Heat Transfer Enhancement in Flue-Gas Systems with Radiation-Intensifying Inserts: An Analytical Approach

Abstract

1. Introduction

2. Analytical Model

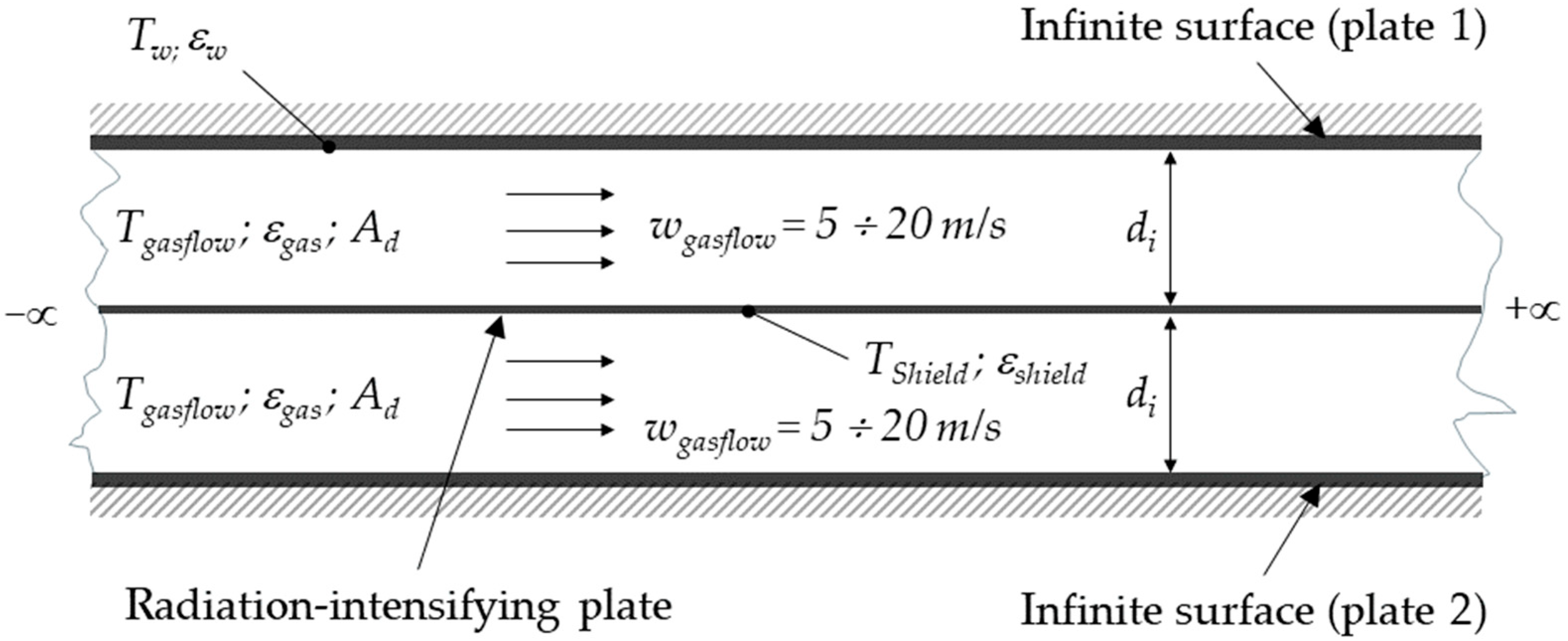

2.1. Boundary Conditions When the Radiation-Intensifying Plate Is Placed Between Two Infinite Plates

2.2. Governing Equations for Heat Transfer Calculations

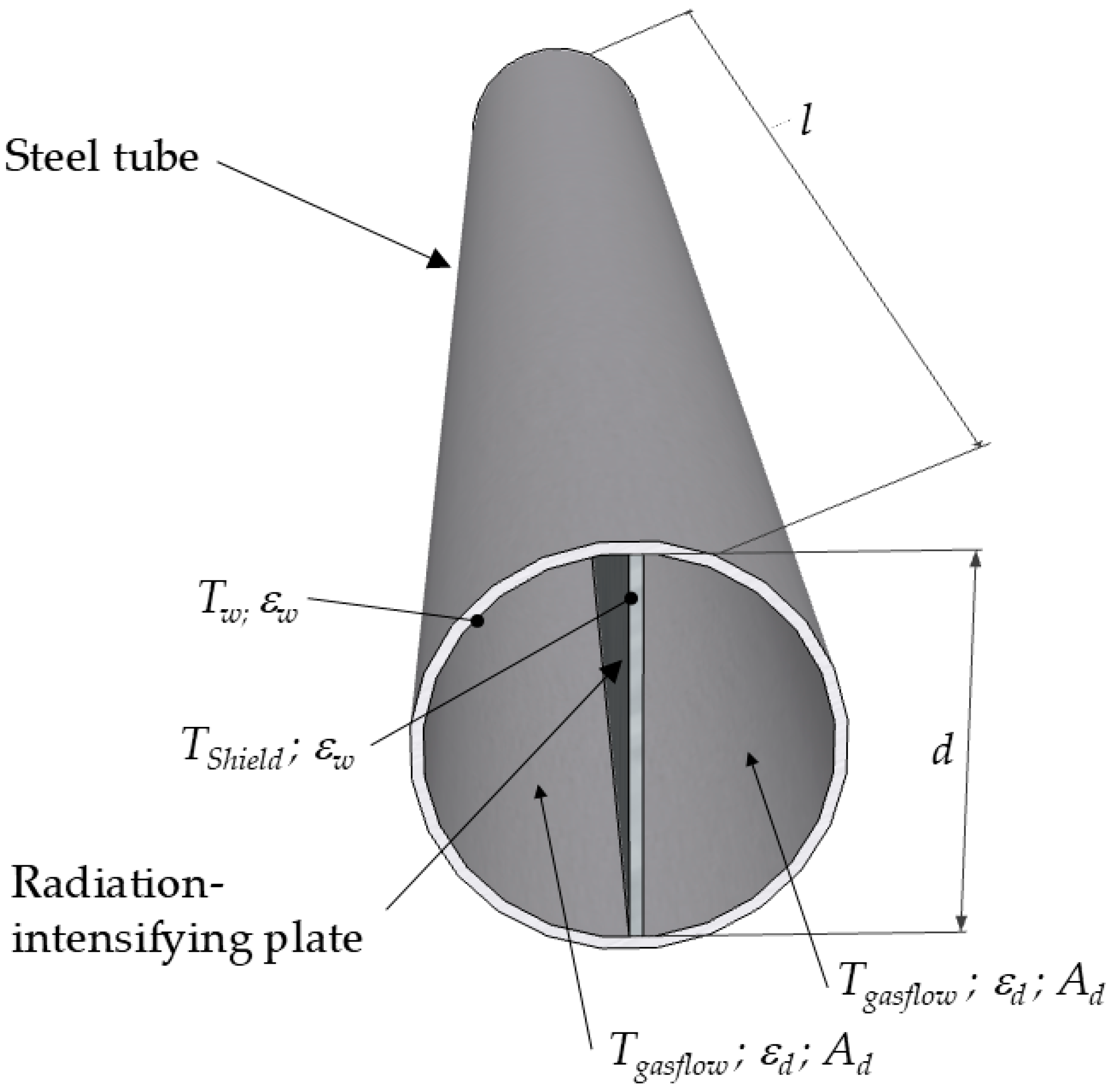

2.3. Boundary Conditions When the Radiation-Intensifying Plate Is Placed into the Tube of the Flue-Gas Boiler

2.4. Governing Equations for Heat Transfer Calculations

2.5. Limitations of the Analytical Approach

3. Results

3.1. The Case of the Radiation-Intensifying Plate Is Positioned Between Two Infinite Plates

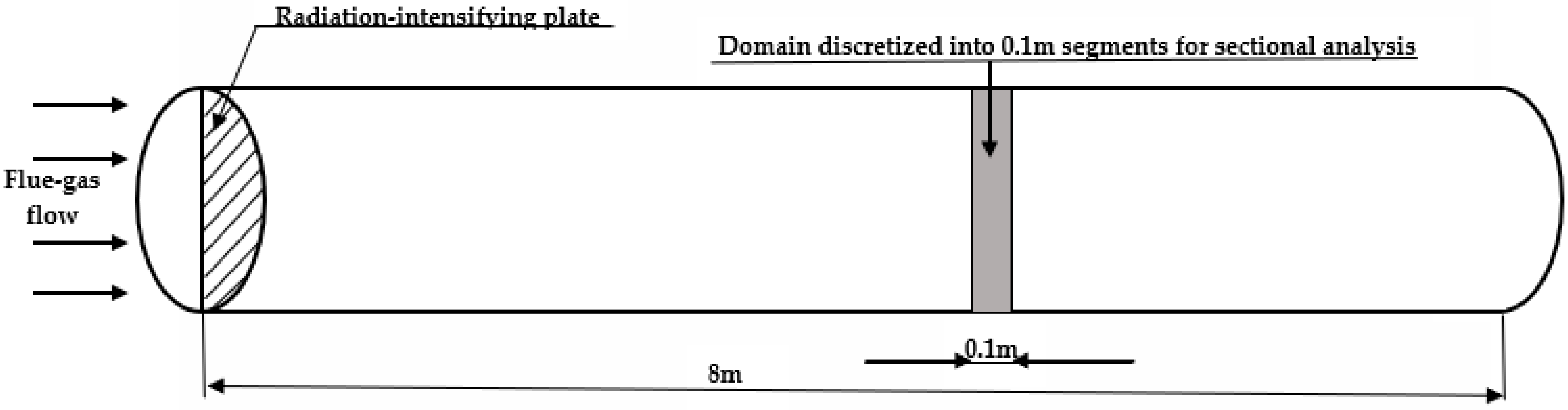

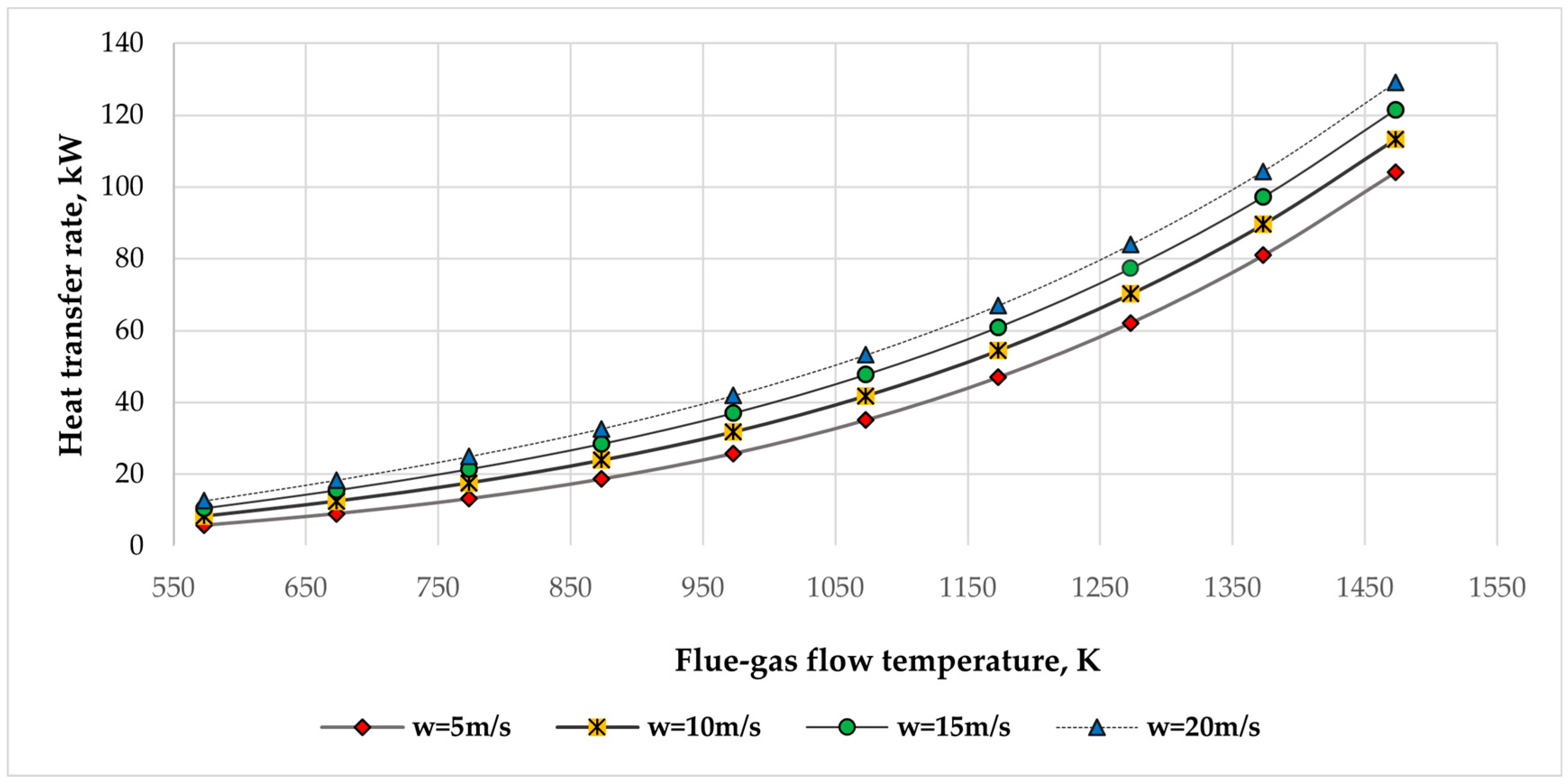

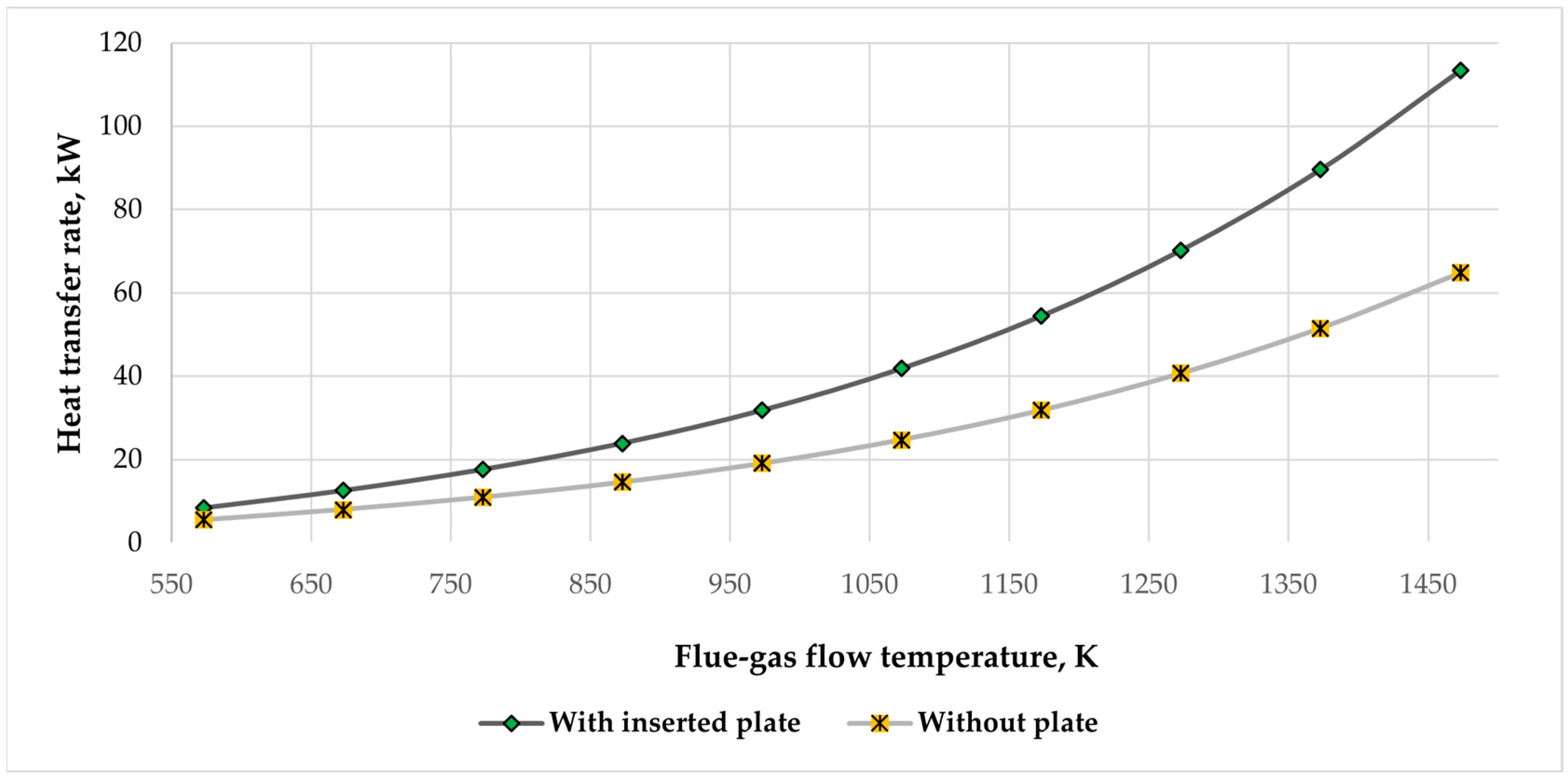

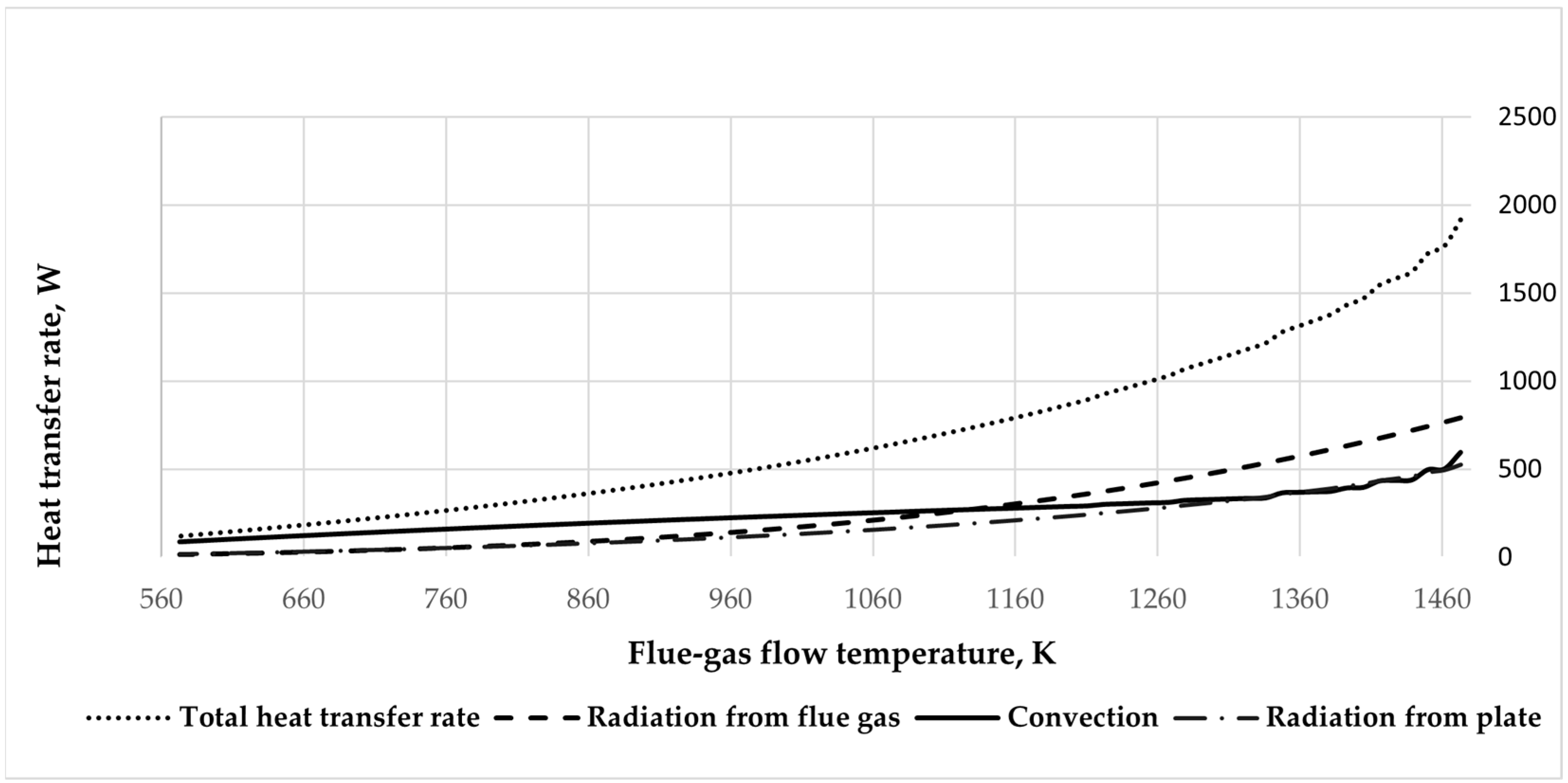

3.2. The Case of the Radiation-Intensifying Plate Is Positioned in the Pipe

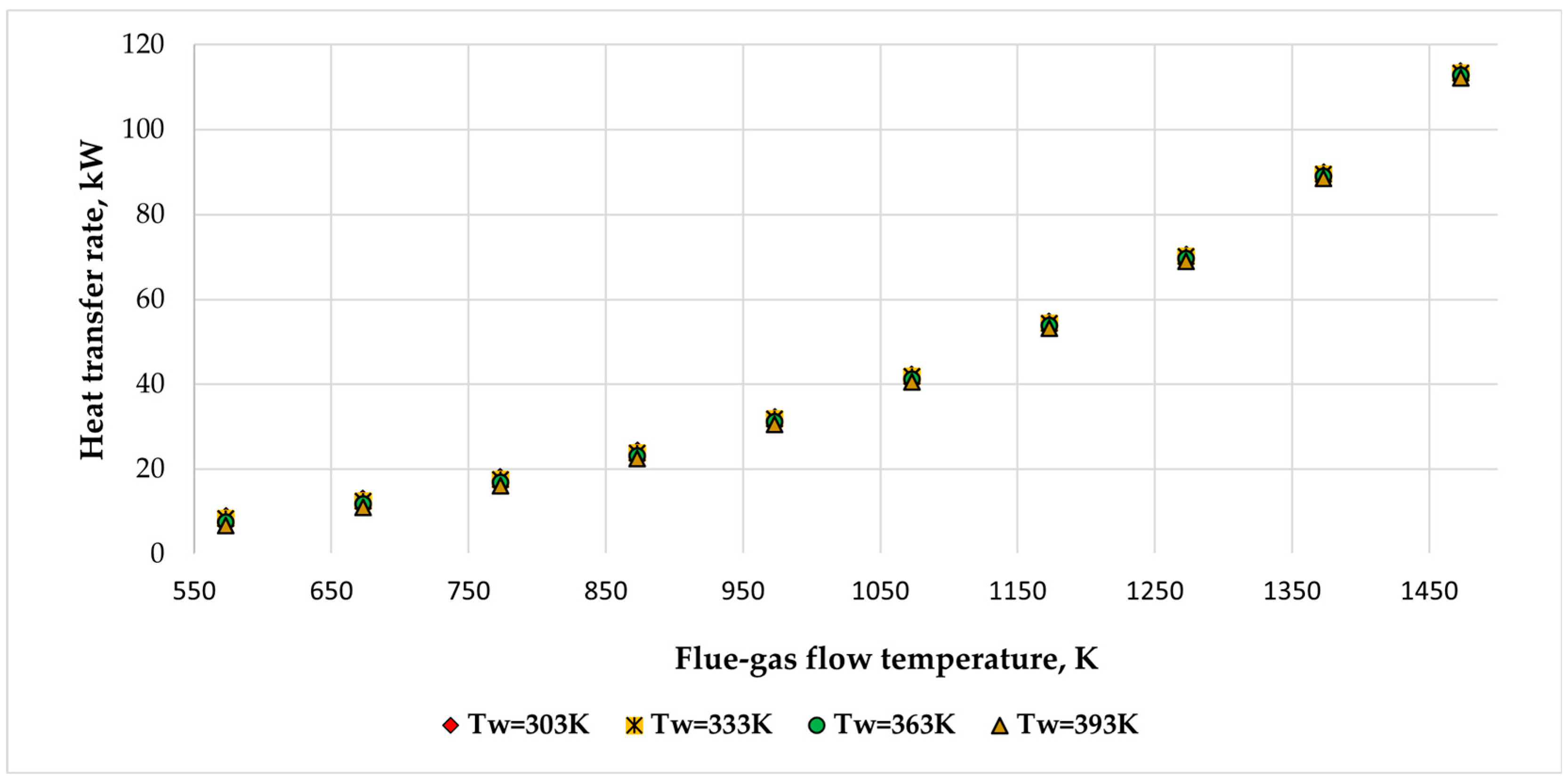

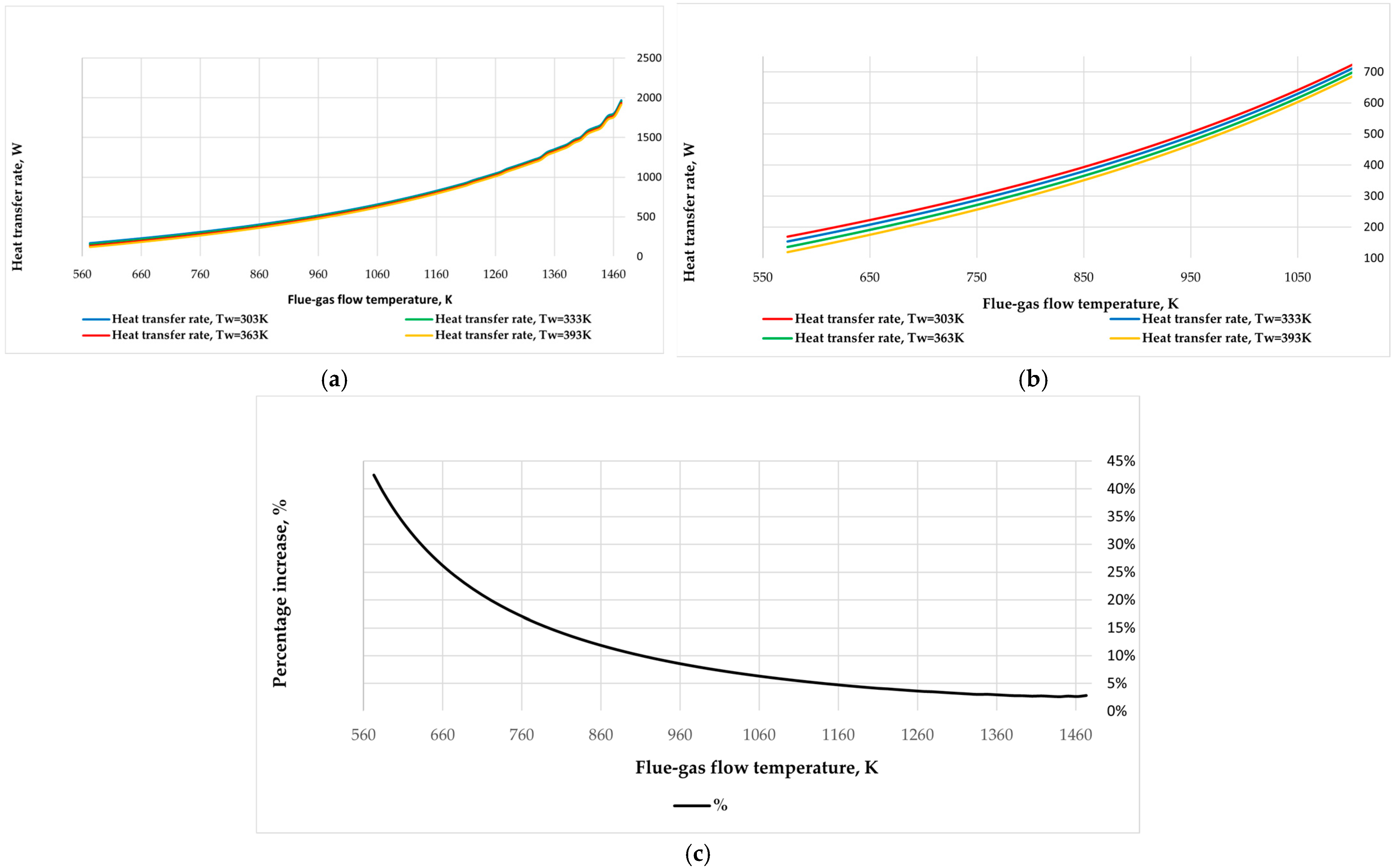

3.2.1. Heat Transfer Rate Comparison at Different Temperatures of the Pipe Wall

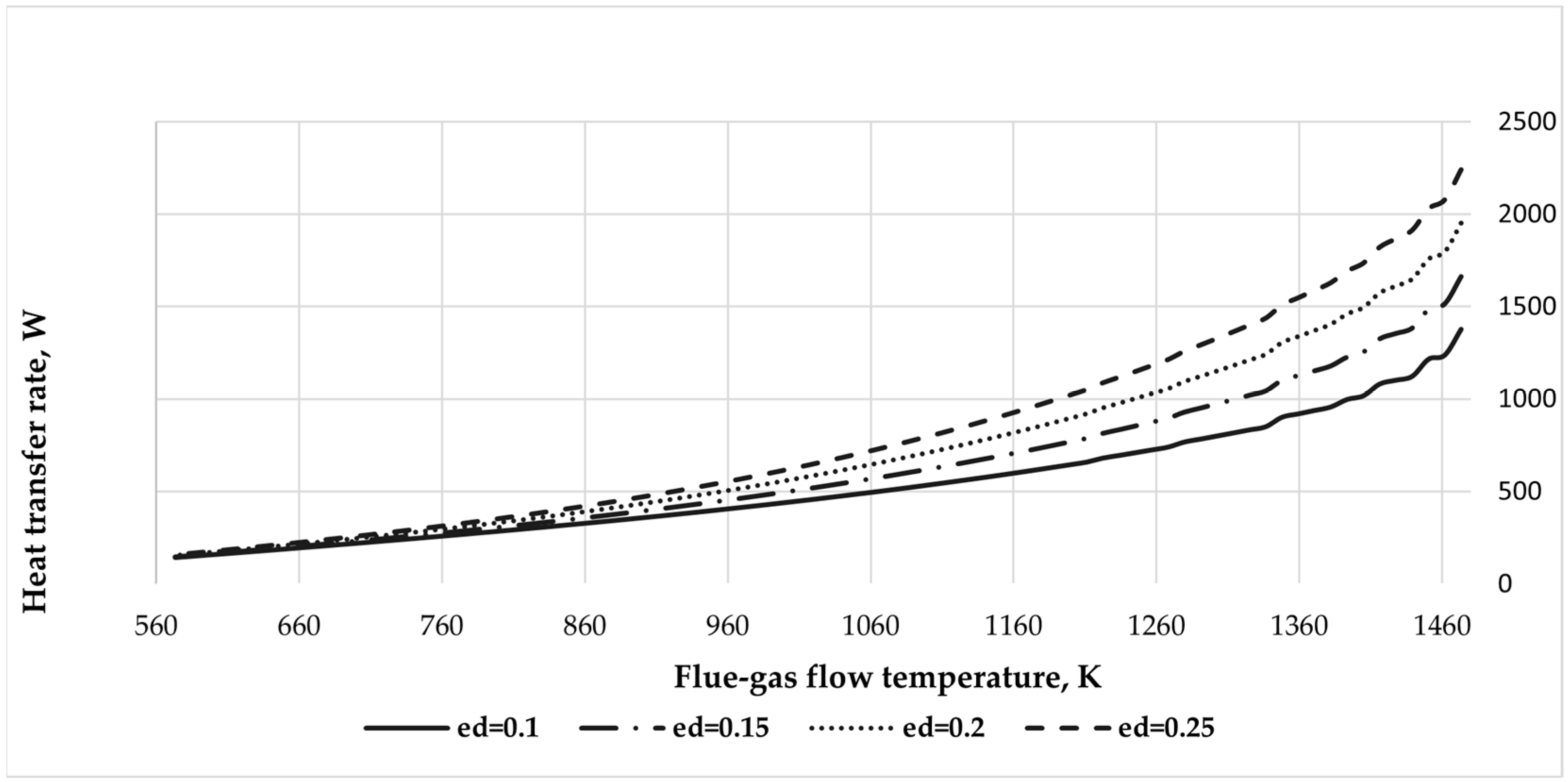

3.2.2. Heat Transfer Rate Comparison in Different Spectral Emissivities of Flue-Gas Flow

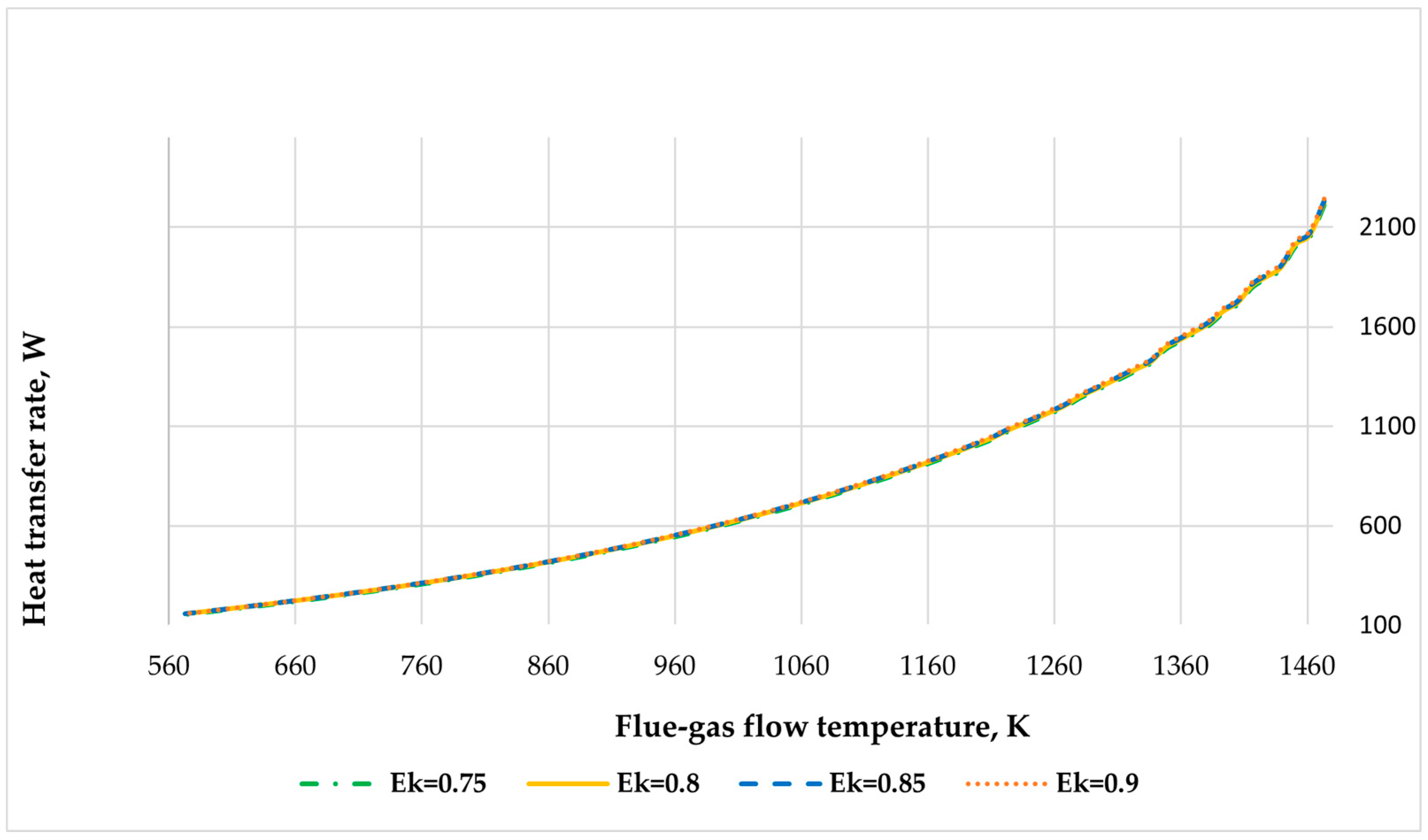

3.2.3. Heat Transfer Rate Comparison in Different Body Spectral Emissivity of Pipe and Inserted Plate Material

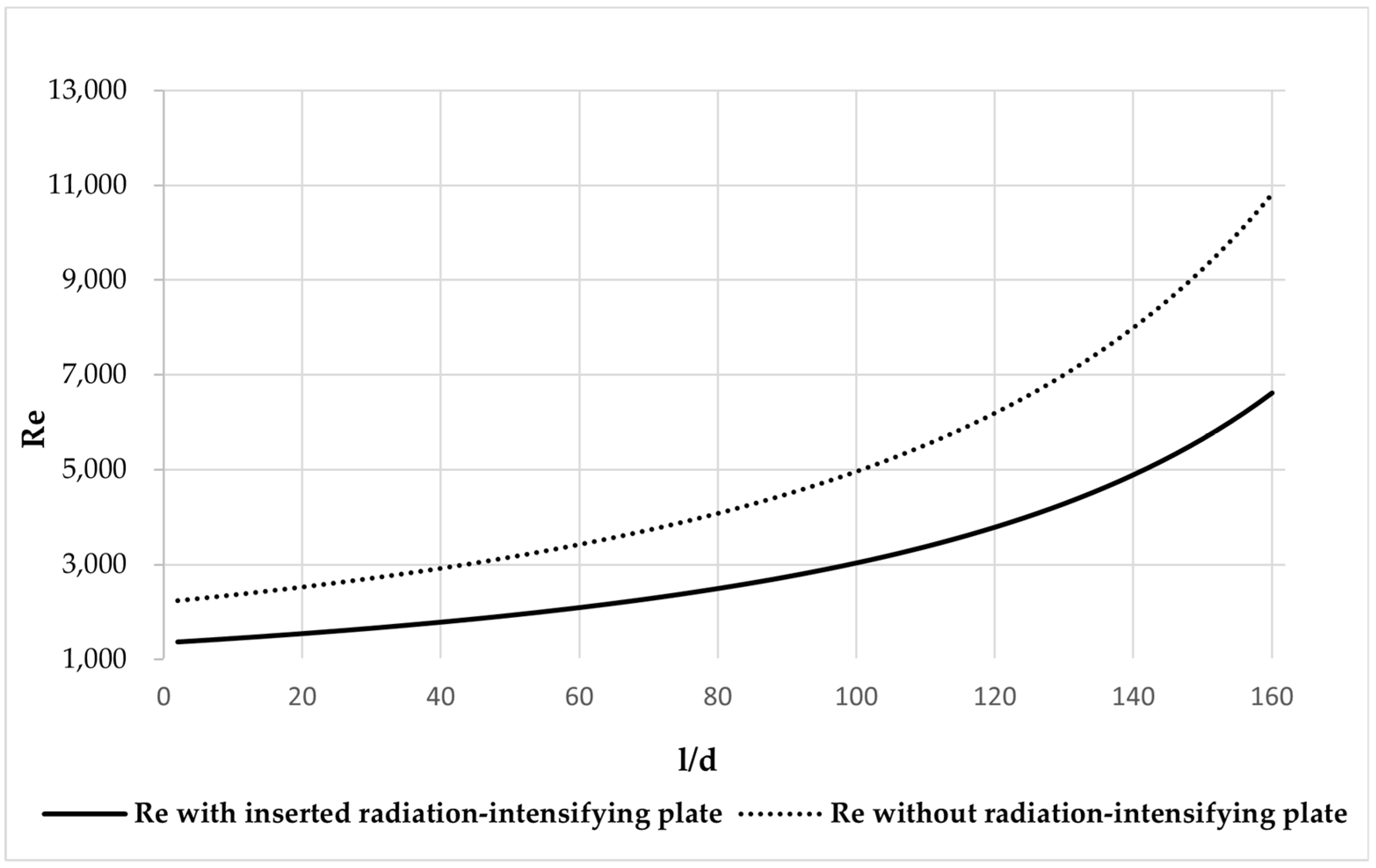

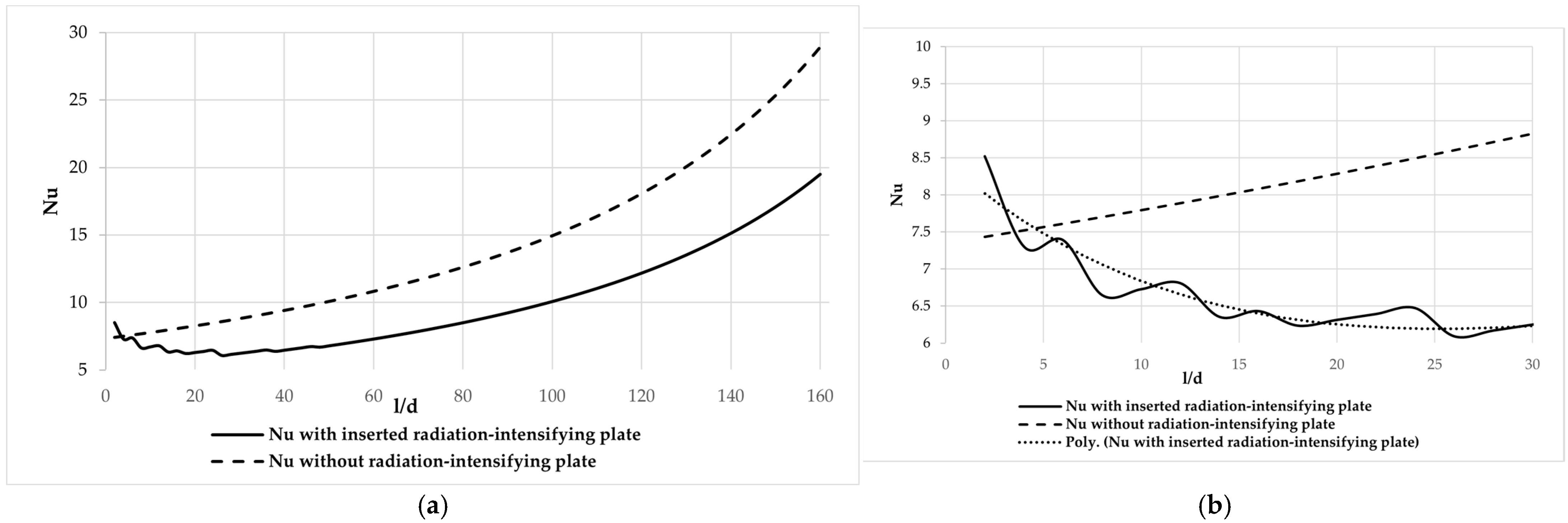

3.2.4. Correlation of Reynolds and Nusselt Numbers with Geometrical Ratios

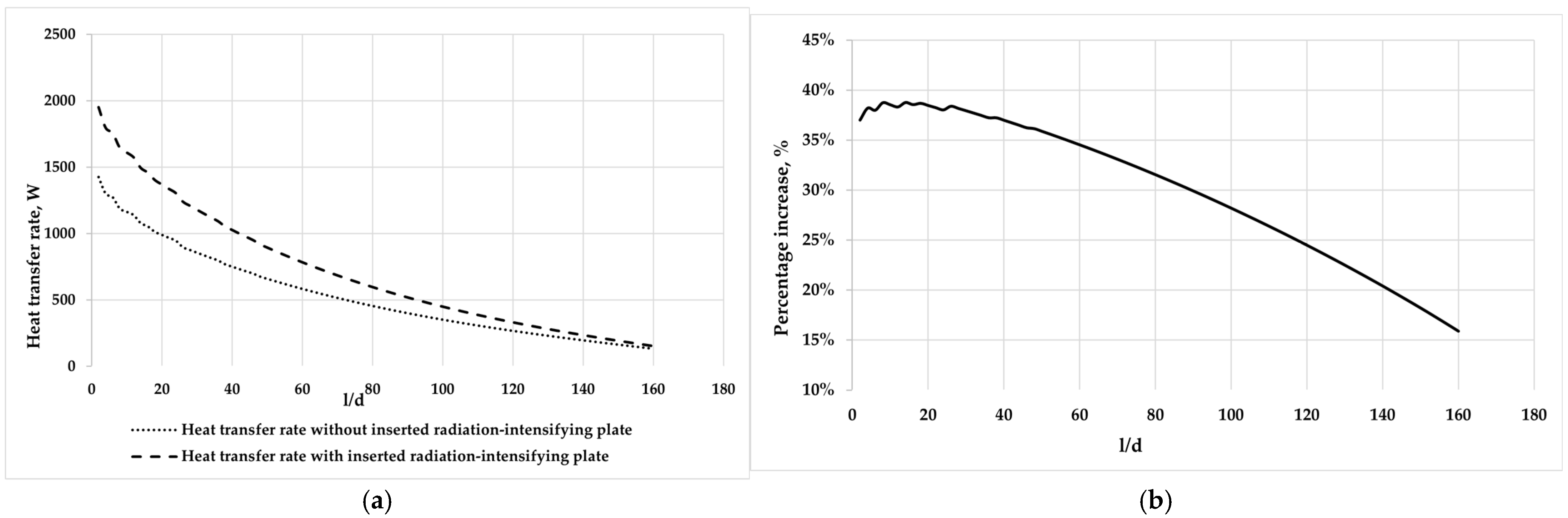

3.2.5. Comparison of the Overall Heat Transfer Rate Increase

3.3. Summary of the Results

4. Discussion and Key Findings

5. Conclusions and Future Scope

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Ad | absorption coefficient of the flue-gas flow | Re | Reynolds number |

| C0 | absolutely black body radiation coefficient, W/m2·K4 | SLR | systematic literature review |

| d | characteristic dimension of channel, m | Tgasflow | flue-gas temperature, K |

| dek | characteristic dimension of channel, m | Tshield | temperature of inserted shield, K |

| f | cross-sectional area of the channel, m2 | Tw | temperature of wall, K |

| Fs | wall surface area, m2 | w | velocity of flow gas, m/s |

| Fshield | surface area of shield, m2 | α | heat transfer coefficient, W/K |

| Fshield | surface area of shield, m2 | β | thermal expansion coefficient of the fluid volume, 1/K |

| g | gravity acceleration, m/s2 | Δ | difference |

| Gr | Grashof number | ε | spectral emissivity of the wall |

| l | length of pipe, m | εd | spectral emissivity of the gas flow |

| Nu | Nusselt number | εl | multiplier for laminar flow |

| P | the perimeter of the channel, m | εt | emissivity of the surface system |

| Prf | Prandtl number of flue-gas flow | εt | multiplier for turbulent flow |

| Prp | Prandtl number of wall | λ | thermal conductivity coefficient, W/m∙K |

| Qcon | amount of heat received by convection from the flue-gas flow, W | σ0 | Stefan–Boltzmann constant, W/m2·K4 |

| Qr | amount of heat received by radiation from the flue-gas flow, W | υ | kinematic viscosity, m2/s |

| Qrshield | amount of heat radiated from shield to the walls, W | φshield | angular coefficient of radiation from the shield |

References

- Darbandi, T.; Risberg, M.; Westerlund, L. Enhancing particle segregation in stem wood combustion flue gas wet scrubbers: Experimental investigation of operational conditions. Case Stud. Therm. Eng. 2024, 64, 105427. [Google Scholar] [CrossRef]

- Ilona, J.; Choate, W.T.; Davidson, A. Waste Heat Recovery. Technology and Opportunities in US Industry; BCS, Inc.: Laurel, MD, USA, 2008. [Google Scholar]

- Suanes, G.; Bolonio, D.; Cantero, A.; Yenes, J.I. Principles for the Design of a Biomass-Fueled Internal Combustion Engine. Energies 2024, 17, 1700. [Google Scholar] [CrossRef]

- Belousov, A.; Lushpeev, V.; Sokolov, A.; Sultanbekov, R.; Tyan, Y.; Ovchinnikov, E.; Shvets, A.; Bushuev, V.; Islamov, S. Experimental Research of the Possibility of Applying the Hartmann–Sprenger Effect to Regulate the Pressure of Natural Gas in Non-Stationary Conditions. Processes 2025, 13, 1189. [Google Scholar] [CrossRef]

- Zhien, C.Y.; Al-attab, K.A.; Enagi, I.I.; Mohamed, A.R.; Badruddin, I.A.; Kamangar, S.; Baig, M.A.A. Numerical evaluation of low-grade producer gas flow and combustion characteristics in swirl combustor. Case Stud. Therm. Eng. 2025, 69, 106008. [Google Scholar] [CrossRef]

- Shank, K.; Tiari, S. A review on active heat transfer enhancement techniques within latent heat thermal energy storage systems. Energies 2023, 16, 4165. [Google Scholar] [CrossRef]

- Nitturi, L.K.; Kapu, V.K.S.; Gugulothu, R.; Kaleru, A.; Vuyyuri, V.; Farid, A. Augmentation of heat transfer through passive techniques. Heat Transf. 2023, 52, 4422–4449. [Google Scholar] [CrossRef]

- Kakaç, S.; Pramuanjaroenkij, A. Review of convective heat transfer enhancement with nanofluids. Int. J. Heat Mass Transf. 2009, 52, 3187–3196. [Google Scholar] [CrossRef]

- Garg, M.O.; Nautiyal, H.; Khurana, S.; Shukla, M.K. Heat transfer augmentation using twisted tape inserts: A review. Renew. Sustain. Energy Rev. 2016, 63, 193–225. [Google Scholar]

- Marzouk, S.A.; Al-Sood, M.M.A.; El-Said, E.M.; Younes, M.M.; El-Fakharany, M.K. A comprehensive review of methods of heat transfer enhancement in shell and tube heat exchangers. J. Therm. Anal. Calorim. 2023, 148, 7539–7578. [Google Scholar] [CrossRef]

- Deshmukh, P.W.; Kasar, S.V.; Prabhu, S.V. A comprehensive compendium on passive augmentation techniques for enhancement of single-phase heat transfer coefficients in heat exchanger tubes under laminar and turbulent flow conditions. Heat Transf. Eng. 2023, 44, 530–579. [Google Scholar] [CrossRef]

- Xin, Z.; Chen, J.; Gu, S.; Li, K. Passive enhancement of heat transfer in a microchannel by an adjoint system of cylinder and flexible beam. Numer. Heat Transf. Part A Appl. 2022, 82, 765–787. [Google Scholar] [CrossRef]

- Sagar, J.P.; Ankith, B.; Rao, P.S.; Reddy, P.R.; Elipey, M.K. A review on heat transfer enhancement methods for a heat exchanger. In Proceedings of the 8th Annual International Seminar on Trends in Science And Science Education (AISTSSE) 2021, Medan, Indonesia, 3 November 2022; Volume 2648. [Google Scholar]

- Pavel, B.I.; Mohamad, A.A. An experimental and numerical study on heat transfer enhancement for gas heat exchangers fitted with porous media. Int. J. Heat Mass Transf. 2004, 47, 4939. [Google Scholar] [CrossRef]

- Hong, Y.; Du, J.; Li, Q.; Xu, T.; Li, W. Thermal-hydraulic performances in multiple twisted tapes inserted sinusoidal rib tube heat exchangers for exhaust gas heat recovery applications. Energy Convers. Manag. 2019, 185, 271. [Google Scholar] [CrossRef]

- Neshumayev, D. Experimental and Numerical Investigation of Combined Heat Transfer Enhancement Technique in Gas-Heated Channels; Tallinn University of Technology Press: Tallinn, Estonia, 2005. [Google Scholar]

- Morelli, A.; Tognoli, M.; Ghidoni, A.; Najafi, B.; Rinaldi, F. Reduced FV modelling based on CFD database and experimental validation for the thermo-fluid dynamic simulation of flue gases in horizontal fire-tubes. Int. J. Heat Mass Transf. 2022, 194, 123033. [Google Scholar] [CrossRef]

- Jasinski, P.B. Numerical Study of Heat Transfer Intensification in a Circular Tube Using a Thin, Radiation-Absorbing Insert. Part 2: Thermal Performance. Energies 2021, 14, 4533. [Google Scholar] [CrossRef]

- Dewey, A.; Drahota, A. Introduction to Systematic Reviews: Online Learning Module Cochrane Training. 2016. Available online: https://www.cochrane.org/learn/courses-and-resources/interactive-learning/module-1-introduction-conducting-systematic-reviews (accessed on 15 March 2025).

- Cooke, A.; Smith, D.; Booth, A. Beyond PICO: The SPIDER tool for qualitative evidence synthesis. Qual. Health Res. 2012, 22, 1435–1443. [Google Scholar] [CrossRef]

- Cambridge Dictionary. Volume 2025, No. 02.11. Available online: https://dictionary.cambridge.org/dictionary/english/eligibility (accessed on 10 May 2025).

- Ma, X.; Hu, S.; Hu, W.; Luo, Y.; Cheng, H. Experimental investigation of waste heat recovery of thermoelectric generators with temperature gradient. Int. J. Heat Mass Transf. 2022, 185, 122342. [Google Scholar] [CrossRef]

- Vahidifar, S.; Banihashemi, S. Experimental and numerical evaluation of heat transfer enhancement by internal flow excitation. Int. J. Therm. Sci. 2023, 192, 108395. [Google Scholar] [CrossRef]

- Bisetto, A.; Del Col, D.; Schievano, M. Fire tube heat generators: Experimental analysis and modeling. Appl. Therm. Eng. 2014, 78, 236. [Google Scholar] [CrossRef]

- Azari, A.; Derakhshandeh, M. An experimental comparison of convective heat transfer and friction factor of Al2O3 nanofluids in a tube with and without butterfly tube inserts. J. Taiwan Inst. Chem. Eng. 2015, 52, 31. [Google Scholar] [CrossRef]

- Awais, M.; Bhuiyan, A.A. Heat transfer enhancement using different types of vortex generators (VGs): A review on experimental and numerical activities. Therm. Sci. Eng. Prog. 2018, 5, 524. [Google Scholar] [CrossRef]

- Morelli, A.; Ghidoni, A.; Lezzi, A.M.; Noventa, G. Integrated approach based on surrogate optimization and CFD for the design of helical turbulators. Therm. Sci. Eng. Prog. 2023, 39, 101741. [Google Scholar] [CrossRef]

- Subirana, A.M.; Solano, J.P.; Herrero-Martín, R.; García, A.; Pérez-García, J. Mixed convection phenomena in tubes with wire coil inserts. Therm. Sci. Eng. Prog. 2023, 42, 101839. [Google Scholar] [CrossRef]

- Sharifi, K.; Sabeti, M.; Rafiei, M.; Mohammadi, A.H.; Ghaffari, A.; Asl, M.H.; Yousefi, H. A good contribution of computational fluid dynamics (CFD) and GA-ANN methods to find the best type of helical wire inserted tube in heat exchangers. Int. J. Therm. Sci. 2020, 154, 106398. [Google Scholar] [CrossRef]

- Louahdi, M.; Salhi, J.; Essaouini, H.; Zarrouk, T.; Lahlaouti, M.L. Three-dimensional analysis for optimizing thermo-hydrodynamic performance of heat exchangers with perforated semi-circular inserts. Case Stud. Therm. Eng. 2024, 60, 104611. [Google Scholar] [CrossRef]

- Javadi, S.M.; Banihashemi, S. Study of thermal performance and optimization of city gas station heaters equipped with turbulator in the fire tube section. Therm. Sci. Eng. Prog. 2022, 37, 101573. [Google Scholar] [CrossRef]

- Kamaei, R.; Izadi, M.; Altnji, S.; Majdoub, F.; Hajjar, A.; Alqurashi, F.; Mohamed, M.H.; Hamida, M.B.B. All-around review on applying passive strategies to improve heat exchanger performance using inserts and turbulators applied in thermal storage. Int. Commun. Heat Mass Transf. 2024, 159, 108234. [Google Scholar] [CrossRef]

- Neshumayev, D.; Ots, A.; Laid, J.; Tiikma, T. Experimental investigation of various turbulator inserts in gas-heated channels. Exp. Therm. Fluid Sci. 2004, 28, 877. [Google Scholar] [CrossRef]

- Neshumayev, D.; Tiikma, T. Radiation heat transfer of turbulator inserts in gas heated channels. Heat Transf. Res. 2008, 39, 403–412. [Google Scholar] [CrossRef]

- Murthy, H.M.S.; Hegde, R.N.; Rai, N. Effect on performance of a CTHE by using twisted tapes and Al2O3 nanofluids: An experimental study and correlation development. Sādhanā 2024, 49, 205. [Google Scholar] [CrossRef]

- Abd-Elhady, M.S.; Malayeri, M.R. Mitigation of Soot Deposition in Exhaust Gas Recirculation Coolers Using a Spiral Insert. Aerosol Sci. Technol. 2014, 48, 184. [Google Scholar] [CrossRef]

- Qudah, S.A.; Radwan, A.; El-Sharkawy, I.I. Experimental analysis of heat transfer in a circular tube fitted with new twisted tape insert with rings using response surface methodology. Int. J. Heat Fluid Flow 2025, 112, 109713. [Google Scholar] [CrossRef]

- Abbas, A.; Ayub, Z.; Ayub, A.; Li, W.; Khan, S. Comparing single-phase thermal hydraulic performance of a right and left turn twisted tape insert in a tube. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 123. [Google Scholar] [CrossRef]

- Ifraj, N.F.; Fahad, M.K.; Tahsin, S.H.; Haque, M.R.; Haque, M.M. Numerical investigation of the thermal performance optimization inside a heat exchanger tube using different novel combination of perforations on Y-shaped insert. Int. J. Therm. Sci. 2023, 194, 108583. [Google Scholar] [CrossRef]

- Maleki, N.M.; Pourahmad, S.; Tavousi, E.; Perera, N.; Talebizadehsardari, P.; Keshmiri, A. Thermal-frictional behavior of solid magnetic strip turbulator and helical coiled wire turbulator inside a double tube heat exchanger. Int. Commun. Heat Mass Transf. 2025, 161, 108406. [Google Scholar] [CrossRef]

- Ifraj, N.F.; Akter, F.; Fahad, M.K.; Ahmed, D.H. Thermal-hydraulic performance enhancement with minimum entropy generation of a heat exchanger using fidget spinner vortex generators. Int. Commun. Heat Mass Transf. 2025, 162, 108610. [Google Scholar] [CrossRef]

- Khoshvaght-Aliabadi, M.; Akbari, M.H.; Hormozi, F. An empirical study on vortex-generator insert fitted in tubular heat exchangers with dilute Cu–water nanofluid flow. Chin. J. Chem. Eng. 2016, 24, 728. [Google Scholar] [CrossRef]

- Sharma, B. Effect of flow structure on heat transfer in compact heat exchanger by using finite thickness winglet at acute angle. J. Therm. Eng. 2017, 3, 1149–1162. [Google Scholar] [CrossRef]

- Keshari, V.; Maiya, M.P. Design and investigation of hydriding alloy based hydrogen storage reactor integrated with a pin fin tube heat exchanger. Int. J. Hydrogen Energy 2018, 43, 7081. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, M.; Li, Y.; Wang, Y.; Ge, M. Numerical investigation of an exhaust thermoelectric generator with a perforated plate. Energy 2022, 263, 125776. [Google Scholar] [CrossRef]

- Al-haidari, S.R.; Al-obaidi, A.R. Evaluation of hydraulic thermal flow and heat performance augmentation in a 3D tube fitted with varying concavity dimple turbulator configurations. Heat Transf. 2024, 54, 420. [Google Scholar] [CrossRef]

- Banihashemi, S.; Assari, M.; Javadi, S.; Vahidifar, S. The Effect of Flow Excitation with Stationary and Rotating Obstacles in a Heat Exchanger Tube on Thermal–Hydraulic Characteristics. Iran. J. Sci. Technol. Trans. Mech. Eng. 2022, 46, 465–480. [Google Scholar] [CrossRef]

- Zhang, J.M.; Sutton, W.H.; Lai, F.C. Enhancement of heat transfer using porous convection-to-radiation converter for laminar flow in a circular duct. Int. J. Heat Mass Transf. 1997, 40, 39–48. [Google Scholar] [CrossRef]

- Plotnikov, L.; Osipov, L. The Influence of Gas-Dynamic Non-Stationarity of Air Flow on the Heat Transfer Coefficient in Round and Triangular Straight Pipes with Different Turbulence Intensities. Appl. Sci. 2024, 14, 7758. [Google Scholar] [CrossRef]

- Rinik, R.A.; Bhuiyan, A.A.; Karim, M.R. Enhancement of heat transfer using elliptical twisted inner pipe with convergent conical ring turbulator for turbulent flow in double pipe heat exchanger. Int. J. Therm. Sci. 2025, 210, 109558. [Google Scholar] [CrossRef]

- Salman, Z.; Kadhim, Z.; Khalaf, K. Numerical study of helical tape inserts for air to oil double pipe heat exchanger. J. Mech. Eng. Res. Dev. 2021, 44, 207–220. [Google Scholar]

- Güngör, A.; Khanlari, A.; Sözen, A.; Variyenli, H.I. Numerical and experimental study on thermal performance of a novel shell and helically coiled tube heat exchanger design with integrated rings and discs. Int. J. Therm. Sci. 2022, 182, 107781. [Google Scholar] [CrossRef]

- Mei, B.; Abed, A.M.; Patel, P.; Kulshreshta, A.; Ayed, H.; Mouldi, A.; Mahariq, I. A numerical investigation for heat transfer enhancement possibility for a novel perforated twisted hyperbolic turbulator (PTHT) inside a heated tube. Case Stud. Therm. Eng. 2024, 65, 105666. [Google Scholar] [CrossRef]

- Banihashemi, S.; Assari, M.; Javadi, S.; Vahidifar, S. Study the effect of innovative active and passive methods on thermal characteristics and turbulent flow behaviour in a heat exchanger pipe. J. Therm. Anal. Calorim. 2024, 149, 777–797. [Google Scholar] [CrossRef]

- Pulin, A.; Laptev, M.; Kortikov, N.; Barskov, V.; Roschenko, G.; Alisov, K.; Talabira, I.; Gong, B.; Rassokhin, V.; Popovich, A.; et al. Numerical Investigation of Heat Transfer Intensification Using Lattice Structures in Heat Exchangers. Energies 2024, 17, 3333. [Google Scholar] [CrossRef]

- Assari, M.; Banihashemi, S.; Setareh, M.; Joudakinia, M. Investigating the Performance and Thermal Characteristics of Turbulent Flow in a Heat Exchanger Tube with Gridded Oval Slant Inserts. Iran. J. Sci. Technol. Trans. Mech. Eng. 2024, 48, 629–645. [Google Scholar] [CrossRef]

- Karami, A.; Ranjbar, B.; Rahimi, M.; Mohammadi, F. Novel hybrid neuro-fuzzy model to anticipate the heat transfer in a heat exchanger equipped with a new type of self-rotating tube insert. Eur. Phys. J. E 2022, 45, 92. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Yang, L.; Su, Z.; Song, J.; Liu, S.; Li, X. Research progress on boiling heat transfer of nanofluids with emphasis on IVR-ERVC strategy. Therm. Sci. Eng. Prog. 2023, 39, 101716. [Google Scholar] [CrossRef]

- Hukkeri, K. VDI Heat Atlas: With 1011 Figures and 539 Tables; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Gimbutis, G.; Kajutis, K.; Krukonis, V. Šiluminė Technika; Mokslas: Vilnius, Lithuania, 1993. [Google Scholar]

| l/d | 1 | 2 | 5 | 10 | 15 | 20 | 30 | 40 | 50 |

|---|---|---|---|---|---|---|---|---|---|

| 1.9 | 1.7 | 1.44 | 1.28 | 1.18 | 1.13 | 1.0 | 1.02 | 1.0 |

| Re | l/d | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 5 | 10 | 15 | 20 | 30 | 45 | 50 and More | |

| 1 · 104 | 1.65 | 1.50 | 1.34 | 1.23 | 1.17 | 1.13 | 1.07 | 1.03 | 1.0 |

| 2 · 104 | 1.51 | 1.40 | 1.27 | 1.18 | 1.13 | 1.10 | 1.05 | 1.02 | 1.0 |

| 5 · 104 | 1.34 | 1.27 | 1.18 | 1.13 | 1.10 | 1.08 | 1.04 | 1.02 | 1.0 |

| 1 · 105 | 1.28 | 1.22 | 1.15 | 1.10 | 1.08 | 1.06 | 1.03 | 1.02 | 1.0 |

| 1 · 106 | 1.14 | 1.11 | 1.08 | 1.05 | 1.04 | 1.03 | 1.02 | 1.01 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menkeliūnienė, J.; Jonynas, R.; Paukštaitis, L.; Balčius, A.; Buinevičius, K. Heat Transfer Enhancement in Flue-Gas Systems with Radiation-Intensifying Inserts: An Analytical Approach. Energies 2025, 18, 3383. https://doi.org/10.3390/en18133383

Menkeliūnienė J, Jonynas R, Paukštaitis L, Balčius A, Buinevičius K. Heat Transfer Enhancement in Flue-Gas Systems with Radiation-Intensifying Inserts: An Analytical Approach. Energies. 2025; 18(13):3383. https://doi.org/10.3390/en18133383

Chicago/Turabian StyleMenkeliūnienė, Justina, Rolandas Jonynas, Linas Paukštaitis, Algimantas Balčius, and Kęstutis Buinevičius. 2025. "Heat Transfer Enhancement in Flue-Gas Systems with Radiation-Intensifying Inserts: An Analytical Approach" Energies 18, no. 13: 3383. https://doi.org/10.3390/en18133383

APA StyleMenkeliūnienė, J., Jonynas, R., Paukštaitis, L., Balčius, A., & Buinevičius, K. (2025). Heat Transfer Enhancement in Flue-Gas Systems with Radiation-Intensifying Inserts: An Analytical Approach. Energies, 18(13), 3383. https://doi.org/10.3390/en18133383