Review of Challenges in Heat Exchanger Network Development for Electrified Industrial Energy Systems

Abstract

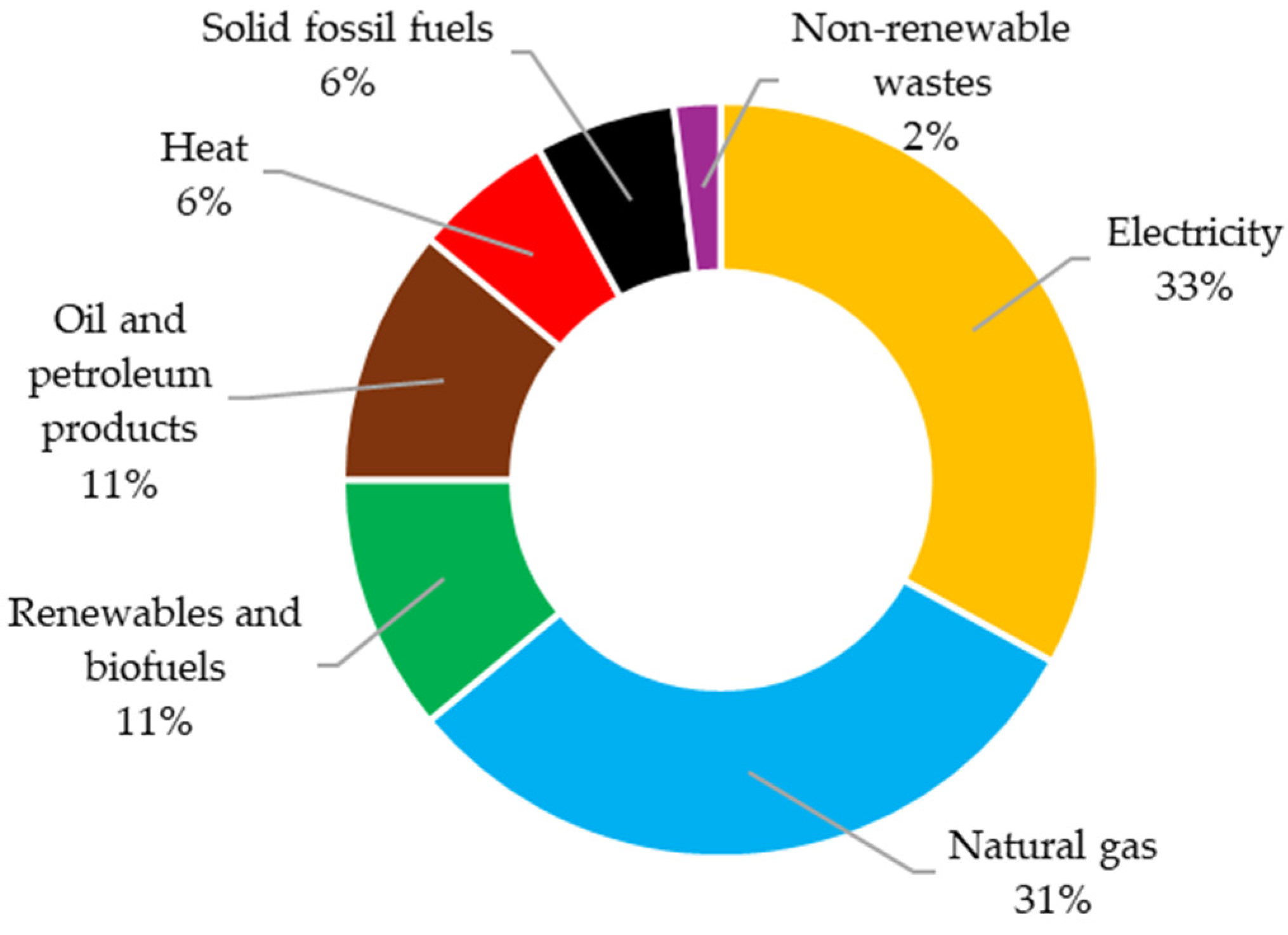

1. Introduction

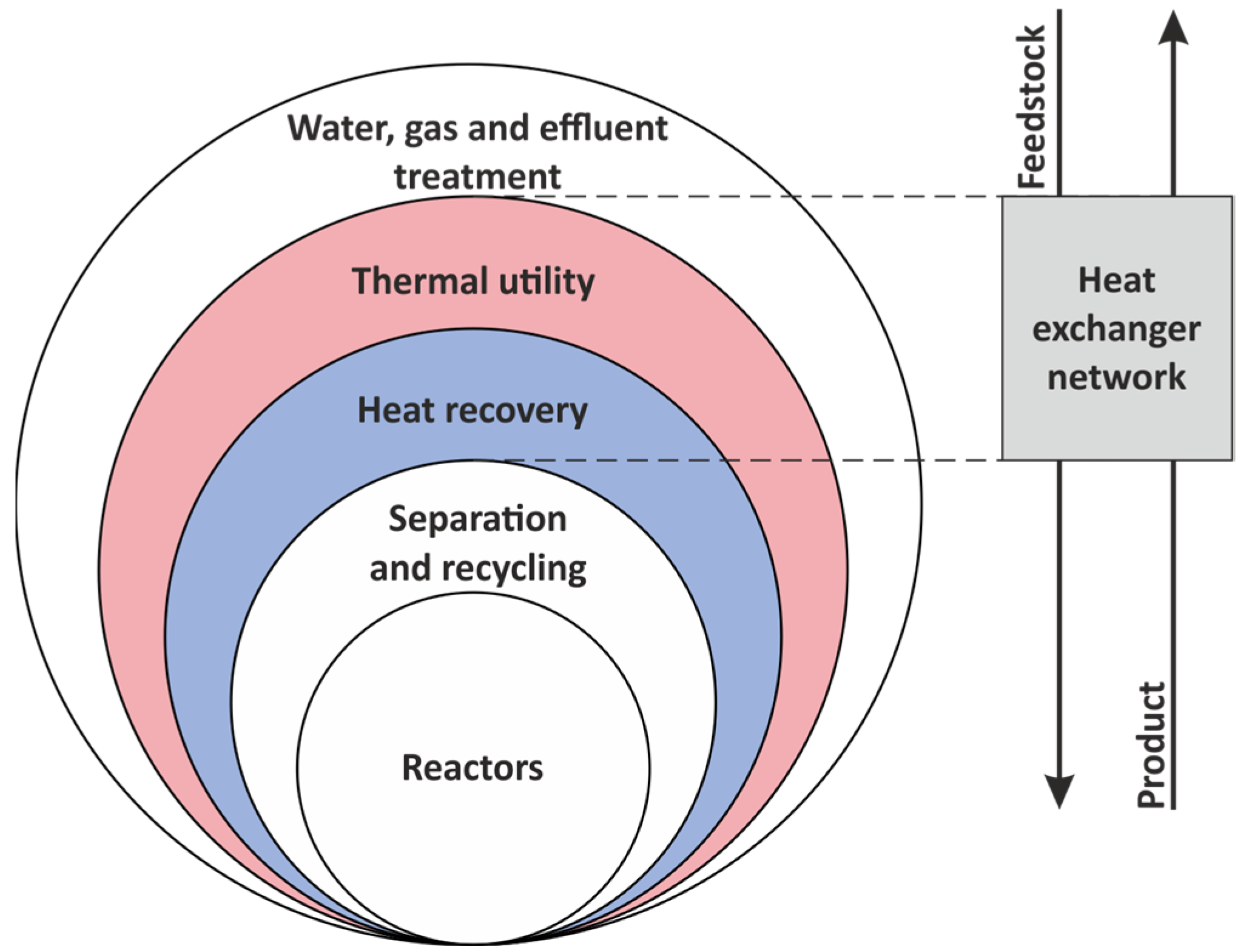

2. Challenges in Heat Exchanger Network Developments

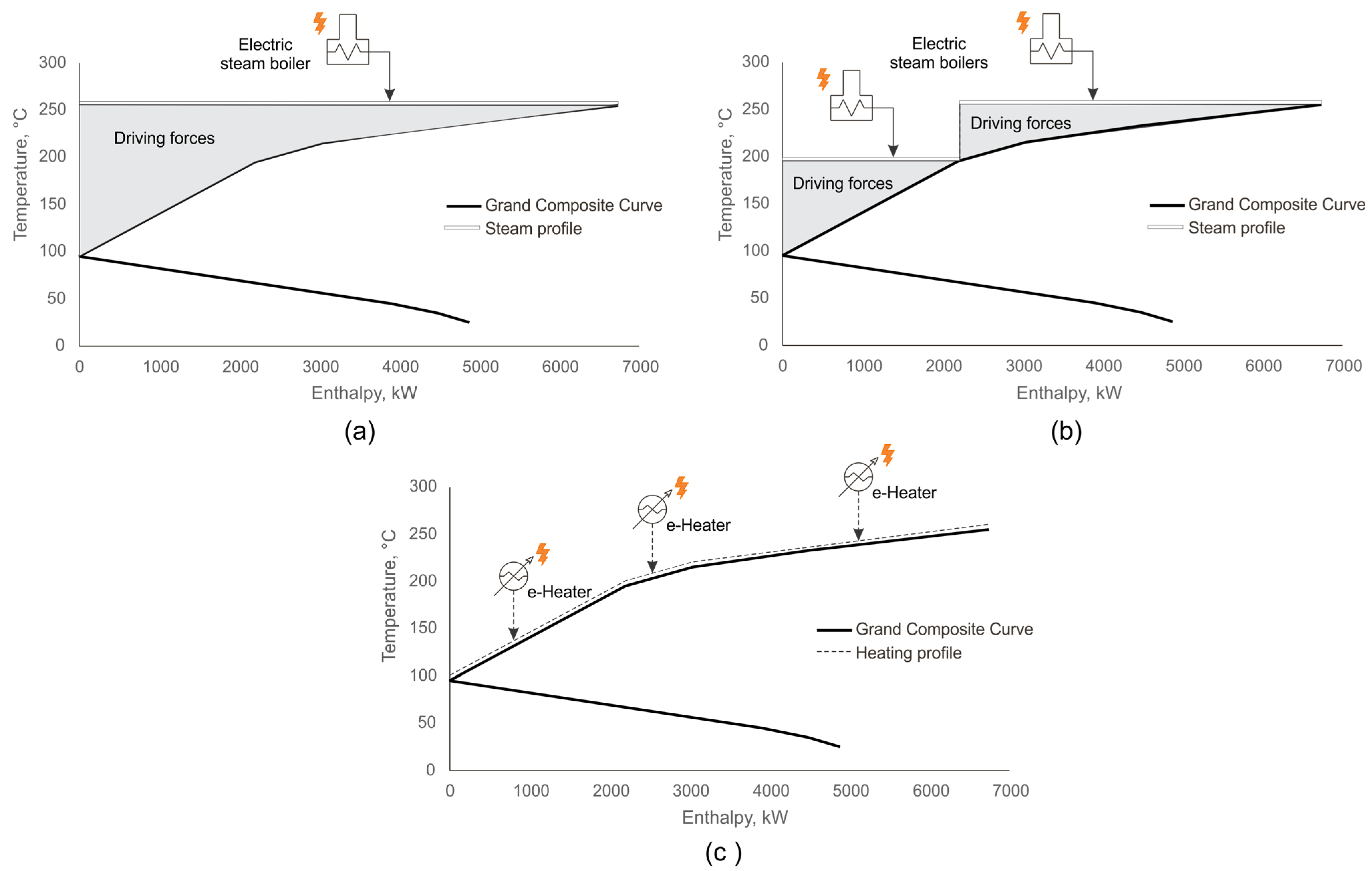

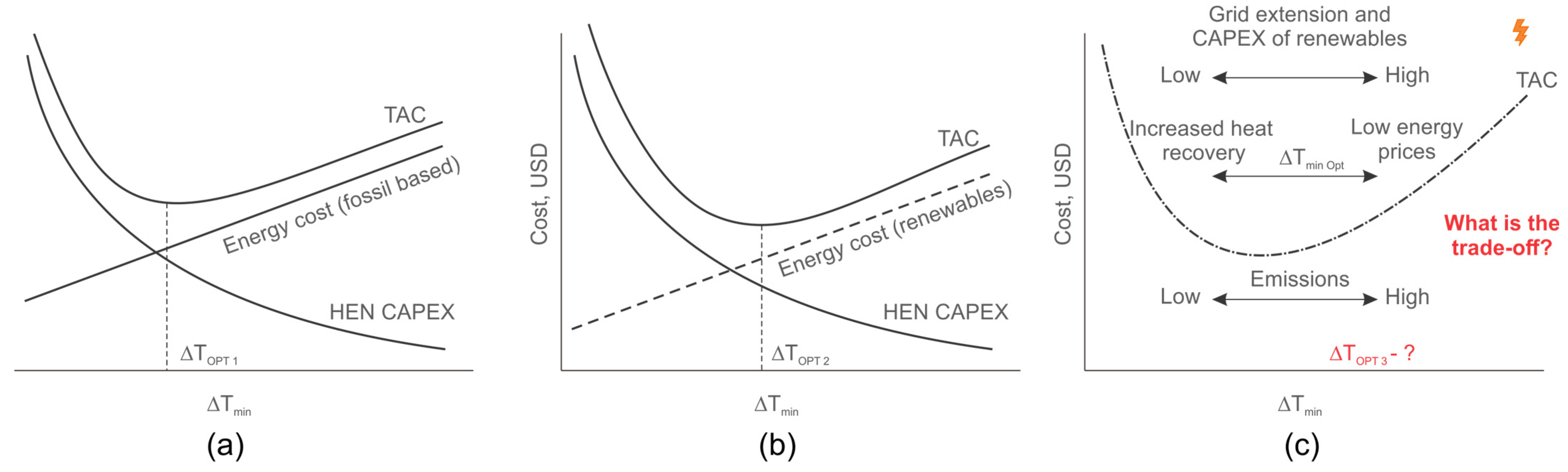

2.1. Multiple Utility and Driving Forces

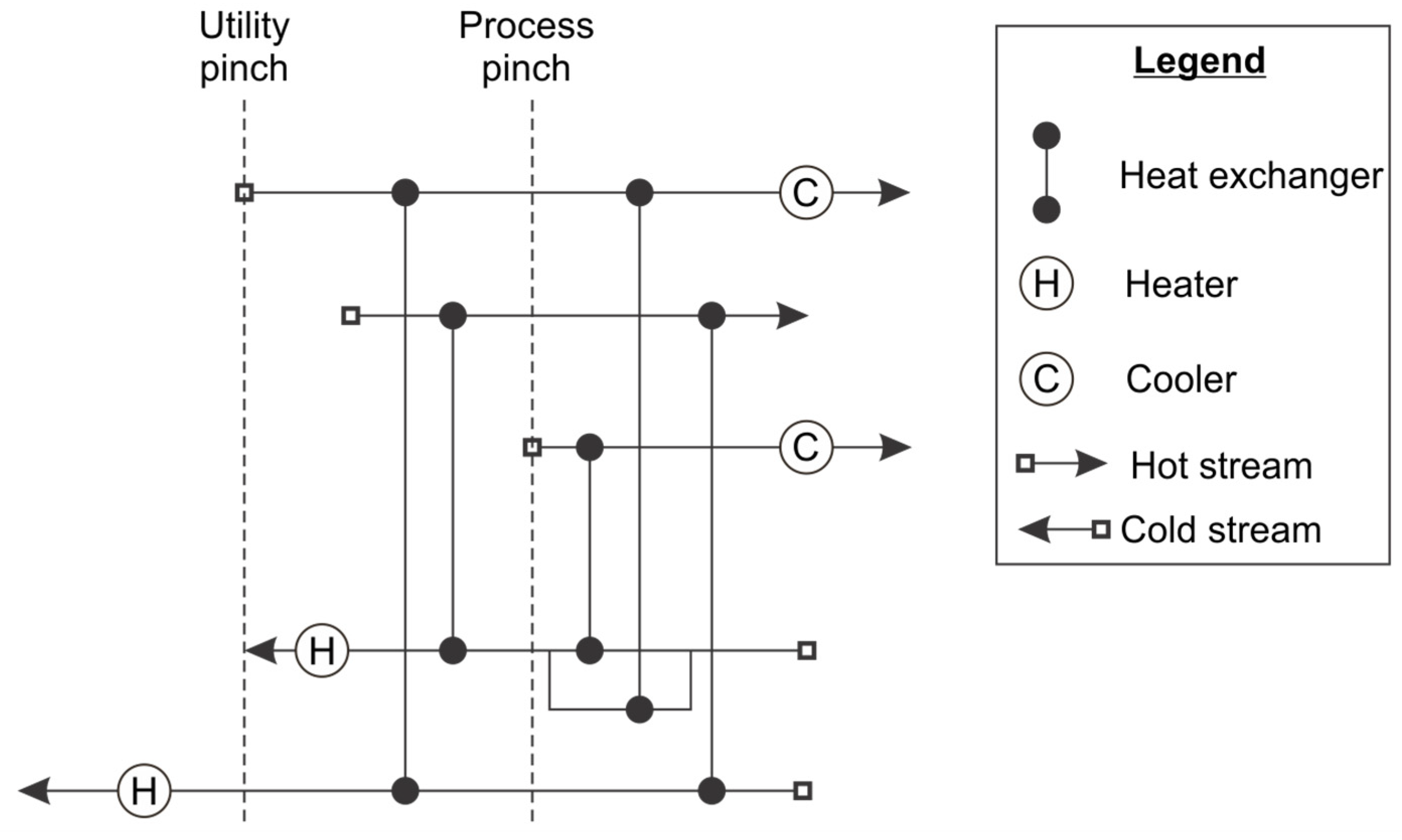

2.2. Multi-Pinch Problem

2.3. The Use of Heat Pumps, Mechanical Vapour Recompression and Organic Rankine Cycle

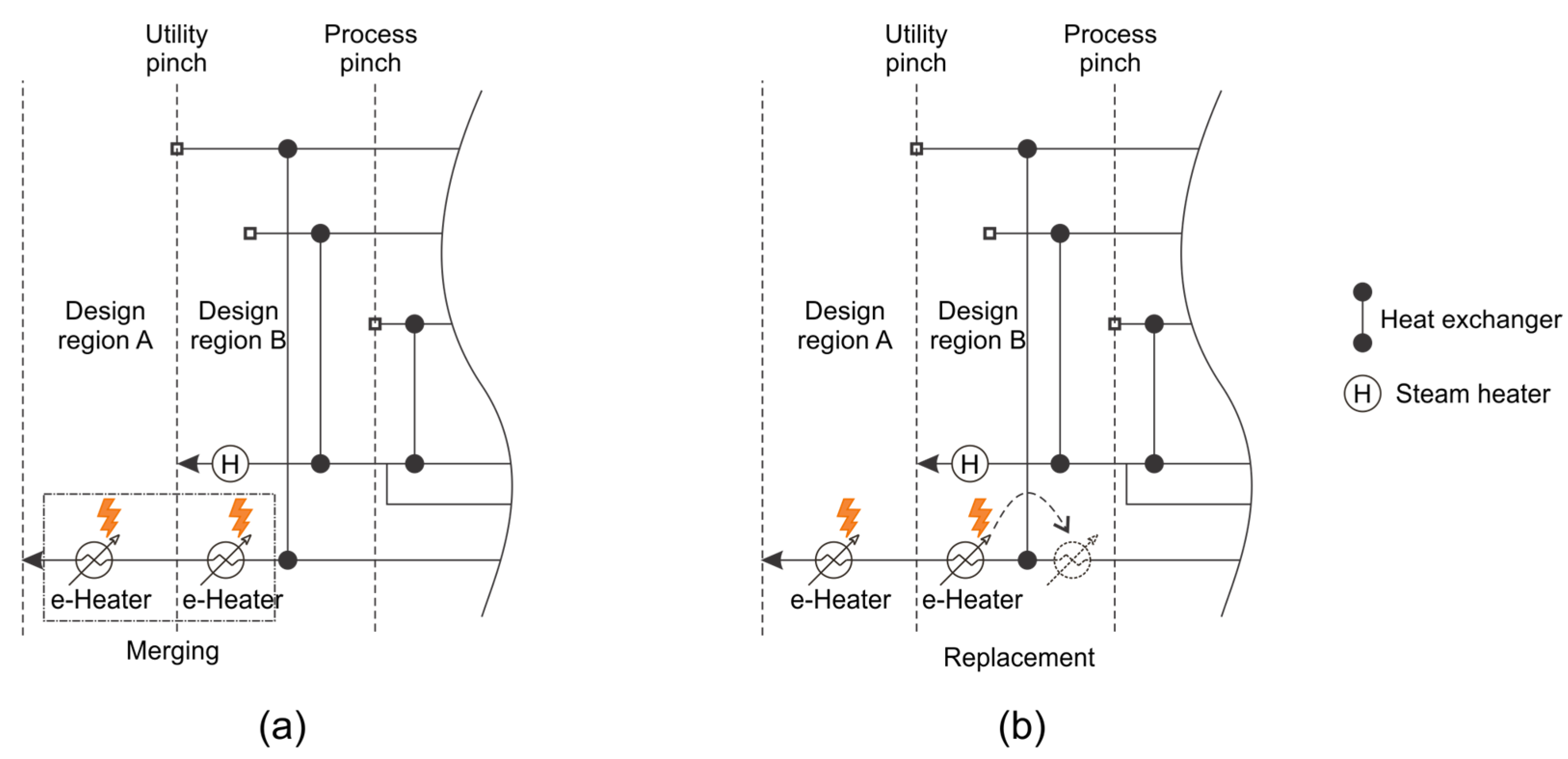

2.3.1. Heat Pumps

2.3.2. Mechanical Vapour Recompression

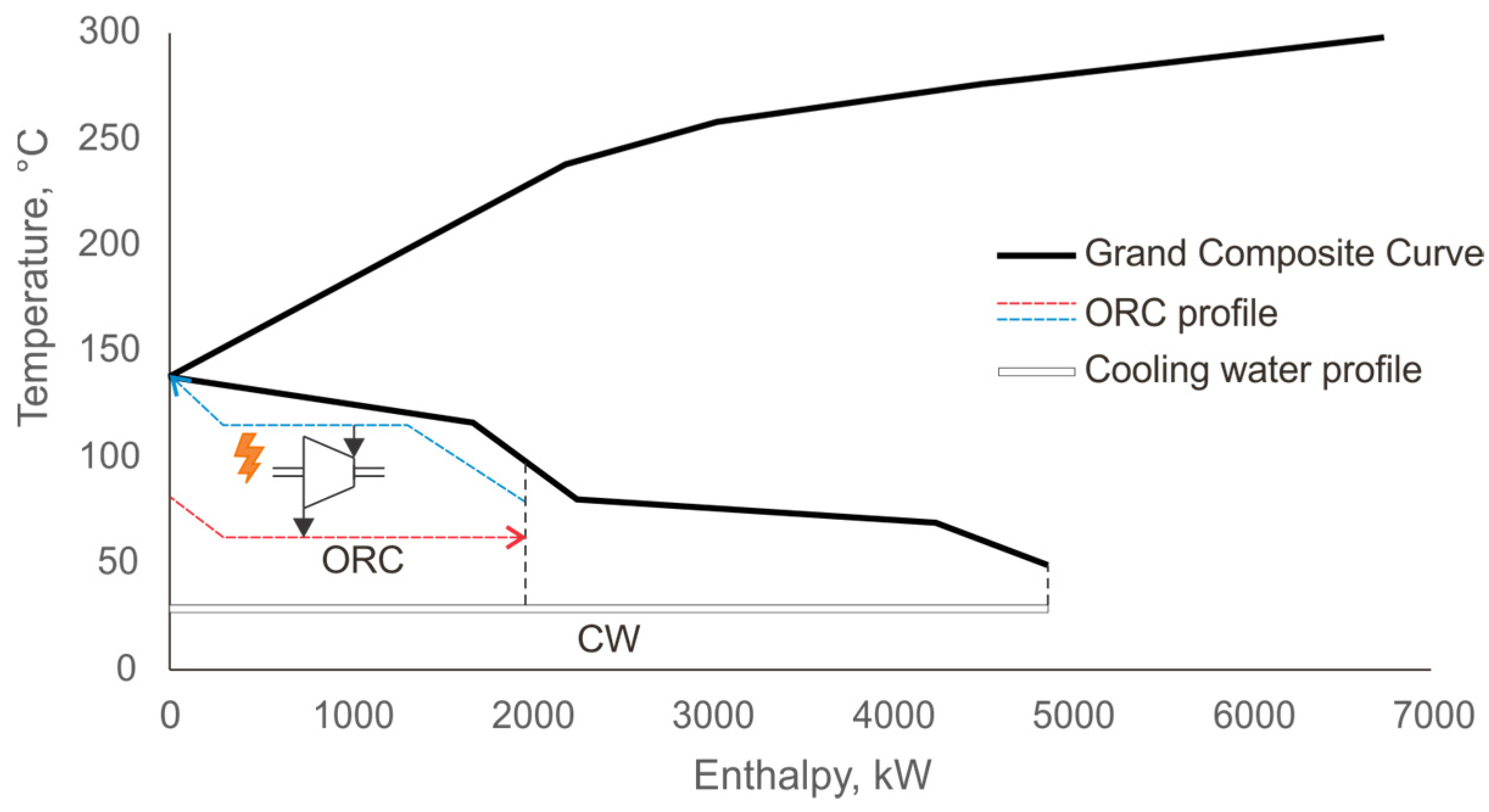

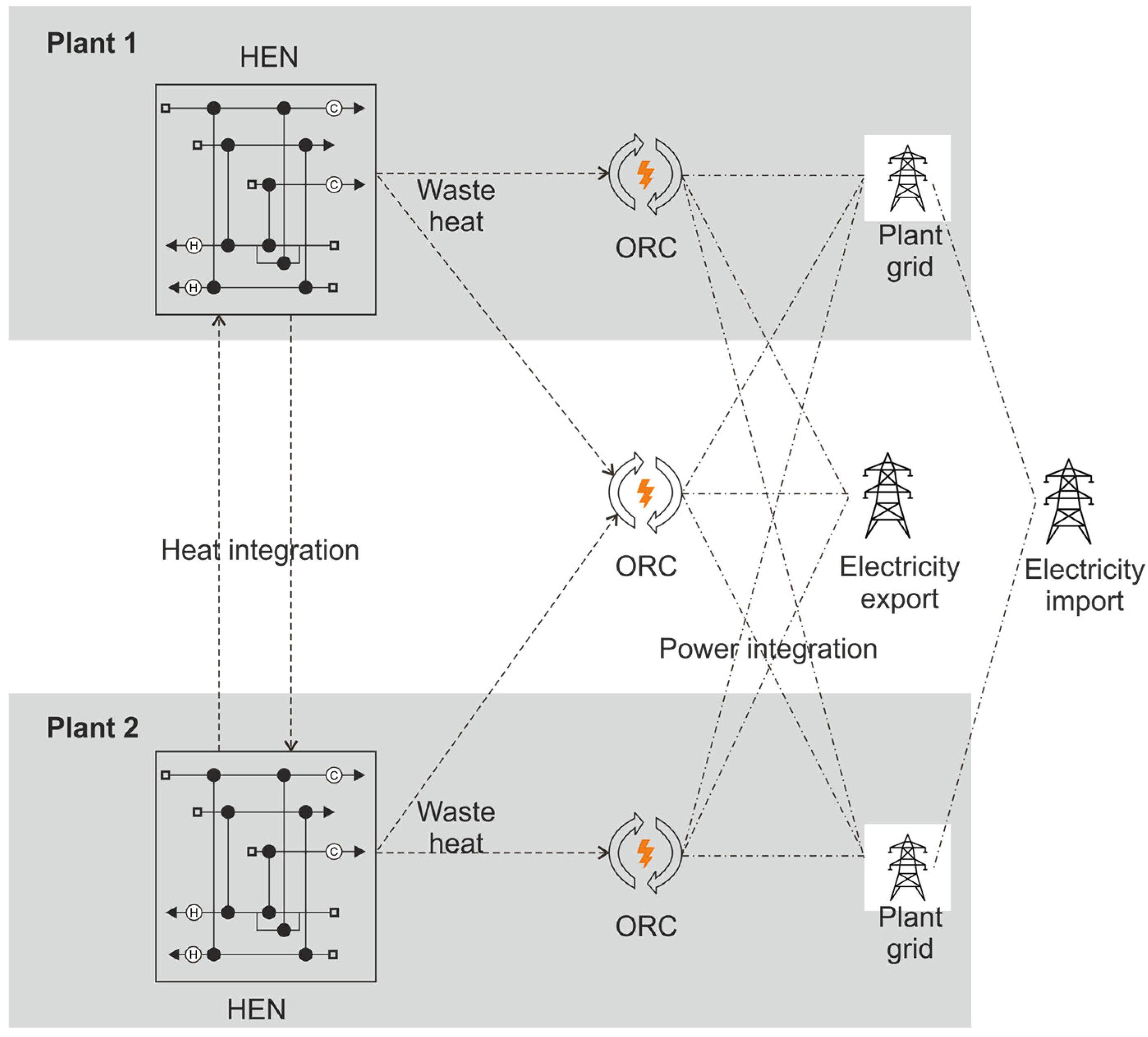

2.3.3. Organic Rankine Cycle

2.4. The Role of Energy Efficiency

2.5. Heat Transfer Enhancement

2.6. CAPEX and OPEX Assessments

2.7. Equipment Challenges

2.8. Energy Storage Involvement

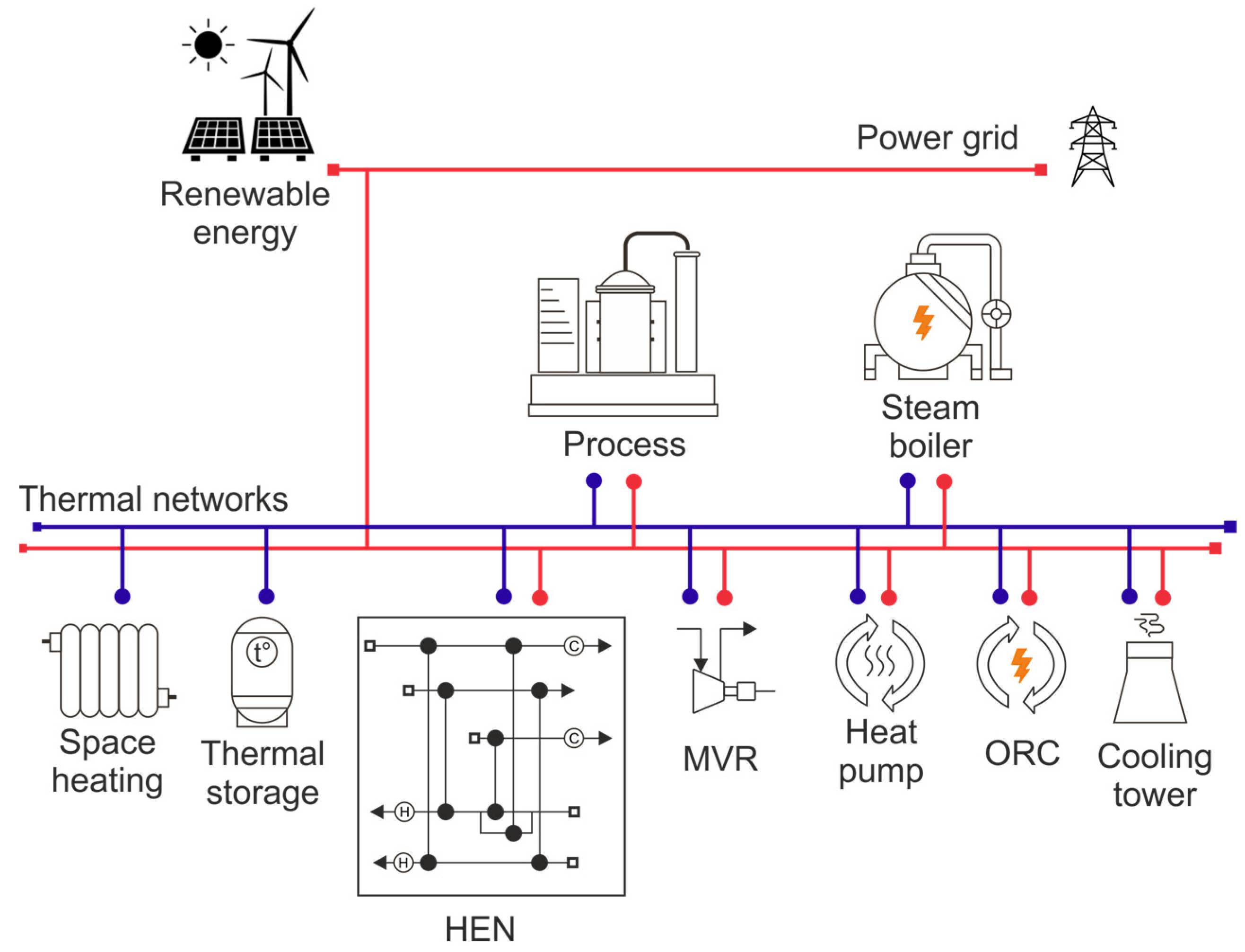

3. Rethinking of Heat Exchanger Networks for Electrified Industrial Energy Systems

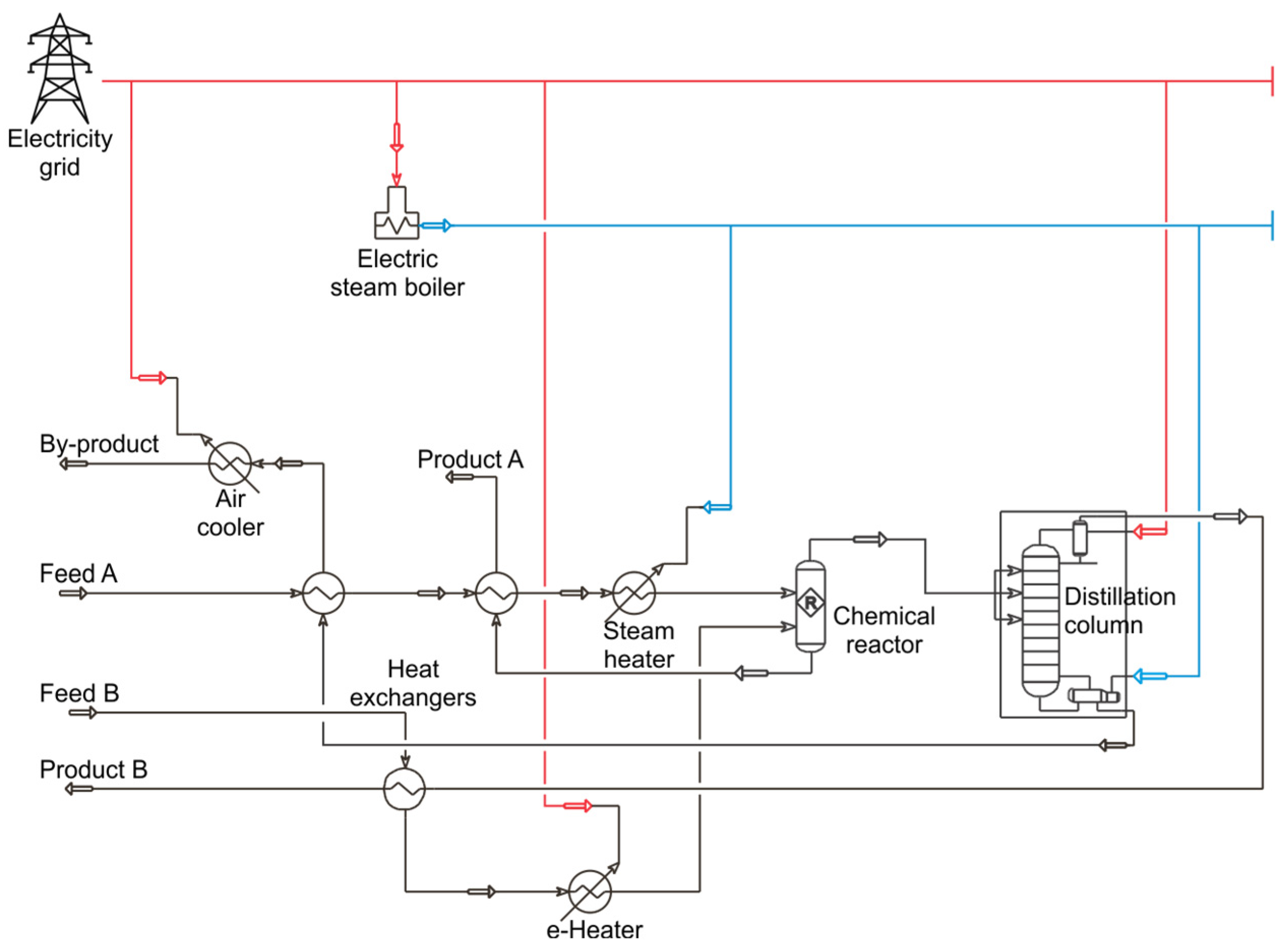

3.1. Interpretation and Development of HEN for Industrial Energy Systems

- Heat pumps, which should be clearly delineated into input and output streams, along with annotations of their COP, which should aptly represent the efficiency of these systems;

- The illustration of MVR systems must encompass both thermal and mechanical flow metrics to reflect their dual operational characteristics;

- A thorough integration of ORCs should capture the nuances of waste heat recovery mechanisms and the associated power generation cycles;

- Energy storage, utilising both the process waste heat and process heating under varying energy supply and waste heat demand sides;

- Steam boilers, electric heaters/furnaces, plasma heaters, and microwave heaters are also available. These components should be represented with comprehensive inflows that illustrate their fuel or electric inputs juxtaposed against their thermal output. It is essential to distinctly differentiate the roles of utility heat and process heat.

- The identification of underutilised heat sources or sinks to enhance energy efficiency;

- The visualisation of energy recirculation loops to enable the assessment of their efficiency and performance;

- The assessment of dependencies on external energy utilities, which will allow for enhanced resilience and sustainability;

- The highlighting of modular or scalable components to facilitate adaptability in the face of changing energy demands or technological advancements.

3.2. Revisiting the Approaches for Heat Exchanger Network Design and Retrofit in the Age of Industrial Electrification

- Define stream data (supply/demand temperatures, heat capacity flows);

- Calculate composite curves and determine pinch points;

- Set up the LP model with constraints for energy balance and capacity limits;

- Minimize the total utility cost (objective function);

- Solve to obtain MER targets (minimum heating/cooling utilities).

- Assume or predefine a network topology (e.g., matches);

- Formulate the energy balance, temperature approach, and exchanger area constraints;

- Define the nonlinear objective, e.g., minimize the total cost or total exchanger area;

- Define a superstructure of all feasible stream matches;

- Introduce binary variables to model the presence/absence of each match;

- Formulate the nonlinear heat balance, temperature constraints, and cost models;

- Define the objective, e.g., minimize the total annualized cost (CAPEX + OPEX);

- Define all relevant objectives (e.g., minimize CO2 emissions, utility cost, or area);

- Choose a multi-objective optimization strategy (e.g., scalarization, Pareto-based);

- Formulate necessary constraints (same as in NLP or MINLP);

- Generate a solution set (Pareto front) that represents trade-offs;

- Use decision-making criteria (e.g., economic value, policy targets) to select the final design.

4. Case Studies in Different Industries

4.1. Oil and Gas

4.2. Food Processing

4.3. Chemical Industry

4.4. Others

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rosenow, J.; Eyre, N. Reinventing Energy Efficiency for Net Zero. Energy Res. Soc. Sci. 2022, 90, 102602. [Google Scholar] [CrossRef]

- Industry-Energy System. Available online: https://www.iea.org/energy-system/industry (accessed on 15 July 2024).

- Net Zero Emissions by 2050 Scenario (NZE)–Global Energy and Climate Model–Analysis. Available online: https://www.iea.org/reports/global-energy-and-climate-model/net-zero-emissions-by-2050-scenario-nze (accessed on 15 July 2024).

- Final Energy Consumption in Industry-Detailed Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Final_energy_consumption_in_industry_-_detailed_statistics (accessed on 14 May 2025).

- Fleiter, T.; Rehfeldt, M.; Neusel, L.; Hirzel, S.; Neuwirth, M.; Schwotzer, C.; Kaiser, F.; Gondorf, C. CO2-Neutral Process Heat Using Electrification and Hydrogen. Perspect.-Policy Brief. 2024, 5–35. [Google Scholar] [CrossRef]

- Schiffer, Z.J.; Manthiram, K. Electrification and Decarbonization of the Chemical Industry. Joule 2017, 1, 10–14. [Google Scholar] [CrossRef]

- Mallapragada, D.S.; Dvorkin, Y.; Modestino, M.A.; Esposito, D.V.; Smith, W.A.; Hodge, B.-M.; Harold, M.P.; Donnelly, V.M.; Nuz, A.; Bloomquist, C.; et al. Decarbonization of the Chemical Industry through Electrification: Barriers and Opportunities. Joule 2023, 7, 23–41. [Google Scholar] [CrossRef]

- Sorknæs, P.; Johannsen, R.M.; Korberg, A.D.; Nielsen, T.B.; Petersen, U.R.; Mathiesen, B.V. Electrification of the Industrial Sector in 100% Renewable Energy Scenarios. Energy 2022, 254, 124339. [Google Scholar] [CrossRef]

- Tang, C.; Zhang, Q. Green Electrification of the Chemical Industry Toward Carbon Neutrality. Engineering 2023, 29, 22–26. [Google Scholar] [CrossRef]

- Meng, M.; Niu, D. Modeling CO2 Emissions from Fossil Fuel Combustion Using the Logistic Equation. Energy 2011, 36, 3355–3359. [Google Scholar] [CrossRef]

- Ray, A.; De, S. Renewable Electricity Generation–Effect on GHG Emission. In Encyclopedia of Renewable and Sustainable Materials; Hashmi, S., Choudhury, I.A., Eds.; Elsevier: Oxford, UK, 2020; pp. 728–735. [Google Scholar]

- Khan, I. Importance of GHG Emissions Assessment in the Electricity Grid Expansion towards a Low-Carbon Future: A Time-Varying Carbon Intensity Approach. J. Clean. Prod. 2018, 196, 1587–1599. [Google Scholar] [CrossRef]

- Aryai, V.; Goldsworthy, M. Real-Time High-Resolution Modelling of Grid Carbon Emissions Intensity. Sustain. Cities Soc. 2024, 104, 105316. [Google Scholar] [CrossRef]

- Fleten, S.-E.; Näsäkkälä, E. Gas-Fired Power Plants: Investment Timing, Operating Flexibility and CO2 Capture. Energy Econ. 2010, 32, 805–816. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. The Levelized Cost of Energy and Modifications for Use in Electricity Generation Planning. Energy Rep. 2023, 9, 495–534. [Google Scholar] [CrossRef]

- Fu, C.; Anantharaman, R.; Jordal, K.; Gundersen, T. Thermal Efficiency of Coal-Fired Power Plants: From Theoretical to Practical Assessments. Energy Convers. Manag. 2015, 105, 530–544. [Google Scholar] [CrossRef]

- Pourhedayat, S.; Hu, E.; Chen, L. Performances of a Gas Turbine Power Plant with a Direct Evaporative Saturator. Therm. Sci. Eng. Prog. 2024, 56, 103047. [Google Scholar] [CrossRef]

- Melani, A.H.A.; Murad, C.A.; Caminada Netto, A.; de Souza, G.F.M.; Nabeta, S.I. Criticality-Based Maintenance of a Coal-Fired Power Plant. Energy 2018, 147, 767–781. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, Q.; Liu, L.; Zhou, D. Renewable Energy Investment under the Market-Oriented Transition of Policies. Energy Policy 2025, 204, 114683. [Google Scholar] [CrossRef]

- Lupi, C.; Anderson, C.B.; Picotti, G.; Cholette, M.E.; Manzolini, G. Design of Solar Fields for Concentrated Solar Power Plants Considering Operation & Maintenance Activities. Sol. Energy 2025, 297, 113564. [Google Scholar] [CrossRef]

- Zhang, F.; Si, G.; Chen, Z.; Zheng, M.; Xia, T.; Xi, L. A Multi-Faceted Opportunistic-Based Maintenance Optimization in Offshore Wind Farms Using Long-Term Wind Speed Forecasting. Renew. Energy 2025, 255, 123826. [Google Scholar] [CrossRef]

- Bolton, R.; Poulter, H. Low Carbon Technologies and the Grid: Analysing Regulation and Transitions in Electricity Networks. Environ. Innov. Soc. Transit. 2025, 55, 100964. [Google Scholar] [CrossRef]

- Daniels, L.; Coker, P.; Potter, B. Embodied Carbon Dioxide of Network Assets in a Decarbonised Electricity Grid. Appl. Energy 2016, 180, 142–154. [Google Scholar] [CrossRef]

- Siesing, L.; Lundström, F.; Frogner, K.; Cedell, T.; Andersson, M. Towards Energy Efficient Heating in Industrial Processes-Three Steps to Achieve Maximized Efficiency in an Induction Heating System. Procedia Manuf. 2018, 25, 404–411. [Google Scholar] [CrossRef]

- Denev, J.A.; Dinkov, I.; Bockhorn, H. Burner Design for an Industrial Furnace for Thermal Post-Combustion. Energy Procedia 2017, 120, 484–491. [Google Scholar] [CrossRef]

- Cookson, E.J.; Floyd, D.E.; Shih, A.J. Design, Manufacture, and Analysis of Metal Foam Electrical Resistance Heater. Int. J. Mech. Sci. 2006, 48, 1314–1322. [Google Scholar] [CrossRef]

- Daryabeigi, E.; Zafari, A.; Shamshirband, S.; Anuar, N.B.; Kiah, M.L.M. Calculation of Optimal Induction Heater Capacitance Based on the Smart Bacterial Foraging Algorithm. Int. J. Electr. Power Energy Syst. 2014, 61, 326–334. [Google Scholar] [CrossRef]

- Dai, W.; Ma, Y.; Zhang, W.; Yang, Y.; Yin, S.; Zhu, H. High-Efficiency Microwave Heating System for Continuously Processing Tubular Materials. J. Clean. Prod. 2025, 497, 145159. [Google Scholar] [CrossRef]

- Padmanabhan, S.B.; Mabrouk, M.T.; Lacarrière, B. Neural-Accelerated Dynamic Modeling of Heat Pumps. Appl. Therm. Eng. 2025, 274, 126653. [Google Scholar] [CrossRef]

- Hasanuzzaman, M.; Rahim, N.A.; Hosenuzzaman, M.; Saidur, R.; Mahbubul, I.M.; Rashid, M.M. Energy Savings in the Combustion Based Process Heating in Industrial Sector. Renew. Sustain. Energy Rev. 2012, 16, 4527–4536. [Google Scholar] [CrossRef]

- Verougstraete, B.; Gholami, M.; Gomez-Rueda, Y.; Pérez-Botella, E.; Schoukens, M.; Van Assche, T.R.C.; Denayer, J.F.M. Advancements and Challenges in Electric Heating for Enhanced Temperature Swing Adsorption Processes. Sep. Purif. Technol. 2025, 353, 128522. [Google Scholar] [CrossRef]

- Lincoln, B.J.; Kong, L.; Schlosser, F.; Walmsley, T.G. Process Integration and Electrification for Retrofit: Case Studies of Milk Evaporator Systems. Case Stud. Therm. Eng. 2024, 60, 104601. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, M.; Wang, C.; Wang, Z.; Chong, D.; Yan, J. Exergy Analysis of the Regulating Measures of Operational Flexibility in Supercritical Coal-Fired Power Plants during Transient Processes. Appl. Energy 2019, 253, 113487. [Google Scholar] [CrossRef]

- Lopes, R.A.; Silva, F.; Menezes-Barros, R.; Amaro, N.; de Carvalho, A.G.; Martins, J. Exploring Energy Flexibility from Smart Electrical Water Heaters to Improve Electrification Benefits in Residential Buildings: Findings from Real-World Operation. Energy 2025, 316, 134381. [Google Scholar] [CrossRef]

- Zhong, Q.; Zhang, Z.; Wang, H.; Zhang, X.; Wang, Y.; Wang, P.; Ma, F.; Yue, Q.; Du, T.; Chen, W.-Q.; et al. Incorporating Scarcity into Footprints Reveals Diverse Supply Chain Hotspots for Global Fossil Fuel Management. Appl. Energy 2023, 349, 121692. [Google Scholar] [CrossRef]

- Palander, T. Modelling Renewable Supply Chain for Electricity Generation with Forest, Fossil, and Wood-Waste Fuels. Energy 2011, 36, 5984–5993. [Google Scholar] [CrossRef]

- Gailani, A.; Cooper, S.; Allen, S.; Pimm, A.; Taylor, P.; Gross, R. Assessing the Potential of Decarbonization Options for Industrial Sectors. Joule 2024, 8, 576–603. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, Y.; Zhang, L.; Gu, H.; Liao, Y. Natural Resources, Cleaner Electricity Production and Economic Performance. Resour. Policy 2023, 86, 104271. [Google Scholar] [CrossRef]

- Li, N.; Klemeš, J.J.; Sunden, B.; Wu, Z.; Wang, Q.; Zeng, M. Heat Exchanger Network Synthesis Considering Detailed Thermal-Hydraulic Performance: Methods and Perspectives. Renew. Sustain. Energy Rev. 2022, 168, 112810. [Google Scholar] [CrossRef]

- Tan, R.R.; Migo-Sumagang, M.V.; Aviso, K.B. Plan Durable Carbon Dioxide Removal with Pinch Analysis. Process Integr. Optim. Sustain. 2024, 9, 427–430. [Google Scholar] [CrossRef]

- Yee, T.F.; Grossmann, I.E. Simultaneous Optimization Models for Heat Integration—II. Heat Exchanger Network Synthesis. Comput. Chem. Eng. 1990, 14, 1165–1184. [Google Scholar] [CrossRef]

- Ciric, A.R.; Floudas, C.A. A Retrofit Approach for Heat Exchanger Networks. Comput. Chem. Eng. 1989, 13, 703–715. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Kravanja, Z. Forty Years of Heat Integration: Pinch Analysis (PA) and Mathematical Programming (MP). Curr. Opin. Chem. Eng. 2013, 2, 461–474. [Google Scholar] [CrossRef]

- Varbanov, P.S.; Doyle, S.; Smith, R. Modelling and Optimization of Utility Systems. Chem. Eng. Res. Des. 2004, 82, 561–578. [Google Scholar] [CrossRef]

- Čuček, L.; Boldyryev, S.; Klemeš, J.J.; Kravanja, Z.; Krajačić, G.; Varbanov, P.S.; Duić, N. Approaches for Retrofitting Heat Exchanger Networks within Processes and Total Sites. J. Clean. Prod. 2019, 211, 884–894. [Google Scholar] [CrossRef]

- Knorr, L.; Buchenau, N.; Schlosser, F.; Divkovic, D.; Prina, M.G.; Meschede, H. Electrification and Flexibility of Process Heat in Energy System Modelling: A Review. Renew. Sustain. Energy Rev. 2025, 216, 115698. [Google Scholar] [CrossRef]

- Abadi, M.M.; Tang, H.; Rashidi, M.M. A Review of Simulation and Numerical Modeling of Electric Arc Furnace (EAF) and Its Processes. Heliyon 2024, 10, e32157. [Google Scholar] [CrossRef]

- Wang, M.C.; Chen, Y.P.; Wu, J.F.; Dong, C. Heat Transfer Enhancement of Folded Helical Baffle Electric Heaters with One-plus-Two U-Tube Units. Appl. Therm. Eng. 2016, 102, 586–595. [Google Scholar] [CrossRef]

- Mineev, A.B. Chapter 9-Plasma Heating Systems. In Fundamentals of Magnetic Thermonuclear Reactor Design; Woodhead Publishing Series in Energy; Glukhikh, V., Filatov, O., Kolbasov, B., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 281–290. [Google Scholar]

- Schoeneberger, C.; Zhang, J.; McMillan, C.; Dunn, J.B.; Masanet, E. Electrification Potential of U.S. Industrial Boilers and Assessment of the GHG Emissions Impact. Adv. Appl. Energy 2022, 5, 100089. [Google Scholar] [CrossRef]

- Shenoy, U.V.; Sinha, A.; Bandyopadhyay, S. Multiple Utilities Targeting for Heat Exchanger Networks. Chem. Eng. Res. Des. 1998, 76, 259–272. [Google Scholar] [CrossRef]

- Linnhoff, B.; Ahmad, S. Cost Optimum Heat Exchanger Networks—1. Minimum Energy and Capital Using Simple Models for Capital Cost. Comput. Chem. Eng. 1990, 14, 729–750. [Google Scholar] [CrossRef]

- Kim, J.-K.; Son, H.; Yun, S. Heat Integration of Power-to-Heat Technologies: Case Studies on Heat Recovery Systems Subject to Electrified Heating. J. Clean. Prod. 2022, 331, 130002. [Google Scholar] [CrossRef]

- Kim, J.-K. Studies on the Conceptual Design of Energy Recovery and Utility Systems for Electrified Chemical Processes. Renew. Sustain. Energy Rev. 2022, 167, 112718. [Google Scholar] [CrossRef]

- Trivedi, K.K.; O’Neill, B.K.; Roach, J.R. Synthesis of Heat Exchanger Networks Featuring Multiple Pinch Points. Comput. Chem. Eng. 1989, 13, 291–294. [Google Scholar] [CrossRef]

- Pavão, L.V.; Costa, C.B.B.; Ravagnani, M.A.S.S. Multiple Utilities Targeting in Energy Integration Considering Rigorous Temperature-Enthalpy Relations. Chem. Eng. Sci. 2023, 276, 118763. [Google Scholar] [CrossRef]

- Linnhoff, B.; Smith, R. Pinch Principle. Mech. Eng. 1988, 110, 70–73. [Google Scholar]

- Floudas, C.A.; Ciric, A.R.; Grossmann, I.E. Automatic Synthesis of Optimum Heat Exchanger Network Configurations. AIChE J. 1986, 32, 276–290. [Google Scholar] [CrossRef]

- Nemet, A.; Isafiade, A.J.; Klemeš, J.J.; Kravanja, Z. Two-Step MILP/MINLP Approach for the Synthesis of Large-Scale HENs. Chem. Eng. Sci. 2019, 197, 432–448. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, L.; Xing, Y.; Du, J. A Novel Two-Step Approach for Multi-Plant Indirect HENs Design. Chem. Eng. Sci. 2024, 285, 119559. [Google Scholar] [CrossRef]

- Huber, D. Multi-Objective Heat Exchanger Network Synthesis: Simultaneous Optimization of Heat Integration and Process Design. Ph.D. Thesis, Technische Universität Wien, Vienna, Austria, 2024. [Google Scholar]

- Meng, W.; Wang, D.; Zhou, H.; Liao, Z.; Hong, X.; Li, G. Design and Analysis for Chemical Process Electrification Based on Renewable Electricity: Coal-to-Methanol Process as a Case Study. Energy Convers. Manag. 2023, 292, 117424. [Google Scholar] [CrossRef]

- Pierri, E.; Hellkamp, D.; Thiede, S.; Herrmann, C. Enhancing Energy Flexibility through the Integration of Variable Renewable Energy in the Process Industry. Procedia CIRP 2021, 98, 7–12. [Google Scholar] [CrossRef]

- Boldyryev, S.; Gil, T. Debottlenecking of Existing Hydrocracking Unit by Improved Heat Recovery for Energy and Carbon Dioxide Savings. Energy Convers. Manag. 2021, 238, 114164. [Google Scholar] [CrossRef]

- Cormos, C.-C.; Petrescu, L.; Cormos, A.-M.; Dragan, S.; Dinca, C.; Sandru, M. Integration of Renewable Energy and CO2 Capture and Utilization Technologies for Decarbonization of Energy Intensive Process Industries. In Computer Aided Chemical Engineering, Proceedings of the 33 European Symposium on Computer Aided Process Engineering, Athens, Greece, 18–21 June 2023; Kokossis, A.C., Georgiadis, M.C., Pistikopoulos, E., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; Volume 52, pp. 2777–2784. [Google Scholar]

- Boldyryev, S.; Ilchenko, M.; Kaldybaeva, B.; Krajacic, G. Modelling of the Use of Renewable Energies and Energy-Saving Measures for Polymer Chemical Plant. Chem. Eng. Trans. 2023, 103, 535–540. [Google Scholar] [CrossRef]

- Wallerand, A.S.; Kermani, M.; Kantor, I.; Maréchal, F. Optimal Heat Pump Integration in Industrial Processes. Appl. Energy 2018, 219, 68–92. [Google Scholar] [CrossRef]

- Walmsley, T.G.; Lincoln, B.J.; Padullés, R.; Cleland, D.J. Advancing Industrial Process Electrification and Heat Pump Integration with New Exergy Pinch Analysis Targeting Techniques. Energies 2024, 17, 2838. [Google Scholar] [CrossRef]

- Walden, J.V.M.; Stathopoulos, P. The Impact of Heat Pump Load Flexibility on Its Process Integration and Economics. J. Clean. Prod. 2024, 462, 142643. [Google Scholar] [CrossRef]

- Boldyryev, S.; Ilchenko, M.; Krajačić, G. Improving the Economic Efficiency of Heat Pump Integration into Distillation Columns of Process Plants Applying Different Pressures of Evaporators and Condensers. Energies 2024, 17, 951. [Google Scholar] [CrossRef]

- Walden, J.V.M.; Wellig, B.; Stathopoulos, P. Heat Pump Integration in Non-Continuous Industrial Processes by Dynamic Pinch Analysis Targeting. Appl. Energy 2023, 352, 121933. [Google Scholar] [CrossRef]

- Ibrić, N.; Ahmetović, E.; Kravanja, Z.; Gundersen, T. Synthesis of Heat-Integrated Water Networks: Integration of Heat Pumps. Appl. Therm. Eng. 2024, 254, 123760. [Google Scholar] [CrossRef]

- Flórez-Orrego, D.; Domingos, M.E.R.; Maréchal, F. Techno-Economic and Environmental Analysis of High Temperature Heat Pumps Integration into Industrial Processes: The Ammonia Plant and Pulp Mill Cases. Sustain. Energy Technol. Assess. 2023, 60, 103560. [Google Scholar] [CrossRef]

- Bobbo, S.; Lombardo, G.; Menegazzo, D.; Vallese, L.; Fedele, L. A Technological Update on Heat Pumps for Industrial Applications. Energies 2024, 17, 4942. [Google Scholar] [CrossRef]

- Mekidiche-Martinez, Z.; Caballero, J.A.; Labarta, J.A. Efficient Use of Energy in Distillation: Advancing towards the Electrification of the Chemical Industry. In Computer Aided Chemical Engineering, Proceedings of the 34 European Symposium on Computer Aided Process Engineering/15 International Symposium on Process Systems Engineering, Florence, Italy, 2–6 June 2024; Manenti, F., Reklaitis, G.V., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; Volume 53, pp. 103–108. [Google Scholar]

- Cui, C.; Qi, M.; Zhang, X.; Sun, J.; Li, Q.; Kiss, A.A.; Wong, D.S.-H.; Masuku, C.M.; Lee, M. Electrification of Distillation for Decarbonization: An Overview and Perspective. Renew. Sustain. Energy Rev. 2024, 199, 114522. [Google Scholar] [CrossRef]

- Yu, A.; Ye, Q.; Li, J.; Wang, Y.; Rui, Q. Energy-Saving Improvement of Heat Integration and Heat Pump for Separating Multi-Azeotropes Mixture via Novel Pressure Swing Distillation. Chem. Eng. Sci. 2023, 282, 119239. [Google Scholar] [CrossRef]

- Boldyryev, S.; Kuznetsov, M.; Ryabova, I.; Krajačić, G.; Kaldybaeva, B. Assessment of Renewable Energy Use in Natural Gas Liquid Processing by Improved Process Integration with Heat Pumps. e-Prime-Adv. Electr. Eng. Electron. Energy 2023, 5, 100246. [Google Scholar] [CrossRef]

- Cui, C.; Zhang, X.; Qi, M.; Lyu, H.; Sun, J.; Kiss, A.A. Fully Electrified Heat Pump Assisted Distillation Process by Flash Vapour Circulation. Chem. Eng. Res. Des. 2024, 206, 280–284. [Google Scholar] [CrossRef]

- Janković, T.; Straathof, A.J.J.; Kiss, A.A. Thermally Self-Sufficient Heat Pump-Assisted Azeotropic Dividing-Wall Column for Biofuels Recovery from Isopropanol-Butanol-Ethanol Fermentation. Chem. Eng. Process.-Process Intensif. 2024, 197, 109689. [Google Scholar] [CrossRef]

- Miao, G.; Ma, Y.; Yang, C.; Tong, B.; Li, G.; Xiao, J. The Effective Synthesis of Heat-Pump Assisted Distillation Process with Multiple Columns for Light Hydrocarbon Separation. Chem. Eng. Sci. 2023, 269, 118449. [Google Scholar] [CrossRef]

- Lincoln, B.J.; Kong, L.; Pineda, A.M.; Walmsley, T.G. Process Integration and Electrification for Efficient Milk Evaporation Systems. Energy 2022, 258, 124885. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, L.; Liu, Z.; Hao, L.; Wei, H. Synergy of Electrification and Energy Efficiency Improvement via Vapor Recompression Heat Pump and Heat Exchanger Network to Achieve Decarbonization of Extractive Distillation. Sep. Purif. Technol. 2022, 293, 121065. [Google Scholar] [CrossRef]

- Wang, H.; Yu, P.; Chen, L.; Chen, L.; Sun, B. Simulation and Modification of an Ethane-Ethylene Separation Unit Using Vapor Recompression Heat Pump: Energy, Exergy, and Economic Analyses. Appl. Therm. Eng. 2024, 239, 121993. [Google Scholar] [CrossRef]

- Aeowjaroenlap, H.; Strohm, J.; Udugama, I.; Yu, W.; Young, B. Dynamic Modelling of a Milk Triple Effect Falling Film Evaporator with Mechanical Vapor Recompression. In Computer Aided Chemical Engineering, Proceedings of the 34 European Symposium on Computer Aided Process Engineering/15 International Symposium on Process Systems Engineering, Florence, Italy, 2–6 June 2024; Manenti, F., Reklaitis, G.V., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; Volume 53, pp. 475–480. [Google Scholar]

- Atalar, I.; Tugrul, K.M.; Gorgulu, A.; Konar, N. 5-Vapor Recompression Systems for Food Processing Evaporators. In Evaporation Technology in Food Processing; Jafari, S.M., Çapanoglu, E., Karaca, A.C., Eds.; Woodhead Publishing: Cambridge, UK, 2024; pp. 85–101. [Google Scholar]

- Guedes do Nascimento, L.; Costa Monteiro, L.P.; de Cássia Colman Simões, R.; Prata, D.M. Eco-Efficiency Analysis and Intensification of the Biodiesel Production Process through Vapor Recompression Strategy. Energy 2023, 275, 127479. [Google Scholar] [CrossRef]

- Si, Z.; Han, D.; Gu, J.; Song, Y.; Liu, Y. Exergy Analysis of a Vacuum Membrane Distillation System Integrated with Mechanical Vapor Recompression for Sulfuric Acid Waste Treatment. Appl. Therm. Eng. 2020, 178, 115516. [Google Scholar] [CrossRef]

- Yuan, H.; Luo, Y.; Yuan, X. Synthesis of Heat-Integrated Distillation Sequences with Mechanical Vapor Recompression by Stochastic Optimization. Comput. Chem. Eng. 2022, 165, 107922. [Google Scholar] [CrossRef]

- Han, D.; Si, Z.; Chen, J. Analysis of an Intermittent Mechanical Vapor Recompression Evaporation System. Appl. Therm. Eng. 2021, 193, 116996. [Google Scholar] [CrossRef]

- Woolway, M.; Majozi, T. On the Application of a Metaheuristic Suite with Parallel Implementations for the Scheduling of Multipurpose Batch Plants. Comput. Chem. Eng. 2019, 126, 371–390. [Google Scholar] [CrossRef]

- Chen, J.; Han, D.; Hang, Z.; Si, Z. Experimental Investigation of a Novel Batch Evaporation System Coupled Mechanical Vapor Recompression Technology and Steam Heat Storage Technology. Innov. Food Sci. Emerg. Technol. 2021, 68, 102616. [Google Scholar] [CrossRef]

- Agner, R.; Gruber, P.; Wellig, B. Model Predictive Control of Heat Pumps with Thermal Energy Storages in Industrial Processes. Energies 2024, 17, 4823. [Google Scholar] [CrossRef]

- Loni, R.; Najafi, G.; Bellos, E.; Rajaee, F.; Said, Z.; Mazlan, M. A Review of Industrial Waste Heat Recovery System for Power Generation with Organic Rankine Cycle: Recent Challenges and Future Outlook. J. Clean. Prod. 2021, 287, 125070. [Google Scholar] [CrossRef]

- Hipólito-Valencia, B.J.; Rubio-Castro, E.; Ponce-Ortega, J.M.; Serna-González, M.; Nápoles-Rivera, F.; El-Halwagi, M.M. Optimal Design of Inter-Plant Waste Energy Integration. Appl. Therm. Eng. 2014, 62, 633–652. [Google Scholar] [CrossRef]

- Boldyryev, S.; Gil, T.; Krajačić, G.; Khussanov, A. Total Site Targeting with the Simultaneous Use of Intermediate Utilities and Power Cogeneration at the Polymer Plant. Energy 2023, 279, 128034. [Google Scholar] [CrossRef]

- Mateu-Royo, C.; Mota-Babiloni, A.; Navarro-Esbrí, J.; Peris, B.; Molés, F.; Amat-Albuixech, M. Multi-Objective Optimization of a Novel Reversible High-Temperature Heat Pump-Organic Rankine Cycle (HTHP-ORC) for Industrial Low-Grade Waste Heat Recovery. Energy Convers. Manag. 2019, 197, 111908. [Google Scholar] [CrossRef]

- Pili, R.; Romagnoli, A.; Jiménez-Arreola, M.; Spliethoff, H.; Wieland, C. Simulation of Organic Rankine Cycle–Quasi-Steady State vs Dynamic Approach for Optimal Economic Performance. Energy 2019, 167, 619–640. [Google Scholar] [CrossRef]

- Eveloy, V.; Rodgers, P.; Qiu, L. Integration of an Atmospheric Solid Oxide Fuel Cell-Gas Turbine System with Reverse Osmosis for Distributed Seawater Desalination in a Process Facility. Energy Convers. Manag. 2016, 126, 944–959. [Google Scholar] [CrossRef]

- White, M.T.; Oyewunmi, O.A.; Haslam, A.J.; Markides, C.N. Industrial Waste-Heat Recovery through Integrated Computer-Aided Working-Fluid and ORC System Optimisation Using SAFT-γ Mie. Energy Convers. Manag. 2017, 150, 851–869. [Google Scholar] [CrossRef]

- Pili, R.; Romagnoli, A.; Spliethoff, H.; Wieland, C. Techno-Economic Analysis of Waste Heat Recovery with ORC from Fluctuating Industrial Sources. Energy Procedia 2017, 129, 503–510. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Feng, X. Optimal Design of Industrial Cooling Water Systems Considering Economic Performance and Water Savings. Comput. Chem. Eng. 2022, 167, 108021. [Google Scholar] [CrossRef]

- Guo, F.; Zhu, X.; Li, P.; Yang, X. Low-Grade Industrial Waste Heat Utilization in Urban District Heating: Simulation-Based Performance Assessment of a Seasonal Thermal Energy Storage System. Energy 2022, 239, 122345. [Google Scholar] [CrossRef]

- Boldyryev, S.; Krajačić, G.; Garafulić, E. Identification of Industrial Waste Heat Potential for District Heating Systems by Pinch-Based Systematic Graphical Approach. Energy Convers. Manag. 2025, 333, 119804. [Google Scholar] [CrossRef]

- Peris, B.; Navarro-Esbrí, J.; Mateu-Royo, C.; Mota-Babiloni, A.; Molés, F.; Gutiérrez-Trashorras, A.J.; Amat-Albuixech, M. Thermo-Economic Optimization of Small-Scale Organic Rankine Cycle: A Case Study for Low-Grade Industrial Waste Heat Recovery. Energy 2020, 213, 118898. [Google Scholar] [CrossRef]

- Lykas, P.; Atsonios, K.; Gkountas, A.; Bakalis, P.; Manolakos, D.; Grammelis, P.; Itskos, G.; Nikolopoulos, N. Energy, Exergy, and Economic Comparison of ORC with Quasi-Isothermal Expansion with Other ORC Designs for Low-Grade Waste Heat Recovery. Therm. Sci. Eng. Prog. 2024, 55, 103010. [Google Scholar] [CrossRef]

- Boldyryev, S.; Shamraev, A.A.; Shamraeva, E.O. The Design of the Total Site Exchanger Network with Intermediate Heat Carriers: Theoretical Insights and Practical Application. Energy 2021, 223, 120023. [Google Scholar] [CrossRef]

- Chin, H.H.; Varbanov, P.S.; Wan Alwi, S.R.; Manan, Z.A.; Martincová, J.V. Blockchain-Based Concept for Total Site Heat Integration: A Pinch-Based Smart Contract Energy Management in Industrial Symbiosis. Energy 2024, 305, 132261. [Google Scholar] [CrossRef]

- Gómez-de-Arteche-Botas, M.; Iturralde-Iñarga, J.; Fúnez-Guerra, C. Heat Pump Integration for Waste Heat Recovery from a 20 MWe Green Hydrogen Plant to Increase Global Efficiency. Int. J. Hydrogen Energy 2025, 142, 777–783. [Google Scholar] [CrossRef]

- Wang, K.; Xue, Y.; Guo, Q.; Shahidehpour, M.; Zhou, Q.; Wang, B.; Sun, H. A Coordinated Reconfiguration Strategy for Multi-Stage Resilience Enhancement in Integrated Power Distribution and Heating Networks. IEEE Trans. Smart Grid 2023, 14, 2709–2722. [Google Scholar] [CrossRef]

- Zhai, X.; Li, Z.; Li, Z.; Xue, Y.; Chang, X.; Su, J.; Jin, X.; Wang, P.; Sun, H. Risk-Averse Energy Management for Integrated Electricity and Heat Systems Considering Building Heating Vertical Imbalance: An Asynchronous Decentralized Approach. Appl. Energy 2025, 383, 125271. [Google Scholar] [CrossRef]

- Brückner, A.; Wölke, M.; Hein-Pensel, F.; Schero, E.; Winkler, H.; Jabs, I. Assessing Industry 5.0 Readiness—Prototype of a Holistic Digital Index to Evaluate Sustainability, Resilience and Human-Centered Factors. Int. J. Inf. Manag. Data Insights 2025, 5, 100329. [Google Scholar] [CrossRef]

- Gawusu, S.; Solahudeen Tando, M.; Ahmed, A.; Abdulai Jamatutu, S.; Afriyie Mensah, R.; Das, O.; Mohammed, A.-L.; Nandom Yakubu, I.; Ackah, I. Decentralized Energy Systems and Blockchain Technology: Implications for Alleviating Energy Poverty. Sustain. Energy Technol. Assess. 2024, 65, 103795. [Google Scholar] [CrossRef]

- Garrido, S.; Muniz, J.; Batista Ribeiro, V. Operations Management, Sustainability & Industry 5.0: A Critical Analysis and Future Agenda. Clean. Logist. Supply Chain 2024, 10, 100141. [Google Scholar] [CrossRef]

- Linnhoff, B.; Ahmad, S. Supertargeting: Optimum Synthesis of Energy Management Systems. J. Energy Resour. Technol. 1989, 111, 121–130. [Google Scholar] [CrossRef]

- World Energy Outlook 2023–Analysis. Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 18 October 2024).

- Hesselgreaves, J.E.; Law, R.; Reay, D. Compact Heat Exchangers: Selection, Design and Operation; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Alizadeh Zolbin, M.; Tahouni, N.; Panjeshahi, M.H. Total Site Integration Considering Wind /Solar Energy with Supply/Demand Variation. Energy 2022, 252, 123928. [Google Scholar] [CrossRef]

- Das, S.; Rasouli, E.; Ziev, T.; Lamprinakos, N.; Seo, J.; Rollett, A.; Vaishnav, P.; Narayanan, V. Design and Techno Economic Optimization of an Additively Manufactured Compact Heat Exchanger for High Temperature and High Pressure Applications. Appl. Therm. Eng. 2024, 245, 122778. [Google Scholar] [CrossRef]

- Colgan, N.; Nellis, G.; Anderson, M. Experimental Measurement of the Pressure Drop and Heat Transfer Characteristics of a Crossflow Heat Exchanger in Low-Density Flows. Int. J. Heat Mass Transf. 2024, 219, 124782. [Google Scholar] [CrossRef]

- Klemes, J.J.; Arsenyeva, O.; Kapustenko, P.; Tovazhnyanskyy, L. Compact Heat Exchangers for Energy Transfer Intensification: Low Grade Heat and Fouling Mitigation; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Kiepfer, H.; Stannek, P.; Grundler, M.; Bart, H.-J. Development and Thermal Performance of a Thermoplastic-Graphite-Composite Based Plate Heat Exchanger for Use in Corrosive Media. Appl. Therm. Eng. 2024, 236, 121581. [Google Scholar] [CrossRef]

- Güler, O.V.; Gürel, B.; Kurtuluş, K.; Aryanfar, Y.; Castellanos, H.G.; Göltaş, M.; Keçebaş, A.; Akkaya, V.R. Thermo-Hydraulic Efficiency of Lung-Inspired Compact Plate Heat Exchangers Made Using Additive Manufacturing Techniques with Steel, Aluminum and Titanium Powders. Chem. Eng. Sci. 2024, 283, 119378. [Google Scholar] [CrossRef]

- Jafari-Asl, J.; Lara Montaño, O.D.; Mirjalili, S.; Faes, M.G.R. A Meta-Heuristic Approach for Reliability-Based Design Optimization of Shell-and-Tube Heat Exchangers. Appl. Therm. Eng. 2024, 248, 123161. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, P.; Wang, S.; Lyu, P.; Liu, X.; Rao, Z. Heat Transfer Enhancement of Latent Functional Thermal Fluid in Microchannel with Pin Fins. Int. J. Heat Mass Transf. 2025, 244, 126921. [Google Scholar] [CrossRef]

- Liu, J.; Wu, H.; Hua, X.; Wei, J.; Liu, Z. Enhanced Flow Boiling Heat Transfer in Embedded Hybrid Distributed Jet/Pin-Fin Microchannel Heat Sink. Exp. Therm. Fluid Sci. 2025, 168, 111508. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Zhu, P.; Li, J.; Li, Y.; Zhou, C.; Qiu, Q.; Jing, X.; Paik, K.-W.; He, P. Recent Achievements and Performance of Nanomaterials in Microwave Absorption and Electromagnetic Shielding. Adv. Colloid Interface Sci. 2025, 335, 103336. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, S.; Arain, M.B.; Shah, A.; Soylak, M. Applications of Zirconium Based Electrochemical Sensors for Smart Sensing, Energy Production, Biosensing and Environmental Sustainability. Sens. Actuators B Chem. 2025, 441, 137990. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Wang, Q.-W.; Varbanov, P.S.; Zeng, M.; Chin, H.H.; Lal, N.S.; Li, N.-Q.; Wang, B.; Wang, X.-C.; Walmsley, T.G. Heat Transfer Enhancement, Intensification and Optimisation in Heat Exchanger Network Retrofit and Operation. Renew. Sustain. Energy Rev. 2020, 120, 109644. [Google Scholar] [CrossRef]

- Babaelahi, M.; Sadri, S.; Al-Jaberi, O. Numerical Modeling and Multi-Objective Optimization of Helically Grooved Tube Geometry in Shell-and-Tube Heat Exchangers: A Comprehensive Analysis of Heat Transfer Enhancement, Turbulence Characteristics, and Pressure Drop Using COMSOL Multiphysics. Chem. Eng. Sci. 2025, 311, 121638. [Google Scholar] [CrossRef]

- Alipour, R.; Alipour, R.; Rezaeimanesh, M.; Tahan, M.H.; Dehghan, M. Heat Transfer Enhancement in a Tubular Heat Exchanger Fitted with a Novel Baffle: A Numerical Study and Experimental Validation. Int. J. Therm. Sci. 2025, 215, 109936. [Google Scholar] [CrossRef]

- Beigzadeh, R.; Soltanian, S.; Tofangchi, D. Enhancing Heat Transfer Efficiency in Heat Exchangers: A Fusion of Computational Fluid Dynamics and Genetic Algorithm for Circular Baffle Optimization. Int. J. Heat Fluid Flow 2025, 112, 109726. [Google Scholar] [CrossRef]

- Sun, Y.; Li, D.; Ji, J.; Hua, Z. Numerical Study of Structural Parameters of Perforated Baffle on Heat Transfer Enhancement in Coiled Elastic Copper Tube Heat Exchanger. Appl. Therm. Eng. 2025, 260, 124993. [Google Scholar] [CrossRef]

- Liu, S.; Chen, Z.; Yin, S.; Tu, A.; Zhu, D. Heat Transfer Enhancement Characteristic of Twisted Elliptical Tube Heat Exchanger at High Re Condition and Its Energy-Saving Application in Mechanical Vapor Recompression System. Chem. Eng. Process.-Process Intensif. 2025, 210, 110214. [Google Scholar] [CrossRef]

- Rinik, R.A.; Bhuiyan, A.A.; Karim, M.R. Enhancement of Heat Transfer Using Elliptical Twisted Inner Pipe with Convergent Conical Ring Turbulator for Turbulent Flow in Double Pipe Heat Exchanger. Int. J. Therm. Sci. 2025, 210, 109558. [Google Scholar] [CrossRef]

- Boujelbene, M.; Mehryan, S.A.M.; Abidi, A.; Ahmed Alashaari, G.A.; Alshehery, S.; Khedher, N.B.; Mahariq, I.; Shah, N.A. Experimental Investigation of a Novel Approach to Enhance Heat Transfer in Double-Tube Heat Exchangers through the Utilization of a Vibrating Latex Strip Turbulator. Int. Commun. Heat Mass Transf. 2025, 160, 108371. [Google Scholar] [CrossRef]

- Crystal, R.V.; Crittenden, T.; Glezer, A.; Garimella, S. Enhancement of Air-Side Heat Transfer in Crossflow Heat Exchangers Using Auto-Fluttering Reeds. Appl. Therm. Eng. 2025, 258, 124617. [Google Scholar] [CrossRef]

- Hu, W.; Du, Y.; Hu, P.; Wang, D. Numerical Characterization of Heat Transfer in a Convection-Enhanced Perforated Tube-Plate Radiant Heat Exchanger. Appl. Therm. Eng. 2025, 274, 126573. [Google Scholar] [CrossRef]

- Mahmoudinezhad, S.; Sadi, M.; Ghiasirad, H.; Arabkoohsar, A. A Comprehensive Review on the Current Technologies and Recent Developments in High-Temperature Heat Exchangers. Renew. Sustain. Energy Rev. 2023, 183, 113467. [Google Scholar] [CrossRef]

- Erdinç, M.T.; Dalgıç, İ.; Kutlu, C.; Dik, A.; Tokgoz, N.; Su, Y.; Riffat, S. A Comprehensive Review of Miscellaneous Heat Transfer Enhancement Designs of Phase Change Material Integrated Heat Exchanger. Int. Commun. Heat Mass Transf. 2025, 164, 108791. [Google Scholar] [CrossRef]

- Wang, J.; Qian, C.; Yu, B.; Zhang, F.; Ma, R.; Shi, J.; Chen, J. Design and Optimization of Additive Manufactured Fischer-Koch-Structured Heat Exchanger for Enhanced Heat Transfer Efficiency. Int. Commun. Heat Mass Transf. 2024, 159, 108078. [Google Scholar] [CrossRef]

- Dabestani, A.; Kahani, M. CFD Analysis of Rotation Effect on Flow Patterns and Heat Transfer Enhancement in a Horizontal Spiral Tube Heat Exchanger. Case Stud. Therm. Eng. 2024, 64, 105494. [Google Scholar] [CrossRef]

- Riyadi, T.W.B.; Herawan, S.G.; Tirta, A.; Ee, Y.J.; Hananto, A.L.; Paristiawan, P.A.; Yusuf, A.A.; Venu, H.; Irianto; Veza, I. Nanofluid Heat Transfer and Machine Learning: Insightful Review of Machine Learning for Nanofluid Heat Transfer Enhancement in Porous Media and Heat Exchangers as Sustainable and Renewable Energy Solutions. Results Eng. 2024, 24, 103002. [Google Scholar] [CrossRef]

- Sun, J.; Wu, Z.; Li, W.; Liu, Z. Coupling Effects of Micro/Nano-Scale Surface Modification and Electric Current Application on Fouling Resistance and Heat Transfer. Int. J. Heat Mass Transf. 2024, 235, 126178. [Google Scholar] [CrossRef]

- Sun, L.; Wan, C.; Zhu, T.; Luo, X. Inverse System Based Decoupling Design and Control Strategy for Crude Oil Heat Exchanger Networks. Appl. Therm. Eng. 2025, 258, 124509. [Google Scholar] [CrossRef]

- Niu, J.; Wang, J.; Liu, X.; Dong, L. An Active Control Strategy for Simultaneously Achieving Turbulent Drag Reduction and Heat Transfer Enhancement in Heat Exchangers: Oscillation of Micro Cuboid Vortex Generators. Int. Commun. Heat Mass Transf. 2024, 159, 108315. [Google Scholar] [CrossRef]

- Xie, R.; Deng, X.; Yin, Y.; Fayziyeva, D.; Eyvazov, E.; Liu, F. Economic Viability of High-Performance Cycle Systems: Energy and Cost Efficiency Insights. Energy Strategy Rev. 2025, 59, 101675. [Google Scholar] [CrossRef]

- Ulyev, L.; Boldyryev, S.; Kuznetsov, M. Investigation of Process Stream Systems for Targeting Energy-Capital Trade-Offs of a Heat Recovery Network. Energy 2023, 263, 125954. [Google Scholar] [CrossRef]

- Son, H.; Kim, M.; Kim, J.-K. Sustainable Process Integration of Electrification Technologies with Industrial Energy Systems. Energy 2022, 239, 122060. [Google Scholar] [CrossRef]

- El Bakali, S.; Ouadi, H.; Gheouany, S. Efficient Real-Time Cost Optimization of a Two-Layer Electric Water Heater System under Model Uncertainties. Energy Convers. Manag. 2024, 304, 118190. [Google Scholar] [CrossRef]

- Elwardany, M. Enhancing Steam Boiler Efficiency through Comprehensive Energy and Exergy Analysis: A Review. Process Saf. Environ. Prot. 2024, 184, 1222–1250. [Google Scholar] [CrossRef]

- Zang, G.; Sun, P.; Elgowainy, A.; Bobba, P.; McMillan, C.; Ma, O.; Podkaminer, K.; Rustagi, N.; Melaina, M.; Koleva, M. Cost and Life Cycle Analysis for Deep CO2 Emissions Reduction of Steelmaking: Blast Furnace-Basic Oxygen Furnace and Electric Arc Furnace Technologies. Int. J. Greenh. Gas Control 2023, 128, 103958. [Google Scholar] [CrossRef]

- Ryland, M.; He, W. Heating Economics Evaluated against Emissions: An Analysis of Low-Carbon Heating Systems with Spatiotemporal and Dwelling Variations. Energy Build. 2022, 277, 112561. [Google Scholar] [CrossRef]

- Razzaq, A.; Sharif, A.; Yang, X.; Dogan, E. Influence Mechanism of Electricity Price Distortion on Industrial Green Transformation: A Spatial Analysis of Chinese Regions. Energy Econ. 2024, 130, 107308. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Uhlmann, M.; Schiffmann, J.; Bertsch, S.S. High Temperature Heat Pumps: Market Overview, State of the Art, Research Status, Refrigerants, and Application Potentials. Energy 2018, 152, 985–1010. [Google Scholar] [CrossRef]

- Jiang, J.; Hu, B.; Wang, R.Z.; Deng, N.; Cao, F.; Wang, C.-C. A Review and Perspective on Industry High-Temperature Heat Pumps. Renew. Sustain. Energy Rev. 2022, 161, 112106. [Google Scholar] [CrossRef]

- Yang, L.; Yang, Z.; Akram, N.; Wang, B.; Tao, H.; Chang, C.; Mo, W.; Shen, W.; Zhang, N.; Smith, R. An Integrated Algorithm Framework for Multi-Objective Optimization of Heat Exchanger Networks Considering Temperature-Dependent Heat Capacity. Chem. Eng. Sci. 2025, 305, 121183. [Google Scholar] [CrossRef]

- Boldyryev, S.; Gil, T.; Ilchenko, M. Environmental and Economic Assessment of the Efficiency of Heat Exchanger Network Retrofit Options Based on the Experience of Society and Energy Price Records. Energy 2022, 260, 125155. [Google Scholar] [CrossRef]

- Mughees, N.; Mughees, A.; Mughees, A.; Ejsmont, K. Optimizing Electrical and Thermal Energy Storage Systems for Hour-Ahead Integrated Demand Response in Industries. Energy Rep. 2025, 13, 4441–4458. [Google Scholar] [CrossRef]

- Bühler, F.; Zühlsdorf, B.; Nguyen, T.-V.; Elmegaard, B. A Comparative Assessment of Electrification Strategies for Industrial Sites: Case of Milk Powder Production. Appl. Energy 2019, 250, 1383–1401. [Google Scholar] [CrossRef]

- Bielefeld, S.; Cvetković, M.; Ramirez, A.R. Electrification in the Petrochemical Industry: Can Flexibility Enable Low-Carbon Utility Systems? In Computer Aided Chemical Engineering, Proceedings of the 34 European Symposium on Computer Aided Process Engineering/15 International Symposium on Process Systems Engineering, Florence, Italy, 2–6 June 2024; Manenti, F., Reklaitis, G.V., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; Volume 53, pp. 2227–2232. [Google Scholar]

- Richards, T. Immersion Heater Design. Met. Finish. 2007, 105, 657–666. [Google Scholar] [CrossRef]

- dela Rosa, L.; Mande, C.; Ellis, M.J. Practical Strategies for Managing Resistance Heating in Heat Pump Water Heater Predictive Control. Chem. Eng. Res. Des. 2025, 215, 180–192. [Google Scholar] [CrossRef]

- Frimpong, A.J.; Tan, G.; Zhang, Y.; Ye, J.; Agyeman, P.K.; Kyei, S.K.; Olayode, I.O. Experimental Investigation Supported by Artificial Neural Networks (ANNs) for Predicting the Heating Performance of a Cyclone Separator Coupled with Induction Heating Coil. Process Saf. Environ. Prot. 2023, 180, 451–474. [Google Scholar] [CrossRef]

- Polski, C.; Polski, T.; Roman, J.; Wróblewski, R.; Bartoszewicz, J.; Ceran, B. A Novel Concept to Improve the Flexibility of Steam Power Plants Using an Electric Feedwater Heater. Appl. Therm. Eng. 2024, 236, 121661. [Google Scholar] [CrossRef]

- Kamran, H.; Mudassir, U.; Ali, A.M.; Kamal, K.; Ratlamwala, T.A.H.; Raza, M.A.; Khan, K. Simulation and Modeling of Copper-Chlorine Cycle, Molten Carbonate Fuel Cell alongside a Heat Recovery System Named Regenerative Steam Cycle and Electric Heater with the Incorporation of PID Controller in MATLAB/SIMULINK. Int. J. Hydrogen Energy 2022, 47, 40462–40475. [Google Scholar] [CrossRef]

- Chen, Y.; Zeng, H.; Wang, J.; Chen, H.; Zhu, J. Heat Transfer Performance of a Downhole Electric Tubular Resistive Heater. Appl. Sci. 2022, 12, 9508. [Google Scholar] [CrossRef]

- Cui, Y.; Cui, Z.; Wang, Y. Heat Exchanger Network Synthesis Considering Detailed Heat Exchanger Design under Fouling. Chem. Eng. Res. Des. 2025, 218, 525–538. [Google Scholar] [CrossRef]

- Trafczynski, M.; Markowski, M.; Urbaniec, K. Energy Saving Potential of a Simple Control Strategy for Heat Exchanger Network Operation under Fouling Conditions. Renew. Sustain. Energy Rev. 2019, 111, 355–364. [Google Scholar] [CrossRef]

- Pogiatzis, T.; Ishiyama, E.M.; Paterson, W.R.; Vassiliadis, V.S.; Wilson, D.I. Identifying Optimal Cleaning Cycles for Heat Exchangers Subject to Fouling and Ageing. Appl. Energy 2012, 89, 60–66. [Google Scholar] [CrossRef]

- Hou, G.; Zhang, D.; Yan, Q.; Wang, S.; Ma, L.; Jiang, M. Application of Machine Learning Algorithms in Real-Time Fouling Monitoring of Plate Heat Exchangers. Int. Commun. Heat Mass Transf. 2025, 164, 108809. [Google Scholar] [CrossRef]

- Li, W.; Wang, S.; Xu, S.; Wang, Q.; Markides, C.N. An Intensive Review of ORC-Based Pumped Thermal Energy Storage. Energy 2025, 330, 136792. [Google Scholar] [CrossRef]

- Sakib, S.; Hossain, M.B.; Zamee, M.A.; Hossain, M.J.; Habib, M.A. Role of Battery Energy Storage Systems: A Comprehensive Review on Renewable Energy Zones Integration in Weak Transmission Networks. J. Energy Storage 2025, 128, 117223. [Google Scholar] [CrossRef]

- Abdellatif, H.E.; Belaadi, A.; Arshad, A.; Bourchak, M. Modeling and Performance Analysis of Phase Change Materials in Advanced Thermal Energy Storage Systems: A Comprehensive Review. J. Energy Storage 2025, 121, 116517. [Google Scholar] [CrossRef]

- Zhang, H.; Baeyens, J.; Cáceres, G.; Degrève, J.; Lv, Y. Thermal Energy Storage: Recent Developments and Practical Aspects. Prog. Energy Combust. Sci. 2016, 53, 1–40. [Google Scholar] [CrossRef]

- Yekini Suberu, M.; Wazir Mustafa, M.; Bashir, N. Energy Storage Systems for Renewable Energy Power Sector Integration and Mitigation of Intermittency. Renew. Sustain. Energy Rev. 2014, 35, 499–514. [Google Scholar] [CrossRef]

- Er, H.A.; Wan Alwi, S.R.; Manan, Z.A.; Klemeš, J.J. Simultaneous Retrofit of Direct and Indirect Heat Exchanger Storage Network (HESN) via Individual Batch Process Stream Mapping. Energy 2022, 261, 125052. [Google Scholar] [CrossRef]

- Suraparaju, S.K.; Samykano, M.; Vennapusa, J.R.; Rajamony, R.K.; Balasubramanian, D.; Said, Z.; Pandey, A.K. Challenges and Prospectives of Energy Storage Integration in Renewable Energy Systems for Net Zero Transition. J. Energy Storage 2025, 125, 116923. [Google Scholar] [CrossRef]

- Mussawar, O.; Mayyas, A. Economic Assessment of Hybrid Energy Storage for Multi-Energy Arbitrage in Wholesale Electricity Markets Using an Optimization-Based Approach. Int. J. Hydrogen Energy 2025, 141, 75–87. [Google Scholar] [CrossRef]

- Vaziri Rad, M.A.; Kasaeian, A.; Niu, X.; Zhang, K.; Mahian, O. Excess Electricity Problem in Off-Grid Hybrid Renewable Energy Systems: A Comprehensive Review from Challenges to Prevalent Solutions. Renew. Energy 2023, 212, 538–560. [Google Scholar] [CrossRef]

- Ghelasi, P.; Ziel, F. From Day-Ahead to Mid and Long-Term Horizons with Econometric Electricity Price Forecasting Models. Renew. Sustain. Energy Rev. 2025, 217, 115684. [Google Scholar] [CrossRef]

- Passalis, N.; Dimitriadis, C.N.; Georgiadis, M.C. Residual Adaptive Input Normalization for Forecasting Renewable Energy Generation in Multiple Countries. Pattern Recognit. Lett. 2025, 196, 52–58. [Google Scholar] [CrossRef]

- Golmohamadi, H. Demand-Side Management in Industrial Sector: A Review of Heavy Industries. Renew. Sustain. Energy Rev. 2022, 156, 111963. [Google Scholar] [CrossRef]

- Leherbauer, D.; Schulz, J.; Egyed, A.; Hehenberger, P. Demand-Side Management in Less Energy-Intensive Industries: A Systematic Mapping Study. Renew. Sustain. Energy Rev. 2025, 212, 115315. [Google Scholar] [CrossRef]

- Gioanola, G.; Bastida, H.; Guelpa, E.; Verda, V.; Sciacovelli, A. Innovative Methodology for Optimized Design and Thermo-Economic Analysis of Pillow-Plate Latent Heat Thermal Energy Storage: A Case Study on Heat Recovery in the Brewing Industry. Energy Convers. Manag. 2025, 341, 120025. [Google Scholar] [CrossRef]

- Wohlgenannt, P.; Huber, G.; Rheinberger, K.; Kolhe, M.; Kepplinger, P. Comparison of Demand Response Strategies Using Active and Passive Thermal Energy Storage in a Food Processing Plant. Energy Rep. 2024, 12, 226–236. [Google Scholar] [CrossRef]

- Du, S.; Chen, Z.; Agrawal, R. Assessing Large Energy Storage Requirements for Chemical Plants Powered with Solar and/or Wind Electricity. Chem. Eng. J. 2025, 505, 158863. [Google Scholar] [CrossRef]

- Liu, X.; Wei, L.; Lv, L.; Zhou, H. Experimental Study on Thermal Energy Storage for Thermal Power Flexibility Retrofit Combined with Waste Resource Utilization in Steel Industry: Using Single-Piece Stacking Bed as an Example. J. Energy Storage 2025, 109, 115203. [Google Scholar] [CrossRef]

- Akpomiemie, M.O.; Smith, R. Cost-Effective Strategy for Heat Exchanger Network Retrofit. Energy 2018, 146, 82–97. [Google Scholar] [CrossRef]

- El-halwagi, M.M. Chapter 16-Mathematical Techniques for the Synthesis of Heat-Exchange Networks. In Sustainable Design Through Process Integration, 3rd ed.; El-halwagi, M.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2025; pp. 411–425. [Google Scholar]

- Biegler, L.T.; Zavala, V.M. Large-Scale Nonlinear Programming Using IPOPT: An Integrating Framework for Enterprise-Wide Dynamic Optimization. Comput. Chem. Eng. 2009, 33, 575–582. [Google Scholar] [CrossRef]

- UCSD Optimization Software. Available online: https://ccom.ucsd.edu/~optimizers/solvers/snopt/ (accessed on 17 June 2025).

- Hagedorn, D.F.; Kuper, L.; Zoellmann, M.; Reinert, C.; von der Assen, N. Dyn2Heat—MILP Heat Exchanger Network Design for Batch Processes via Dynamic Optimization. Comput. Chem. Eng. 2025, 200, 109167. [Google Scholar] [CrossRef]

- DICOPT. Available online: https://www.gams.com/latest/docs/S_DICOPT.html (accessed on 17 June 2025).

- BARON. Available online: https://www.gams.com/49/docs/S_BARON.html (accessed on 17 June 2025).

- Yang, Z.; Pan, T.; Chang, C.; Zhang, S.; Zhang, N.; Smith, R. Multi-Objective-Period Heat Exchanger Network Synthesis and Decarbonization for Industrial-Scale Crude Oil Distillation System. Energy 2025, 326, 136300. [Google Scholar] [CrossRef]

- Yee, T.F.; Grossmann, I.E.; Kravanja, Z. Simultaneous Optimization Models for Heat Integration—I. Area and Energy Targeting and Modeling of Multi-Stream Exchangers. Comput. Chem. Eng. 1990, 14, 1151–1164. [Google Scholar] [CrossRef]

- Zhao, K.; Zhao, L.; Tang, Q.Q.; Chen, Q.L.; He, C.; Zhang, B.J. A Novel Optimization Framework Integrating Multiple Initialization, Automatic Topologization and MINLP Reduction to Accelerate Large-Scale Heat Exchanger Network Synthesis. Energy 2024, 307, 132508. [Google Scholar] [CrossRef]

- Barbaro, A.; Bagajewicz, M.J. New Rigorous One-Step MILP Formulation for Heat Exchanger Network Synthesis. Comput. Chem. Eng. 2005, 29, 1945–1976. [Google Scholar] [CrossRef]

- Ahmetović, E.; Ibrić, N.; Kravanja, Z.; Grossmann, I.E.; Maréchal, F.; Čuček, L.; Kermani, M. Simultaneous Optimisation and Heat Integration of Evaporation Systems Including Mechanical Vapour Recompression and Background Process. Energy 2018, 158, 1160–1191. [Google Scholar] [CrossRef]

- Patel, D.N.; Matalon, P.; Oluleye, G. A Novel Temporal Mixed-Integer Market Penetration Model for Cost-Effective Uptake of Electric Boilers in the UK Chemical Industry. J. Clean. Prod. 2024, 446, 141156. [Google Scholar] [CrossRef]

- Ibrić, N.; Fu, C.; Gundersen, T. Simultaneous Optimization of Work and Heat Exchange Networks. Energies 2024, 17, 1753. [Google Scholar] [CrossRef]

- Stampfli, J.A.; Ong, B.H.Y.; Olsen, D.G.; Wellig, B.; Hofmann, R. Multi-Objective Evolutionary Optimization for Multi-Period Heat Exchanger Network Retrofit. Energy 2023, 281, 128175. [Google Scholar] [CrossRef]

- Linnhoff, B.; Hindmarsh, E. The Pinch Design Method for Heat Exchanger Networks. Chem. Eng. Sci. 1983, 38, 745–763. [Google Scholar] [CrossRef]

- Kemp, I.C.; Lim, J.S. Pinch Analysis for Energy and Carbon Footprint Reduction, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2020; ISBN 978-0-08-102536-9. [Google Scholar]

- Padullés, R.; Walmsley, T.G.; Lincoln, B.J.; Andersen, M.P.; Jensen, J.K.; Elmegaard, B. Process Integration and Electrification through Multiple Heat Pumps Using a Lorenz Efficiency Approach. Energy 2024, 311, 133348. [Google Scholar] [CrossRef]

- Yuan, T.; Mao, Y. A Review of Pinch Analysis Techniques and Extended Application in Power Systems. Renew. Sustain. Energy Rev. 2024, 202, 114684. [Google Scholar] [CrossRef]

- Foo, D.C.Y. Process Integration for Resource Conservation, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2025. [Google Scholar]

- Bou Malham, C.; Zoughaib, A.; Rivera Tinoco, R.; Schuhler, T. Hybrid Optimization Methodology (Exergy/Pinch) and Application on a Simple Process. Energies 2019, 12, 3324. [Google Scholar] [CrossRef]

- Santos, L.F.; Costa, C.B.B.; Caballero, J.A.; Ravagnani, M.A.S.S. Synthesis and Optimization of Work and Heat Exchange Networks Using an MINLP Model with a Reduced Number of Decision Variables. Appl. Energy 2020, 262, 114441. [Google Scholar] [CrossRef]

- Tan, R.R.; Migo-Sumagang, M.V.; Aviso, K.B. Recent Trends in Optimization Models for Industrial Decarbonization. Curr. Opin. Chem. Eng. 2025, 48, 101118. [Google Scholar] [CrossRef]

- Angsutorn, N.; Chuvaree, R.; Siemanond, K. A Sustainable Retrofit of an Industrial Heat Exchanger Network—A Case Study of a Gas Separation Plant in Thailand (HEN Retrofit on GSP). Process Integr. Optim. Sustain. 2023, 7, 137–162. [Google Scholar] [CrossRef]

- Lee, J.; Park, H.; Lee, S.; Kim, J.-K. Process Design and Integration for the Electrification of a SMR-Based Hydrogen Plant with Absorption-Based CO2 Capture. Appl. Therm. Eng. 2025, 262, 125274. [Google Scholar] [CrossRef]

- Sahl, A.B.; Orosz, Á.; How, B.S.; Friedler, F.; Teng, S.Y. Electrification of Oil Refineries through Multi-Objective Multi-Period Graph-Theoretical Planning: A Crude Distillation Unit Case Study. J. Clean. Prod. 2024, 434, 140179. [Google Scholar] [CrossRef]

- Wang, D.; Wu, B.; Meng, W.; Zhou, H.; Liao, Z.; Hong, X. Analysis of Electrification Reconfiguration for the Coal to Ethylene Glycol Process Integrated with Renewable Energy. Int. J. Hydrogen Energy 2024, 67, 361–372. [Google Scholar] [CrossRef]

- Kuznetsov, M.; Boldyryev, S.; Kenzhebekov, D.; Kaldybaeva, B. Improving Inter-Plant Integration of Syngas Production Technologies by the Recycling of CO2 and by-Product of the Fischer-Tropsch Process. Int. J. Hydrogen Energy 2022, 47, 31755–31772. [Google Scholar] [CrossRef]

- Cantu Rodriguez, R.; Palacios-Garcia, E.J.; Deconinck, G. Redesign for Flexibility through Electrification: Multi-Objective Optimization of the Operation of a Multi-Energy Industrial Steam Network. Appl. Energy 2024, 362, 122981. [Google Scholar] [CrossRef]

- Chu, Z.; Zhang, N.; Smith, R. Modelling and Integration of Multi-Parallel Organic Rankine Cycles into Total Site. Energy 2022, 260, 124985. [Google Scholar] [CrossRef]

- Boldyryev, S.; Mikulčić, H.; Krajačić, G.; Duić, N. Waste Heat Utilisation of Croatian Cement Industry Accounting Total Site Demands. In Computer Aided Chemical Engineering, Proceedings of the 26 European Symposium on Computer Aided Process Engineering, Portorož, Slovenia, 12–15 June 2016; Kravanja, Z., Bogataj, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 38, pp. 2223–2228. [Google Scholar]

- Vermeiren, J.; Dilissen, N.; Goovaerts, V.; Vleugels, J. Electrification of Clinker and Calcination Treatments in the Cement Sector by Microwave Technology–A Review. Constr. Build. Mater. 2024, 428, 136271. [Google Scholar] [CrossRef]

- Xue, Y.; Zhang, Q.; Jiang, S.; Wang, C.; Lin, Q. Enhanced Low-Temperature Waste Heat Recovery in Ethyl Acetate / Cyclohexane Separation Using Heat Integration and ORC-Assisted Pressure-Swing Distillation. Process Saf. Environ. Prot. 2025, 197, 106977. [Google Scholar] [CrossRef]

- Skiborowski, M.; Kruber, K.F. Exergy-Based Optimization for the Synthesis of Heat Pump Assisted Distillation Columns. In Computer Aided Chemical Engineering, Proceedings of the 34 European Symposium on Computer Aided Process Engineering/15 International Symposium on Process Systems Engineering, Florence, Italy, 2–6 June 2024; Manenti, F., Reklaitis, G.V., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; Volume 53, pp. 1351–1356. [Google Scholar]

- Boldyryev, S.; Shamraev, A.A.; Shamraeva, E.O. The Retrofit of the Calcium Chloride Production by Pinch Approach and Process Modifications. Appl. Therm. Eng. 2021, 189, 116775. [Google Scholar] [CrossRef]

- Ryan, E.; McDaniel, B.; Kosanovic, D. Application of Thermal Energy Storage with Electrified Heating and Cooling in a Cold Climate. Appl. Energy 2022, 328, 120147. [Google Scholar] [CrossRef]

| Aspect | Fossil-Fuel-Based Heat Supply | Electricity-Based Heat Supply |

|---|---|---|

| Energy Source | Combustion of coal, natural gas, oil | Electricity from grid or renewable sources (e.g., wind, solar, etc.) |

| Emissions | High (CO2, NOx, SOx emissions) [10] | Very low if sourced from renewables, varies with grid mix [11] |

| Efficiency | 30–60% due to combustion losses [16,17] | 90% and higher with technologies like resistance or induction heating [24] |

| Heat Transfer Method | Direct flame or hot gases [25] | Electric resistance [26], induction [27], microwave [28], or heat pumps [29] |

| Temperature range | High temperatures up to 2000 °C [30] | Some technologies limited in max temperature [31]; high-temperature options emerging |

| Infrastructure compatibility | Widely compatible with existing systems | May require retrofitting or new equipment [32] |

| Operational flexibility | Slower response times, good for base load [33] | Fast response, better for dynamic operation and smart control [34] |

| Fuel supply chain | Requires transport, storage, and handling of fuels [35] | Simpler logistics, just grid or onsite electricity [36] |

| Air pollutants | Produces particulates, NOx, SOx, etc. [10] | Virtually none at point of use [11] |

| Decarbonization potential | Limited, unless using carbon capture and storage [37] | High, especially with clean electricity [38] |

| Maintenance requirements | Higher due to moving parts and combustion residues [18] | Lower for many electric systems [20,21] |

| Initial investment | Generally lower upfront for existing technologies [14] | Higher initial cost with possible long-term savings [19] |

| Aspect | LP | NLP | MINLP | MOO |

|---|---|---|---|---|

| Focus | Utility targeting | Detailed heat load optimization | Structure + parameter optimization | Trade-off analysis between multiple goals |

| Variables | Continuous (linear) | Continuous (nonlinear) | Mixed (binary + continuous) | Continuous/mixed, multi-objective |

| Topology decision | Not included | Fixed | Optimized | May be optimized |

| Objective function | Single (cost or utility) | Single (cost or area) | Single (cost, often annualized) | Multiple (cost, emissions, etc.) |

| Complexity | Low | Medium | High | High (especially with Pareto analysis) |

| Solver requirements | Simple LP solvers | Nonlinear solvers | MINLP solvers | MOO or evolutionary algorithms |

| Application | Early design targeting | Detailed retrofit optimization | Full design with discrete choices | Sustainable and policy-driven decisions |

| Industry/ Process | Technology/ Strategy | Energy Savings | Emissions Reduction | Cost Impact | References |

|---|---|---|---|---|---|

| Milk evaporation | Heat pump + MVR integration | ~56% | 82% | 32% OPEX reduction | [82,160] |

| Gas separation | HEN retrofit with NLP optimization | Not quantified | Not quantified | Financial benefits reported | [212] |

| Crude oil distillation | Multi-objective HEN optimization + waste heat recovery | Not quantified | Substantial | Improved energy distribution, cost-effective | [196] |

| Hydrogen production (SMR + CO2 Capture) | Electrified heat pumps + electric heaters | Moderate | Not specified | Profitable under 2020 price scenarios | [213] |

| Coal-to-ethylene glycol | Process electrification + renewables integration | ~50% efficiency improvement | Reduced CO2 | Not specified | [215] |

| Olefins plant | Electrification + TES + hydrogen utility | Dynamic optimization | Low-carbon utility system | Optimized operational costs | [161] |

| Oil refining (crude unit) | Multi-period retrofit planning with electrification | Not specified | Environmental gains noted | Cost-effective retrofitting | [214] |

| Syngas and Fischer-Tropsch | HEN + CO2 recycling | Electricity reduction | Increased revenue via CO2 use | Revenue boost and energy efficiency | [216] |

| Steam network (Total Site) | Electrification + TES + flexibility modelling | Not specified | 18 tCO2/day | Reduced blow-off steam, higher profitability | [217] |

| Cement | Parallel ORCs + HEN optimization | 43% power self-coverage | Not specified | Increased profitability | [218,219] |

| Cement (Clinker/calcination) | Electrification via microwave technology | Not quantified | High potential | Under review | [220] |

| Ethyl acetate separation | MVR + ORC + pressure-swing distillation | 17% energy efficiency gain | Not specified | 8% reduction in total annual cost | [221] |

| Acetone-water distillation | MVR + exergy optimization for heat pump integration | Improved internal efficiency | Not specified | Conceptual design improvement | [222] |

| Calcium chloride production | HEN retrofit + MVR | 51% steam reduction | 19 ktCO2/year | CAPEX savings potential via electric boilers | [223] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boldyryev, S.; Ivashchuk, O.S.; Krajačić, G.; Atamanyuk, V.M. Review of Challenges in Heat Exchanger Network Development for Electrified Industrial Energy Systems. Energies 2025, 18, 3685. https://doi.org/10.3390/en18143685

Boldyryev S, Ivashchuk OS, Krajačić G, Atamanyuk VM. Review of Challenges in Heat Exchanger Network Development for Electrified Industrial Energy Systems. Energies. 2025; 18(14):3685. https://doi.org/10.3390/en18143685

Chicago/Turabian StyleBoldyryev, Stanislav, Oleksandr S. Ivashchuk, Goran Krajačić, and Volodymyr M. Atamanyuk. 2025. "Review of Challenges in Heat Exchanger Network Development for Electrified Industrial Energy Systems" Energies 18, no. 14: 3685. https://doi.org/10.3390/en18143685

APA StyleBoldyryev, S., Ivashchuk, O. S., Krajačić, G., & Atamanyuk, V. M. (2025). Review of Challenges in Heat Exchanger Network Development for Electrified Industrial Energy Systems. Energies, 18(14), 3685. https://doi.org/10.3390/en18143685