Energy Valorization and Resource Recovery from Municipal Sewage Sludge: Evolution, Recent Advances, and Future Prospects

Abstract

1. Introduction

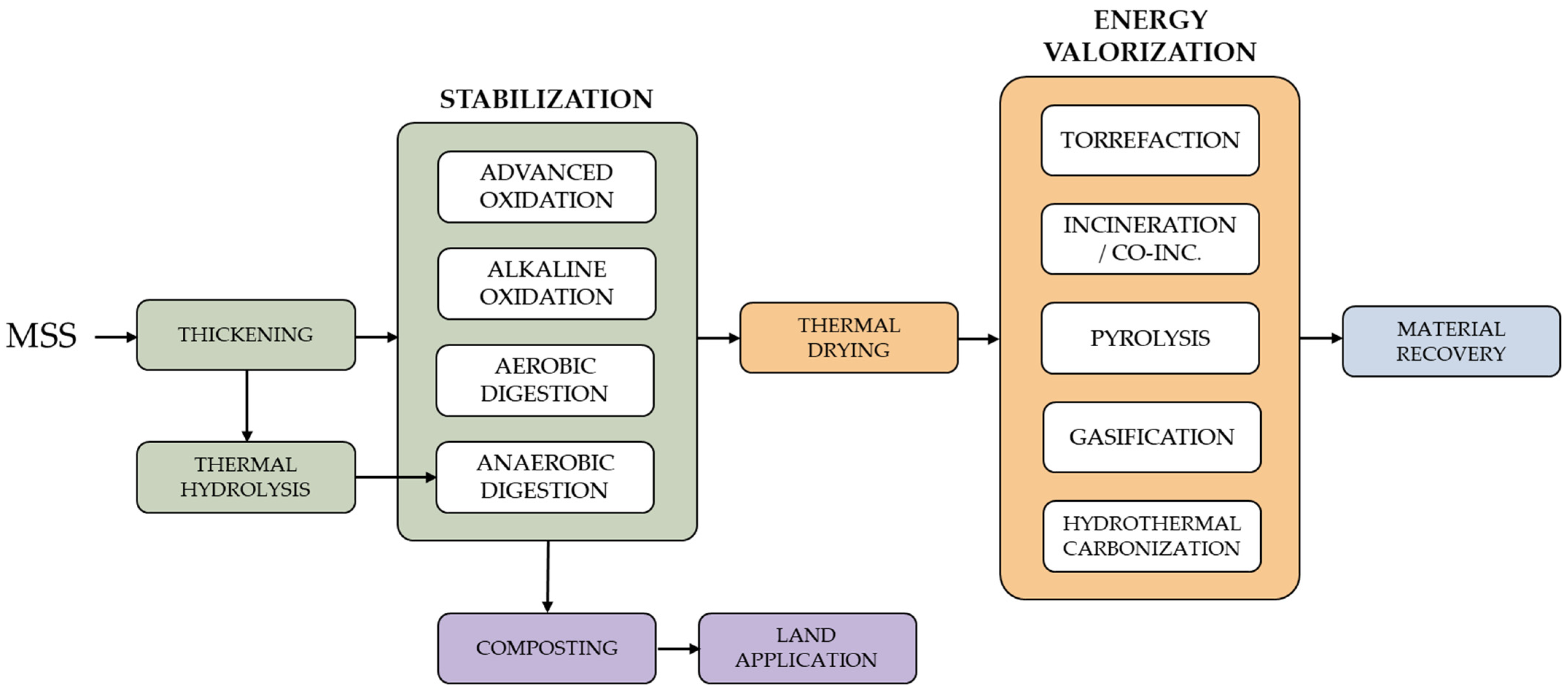

2. Current Methods of Sewage Sludge Treatment and Valorization

2.1. Overview of Treatment Processes

- Biological stabilization: This operation can be aerobic or anaerobic.

2.2. Regulatory Landscape

- Directive 91/271/EEC (Urban Waste Water Treatment Directive) governs the collection and treatment of municipal wastewater [51].

- Framework Directive 2008/98/EC sets the waste management hierarchy, traceability, and transport rules [52].

- Directive 2010/75/EU on industrial emissions establishes performance limits and BATs for digestion, drying, and incineration [53].

- Directive 86/278/EEC (Sewage Sludge Directive) regulates land application by imposing heavy-metal limits [5].

2.3. Drivers, Gaps, and Recent Advances in Sustainable Sludge Management

- Techno-economic optimization: More detailed site-specific studies are needed to evaluate the performance, scalability, and cost-effectiveness of advanced treatment technologies under varied operational conditions.

- Regulatory and policy alignment: The absence of harmonized standards and economic incentives often delays the adoption of innovative sludge valorization strategies, especially in low- and middle-income regions.

- Digital tools and process monitoring: The application of smart monitoring, automation, and data-driven decision-making in sludge treatment remains limited. Research into digital integration can enhance process efficiency and compliance.

3. Energy Recovery from Sewage Sludge

3.1. Anaerobic Digestion

3.2. Thermal Processes

3.2.1. Drying

3.2.2. Torrefaction

3.2.3. Incineration and Co-Incineration

3.2.4. Pyrolysis and Gasification

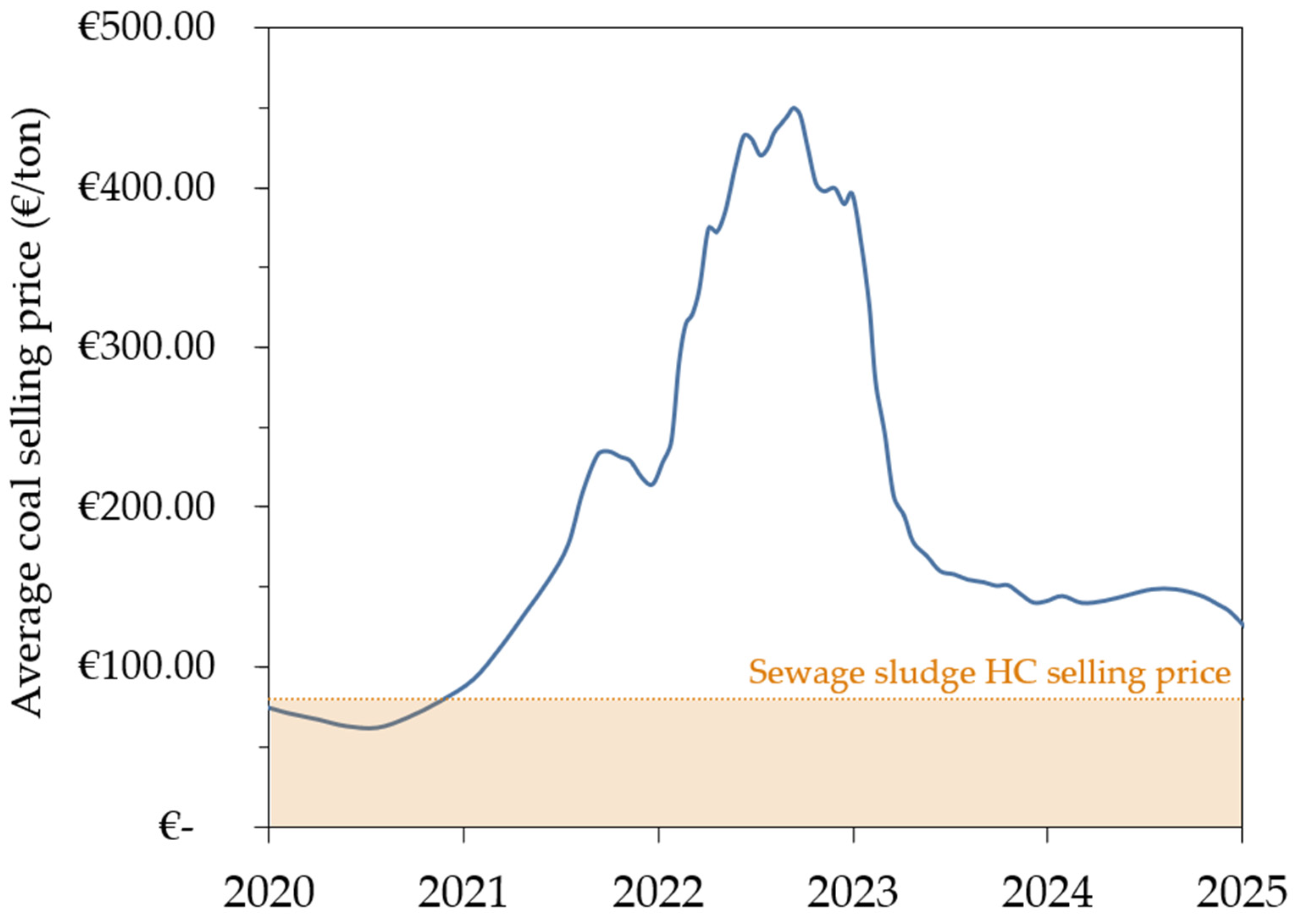

3.2.5. Hydrothermal Carbonization

3.3. Technological Advances and Process Integration

3.4. Tecnology Comparison

4. Economic, Environmental, and Future Considerations

4.1. Techno-Economic Analysis

4.2. Life-Cycle Assessment (LCA)

4.3. Future Outlook

- Large activated sludge plants: The most advantageous option is an on-site hybrid process that couples the HTC of surplus sludge with anaerobic digestion of the process water and subsequent leaching of the HC. This configuration maximizes biomethane production, minimizes residual solids, and yields a sterilized, phosphorus-rich HC that, after partial removal of heavy metals, can be marketed as a fertilizer or soil improver.

- Medium-to-small plants: For these facilities, the outlook favors practical, sustainable thermal techniques (HTC or mild thermolysis) with the off-site treatment of the dewatered material, which is then directed either to agronomic use or to phosphorus recovery. Because the process water cannot be recycled into the biological loop, it requires polishing via membrane filtration followed by oxidation.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| ARG | Antibiotic resistance genes |

| AS | Aerobic stabilization |

| ASP | Activated sludge processes |

| ATAD | Autothermal thermophilic aerobic digestion |

| BAT | Best available technology |

| CAPEX | Capital expenditure |

| CHP | Combined heat and power |

| CINC | Co-incineration in cement kilns |

| CINP | Co-incineration in coal power plants |

| COD | Chemical oxygen demand |

| CSTR | Continuous stirred-tank reactor |

| DS | Dry solid |

| EQ | Exceptional quality |

| EU | European Union |

| FAHP | Fuzzy Analytic Hierarchy Process |

| FOG | Fat, oil, and grease |

| GWP | Global warming potential |

| HC | Hydrochar |

| HTC | Hydrothermal carbonization |

| IoT | Internet of Things |

| IRR | Internal rate of return |

| LHV | Lower heating value |

| MEC | Microbial electrolysis cell |

| MP | Microplastics |

| MSS | Municipal sewage sludge |

| MSW | Municipal solid waste |

| MWCNT | Multi-walled carbon nanotubes |

| NPV | Net present value |

| OECD | Organisation for Economic Co-operation and Development |

| OPEX | Operational Expenditure |

| PE | Population equivalent |

| PFAS | Perfluorinated alkylated substances |

| POTWs | Publicly owned treatment works |

| PPCPS | Pharmaceutical and personal care products |

| SC | Sensitivity coefficient |

| SCWG | Supercritical-water-gasification |

| SS | Sewage sludge |

| SWOT | Strengths–Weaknesses–Opportunities–Threats |

| TH | Thermal hydrolysis |

| TS | Total solids |

| VFA | Volatile fatty acids |

| VS | Volatile solids |

| WEF | Water Environment Federation |

| WO | Wet oxidation |

| WRRFs | Water resource recovery facilities |

| WtE | Waste-to-energy |

| WWTPs | Wastewater treatment plants |

| AD | Anaerobic digestion |

| AS | Aerobic stabilization |

| ASP | Activated sludge processes |

| ATAD | Autothermal thermophilic aerobic digestion |

| BAT | Best available technology |

| CAPEX | Capital expenditure |

| CHP | Combined heat and power |

| CINC | Co-incineration in cement kilns |

| CINP | Co-incineration in coal power plants |

| COD | Chemical oxygen demand |

| CSTR | Continuous stirred-tank reactor |

| DS | Dry solid |

| EQ | Exceptional quality |

| EU | European Union |

| FOG | Fat, oil, and grease |

| GWP | Global warming potential |

| HC | Hydrochar |

| HTC | Hydrothermal carbonization |

| IRR | Internal rate of return |

| LHV | Lower heating value |

| MP | Microplastics |

| MSS | Municipal sewage sludge |

| MSW | Municipal solid waste |

| NPV | Net present value |

| OECD | Organisation for Economic Co-operation and Development |

| OPEX | Operational Expenditure |

| PE | Population equivalent |

| PFAS | Perfluorinated alkylated substances |

| POTWs | Publicly owned treatment works |

| PPCPS | Pharmaceutical and personal care products |

| SC | Sensitivity coefficient |

| SCWG | Supercritical-water-gasification |

| SS | Sewage sludge |

| TH | Thermal hydrolysis |

| TS | Total solids |

| VS | Volatile solids |

| WEF | Water Environment Federation |

| WO | Wet oxidation |

| WRRFs | Water resource recovery facilities |

| WtE | Waste-to-energy |

| WWTPs | Wastewater treatment plants |

References

- Zhao, P.; Shen, Y.; Ge, S.; Yoshikawa, K. Energy Recycling from Sewage Sludge by Producing Solid Biofuel with Hydrothermal Carbonization. Energy Convers. Manag. 2014, 78, 815–821. [Google Scholar] [CrossRef]

- Feng, J.; Burke, I.T.; Chen, X.; Stewart, D.I. Assessing Metal Contamination and Speciation in Sewage Sludge: Implications for Soil Application and Environmental Risk. Rev. Environ. Sci. Bio/Technol. 2023, 22, 1037–1058. [Google Scholar] [CrossRef]

- Woo, D.C.Y.; Goh, Q.H.; Poh, P.E.; Chew, I.M.L. A Technoeconomic Analysis of Sewage Sludge Valorization for Carbon Emission Reduction. Biomass Convers. Biorefinery 2023, 13, 13591–13604. [Google Scholar] [CrossRef]

- Sewage Sludge Laws and Regulations US EPA. Available online: https://www.epa.gov/biosolids/sewage-sludge-laws-and-regulations (accessed on 20 April 2025).

- Directive-86/278-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/eli/dir/1986/278/oj/eng (accessed on 20 April 2025).

- Biney, M.A.; Gusiatin, M.Z.; Trakal, L.; Moško, J.; Pohořelý, M. Utilization of Co-Substrates in Municipal Sewage Sludge Co-Pyrolysis: Yields and Characterization of Biochar, Bio-Oil, and Syngas, with Economic Feasibility Analysis. J. Anal. Appl. Pyrolysis 2025, 189, 107091. [Google Scholar] [CrossRef]

- Di Giacomo, G.; Romano, P. Evolution and Prospects in Managing Sewage Sludge Resulting from Municipal Wastewater Purification. Energies 2022, 15, 5633. [Google Scholar] [CrossRef]

- Romano, P.; Stampone, N.; Di Giacomo, G. Evolution and Prospects of Hydrothermal Carbonization. Energies 2023, 16, 3125. [Google Scholar] [CrossRef]

- Uggetti, E.; Llorens, E.; Pedescoll, A.; Ferrer, I.; Castellnou, R.; García, J. Sludge Dewatering and Stabilization in Drying Reed Beds: Characterization of Three Full-Scale Systems in Catalonia, Spain. Bioresour. Technol. 2009, 100, 3882–3890. [Google Scholar] [CrossRef]

- Yan, S.; Bala Subramanian, S.; Tyagi, R.D.; Surampalli, R.Y. Wastewater Sludge Characteristics. In Sustainable Sludge Management: Production of Value Added Products; ASCE: Reston, VA, USA, 2009; pp. 6–36. [Google Scholar] [CrossRef]

- Major, N.; Schierstaedt, J.; Jechalke, S.; Nesme, J.; Ban, S.G.; Černe, M.; Sørensen, S.J.; Ban, D.; Schikora, A. Composted Sewage Sludge Influences the Microbiome and Persistence of Human Pathogens in Soil. Microorganisms 2020, 8, 1020. [Google Scholar] [CrossRef]

- Ormaniec, P.; Baczyński, T.P. Hidden Contaminants: Unveiling the Content of Microplastics in Municipal Sewage Sludge That May Affect Soil Ecosystems. Desalination Water Treat. 2025, 322, 101132. [Google Scholar] [CrossRef]

- Ma, M.Y.; Xu, D.H.; Guo, Y.; Wang, S.Z.; He, Y.L. Impacts of Microplastics in Municipal Sludge Pyrolysis-Gasification: Melt-Induced Microaggregation and Increased Deposition Risk. Renew. Sustain. Energy Rev. 2025, 214, 115542. [Google Scholar] [CrossRef]

- Ternes, T.A.; Herrmann, N.; Bonerz, M.; Knacker, T.; Siegrist, H.; Joss, A. A Rapid Method to Measure the Solid–Water Distribution Coefficient (Kd) for Pharmaceuticals and Musk Fragrances in Sewage Sludge. Water Res. 2004, 38, 4075–4084. [Google Scholar] [CrossRef] [PubMed]

- Sörengård, M.; Campos-Pereira, H.; Ullberg, M.; Lai, F.Y.; Golovko, O.; Ahrens, L. Mass Loads, Source Apportionment, and Risk Estimation of Organic Micropollutants from Hospital and Municipal Wastewater in Recipient Catchments. Chemosphere 2019, 234, 931–941. [Google Scholar] [CrossRef]

- Reyes-Contreras, C.; Neumann, P.; Barriga, F.; Venegas, M.; Domínguez, C.; Bayona, J.M.; Vidal, G. Organic Micropollutants in Sewage Sludge: Influence of Thermal and Ultrasound Hydrolysis Processes Prior to Anaerobic Stabilization. Environ. Technol. 2018, 41, 1358–1365. [Google Scholar] [CrossRef]

- Rapporto Rifiuti Speciali—Edizione 2024—Italiano. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/rapporto-rifiuti-speciali-edizione-2024 (accessed on 20 April 2025).

- Jenkins, D.; Wanner, J. Activated Sludge—100 Years and Counting; IWA Publishing: London, UK, 2014; Volume 13. [Google Scholar] [CrossRef]

- Papastergiadis, E.; Sklari, S.; Zouboulis, A.; Chasiotis, A.; Samaras, P. The Use of Steelmaking Slag for Sewage Sludge Stabilization. Desalination Water Treat. 2015, 55, 1697–1702. [Google Scholar] [CrossRef]

- Water and Wastewater Engineering: Design Principles and Practice, Second Edition-Mackenzie Davis-Libro in Lingua Inglese-McGraw-Hill Education-| Feltrinelli. Available online: https://www.lafeltrinelli.it/water-wastewater-engineering-design-principles-libro-inglese-mackenzie-davis/e/9781260132274?srsltid=AfmBOopnsYmZaJAON8I_bCDrxXfMargjlM_pik5tDD4Hs6CGWHwG_X1_ (accessed on 25 May 2025).

- Samaras, P.; Papadimitriou, C.A.; Haritou, I.; Zouboulis, A.I. Investigation of Sewage Sludge Stabilization Potential by the Addition of Fly Ash and Lime. J. Hazard. Mater. 2008, 154, 1052–1059. [Google Scholar] [CrossRef]

- William, O.W. Method for Lime Stabilization of Wastewater Treatment Plant Sludges. U.S. Patent US4306978A, 22 December 1980. [Google Scholar]

- Kosowski, P.; Szostek, M.; Pieniazek, R.; Antos, P.; Skrobacz, K.; Piechowiak, T.; Zaczek, A.; Józefczyk, R.; Balawejder, M. New Approach for Sewage Sludge Stabilization with Ozone. Sustainability 2020, 12, 886. [Google Scholar] [CrossRef]

- Ki, Y.P.; Ahn, K.H.; Sung, K.M.; Jong, H.H.; Jae, H.K. Feasibility of Sludge Ozonation for Stabilization and Conditioning. Ozone Sci. Eng. 2003, 25, 73–80. [Google Scholar] [CrossRef]

- Ki, D.; Kupferer, R.; Torres, C.I. High-Rate Stabilization of Primary Sludge in a Single-Chamber Microbial Hydrogen Peroxide Producing Cell. Environ. Sci. Water Res. Technol. 2019, 5, 1124–1131. [Google Scholar] [CrossRef]

- Semblante, G.U.; Hai, F.I.; Dionysiou, D.D.; Fukushi, K.; Price, W.E.; Nghiem, L.D. Holistic Sludge Management through Ozonation: A Critical Review. J. Environ. Manag. 2017, 185, 79–95. [Google Scholar] [CrossRef]

- Tuncay, S.; Akcakaya, M.; Icgen, B. Ozonation of Sewage Sludge Prior to Anaerobic Digestion Led to Methanosaeta Dominated Biomethanation. Fuel 2022, 313, 122690. [Google Scholar] [CrossRef]

- Badalians Gholikandi, G.; Zakizadeh, N.; Masihi, H. Application of Peroxymonosulfate-Ozone Advanced Oxidation Process for Simultaneous Waste-Activated Sludge Stabilization and Dewatering Purposes: A Comparative Study. J. Environ. Manag. 2018, 206, 523–531. [Google Scholar] [CrossRef]

- Ge, D.; Wu, W.; Li, G.; Wang, Y.; Li, G.; Dong, Y.; Yuan, H.; Zhu, N. Application of CaO2-Enhanced Peroxone Process to Adjust Waste Activated Sludge Characteristics for Dewaterability Amelioration: Molecular Transformation of Dissolved Organic Matters and Realized Mechanism of Deep-Dewatering. Chem. Eng. J. 2022, 437, 135306. [Google Scholar] [CrossRef]

- Gao, S.; Wang, Y.; Zhang, D.; Fan, X.; Guo, Y.; Li, E.; Zheng, H. Insight to Peroxone-Fe(III) Joint Conditioning-Horizontal Electro-Dewatering Process on Water Reduction in Activated Sludge: Performance and Mechanisms. J. Hazard. Mater. 2021, 402, 123441. [Google Scholar] [CrossRef]

- Geng, N.; Wang, Y.; Zhang, D.; Fan, X.; Li, E.; Han, Z.; Zhao, X. An Electro-Peroxone Oxidation-Fe(III) Coagulation Sequential Conditioning Process for the Enhanced Waste Activated Sludge Dewatering: Bound Water Release and Organics Multivariate Change. Sci. Total Environ. 2022, 833, 155272. [Google Scholar] [CrossRef]

- Pembroke, J.T.; Ryan, M.P. Autothermal Thermophilic Aerobic Digestion (ATAD) for Heat, Gas, and Production of a Class A Biosolids with Fertilizer Potential. Microorganisms 2019, 7, 215. [Google Scholar] [CrossRef] [PubMed]

- Bartkowska, I.; Biedka, P.; Tałałaj, I.A. Production of Biosolids by Autothermal Thermophilic Aerobic Digestion (ATAD) from a Municipal Sewage Sludge: The Polish Case Study. Energies 2020, 13, 6258. [Google Scholar] [CrossRef]

- Design of Municipal Wastewater Treatment Plants: WEF Manual of Practice No. 8 ASCE Manuals and Reports on Engineering Practice No. 76, Fifth Edition McGraw-Hill Education—Access Engineering. Available online: https://www.accessengineeringlibrary.com/content/book/9780071663588 (accessed on 25 May 2025).

- Achinas, S.; Achinas, V.; Euverink, G.J.W. Chapter 2—Microbiology and Biochemistry of Anaerobic Digesters: An Overview. In Bioreactors: Sustainable Design and Industrial Applications in Mitigation of GHG Emissions; Elsevier: Amsterdam, The Netherlands, 2020; pp. 17–26. [Google Scholar] [CrossRef]

- Jenicek, P.; Bartacek, J.; Kutil, J.; Zabranska, J.; Dohanyos, M. Potentials and Limits of Anaerobic Digestion of Sewage Sludge: Energy Self-Sufficient Municipal Wastewater Treatment Plant? Water Sci. Technol. 2012, 66, 1277–1281. [Google Scholar] [CrossRef]

- Steinberg, L.M.; Regan, J.M. Phylogenetic Comparison of the Methanogenic Communities from an Acidic, Oligotrophic Fen and an Anaerobic Digester Treating Municipal Wastewater Sludge. Appl. Environ. Microbiol. 2008, 74, 6663–6671. [Google Scholar] [CrossRef]

- Hanum, F.; Yuan, L.C.; Kamahara, H.; Aziz, H.A.; Atsuta, Y.; Yamada, T.; Daimon, H. Treatment of Sewage Sludge Using Anaerobic Digestion in Malaysia: Current State and Challenges. Front. Energy Res. 2019, 7, 411861. [Google Scholar] [CrossRef]

- Arthurson, V. Proper Sanitization of Sewage Sludge: A Critical Issue for a Sustainable Society. Appl. Environ. Microbiol. 2008, 74, 5267–5275. [Google Scholar] [CrossRef]

- Malmborg, J.; Magnér, J. Pharmaceutical Residues in Sewage Sludge: Effect of Sanitization and Anaerobic Digestion. J. Environ. Manag. 2015, 153, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, V.K.; Lo, S.L. Energy and Resource Recovery from Sludge: Full-Scale Experiences. In Environmental Materials and Waste: Resource Recovery and Pollution Prevention; Academic Press: Cambridge, MA, USA, 2016; pp. 221–244. [Google Scholar] [CrossRef]

- Behavior of the Mesophilic and Thermophilic Anaerobicdigestion in the Stabilization of Municipal Wastewater Sludge(Part 1) Request PDF. Available online: https://www.researchgate.net/publication/230689708_BEHAVIOR_OF_THE_MESOPHILIC_AND_THERMOPHILIC_ANAEROBICDIGESTION_IN_THE_STABILIZATION_OF_MUNICIPAL_WASTEWATER_SLUDGEPART_1 (accessed on 25 May 2025).

- Parkin, G.F.; Owen, W.F. Fundamentals of Anaerobic Digestion of Wastewater Sludges. J. Environ. Eng. 1986, 112, 867–920. [Google Scholar] [CrossRef]

- Erdirencelebi, D.; Bayhan, C. Feasibility and Potential of Separate Anaerobic Digestion of Municipal Sewage Sludge Fractions. Water SA 2020, 46, 123–130. [Google Scholar] [CrossRef]

- Jamal, A.; Norieh, N.; Farzadkia, M. Comparison of Aerobic and Lime Stabilization Methods for Evaluation of Sewage Sludge Reuse. J. Environ. Sci. Technol. 2011, 4, 182–190. [Google Scholar] [CrossRef][Green Version]

- Bolzonella, D.; Innocenti, L.; Cecchi, F. Biological Nutrient Removal Wastewater Treatments and Sewage Sludge Anaerobic Mesophilic Digestion Performances. Water Sci. Technol. 2002, 46, 199–208. [Google Scholar] [CrossRef]

- Judd, S. Watermaths: Process Fundamentals for the Design and Operation of Water and Wastewater Treatment Technologies; IWA: London, UK, 2019. [Google Scholar] [CrossRef]

- Introduction to Sludge Dewatering the MBR Site. Available online: https://www.thembrsite.com/introduction-sludge-dewatering (accessed on 25 May 2025).

- Aghalari, Z.; Dahms, H.U.; Sillanpää, M.; Sosa-Hernandez, J.E.; Parra-Saldívar, R. Effectiveness of Wastewater Treatment Systems in Removing Microbial Agents: A Systematic Review. Glob. Health 2020, 16, 13. [Google Scholar] [CrossRef]

- Zikakis, D.; Chauzy, J.; Droubogianni, I.; Georgakopoulos, A.; Aktor, S.A.; Cambi, A.S. Thermal Hydrolysis of Waste Activated Sludge Only at the Psyttalia WWTP in Athens: Operation Feedbacks. Available online: https://conferences.aquaenviro.co.uk/wp-content/uploads/sites/7/2018/04/Chauzy-J.pdf (accessed on 25 May 2025).

- EUR-Lex-31991L0271-EN. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:31991L0271:EN:HTML (accessed on 25 May 2025).

- Directive-2008/98-EN-Waste Framework Directive-EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32008L0098 (accessed on 25 May 2025).

- Directive-2010/75-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32010L0075 (accessed on 25 May 2025).

- Directive-2000/60-EN-Water Framework Directive-EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32000L0060 (accessed on 25 May 2025).

- Directive-91/676-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX:31991L0676 (accessed on 25 May 2025).

- ASCE’s 2025 Infrastructure Report Card. Available online: https://infrastructurereportcard.org/cat-item/wastewater-infrastructure/ (accessed on 25 May 2025).

- Durdević, D.; Trstenjak, M.; Hulenić, I. Sewage Sludge Thermal Treatment Technology Selection by Utilizing the Analytical Hierarchy Process. Water 2020, 12, 1255. [Google Scholar] [CrossRef]

- Gómez Vidal, A.; Machado, F.; Datshkovsky, D. Water and Sanitation Services in Latin America: Access and Quality Outlook. 2021. Available online: https://doi.org/10.18235/0003285 (accessed on 25 May 2025).

- Bertomeu Sanchez, S.; Serebrisky, T. Water and Sanitation in Latin America and the Caribbean: An Update on the State of the Sector. SSRN Electron. J. 2018. [Google Scholar] [CrossRef]

- Martin-Hurtado, R.; Nolasco, D. Managing Wastewater as a Resource in Latin America and the Caribbean (LAC) towards a Circular Economy Approach. Available online: https://programme.worldwaterweek.org/Content/ProposalResources/allfile/managing_wastewater_as_a_resource_in_lac.pdf (accessed on 25 May 2025).

- AD503: Water and Sanitation: On-the-Ground Realities Challenge African Governments to Act—Afrobarometer. Available online: https://www.afrobarometer.org/publication/ad503-water-and-sanitation-ground-realities-challenge-african-governments-act/ (accessed on 25 May 2025).

- Wastewater Treatment and Reuse in MENA Countries—Fanack Water. Available online: https://water.fanack.com/publications/wastewater-treatment-reuse-mena-countries/#:~%7B%7D:text= (accessed on 25 May 2025).

- Siddiqui, M.I.; Rameez, H.; Farooqi, I.H.; Basheer, F. Recent Advancement in Commercial and Other Sustainable Techniques for Energy and Material Recovery from Sewage Sludge. Water 2023, 15, 948. [Google Scholar] [CrossRef]

- Anyame Bawa, S.; Chan, A.; Wrobel-Tobiszewska, A.; Hardie, M.; Towns, C. A Review of Methods for Mitigating Microplastic Contamination in Biosolids from Wastewater Treatment Plants before Agricultural Soil Application. Sci. Total Environ. 2024, 957, 177360. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Yin, Z.; Gu, R.; Liu, C.; Xu, N.; Sun, Z.; Jing, L.; Niu, X. Anaerobic Digestion of Municipal Sewage Sludge Integrated with Brewery Wastewater Treatment: Importance of Temperature and Mixing Ratio. Water 2023, 15, 2902. [Google Scholar] [CrossRef]

- Silva, I.S.J.; Gouveia, B.F.L.; Azevedo, A.F.S.; Fernandes, E.C.; Duarte, E.C.N.F.A. Sewage Sludge Co-Digestion with Mango Peel Liquor: Impact of Hydraulic Retention Time on Methane Yield and Bioenergy Recovery. J. Sustain. Dev. Energy Water Environ. Syst. 2023, 11, 1110454. [Google Scholar] [CrossRef]

- Saghouri, M.; Abdi, R.; Ebrahimi-Nik, M.; Rohani, A.; Maysami, M. Modeling and Optimization of Biomethane Production from Solid-State Anaerobic Co-Digestion of Organic Fraction Municipal Solid Waste and Other Co-Substrates. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 8564–8580. [Google Scholar] [CrossRef]

- Li, B.; Dong, Z.; Yue, Y.; Xu, C.; Li, Z.; Yu, J.; Hu, T. Hydrogen and Methane Production in a Two-Stage Thermophilic Anaerobic Digestion System by Co-Digestion of Kitchen Waste and Municipal Sewage Sludge with a High Solid Content. Environ. Eng. Sci. 2023, 40, 253–261. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dębowski, M.; Zieliński, M. Long-Term Pre-Treatment of Municipal Sewage Sludge with Solidified Carbon Dioxide (SCO2)—Effect on Anaerobic Digestion Efficiency. Appl. Sci. 2023, 13, 3075. [Google Scholar] [CrossRef]

- Liu, F.; Cheng, W.; Xu, J.; Wan, T.; Wang, M.; Ren, J.; Ning, M.; Zhang, H.; Zhou, X. Enhancing Short-Chain Fatty Acids Production via Acidogenic Fermentation of Municipal Sewage Sludge: Effect of Sludge Characteristics and Peroxydisulfate Pre-Oxidation. Biotechnol. J. 2024, 19, 2300540. [Google Scholar] [CrossRef]

- Szaja, A.; Szulżyk-Cieplak, J.; Łagód, S.; Kuzioła, E. Recent Developments in the Application of Ultrasonication in Pre-Treatment of Municipal Sewage Sludge. J. Ecol. Eng. 2023, 24, 223–234. [Google Scholar] [CrossRef]

- Chang, H.; Zhao, Y.; Li, X.; Damgaard, A.; Christensen, T.H. Review of Inventory Data for the Biological Treatment of Sewage Sludge. Waste Manag. 2023, 156, 66–74. [Google Scholar] [CrossRef] [PubMed]

- Hamze, A.; Zakaria, B.S.; Zaghloul, M.S.; Ganatsios, A.; Chrysochoou, D.; Dhar, B.R.; Elbeshbishy, E. Novel Bioaugmentation Process to Enhance Anaerobic Digestion of Municipal Sewage Sludge. Renew. Energy 2024, 236, 121370. [Google Scholar] [CrossRef]

- Giannopoulos, G.; Tzanakakis, V.A.; Duelli, G.; Anastopoulos, I.; Aschonitis, V.G.; Arampatzis, G.; Barouchas, P.E. Municipal Sewage Sludge Treatment and Soil PH Conclusively Affect the Nitrogen Dynamics of Amended Soils. Environ. Adv. 2025, 19, 100618. [Google Scholar] [CrossRef]

- Szaja, A.; Bartkowska, I. Effect of Microwave and Ultrasonic Pre-Treatments on Anaerobic Co-Digestion of Orange Wastes and Municipal Sewage Sludge: A Case Study. Desalination Water Treat. 2024, 320, 100754. [Google Scholar] [CrossRef]

- Machhirake, N.; Singh, D.; Yadav, B.R.; Tembhare, M.; Kumar, S. Optimizing Alkali-Pretreatment Dosage for Waste-Activated Sludge Disintegration and Enhanced Biogas Production Yield. Environ. Res. 2024, 252, 118876. [Google Scholar] [CrossRef]

- Zhang, C.; Rahnuma, K.; Hou, L.; Liu, X.; Tang, Y.; Pavlostathis, S.G. Energy and Economic Assessment of Hydrothermal-Treatment-Coupled Anaerobic Digestion. Renew. Sustain. Energy Rev. 2024, 202, 114674. [Google Scholar] [CrossRef]

- Hamze, A.; Zakaria, B.S.; Zaghloul, M.S.; Dhar, B.R.; Elbeshbishy, E. Comprehensive Hydrothermal Pretreatment of Municipal Sewage Sludge: A Systematic Approach. J. Environ. Manag. 2024, 361, 121194. [Google Scholar] [CrossRef] [PubMed]

- Bernat, K.; Le, T.C.T.; Kulikowska, D.; Thapa, R. Anaerobic Digestion as a Possible Method of Managing Waste from Mushroom Production with Sewage Sludge as Co-Substrate. Energies 2024, 17, 1938. [Google Scholar] [CrossRef]

- Szaja, A.; Czarnota, J.; Masłoń, A.; Lebiocka, M. An Effective Energetic Application of Orange Waste in Multi-Component Co-Digestion with Municipal Sewage Sludge. Appl. Sci. 2025, 15, 1537. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, L.; Liu, M.; Lei, Z.; Li, Z.; Zhang, W.; Ren, S.; Wang, Z.; Shui, H.; Yan, J. Synergistic Reduction of NO/SO2 through Co-Firing Municipal Sewage Sludge with Coal Gangue. Chem. Eng. J. 2024, 496, 154025. [Google Scholar] [CrossRef]

- Song, K.; Yin, R.; Hao, B.; Gao, Y.; Zhao, Z.; Zheng, A.; Chang, G.; Li, J.; Zhang, J. Synergistic Effects during Co-Pyrolysis of Microalgal Residues and Municipal Sewage Sludge in an H2-Containing Atmosphere: Pyrolysis Characteristic and Kinetics. Algal Res. 2025, 88, 104013. [Google Scholar] [CrossRef]

- Cheng, Y.; Guo, Z.; Hong, R.; Chen, N.; Han, R. Enhanced Production of Hydrogen-Rich Gas from Municipal Sewage Sludge Gasification Using a CaO-RM Composite Catalyst. Int. J. Hydrogen Energy 2024, 77, 824–833. [Google Scholar] [CrossRef]

- Wang, Y.; Veksha, A.; Ong, J.; Ueki, Y.; Yoshiie, R.; Naruse, I.; Lisak, G. The Role of Post-Pyrolysis Carbon Dioxide Capture in Hydrogen Recovery from Waste-Derived Pyrolysis Gas. Fuel 2025, 381, 133293. [Google Scholar] [CrossRef]

- Qian, Y.; Liang, D.; Shen, D.; Wang, X.; Wang, F.; Bai, S.; Lan, Y. Formation Characteristics of Volatile Organic Compounds during Co-Heating of Municipal Sewage Sludge and Municipal Solid Waste Incineration Fly Ash. J. Energy Inst. 2025, 119, 102016. [Google Scholar] [CrossRef]

- Yang, H.; Guo, Y.; Fang, N.; Dong, B. Life Cycle Assessment of Greenhouse Gas Emissions of Typical Sewage Sludge Incineration Treatment Route Based on Two Case Studies in China. Environ. Res. 2023, 231, 115959. [Google Scholar] [CrossRef]

- Dramé, S.I.; Oba, O.A.; Aydinlik, N.P. Environmental and Ecological Risk Assessment of Municipal Sewage Sludge Management Using a Sustainable Solar Drying System. Water Sci. Technol. 2023, 88, 151–168. [Google Scholar] [CrossRef] [PubMed]

- Aidabulov, M.; Zhakupov, D.; Zhunussova, K.; Temireyeva, A.; Shah, D.; Sarbassov, Y. Thermal Characterization, Kinetic Analysis and Co-Combustion of Sewage Sludge Coupled with High Ash Ekibastuz Coal. Energies 2023, 16, 6634. [Google Scholar] [CrossRef]

- Ruan, R.; Cui, B.; Yu, S.; Jia, S.; Deng, S.; Wang, X.; Tan, H. Experimental Study on the Formation Characteristics of PM0.4 from Preheating Combustion of Sewage Sludge. Fuel 2023, 352, 129132. [Google Scholar] [CrossRef]

- Vali, N.; Combres, A.; Hosseinian, A.; Pettersson, A. The Effect of the Elemental Composition of Municipal Sewage Sludge on the Phosphorus Recycling during Pyrolysis, with a Focus on the Char Chemistry—Modeling and Experiments. Separations 2023, 10, 31. [Google Scholar] [CrossRef]

- Xiang, L.; Li, H.; Wang, Y.; Qu, L.; Xiao, D. Energy Utilization Assessment of Municipal Sewage Sludge Based on SWOT-FAHP Analysis. Water 2023, 15, 260. [Google Scholar] [CrossRef]

- He, T.; Zhang, M.; Jin, B. Co-Pyrolysis of Sewage Sludge as Additive with Phytoremediation Residue on the Fate of Heavy Metals and the Carbon Sequestration Potential of Derived Biochar. Chemosphere 2023, 314, 137646. [Google Scholar] [CrossRef] [PubMed]

- Qu, Z.; Wei, X.; Chen, W.; Wang, F.; Wang, Y.; Long, J. Co-Combustion Characteristics of Municipal Sewage Sludge and Coal in a Lab-Scale Fluidized Bed Furnace. Energies 2023, 16, 2374. [Google Scholar] [CrossRef]

- Czerski, G.; Śpiewak, K.; Makowska, D.; Grycova, B. Study on Steam Co-Gasification of Waste Tire Char and Sewage Sludge. Energies 2023, 16, 2156. [Google Scholar] [CrossRef]

- Ali, M.; Mahmood, F.; Magoua, M.C.; Tang, J.; Li, B. Influence of Hydrolysis on Pyrolysis Products from Sewage Sludge. Therm. Sci. 2024, 28, 3817–3824. [Google Scholar] [CrossRef]

- He, T.; Zhang, M.; Jin, B. Insight into the Synergistic Effect and Products Distribution during Co-Pyrolysis of Phytoremediation Residue and Municipal Sewage Sludge through Experiment and Reaction Force Field Simulation. Fuel 2023, 333, 126326. [Google Scholar] [CrossRef]

- Kalak, T.; Tachibana, Y. Utilizing Sewage Sludge Slag, a By-Product of the Circulating Fluidized Bed Combustion Process, to Efficiently Remove Copper from Aquatic Environment. Energies 2023, 16, 5688. [Google Scholar] [CrossRef]

- Yan, J.; Wu, Y.; Zhang, L.; Huang, S.; Lei, Z.; Li, Z.; Zhang, W.; Ren, S.; Wang, Z.; Shui, H. Synergistic Retention of Heavy Metals and In-Situ Reduction of NO and SO2 by Co-Combustion of Sewage Sludge and Coal Gangue: A Promising Approach for Contaminant Management and Emission Reduction. Fuel Process. Technol. 2023, 252, 107984. [Google Scholar] [CrossRef]

- Radwaniecka, E.; Chwiałkowski, W.; Mulkiewicz, E.; Kumirska, J. Impact of Biochar from Sewage Sludge on Vegetable Growth and Metal Uptake: An Example of Radish and Butterhead Lettuce. Naft. Gaz 2025, 81, 117–127. [Google Scholar] [CrossRef]

- Malinowska, E.; Kania, P. The Effect of Waste Organic Matter on the Soil Chemical Composition After Three Years of Miscanthus x giganteus Cultivation in East-Central Poland. Sustainability 2025, 17, 2523. [Google Scholar] [CrossRef]

- Żukowska, G.; Futa, B.; Myszura-Dymek, M. Biochemical Parameters of Fallow Light Soil Enriched with Sewage Sludge. Agriculture 2024, 14, 1810. [Google Scholar] [CrossRef]

- Holatko, J.; Kucerik, J.; Mustafa, A.; Lonova, K.; Siddiqui, M.H.; Naveed, M.; Hammerschmiedt, T.; Kintl, A.; Malicek, O.; Chorazy, T.; et al. Influence of Biochar Feedstock Blends on Soil Enzyme Activity, Nutrient Cycling, Lettuce Biomass Accumulation and Photosynthesis. BMC Plant Biol. 2025, 25, 323. [Google Scholar] [CrossRef] [PubMed]

- Vayena, G.; Ghofrani-Isfahani, P.; Ziomas, A.; Grimalt-Alemany, A.; Lin, M.K.T.H.; Ravenni, G.; Angelidaki, I. Impact of Biochar on Anaerobic Digestion Process and Microbiome Composition; Focusing on Pyrolysis Conditions for Biochar Formation. Renew. Energy 2024, 237, 121569. [Google Scholar] [CrossRef]

- Li, Q.; Zhong, Z.; Yang, Y.; Qi, R.; Du, H.; Zheng, X. Effect of Sludge-Based Biochar on the Stabilization of Cd in Soil: Experimental and Theoretical Studies. Int. J. Phytoremediation 2025, 27, 941–948. [Google Scholar] [CrossRef]

- Širić, I.; Alhag, S.K.; Al-Shahari, E.A.; Andabaka, Ž.; Kumar, P.; Abou Fayssal, S.; Adelodun, B.; Eid, E.M. Application of Biosolid for Berseem Clover Fertilization: Fodder Characteristics and Health Risk Assessment. Chil. J. Agric. Res. 2024, 84, 349–361. [Google Scholar] [CrossRef]

- Tóth, C.; Simon, L.; Tóth, B. Microanatomical Properties of Energy Willow (Salix spp.) Leaves after Exposure to Potentially Toxic Elements from Wastewater Solids and Wood Ash. Agronomy 2024, 14, 1625. [Google Scholar] [CrossRef]

- Li, F.; Wang, H.; Yang, H.; Xu, X.; Ding, T.; Wang, Q. Control of Heavy Metal Pollution with Rice Husk Biochar in Sewage Sludge Compost Amended Soil. J. Soil Sci. Plant Nutr. 2025, 25, 2786–2797. [Google Scholar] [CrossRef]

- Bik-Małodzińska, M. The Impact of Waste Application on the Reclamation and Biological Life of Degraded Soils. Sustainability 2024, 16, 8126. [Google Scholar] [CrossRef]

- Malinowska, E.; Torma, S. Evaluation of Organic Waste Long-Term Effects on Cellulose, Hemicellulose and Lignin Content in Energy Grass Species Grown in East-Central Poland. Energies 2024, 17, 5598. [Google Scholar] [CrossRef]

- Ahmad, K.; Ejaz, A.; Khan, Z.I.; Batool, A.I.; Asfaq, A.; Mansoor, S.; Ahmad, T.; Mehmood, N.; Memona, H.; Mahpara, S.; et al. Bioavailability of molybdenum in soil and fodder crops: Toxicity analysis and health risk assessment. Pak. J. Bot. 2024, 56, 331–338. [Google Scholar] [CrossRef]

- Lin, L.; Qin, J.; Zhang, Y.; Yin, J.; Guo, G.; Khan, M.A.; Liu, Y.; Liu, Q.; Wang, Q.; Chang, K.; et al. Assessing the Suitability of Municipal Sewage Sludge and Coconut Bran as Breeding Medium for Oryza sativa L. Seedlings and Developing a Standardized Substrate. J. Environ. Manag. 2023, 344, 118644. [Google Scholar] [CrossRef]

- Lopushnyak, V.; Hrytsulyak, H.; Lopushniak, H.; Voloshyn, Y. Integral Assessment of Pollution of Sod-Podzolic Soils by Application of Sewage Sludge under Miscanthus x giganteus. Int. J. Environ. Stud. 2023, 80, 476–487. [Google Scholar] [CrossRef]

- Chen, X.; Feng, J.; Mou, H.; Liang, Z.; Ding, T.; Chen, S.; Li, F. Utilization of Indole Acetic Acid with Leucadendron rubrum and Rhododendron pulchrum for the Phytoremediation of Heavy Metals in the Artificial Soil Made of Municipal Sewage Sludge. Toxics 2023, 11, 43. [Google Scholar] [CrossRef]

- Wiater, J.; Sulewska, M. Heavy Metal Speciation in Municipal Sewage Sludge Depending on Treatment Method. Desalination Water Treat. 2023, 301, 159–172. [Google Scholar] [CrossRef]

- Radziemska, M.; Gusiatin, M.Z.; Mazur, Z.; Radzevičius, A.; Bęś, A.; Šadzevičius, R.; Holatko, J.; Dapkienė, M.; Adamonytė, I.; Brtnicky, M. Composite Biochar with Municipal Sewage Sludge Compost—A New Approach to Phytostabilization of PTE Industrially Contaminated Soils. Energies 2023, 16, 1778. [Google Scholar] [CrossRef]

- Li, F.; Chen, X.; Feng, J.; Liang, Z.; Xu, X.; Ding, T. Ryegrass Extraction of Heavy Metals from Municipal Sewage Sludge Compost-Amended Soils Assisted with Citric Acid. Environ. Sci. Pollut. Res. 2023, 30, 33598–33608. [Google Scholar] [CrossRef] [PubMed]

- Antonious, G.F.; Turley, E.T.; Gyawali, B.R.; Freeman, A.C. Influence of Biochar and Animal Manures Application on Ammonia and Nitrate Concentrations in the Root and Shoot of Three Varieties of Turnips. Agriculture 2023, 13, 137. [Google Scholar] [CrossRef]

- Januševičius, T.; Mažeikienė, A.; Danila, V.; Paliulis, D. The Characteristics of Sewage Sludge Pellet Biochar Prepared Using Two Different Pyrolysis Methods. Biomass Convers. Biorefinery 2024, 14, 891–900. [Google Scholar] [CrossRef]

- Koutroubas, S.D.; Antoniadis, V.; Damalas, C.A.; Fotiadis, S. Municipal Sewage Sludge Effects on Maize Yield, Nitrogen Use Efficiency, and Soil Properties. J. Soil Sci. Plant Nutr. 2023, 23, 1209–1221. [Google Scholar] [CrossRef]

- Gusiatin, M.Z.; Pasieczna-Patkowska, S.; Bálintová, M.; Kuśmierz, M. Treatment of Wastewater from Soil Washing with Soluble Humic Substances Using Biochars and Activated Carbon. Energies 2023, 16, 4311. [Google Scholar] [CrossRef]

- Guo, G.; Zhang, D.; Lei, M.; Wan, X.; Yang, J.; Wei, H.; Chen, S. Phytoextraction of As by Pteris vittata L. Assisted with Municipal Sewage Sludge Compost and Associated Mechanism. Sci. Total Environ. 2023, 893, 164705. [Google Scholar] [CrossRef]

- Myszura-Dymek, M.; Żukowska, G. The Influence of Sewage Sludge Composts on the Enzymatic Activity of Reclaimed Post-Mining Soil. Sustainability 2023, 15, 4749. [Google Scholar] [CrossRef]

- Banda, B.; Habtu, N.G.; Gebreeyessus, G.D.; Meshesha, B.T. Vermicomposting as an Effective Approach to Municipal Sewage Sludge Management through Optimization of the Selected Process Variables. Water Sci. Technol. 2023, 88, 1957–1973. [Google Scholar] [CrossRef]

- Deng, W.; Zhang, Y.; Hu, M.; Wang, R.; Su, Y. Optimization of Nitrogen-Doped Sludge Char Preparation and Mechanism Study for Catalytic Oxidation of NO at Room Temperature. J. Environ. Sci. 2025, 150, 503–514. [Google Scholar] [CrossRef]

- Agoe, A.K.; Poulopoulos, S.G.; Sarbassov, Y.; Shah, D. Investigation of Sewage Sludge–Derived Biochar for Enhanced Pollutant Adsorption: Effect of Particle Size and Alkali Treatment. Energies 2024, 17, 4554. [Google Scholar] [CrossRef]

- Zhao, L.; Gao, X.; Liu, X.; Li, H.; Luo, Y.; Qin, S. Reduction of Typical Antibiotic Resistance Genes and Mobile Gene Elements in Sewage Sludge During Sludge Bioleaching with Acidithiobacillus ferrooxidans. Water Air Soil Pollut. 2024, 235, 263. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.; Fang, W.; Wang, R.; Wang, X.; Wang, X.; Zheng, G.; Zhou, L. Persistence Evaluation of Fecal Pollution Indicators in Dewatered Sludge and Dewatering Filtrate of Municipal Sewage Sludge: The Impacts of Ambient Temperature and Conditioning Treatments. Water Res. 2025, 268, 122641. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Huo, Q.; Chang, Y.; Man, X. Preparation of Sludge-Derived Spinel Ferrite Nanoparticles for Highly Efficient Adsorption of Pb(II) from Water: Adsorption Behaviour and Mechanism Interpretation via Advanced Statistical Physics Model. J. Environ. Chem. Eng. 2024, 12, 113955. [Google Scholar] [CrossRef]

- Zeng, Y.; Xu, Z.; Dong, B. Enhanced Cu2+ and Cd2+ Removal by a Novel Co-Pyrolysis Biochar Derived from Sewage Sludge and Phosphorus Tailings: Adsorption Performance and Mechanisms. Environ. Geochem. Health 2024, 46, 396. [Google Scholar] [CrossRef]

- Kleemann, N.; Jaeschke, D.; Silveira, N.; Pinto, L.; Cadaval, T.; Arias, J.; Barbosa, S.; Primel, E.; Bamberg, A. Evaluation of the Adsorption Potential of Benzo(a)Pyrene in Coal Produced from Sewage Treatment Station Sludge. Fluids 2025, 10, 98. [Google Scholar] [CrossRef]

- Meservey, A.; Külaots, I.; Bryant, J.D.; Gray, C.; Wahl, J.; Manz, K.E.; Pennell, K.D. Adsorption of Per- and Polyfluoroalkyl Substances on Biochar Derived from Municipal Sewage Sludge. Chemosphere 2024, 365, 143331. [Google Scholar] [CrossRef]

- Sylwan, I.; Bergna, D.; Runtti, H.; Westholm, L.J.; Thorin, E. Primary and Digested Sludge-Derived Char as a Cd Sorbent: Feasibility of Local Utilisation. Water Sci. Technol. 2023, 88, 2917–2930. [Google Scholar] [CrossRef]

- Kujawa, S.; Niedbała, G.; Czekała, W.; Pentoś, K. Neural Image Analysis for the Determination of Total and Volatile Solids in a Composted Sewage Sludge and Maize Straw Mixture. Appl. Sci. 2023, 13, 3363. [Google Scholar] [CrossRef]

- Kulbat, E.; Czerwionka, K. Influence of Phosphorus Speciation on Its Chemical Removal from Reject Water from Dewatering of Municipal Sewage Sludge. Energies 2023, 16, 1260. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, Y.; Mei, T.; Wang, S.; Zhang, L.; Sun, H.; Liao, X. Oxalated Zero-Valent Iron Catalyzed Ozonation for Effective Removal of Antibiotic Resistance Genes from Municipal Sewage Sludge. J. Environ. Chem. Eng. 2023, 11, 109717. [Google Scholar] [CrossRef]

- Ciesielczuk, T.; Głowacki, M.; Rosik-Dulewska, C.; Poluszyńska, J. Extraction of Heavy Metals and Phosphorus from Sewage Sludge Ashes. J. Ecol. Eng. 2025, 26, 185–195. [Google Scholar] [CrossRef] [PubMed]

- Szulej, J.; Ogrodnik, P.; Chyliński, F.; Klimek, B.; Powęzka, A.; Żółtowski, M.; Baryłka, A. The Use of Recycled Ceramics and Ash from Municipal Sewage Sludge as Concrete Fillers. Sustainability 2024, 16, 11251. [Google Scholar] [CrossRef]

- Yu, G.; Yao, Y.; Shi, J.; Fu, Y.; Kong, X. The Reuse of Waste Glass to Enhance Strength during the Introduction of Municipal Sewage Sludge in Shale Brick Manufacturing. J. Mater. Cycles Waste Manag. 2024, 26, 3681–3698. [Google Scholar] [CrossRef]

- da Silva, J.B.; Zat, T.; Werner, E.S.; Brehm, F.A.; Gonçalves, J.P.; Souza, M.T.; Rodríguez, E.D. Recycling of Municipal Sewage Sludge from Brazilian Wastewater Treatment Plants for the Manufacture of Environmentally Friendly Ceramic Bricks. Case Stud. Constr. Mater. 2024, 21, e03610. [Google Scholar] [CrossRef]

- Yu, L.; Shen, X.; Ding, C.; Zhang, Y.; Zhang, C.; Han, Z. Valorization of Waste Slag and Sludge with SiC for the Manufacturing of Lightweight Porous Ceramic Composites: Mineral Evolution, Pore-Forming Mechanism and Performance Implications. Chem. Eng. J. 2025, 511, 161790. [Google Scholar] [CrossRef]

- Yu, L.; Shen, X.; Zhang, Y.; Liu, H.; Zhang, C.; Han, Z. Raw Material Design, Sintering Temperature Optimization and Development Mechanism Investigation of Self-Foaming Porous Bricks with High Solid Waste Addition. Chem. Eng. J. 2024, 495, 153711. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, Y.; Zhang, Z.; Mao, H.; Han, H.; Yang, J. Recycling Reuse of Municipal Sewage Sludge in Sustainable Structural Materials: Preparation, Properties, Crystallization and Microstructure Analyses. Constr. Build. Mater. 2023, 398, 132507. [Google Scholar] [CrossRef]

- Kalak, T.; Szypura, P.; Cierpiszewski, R.; Ulewicz, M. Modification of Concrete Composition Doped by Sewage Sludge Fly Ash and Its Effect on Compressive Strength. Materials 2023, 16, 4043. [Google Scholar] [CrossRef]

- Zacher, A.; Vitow, N.; Heinrich, S.; Leinweber, P.K. The Phosphorus Fertilizer Effect of Biochar from Municipal Sewage Sludge. Arch. Agron. Soil Sci. 2025, 71, 1–13. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, A.; He, X.; Tang, Y.; Yu, Z.; Yu, Y.; Wu, Q.; Dai, B. Process Simulation and Techno-Economic Analysis of 400 t/d Pilot Plant for Municipal Sewage Sludge Drying and Combustion. Process Saf. Environ. Prot. 2025, 196, 106833. [Google Scholar] [CrossRef]

- Sen, T.K.; Yeneneh, A.M.; Jafary, T.; Al Balushi, K.; Hong, E.; Adewole, J.K.; Al Hinai, M.H.; Shinde, S. Municipal Sewage Sludge Dewatering Performance Enhancement by Ultrasonic Cavitation and Advanced Oxidation: A Case Study. Water Sci. Technol. 2024, 89, 2593–2604. [Google Scholar] [CrossRef] [PubMed]

- Xiang, T.; Shi, C.; Guo, Y.; Zhang, J.; Min, W.; Sun, J.; Liu, J.; Yan, X.; Liu, Y.; Yao, L.; et al. Effect-Directed Analysis of Androgenic Compounds from Sewage Sludges in China. Water Res. 2024, 256, 121652. [Google Scholar] [CrossRef]

- Sakai, K.; Hidayat, F.; Maeda, K.; Sakake, A.; Fujishima, K.; Ojima, M.; Jinya, K.; Tashiro, Y. Different Traits for Cold Tolerance of Extremely Thermophilic Calditerricola Strains Isolated from Mesothermal Municipal Sewage Sludge and Its Hyperthermal Compost. J. Biosci. Bioeng. 2024, 137, 290–297. [Google Scholar] [CrossRef]

- Espinoza-Guillen, J.A.; Alderete-Malpartida, M.B.; Gallegos-Huamán, R.L.; Paz-Rosales, Y.M.; Domínguez-Vivar, R.M.; Bujaico-León, C. Ecological Risk Assessment and Identification of Sources of Heavy Metals Contamination in Sewage Sludge from Municipal Wastewater Treatment Plants in the Metropolitan Area of Lima-Callao, Peru. Environ. Dev. Sustain. 2024, 26, 1559–1590. [Google Scholar] [CrossRef]

- Tan, Y.; Cao, X.; Chen, S.; Ao, X.; Li, J.; Hu, K.; Liu, S.; Penttinen, P.; Yang, Y.; Yu, X.; et al. Antibiotic and Heavy Metal Resistance Genes in Sewage Sludge Survive during Aerobic Composting. Sci. Total Environ. 2023, 866, 161386. [Google Scholar] [CrossRef]

- Meng, F.; Sun, S.; Geng, J.; Ma, L.; Jiang, J.; Li, B.; Yabo, S.D.; Lu, L.; Fu, D.; Shen, J.; et al. Occurrence, Distribution, and Risk Assessment of Quinolone Antibiotics in Municipal Sewage Sludges throughout China. J. Hazard. Mater. 2023, 453, 131322. [Google Scholar] [CrossRef]

- Hu, W.; Zhou, Y.; Lu, J.; Sheng, J.; Jin, Z. Remote Sensing Detection and Resource Utilisation of Urban Sewage Sludge Based on Mobile Edge Computing. Ecol. Chem. Eng. S 2023, 30, 275–282. [Google Scholar] [CrossRef]

- Kuehr, S.; Kaegi, R.; Raths, J.; Sinnet, B.; Kipf, M.; Philipp, M.; Rehkämper, M.; Moore, R.E.T.; Young, G.; Jensen, K.A.; et al. Time-Efficient Approach for Environmental Transformation and Bioavailability Assessment of Isotopically Enriched Nanoparticles to Increase Environmental Relevance. Sci. Total Environ. 2025, 971, 178997. [Google Scholar] [CrossRef]

- Lima, D.; Li, L.; Appleby, G. A Review of Renewable Energy Technologies in Municipal Wastewater Treatment Plants (WWTPs). Energies 2024, 17, 6084. [Google Scholar] [CrossRef]

- Gusiatin, M.Z.; Kulikowska, D.; Bernat, K. Municipal Sewage Sludge as a Resource in the Circular Economy. Energies 2024, 17, 2474. [Google Scholar] [CrossRef]

- Biney, M.; Gusiatin, M.Z. Biochar from Co-Pyrolyzed Municipal Sewage Sludge (MSS): Part 2: Biochar Characterization and Application in the Remediation of Heavy Metal-Contaminated Soils. Materials 2024, 17, 3850. [Google Scholar] [CrossRef] [PubMed]

- Mikulionok, I.O. A State of Art and Prospects of Municipal Sewage Sludge Management. Energy Tehnol. I Resur. 2025, 82, 77–106. [Google Scholar] [CrossRef]

- Pelagalli, V.; Langone, M.; Matassa, S.; Race, M.; Tuffi, R.; Papirio, S.; Lens, P.N.L.; Lazzazzara, M.; Frugis, A.; Petta, L.; et al. Pyrolysis of Municipal Sewage Sludge: Challenges, Opportunities and New Valorization Routes for Biochar, Bio-Oil, and Pyrolysis Gas. Environ. Sci 2024, 10, 2282–2312. [Google Scholar] [CrossRef]

- Yang, Y.; Du, Z.; Cao, C.; Duan, P. Production of High Value-Added Carbon Material Precursors via Direct Hydrothermal Conversion of Municipal Sewage Sludge Coupled with Air Flotation Separation: A Review. Sci. Total Environ. 2025, 982, 179655. [Google Scholar] [CrossRef]

- Biney, M.; Gusiatin, M.Z. Biochar from Co-Pyrolyzed Municipal Sewage Sludge (MSS): Part 1: Evaluating Types of Co-Substrates and Co-Pyrolysis Conditions. Materials 2024, 17, 3603. [Google Scholar] [CrossRef]

- Singh, J.; Verma, M. Waste Derived Modified Biochar as Promising Functional Material for Enhanced Water Remediation Potential. Environ. Res. 2024, 245, 117999. [Google Scholar] [CrossRef]

- Yu, S.; Deng, S.; Zhou, A.; Wang, X.; Tan, H. Life Cycle Assessment of Energy Consumption and GHG Emission for Sewage Sludge Treatment and Disposal: A Review. Front. Energy Res. 2023, 11, 1123972. [Google Scholar] [CrossRef]

- Strugała-Wilczek, A.; Basa, W.; Pankiewicz-Sperka, M.; Xu, D.; Duan, P.; Hao, B.; Wang, Y.; Leng, L.; Yang, L.; Fan, L.; et al. Distribution Characteristics and Migration Pathways of Metals during Hydrothermal Liquefaction of Municipal Sewage Sludge in the Presence of Various Catalysts. Sci. Total Environ. 2024, 920, 171023. [Google Scholar] [CrossRef]

- Lu, J.; Veksha, A.; Lisak, G. Conversion of Municipal Sewage Sludge into Biogenic Multi-Walled Carbon Nanotubes and Hydrogen Using X-Mo/MgO (X = Co, Fe, Ni) Catalysts through Pyrolysis-Chemical Vapor Deposition Process. Chem. Eng. J. 2024, 496, 153794. [Google Scholar] [CrossRef]

- Anders, A.; Cakir, H.; Ohnemüller, F.; Platen, H.; Kornhaas, U.; Weigand, H. Phosphorus Recovery from Municipal Sewage Sludge Using Bio-Based Re-Dissolution with Acetate and Precipitation as Calcium Phosphate on Dolomite Seed Grains—A Pilot-Scale Study under Real-World Conditions. Process Saf. Environ. Prot. 2025, 195, 106707. [Google Scholar] [CrossRef]

- khatri, A.; Ghai, M.K.; Thakur, I.S. Fabrication of Heterogeneous Catalyst for Production of Biodiesel Form Municipal Sludge. Process Saf. Environ. Prot. 2024, 191, 1859–1871. [Google Scholar] [CrossRef]

- Liu, J.; Liu, H.; He, C.; Xiao, H.; Jin, M.; Yao, H. Correlation between Sewage Sludge Pore Structure Evolution and Water Filtration Performance: Effect of Thermal Hydrolysis with or without Carbonaceous Skeleton-Assisted. Water Res. 2025, 268, 122578. [Google Scholar] [CrossRef]

- Govindasamy, G.; Jaya Balaji, P.K. Configuring Municipal Solid and Liquid Waste Treatment Plants into Bio-Refinery to Achieve Sustainable Development Goals. J. Mater. Cycles Waste Manag. 2025, 27, 2016–2031. [Google Scholar] [CrossRef]

- Pan, F.; Lan, J. Low-Carbon Multigeneration System Integrating Solar Collectors, Biowaste Gasification, and Water Harvesting: Thermodynamic and Economic Optimization. Appl. Therm. Eng. 2025, 267, 125789. [Google Scholar] [CrossRef]

- Wołejko, E.; Wydro, U.; Szaja, A.; Montusiewicz, A.; Lebiocka, M. Enzymatic Activity in the Anaerobic Co-Digestion of Cavitated Coffee Waste and Sewage Sludge. Energies 2025, 18, 0187. [Google Scholar] [CrossRef]

- Wei, D.; An, D.; Wang, T.; Zhang, H.; Guo, Y.; Sun, B. Influence of Fuel Distribution on Co-Combustion of Sludge and Coal in a 660 MW Tangentially Fired Boiler. Appl. Therm. Eng. 2023, 227, 120344. [Google Scholar] [CrossRef]

- Azevedo, A.; Lapa, N.; Moldão, M.; Duarte, E. Opportunities and Challenges in the Anaerobic Co-Digestion of Municipal Sewage Sludge and Fruit and Vegetable Wastes: A Review. Energy Nexus 2023, 10, 100202. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dębowski, M.; Zieliński, M.; Bartkowska, I.; Wasilewski, A.; Łapiński, D.; Ofman, P. The Use of Solidified Carbon Dioxide in the Aerobic Granular Sludge Pre-Treatment before Thermophilic Anaerobic Digestion. Appl. Sci. 2023, 13, 7864. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dębowski, M.; Zieliński, M. Effect of Pharmaceutical Sludge Pre-Treatment with Fenton/Fenton-like Reagents on Toxicity and Anaerobic Digestion Efficiency. Int. J. Environ. Res. Public Health 2022, 20, 271. [Google Scholar] [CrossRef] [PubMed]

- Rocha, M.E.; Mangiavacchi, N.; Marques, M.; Teixeira, L. Succession from Acetoclastic to Hydrogenotrophic Microbial Community during Sewage Sludge Anaerobic Digestion for Bioenergy Production. Biotechnol. Lett. 2024, 46, 997–1011. [Google Scholar] [CrossRef] [PubMed]

- Giwa, A.S.; Maurice, N.J.; Luoyan, A.; Liu, X.; Yunlong, Y.; Hong, Z. Advances in Sewage Sludge Application and Treatment: Process Integration of Plasma Pyrolysis and Anaerobic Digestion with the Resource Recovery. Heliyon 2023, 9, e19765. [Google Scholar] [CrossRef] [PubMed]

- Sen, A. Mass Transfer Operations, 2nd ed.; Treybal, R.E., Ed.; McGraw Hill: New York, NY, USA, 1968. [Google Scholar]

- Masmoudi, A.; Ben Sik Ali, A.; Dhaouadi, H.; Mhiri, H. Comparison Between Two Solar Drying Techniques of Sewage Sludge: Draining Solar Drying and Drying Bed. Waste Biomass Valorization 2021, 12, 4089–4102. [Google Scholar] [CrossRef]

- Camelin, E.; Cristina, G.; Simelton, E.; Fino, D.; Tommasi, T. The Bioenergy-Fertilizer Nexus: A Challenge Achievable from Municipal Wastewater; Springer: Berlin/Heidelberg, Germany, 2021; pp. 143–166. [Google Scholar] [CrossRef]

- An-nori, A.; Ezzariai, A.; El Mejahed, K.; El Fels, L.; El Gharous, M.; Hafidi, M. Solar Drying as an Eco-Friendly Technology for Sewage Sludge Stabilization: Assessment of Micropollutant Behavior, Pathogen Removal, and Agronomic Value. Front. Environ. Sci. 2022, 10, 814590. [Google Scholar] [CrossRef]

- Gross, T.S.C. Thermal Drying of Sewage Sludge. Water Environ. J. 1993, 7, 255–261. [Google Scholar] [CrossRef]

- LOWE, P. Developments in the Thermal Drying of Sewage Sludge. Water Environ. J. 1995, 9, 306–316. [Google Scholar] [CrossRef]

- Acharya, B.; Sule, I.; Dutta, A. A Review on Advances of Torrefaction Technologies for Biomass Processing. Biomass Convers. Biorefinery 2012, 2, 349–369. [Google Scholar] [CrossRef]

- Pulka, J.; Manczarski, P.; Stepien, P.; Styczyńska, M.; Koziel, J.A.; Białowiec, A. Waste-to-Carbon: Is the Torrefied Sewage Sludge with High Ash Content a Better Fuel or Fertilizer? Materials 2020, 13, 954. [Google Scholar] [CrossRef] [PubMed]

- Białowiec, A.; Pulka, J.; Styczyńska, M.; Koziel, J.A.; Kalka, J.; Jureczko, M.; Felis, E.; Manczarski, P. Is Biochar from the Torrefaction of Sewage Sludge Hazardous Waste? Materials 2020, 13, 3544. [Google Scholar] [CrossRef]

- Tic, W.J.; Guziałowska-Tic, J.; Pawlak-Kruczek, H.; Wóznikowski, E.; Zadorozny, A.; Niedźwiecki, Ł.; Wnukowski, M.; Krochmalny, K.; Czerep, M.; Ostrycharczyk, M.; et al. Novel Concept of an Installation for Sustainable Thermal Utilization of Sewage Sludge. Energies 2018, 11, 748. [Google Scholar] [CrossRef]

- Pulka, J.; Manczarski, P.; Koziel, J.A.; Białowiec, A. Torrefaction of Sewage Sludge: Kinetics and Fuel Properties of Biochars. Energies 2019, 12, 565. [Google Scholar] [CrossRef]

- Li, M.; Wang, H.; Huang, Z.; Yuan, X.; Tan, M.; Jiang, L.; Wu, Z.; Qin, X.; Li, H. Comparison of Atmospheric Pressure and Gas-Pressurized Torrefaction of Municipal Sewage Sludge: Properties of Solid Products. Energy Convers. Manag. 2020, 213, 112793. [Google Scholar] [CrossRef]

- Nguyen, Q.; Nguyen, D.D.; Vothi, H.; He, C.; Goodarzi, M.; Bach, Q.V. Isothermal Torrefaction Kinetics for Sewage Sludge Pretreatment. Fuel 2020, 277, 118103. [Google Scholar] [CrossRef]

- Herbert, L. Corporate Identity Guide: The Chartered Institution of Wastes Management. 2002. Available online: https://www.academia.edu/36572012/Corporate_Identity_Guide_The_Chartered_Institution_of_Wastes_Management_June_2002_CENTENARY_HISTORY_OF_WASTE_AND_WASTE_MANAGERS_IN_LONDON_AND_SOUTH_EAST_ENGLAND (accessed on 25 May 2025).

- Guo, X.; Yuan, S.; Xu, Y.; Qian, G. Effects of Phosphorus and Iron on the Composition and Property of Portland Cement Clinker Utilized Incinerated Sewage Sludge Ash. Constr. Build. Mater. 2022, 341, 127754. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, C.; Champagne, P.; Mabee, W. Overview of Current Biological and Thermo-Chemical Treatment Technologies for Sustainable Sludge Management. Waste Manag. Res. 2014, 32, 586–600. [Google Scholar] [CrossRef]

- Han, X.; Niu, M.; Jiang, X.; Liu, J. Combustion Characteristics of Sewage Sludge in a Fluidized Bed. Ind. Eng. Chem. Res. 2012, 51, 10565–10570. [Google Scholar] [CrossRef]

- Schnell, M.; Horst, T.; Quicker, P. Thermal Treatment of Sewage Sludge in Germany: A Review. J. Environ. Manag. 2020, 263, 110367. [Google Scholar] [CrossRef]

- Agency, G.E. Sewage Sludge Disposal in the Federal Republic of Germany; German Environment Agency: Berlin, Germany, 2019. [Google Scholar]

- Dichtl, N.; Rogge, S.; Bauerfeld, K. Novel Strategies in Sewage Sludge Treatment. Clean Soil Air Water 2007, 35, 473–479. [Google Scholar] [CrossRef]

- Dowbysz, A.; Kukfisz, B.; Samsonowicz, M.; Bihałowicz, J.S. Determination of the Self-Ignition Behavior of the Accumulation of Sludge Dust and Sludge Pellets from the Sewage Sludge Thermal Drying Station. Energies 2022, 16, 46. [Google Scholar] [CrossRef]

- Kasina, M.; Jarosz, K. Chemical and Microbiological Techniques for Recovery and/or Removal of Elements from Incinerated Sewage Sludge Ash—A Review of Basic Methods. Energies 2023, 16, 1840. [Google Scholar] [CrossRef]

- Ławińska, O.; Korombel, A.; Zajemska, M. Pyrolysis-Based Municipal Solid Waste Management in Poland—SWOT Analysis. Energies 2022, 15, 510. [Google Scholar] [CrossRef]

- Borella, M.; Casazza, A.A.; Garbarino, G.; Riani, P.; Busca, G. A Study of the Pyrolysis Products of Kraft Lignin. Energies 2022, 15, 991. [Google Scholar] [CrossRef]

- Pyrolysis of Exhausted Olive Oil Husks Coupled with Two-Stages Thermal Decomposition of Aqueous Olive Oil Mills Effluents. Available online: https://www.researchgate.net/publication/283627424_Pyrolysis_of_Exhausted_Olive_Oil_Husks_Coupled_with_Two-Stages_Thermal_Decomposition_of_Aqueous_Olive_Oil_Mills_Effluents (accessed on 25 May 2025).

- Parsley, D.; Ciora, R.J.; Flowers, D.L.; Laukaitaus, J.; Chen, A.; Liu, P.K.T.; Yu, J.; Sahimi, M.; Bonsu, A.; Tsotsis, T.T. Field Evaluation of Carbon Molecular Sieve Membranes for the Separation and Purification of Hydrogen from Coal- and Biomass-Derived Syngas. J. Membr. Sci. 2014, 450, 81–92. [Google Scholar] [CrossRef]

- Hämäläinen, A.; Kokko, M.; Chatterjee, P.; Kinnunen, V.; Rintala, J. The Effects of Digestate Pyrolysis Liquid on the Thermophilic Anaerobic Digestion of Sewage Sludge—Perspective for a Centralized Biogas Plant Using Thermal Hydrolysis Pretreatment. Waste Manag. 2022, 147, 73–82. [Google Scholar] [CrossRef]

- Chen, Y.; Yi, L.; Li, S.; Yin, J.; Jin, H. Catalytic Gasification of Sewage Sludge in near and Supercritical Water with Different Catalysts. Chem. Eng. J. 2020, 388, 124292. [Google Scholar] [CrossRef]

- Nipattummakul, N.; Ahmed, I.I.; Kerdsuwan, S.; Gupta, A.K. Hydrogen and Syngas Production from Sewage Sludge via Steam Gasification. Int. J. Hydrogen Energy 2010, 35, 11738–11745. [Google Scholar] [CrossRef]

- Gai, C.; Guo, Y.; Liu, T.; Peng, N.; Liu, Z. Hydrogen-Rich Gas Production by Steam Gasification of Hydrochar Derived from Sewage Sludge. Int. J. Hydrogen Energy 2016, 41, 3363–3372. [Google Scholar] [CrossRef]

- Gallifuoco, A.; Taglieri, L.; Scimia, F.; Papa, A.A.; Di Giacomo, G. Hydrothermal Conversions of Waste Biomass: Assessment of Kinetic Models Using Liquid-Phase Electrical Conductivity Measurements. Waste Manag. 2018, 77, 586–592. [Google Scholar] [CrossRef] [PubMed]

- Hu, B.; Yu, S.H.; Wang, K.; Liu, L.; Xu, X.W. Functional Carbonaceous Materials from Hydrothermal Carbonization of Biomass: An Effective Chemical Process. Dalton Trans. 2008, 40, 5414–5423. [Google Scholar] [CrossRef]

- Giacomo, D.; Romano, G.; Giacomo, G.D.; Romano, P. Evolution of the Olive Oil Industry along the Entire Production Chain and Related Waste Management. Energies 2022, 15, 465. [Google Scholar] [CrossRef]

- Libra, J.A.; Ro, K.S.; Kammann, C.; Funke, A.; Berge, N.D.; Neubauer, Y.; Titirici, M.M.; Fühner, C.; Bens, O.; Kern, J.; et al. Hydrothermal Carbonization of Biomass Residuals: A Comparative Review of the Chemistry, Processes and Applications of Wet and Dry Pyrolysis. Biofuels 2011, 2, 71–106. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, W.; Chen, C.; Zhang, H.; Lin, N.; Su, Y. Influence of Reaction Conditions on the Catalytic Activity of a Nickel during the Supercritical Water Gasification of Dewatered Sewage Sludge. J. Supercrit. Fluids 2018, 140, 356–363. [Google Scholar] [CrossRef]

- Gong, W.; Zhou, Z.; Liu, Y.; Wang, Q.; Guo, L. Catalytic Gasification of Sewage Sludge in Supercritical Water: Influence of K2CO3 and H2O2 on Hydrogen Production and Phosphorus Yield. ACS Omega 2020, 5, 3389–3396. [Google Scholar] [CrossRef]

- Fan, C.; Jin, H. Numerical Simulation of Gasification of a Shrinking Char Particle in Supercritical Water. Fuel 2022, 318, 123692. [Google Scholar] [CrossRef]

- Adar, E.; Ince, M.; Bilgili, M.S. Supercritical Water Gasification of Sewage Sludge by Continuous Flow Tubular Reactor: A Pilot Scale Study. Chem. Eng. J. 2020, 391, 123499. [Google Scholar] [CrossRef]

- Ruya, P.M.; Purwadi, R.; Lim, S.S. Supercritical Water Gasification of Sewage Sludge for Power Generation– Thermodynamic Study on Auto-Thermal Operation Using Aspen Plus. Energy Convers. Manag. 2020, 206, 112458. [Google Scholar] [CrossRef]

- Acelas, N.Y.; López, D.P.; Wim Brilman, D.W.F.; Kersten, S.R.A.; Kootstra, A.M.J. Supercritical Water Gasification of Sewage Sludge: Gas Production and Phosphorus Recovery. Bioresour. Technol. 2014, 174, 167–175. [Google Scholar] [CrossRef]

- Gururani, P.; Bhatnagar, P.; Bisht, B.; Jaiswal, K.K.; Kumar, V.; Kumar, S.; Vlaskin, M.S.; Grigorenko, A.V.; Rindin, K.G. Recent Advances and Viability in Sustainable Thermochemical Conversion of Sludge to Bio-Fuel Production. Fuel 2022, 316, 123351. [Google Scholar] [CrossRef]

- Rahman, T.; Jahromi, H.; Roy, P.; Adhikari, S.; Hassani, E.; Oh, T.S. Hydrothermal Liquefaction of Municipal Sewage Sludge: Effect of Red Mud Catalyst in Ethylene and Inert Ambiences. Energy Convers. Manag. 2021, 245, 114615. [Google Scholar] [CrossRef]

- Kapusta, K. Effect of Ultrasound Pretreatment of Municipal Sewage Sludge on Characteristics of Bio-Oil from Hydrothermal Liquefaction Process. Waste Manag. 2018, 78, 183–190. [Google Scholar] [CrossRef]

- Badrolnizam, R.S.; Elham, O.S.J.; Hadzifah, S.N.; Husain, M.H.N.; Hidayu, A.R.; Mohammad, N.F.; Mohamad Daud, A.R. Sewage Sludge Conversion via Hydrothermal Liquefaction (HTL)—A Preliminary Study. J. Phys. Conf. Ser. 2019, 1349, 012108. [Google Scholar] [CrossRef]

- Hu, M.; Ye, Z.; Zhang, H.; Chen, B.; Pan, Z.; Wang, J. Thermochemical Conversion of Sewage Sludge for Energy and Resource Recovery: Technical Challenges and Prospects. Environ. Pollut. Bioavailab. 2021, 33, 145–163. [Google Scholar] [CrossRef]

- Amrullah, A.; Matsumura, Y. Supercritical Water Gasification of Sewage Sludge in Continuous Reactor. Bioresour. Technol. 2018, 249, 276–283. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S. Supercritical Water Oxidation for Environmentally Friendly Treatment of Organic Wastes. In Advanced Supercritical Fluids Technologies; IntechOpen: Rijeka, Croatia, 2020. [Google Scholar] [CrossRef]

- 4th International Symposium on Hydrothermal Carbonization. Available online: https://htc2025neworleans.netlify.app/ (accessed on 26 May 2025).

- Guo, S.; Mu, J.; Zhao, D.; Qu, H.; Sun, B.; Li, X.; Yang, L. Gasification Performance of Wet Hydrochar from Co-Hydrothermal Carbonization of High-Moisture Sludge and Fungus Bran. J. Environ. Chem. Eng. 2024, 12, 113901. [Google Scholar] [CrossRef]

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Coupling Hydrothermal Carbonization with Anaerobic Digestion for Sewage Sludge Treatment: Influence of HTC Liquor and Hydrochar on Biomethane Production. Energies 2020, 13, 6262. [Google Scholar] [CrossRef]

- Aragón-Briceño, C.I.; Ross, A.B.; Camargo-Valero, M.A. Mass and Energy Integration Study of Hydrothermal Carbonization with Anaerobic Digestion of Sewage Sludge. Renew. Energy 2021, 167, 473–483. [Google Scholar] [CrossRef]

- Brown, A.E.; Hammerton, J.M.; Camargo-valero, M.A.; Ross, A.B. Integration of Hydrothermal Carbonisation and Anaerobic Digestion for the Energy Valorisation of Grass. Energies 2022, 15, 3495. [Google Scholar] [CrossRef]

- Parmar, K.R.; Ross, A.B. Integration of Hydrothermal Carbonisation with Anaerobic Digestion; Opportunities for Valorisation of Digestate. Energies 2019, 12, 1586. [Google Scholar] [CrossRef]

- Oliveira, A.S.; Sarrión, A.; Baeza, J.A.; Diaz, E.; Calvo, L.; Mohedano, A.F.; Gilarranz, M.A. Integration of Hydrothermal Carbonization and Aqueous Phase Reforming for Energy Recovery from Sewage Sludge. Chem. Eng. J. 2022, 442, 136301. [Google Scholar] [CrossRef]

- Liu, H.; Hu, G.; Basar, I.A.; Li, J.; Lyczko, N.; Nzihou, A.; Eskicioglu, C. Phosphorus Recovery from Municipal Sludge-Derived Ash and Hydrochar through Wet-Chemical Technology: A Review towards Sustainable Waste Management. Chem. Eng. J. 2021, 417, 129300. [Google Scholar] [CrossRef]

- Pérez, C.; Boily, J.F.; Jansson, S.; Gustafsson, T.; Fick, J. Acid-Induced Phosphorus Release from Hydrothermally Carbonized Sewage Sludge. Waste Biomass Valorization 2021, 12, 6555–6568. [Google Scholar] [CrossRef]

- MacDermid-Watts, K.; Pradhan, R.; Dutta, A. Catalytic Hydrothermal Carbonization Treatment of Biomass for Enhanced Activated Carbon: A Review. Waste Biomass Valorization 2020, 12, 2171–2186. [Google Scholar] [CrossRef]

- Hydrothermal Carbonization: Influence of Plant Capacity, Feedstock Choice and Location on Product Cost. Available online: https://www.researchgate.net/publication/260056047_Hydrothermal_carbonization_Influence_of_plant_capacity_feedstock_choice_and_location_on_product_cost (accessed on 26 May 2025).

- Das, T.; Al-Waili, I.; Balasubramanian, V.; Appleby, G.; Kaparaju, P.; Parthasarathy, R.; Eshtiaghi, N. Process Modelling and Techno-Economic Analysis of Anaerobic Digestion of Sewage Sludge Integrated with Wet Oxidation Using a Gravity Pressure Vessel and Thermal Hydrolysis. Sci. Total Environ. 2024, 912, 169024. [Google Scholar] [CrossRef]

- Silva Thomsen, L.B.; Anastasakis, K.; Biller, P. Hydrothermal Liquefaction Potential of Wastewater Treatment Sludges: Effect of Wastewater Treatment Plant and Sludge Nature on Products Distribution. Fuel 2024, 355, 129525. [Google Scholar] [CrossRef]

- Guo, S.; Mu, J.; Gao, L.; Ge, L.; Lisak, G. Enhancing Energy Yield and Reducing Environmental Impact through Co-Hydrothermal Carbonization of Undehydrated Sewage Sludge and Fungus Bran. J. Environ. Chem. Eng. 2024, 12, 114051. [Google Scholar] [CrossRef]

- Bagheri, M.; Wetterlund, E. Introducing Hydrothermal Carbonization to Sewage Sludge Treatment Systems—A Way of Improving Energy Recovery and Economic Performance? Waste Manag. 2023, 170, 131–143. [Google Scholar] [CrossRef]

- Yue, W.; Yu, W.; Cao, Z.; Wang, K.; Chen, Z.; Si, X. Current Status and Trends of Municipal Sludge Treatment and Disposal in China. Glob. NEST J. 2024, 26, 06161. [Google Scholar] [CrossRef]

- Liu, H.; Qiao, H.; Liu, S.; Wei, G.; Zhao, H.; Li, K.; Weng, F. Energy, Environment and Economy Assessment of Sewage Sludge Incineration Technologies in China. Energy 2023, 264, 126294. [Google Scholar] [CrossRef]

- Li, H.; Jin, C.; Mundree, S. Hybrid Environmental and Economic Assessment of Four Approaches Recovering Energy from Sludge with Variant Organic Contents. J. Clean. Prod. 2017, 153, 131–138. [Google Scholar] [CrossRef]

- Ochieng, R.; Sarker, S. Energy and Techno-Economic Analysis of Integrated Supercritical Water Gasification of Sewage Sludge and Fast Pyrolysis of Wood for Power, Heat, and Hydrogen Production. Chem. Eng. Sci. 2025, 306, 121236. [Google Scholar] [CrossRef]

- Lombardi, L.; Nocita, C.; Bettazzi, E.; Fibbi, D.; Carnevale, E. Environmental Comparison of Alternative Treatments for Sewage Sludge: An Italian Case Study. Waste Manag. 2017, 69, 365–376. [Google Scholar] [CrossRef]

- Mohamed, B.A.; Ruan, R.; Bilal, M.; Periyasamy, S.; Awasthi, M.K.; Rajamohan, N.; Leng, L. Sewage Sludge Co-Pyrolysis with Agricultural/Forest Residues: A Comparative Life-Cycle Assessment. Renew. Sustain. Energy Rev. 2024, 192, 114168. [Google Scholar] [CrossRef]

- Teoh, S.K.; Li, L.Y. Feasibility of Alternative Sewage Sludge Treatment Methods from a Lifecycle Assessment (LCA) Perspective. J. Clean. Prod. 2020, 247, 119495. [Google Scholar] [CrossRef]

- Ding, A.; Zhang, R.; Ngo, H.H.; He, X.; Ma, J.; Nan, J.; Li, G. Life Cycle Assessment of Sewage Sludge Treatment and Disposal Based on Nutrient and Energy Recovery: A Review. Sci. Total Environ. 2021, 769, 144451. [Google Scholar] [CrossRef]

- Farru, G.; Scheufele, F.B.; Paniagua, D.M.; Keller, F.; Jeong, C.; Basso, D. Business and Market Analysis of Hydrothermal Carbonization Process: Roadmap toward Implementation. Agronomy 2024, 14, 541. [Google Scholar] [CrossRef]

| Component | Composition (% of TS) |

|---|---|

| Volatile solids | 60–80 |

| Grease and fats | |

| Ether soluble | 6–30 |

| Ether extract | 7–35 |

| Protein | 20–30 |

| Nitrogen (N) | 1.5–4 |

| Phosphorus (P2O5) | 0.8–2.8 |

| Potash (K2O) | 0–1 |

| Cellulose | 8.0–15.0 |

| Iron (not as sulfide) | 2.0–4.0 |

| Silica (SiO2) | 15.0–20.0 |

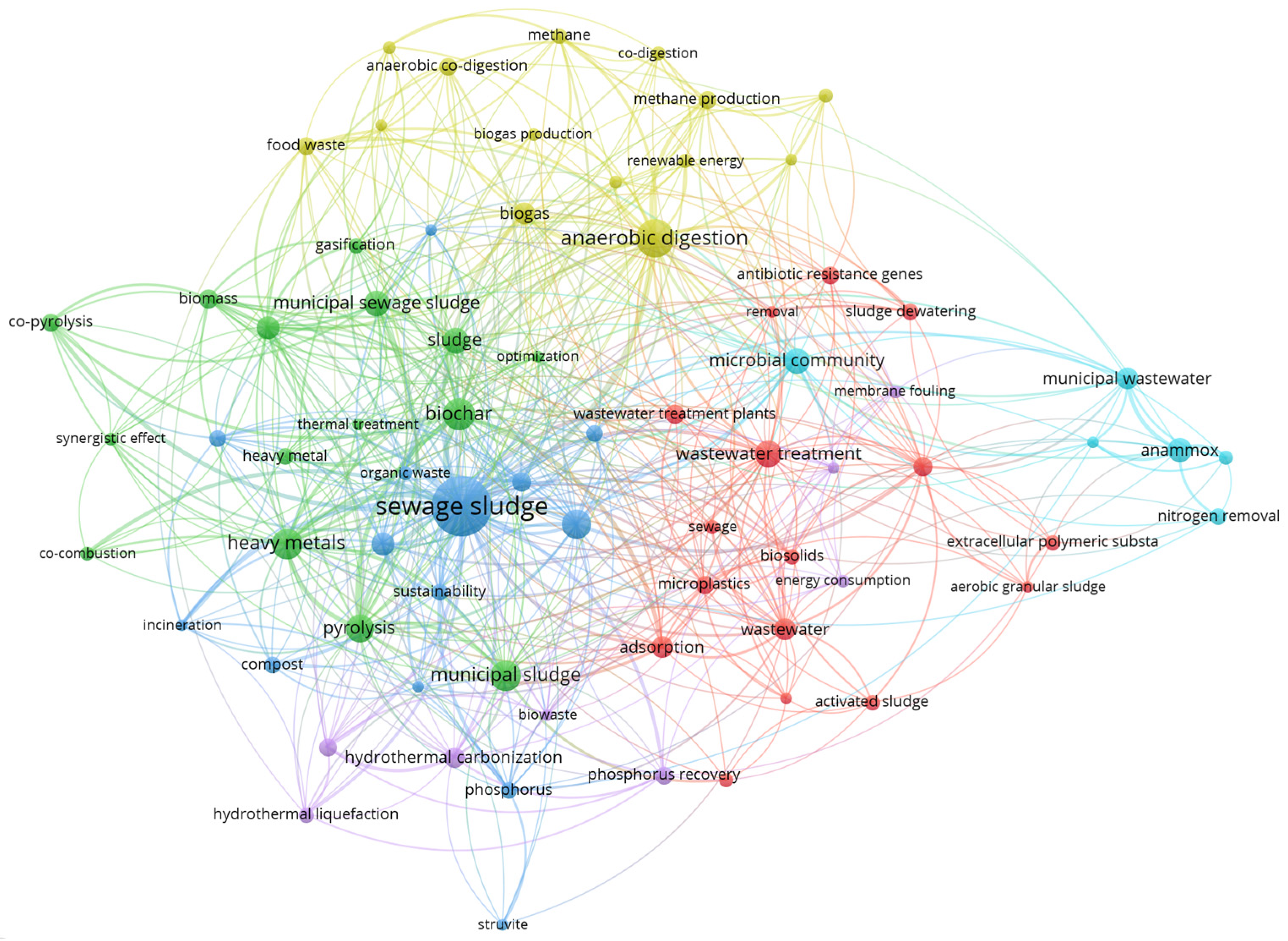

| Cluster Theme | Representative Keywords | N. Articles | Ref. |

|---|---|---|---|

| Anaerobic digestion and co-digestion—methane/H2 production, pretreatment to boost biogas | AD, co-digestion, VFA *, methane yield, organic loading, hydrothermal-AD | 16 | [65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80] |

| Thermal processing and energy (pyrolysis/gasification/combustion)—syngas, bio-oil, kinetic synergy, flue gas control | Pyrolysis, gasification, co-combustion, syngas, activation energy | 18 | [81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98] |

| Composting, vermicomposting and soil amendment—nutrient recovery, plant growth, soil enzymes | Compost, vermicompost, biochar soil, plant uptake, phytostabilization | 25 | [99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123] |

| Adsorbents and pollutant removal—sludge-derived sorbents for metals, PFAS, P, ARG * reduction | Adsorption, biochar sorbent, heavy metals, PFAS, ARG, P recovery | 16 | [97,118,120,124,125,126,127,128,129,130,131,132,133,134,135,136] |

| Construction and ceramic materials—bricks, concrete, foamed ceramics, nano-biochar fillers | Brick, concrete, ceramic, compressive strength, sintering | 7 | [137,138,139,140,141,142,143] |

| Environmental risk, monitoring and surveys—ARG/microplastics loads, IoT sensing, risk indices | Risk, ARG, microplastics, IoT *, monitoring, survey | 13 | [12,87,133,144,145,146,147,148,149,150,151,152,153] |

| Life-cycle assessment, reviews, and policy—comparative LCA, SWOT/FAHP *, national inventories | LCA, review, SWOT, survey, policy, circular economy | 12 | [72,86,91,154,155,156,157,158,159,160,161,162] |

| Integrated biorefinery and advanced catalytic routes—multigeneration plants, HTL-AD-MEC *, specialty catalysts | Biorefinery, catalyst, multigeneration, HTL, MWCNT *, biodiesel | 11 | [82,83,84,124,163,164,165,166,167,168,169] |

| Technology | Main Advantages | Main Drawbacks |

|---|---|---|

| AD | Mature, positive energy balance, adaptable to co-digestion | Requires strict process control; digestate handling |

| Thermal hydrolysis + AD | +20–40% methane; better dewaterability | High-pressure steam demand |

| HTC | Treats wet sludge; produces high-energy hydrochar; captures phosphorus | Process-water treatment; comparatively high CAPEX |

| Drying | Reduces transport costs; enables pellet fuel | Significant heat demand; odor/emission control |

| Torrefaction | Upgrades fuel quality; eases downstream pyrolysis/gasification | Needs prior drying; condensate management |

| Incineration/co-incineration | Complete pathogen and micropollutant destruction; phosphorus-rich ash | High capital/operating cost; stringent flue-gas limits |

| Pyrolysis | Generates bio-oil and biochar for energy/material use | Requires low-moisture feed; tar clean-up |

| Gasification | Produces syngas/hydrogen; large volume reduction | Tar reforming CAPEX; economical only at large scale |

| Target | Timeline | Operational Significance |

|---|---|---|

| Cost parity with conventional disposal options | 2028 | The total HTC treatment cost (CAPEX + OPEX) must equal that of incineration or composting |

| 20% cost reduction versus current state-of-the-art techniques | 2033 | Achieved through learning-curve effects and plant standardization |

| 80% of products for carbon capture or bio-energy, 20% for high-value materials | 2030 | Market focus on sludge/MSW-derived biochar and nutrient-recovery fertilizers |

| 50,000 t day−1 of residues treated worldwide | 2035 | Global rollout of HTC plants in urban (sludge) and agro-industrial settings |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romano, P.; Zuffranieri, A.; Di Giacomo, G. Energy Valorization and Resource Recovery from Municipal Sewage Sludge: Evolution, Recent Advances, and Future Prospects. Energies 2025, 18, 3442. https://doi.org/10.3390/en18133442

Romano P, Zuffranieri A, Di Giacomo G. Energy Valorization and Resource Recovery from Municipal Sewage Sludge: Evolution, Recent Advances, and Future Prospects. Energies. 2025; 18(13):3442. https://doi.org/10.3390/en18133442

Chicago/Turabian StyleRomano, Pietro, Adriana Zuffranieri, and Gabriele Di Giacomo. 2025. "Energy Valorization and Resource Recovery from Municipal Sewage Sludge: Evolution, Recent Advances, and Future Prospects" Energies 18, no. 13: 3442. https://doi.org/10.3390/en18133442

APA StyleRomano, P., Zuffranieri, A., & Di Giacomo, G. (2025). Energy Valorization and Resource Recovery from Municipal Sewage Sludge: Evolution, Recent Advances, and Future Prospects. Energies, 18(13), 3442. https://doi.org/10.3390/en18133442