Comparative Life Cycle Analysis for Duct Air Conditioning Systems Based on Evaporative and Vapor Compression Technologies

Abstract

1. Introduction

2. Materials and Methods

2.1. Method of Assessing Environmental Impact

- A constant volumetric fresh air flow amounting to 800 m3/h was assumed.

- The lifespans of the compared products and, consequently, their operation periods are the same (summer seasons over 10 years).

- After the operation period, both units will be recycled.

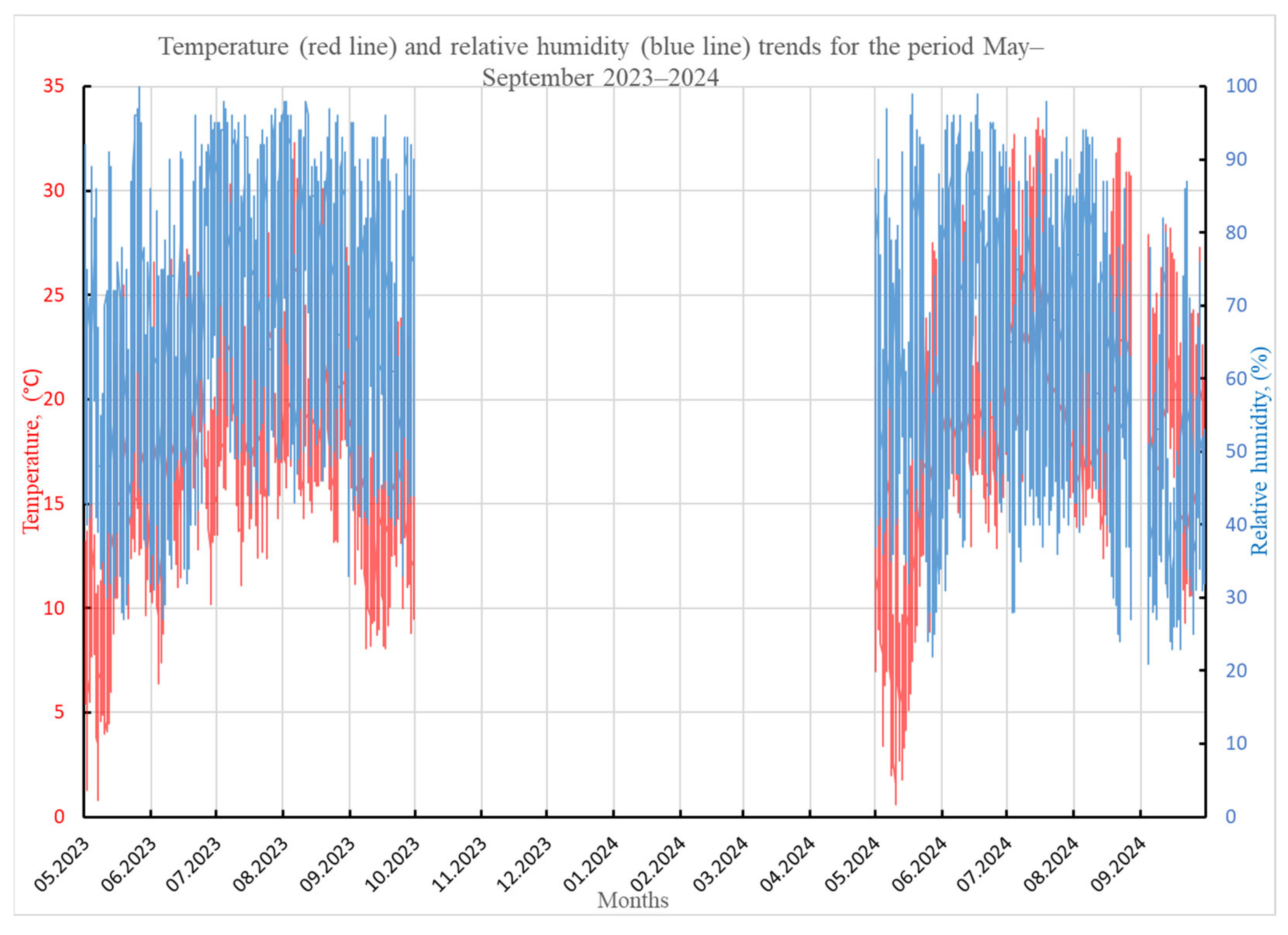

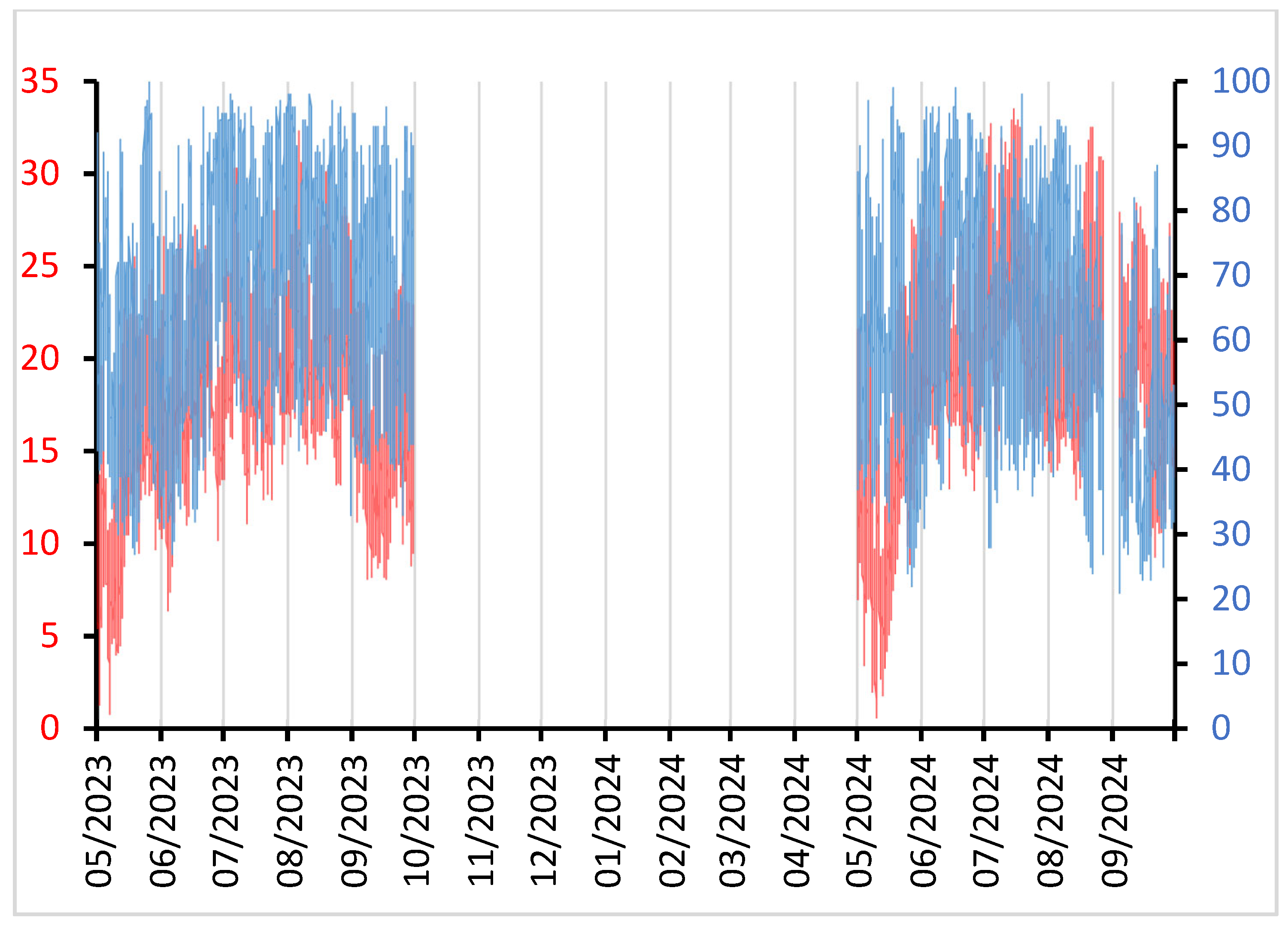

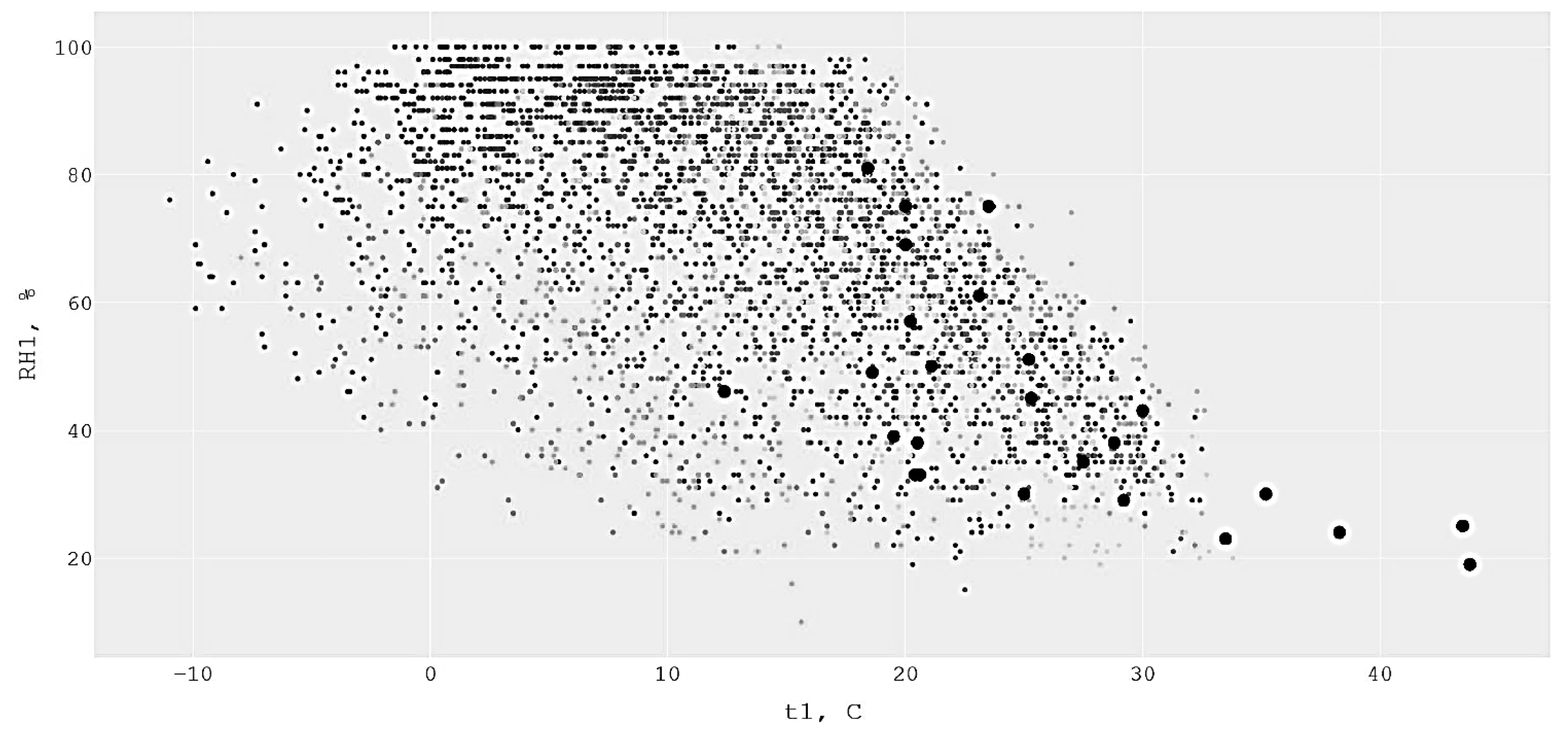

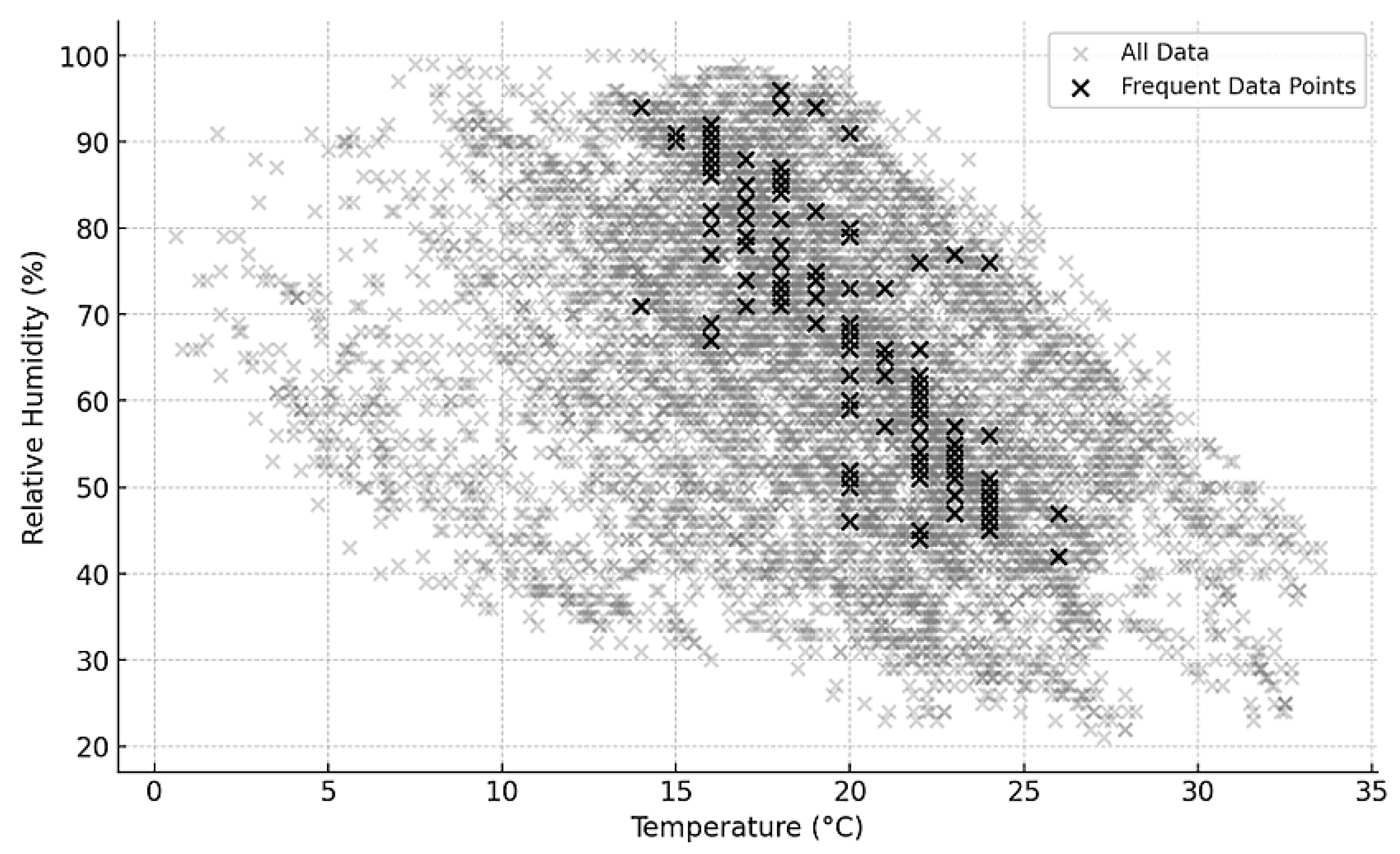

- The outside air parameters for the operation time were based on the measurements for May–September period in 2023 and 2024.

- Following the provisions of ISO 14044 standard, saying that exclusion of given processes is permitted if it does not significantly change the general conclusion of the analysis, the installation elements of the cooling systems (pipe connections, cables, etc.) were excluded from the product system boundaries as identical for both compared scenarios.

- The analyses adopted mass (physical) allocation approach.

- The LCIA procedures were carried out using cutoff parameter of 0.0001, meaning that the processes with the contribution to total impact smaller than 0.01% were neglected.

- The uncertainty analysis was carried out by means of Monte Carlo simulations with 5000 iterations. Input parameters were assigned lognormal distributions based on the uncertainty factors available in the ecoinvent 3.8 database. Output results were presented as the confidence intervals for 5th and 95th percentiles obtained for individual endpoint categories.

- Since AC units are assumed to be operated in the city of Sumy (using historical statistical data as input conditions), the Ukrainian electricity mix was adopted.

- The initial amount of the refrigerant (R-32) necessary for operating VCRM was 1.075 kg, including 50 g per meter of 3.5 m connecting installation.

- Length of air ducts for both systems is equal and comprises 15 m.

- 5 kW AC unit passport specifications and a targeted supply flow rate of 800 m3/h of cooled air to the consumer were assumed for both systems. Notably, the energy efficiency of evaporative cooling units grows more intensively with the increase in the installed cooling capacity compared to VCRM.

- The leakage of the refrigerant was assumed to be 1.12% per year [42].

- A building for the installed AC system is a thermally well insulated changing room of a sports hall, with no extra heat fluxes except internal sources.

2.2. Data Collection

- Air from the environment is supplied by a fan into the apparatus and is then divided into two components.

- The working flow passes through a system of dry channels (where it transfers heat to the adjacent wet channels and is cooled at constant moisture content) and then through wet channels (where the air is heated and saturated with water vapor at a constant relative humidity, RH).

- Meanwhile, the second component of the incoming air flow is the product flow (cooled air delivered to the consumer). Passing through its set of dry channels, the product flow gives off its heat to the wet channels and, thus, cools at a constant moisture content.

2.3. Historical Climate Data for the Considered Region

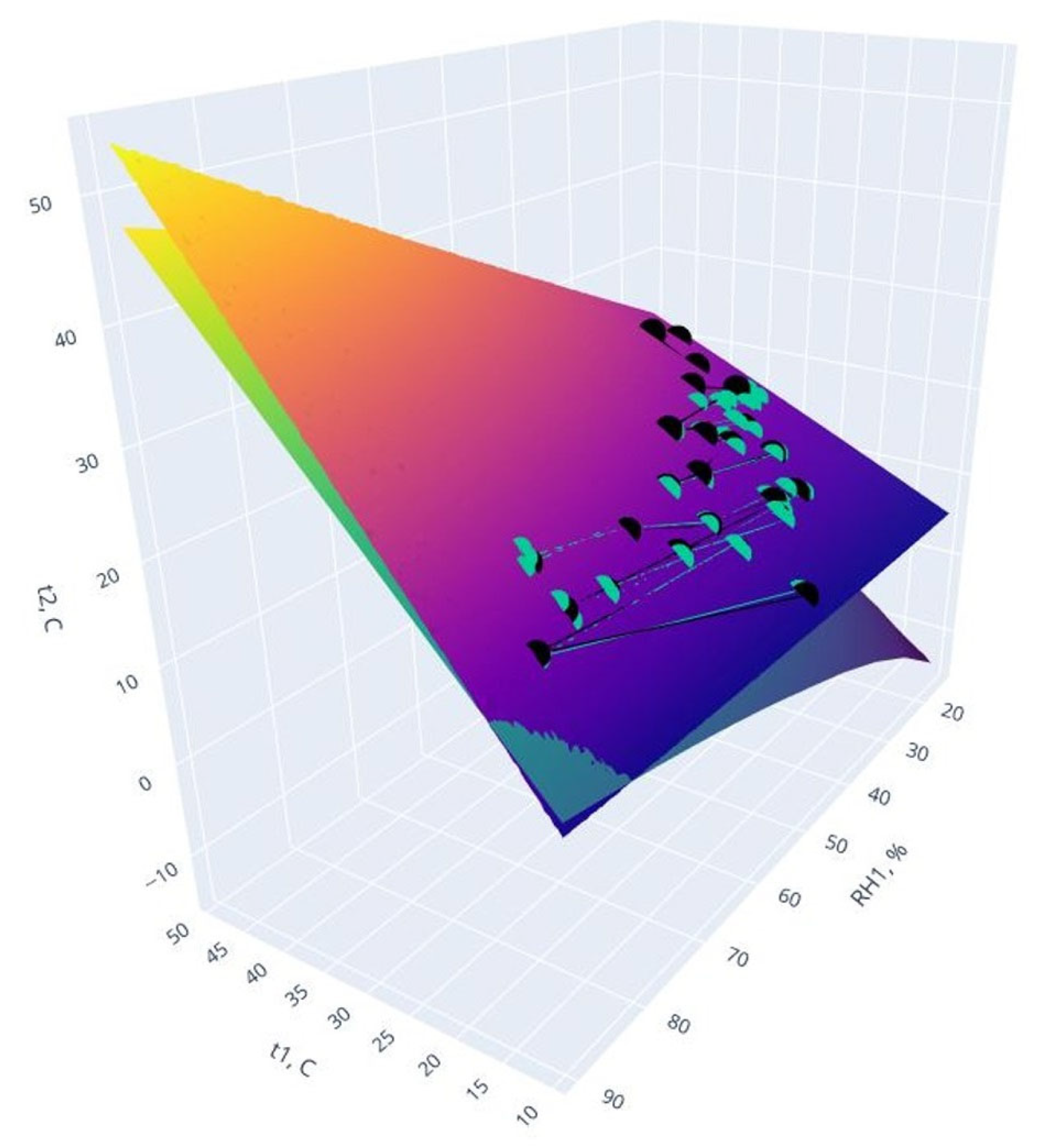

2.4. Method for Assessing and Predicting the Cooling Capacity and Energy Efficiency of Vapor Compression Evaporative Cooling Systems

- Environmental parameters (ambient temperature, relative humidity);

- Operational configurations of equipment.

- 1.

- For the range from target room temperature 19 °C to 24 °C (due to the lack of experimental data), it is proposed to accept COP value at the maximum feasible level for the VCRM unit considered:

- 2.

- For the actual ambient temperature, the actual cooling capacity of the VCRM AC unit is calculated to supply the required 800 m3/h of cooled air to the consumer:where is the mass flow rate of the supplied air, is the specific heat capacity of the supplied air, is primary air dry-bulb temperature at VCRM AC unit input (this temperature is equal to ambient temperature as a rule), is dry-bulb temperature of the supplied cooled air at VCRM AC unit output. For the considered calculation method, .

- 3.

- The specific power consumption of the air conditioning system per 1 degree Celsius is calculated at a given mass flow rate and a given coefficient of performance or for the corresponding temperature ranges:

- 4.

- The total cooling energy of the VCRM AC unit is calculated for the considered time period of historical data, :

- 5.

- Energy expended on the operation of VCRM AC to achieve the target temperature for the i-th time interval of historical data, , is as follows:

- 6.

- The total energy consumption the VCRM AC unit is calculated for the considered time period of historical data, :

- 7.

- The reduced seasonal performance coefficient of the VCRM AC plant was calculated as follows:

2.5. Method for Assessing and Predicting the Cooling Capacity and Energy Efficiency of IREC Cooling Systems

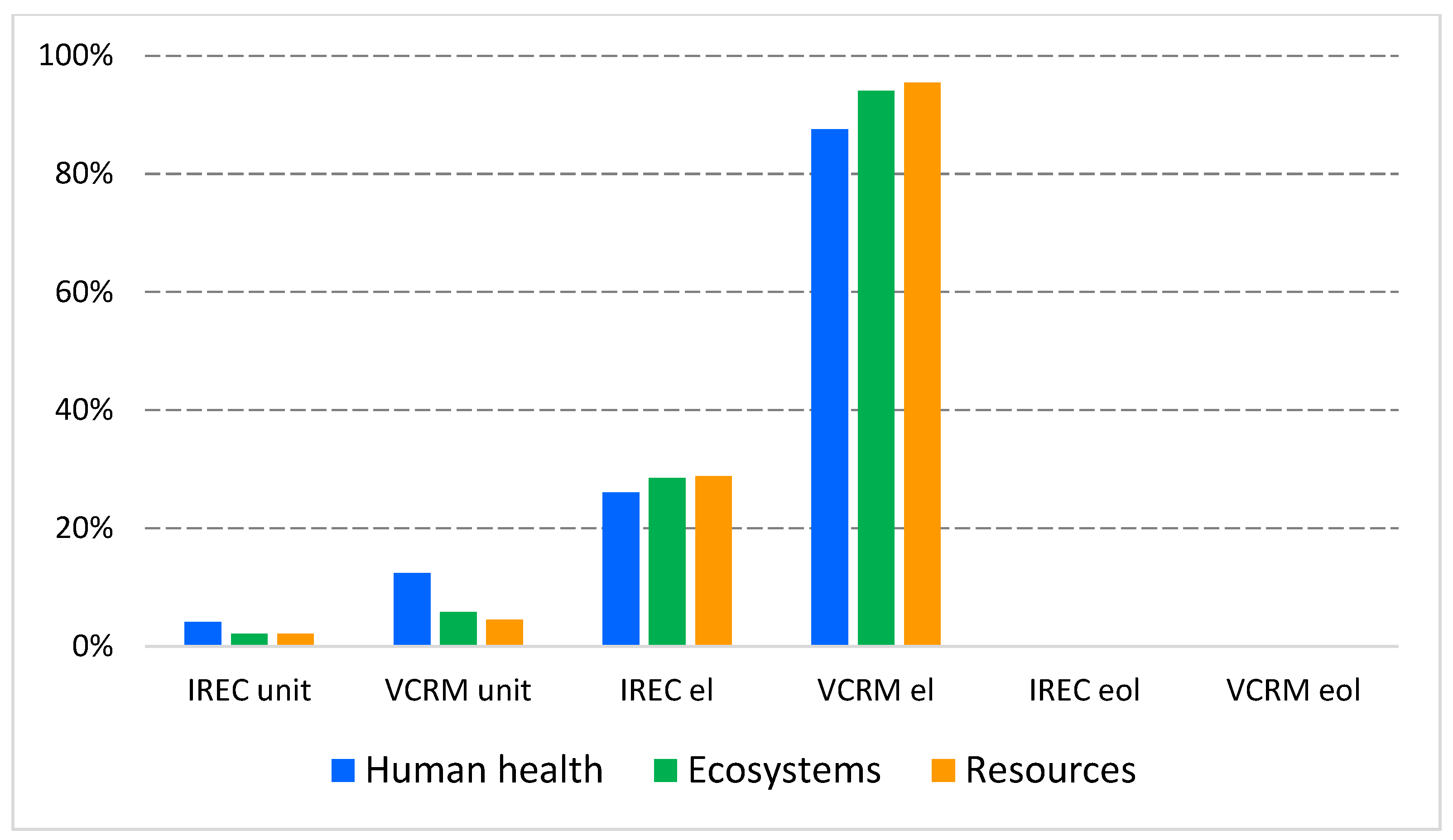

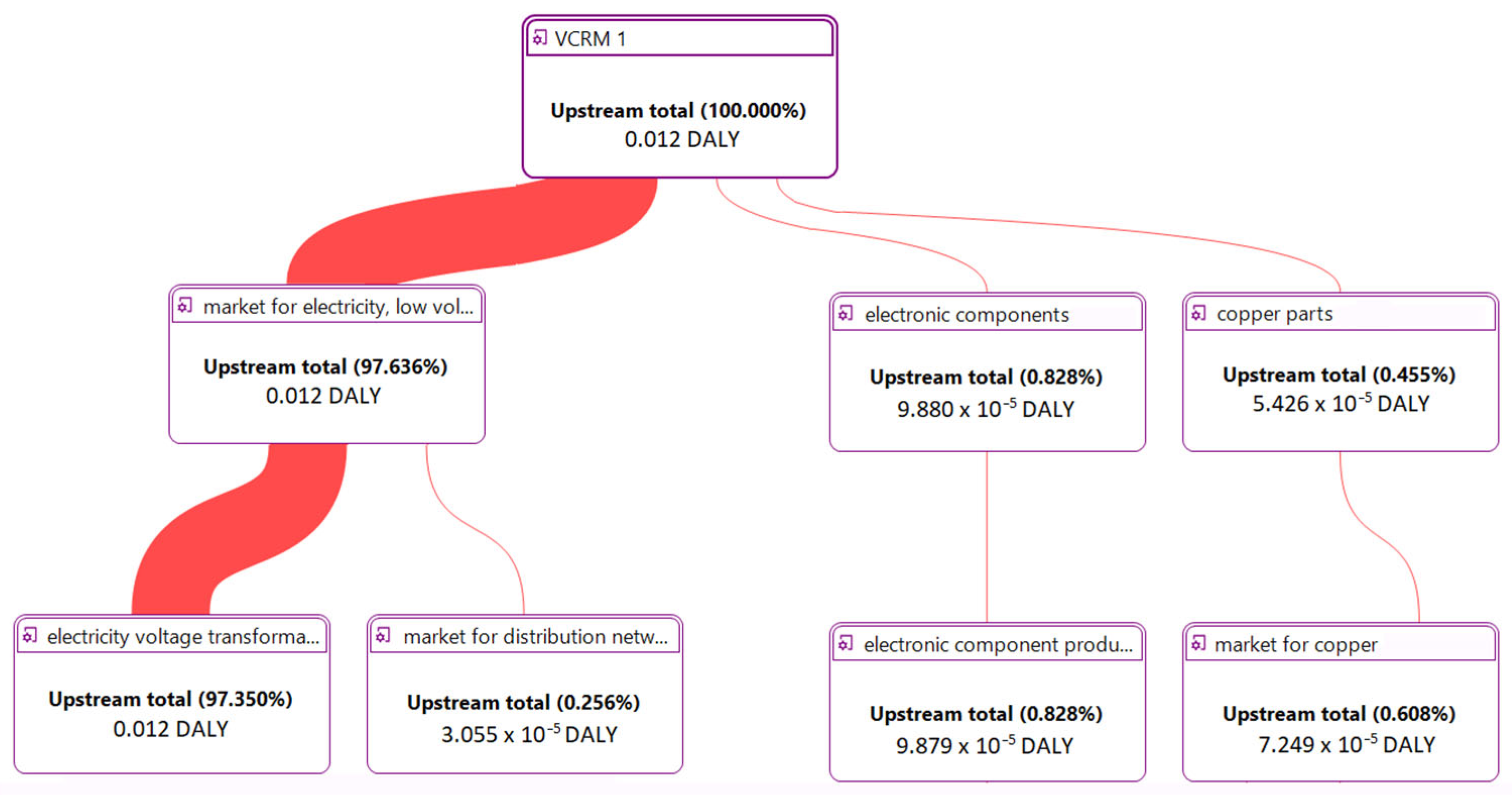

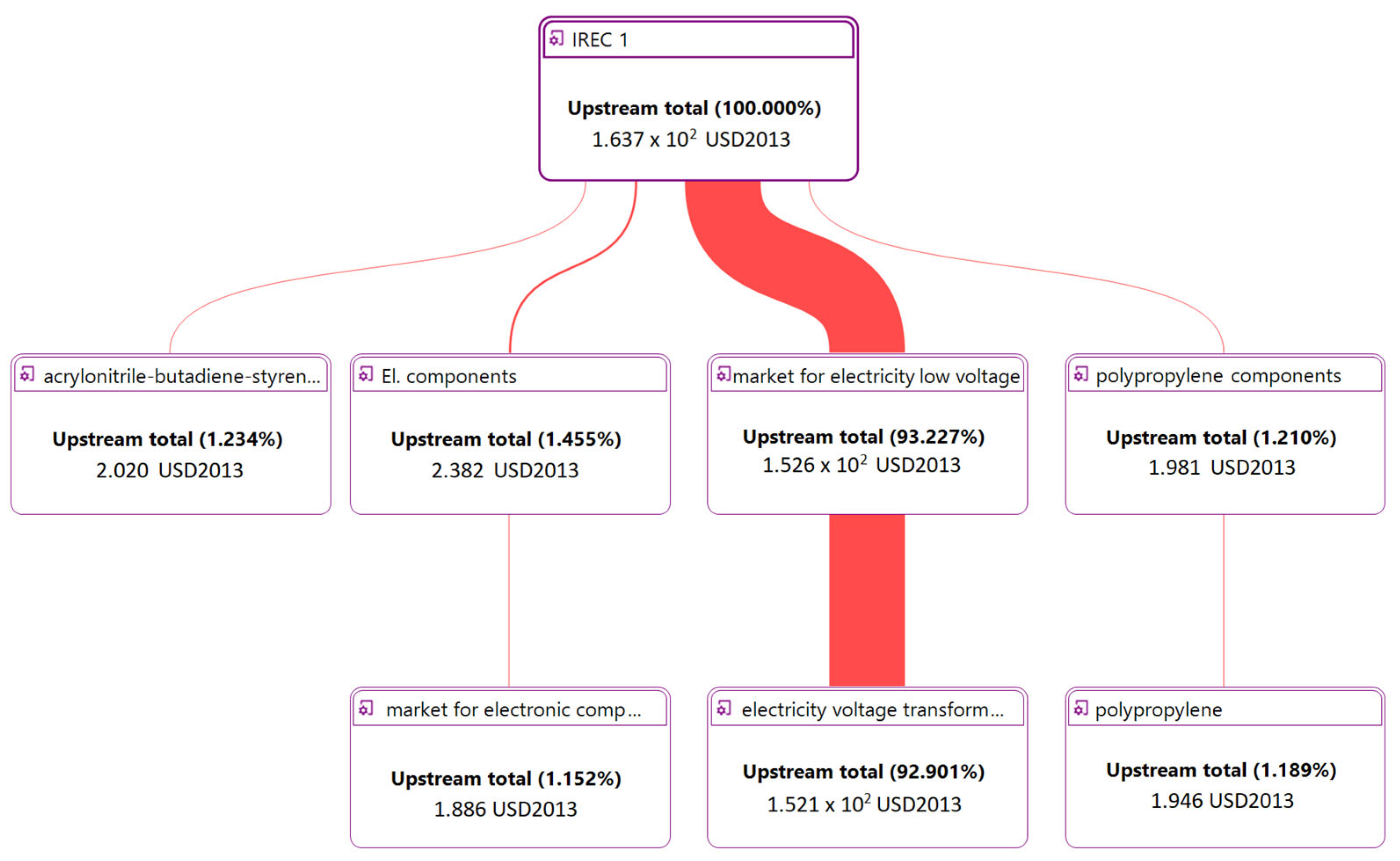

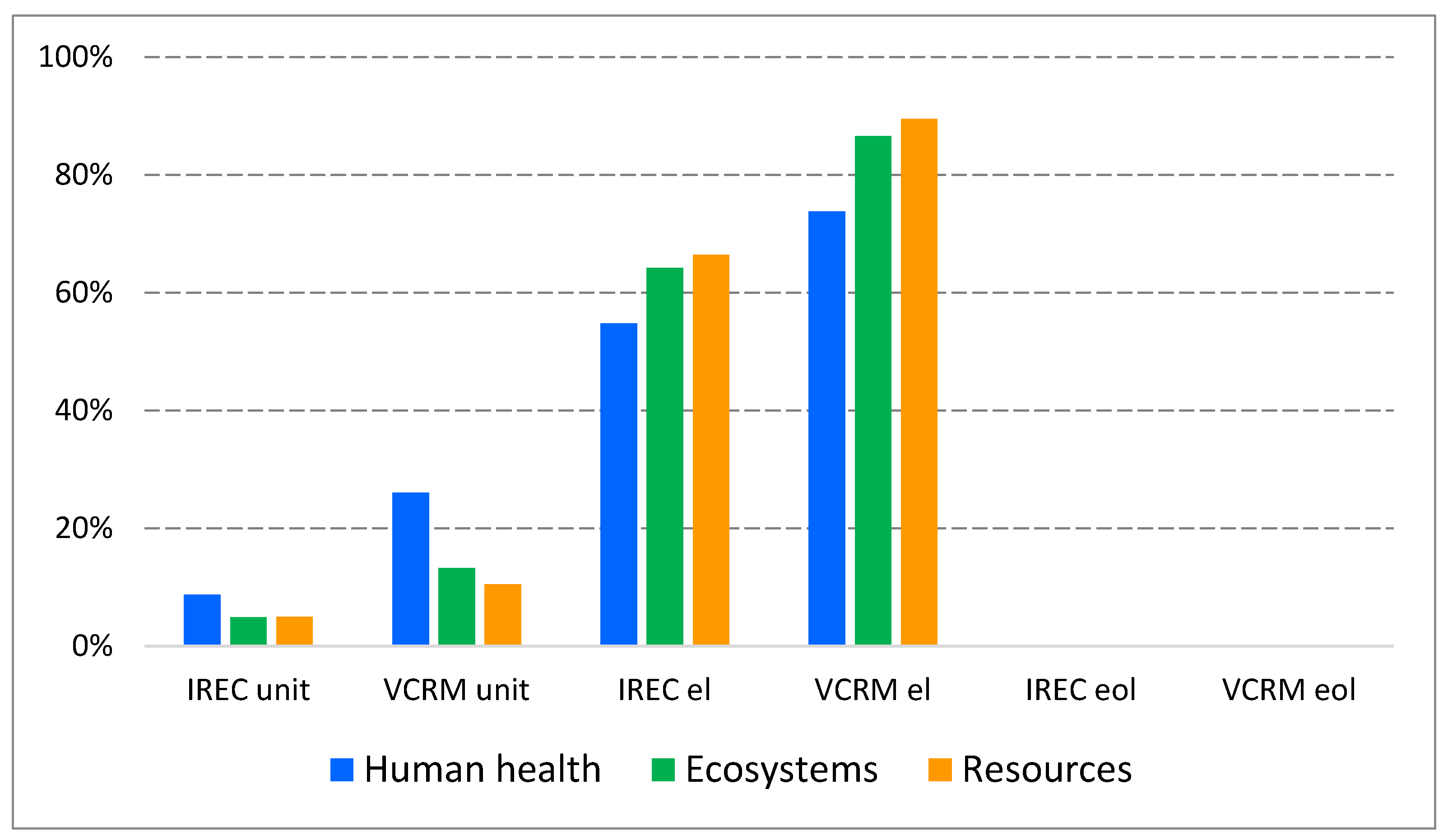

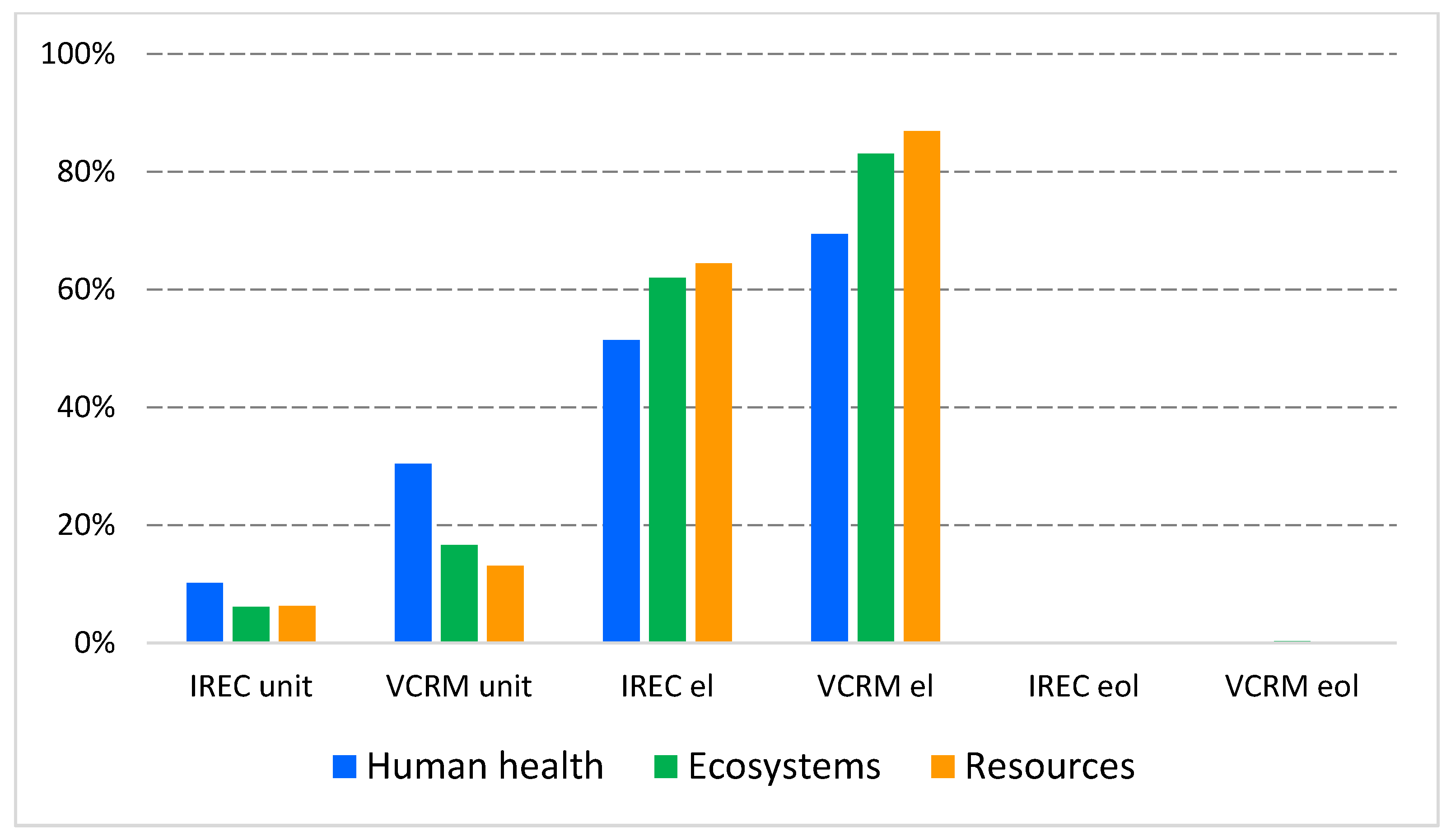

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agostini, B.; Fabbri, M.; Park, J.E.; Wojtan, L.; Thome, J.R.; Michel, B. State of the Art of High Heat Flux Cooling Technologies. Heat Transf. Eng. 2007, 28, 258–281. [Google Scholar] [CrossRef]

- Kumar Sharma, K.; Gupta, R.L.; Katarey, S. Performance Improvement of Air Conditioning System Using Applications of Evaporative Cooling: A Review Paper. Int. J. Therm. Eng. 2016, 2, 1–5. [Google Scholar] [CrossRef]

- IEA Report. Air Conditioning Use Emerges as One of The Key Drivers of Global Electricity-Demand Growth. Available online: https://www.iea.org/news/air-conditioning-use-emerges-as-one-of-the-key-drivers-of-global-electricity-demand-growth (accessed on 30 May 2025).

- Ko, J.; Jeong, J.H. Status and Challenges of Vapor Compression Air Conditioning and Heat Pump Systems for Electric Vehicles. Appl. Energy 2024, 375, 124095. [Google Scholar] [CrossRef]

- Wang, C.; Lei, B.; Zhang, Z.; Liu, Q.; Wu, J. Theoretical Study on the Vapor Compression Cycles with Nearly Isothermal Compression for Various LGWP Refrigerants Using Oil Injection. Appl. Therm. Eng. 2025, 264, 125510. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Dong, J.; Yao, Y. Advances in Vapor Compression Air Source Heat Pump System in Cold Regions: A Review. Renew. Sustain. Energy Rev. 2018, 81, 353–365. [Google Scholar] [CrossRef]

- Rostamzadeh, H.; Rostamzadeh, J.; Matin, P.S.; Ghaebi, H. Novel Dual-Loop Bi-Evaporator Vapor Compression Refrigeration Cycles for Freezing and Air-Conditioning Applications. Appl. Therm. Eng. 2018, 138, 563–582. [Google Scholar] [CrossRef]

- Skye, H.M.; Domanski, P.A.; Brignoli, R.; Lee, S.; Bae, H. Validation of and Optimization with a Vapor Compression Cycle Model Accounting for Refrigerant Thermodynamic and Transport Properties: With Focus on Low-GWP Refrigerants for Air-Conditioning. Int. J. Refrig. 2023, 147, 106–120. [Google Scholar] [CrossRef]

- Subiantoro, A.; Ooi, K.T. Economic Analysis of the Application of Expanders in Medium Scale Air-Conditioners with Conventional Refrigerants, R1234yf and CO2. Int. J. Refrig. 2013, 36, 1472–1482. [Google Scholar] [CrossRef]

- She, X.; Yin, Y.; Zhang, X. A Proposed Subcooling Method for Vapor Compression Refrigeration Cycle Based on Expansion Power Recovery. Int. J. Refrig. 2014, 43, 50–61. [Google Scholar] [CrossRef]

- Miyawaki, K.; Shikazono, N. Experimental Evaluation of NIR Spectroscopic Characteristics of Liquid R32, R1234yf and R454C Refrigerants. Int. Commun. Heat Mass Transf. 2024, 156, 107633. [Google Scholar] [CrossRef]

- Hossain, M.N.; Ghosh, K. A Comparative Study of Plain and Enhanced Helical Microfin Evaporator Tube with Drift Flux-Based Entropy Generation Model for R32 and R410A Refrigerants. Int. J. Heat Mass Transf. 2023, 215, 124441. [Google Scholar] [CrossRef]

- Maeda, S.; Thu, K.; Maruyama, T.; Miyazaki, T. Critical Review on the Developments and Future Aspects of Adsorption Heat Pumps for Automobile Air Conditioning. Appl. Sci. 2018, 8, 2061. [Google Scholar] [CrossRef]

- Islam, M.A.; Mitra, S.; Thu, K.; Saha, B.B. Study on Thermodynamic and Environmental Effects of Vapor Compression Refrigeration System Employing First to Next-Generation Popular Refrigerants. Int. J. Refrig. 2021, 131, 568–580. [Google Scholar] [CrossRef]

- Mtibaa, A.; Sessa, V.; Guerassimoff, G.; Alajarin, S. Refrigerant Leak Detection in Industrial Vapor Compression Refrigeration Systems Using Machine Learning. Int. J. Refrig. 2024, 161, 51–61. [Google Scholar] [CrossRef]

- Lai, L.; Wang, X.; Hu, E.; Choon Ng, K. A Vision of Dew Point Evaporative Cooling: Opportunities and Challenges. Appl. Therm. Eng. 2024, 244, 122683. [Google Scholar] [CrossRef]

- Liu, X.; Jing, C.; Lyu, S. Performance Study of Indirect Perforated Dew-Point Evaporative Coolers. Available online: https://www.researchsquare.com/article/rs-4248663/v1 (accessed on 30 May 2025).

- Khan, I.; Khalid, W.; Ali, H.M.; Sajid, M.; Ali, Z.; Ali, M. An Experimental Investigation on the Novel Hybrid Indirect Direct Evaporative Cooling System. Int. Commun. Heat Mass Transf. 2024, 155, 107503. [Google Scholar] [CrossRef]

- Romero-Lara, M.J.; Comino, F.; Ruiz de Adana, M. Experimental Assessment of the Energy Performance of a Renewable Air-Cooling Unit Based on a Dew-Point Indirect Evaporative Cooler and a Desiccant Wheel. Energy Convers. Manag. 2024, 310, 118486. [Google Scholar] [CrossRef]

- Xiao, X.; Liu, J. A State-of-Art Review of Dew Point Evaporative Cooling Technology and Integrated Applications. Renew. Sustain. Energy Rev. 2024, 191, 114142. [Google Scholar] [CrossRef]

- Sajjad, U.; Abbas, N.; Hamid, K.; Abbas, S.; Hussain, I.; Ammar, S.M.; Sultan, M.; Ali, H.M.; Hussain, M.; Rehman, T.U.; et al. A Review of Recent Advances in Indirect Evaporative Cooling Technology. Int. Commun. Heat Mass Transf. 2021, 122, 105140. [Google Scholar] [CrossRef]

- Zhu, G.; Wen, T.; Wang, Q.; Xu, X. A Review of Dew-Point Evaporative Cooling: Recent Advances and Future Development. Appl. Energy 2022, 312, 118785. [Google Scholar] [CrossRef]

- Kapilan, N.; Isloor, A.M.; Karinka, S. A Comprehensive Review on Evaporative Cooling Systems. Results Eng. 2023, 18, 101059. [Google Scholar] [CrossRef]

- Yang, Y.; Ren, C.; Yang, C.; Tu, M.; Luo, B.; Fu, J. Energy and Exergy Performance Comparison of Conventional, Dew Point and New External-Cooling Indirect Evaporative Coolers. Energy Convers. Manag. 2021, 230, 113824. [Google Scholar] [CrossRef]

- Sohani, A.; Sayyaadi, H.; Mohammadhosseini, N. Comparative Study of the Conventional Types of Heat and Mass Exchangers to Achieve the Best Design of Dew Point Evaporative Coolers at Diverse Climatic Conditions. Energy Convers. Manag. 2018, 158, 327–345. [Google Scholar] [CrossRef]

- Bhat, S.A.; Sajjad, U.; Hussain, I.; Yan, W.M.; Raza, H.M.U.; Ali, H.M.; Sultan, M.; Omar, H.; Azam, M.W.; Bozzoli, F.; et al. Experiments and Modeling on Thermal Performance Evaluation of Standalone and M-Cycle Based Desiccant Air-Conditioning Systems. Energy Rep. 2024, 11, 1445–1454. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T.; Koyama, S.; Maisotsenko, V.S. Overview of the Maisotsenko Cycle—A Way towards Dew Point Evaporative Cooling. Renew. Sustain. Energy Rev. 2016, 66, 537–555. [Google Scholar] [CrossRef]

- Hussain, T. Optimization and Comparative Performance Analysis of Conventional and Desiccant Air Conditioning Systems Regenerated by Two Different Modes for Hot and Humid Climates: Experimental Investigation. Energy Built Environ. 2023, 4, 281–296. [Google Scholar] [CrossRef]

- Pandelidis, D.; Niemierka, E.; Pacak, A.; Jadwiszczak, P.; Cichoń, A.; Drąg, P.; Worek, W.; Cetin, S. Performance Study of a Novel Dew Point Evaporative Cooler in the Climate of Central Europe Using Building Simulation Tools. Build. Environ. 2020, 181, 107101. [Google Scholar] [CrossRef]

- Zhao, H.; Li, Q.; Wang, Z.; Wu, T.; Zhang, M. Synthesis of MIL-101 (Cr) and Its Water Adsorption Performance. Microporous Mesoporous Mater. 2020, 297, 110044. [Google Scholar] [CrossRef]

- Kandeal, A.W.; Joseph, A.; Elsharkawy, M.; Elkadeem, M.R.; Hamada, M.A.; Khalil, A.; Eid Moustapha, M.; Sharshir, S.W. Research Progress on Recent Technologies of Water Harvesting from Atmospheric Air: A Detailed Review. Sustain. Energy Technol. Assess. 2022, 52, 102000. [Google Scholar] [CrossRef]

- Harrouz, J.P.; Katramiz, E.; Ghali, K.; Ouahrani, D.; Ghaddar, N. Life Cycle Assessment of Desiccant—Dew Point Evaporative Cooling Systems with Water Reclamation for Poultry Houses in Hot and Humid Climate. Appl. Therm. Eng. 2022, 210, 118419. [Google Scholar] [CrossRef]

- Tariq, R.; Sheikh, N.A.; Bassam, A.; Xamán, J. Analysis of Maisotsenko Humid Air Bottoming Cycle Employing Mixed Flow Air Saturator. Heat Mass Transf. 2019, 55, 1477–1489. [Google Scholar] [CrossRef]

- Alam, M.S.; Zubir, M.N.B.M.; Muhamad, M.R.; Kazi, S.N.; Öztop, H.F.; Abdullah, S.; Shaikh, K. A Technological Review of Dew Point Evaporative Cooling: Experimental, Analytical, Numerical and Optimization Perspectives. J. Build. Eng. 2024, 91, 109544. [Google Scholar] [CrossRef]

- Khliyeva, O.; Shestopalov, K.; Ierin, V.; Zhelezny, V.; Chen, G.; Neng, G. Environmental and Energy Comparative Analysis of Expediency of Heat-Driven and Electrically-Driven Refrigerators for Air Conditioning Application. Appl. Therm. Eng. 2023, 219, 119533. [Google Scholar] [CrossRef]

- Alberto Huerta-Reynoso, E.; Alfredo López-Aguilar, H.; Alberto Gómez, J.; Guadalupe Gómez-Méndez, M.; Pérez-Hernández, A. Biogas Power Energy Production from a Life Cycle Thinking. In New Frontiers on Life Cycle Assessment-Theory and Application; IntechOpen: London, UK, 2019. [Google Scholar]

- Solano–Olivares, K.; Romero, R.J.; Santoyo, E.; Herrera, I.; Galindo–Luna, Y.R.; Rodríguez–Martínez, A.; Santoyo-Castelazo, E.; Cerezo, J. Life Cycle Assessment of a Solar Absorption Air-Conditioning System. J. Clean. Prod. 2019, 240, 118206. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- The European FluoroCarbons Technical Committee. Available online: https://www.fluorocarbons.org/news/vdkf-reports-1-12-average-leakage-rates-from-all-plant-types-in-2022/ (accessed on 29 April 2025).

- Shevchenko, S.; Levchenko, D.; Manzharov, A. Innovative Ideas LLC. Available online: https://www.innovativeideas.pro/reports/Report_II_ENG.pdf (accessed on 30 May 2025).

- U4E Energy-Efficient and Climate-Friendly Air Conditioners. 2019. Available online: https://united4efficiency.org/wp-content/uploads/2021/11/U4E_AC_Model-Regulation_EN_2021-11-08.pdf (accessed on 30 May 2025).

- Yumoto, Y.; Ichikawa, T.; Nobe, T.; Kametani, S. Study on Performance Evaluation of a Split Air Conditioning System Under the Actual Conditions. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 10–14 July 2022. Paper 757. [Google Scholar]

- Andrade, Á.; Restrepo, Á.; Tibaquirá, J.E. EER or Fcsp: A Performance Analysis of Fixed and Variable Air Conditioning at Different Cooling Thermal Conditions. Energy Rep. 2021, 7, 537–545. [Google Scholar] [CrossRef]

- Aynur, T.N. Variable Refrigerant Flow Systems: A Review. Energy Build. 2010, 42, 1106–1112. [Google Scholar] [CrossRef]

- Park, Y.C.; Kim, Y.C.; Min, M.K. Performance Analysis on a Multi-Type Inverter Air Conditioner. Energy Convers. Manag. 2001, 42, 1607–1621. [Google Scholar] [CrossRef]

- Meteostat. Available online: https://meteostat.net/en/place/ua/sumy?s=33275&t=2025-03-04/2025-03-11 (accessed on 30 April 2025).

- Choi, K.; Chong, K. Modified Inverse DistanceWeighting Interpolation for Particulate Matter Estimation and Mapping. Atmosphere 2022, 13, 846. [Google Scholar] [CrossRef]

- Attorre, F.; Alfo, M.; De Sanctis, M.; Francesconi, F.; Bruno, F. Comparison of Interpolation Methods for Mapping Climatic and Bioclimatic Variables at Regional Scale. Int. J. Climatol. 2007, 27, 1825–1843. [Google Scholar] [CrossRef]

- Tan, J.; Xie, X.; Zuo, J.; Xing, X.; Liu, B.; Xia, Q.; Zhang, Y. Coupling Random Forest and Inverse Distance Weighting to Generate Climate Surfaces of Precipitation and Temperature with Multiple-Covariates. J. Hydrol. 2021, 598, 126270. [Google Scholar] [CrossRef]

- Wang, H.K.; Chien, C.F. An Inverse-Distance Weighting Genetic Algorithm for Optimizing the Wafer Exposure Pattern for Enhancing OWE for Smart Manufacturing. Appl. Soft Comput. 2020, 94, 106430. [Google Scholar] [CrossRef]

- Cai, J.; Yu, W.; Xu, W.; Wang, K. Research on Air-Conditioning Operation Energy Saving in Internet Data Center. In Proceedings of the 2022 8th International Conference on Hydraulic and Civil Engineering: Deep Space Intelligent Development and Utilization Forum (ICHCE), Xi’an, China, 25–27 November 2022; pp. 1273–1276. [Google Scholar] [CrossRef]

- Liu, F.; Wang, Z.; Zhang, Q. The Application of a Modular Air Conditioning System in Data Center. Procedia Eng. 2017, 205, 2600–2606. [Google Scholar] [CrossRef]

- Amoabeng, K.O.; Opoku, R.; Boahen, S.; Obeng, G.Y. Analysis of Indoor Set-Point Temperature of Split-Type ACs on Thermal Comfort and Energy Savings for Office Buildings in Hot-Humid Climates. Energy Built Environ. 2023, 4, 368–376. [Google Scholar] [CrossRef]

- Almogbel, A.; Alkasmoul, F.; Aldawsari, Z.; Alsulami, J.; Alsuwailem, A. Comparison of Energy Consumption between Non-Inverter and Inverter-Type Air Conditioner in Saudi Arabia. Energy Transit. 2020, 4, 191–197. [Google Scholar] [CrossRef]

- Lim, J.; Yoon, M.S.; Al-Qahtani, T.; Nam, Y. Feasibility Study on Variable-Speed Air Conditioner under Hot Climate Based on Real-Scale Experiment and Energy Simulation. Energies 2019, 12, 1489. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, J.; Xia, X. Energy Consumption of Air Conditioners at Different Temperature Set Points. In Proceedings of the IEEE AFRICON Conference, Victoria Falls, Zambia, 13–15 September 2011. [Google Scholar] [CrossRef]

- Dapito, J.L.; Chua, A.Y. Coefficient of Performance Prediction Model for an On-Site Vapor Compression Refrigeration System Using Artificial Neural Network. Int. J. Technol. 2024, 15, 505–516. [Google Scholar] [CrossRef]

- Belman-Flores, J.M.; Ledesma, S. Statistical Analysis of the Energy Performance of a Refrigeration System Working with R1234yf Using Artificial Neural Networks. Appl. Therm. Eng. 2015, 82, 8–17. [Google Scholar] [CrossRef]

- Viet, D.N.; Pham, H.-L.; Tokura, S.; Nguyen, V.-D.; Nguyen, N.-A.; Lai, N.-A. Study on Power Consumption and Energy Performance of Split-Type Air-Conditioners. J. Sci. Technol. 2014, 100, 31–035. [Google Scholar]

- Setyawan, A.; Najmudin, H.; Badarudin, A.; Sunardi, C. Evaluation of Split-Type Air Conditioner Performance under Constant Outdoor Moisture Content and Varied Dry-Bulb Temperature. Int. J. Heat Technol. 2022, 40, 1277–1286. [Google Scholar] [CrossRef]

- Mitrakusuma, W.H.; Badarudin, A.; Susilawati; Najmudin, H.; Setyawan, A. Performance of Split-Type Air Conditioner under Varied Outdoor Air Temperature at Constant Relative Humidity. J. Adv. Res. Fluid Mech. Therm. Sci. 2022, 90, 42–54. [Google Scholar] [CrossRef]

- Aziz, A.N.; Mahmoud, S.; Al-Dadah, R.; Ismail, M.A.; Almesfer, M.K. Impact of Ambient Temperature and Humidity on the Performance of Vapour Compression Air Conditioning System-Experimental and Numerical Investigation. CFD Lett. 2024, 16, 1–21. [Google Scholar] [CrossRef]

- Wookey, R. Minimum Home Temperature Thresholds for Health in Winter: A Systematic Literature Review; Public Health England: London, UK, 2014.

- Salthammer, T.; Morrison, G.C. Temperature and Indoor Environments. Indoor Air 2022, 32, e13022. [Google Scholar] [CrossRef]

- BS EN 14825:2022; Air Conditioners, Liquid Chilling Packages and Heat Pumps, with Electrically Driven Compressors, for Space Heating and Cooling, Commercial and Process Cooling. Testing and Rating at Part Load Conditions and Calculation of Seasonal Performance. British Standards Institution: London, UK, 2022.

| Material/Component | Unit | Amount |

|---|---|---|

| Steel | kg | 17.0 |

| Zinc galvanized steel sheet | kg | 37.5 |

| Copper | kg | 26.1 |

| Polyvinyl chloride (PVC) | kg | 2.35 |

| Acrylonitrile-butadiene-styrene (ABS) | kg | 5.0 |

| Polyurethane (PUR) foam | kg | 0.4 |

| Electronics components | kg | 3.0 |

| Cables | kg | 5.7 |

| Refrigerant (R-32) | kg | 1.195 |

| Compressor lubrication oil | kg | 0.375 |

| Material/Component | Unit | Amount |

|---|---|---|

| Steel | kg | 12.3 |

| Stainless steel | kg | 0.06 |

| Zinc galvanized steel sheet | kg | 31.0 |

| Aluminum | kg | 1.803 |

| Copper | kg | 5.7 |

| Brass | kg | 3.21 |

| Polyvinyl chloride (PVC) | kg | 1.565 |

| Polypropylene (PP) | kg | 2.9 |

| Acrylonitrile-butadiene-styrene (ABS) | kg | 2.5 |

| Silicon | kg | 0.15 |

| Rubber | kg | 1.3 |

| Electronics components | kg | 0.43 |

| Year | Month | ||||

|---|---|---|---|---|---|

| May | June | July | August | September | |

| 2021 | 14.13 | 20.18 | 23.72 | 21.77 | 12.10 |

| 2022 | 12.18 | 20.33 | 19.72 | 22.39 | 11.77 |

| 2023 | 14.32 | 18.43 | 20.14 | 21.42 | 16.22 |

| 2024 | 14.22 | 20.77 | 23.95 | 21.27 | 19.38 |

| No | , °C | , % | , °C | , °C | , °C | , W | , kg/h | ||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 12.4 | 46.0 | 8.0 | 1.1 | 7.1 | 38.9 | 83.0 | 183.0 | 3.2 |

| 2 | 18.4 | 81.0 | 16.2 | 15.1 | 16.3 | 66.7 | 104.8 | 184.0 | 1.6 |

| 3 | 18.6 | 49.0 | 12.5 | 7.7 | 12.5 | 56.0 | 100.0 | 184.0 | 4.0 |

| 4 | 19.5 | 39.0 | 12.1 | 5.2 | 11.8 | 51.7 | 96.1 | 184.0 | 4.8 |

| 5 | 20.2 | 57.0 | 15.0 | 11.4 | 14.9 | 59.1 | 98.1 | 181.0 | 4.0 |

| 6 | 20.0 | 69.0 | 16.2 | 14.1 | 16.3 | 64.4 | 102.7 | 185.0 | 2.4 |

| 7 | 20.0 | 75.0 | 17.0 | 15.4 | 17.1 | 65.2 | 103.4 | 184.0 | 2.4 |

| 8 | 20.4 | 33.0 | 12.3 | 3.6 | 11.6 | 48.2 | 92.0 | 181.0 | 4.8 |

| 9 | 20.5 | 38.0 | 13.2 | 5.7 | 12.4 | 49.3 | 90.1 | 180.0 | 4.8 |

| 10 | 21.1 | 50.0 | 14.8 | 10.3 | 14.7 | 58.3 | 98.4 | 185.0 | 4.0 |

| 11 | 23.1 | 61.0 | 18.0 | 15.2 | 18.0 | 64.6 | 100.0 | 185.0 | 3.2 |

| 12 | 23.5 | 75.0 | 20.4 | 18.8 | 20.3 | 66.0 | 96.9 | 184.0 | 2.4 |

| 13 | 25.0 | 30.0 | 14.7 | 6.2 | 14.4 | 54.8 | 97.2 | 184.0 | 4.8 |

| 14 | 25.2 | 51.0 | 18.2 | 14.4 | 18.2 | 64.8 | 100.0 | 184.0 | 4.8 |

| 15 | 25.3 | 45.0 | 17.5 | 12.5 | 17.3 | 60.9 | 97.5 | 183.0 | 4.8 |

| 16 | 28.8 | 38.0 | 18.6 | 13.1 | 18.7 | 65.0 | 101.0 | 186.0 | 6.4 |

| 17 | 29.2 | 29.0 | 16.6 | 9.4 | 17.2 | 63.6 | 105.0 | 184.0 | 4.8 |

| 18 | 30.0 | 43.0 | 20.6 | 16.1 | 20.7 | 67.6 | 101.1 | 185.0 | 5.6 |

| 19 | 33.5 | 23.0 | 18.4 | 9.5 | 18.7 | 62.9 | 102.0 | 184.0 | 9.6 |

| 20 | 35.2 | 30.0 | 20.4 | 15.0 | 21.7 | 73.3 | 109.6 | 183.0 | 8.8 |

| 21 | 38.3 | 24.0 | 20.4 | 14.2 | 22.1 | 74.3 | 110.5 | 184.0 | 9.6 |

| 22 | 43.5 | 25.0 | 23.8 | 19.2 | 26.0 | 81.1 | 112.6 | 185.0 | 10.4 |

| 23 | 43.8 | 19.0 | 21.4 | 15.1 | 24.1 | 78.0 | 113.7 | 186.0 | 10.4 |

| Parameter | IREC1 | VCRM1 | VCRM2 |

|---|---|---|---|

| Cooling energy, kW·h | 4620 | 4640 | 4640 |

| Electricity consumption, kW·h | 1326 | 4359 | 1786 |

| Category | Unit | IREC1 | VCRM1 |

|---|---|---|---|

| Fine particulate matter formation | kg PM2.5 eq | 1.7 × 100 | 5.6 × 100 |

| Fossil resource scarcity | kg oil eq | 1.0 × 103 | 3.3 × 103 |

| Freshwater ecotoxicity | kg 1,4-DCB | 3.4 × 102 | 1.2 × 103 |

| Freshwater eutrophication | kg P eq | 2.0 × 100 | 6.4 × 100 |

| Global warming | kg CO2 eq | 4.0 × 103 | 1.3 × 104 |

| Human carcinogenic toxicity | kg 1,4-DCB | 2.1 × 102 | 7.0 × 102 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | 5.9 × 103 | 2.0 × 104 |

| Ionizing radiation | kBq Co-60 eq | 6.0 × 101 | 6.7 × 103 |

| Land use | m2a crop eq | −2.2 × 100 | −1.0 × 101 |

| Marine ecotoxicity | kg 1,4-DCB | 4.3 × 102 | 1.6 × 103 |

| Marine eutrophication | kg N eq | 1.6 × 10−1 | 5.6 × 10−1 |

| Mineral resource scarcity | kg Cu eq | 8.6 × 100 | 3.8 × 101 |

| Ozone formation, Human health | kg NOx eq | 2.9 × 100 | 9.6 × 100 |

| Ozone formation, Terrestrial ecosystems | kg NOx eq | 3.0 × 100 | 9.8 × 100 |

| Stratospheric ozone depletion | kg CFC11 eq | 1.4 × 10−3 | 4.4 × 10−3 |

| Terrestrial acidification | kg SO2 eq | 3.9 × 100 | 1.3 × 101 |

| Terrestrial ecotoxicity | kg 1,4-DCB | 1.5 × 104 | 5.7 × 104 |

| Water consumption | m3 | 3.2 × 101 | 1.0 × 102 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marcinkowski, A.; Levchenko, D. Comparative Life Cycle Analysis for Duct Air Conditioning Systems Based on Evaporative and Vapor Compression Technologies. Energies 2025, 18, 3475. https://doi.org/10.3390/en18133475

Marcinkowski A, Levchenko D. Comparative Life Cycle Analysis for Duct Air Conditioning Systems Based on Evaporative and Vapor Compression Technologies. Energies. 2025; 18(13):3475. https://doi.org/10.3390/en18133475

Chicago/Turabian StyleMarcinkowski, Andrzej, and Dmytro Levchenko. 2025. "Comparative Life Cycle Analysis for Duct Air Conditioning Systems Based on Evaporative and Vapor Compression Technologies" Energies 18, no. 13: 3475. https://doi.org/10.3390/en18133475

APA StyleMarcinkowski, A., & Levchenko, D. (2025). Comparative Life Cycle Analysis for Duct Air Conditioning Systems Based on Evaporative and Vapor Compression Technologies. Energies, 18(13), 3475. https://doi.org/10.3390/en18133475