Environmental Impact Assessment of Heat Storage System in Rock-Bed Accumulator

Abstract

1. Introduction

2. Materials and Methods

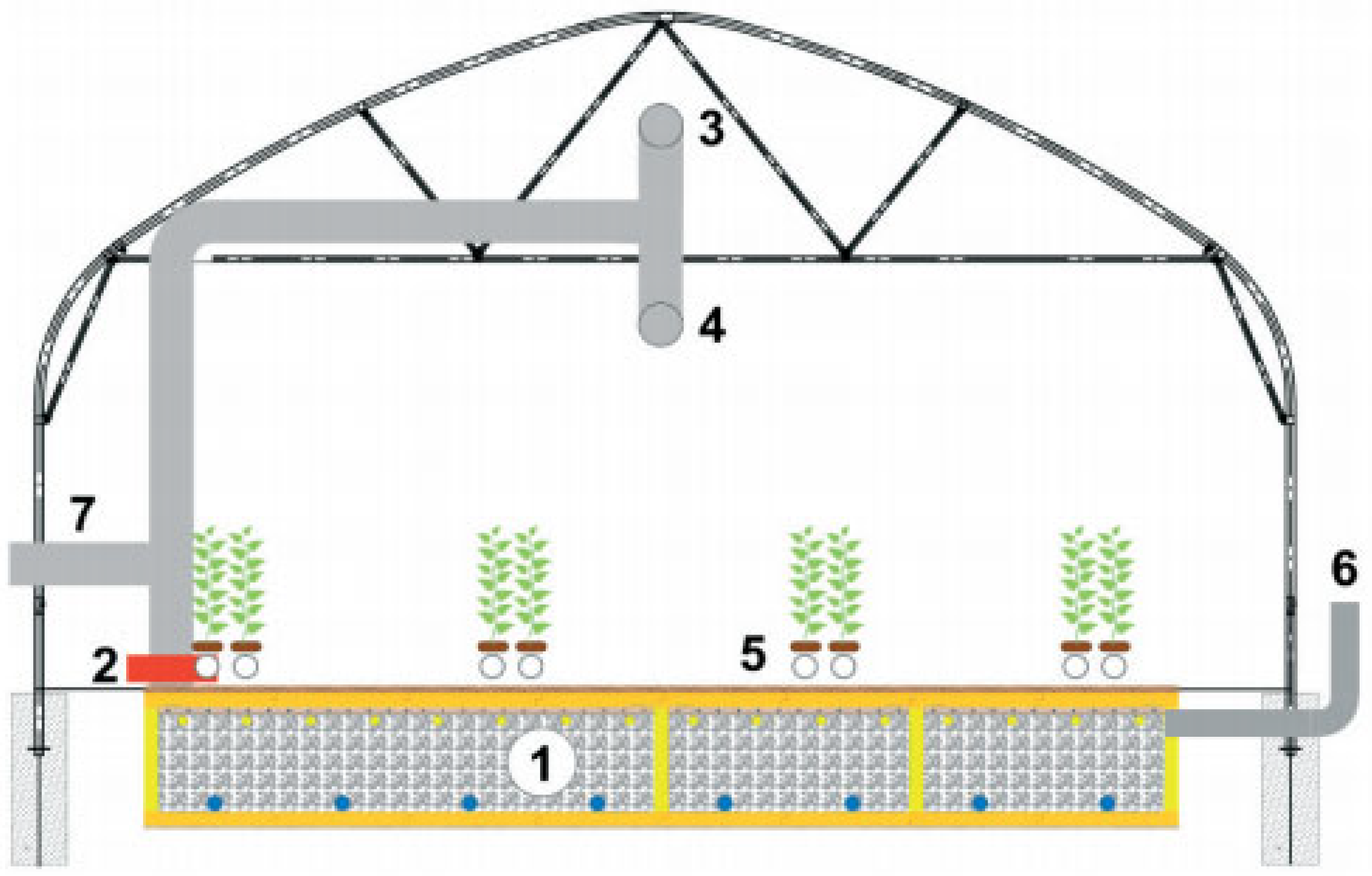

2.1. Characteristics of the Analyzed Object

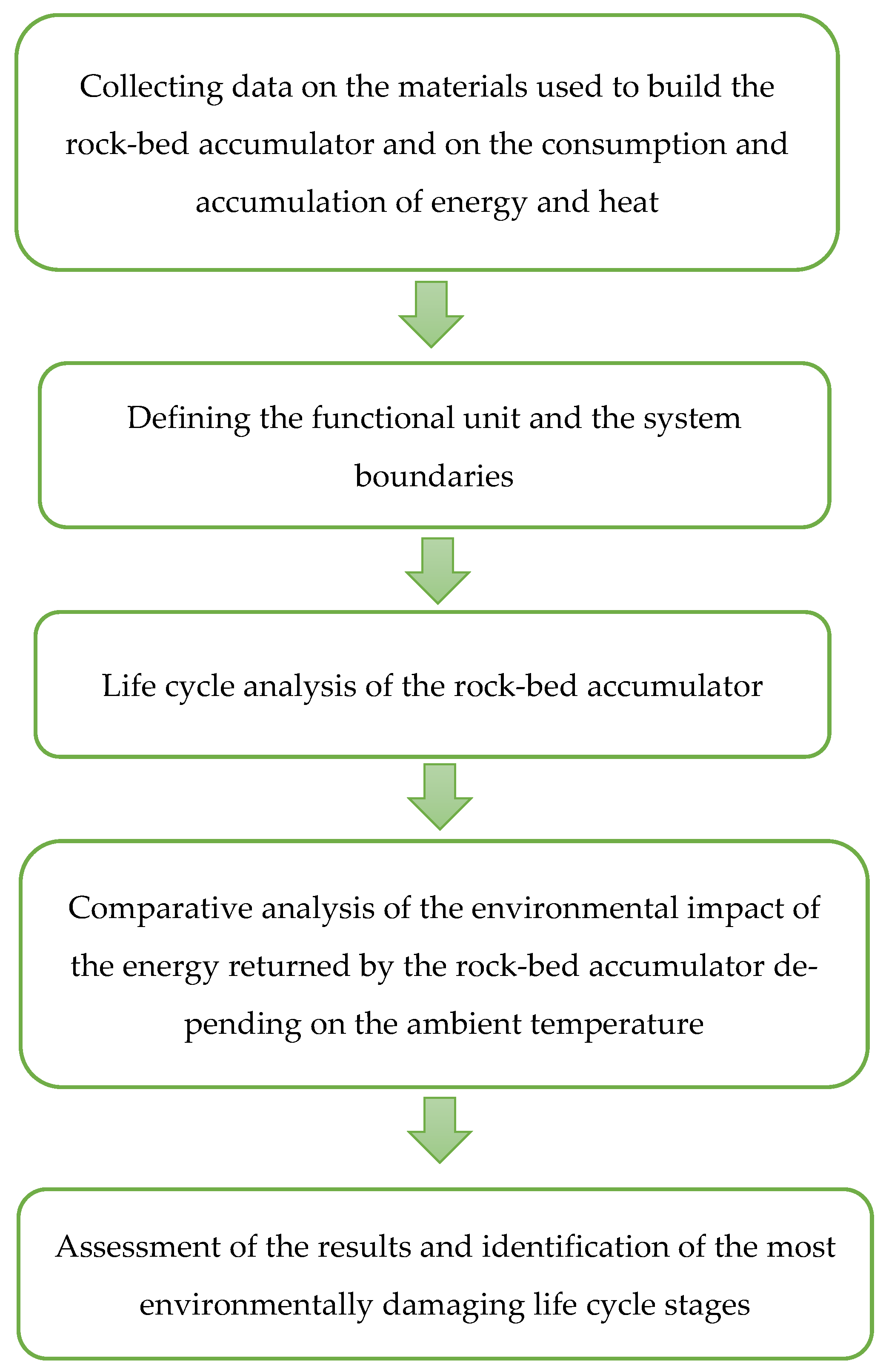

2.2. Scope of Analyses

2.3. LCA Modelling

2.3.1. Purpose, Scope, Functional Unit, System Boundaries, and Life Cycle Inventory

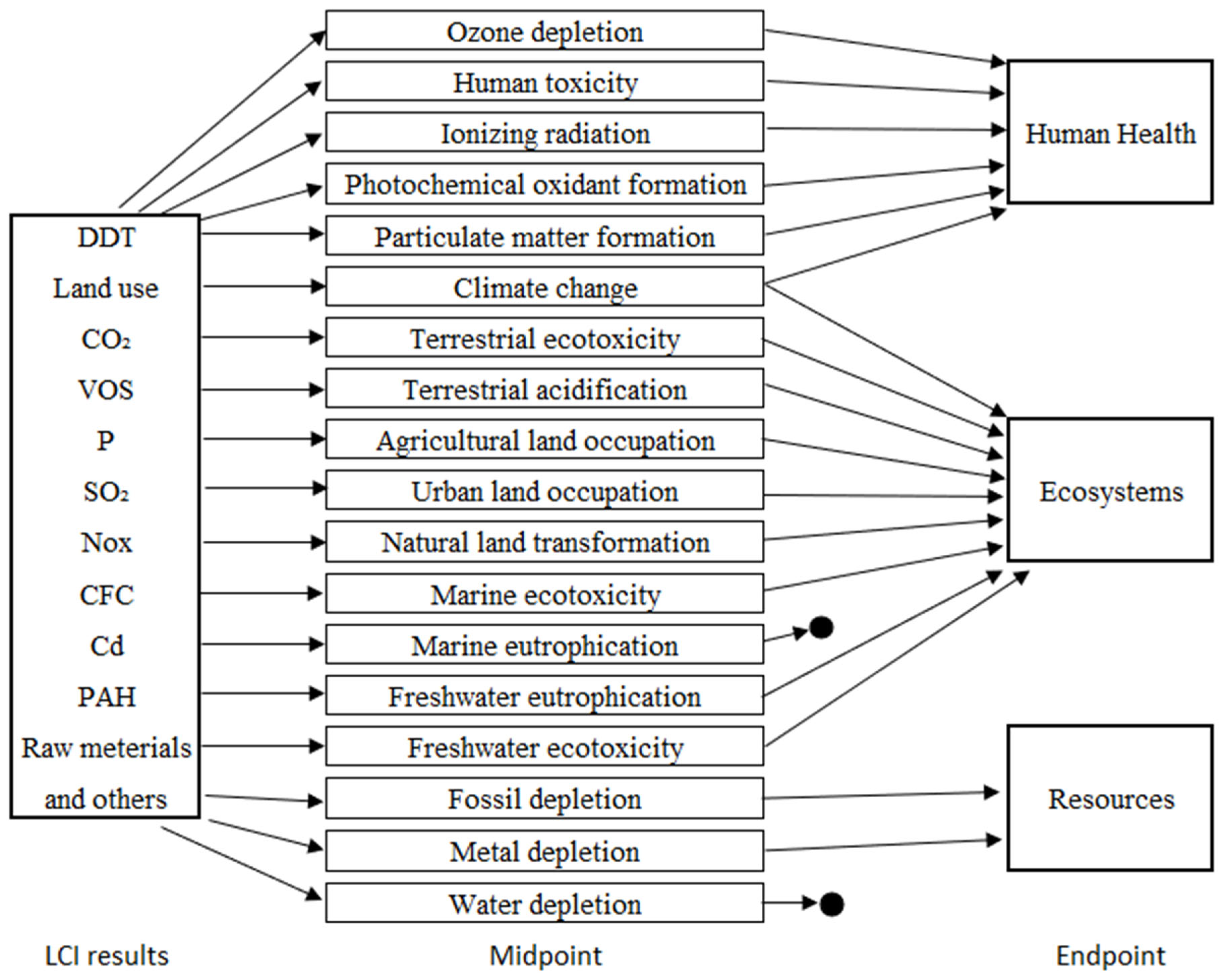

2.3.2. Environmental Impact Assessment

- Im—total impact in midpoint category m (e.g., kg CO2 eq, kg 1,4-DB eq, kg SO2 eq);

- Ei—quantity of elementary flow (e.g., emission or resource use) i (e.g., kg);

- CFi,m—characterization factor linking flow i to impact category m;

- n—total number of elementary flows considered.

- EGHGm—total emissions of greenhouse gas m (e.g., CO2, CH4, N2O);

- CFE,m—characterization factor converting emissions of gas m into CO2-equivalent (where for GWP100 (for a 100-year horizon): CO2 = 1, CH4 = 25 and N2O = 298).

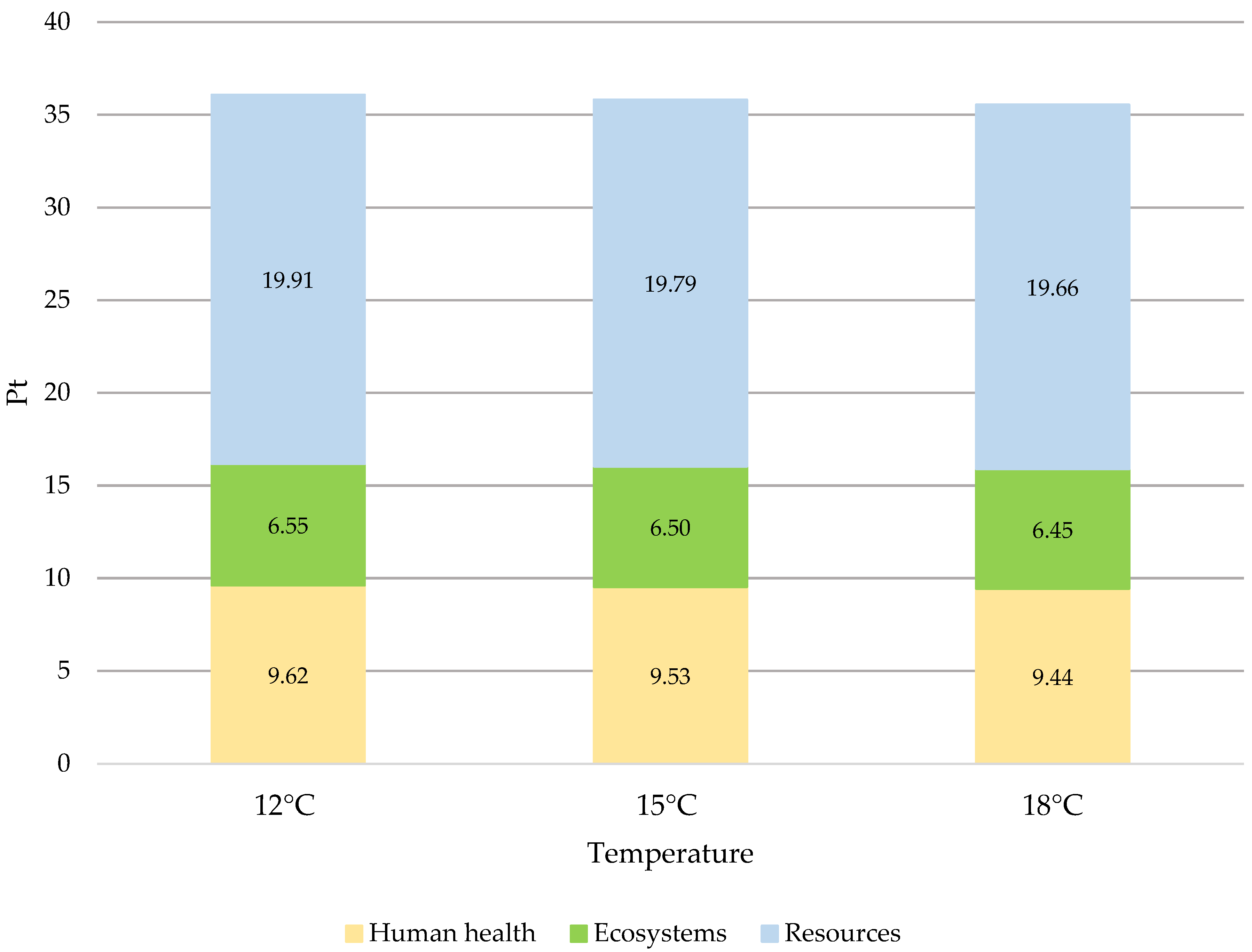

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sowa, S. Odnawialne źródła energii jako źródło energii zużywanej. Inst. Gospod. Górnik Surowcami Energ. PAN 2018, 105, 187–196. [Google Scholar] [CrossRef]

- Riesener, M.; Kuhn, M.; Hellwig, F.; Ays, J.; Schuh, G. Design for Circularity—Identification of Fields of Action for Ecodesign for the Circular Economy. Procedia CIR 2023, 116, 137–142. [Google Scholar] [CrossRef]

- Gawlik, L.; Mokrzycki, E. Fossil fuels in the national power sector—Problems and challenges. Energy Policy J. 2017, 20, 6–26. [Google Scholar]

- Bodziacki, S.; Malinowski, M.; Famielec, S.; Krakowiak-Bal, A.; Basak, Z.; Łukasiewicz, M.; Wolny-Koładka, K.; Atılgan, A.; Artun, O. Environmental Assessment of Energy System Upgrades in Public Buildings. Energies 2024, 17, 3278. [Google Scholar] [CrossRef]

- Jamrozik, A.; Głuszek, A.; Olejnik, A. Modern methods of energy storage. J. Civ. Eng. Environ. Archit. 2014, 61, 227–236. [Google Scholar] [CrossRef]

- Elalfy, D.A.; Gouda, E.; Kotb, M.F.; Bureš, B.E.; Sedhom, B.E. Comprehensive review of energy storage systems technologies, objectives, challenges, and future trends. Energy Strategy Rev. 2024, 54, 101482. [Google Scholar] [CrossRef]

- Mikola, A.; Kõiv, T.-A.; Maivel, M. Production of domestic hot water with solar thermal collectors in north-European apartment buildings. Int. J. Mech. Eng. Technol. (IJMET) 2016, 7, 58–66. [Google Scholar]

- Hyvönen, J.; Santasalo-Aarnio, A.; Syri, S.; Lehtonen, M. Feasibility study of energy storage options for photovoltaic electricity generation in detached houses in Nordic climates. J. Energy Storage 2022, 54, 105330. [Google Scholar] [CrossRef]

- Zsiborács, H.; Vincze, A.; Pintér, G.; Baranyai, N.H. The potentials of thermal energy storage using domestic electric water heater technology with PV systems in the EU countries. MRS Energy Sustain. 2024, 11, 74–91. [Google Scholar] [CrossRef]

- Ferrara, M.; Fabrizio, E. Optimized design and integration of energy storage in Solar-Assisted Ground-Source Heat Pump systems. Build. Simul. 2023, 16, 1933–1948. [Google Scholar] [CrossRef]

- Larwa, B.; Kupiec, K. Heat transfer in the ground with a horizontal heat exchanger installed—Long-term thermal effects. Appl. Therm. Eng. 2020, 164, 114539. [Google Scholar] [CrossRef]

- Ajibade, H.; Ujah, C.O.; Nnakwo, K.C.; Kallon, D.V.V. Improvement in battery technologies as panacea for renewable energy crisis. Discov. Appl. Sci. 2024, 6, 374. [Google Scholar] [CrossRef]

- Wojciechowski, H. Energy storage technologies. Part II. INSTAL 2017, 3, 16–27. [Google Scholar]

- Trovò, A.; Rugna, M.; Poli, N.; Guarnieri, M. Prospects for industrial vanadium flow batteries. Ceram. Int. 2023, 49, 24487–24498. [Google Scholar] [CrossRef]

- Mbendane, B.; Abe, B.; Richards, C. Analysis of Supercapacitors in Renewable Energy Systems for Managing Power Fluctuations. Int. J. Energy Res. 2024, 1, 4575761. [Google Scholar] [CrossRef]

- Vecchi, A.; Li, Y.; Ding, Y.; Mancarella, P.; Sciacovelli, A. Liquid air energy storage (LAES): A review on technology state-of-the-art, integration pathways and future perspectives. Adv. Appl. Energy 2021, 3, 100047. [Google Scholar] [CrossRef]

- Damak, C.; Leducq, D.; Hoang, H.M.; Negro, D.; Delahaye, A. Liquid Air Energy Storage (LAES) as a large-scale storage technology for renewable energy integration—A review of investigation studies and near perspectives of LAES. Int. J. Refrig. 2020, 110, 208–218. [Google Scholar] [CrossRef]

- Rabi, A.M.; Radulovic, J.; Buick, J.M. Pumped Thermal Energy Storage Technology (PTES): Review. Thermo 2023, 3, 396–411. [Google Scholar] [CrossRef]

- Blakers, A.; Stocks, M.; Lu1, B.; Cheng, C. A review of pumped hydro energy storage. Prog. Energy 2021, 3, 022003. [Google Scholar] [CrossRef]

- De Felice, M.; Koolen, D.; Kanellopoulos, K.; Busch, S.; Zucker, A. Climate variability on Fit for 55 European power systems. PLoS ONE 2023, 18, e0289705. [Google Scholar] [CrossRef]

- Kurpaska, S.; Knaga, J.; Latała, H.; Cupiał, M.; Konopacki, P.; Hołownicki, R. The Comparison of Different Types of Heat Accumulators and Benefits of Their Use in Horticulture. Sensors 2020, 20, 1417. [Google Scholar] [CrossRef]

- Kurpaska, S.; Wolny-Koładka, K.; Malinowski, M.; Tomaszek, K.; Latała, H. Thermal-Mass and Microbiological Analysis of Forced Air Flow through the Stone Heat Accumulator Bed. Energies 2023, 16, 4456. [Google Scholar] [CrossRef]

- Bach, R.; Mohtashami, N.; Hildebrand, L. Comparative Overview on LCA Software Programs for Application in the Facade Design Process. J. Facade Des. Eng. 2019, 7, 13–25. [Google Scholar] [CrossRef]

- Díaz-Ramírez, M.C.; Ferreira, V.J.; García-Armingol, T.; López-Sabirón, A.M.; Ferreira, G. Battery Manufacturing Resource Assessment to Minimise Component Production Environmental Impacts. Sustainability 2020, 12, 6840. [Google Scholar] [CrossRef]

- Blume, N.; Becker, M.; Turek, T.; Minke, C. Life cycle assessment of an industrial-scale vanadium flow battery. J. Ind. Ecol. 2022, 26, 1796–1808. [Google Scholar] [CrossRef]

- Wickerts, S.; Arvidsson, R.; Nordelöf, A.; Svanström, M.; Johansson, P. Prospective life cycle assessment of sodium-ion batteries made from abundant elements. J. Ind. Ecol. 2024, 28, 116–129. [Google Scholar] [CrossRef]

- Peters, J.; Buchholz, D.; Passerini, S.; Weil, M. Life cycle assessment of sodium-ion batteries. Energy Environ. Sci. 2016, 9, 1744–1751. [Google Scholar] [CrossRef]

- Zhang, K.; Zheng, M.; Mo, J. Life Cycle Environmental Impact of Pumped Hydro Energy Storage. E3S Web Conf. 2023, 441, 02004. [Google Scholar] [CrossRef]

- EU Science Hub. Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/#TMY (accessed on 2 April 2025).

- Weather Online. Available online: https://www.weatheronline.pl (accessed on 2 April 2024).

- Konopacki, P. System Magazynowania Ciepła w Akumulatorze ze Złożem Kamiennym—Analiza Energetyczna i Wpływ na Mikroklimat w Tunelu Foliowym; Inżynieria Rolnicza: Kraków, Poland, 2019; pp. 3–114. [Google Scholar]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Soleymani Angili, T.; Grzesik, K.; Jerzak, W. Comparative Life Cycle Assessment of Catalytic Intermediate Pyrolysis of Rapeseed Meal. Energies 2023, 16, 2004. [Google Scholar] [CrossRef]

- Zsembinszki, G.; Llantoy, N.; Palomba, V.; Frazzica, A.; Dallapiccola, M.; Trentin, F.; Cabeza, L.F. Life Cycle Assessment (LCA) of an Innovative Compact Hybrid Electrical-Thermal Storage System for Residential Buildings in Mediterranean Climate. Sustainability 2021, 13, 5322. [Google Scholar] [CrossRef]

- Llantoy, N.; Zsembinszki, G.; Palomba, V.; Frazzica, A.; Dallapiccola, M.; Trentin, F.; Cabeza, L.F. Life Cycle Assessment of an Innovative Hybrid Energy Storage System for Residential Buildings in Continental Climates. Appl. Sci. 2021, 11, 3820. [Google Scholar] [CrossRef]

- Kurpaska, S.; Latała, H.; Kiełbasa, S.; Sporysz, M.; Gliniak, M.; Famielec, S.; Łapczyńska-Kordon, B. Experimental and modeling approach to heat and mass transfer in a porous bed of a rock-bed heat accumulator. Int. J. Heat Mass Transf. 2021, 179, 121654. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe 2016: A harmonized life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; van Zelm, R. ReCiPE 2008: A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; Ministry of VROM: The Hague, The Netherlands, 2009; Volume 1, pp. 1–126. [Google Scholar]

- Shu, X.; Guo, Y.; Yang, W.; Wei, K.; Zhu, G. Life-cycle assessment of the environmental impact of the batteries used in pure electric passenger cars. Energy Rep. 2021, 7, 2302–2315. [Google Scholar] [CrossRef]

- Marcinkiewicz, P.; Famielec, S.; Bodziacki, S. Środowiskowa ocena procesów produkcyjnych wybranych karm dla zwierząt domowych. Infrastrukt. Ekol. Teren. Wiej. 2023, 18, 254–276. [Google Scholar] [CrossRef]

- Database & Support Team at PRé Sustainability. SimaPro Database Manual Methods Library; Pré Sustainability: Amersfoort, The Netherlands, 2022; pp. 1–56. [Google Scholar]

- Weber, S.; Peters, J.F.; Baumann, M.; Weil, M. Life Cycle Assessment of a Vanadium Redox Flow Battery. Environ. Sci. Technol. 2018, 52, 10864–10873. [Google Scholar] [CrossRef]

- Jasper, F.B.; Späthe, J.; Baumann, M.; Peters, J.F.; Ruhland, J.; Weil, M. Life cycle assessment (LCA) of a battery home storage system based on primary data. J. Clean. Prod. 2022, 366, 132899. [Google Scholar] [CrossRef]

| No. | Type of Material | Qty. | Unit |

|---|---|---|---|

| 1 | Rock | 1078.075 | kg·m−2 |

| 2 | Insulation (styrodur) | 11.353 | kg·m−2 |

| 3 | Black film | 0.248 | kg·m−2 |

| 4 | 110 mm diameter PVC pipes | 1.318 | kg·m−2 |

| 5 | 80 mm diameter drainage pipes | 0.214 | kg·m−2 |

| 6 | Agrotextile | 0.164 | kg·m−2 |

| 7 | Sand | 166.631 | kg·m−2 |

| 8 | Reinforced concrete retaining slabs 6 cm thick | 0.107 | kg·m−2 |

| 9 | Concrete posts for slabs | 0.120 | kg·m−2 |

| No. | Type of Material | Qty. | Unit |

|---|---|---|---|

| 1 | Sand | 292.620 | kg·m−2 |

| 2 | Agrotextile | 0.059 | kg·m−2 |

| 3 | Transport of materials and excavator operation | 146.88 | tkm∙m−2 |

| No. | Type of Material | Qty. | Unit |

|---|---|---|---|

| 1 | 300 mm diameter galvanized pipe | 0.582 | kg·m−2 |

| 2 | 300 mm diameter PCV | 0.767 | kg·m−2 |

| 3 | 250 mm diameter PCV | 0.914 | kg·m−2 |

| 4 | 300 mm diameter damper | 0.064 | kg·m−2 |

| 5 | 250 mm diameter damper | 0.080 | kg·m−2 |

| 6 | Servo motor for dampers | 0.225 | kg·m−2 |

| 7 | –plastic | 0.037 | kg·m−2 |

| 8 | –electronics | 0.016 | kg·m−2 |

| 9 | –metal | 0.171 | kg·m−2 |

| 10 | 7.5 kW motor | 1.003 | kg·m−2 |

| 11 | –including copper | 0.160 | kg·m−2 |

| 12 | Centrifugal fan | 1.136 | kg·m−2 |

| 13 | 250 mm diameter galvanized damper | 0.032 | kg·m−2 |

| 14 | 200 mm diameter galvanized damper | 0.043 | kg·m−2 |

| 15 | Servo motor for dampers | 0.168 | kg·m−2 |

| 16 | –plastic | 0.028 | kg·m−2 |

| 17 | –electronics | 0.012 | kg·m−2 |

| 18 | –metal | 0.128 | kg·m−2 |

| 19 | 250 mm diameter PCV pipe | 0.686 | kg·m−2 |

| 20 | 200 mm diameter PCV pipe | 0.610 | kg·m−2 |

| 21 | 160 mm diameter PCV pipe | 0.225 | kg·m−2 |

| 22 | 110 mm diameter PCV pipe | 0.647 | kg·m−2 |

| Month | Charging (Electricity from PV) | Discharging (Electricity from the Grid) | Total | Unit |

|---|---|---|---|---|

| April | 8.12 | 24.37 | 32.49 | kWh·m−2 |

| May | 4.48 | 3.96 | 8.44 | kWh·m−2 |

| June | 4.89 | 1.67 | 6.56 | kWh·m−2 |

| July | 12.28 | 3.83 | 16.11 | kWh·m−2 |

| August | 6.41 | 0.47 | 6.88 | kWh·m−2 |

| September | 4.67 | 12.69 | 17.36 | kWh·m−2 |

| October | 1.88 | 9.93 | 11.81 | kWh·m−2 |

| Average | 6.10 | 8.13 | 14.23 | kWh·m−2 |

| Season total | 42.73 | 56.92 | 99.65 | kWh·m−2 |

| Month | Charging | Discharging | Unit |

|---|---|---|---|

| April | 7.91 | 16.50 | kWh·m−2 |

| May | 5.40 | 2.50 | kWh·m−2 |

| June | 10.10 | 1.50 | kWh·m−2 |

| July | 21.60 | 4.70 | kWh·m−2 |

| August | 14.10 | 2.40 | kWh·m−2 |

| September | 3.90 | 9.20 | kWh·m−2 |

| October | 2.40 | 8.90 | kWh·m−2 |

| Average | 9.34 | 6.53 | kWh·m−2 |

| Season total | 65.41 | 45.70 | kWh·m−2 |

| Sel | Impact Category | Unit | Obtaining Materials and Construction of a Rock-Bed Accumulator | Transport of Materials | Electricity from the Grid | Heat Stored in the Accumulator | Obtaining Energy from Photovoltaic Panels |

|---|---|---|---|---|---|---|---|

| 1 | Climate change | kg CO2 eq | 320.429 | 32.260 | 66.603 | −22.174 | −45.732 |

| 2 | Ozone depletion | kg CFC-11 eq | 0.002 | 5.71 × 10−6 | 7.58 × 10−7 | −1.39 × 10−6 | 6.82 × 10−8 |

| 3 | Terrestrial acidification | kg SO2 eq | 0.833 | 0.105 | 0.349 | −0.160 | −0.231 |

| 4 | Freshwater eutrophication | kg P eq | 0.038 | 0.003 | 0.072 | −0.010 | −0.051 |

| 5 | Marine eutrophication | kg N eq | 0.043 | 0.005 | 0.020 | −0.006 | −0.013 |

| 6 | Human toxicity | kg 1,4-DB eq | 61.069 | 6.366 | 48.713 | −9.820 | −30.761 |

| 7 | Photochemical oxidant formation | kg NMVOC | 1.104 | 0.126 | 0.144 | −0.069 | −0.091 |

| 8 | Particulate matter formation | kg PM10 eq | 0.330 | 0.048 | 0.102 | −0.057 | −0.066 |

| 9 | Terrestrial ecotoxicity | kg 1,4-DB eq | 0.009 | 0.007 | 0.002 | −0.001 | 0.005 |

| 10 | Freshwater ecotoxicity | kg 1,4-DB eq | 1.582 | 0.236 | 2.112 | −0.736 | −0.825 |

| 11 | Marine ecotoxicity | kg 1,4-DB eq | 1.537 | 0.251 | 1.935 | −0.655 | −0.771 |

| 12 | Ionizing radiation | kBq U235 eq | 6.234 | 2.563 | 1.833 | −4.848 | −0.744 |

| 13 | Agricultural land occupation | m2a | 1.481 | 0.426 | 2.345 | −0.791 | −1.556 |

| 14 | Urban land occupation | m2a | 1.779 | 1.394 | 0.298 | −0.162 | −0.179 |

| 15 | Natural land transformation | m2 | 0.020 | 0.011 | 0.002 | −0.003 | −0.001 |

| 16 | Water depletion | m3 | 8.241 | 0.095 | 0.128 | −0.163 | 0.048 |

| 17 | Metal depletion | kg Fe eq | 55.466 | 1.527 | 0.940 | −1.971 | 0.871 |

| 18 | Fossil depletion | kg oil eq | 87.506 | 11.397 | 17.586 | −5.812 | −12.081 |

| Sel | Impact Category | Unit | 12 °C | 15 °C | 18 °C |

|---|---|---|---|---|---|

| 1 | Climate change | kg CO2 eq | 354.001 | 351.387 | 348.780 |

| 2 | Ozone depletion | kg CFC-11 eq | 0.002 | 0.002 | 0.002 |

| 3 | Terrestrial acidification | kg SO2 eq | 0.915 | 0.896 | 0.877 |

| 4 | Freshwater eutrophication | kg P eq | 0.054 | 0.052 | 0.051 |

| 5 | Marine eutrophication | kg N eq | 0.050 | 0.049 | 0.049 |

| 6 | Human toxicity | kg 1,4-DB eq | 76.724 | 75.566 | 74.412 |

| 7 | Photochemical oxidant formation | kg NMVOC | 1.222 | 1.214 | 1.206 |

| 8 | Particulate matter formation | kg PM10 eq | 0.365 | 0.358 | 0.351 |

| 9 | Terrestrial ecotoxicity | kg 1,4-DB eq | 0.021 | 0.021 | 0.021 |

| 10 | Freshwater ecotoxicity | kg 1,4-DB eq | 2.455 | 2.368 | 2.282 |

| 11 | Marine ecotoxicity | kg 1,4-DB eq | 2.375 | 2.298 | 2.221 |

| 12 | Ionizing radiation | kBq U235 eq | 5.609 | 5.038 | 4.468 |

| 13 | Agricultural land occupation | m2a | 1.998 | 1.904 | 1.811 |

| 14 | Urban land occupation | m2a | 3.150 | 3.131 | 3.111 |

| 15 | Natural land transformation | m2 | 0.030 | 0.030 | 0.029 |

| 16 | Water depletion | m3 | 8.368 | 8.349 | 8.330 |

| 17 | Metal depletion | kg Fe eq | 57.065 | 56.833 | 56.601 |

| 18 | Fossil depletion | kg oil eq | 99.282 | 98.597 | 97.914 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malinowski, M.; Bodziacki, S.; Famielec, S.; Huptyś, D.; Kurpaska, S.; Latała, H.; Basak, Z. Environmental Impact Assessment of Heat Storage System in Rock-Bed Accumulator. Energies 2025, 18, 3360. https://doi.org/10.3390/en18133360

Malinowski M, Bodziacki S, Famielec S, Huptyś D, Kurpaska S, Latała H, Basak Z. Environmental Impact Assessment of Heat Storage System in Rock-Bed Accumulator. Energies. 2025; 18(13):3360. https://doi.org/10.3390/en18133360

Chicago/Turabian StyleMalinowski, Mateusz, Stanisław Bodziacki, Stanisław Famielec, Damian Huptyś, Sławomir Kurpaska, Hubert Latała, and Zuzanna Basak. 2025. "Environmental Impact Assessment of Heat Storage System in Rock-Bed Accumulator" Energies 18, no. 13: 3360. https://doi.org/10.3390/en18133360

APA StyleMalinowski, M., Bodziacki, S., Famielec, S., Huptyś, D., Kurpaska, S., Latała, H., & Basak, Z. (2025). Environmental Impact Assessment of Heat Storage System in Rock-Bed Accumulator. Energies, 18(13), 3360. https://doi.org/10.3390/en18133360