Energy Efficiency and Sustainability of Additive Manufacturing as a Mass-Personalized Production Mode in Industry 5.0/6.0

Abstract

1. Introduction

1.1. Genesis of the Issue

1.2. Scientific and Economic Gaps

2. Materials and Methods

2.1. Dataset

2.2. Methods

- Item 3:justification,

- Item 4: objectives,

- Item 5: eligibility criteria,

- Item 6: information sources,

- Item 7: search strategy,

- Item 8: selection process,

- Item 9: data collection process,

- Item 13a: synthesis methods,

- Item 20b: synthesis results, and

- Item 23a: discussion.

3. Results

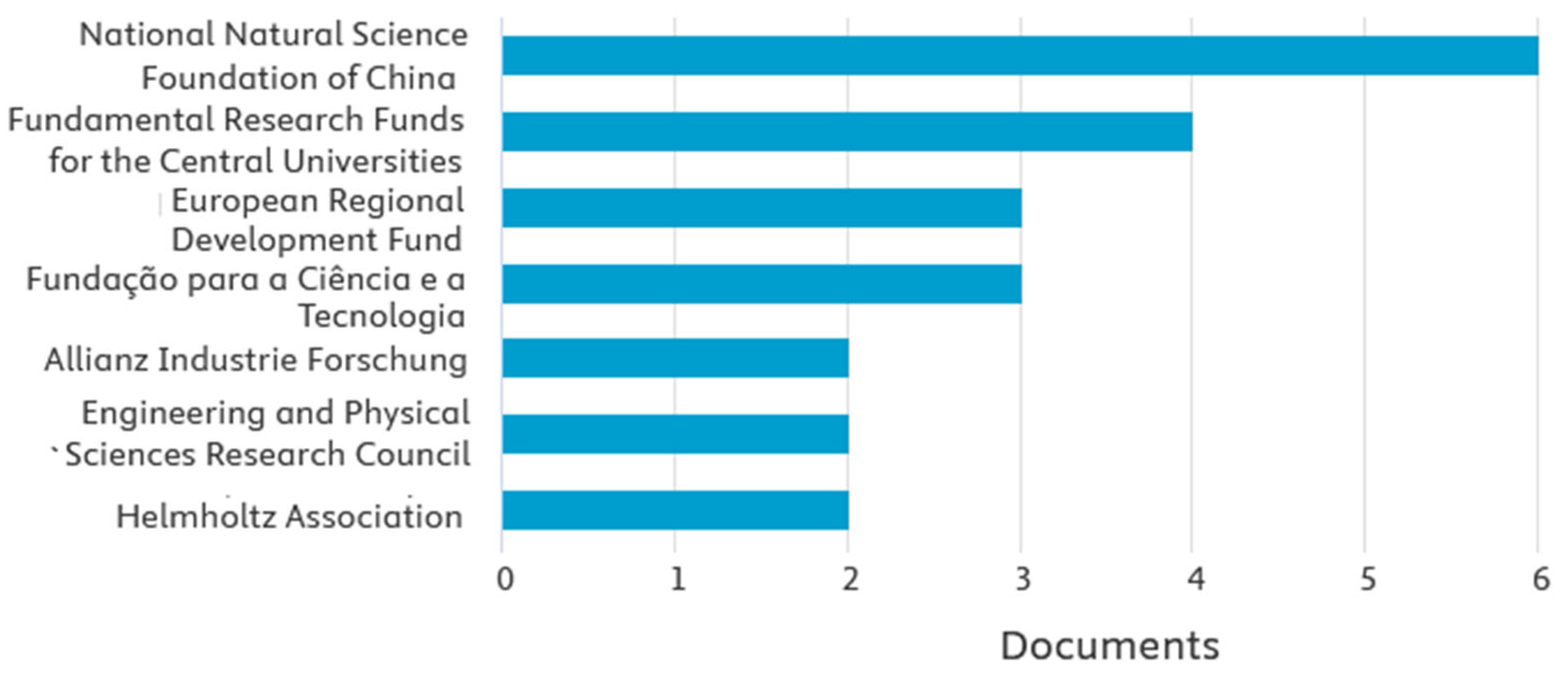

3.1. Data Sources

- In the WoS database, the “Subject” field (consisting of title, abstract, keywords plus and other keywords) was used;

- In the Scopus database, the article title, abstract and keywords were used;

- In PubMed and dblp databases: manual sets of keywords were used.

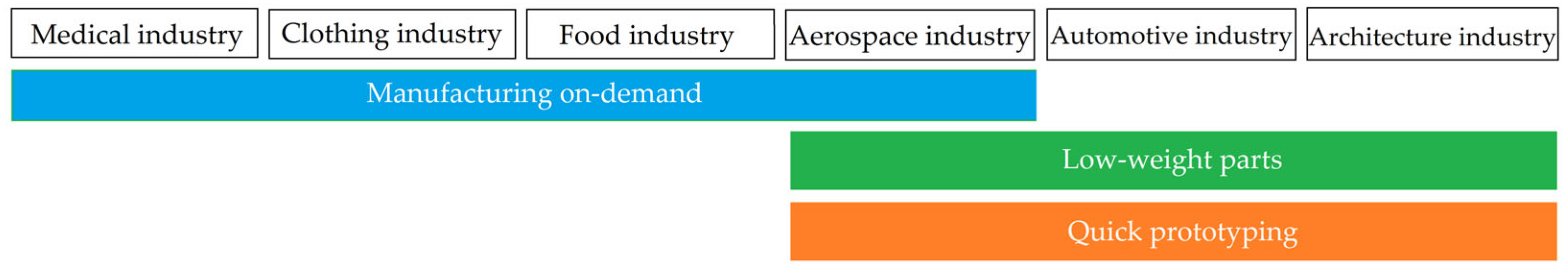

3.2. Role of 3D Printing as a Mass-Personalized Production Mode in Industry 5.0/6.0

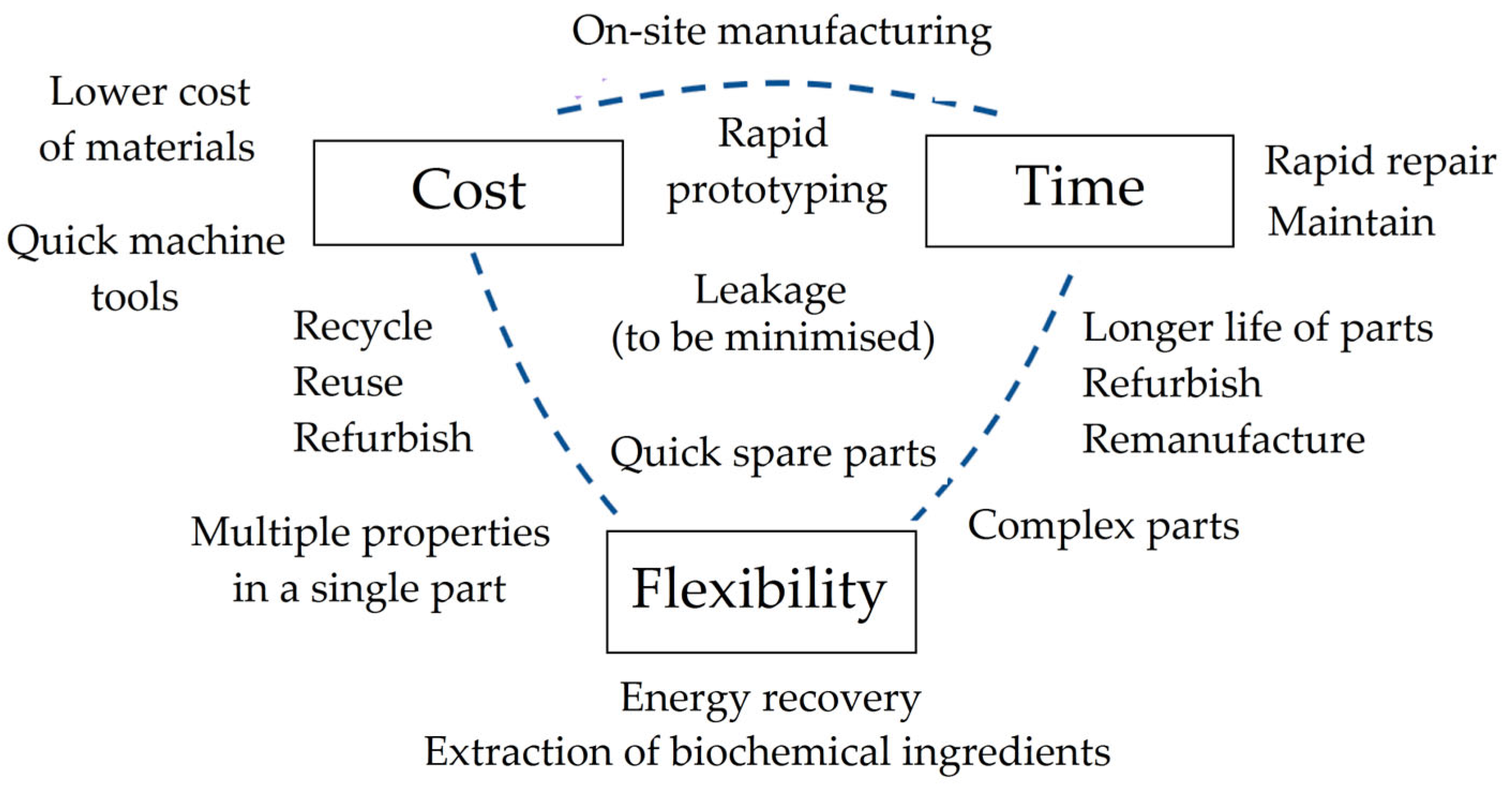

3.3. Circular Economy Enabling the Reuse of Materials and Local Repair/Remanufacturing

3.4. Balancing Personalization, Efficiency and Ecological Responsibility

3.5. Flexible, User-Centric Ecosystem

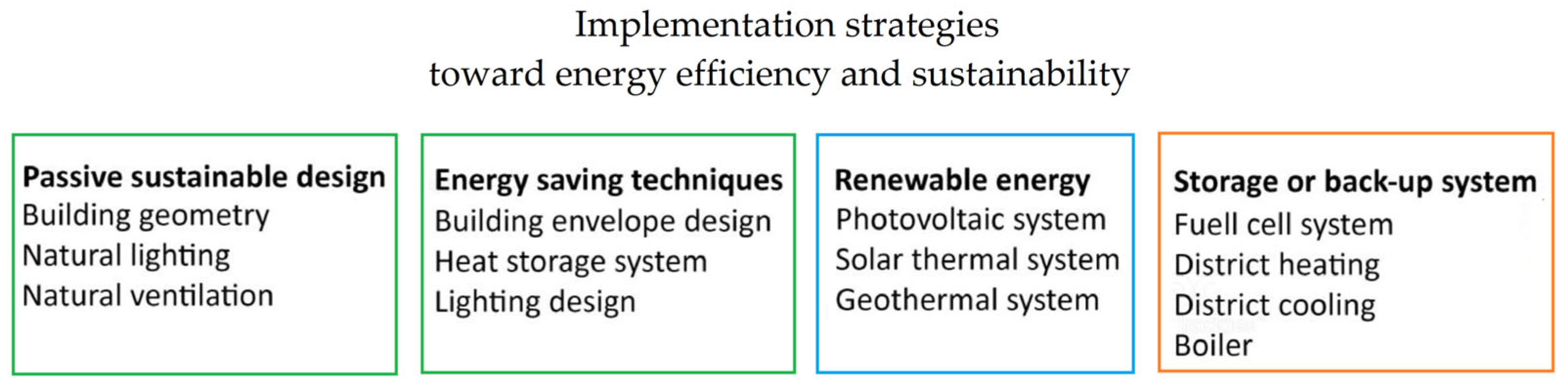

3.6. Energy Efficiency

4. Discussion

4.1. Scientific Consequences of Achievement

4.2. Economic Consequences of Achievement

4.3. Societal Consequences of Achievement

4.4. Limitations

4.5. Directions of Further Research

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3D | Three dimensional |

| AI | Artificial intelligence |

| AM | Additive manufacturing |

| FDM | Fused deposition modeling |

| LCA | Life-cycle assessment |

| SLA | Stereolithography |

| SLS | Selective laser sintering |

References

- Różycki, R.; Solarska, D.A.; Waligóra, G. Energy-Aware Machine Learning Models—A Review of Recent Techniques and Perspectives. Energies 2025, 18, 2810. [Google Scholar] [CrossRef]

- Kumar, U.; Kumar, R.; Singh, M.; Singh, H.; Singh, R.; Chabra, R. A critical review on history of industrial revolutions. AIP Conf. Proc. 2025, 3185, 020097. [Google Scholar]

- Madsen, D.O.; Slatten, K.; Berg, T. From Industry 4.0 to Industry 6.0: Tracing the evolution of industrial paradigms through the lens of management fashion theory. Systems 2025, 13, 387. [Google Scholar] [CrossRef]

- Ray, S.; Bhattacharyya, S. Roadmap for heathcare transformation: Leveraging Industry 6.0. In Exploration of Transformative Technologies in Healthcare 6.0; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 1–3. [Google Scholar]

- Machado, C.; da Silva Nogueira, C. Industry 6.0: Why talk about it now? In From Industry 4.0 to Industry 6.0; John Wiley & Sons: Hoboken, NJ, USA, 2025; pp. 291–305. [Google Scholar]

- Kuwar, V.; Sonavaney, V.; Shankar, U.; Yadav, A.; Radhakrishnan, V.; Upreti, K.; Gupta, K.; Jain, R. Workforce transformation and value creation in the era of Industry 4.0, 5.0 and 6.0: Challenges and enablers. Int. J. Basic Appl. Sci. 2025, 14, 314–324. [Google Scholar] [CrossRef]

- Rojek, I.; Dostatni, E.; Mikołajewski, D.; Pawłowski, L.; Wegrzyn-Wolska, K. Modern approach to sustainable production in the context of Industry 4.0. Bulletion Pol. Acad. Sci. Tech. Sci. 2022, 70, e143828. [Google Scholar] [CrossRef]

- González-Torres, M.; Pérez-Lombard, L.; Coronel, J.F.; Maestre, I.R.; Bertoldi, P. Activity and efficiency trends for the residential sector across countries. Energy Build. 2022, 273, 112428. [Google Scholar] [CrossRef]

- Wu, C.J.; Raghavendra, R.; Gupta, U.; Acun, B.; Ardalani, N.; Maeng, K.; Hazelwood, K. Sustainable AI: Environmental implications, challenges and opportunities. Proc. Mach. Learn. Syst. 2022, 4, 795–813. [Google Scholar]

- Rojek, I.; Mikołajewski, D.; Kotlarz, P.; Tyburek, K.; Kopowski, J.; Dostatni, E. Traditional Artificial Neural Networks Versus Deep Learning in Optimization of Material Aspects of 3D Printing. Materials 2021, 14, 7625. [Google Scholar] [CrossRef]

- Rojek, I.; Dostatni, E. Machine learning methods for optimal compatibility of materials in ecodesign. Bull. Pol. Acad. Sci.-Tech. Sci. 2020, 68, 199–206. [Google Scholar] [CrossRef]

- Stryczewska, H.D.; Boiko, O.; Stępień, M.A.; Lasek, P.; Yamazato, M.; Higa, A. Selected Materials and Technologies for Electrical Energy Sector. Energies 2023, 16, 4543. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Kopowski, J. Specificity of 3D Printing and AI-Based Optimization of Medical Devices Using the Example of a Group of Exoskeletons. Appl. Sci. 2023, 13, 1060. [Google Scholar] [CrossRef]

- Samudrala, M.; Mujeeb, S.; Lanjewar, B.A.; Chippagiri, R.; Kamath, M.; Ralegaonkar, R.V. 3D-Printable Concrete for Energy-Efficient Buildings. Energies 2023, 16, 4234. [Google Scholar] [CrossRef]

- Mujeeb, S.; Samudrala, M.; Lanjewar, B.A.; Chippagiri, R.; Kamath, M.; Ralegaonkar, R.V. Development of Alkali-Activated 3D Printable Concrete: A Review. Energies 2023, 16, 4181. [Google Scholar] [CrossRef]

- Nemova, D.; Kotov, E.; Andreeva, D.; Khorobrov, S.; Olshevskiy, V.; Vasileva, I.; Zaborova, D.; Musorina, T. Experimental Study on the Thermal Performance of 3D-Printed Enclosing Structures. Energies 2022, 15, 4230. [Google Scholar] [CrossRef]

- Budzik, G.; Tomaszewski, K.; Soboń, A. Opportunities for the Application of 3D Printing in the Critical Infrastructure System. Energies 2022, 15, 1656. [Google Scholar] [CrossRef]

- Liu, B.; Wang, F. The Impact of the Global Digital Economy on Carbon Emissions: A Review. Sustainability 2025, 17, 5044. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, N.; Wang, S.; Dong, J.; Pan, X. Spatiotemporal Evolution and Influencing Factors of Carbon Emission Efficiency in Western Valley Cities in China. Sustainability 2025, 17, 5025. [Google Scholar] [CrossRef]

- Xia, W.; Geng, Y.; Zhao, C.; Tao, M.; Qiu, X. Towards Sustainable Minerals for Energy Transition: LCA Insights from an Open-Pit Molybdenum–Copper Mine. Sustainability 2025, 17, 4849. [Google Scholar] [CrossRef]

- Jamil, U.; Pearce, J.M. Regenerative Agrivoltaics: Integrating Photovoltaics and Regenerative Agriculture for Sustainable Food and Energy Systems. Sustainability 2025, 17, 4799. [Google Scholar] [CrossRef]

- Pimenow, S.; Pimenowa, O.; Prus, P.; Niklas, A. The Impact of Artificial Intelligence on the Sustainability of Regional Ecosystems: Current Challenges and Future Prospects. Sustainability 2025, 17, 4795. [Google Scholar] [CrossRef]

- Kim, T.G.; Shim, D.S.; Shin, D.Y.; Lee, K.J. Effect of building direction on mechanical and microstructural characterization of 630 stainless steel fabricated by combination of metal additive manufacturing techniques (Powder bed fusion and directed energy deposition). J. Manuf. Process. 2025, 149, 179–197. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Manalo, A.; Alajarmeh, O.; Sorbello, C.D.; Weerakoon, S.; Ngo, T.D.; Benmokrane, B. Advancing polymer composites in civil infrastructure through 3D printing. Autom. Constr. 2025, 177, 106311. [Google Scholar] [CrossRef]

- Pandey, P.K.; Pandey, P.K.; Mahajan, S.; Paul, J.; Iyer, S. Digital Twin and Virtual Reality, Augmented Reality, and Mixed Reality. In Digital Twins for Smart Cities and Villages; Elsevier: Amsterdam, The Netherlands, 2024. [Google Scholar]

- Pimenow, S.; Pimenowa, O.; Prus, P. Challenges of Artificial Intelligence Development in the Context of Energy Consumption and Impact on Climate Change. Energies 2024, 17, 5965. [Google Scholar] [CrossRef]

- Zhou, G.; Zhou, L. Ecological meteorology: Origin, concept, and prospects. KexueTongbao/Chin. Sci. Bull. 2021, 66, 210–218. [Google Scholar] [CrossRef]

- Zhou, B.; Zhu, Y.; Yu, H.; Xu, J. Current state, critical review and future prospects of research on tourism ecological security. ShengtaiXuebao 2025, 45, 1049–1058. [Google Scholar]

- Mainar-Toledo, M.D.; González García, I.; Leiva, H.; Fraser, J.; Persson, D.; Parker, T. Environmental and Economic Benefits of Waste Heat Recovery as a Symbiotic Scenario in Sweden. Energies 2025, 18, 1636. [Google Scholar] [CrossRef]

- Mariutti, E. The Limits of the Current Consensus Regarding the Carbon Footprint of Photovoltaic Modules Manufactured in China: A Review and Case Study. Energies 2025, 18, 1178. [Google Scholar] [CrossRef]

- Magazzino, C.; Gattone, T.; Usman, M.; Valente, D. Unleashing the power of innovation and sustainability: Transforming cereal production in the BRICS countries. Ecol. Indic. 2024, 167, 112618. [Google Scholar] [CrossRef]

- Moldavan, L.; Pimenowa, O.; Prus, P.; Pimenow, S. Pollution Problems in the Economic Agricultural Sector: Evaluating the Impact on Natural Resources and Solutions for Improvement. Sustainability 2024, 16, 11294. [Google Scholar] [CrossRef]

- Chiloane, C.; Dube, T.; Shoko, C. Impacts of groundwater and climate variability on terrestrial groundwater dependent ecosystems: A review of geospatial assessment approaches and challenges and possible future research directions. Geocarto Int. 2022, 37, 6755–6779. [Google Scholar] [CrossRef]

- Shahid, M.S.B.; Rifat, H.R.; Uddin, M.A.; Islam, M.M.; Mahmud, M.Z.; Sakib, M.K.H.; Roy, A. Hypertuning-Based Ensemble Machine Learning Approach for Real-Time Water Quality Monitoring and Prediction. Appl. Sci. 2024, 14, 8622. [Google Scholar] [CrossRef]

- Gbashi, S.; Njobeh, P.B. Enhancing Food Integrity through Artificial Intelligence and Machine Learning: A Comprehensive Review. Appl. Sci. 2024, 14, 3421. [Google Scholar] [CrossRef]

- Bumanis, N.; Kviesis, A.; Paura, L.; Arhipova, I.; Adjutovs, M. Hen Egg Production Forecasting: Capabilities of Machine Learning Models in Scenarios with Limited Data Sets. Appl. Sci. 2023, 13, 7607. [Google Scholar] [CrossRef]

- Zhu, Y.; Lu, L.; Li, Z.; Wang, S.; Yao, Y.; Wu, W.; Pandey, R.; Tariq, A.; Luo, K.; Li, Q. Monitoring Land Use Changes in the Yellow River Delta Using Multi-Temporal Remote Sensing Data and Machine Learning from 2000 to 2020. Remote Sens. 2024, 16, 1946. [Google Scholar] [CrossRef]

- Feng, K.; Mao, D.; Zhen, J.; Pu, H.; Yan, H.; Wang, M.; Wang, D.; Xiang, H.; Ren, Y.; Luo, L.; et al. Potential of Sample Migration and Explainable Machine Learning Model for Monitoring Spatiotemporal Changes of Wetland Plant Communities. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2024, 17, 9894–9906. [Google Scholar] [CrossRef]

- Morshed, M.M.; Fattah, M.A.; Morshed, S.R.; Sydunnaher, S. Assessment and prediction of mega-infrastructure projects on rural ecosystems using machine learning algorithms. Environ. Dev. Sustain. 2024. [Google Scholar] [CrossRef]

- Habeeb, H.N.; Mustafa, Y.T. Deep learning approaches for estimating forest vegetation cover and exploring influential ecosystem factors. Earth Sci. Inform. 2024, 17, 3379–3396. [Google Scholar] [CrossRef]

- Matyukira, C.; Mhangara, P. Land Cover and Landscape Structural Changes Using Extreme Gradient Boosting Random Forest and Fragmentation Analysis. Remote Sens. 2023, 15, 5520. [Google Scholar] [CrossRef]

- Cheng, X. A Review of Empirical Studies of Cultural Ecosystem Services in National Parks: Current Status and Future Research. Land 2023, 12, 1912. [Google Scholar] [CrossRef]

- Zhang, P.; Li, H. Sustainable Transformation Paths for Value Realization of Eco-Products Empowered by New Quality Productivity: Based on Provincial Panel Data in China. Sustainability 2025, 17, 4773. [Google Scholar] [CrossRef]

- Oswald, F.; Alavi-Borazjani, S.A.; Adams, M.; Alves, F.L. Too Much of a Good Thing? Navigating the Abundance of E&S Metrics in Ports’ Sustainability. Sustainability 2025, 17, 4743. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J. Personalised Production in the Age of Circular Additive Manufacturing. Appl. Sci. 2023, 13, 4912. [Google Scholar] [CrossRef]

- Aheleroff, S.; Philip, R.; Zhong, R.Y.; Xu, X. The Degree of Mass Personalisation under Industry 4. 0. Procedia CIRP 2019, 81, 1394–1399. [Google Scholar] [CrossRef]

- Benitez, G.B.; Ayala, N.F.; Frank, A.G. Industry 4.0 innovation ecosystems: An evolutionary perspective on value cocreation. Int. J. Prod. Econ. 2020, 228, 107735. [Google Scholar] [CrossRef]

- Hsiao, W.P.; Chiu, M.C. A mass personalization methodology based on co-creation. In Moving Integrated Product Development to Service Clouds in the Global Economy; Ios Press: Amsterdam, The Netherlands, 2014; pp. 698–705. [Google Scholar]

- Prendeville, S.; Bocken, N. Sustainable Business Models through Service Design. Procedia Manuf. 2017, 8, 292–299. [Google Scholar] [CrossRef]

- Mandolfo, M.; Chen, S.; Noci, G. Co-creation in new product development: Which drivers of consumer participation? Int. J. Eng. Bus. Manag. 2020, 12, 1847979020913764. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, J.; Gou, H.; Tan, J. A Research Review on the Key Technologies of Intelligent Design for Customized Products. Engineering 2017, 3, 631–640. [Google Scholar] [CrossRef]

- Liu, Z.; Ming, X.; Song, W.; Qiu, S.; Qu, Y. A perspective on value co-creation-oriented framework for smart product-service system. Procedia CIRP 2018, 73, 155–160. [Google Scholar] [CrossRef]

- Chang, C.-H. Do green motives influence green product innovation? The mediating role of green value co-creation. Corp. Soc. Responsib. Environ. Manag. 2018, 26, 330–340. [Google Scholar] [CrossRef]

- Roberts, D.L.; Palmer, R.; Hughes, M. Innovating the product innovation process to enable co-creation. RD Manag. 2022, 52, 484–497. [Google Scholar] [CrossRef]

- Biswas, M.C.; Chakraborty, S.; Bhattacharjee, A.; Mohammed, Z. 4D Printing of Shape Memory Materials for Textiles: Mechanism, Mathematical Modeling, and Challenges. Adv. Funct. Mater. 2021, 31, 2100257. [Google Scholar] [CrossRef]

- Ingemarsdotter, E.; Jamsin, E.; Balkenende, R. Opportunities and challenges in IoT-enabled circular business model implementation—A case study. Resour. Conserv. Recycl. 2020, 162, 105047. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast. Soc. Chang. 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Trenfield, S.J.; Awad, A.; Goyanes, A.; Gaisford, S.; Basit, A.W. 3D Printing Pharmaceuticals: Drug Development to Frontline Care. Trends Pharmacol. Sci. 2018, 39, 440–451. [Google Scholar] [CrossRef]

- Garrido, J.; Silva, D.; Portela, B.; Lekube, B. Integrated User-Oriented Service for 3D Printing Environments with Recycled Material from Maritime Plastic Waste. Appl. Sci. 2021, 11, 3787. [Google Scholar] [CrossRef]

- Ramírez-Escamilla, H.G.; Martínez-Rodríguez, M.C.; Padilla-Rivera, A.; Domínguez-Solís, D.; Campos-Villegas, L.E. Advancing Toward Sustainability: A Systematic Review of Circular Economy Strategies in the Textile Industry. Recycling 2024, 9, 95. [Google Scholar] [CrossRef]

- Li, W.C.; Tse, H.F.; Fok, L. Plastic waste in the marine environment: A review of sources, occurrence and effects. Sci. Total Environ. 2016, 566–567, 333–349. [Google Scholar] [CrossRef]

- Nisa, H.; Van Amber, R.; English, J.; Islam, S.; McCorkill, G.; Alavi, A. A Systematic Review of Reimagining Fashion and Textiles Sustainability with AI: A Circular Economy Approach. Appl. Sci. 2025, 15, 5691. [Google Scholar] [CrossRef]

- Perez-Garcia, S.; Gonzalez-Gaya, C.; Sebastian, M.A. Enhancing Asset Reliability and Sustainability: A Comparative Study of Neural Networks and ARIMAX in Predictive Maintenance. Appl. Sci. 2025, 15, 5266. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M.; Gola, A. Maintenance 4.0 technologies for sustainable manufacturing-an overview. IFAC-PapersOnLine 2019, 52, 91–96. [Google Scholar] [CrossRef]

- Tiddens, W.; Braaksma, J.; Tinga, T. Exploring predictive maintenance applications in industry. J. Qual. Maint. Eng. 2022, 28, 68–85. [Google Scholar] [CrossRef]

- Uusitalo, T.; Rana, P.; Granados, M.H.; Macchi, M. Sustainable manufacturing: Challenges, approaches and a roadmap. In Value Networks in Manufacturing: Sustainability and Performance Excellence; Springer: Cham, Switzerland, 2017; pp. 27–41. [Google Scholar]

- Peças, P.; Encarnação, J.; Gambôa, M.; Sampayo, M.; Jorge, D. Pdca 4.0: A new conceptual approach for continuous improvement in the industry 4.0 paradigm. Appl. Sci. 2021, 11, 7671. [Google Scholar] [CrossRef]

- Ahmed, S.; Nielsen, I.E.; Tripathi, A.; Siddiqui, S.; Ramachandran, R.P.; Rasool, G. Transformers in time-series analysis: A tutorial. Circuits Syst. Signal Process. 2023, 42, 7433–7466. [Google Scholar] [CrossRef]

- van Wijk, A.; van Wijk, I. 3D Printing with Biometerials. Towards a Sustainable and Circular Economy; TU Delft: Delft, The Netherlands, 2015. [Google Scholar]

- Dams, B.; Chen, B.; Shepherd, P.; Ball, R.J. Development of Cementitious Mortars for Aerial Additive Manufacturing. Appl. Sci. 2023, 13, 641. [Google Scholar] [CrossRef]

- Bănică, C.-F.; Sover, A.; Anghel, D.-C. Printing the Future Layer by Layer: A Comprehensive Exploration of Additive Manufacturing in the Era of Industry 4.0. Appl. Sci. 2024, 14, 9919. [Google Scholar] [CrossRef]

- Haghighat Naeini, E.; Sekula, R. Evaluation of Additive Manufacturing Feasibility in the Energy Sector: A Case Study of a Gas-Insulated High-Voltage Switchgear. Appl. Sci. 2024, 14, 6237. [Google Scholar] [CrossRef]

- Shufrin, I.; Pasternak, E.; Dyskin, A. Environmentally Friendly Smart Construction—Review of Recent Developments and Opportunities. Appl. Sci. 2023, 13, 12891. [Google Scholar] [CrossRef]

- RežekJambrak, A.; Nutrizio, M.; Djekić, I.; Pleslić, S.; Chemat, F. Internet of Nonthermal Food Processing Technologies (IoNTP): Food Industry 4.0 and Sustainability. Appl. Sci. 2021, 11, 686. [Google Scholar] [CrossRef]

- Imtiaz, L.; Rehman, S.K.U.; Ali Memon, S.; Khizar Khan, M.; Faisal Javed, M. A Review of Recent Developments and Advances in Eco-Friendly Geopolymer Concrete. Appl. Sci. 2020, 10, 7838. [Google Scholar] [CrossRef]

- Juraski, A.C.; Sharma, S.; Sparanese, S.; da Silva, V.A.; Wong, J.; Laksman, Z.; Flannigan, R.; Rohani, L.; Willerth, S.M. 3D bioprinting for organ and organoid models and disease modeling. Expert Opin. Drug Discov. 2023, 18, 1043–1059. [Google Scholar] [CrossRef]

- Rothbauer, M.; Eilenberger, C.; Spitz, S.; Bachmann, B.E.M.; Kratz, S.R.A.; Reihs, E.I.; Windhager, R.; Toegel, S.; Ertl, P. Recent Advances in Additive Manufacturing and 3D Bioprinting for Organs-On-A-Chip and Microphysiological Systems. Front. Bioeng. Biotechnol. 2022, 10, 837087. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Mao, M.; Li, X.; Chua, C.K. Bioprinting of 3D Functional Tissue Constructs. Int. J. Bioprint. 2021, 7, 395. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Chang, S.Y.; Gan, S.W.; Ma, S.; Lu, W.F.; Yen, C.C. Nanocomposite bioinks for 3D bioprinting. Acta Biomater. 2022, 151, 45–69. [Google Scholar] [CrossRef]

- Simorgh, S.; Alasvand, N.; Khodadadi, M.; Ghobadi, F.; Malekzadeh Kebria, M.; Brouki Milan, P.; Kargozar, S.; Baino, F.; Mobasheri, A.; Mozafari, M. Additive manufacturing of bioactive glass biomaterials. Methods 2022, 208, 75–91. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuan, X. Applications and future of automated and additive manufacturing for power electronics components and converters. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 10, 4509–4525. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Vaimann, T.; Rassõlkin, A. State of the art of additively manufactured electromagnetic materials for topology optimized electrical machines. Addit. Manuf. 2022, 55, 102778. [Google Scholar] [CrossRef]

- Jung, J.; Maeda, M.; Chang, A.; Bhandari, M.; Ashapure, A.; Landivar-Bowles, J. The potential of remote sensing and artificial intelligence as tools to improve the resilience of agriculture production systems. Curr. Opin. Biotechnol. 2021, 70, 15–22. [Google Scholar] [CrossRef]

- Köbnick, P.; Velu, C.; McFarlane, D. Preparing for industry 4.0: Digital business model innovation in the food and beverage industry. Int. J. Mechatron. Manuf. Syst. 2020, 13, 59–89. [Google Scholar] [CrossRef]

- Tay, R.Y.; Song, Y.; Yao, D.R.; Gao, W. Direct-Ink-Writing 3D-Printed Bioelectronics. Mater. Today 2023, 71, 135–151. [Google Scholar] [CrossRef]

- Popov, V.V.; Grilli, M.L.; Koptyug, A.; Jaworska, L.; Katz-Demyanetz, A.; Klobčar, D.; Balos, S.; Postolnyi, B.O.; Goel, S. Powder Bed Fusion Additive Manufacturing Using Critical Raw Materials: A Review. Materials 2021, 14, 909. [Google Scholar] [CrossRef]

- Perera, J.C.; Gopalakrishnan, B.; Bisht, P.S.; Chaudhari, S.; Sundaramoorthy, S. A Sustainability-Based Expert System for Additive Manufacturing and CNC Machining. Sensors 2023, 23, 7770. [Google Scholar] [CrossRef] [PubMed]

- Ulkir, O. Energy-Consumption-Based Life Cycle Assessment of Additive-Manufactured Product with Different Types of Materials. Polymers 2023, 15, 1466. [Google Scholar] [CrossRef] [PubMed]

- Kretzschmar, N.; Chekurov, S.; Salmi, M.; Tuomi, J. Evaluating the Readiness Level of Additively Manufactured Digital Spare Parts: An Industrial Perspective. Appl. Sci. 2018, 8, 1837. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Prasittisopin, L. How 3D printing technology makes cities smarter: A review, thematic analysis, and perspectives. Smart Cities 2024, 7, 3458–3488. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The Circular Economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Campbell-Johnston, K.; Vermeulen, W.J.V.; Reike, D.; Brullot, S. The Circular Economy and Cascading: Towards a Framework. Resour. Conserv. Recycl. 2020, 7, 100038. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards Sustainable Development through the Circular Economy—A Review and Critical Assessment on Current Circularity Metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Popescu, C.; Dissanayake, H.; Mansi, E.; Stancu, A. Eco Breakthroughs: Sustainable Materials Transforming the Future of Our Planet. Sustainability 2024, 16, 10790. [Google Scholar] [CrossRef]

- Al-Raqeb, H.; Ghaffar, S.H. 3D Concrete Printing in Kuwait: Stakeholder Insights for Sustainable Waste Management Solutions. Sustainability 2025, 17, 200. [Google Scholar] [CrossRef]

- Aldahash, S. Implementation of Additive Manufacturing Technologies for the Growth and Sustainability of Manufacturing SMEs in Saudi Arabia: An Exploratory Study. Sustainability 2025, 17, 1249. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Sadoon, A.; Bassuoni, M.T.; Ghazy, A. Utilizing Agricultural Residues from Hot and Cold Climates as Sustainable SCMs for Low-Carbon Concrete. Sustainability 2024, 16, 10715. [Google Scholar] [CrossRef]

- Romani, A.; Levi, M. Large-Format Material Extrusion Additive Manufacturing for Circular Economy Practices: A Focus on Product Applications with Materials from Recycled Plastics and Biomass Waste. Sustainability 2024, 16, 7966. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

| Name of Stage | Tasks |

|---|---|

| Defining research goals | Defining exact goals of the bibliometric analysis |

| Selecting bibliometric databases | Choosing appropriate datasets and developing research queries according to the study goals |

| Data preprocessing/preparation | Removing duplicates and irrelevant records from the collected dataset, organizing the records to adapt them to the requirements of the ML training set |

| Bibliometric software selection | Selection of optimal tools from the area of bibliometric software for analysis |

| Data analysis | Description/keywords, type of publication, author, affiliation, area/topic, country, etc. |

| Analysis results/visualization(where possible) | Presentation of the results to emphasize insights |

| Interpretation of resultsand discussion | Interpreting results in the context of the research goals |

| Parameter/Feature | Detailed Description |

|---|---|

| Inclusion criteria | Books, book chapters, articles (original, reviews, editorials), and conference proceedings, in English |

| Exclusion criteria | Articles, books, chapters older than 10 years, letters, conference abstracts without full text, other languages than English |

| Keywords used | Machine learning, climate change, energy optimization/optimization |

| Used field codes (WoS) | “Subject” field (consisting of title, abstract, keyword plus and other keywords) |

| Used fields (Sopus) | Article title, abstract and keywords |

| Used fields (PubMed) | Manually |

| Used fields (dblp) | Manually |

| Boolean operators used | No |

| Filters used | Results were refined by year of publication, document type (e.g., articles and reviews), and subject area (e.g., industry, engineering, computer science, and physics) |

| Iteration/validation option(s) | The query is used iteratively, refined in subsequent iterations based on the results, and verified by checking whether relevant publications appear among the top results |

| Wildcarts and leverage truncation | Used symbol * for word variations (e.g., “energ*” for “energy” or “energetic”) and symbol ? for alternative spellings (e.g., “optimi?ation”) |

| Parameter/Feature | Value |

|---|---|

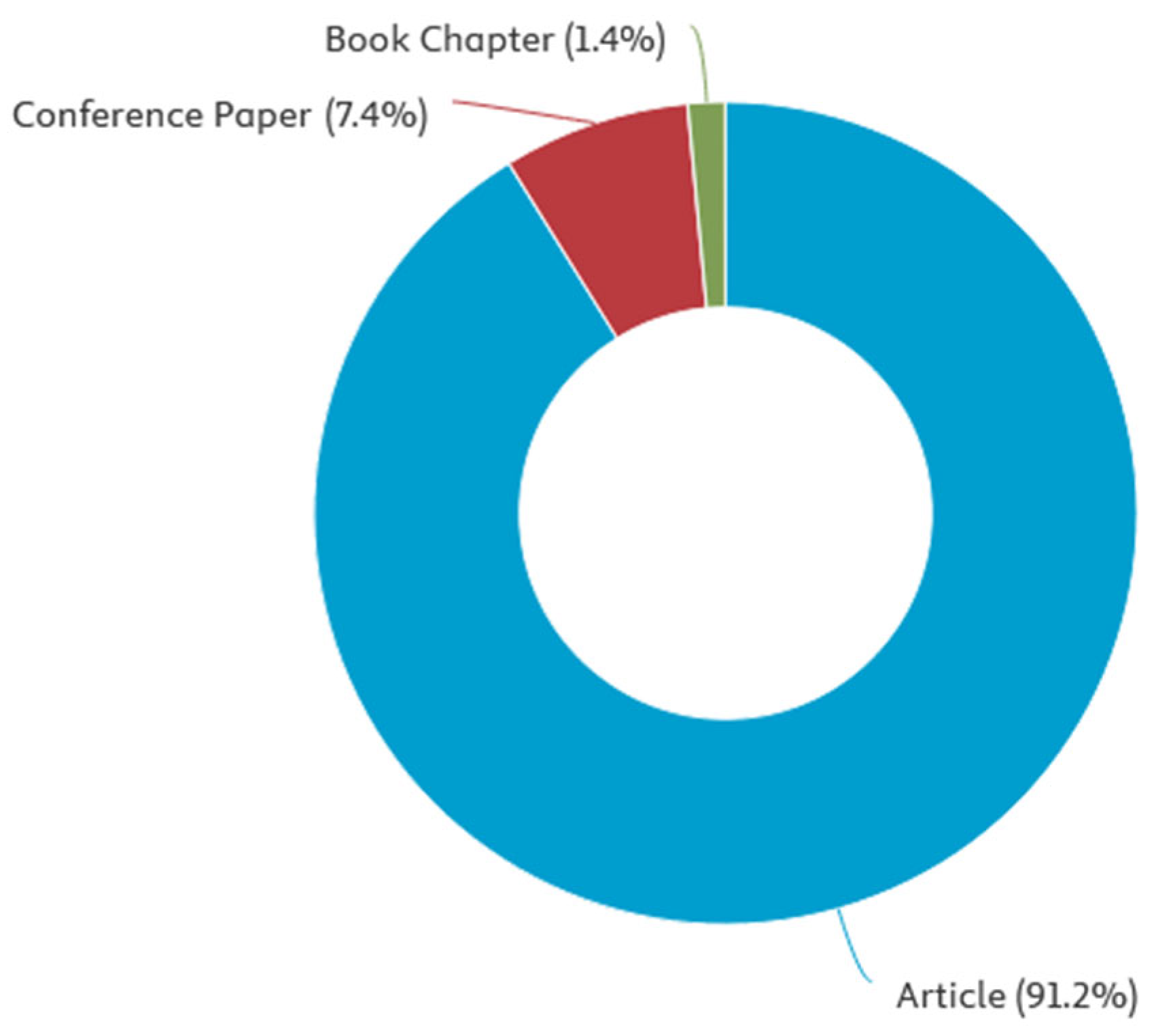

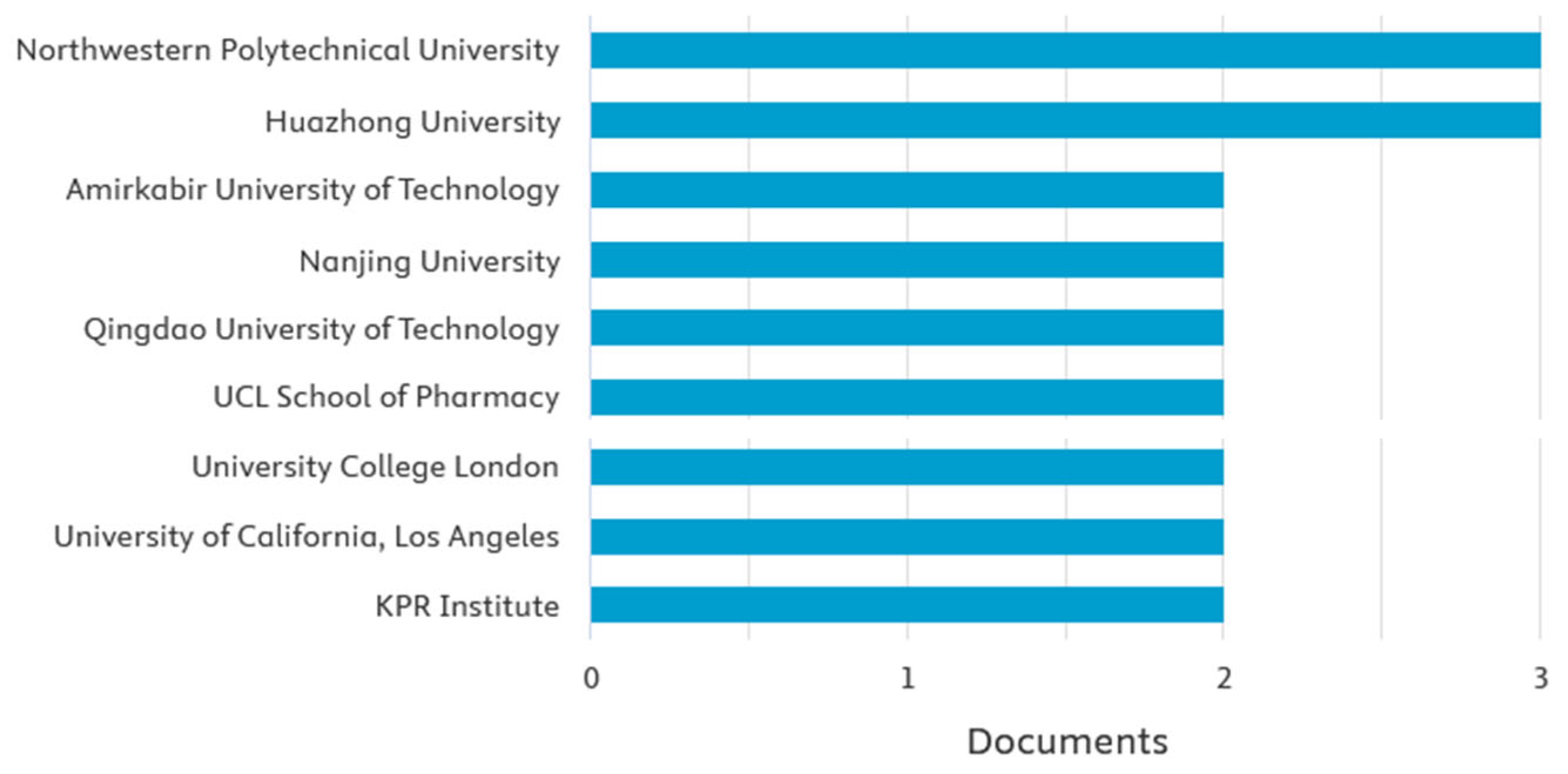

| Leading types of publication | Article (91.20%) |

| Leading areas of science | Engineering (30.40%), Material science (30.40%), Physics and Astronomy (14.5%) |

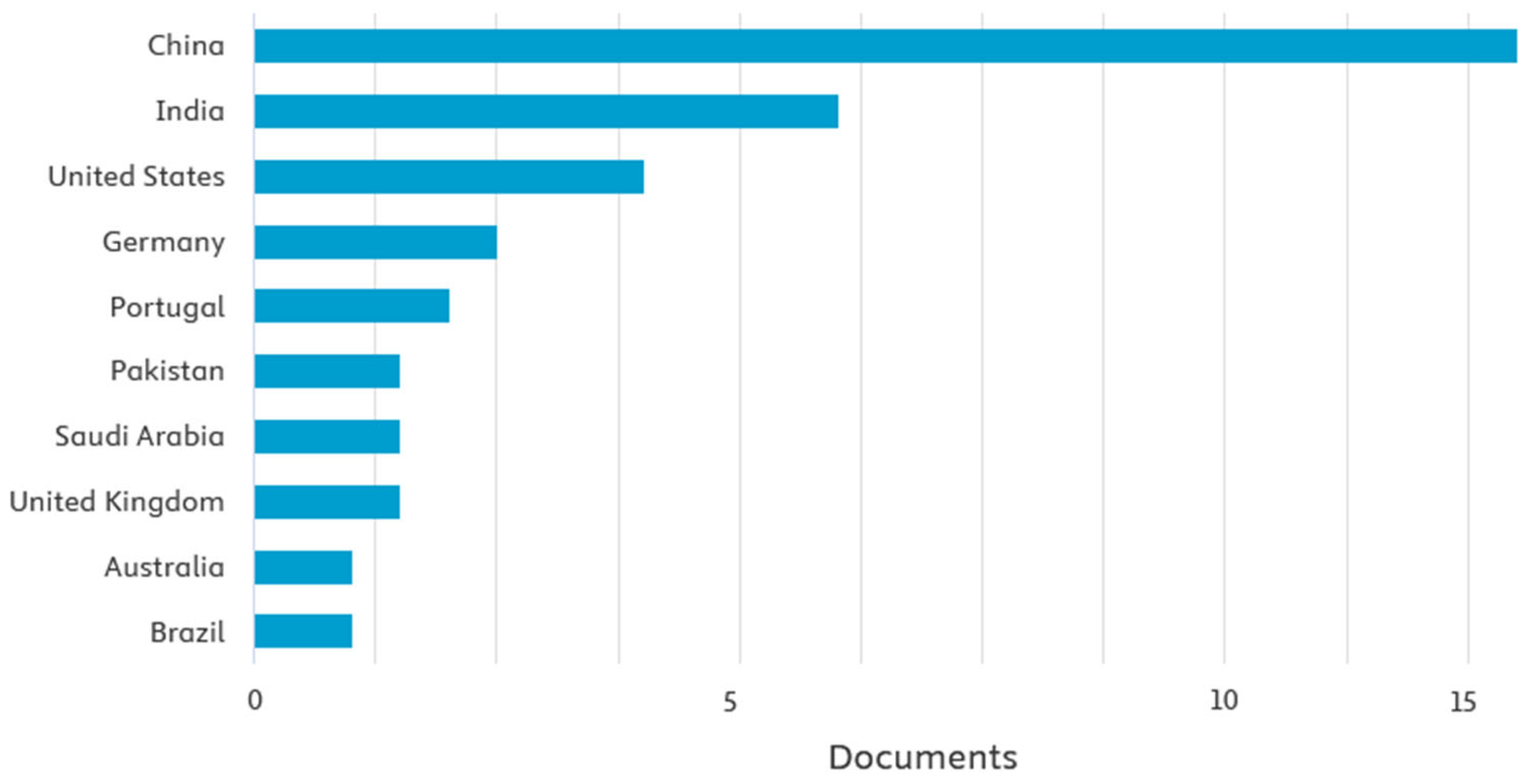

| Leading countries | China, India, USA, Germany |

| Leading scientists | Asif, M.; Khalid, M.; Naeem, G. |

| Leading affiliations | Northwestern Polytechnical University, Huazhong University |

| Leading funders (where information available) | National Science Foundation of China |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojek, I.; Mikołajewski, D.; Kopowski, J.; Bednarek, T.; Tyburek, K. Energy Efficiency and Sustainability of Additive Manufacturing as a Mass-Personalized Production Mode in Industry 5.0/6.0. Energies 2025, 18, 3413. https://doi.org/10.3390/en18133413

Rojek I, Mikołajewski D, Kopowski J, Bednarek T, Tyburek K. Energy Efficiency and Sustainability of Additive Manufacturing as a Mass-Personalized Production Mode in Industry 5.0/6.0. Energies. 2025; 18(13):3413. https://doi.org/10.3390/en18133413

Chicago/Turabian StyleRojek, Izabela, Dariusz Mikołajewski, Jakub Kopowski, Tomasz Bednarek, and Krzysztof Tyburek. 2025. "Energy Efficiency and Sustainability of Additive Manufacturing as a Mass-Personalized Production Mode in Industry 5.0/6.0" Energies 18, no. 13: 3413. https://doi.org/10.3390/en18133413

APA StyleRojek, I., Mikołajewski, D., Kopowski, J., Bednarek, T., & Tyburek, K. (2025). Energy Efficiency and Sustainability of Additive Manufacturing as a Mass-Personalized Production Mode in Industry 5.0/6.0. Energies, 18(13), 3413. https://doi.org/10.3390/en18133413