Optimization and Estimation of the State of Charge of Lithium-Ion Batteries for Electric Vehicles

Abstract

1. Introduction

1.1. Literature Review on State of Charge (SOC) Estimation Methods

1.2. Paper Contributions

- (a)

- Optimal noise suppression and better temporal control of the covariance matrix in the battery SOC estimation process.

- (b)

- An assessment of the accuracy and robustness of the SOC estimation by determining a range within which online noise covariance updates are possible for good noise estimation over time.

- (c)

- The proposed simulation conditions are very close to industrial reality, as parameter estimation varies greatly depending on the technologies used by battery manufacturers. Data are estimated in a highly variable manner depending on the online experimental conditions of different manufacturers, although the technical operating characteristics of the batteries vary considerably within the same ranges. This reality makes the simulation protocol highly stochastic, which represents a major challenge for this study. Emphasis is placed on highlighting the chaotic fluctuations recorded during model estimation and validation using stability margins.

- (d)

- A case study of four lithium battery manufacturers (Turnigy, LG, SAMSUNG, PANASONIC) for temperatures of 40 °C, 25 °C, 10 °C, 0 °C and −10 °C, and whose internal parameters of these different models are identified by second-order linear Taylor development with a positioning in relation to the literature and current standards with recommendations for sustainable development of the automotive sector.

1.3. Organization of the Article

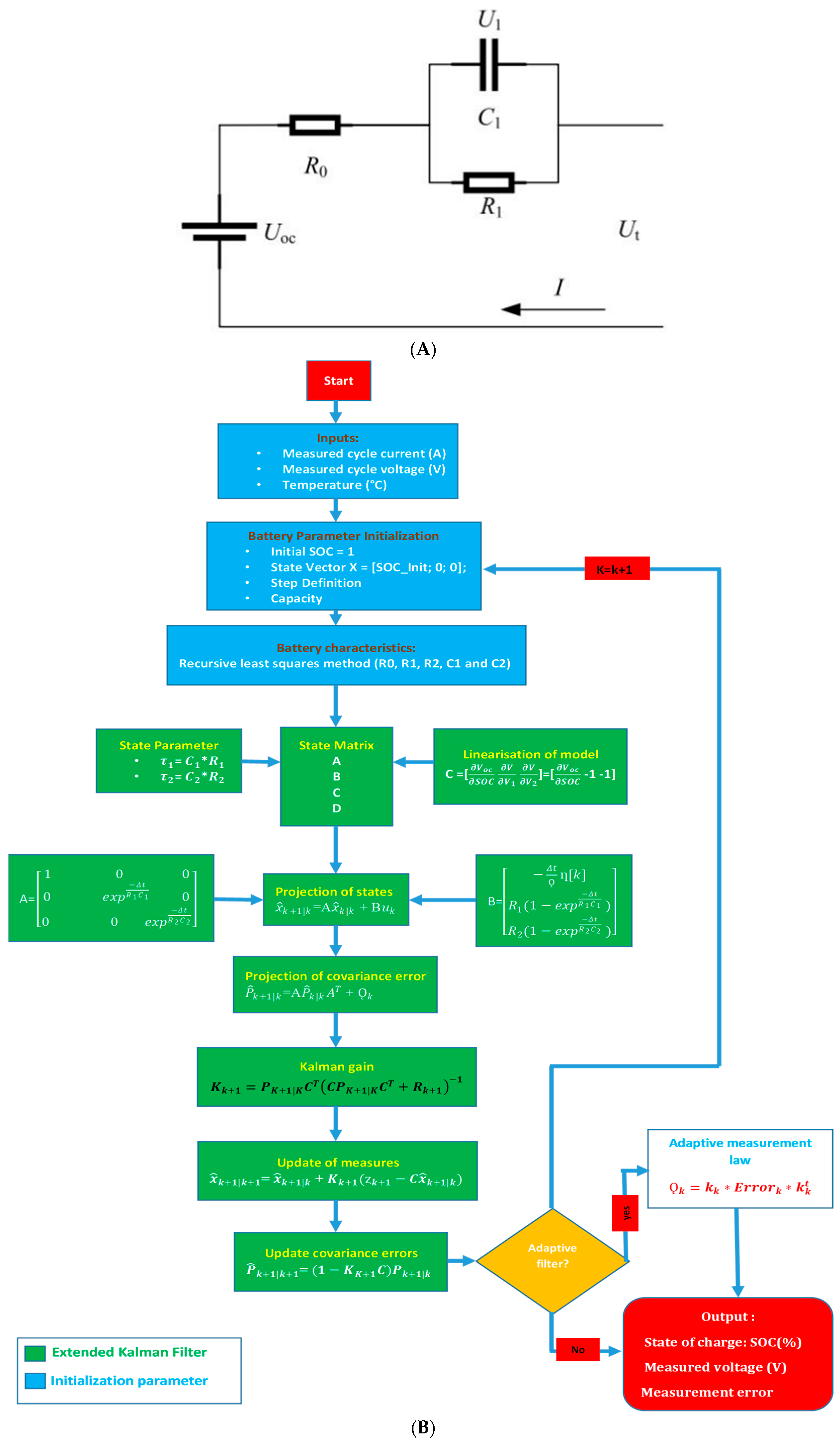

2. System Modeling

2.1. Battery Architecture

2.2. Parameter Estimation

- (a)

- Initialization

- (b)

- Time update

- (c)

- Kalman gainwhere Ck is the Jacobian matrix of g(x)

- (d)

- Updating measurements

- (e)

- Covariance matrix of estimation errors

2.3. Proposed Method

3. Results and Discussion

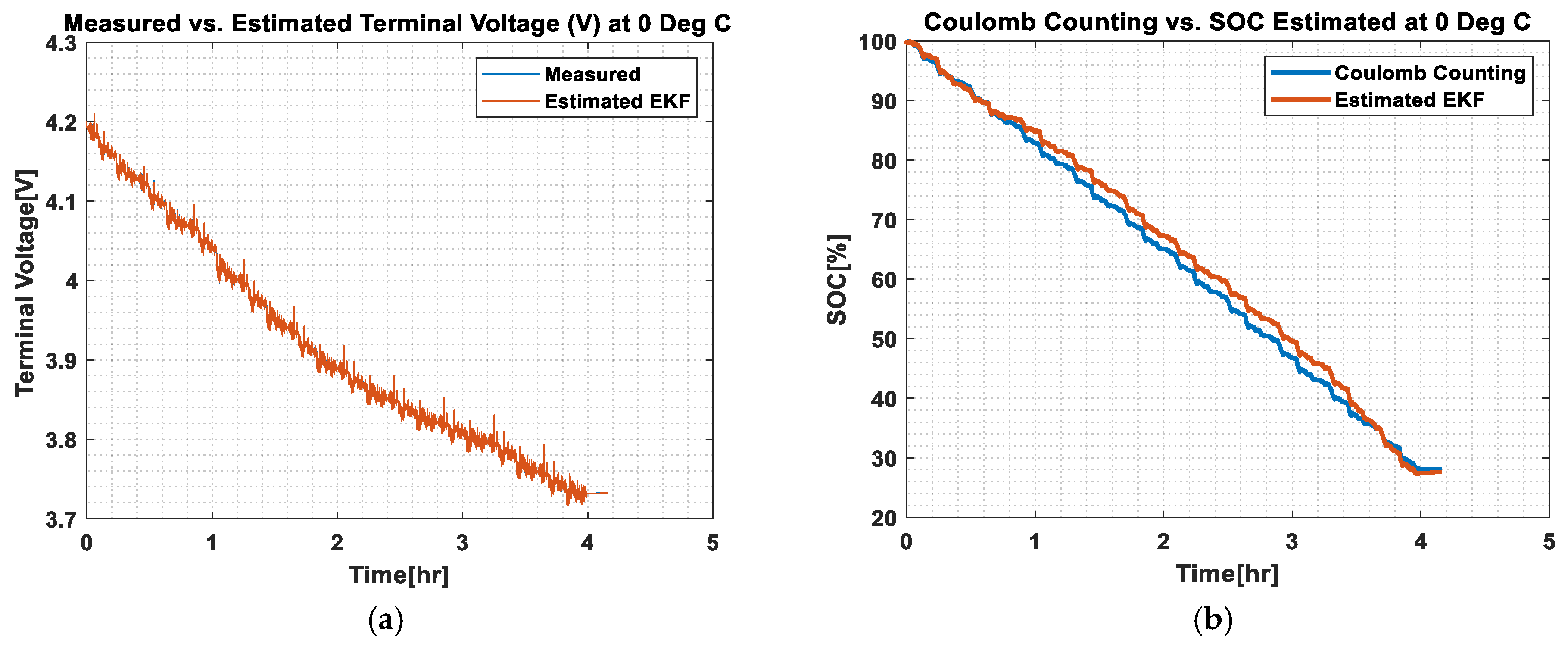

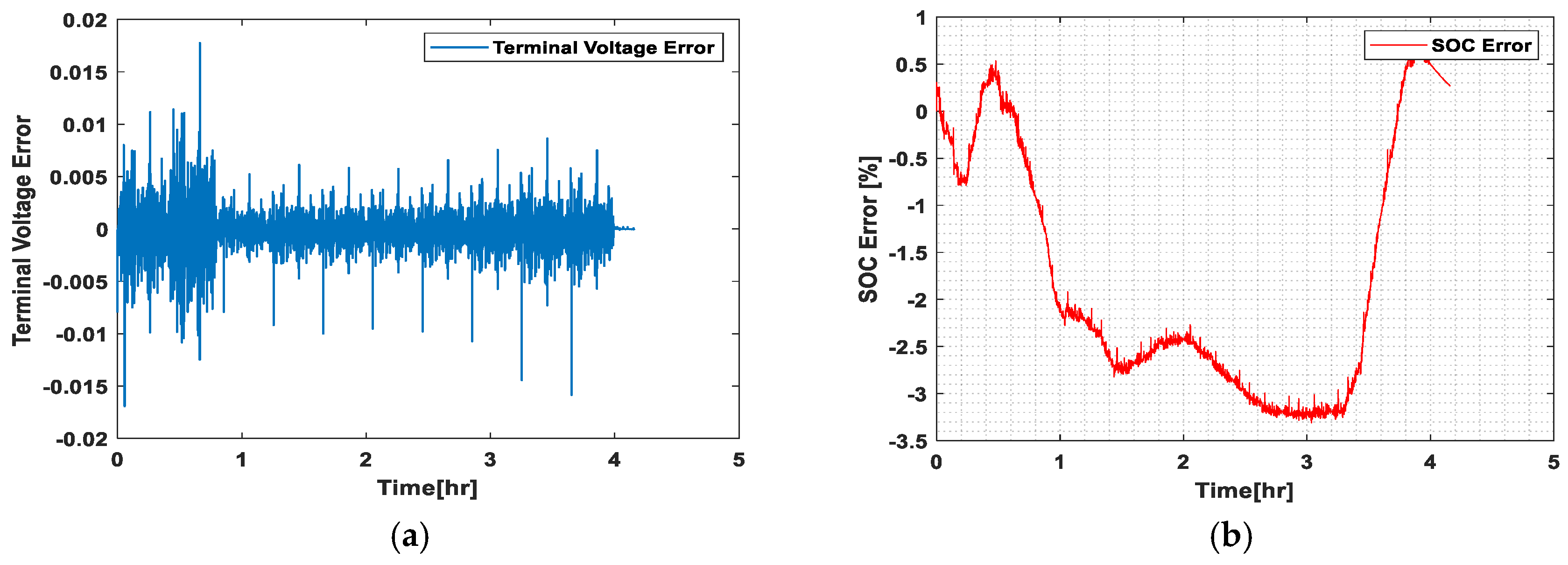

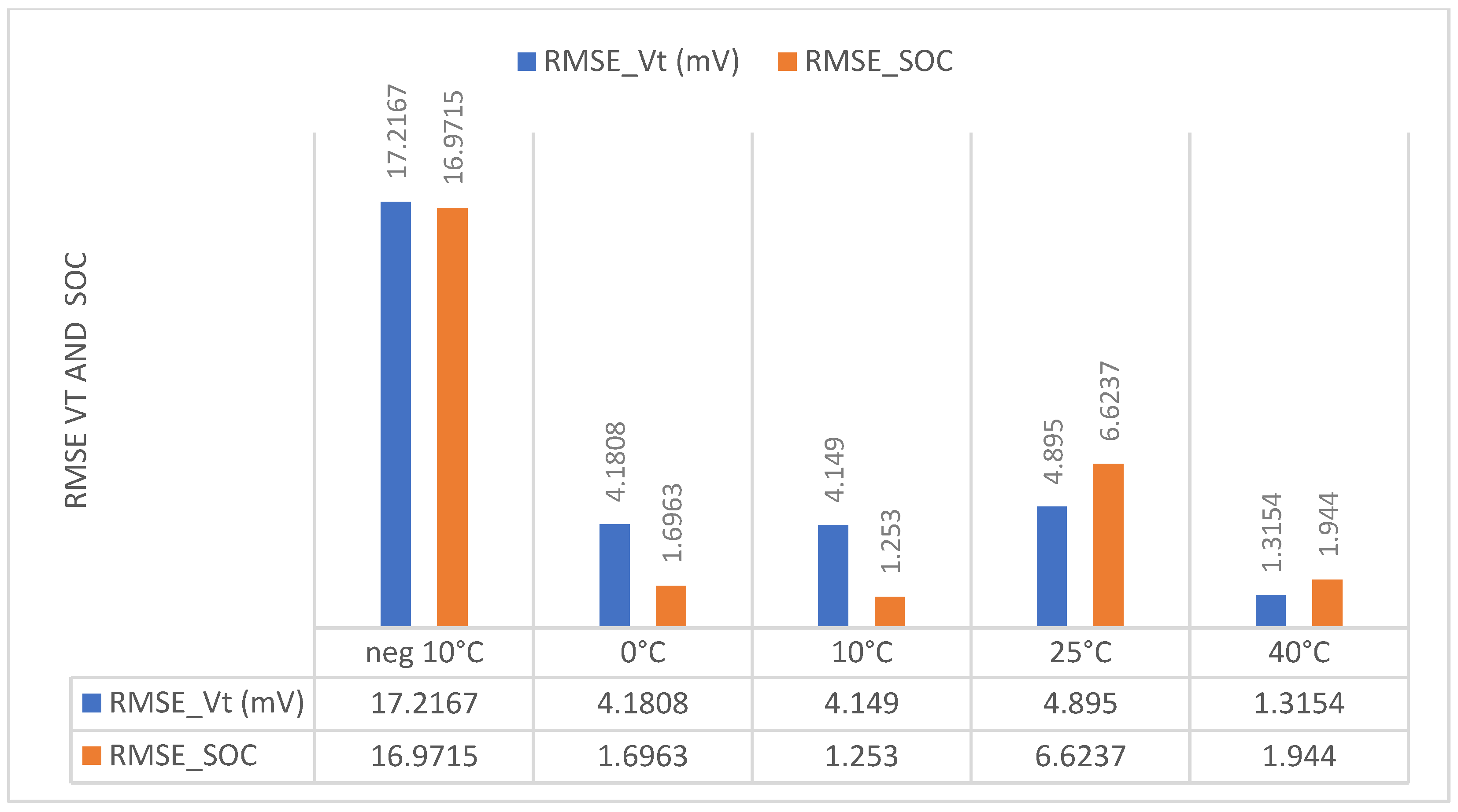

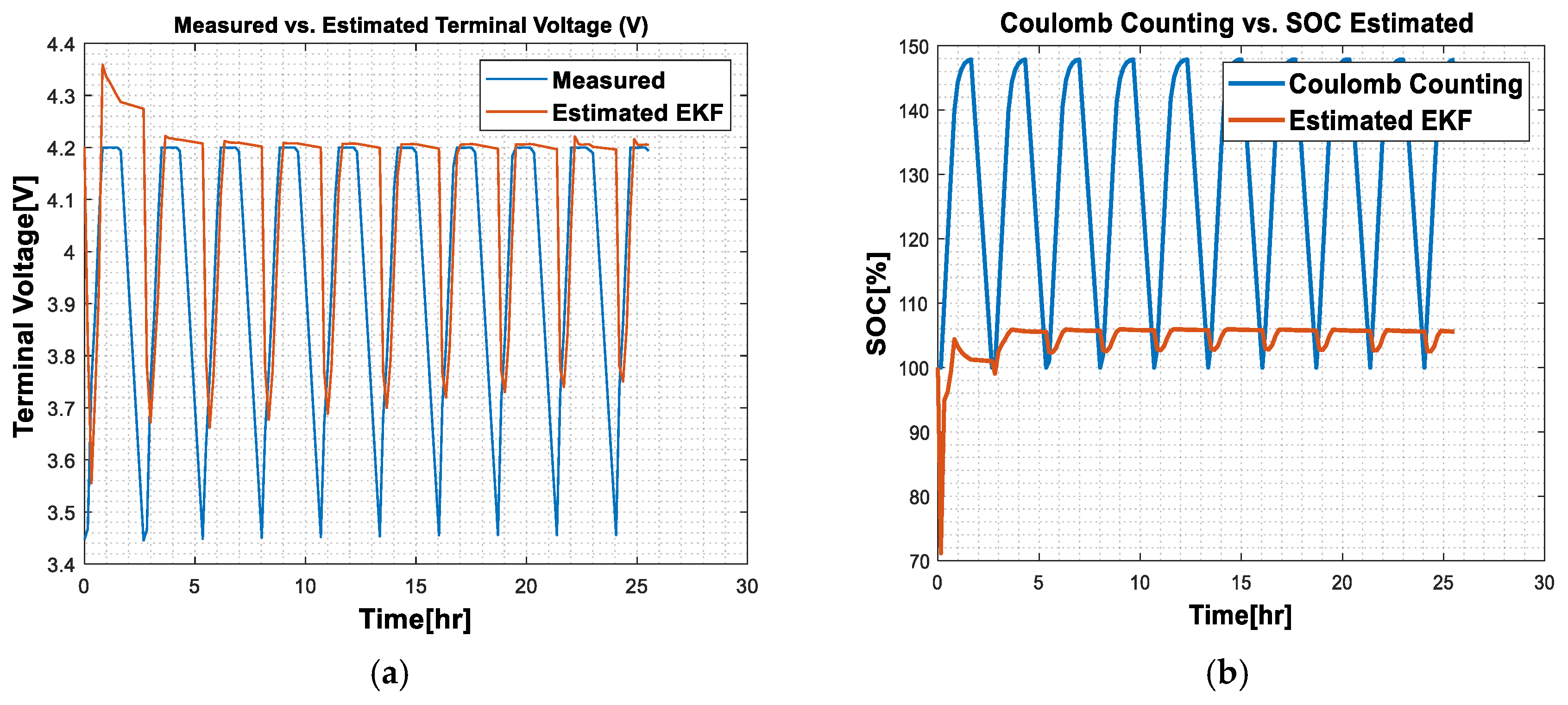

3.1. Results Obtained on the Rotating Graphene Model

- (a)

- Ambient temperature at 0 °C

- (b) Ambient temperature at 25 °C

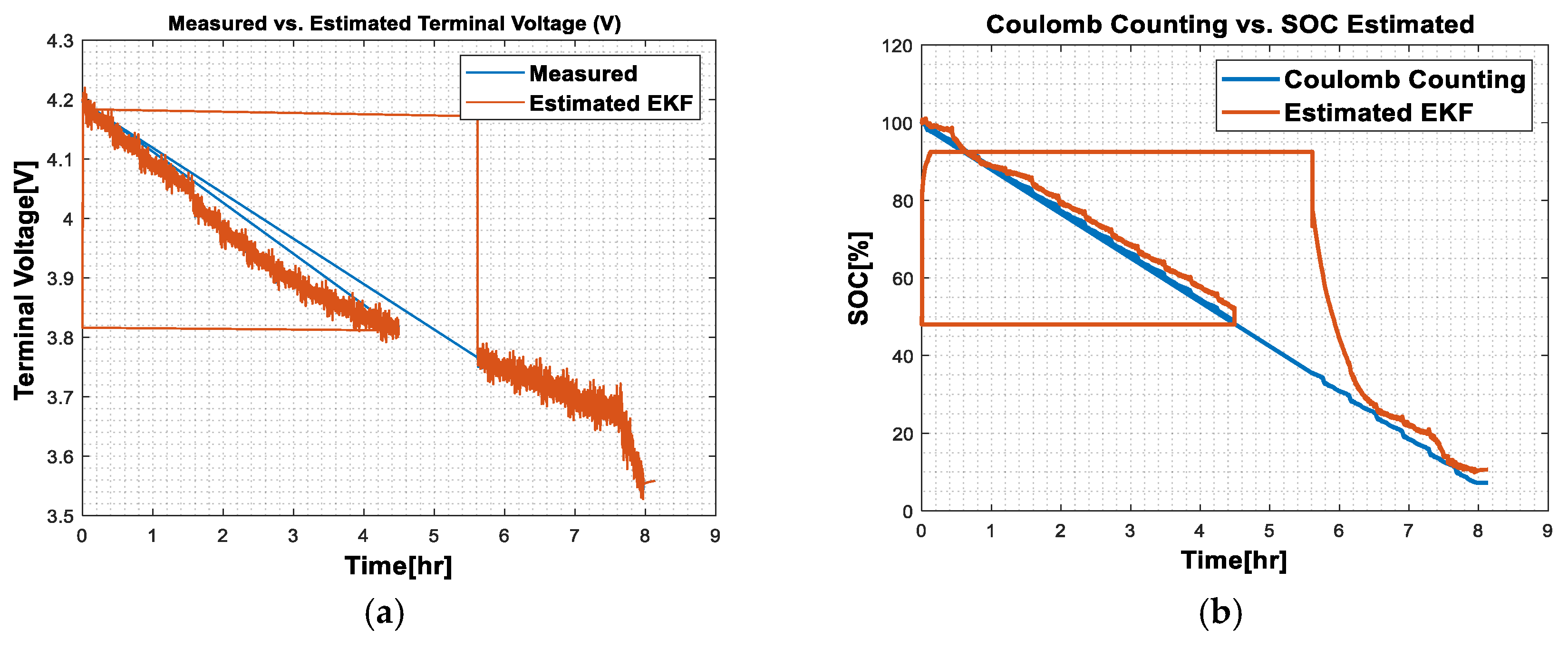

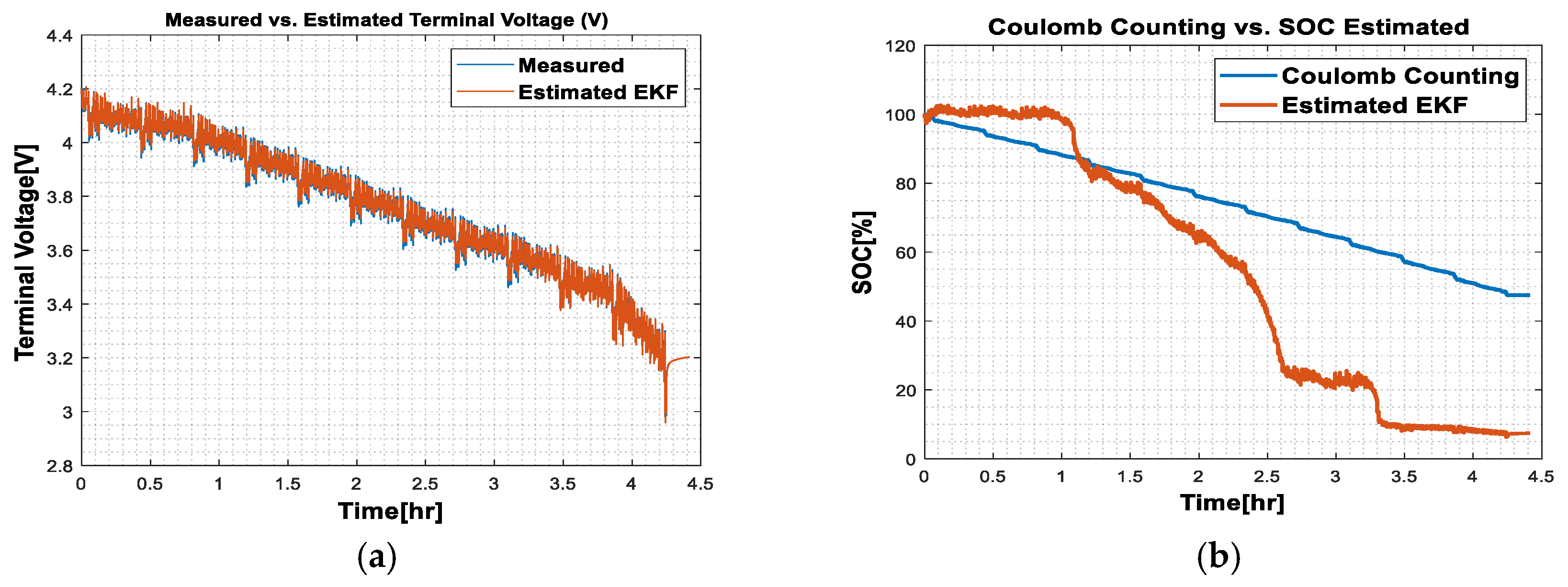

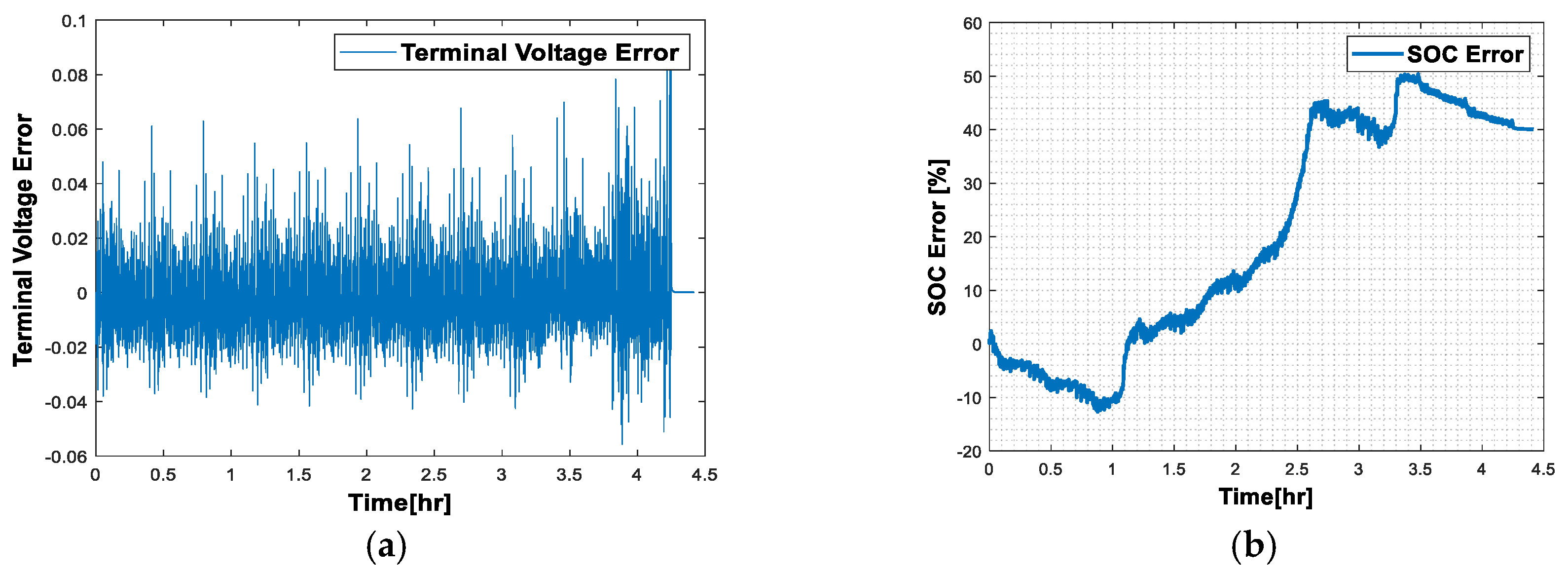

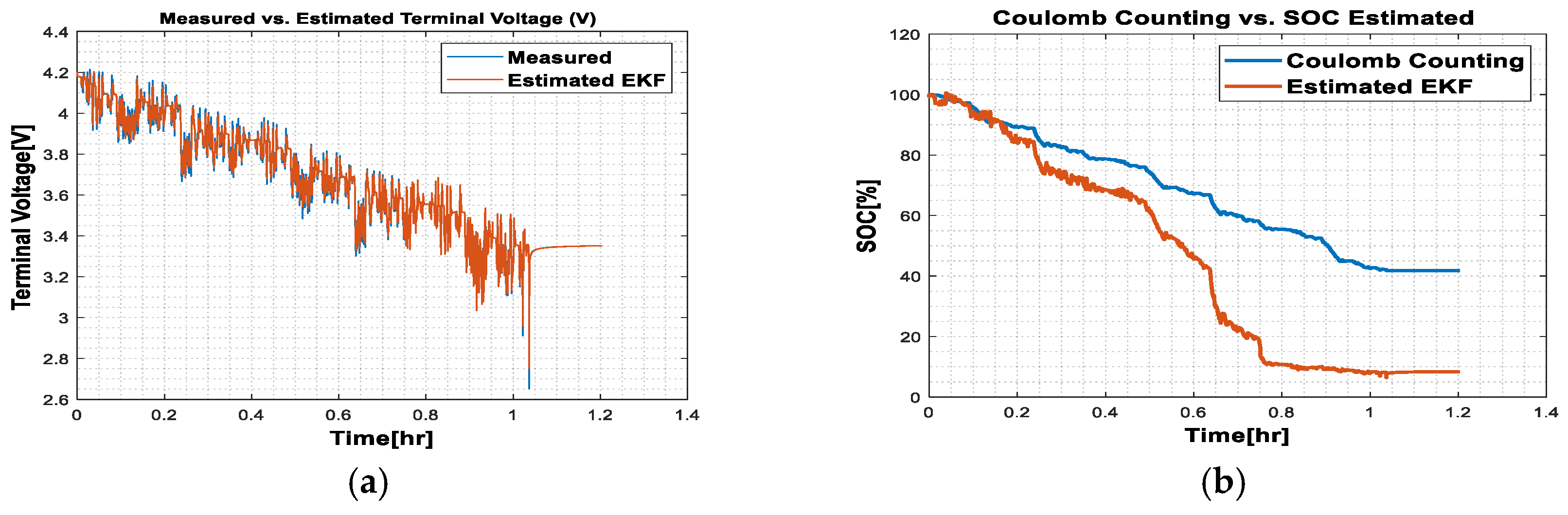

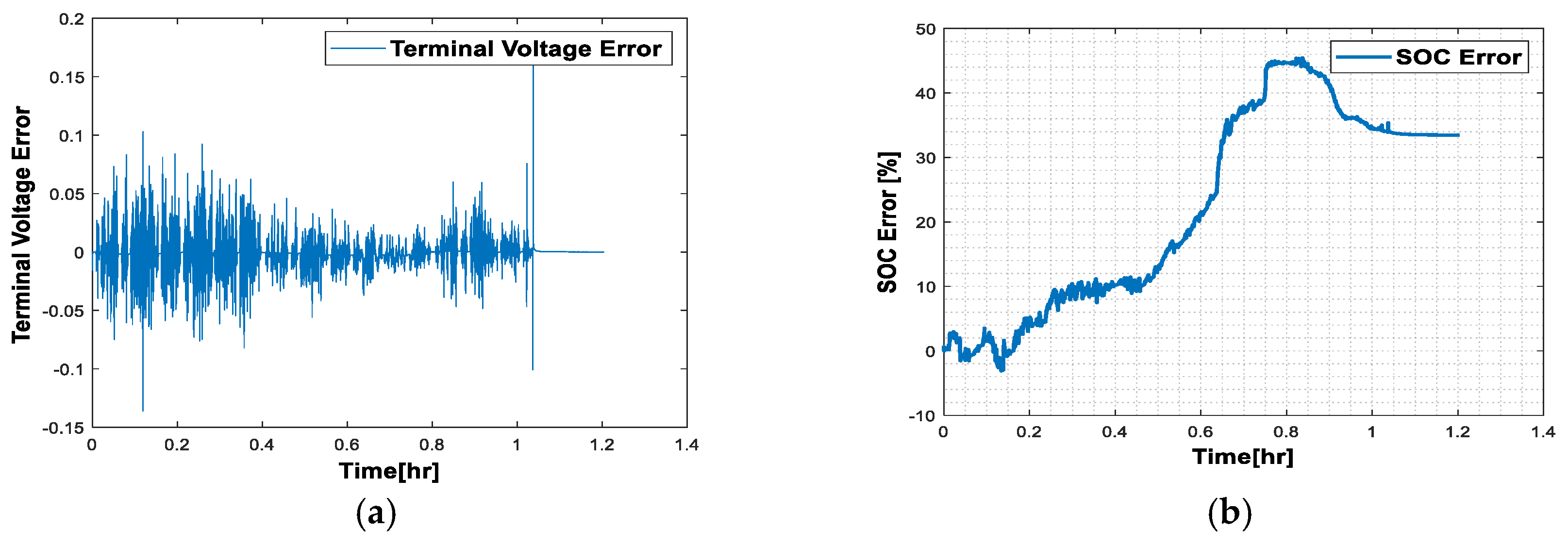

3.2. Results Obtained on the LG 18650HG2 Li-Ion Model

- (a)

- Ambient temperature at 40 °C

- (b) Ambient temperature at 25 °C

- Risk of Failure: Such a large deviation may indicate that the battery is at risk of failure. This may be due to a severely degraded battery or serious problems in the measurement system.

- Poor Energy Management: Significant errors in the SOC can lead to poor energy management. For example, the battery may be overcharged or discharged excessively, which can shorten its lifespan and affect overall system performance.

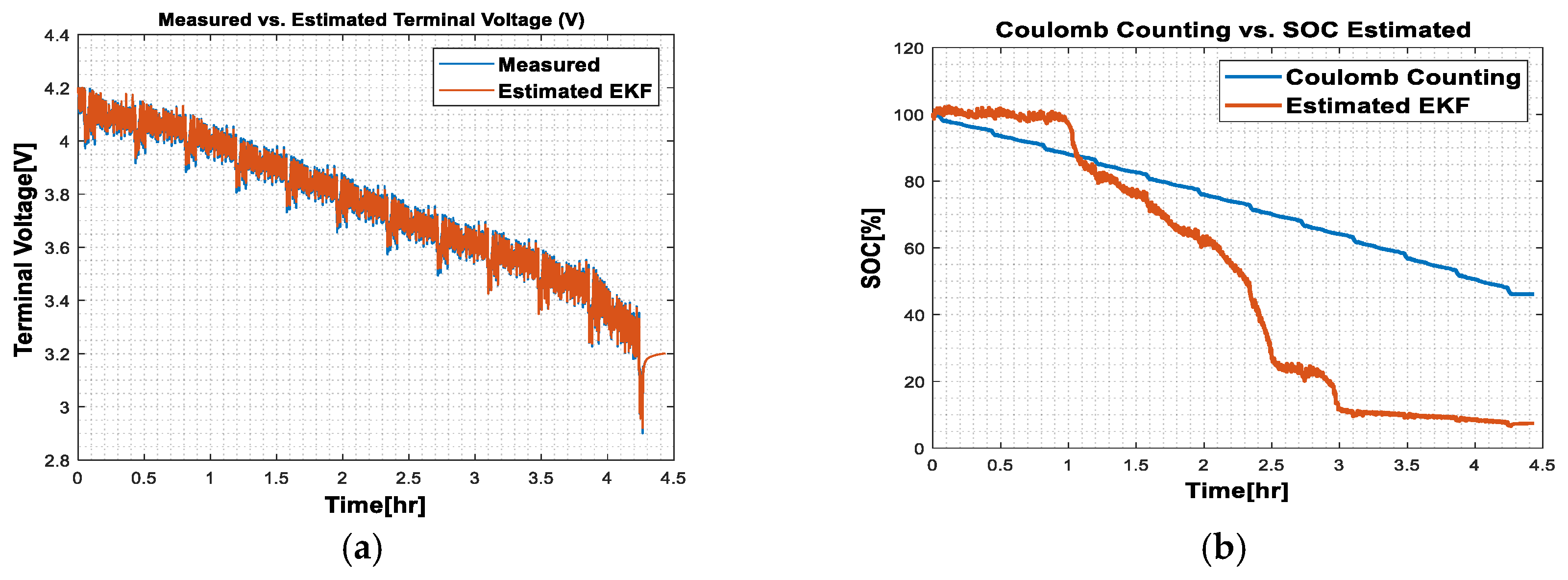

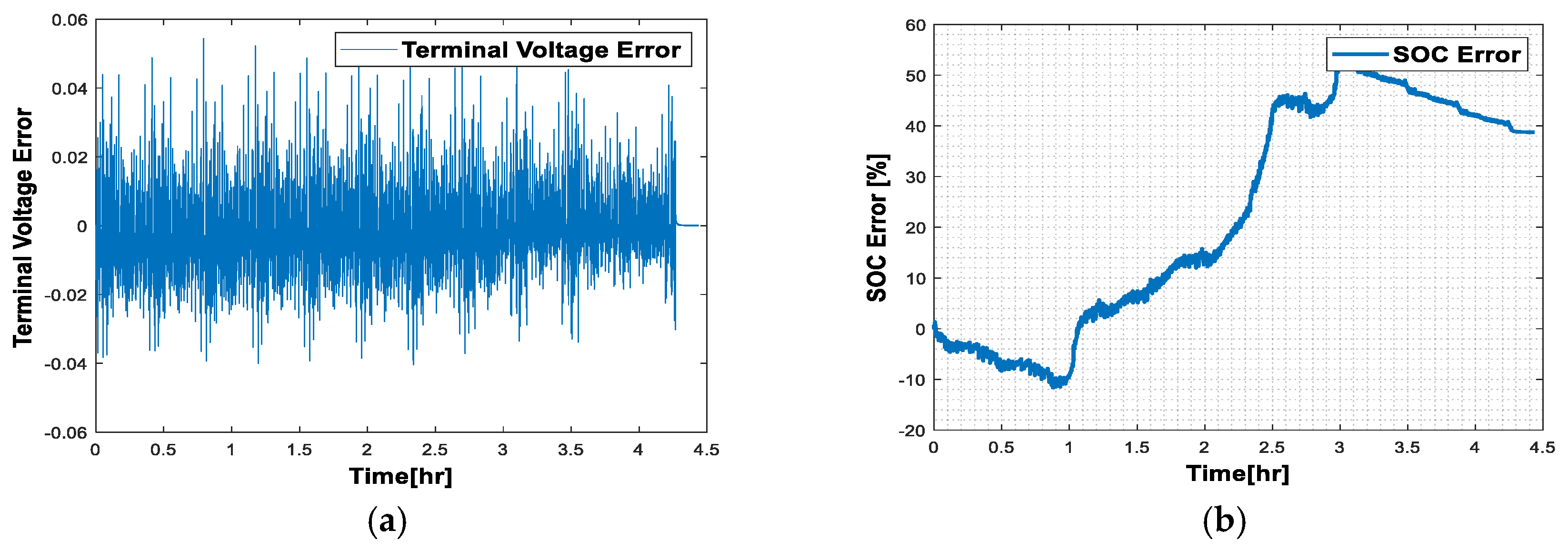

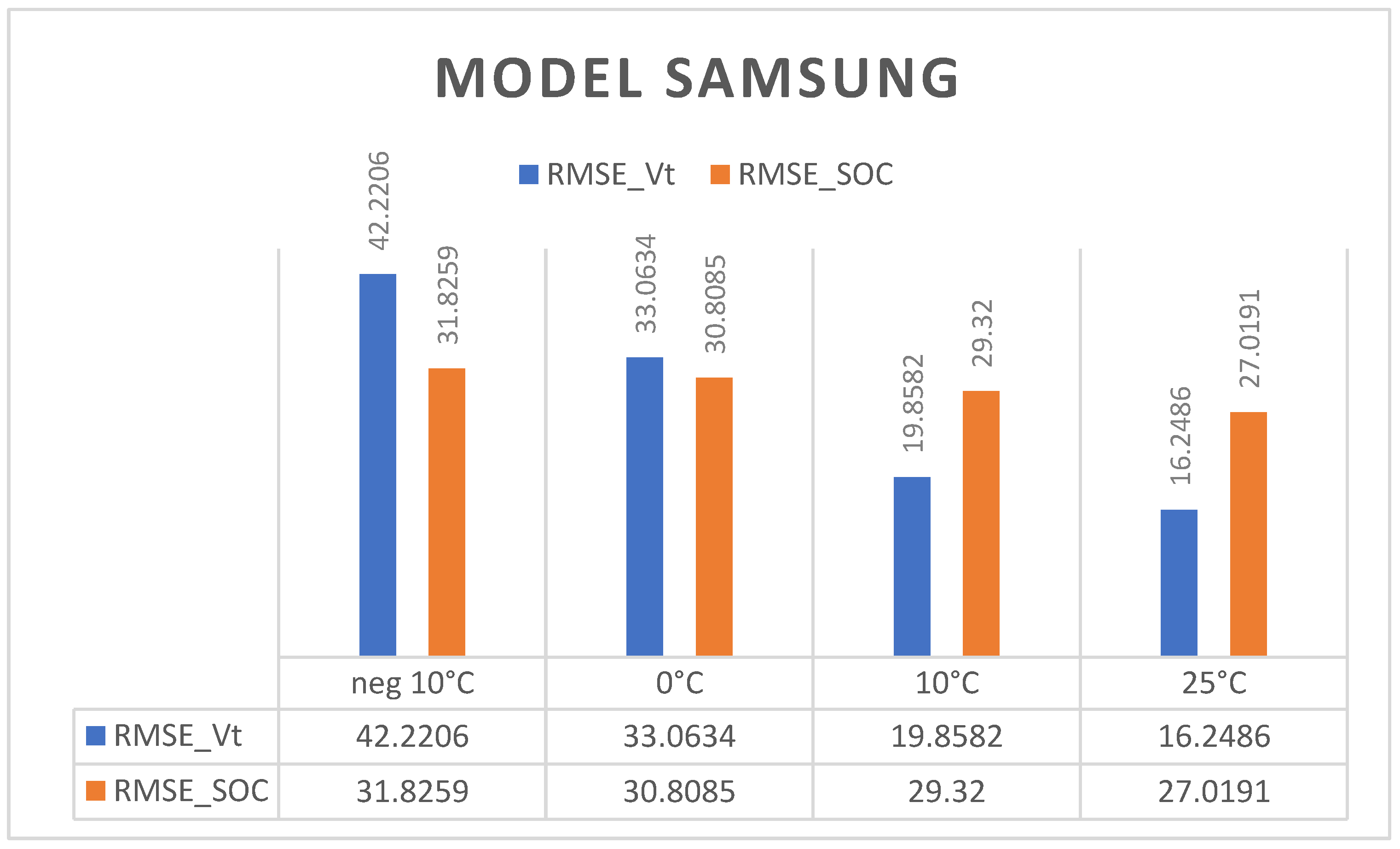

3.3. Results Obtained on the Samsung INR21700 30T Battery Model

- Ambient temperature at 25 °C

3.4. Results on Battery Model Panasonic 18650pf Li-Ion Battery

- Ambient temperature at 25 °C

3.5. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature/Abbreviations

| LAMPE | loss of a positive active ingredient |

| LAMNE | negative loss of active ingredient |

| GLPSO | the global average particle swarm optimization algorithm |

| FEK | Extended Kalman Filter |

| FAST | Technical System Analysis Function |

| EM | electrochemical model |

| ECM | equivalent circuit model |

| FEKA | adapted extended Kalman filter |

| MCR | recursive least squares method |

| EKF | extended kalman filter algorithm |

| AEKF | adaptive extended Kalman filter algorithm |

| RMSE | root mean square error |

| OCV | open circuit voltage |

| UDDS | urban dynamometer driving program |

| HWFET | energy saving test |

| NiCd | nickel-cadmium |

| KOH | potassium hydroxide |

| Ni-MH | Nickel Metal Hydride |

| Wh/l | volumetric energy density |

| Wh/kg | massive energy density |

| SOC | Charging status |

| SOH | Health status |

| LiMO2 | transition metal oxides |

| LiCoO2 | lithium cobalt oxide |

| NMC | the positive electrode |

| LFP | positive electrodes |

| LLI | loss of cycling lithium |

| LA92 | dynamometric test |

| US06 | aggressive driving |

| HPPC | high-performance primitive collection |

Appendix A

| Ref | Mathematical Equations | Constraints | Variable Designation |

|---|---|---|---|

| [15] | Life extension model = model parameters | The state vector is represented by X(t), the input vector is U(t), while the output vector is Y(t). The system parameters are defined by A, C and B. | |

| [25] | e(k) = z(k) − z (k|k − 1) S(k) = H(k)P(k|k − 1)H(k)T + R(k) K(k) = P(k|k − 1)H(k)TS(k) x(k|k) = x(k|k − 1) + K(k)e(k) P(k|k) = [I − K(k)H(k)]P(k|k − 1) | Residual capacity model = load variables | The measurement z(k), innovation e(k), predicted value Z(k|k − 1), the estimate of the state x(k|k), associated covariance matrix P(k|k) |

| [26] | − | Long-term estimation model = variables | K, the polarization constant expressed in V, Q the capacity of the battery expressed in Ah, A the amplitude of the exponential zone expressed in V, B a constant expressed in A-1h-1, it the current charge of the battery, E0 the constant voltage of the battery, |

| [29] | yk = E0 − Rik − Ki/SoC y = E0 − Rik + K2ln(SoC) + K4ln(1 − SoC) | Aging model = aging variables | E0 is the DC compensation; Rik is the internal resistance; ik is the current; Kx and the constants are used to adjust the curve |

| [18] | y(k) = θ(k)Tφ(k) K0 = P0(k) = [I − K0φ(k)T]P0(k − 1) | Impact of temperature = temperature | Vb: main branch voltage (V), Erno: open circuit voltage at full load (V), Ko: constant (V 1 °C); e: internal temperature (OK) RD: resistance at the battery terminals (n), Roo: constant resistance (n), |

| [19] | yk + 1 = Akyk + Bkuk + Γkξk; wk = Ckyk + Dkuk + ηk, xk + 1 = Akxk + Γkξk vk = Ckxk + ηk | Cycle optimization = charge cycles | yk is the n-state vector of the process. Ak is the (n,n)-deterministic state transition matrix, uk is the deterministic ordering m-vector, Bk is the deterministic (n,m)-matrix which connects the command uk to the state yk + 1, ξk is the p-vector of white noise, which models the error of the process, with a mean and a known (p,p)-covariance variance matrix Qk, Γk is the deterministic (n,p)-matrix which connects the white noise ξk to the state yk + 1, wk is the observation q-vector |

| [20] | E = E0 − k Q Q − it + Aexp (−B.it) | Experimental validation = experimental data | E is the no-load voltage (V) E0 is the constant battery voltage (V) K is the bias voltage (V) Q is the battery capacity (Ah) This is the current battery charge (Ah) A is the amplitude of the exponential zone (V) B is the inverse of the time constant of the exponential zone (Ah)-1. |

| [21] | = F(x,u) w y = G(x,u) v | Precision = comparative methods | X the SOC; w represents errors due to external disturbances as well as modeling errors, v represents the measurement errors. |

References

- Bockrath, S.; Lorentz, V.; Pruckner, M. State of health estimation of lithium-ion batteries with a temporal convolutional neural network using partial load profiles. Appl. Energy 2023, 329, 120307. [Google Scholar] [CrossRef]

- Zheng, L.; Zhu, J.; Lu, D.D.-C.; Wang, G.; He, T. Incremental capacity analysis and differential voltage analysis based state of charge and capacity estimation for lithium-ion batteries. Energy 2018, 150, 759–769. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, Z.; Wu, Y.; Yan, L.; Jiang, F.; Peng, J. An online hybrid estimation method for the core temperature of Lithium-ion battery with model noise compensation. Appl. Energy 2022, 327, 120037. [Google Scholar] [CrossRef]

- Sun, L.; Li, G.; You, F. Combined internal resistance and state-of-charge estimation of lithium-ion battery based on extended state observer. Renew. Sustain. Energy Rev. 2020, 131, 109994. [Google Scholar] [CrossRef]

- Gong, D.; Gao, Y.; Kou, Y.; Wang, Y. State of health estimation for lithium-ion battery based on energy features. Energy 2022, 257, 124812. [Google Scholar] [CrossRef]

- Yang, Y.; Bremner, S.; Menictas, C.; Kay, M. Battery energy storage system size determination in renewable energy systems: A review. Renew. Sustain. Energy Rev. 2018, 91, 109–125. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, Y.; Yang, F.; Peng, W. State of health estimation of lithium-ion battery with automatic feature extraction and self-attention learning mechanism. J. Power Sources 2023, 556, 232466. [Google Scholar] [CrossRef]

- Apostolou, D.; Xydis, G. A literature review on hydrogen refuelling stations and infrastructure. Current status and future prospects. Renew. Sustain. Energy Rev. 2019, 113, 109292. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.; Wang, S.; Xu, W.; Fan, Y.; Liu, Y. Joint dynamic strategy of Bayesian regularized back propagation neural network with strong robustness—Extended Kalman filtering for the battery state-of-charge prediction. Int. J. Electrochem. Sci. 2021, 16, 21118. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, C.; Han, F.; Zhang, F.; Zhou, D.; Xu, S.; Liu, H.; Li, X.; Liu, J. Improving the cycle stability of FeCl3-graphite intercalation compounds by polar Fe2O3 trapping in lithium-ion batteries. Nano Res. 2019, 12, 1836–1844. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, C.; Han, F.; Wang, F.; Zhang, F.; Shen, W.; Ye, C.; Li, X.; Liu, J. Towards high-volumetric performance of Na/Li-ion batteries: A better anode material with molybdenum pentachloride—Graphite intercalation compounds (MoCl5–GICs). J. Mater. Chem. A 2020, 8, 2430–2438. [Google Scholar] [CrossRef]

- Tong, J.; Xiao, X.; Liang, X.; von Solms, N.; Huo, F.; He, H.; Zhang, S. Insights into the solvation and dynamic behaviors of a lithium salt in organic- and ionic liquid-based electrolytes. Phys. Chem. Chem. Phys. 2019, 21, 19216–19225. [Google Scholar] [CrossRef]

- Tan, X.F.; McDonald, S.D.; Gu, Q.; Hu, Y.; Wang, L.; Matsumura, S.; Nishimura, T.; Nogita, K. Characterisation of lithium-ion battery anodes fabricated via in-situ Cu6Sn5 growth on a copper current collector. J. Power Sources 2019, 415, 50–61. [Google Scholar] [CrossRef]

- Philippe, B. Etude D’interfaces Électrode/Électrolyte Dans Des Batteries Li-ion par Spectroscopie Photoélectronique à Différentes Profondeurs. Ph.D. Thesis, Université de Pau et des Pays de l’Adour, Pau, France, 2013. [Google Scholar]

- Peng, J.; Luo, J.; He, H.; Lu, B. An improved state of charge estimation method based on cubature Kalman filter for lithium-ion batteries. Appl. Energy 2019, 253, 113520. [Google Scholar] [CrossRef]

- Pastor-Fernández, C.; Yu, T.F.; Widanage, W.D.; Marco, J. Critical review of non-invasive diagnosis techniques for quantification of degradation modes in lithium-ion batteries. Renew. Sustain. Energy Rev. 2019, 109, 138–159. [Google Scholar] [CrossRef]

- Mouodo, L.V.A.; Ali, A.-H.M.; Tamba, J.G.; Olivier, T.S.M. Comparison and classification of six reference currents extraction algorithms for harmonic compensation on a stochastic power network: Case of the TLC hybrid filter. Cogent Eng. 2022, 9, 2076322. [Google Scholar] [CrossRef]

- Chen, S.; Wen, H.; Wu, J.; Lei, W.; Hou, W.; Liu, W.; Xu, A.; Jiang, Y. Internet of Things Based Smart Grids Supported by Intelligent Edge Computing. IEEE Access 2019, 7, 74089–74102. [Google Scholar] [CrossRef]

- Chen, Z.P.; Wang, Q.T. The Application of UKF Algorithm for 18650-type Lithium Battery SOH Estimation. Appl. Mech. Mater. 2014, 519, 1079–1084. [Google Scholar] [CrossRef]

- Chen, Z.; Mi, C.C.; Fu, Y.; Xu, J.; Gong, X. Online battery state of health estimation based on Genetic Algorithm for electric and hybrid vehicle applications. J. Power Sources 2013, 240, 184–192. [Google Scholar] [CrossRef]

- Mouodo, L.V.A.; Ali, A.-H.M.; Mayi, O.T.S.; Tamba, J.G.; Axaopoulos, P. Recent Progress and Challenges of Algorithms for Reducing Power Losses and Optimal Reconfiguration of Voltage Profiles for Distribution Networks. Int. J. Electron. Commun. Eng. 2024, 11, 176–194. [Google Scholar] [CrossRef]

- Chikkannanavar, S.B.; Bernardi, D.M.; Liu, L. A review of blended cathode materials for use in Li-ion batteries. J. Power Sources 2014, 248, 91–100. [Google Scholar] [CrossRef]

- Cleary, B.; Duffy, A.; O’Connor, A.; Conlon, M.; Fthenakis, V.; Oconnor, A. Assessing the Economic Benefits of Compressed Air Energy Storage for Mitigating Wind Curtailment. IEEE Trans. Sustain. Energy 2015, 6, 1021–1028. [Google Scholar] [CrossRef]

- Cui, Y.; Zuo, P.; Du, C.; Gao, Y.; Yang, J.; Cheng, X.; Ma, Y.; Yin, G. State of health diagnosis model for lithium ion batteries based on real-time impedance and open circuit voltage parameters identification method. Energy 2018, 144, 647–656. [Google Scholar] [CrossRef]

- Xia, B.; Chen, C.; Tian, Y.; Wang, M.; Sun, W.; Xu, Z. State of charge estimation of lithium-ion batteries based on an improved parameter identification method. Energy 2015, 90, 1426–1434. [Google Scholar] [CrossRef]

- Ng, K.S.; Moo, C.-S.; Chen, Y.-P.; Hsieh, Y.-C. Enhanced coulomb counting method for estimating state-of-charge and state-of-health of lithium-ion batteries. Appl. Energy 2009, 86, 1506–1511. [Google Scholar] [CrossRef]

- Yang, N.; Zhang, X.; Li, G. State of charge estimation for pulse discharge of a LiFePO4 battery by a revised Ah counting. Electrochim. Acta 2015, 151, 63–71. [Google Scholar] [CrossRef]

- Yang, R.; Xiong, R.; He, H.; Mu, H.; Wang, C. A novel method on estimating the degradation and state of charge of lithium-ion batteries used for electrical vehicles. Appl. Energy 2017, 207, 336–345. [Google Scholar] [CrossRef]

- Mouodo, L.V.A.; Ali, A.-H.M.; Thierry, S.M.O.; Moteyo, A.D.; Tamba, J.G.; Axaopoulos, P. Comparison and classification of photovoltaic system architectures for limiting the impact of the partial shading phenomenon. Heliyon 2024, 10, e36670. [Google Scholar] [CrossRef]

- Yang, F.; Li, W.; Li, C.; Miao, Q. State-of-charge estimation of lithium-ion batteries based on gated recurrent neural network. Energy 2019, 175, 66–75. [Google Scholar] [CrossRef]

- Tang, X.; Gao, F.; Zou, C.; Yao, K.; Hu, W.; Wik, T. Load-responsive model switching estimation for state of charge of lithium-ion batteries. Appl. Energy 2019, 238, 423–434. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Gong, J. A multi-model probability SOC fusion estimation approach using an improved adaptive unscented Kalman filter technique. Energy 2017, 141, 1402–1415. [Google Scholar] [CrossRef]

- Shen, Y. Improved chaos genetic algorithm based state of charge determination for lithium batteries in electric vehicles. Energy 2018, 152, 576–585. [Google Scholar] [CrossRef]

- Zheng, F.; Xing, Y.; Jiang, J.; Sun, B.; Kim, J.; Pecht, M. Influence of different open circuit voltage tests on state of charge online estimation for lithium-ion batteries. Appl. Energy 2016, 183, 513–525. [Google Scholar] [CrossRef]

- Huang, F.; Ma, J.; Xia, H.; Huang, Y.; Zhao, L.; Su, S.; Kang, F.; He, Y.-B. Capacity Loss Mechanism of the Li4Ti5O12 Microsphere Anode of Lithium-Ion Batteries at High Tem-perature and Rate Cycling Conditions. ACS Appl. Mater. Interfaces 2019, 11, 37357–37364. [Google Scholar] [CrossRef]

- Dey, S.; Ayalew, B.; Pisu, P. Combined estimation of State-of-Charge and State-of-Health of Li-ion battery cells using SMO on electrochemical model. In Proceedings of the 2014 13th International Workshop on Variable Structure Systems (VSS), Nantes, France, 29 June–2 July 2014; pp. 1–6, ISSN 2158-3986. [Google Scholar]

- Dimitrov, R.S. The Paris Agreement on Climate Change: Behind Closed Doors. Glob. Environ. Politics 2016, 16, 1–11. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, X.; Duan, L.; Gong, Q.; Wang, Y.; Ao, X. A novel method for state of health estimation of lithium-ion batteries based on fractional-order differential voltage-capacity curve. Appl. Energy 2024, 377 Pt 2, 124404. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, S.; Li, W.; Miao, Q. State-of-charge estimation of lithium-ion batteries using LSTM and UKF. Energy 2020, 201, 117664. [Google Scholar] [CrossRef]

- Sheng, H.; Xiao, J. Electric vehicle state of charge estimation: Nonlinear correlation and fuzzy support vector machine. J. Power Sources 2015, 281, 131–137. [Google Scholar] [CrossRef]

- Zahid, T.; Xu, K.; Li, W.; Li, C.; Li, H. State of charge estimation for electric vehicle power battery using advanced machine learning algorithm under diversified drive cycles. Energy 2018, 162, 871–882. [Google Scholar] [CrossRef]

- Alsuwian, T.; Ansari, S.; Zainuri, M.A.A.M.; Ayob, A.; Hussain, A.; Lipu, M.H.; Alhawari, A.R.; Almawgani, A.; Almasabi, S.; Hindi, A.T. A review of expert hybrid and co-estimation techniques for SOH and RUL estimation in battery management system with electric vehicle application. Expert Syst. Appl. 2024, 246, 123123. [Google Scholar] [CrossRef]

- Ali, A.M.; Mouodo, L.V.A.; Patrice, N.N.T.; Tamba, J.G.; Axaopoulos, P. Simulation and Innovative Digital Modeling Approach for Improving the Dynamic Performances of HVDC MMC Systems: Case of an AVM-MMC Migration. Int. J. Electron. Commun. Eng. 2024, 11, 77–90. [Google Scholar] [CrossRef]

- Chemali, E.; Kollmeyer, P.J.; Preindl, M.; Emadi, A. State-of-charge estimation of Li-ion batteries using deep neural networks: A machine learning approach. J. Power Sources 2018, 400, 242–255. [Google Scholar] [CrossRef]

- Mouodo, L.V.A.; Ali, A.-H.M.; Tamba, J.G.; Olivier, T.S.M. Experimental Characterization of Reference Currents for Harmonic Compensation: Case of the TLC Hybrid Filter. Int. Rev. Electr. Eng. 2024, 19, 40. [Google Scholar] [CrossRef]

- Tian, Y.; Lai, R.; Li, X.; Xiang, L.; Tian, J. A combined method for state-of-charge estimation for lithium-ion batteries using a long short-term memory network and an adaptive cubature Kalman filter. Appl. Energy 2020, 265, 114789. [Google Scholar] [CrossRef]

- Cui, Z.; Dai, J.; Sun, J.; Li, D.; Wang, L.; Wang, K.; Pereira, A.M.B. Hybrid Methods Using Neural Network and Kalman Filter for the State of Charge Estimation of Lithium-Ion Battery. Math. Probl. Eng. 2022, 2022, 9616124. [Google Scholar] [CrossRef]

- Bian, C.; He, H.; Yang, S. Stacked bidirectional long short-term memory networks for state-of-charge estimation of lithium-ion batteries. Energy 2020, 191, 116538. [Google Scholar] [CrossRef]

- Tang, X.; Liu, B.; Lv, Z.; Gao, F. Observer based battery SOC estimation: Using multi-gain-switching approach. Appl. Energy 2017, 204, 1275–1283. [Google Scholar] [CrossRef]

- Dai, H.; Guo, P.; Wei, X.; Sun, Z.; Wang, J. ANFIS (adaptive neuro-fuzzy inference system) based online SOC (State of Charge) correction considering cell divergence for the EV (electric vehicle) traction batteries. Energy 2015, 80, 350–360. [Google Scholar] [CrossRef]

- Dong, X.; Zhang, C.; Jiang, J. Evaluation of SOC Estimation Method Based on EKF/AEKF under Noise Interference. Energy Procedia 2018, 152, 520–525. [Google Scholar] [CrossRef]

- Sun, D.; Yu, X.; Wang, C.; Zhang, C.; Huang, R.; Zhou, Q.; Amietszajew, T.; Bhagat, R. State of charge estimation for lithium-ion battery based on an Intelligent Adaptive Extended Kalman Filter with improved noise estimator. Energy 2021, 214, 119025. [Google Scholar] [CrossRef]

- Zhai, X.; Li, Z.; Li, Z.; Xue, Y.; Chang, X.; Su, J.; Jin, X.; Wang, P.; Sun, H. Risk-averse energy management for integrated electricity and heat systems considering building heating vertical imbalance: An asynchronous decentralized approach. Appl. Energy 2025, 383, 125271. [Google Scholar] [CrossRef]

- Ding, B.; Li, Z.; Li, Z.; Xue, Y.; Chang, X.; Su, J.; Sun, H. Cooperative Operation for Multiagent Energy Systems Integrated with Wind, Hydrogen, and Buildings: An Asymmetric Nash Bargaining Approach. IEEE Trans. Ind. Inform. 2025. [Google Scholar] [CrossRef]

- Guo, P.; Xu, Q.; Yue, Y.; Ma, F.; He, Z.; Luo, A.; Guerrero, J.M. Analysis and Control of Modular Multilevel Converter with Split Energy Storage for Railway Traction Power Conditioner. IEEE Trans. Power Electron. 2020, 35, 1239–1255. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.; Wang, M.; Yang, K.; Ge, Y.; Wang, K.; Lin, H.; Pan, P.; Hu, H.; He, Z.; et al. Multi-Timescale Reward-Based DRL Energy Management for Regenerative Braking Energy Storage System. IEEE Trans. Transp. Electrif. 2025, 11, 7488–7500. [Google Scholar] [CrossRef]

| Ref. | Themes | Dynamic Parameters | Benefits | Disadvantages |

|---|---|---|---|---|

| [42] | Optimization of the state of charge of lithium batteries with integration of the Kalman algorithm | State of charge, temperature, and current | 15% reduction in error during load state estimation | Sensitivity to temperature variations, which can affect the accuracy of the estimate |

| [43] | Mitigation of the influence of temperature on the state of charge of lithium batteries with the Kalman algorithm | Battery age, charge cycles, temperature | Reduced the impact of temperature on state of charge estimation by 25% | Need adjustments for extreme temperature ranges |

| [44] | Comparison of Kalman algorithms in the management of lithium batteries for electric vehicles | Voltage, current, temperature | Comparison of methods and superiority of the Kalman algorithm | Accumulated modeling complexity for nonlinear systems |

| [45] | Improvement of charging and discharging of lithium batteries with the Kalman algorithm | Charging and discharging strategies | Extended battery life by 25% | Need for in-depth studies on the long-term impact of charging and discharging strategies |

| [46] | Optimizing Battery Life Using the Kalman Filter Algorithm in Electric Vehicles | Battery internal resistance, state of charge, discharge power | Extended battery life by 20% | Need for additional experimental validations for various driving profiles |

| [47] | Superiority of Kalman Filter Algorithm in State of Charge Estimation Compared to Machine Learning Methods | Machine Learning based methods, comparison with the Kalman algorithm | Superiority of Kalman algorithm with 85% accuracy | Need for additional comparisons with nonlinear methods for comprehensive evaluation |

| [48] | Evaluation of residual capacity of lithium batteries under variable load using Kalman filter algorithm | Residual capacity, load variations | Accurate estimation of residual battery capacity | Need for additional data for varied load scenarios |

| [49] | Experimental study of the effectiveness of the Kalman filter algorithm for the management of lithium batteries in electric vehicles | Experimental validation, agreement with real data | Experimental confirmation of the effectiveness of the Kalman filter algorithm | Sensitivity to experimental conditions that may affect validation |

| [50] | Predicting battery aging using multivariable models with the Kalman Filter algorithm | Battery aging, temperature, and charging cycles | Accurate prediction of battery aging | Sensitivity to variations in load conditions for long-term predictions |

| [23] | Adaptive energy management with Kalman filter algorithm for electric vehicle batteries | Variable driving profiles, adaptation to conditions | Development of adaptive models for efficient energy management | Limited adaptability to sudden changes in driving conditions |

| [17] | Estimation of long-term state of charge in lithium batteries using Kalman filter algorithm | Estimated load, long-term data | 92% reliability in estimating the state of charge | Need for long-term studies to confirm reliability under various conditions |

| Input: Current, Vt_Actual, Temperature |

| 1. Load data: |

| load ‘BatteryModel.mat’; load ‘SOC-OCV.mat’; |

| 2. Initialization |

| SOC_Init = 1 X = [SOC_Init 0 0], % DeltaT = 1 Qn_rated = 4.81 ∗ 3600 |

| 3. Extrapolation of the OCV COCV = polyfit(SOC_OCV.SOC, SOC_OCV.OCV, 11) |

| 4. Parameter of EFK R, Q, P |

| n_x = size(X,1) R_x = 2.5 ∗ e−5 P_x = [0.025 0 0 0 0.01 0 0 0 0.01] Q_x = [1.0 ∗ e−6 0 0 0 1.0 ∗ e−5 0 0 0 1.0 ∗ e−5] |

| 5. Initialization of outputs SOC_Estimated = [] Vt_Estimated = [] Vt_Error = [] ik = length (Current) |

| 6. Kalman filter for k = 1:1:ik T = Temperature (k), % °C U = Current (k), % A SOC = X(1) V1 = X(2) V2 = X(3) 7. Evaluation of battery parameters using the least squares method R0 = F_R0(T, SOC) R1 = F_R1(T, SOC) R2 = F_R2(T, SOC) C1 = F_C1(T, SOC) C2 = F_C2(T, SOC) |

| 8. Determination of state matrices 9. State Equation: Covariance error: |

| Updated estimates |

| Covariance error update |

| Adaptive covariance law |

| End |

| Symbol | Value | Description |

|---|---|---|

| ||

| Capacity | 5000 mAh | Cell capacity |

| Temperature | −10 °C, 0 °C, 10 °C, 25 °C and 40 °C | Room temperature |

| Charging voltage | 4.2 V (5 mA) | |

| ||

| Capacity | 3 Ah | Cell capacity |

| Temperature | −10 °C, 0 °C, 10 °C, 25 °C and 40 °C | Room temperature |

| Charging voltage | 5 Volt | |

| ||

| Capacity | 2900 mAh | Cell capacity |

| Temperature | −10 °C, 0 °C, 10 °C, 25 °C | Room temperature |

| Charging voltage | 4.2 V (50 mA) | |

| ||

| Capacity | 3000 mAh | Cell capacity |

| Temperature | −10 °C, 0 °C, 10 °C, 25 °C and 40 °C | Room temperature |

| Charging voltage | 4.2 V (10 mA) | |

| Temperature | RMSE (SOC) | RMSE (OCV) |

|---|---|---|

| Turnigy graphene | ||

| 40 °C | 1.944 | 1.3154 |

| 25 °C | 9.6237 | 4.895 |

| 10 °C | 1.253 | 4.149 |

| 0 °C | 1.6963 | 4.1808 |

| −10 °C | 16.9715 | 17.2167 |

| LG | ||

| −10 °C | 15.3396 | 33.1543 |

| 25 °C | 31.4471 | 8.625 |

| 40 °C | 29.407 | 10.727 |

| SAMSUNG | ||

| −10 °C | 31.8259 | 42.2206 |

| 0 °C | 30.8085 | 33.0634 |

| 10 °C | 29.32 | 19.8582 |

| 25 °C | 27.0191 | 16.2486 |

| PANASONIC | ||

| −10 °C | 25.0162 | 206.7898 |

| 0 °C | 25.8778 | 415.1215 |

| 10 °C | 50.1941 | 338.5054 |

| 25 °C | 32.432 | 248.0957 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Assiene Mouodo, L.V.; Axaopoulos, P.J. Optimization and Estimation of the State of Charge of Lithium-Ion Batteries for Electric Vehicles. Energies 2025, 18, 3436. https://doi.org/10.3390/en18133436

Assiene Mouodo LV, Axaopoulos PJ. Optimization and Estimation of the State of Charge of Lithium-Ion Batteries for Electric Vehicles. Energies. 2025; 18(13):3436. https://doi.org/10.3390/en18133436

Chicago/Turabian StyleAssiene Mouodo, Luc Vivien, and Petros J. Axaopoulos. 2025. "Optimization and Estimation of the State of Charge of Lithium-Ion Batteries for Electric Vehicles" Energies 18, no. 13: 3436. https://doi.org/10.3390/en18133436

APA StyleAssiene Mouodo, L. V., & Axaopoulos, P. J. (2025). Optimization and Estimation of the State of Charge of Lithium-Ion Batteries for Electric Vehicles. Energies, 18(13), 3436. https://doi.org/10.3390/en18133436