Integrated Analysis of Pore and Fracture Networks in Deep Coal Seams: Implications for Enhanced Reservoir Stimulation

Abstract

1. Introduction

2. Geological Overview

3. Experimental Materials and Methods

3.1. Sample Selection and Preparation

3.2. Experimental Principles and Methods

3.2.1. NMR Technology

3.2.2. High-Pressure Mercury Intrusion Method

3.2.3. Low-Temperature N2 Adsorption Method

3.2.4. Low-Pressure CO2 Adsorption Method

3.2.5. Micro-Computed Tomography (Micro-CT)

3.2.6. Scanning Electron Microscope (SEM)

3.2.7. Methane Isothermal Adsorption

4. Results

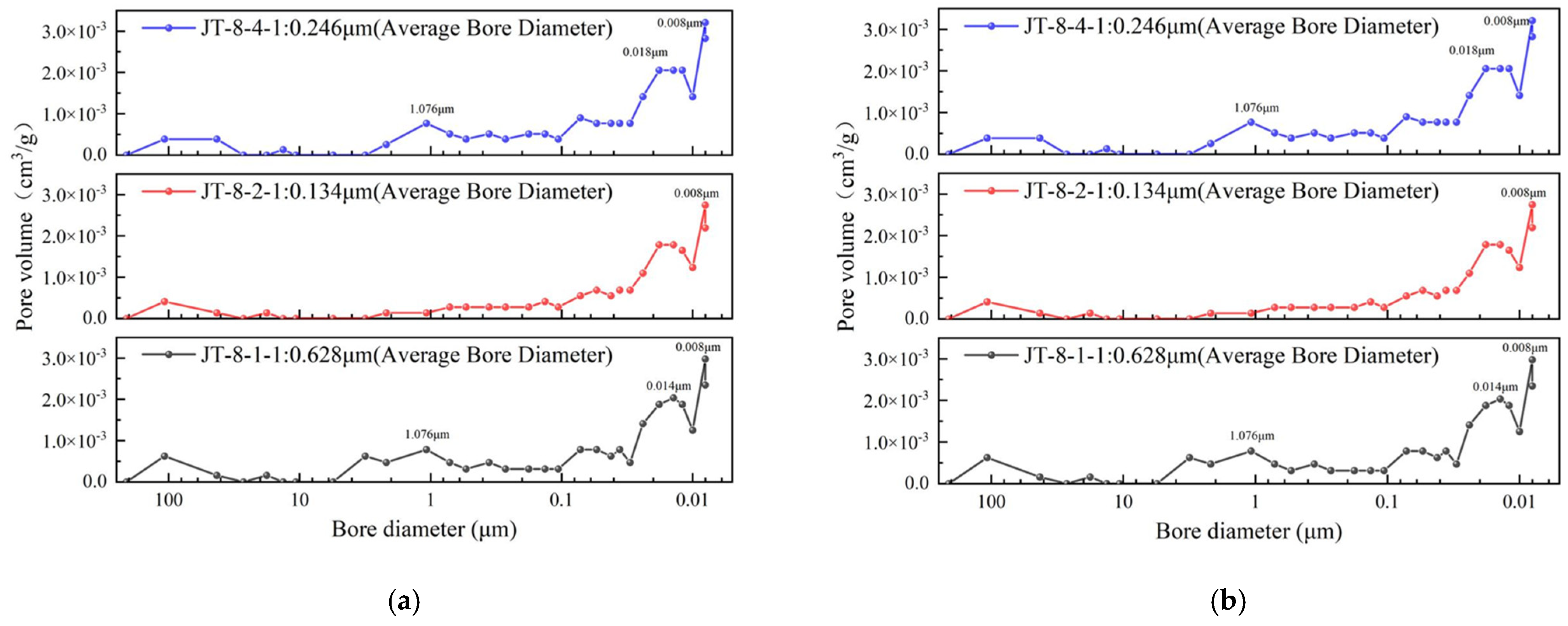

4.1. Pore Distribution Characteristics from NMR

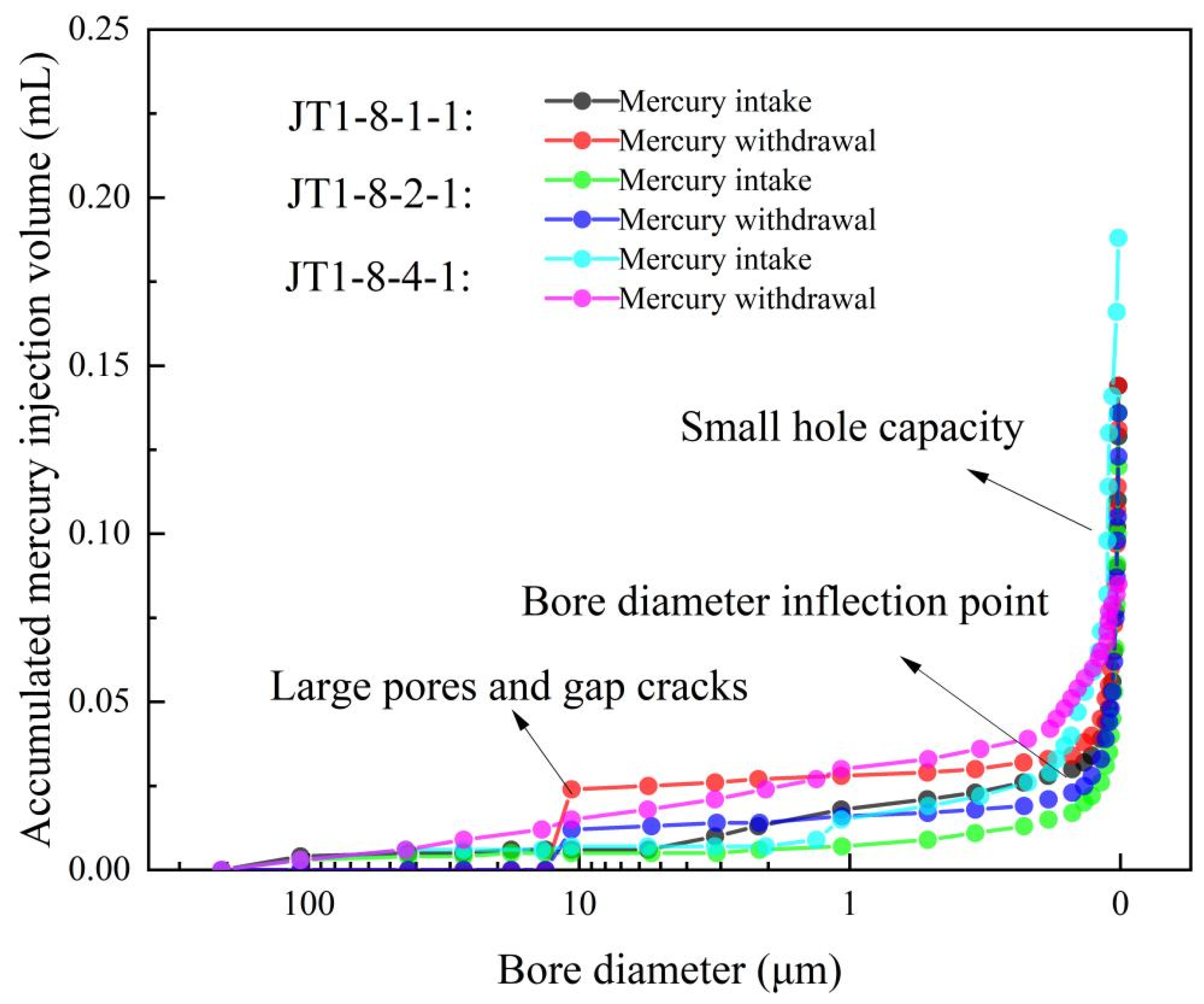

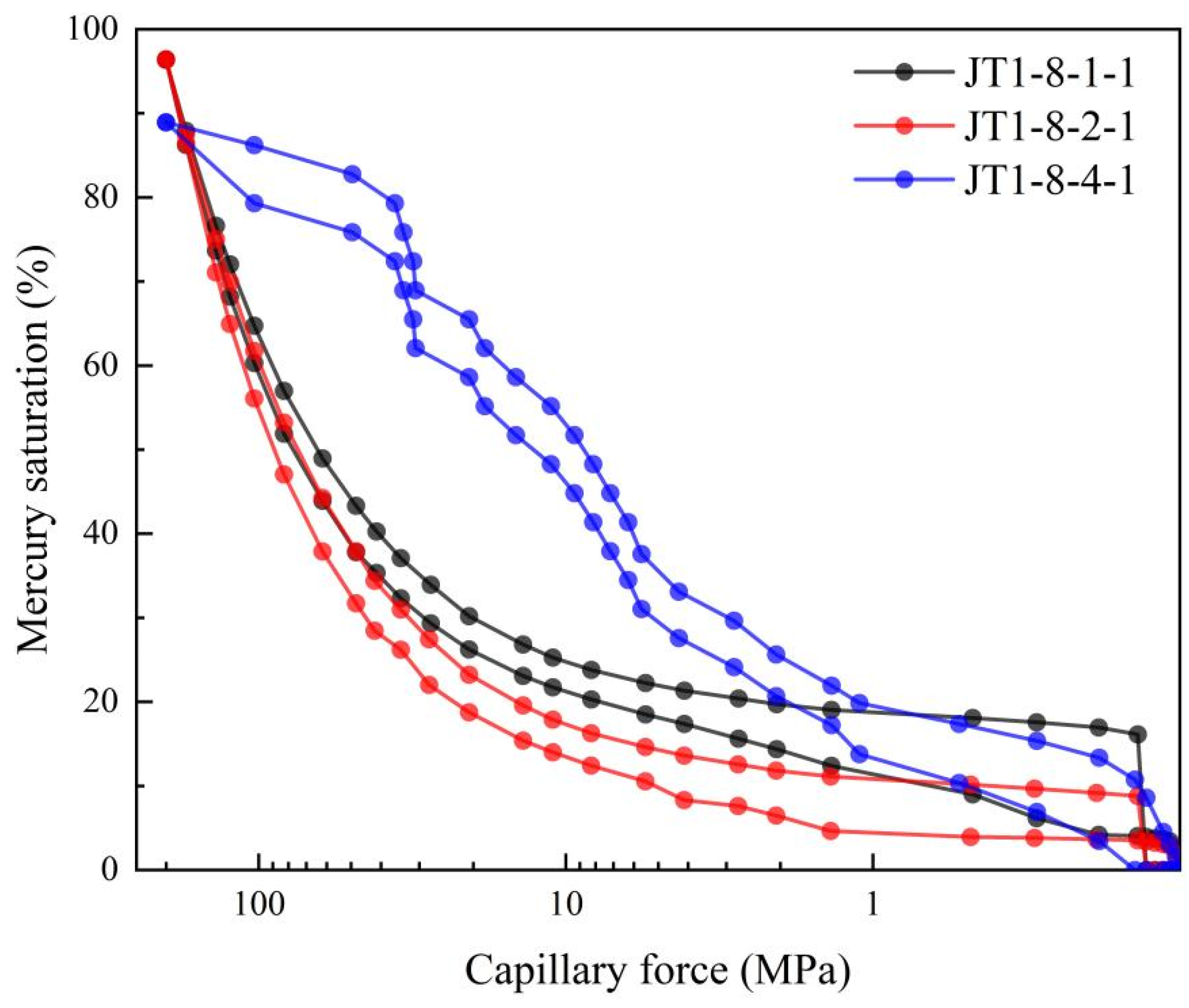

4.2. Pore Distribution Characteristics from High-Pressure Mercury Intrusion Experiments

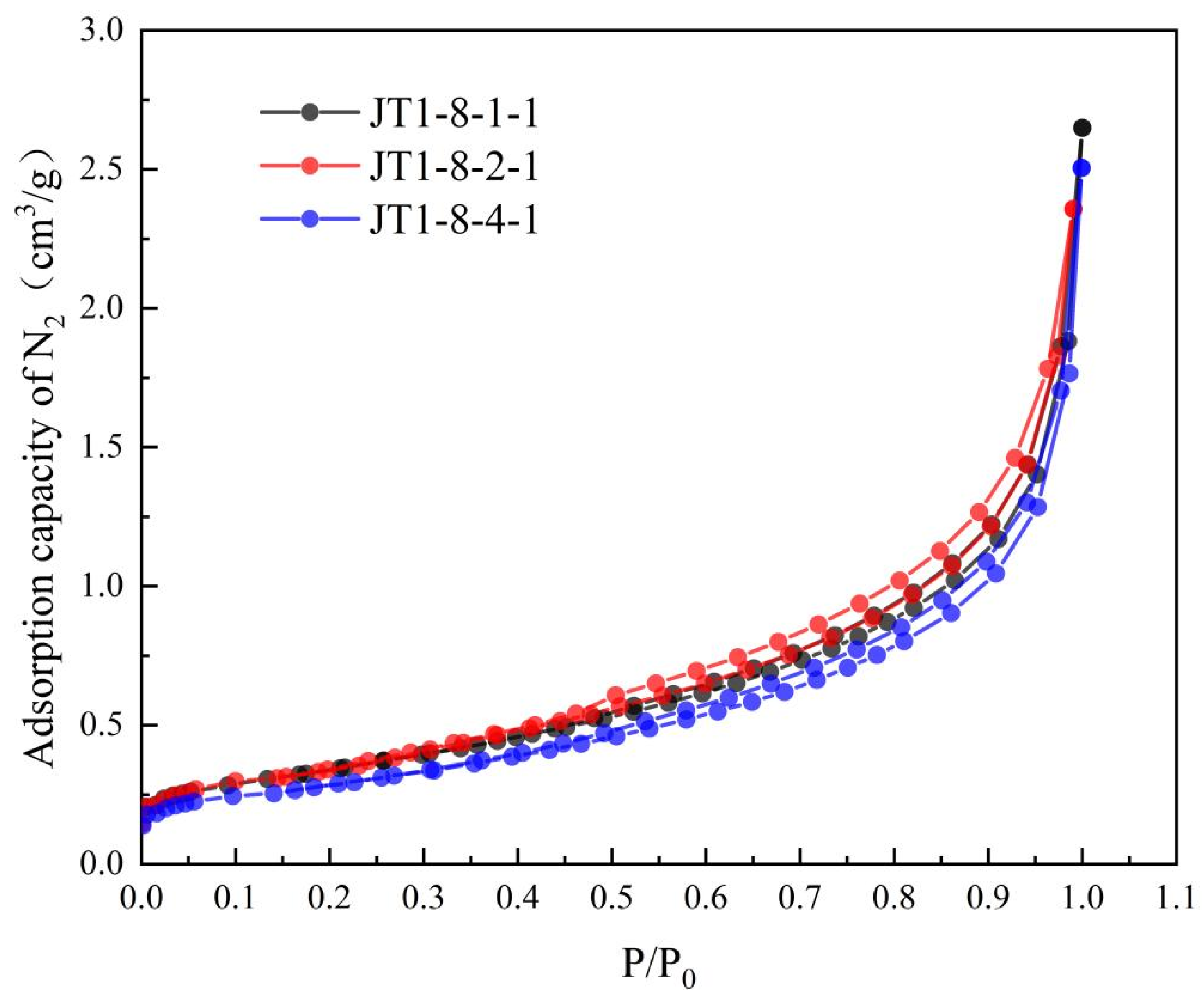

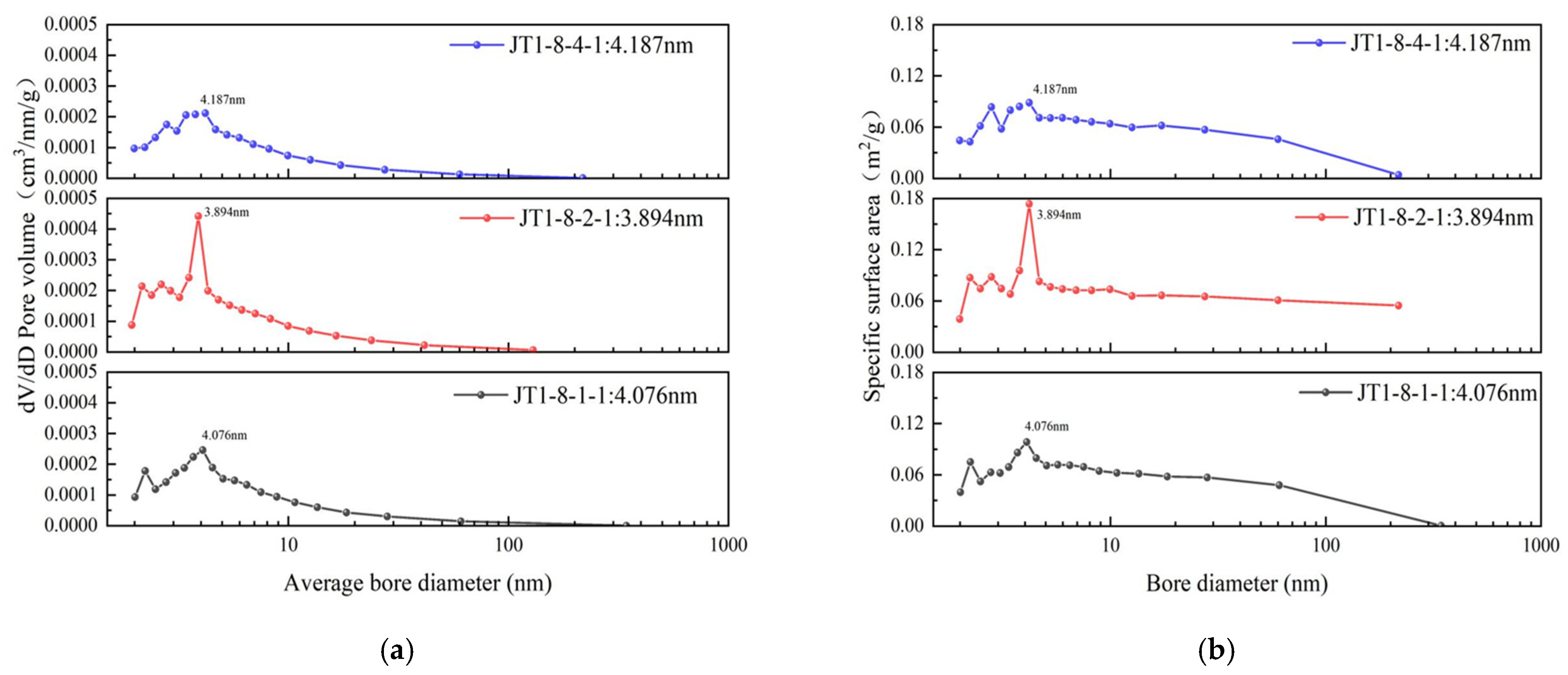

4.3. Pore Distribution Characteristics from Low-Temperature N2 Adsorption Experiments

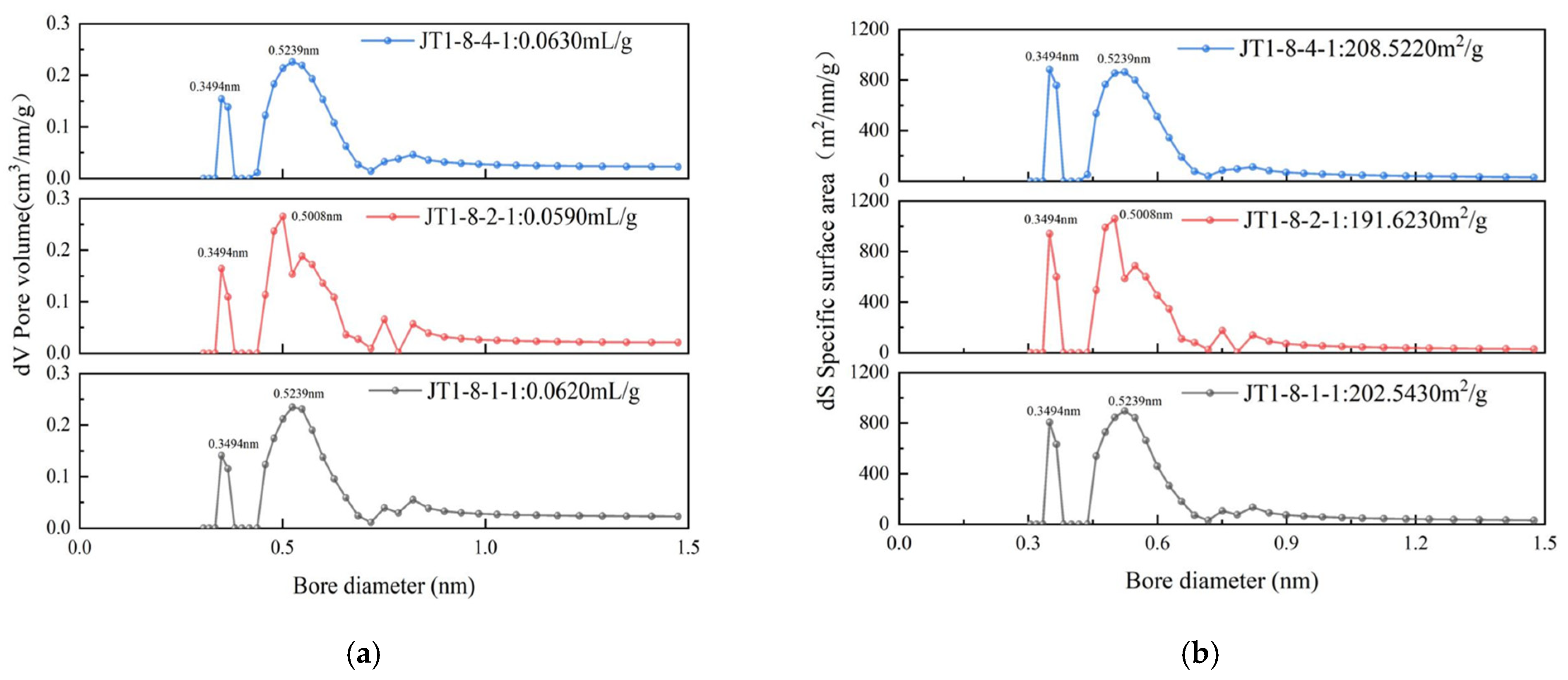

4.4. Pore Distribution Characteristics from Low-Pressure CO2 Adsorption Experiments

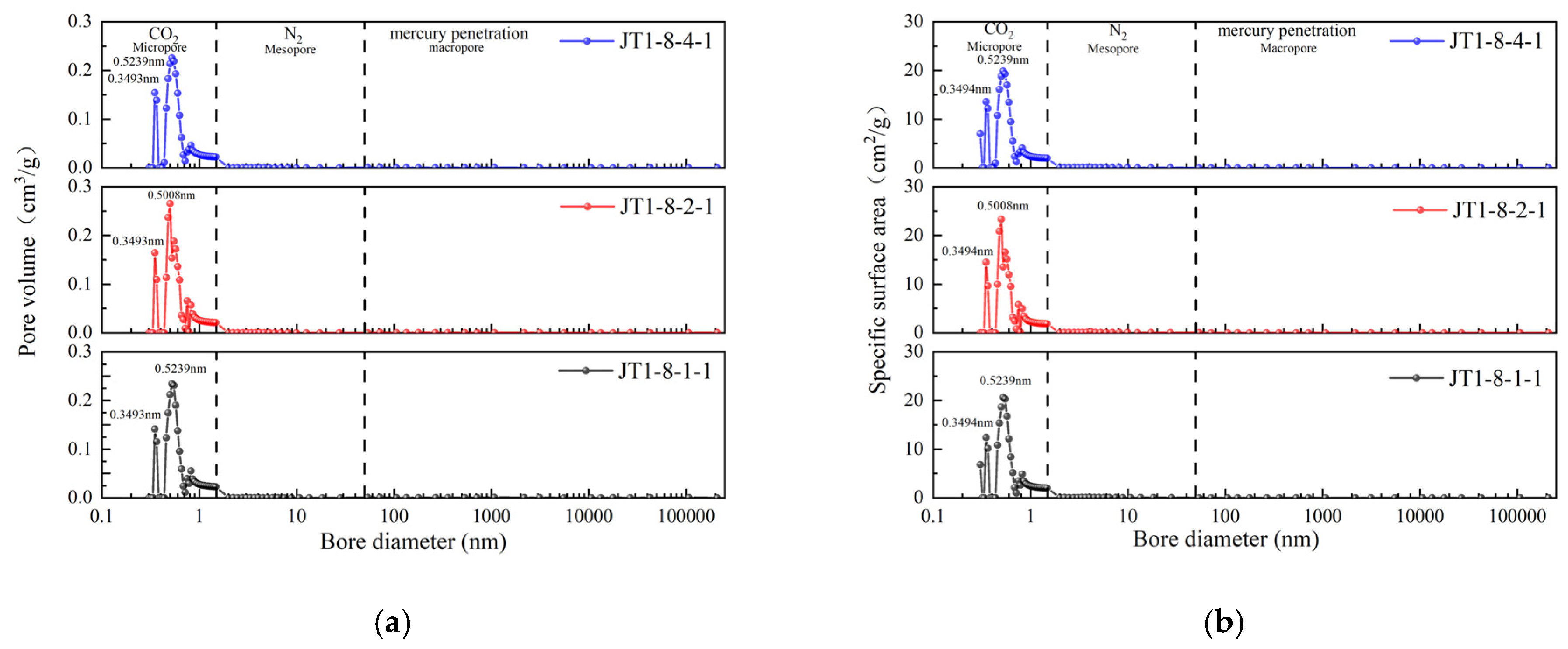

4.5. Pore Distribution Characteristics of Coal Rock Characterized by Multiple Complementary Techniques

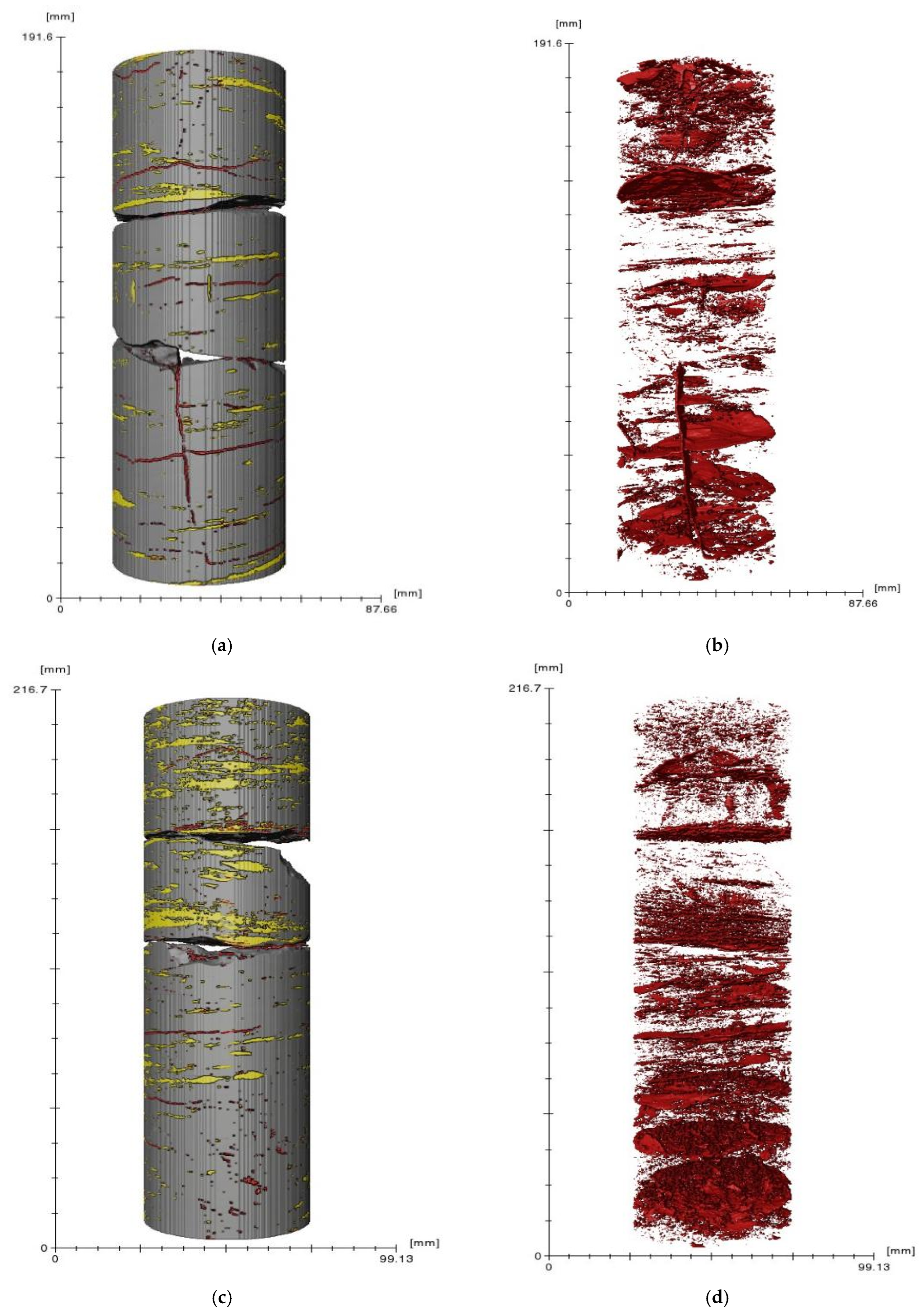

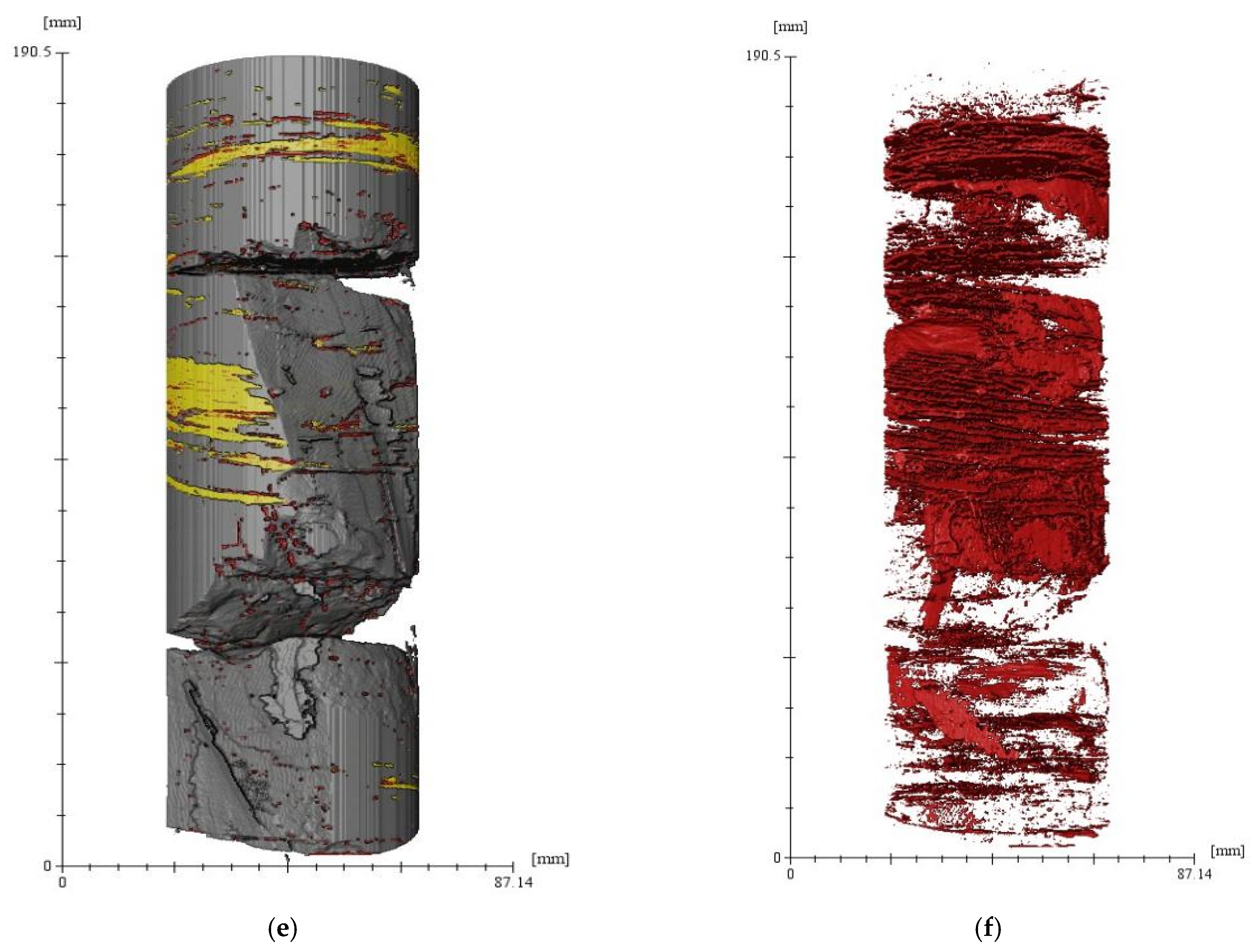

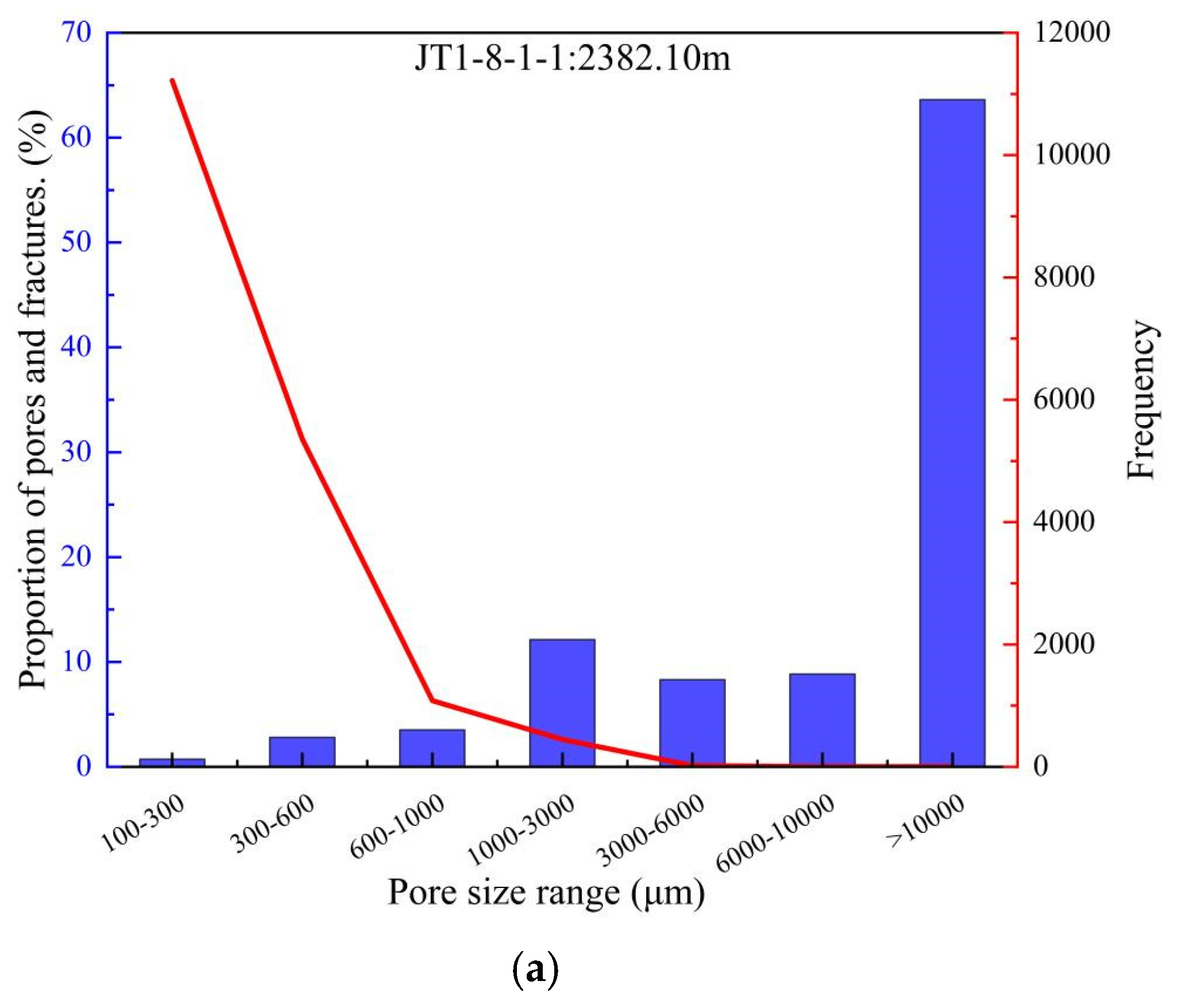

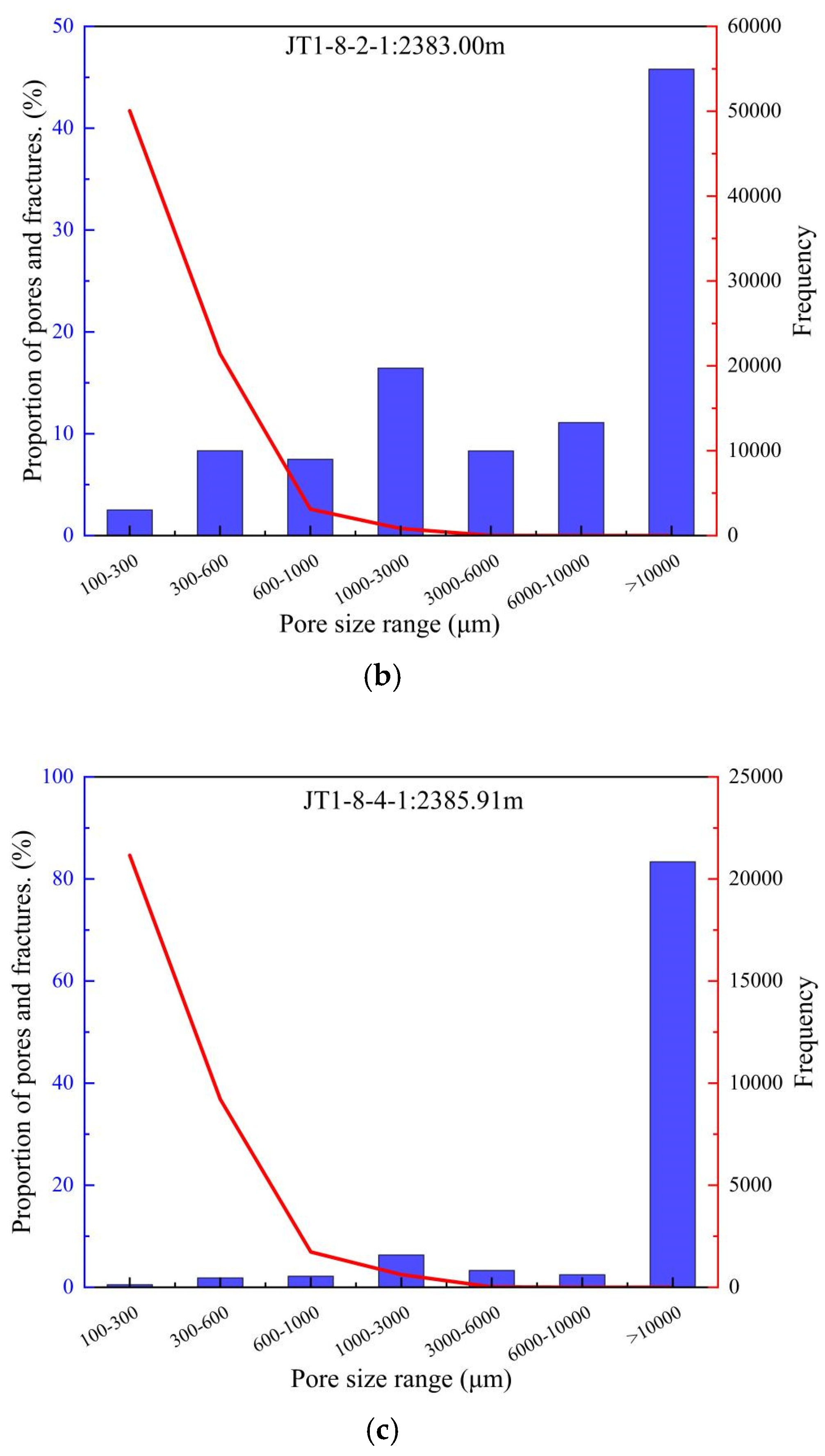

4.6. Pore Distribution Characteristics Based on Micro-CT Experiments

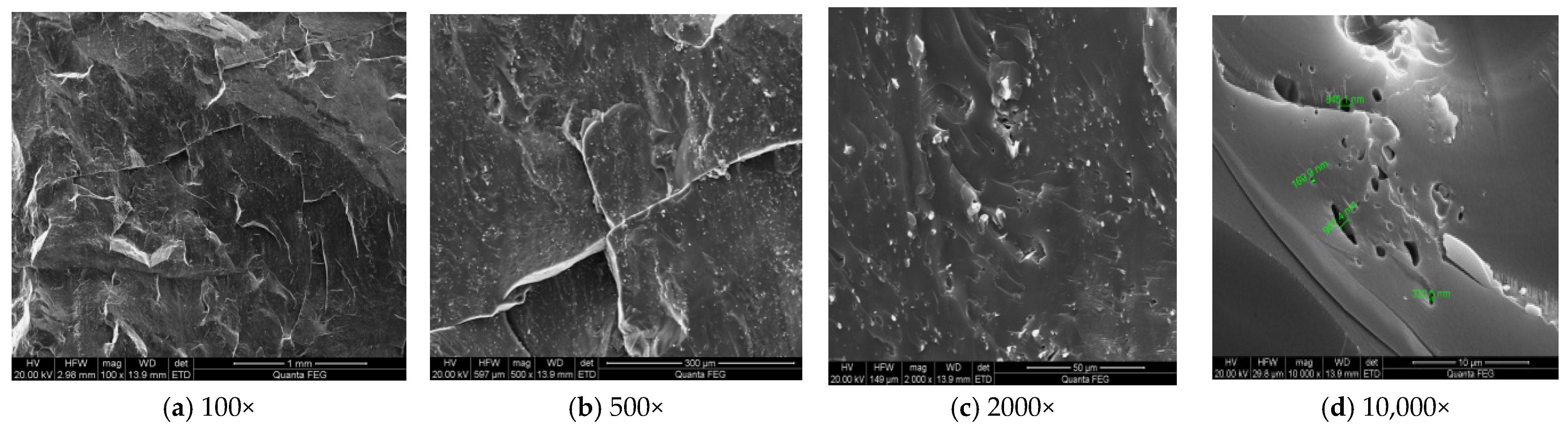

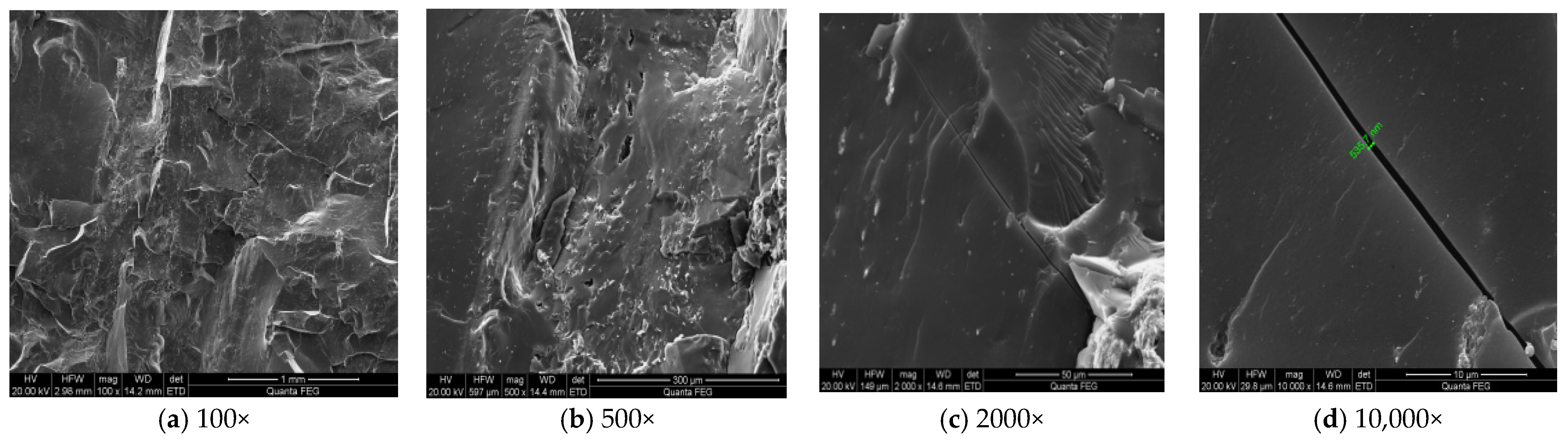

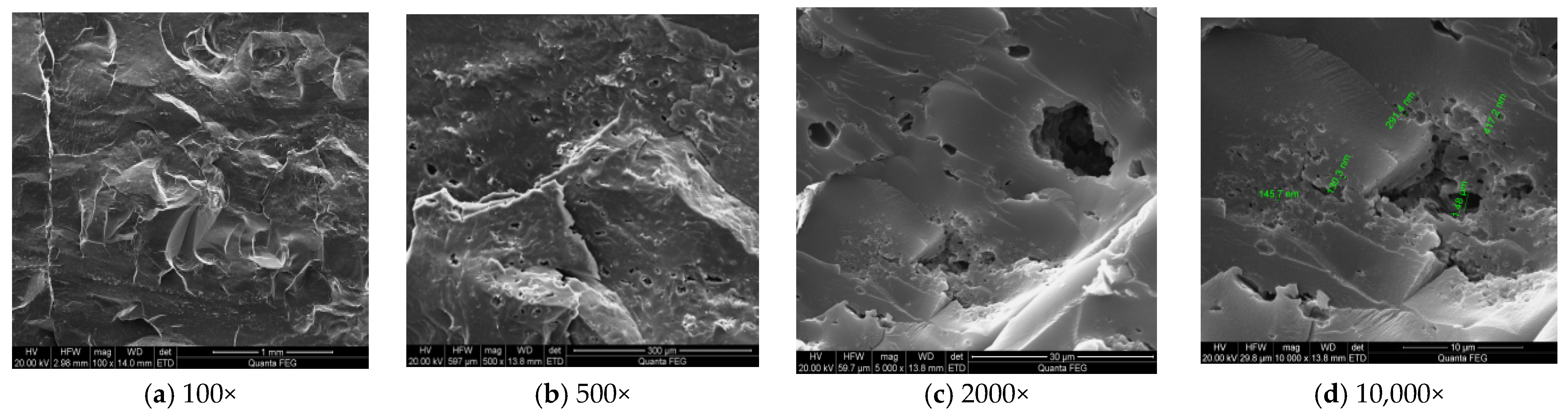

4.7. Pore Distribution Characteristics Based on SEM Experiments

4.8. Characteristics of Methane Isothermal Adsorption

5. Discussion

5.1. Detailed Elucidation of the Fine Characteristics of the MultiScale Pore–Fracture System and Its Significance for Coalbed Methane Occurrence

5.2. Precise Revelation of the Micro-Nanoscale Pore Structure and Spatial Distribution Characteristics of Coal Reservoirs

5.3. Scientific Elucidation of the Different Mechanisms of Micropores and Micropores Fractures in Reservoir Modification

5.4. Provision of Targeted R&D Basis for Novel Deep Reservoir Enhancement Technologies

6. Conclusions

- (1)

- The coal samples exhibit a dual pore–fracture system dominated by micropores. Micropores smaller than 2 nm account for 98.11% of the total pore volume, while microfractures contribute only 0.74% on average. Despite their low volume fraction, microfractures are well connected in three-dimensional space and play a critical role in linking isolated micropores, forming a complex pore–fracture network essential for gas storage and migration in deep coal seams.

- (2)

- Micro-CT imaging reveals that microfractures ranging from 100 to 300 μm comprise 40–80% of the total fracture volume in the samples, effectively enhancing the reservoir’s permeability. In contrast, N2 and CO2 adsorption as well as MIP results indicate widespread development of nanopores, yet with poor connectivity, contributing minimally to permeability. Therefore, gas occurrence is primarily controlled by micropores, while gas transport is dominated by the connectivity of microfractures.

- (3)

- Functional differentiation across pore-size scales is clearly observed. Micropores (<1.5 nm) contribute 99.6% of the total specific surface area and pore volume, serving as the principal adsorption space. Mesopores (1.5–50 nm) act as secondary storage sites, while macropores and microfractures (>50 nm) primarily affect gas transport and seepage connectivity. This understanding provides theoretical guidance for reservoir partitioning into desorption and flow zones in staged fracturing designs.

- (4)

- Methane isothermal adsorption experiments show that the Langmuir volumes of the three coal samples are 23.821, 22.278, and 21.087 m3/t, respectively, with a strong positive correlation to micropore volume and specific surface area. With increasing burial depth, coal compactness intensifies and adsorption capacity decreases, indicating significant interlayer heterogeneity. These results suggest that stratified and segmented stimulation strategies should be adopted to accommodate differences in micropore development.

- (5)

- The integrated use of NMR, MIP, CO2/N2 adsorption, SEM, and micro-CT demonstrates the complementary strengths of each method in characterizing pores across scales, enabling a comprehensive assessment of fracture–pore architecture from nanometers to microns. This approach provides key parameters for reservoir evaluation, fracture network modeling, and fracturing fluid optimization, offering a technical foundation for the precise modification of deep coal reservoirs and the efficient development of CBM.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, Y.J.; Yang, Z.Z.; Li, X.G.; Han, J.X.; Ji, G.F. Problems and Methods for Optimization of Hydraulic Fracturing of Deep Coal Beds in China. Chem. Technol. Fuels Oils 2015, 51, 41–48. [Google Scholar] [CrossRef]

- Xu, F.Y.; Hou, W.; Xiong, X.Y.; Xu, B.R.; Wu, P.; Wang, H.Y.; Feng, K.; Yu, J.; Li, S.G.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 669–682. [Google Scholar] [CrossRef]

- Li, S.; Tang, D.Z.; Xu, H.; Tao, S. Progress in geological researches on the deep coalbed methane reservoirs. Earth Sci. Front. 2016, 23, 10–16. [Google Scholar]

- Chen, Z.L. Geological unit division and development countermeasures of deep coalbed methane in Southern Yanchuan Block. Coal Geol. Explor. 2021, 49, 13–20. [Google Scholar]

- Yang, J.S.; Feng, P.; Tang, S.L.; Tang, D.Z.; Wang, M.Z.; Li, S.; Zhao, Y.; Li, Z.W. Phase control factors and content prediction model of deep coalbed methane in Daning-Jixian block. Acta Pet. Sin. 2023, 44, 1879–1891. [Google Scholar]

- Li, S.; Qin, Y.; Tang, D.Z.; Shen, J.; Wang, J.J.; Chen, S.D. A comprehensive review of deep coalbed methane and recent developments in China. Int. J. Coal Geol. 2023, 279, 104369. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Wei, J.G.; Zhou, X.F.; Shamil, S.; Yuriy, K.; Yang, E.L.; Yang, Y.; Wang, A.L. High-pressure mercury intrusion analysis of pore structure in typical lithofacies shale. Energy 2024, 295, 130879. [Google Scholar] [CrossRef]

- Lu, F.C.; Liu, Z.Y.; Zhang, X.B.; Jia, B.; Wang, Y.F.; Liu, S.; Tang, Y.J.; Liu, J.J.; Liu, P. Study on full-scale pores characterization and heterogeneity of coal based on low-temperature nitrogen adsorption and low-field nuclear magnetic resonance experimentse. Sci. Rep. 2024, 14, 16910. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.G.; Zhang, L.; Hou, J.L. Characterization on pore structure of tectonic coals based on the method of mercury intrusion, carbon dioxide adsorption. J. China Coal Soc. 2019, 44, 1188–1196. [Google Scholar]

- Mou, P.W.; Pan, J.N.; Niu, Q.H.; Wang, Z.Z.; Li, Y.B.; Song, D.Y. Coal Pores: Methods, Types, and Characteristics. Energy Fuel 2021, 35, 7467–7484. [Google Scholar] [CrossRef]

- Li, X.S.; Ju, Y.W.; Hou, Q.L.; Li, Z.; Wei, M.M.; Fan, J.J. Characterization of Coal Porosity for Naturally Tectonically Stressed Coals in Huaibei Coal Field, China. Sci. World J. 2014, 2014, 560450. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.Y.; Jin, Y.; Liu, X.H.; Zheng, J.L.; Liu, S.X. Characterizing the Complexity Assembly of Pore Structure in a Coal Matrix: Principle, Methodology, and Modeling Application. JGR Solid Earth 2020, 125, e2020JB020110. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.M.M.; Chalmers, G.R.L.; He, L.; Melnichenko, Y.B.; Padinski, A.P.; Blach, T.P. Pore Structure Characterization of North American Shale Gas Reservoirs Using USANS/SANS, Gas adsorption, and Mercury Intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Wang, G.; Shen, J.N.; Chu, X.Y.; Cao, C.J.; Jiang, C.H.; Zhou, X.H. Characterization and analysis of pores and fissures of high-rank coal based on CT three-dimensional reconstruction. J. China Coal Soc. 2017, 42, 2074–2080. [Google Scholar]

- Pan, J.N.; Zhu, H.T.; Hou, Q.L.; Wang, H.C.; Wang, S. Macromolecular and pore structures of Chinese tectonically deformed coal studied by atomic force microscopy. Fuel 2015, 139, 94–101. [Google Scholar] [CrossRef]

- Zhou, S.D.; Liu, D.M.; Cai, Y.D.; Yao, Y.B.; Li, Z.T. 3D characterization and quantitative evaluation of pore-fracture networks of two Chinese coals using FIB-sem tomography. Int. J. Coal Geol. 2017, 174, 41–54. [Google Scholar] [CrossRef]

- Chen, C.C.; Dong, X.H.; Chen, Y.P.; Dong, Z.; Zhao, B.; Jiang, L.L.; Chen, Z.X. Characterization of the Porosity and Permeability of Gasified Coal in UCG Process: An Experimental and Simulation Study. ACS Omega 2025, 10, 1308–1319. [Google Scholar] [CrossRef]

- Ramandi, H.L.; Mostaghimi, P.; Armstrong, R.T.; Saadatfar, M.; Pinczewski, W.V. Porosity and permeability characterization of coal: A micro-computed tomography study. Int. J. Coal Geol. 2016, 154–155, 57–68. [Google Scholar] [CrossRef]

- Zhang, X.M.; Wang, S.Q.; Chen, H.; Deng, J.; Huo, L. Micro morphology and pore structure of macerals in coal observed by atomic force microscopy (AFM). Coal Sci. Technol. 2023, 51, 127–132. [Google Scholar]

- Li, G.Y.; Yao, Y.B.; Wang, H.; Meng, L.J.; Li, P.J.; Zhang, Y.C.; Wang, J.W.; Ma, L.M. Deep coalbed methane resources in the Shenmu-Jiaxian block, Ordos Basin, China:Geological characteristics and potential for exploration and exploitation. Coal Geol. Explor. 2024, 52, 70–80. [Google Scholar]

- GT/T6948-2008; Method of Determining Microscopically the Reflectance of Vitrinite in Coal. Standards Press of China: Beijing, China, 2008.

- SY/T6414-2014; Maceral Identidication and Statistical Methods on Polished Surfaces of Whole Rocks. Standards Press of China: Beijing, China, 2014.

- GB/T 30732-2014; Proximate Analysis of Coal by Instrumental Method. Standards Press of China: Beijing, China, 2014.

- Yao, Y.B.; Liu, D.M. Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coals. Fuel 2012, 95, 152–158. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, D.M.; Tang, D.Z.; Tang, S.H.; Huang, W.H. Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. Int. J. Coal Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Liu, Y.L.; Tang, D.Z.; Xu, H.; Zhao, J.L.; Li, B.Y. Description of the Storage-Permeability Under the Control of Macrolithotypes Based on the Nuclear Magnetic Resonance. Geol. J. China Univ. 2016, 22, 543–548. [Google Scholar]

- Tian, H.; Zhang, S.C.; Liu, S.Y.; Zhang, H. Determination of organic-rich shale pore features by mercury injectionand gas adsorption methods. Acta Pet. Sin. 2012, 33, 419–427. [Google Scholar]

- Gao, L.X. BET Analysis of Physical Properties of Porous Materials. Guangdong Chem. Ind. 2021, 48, 94–95. [Google Scholar]

- GB/T 21650.2-2008; Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Part 2: Analysis of Mesopores and Macropores by Gas Adsorption. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- Hu, R.Z. Measurement of Powder Particles and Pores; Metallurgical Industry Press: Beijing, China, 1982. [Google Scholar]

- Brunauer, S.; Emmettm, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Bustin, R.M.; Bustin, A.; Ross, D.; Chalmers, G. Shale Gas Opport Unities and Challenges; AAPG Annual Convention: San Antonio, TX, USA, 2008. [Google Scholar]

- Ravikovith, P.T.; Haller, G.L.; Neimark, A.V.; Neimark, A.B. Density functional theory model for calculating pore size distributions: Pore structure of nanoporous catalysts. Adv. Colloid Interface Sci. 1998, 76–77, 203–226. [Google Scholar] [CrossRef]

- Song, D.Y.; Ji, X.F.; Li, Y.B.; Zhao, H.T.; Song, B.Y.; He, K.K. Heterogeneous development of micropores in medium-high rank coal and its relationship with adsorption capacity. Int. J. Coal Geol. 2020, 226, 103497. [Google Scholar] [CrossRef]

- Liu, Y.W.; Zhang, S.; Zuo, W.Q.; Han, H.K.; Xu, P. tudy on differences of pore structure of typical soft and hard coal. Coal Sci. Technol. 2021, 49, 98–106. [Google Scholar]

- Soltanmohammadi, R.; Faroughi, S. A comparative analysis of super-resolution techniques for enhancing micro-CT images of carbonate rocks. Appl. Comput. Geosci. 2023, 20, 100143. [Google Scholar] [CrossRef]

- Vasarhelyi, L.; Konya, Z.; Kukovecz, A.; Vajtai, R. Kukovecz AMicrocomputed tomography–based characterization of advanced materials: A review. Mater. Today Adv. 2020, 8, 100084. [Google Scholar] [CrossRef]

- Kelly, S.; El-sobky, H.; Carlos, T.V.; Matthew, T.B. Assessing the utility of FIB-SEM images for shale digital rock physics. Adv. Water Resour. 2016, 95, 302–316. [Google Scholar] [CrossRef]

- GB/T 17366-1998; Methods of Mineral and Rock Specimen Preparation for EPMA. Standardization Administration of the People’s Republic of China: Beijing, China, 1998.

- SY/T 5162-2014; Analytical Method of rock Sample by Scanning Eletron Microscope. Petroleum Industry Press: Beijing, China, 2014.

- Yang, Y.; Liu, S.M.; Zhao, W.; Wang, L. Intrinsic relationship between Langmuir sorption volume and pressure for coal: Experimental and thermodynamic modeling study. Fuel 2019, 241, 105–117. [Google Scholar] [CrossRef]

- GB/T 19560-2008; Experimental Method of High-Pressure Isothermal Adsorption to Coal. Standards Press of China: Beijing, China, 2008.

- Bell, G.J.; Rakop, K.C. Hysteresis of methane/coal sorption isotherms. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers, New Orleans, LA, USA, 5–8 October 1986. [Google Scholar]

- Clarkson, C.R.; Bustion, R.M.; Levy, J.H. Application of the mono/multilayer and adsorption potential theories to coal methane adsorption isotherms at elevated temperature and pressure. Carbon 1997, 35, 1689–1705. [Google Scholar] [CrossRef]

- Mavor, M.; Owen, L.; Pratt, T. Measurement and evaluation of coal sorption isotherm data. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers, New Orleans, LA, USA, 23–26 September 1990. [Google Scholar]

- Ruppel, T.C.; Grein, C.T.; Bientock, D. Adsorption of methane on dry coal at elevated pressure. Fuel 1974, 53, 152–162. [Google Scholar] [CrossRef]

- Li, J.Z.; Guo, P.G.; Xie, W.H.; Chu, J.Q.; Yin, Z.Q.; Yuan, A.Y.; Zhang, M.; Jiao, Z.H. Experimental Study on Adsorption Pore Structure and Gas Migration of Coal Reservoir Using Low-Field Nuclear Magnetic Resonance. Adv. Civ. Eng. 2020, 9, 8839819. [Google Scholar] [CrossRef]

- Li, A.; Ding, W.L.; Wang, R.Y.; He, J.H.; Wang, X.H.; Sun, Y.X.; Gu, Y.; Jiao, N.L. Petrophysical characterization of shale reservoir based on nuclear magnetic resonance (NMR) experiment: A case study of Lower Cambrian Qiongzhusi Formation in eastern Yunnan Province, South China. J. Nat. Gas Sci. Eng. 2017, 37, 29–38. [Google Scholar] [CrossRef]

- Wang, K.; Qiao, P.; Wang, Z.S.; Liu, X.G.; Li, Y. Multiple scale pore size characterization of coal based on carbon dioxide and liquid nitrogen adsorption, high-pressure mercury intrusion and low field nuclear magnetic resonance. China Min. Mag. 2017, 26, 146–152. [Google Scholar]

- Zhu, G.G.; Xie, Z.T.; Wang, T.; Hu, H.Y.; Wang, D.X. Microscopic pore structure characteristics of Shanxi Formation coal reservoir in Daning-Jixian block. Saf. Coal Mines 2024, 55, 31–42. [Google Scholar]

- Shen, R.; Zhang, X.Y.; Ke, Y.B.; Xiong, W.; Guo, H.K.; Liu, G.H.; Zhou, H.T.; Yang, H. An integrated pore size distribution measurement method of small angle neutron scattering and mercury intrusion capillary pressure. Sci. Rep. 2021, 11, 17458. [Google Scholar] [CrossRef]

- Wang, P.F.; Jiang, Z.X.; Chen, L.; Yin, L.S.; Li, Z.; Zhang, C.; Tang, X.L.; Wang, G.Z. Pore structure characterization for the Longmaxi and Niutitang shales in the Upper Yangtze Platform, South China: Evidence from focused ion beam–He ion microscopy, nano-computerized tomography and gas adsorption analysis. Mar. Pet. Geol. 2016, 77, 1323–1337. [Google Scholar] [CrossRef]

- Lin, Z.T.; Liu, D.M.; Cai, Y.D.; Wang, Y.P.; Teng, J. Adsorption pore structure and its fractal characteristics of coals by N2 adsorption/desorption and FESEM image analyses. Fuel 2019, 257, 116031. [Google Scholar]

- Horikawa, T.; Do, D.D.; Nicholson, D. Capillary condensation of adsorbates in porous materials. Adv. Colloid Interface Sci. 2011, 169, 40–58. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Tian, F.H.; Deng, Z.; Hu, H.Y. The Characteristic Development of Micropores in Deep Coal and Its Relationship with Adsorption Capacity on the Eastern Margin of the Ordos Basin, China. Minerals 2023, 13, 302–324. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, H.Y.; Jiang, Z.X. Influence of deep coal pore and fracture structure on occurrence of coalbed methane: A case study of Daning-Jixian Block in the eastern margin of Ordos Basin. Coal Sci. Technol. 2024, 52, 106–123. [Google Scholar]

- Liu, D.M.; Qiu, F.; Liu, N.; Cai, Y.D.; Guo, Y.L.; Zhao, B.; Qiu, Y.K. Pore structure characterization and its significance for gas adsorption in coals: A comprehensive review. Unconv. Resour. 2022, 2, 139–157. [Google Scholar] [CrossRef]

- Nie, B.S.; Liu, X.F.; Yang, L.L.; Meng, J.Q.; Li, X.C. Pore structure characterization of different rank coals using gas adsorption and scanning electron microscopy. Fuel 2015, 158, 908–917. [Google Scholar] [CrossRef]

- Schlumberger, C.; Thommes, M. Characterization of Hierarchically Ordered Porous Materials by Physisorption and Mercury Porosimetry—A Tutorial Review. Adv. Mater. Interfaces 2021, 8, 2002181. [Google Scholar] [CrossRef]

- Yin, T.T.; Liu, D.M.; Cai, Y.D.; Zhou, Y.F. Methane adsorption constrained by pore structure in high-rank coals using FESEM, CO2 adsorption, and NMRC techniques. Energy Sci. Eng. 2019, 7, 255–271. [Google Scholar] [CrossRef]

- Mohammad, A.; Dana, A. Guidelines for the use and interpretation of adsorption isotherm models: A review. J. Hazard. Mater. 2020, 393, 122383. [Google Scholar]

- Feng, P.; Li, S.; Tang, S.L.; Tang, D.Z.; Zhang, C.; Yang, J.S.; Liu, N.X.; Zhong, G.H. Estimation of Adsorption Isotherm for Deep Coalbed Methane: A Monolayer-Filling Model Based on Pore Fractal Dimension. Energy Fuel 2024, 28, 1987–2000. [Google Scholar] [CrossRef]

- Wang, J.H. Multi-Fractal Characteristics of Pore Structure of Coal Rock in Low and Medium Rank CBM Reservoirs. J. Petrochem. Univ. 2019, 32, 26–32. [Google Scholar]

- Wang, X.H.; Peng, Y.; Wang, J.Y.; Zeng, Q. Pore structure damages in cement-based materials by mercury intrusion: A non-destructive assessment by X-ray computed tomography. Materials 2019, 12, 2220–2236. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Miller, J.D. Current developments and applications of micro-CT for the 3D analysis of multiphase mineral systems in geometallurgy. Earth-Sci. Rev. 2020, 211, 103406. [Google Scholar] [CrossRef]

- Wang, G.; Qin, X.J.; Han, D.Y.; Liu, Z.Y. Study on seepage and deformation characteristics of coal microstructure by 3D reconstruction of CT images at high temperatures. Int. J. Min. Sci. Technol. 2021, 31, 175–185. [Google Scholar] [CrossRef]

- Wang, Y. Nanoscale Pore Structure Evolution and Shale Gas Occurrence of Longmaxi Formation in Upper Yangtze Area; China University of Mining and Technology: Beijing, China, 2017. [Google Scholar]

- Clarkson, C.R.; Butin, R.M. The effect of pore structure and gas pressure upon the transport properties of coal: A laboratory and modeling study.1. Isotherms and pore volume distributions. Fuel 1999, 78, 1333–1344. [Google Scholar] [CrossRef]

- Swenson, H.; Stadie, N.P. Langmuir’s Theory of Adsorption: A Centennial Review. Langmuir 2019, 35, 5409–5426. [Google Scholar] [CrossRef]

- Zhang, S.S.; Wu, C.F.; Liu, H.C. Comprehensive characteristics of pore structure and factors influencing micropore development in the Laochang mining area, eastern Yunnan, China. J. Pet. Sci. Eng. 2020, 190, 107090. [Google Scholar] [CrossRef]

- Pan, J.N.; Zhao, Y.Q.; Hou, Q.L.; Jin, Y. Nanoscale pores in coal related to coal rank and deformation structures. Transp. Porous Media 2015, 107, 543–554. [Google Scholar] [CrossRef]

- Chen, Y.P.; Pan, Z.J. Reservoir properties of Chinese tectonic coal: A review. Fuel 2020, 260, 116350. [Google Scholar] [CrossRef]

- Ni, H.Y.; Liu, J.F.; Chen, T.; Chen, S.J.; Meng, Q.B. Coal permeability prediction method based on the microscopic pore-fracture dual-porosity structure. J. Pet. Sci. Eng. 2022, 211, 110107. [Google Scholar] [CrossRef]

- Peng, N.; He, S.; Hu, Q.H.; Zhang, B.Q.; He, X.P.; Zhai, G.Y.; He, C.C.; Yang, R. Organic nanopore structure and fractal characteristics of Wufeng and lower member of Longmaxi shales in southeastern Sichuan, China. Mar. Pet. Geol. 2019, 103, 456–472. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, S.D.; Wu, J.Q.; Li, Z.; Wang, X.Y. Full-Scale Pore Structure Characterization and Its Impact on Methane Adsorption Capacity and Seepage Capability: Differences between Shallow and Deep Coal from the Tiefa Basin in Northeastern China. Fract Fract. 2024, 8, 48–75. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Reinoso, F.R.; Rouquerol, J.; Kenneth, S.W.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Hu, B.; Cheng, Y.P.; Pan, Z.J. Classification methods of pore structures in coal: A review and new insight. Gas Sci. Eng. 2023, 110, 204876. [Google Scholar] [CrossRef]

- Liu, Y.X.; Hao, C.M.; Wang, Z.Y.; Xie, J.N.; Zhao, W.B.; Meng, F.B.; Han, Y.N. Micropore distribution and methane adsorption process and mechanism in bituminous coals: A molecular dynamics simulation study. J. Environ. Chem. Eng. 2024, 12, 112139. [Google Scholar] [CrossRef]

- Zhan, H.M.; Li, X.Z.; Hu, Z.M.; Duan, X.G.; Guo, W.; Li, Y.L. Influence of Particle Size on the Low-Temperature Nitrogen Adsorption of Deep Shale in Southern Sichuan, China. Minerals 2022, 12, 302–320. [Google Scholar] [CrossRef]

- Yuan, T.; Wei, Y.L.; Chen, S.W.; Liu, W.; Zhao, L.Y.; Zhang, X. Study on Mechanical Properties and Crack Propagation of Raw Coal with Different Bedding Angles based on CT Scanning. ACS Omega 2022, 7, 27185–27195. [Google Scholar] [CrossRef]

- Lin, H.Y.; Tian, S.X.; Jiao, A.J.; Cao, Z.Y.; Song, K.; Zou, Y.H. Pore Characteristics and Fractal Dimension Analysis of Tectonic Coal and Primary-Structure Coal: A Case Study of Sanjia Coal Mine in Northern Guizhou. ACS Omega 2022, 7, 27300–277311. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, X.X.; Wang, Z.Z.; Qiao, L.; Shao, S.T. Research on comprehensive characterization of deep coal full aperture structure and burial depth effect. Sci. Rep. 2025, 15, 4510. [Google Scholar] [CrossRef] [PubMed]

| Coal Sample Number | Depth m | Ro,max % | Porosity % | Maceral Composition | Industrial Analysis | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Vitrinite | Inertinite | Exinite | Mineral Matter | Moisture Content | Ash Content | Volatile Matter | Total Carbon | ||||

| JT1-8-1-1 | 2382.10 | 2.35 | 7.85 | 77.20 | 19.40 | 1.00 | 2.40 | 0.65 | 4.36 | 9.45 | 85.54 |

| JT1-8-2-1 | 2383.00 | 2.35 | 6.65 | 77.80 | 16.60 | 1.80 | 3.80 | 0.96 | 9.37 | 9.10 | 80.57 |

| JT1-8-4-1 | 2385.91 | 2.36 | 6.98 | 81.20 | 14.80 | 0.80 | 3.20 | 0.70 | 5.83 | 8.52 | 84.95 |

| Coal Sample Name | Density (g/cm3) | Scan Length (mm) | Scanning Diameter (mm) |

|---|---|---|---|

| JT1-8-1-1 | 1.45 | 166.328 | 60 |

| JT1-8-2-1 | 1.46 | 191.311 | 60 |

| JT1-8-4-1 | 1.43 | 168.804 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leng, K.; Guan, B.; Jiang, C.; Liu, W. Integrated Analysis of Pore and Fracture Networks in Deep Coal Seams: Implications for Enhanced Reservoir Stimulation. Energies 2025, 18, 3235. https://doi.org/10.3390/en18133235

Leng K, Guan B, Jiang C, Liu W. Integrated Analysis of Pore and Fracture Networks in Deep Coal Seams: Implications for Enhanced Reservoir Stimulation. Energies. 2025; 18(13):3235. https://doi.org/10.3390/en18133235

Chicago/Turabian StyleLeng, Kaiqi, Baoshan Guan, Chen Jiang, and Weidong Liu. 2025. "Integrated Analysis of Pore and Fracture Networks in Deep Coal Seams: Implications for Enhanced Reservoir Stimulation" Energies 18, no. 13: 3235. https://doi.org/10.3390/en18133235

APA StyleLeng, K., Guan, B., Jiang, C., & Liu, W. (2025). Integrated Analysis of Pore and Fracture Networks in Deep Coal Seams: Implications for Enhanced Reservoir Stimulation. Energies, 18(13), 3235. https://doi.org/10.3390/en18133235