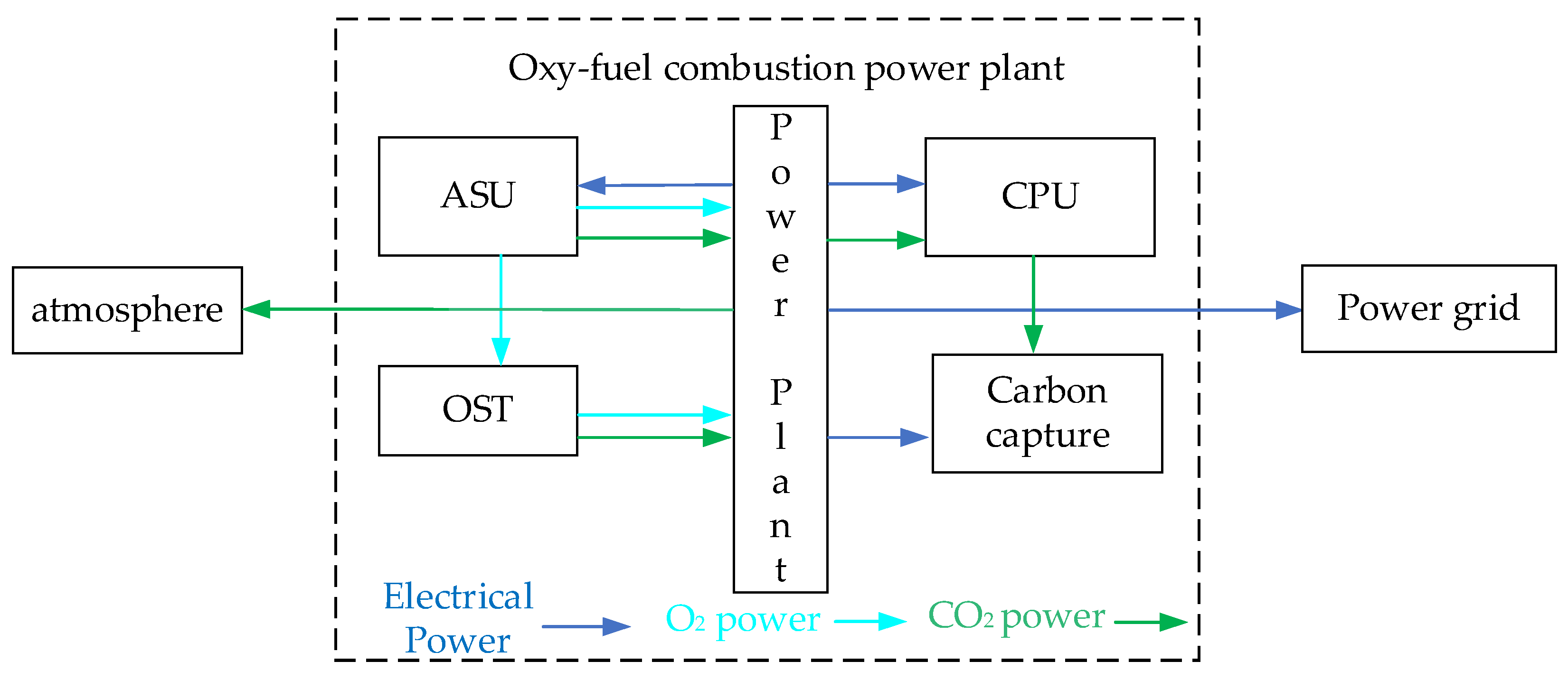

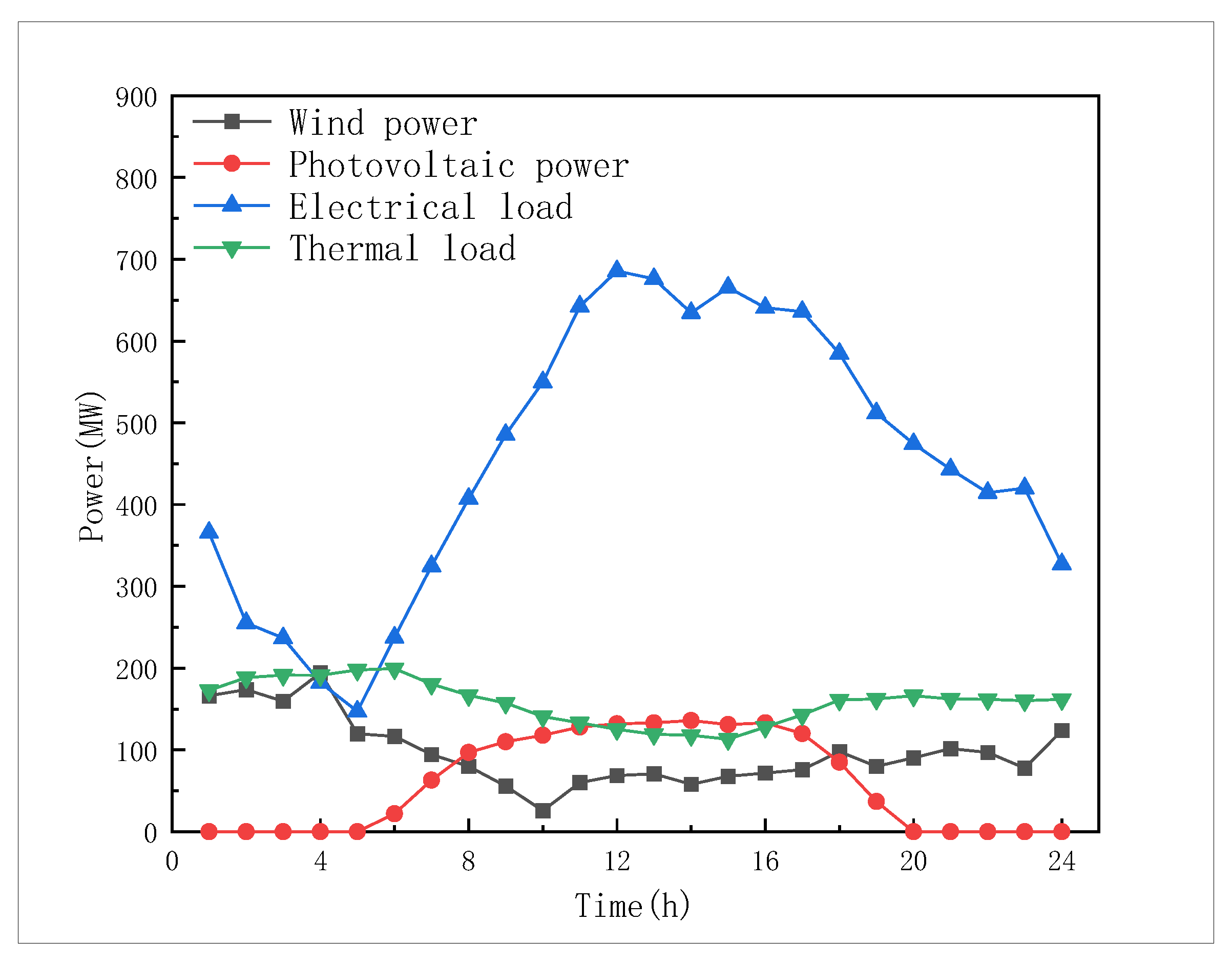

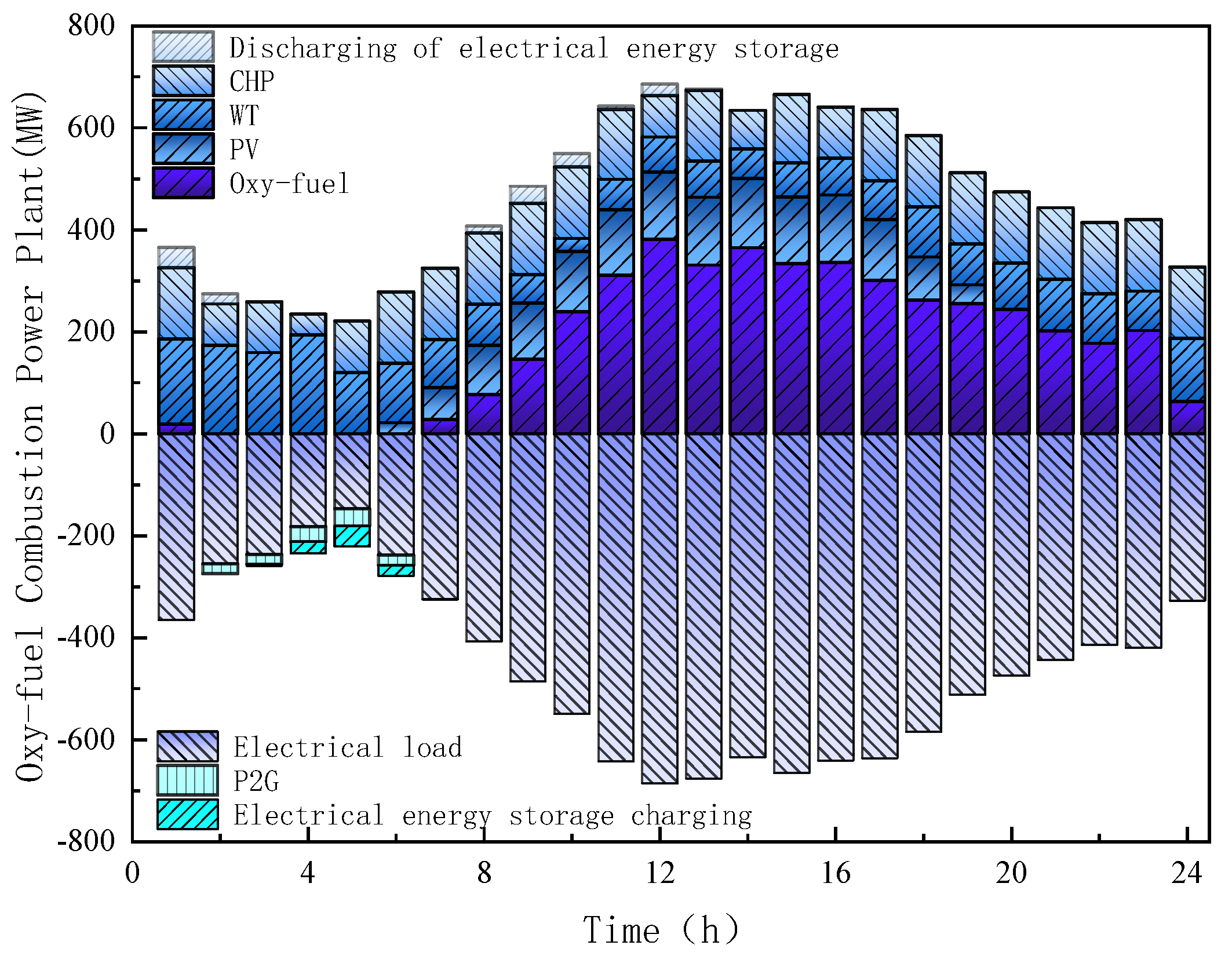

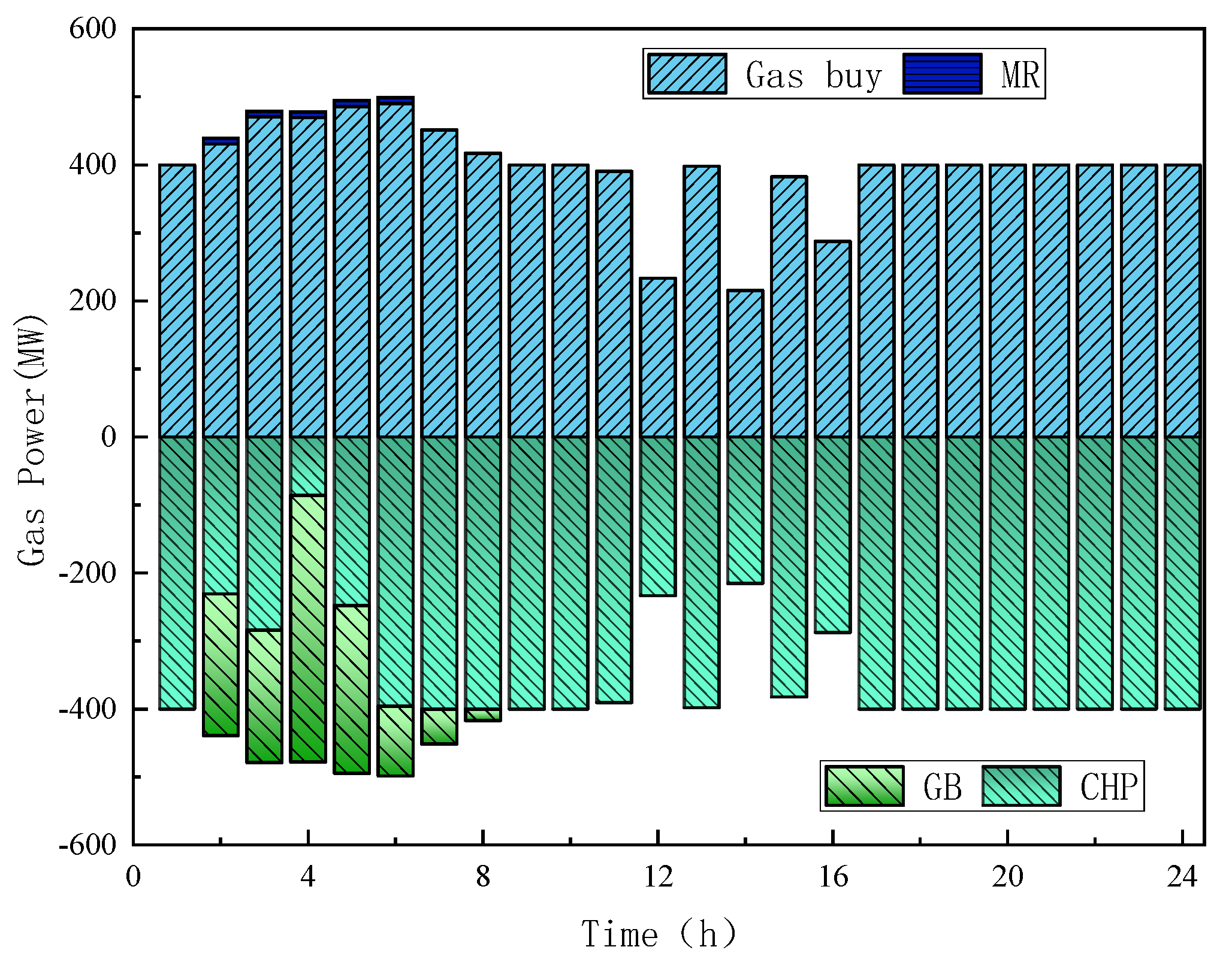

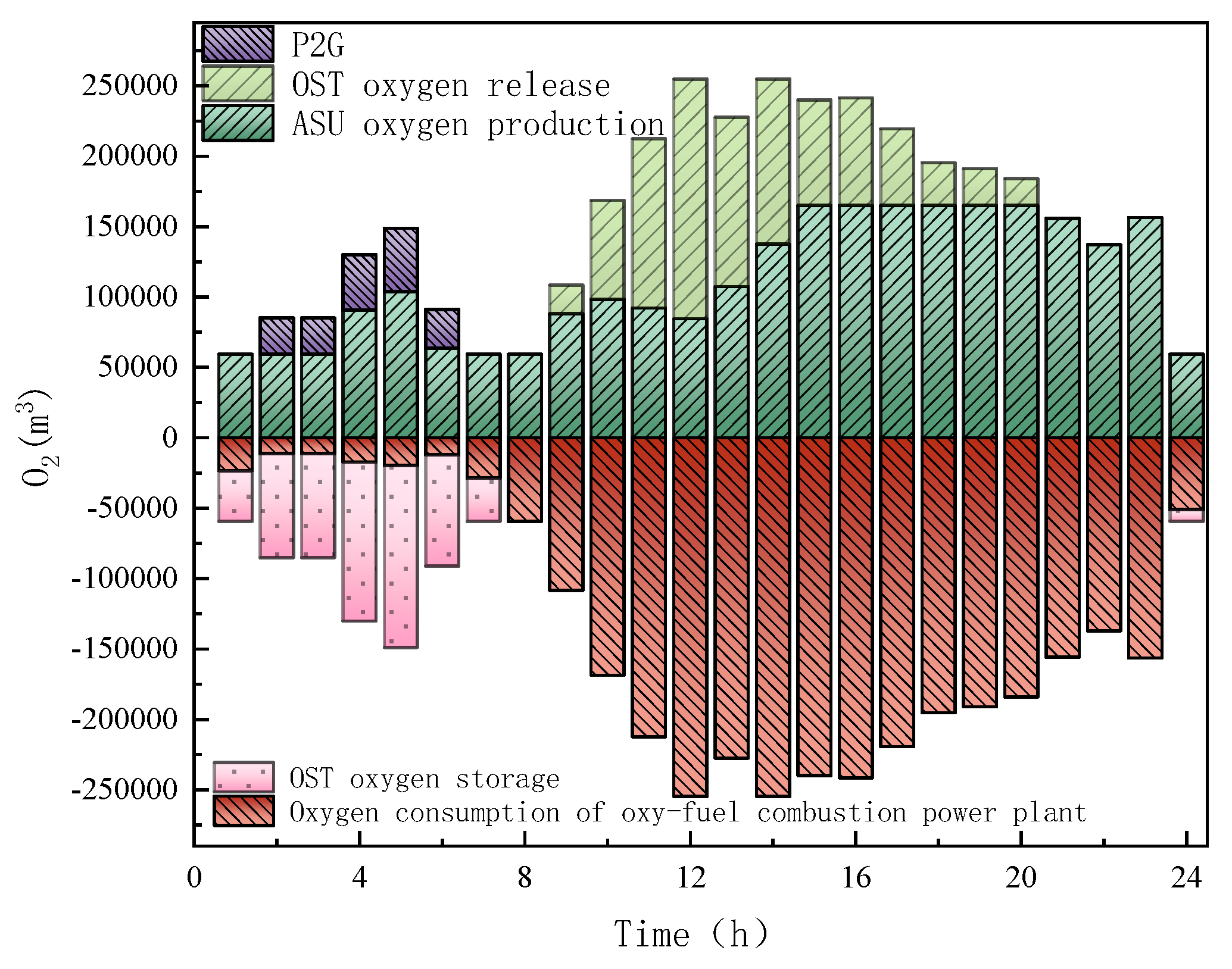

An optimal scheduling model was developed incorporating oxy-fuel combustion technology, two-stage P2G conversion, and Combined Heat and Power (CHP) units, thereby enhancing the multi-energy coupling among electricity, heat, gas, and oxygen storage systems.

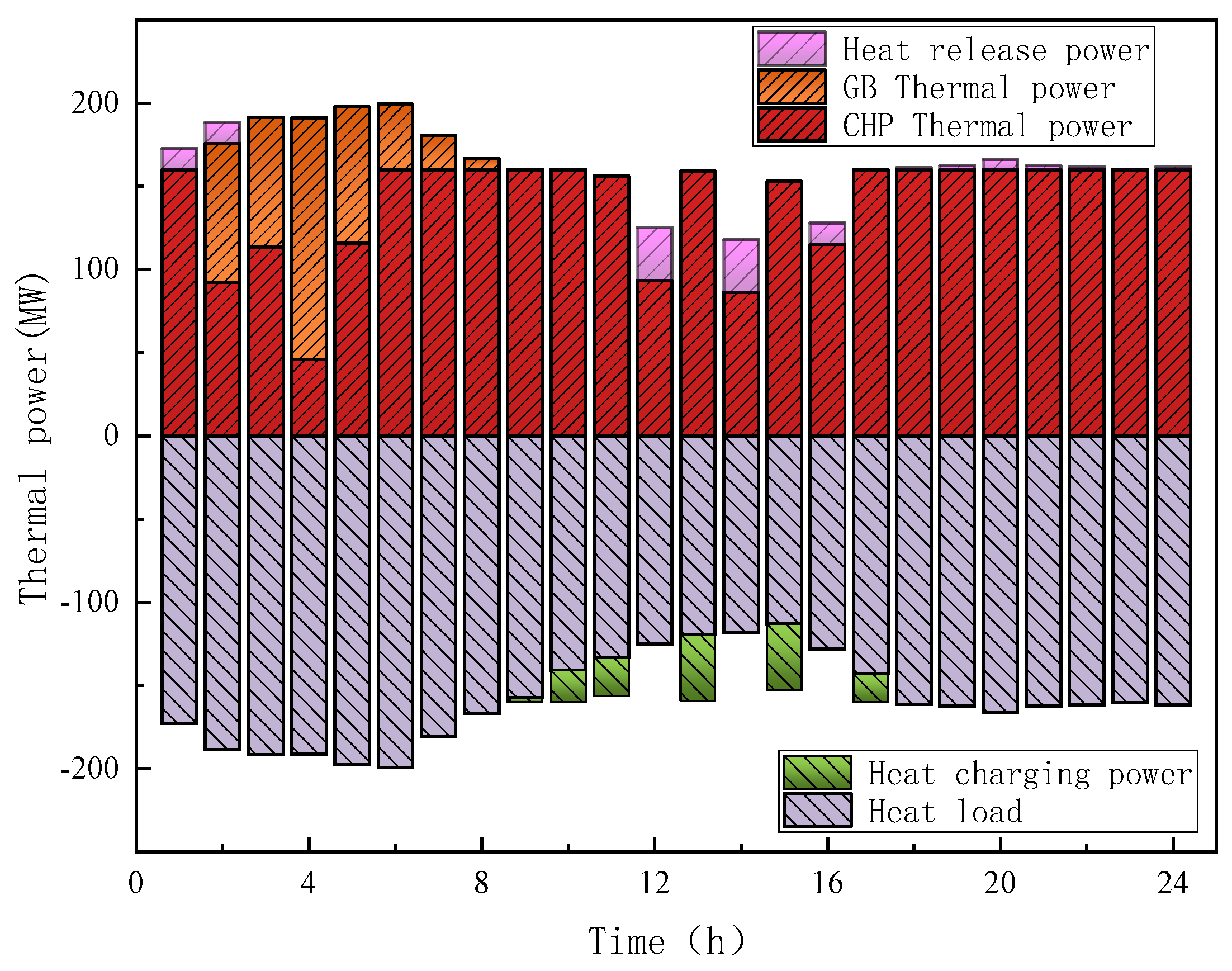

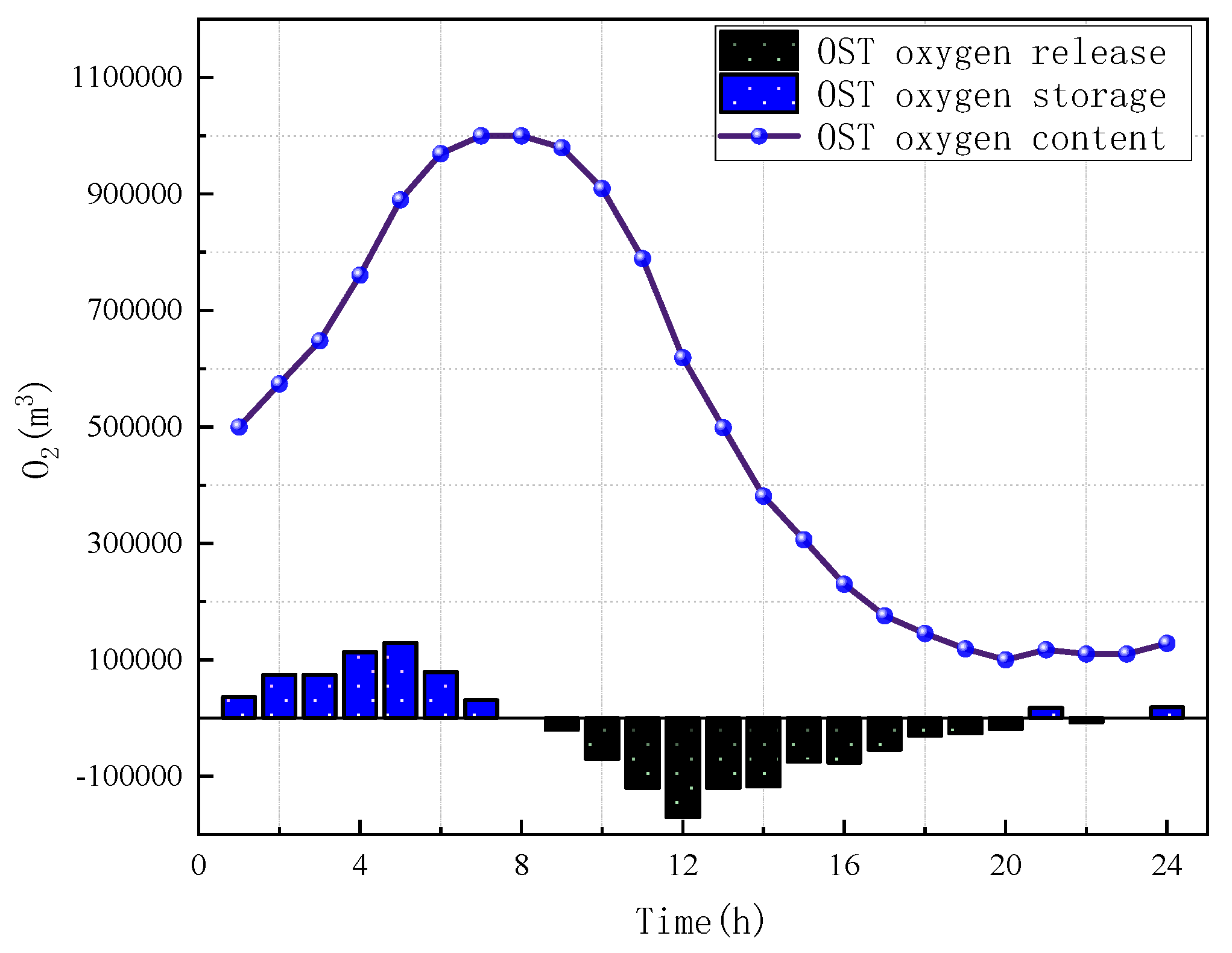

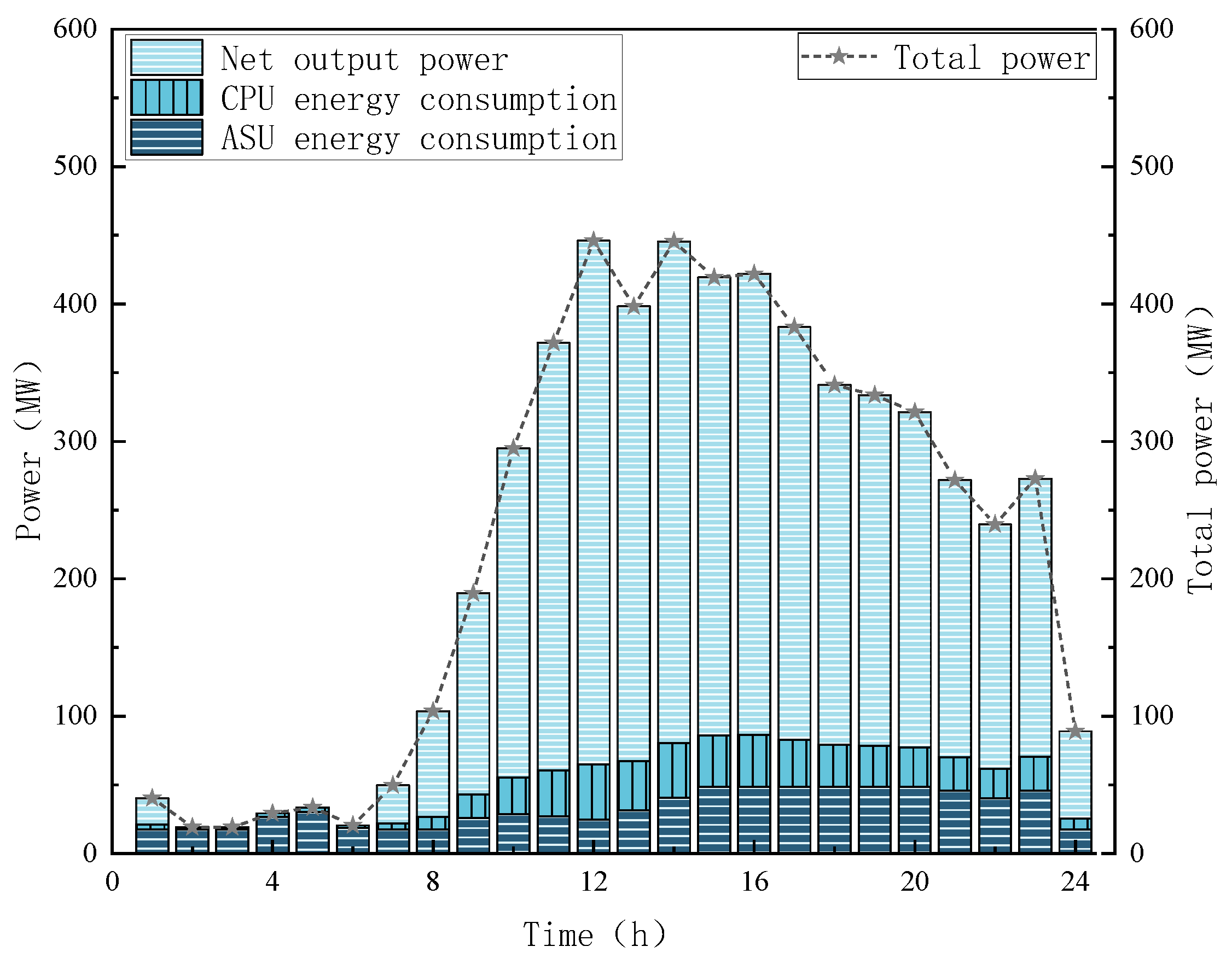

The oxygen storage tank in oxy-fuel plants implements valley-storage/peak-release strategies to optimize oxygen supply flexibility while reducing energy consumption of air separation units (ASU). Coupled with battery/thermal storage systems enabling dual-peak regulation of electricity and heat loads, this configuration coordinates multi-energy outputs across timeframes, demonstrating energy storage’s critical role in enhancing system flexibility.

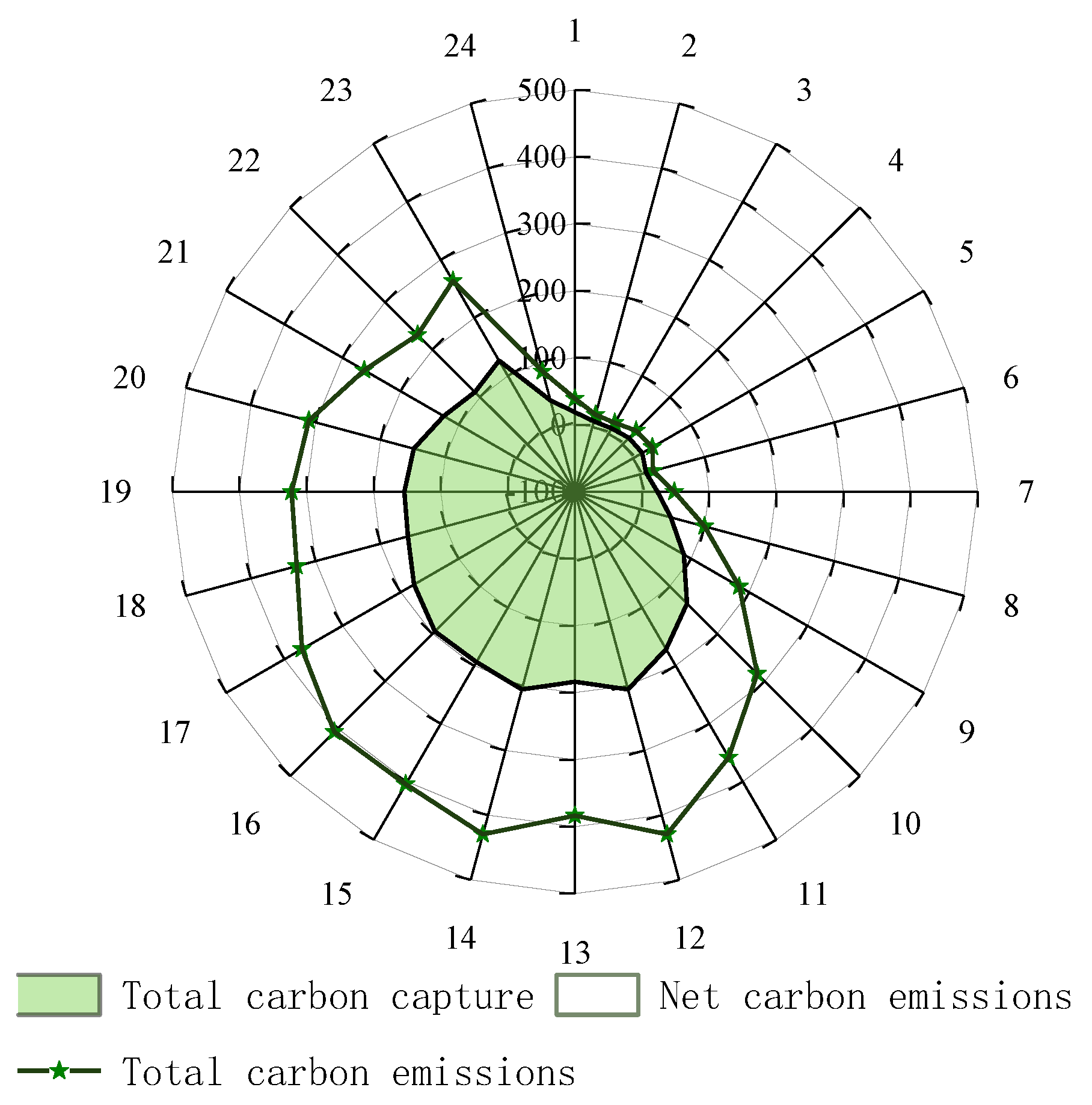

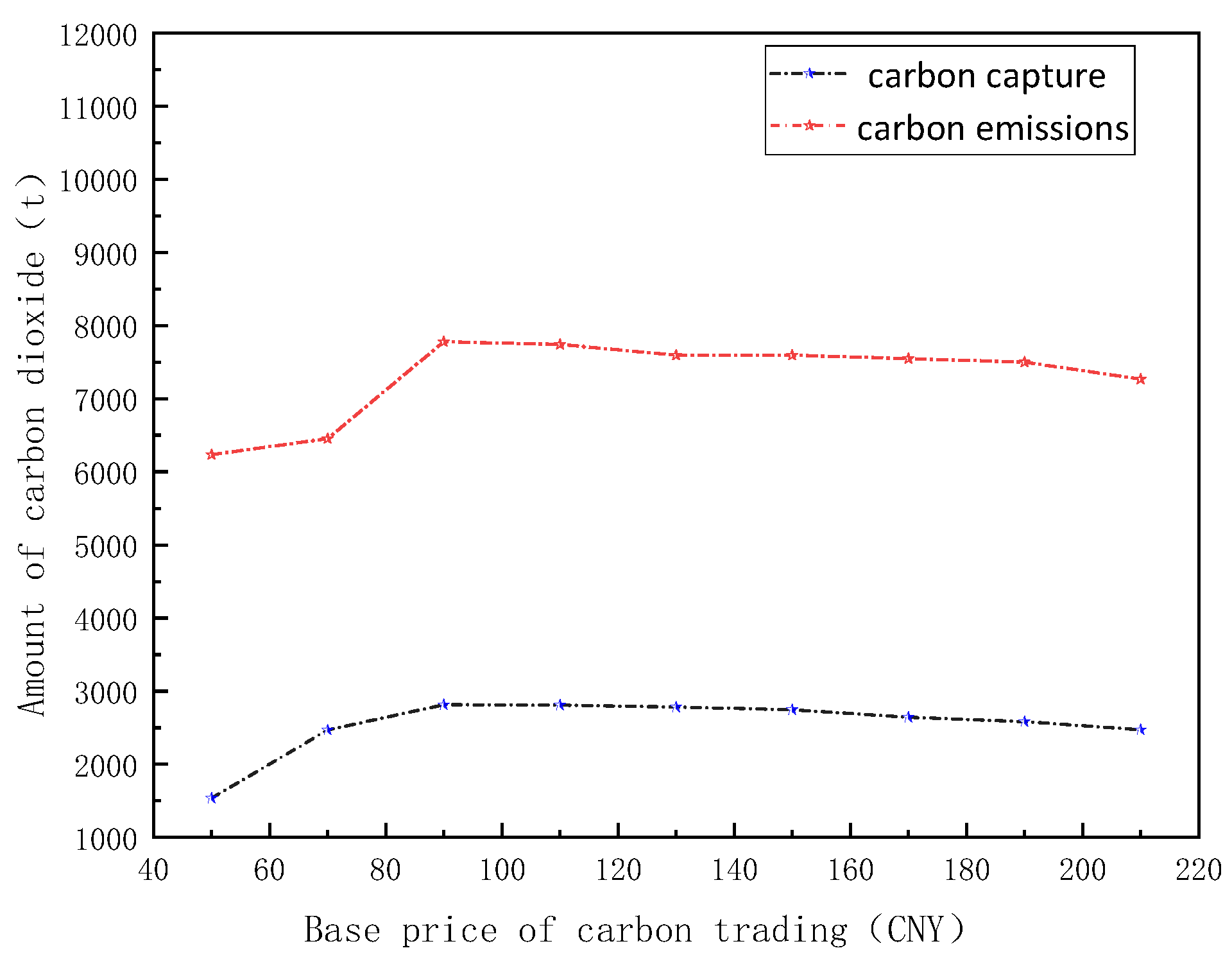

The continuous refinement of the CET mechanism drives synergistic enhancements in system economic viability and low-carbon performance, where cross-mechanism interoperability resolves the inherent economic–environmental trade-off through resource coordination.

The main research content of this paper is as follows. First,

Section 2 introduces the integrated energy system architecture and establishes mathematical models for various energy conversion and storage devices.

Section 3 develops an optimal dispatch model with the objective of minimizing operational costs. In

Section 4, case studies are conducted to analyze the system benefits under four operational modes. Finally, conclusions are drawn in

Section 5.