Abstract

The growing integration of renewable energy and electric vehicle loads in parks has intensified the intermittency of photovoltaic (PV) output and demand-side uncertainty, complicating energy storage system design and operation. Meanwhile, under carbon neutrality goals, the energy system must balance economic efficiency with emission reductions, raising the bar for storage planning. To address these challenges, this study proposes a two-stage robust optimization method for shared energy storage configuration in a park-level integrated PV–storage–charging system (PV-SESS-CS). The method considers the uncertainties of PV and electric vehicle (EV) loads and incorporates carbon emission reduction benefits. First, a configuration model for shared energy storage that accounts for carbon emission reduction is established. Then, a two-stage robust optimization model is developed to characterize the uncertainties of PV output and EV charging demand. Typical PV output scenarios are generated using Latin Hypercube Sampling, and representative PV profiles are extracted via K-means clustering. For EV charging loads, uncertainty scenarios are generated using Monte Carlo Sampling. Finally, simulations are conducted based on real-world industrial park data. The results demonstrate that the proposed method can effectively mitigate the negative impact of source-load fluctuations, significantly reduce operating costs, and enhance carbon emission reductions. This study provides strong methodological support for optimal energy storage planning and low-carbon operation in park-level PV-SESS-CS.

1. Introduction

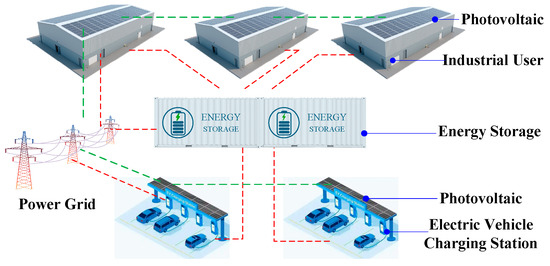

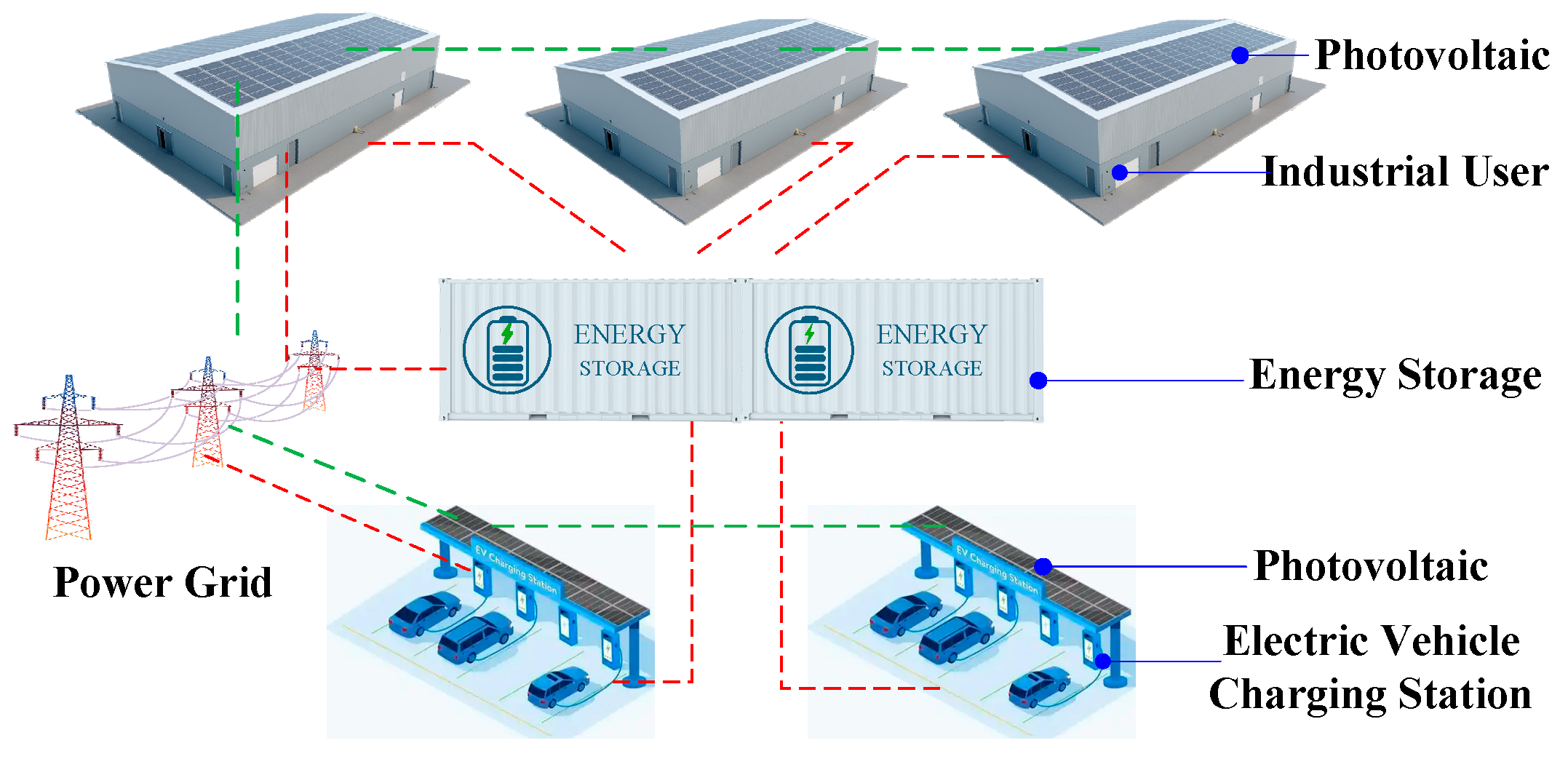

With the continuous growth of the global economy, the demand for electricity in industrial parks is rising, and the wide application of electric vehicles (EVs) has further aggravated the demand for charging energy in industrial parks [1]. In this context, the construction of the charging station (CS) integrated with a photovoltaic and shared energy storage system (PV-SESS-CS) in the park has become an efficient solution. By integrating stable industrial loads into PV-SESS-CS, a deeply coupled and integrated operation pattern of ‘generation–load–storage–charging’ can be established. Given that most industrial parks in China adopt a unified electricity account and centralized settlement mechanism, all users typically share a common grid connection point and a single electricity account, with all electricity transactions settled collectively by the park operator. As a result, the shared energy storage system (SESS) generally lacks the metering, access rights, and pricing mechanisms required to participate in electricity markets and is primarily used for internal load balancing and photovoltaic (PV) output optimization within the park. In the planning and construction of SESS, how to rationally allocate energy storage capacity has become a key issue. Reasonable energy storage capacity configuration can not only optimize the operating efficiency of the power system but also provide necessary power support when the photovoltaic output is insufficient or the charging demand of electric vehicles is at its peak [2]. In addition, carbon emission reduction has become an important factor in the development of industrial parks. Considering carbon reduction benefits in the energy storage configuration process not only helps reduce greenhouse gas emissions but also brings policy support and economic incentives to the park, thereby enhancing its capacity for sustainable development [3].

In terms of energy optimization in the park, the current research mainly focuses on the planning and design of multi-energy and multi-network integration. Reference [4] proposed an energy system integration model for industrial parks considering multi-network integration and introduced a step-by-step carbon trading mechanism into the model to reduce carbon emissions and optimize the scheduling of carbon trading models. Aiming at the problems of a low-energy utilization rate, unreasonable energy structure and large peak-valley power differences in industrial parks, reference [5] proposed a regional integrated energy system management strategy based on energy cascade utilization, which realized the high efficiency and stability of the system. The integration of PV and buildings provides a flexible form of energy use for the park. Reference [6] summarizes the technology of combining the energy storage system with building-integrated photovoltaics (BIPVs); analyzes the current situation, research, development, application, obstacles and challenges of BIPV with the energy storage system; and proposes that the integration of BIPV and energy storage can improve the reliability of energy utilization in the park. The above literature provides useful help for the energy application of the park, but it is difficult to cope with the increasing demand for EV charging, and it is difficult to ensure the low-carbon energy consumption of the park.

At the same time, the energy demand and timing of the park, including PV, energy storage and EV charging piles, are complex. At present, most of the research is on the integrated CS or energy hub including PV and energy storage. Reference [7] proposed a two-stage robust planning operation collaborative optimization method considering renewable energy uncertainty and multi-load demand and studied the scale determination problem and accurate economic model of energy storage system, but the study lacked consideration of carbon emission reductions. A unified planning model of distributed generation and EV CSs considering multiple uncertainties and battery degradation is established. Reference [8] proposed a unified planning model of distributed generation and EV CSs considering multiple uncertainties and battery degradation and used the Latin Hypercube Sampling (LHS) method to generate multiple scenarios to describe the uncertainty of renewable energy and load demand. In reference [9], a new energy collaboration framework integrating community energy storage and a PV CS cluster is proposed, which aims to balance grid load, improve energy utilization, enhance power system stability, and provide guidance for the planning of PV-SESS-CS in the park. However, the above research rarely covered the coordinated scheduling of PV-SESS-CS in the park. The configuration method of shared energy storage considering the fluctuations in PV and charging in the park needs to be further studied.

The optimal allocation of shared energy storage in low-carbon parks considering the uncertainty of PV output and EV charging involves the randomness of PV and charging, which adds a new burden to the planning of shared energy storage in parks, and it is necessary to study effective solution algorithms. In reference [10], a multi-objective robust optimization strategy is proposed to deal with the uncertainties caused by distributed generation, the diversity of demand response and the flexibility of topology. By constructing an uncertainty set for predicting the maximum output of PV power generation, the optimization results under different uncertainty sets are obtained. Reference [11] investigates the lifecycle coordinated planning of Multi-Energy Ship Microgrids and proposes a two-stage robust optimization framework that accounts for thermal inertia and ship navigation uncertainties, such as wave and wind disturbances, thereby enhancing system safety and economic efficiency during maritime operations. Reference [12] addresses the planning of Networked Hydrogen-Electrical Microgrids and highlights the importance of the demand-inducing effect, where hydrogen refueling demand is influenced by infrastructure investment. To capture this endogeneity, a trilevel stochastic-robust optimization model is developed using decision-dependent uncertainty, providing a flexible and rigorous framework for modeling such interdependencies. Specifically, the aforementioned studies focus on planning problems involving various complex energy resources and operational characteristics, such as diesel generators, gas turbines, hydrogen storage systems, hydrogen refueling stations, wind/PV renewable generation, propulsion loads, and the thermal inertia of ships. Their primary objectives are often long-term investment and operation planning under multi-source coupling or maritime energy supply scenarios.

Based on the historical data-driven search algorithm, reference [13] proposed a PV and energy storage capacity allocation method for the integrated PV and energy storage CS and obtained the configuration capacity of energy storage with the goal of maximizing economic benefits. However, the existing research is still insufficient in considering the multi-energy coupling characteristics and complex load fluctuation in the industrial park, especially in the flexibility and economic guarantee of energy storage configuration.

In summary, in view of the shortcomings of existing research on the optimal allocation of shared energy storage capacity in park-level PV-SESS-CS systems, this study proposes an optimal allocation method for shared energy storage in low-carbon parks, considering the uncertainties of PV output and EV charging. The main contributions of this study are summarized as follows:

- (1)

- A shared energy storage configuration model is developed that incorporates carbon emission reduction benefits via the China Certified Emission Reduction (CCER) market mechanism, offering a policy-aligned pathway for low-carbon park operations.

- (2)

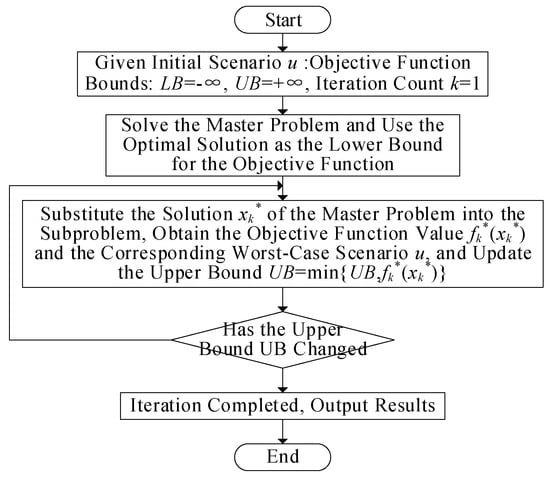

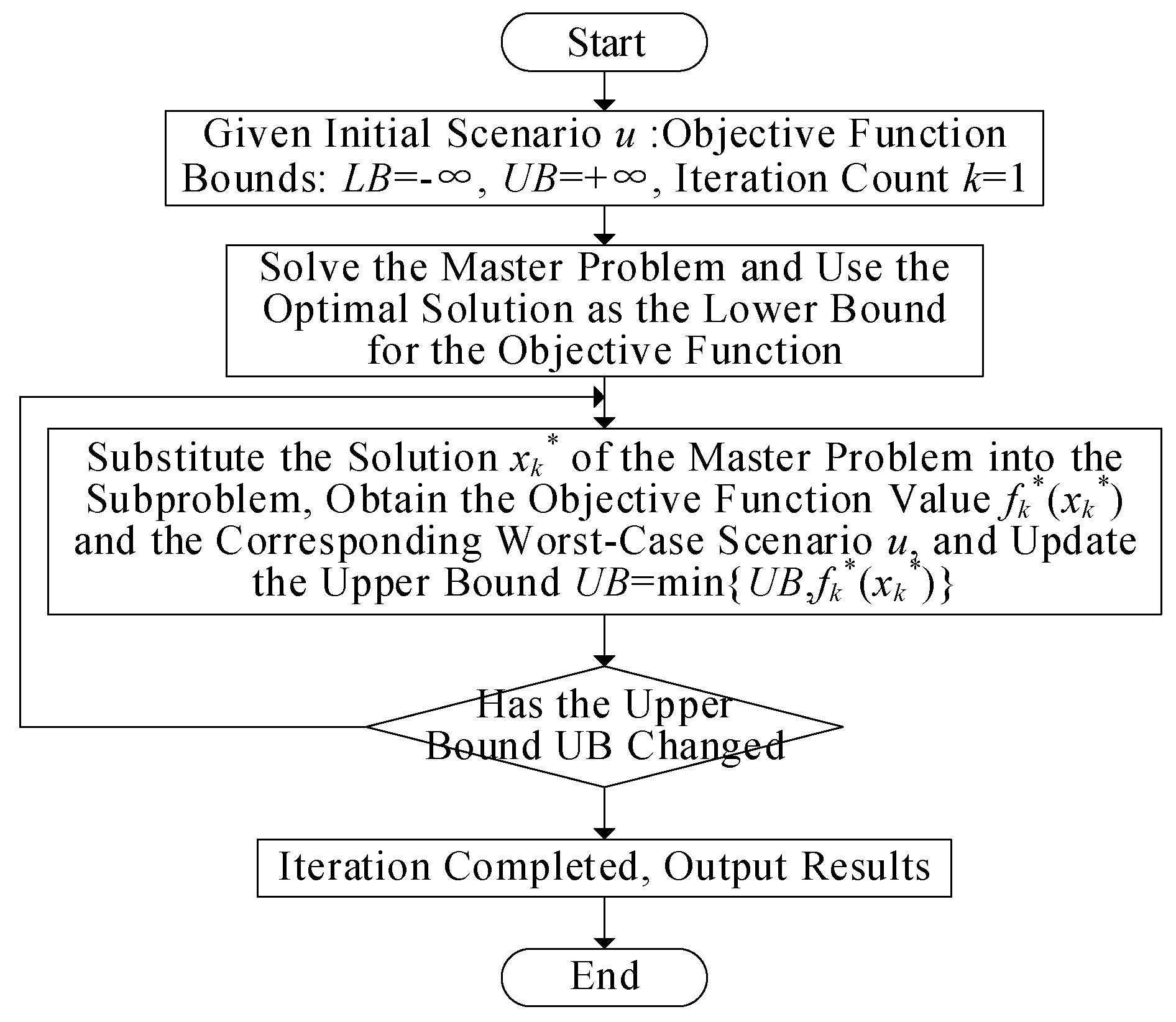

- A two-stage robust optimization model is proposed to address the dual uncertainties of PV output and EV charging demand and is solved using a column-and-constraint generation (C&CG) algorithm to ensure solution feasibility and robustness.

- (3)

- LHS and K-means clustering are employed to generate representative PV output scenarios, while an EV charging model combined with Monte Carlo Sampling (MCS) is used to construct load demand scenarios, ensuring the accurate and efficient characterization of system uncertainties.

- (4)

- Simulation studies based on a typical industrial park are carried out to verify the effectiveness of the proposed method in improving economic performance and carbon reduction, demonstrating its practical applicability in shared energy storage planning under park-level PV-SESS-CS systems.

The structure of this paper is as follows: Section 2 introduces the park architecture with optical storage and the configuration model of SESS. Section 3 establishes a two-stage robust optimal configuration model and solution method considering the uncertainty of PV output and EV charging load. Section 4 introduces the method of generating PV output and EV charging load data. Section 5 presents the example analysis. The economics and effectiveness of the proposed method are verified via a scenario comparison. Section 6 summarizes this study and gives the future development direction.

4. Generation of Uncertain Scenarios of EV Charging Load and PV Output

4.1. EV Charging Load Scenario Generation

4.1.1. Charging Uncertainty Scene Generation Method

The charging behavior of a single EV owner is random and disorderly, but on the whole, the charging law will be affected by the working hours and travel rules of employees in the industrial park. Based on the statistical results of household car travel in a country for one year, this study makes a certain degree of adjustment based on the difference between daily travel and work to make it more in line with the actual situation of employees in industrial parks [18]. After adjustment, the probability density function of the owner’s arrival time in the industrial park is:

where x is the time when the owner arrives at the industrial park; expected value = 12.0; standard deviation = 6.0. Suppose that the owner arrives at the industrial park and starts charging; the working time can be regarded as the time when the EV starts charging.

The probability density function of the daily mileage of EVs is:

where d is the daily mileage of EVs; expected value = 3.5; standard deviation = 0.88.

The battery capacity of EVs in circulation on the market presents a certain diversity. According to the collected statistical information, the battery capacity of EVs is mainly concentrated in the range of 15 kWh to 60 kWh. In order to facilitate the subsequent calculation and processing, this study selects the uniform probability distribution model in the range of 15 kWh to 60 kWh to simulate the battery capacity differences in different EVs. The probability density function is shown in Equation (44).

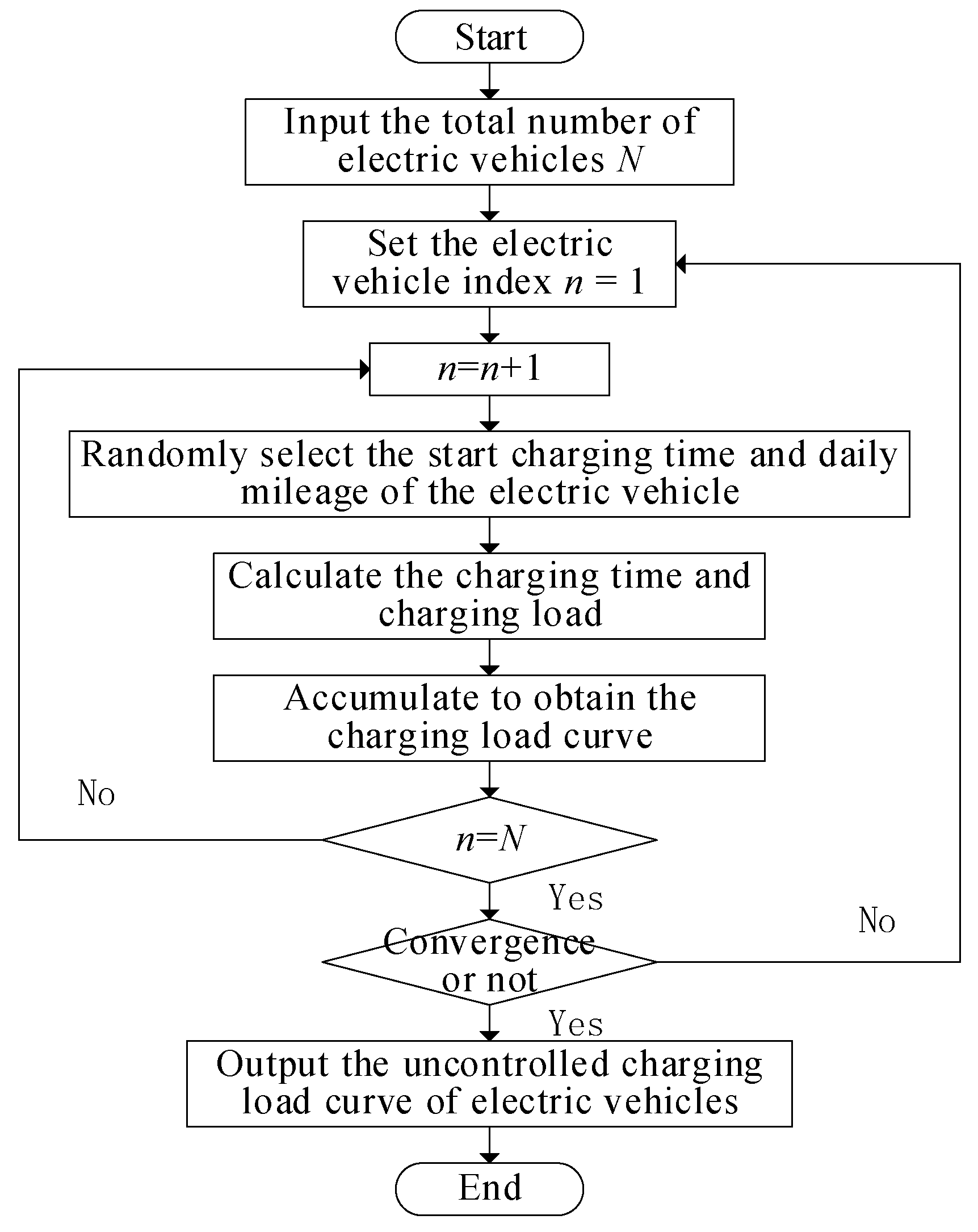

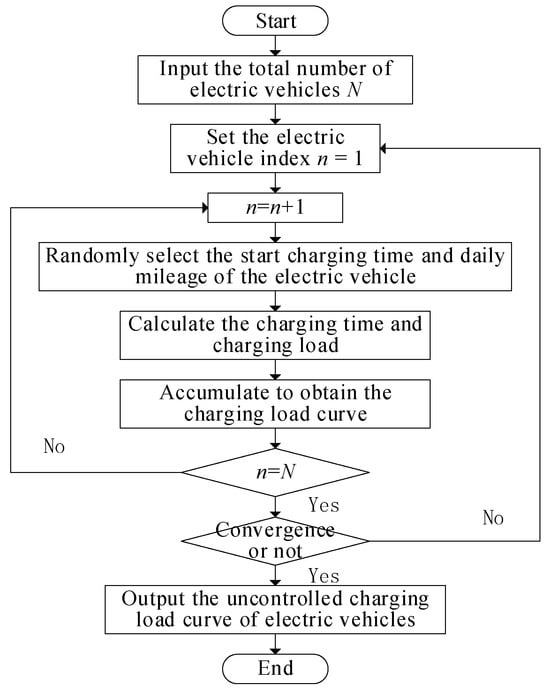

In this study, MCS is used to simulate the disorderly charging behavior of park owners. Suppose that the EV is charged once a day until it is full. In the company’s work charging scenario, EVs usually adopt a slow charging method with a more stable charging process and less impact on battery life. Therefore, the whole charging process of EVs can be approximated as constant power charging. The simulation process of the disordered charging load of EVs is shown in Figure 3, and the specific steps are as follows.

Figure 3.

Flow chart of electric vehicle charging load calculation based on MCS.

- (1)

- Input the maximum number of simulations and the total number of electric vehicles, and initialize them.

- (2)

- According to the probability model mentioned above, the charging start time and daily mileage of the owner are randomly generated.

- (3)

- The charging power is calculated by combining the relevant parameters of the electric vehicle, and the charging load is accumulated.

- (4)

- After the calculation of the charging load of all electric vehicles is completed, the next simulation is carried out. After the number of simulations reaches the maximum value, the average value is taken to output the disordered charging load curve of electric vehicles.

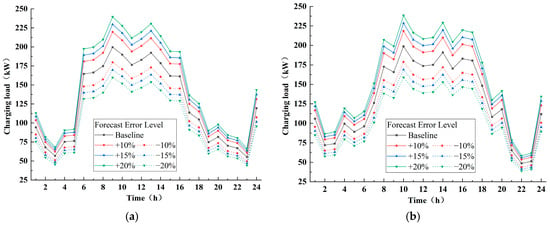

4.1.2. Charging Load Fluctuation Curve of EV

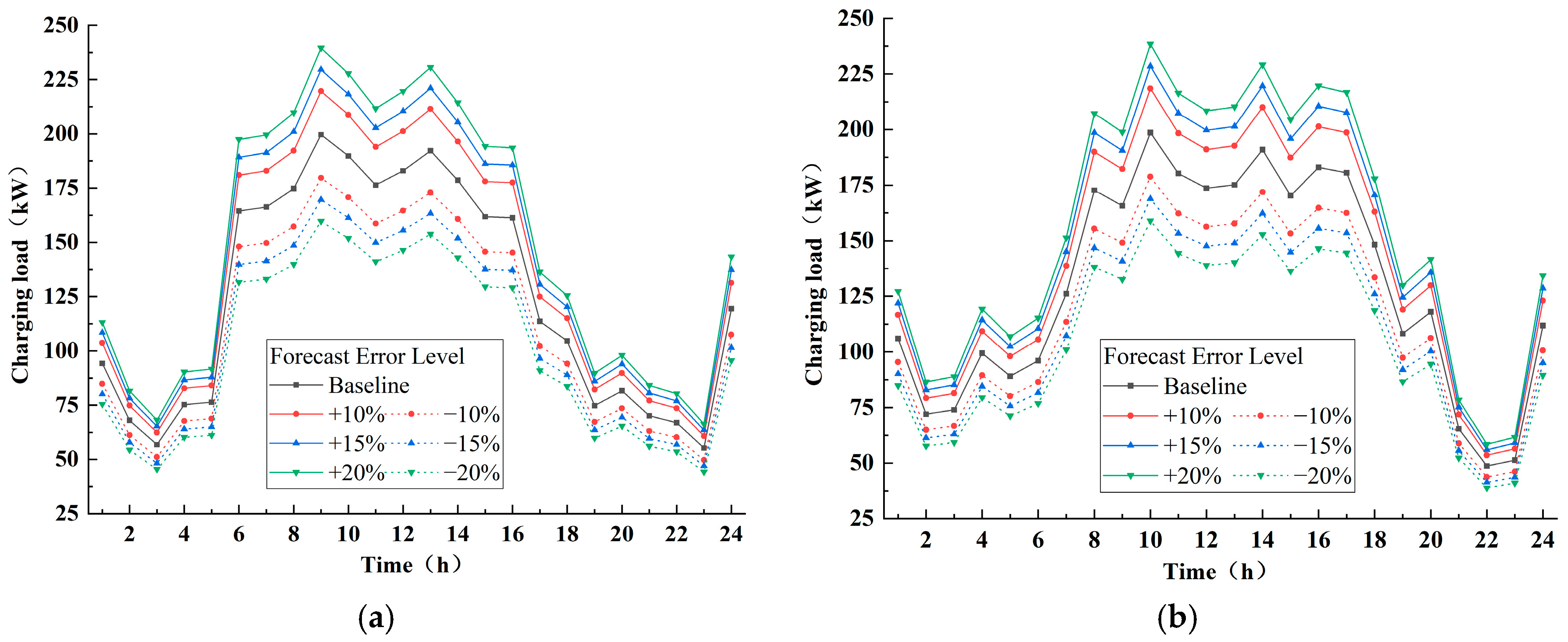

This study takes an industrial park as an example. It is assumed that there are 800 EVs in the park; two CSs, CS A and CS B, are responsible for meeting the charging needs of half of the EVs in the park. By investigating most of the EVs, we can establish that the unit power consumption of EVs is about 14 kWh/100 km, that is, 7.1 km per kilowatt-hour. Within 24 h, the charging load curves of the park CS A and CS B shown in Figure 4 can be obtained by using the method in Section 4.1.1.

Figure 4.

Predicted charging load curves of CS A and CS B under different forecast errors. (a) CS A; (b) CS B.

It can be seen from Figure 4 that the daily charging load of the CS shows a significant peak–valley characteristic: the CS will experience the highest load during the period from 8:00 to 16:00 during the day, and the charging demand reaches the peak. During the period from 19:00 p.m. to 5:00 the next day, the charging demand drops to the bottom, and the number of charging vehicles is small at this time, which is consistent with the behavior pattern of people’s daytime work.

Based on the analysis of the charging station’s operational data, it is observed that the load forecast error typically ranges from 5% to 15%. Therefore, in Figure 3, deviation curves of charging load forecasts are plotted for different values of . To better reflect the fluctuations in actual operation and capture the system behavior under adverse scenarios, the values of a are set to 10%, 15%, and 20% for the simulation analysis in Section 4. For example, when , it indicates that the actual load of the charging station fluctuates within ±15% of the forecasted value, bounded by the corresponding upper- and lower-deviation curves.

4.2. Generation of PV Output Scene in Park

4.2.1. Random Scene Generation Method of PV Output in Park

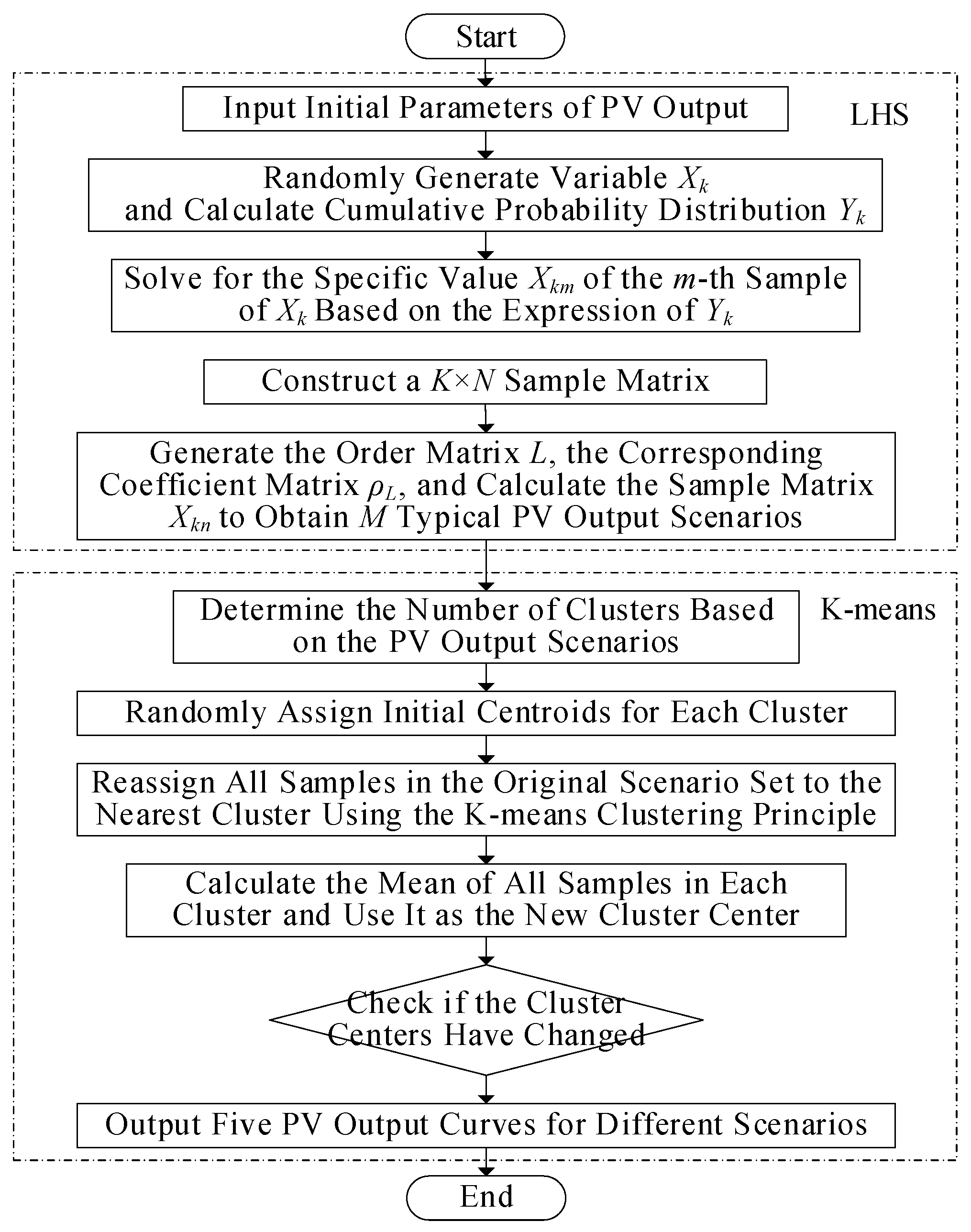

In this study, the LHS function is used to generate PV output scene samples, and the K-means algorithm is used for clustering and reduction to generate PV output data that are more in line with the actual operation needs of the park, so as to provide more accurate and targeted solutions in the scene generation of the optical storage and charging system in industrial parks [19]. The simulation process of PV output scenario generation is shown in Figure 5, and the specific steps are as follows.

Figure 5.

Flow chart of PV output generated by LHS and K-means clustering.

- (1)

- The initial parameters of the PV system are input, and the sample values of the key variables are generated by LHS. The specific values are calculated using the cumulative probability distribution function, and the sample matrix of K*N is constructed. The initial PV output scene is generated by combining the order matrix and the coefficient matrix.

- (2)

- Set the number of clusters, randomly assign the initial centroid, and assign each scene to the nearest initial centroid corresponding cluster.

- (3)

- Calculate the mean value of the scene in each cluster as the new centroid, reassign all scenes to the cluster corresponding to the new centroid, and repeat the iteration until the centroid position is stable.

- (4)

- Select the scene corresponding to the final centroid of each cluster, and output the representative PV output curve for the optimization analysis of SESS.

4.2.2. PV Output Random Fluctuation Curve

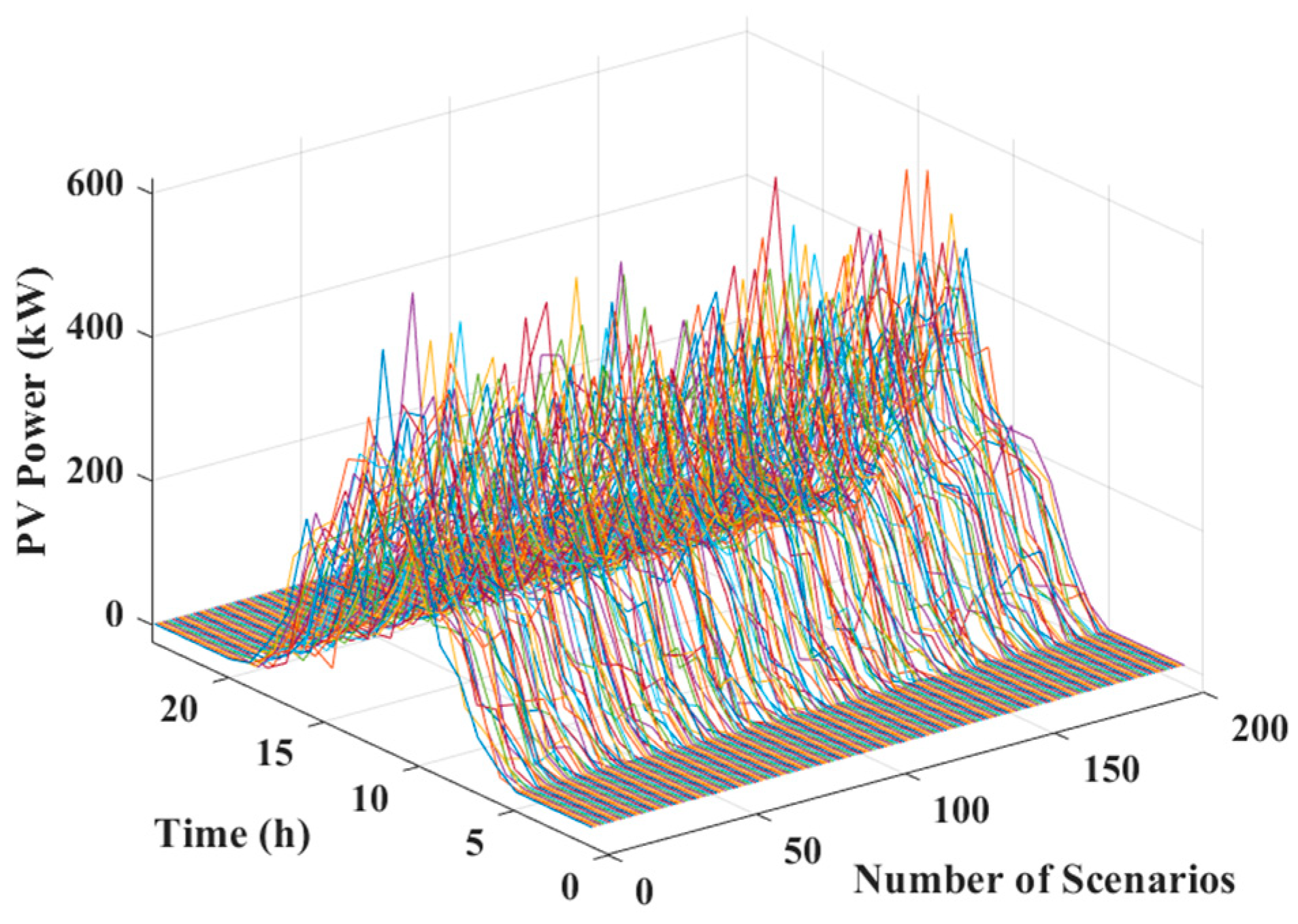

The PV output is significantly influenced by solar irradiance, and different weather conditions can lead to considerable variations in PV generation. Due to the complex and dynamic nature of daily weather changes, it is difficult to accurately classify PV output levels solely based on weather types. Therefore, this study uses the typical daily PV output curve from a real industrial park as reference data. A total of 200 PV output scenarios are generated using LHS, as shown in Figure 6.

Figure 6.

PV output curves of 200 scenarios generated by LHS sampling.

For the generated large number of PV scenarios, in order to reduce the calculation time and reduce the computational complexity, the K-means clustering algorithm is selected to reduce the scenarios. The number of clustering scenarios is set to 5, and the typical daily output curves of PVs built by IU 1, IU 2, IU 3 and CS A and CS B are obtained, as shown in Figure 6. The reduced scene is similar to the original scene set, which can well characterize the change trend of PV output, and the number of reduced scenes is reduced, which reduces the computational complexity in the subsequent optimization research.

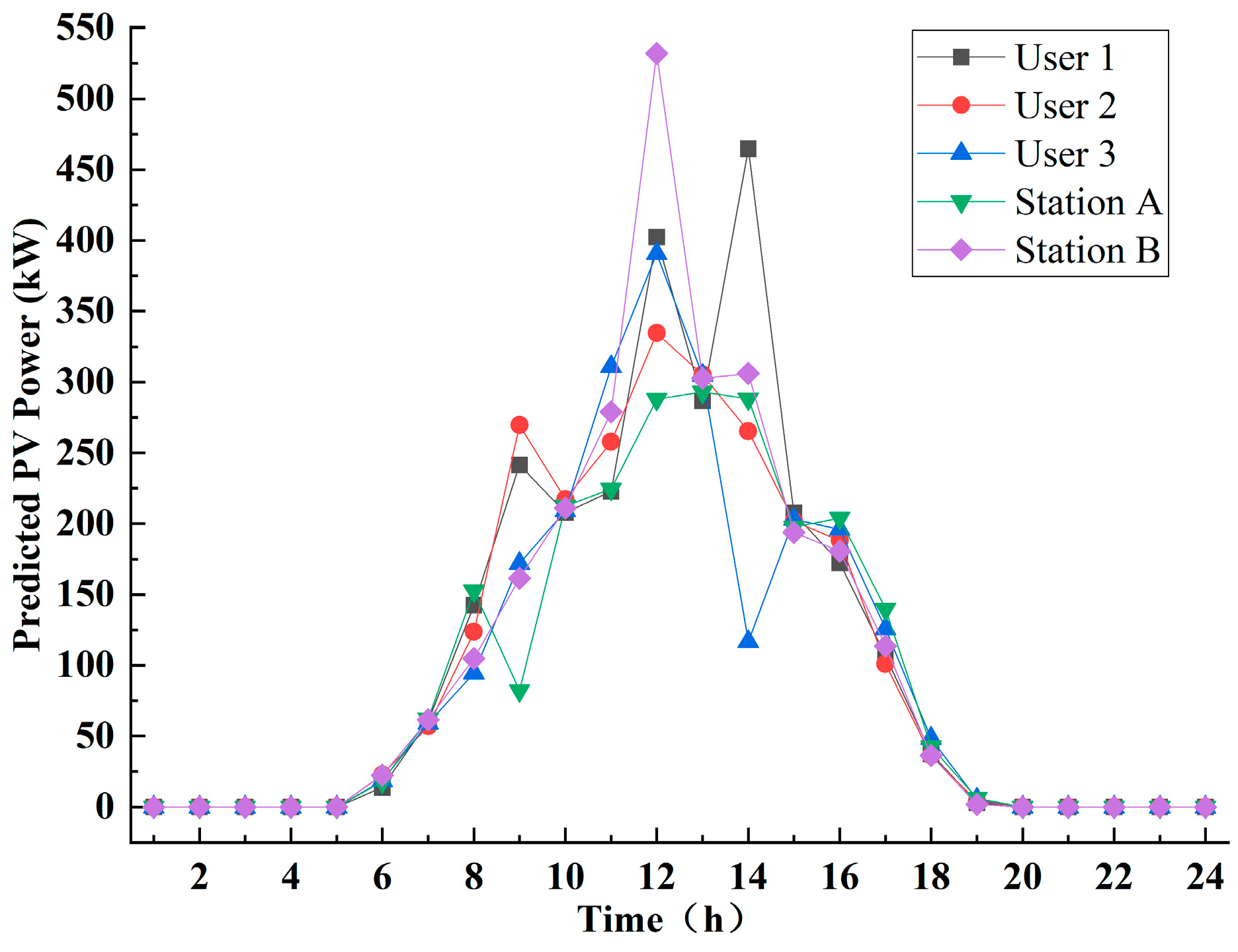

To reduce computational complexity and improve solution efficiency, this study applies the K-means clustering algorithm to perform scenario reduction on the large number of generated PV output scenarios. The number of clusters is set to five, corresponding to the number of users—three IUs (User 1, User 2, and User 3) and two CSs (Station A and Station B). The clustering results are illustrated in Figure 7.

Figure 7.

Predicted PV output profiles of three IUs and two CSs.

Each cluster corresponds to the predicted PV output profile of one user, resulting in five typical PV generation curves for the three IUs and two CSs. The reduced set of representative scenarios effectively captures the variation patterns of the original dataset while significantly reducing the computational burden in the subsequent optimization model.

As shown in Figure 7, PV output is strongly correlated with solar irradiance and exhibits a clear diurnal pattern. The output remains at zero during nighttime hours when there is no sunlight and reaches its maximum around midday (12:00–14:00), when solar irradiance is strongest. The five users show similar output profiles, indicating that their PV systems follow comparable generation patterns driven by solar conditions. Meanwhile, the slight differences among the curves reflect possible variations in installation orientation, shading, or system efficiency. These results confirm that the reduced scenarios not only preserve the key temporal features of solar generation but also maintain user-specific characteristics, ensuring both representativeness and diversity for modeling purposes.

Based on the analysis of operational data from photovoltaic power stations, it is found that the PV output forecast error typically ranges between 10% and 20%. To better capture the fluctuations observed in actual operation and to reflect the system’s performance under adverse conditions, this study sets the value of to 15%, 20%, and 25% for the simulation analysis in Section 4. Similar to the load profiles shown in Figure 4, different values of represent the fluctuation range of actual PV output under the corresponding prediction errors.

5. Case Analysis

In this study, the industrial park power grid shown in Figure 1 is taken as the research example. There are three IUs, two CSs, five self-built PV systems in the park, and one SESS is proposed to be configured. The validity of the shared energy storage configuration model and solution algorithm for low-carbon operation of the park considering the uncertainty of PV output and EV charging proposed in this study is verified by setting the original parameters.

5.1. Parameter Settings

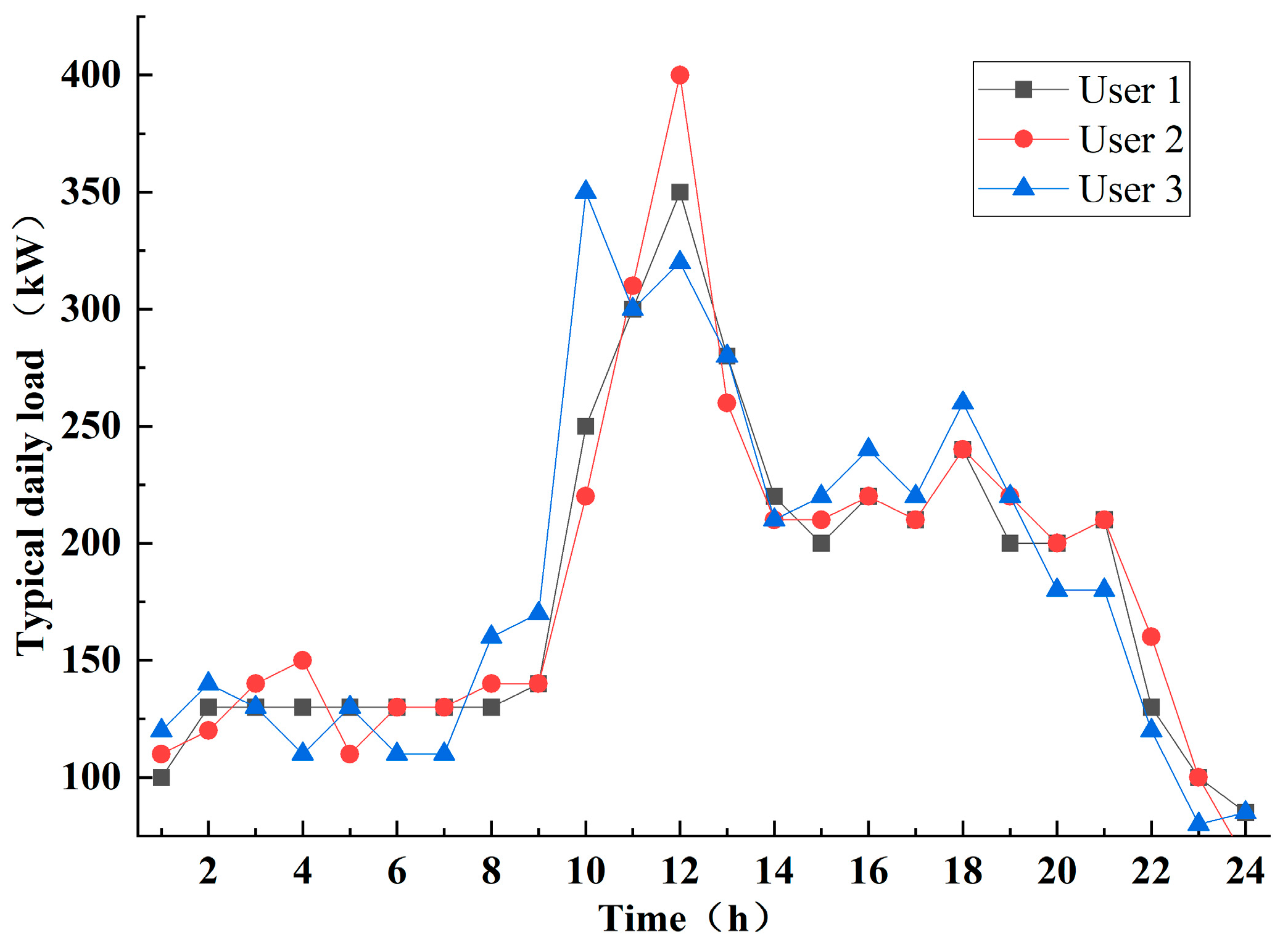

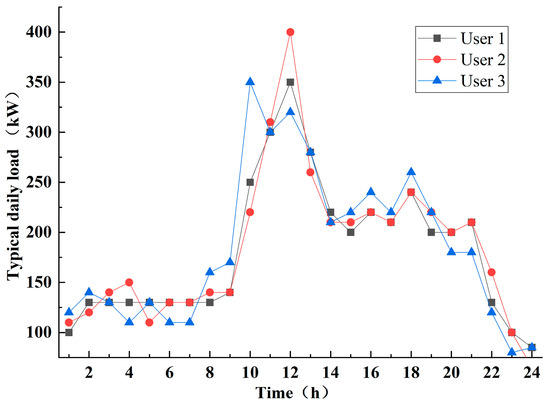

In this study, three IUs and two CSs are selected for example analysis. The typical daily load curves of the three IUs are known, as shown in Figure 8. In addition, the forecasted load curves for the two CSs were generated in Section 4.1.2, as shown in Figure 4. The predicted PV output curves for the three IUs and two CSs were generated in Section 4.2.2, as illustrated in Figure 7. The optimization model is solved using the Gurobi solver from MATLAB R2023b.

Figure 8.

Typical daily load curves of IU 1, IU 2 and IU 3.

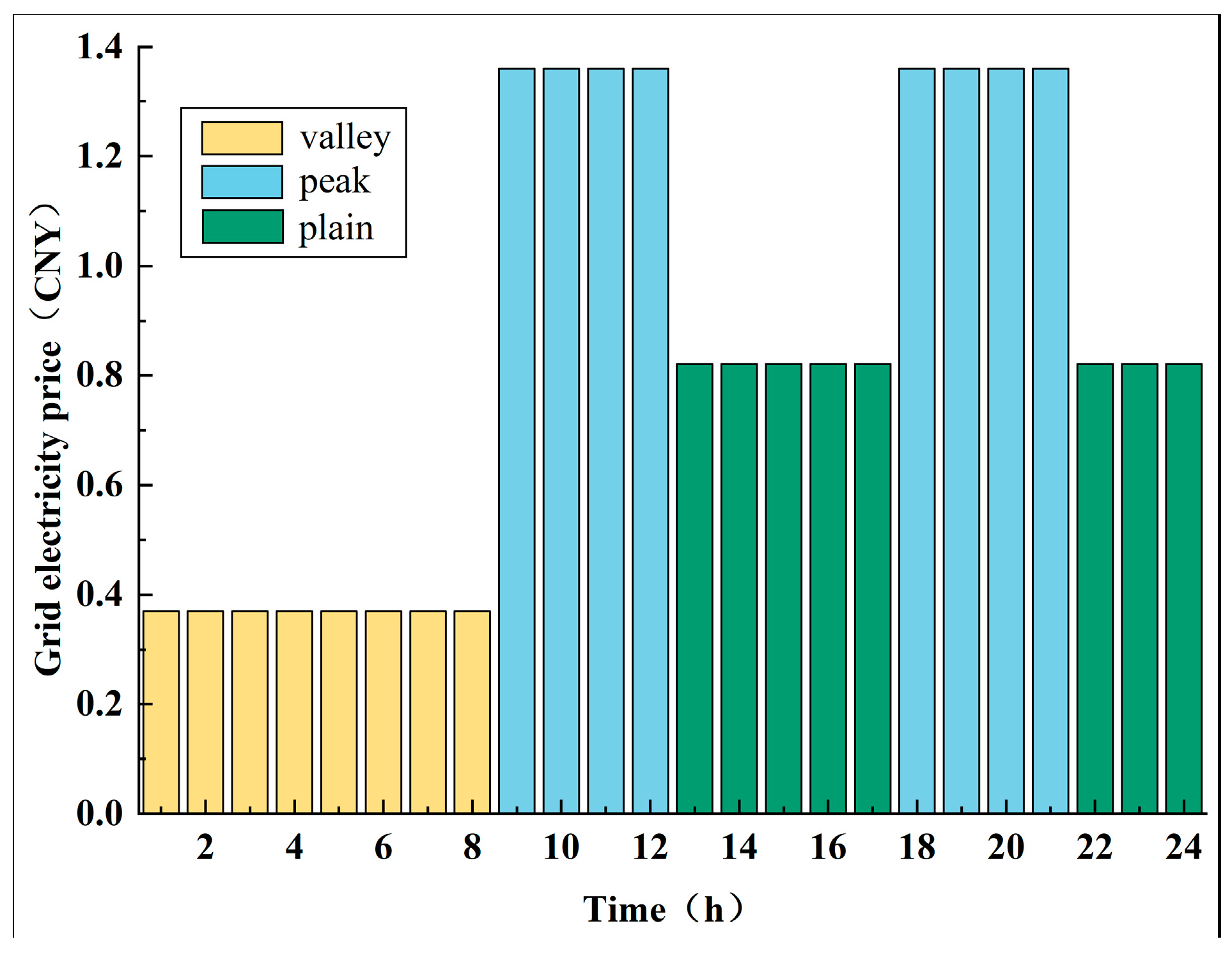

The specific parameters [20] are listed in Table 1. The grid marginal emission factor is set to t CO2/kWh, based on the average marginal emission factor of China’s national power grid in a given year (refer to the Research on the Calculation Method of Baseline and Marginal Emission Factors for Regional Power Grids in China, China Electricity Council, or relevant statistical reports). The carbon price parameter is based on the average daily transaction price of the first batch of CCERs following the resumption of registration in the national voluntary greenhouse gas emissions trading market. A relatively conservative low-end value of 80.5 CNY/t CO2 is adopted [21]. The time-of-use electricity price of IUs, CSs and SESS in the park to purchase electricity from the power grid is shown in Figure 9, and the selling price of PV to the power grid is set to 0.4 CNY/kWh.

Table 1.

Values of each parameter.

Figure 9.

Time-of-use price diagram of purchasing electricity from power grid.

5.2. Analysis of Results

Based on the previous analysis and research on the operation data of PV power stations and CSs, the PV prediction error a is set to be 15% and the load prediction error a is set to be 10%, so as to accurately reflect the uncertainty in actual operation and evaluate the robustness of the system. In addition, in order to further highlight the improvement in the energy efficiency of the park due to carbon emission reductions, this study sets up two comparative scenarios as follows:

Scenario 1: Optimal configuration model of energy storage system considering source-load uncertainty;

Scenario 2: Optimal configuration model of energy storage system considering source-load uncertainty and carbon emission reduction benefits.

The energy storage module needs to be configured in a gradient manner in practical applications, and 50 kWh is a common standard module capacity in the current energy storage market, which is in line with the standardized design of most energy storage systems. Therefore, the subsequent energy storage capacity is designed under step optimization; that is, the energy storage capacity with different uncertain values is 50 kWh as the capacity unit of each gradient.

The uncertainties in PV output and EV charging load impact both the daily operating cost and the storage capacity configuration of the park. Under the condition where the parameter is set as , four simulation cases are constructed for Scenario 1 and Scenario 2 [22], respectively, and the results are shown in Table 2.

Table 2.

Daily user cost and energy storage capacity under different uncertainty values.

When the uncertainty parameter is equal to 0, the two-stage robust optimization model is equivalent to deterministic optimization. It can be seen from Table 2 that with an increase in PV and load uncertainty, the daily cost and energy storage capacity configuration of users are also improved accordingly. In particular, in Scenario 1 and Scenario 2, when the uncertainty value changes from to , the user’s daily cost increases, but the energy storage capacity configuration results are consistent, because this study considers the energy storage gradient configuration problem. If this problem is ignored, the energy storage capacity configuration will also increase. Therefore, when the park formulates its day-ahead scheduling plan, the more uncertain factors included, the more conservative the plan is, resulting in increased costs; on the contrary, if the consideration of uncertainty is reduced, although the cost can be reduced, the risk of the scheme will increase. By comparing Scenario 1 and Scenario 2, it can be seen that when and take different values, although the energy storage capacity configuration results are the same, the daily operating cost of Scenario 2 is always lower than the daily operating cost of Scenario 1, which is related to Scenario 2. After considering carbon emission reduction, it affects the daily operation strategy of SCs and obtains additional carbon emission reduction benefits.

The larger the value is, the more time periods the PV output takes to the minimum value of the prediction interval and the CS load takes to the maximum value of the prediction interval. Therefore, the power shortage of the power users in the park increases accordingly, and the power surplus decreases accordingly, resulting in a continuous increase in electricity purchase and a continuous decrease in electricity sales. The changes in electricity purchase and sales of power users in the park with value are shown in Table 3.

Table 3.

User’s electricity purchase and sales and PV electricity sales under different uncertainty values.

It can be seen from Table 3 that with an increase in the uncertainty value, the amount of electricity purchased by users from the power grid is increasing, and the amount of electricity directly supplied by PV output to IUs and CSs is decreasing, which leads to an increase in user cost. This is because as the value increases, the PV output decreases, the CS load increases, the power gap increases, and the worst-case scenario becomes worse. The PV output gradually fails to meet the user’s needs, and the user’s electricity sales continue to decrease. External purchases continue to rise, resulting in rising costs. Comparing Scenario 1 and Scenario 2, it can be seen that when and take different values, Scenario 2 significantly reduces the amount of electricity purchased from the grid and sold to the grid compared with Scenario 1, and the PV output directly supplies users and CSs. The amount of electricity increased significantly, and the park gave priority to the use of PV output to supply itself, achieving local consumption of PV output and reducing the impact on grid stability.

In addition to the uncertainty value, the error of power prediction will also have a certain impact on the economy. At and , the impact of different prediction errors on costs is shown in Table 4.

Table 4.

User daily cost and energy storage capacity configuration under different prediction errors.

From Table 4, it can be seen that with an increase in prediction error, the daily cost of users continues to increase, but the energy storage capacity configuration remains unchanged. This is not only because this study considers the energy storage gradient configuration problem but also because the prediction error is too large, resulting in a large power shortage. Therefore, the park tends to increase external power purchase rather than excessive configuration of energy storage capacity. When formulating its day-ahead scheduling plan in the park, the greater the prediction error considered, the more conservative the plan is, resulting in increased costs; on the contrary, if the consideration of prediction error is reduced, although the cost can be reduced, the risk of the scheme will also increase. Comparing Scenario 1 and Scenario 2, it can be seen that when and take different values, the daily operating cost of Scenario 2 is greatly increased compared with Scenario 1. This is related to the fact that Scenario 2 considers carbon emission reduction, which affects the daily operation strategy of CSs and obtains additional carbon emission reduction benefits.

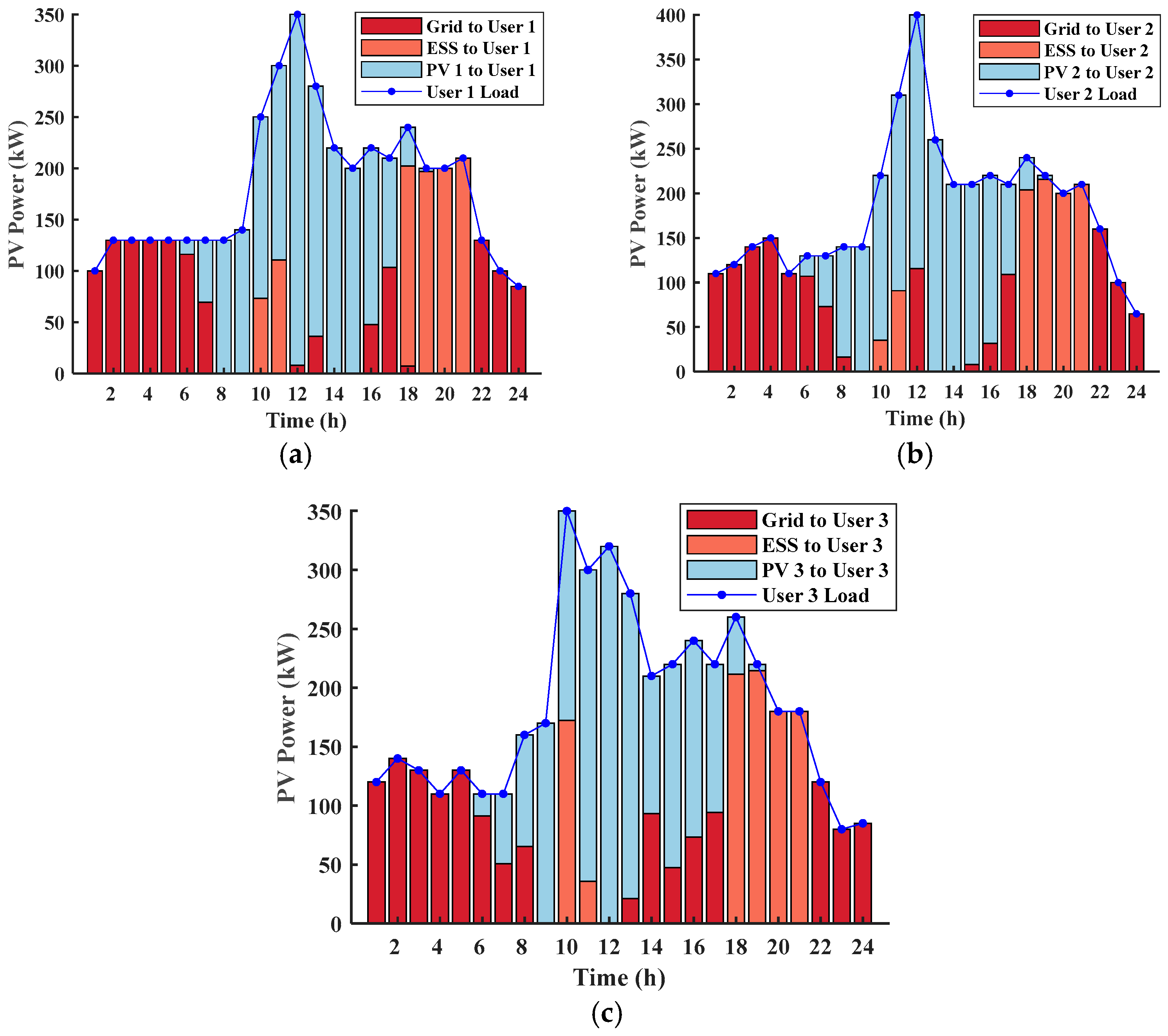

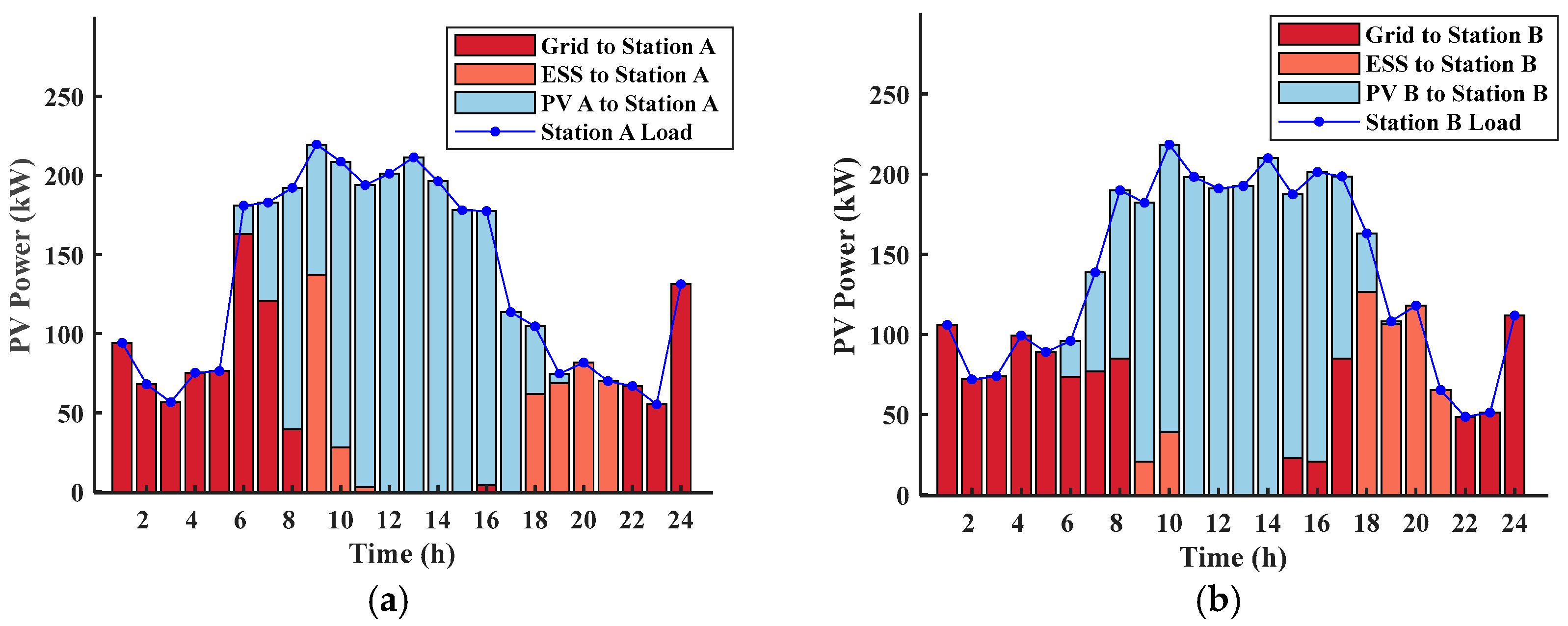

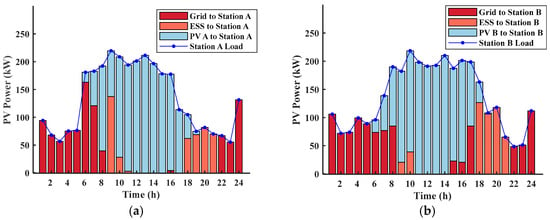

Taking , as an example, after the model is solved, the load of the CS is adjusted to the maximum value of the load prediction range, and the power generation of the PV system is set to the minimum value in the predicted value, so that the power shortage becomes the largest, that is, the worst scenario. At this time, the power balance of IU 1, IU 2, and IU 3 is shown in Figure 10, and the power balance of CS A and CS B is shown in Figure 11.

Figure 10.

Power balance diagrams of IU 1, IU 2 and IU 3. (a) IU 1; (b) IU 2; (c) IU 3.

Figure 11.

Power balance diagrams of CS A and CS B. (a) CS A; (b) CS B.

It can be seen from Figure 10 that in order to achieve better cost-effectiveness, each user preferentially uses its own PV power supply. Particularly at noon, the PV output can basically cover the power load of IU 1, IU 2 and IU 3. After meeting the industrial users’ demand, the surplus PV generation is used either to charge the SESS or to be sold to the grid. At 10 h, 11 h and 18–21 h, the PV output is insufficient. Due to the high electricity price from the power grid, IU 1, IU 2 and IU 3 tend to use the power of SESS. This practice is also consistent with the user’s electricity consumption habits.

Figure 11 shows a power balance diagram of the two CSs. At noon, the PV output power is greater than the power load of the CS. After the PV meets the load of the CS, the excess power will be delivered to the energy storage station or sold to the grid. When 18 h–21 h is the evening peak of electricity consumption, the electricity purchase price from the power grid is higher, and the CS preferentially uses the power of SESS to realize the cyclic scheduling of energy. When SESS is exhausted or the electricity price is reduced, the power grid is used for power supply. From the above analysis, it can be seen that the use of SESS in the peak load period of the power grid is helpful to reduce the pressure on the power grid and optimize the operation of the whole power system.

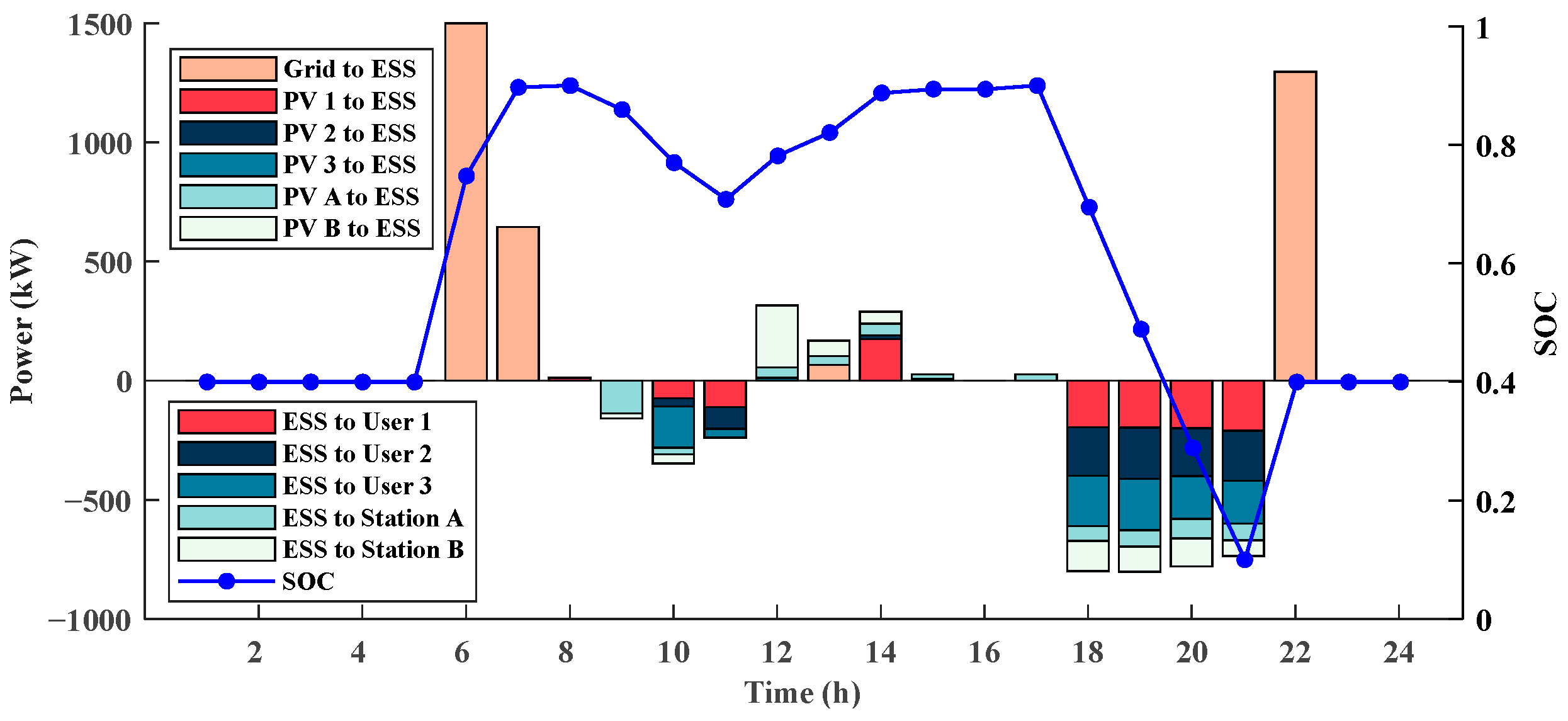

Figure 12 shows a charging and discharging power accumulation diagram of SESS and the state of the charge curve of SESS. When SESS is charged, the power value is positive and negative when discharged.

Figure 12.

Charging and discharging power and state of charge curve of SESS.

It can be seen from Figure 12 that under the time-of-use electricity price mechanism, SESS purchases a large amount of electricity from the power grid at 6 h, 7 h, and 22 h, and discharges at 9–11 h and 18–21 h, thereby storing the electricity during the valley electricity price period and selling it during the peak electricity price period, effectively reducing the cost of purchasing electricity. Because the load peak period of power users (10:00–18:00) and the load peak period of CSs (6:00–17:00) match the peak period of PV output (10:00–15:00) in time, the power supply of the PV system to SESS is not significant. However, it can also collect a small amount of surplus power during the peak period of PV output and release this power during the peak period of CS load, which improves the energy utilization efficiency, cuts the peak and fills the valley, improves the economic benefit and enhances the stability of the power grid.

To evaluate the impact of storage cost variations on system performance, a sensitivity analysis was conducted under different values of the unit capacity cost coefficient . Since the initial investment of the storage system is mainly influenced by the price of battery cells, which is directly reflected in the parameter , 1100 CNY/kWh was taken as the baseline, with a step size of 100 CNY/kWh in the range of 900 to 1200 CNY/kWh. The effects on users’ daily operating costs and the configuration of storage capacity are shown in Table 5.

Table 5.

Daily operating cost and storage capacity configuration under different unit capacity costs.

As shown in Table 5, with an increase in the unit cost of storage capacity , the park’s daily operating cost steadily rises, while the configured storage capacity remains fixed at 4100 kWh. This outcome is primarily due to the stepwise storage configuration adopted in this study, where capacity adjustments follow a 50 kWh increment, and the current cost range does not trigger a change in the optimal sizing threshold. In addition, further reducing the storage size to lower investment costs would significantly compromise the system’s flexibility and increase reliance on grid electricity, thereby diminishing overall economic performance. This result indicates that, within a certain cost range, the configured storage capacity remains stable and robust.

Table 6 shows the benefits of Scenario 1 and Scenario 2 in terms of electric energy and carbon trading. The economic and environmental benefits of the two shared energy storage configuration scenarios are compared and analyzed, and the optimization effect of carbon emission reduction benefits on the operation strategy and energy storage configuration of the park’s SESS is clarified.

Table 6.

Income comparison between Scenario 1 and Scenario 2.

From Table 6, it can be seen that the daily operation cost of SESS under Scenario 1 is CNY 7433.1, and the daily operation cost under Scenario 2 is CNY 6830.7, which is 8.10% lower than that of Scenario 1. Among them, the power grid purchase cost increased by CNY 30.4, but the carbon emission reduction benefit of SESS in the carbon market was CNY 632.83. It can be seen that in the case of Scenario 1, the SESS can save a total of CNY 602.4 per day. Within the 10-year service life of energy storage, each user can save about CNY 2.1084 million. In addition, the carbon emission reduction in SESS under Scenario 2 is 11.00% higher than that under Scenario 1. The daily operation can reduce 0.68 t of carbon emissions and save 0.33 t of standard coal (assuming that the mass of 1000 kWh PV output replacing standard coal is 0.32 t).

In summary, Scenario 2 is significantly better than Scenario 1. By incorporating carbon emission reduction benefits into the optimization objectives, not only can the economic benefits of photovoltaic charging stations be effectively improved but, also, the operation strategy of energy storage systems can be effectively optimized without relying on mandatory emission constraints, achieving a synergistic improvement in environmental and economic benefits. This market-based emission reduction pathway not only validates the guiding role of carbon price signals in the construction of low-carbon power systems but also provides practical examples for promoting the consumption of renewable energy and reducing carbon emissions through economic incentives. It has important reference value for promoting the green and low-carbon transformation of the power industry.

6. Conclusions

Aiming at the uncertainty of photovoltaic output and charging station load, a low-carbon park shared energy storage optimization configuration method considering the uncertainty of photovoltaic output and electric vehicle charging is proposed. By analyzing the collaborative operation characteristics of industrial users in the park, self-built photovoltaic and shared energy storage power stations in electric vehicle charging stations, and constructing industrial park operation scenarios, the optimization configuration of energy storage capacity is achieved. The proposed model takes into account the uncertainty of photovoltaic output and charging station load. By solving the two-stage robust optimization model, the park can achieve the energy storage configuration with the minimum system operating cost in the worst-case scenario. By adjusting uncertain parameters and predicting error values, the conservatism of configuration schemes can be flexibly adjusted, which is beneficial for industrial parks to make reasonable choices between operating costs and risks. The calculation results show that the construction of shared energy storage is significantly better than the scheme without energy storage configuration. Shared energy storage can not only significantly reduce operating costs but also effectively suppress the adverse effects of source load fluctuations, increase the operating efficiency and reliability of photovoltaic systems, and reduce energy waste. By incorporating carbon emission reduction benefits into optimization objectives, this study’s scheme can effectively reduce carbon dioxide emissions, improve carbon emission reduction levels, guide energy storage systems to optimize their operational strategies, reduce operating costs, and achieve a synergistic improvement in environmental and economic benefits.

Author Contributions

Conceptualization, S.J. and J.L.; methodology, S.J.; software, L.L. and W.S.; validation, S.J. and J.L.; formal analysis, L.L.; investigation, W.S.; resources, J.W.; data curation, S.J.; writing—original draft preparation, L.L.; writing—review and editing, S.J.; visualization, J.W.; supervision, S.J.; project administration, J.L.; funding acquisition, J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded and supported by Funding for Basic Science (Natural Science) Research Projects in Higher Education Institutions in Jiangsu Province (23KJB470013), and, in part, by Key Laboratory of Control of Power Transmission and Conversion (SJTU), Ministry of Education (2023AC04).

Data Availability Statement

The data in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sarda, J.; Patel, N.; Patel, H.; Vaghela, R.; Brahma, B.; Bhoi, A.K.; Barsocchi, P. A Review of the Electric Vehicle Charging Technology, Impact on Grid Integration, Policy Consequences, Challenges and Future Trends. Energy Rep. 2024, 12, 5671–5692. [Google Scholar] [CrossRef]

- Yao, M.; Da, D.; Lu, X.; Wang, Y. A Review of Capacity Allocation and Control Strategies for Electric Vehicle Charging Stations with Integrated Photovoltaic and Energy Storage Systems. World Electr. Veh. J. 2024, 15, 101. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, L.; Zhao, Z.; Wang, L. Comprehensive Benefits Analysis of Electric Vehicle Charging Station Integrated Photovoltaic and Energy Storage. J. Clean. Prod. 2021, 302, 126967. [Google Scholar] [CrossRef]

- Luo, J.; Fan, F.; Tai, N.; Chen, Z.; Pu, C.; Zhang, X. Low-Carbon Economic Optimization for Park Integrated Energy System Considering Multi-Network Integration. In Proceedings of the 2023 IEEE/IAS Industrial and Commercial Power System Asia (I&CPS Asia), Chongqing, China, 7–9 July 2023; pp. 2160–2165. [Google Scholar]

- Zhu, X.; Yang, J.; Pan, X.; Li, G.; Rao, Y. Regional Integrated Energy System Energy Management in an Industrial Park Considering Energy Stepped Utilization. Energy 2020, 201, 117589. [Google Scholar] [CrossRef]

- Alshareef, R.S.; Maghrabie, H.M. Building-Integrated Photovoltaics with Energy Storage Systems—A Comprehensive Review. J. Energy Storage 2025, 116, 115916. [Google Scholar] [CrossRef]

- Chen, C.; Sun, H.; Shen, X.; Guo, Y.; Guo, Q.; Xia, T. Two-Stage Robust Planning-Operation Co-Optimization of Energy Hub Considering Precise Energy Storage Economic Model. Appl. Energy 2019, 252, 113372. [Google Scholar] [CrossRef]

- Zhou, S.; Han, Y.; Mahmoud, K.; Darwish, M.M.F.; Lehtonen, M.; Yang, P.; Zalhaf, A.S. A Novel Unified Planning Model for Distributed Generation and Electric Vehicle Charging Station Considering Multi-Uncertainties and Battery Degradation. Appl. Energy 2023, 348, 121566. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, J.; Cui, S.; Zhu, R. An Energy Collaboration Framework Considering Community Energy Storage and Photovoltaic Charging Station Clusters. J. Energy Storage 2025, 116, 115976. [Google Scholar] [CrossRef]

- Xu, T.; Ren, Y.; Guo, L.; Wang, X.; Liang, L.; Wu, Y. Multi-Objective Robust Optimization of Active Distribution Networks Considering Uncertainties of Photovoltaic. Int. J. Electr. Power Energy Syst. 2021, 133, 107197. [Google Scholar] [CrossRef]

- Yang, N.; Xu, G.; Fei, Z.; Li, Z.; Du, L.; Guerrero, J.M.; Huang, Y.; Yan, J.; Xing, C.; Li, Z. Two-Stage Coordinated Robust Planning of Multi-Energy Ship Microgrids Considering Thermal Inertia and Ship Navigation. IEEE Trans. Smart Grid 2025, 16, 1100–1111. [Google Scholar] [CrossRef]

- Sun, X.; Cao, X.; Zeng, B.; Zhai, Q.; Başar, T.; Guan, X. Stochastic-Robust Planning of Networked Hydrogen-Electrical Microgrids: A Study on Induced Refueling Demand. IEEE Trans. Smart Grid 2025, 16, 115–130. [Google Scholar] [CrossRef]

- Pan, X.; Liu, K.; Wang, J.; Hu, Y.; Zhao, J. Capacity Allocation Method Based on Historical Data-Driven Search Algorithm for Integrated PV and Energy Storage Charging Station. Sustainability 2023, 15, 5480. [Google Scholar] [CrossRef]

- Li, L.; Cao, X.; Zhang, S. Shared Energy Storage System for Prosumers in a Community: Investment Decision, Economic Operation, and Benefits Allocation under a Cost-Effective Way. J. Energy Storage 2022, 50, 104710. [Google Scholar] [CrossRef]

- Tasneem, O.; Tasneem, H.; Xian, X. Lithium-Ion Battery Technologies for Grid-Scale Renewable Energy Storage. Next Res. 2025, 2, 100297. [Google Scholar] [CrossRef]

- Dong, X.-J.; Shen, J.-N.; Liu, C.-W.; Ma, Z.-F.; He, Y.-J. Simultaneous Capacity Configuration and Scheduling Optimization of an Integrated Electrical Vehicle Charging Station with Photovoltaic and Battery Energy Storage System. Energy 2024, 289, 129991. [Google Scholar] [CrossRef]

- Ma, Y.; Xu, W.; Yang, H.; Zhang, D. Two-Stage Stochastic Robust Optimization Model of Microgrid Day-Ahead Dispatching Considering Controllable Air Conditioning Load. Int. J. Electr. Power Energy Syst. 2022, 141, 108174. [Google Scholar] [CrossRef]

- Zhang, M.; Yan, Q.; Guan, Y.; Ni, D.; Agundis Tinajero, G.D. Joint Planning of Residential Electric Vehicle Charging Station Integrated with Photovoltaic and Energy Storage Considering Demand Response and Uncertainties. Energy 2024, 298, 131370. [Google Scholar] [CrossRef]

- Zhao, G.; Yu, C.; Huang, H.; Yu, Y.; Zou, L.; Mo, L. Optimization Scheduling of Hydro–Wind–Solar Multi-Energy Complementary Systems Based on an Improved Enterprise Development Algorithm. Sustainability 2025, 17, 2691. [Google Scholar] [CrossRef]

- Li, J.; Liu, D.; Jiang, S.; Wu, L. Optimal Configuration of Shared Energy Storage System in Microgrid Cluster: Economic Analysis and Planning for Hybrid Self-Built and Leased Modes. J. Energy Storage 2024, 104, 114624. [Google Scholar] [CrossRef]

- National Greenhouse Gas Voluntary Emission Reduction Trading System. Available online: https://www.ccer.com.cn/ (accessed on 10 June 2025).

- Xiao, H.; Long, F.; Zeng, L.; Zhao, W.; Wang, J.; Li, Y. Optimal Scheduling of Regional Integrated Energy System Considering Multiple Uncertainties and Integrated Demand Response. Electr. Power Syst. Res. 2023, 217, 109169. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).