Abstract

Water, acetone, and TiO2/nano-silver water (NSW) nanofluids were investigated as working fluids in loop thermosyphon battery thermal management systems (LTBMS) under simulated electric vehicle (EV) conditions to evaluate scalability and robustness across inclinations (0° to 60°) and ambient temperatures (−10 °C to 20 °C). Experimental conditions were established with 60 °C as the reference temperature, corresponding to the onset of battery thermal runaway, to ensure relevance to critical thermal management scenarios. Results indicate that LTBMS A maintained battery cell temperatures at 50.4 °C with water and 31.6 °C with acetone under a 50 W heat load. In contrast, LTBMS B achieved cell temperatures of 41.8 °C with water and 42.8 °C with 0.01 vol% TiO2 nanofluid, however, performance deteriorated at higher nanofluid concentrations due to increased viscosity and related thermophysical constraints. In heating mode, LTBMS A elevated cell temperatures by 16 °C at an ambient temperature of −10 °C using acetone, while LTBMS B attained 52–55 °C at a 100 W heat load with nanofluids. The lightweight LTBMS design demonstrated superior thermal performance compared to conventional air-cooling systems and performance comparable to liquid-cooling systems. Pure water proved to be the most effective working fluid, while nanofluids require further optimization to enhance their practical applicability in EV thermal management.

1. Introduction

Electric vehicles (EVs) represent a transformative shift in transportation, combining sustainability and innovation to address global energy challenges. Central to their performance is the thermal management of high energy density lithium-ion batteries, which are prone to overheating during rapid charge-discharge cycles and require heating in cold climates to maintain optimal operation. Effective battery thermal management systems (BTMSs) are critical for enhancing efficiency, ensuring safety, and extending battery longevity [1,2,3]. Existing battery thermal management system (BTMS) technologies are reviewed and categorized into three groups: conventional cooling methods, heat pipe-based systems, and hybrid and emerging technologies. Through a critical evaluation of these approaches, key research gaps are identified, particularly in managing the 60 °C onset temperature of battery thermal runaway and optimizing dual-purpose thermal management. The proposed loop thermosyphon-based BTMS addresses these gaps by offering an efficient, dual-function (cooling and heating) solution designed for next-generation electric vehicles (EVs).

1.1. The Principle of Heat Pipes

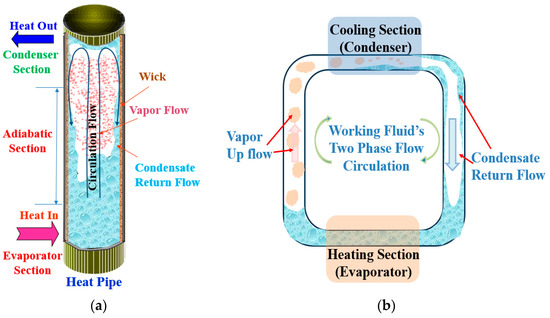

Heat pipes and loop thermosyphons utilize phase change principles for efficient heat transfer, as illustrated in Figure 1. Conventional heat pipes, as shown in Figure 1a, absorb heat in the evaporator section, where the working fluid boils into vapor, which then travels under pressure gradients to the condenser section, releasing latent heat upon condensation. A wick structure facilitates liquid return to the evaporator via capillary action, enabling orientation-independent operation [4,5]. In contrast, the loop thermosyphon, depicted in Figure 1b, is a wickless, closed-loop system relying on pressure difference and gravity-driven circulation. The working fluid evaporates at the heat source, flows to the condenser to release heat, and returns to the evaporator without a wick, simplifying design but requiring proper orientation [6,7]. This wickless copper-based loop thermosyphon, used in the LTBMS, reduces complexity and cost, achieving cell temperatures with uniformity. Its scalability makes it ideal for EV battery cooling and extends to other energy storage systems, such as supercapacitors in railway traction [8] and regenerative braking [9], offering a versatile, cost-effective thermal management solution.

Figure 1.

Principle of heat pipes. (a) Heat pipe; (b) Loop thermosyphon.

1.2. Heat Pipes in Battery Thermal Management Systems (BTMS)

The evolution of EV battery systems has intensified thermal management demands. Early air-cooling systems, while simple and cost-effective, proved inadequate for modern high energy density batteries due to limited heat dissipation and poor thermal uniformity, often resulting in cell temperatures exceeding 60 °C under high loads [4,10]. Liquid cooling systems, using fluids like water or ethylene glycol, offer improved thermal regulation, maintaining cell temperatures below 50 °C, but introduce significant weight and complexity due to pumps and reservoirs, increasing maintenance and energy consumption [11]. To address these limitations, heat pipe-based solutions have gained prominence. Studies like Liu et al. modeled the dynamic thermal characteristics of heat pipes for EV battery cooling, demonstrating their ability to manage transient heat loads effectively [12]. Similarly, Sun and Dixon explored air-cooled strategies enhanced by heat pipes, achieving improved thermal regulation over traditional methods [13]. The proposed LTBMS leverages a wickless loop thermosyphon to combine the simplicity of air cooling with the efficiency of liquid cooling, offering a lightweight and passive solution capable of maintaining cell temperatures below 55 °C at 50 W, as detailed in subsequent sections. Oh et al. [14] developed a two-phase immersion cooling system with heat pipes using NovecTM 649, achieving thermal resistance of 0.3848–0.4549 °C/W and maintaining 27–34 °C at 10–20 W. Kim et al. [15] investigated heat pipe-embedded immersion cooling, emphasizing wick structures and porosity for efficient heat exchange. Chi et al. [16,17] and Chung et al. [18] explored oscillating heat pipes (OHPs) for bottom cooling, achieving 0.6 °C/W resistance and temperatures below 60 °C at 14 W, with ethanol and coolant temperature as key variables. Lee et al. [19] proposed anti-gravity 3D pulsating heat pipes (PHPs) with methanol and Novec7100, identifying optimal filling ratios (15–20%) for 50–150 W, with design variations affecting performance. Validated by experiments and 1D modeling, these scalable solutions mitigate thermal runaway and improve energy efficiency for EV battery applications. These advancements underscore heat pipes’ potential as a passive, efficient alternative for BTMS [10,11,12,13,14,15,16,17,18,19].

1.3. Hybrid Systems and Emerging Technologies

To address the limitations of standalone heat pipe systems, hybrid BTMS integrating phase change materials (PCMs) and advanced fluids have gained attention. Lv et al. [20] enhanced PCMs with low-density polyethylene and fins, improving heat absorption and temperature uniformity. Nazir et al. [21] reviewed PCM advancements, noting their ability to buffer thermal spikes during high discharge rates. Fang et al. [22] combined PCMs with porous materials, enhancing thermal conductivity and stability. Advanced working fluids, such as nanofluids containing TiO2 or silver nanoparticles, have also been explored to improve heat transfer efficiency [21,22]. He et al. [23] and Liu et al. [24] emphasized structural integration of heat pipes into battery modules to minimize thermal gradients and enhance safety. Computational fluid dynamics (CFD) and artificial intelligence (AI) have further optimized these systems, with Nicholls [25] and Wang et al. [26] demonstrating improved heat dissipation through multilevel simulations and nano-emulsion PCMs. Two-phase loop thermosyphons, as studied by Jang et al. [27] and Kong et al. [28], offer simplicity and reliability by eliminating wick structures, making them suitable for EV applications. However, challenges remain in optimizing nanofluid concentrations, ensuring sustainability, and scaling these systems for high-voltage batteries, as noted by Goodenough and Kim [29], Hu et al. [30], and Yang et al. [31].

1.4. Innovative Applications: Two-Phase Loop Thermosyphons

Two-phase loop thermosyphons represent a promising advancement in battery thermal management systems (BTMS), offering simplicity, reliability, and passive operation compared to traditional heat pipes or liquid cooling systems. Unlike wicked heat pipes, loop thermosyphons rely on gravity-driven circulation, eliminating capillary structures and reducing manufacturing complexity and cost [27,28]. While loop thermosyphons have been extensively utilized in stationary applications, such as heat dissipation in data centers and communication base stations [32]; their application to electric vehicle (EV) BTMS remains unprecedented, as no prior studies have reported their use for lithium-ion battery thermal management in EVs. This research gap underscores the potential for innovative thermal management solutions tailored to EV requirements. Adapting loop thermosyphons to EV BTMS presents significant challenges absent in stationary systems. EVs operate under dynamic inclinations (0–60° in roll and yaw), which can disrupt gravity-driven fluid circulation, reducing heat transfer efficiency [27]. Extreme ambient temperatures (−10 °C to 20 °C) require robust performance in both cooling and heating modes to prevent thermal runaway and maintain battery performance in cold climates [12]. Stringent weight and space constraints necessitate lightweight, compact designs without compromising thermal conductivity [29]. Additionally, the use of advanced working fluids, such as nanofluids, introduces challenges related to viscosity and nanoparticle aggregation, which can hinder circulation and increase thermal resistance [21]. These issues demand novel designs capable of dual functionality and scalability for dynamic EV applications. Research on loop thermosyphons for EV BTMS is sparse, with most studies focusing on heat pipes or liquid cooling systems [12,13,14,15,16,17,18,19]. Jang et al. [27] investigated loop thermosyphons under nonuniform heating for pouch-type batteries, demonstrating potential for thermal uniformity, but did not address EV-specific conditions like inclinations or cold climate heating. Kong et al. [28] explored synergistic battery protection approaches but focused on electrochemical rather than thermal management. In stationary applications, loop thermosyphons have achieved high heat transfer efficiencies [32], but their adaptation to EVs requires overcoming orientation sensitivity and integrating advanced fluids, which remain underexplored [21,22]. This gap highlights the need for research into loop thermosyphons for EV BTMS to advance sustainable thermal management solutions.

1.5. Research Gaps and Current Study

As compared in Table 1, recent advancements in battery thermal management systems (BTMS) have explored various cooling methods to enhance thermal performance. Air cooling remains the most cost-effective but is inadequate for high-performance applications, often leading to temperatures exceeding safe limits. Liquid cooling systems, while more efficient, introduce complexity and higher costs. Phase change materials (PCMs) provide passive cooling but are not yet widely commercialized. Heat pipe cooling offers flexibility and efficiency but requires careful integration. Hybrid systems that combine multiple cooling methods show promise in optimizing performance. Direct liquid cooling has demonstrated superior thermal performance, particularly in high-demand scenarios, while nanofluid cooling is emerging as a highly effective solution, although still largely in the research phase. These insights contribute to the development of safer and more efficient battery systems for electric vehicles and energy storage applications, highlighting the need for ongoing research and innovation in battery cooling technologies [33,34,35,36,37,38].

Table 1.

Comparison of battery cooling methods.

Despite advancements in battery thermal management systems (BTMS), several research gaps and challenges remain. Most studies focus exclusively on cooling, overlooking the need for heating in subzero climates to maintain lithium-ion battery performance [12,13,14,15,16,17,18,19]. Additionally, hybrid systems and nanofluids, while improving thermal performance, introduce complexity and high viscosity at elevated concentrations, hindering fluid circulation and scalability [21,22]. The sustainability and cost-effectiveness of heat pipe-based BTMS also require further exploration, as manufacturing precision, recyclable materials, and non-toxic fluids are critical for practical EV adoption [29,30]. Moreover, comprehensive evaluations under real-world EV conditions, such as varying inclinations and ambient temperatures, are lacking. The present study addresses these gaps by proposing a loop thermosyphon-based BTMS (LTBMS) that enables both cooling and heating. Its wickless, air-cooled design eliminates pumps and complex liquid systems, enhancing reliability and reducing costs. By systematically testing parameters such as working fluid type, filling ratio, inclination angle, ambient temperature, and heating load under simulated EV conditions, this study demonstrates a scalable, sustainable solution for next-generation BTMS.

However, challenges persist. High nanoparticle concentrations in nanofluids increase viscosity, impairing siphon dynamics and heat transfer efficiency [32]. Manufacturing heat pipes demands cost-effective methods and lightweight materials, such as carbon composites, to minimize EV weight while maintaining performance [29,31]. Future research should focus on hybrid systems integrating heat pipes with phase change materials (PCMs) and liquid cooling, optimized via computational fluid dynamics (CFD) and artificial intelligence (AI), to meet high-voltage battery demands. Addressing engineering constraints, including system weight and cost, will be crucial for practical EV implementation.

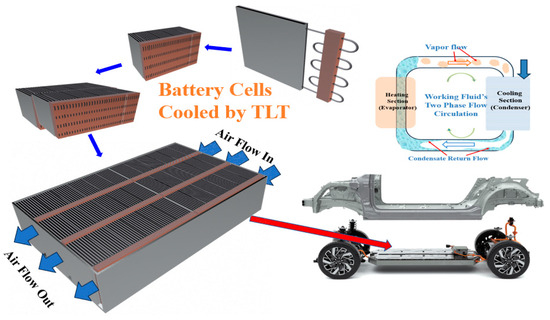

The present study introduces a novel loop thermosyphon-based battery thermal management system (LTBMS) featuring three key innovations: (1) a simplified wickless loop thermosyphon design fabricated from copper to ensure superior thermal conductivity, cost-effective production, and scalability; (2) the use of TiO2 and nano-silver water nanofluids to enhance heat transfer performance; and (3) a hybrid air cooling approach that integrates passive thermosyphon circulation with active airflow for optimized thermal efficiency. As shown in Figure 2, the proposed BTMS is based on a straightforward air cooling concept, moving away from conventional complex liquid cooling systems. The originality of this research lies in its emphasis on practical applicability: that loop thermosyphons eliminate the need for wicks or additional components, resulting in a simpler, more reliable, and cost-effective solution suitable for electric vehicle (EV) applications. Through experiments conducted under controlled conditions simulating real-world electric vehicle operation, this study provides critical insights into the design and optimization of loop thermosyphon-based battery thermal management systems (BTMS). These systems are engineered to meet the stringent thermal demands of modern high-capacity lithium-ion batteries, particularly in maintaining cell temperatures below the 60 °C thermal runaway onset threshold. The findings contribute to the development of next-generation BTMS that are highly efficient, scalable, and economically viable.

Figure 2.

Concept of battery thermal management system.

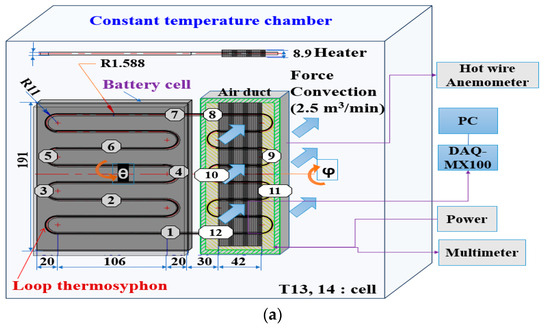

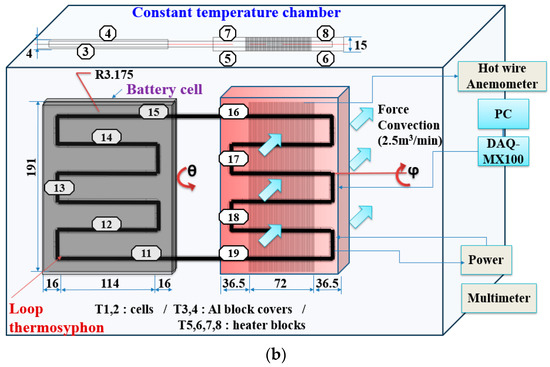

2. Experimental

The present study investigates the thermal performance of a loop thermosyphon-based battery thermal management system (LTBMS) designed to regulate lithium-ion batteries in electric vehicles (EVs) under both cooling and heating conditions. Two configurations, LTBMS A and LTBMS B, were developed to assess the impact of thermosyphon pipe diameter and structural design on heat transfer efficiency and temperature control. Figure 3 provides a detailed schematic of the experimental apparatus, which integrates a loop thermosyphon with battery simulators and an air-cooled condenser section. The design of the LTBMS system and experimental conditions were established based on pre-simulation results of battery heat transfer behavior using thermal resistance modeling. These simulations informed the selection of working fluids, loop geometry, and operating orientation and set the design objective of maintaining battery temperatures below 60 °C under 50 W of thermal input. This threshold reflects practical thermal management needs in EV battery packs. Further analysis on how varying heat generation rates affect thermal response will be pursued in future designs beyond the scope of this study.

Figure 3.

Loop thermosyphon battery thermal management systems. (a) LTBMS A; (b) LTBMS B.

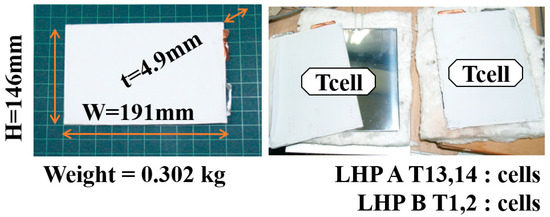

The battery simulator, designed to replicate the thermal behavior of a lithium-ion polymer battery cell, consists of two fully discharged lithium-ion polymer cells (191 mm × 146 mm × 8 mm), each paired with a 50 W electronic plate heater block to simulate heat generation during discharge cycles, as shown in Figure 4. The thermal parameters of the simulator were determined by comparing temperature measurements under controlled heat inputs (50 W) with the known heat capacity of water as a reference fluid in a calibrated thermal setup. This method involved measuring the temperature rise in the simulator relative to a water-based reference under identical heat loads, yielding a thermal conductivity of k = 0.45 W/m·°C ± 1.5% and a specific heat capacity of C = 0.15 cal/g·°C ± 15.5%. These values were validated against the literature data from [39,40], which reported thermal conductivities of 0.4–0.5 W/m·°C for lithium-ion battery electrodes under similar discharge conditions, and [39], which reported specific heat capacities of 0.17–0.26 cal/g·°C for lithium-ion cells in dynamic thermal models [40]. This validation confirms the simulator’s representativeness for EV battery applications. Embedded copper thermosyphon pipes in direct contact with the cell surface maximize heat transfer efficiency, while the heater block, featuring embedded heating wires, provides a controlled and repeatable heat source to replicate thermal loads encountered in EV operation. Heat generation was measured at 50 W using a Hioki 3286-20 clamp power meter (Hioki E.E. Corporation, Ueda, Japan, ±1.8% accuracy), corresponding to a 1–2C discharge rate for ~20–30 Ah cells. This was validated against Bernardi’s simplified heat generation model (Q = I2R + I∙T∙ΔS, I2R for Joule heating, I∙T∙ΔS for entropic heat), which predicts 48–70 W for 1–2C discharge of Li-ion cells. The measured 50 W aligns within this range, confirming accuracy. A baseline test under natural convection (50 W, no cooling) showed the simulator reached 60 °C in 20 min, consistent with Li-ion cell behavior [41,42].

Figure 4.

Lithium-ion polymer battery simulator heating module.

The loop thermosyphon, fabricated from copper tubing, connects the battery cells to an air-cooled condenser equipped with 0.5 mm thick aluminum fins. LTBMS A utilizes a thermosyphon pipe with a one-eighth-inch (3.175 mm) diameter, complemented by 29 fins (8.9 mm × 191 mm), a 42 mm × 191 mm duct, and a single 120 mm × 120 mm fan delivering an airflow rate of 2.5 m3/min. In contrast, LTBMS B employs a larger one-quarter-inch (6.35 mm) diameter pipe, paired with 53 fins (15 mm × 191 mm), a 72 mm × 191 mm duct, and two 80 mm × 80 mm fans, collectively maintaining the same 2.5 m3/min airflow. These structural differences allow for a comparative evaluation of heat transfer capacity and fluid circulation dynamics, with LTBMS B designed to offer enhanced flexibility for testing diverse working fluids and conditions. Heating wires embedded between the condenser fins enable controlled heating, reversing the thermosyphon’s flow direction for low-temperature scenarios, thus supporting the system’s dual-purpose functionality. Table 2 summarizes the specifications of both configurations, highlighting the key design variations.

Table 2.

Specification experimental two LTBMS.

Prior to testing, each loop thermosyphon was evacuated to a pressure of 5 × 10−3 torr using a DPF-4Z & GHP 240K vacuum pump (KODIVAC, Seoul, The Republic of Korea, ultimate pressure 1 × 10−7 torr) to eliminate non-condensable gases, ensuring efficient phase change operation. Various working fluids were introduced to evaluate their thermal properties. Pure water, selected for its high latent heat of vaporization and thermal stability, and acetone, chosen for its low boiling point and suitability for subzero heating, were tested as baseline fluids. Two LTBMS models were tested to address scalability challenges in EV battery thermal management, balancing cost, weight, and performance. LTBMS A utilized cost-effective baseline fluids: pure water, selected for its high latent heat of vaporization and thermal stability, and acetone, chosen for its low boiling point and suitability for subzero heating to establish a low-cost reference. LTBMS B employed nanofluids, supplied by Advanced Nano Products (ANP Inc., Sejong, The Republic of Korea), consisting of TiO2 nanoparticles and nano silver water (NSW) dispersed in pure water at volume concentrations of 0.01%, 0.05%, 0.1%, and 0.5%, with hybrid nanofluids (TiO2 + NSW) tested at 5:5 and 8:2 ratios (0.1% total concentration). Nanofluid stability during the experiment was ensured through controlled preparation and short test duration. Both TiO2 and nano-silver water (NSW) nanofluids were freshly prepared via a 2 h ultrasonication process immediately prior to testing. Although some degree of sedimentation or aggregation was observed, this study was not specifically aimed at investigating time-dependent changes in nanofluid properties. Therefore, no detailed analysis was conducted on long-term stability or property evolution. Nevertheless, while slight color changes in the nanofluid were observed after each experiment, consistent temperature responses were still detected throughout operation, suggesting that short-term dispersion stability is acceptable under operational conditions. However, nanoparticle sedimentation and aggregation may still act as potential factors limiting the performance of the nanofluid system.

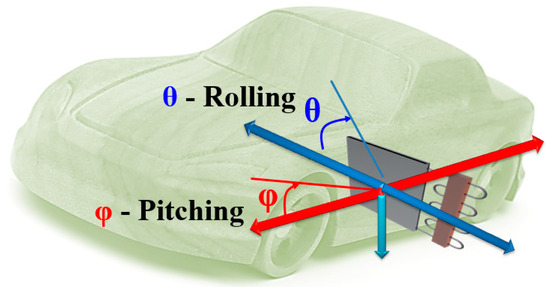

A filling ratio of 40% of the thermosyphon volume was selected based on preliminary tests to optimize liquid slug formation and vapor transport in the wickless loop thermosyphon, ensuring stable gravity-driven circulation under cooling (50 W) and heating (100 W) conditions (Table 3). Also, this ratio aligns with the literature findings, such as many of the previous literature [43,44,45,46], which recommend filling ratios of 40–60% for loop thermosyphons to ensure sufficient liquid inventory for evaporator wetting and efficient heat transfer. Also, in conventional vehicle design, as shown in Figure 5, typical driving angles are generally constrained to less than 7° for rolling, less than 5° for pitching, and approximately 15° for gradeability (corresponding to a 30% slope) [47]. Based on these constraints, the operational performance of the loop thermosiphon is expected to remain largely unaffected by variations in charge rate under such angular conditions. Moreover, the optimal filling ratio under these inclined orientations is anticipated to deviate only marginally from the baseline configuration at θ = 0° and φ = 0°. Therefore, the influence of angular orientation on the optimal filling ratio was considered beyond the scope of this study.

Table 3.

Experimental condition.

Figure 5.

Experimental TLT orientation.

Experiments were conducted in controlled cooling and heating modes to simulate EV battery operation across a range of ambient temperatures and vehicle orientations, as outlined in Table 3. For cooling mode, LTBMS A was tested with pure water and acetone at heat inputs of 25 W and 50 W, maintaining an ambient air temperature (Tair) of 10 °C. In this study, the inclination angles were extensively varied to replicate extreme driving conditions. The roll angle (θ) was adjusted from 300° to 60° with the pitch angle (φ) fixed at 0°, and the pitch angle (φ) was varied from 0° to 60° with θ fixed at 0°. These angles far exceed the typical range used in conventional vehicle design, thereby enabling an assessment of the applicability of the loop thermosiphon under extreme orientation conditions [47]. LTBMS B was evaluated at 50 W with pure water, TiO2 nanofluids, NSW, and hybrid nanofluids under identical conditions. In heating mode, LTBMS A utilized acetone to achieve target cell temperatures of 50 °C to 65 °C at ambient temperatures of −10 °C to 20 °C (Table 3). This was accomplished by activating heating wires embedded in the condenser section (Figure 3), which served as the evaporator, vaporizing the acetone. The vapor transferred heat to the battery cells (acting as the condenser), where it condensed, releasing latent heat to raise cell temperatures. The power input to the heaters was regulated using a 5 kVA Slide-AC voltage regulator (Pusan Electronics, Pusan, The Republic of Korea) to achieve steady-state target temperatures, monitored via K-type thermocouples at the cell surfaces and evaporator/condenser inlets (Figure 3). LTBMS B was tested with pure water, TiO2 nanofluids (0.01% to 0.5%), and TiO2 + NSW (5:5, 0.1%) at a 100 W heat input, following the same procedure, with the condenser section heated to vaporize the fluid and transfer heat to the cells.

Temperature measurements were performed using K-type thermocouples with an accuracy of ±0.05% of reading (OMEGA, Seoul, The Republic of Korea), positioned at 12 critical locations per system, including the evaporator inlet/outlet, condenser inlet/outlet, and cell surfaces, as depicted in Figure 3. Data were recorded at 1 s intervals using a Yokogawa MX100 (Yokogawa Inc., Tokyo, Japan) data acquisition system interfaced with a PC running MX100 software (R3.03.01). Power input was regulated with a 5 kVA Slide-AC voltage regulator (Pusan Electronics, Pusan, The Republic of Korea) and measured using a Hioki 3286-20 clamp power meter (Hioki Korea, Seoul, The Republic of Korea, accuracy ±1.3% for current, ±3 digits for power). Airflow velocity was verified with a Lutron AM-4204HA hot wire anemometer (Lutron Electronic Enterprise Co., Ltd., Taipei, Taiwan, accuracy ±5%). Measurement uncertainties were assessed to ensure data reliability. Temperature fluctuations stabilized at ±0.1 °C after calibration, power input uncertainty was ±1.8% at 50 W (due to ±0.75% + 10 digits for voltage and ±1.3% for current), and airflow uncertainty was ±0.125 m3/min at 2.5 m3/min. These errors primarily arose from instrument limitations, but their impact was minimized through repeated measurements and steady-state averaging.

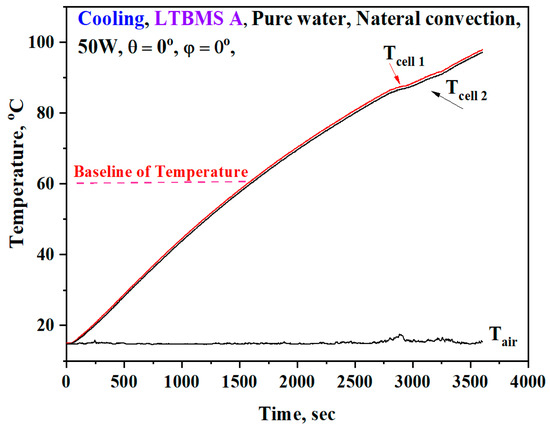

The lithium-ion polymer battery simulator, shown in Figure 4, replicates a fully discharged cell with embedded copper thermosyphon pipes for direct surface contact, maximizing heat transfer efficiency. The condenser section, equipped with fins and a duct, ensures uniform airflow distribution, with the system’s ability to switch between clockwise (cooling) and counterclockwise (heating) flow directions validated through temperature profile observations. As shown in Figure 6, baseline tests conducted under natural convection without thermosyphon operation confirmed the necessity of an active thermal management system. Under a heat load of 50 W, the cell temperature exceeded 55 °C within 23 min. This result provided an experimental environment in which the temperature was maintained below 60 °C, which is considered the onset point of thermal runaway for the battery in this study [1,24,29,30]. Additionally, environmental conditions for subzero testing were carefully controlled using a refrigerated chamber. This experimental approach establishes a robust framework for evaluating the dual-purpose thermal management capabilities of the LTBMS, offering precise insights into its performance across various operational scenarios. A comparative experiment conducted under natural convection without thermosyphon activation, as also shown in Figure 6, revealed a continuous rise in cell temperature. The temperature surpassed the operational limit of 55 °C for lithium-polymer batteries within 23 min and reached 98 °C after one hour. These results highlight the critical importance of implementing efficient thermal management solutions, particularly as battery technologies evolve to support longer ranges, faster charging, and higher overall performance. Loop-type thermosyphons, such as LTBMS A and B, play a vital role in preventing thermal runaway and ensuring safe, optimal operating conditions.

Figure 6.

Natural convection (no thermosyphon operation) (cooling).

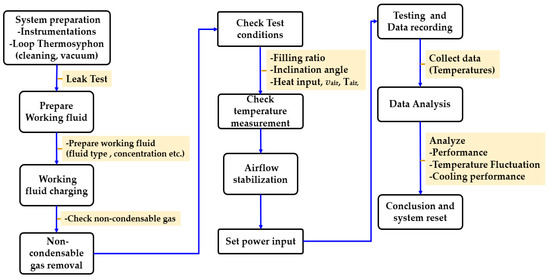

As described in Figure 7, the experimental procedure for the loop thermosyphon-based battery thermal management system (TBTMS) was conducted through the following sequential steps: (1) System preparation—cleaning with ethanol and distilled water followed by vacuum drying and leak testing at 5 × 10−3 torr; (2) Working fluid charging—evacuating the system using a vacuum pump (KODIVAC, Seoul, The Republic of Korea) and precisely injecting 40% of the inner volume of either water or acetone; (3) Non-condensable gas removal—additional evacuation to prevent gas plugs; (4) Heating condition setup—gradually applying 50 W power to the evaporator for approximately 1 h; (5) Airflow stabilization—maintaining stable flow velocity (~2.5 m3/min) for 10 min using a slip switch; (6) Temperature measurement—recording data using 12 calibrated K-type thermocouples (±0.05% accuracy) after reaching steady-state (40–60 min); (7) Analyze measurement errors; (8) System reset—cleaning and recharging for subsequent fluid tests. All experiments were designed to simulate real driving conditions (θ = 30°, 60°).

Figure 7.

Workflow of experimental procedure.

3. Result and Discussion

Battery Cooling Statement

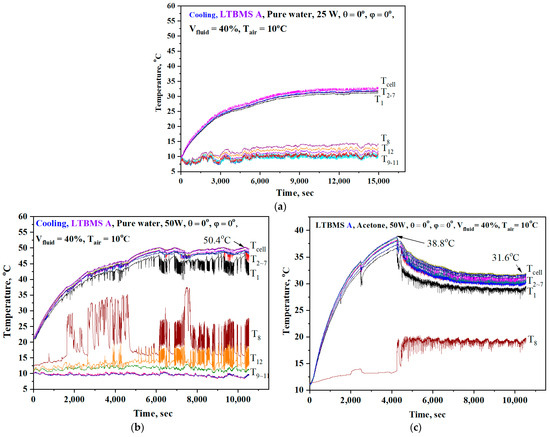

To evaluate system performance, experiments were conducted using a benchmark heat load of 50 W per cell, providing insights into thermal behavior and scalability for future high-capacity batteries. Without adequate heat dissipation, similar thermal outcomes are expected under various operating conditions, though timeframes may vary, emphasizing the importance of effective thermal management for safe and reliable battery operation. The experimental results for LTBMSs A and B, conducted over 4 h durations with temperature data analyzed during the latter 3 h after convergence, revealed distinct thermal behaviors under varying conditions. For LTBMS A with a 25 W heat input, as shown in Figure 8a, the flow of the working fluid appeared insufficient, with the maximum temperature reaching 31.9 °C. Although the evaporator and condenser temperatures remained stable, the heat generation was inadequate to ensure active circulation, indicating performance limitations under low heat inputs. At 50 W using distilled water, as shown in Figure 8b, LTBMS A achieved a stable maximum cell temperature (Tcell) of 50.4 °C, with minimal fluctuations (±2.1%) around the steady-state temperature of 50 °C, demonstrating effective thermal regulation despite continuous oscillations in the loop-type thermosyphon. The pipe temperature (T8) at the condenser inlet exhibited rapid oscillations between 13.9 °C and 37.5 °C, confirming efficient phase change-driven heat transfer of the full 50 W load. When acetone replaced distilled water at 50 W, as shown in Figure 8c, LTBMS A demonstrated improved heat transfer performance, converging at 31.6 °C but with a rapid initial temperature rise and a peak of 38.8 °C. This highlights a trade-off between faster heat dissipation and transient instability due to acetone’s lower boiling point and higher vapor pressure.

Figure 8.

Transient temperature variation of cell 50 W (Cooling), pure water, LTBMS A. (a) Water, Q = 25 W. (b) Water, Q = 50 W. (c) Acetone, Q = 50 W.

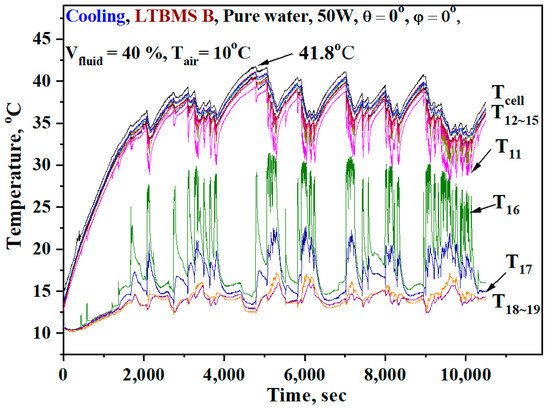

For LTBMS B, as shown in Figure 9, experiments at 25 W were not conducted due to its larger pipe heat capacity. At 50 W, LTBMS B achieved a maximum Tcell of 41.8 °C but exhibited larger temperature fluctuations (±12%, 32.8–41.8 °C), reflecting a compromise between higher heat transfer capacity and reduced thermal stability. These findings underscore the importance of balancing heat transfer efficiency, temperature stability, and working fluid properties. LTBMS A offers stable performance with water and faster cooling with acetone, while LTBMS B prioritizes higher capacity at the cost of increased variability. Design optimizations, such as addressing fluid pressure dynamics and asymmetric loop configurations, are necessary for practical applications to harmonize these competing demands and ensure reliable thermal management in next-generation battery systems.

Figure 9.

Transient temperature variation of Cell 50 W (cooling), pure water, LTBMS B.

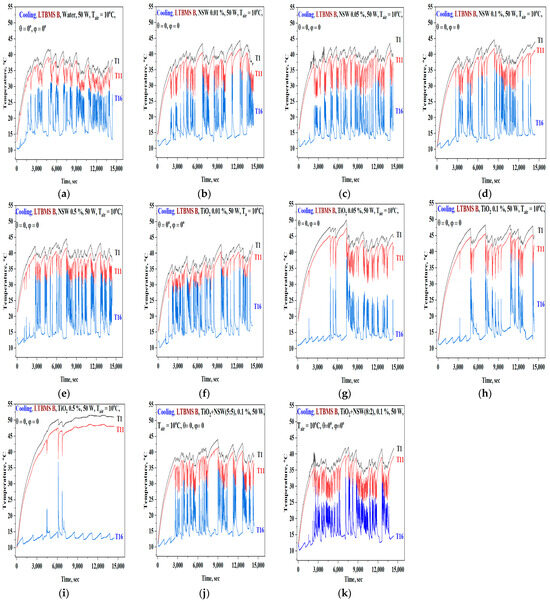

Based on Figure 10, the temperature profile across the loop type LTBMS was analyzed for different working fluids and configurations. In LTBMS A (Figure 10a), the evaporator temperature for pure water exceeded 50 °C, while acetone maintained a lower temperature of approximately 30 °C due to its lower boiling point (56.2 °C) and reduced latent heat of vaporization. This indicates that acetone facilitates more efficient evaporation at lower temperatures. In LTBMS B (Figure 10b), which operated with an expanded capacity, both pure water and nanofluids (TiO2 0.01%, NSW 0.01%, and TiO2 + NSW 0.1%) maintained evaporator temperatures between 40 and 45 °C. As illustrated in Figure 10, based on the temperature profiles along the loop for LTBMS A and B under cooling conditions, the analysis revealed distinct thermal performance characteristics influenced by the operating fluid properties and system configuration. In LTBMS A, acetone demonstrated superior performance in both the evaporator and condenser sections. Its lower boiling point and reduced latent heat of vaporization enabled more efficient phase-change behavior, maintaining a significantly lower temperature in the evaporator (approximately 17 °C lower) and slightly higher (1.3 °C higher) in the condenser compared to other fluids. This resulted in more effective convective heat transfer between the cell and air, facilitating efficient thermal management. However, its flammability limits its applicability in electric vehicle cooling systems. In contrast, LTBMS B, which operated with an expanded capacity, showed improved thermal performance when using nanofluids. When pure water was used as the working fluid, it maintained the lowest temperature in the evaporator, as shown in Figure 10. Even when the most optimal nanofluid was used, water was found to have superior heat dissipation capabilities. As illustrated in Figure 10b, water exhibits excellent heat transfer performance in the evaporator section of the loop thermosyphon due to its high latent heat of vaporization. In comparison, nanofluids show slightly higher temperatures in the evaporator, which is likely due to increased flow resistance. In the condenser section, TiO2 nanofluids reach higher temperatures than water, indicating improved condensation efficiency. This enhancement may be attributed to mechanisms such as surface deposition of nanoparticles. Higher concentrations of nanoparticles also lead to increased viscosity and circulation resistance, emphasizing the importance of optimizing nanofluid concentration for balanced performance. These findings highlight the importance of selecting appropriate working fluids to ensure thermal efficiency and stable operation of loop thermosyphon systems. Nanofluids offer a promising solution by combining improved heat transfer characteristics with manageable flow behavior. The temperature distribution provides a clear visual representation of the system’s thermal behavior and demonstrates that a carefully chosen mixture of base fluids and nanofluids can significantly improve cooling efficiency.

Figure 10.

Temperature profile along the loop, cooling case (LTBMS A and B). (a) LTBMS A (b) LTBMS B.

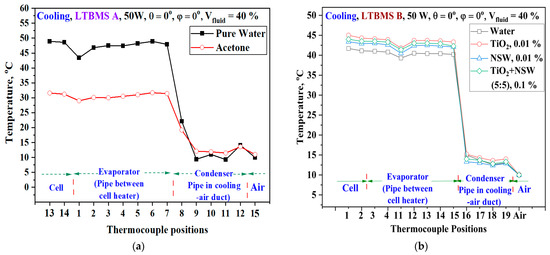

Figure 11a–k illustrates the temperature characteristics of a Loop Thermosyphon Battery Management System (LTBMS) using water and various concentrations of nanofluids (silver nanofluid NSW, TiO2 nanofluid, and TiO2 + NSW hybrid) as working fluids. Experimental results show that water and the TiO2 + NSW 8:2 hybrid nanofluid at 0.1% concentration exhibited the lowest peak temperatures compared to other concentrations and single nanofluid systems, indicating optimized heat transfer efficiency. When using NSW, increasing concentrations (from 0.01% to 0.1%) resulted in Peak temperatures slightly higher than water, but continuous temperature oscillations between T11 (between condenser and evaporator) and T16 (between evaporator and condenser) confirmed smooth circulation. The observation that T11 exhibited higher temperature oscillations than T16 suggests that the fluid circulates in a counterclockwise direction. As shown in Figure 11b–e, despite variations in maximum temperature with increasing NSW concentration, the system operated smoothly; however, the temperature oscillation amplitude at T16 (condenser outlet) increased, likely due to enhanced particle activity during condensation with higher silver nanoparticle concentrations [48,49,50,51,52,53].

Figure 11.

Transient temperature variation with various working fluids (cooling). (a) Water; (b) NSW, 0.01%; (c) NSW, 0.05%; (d) NSW, 0.1%; (e) NSW, 0.5%; (f) TiO2, 0.01%; (g) TiO2, 0.05%; (h) TiO2, 0.1%; (i) TiO2, 0.5%; (j) TiO2, + NSW (5:5), 0.1%; (k) TiO2, + NSW (8:2), 0.1%.

In contrast, Figure 11f–j illustrates that as the concentration of TiO2 nanofluid increased (except at 0.01 vol%), the oscillation period lengthened, and temperature oscillations at T11 and T16 nearly vanished, accompanied by an increase in temperature. This indicates that higher concentrations of non-metallic TiO2 nanoparticles introduced significant resistance, such as increased viscosity and particle aggregation, which counteracted the heat transfer enhancement expected from particle collisions. For water, the temperature oscillation amplitude at T11 and T16 was relatively small compared to nanofluids, attributable to its low thermal conductivity and reliance on natural convection without particle interactions, potentially indicating insufficient circulation momentum compared to nanofluids. In Figure 11j,k, the TiO2 + NSW hybrid nanofluid showed a decrease in T11–T16 temperature oscillation amplitude as TiO2 nanoparticle concentration increased, suggesting that the rise in non-metallic particles reduced interactions among metallic NSW particles, thereby stabilizing operation.

Linking these experimental findings to the step-by-step heat transfer mechanisms of nanofluids provides clear physical insights. The first stage, thermal conductivity enhancement, leverages the high thermal conductivity of nanoparticles to boost the base fluid (water)’s heat transfer, reflected in the reduced peak temperatures for NSW 0.01% and TiO2 + NSW 0.1%. The second stage, Brownian motion induction, involves random thermal motion of nanoparticles generating micro convection to enhance heat diffusion, notably improving stability in NSW 0.01%. The third stage, heat transfer path expansion, increases the heat transfer surface area through interactions between nanoparticles and the base fluid, with NSW’s high conductivity and TiO2 + NSW 8:2’s synergy contributing to the reduced T11–T16 amplitude. The fourth stage, turbulence induction, enhances convective heat transfer at low concentrations by inducing micro turbulence, as evidenced by the changing oscillation periods and amplitudes in NSW with increasing concentration. The final stage, concentration-dependent limitation, sees increased thermal resistance due to particle aggregation and viscosity rise at high concentrations (0.1% or above); metallic NSW amplified T16 amplitude via enhanced condensation activity, while non-metallic TiO2 reduced T11–T16 oscillations and raised temperatures due to diminished particle collision effects and fluid interactions.

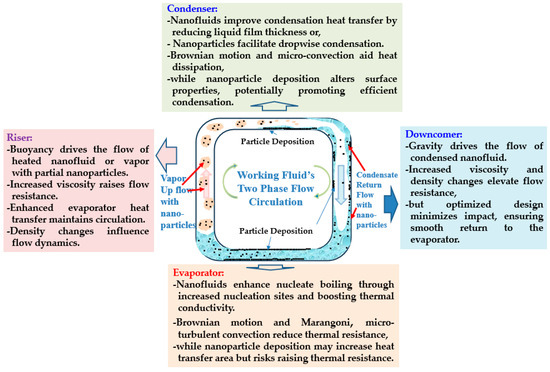

As described above in Figure 12, based on the results of Figure 11, in a two-phase loop thermosyphon, nanofluids enhance heat transfer and flow dynamics across the evaporator, condenser, and transport sections. In the evaporator, nanoparticles increase thermal conductivity, promote bubble nucleation, and induce Marangoni and micro-convection, enhancing boiling heat transfer, though high concentrations increase viscosity, reducing efficiency. In the condenser, nanoparticles facilitate dropwise condensation, reduce thermal resistance, and enhance heat dissipation through Brownian motion and additional conduction pathways, with hybrid nanofluids (TiO2 + NSW) achieving low outlet temperatures. In the transport section, low concentration nanofluids ensure smooth gravity-driven circulation, but high viscosity at elevated concentrations impairs flow, particularly at non-optimal inclinations, where pure water outperforms due to its low viscosity and stable flow [54,55,56,57,58,59,60]. Overall, nanofluids reduce the amplitude of temperature fluctuation compared to water at low concentrations (0.01~0.05%), enhancing thermal management, but their efficiency declines at high concentrations. The TiO2 + NSW 8:2 hybrid nanofluid at 0.1% maintained similar amplitude and smooth operation, suggesting potential for optimization. This study indicates that nanofluid use can improve the heat transfer characteristics of loop thermosyphons, with possibilities for further optimization or lightweight design using diverse nanofluid combinations.

Figure 12.

Nanofluid heat and flow mechanism in two-phase loop thermosyphon.

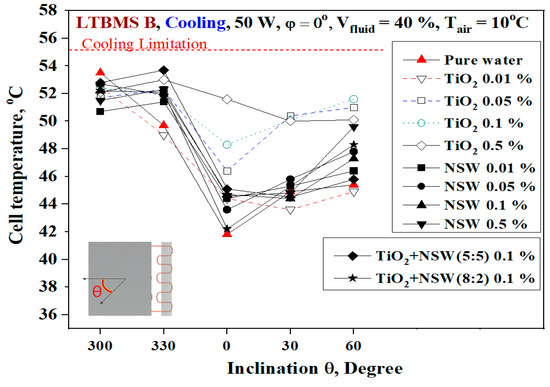

Figure 13 and Figure 14 present the variations in cell temperature within the LTBMS B-based cooling system influenced by different working fluids and inclination angles (θ and φ). Figure 13 illustrates how the maximum cell temperature changes with the roll angle (θ). At θ = 300°, where the evaporator is positioned upward, the cell temperature reaches its peak (~52–55 °C). This can be attributed to increased resistance to liquid circulation due to the elevated position of the evaporator, resulting in higher thermal buildup. Conversely, at θ = 0° (horizontal orientation), the lowest cell temperature is observed due to the optimal balance between gravitational and pressure forces, which facilitates efficient fluid circulation between the evaporator and condenser. As θ approaches 0°, the temperature decreases symmetrically and then increases again beyond this point, confirming effective operation even under non-optimal orientations. Among the tested working fluids, pure water demonstrated superior cooling performance, achieving a minimum cell temperature of 41.8 °C at θ = 0°. Nanofluids such as TiO2 0.01% and nano-silver water (NSW) 0.01% maintained slightly higher temperatures (44–45 °C), while hybrid nanofluids like TiO2 + NSW (8:2) 0.1% exhibited temperatures around 42.2 °C, showing comparable performance to pure water, but TiO2 + NSW (5:5) 0.1% showed worse performance than water. However, high-concentration nanofluids like TiO2-0.5% showed reduced effectiveness due to increased viscosity and flow resistance, causing the cell temperature to rise to 51.6 °C. In addition, when the evaporator is positioned below the condenser within the range of 0° < θ ≤ 60°, the cell temperature also increased. This is believed to be due to pressure variations inside the system caused by the vertical position of the working fluid. Figure 13 and Figure 14 clearly show the maximum battery temperatures reached by the cooling systems presented in Table 1. These results demonstrate that the proposed approach successfully meets the target cooling temperature range, which has been identified as optimal in previous studies. This performance is maintained even under real automotive driving conditions, taking into account the influence of varying installation angles.

Figure 13.

Cell temperature on θ (cooling case), LTBMS B.

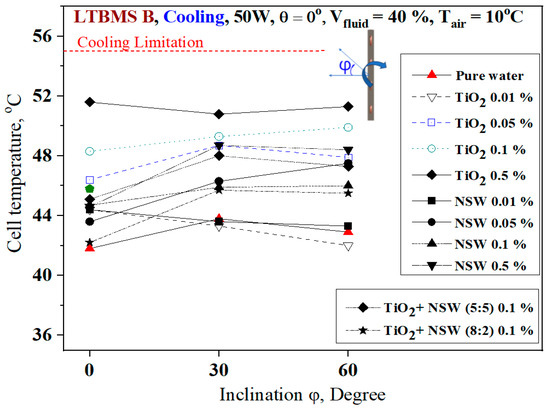

Figure 14.

Cell temperature on φ (cooling case), LTBMS B.

Figure 14 presents the effect of rotational angle (φ) on cell temperature. As φ increases, the resistance to returning condensed liquid from the condenser to the evaporator also increases, leading to higher cell temperatures. For pure water, the temperature rises from ~41.8 °C at φ = 0° to ~43.8 °C at φ = 90°. High-viscosity nanofluids such as TiO2 0.5% and NSW 0.5% exceeded 48 °C at higher φ values, indicating limitations in circulation due to excessive viscosity. Similarly, hybrid nanofluids, such as TiO2 + NSW (5:5) at 0.1% and TiO2 + NSW (8:2) at 0.1%, also showed an increase in cell temperature with increasing φ, reaching 51.3 °C and 45.5 °C, respectively. In the case of TiO2 and NSW at 0.01%, unlike other cases, an increase in φ resulted in a decrease in cell temperature. However, for higher concentrations such as TiO2 at 0.5%, changes in the φ angle appeared to have little effect. Unlike Figure 13, Figure 14 shows that the influence of the φ angle was less significant compared to the θ orientation, since the position of the evaporator did not change vertically. Therefore, the impact of φ angle variation was smaller compared to the effect observed with changes in the θ angle.

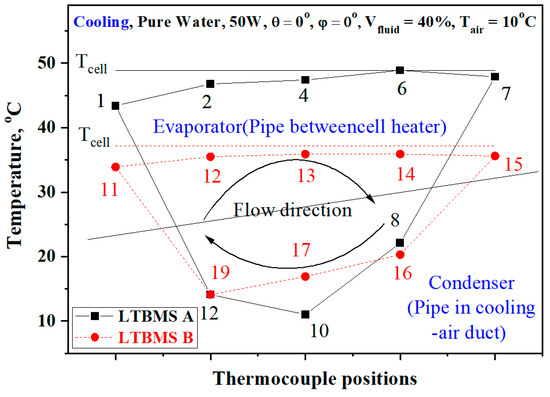

In the loop thermosiphon system, the working fluid circulates in a clockwise direction, transferring heat from the evaporator (battery cell region) to the condenser (cooling duct), as illustrated in the Figure 15. Initially, the fluid at thermocouple position #1 in LTBMS A reaches approximately 45 °C, absorbing heat from the battery cell, and gradually increases to around 50 °C at positions #6 and #7, indicating maximum heat absorption in the evaporator. In LTBMS B, the temperature at the evaporator starts lower, at 30 °C at #11, rising to 35–38 °C near #15, suggesting differences in thermal transport efficiency between the two designs. As the fluid moves into the condenser region at position #8, it undergoes a sharp temperature drop in LTBMS A, decreasing from 25 °C to approximately 12 °C at #12, indicating effective heat dissipation. In LTBMS B, however, the cooling process is more gradual, with the lowest temperature reaching 14 °C at #19 before recirculation. The condensed liquid then returns to the evaporator due to gravity, completing the cycle. The flow dynamics within the loop thermosiphon ensure continuous heat removal from the battery cell, preventing thermal buildup and maintaining an optimal steady-state temperature of ~32.5 °C, as observed at T13 (35.9 °C) and T14 (35.9 °C). The temperature fluctuations of ±2.9% (1.9 °C) at T13 and ±2% (1.3 °C) at T14 confirm the stability of the system, ensuring uniform heat dissipation while operating efficiently within the thermal limits of the battery.

Figure 15.

Temperature profiles along thermocouple positions (cooling case), LTBMS A and B.

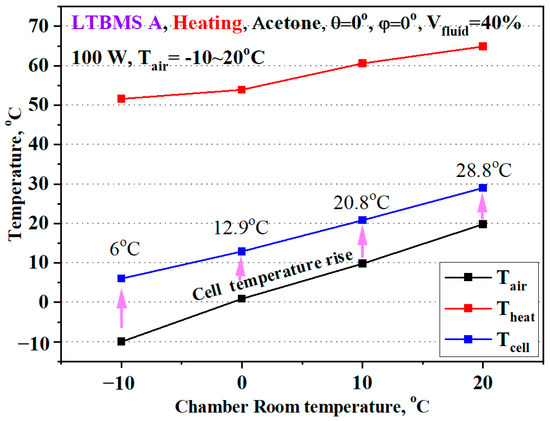

Also, Figure 16 provides a detailed analysis of the heating performance of the LTBMS A system, utilizing acetone as the working fluid, under varying ambient air temperatures (−10 °C, 0 °C, 10 °C, and 20 °C). The target cell temperatures of 50 °C to 65 °C were achieved by activating the heating wires embedded in the condenser section (Figure 3), which functioned as the evaporator during heating mode. The applied power, regulated by a 5 kVA Slide-AC voltage regulator, vaporized the acetone, transferring heat via vapor flow to the battery cells (acting as the condenser). The condensed liquid returned to the heater via gravity-driven circulation, completing the cycle. The heater temperature increased from approximately 52 °C at −10 °C ambient temperature to about 68 °C at 20 °C, while the cell temperature rose proportionally, from 6 °C to 28.8 °C across these conditions. At −10 °C, the system achieved a cell temperature increase of 16 °C at a heater target of 50 °C, demonstrating effective heat transfer in low-temperature environments. At 0 °C, the cell temperature increased by 12.9 °C; at 10 °C by 20.8 °C; and at 20 °C by 28.8 °C, highlighting consistent performance. The efficiency of this process is attributed to acetone’s low boiling point (56.2 °C) and high latent heat of vaporization, enabling rapid phase transitions and stable heat delivery to the cells, as monitored by thermocouples at positions T13 and T14 (Figure 3). The results confirm that the LTBMS A system provides stable and efficient thermal management, ensuring optimal battery temperatures even under extreme environmental conditions.

Figure 16.

Battery heating on various outdoor conditions, LTBMS A.

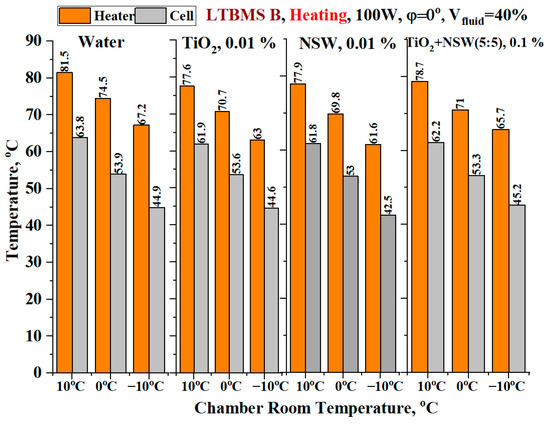

Figure 17 presents an analysis of the heating performance of an LTBMS-B-based battery cooling system using various working fluids under different ambient temperatures (−10 °C, 0 °C, and 10 °C). The tested fluids include water, TiO2 0.01%, NSW 0.01%, and a hybrid nanofluid (TiO2-NSW 5:5, 0.1%). Across all scenarios, the heater temperature and the corresponding rise in cell temperature showed consistent trends, indicating that all fluids effectively transferred heat through the LTBMS-B system. At an ambient temperature of 10 °C, water demonstrated slightly superior performance, reaching a heater temperature of 81.4 °C and a cell temperature of 63.8 °C. Meanwhile, the hybrid nanofluid performed particularly well in colder conditions (−10 °C and 0 °C), maintaining stable heat transfer. These results highlight the adaptability and efficiency of the LTBMS-B system in managing heat transfer under varying environmental conditions. The uniformity in performance across different fluids suggests that the system can flexibly operate with various working fluids, making it a robust choice for battery thermal management applications.

Figure 17.

Battery heating on various outdoor conditions and working fluid, LTBMS B.

4. Conclusions

The study on a loop thermosyphon-based battery thermal management system (LTBMS) for next-generation electric vehicle batteries demonstrated its effectiveness in maintaining optimal battery temperatures under diverse conditions. In cooling experiments, LTBMS A maintained cell temperatures at 50.4 °C with distilled water and 31.6 °C with acetone under a 50 W heat load, while LTBMS B achieved 41.6 °C with water, 42.1 °C with TiO2 + NSW (8:2, 0.1%) hybrid nanofluid, and 42.8 °C with TiO2 (0.01%) nanofluid at 0° inclination, with temperatures remaining below 53.5 °C even at θ = 300°.

The system effectively managed heat dissipation at 25 W for LTBMS A and 50 W for LTBMS B across inclinations up to 60° in roll and pitch, simulating real-world driving conditions. In heating mode at an ambient temperature of −10 °C, LTBMS A increased cell temperatures by 16 °C with a heater target of 50 °C, while LTBMS B achieved 52–55 °C with a 100 W input, depending on the working fluid.

Among nanofluids, the TiO2 + NSW (8:2, 0.1%) hybrid and TiO2 (0.01%) nanofluids exhibited comparable peak temperatures, but pure water consistently delivered the lowest cell temperatures and the most stable operation due to its low viscosity. Higher TiO2 concentrations showed reduced performance due to increased viscosity and nanoparticle aggregation. These findings confirm the LTBMS’s robustness and effectiveness for dual-purpose thermal management in electric vehicles across various operating conditions and fluid types.

Author Contributions

Conceptualization, J.-C.J. and S.-H.R.; data curation, J.-S.L.; formal analysis, J.-C.J., T.-K.L. and S.-H.R.; investigation, J.-C.J., T.-K.L. and S.-H.R.; methodology, J.-C.J., T.-K.L. and S.-H.R.; project administration, S.-H.R.; supervision, S.-H.R.; writing—original draft, J.-C.J. and S.-H.R.; writing—review and editing, T.-K.L., J.-S.L. and S.-H.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF), funded by the Ministry of Education (Grant number: RS-2022-NR075636).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| LTBMS | Loop thermosyphon battery thermal management system |

| NSW | Nano silver water nanofluid |

| T | Static temperature, °C |

| V | Volume, m3 |

| Greek | |

| θ | Rolling angle, degree |

| φ | Pitching angle, degree |

| Subscripts | |

| air | Air |

| Fluid | Working fluid |

References

- Feng, X.; Ren, D.; He, X.; Ouyang, M. Mitigating thermal runaway of lithium-ion batteries. Joule 2020, 4, 743–770. [Google Scholar] [CrossRef]

- Chen, L.; Fan, X.; Hu, E.; Ji, X.; Chen, J.; Hou, S.; Deng, T.; Li, J.; Su, D.; Yang, X.; et al. Achieving high energy density through increasing the output voltage: A highly reversible 5.3 V battery. Chem 2019, 5, 896–912. [Google Scholar] [CrossRef]

- Sun, X.; Yan, C.; Chen, Y.; Si, W.; Deng, J.; Oswald, S.; Liu, L.; Schmidt, O.G. Three-dimensionally “curved” NiO nanomembranes as ultrahigh rate capability anodes for Li-ion batteries with long cycle lifetimes. Adv. Energy Mater. 2014, 4, 1300912. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, J.; Gu, J.; Zhang, Q. The effects of electrode thickness on the electrochemical and thermal characteristics of lithium-ion battery. Appl. Energy 2015, 139, 220–229. [Google Scholar] [CrossRef]

- Chen, K.; Hou, J.; Song, M.; Wang, S.; Wu, W.; Zhang, Y. Design of battery thermal management system based on phase change material and heat pipe. Appl. Therm. Eng. 2021, 188, 116665. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, Q.; Huang, C.; Liu, X. Investigation of the thermal performance of phase change material/mini-channel coupled battery thermal management system. Appl. Energy 2016, 164, 659–669. [Google Scholar] [CrossRef]

- Behi, H.; Karimi, D.; Jaguemont, J.; Ghanbarpour, M.; Berecibar, M. Heat pipe air-cooled thermal management system for lithium-ion batteries: High power applications. Appl. Therm. Eng. 2021, 183, 116240. [Google Scholar] [CrossRef]

- Guo, P.; Xu, Q.; Yue, Y.; Ma, F.; He, Z.; Luo, A.; Guerrero, J.M. Analysis and Control of Modular Multilevel Converter With Split Energy Storage for Railway Traction Power Conditioner. IEEE Trans. Power Electron. 2020, 35, 1239–1255. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.; Wang, M.; Yang, K.; Ge, Y.; Wang, K.; Lin, H.; Pan, P.; Hu, H.; He, Z.; et al. Multi-Timescale Reward-Based DRL Energy Management for Regenerative Braking Energy Storage System. IEEE Trans. Transp. Electrif. 2025, 11, 7488–7500. [Google Scholar] [CrossRef]

- Zhao, C.; Ju, S.; Xue, Y.; Ren, T.; Ji, Y.; Chen, X. China’s energy transitions for carbon neutrality: Challenges and opportunities. Carbon Neutrality 2022, 1, 7. [Google Scholar] [CrossRef]

- Xu, B.; Lee, J.; Kwon, D.; Kong, L.; Pecht, M. Mitigation strategies for Li-ion battery thermal runaway: A review. Renew. Sustain. Energy Rev. 2021, 150, 111437. [Google Scholar] [CrossRef]

- Liu, F.; Lan, F.; Chen, J. Dynamic thermal characteristics of heat pipe via segmented thermal resistance model for electric vehicle battery cooling. J. Power Sources 2016, 321, 57–70. [Google Scholar] [CrossRef]

- Sun, H.; Dixon, R. Development of cooling strategy for an air-cooled lithium-ion battery pack. J. Power Sources 2014, 272, 404–414. [Google Scholar] [CrossRef]

- Oh, I.-T.; Lee, J.-S.; Han, J.-S.; Lee, S.-W.; Kim, S.-J.; Rhi, S.-H. Li-ion battery immersed heat pipe cooling technology for electric vehicles. Electronics 2023, 12, 4931. [Google Scholar] [CrossRef]

- Kim, S.-J.; Lee, J.-S.; Rhi, S.-H. Heat Pipe Embedded Battery Cooling System for Future Electric Vehicle. Batteries 2025, 11, 164. [Google Scholar] [CrossRef]

- Chi, R.-G.; Chung, W.-S.; Rhi, S.-H. Thermal characteristics of an oscillating heat pipe cooling system for electric vehicle Li-ion batteries. Energies 2018, 11, 655. [Google Scholar] [CrossRef]

- Chi, R.-G.; Rhi, S.-H. Oscillating heat pipe cooling system of electric vehicle’s Li-ion batteries with direct contact bottom cooling mode. Energies 2019, 12, 1698. [Google Scholar] [CrossRef]

- Chung, W.-S.; Lee, J.-S.; Rhi, S.-H. Thermal management system using pulsating heat pipe of cylindrical battery cell. J. Mech. Sci. Technol. 2023, 37, 6711–6725. [Google Scholar] [CrossRef]

- Lee, J.-S.; Kim, S.-J.; Han, W.-S.; Rhi, S.-H. Anti-Gravity 3D Pulsating Heat Pipe for Cooling Electric Vehicle Batteries. Energies 2024, 17, 2283. [Google Scholar] [CrossRef]

- Lv, Y.; Yang, X.; Li, X.; Zhang, G.; Wang, Z. Experimental study on a novel battery thermal management technology based on low-density polyethylene-enhanced composite phase change materials coupled with low fins. Appl. Energy 2016, 178, 376–382. [Google Scholar] [CrossRef]

- Nazir, H.; Batool, M.; Osorio, F.J.B.; Xu, X.; Phelan, P.; Inamuddin. Recent developments in phase change materials for energy storage applications: A review. Int. J. Heat Mass Transf. 2019, 129, 491–523. [Google Scholar] [CrossRef]

- Fang, M.; Zhou, J.; Fei, H.; Yang, K.; He, R. Porous-material-based composite phase change materials for a lithium-ion battery thermal management system. Energy Fuels 2022, 36, 4153–4173. [Google Scholar] [CrossRef]

- He, F.; Li, X.; Ma, L. Combined experimental and numerical study of thermal management of battery module consisting of multiple Li-ion cells. Int. J. Heat Mass Transf. 2014, 72, 622–629. [Google Scholar] [CrossRef]

- Liu, K.; Liu, Y.; Lin, D.; Pei, A.; Cui, Y. Materials for lithium-ion battery safety. Sci. Adv. 2018, 4, eaas9820. [Google Scholar] [CrossRef] [PubMed]

- Nicholls, R. Lithium-Ion 18650 Cylindrical Battery Thermal Management: Multi-Level CFD Simulations Utilising Phase Change Materials for Enhanced Performance. Ph.D. Thesis, University of Staffordshire, Stoke-on-Trent, UK, 2024. Available online: https://eprints.staffs.ac.uk/id/eprint/8505 (accessed on 18 January 2025).

- Wang, F.; Cao, J.; Ling, Z.; Zhang, Z.; Fang, X. Experimental and simulative investigations on a phase change material nano-emulsion-based liquid cooling thermal management system for a lithium-ion battery pack. Energy 2020, 207, 118215. [Google Scholar] [CrossRef]

- Jang, D.S.; Ham, S.H.; Kim, J.; Kim, Y. Thermal and aging performance characteristics of pouch-type lithium-ion battery using heat pipes under nonuniform heating conditions. Appl. Therm. Eng. 2024, 236, 121891. [Google Scholar] [CrossRef]

- Kong, F.; Yu, F.; Lu, W.; Yuan, Z.; Qian, B. An organic/inorganic synergistic electrolysis for overcharge protection of electric vehicle batteries. Ind. Eng. Chem. Res. 2019, 58, 1787–1793. [Google Scholar] [CrossRef]

- Goodenough, J.B.; Kim, Y. Challenges for rechargeable Li batteries. Chem. Mater. 2010, 22, 587–603. [Google Scholar] [CrossRef]

- Hu, M.; Pang, X.; Zhou, Z. Recent progress in high-voltage lithium-ion batteries. J. Power Sources 2013, 237, 229–242. [Google Scholar] [CrossRef]

- Yang, C.-P.; Yin, Y.-X.; Zhang, S.-F.; Li, N.-W.; Guo, Y.-G. Accommodating lithium into 3D current collectors with a submicron skeleton towards long-life lithium metal anodes. Nat. Commun. 2015, 6, 8058. [Google Scholar] [CrossRef]

- Ghorabaee, H.; Sarmasti Emami, M.R.; Moosakazemi, F.; Karimi, N.; Cheraghian, G.; Afrand, M. The Use of Nanofluids in Thermosyphon Heat Pipe: A Comprehensive Review. Powder Technol. 2021, 394, 785–806. [Google Scholar] [CrossRef]

- Akbarzadeh, M.; Kalogiannis, T.; Jaguemont, J.; Jin, L.; Karimi, D.; Beheshti, H.; Van Mierlo, J.; Berecibar, M. A Comparative Study between Air Cooling and Liquid Cooling Thermal Management Systems for a High-Energy Lithium-Ion Battery Module. Appl. Therm. Eng. 2021, 11, 117503. [Google Scholar] [CrossRef]

- Garud, K.S.; Tai, L.D.; Hwang, S.-G.; Nguyen, N.-H.; Lee, M.-Y. A Review of Advanced Cooling Strategies for Battery Thermal Management Systems in Electric Vehicles. Symmetry 2023, 15, 1322. [Google Scholar] [CrossRef]

- Choi, H.; Lee, H.; Han, U.; Jung, J.; Lee, H. Comparative Evaluation of Liquid Cooling-Based Battery Thermal Management Systems: Fin Cooling, PCM Cooling, and Intercell Cooling. Int. J. Energy Res. 2024, 2024, 5395508. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Q.; Wang, Z.; Cheng, X. A Review of Power Battery Cooling Technologies. Renew. Sustain. Energy Rev. 2025, 213, 115494. [Google Scholar] [CrossRef]

- Tai, L.D.; Garud, K.S.; Hwang, S.-G.; Lee, M.-Y. A Review on Advanced Battery Thermal Management Systems for Fast Charging in Electric Vehicles. Batteries 2024, 10, 372. [Google Scholar] [CrossRef]

- Xu, L.; Wang, S.; Xi, L.; Li, Y.; Gao, J. A Review of Thermal Management and Heat Transfer of Lithium-Ion Batteries. Energies 2024, 17, 3873. [Google Scholar] [CrossRef]

- Tang, Y.; Li, T.; Cheng, X. Review of Specific Heat Capacity Determination of Lithium-Ion Battery. Energy Procedia 2019, 158, 4967–4973. [Google Scholar] [CrossRef]

- Droese, D.; Kowal, J. Thermal Characterisation of Automotive-Sized Lithium-Ion Pouch Cells Using Thermal Impedance Spectroscopy. Appl. Sci. 2023, 13, 2870. [Google Scholar] [CrossRef]

- Lee, G. Electro-Thermal Analysis of a Pouch–Type Lithium–Ion Battery with a High Discharge Rate for Urban Air Mobility. Batteries 2023, 9, 476. [Google Scholar] [CrossRef]

- Patil, M.S.; Panchal, S.; Kim, N.; Lee, M.-Y. Cooling Performance Characteristics of 20 Ah Lithium-Ion Pouch Cell with Cold Plates along Both Surfaces. Energies 2018, 11, 2550. [Google Scholar] [CrossRef]

- Franco, A.; Filippeschi, S. Closed loop two-phase thermosyphon of small dimensions: A review of the experimental results. Microgravity Sci. Technol. 2012, 24, 165–179. [Google Scholar] [CrossRef]

- Daraghmeh, H.M.; Sulaiman, M.W.; Yang, K.-S.; Wang, C.-C. Investigation of Separated Two-Phase Thermosiphon Loop for Relieving the Air-Conditioning Loading in Datacenter. Energies 2019, 12, 105. [Google Scholar] [CrossRef]

- Kloczko, S.; Faghri, A. Experimental Investigation on Loop Thermosyphon Thermal Performance with Flow Visualization. Int. J. Heat Mass Transf. 2020, 150, 119312. [Google Scholar] [CrossRef]

- Tong, Z.; Han, Z.; Fang, C.; Wen, X. Two-Phase Thermosyphon Loop with Different Working Fluids Used in Data Centers. Int. J. Heat Mass Transf. 2023, 214, 124393. [Google Scholar] [CrossRef]

- Gillespie, T.D. Fundamentals of Vehicle Dynamics; SAE International: Warrendale, PA, USA, 1992; ISBN 978-1-56091-199-9. [Google Scholar]

- Vidonscky Pinto, R.; Sanzovo Fiorelli, F.A. Review of the Mechanisms Responsible for Heat Transfer Enhancement Using Nanofluids. Appl. Them. Eng. 2016, 108, 720–739. [Google Scholar] [CrossRef]

- Govindasamy, M.; Ezhumalai, M.; Dhairiyasamy, R.; Varshney, D.; Singh, S.; Gabiriel, D. Comprehensive Investigation into the Thermal Performance of Nanofluid-Enhanced Heat Pipes for Advanced Thermal Management Systems. Eng 2025, 6, 55. [Google Scholar] [CrossRef]

- Buschmann, M.H. Nanofluids in thermosyphons and heat pipes: Overview of recent experiments and modelling approaches. Int. J. Therm. Sci. 2013, 72, 1–17. [Google Scholar] [CrossRef]

- Pathak, S.K.; Kumar, R.; Goel, V.; Pandey, A.K.; Tyagi, V.V. Recent advancements in thermal performance of nano-fluids charged heat pipes used for thermal management applications: A comprehensive review. Appl. Therm. Eng. 2022, 216, 119023. [Google Scholar] [CrossRef]

- Wang, X.; Luo, L.; Xiang, J.; Lin, Z.; Shittu, S.; Wang, Z. A comprehensive review on the application of nanofluid in heat pipe based on the machine learning: Theory, application and prediction. Renew. Sustain. Energy Rev. 2021, 150, 111434. [Google Scholar] [CrossRef]

- Mohite, D.; Goyal, A.; Singh, A.; Ansari, M.; Patil, K.; Yadav, P.D.; Patil, M.; Londhe, P.; Patil, K. Improvement of Thermal Performance through Nanofluids in Industrial Applications: A Review on Technical Aspects. Mater. Today Proc. 2024; in press. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Hormozi, F.; Peyghambarzadeh, S.M. Role of nanofluid fouling on thermal performance of a thermosyphon: Are nanofluids reliable working fluid? Appl. Therm. Eng. 2015, 82, 212–224. [Google Scholar] [CrossRef]

- Sundar, L.S.; Singh, M.K.; Sousa, A.C.M. Enhanced heat transfer and friction factor of MWCNT–Fe3O4/water hybrid nanofluids. Int. Commun. Heat Mass Transf. 2014, 52, 73–83. [Google Scholar] [CrossRef]

- Aydın, Y.; Gürü, M.; Sözen, A. Experimental Investigation on Thermal Performance of Thermosyphon Heat Pipe Using Dolomite/Deionized Water Nanofluid Depending on Nanoparticle Concentration and Surfactant Type. Heat Transf. Res. 2020, 51, 1079–7085. [Google Scholar] [CrossRef]

- Shafahi, M.; Bianco, V.; Vafai, K.; Manca, O. An investigation of the thermal performance of cylindrical heat pipes using nanofluids. Int. J. Heat Mass Transf. 2010, 53, 376–383. [Google Scholar] [CrossRef]

- Kang, S.-W.; Wei, W.-C.; Tsai, S.-H.; Yang, S.-Y. Experimental investigation of silver nano-fluid on heat pipe thermal performance. Appl. Therm. Eng. 2006, 26, 2377–2382. [Google Scholar] [CrossRef]

- Qu, J.; Wu, H.-Y.; Cheng, P. Thermal performance of an oscillating heat pipe with Al2O3–water nanofluids. Int. Commun. Heat Mass Transf. 2010, 37, 111–115. [Google Scholar] [CrossRef]

- Cacua, K.; Buitrago-Sierra, R.; Pabón, E.; Gallego, A.; Zapata, C.; Herrera, B. Nanofluids stability effect on a thermosyphon thermal performance. Int. J. Therm. Sci. 2020, 153, 106347. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).