Hybrid NARX Neural Network with Model-Based Feedback for Predictive Torsional Torque Estimation in Electric Drive with Elastic Connection

Abstract

1. Introduction

- Proactive Prediction: Unlike model-based estimators or observers such as SMO, DOB, Luenberger Observer, and other state observers, the proposed method estimates torsional torque one step ahead. This enables anticipatory control, which reactive observers cannot provide. Anticipatory control is crucial for proactive vibration damping, as it helps to reduce torsional oscillations before they fully develop. This improves the efficiency of the drive and prevents the drive from wear and tear caused by vibration. This capability is essential in applications such as electromobility, where proactive vibration damping can extend drivetrain life, reduce noise, and improve passenger comfort.

- Inherent Robustness: The design of both the NARX NN and the model-based feedback is independent of the load-side parameters, such as the load inertia and shaft stiffness. As a result, the proposed method is inherently robust to changes in these parameters. This eliminates extensive tuning, critical design adjustments, and the optimisation process, all of which contribute to numerical complexity and make real-time implementation more difficult.

- Modest Complexity for Implementation: The incorporation of model-based feedback helps the NARX NN to generalise effectively with a simple network structure. Specifically, the proposed method achieves efficient results using just five neurons and one hidden layer. Since the model-based feedback involves only simple mathematical calculations, the proposed method is suitable for real-time implementation.

- The proposed method is compared with different types of neural network estimators and shows superiority in terms of generalisation under parameter changes and network simplicity.

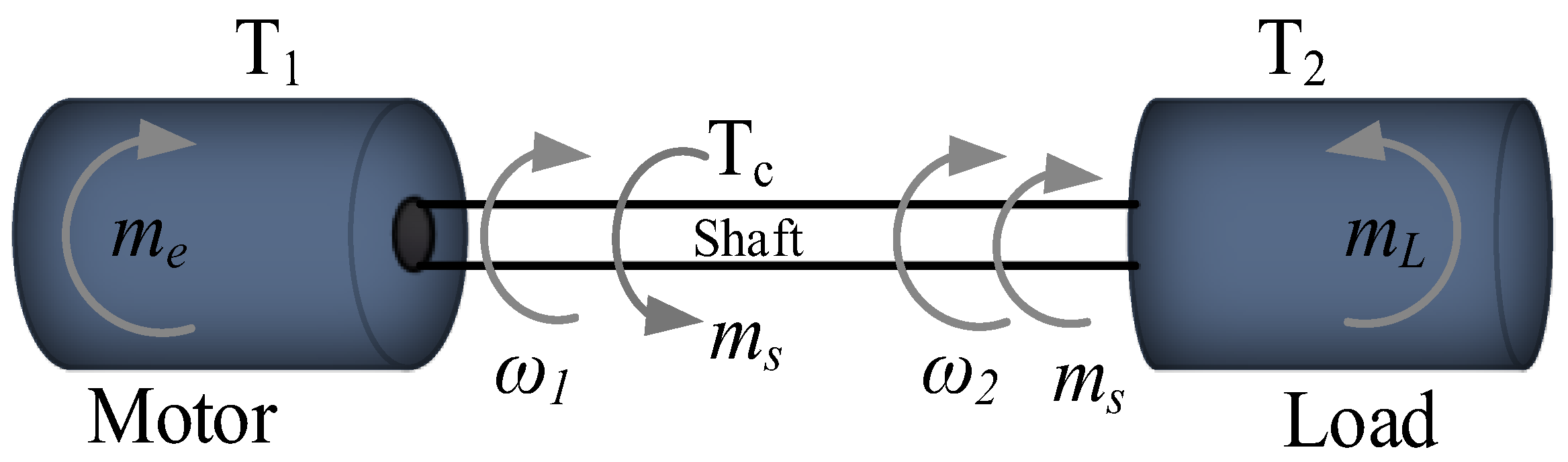

2. Mathematical Modelling of the Considered Dual-Mass Drive

3. NARX NN

- -

- Dynamic Memory Structure: NARX NNs use delay buffers to capture time-lagged dependencies, making them suitable for two-mass drives, where rapid interaction between variables such as speed, torque, and load raises the complexity of the system.

- -

- Nonlinear Modelling Capability: Unlike linear models, NARX NNs can approximate complex nonlinear relationships, enabling more reliable estimation under parameter variations and external disturbances.

- -

- Training Efficiency: In an open-loop configuration, NARX NNs benefit from actual feedback during training. This reduces error propagation and promotes more stable and robust learning.

- -

- Flexibility: NARX NNs are robust and adaptable to diverse system architectures and operating conditions, making them effective for parameter estimation, control optimisation, and fault diagnosis of electric drives.

4. Modelling of Hybrid NARX NN with Model-Based Feedback

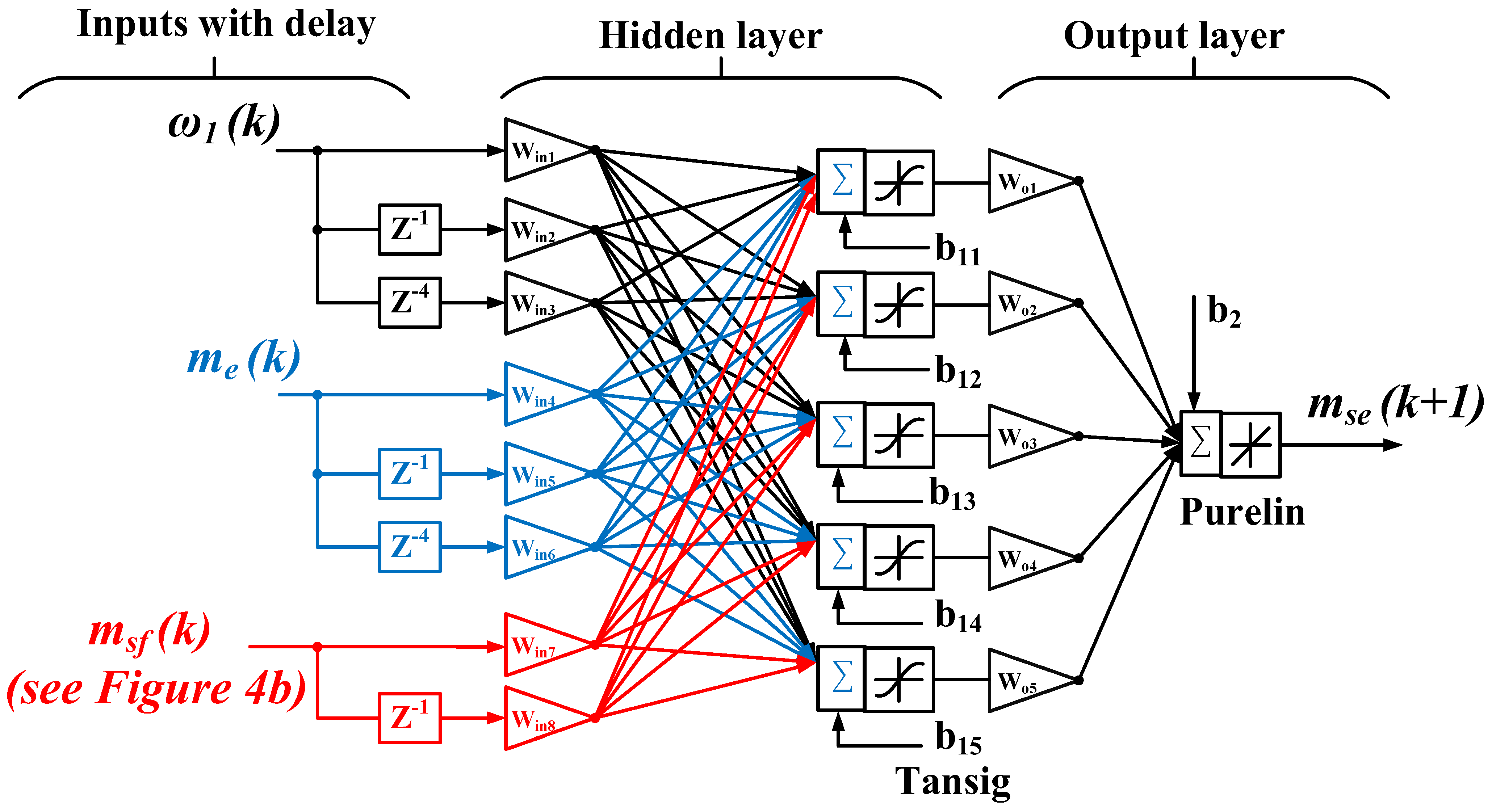

- Input Layer: The exogenous inputs consist of motor speed (ω1) and motor torque (me) at discrete time steps k, k−1, and k−4. Additionally, the model-based feedback signal (msf) is included at steps k and k−1. This delay selection was determined empirically through simulation studies. The complete input vector is defined in Equation (11):

- Hidden Layer: The hidden layer consists of five neurons, each employing a hyperbolic tangent activation function. The output of the jth neuron is expressed as follows:where m is the number of inputs = 1, 2, …, 8, j is a number of neurons = 1, 2, …, 5, wji (1) are input-to-hidden weights, and bj (1) are biases.

- Output Layer: The output layer comprises one neuron with a linear activation function, which is applied to estimate one-step-ahead torsional torque mse (k + 1). The corresponding equation is presented in Equation (13):where j = 1, 2, …, 5 corresponds to the number of hidden neurons, wj(2) are hidden-to-output weights, and b(2) is output bias.

- Loss function with Regularisation: To protect against overfitting and achieve good generalisation, the loss function combines Mean Squared Error (MSE) and L2 regularisation. This is indicated in Equation (14):where ms (k + 1) and mse (k + 1) are the actual and estimated torsional torques at step time k + 1, respectively, N is the number of training samples, and λ is the regularisation hyperparameter, optimised via Bayesian regularisation with the value of 0.001.

5. Results

5.1. Testing of NARX NN Estimator

5.1.1. Testing in an Open-Loop Structure/Offline Testing

5.1.2. Testing of NARX NN in a Closed-Loop Structure

5.2. Experimental Verification

- RMSE: 0.0081 (95% CI: 0.0076–0.0086)

- MAE: 0.0049 (95% CI: 0.0048–0.0049)

6. Conclusions and Future Work

- -

- A NARX NN was trained using motor speed and torque as input signals, with the torsional torque as the target output. During offline simulations, the actual torsional torque (available from the simulation) was used as feedback to train, test, and validate the network. In real-time implementation, the NARX NN operates in an open-loop structure, where a model-based torsional torque is used as feedback instead of the network’s estimation.

- -

- For strong estimation accuracy and generalisation, the model-based feedback must be robust to measurement noise and parameter variation. To ensure this, a comparative study was conducted between the widely used filtered derivative disturbance observer (FDDOB) and the newly developed integral-based disturbance observer (IDOB). The IDOB demonstrated superior performance and was therefore selected for the proposed approach.

- -

- The proposed IDOB design is independent of the load parameters, which makes it inherently robust to load parameter changes. This eliminates the need for intensive tuning and parameter adjustment, which is a major drawback in state observers such as Luenberger Observers.

- -

- Although other model-based estimation methods like SMO, KF, EKF, and UKF could also be considered, the IDOB has a simpler design while maintaining robustness to load parameter changes without requiring additional tuning and complex setups.

- -

- Given these advantages, the IDOB was used to compute the torsional torque as feedback input to the open-loop NARX NN, forming a hybrid estimator for one-step-ahead torsional torque estimation. The NARX NN uses present and historical values of the motor speed, motor torque, and the calculated torsional torque to perform the estimation.

- -

- The proposed estimator was tested on a two-mass drive system with an IP controller and additional feedback from the estimated torsional torque. Both simulation and experimental results confirm the proposed estimator’s accuracy, robustness to noise, and adaptability to parameter variation, leading to effective vibration damping and smooth system operation.

- -

- The generalisation capability and computational efficiency of the proposed method were compared with several existing neural network estimators, including Long Short-Term Memory (LSTM) networks, Convolutional Neural Networks (CNNs), parallel neural networks, and feedforward neural networks trained using the Levenberg–Marquardt algorithm and genetic algorithms. The proposed method showed superior performance in terms of both generalisation and simplicity.

- -

- Enhancing training by experimenting with different activation functions, optimisation algorithms, and noise injections, and performing a more in-depth analysis of the estimator’s performance under variation in disturbance types and levels.

- -

- Improving damping performance by incorporating additional feedback from the torsional torque derivative. This will increase the quality and reliability of the proposed method for practical implementation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yue, H.; He, H.; Han, M. Study on torsional vibration characteristics and suppression of electric vehicles with dual-motor drive system. J. Frankl. Inst. 2023, 360, 380–402. [Google Scholar] [CrossRef]

- Szabat, K.; Orłowska-Kowalska, T. Vibration Suppression in a Two-Mass Drive System Using PI Speed Controller and Additional Feedbacks—Comparative Study. IEEE Trans. Ind. Electron. 2007, 54, 1193–1206. [Google Scholar] [CrossRef]

- Liu, X.; Qiu, J.; Kambrath, J.K.; Wang, Y.; Loh, C.P.; Blaabjerg, F. Torsional Vibration Suppression Control for Inverter-Driven Multi-Rotating Mass System Using Non-Ideal Generalised Integrator. IEEE Trans. Power Electron. 2024, 39, 2594–2607. [Google Scholar] [CrossRef]

- Dou, J.; Li, Z.; Yao, H.; Ding, M.; Wei, G. Torsional vibration suppression and electromechanical coupling characteristics of electric drive system considering misalignment. Appl. Math. Mech. 2024, 45, 1987–2010. [Google Scholar] [CrossRef]

- Derugo, P.; Kahsay, A.H.; Szabat, K.; Shikata, K.; Katsura, S. A Novel PI-Based Control Structure with Additional Feedback from Torsional Torque and Its Derivative for Damping Torsional Vibrations. Energies 2024, 17, 4786. [Google Scholar] [CrossRef]

- Zeinali, M.; Zanjani, S.M.; Yaghoubi, S.; Mosavi, A.; Fathollahi, A. Torque control in a two-mass resonant system: Simulation and dynamic analysis. In Proceedings of the 2023 IEEE 17th International Symposium on Applied Computational Intelligence and Informatics (SACI), Timisoara, Romania, 23–26 May 2023; IEEE: Piscataway Township, NJ, USA, 2023; pp. 551–556. [Google Scholar]

- Serkies, P.; Szabat, K. Effective damping of the torsional vibrations of the drive system with an elastic joint based on the forced dynamic control algorithms. J. Vib. Control. 2019, 25, 2225–2236. [Google Scholar] [CrossRef]

- Li, Q.; Xu, Q.; Wu, R. Low-frequency vibration suppression control in a two-mass system by using a torque feed-forward and disturbance torque observer. J. Power Electron. 2016, 16, 249–258. [Google Scholar] [CrossRef]

- Ye, J.; Cui, J.; Chu, Z. Experimental study of vibration suppression for uncertain two-mass torsional system. In Proceedings of the 2016 12th IEEE International Conference on Control and Automation (ICCA), Mauritius, Africa, 8–11 May 2016; IEEE: Piscataway Township, NJ, USA, 2016; pp. 996–1001. [Google Scholar]

- Derugo, P.; Szabat, K. Damping of torsional vibrations of two-mass system using adaptive low computational cost fuzzy PID controller. In Proceedings of the 2015 IEEE 11th International Conference on Power Electronics and Drive Systems, Sydney, Australia, 9–12 June 2015; IEEE: Piscataway Township, NJ, USA, 2015; pp. 1162–1165. [Google Scholar]

- Yang, M.; Wang, C.; Xu, D.; Zheng, W.; Lang, X. Shaft torque limiting control using shaft torque compensator for two-inertia elastic system with backlash. IEEE/ASME Trans. Mechatron. 2016, 21, 2902–2911. [Google Scholar] [CrossRef]

- Liu, X.; Qi, Y.; Tang, Y.; Guan, Y.; Wang, P.; Blaabjerg, F. Unified active damping control algorithm of inverter for LCL resonance and mechanical torsional vibration suppression. IEEE Trans. Ind. Electron. 2021, 69, 6611–6623. [Google Scholar] [CrossRef]

- Kaminski, M.; Malarczyk, M. Hardware implementation of neural shaft torque estimator using low-cost microcontroller board. In Proceedings of the 2021 25th International Conference on Methods and Models in Automation and Robotics (MMAR), Międzyzdroje, Poland, 23–28 August 2021; IEEE: Piscataway Township, NJ, USA, 2021; pp. 372–377. [Google Scholar]

- Li, W.; Hori, Y. Vibration suppression using single neuron-based PI fuzzy controller and fractional-order disturbance observer. IEEE Trans. Ind. Electron. 2007, 54, 117–126. [Google Scholar] [CrossRef]

- Padron, J.; Kawai, Y.; Yokokura, Y.; Ohishi, K.; Miyazaki, T. A Method for Gear Impact Suppression In Torsion Torque Control of Two-Inertia Systems with Backlash. In Proceedings of the 2021 IEEE 30th International Symposium on Industrial Electronics (ISIE), Kyoto, Japan, 20–23 June 2021; IEEE: Piscataway Township, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Saarakkala, S.E.; Hinkkanen, M. State-space speed control of two-mass mechanical systems: Analytical tuning and experimental evaluation. IEEE Trans. Ind. Appl. 2014, 50, 3428–3437. [Google Scholar] [CrossRef]

- Niu, Z.; Huang, W.; Zhu, S.; Jia, B.; Zhu, Q.; Lu, X. Controller Design and Shaft Torque Vibration Suppression for Servomechanism With Elasticity. IEEE Trans. Ind. Applications. 2024, 60, 8833–8844. [Google Scholar] [CrossRef]

- Wang, C.; Chen, S.; Zhuang, Y.; Pan, J. Limiting Control and Accurate Observation of Transmission Torque and Its Jerk in Elastic Servo Systems. IEEE/ASME Trans. Mechatronics 2024, 1–11. [Google Scholar] [CrossRef]

- Zhang, G. Comparison of control schemes for two-inertia system. In Proceedings of the IEEE 1999 International Conference on Power Electronics and Drive Systems, PEDS’99 (Cat. No. 99TH8475), Hong Kong SAR, China, 27–29 July 1999; IEEE: Piscataway Township, NJ, USA, 1999; Volume 1, pp. 573–578. [Google Scholar]

- Wang, C.; Zhuang, Y.; Yang, J.; Liu, Y.; Pan, J. Characteristic Analysis and Control Loop Design of Transmission Torque and Jerk for Flexible Joint Servo Systems. IEEE Trans. Power Electron. 2024, 39, 8528–8539. [Google Scholar] [CrossRef]

- Ma, Y.; Qin, T.; Li, Y. Nonlinear extended state observer based super-twisting terminal sliding mode synchronous control for parallel drive systems. IEEE/ASME Trans. Mechatron. 2023, 28, 3087–3098. [Google Scholar] [CrossRef]

- Wang, C.; Liu, J.; Xin, L.; Li, G.; Pan, J. Design of full-order state observer for two-mass joint servo system based on the fixed gain filter. IEEE Trans. Power Electron. 2022, 37, 10466–10475. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, K.; Zhou, J.; Sang, P.; Wu, H.; Chen, Y. Linear extended state observer based anti-interference robust position tracking control for two-inertia systems with uncertain load disturbance. In Proceedings of the 2022 25th International Conference on Electrical Machines and Systems (ICEMS), Chiang Mai, Thailand, 29 November–2 December 2022; IEEE: Piscataway Township, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Wang, C.; Yang, M.; Zheng, W.; Long, J.; Xu, D. Vibration suppression with shaft torque limitation using explicit MPC-PI switching control in elastic drive systems. IEEE Trans. Ind. Electron. 2015, 62, 6855–6867. [Google Scholar] [CrossRef]

- Szabat, K.; Orlowska-Kowalska, T. Performance Improvement of Industrial Drives With Mechanical Elasticity Using Nonlinear Adaptive Kalman Filter. IEEE Trans. Ind. Electron. 2008, 55, 1075–1084. [Google Scholar] [CrossRef]

- Mahapatra, S.; Shrivastava, A.; Sahoo, B.; Mohanty, A.R. Estimation of torque variation due to torsional vibration in a rotating system using a kalman filter-based approach. J. Vib. Eng. Technol. 2023, 11, 1939–1950. [Google Scholar] [CrossRef]

- Wu, J.; Walker, P.D.; Ruan, J.; Zhang, N. Target torque estimation for gearshift in dual clutch transmission with uncertain parameters. Appl. Math. Model. 2017, 51, 1–20. [Google Scholar] [CrossRef]

- Dróżdż, K.; Orłowska-Kowalska, T.; Szabat, K. Application of the modified fuzzy Kalman filter to states estimation of the two-mass system. In Proceedings of the 2015 IEEE International Conference on Industrial Technology (ICIT), Seville, Spain, 17–19 March 2015; IEEE: Piscataway Township, NJ, USA, 2015; pp. 634–639. [Google Scholar]

- Lin, C.; Sun, S.; Yi, J.; Walker, P.; Zhang, N. Accelerated adaptive super twisting sliding mode observer-based drive shaft torque estimation for electric vehicle with automated manual transmission. IET Intell. Transp. Syst. 2019, 13, 160–167. [Google Scholar] [CrossRef]

- Chang, H.; Lu, S.; Huang, G.; Zheng, S.; Song, B. An extended active resonance suppression scheme based on a dual-layer network for high-performance double-inertia drive system. IEEE Trans. Power Electron. 2023, 38, 13717–13729. [Google Scholar] [CrossRef]

- Yang, C.; Song, B.; Xie, Y.; Tang, X. Online parallel estimation of mechanical parameters for PMSM drives via a network of interconnected extended sliding-mode observers. IEEE Trans. Power Electron. 2021, 36, 11818–11834. [Google Scholar] [CrossRef]

- Yang, M.; Zheng, W.; Yang, K.; Xu, D. Suppression of mechanical resonance using torque disturbance observer for two-inertia system with backlash. In Proceedings of the 2015 9th International Conference on Power Electronics and ECCE Asia (ICPE-ECCE Asia), Seoul, Republic of Korea, 1–5 June 2015; IEEE: Piscataway Township, NJ, USA, 2015; pp. 1860–1866. [Google Scholar]

- Wang, M.; Sun, L.; Yin, W.; Dong, S.; Liu, J. A novel sliding mode control for series elastic actuator torque tracking with an extended disturbance observer. In Proceedings of the 2015 IEEE International Conference on Robotics and Biomimetics (ROBIO), Zhuhai, China, 6–9 December 2015; IEEE: Piscataway Township, NJ, USA, 2015; pp. 2407–2412. [Google Scholar]

- Kim, D.H.; Choi, S.B. Extended high-order disturbance observer-based clutch actuator model uncertainty estimation of ball-ramp dual-clutch transmission. IEEE Trans. Control. Syst. Technol. 2022, 31, 1220–1234. [Google Scholar] [CrossRef]

- Magnani, G.; Rocco, P.; Bascetta, L.; Rusconi, A. On the use of Torque Disturbance Observers in 2-mass systems with application to a robotic joint. In Proceedings of the 2013 IEEE International Conference on Mechatronics (ICM), Vicenza, Italy, 27 February–1 March 2013; IEEE: Piscataway Township, NJ, USA, 2013; pp. 798–803. [Google Scholar]

- Sugiura, K.; Hori, Y. Vibration suppression in 2-and 3-mass system based on the feedback of imperfect derivative of the estimated torsional torque. IEEE Trans. Ind. Electron. 1996, 43, 56–64. [Google Scholar] [CrossRef]

- Rahimi, M.; Beiki, A. Efficient modification of the control system in PMSG-based wind turbine for improvement of the wind turbine dynamic response and suppression of torsional oscillations. Int. Trans. Electr. Energy Syst. 2018, 28, e2578. [Google Scholar] [CrossRef]

- Orlowska-Kowalska, T.; Szabat, K. Neural-network application for mechanical variables estimation of a two-mass drive system. IEEE Trans. Ind. Electron. 2007, 54, 1352–1364. [Google Scholar] [CrossRef]

- Orlowska-Kowalska, T.; Kaminski, M. Application of the OBD method for optimization of neural state variable estimators of the two-mass drive system. Neurocomputing 2009, 72, 3034–3045. [Google Scholar] [CrossRef]

- Shang, D.; Li, X.; Yin, M.; Li, F. Dynamic modeling and control for dual-flexible servo system considering two-dimensional deformation based on neural network compensation. Mech. Mach. Theory 2022, 175, 104954. [Google Scholar] [CrossRef]

- Kamiński, M.; Szabat, K. Neuro-fuzzy state variables estimators of a two-mass drive system. In Proceedings of the 2015 IEEE International Conference on Industrial Technology (ICIT), Seville, Spain, 17–19 March 2015; IEEE: Piscataway Township, NJ, USA, 2015; pp. 1723–1728. [Google Scholar]

- Kaczmarczyk, G.; Stanislawski, R.; Kaminski, M. Deep-Learning Techniques Applied for State-Variables Estimation of Two-Mass System. Energies 2025, 18, 568. [Google Scholar] [CrossRef]

- Kamiński, M. Neural estimators of two-mass system optimized using the Levenberg-Marquardt training and genetic algorithm. In Proceedings of the 2016 21st International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 29 August–1 September 2016; IEEE: Piscataway Township, NJ, USA, 2016; pp. 559–564. [Google Scholar]

- Hatata, A.Y.; Eladawy, M. Prediction of the true harmonic current contribution of nonlinear loads using NARX neural network. Alex. Eng. J. 2018, 57, 1509–1518. [Google Scholar] [CrossRef]

- Asvadi-Kermani, O.; Felegari, B.; Momeni, H.; Davari, S.A.; Rodriguez, J. Dynamic neural-based model predictive voltage controller for an interleaved boost converter with adaptive constraint tuning. IEEE Trans. Ind. Electron. 2023, 70, 12739–12751. [Google Scholar] [CrossRef]

- Capriglione, D.; Carratù, M.; Pietrosanto, A.; Sommella, P. NARX ANN-based instrument fault detection in motorcycle. Measurement 2018, 117, 304–311. [Google Scholar] [CrossRef]

- Araújo, V.G.D.; Bissiriou, A.O.S.; Villanueva, J.M.M.; Villarreal, E.R.L.; Salazar, A.O.; Teixeira, R.D.A.; Fonsêca, D.A.D.M. Monitoring and Diagnosing Faults in Induction Motors’ Three-Phase Systems Using NARX Neural Network. Energies 2024, 17, 4609. [Google Scholar] [CrossRef]

- Xia, Y.; Xu, Y.; Gou, B.; Deng, Q. A learning-based method for speed sensor fault diagnosis of induction motor drive systems. IEEE Trans. Instrum. Meas. 2021, 71, 1–10. [Google Scholar] [CrossRef]

- Liu, J.; Li, T.; Zhang, Z.; Chen, J. NARX prediction-based parameters online tuning method of intelligent PID system. IEEE Access 2020, 8, 130922–130936. [Google Scholar] [CrossRef]

| Model-Based Torsional Torque Calculation | MAE | |

|---|---|---|

| Without Noise | With Noise | |

| IDOB | 0.0145 | 0.0192 |

| FDDOB | 0.0375 | 0.0474 |

| T2N | 2*T2N | 3*T2N | 0.5*T2N | |

|---|---|---|---|---|

| RMSE | 0.0098 | 0.0150 | 0.0180 | 0.0070 |

| MAE | 0.0050 | 0.0083 | 0.0105 | 0.0034 |

| T2N | 2*T2N | 3*T2N | 0.5*T2N | |

|---|---|---|---|---|

| RMSE | 0.0194 | 0.0154 | 0.0167 | 0.0070 |

| MAE | 0.0129 | 0.0116 | 0.0129 | 0.0175 |

| T2N | 2 T2N | 3 T2N | |

|---|---|---|---|

| RMSE | 0.0061 | 0.0063 | 0.0070 |

| MAE | 0.0047 | 0.0047 | 0.0057 |

| Neural Network Estimator Type | MAE for | Error Increasing (+) or Decreasing (−) Factor Compared to Nominal Value | |||

|---|---|---|---|---|---|

| Nominal Value of Load Time Constant (T2N) | Twice the Nominal Value of Load Time Constant (2*T2N) | Three Times the Nominal Value of Load Time Constant (3*T2N) | Twice the Nominal Value (2*T2N) | Three Times the Nominal Value (3*T2N) | |

| LSTM [42] | 2.05% | N/A | 9.09% | N/A | +7.04% |

| CNN [42] | 2.02% | N/A | 9.10% | N/A | +7.08% |

| Parallel neural network, [42] | 2.07% | N/A | 8.36% | N/A | +6.29% |

| Feed forward NN optimised by Levenberg–Marquardt training and genetic algorithm [43] | 1.00% | 2.54% | N/A | 1.54% | N/A |

| Proposed method (NARX NN + model-based feedback) | 0.47% | 0.47% | 0.57% | 0% | 0.1% |

| Neural Network Estimator Type | Number of Inputs | Number of Hidden Layers | Total Number of Hidden/Output Layer Neurons | Hidden/Output Layer Activation Function Type | Filter Application |

|---|---|---|---|---|---|

| LSTM [1] | 2 | 4 | 85 | sigmoid and tanh/linear | Yes |

| CNN [1] | 2 | 3 | 96 | sigmoid, and tanh/linear | Yes |

| Parallel neural network [1] | 2 | 7 | 117 | ReLU, sigmoid, and tanh/linear | Yes |

| Feed forward NN optimised by Levenberg–Marquardt training and genetic algorithm [2] | 6 | 2 | 12 | tanh/linear | Yes, with a 5 ms filter time constant |

| Proposed method (NARX NN + model-based feedback) | 5 | 1 | 6 neurons, and an additional 3 integration, 3 summation, and 3 multiplication operations from the model-based feedback. | tanh/linear | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kahsay, A.H.; Derugo, P.; Majdański, P.; Zawiślak, R. Hybrid NARX Neural Network with Model-Based Feedback for Predictive Torsional Torque Estimation in Electric Drive with Elastic Connection. Energies 2025, 18, 3770. https://doi.org/10.3390/en18143770

Kahsay AH, Derugo P, Majdański P, Zawiślak R. Hybrid NARX Neural Network with Model-Based Feedback for Predictive Torsional Torque Estimation in Electric Drive with Elastic Connection. Energies. 2025; 18(14):3770. https://doi.org/10.3390/en18143770

Chicago/Turabian StyleKahsay, Amanuel Haftu, Piotr Derugo, Piotr Majdański, and Rafał Zawiślak. 2025. "Hybrid NARX Neural Network with Model-Based Feedback for Predictive Torsional Torque Estimation in Electric Drive with Elastic Connection" Energies 18, no. 14: 3770. https://doi.org/10.3390/en18143770

APA StyleKahsay, A. H., Derugo, P., Majdański, P., & Zawiślak, R. (2025). Hybrid NARX Neural Network with Model-Based Feedback for Predictive Torsional Torque Estimation in Electric Drive with Elastic Connection. Energies, 18(14), 3770. https://doi.org/10.3390/en18143770