Energy Assessment of Hazelnut Shells (Corylus avellana L.) of Selected Turkish Varieties

Abstract

1. Introduction

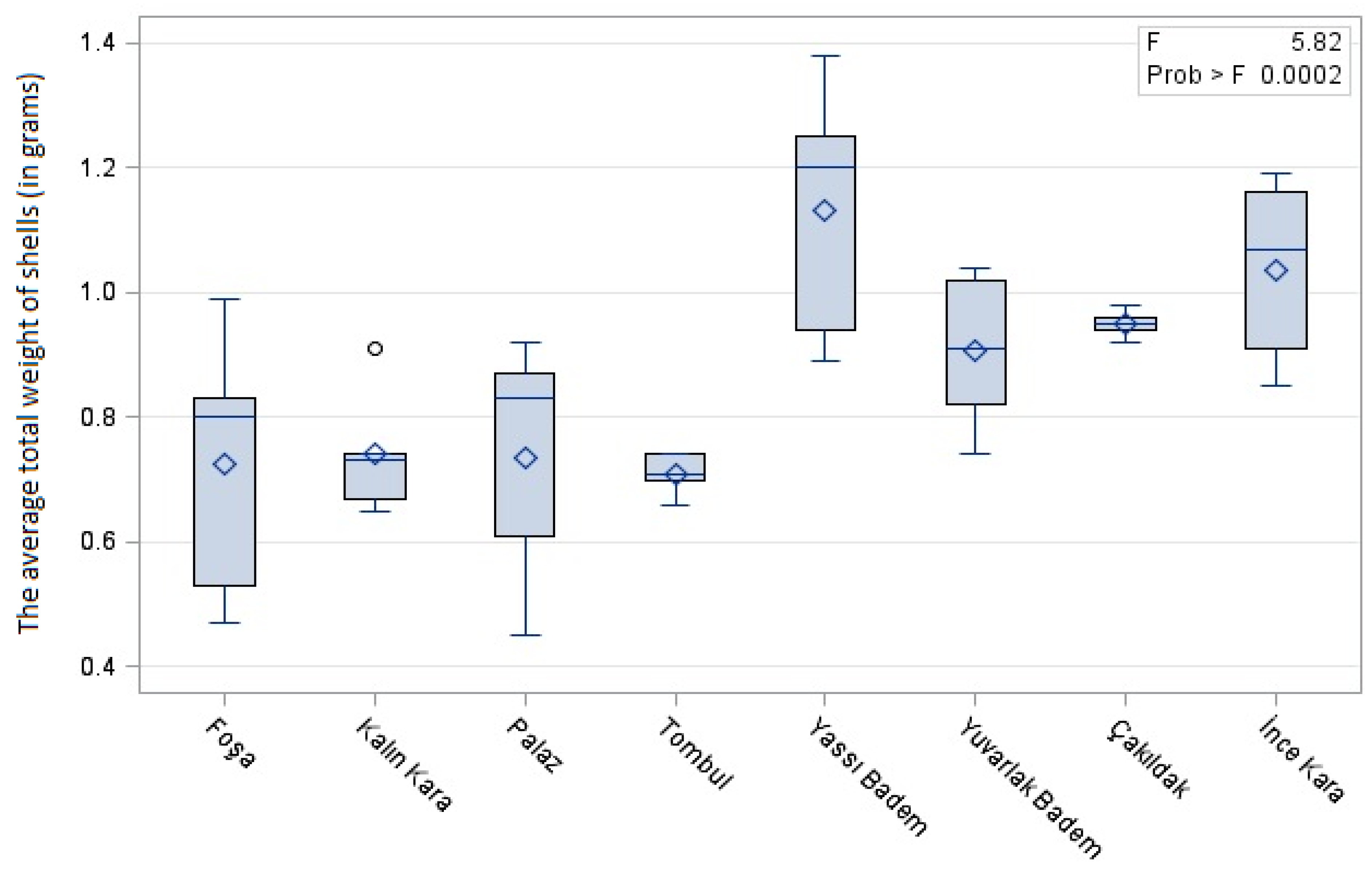

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Solís, A.; Rocha, S.; König, M.; Adam, R.; Garcés, H.; Candia, C.; Muñoz, R.; Azócar, L. Preliminary assessment of hazelnut shell biomass as a raw material for pellet production. Fuel 2023, 333, 126517. [Google Scholar] [CrossRef]

- Food Agricultural Organization of the United Nations, FAO. Available online: http://www.fao.org/faostat/en/#data/QC;2021 (accessed on 1 May 2025).

- International Nut and Dried Fruit Council Foundation (INC). Statistical Yearbook 457 2022/2023. Available online: https://www.nutfruit.org/industry/technical458resources?category=statistical-yearbooks (accessed on 6 May 2025).

- Balik, H.I.; Balık, S.K.; Beyhan, N.; Erdogan, V. Hazelnut Cultivars; Trabzon Commodity Exchange: Trabzon, Turkey, 2016; ISBN 978-605-137-559-5. [Google Scholar]

- Ceylan, F.D.; Adrar, N.; Bolling, B.W.; Capanoglu, E. Valorisation of Hazelnut By-Products: Current Applications and Future Potential. Biotechnol. Genet. Eng. Rev. 2022, 39, 586–621. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Lin, H.; Lin, Z. Hazelnut and Its By-Products: A Comprehensive Review of Nutrition, Phytochemical Profile, Extraction, Bioactivities and Applications. Food Chem. 2023, 413, 135576. [Google Scholar] [CrossRef]

- Aydemir, B.; Yilgin, M. Findik Kabugunum Torrefaksiyon ve Yanma davransinin Incelenmesi. Karadeniz Fen Bilim. Derg. 2022, 12, 51–65. [Google Scholar] [CrossRef]

- Calà, E.; Fracchia, A.; Robotti, E.; Gulino, F.; Gullo, F.; Oddone, M.; Massacane, M.; Cordone, G.; Aceto, M. On the Traceability of the Hazelnut Production Chain by Means of Trace Elements. Molecules 2022, 27, 3854. [Google Scholar] [CrossRef]

- Alasalvar, C.; Salvadó, J.-S.; Ros, E. Bioactives and Health Benefits of Nuts and Dried Fruits. Food Chem. 2020, 314, 126192. [Google Scholar] [CrossRef]

- Wojdyło, A.; Turkiewicz, I.P.; Tkacz, K.; Nowicka, P.; Bobak, Ł. Nuts as Functional Foods: Variation of Nutritional and Phytochemical Profiles and Their in Vitro Bioactive Properties. Food Chem. X 2022, 15, 100418. [Google Scholar] [CrossRef]

- Gantner, M.; Czernyszewicz, E.; Kopczyńska, K.; Król, K. The competitiveness of Polish hazelnut varieties depending on their quality as determined by physicochemical properties. Zesz. Nauk. SGGW Ekon. Organ. Gospod. Żywnościowej 2017, 118, 127. [Google Scholar] [CrossRef]

- Barczak, B.; Klugmann-Radziemska, E.; Januszewicz, K. Od odpadów rolniczych do wysokowydajnego sorbentu. Węgiel aktywny pochodzący z łupin orzechów laskowych do oczyszczania wody i ścieków. Przemysł Chem. 2023, 1, 895–899. [Google Scholar] [CrossRef]

- Pérez-Armada, L.; Rivas, S.; González, B.; Moure, A. Extraction of phenolic compounds from hazelnut shells by green processes. J. Food Eng. 2019, 255, 1–8. [Google Scholar] [CrossRef]

- An, N.; Turp, M.T.; Türkeş, M.; Kurnaz, M.L. Mid-Term Impact of Climate Change on Hazelnut Yield. Agriculture 2020, 10, 159. [Google Scholar] [CrossRef]

- Ollani, S.; Peano, C.; Sottile, F. Recent Innovations on the Reuse of Almond and Hazelnut By-Products: A Review. Sustainability 2024, 16, 2577. [Google Scholar] [CrossRef]

- Carmona Rene, J.; Riquelme Alejandro, A. Gonzalez Gillian European Hazelnut Shell as a Source of Extractives and Bio-Oil. Chem. Eng. Trans. 2024, 109, 349–354. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.P.; Pigosso, D.C.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- Staśkiewicz, M.; Lelicińska-Serafin, K. Minerały Antropogeniczne a Gospodarka o Obiegu Zamkniętym; Polski Rynek Węgla: Katowice, Poland, 2025; Available online: https://polskirynekwegla.pl/sites/default/files/elfinder/GOZ/mineraly-antropogeniczne.pdf (accessed on 16 June 2025).

- Siwal, S.S.; Zhang, Q.; Devi, N.; Saini, A.K.; Saini, V.; Pareek, B.; Gaidukovs, S.; Thakur, V.K. Recovery processes of sustainable energy using differentbiomass and wastes. Renew. Sustain. Energy Rev. 2021, 150, 111483. [Google Scholar] [CrossRef]

- Werle, S. Termiczne Przetwarzanie Biomasy Odpadowej, Jako Element Gospodarki o Obiegu Zamkniętego; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2021; Available online: https://delibra.bg.polsl.pl/Content/73118/MPS-891_Termiczne-przetwarzanie-biomasy-odpadowej_WerleS_2021.pdf (accessed on 16 June 2025).

- Allegrini, A.; Salvaneschi, P.; Schirone, B.; Cianfaglione, K.; Di Michele, A. Multipurpose plant species and circular economy: Corylus avellana L. as a study case. Front. Biosci.-Landmark 2022, 27, 11. [Google Scholar] [CrossRef]

- Serocka, A. Renewable energy sources as an element of state energy security management. Zesz. Nauk. Politech. Częstochowskiej. Zarządzanie 2022, 46, 88–100. [Google Scholar] [CrossRef]

- García, R.; Gil, M.V.; Rubiera, F.; Pevida, C. Pelletization of wood and alternative residual biomass blends for producing industrial quality pellets. Fuel 2019, 251, 739–753. [Google Scholar] [CrossRef]

- Thompson, S.; Rough, S. The densification of cocoa bean shells for bioenergy purposes. Biomass Bioenergy 2021, 148, 106057. [Google Scholar] [CrossRef]

- Licursi, D.; Antonetti, C.; Di Fidio, N.; Fulignati, S.; Benito, P.; Puccini, M.; Vitolo, S.; Raspolli Galletti, A.M. Conversion of the hydrochar recovered after levulinic acid production into activated carbon adsorbents. Waste Manag. 2023, 168, 235–245. [Google Scholar] [CrossRef]

- Guney, M.S. Utilization of hazelnut husk as biomass. Sustain. Energy Technol. Assess. 2013, 4, 72–77. [Google Scholar] [CrossRef]

- Mirowski, T. Wykorzystanie biomasy na cele grzewcze a ograniczenie emisji zanieczyszczeń powietrza z sektora komunalno-bytowego, Annual Set The Environment Protection. Rocz. Ochr. Sr. 2016, 18, 466–477. [Google Scholar]

- Rokni, E.; Ren, X.; Panahi, A.; Levendis, Y.A. Emissions of SO2, NOx, CO2, and HCl from Cofiring of coals with raw and torrefied biomass fuels. Fuel 2018, 211, 363–374. [Google Scholar] [CrossRef]

- Karata, S.; Yavuz; IİsLam, A.; Tonkaz, T.; Özkutlu, F.; Rovira, M.; Romero, A.; Cristofori, V.; Silvestri, C.; Speranza, S.; et al. Examination of modern and traditional applications in hazelnut production, in IX International Congress on Hazelnut. Acta Hortic. 2017, 1226, 329–332. [Google Scholar]

- Sezer, A.; Dolar, F.S.; Lucas, S.J.; Köse, Ç.; Gümüş, E. First report of the recently introduced, destructive powdery mildew Erysiphe corylacearum on hazelnut in Turkey. Phytoparasitica 2017, 45, 577–581. [Google Scholar] [CrossRef]

- Şenol, H. Biogas potential of hazelnut shells and hazelnut wastes in Giresun City. Biotechnol. Rep. 2019, 24, e00361. [Google Scholar] [CrossRef]

- EN-ISO 1928:2020; Coal and Coke—Determination of Gross Calorific Value. International Organization for Standardization: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/75883.html (accessed on 28 August 2024).

- EN-ISO 18122:2022; Solid Biofuels—Determination of Ash Content. International Organization for Standardization: Geneva, Switzerland, 2022. Available online: https://www.iso.org/standard/83190.html (accessed on 28 August 2024).

- EN-ISO 18123:2016-01; Solid Fuels—Determination of Volatile Content by Gravimetric Method. International Organization for Standardization: Geneva, Switzerland, 2016. Available online: https://www.iso.org/obp/ui/#iso:std:iso:18123:ed-2:v1:en (accessed on 28 August 2024).

- EN-ISO 18134-1:2022; Solid Biofuels—Determination of Moisture Content—Oven Dry Method Part 1: Reference Method. International Organization for Standardization: Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/83191.html (accessed on 28 August 2024).

- Choudhury, N.D.; Saha, N.; Phukan, B.R.; Kataki, R. Characterization and Evaluation of Energy Properties of Pellets Produced from Coir Pith, Saw Dust and Ipomoea Carnea and Their Blends. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 45, 1–18. [Google Scholar] [CrossRef]

- EN-ISO 16948:2015-07; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. International Organization for Standardization: Geneva, Switzerland, 2015.

- EN-ISO 16994:2016; Solid Biofuels—Determination of Total Content of Sulphur and Chlorine. International Organization for Standardization: Geneva, Switzerland, 2016.

- Alves, J.L.F.; da Silva, J.C.G.; Mumbach, G.D.; Domenico, M.D.; da Silva Filho, V.F.; de Sena, R.F.; Machado, R.A.F.; Marangoni, C. Insights into the Bioenergy Potential of Jackfruit Wastes Considering Their Physicochemical Properties, Bioenergy Indicators, Combustion Behaviors, and Emission Characteristics. Renew. Energy 2020, 155, 1328–1338. [Google Scholar] [CrossRef]

- Maj, G. Emission Factors and Energy Properties of Agro and Forest Biomass in Aspect of Sustainability of Energy Sector. Energies 2018, 11, 1516. [Google Scholar] [CrossRef]

- Kovacs, H.; Szemmelveisz, K.; Koós, T. Theoretical and Experimental Metals Flow Calculations during Biomass Combustion. Fuel 2016, 185, 524–531. [Google Scholar] [CrossRef]

- Paraschiv, L.S.; Serban, A.; Paraschiv, S. Calculation of Combustion Air Required for Burning Solid Fuels (Coal / Biomass / Solid Waste) and Analysis of Flue Gas Composition. Energy Reports 2020, 6, 36–45. [Google Scholar] [CrossRef]

- Borkowska, A.; Klimek, K.; Maj, G.; Kapłan, M. Analysis of the Energy Potential of Hazelnut Husk Depending on the Variety. Energies 2024, 17, 3933. [Google Scholar] [CrossRef]

- Noszczyk, T.; Dyjakon, A.; Koziel, J.A. Kinetic Parameters of Nut Shells Pyrolysis. Energies 2021, 14, 682. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.-C.; Li, W.-Y.; Feng, J. Ash Contents and Ash-Forming Elements of Biomass and Their Significance for Solid Biofuel Combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Rahimi, Z.; Anand, A.; Gautam, S. An Overview on Thermochemical Conversion and Potential Evaluation of Biofuels Derived from Agricultural Wastes. Energy Nexus 2022, 7, 100125. [Google Scholar] [CrossRef]

- Torreiro, Y.; Pérez, L.; Piñeiro, G.; Pedras, F.; Rodríguez-Abalde, A. The Role of Energy Valuation of Agroforestry Biomass on the Circular Economy. Energies 2020, 13, 2516. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; González-Aguirre, J.A.; Poveda Giraldo, J.A.; Cardona Alzate, C.A. Thermochemical Processing of Woody Biomass: A Review Focused on Energy-Driven Applications and Catalytic Upgrading. Renew. Sustain. Energy Rev. 2021, 136, 110376. [Google Scholar] [CrossRef]

- Mitchell, E.J.S.; Gudka, B.; Whittaker, C.; Shield, I.; Price-Allison, A.; Maxwell, D.; Jones, J.M.; Williams, A. The Use of Agricultural Residues, Wood Briquettes and Logs for Small-Scale Domestic Heating. Fuel Process. Technol. 2020, 210, 106552. [Google Scholar] [CrossRef]

- Borkowska, A.; Maj, G.; Klimek, K.E.; Kapłan, M. The Determination of Woody Biomass Resources and Their Energy Potential from Hazelnut Tree Cultivation. Energies 2024, 17, 4536. [Google Scholar] [CrossRef]

- Turan, A.; Islam, A. Effect of Drying Methods on Some Chemical Characteristics of Hazelnuts (Corylus avellana L.) during storage. J. Inst. Sci. Tech. 2018, 8, 11–19. [Google Scholar] [CrossRef]

- Hebda, T.; Brzychczyk, B.; Francik, S.; Pedryc, N. Evaluation of Suitability of Hazelnut Shell Energy for Production of Biofuels. In Proceedings of the 17th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23 May 2018. [Google Scholar]

- Mladenović, M.; Vucicevic, B.; Marinkovic, A.; Buha-Markovic, J. Combustion of Waste Solids in a Fluidized Bed to Generate Sustainable Energy. Hem. Ind. 2024, 61, 8. [Google Scholar] [CrossRef]

- Güleç, F.; Pekaslan, D.; Williams, O.; Lester, E. Predictability of Higher Heating Value of Biomass Feedstocks via Proximate and Ultimate Analyses—A Comprehensive Study of Artificial Neural Network Applications. Fuel 2022, 320, 123944. [Google Scholar] [CrossRef]

- Matin, A.; Brandić, I.; Voća, N.; Bilandžija, N.; Matin, B.; Jurišić, V.; Antonović, A.; Krička, T. Changes in the Properties of Hazelnut Shells Due to Conduction Drying. Agriculture 2023, 13, 589. [Google Scholar] [CrossRef]

- Smith, J.D.; Alembath, A.; Al-Rubaye, H.; Yu, J.; Gao, X.; Golpour, H. Validation and Application of a Kinetic Model for Downdraft Biomass Gasification Simulation. Chem. Eng. Technol. 2019, 42, 2505–2519. [Google Scholar] [CrossRef]

- Marcantonio, V.; Bocci, E.; Monarca, D. Development of a chemical quasi-equilibrium model of biomass waste gasification in a fluidized-bed reactor by using Aspen plus. Energies 2019, 13, 53. [Google Scholar] [CrossRef]

- Demirbaş, A. Fuel Characteristics of Olive Husk and Walnut, Hazelnut, Sunflower, and Almond Shells. Energy Sources 2002, 24, 215–221. [Google Scholar] [CrossRef]

- Sezer, S.; Özveren, U. Investigation of Hazelnut Husk Combustion by using A Novel Non-linear Kinetic Model through Thermogravimetric Analysis. Sak. Univ. J. Sci. 2021, 25, 326–338. [Google Scholar] [CrossRef]

| PARAMETER | METHOD | EQUIPMENT |

|---|---|---|

| Energetic properties | ||

| Higher heating value (HHV; MJ·kg−1) | EN-ISO 1928:2020 [34] | Isoperibolic calorimeter LECO AC 600 (LECO Corporation, Saint Joseph, MI, USA, 2012) |

| Lower heating value (LHV; MJ·kg−1) | ||

| Proximate analysis | ||

| Ash (A; %) | EN-ISO 18122:2022 [35] | Thermogravimetric analyzer LECO TGA 701 (LECO Corporation, Saint Joseph, MI, USA, 2013) |

| Volatile matter (V; %) | EN-ISO 18123:2023 [36] | |

| Moisture (M; %) | EN-ISO 18134:2023 [37] | |

| Fixed carbon (FC; %) | FC = 100 − V − A − M [38] | |

| Ultimate analysis | ||

| Carbon (C; %) | EN-ISO 16948:2015 [39] | Elemental analyzer LECO CHNS 628 (LECO Corporation, Saint Joseph, MI, USA, 2012) |

| Hydrogen (H; %) | ||

| Nitrogen (N; %) | ||

| Sulfur (S; %) | EN-ISO 16994:2016 [40] | |

| Oxygen (O; %) | O = 100 − A − H − C − S − N [41] | |

| PARAMETER | METHOD AND EQUIPMENT |

|---|---|

| Carbon monoxide emission factor (Ec) of chemically pure coal (CO; kg·Mg−1) | CO—carbon monoxide emission factor (kg·kg−1), —molar mass ratio of carbon monoxide and carbon, EC—emission factor of chemically pure coal (kg·kg−1), C/CO—part of the carbon emitted as CO (for biomass 0.06). |

| Carbon dioxide emission factor (CO2; kg·Mg−1) | CO2—carbon dioxide emission factor (kg·kg−1)—molar mass ratio of carbon dioxide and pure coal—molar mass ratio of carbon dioxide and carbon monoxide—molar mass ratio of carbon and methane, ECH4—methane emission factor, ENMVOC—emission index of non-methane VOCs (for biomass 0.009). |

| Sulphur dioxide emission factor (SO2; kg·Mg−1) | SO2–sulfur dioxide emission factor (kg·kg−1), 2—molar mass ratio of SO2 and sulfur, S—sulfur content in fuel (%), r—coefficient determining the part of total sulfur retained in the ash. |

| Emission factor was calculated from NOX (kg·Mg−1) |

, NOx—NOx emission factor (kg·kg−1)—molar mass ratio of nitrogen dioxide to nitrogen. The molar mass of nitrogen dioxide is considered due to the fact that nitrogen oxide in the air oxidizes very soon to nitrogen dioxide, N/C—nitrogen-to-carbon ratio in biomass, NOx/N—part of nitrogen emitted as NOx (for biomass 0.122). |

| PARAMETER | METHOD AND EQUIPMENT |

|---|---|

| Theoretical oxygen demand (VO2; Nm3·kg−1) |

, C—biomass carbon content (%), H—biomass hydrogen content (%), S—biomass sulfur content (%), O—biomass oxygen content). |

| Stoichiometric volume of dry air required to burn 1 kg of biomass (Voa; Nm3·kg−1) | When the oxygen content in the air is 21%, which participates in the combustion process in the boiler, the stoichiometric volume of dry air required to burn 1 kg of biomass. |

| Carbon dioxide content of the combustion products (VCO2; Nm3·kg−1) | |

| Content of sulfur dioxide (VSO2; Nm3·kg−1) | , |

| Water vapor content of exhaust gas (VH2O; Nm3·kg−1) |

, Component of water vapor volume from the hydrogen combustion process Volume of moisture contained in the combustion air ; ; M—fuel moisture content (%), x—air absolute humidity (kg H2O·kg−1 dry air). |

| Theoretical nitrogen content in exhaust gas ; Nm3·kg−1) | , Considering that the nitrogen in the exhaust comes from the fuel composition and the combustion air, and the nitrogen content in the air is 79%. |

| Total stoichiometric volume of dry exhaust gas Nm3·kg−1) | |

| Total volume of exhaust gases ; Nm3·kg−1) | Assuming that biomass combustion is carried out under stoichiometric conditions, i.e., using the minimum amount of air required for combustion (λ = 1), a minimum exhaust gas volume will be obtained. |

| Name | HHV (MJ·kg−1) | LHV (MJ·kg−1) | MC% | A% | V% | FC |

|---|---|---|---|---|---|---|

| Çakıldak | 19.02 ± 0.06 b | 17.72 ± 0.06 b | 9.96 ± 0.01 e | 1.00 ± 0.02 b | 66.53 ± 0.29 a | 22.52 ± 0.27 a |

| Foşa | 18.37 ± 0.09 d | 17.05 ± 0.09 d | 11.94 ± 0.03 a | 1.29 ± 0.08 a | 64.77 ± 0.39 c | 22.01 ± 0.33 a |

| İnce Kara | 18.70 ± 0.03 c | 17.41 ± 0.03 c | 10.28 ± 0.08 d | 1.25 ± 0.01 a | 66.20 ± 0.16 ab | 22.27 ± 0.09 a |

| Kalın Kara | 18.61 ± 0.09 c | 17.33 ± 0.09 c | 9.22 ± 0.05 f | 1.29 ± 0.07 a | 66.82 ± 0.38 a | 22.67 ± 0.42 a |

| Palaz | 18.67 ± 0.02 c | 17.37 ± 0.02 c | 10.46 ± 0.07 c | 1.10 ± 0.05 b | 66.02 ± 0.31 ab | 22.42 ± 0.24 a |

| Tombul | 18.91 ± 0.02 b | 17.61 ± 0.02 b | 10.20 ± 0.01 d | 1.11 ± 0.01 b | 66.22 ± 0.28 ab | 22.47 ± 0.28 a |

| Yassı Badem | 19.20 ± 0.02 c | 17.90 ± 0.03 c | 9.97 ±0.03 e | 1.03 ± 0.02 b | 66.30 ± 0.05 bc | 22.70 ± 0.05 a |

| Yuvarlak Badem | 18.63 ± 0.03 a | 17.33 ± 0.04 a | 10.73 ± 0.01 b | 1.10 ± 0.01 b | 65.47 ± 0.25 a | 22.71 ± 0.05 a |

| p-value | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0606 |

| Name | C% | H% | N% | S% | O% | H/C | N/C | O/C |

|---|---|---|---|---|---|---|---|---|

| Çakıldak | 47.32 ± 0.03 a | 7.41 ± 0.03 a | 0.46 ± 0.01 ab | 0.03 ± 0.00 c | 43.79 ± 0.04 c | 1.57 ± 0.01 ab | 0.01 ± 0.00 ab | 0.69 ± 0.00 d |

| Foşa | 45.69 ± 0.10 d | 7.39 ± 0.05 a | 0.45 ± 0.06 ab | 0.03 ± 0.00 b | 45.16 ± 0.16 a | 1.62 ± 0.01 a | 0.01 ± 0.00 ab | 0.74 ± 0 a |

| İnce Kara | 46.47 ± 0.09 c | 7.37 ± 0.02 a | 0.5 ± 0.02 ab | 0.03 ± 0.00 d | 44.39 ± 0.08 bc | 1.59 ± 0.00 a | 0.01 ± 0.00 ab | 0.72 ± 0.00 bc |

| Kalın Kara | 46.73 ± 0.05 bc | 6.83 ± 0.51 b | 0.54 ± 0.06 a | 0.02 ± 0.00 f | 44.58 ± 0.49 ab | 1.46 ± 0.11 b | 0.01 ± 0.00 a | 0.72 ± 0.01 bc |

| Palaz | 46.48 ± 0.30 c | 7.25 ± 0.08 ab | 0.48 ± 0.05 ab | 0.02 ± 0.00 g | 44.68 ± 0.29 ab | 1.56 ± 0.01 ab | 0.01 ± 0.00 ab | 0.72 ± 0.01 b |

| Tombul | 47.04 ± 0.01 ab | 7.29 ± 0.01 ab | 0.40 ± 0.00 b | 0.03 ± 0.00 e | 44.13 ± 0.02 bc | 1.55 ± 0.00 ab | 0.01 ± 0.00 b | 0.70 ± 0.00 cd |

| Yassı Badem | 47.23 ± 0.04 a | 7.37 ± 0.03 a | 0.44 ± 0.01 ab | 0.03 ± 0.00 a | 43.89 ± 0.09 c | 1.56 ± 0.01 ab | 0.01 ± 0.00 ab | 0.70 ± 0.00 d |

| Yuvarlak Badem | 46.51 ± 0.14 c | 7.27 ± 0.05 ab | 0.47 ± 0.05 ab | 0.02 ± 0.00 h | 44.64 ± 0.15 ab | 1.56 ± 0.01 ab | 0.01 ± 0.00 ab | 0.72 ± 0.01 b |

| p-value | 0.0001 | 0.0291 | 0.0212 | 0.0001 | 0.0001 | 0.0105 | 0.0226 | 0.0001 |

| Name | CO (kg·Mg−1) | NOx (kg·Mg−1) | CO2 (kg·Mg−1) | SO2 (kg·Mg−1) | Dust (kg·Mg−1) |

|---|---|---|---|---|---|

| Çakıldak | 58.29 ± 0.03 a | 1.64 ± 0.02 ab | 1427.47 ± 0.84 a | 0.05 ± 0.00 c | 1.26 ± 0.02 b |

| Foşa | 56.28 ± 0.12 d | 1.59 ± 0.22 ab | 1378.27 ± 2.87 d | 0.06 ± 0.00 b | 1.63 ± 0.10 a |

| İnce Kara | 57.25 ± 0.11 c | 1.77 ± 0.08 ab | 1401.93 ± 2.65 c | 0.05 ± 0.00 d | 1.58 ± 0.01 a |

| Kalın Kara | 57.57 ± 0.06 bc | 1.92 ± 0.21 a | 1409.79 ± 1.54 bc | 0.05 ± 0.00 f | 1.63 ± 0.09 a |

| Palaz | 57.26 ± 0.37 c | 1.68 ± 0.16 ab | 1402.27 ± 9.13 c | 0.05 ± 0.00 g | 1.39 ± 0.06 b |

| Tombul | 57.95 ± 0.02 ab | 1.43 ± 0.00 b | 1419.04 ± 0.42 ab | 0.05 ± 0.00 e | 1.40 ± 0.01 b |

| Yassı Badem | 58.19 ± 0.05 a | 1.56 ± 0.05 ab | 1424.98 ± 1.32 a | 0.06 ± 0.00 a | 1.30 ± 0.03 b |

| Yuvarlak Badem | 57.30 ± 0.18 c | 1.66 ± 0.17 ab | 1403.18 ± 4.30 c | 0.04 ± 0.00 h | 1.39 ± 0.01 b |

| p-value | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

| Name | VoO2 | Voa | VCO2 | VSO2 | VoH2O | VN2 | Voga | Vogu |

|---|---|---|---|---|---|---|---|---|

| Çakıldak | 0.99 ± 0.00 a | 4.72 ± 0.01 a | 0.88 ± 0.00 a | 0.00 ± 0.00 c | 1.71 ± 0.00 a | 4.10 ± 0.00 a | 6.70 ± 0.01 a | 4.99 ± 0.00 a |

| Foşa | 0.95 ± 0.01 b | 4.53 ± 0.03 b | 0.85 ± 0.00 d | 0.00 ± 0.00 b | 1.71 ± 0.01 a | 3.94 ± 0.03 c | 6.50 ± 0.02 bc | 4.79 ± 0.03 d |

| İnce Kara | 0.97 ± 0.00 ab | 4.62 ± 0.01 ab | 0.87 ± 0.00 c | 0.00 ± 0.00 d | 1.70 ± 0.00 a | 4.05 ± 0.01 ab | 6.61 ± 0.01 abc | 4.92 ± 0.01 abc |

| Kalın Kara | 0.94 ± 0.03 b | 4.49 ± 0.16 b | 0.87 ± 0.00 bc | 0.00 ± 0.00 f | 1.60 ± 0.08 b | 3.99 ± 0.08 bc | 6.46 ± 0.16 c | 4.86 ± 0.08 cd |

| Palaz | 0.96 ± 0.01 ab | 4.58 ± 0.06 ab | 0.87 ± 0.01 c | 0.00 ± 0.00 g | 1.68 ± 0.02 ab | 4.00 ± 0.01 bc | 6.54 ± 0.03 abc | 4.87 ± 0.01 cd |

| Tombul | 0.98 ± 0.00 ab | 4.66 ± 0.00 ab | 0.88 ± 0.00 ab | 0.00 ± 0.00 e | 1.69 ± 0.00 a | 4.00 ± 0.00 bc | 6.58 ± 0.01 abc | 4.88 ± 0.00 bc |

| Yassı Badem | 0.99 ± 0.00 a | 4.70 ± 0.01 a | 0.88 ± 0.00 a | 0.00 ± 0.00 a | 1.71 ± 0.01 ab | 4.07 ± 0.02 ab | 6.66 ± 0.02 ab | 4.95 ± 0.02 ab |

| Yuvarlak Badem | 0.96 ± 0.01 ab | 4.59 ± 0.03 ab | 0.87 ± 0.00 c | 0.00 ± 0.00 h | 1.69 ± 0.01 a | 4.00 ± 0.02 bc | 6.55 ± 0.01 abc | 4.87 ± 0.01 cd |

| p-value | 0.0028 | 0.0028 | 0.0001 | 0.0001 | 0.0089 | 0.0002 | 0.0002 | 0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klimek, K.E.; Kordali, S.; Borkowska, A.; Yilmaz, F.; Maj, G. Energy Assessment of Hazelnut Shells (Corylus avellana L.) of Selected Turkish Varieties. Energies 2025, 18, 3612. https://doi.org/10.3390/en18143612

Klimek KE, Kordali S, Borkowska A, Yilmaz F, Maj G. Energy Assessment of Hazelnut Shells (Corylus avellana L.) of Selected Turkish Varieties. Energies. 2025; 18(14):3612. https://doi.org/10.3390/en18143612

Chicago/Turabian StyleKlimek, Kamila E., Saban Kordali, Anna Borkowska, Ferah Yilmaz, and Grzegorz Maj. 2025. "Energy Assessment of Hazelnut Shells (Corylus avellana L.) of Selected Turkish Varieties" Energies 18, no. 14: 3612. https://doi.org/10.3390/en18143612

APA StyleKlimek, K. E., Kordali, S., Borkowska, A., Yilmaz, F., & Maj, G. (2025). Energy Assessment of Hazelnut Shells (Corylus avellana L.) of Selected Turkish Varieties. Energies, 18(14), 3612. https://doi.org/10.3390/en18143612