Quantitative Assessment Method for Industrial Demand Response Potential Integrating STL Decomposition and Load Step Characteristics

Abstract

1. Introduction

1.1. Motivation and Background

1.2. Related Work

1.3. Contributions and Organization

2. Load Feature Extraction Method for Industrial Users Based on Load Decomposition and Response Willingness

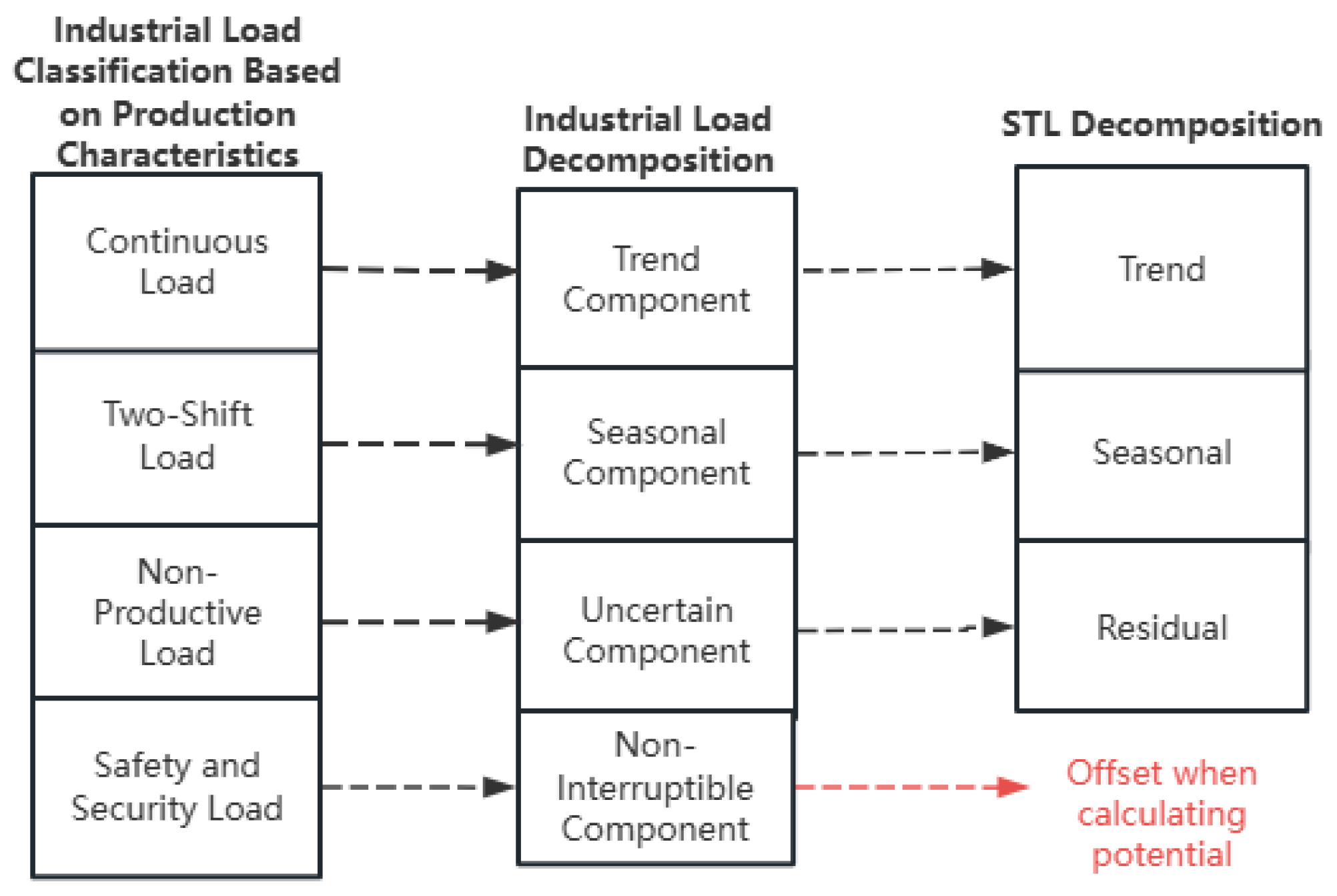

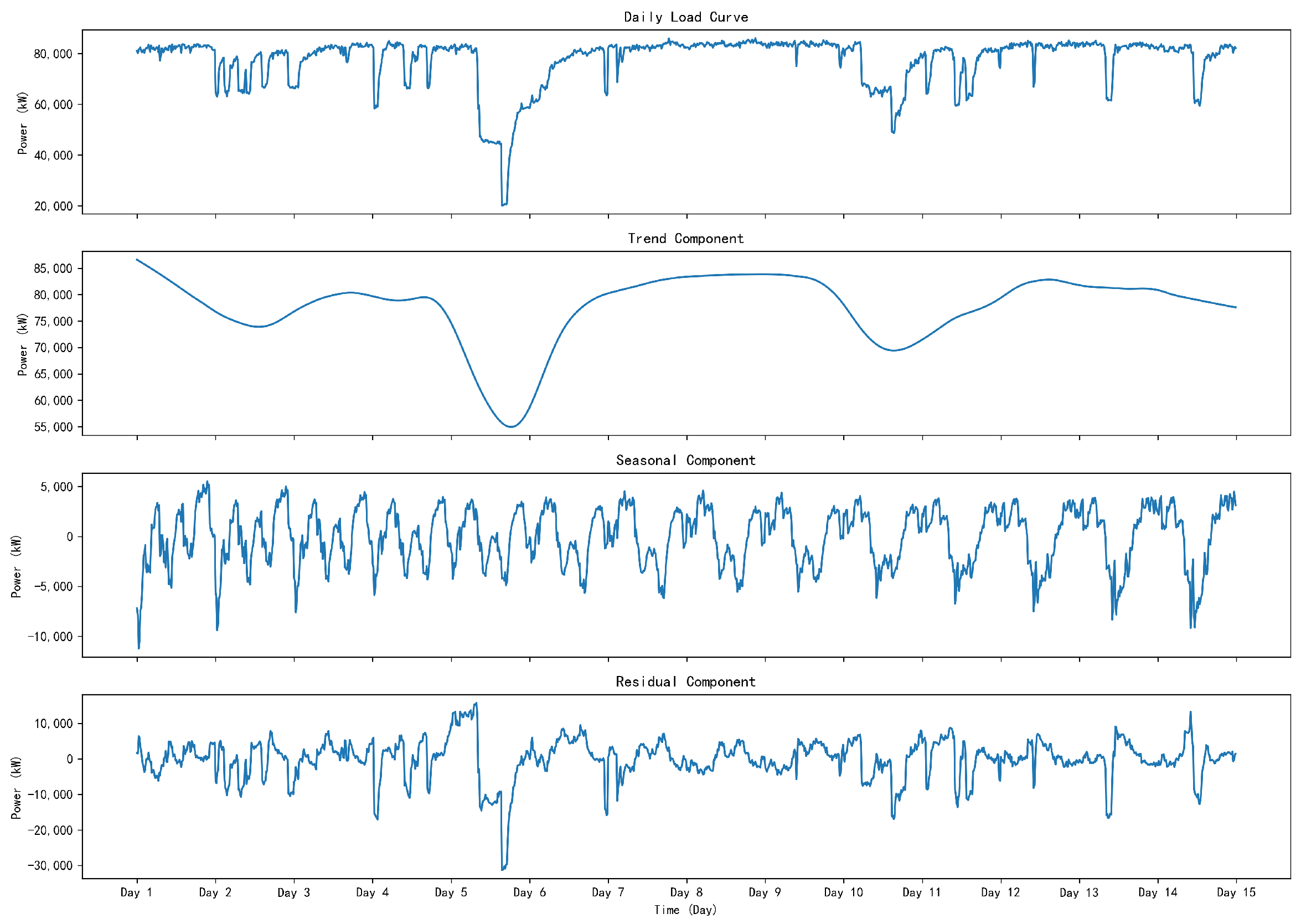

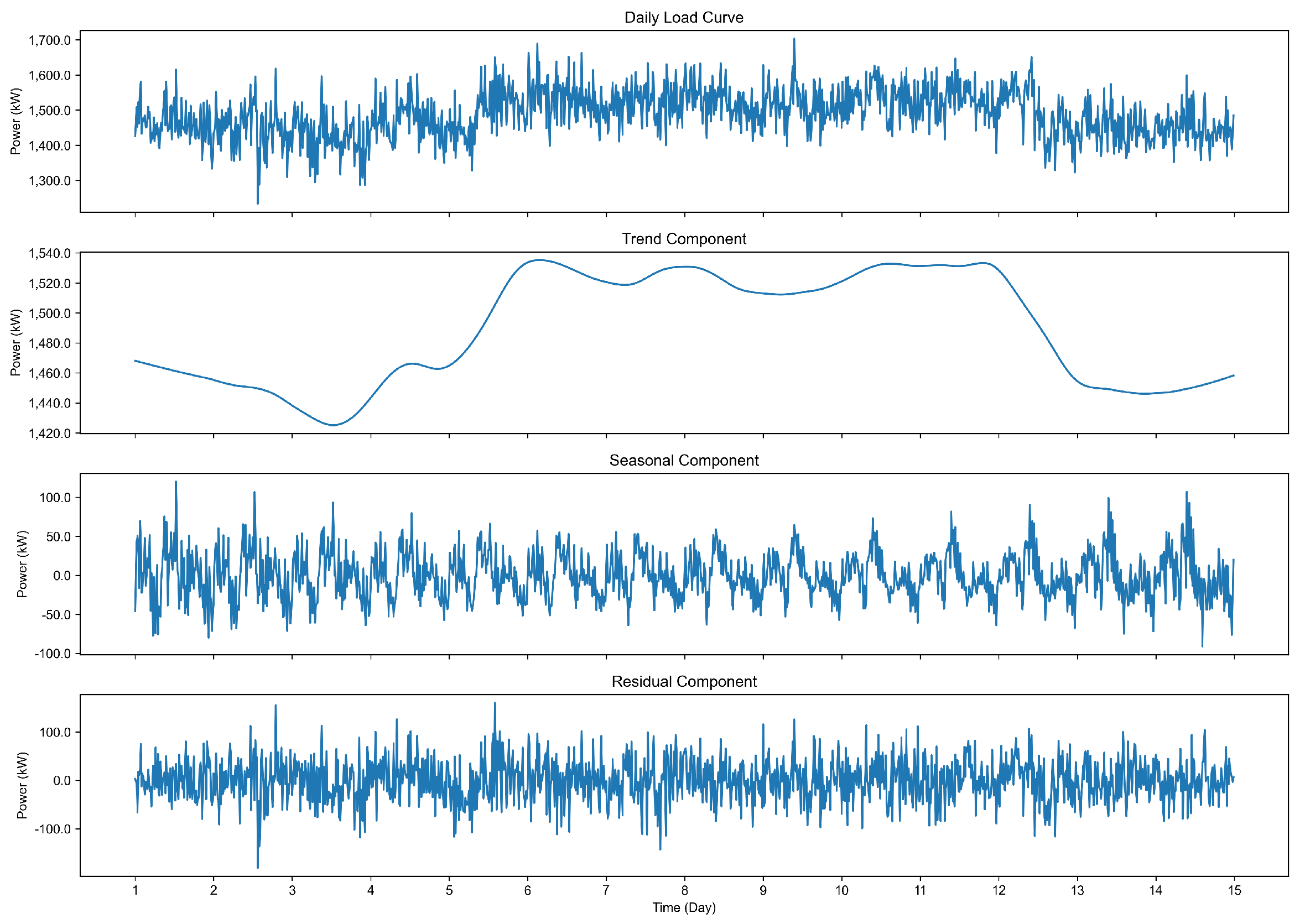

2.1. STL-Based Time-Series Feature Extraction for Industrial Users

- Loads that allow continuous adjustment through control systems;

- Loads that support only binary on/off control and cannot be adjusted during operation;

- Loads affected by unplanned external disturbances;

- Rigid loads that must operate continuously and can only be interrupted during scheduled maintenance or adjustments.

- Trend Component: Represents baseline load driven by production scale, mainly associated with continuously adjustable equipment; its amplitude exhibits near-linear changes with production capacity.

- Seasonal Component: Captures fluctuations caused by periodic switching of equipment groups within the production process, often exhibiting step-like transitions on multiple intra-day timescales.

- Irregular Component: Accounts for stochastic load variations due to unplanned disturbances such as equipment failures or order changes.

- Non-interruptible Component: Reflects base load essential for safe production, which is not interruptible within a single day.

2.1.1. Production Trend Factor

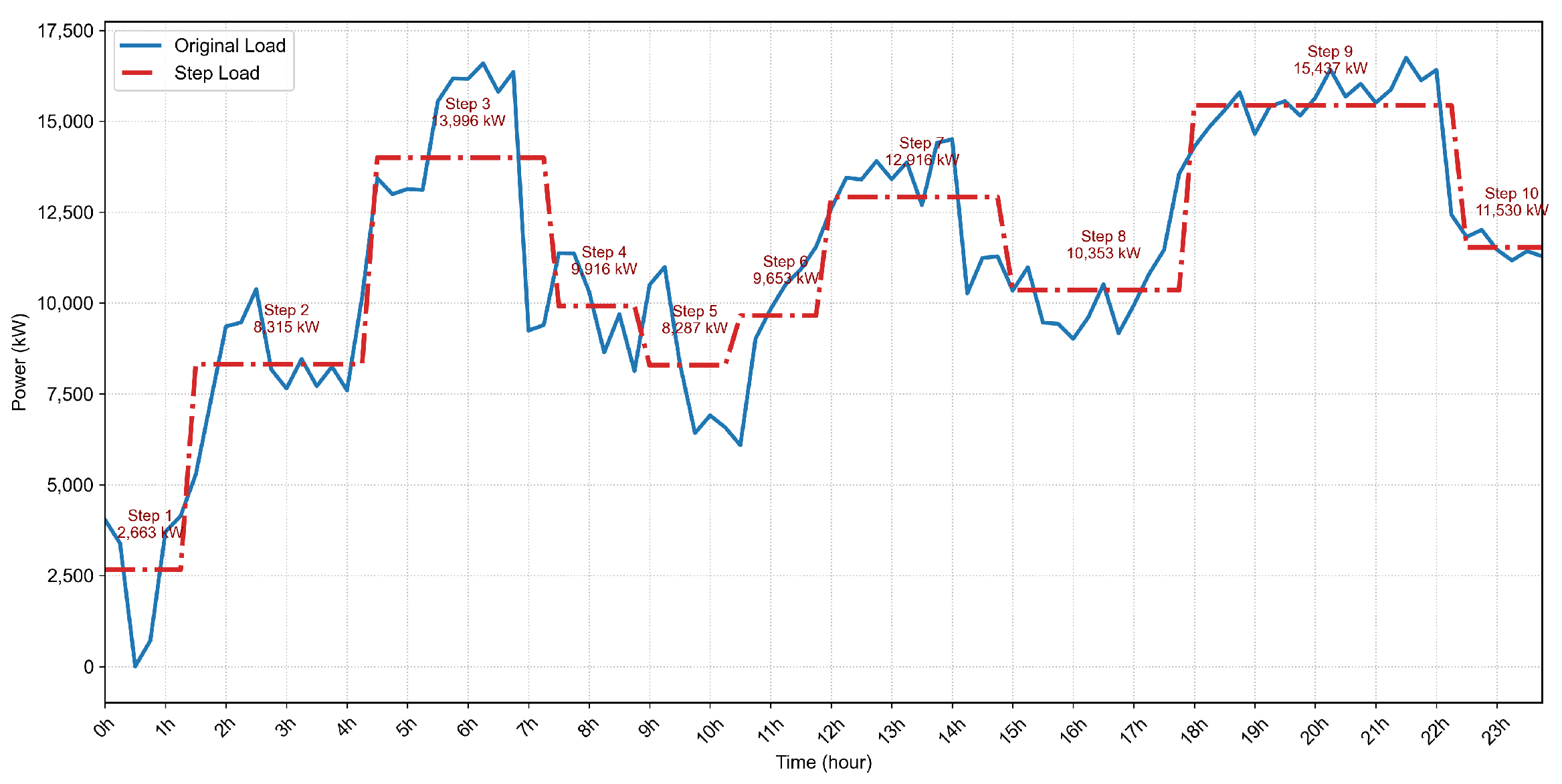

2.1.2. Load Step Matrix

- Apply the STL algorithm to the historical load data to obtain the periodic load component:

- Initialize the load step candidate buffer with the first four load points in , and set the threshold as the criterion for a valid load step:

- Iterate through the periodic load sequence to identify load steps using the following rule:The position index t is updated accordingly. Initialize . If belongs to the same load step as , increment t by 1. If only one of them belongs to a valid step, also increment t. Otherwise, increment t by 1 to continue traversal.

- For each identified load step, record its characteristics aswhere , , and denote the start time, end time, and average load of the j-th step, respectively, extracted from the original periodic load component.

- The extracted load step matrix for day t is denoted as

2.2. Response Feature Analysis Based on Historical Demand Response Invitations

2.2.1. Historical Declared Participation Rate

2.2.2. Historical Effective Response Rate

2.2.3. Industry-Relative Factor

2.2.4. Relative Declared Response Volume

2.2.5. Invitation-to-Declared Price Ratio

2.2.6. Feature Vector Summary

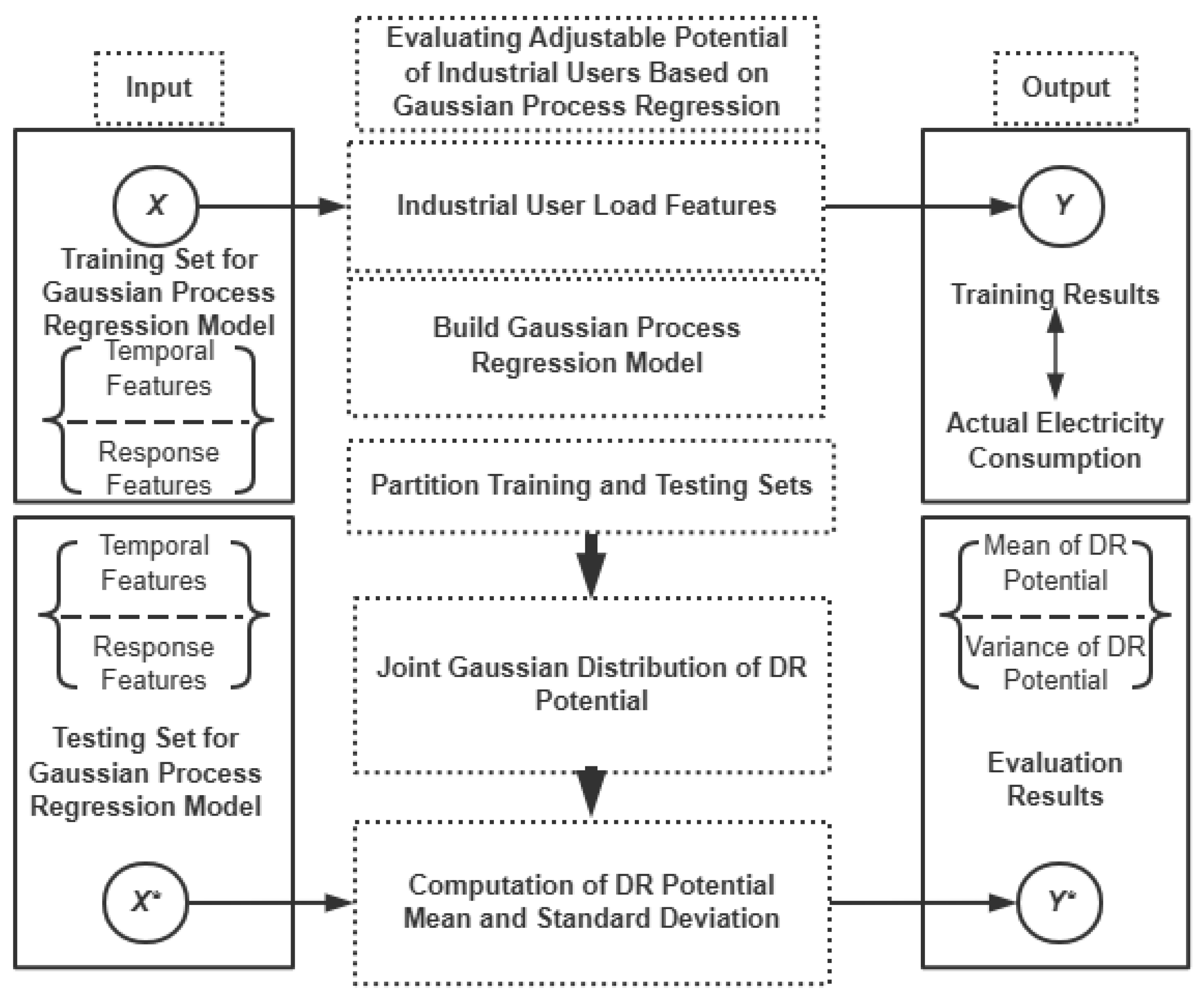

3. Industrial Demand Response Potential Estimation Based on Gaussian Process Regression

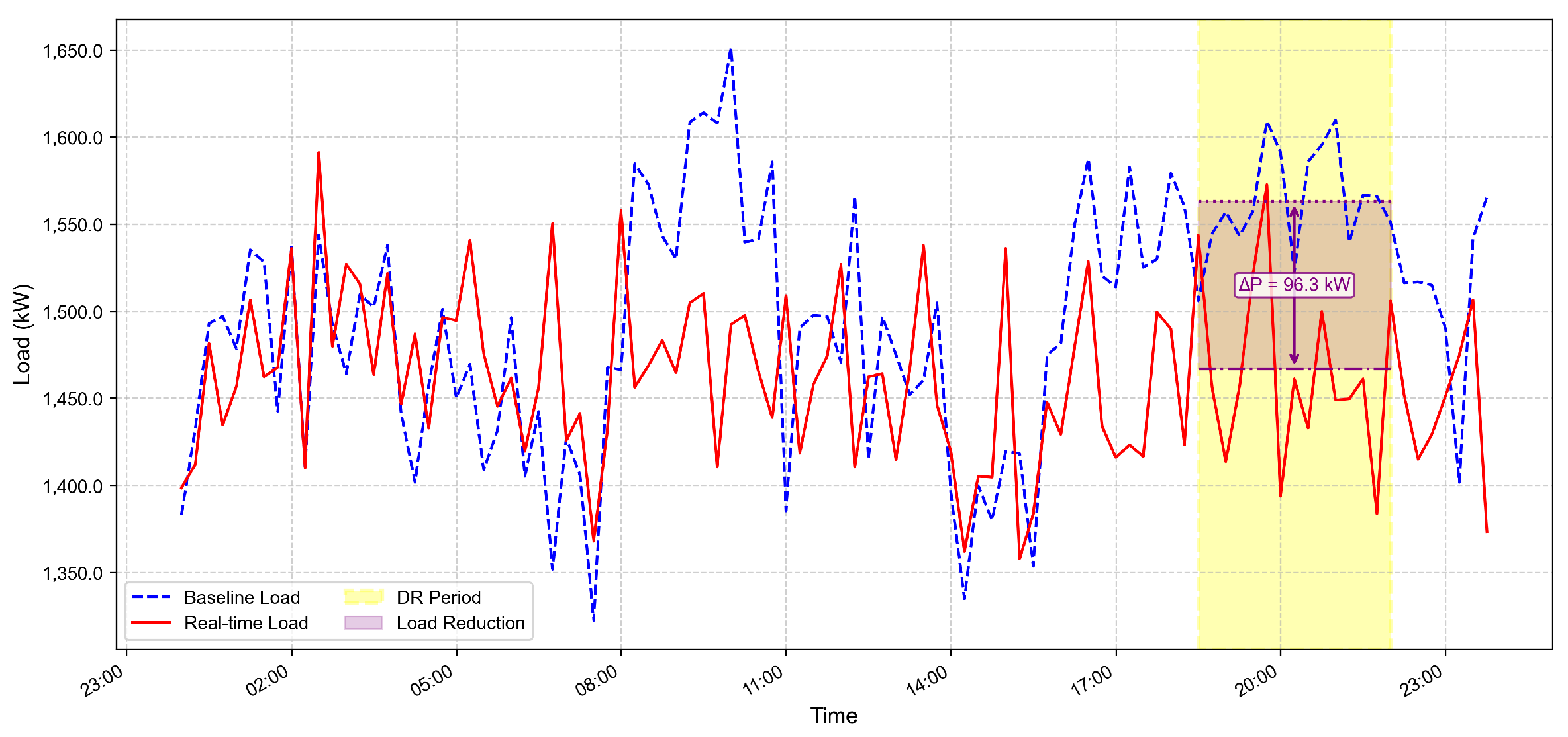

3.1. Baseline Estimation Based on Historical Load Data

3.1.1. Weekday Baseline

- (a)

- Five qualified sample days are obtained;

- (b)

- The search exceeds 30 calendar days.

3.1.2. Non-Weekday Baseline

- (a)

- Three qualified sample days are obtained;

- (b)

- The search exceeds 30 calendar days.

3.2. Power Consumption Estimation in DR Period Based on Gaussian Process Regression

3.2.1. Gaussian Kernel Function

- As , the covariance matrix approximates the identity matrix, and the model captures only highly localized features;

- As , the covariance matrix converges to a matrix of ones, and the model degenerates into a global mean predictor.

| Algorithm 1 K-fold cross-validation procedure for demand response potential estimation. |

|

3.2.2. Gaussian Process Regression Model for Demand Response Energy Estimation

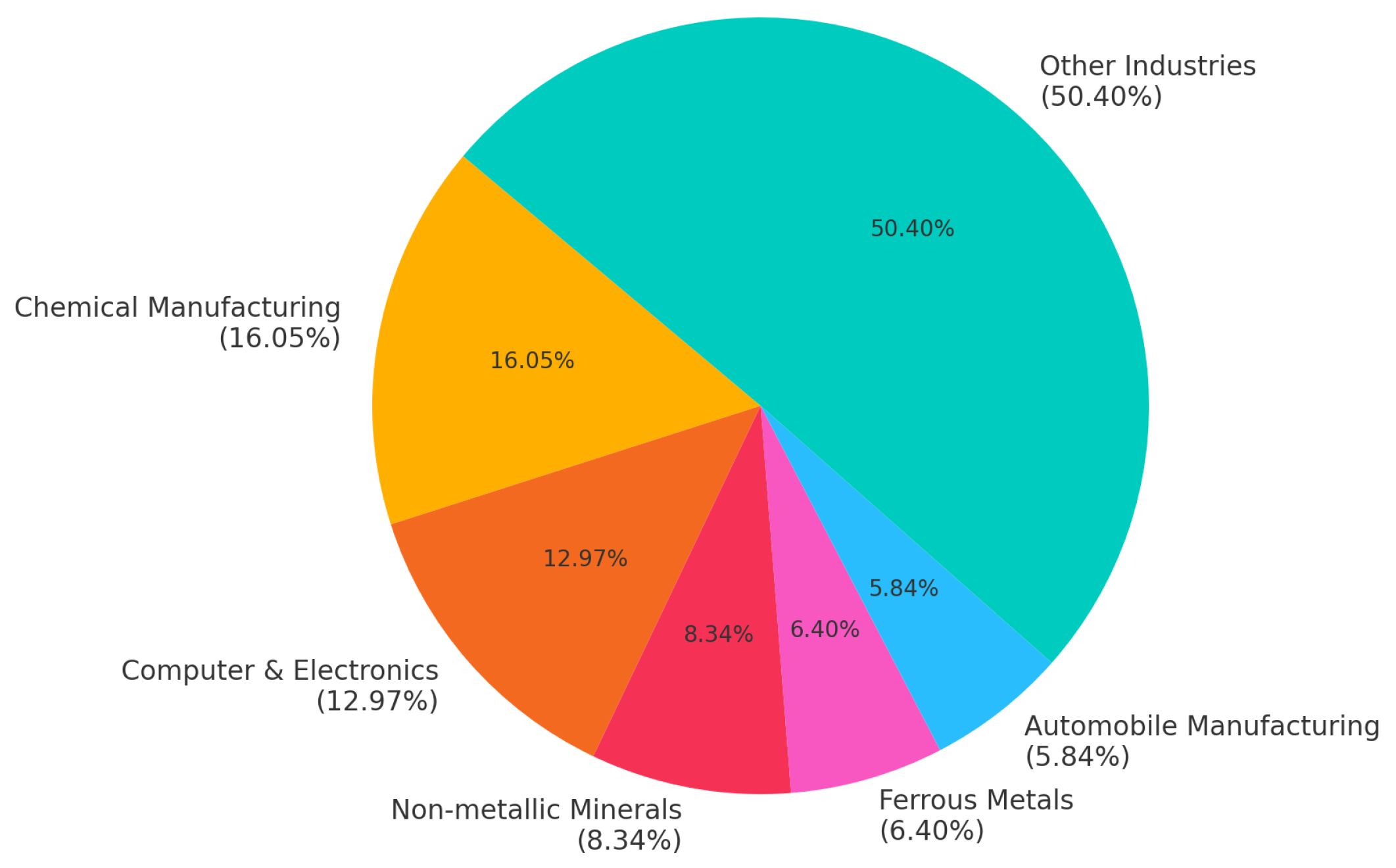

4. Case Study Analysis

- Historical electricity consumption data for the 15 weekdays prior to the response day;

- Historical DR participation records;

- DR registration data submitted by users.

4.1. Load Feature Extraction for Industrial Users

4.1.1. Load Feature Extraction for a Chemical Enterprise

- Historical Declaration Participation Rate: 0.63;

- Historical Effective Response Rate: 1.00;

- Industry-relative Value Added: 0.16;

- Relative Declared Response Volume: 0.56;

- Price Ratio: 1.00.

4.1.2. Load Feature Extraction for a High-Tech Enterprise

- Historical Declaration Participation Rate: 0.27;

- Historical Effective Response Rate: 0.50;

- Industry-relative Value Added: 0.02;

- Relative Declared Response Volume: 0.06;

- Price Ratio: 0.25.

4.2. Effectiveness Verification of the Industrial DR Potential Evaluation Method

- The actual DR response of user i is less than zero, and the mean predicted DR value by the Gaussian Process Regression model is also less than zero—i.e., the model correctly predicted the user would not participate in DR;

- The actual DR response of user i falls within the 95% confidence interval predicted by the model, expressed as Equation (28).

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DR | demand response |

| IDR | industrial demand response |

| GPR | Gaussian Process Regression |

| STL | Seasonal-Trend decomposition using Loess |

| EMD | Empirical Mode Decomposition |

| VMD | Variational Mode Decomposition |

| MAPE | Mean Absolute Percentage Error |

| RSME | Root Mean Squared Error |

| VC | Vapnik–Chervonenkis |

References

- National Energy Administration. Statistical Data of China’s Electric Power Industry in 2024 [EB/OL]. 21 January 2025. Available online: https://www.nea.gov.cn/20250121/097bfd7c1cd3498897639857d86d5dac/c.html (accessed on 1 June 2025).

- Ghafoor, A.; Aldahmashi, J.; Apsley, J.; Djurović, S.; Ma, X.; Benbouzid, M. Intelligent Integration of Renewable Energy Resources Review: Generation and Grid Level Opportunities and Challenges. Energies 2024, 17, 4399. [Google Scholar] [CrossRef]

- Singh, S.; Singh, S. Advancements and challenges in integrating renewable energy sources into distribution grid systems: A comprehensive review. J. Energy Resour. Technol. 2024, 146, 090801. [Google Scholar] [CrossRef]

- Paterakis, N.G.; Erdinç, O.; Catalão, J.P. An overview of Demand Response: Key-elements and international experience. Renew. Sustain. Energy Rev. 2017, 69, 871–891. [Google Scholar] [CrossRef]

- Heffron, R.; Körner, M.F.; Wagner, J.; Weibelzahl, M.; Fridgen, G. Industrial demand-side flexibility: A key element of a just energy transition and industrial development. Appl. Energy 2020, 269, 115026. [Google Scholar] [CrossRef]

- International Energy Agency. Cement Technology Roadmap Plots Path to Cutting CO2 Emissions 24% by 2050; IEA: Paris, France, 2018. [Google Scholar]

- Germscheid, S.H.; Mitsos, A.; Dahmen, M. Demand response potential of industrial processes considering uncertain short-term electricity prices. AIChE J. 2022, 68, e17828. [Google Scholar] [CrossRef]

- dos Santos, S.A.B.; Soares, J.M.; Barroso, G.C.; de Athayde Prata, B. Demand response application in industrial scenarios: A systematic mapping of practical implementation. Expert Syst. Appl. 2023, 215, 119393. [Google Scholar] [CrossRef]

- Dai, X.; Chen, H.; Xiao, D.; He, Q. Review of applications and researches of industrial demand response technology under electricity market environment. Power Syst. Technol. 2022, 46, 4169–4186. [Google Scholar]

- Liu, D.; Sun, Y.; Li, B.; Huo, M.L.; Xi, W.M. Price-based demand response mechanism of prosumer groups considering adjusting elasticity differentiation. Power Syst. Technol. 2020, 44, 2062–2070. [Google Scholar]

- Nilsson, A.; Lazarevic, D.; Brandt, N.; Kordas, O. Household responsiveness to residential demand response strategies: Results and policy implications from a Swedish field study. Energy Policy 2018, 122, 273–286. [Google Scholar] [CrossRef]

- Mari, S.; Bucci, G.; Ciancetta, F.; Fiorucci, E.; Fioravanti, A. A review of non-intrusive load monitoring applications in industrial and residential contexts. Energies 2022, 15, 9011. [Google Scholar] [CrossRef]

- Sun, Q.; Liu, Y.; Hu, J.; Hu, X. Non-intrusive we-energy modeling based on GAN technology. Proc. CSEE 2020, 40, 6784–6793. [Google Scholar]

- Kong, X.Y.; Liu, C.; Wang, C.S.; Li, S.W.; Chen, S.S. Demand response potential assessment method based on deep subdomain adaptation network. Proc. CSEE 2022, 42, 5786–5797. [Google Scholar]

- Di, W.U.; Yunchu, W.A.N.G.; Chunlei, Y.U. Demand response potential evaluation method of industrial users based on Gaussian process regression. Electr. Power Autom. Equip. 2022, 42, 94–101. [Google Scholar]

- Jiang, Z.; Lee, Y.M. Deep Transfer Learning for Thermal Dynamics Modeling in Smart Buildings. In Proceedings of the 2019 IEEE International Conference on Big Data (Big Data), Los Angeles, CA, USA, 9–12 December 2019; IEEE: Los Angeles, CA, USA, 2019; pp. 2033–2037. [Google Scholar]

- Chen, Y.; Li, Y.; Shen, Y. Industrial customer group portrait method based on potential quantization model of load control. Electr. Power Autom. Equip. 2021, 41, 208–216. [Google Scholar]

- Shi, J.; Wen, F.; Cui, P.; Sun, L.; Shang, J.; He, Y. Intelligent energy management of industrial loads considering participation in demand response program. Autom. Electr. Power Syst. 2017, 41, 45–53. [Google Scholar]

- Su, X.; Lyu, R.; Guo, H.; Chen, Q. A Method for Optimal Selection of High-Capacity Industrial Users for Demand Response Based on Load Step Data Processing Mode. Electr. Power 2024, 57, 18–29. [Google Scholar]

- Lee, E.; Baek, K.; Kim, J. Evaluation of demand response potential flexibility in the industry based on a data-driven approach. Energies 2020, 13, 6355. [Google Scholar] [CrossRef]

- Zhu, D. Analysis and Application of Typical Load Electricity Behavior Model. Master’s Thesis, Southeast University, Nanjing, China, 2017. [Google Scholar]

- Wu, D.; Wang, Y.; Li, L.; Lu, P.; Liu, S.; Dai, C.; Pan, Y.; Zhang, Z.; Lin, Z.; Yang, L. Demand response ability evaluation based on seasonal and trend decomposition using LOESS and S–G filtering algorithms. Energy Rep. 2022, 8, 292–299. [Google Scholar] [CrossRef]

- LTrull, O.; García-Díaz, J.C.; Peiró-Signes, A. Multiple seasonal STL decomposition with discrete-interval moving seasonalities. Appl. Math. Comput. 2022, 433, 127398. [Google Scholar]

- Starke, M.; Alkadi, N.; Ma, O. Assessment of Industrial Load for Demand Response Across US Regions of the Western Interconnect; ORNL/TM-2013/407; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2013.

- Hubei Provincial Development and Reform Commission. Detailed Implementation Rules for Power Dispatch Management in Hubei Province [EB/OL]. 11 December 2023. Available online: https://fgw.hubei.gov.cn/fbjd/xxgkml/jgzn/wgdw/nyj/dlddc/tzgg/202312/t20231211_4998169.shtml (accessed on 1 June 2025).

- Ospina, A.M.; Chen, Y.; Bernstein, A.; Dall’Anese, E. Learning-based demand response in grid-interactive buildings via gaussian processes. Electr. Power Syst. Res. 2022, 211, 108406. [Google Scholar] [CrossRef]

- Guo, P.; Wang, Z. Wind turbine spindle state monitoring based on Gaussian process regression and double moving window residual processing. Electr. Power Autom. Equip. 2018, 38, 34–40. [Google Scholar]

- Qi, X.; Ji, Z.; Wu, H.; Zhang, J.; Wang, L. Short-term reliability assessment of generating systems considering demand response reliability. IEEE Access 2020, 8, 74371–74384. [Google Scholar] [CrossRef]

- Xiangsheng, L.E.I.; Zidong, W.U.; Ping, D.O.N.G.; Hongzhou, J.I.A. Method of demand response potential assessment based on two-stage cluster analysis. South. Energy Constr. 2021, 7, 1–10. [Google Scholar]

| Methodology | Description | Advantages | Limitations | References |

|---|---|---|---|---|

| Comprehensive Evaluation | Multi-index systems using weights and scoring | Intuitive and easy to implement | Requires expert input, low adaptability | [10,11] |

| Mechanism-based Modeling | Based on physical/operational constraints of equipment | High accuracy for known systems | High data granularity needed, poor generalization | [12,13] |

| Data-driven Techniques | Regression, clustering, and transfer learning | Adaptive, scalable to large users | Risk of overfitting, depends on data quality | [14,15,16] |

| User ID | Actual Response (kW) | with DR Willingness | Without DR Willingness | ||||

|---|---|---|---|---|---|---|---|

| Mean (kW) | Std Dev (kW) | Mean (kW) | Std Dev (kW) | ||||

| 1 | 1970.63 | 1930.82 | 27.17 | 1 | 1905.60 | 30.88 | 0 |

| 2 | 836.35 | 807.18 | 19.23 | 1 | 816.21 | 21.15 | 1 |

| 3 | 2152.97 | 2104.89 | 39.88 | 1 | 2189.32 | 43.81 | 1 |

| 4 | 13,070.80 | 11,741.39 | 851.23 | 1 | 12,902.34 | 883.18 | 1 |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ |

| 196 | 30,272.19 | 27,615.06 | 905.02 | 0 | 28,133.22 | 932.14 | 0 |

| 197 | 113.38 | 115.02 | 2.11 | 1 | 90.89 | 2.99 | 0 |

| 198 | 68.05 | 68.88 | 1.72 | 1 | 71.77 | 2.32 | 1 |

| Z | 91.4% | 57.1% | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.-W.; Chang, K.; Shao, M.-D.; Lei, H.; Liu, Z.-W. Quantitative Assessment Method for Industrial Demand Response Potential Integrating STL Decomposition and Load Step Characteristics. Energies 2025, 18, 3398. https://doi.org/10.3390/en18133398

Yang Z-W, Chang K, Shao M-D, Lei H, Liu Z-W. Quantitative Assessment Method for Industrial Demand Response Potential Integrating STL Decomposition and Load Step Characteristics. Energies. 2025; 18(13):3398. https://doi.org/10.3390/en18133398

Chicago/Turabian StyleYang, Zhuo-Wei, Kai Chang, Ming-Di Shao, Hao Lei, and Zhi-Wei Liu. 2025. "Quantitative Assessment Method for Industrial Demand Response Potential Integrating STL Decomposition and Load Step Characteristics" Energies 18, no. 13: 3398. https://doi.org/10.3390/en18133398

APA StyleYang, Z.-W., Chang, K., Shao, M.-D., Lei, H., & Liu, Z.-W. (2025). Quantitative Assessment Method for Industrial Demand Response Potential Integrating STL Decomposition and Load Step Characteristics. Energies, 18(13), 3398. https://doi.org/10.3390/en18133398