1. Introduction

Undoubtedly, greenhouse gas emissions are a major driver of global warming, primarily stemming from fossil fuel use in energy production and transportation [

1]. While these fuels have enabled continuous societal progress, they are progressively degrading the vital environmental conditions necessary for human survival. Over recent years, extensive haze coverage in many regions of China has not only stifled economic development but also caused significant health impacts [

2]. Therefore, the effective use of clean energy is crucial to combat this haze. Faced with the dual challenges of energy shortages and environmental degradation, nations all over the world are actively exploring renewable, clean energy sources. They are keenly developing new energy technologies, aiming to reduce the reliance on traditional fossil fuels and address the growing issue of environmental pollution. Among emerging energy solutions, hydrogen is regarded as one of the most promising sources of energy due to its abundant resources, lightweight nature, and high energy density. Hydrogen, as an efficient and environmentally friendly energy carrier, offers numerous advantages. It has a calorific value of approximately 120 MJ·kg

−1, about 2.7 times that of petroleum, and the only product of hydrogen combustion is water, making it exceptionally clean [

3,

4,

5,

6,

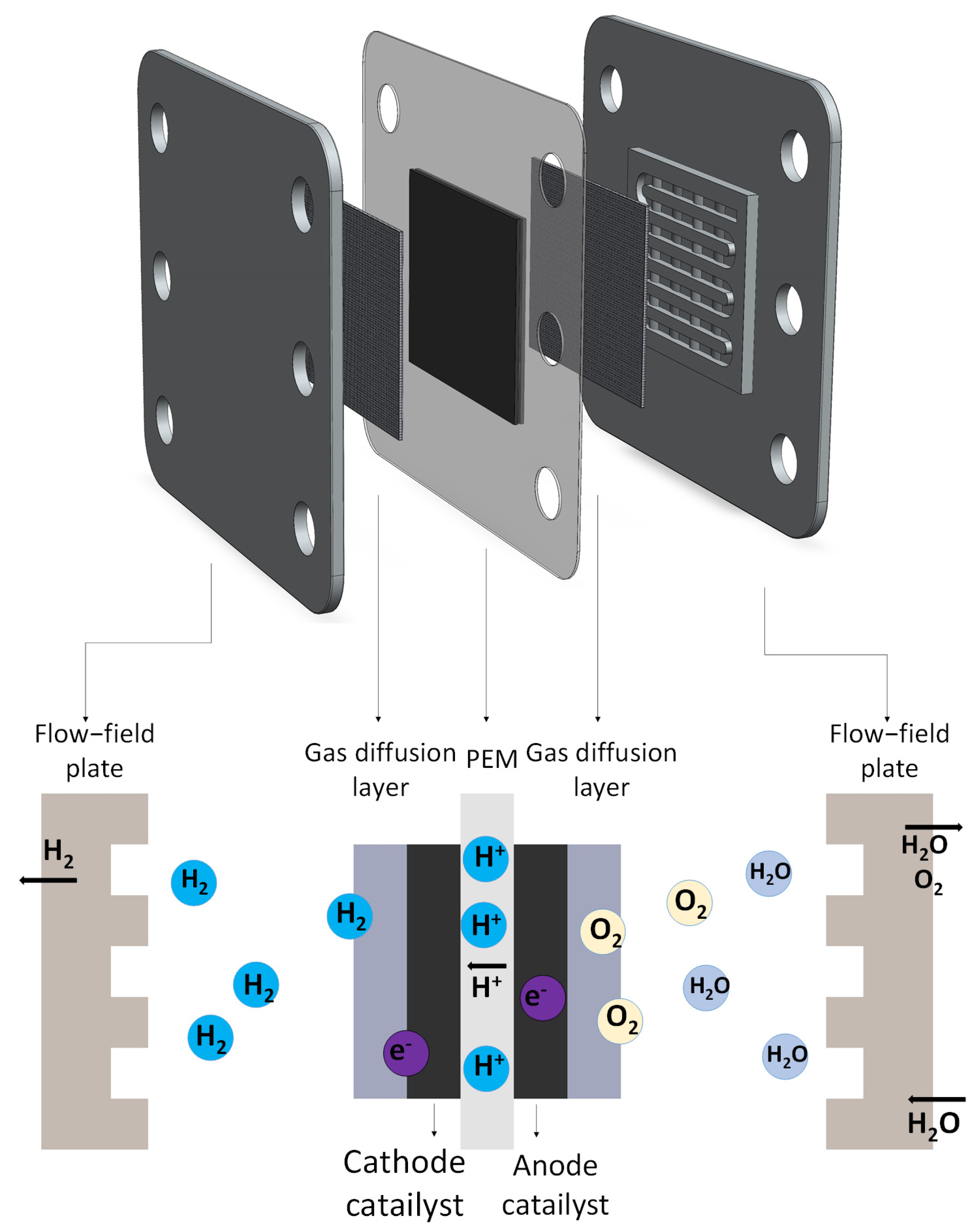

7]. The proton exchange membrane electrolysis cell (PEMEC), which converts water molecules into electrons, hydrogen ions, and oxygen using electrical energy, is especially advantageous. Compared to alkaline and solid oxide electrolysis cells, the PEMEC offers a compact structure, small volume, higher current density, high purity, low-temperature operation, and enhanced safety [

8,

9,

10,

11,

12].

The structural framework of the PEMEC closely resembles that of the PEMFC (proton exchange membrane fuel cell). However, their reaction mechanisms are inverse. During water electrolysis in the PEMEC, water molecules are oxidized on the anode side, releasing oxygen, protons, and electrons, producing oxygen bubbles. These bubbles migrate through the diffusion layer to the channel and are expelled with the liquid water flow. Accumulation of these bubbles in the channel impedes water transfer, adversely affecting performance [

13,

14]. Addressing this, a key challenge in the performance optimization of the PEMEC is ensuring the prompt delivery of liquid water and rapid removal of oxygen gas bubbles. Thus, the flow field design is crucial in the PEMEC. Typical flow field configurations include parallel, serpentine, multi-channel serpentine, and interdigitated patterns [

15]. Detailed assessments of these configurations help to identify the performance variations under different operational conditions. Immerz et al. [

16] analyzed the impact of water flux variations on current density in the single-channel PEMEC, noting minor effects from slight water flux changes but significant performance degradation from water flux deficiencies. Ruiz et al. [

17] found that serpentine channels were most effective for hydrogen production, optimizing current density, flow rates, and thermal management. Exploring various configurations, Yang et al. [

18] determined that parallel grid flow fields produced the highest current density. Ni et al. [

19] observed the dynamics of multiphase flow in the anodic porous transport layer, noting how flow rate, pressure, and water–oxygen ratios influence two-phase flow behavior. Shen et al. [

20] highlighted that strategic perturbations in the flow field enhance reactant transfer to the gas diffusion layer, thereby improving the PEMEC performance. Furthermore, Yang et al. [

21] utilized machine learning to optimize the PEMEC flow field design of the PEMEC, successfully predicting optimal conditions for achieving commercial-scale hydrogen production rates ranging from 50 to 3000 mL⋅min

−1.

In order to improve the performance of PEMEC, innovative research has been carried out on the channel structure of conventional PEMEC. Toghyani et al. [

22] constructed three-dimensional models for five flow field configurations: parallel, single-path serpentine (one-path), dual-path serpentine (two-path), triple-path serpentine (three-path), and quadruple-path serpentine (four-path). They conducted experiments and, through the analysis of numerical and experimental results, concluded that serpentine channels improve the distribution of current density and temperature. Conversely, dual-path serpentines show advantages in terms of pressure drop, current density distribution, and hydrogen molar fraction, among other factors. Olesen et al. [

12,

23] developed a numerical model for three distinct circular, interdigitated anode flow fields, considering electrochemical reactions, heat transfer in the electrolyzer, phase changes of water, and comprehensive bubble transport. Their model accurately predicts the polarization curves of high-current-density electrolyzers at temperatures ranging from 323 K to 353 K. They discovered that at lower water flow rates, oxygen gas bubbles tend to accumulate significantly in the flow field, impeding the diffusion of liquid water. Their research aims to establish reasonable pressure drops, temperatures, and more uniform current density conditions for hydrogen production. Even in relatively straightforward experiments, their findings offer valuable insights for the flow field design of the PEMEC in the future.

To further enhance the flow field performance of the PEMEC, current research increasingly focuses on modifying channel structures or materials. Zhou et al. [

24] examined the effects of uneven channel depths and the porosity of the anode gas diffusion layer on mass transfer characteristics. Their findings indicated that decreasing channel depth while increasing gas diffusion layer porosity significantly enhanced mass transfer at the channel’s outlet, thereby boosting the overall performance of the PEMEC. Wang et al. [

25] introduced a novel interdigitated jet flow field derived from a single serpentine channel, featuring a metal plate with jet orifices. This configuration enhanced liquid saturation, ensured the uniform distribution of temperature and current density, and improved the polarization performance of the PEMEC. Wrubel et al. [

26] simulated a two-dimensional multiphysics model of a PEMEC equipped with a thin-film porous transport layer at the anode, which includes a highly structured pore array. Their simulation, accounting for coupled electrochemical and multiphase transport phenomena, demonstrated that a higher air content promoted water entry into the reaction zone, facilitating the oxygen evolution reaction and membrane hydration. Ma et al. [

27] created a PEMEC model with a 25 cm² active electrode area and three serpentine channels to evaluate electrochemical reactions, mass transfer, and thermal-fluid processes. This model was instrumental in optimizing components, conducting lab tests, and advancing material development, providing crucial insights for future flow field design. Toghyani et al. [

28] replaced traditional bipolar plates with lightweight, rigid, high-temperature-resistant, and corrosion-resistant metal foam. Their study revealed that these structural enhancements significantly lowered pressure and achieved a more uniform distribution of temperature gradient, current density, and hydrogen mass fraction compared to those of double serpentine channels. Finally, Laube et al. [

29] designed a tubular PEMEC that effectively reduced sealing length and the number of components, thereby lowering production costs.

However, conventional serpentine channels are prone to bubble buildup, which can be ameliorated by adding microstructures to the channel [

30]. And the addition of microstructures will inevitably increase the pressure drop inside the channel. The pressure drop inside the channel of a conventional wavy runner increases due to the addition of microstructures [

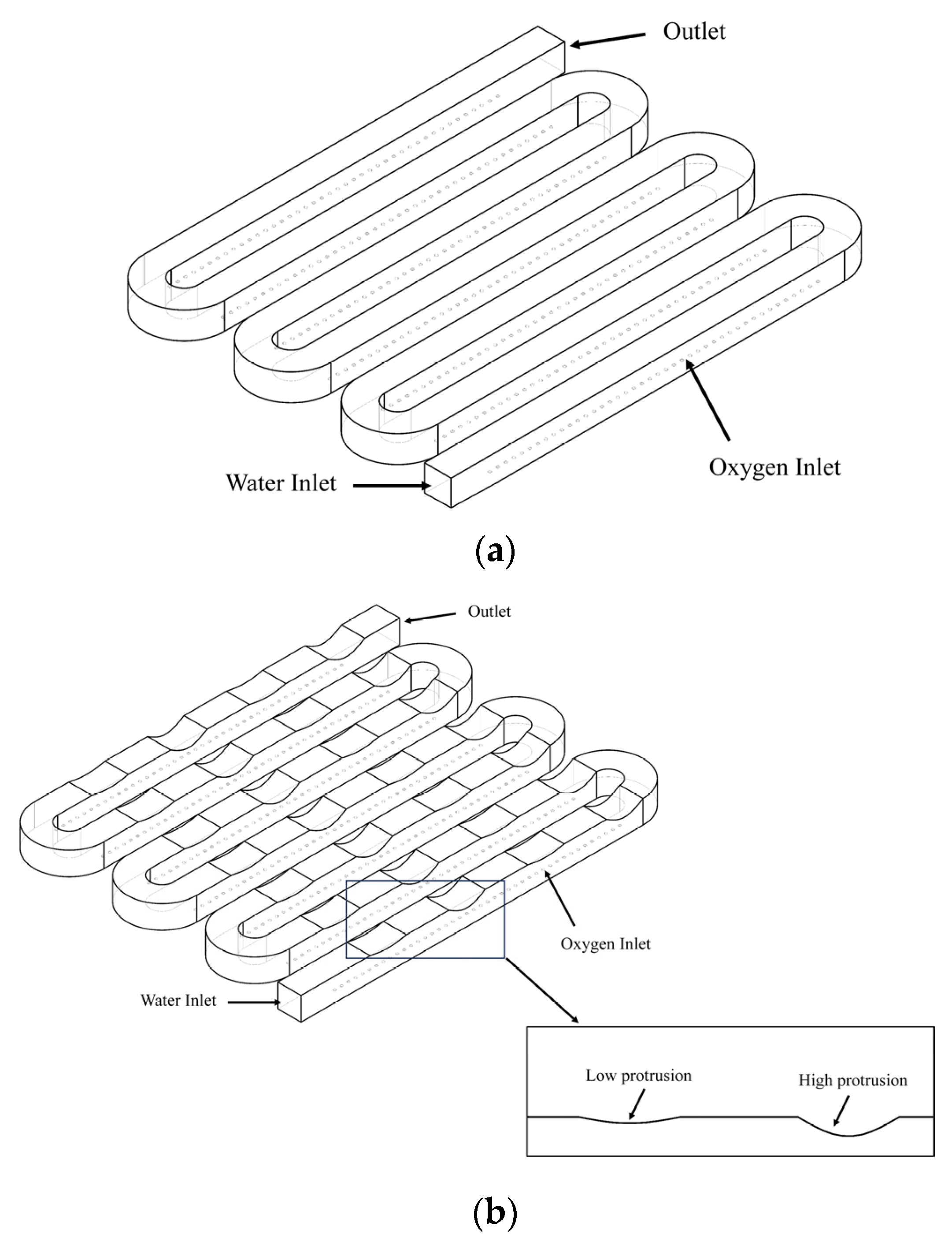

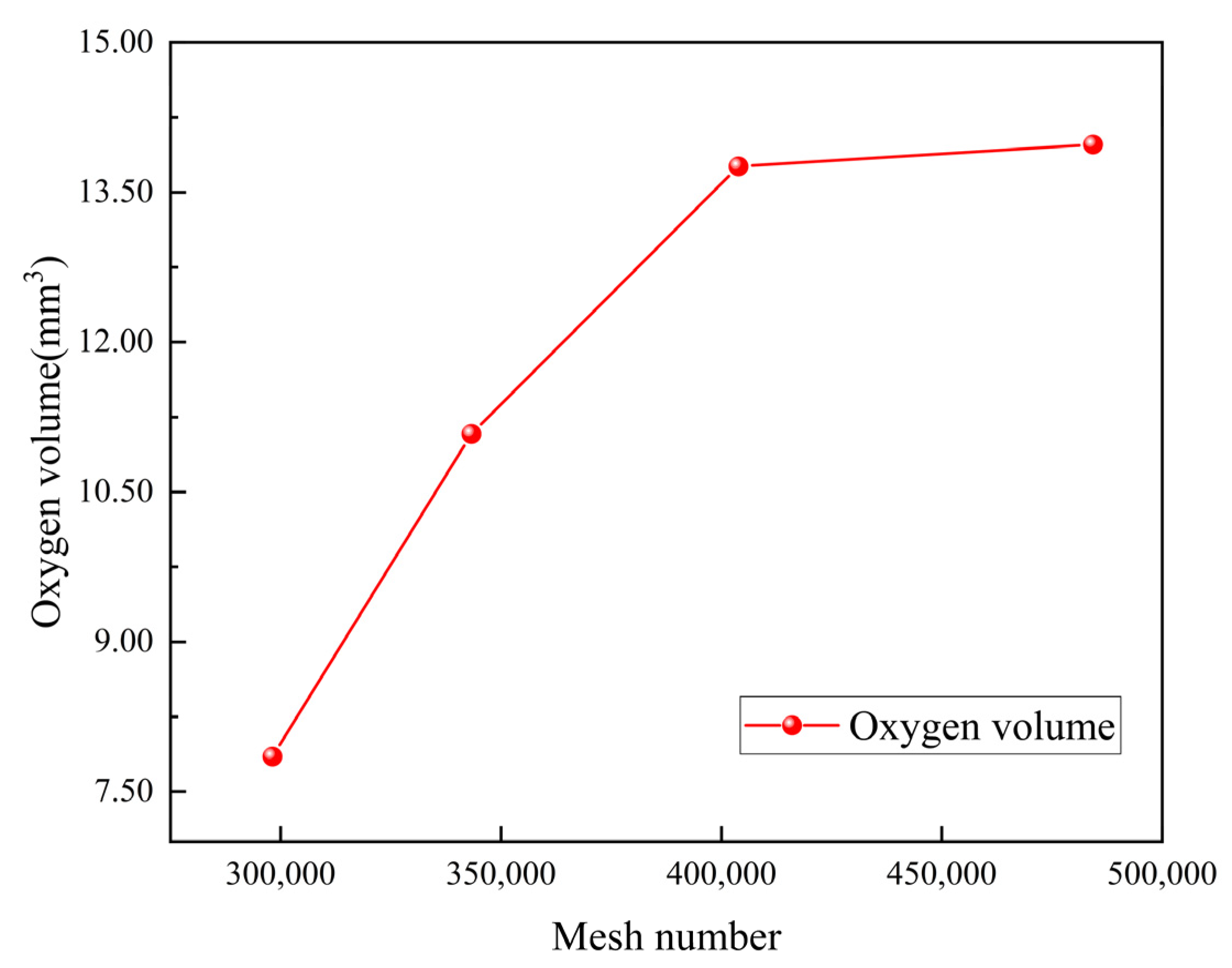

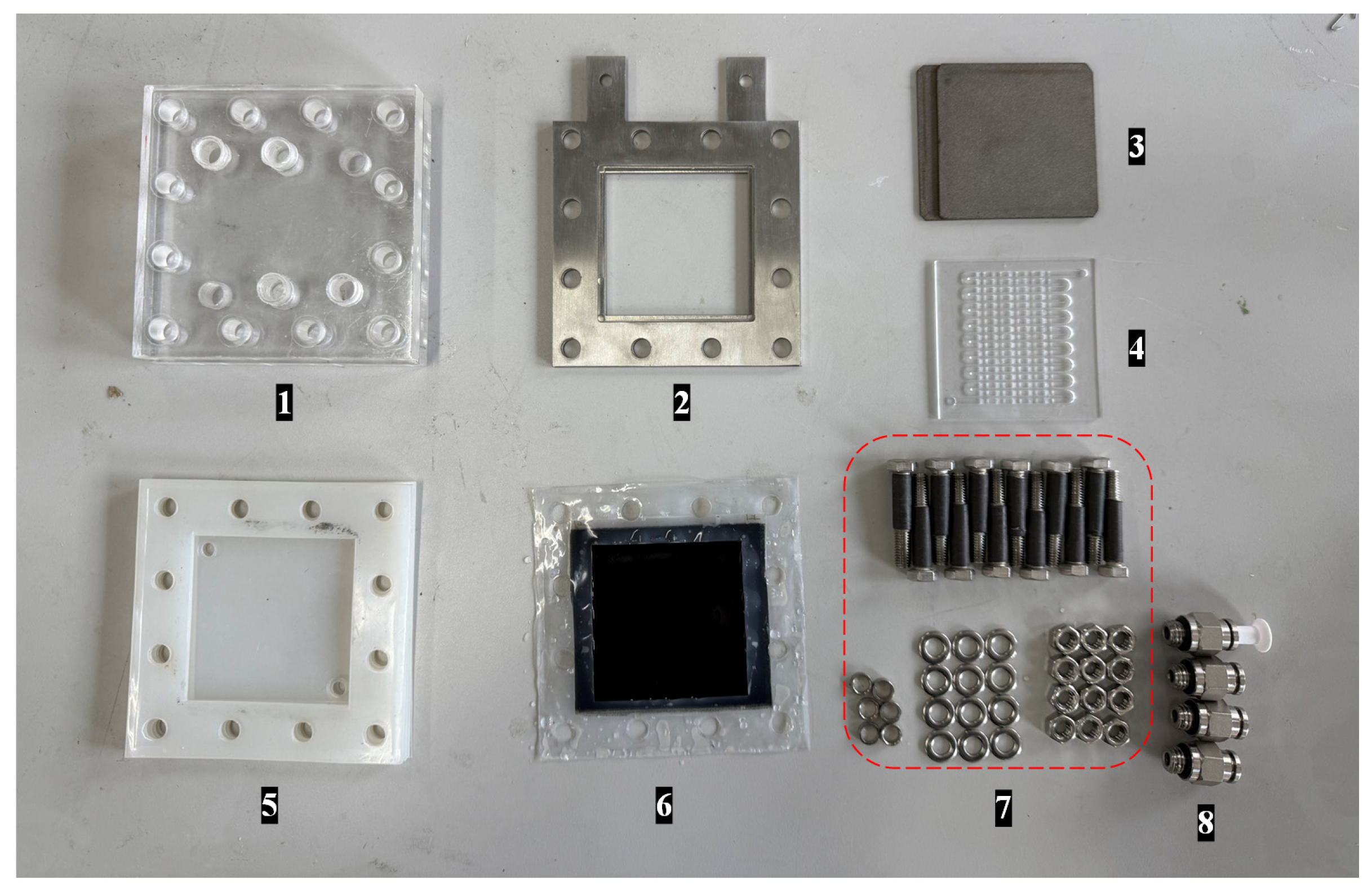

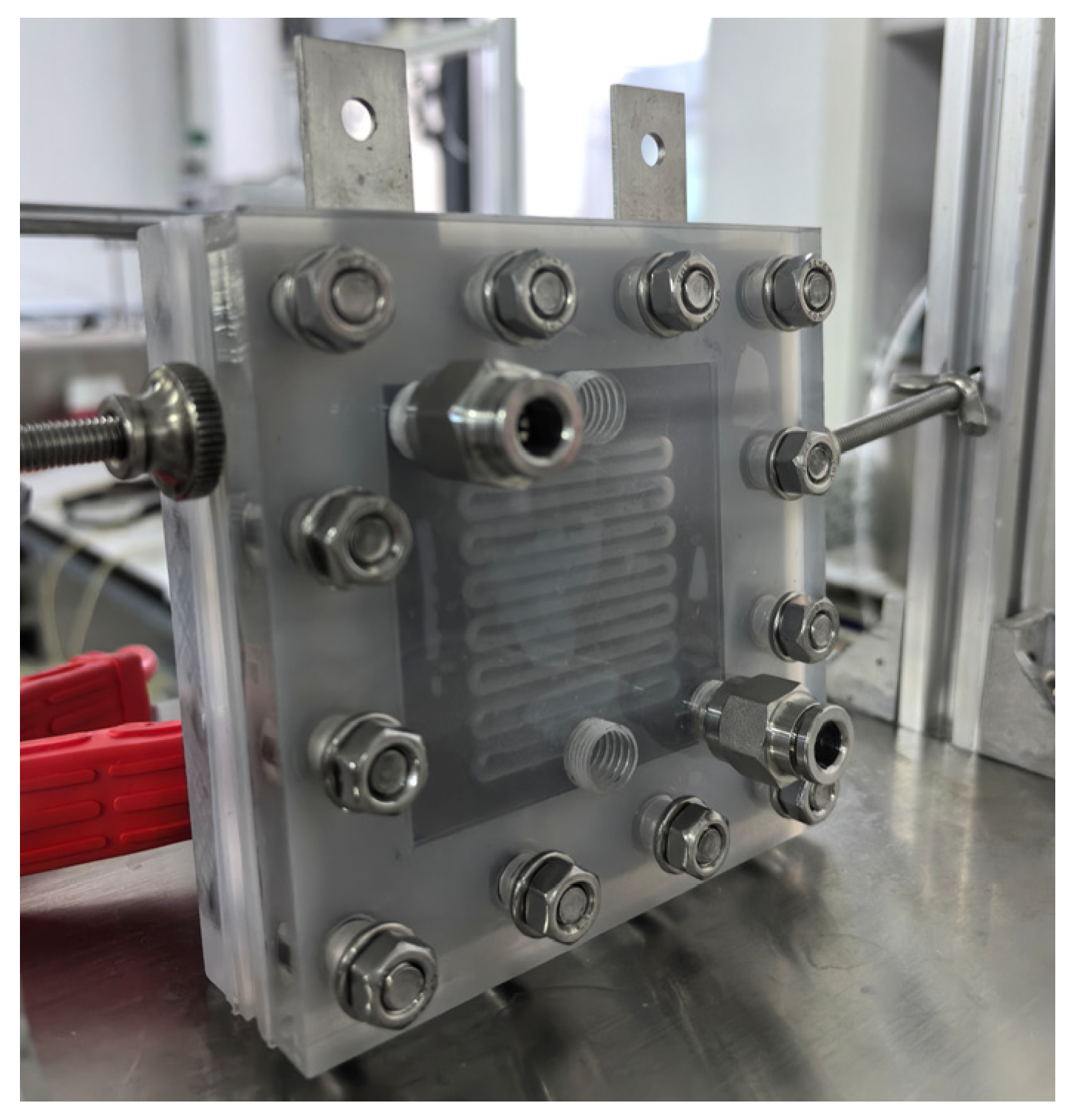

31]. Therefore, in order to minimize the bubble buildup inside the channel and to minimize the pressure drop inside the channel, our research group designed a channel characterized by uneven wave-like protrusions based on the conventional wavy channel. In this study, inspired by the optimization of two-phase flow by Lin et al. [

32], we utilized Solidworks to create a three-dimensional model of the flow channel of the PEMEC, incorporating these wave-like protrusions on the surface of a single serpentine channel. Our investigation primarily examined the impact of these protrusions on the pressure drop of the channel and oxygen output at the outlet. We also compared these results with those from a standard single serpentine channel model. Furthermore, by employing Minitab software (19, MinitabInc, State College, PA, USA) and the Taguchi design method, we optimized the height, breadth, and spacing of the wave-like protrusions, achieving the optimal waveform under various operational conditions. Finally, the polarization curves were compared with the two-phase flow pattern in the flow channel by changing the water supply flow rate and temperature through visualization experiments.

3. Simulation Results and Discussion

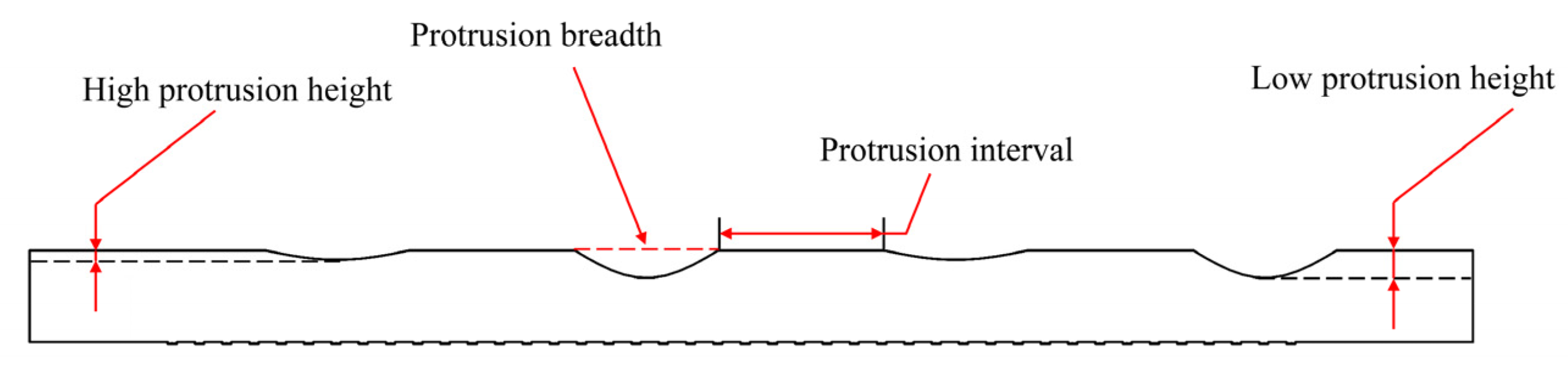

In this section, the primary focus is on evaluating the specific impact of wave-like protrusion structures on the PEMEC channel. This study investigates the effects of the height, breadth, and interval between two protrusions of the wave-like structures on the outlet oxygen volume and the inlet–outlet pressure drop of the channel. It is crucial to emphasize that in the context of this research, changes in the height of the wave-like protrusions refer to simultaneous increases or decreases in the heights of both the high and low protrusions. Protrusion interval variation pertains to changes in the gap between a high and a low protrusion, while breadth variation involves an increase or decrease in the breadth of each protrusion with a constant interval. The comprehensive comparison of these nine channels provides insights into how variations in the geometric parameters of the wave-like protrusions impact the performance of the PEMEC channel in the PEMEC, as indicated by the velocity, the gas coverage area, the outlet oxygen volume, the inlet–outlet pressure drop, and the volumetric gas content.

3.1. The Influence of Protrusion on the Velocity in the Flow Channel

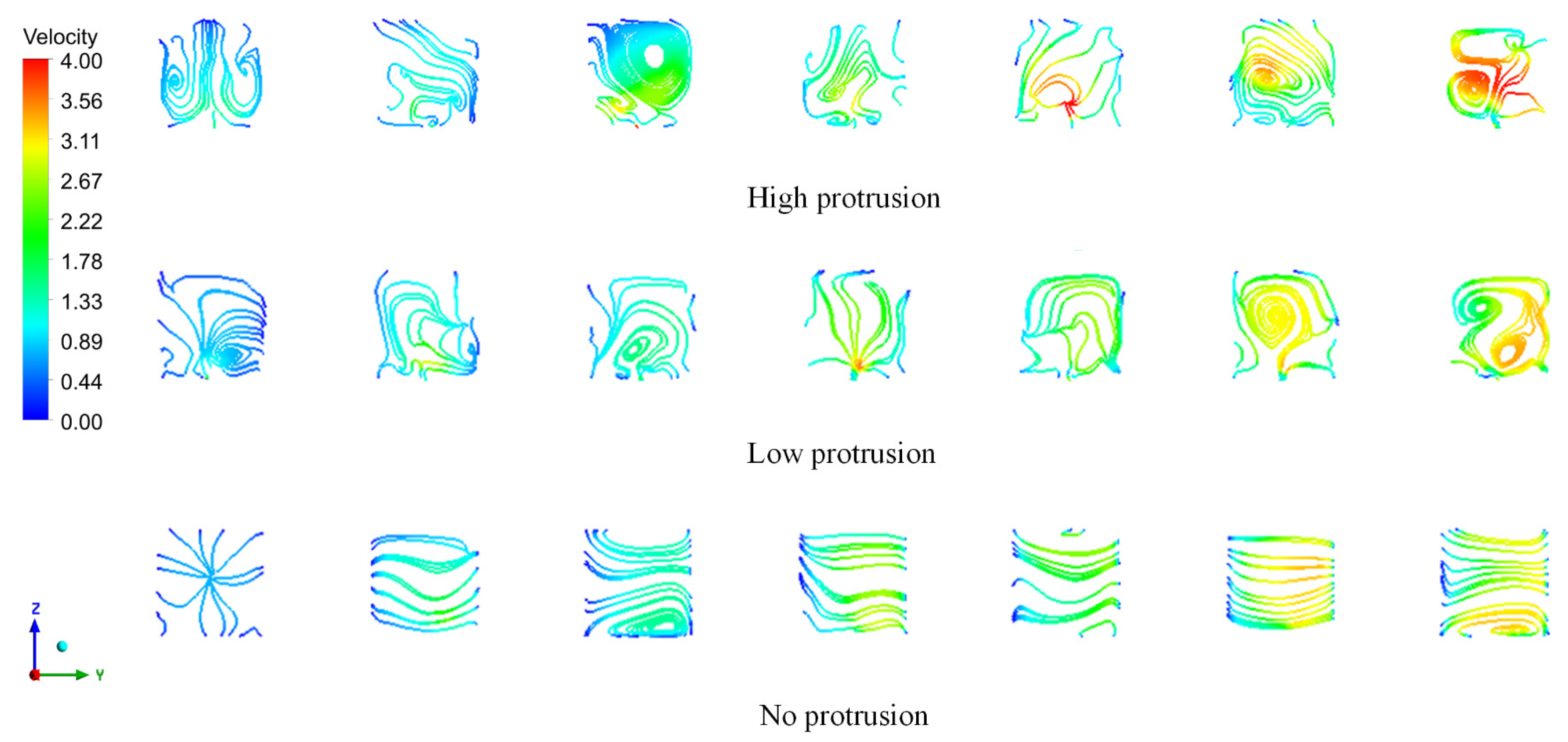

To verify the performance differences between the new channel and the traditional serpentine channel, streamline analysis was performed on the longitudinal cross-sections of the new model with high and low protrusions, as well as the traditional serpentine channel. The cross-sections are closer to the outlet from left to right. The selected high and low protrusion longitudinal cross-sections are located in the middle of a single channel, which helps avoid interference from corners that might influence the streamlined analysis results.

As shown in

Figure 5, due to the short reaction time, the flow rate in the channel near the inlet is relatively low. In contrast, the flow rate in the channel near the outlet changes due to sufficient reaction time and the formation of bubbles, which leads to increases in the flow speed. By comparing the channels with protrusions and those without protrusions, it is evident that protrusions significantly accelerate the fluid flow. This is because the improved structure reduces the height of the channel along the Z-axis, which in turn decreases the cross-sectional area of the channel. Therefore, under the assumption of constant volumetric flow, the flow rate increases, resulting in accelerated flow of the reactants in the areas with protrusions. The reduction in cross-sectional area also increases the flow resistance, promoting flow in the Z-direction and generating more longitudinal turbulence within the channel. This turbulence not only enhances the interaction between bubbles and liquid, improving the uniform distribution of the reactant gas within the channel, but also enables better distribution of the reactant gas toward the gas diffusion layer. Thus, the new channel with protrusion structures exhibits a higher fluid acceleration effect compared to the traditional serpentine channel. Below, the analysis will focus on the gas coverage area, outlet oxygen volume, inlet–outlet pressure drop, and volumetric gas content of the new channel and will specifically discuss the impact of different protrusion structures on the channel’s performance.

3.2. The Influence of Three Variables on the Gas Coverage Area

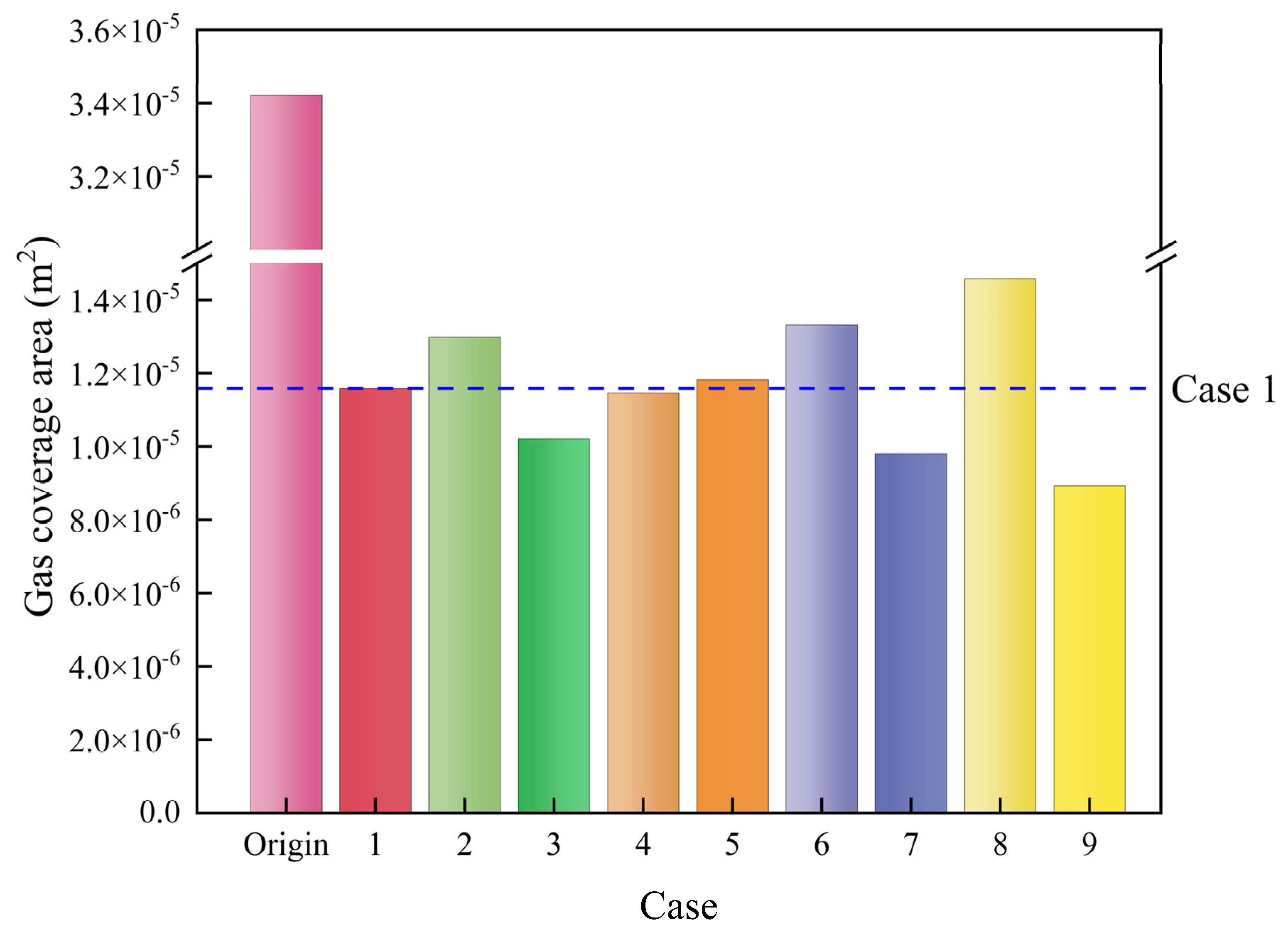

Reducing the gas coverage area on the GDL (gas diffusion layer) surface can significantly enhance electrode surface contact, thereby improving electrolysis efficiency, reducing energy losses, and increasing system stability. As illustrated in

Figure 6, the average gas coverage area on the GDL surface during the simulation process is compared across nine new flow channel designs with protrusion structures and the original serpentine channel design. The results indicate that the gas coverage areas in the nine protrusion flow channels are considerably smaller than that of the original serpentine channel. This improvement is attributed to the fact that the protrusion in the new flow channels effectively increases the water velocity. Higher water velocity generates greater shear lift forces on the bubbles, facilitating their detachment and promoting the formation of smaller bubbles. Furthermore, the likelihood of bubble accumulation into annular flows is reduced, thereby enhancing the gas discharge capability of the flow channel.

Subsequently, the impact of different protrusion parameters on the surface gas coverage area is analyzed. When comparing Case 1, Case 2, and Case 3, it is observed that reducing the height of the protrusion effectively reduces the surface gas coverage area. A comparison of Case 1, Case 4, and Case 5 reveals that the protrusion spacing has a minimal effect on the gas coverage area, although slightly increasing the spacing can marginally reduce the GDL surface coverage. In Case 1, Case 6, and Case 7, it is found that decreasing the protrusion width is the most effective method for reducing the gas coverage area among the three parameters. Finally, a comparison of Case 1, Case 8, and Case 9 demonstrates that simultaneously reducing all three parameters (protrusion height, width, and spacing) also contributes effectively to decreasing the gas coverage area on the GDL surface.

3.3. The Influence of Three Variables on the Outlet Oxygen Volume

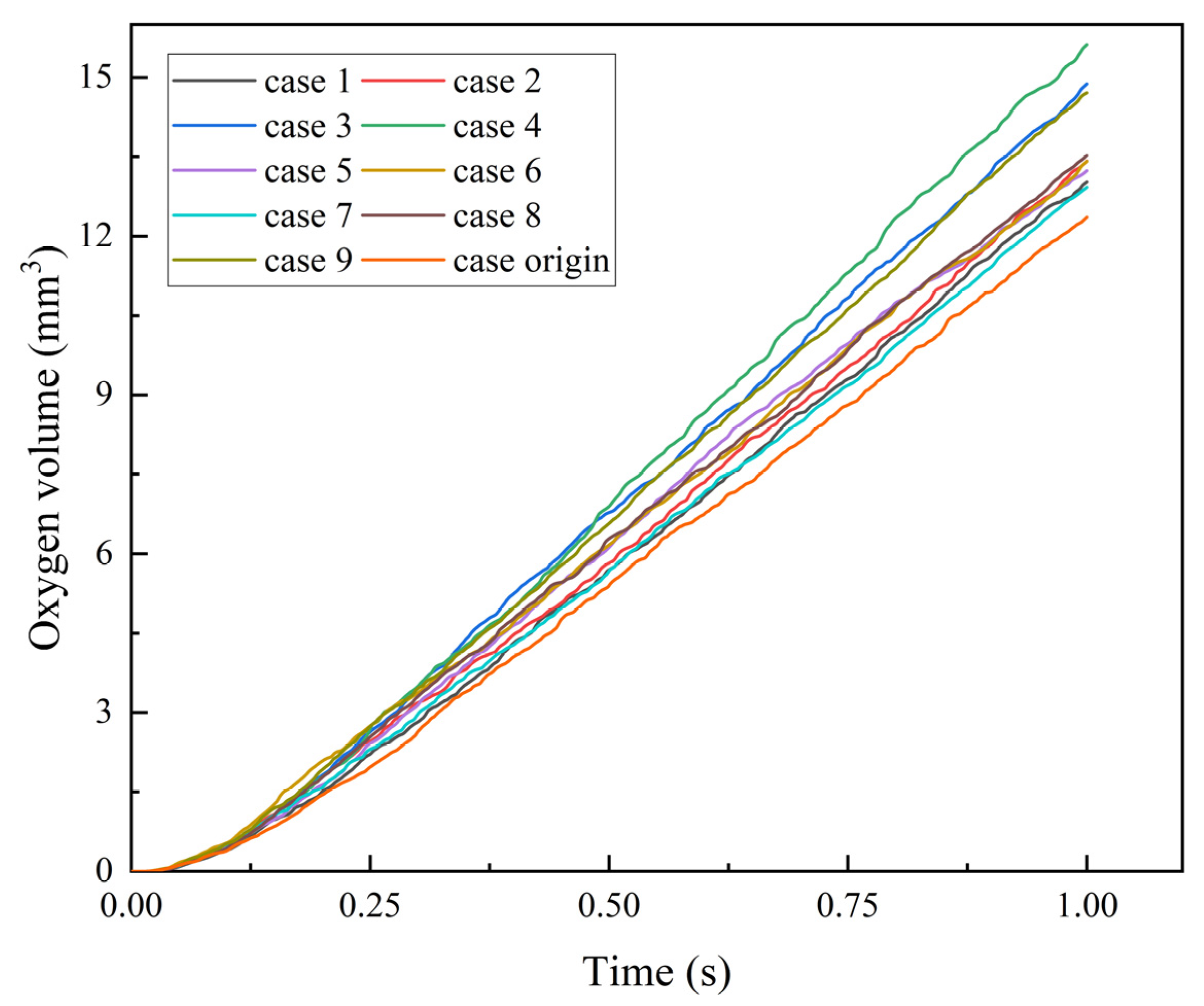

In

Figure 7, baseline parameters are established in Case 1 for subsequent comparisons. Cases 2, 3, and 1 illustrate the effect of varying protrusion heights on the outlet oxygen volume in the PEMEC with a wavy channel. The simulation results demonstrate that the presence of a wavy channel significantly enhances the outlet oxygen volume compared with a standard serpentine channel. Notably, at a protrusion height of 0.25 mm (Case 3), the flow field shows superior performance in oxygen output compared with other configurations. This suggests that excessively high protrusions increase flow resistance and energy loss in water and oxygen transport, indicating the requirement for lower protrusion heights to maximize oxygen output.

Figure 7 also compares Cases 4, 5, and 1, revealing the impact of different wavy protrusion intervals on oxygen output. It is observed that a narrower protrusion interval increases the number of protrusions, enhancing the disturbance effect on the fluid, and forcing it to change direction. This introduces a substantial vertical velocity component that opposes the desired flow direction, leading to energy loss. Therefore, a wider protrusion interval (Case 4) yields a higher oxygen output by reducing undesired velocity components.

Further comparisons in

Figure 7 (Cases 6, 7, and 1) show the influence of varying wavy protrusion breadths on oxygen output. A narrower protrusion breadth increases the slope of the protrusion sides due to its constant height, creating more vortices and dead zones, thereby reducing oxygen output. Conversely, wider protrusions decrease the vertical velocity component when interacting with the water, thus conserving energy and enhancing oxygen output.

Lastly,

Figure 7 (Cases 8, 9, and 1) explores the simultaneous adjustment of breadth, interval, and height of the wavy protrusions. Increasing all three dimensions leads to a larger overall volume of the protrusion, enhancing flow quality within the channel. Conversely, decreasing these parameters allows more protrusion to fit within the same channel length, also benefiting flow quality. These findings highlight that the PEMEC with parametric wavy protrusion significantly outperforms a standard serpentine channel in terms of oxygen discharge rate and efficiency.

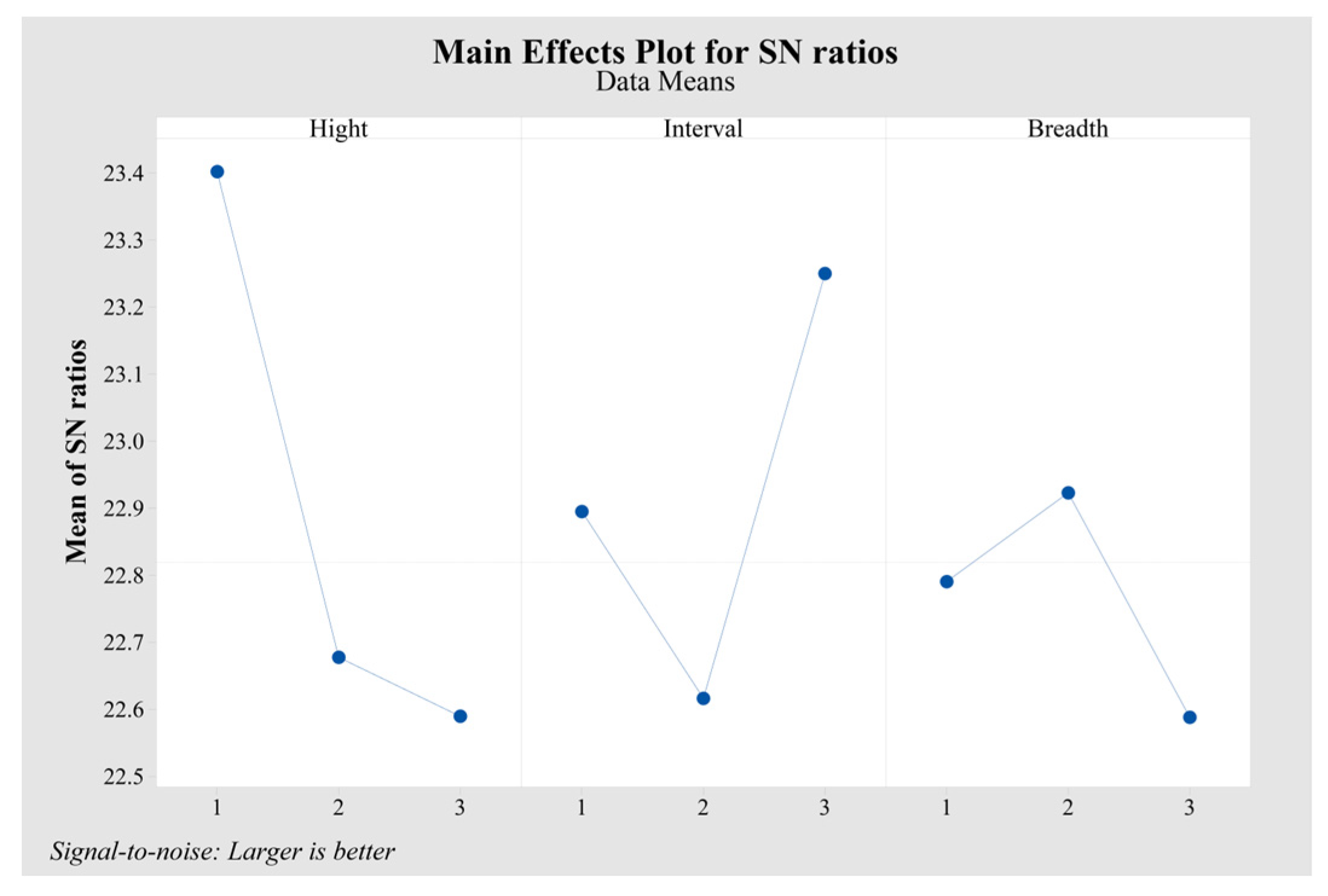

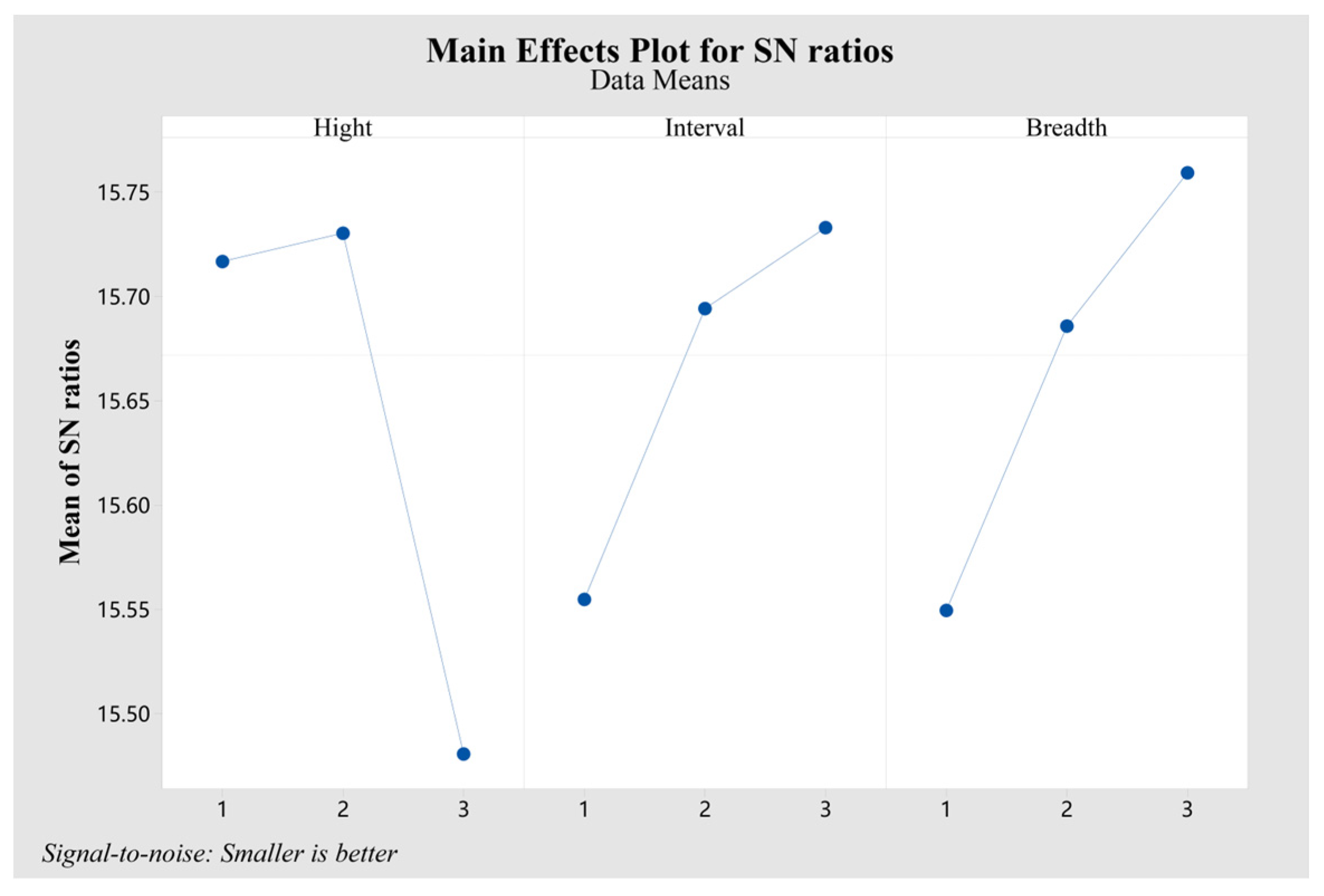

The results of the average signal-to-noise ratio are presented in

Figure 8. As depicted in

Figure 8, the highest signal-to-noise ratio (23.4) is achieved when the high protrusion height is 0.25 mm, the low protrusion height is 0.05 mm, the protrusion interval is 3.8 mm, and the protrusion breadth is 0.5π mm. This implies that under these protrusion conditions, the outlet oxygen volume of the uneven wave-like channel attains its maximum value. The conclusion drawn is that as the height of the protrusions increases, the outlet oxygen volume also increases. The interval between high and low protrusions needs to be maximized to achieve the highest outlet oxygen volume. Meanwhile, the breadth of the protrusions is optimal when moderate, resulting in the maximum outlet oxygen volume. This conclusion is consistent with that of the preceding paragraph.

The magnitude of the difference Δ(The absolute value of the difference between the maximum and minimum values) between the maximum and minimum signal-to-noise ratio values in the figure can determine the significance of the three independent variables. The independent variable with the highest Δ value represents a factor of greater significance. It can be concluded from

Table 5 that the height of the protrusion has the greatest effect on the volume of oxygen exported, followed by the interval, and the breadth has the least effect.

3.4. The Influence of Three Variables on Import and Export Pressure Drop

The two-phase flow regime within the channel has a significant impact on the pressure drop along the channel, which plays a crucial role in the performance of the PEMEC. A more uniform pressure distribution within the channel can result in a smaller pressure drop at the inlet and outlet, leading to reduced energy losses for oxygen and water flowing through the channel. Consequently, the overall flow becomes relatively smoother.

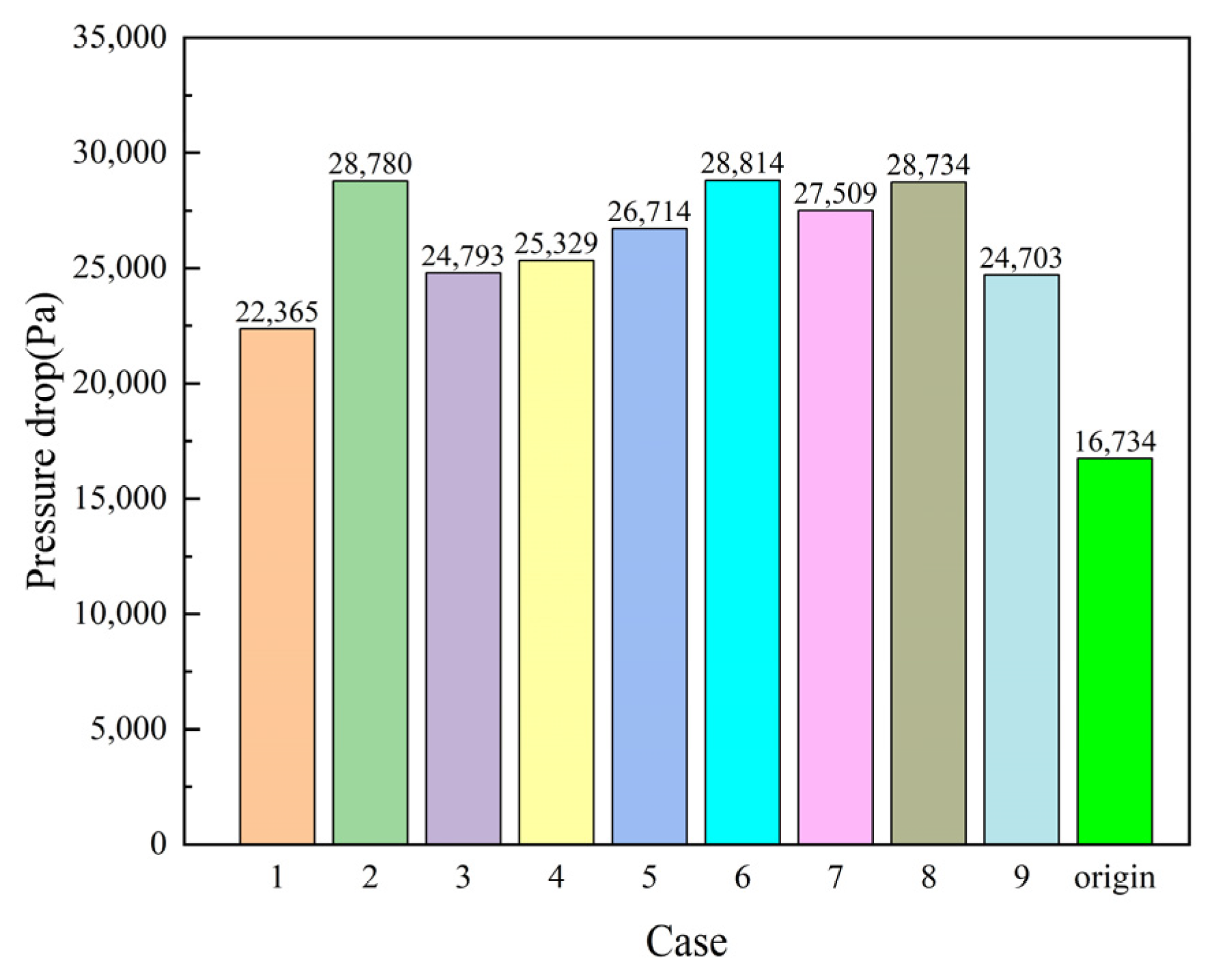

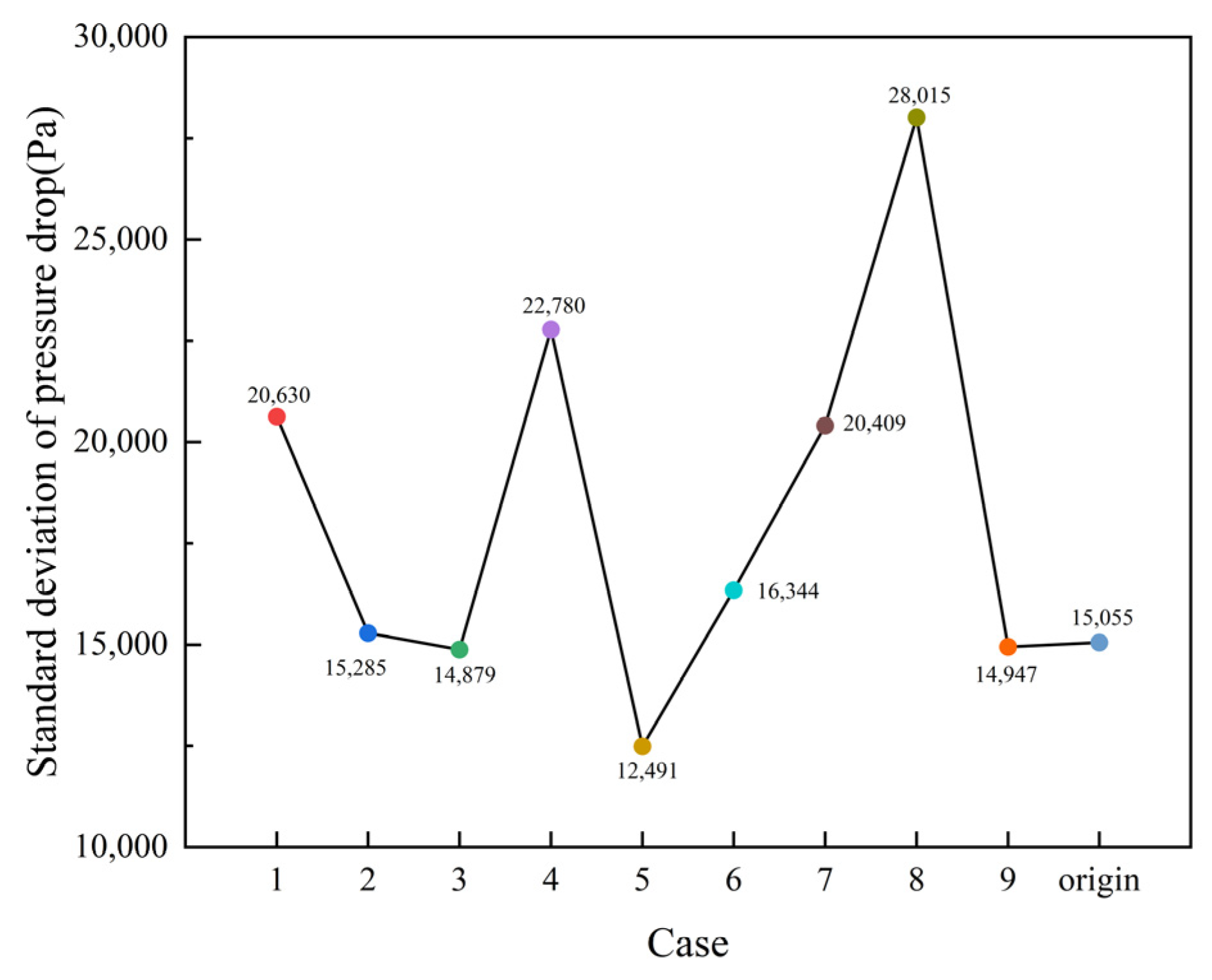

Figure 9 depicts the average inlet and outlet pressure drops of the uneven wavy protrusion channel model and the conventional serpentine channel model employed in this study, while

Figure 10 shows the standard deviation of the pressure drop, providing a comprehensive reflection of the overall stability.

As depicted in

Figure 9 and

Figure 10, compared with the traditional serpentine flow field channel, the flow field channel with uneven wavy protrusions causes more pressure loss. However, considering the higher efficiency of the flow field channel with uneven wavy protrusions than that of the traditional serpentine flow field channel, the difference in pressure drop between the two flow field channels is within a reasonable and acceptable range. When examining Cases 1−3 independently, it is observed that reducing the height of the protrusions can effectively decrease the standard deviation of the inlet and outlet pressure drops. This reduction ensures the uniformity of the reaction throughout the entire process. Analyzing Cases 1, 4, and 5 in

Figure 9 and

Figure 10, we can find that in Case 5, a significant reduction in the standard deviation of pressure drop is achieved despite only a modest increase in pressure, approximately 5% compared with Case 4. This improvement is attributed to better reaction stability in the experimental process. Additionally, we can also find that the protrusion breadth has a minor impact on the pressure drop from Cases 1, 6, and 7 in

Figure 9 and

Figure 10, and the magnitude of the average pressure drop is inversely proportional to the standard deviation of the pressure drop. Finally, an analysis of Case 1, 8, and 9 in

Figure 9 and

Figure 10 indicates that when all three variables increase simultaneously, the change in the average pressure drop is small. However, the standard deviation nearly doubles, suggesting that the simultaneous increase in these three variables intensifies pressure drop fluctuations at the inlet and outlet of the channel, leading to internal oscillations within the cell and consequently a decrease in the performance of the PEMEC.

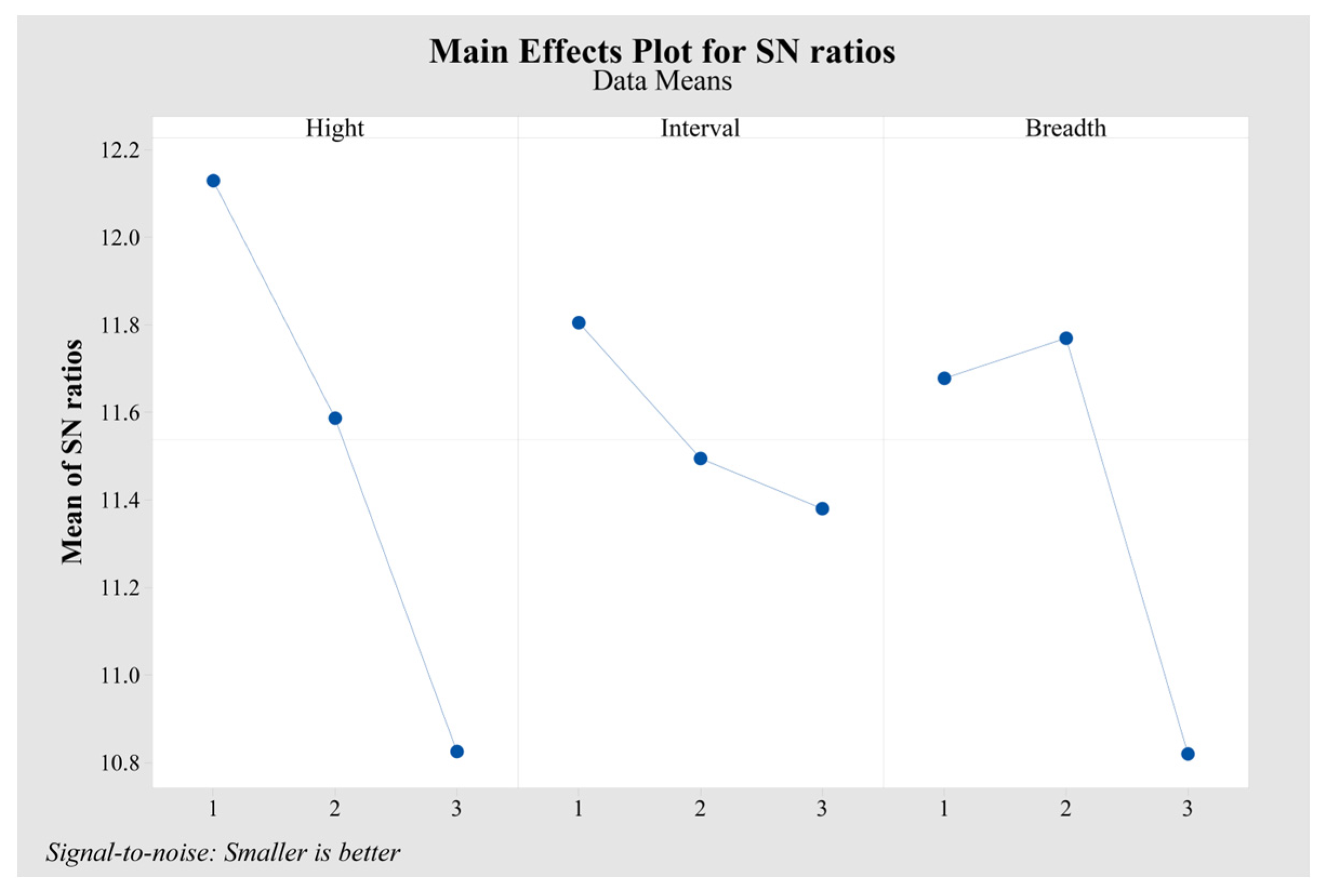

In order to better distinguish which one of the three variables has the greatest impact on the pressure drop, the average value of the pressure drop is optimized for the Taguchi design, with the criterion of “smaller is better”. As can be seen in

Figure 11, an increase in the signal-to-noise ratio means that the inlet–outlet pressure drop can be minimized, thus improving the operating conditions of the PEMEC. It is clear that the signal-to-noise ratio is lowest when the high protrusion height is 0.25 mm, the low protrusion height is 0.05 mm, the protrusion interval is 3 mm, and the protrusion breadth is 0.5π mm. In other words, the inlet–outlet pressure drop decreases as the protrusion height and interval increase. The minimum inlet–outlet pressure drop is obtained when the breadth is taken to the intermediate value of the three sets of data.

Table 6 shows that among the three variables, the height of the protrusion has the greatest effect on the pressure drop, followed by breadth.

3.5. Influence of Different Flow Channel Values on Volumetric Gas Content

The volumetric gas content exerts a pivotal influence on the electrolysis efficiency within the flow channels. Elevated levels of this content indicate a predominance of the gas phase, which can hinder the movement of the liquid electrolyte and induce an uneven current density due to the non-conductive nature of gases. This disparity leads to localized areas of over-voltage and escalated energy usage. High volumetric gas content, therefore, detrimentally affects both gas transfer and electrolysis efficiency.

In the context of this research, the variability in channel volume resulting from different heights, breadths, and intervals of channel protrusions constitutes less than 1% of the total channel volume, exerting a negligible effect on the volumetric gas content of the channel. Therefore, it has been excluded from detailed consideration.

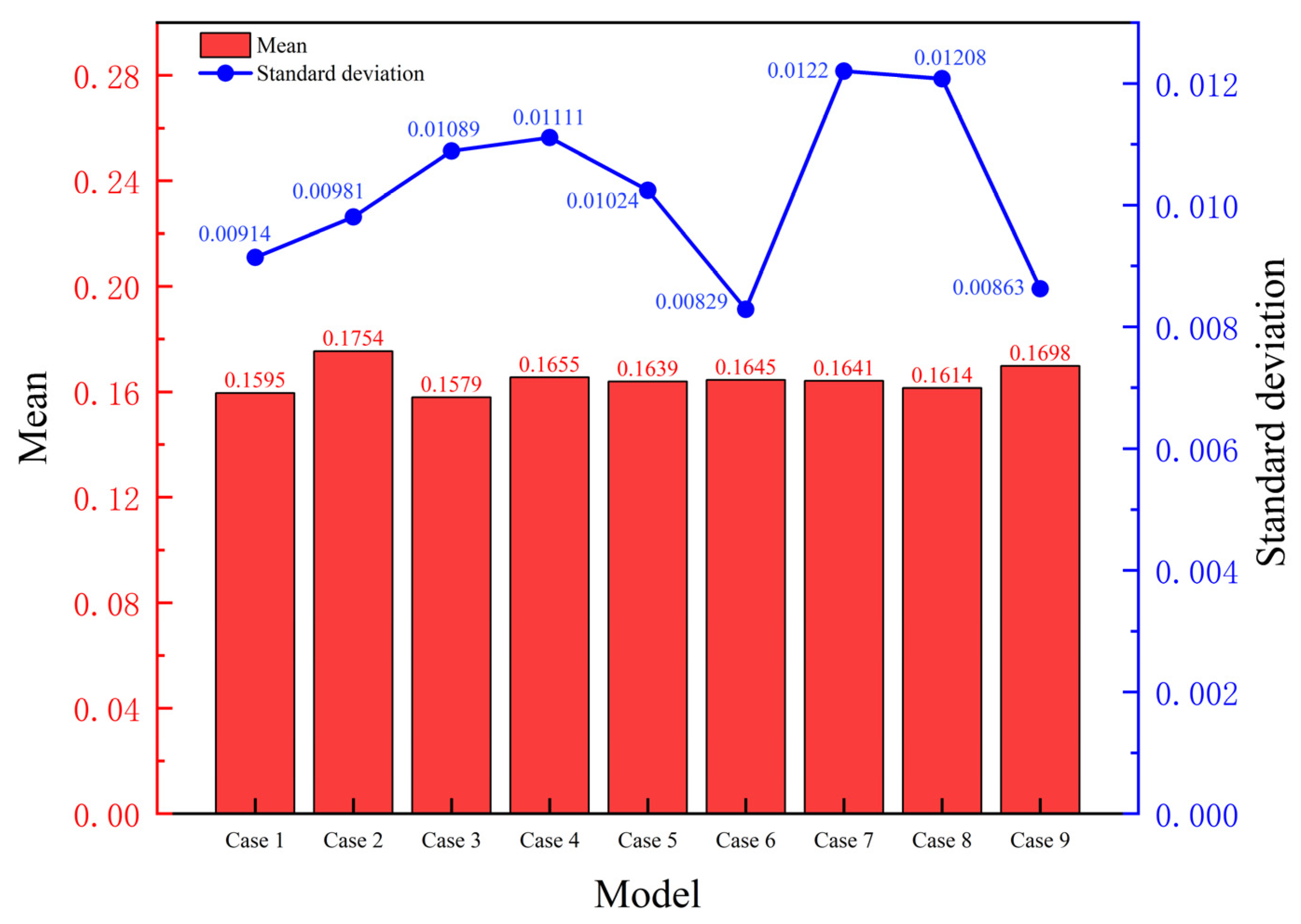

Figure 12 shows the volumetric gas content of nine different uneven wavy-like protrusion channels in this study. It is easy to find that the volumetric gas content of each channel starts to change significantly after 0.1 s. This phenomenon occurs due to the different parameters of the protrusion, resulting in different sizes of bubbles generated by the reaction in the channel. Meanwhile, it can be found that after 0.6 s, the fluctuation degree of each model curve becomes more intense compared with that of the first 0.4 s; this is because with the occurrence of the reaction in the channel, there is a portion of the tiny bubbles adsorbed on the inner wall of the channel, and at this time, the bubbles generated sometimes merge with these tiny bubbles, which makes the individual bubbles larger, resulting in greater fluctuations in the volumetric gas content.

Figure 13 shows the mean and standard deviation of nine uneven wavy-like protrusion channels. The standard deviation illustrates the intensity of gas expulsion and the dimensions of the resulting bubbles. Analyzing the nine sets of data in

Figure 13, it can be found that when the height of the protrusion (Cases 2 and 3) rises, the volumetric gas content of the flow channel rises. In addition, the interval (Cases 4 and 5) is similar to the height in a few ways, and a smaller interval can obtain lower volumetric gas content. The breadth (Cases 6 and 7) and the three variables (Cases 8 and 9) of the protrusion change at the same time for the standard deviation of the volumetric gas content rate and have a greater impact; when the breadth is larger, a smaller standard deviation can be obtained, and the volumetric gas content of bubbles discharged from the flow channel at this time is relatively small. The reason can be attributed to the large breadth of the protrusion, the compression degree of the gas, and the fact that the liquid inside the flow channel is low. The gas turbulence generated inside the flow channel is small because the gas bubbles produced become progressively smaller. The reason can be attributed to the fact that when the breadth of the protrusion is large, the compression of the gas and liquid in the flow channel is low, and the gas turbulence generated in the flow channel is small because the gas bubbles generated are smaller and more uniform.

A Taguchi analysis was deployed to further scrutinize the influence of the three variables on volumetric gas content, optimizing based on the STB approaches.

Figure 14 reveals that optimal SN ratios for volumetric air content are achieved with a protrusion height of 0.3/0.1 mm, an interval of 3.8 mm, and a breadth of 0.6π mm, indicating that these parameters facilitate a reduction in average volumetric air content. Additionally, the maximum delta values presented in

Table 7 affirm that protrusion height has the most substantial impact on volumetric gas content, primarily due to its influence on the volume and morphology of the bubbles within the flow channel.

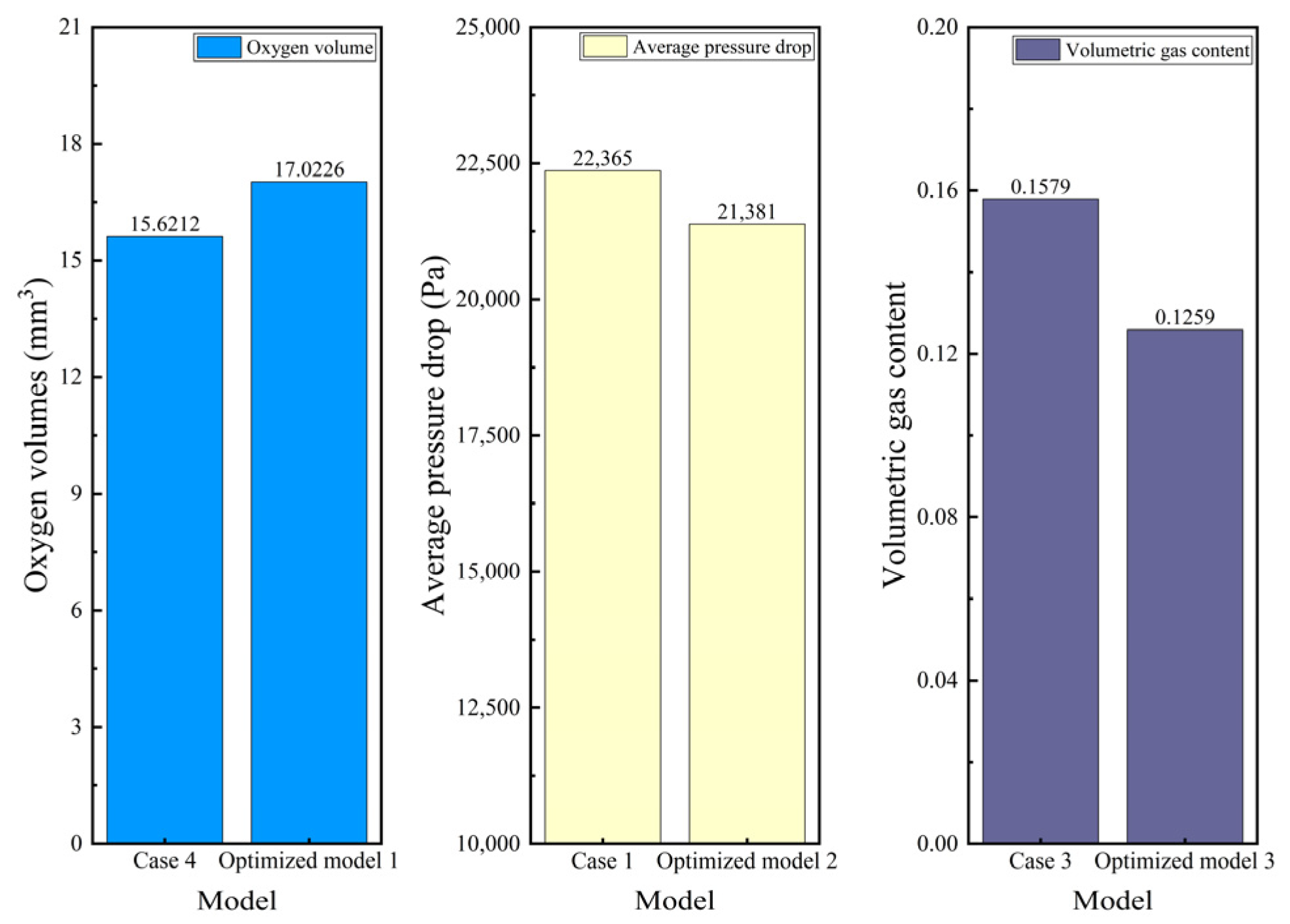

3.6. Validation of Optimization Results

To validate the optimization outcomes of Taguchi’s design, the model data derived from the optimization process were subjected to modeling and simulation under identical fluid and boundary conditions. The results were then compared with the best-performing data set from the original nine data sets, as illustrated in

Figure 15. The three evaluation indices of the runner showed varying degrees of improvement: the outlet oxygen volumes increased by 8.97%, the average pressure drop was reduced by 4.4%, and the volumetric gas content decreased by 20.26%.

5. Conclusions

In order to further optimize the existing PEMEC channel structure, a wave-like uneven protrusion channel was designed. The performance of the PEMEC utilizing the uneven wave-like protrusion channel was investigated through three-dimensional numerical simulations, considering variations in protrusion height, interval, and breadth. A comparative analysis was also conducted to investigate the performance of the PEMEC using a traditional single serpentine channel. Subsequently, the Design of Experiments (DOE) Taguchi optimization algorithm was employed to optimize the waveforms of the protrusions. Finally, experiments were conducted on the novel flow channel. The results of this study are presented below:

1. In comparison with a traditional serpentine channel, the uneven wave-like channel alters the velocity of reactants within the channel due to the physical obstruction of protrusions, leading to improved gas coverage on GDL surfaces and an increase in the volume of outlet oxygen and an enhancement in the performance of the PEMEC.

2. Optimizing the design according to Taguchi methods can lead to improved performance in oxygen outlet volume and pressure drop. Increasing protrusion height, widening protrusion breadth, and adjusting the protrusion interval can enhance oxygen outlet volume. For the highest outlet oxygen volume and reaction efficiency, the optimal conditions are a high protrusion height of 0.35 mm, a low protrusion height of 0.15 mm, a protrusion interval of 3.8 mm, and a protrusion breadth of 0.6π mm, which can boost exported oxygen volume by 8.97%. Similarly, reducing inlet and outlet pressure drop can be achieved by increasing protrusion height, expanding protrusion interval, and widening protrusion breadth. The optimal conditions for the minimum pressure drop after Taguchi’s analysis are as follows: the high protrusion height is 0.35 mm, the low protrusion height is 0.15 mm, the protrusion interval is 3.8 mm, and the protrusion width is 0.6π mm. This makes the reaction process more stable and reduces the inlet and outlet pressure drop by 4.4%.

3. Reduction of the volumetric gas content within the flow channels is achievable through the diminution of protrusion height, the constriction of the protrusion interval, and the expansion of protrusion breadth. Simulation data indicate that an optimal configuration, characterized by a high protrusion height of 0.25 mm, a low protrusion height of 0.05 mm, an interval of 3 mm, and a breadth of 0.6π mm, yields volumetric gas content decreased by 20.26%. This configuration facilitates smaller bubble formation, which in turn enhances the ease of discharge and accelerates the reaction rate within the flow channel.

4. The influence of protrusion height on the volume of outlet oxygen, inlet/outlet pressure drop, and volumetric gas content is more pronounced compared to breadth and interval.

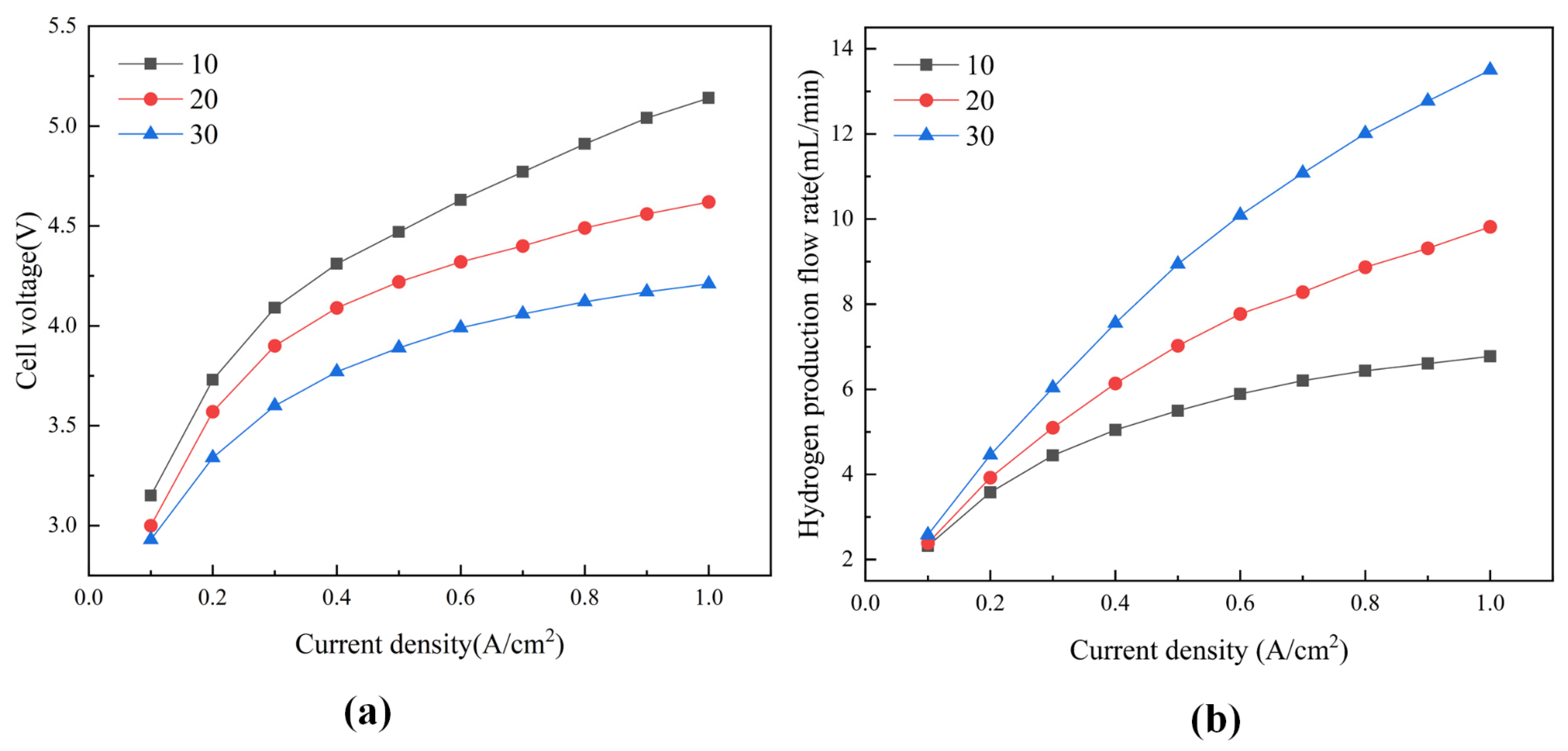

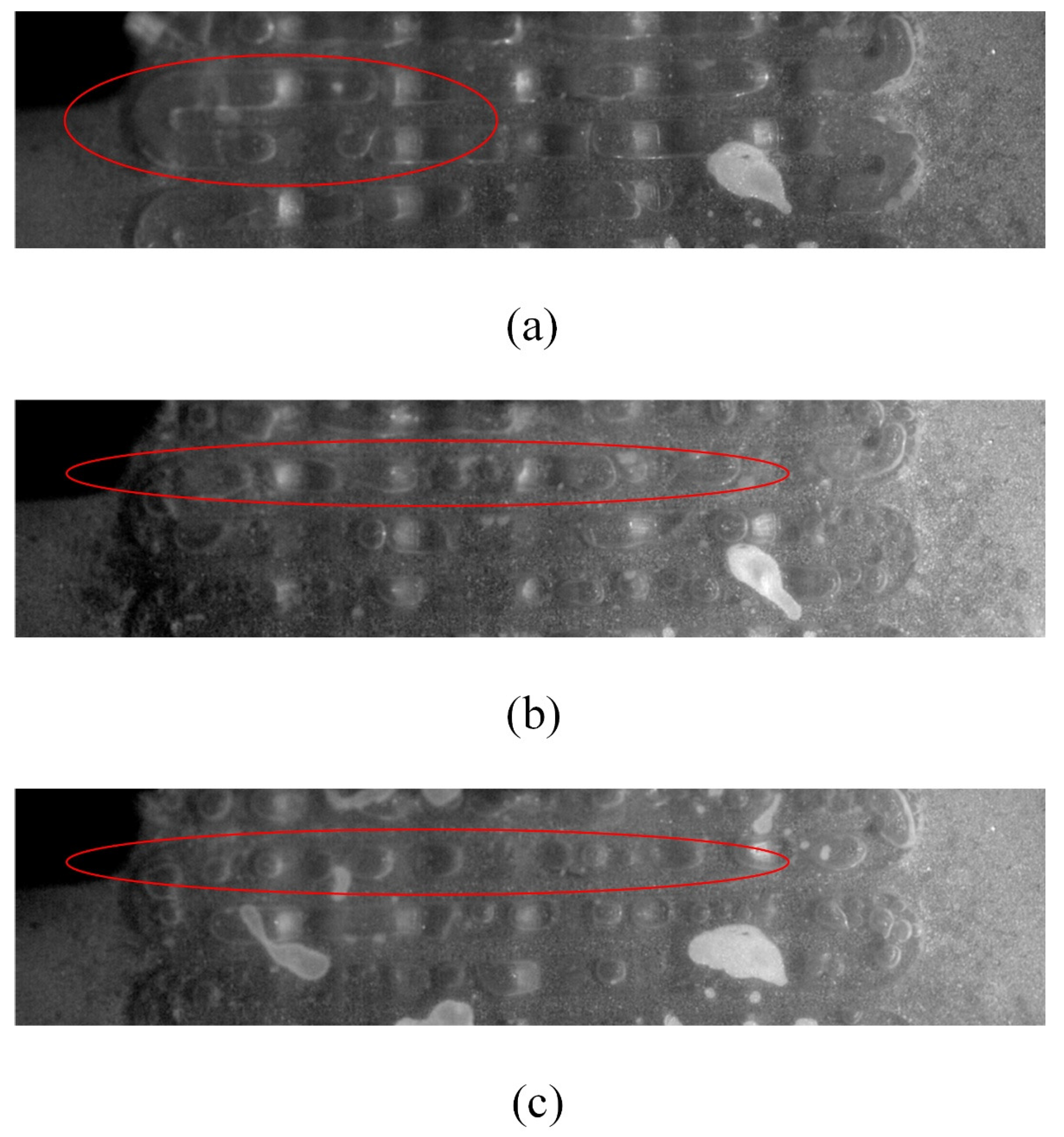

5. Increasing the water supply flow rate from 10 mL/min to 30 mL/min increases the electrolytic cell voltage by 0.93 V and the hydrogen production flow rate by 98.23%. Optimizing the water supply flow rate helps to reduce the concentration polarization improve bubble removal and enhance heat transfer.

6. As the temperature of the water supply increases, the removal of bubbles becomes easier, the size of bubbles in the flow channel decreases significantly, and the hydrogen production efficiency increases.

7. The optimization results obtained in this study are not globally optimal. To refine these results, advanced optimization algorithms, such as genetic algorithms, will be employed to enhance the robustness and accuracy of the flow channel model data. Long-term durability will also be verified through accelerated testing and material coatings, and specific experimental comparisons with manufacturing energy costs, and actual performance gains.