Abstract

Hybrid tractors, as an efficient and environmentally friendly power system, are gradually becoming an important technical choice in the agricultural field. Compared to conventional powertrain systems, hybrid electric powertrains can achieve a 15–40% reduction in fuel consumption. By optimizing the engine operating range and incorporating electric-only driving modes, these systems further contribute to a 20–35% decline in CO2 emissions, along with a significant mitigation of nitrogen oxides (NOx) and particulate matter (PM) emissions. In this paper, the energy management technology of hybrid tractors is reviewed, with emphasis on the energy scheduling between the internal combustion engine and electric motor, the optimization control algorithm, and its practical performance in agricultural applications. Firstly, the basic configuration and working principle of hybrid tractors are introduced, and the cooperative working mode of the internal combustion engine and electric motor is expounded. Secondly, the research progress of energy management strategies is discussed. Then, the application status and challenges of hybrid power systems in agricultural machinery are discussed, and the development trend of hybrid tractors in the fields of intelligence, low carbonization, and high efficiency in the future is prospected. This paper extracts many experiences and methods from the references over the years and provides a comprehensive evaluation.

1. Introduction

China, traditionally recognized as a prominent agricultural nation, has consistently maintained its position at the forefront of global farming technology. According to the National Bureau of Statistics, the total grain output of China in 2024 was projected to reach 706.5 million tons, reflecting an increase of 11.09 million tons compared to the previous year, thereby securing its position as the world’s leading grain producer for numerous consecutive years. However, as the nation intensifies its environmental protection efforts and advances ecological agriculture, the green and sustainable development of agricultural mechanization has emerged as a critical concern. The rapid expansion of agricultural mechanization has positioned the agriculture and forestry sectors as significant contributors to global greenhouse gas emissions [1,2,3], with agricultural machinery accounting for approximately 20% of carbon dioxide, 42% of methane, and 75% of nitrogen oxide emissions [4], thereby exerting substantial environmental impacts. In response to the global call for “carbon peak” and “carbon neutrality”, China has proactively introduced new standards aimed at achieving zero emissions, pollution-free operations, and low-noise technologies for green agricultural machinery within the context of modern agricultural transformation [5]. The “Fourteenth Five Year Plan” for National Agricultural Green Development further outlines specific objectives for the future trajectory of agricultural machinery in China: enhancing the innovation system for green agricultural machinery and equipment, fostering research and development, promoting the upgrading of machinery, and expediting the demonstration and widespread adoption of green and efficient technological solutions.

Against the background of the comprehensive green transformation of agricultural machinery, tractors, as one of the most important power machineries in agricultural production activities [6,7,8,9,10], need to deal with complex field operations in addition to normal road driving [11,12]. Under different working conditions, the signal assigned to the actuator by the drive control system will also lead to different operating speeds and power requirements [13]. Thanks to the great breakthroughs in the field of today’s three types of electric (motor, battery, electronic control) technology, electrification has also become an inevitable trend in the development process of tractors [14,15,16]. With the characteristics of low pollution, low noise, and compact structure [17,18], the motor has become one of the important power sources to replace the engine to achieve all-electric agricultural production in the future [19]. However, due to the limitations of today’s battery technology, although the density of onboard power batteries has been able to reach 150–160 g/wh in recent years [20], because the tractor needs to be supplemented with different agricultural machinery for agricultural production operations, its characteristics of large quality and high demand torque mean that the pure electric tractor cannot fully meet the needs of plowing conditions for the time being. This means that before there are further breakthroughs in battery technology [21,22], pure electric tractors cannot meet the needs of large-scale market promotion. Therefore, by learning from the advanced technology of hybrid electric vehicles in the automotive field [23], the hybrid tractor combined with different power sources is an effective means to respond to a series of issues such as policy and energy conservation and emission reduction [24,25,26].

The continuous evolution of hybrid tractor technology in recent years has significantly expanded the power sources available, moving beyond the simple combination of diesel engines and electric motors [27]. This progress now encompasses a variety of advanced technologies, including hydrogen fuel cells, supercapacitors, methane fuel, and other hybridized energy systems [28]. Currently, hybrid tractor technology remains under active development, with researchers striving to identify solutions that can match or even surpass the performance capabilities of traditional tractors, fully leveraging the advantages of hybrid configurations to facilitate their widespread application [29,30]. As early as 1912, Siemens initiated research into new energy tractors, focusing on pure electric models. Since that time, with the increasing prevalence of hybrid powertrains in the automotive industry and the maturation of hybrid drive technologies, hybrid tractors have gradually advanced into the mainstream. In 2009, the Russian company RUWELPROM unveiled the Belams-3023 series hybrid tractor at the Hannover State Agricultural Machinery Show, featuring a standard 220 kW engine–generator set and a 183 kW asynchronous electric motor [31]. In the same year, the Belarse-3023 model, with a rated power of 225 kW, demonstrated an 18% improvement in fuel economy compared to conventional tractors [31]. In 2019, Steyr introduced an innovative multi-energy hybrid tractor driven by four wheel-edge motors, featuring a torque converter and an independent motor driven power take off (PTO). This design enhanced safety, grip, maneuverability, and response speed while also enabling regenerative braking energy recovery. China, having pioneered the development of the first electric tractor in 1960, launched its first hydrogen-fueled electric tractor, the ET504-H, in 2020, integrating 5G technology. Although domestic research on hybrid tractors began relatively late and initially focused on the electric sector, recent theoretical and experimental advancements in universities have led to significant breakthroughs in key areas.

Currently, China has prioritized the research and development of new energy-saving tractors as a strategic initiative. To effectively adapt to complex operational environments and ensure superior stability and endurance [32], it is imperative to conduct in-depth studies on the driving characteristics and energy management control strategies of hybrid tractors. Given the nature of multiple power sources operating in tandem, it is essential to rationally allocate energy flow between these sources in order to achieve dynamic control. As a result, many researchers draw upon control strategies from the automotive sector to investigate related energy management technologies. The primary objective of energy management within hybrid power systems can be encapsulated as the real-time distribution of output torque/power [33] between the engine and the motor, in alignment with the operational torque and power requirements. This approach aims to reduce fuel consumption, minimize emissions, prolong battery life, and ultimately enhance energy efficiency [34,35]. In general, the most effective path to achieving near-optimal results in energy management strategy (EMS) design is through the application of valuable objective functions and the optimization of powertrain models, thereby improving the energy management controller.

The primary objectives of this paper are outlined as follows: First, an extensive review of the background and current development status of green agriculture is conducted, highlighting the necessity and urgency of research on hybrid tractors. Subsequently, the foundational research status of hybrid tractors is examined, with a particular emphasis on the pivotal role of energy management strategies in the development of hybrid tractor technologies. Following this, a detailed introduction is provided on the structural configuration and modeling methodologies of hybrid tractors, wherein the energy management strategies are categorized into three distinct types: rule-based energy management, optimization-based energy management, and deep learning-based energy management. The characteristics, advantages, and limitations of each strategy are thoroughly reviewed and critically evaluated, with particular attention paid to their respective contributions to the advancement of the research objectives, as supported by the relevant literature. Finally, based on the current technological bottlenecks, future research directions are proposed, and a comprehensive analysis of the existing research gaps is presented.

2. Characteristics and Classification of Hybrid Tractors

Drawing from the application of hybrid power systems in automobiles, it can be observed that hybrid tractors and hybrid vehicles share similarities in their power system structures. However, these hybrid tractor systems are typically more intricate than conventional tractor designs, as they incorporate two or more power sources [36,37]. From a macro perspective, the physical structure of the hybrid tractor can be conceptualized as a system comprising various components and interconnecting elements arranged in distinct configurations, while the control architecture plays a critical role in determining the efficiency of energy flow and distribution. Additionally, due to the tractor’s power system needing to accommodate complex operational conditions such as rotary tillage and plowing, hybrid tractors are categorized into three primary types based on their power drive principles, component arrangement, and control strategies: series, parallel, and series–parallel configurations [38,39,40,41]. The characteristics of these configurations are summarized in Table 1.

2.1. Series Hybrid System

Series hybrid structures usually use an “engine–generator” group as a range extender, using the engine to drive the generator to generate electricity and provide power to the system. Among them, the engine is not used as the driving source of the whole machine but rather relies on the electric motor installed in front of the gearbox to drive the whole machine [42].

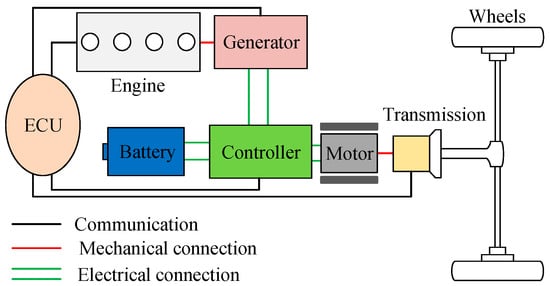

The main idea of the range extender is that under working conditions, the engine should work in the high-efficiency range as much as possible, and the power battery should charge and discharge according to the needs of the electric power, and eventually the charge and discharge balance should be achieved in the cycle condition. From the perspective of energy conversion, the fossil fuel burned by the engine needs to be converted into mechanical energy to promote the generator’s work, and the electric energy is reconverted into mechanical energy by the motor to drive, and the complex energy conversion makes the system have low energy efficiency [43]. At the same time, in order to meet the requirements of high load conditions, serial-connected systems are usually equipped with large-size power sources, such as the increase in the volume and mass of the motor and battery, which makes the whole machine require additional costs [44]. The configuration structure of a series hybrid system is illustrated in Figure 1.

Figure 1.

Diagram of the series hybrid system.

2.2. Parallel Hybrid System

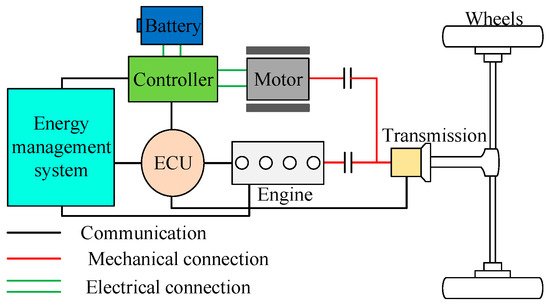

The parallel hybrid power structure uses two sets of relatively independent driving devices, the engine and the motor are arranged in parallel, and the mechanical transmission device [45] can drive the whole machine independently or simultaneously according to the torque and speed under different working conditions [46]. In the parallel structure, the motor can be used to compensate when the engine power is insufficient, so the motor can be directly involved in the drive as a motor or as a generator [47]. Any excess energy can be converted into electrical energy and stored in the battery, to a certain extent allowing the engine to operate in the optimal efficiency range.

The parallel structure can be divided into single-axis parallel and double-axis parallel and can also be divided into four P0–P4 types according to different motor positions. According to the different power requirements, the parallel structure can complete the switch in different working modes, which can be flexibly operated and reduce energy consumption. Compared with the series type, its structure is more compact, it uses energy more efficiently, it saves time, and the cost of the transformation is lower [48]. However, complex structure and poor emission performance have also become drawbacks that need to be addressed. The configuration structure of a series hybrid system is illustrated in Figure 2.

Figure 2.

Diagram of the parallel hybrid system.

2.3. Series–Parallel Hybrid System

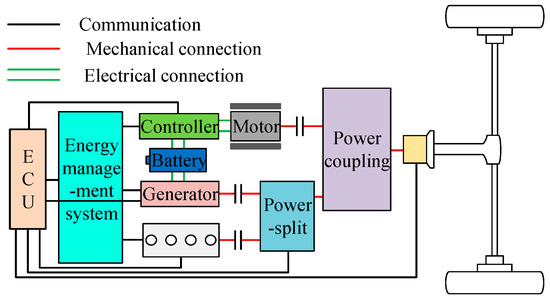

The series–parallel hybrid system combines the advantages of series energy coupling and parallel mechanical coupling [49,50], has a direct mechanical connection between the engine and the drive components, and has an “engine–generator” group of extended range drive mode, thus achieving higher energy efficiency. The hybrid structure can also provide a more abundant drive mode, according to the different operating conditions and the tractor using the control strategy to decide on the most suitable current working conditions of the drive mode, to achieve better comprehensive performance [51]. However, the crisscross structure of the power system means high research and development costs and complex control systems, requiring professional research and development personnel to cooperate for long-term development. Unlike conventional configurations, hybrid structures use power shunt devices to distribute energy between electrical and mechanical forms and can also be called power shunt structures. In addition, the structure uses a planetary gear device or clutch to fully decouple the engine speed from the speed, which means that there is no fixed transmission ratio between the engine and the speed [52]. According to the configuration and connection mode of the components, the power shunt structure can be further divided into three basic types: input power shunt, output power shunt, and composite power shunt. The power shunt structure has a more complex physical structure and requires more complex control algorithms to maintain vehicle performance. Their effective integration ensures that the vehicle can operate optimally in a variety of conditions, resulting in outstanding dynamic performance and fuel economy [53,54]. The configuration structure of a series hybrid system is illustrated in Figure 3.

Figure 3.

Diagram of the series–parallel hybrid system.

Table 1.

Characteristics in different topological configurations.

Table 1.

Characteristics in different topological configurations.

| Powertrain Configuration | Reference | Configuration Characteristic |

|---|---|---|

| Series | [55,56,57,58,59,60,61] | Simple mechanical structure; mainly driven by motor; Low energy efficiency. |

| Parallel | [62,63,64,65] | Braking energy recovery; Relatively high energy efficiency; Low flexibility. |

| Series–parallel | [66,67,68,69] | Complex control strategy; Multi-mode operation; Strong adaptability; Decoupling between vehicle and engine. |

Overall, the series hybrid system is suitable for the low-speed and high-torque operation characteristics of tractors. Its engine can always operate in the optimal efficiency range, significantly improving fuel economy. Moreover, the pure electric mode can achieve zero emissions, but there is energy conversion loss, and its efficiency is relatively low during continuous high-speed operation. In the parallel hybrid system, the engine and the motor can be driven separately or jointly, providing a strong power output under heavy-load conditions such as plowing. The system structure is simple, reliable, and has a relatively low cost, but the optimization of the engine’s working range is limited. The series–parallel hybrid system achieves power splitting through a planetary gear mechanism, combining the advantages of the former two. It can automatically adjust the power distribution strategy according to the farming resistance and maintain the best energy efficiency under complex farmland working conditions. However, the system has high complexity and strict requirements for the control algorithm. Considering the particularity of the working environment of tractors, parallel and series–parallel hybrid systems are currently more widely used. Among them, the parallel hybrid system is more suitable for small- and medium-sized tractors, while the series–parallel hybrid system has more advantages in high-power operation scenarios.

3. Research Status of Energy Management Strategy for Hybrid Tractors

In conventional tractors, the powertrain is typically driven by a single power source, and the fluctuations in rotary tillage resistance vary with the driving speed [70]. To maintain optimal operational performance, the operator adjusts the accelerator pedal in real time. However, in hybrid tractors, a new challenge arises regarding the allocation of power from multiple drive sources at any given moment, necessitating a solution for power distribution among the various drive units. As a result, the control strategy for hybrid tractors generally comprises a two-tier control architecture. The first tier involves low-level or component-level control tasks, where individual powertrain components employ classic feedback control methods. In this tier, the engine control unit (ECU) regulates engine torque [71], while the battery management system (BMS) [72] manages the state of charge (SOC) of the battery. The second tier, referred to as advanced or supervisory control, is responsible for optimizing energy flow within the vehicle while ensuring that the battery pack’s SOC remains within a specified operational range. This supervisory control is facilitated by the EMS, which receives and processes data from the tractor, the rototiller, and the operator. Through analysis and optimization, the EMS generates the optimal operating set points, which are then transmitted to the actuator for execution by the lower-level control layer. Additionally, the EMS determines the most suitable operating mode for the power system, including decisions on start–stop operations for the generator sets and power splitting mechanisms. The EMS features both an inner and outer control structure: the outer layer calculates the total power demand based on a driver model, while the inner layer governs the specific distribution of energy flows between the onboard energy sources. During the design of energy management strategies, it is common for designers to focus primarily on the battery SOC as the key system state variable, often neglecting the role of speed, which is typically influenced by operator control.

In general, the energy management problem can be transformed into an optimization problem in a finite time frame. Although the topologies of hybrid systems are complex and diverse, they are essentially instantaneous in the management of the power flow from the tractor energy converter to achieve the control objectives. The control target can be generally expressed as an integral performance index in the time domain, such as fuel consumption, emissions, power consumption, etc. Therefore, researchers use general formulas to describe the energy management problem of hybrid tractors under different topologies. Considering the general dynamic form of the equation of state, it can be expressed as follows:

where x(t) represents the state vector variable, u(t) represents the control input vector, and t represents the current time.

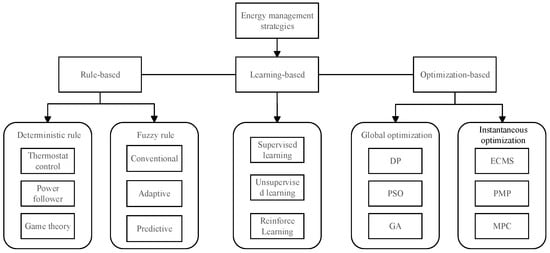

An effective energy management strategy is essential for ensuring that the hybrid tractor meets the power demands under varying operational conditions while simultaneously optimizing the charge and discharge cycles of the battery within the powertrain. This, in turn, contributes to an extended battery lifespan. And there could also be other criteria, such as minimizing the critical component degradation or maximizing the efficiency. Given the inherent uncertainty and complexity of tractor operating conditions, energy management systems for such vehicles are subject to stringent performance requirements, leading to a relatively limited number of tailored strategies for tractors. Drawing upon research in control strategies for hybrid electric vehicles, energy management approaches can be categorized into three primary types [73,74,75]: rule-based strategies, optimization-based strategies, and learning-based strategies, as illustrated in Figure 4.

Figure 4.

Classification of main control strategies.

3.1. Rule-Based Energy Management Strategy

The rule-based energy management strategy typically lacks a predefined set of operational conditions, instead relying on the engineering expertise and professional knowledge of engineers, or on mathematical models, to facilitate the coordination of energy distribution and flow between the two energy sources. This coordination is aimed at evaluating the driving power requirements and certain system states, thereby enabling the engine or motor to operate within its optimal efficiency range and facilitating energy recovery through regenerative braking [76,77]. This approach is characterized by its simplicity and ease of implementation, making it well-suited for the supervision and control of power flow within the powertrain. Researchers have further classified rule-based energy management strategies into two categories: deterministic rule-based strategies and fuzzy logic-based strategies.

3.1.1. Energy Management Strategy Based on Deterministic Rules

Deterministic rule-based energy management strategies, also known as logical threshold control strategies, center on determining a vehicle’s power requirements based on driver operations. It integrates system state inputs with preset thresholds to regulate the flow of energy between different energy sources. The rules are determined based on the power flow analysis of the power system or the heuristic method of human experience, which is to determine the optimal operating point and realize the power allocation through a precalculated lookup table. The strategy is characterized by simple structure, fast response, and wide application. However, its development relies heavily on empirical data and engineering experience and it lacks optimal power distribution under all conditions, which can lead to threshold errors and suboptimal adaptability [78]. Deterministic strategies can be divided into thermostat control methods, power tracking control methods, and state machine control methods.

Jia et al. developed a thermostat control strategy (TC) and a power follower control (PFC) strategy utilizing a high-fidelity forward model for a series hybrid agricultural tractor [79]. This study revealed that the PFC strategy exhibited superior performance in reducing NOx and CO emissions. In ref. [80], the authors implemented a rule-based strategy, achieving a 33.4% reduction in fuel consumption and a 1.6-fold decrease in engine power for a tandem hybrid snow blower. Lee et al. employed dynamic programming (DP) to determine the optimal power division ratio, resulting in a 1.88% improvement in fuel economy within the designed power system model [81]. Addressing port operation tasks, the hybrid tractor discussed in [82] utilized Pontryagin’s minimum principle as an offline optimization framework to guide the adjustment of rule parameters without the need for future power demand prediction. Song et al. [83] introduced a control strategy based on torque auxiliary distribution rules, conducting simulations to compare fuel consumption between conventional and hybrid tractors, ultimately achieving a fuel saving of 0.5143 L/h. Kang et al. considered SOC variations in the regular strategy when tractors operated under diverse complex conditions, such as transportation, mowing, and rotary tillage [84]. Xu et al. [85], aiming to address issues of significant load fluctuations and high energy consumption in field operations, integrated Haar wavelet with a logic rule strategy to enhance the average efficiency of hydrogen fuel cells and reduce equivalent hydrogen consumption.

3.1.2. Energy Management Strategy Based on Fuzzy Rules

The energy management strategy based on fuzzy logic rules represents a practical application of fuzzy control theory in hybrid tractors and can be considered an extension of deterministic rule-based strategies. In this approach, the input parameters for the vehicle controller are typically imprecise or fuzzy, with the fuzzy rule base constructed based on the designer’s expert knowledge [86]. By employing fuzzy rule reasoning, this strategy enables real-time, suboptimal power allocation. Unlike deterministic rule-based approaches, fuzzy logic strategies address the challenge of accurately modeling complex systems in practical engineering contexts and offer flexibility for adjustment and self-adaptation when necessary. However, the development of the fuzzy rule base remains reliant on empirical engineering experience, which leaves room for further refinement. Energy management strategies based on fuzzy logic can be classified into conventional fuzzy control strategies, adaptive fuzzy control strategies, and predictive fuzzy control strategies.

Diba et al. [87] designed a power management system using a fuzzy logic controller to maximize the traction capacity and fuel consumption rate of the designed new architecture hybrid tractor. In [88], considering the limitations of a single algorithm, fuzzy logic control is used to integrate TC and PFC strategies to achieve a reasonable distribution of output power of fuel cells and batteries, which can run continuously for 2.65 h. Zhu et al. [89], in order to solve the problem of the slow dynamic response of the engine, used fuzzy rules to control the clutch oil pressure and increased the motor torque compensation, which effectively reduced the deceleration amplitude of the output shaft, dynamic load coefficient and impact, and shortened the switching time [90]. On the basis of considering the farm operation mode, the multi-mode fuzzy logic controller is adopted to manage the power flow, which can keep the power in the high-efficiency zone under the actual farm conditions. In recent years, more scholars tend to combine intelligent optimization algorithms with fuzzy rule control to optimize membership function and fuzzy rules and reduce the dependence on experience. Zhang et al. [91] used an adaptive fuzzy energy management controller to distribute power between fuel cells and supercapacitors and used genetic algorithm (GA) to optimize key parameters within the fuzzy controller to meet different driving cycles. Tian et al. [92] extracted equivalent factors from the optimal control trajectory obtained through DP to train the online adaptive neuro-fuzzy inference system (ANFIS) model to generate the optimal equivalent factors, showing significant advantages in learning and reasoning.

3.2. Energy Management Strategies Based on Optimization

The energy management strategy based on optimization combines modern control theory. After constructing the control objective function and constraint of the system, the control signal is determined by minimizing the sum of the objective function over time or the instantaneous minimizing objective function, which correspond to two aspects of the optimization strategy, respectively: global optimization and instantaneous optimization. Optimization-based strategies aim to find the best control sequence in the feasible domain that meets the optimization objective, usually using known or predicted driving condition information to calculate the actuator settings.

3.2.1. Global Energy Management Strategy

The global energy management strategy represents a hybrid approach to energy optimization, underpinned by optimal control theory and advanced optimization methodologies. This strategy leverages global optimization frameworks, such as Bellman’s principle of optimality [93] and multi-objective mathematical programming, to construct a system-constrained global optimization model with an emphasis on enhancing vehicle fuel efficiency and reducing emissions. Typically, global optimal control strategies necessitate prior knowledge of the entire driving context in order to perform action search, a requirement that poses significant challenges in real-time applications due to the inherent difficulty of predicting driving conditions in advance. Consequently, while real-time implementation of this strategy is impractical, it serves a valuable role in evaluating the relative merits of alternative control strategies or in the design of online execution protocols based on its principles. Techniques such as linear programming, dynamic programming, stochastic dynamic programming, and genetic algorithms [94,95,96] are classified under the umbrella of global optimal control strategies. Although these methods are capable of providing high accuracy, their computational complexity represents a substantial barrier to broader practical deployment.

In the realm of global energy management research, numerous algorithms have been developed to address optimization challenges with varying degrees of effectiveness. However, given the overarching significance of global optimization and its foundational role as a benchmark strategy, DP has emerged as the most extensively utilized algorithm. DP is a numerical approach designed to resolve multi-level decision-making problems, capable of delivering optimal solutions for issues of diverse complexity. It is particularly suited for tackling the optimal energy management problem as outlined in (1). The control sequence can be characterized as the allocation of power between the engine and the rechargeable energy storage system within a continuous time domain [97]. The associated cost function may encompass fuel consumption, energy usage, emissions, or other predefined objectives.

Zhang et al. [98] employed DP to evaluate fuel consumption under plowing conditions, aiming to assess the fuel economy and operational status of power components in high-power hybrid tractors. Compared to strategies based on the optimal operating line (OOL), this approach achieved a reduction in fuel consumption by approximately 26.87%. Roland et al. [99] integrated DP with Pontryagin’s minimization principle (PMP) to account for engine start-up costs and restrict engine start–stop cycles. This hybrid algorithm demonstrated performance comparable to DP while significantly reducing computational expenses. In ref. [100], a bidirectional long short-term memory (Bi-LSTM) network was utilized for speed prediction, enabling DP-based energy management grounded in short-term speed forecasts, ultimately reducing fuel costs by 8.85%. Furthermore, Dong et al. combined DP with the deep deterministic policy gradient (DDPG) algorithm [101], revealing substantial energy-saving potential. Li proposed a DP-based fuzzy neural network strategy [102], which decreased fuel consumption by 10.2% relative to rule-based strategies. Reference [103] introduced a dual-layer energy control strategy, wherein the upper layer employed adaptive dynamic programming (ADP) to dynamically optimize the equivalent factor based on predictive data. ADP facilitated near-optimal energy distribution and adjusted torque operations in real time according to instantaneous driving conditions.

3.2.2. Instantaneous Energy Management Strategy

The instantaneous energy management strategy is a real-time optimization strategy based on defining the minimum value of the instantaneous cost function at each moment, which includes, but is not limited to, a series of indicators such as fuel consumption, emission pollution, and battery life. The optimal control quantity of the whole is solved by the current system variables, and the target is approximated by iterative and rolling optimization methods. Compared with the global strategy, this strategy has good responsiveness and adaptability and can realize real-time online optimization, so it has been a key research direction in the field of real vehicle applications for a long time. Common transient optimization strategies include equivalent consumption minimization strategy (ECMS) [104,105,106], PMP, and model predictive control (MPC).

Equivalent Consumption Minimization Strategy

The ECMS is a heuristic approach designed to address optimal control problems by dynamically adjusting engine control parameters and operational states, thereby enabling the engine to operate under optimal conditions and achieve minimal equivalent fuel consumption. This strategy operates under the assumption that the battery’s SOC remains balanced, ensuring negligible deviation between initial and final SOC levels. Consequently, all energy consumption can be attributed to fuel usage, with the battery functioning as a reversible energy reservoir. The energy expended during battery discharge is ultimately compensated by the engine at a future time or recovered through regenerative braking. Broadly, the energy flow in ECMS can be categorized into two modes: positive battery power output during discharge and negative battery power output during charging. The energy consumed during discharge is offset by the fuel consumed by the engine, with the amount of fuel replenishment contingent on the battery’s operational state during charging and the energy recuperated through regenerative braking. Electrical energy generated during charging can reduce instantaneous fuel consumption, with its utilization dictated by the driving conditions and imposed load. Within the ECMS framework, the relationship between engine fuel consumption and battery energy usage during charging and discharging can be expressed through the following equation:

where represents instantaneous equivalent fuel consumption; and are actual instantaneous fuel consumption and electric equivalent fuel consumption, respectively. In order to express electricity consumption in the form of fuel consumption, an equivalent factor s(t) is introduced to assign a certain cost to convert electricity into equivalent fuel consumption. Similarly to an engine that consumes actual fuel, and can be defined separately as follows:

where Qlhv is the low calorific value of fossil fuel, ηeng stands for engine efficiency, Peng is the power generated by the engine running at a certain efficiency, s(t) is the equivalent factor, representing the efficiency chain of fuel conversion to electricity and electricity conversion to equivalent fuel consumption, Pbatt is the power of the battery, and p(SOC) is a penalty function that ensures that the SOC does not exceed the allowed range.

Current research on the ECMS in hybrid tractors is progressively expanding [107]. Ozturk et al. [108] conducted a comparative analysis between conventional tractors and hybrid tractors employing the ECMS, revealing that the latter exhibited significant enhancements in both emissions and fuel efficiency through simulations of fuel consumption and CO2 emissions. Radrizzani et al. [109] refined the traditional ECMS approach by integrating a speed controller within the engine, achieving fuel savings without compromising speed tracking performance. Dou et al. [110] utilized the radial basis function (RBF) algorithm to forecast power demand and optimized the equivalent factor in the ECMS using a genetic algorithm, enabling real-time energy distribution based on SOC and mileage.

Building upon existing research, scholars have addressed the limitation of fixed equivalent factors by introducing adaptive equivalent consumption minimization strategies (A-ECMSs), thereby enhancing the real-time applicability of the ECMS algorithm. Zhu et al. [111] developed a fuzzy adaptive equivalent consumption minimization strategy (FA-ECMS) to tackle the issue of the ECMS’s limited adaptability across diverse operating conditions in a parallel hybrid tractor system. This system integrates dual power sources—an engine and a motor—along with hydro-mechanical continuous variable transmission (HMCVT). The approach involves establishing a logical threshold-based pattern division rule and designing a fuzzy proportional–integral (PI) controller to dynamically adjust the equivalent factor based on battery state of charge (SOC). This method achieved fuel consumption reductions of 6.71% and 5.04% during plowing and transportation operations, respectively. A comparative analysis of fuel consumption is presented in Table 2.

Table 2.

Comparison of fuel consumption.

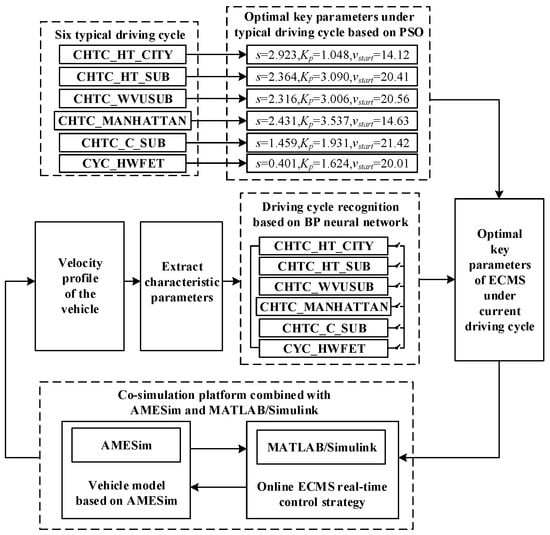

The precise determination and dynamic adjustment of key control parameters are also critical for the practical implementation of ECMS. To achieve self-adaptation in ECMS, Zhang et al. [112] employed a neural network-based driving state recognition algorithm to classify typical operating conditions. Subsequently, they optimized the equivalent factor, penalty function factor, and speed threshold within the ECMS framework using particle swarm optimization (PSO). The effectiveness of this approach was validated through numerical simulations, demonstrating a 14.81% improvement in fuel economy for the A-ECMS. The underlying principle of the proposed A-ECMS is illustrated in Figure 5.

Figure 5.

The principle of A-ECMS proposed in [112].

Pontryagin’s Minimization Principle

The PMP is established as a collection of necessary optimality conditions, enabling the conversion of an optimal solution into the identification of common state parameters within the Hamiltonian function. This approach supports the allocation of control variables across power sources through iterative procedures. PMP offers a robust framework for addressing optimization problems constrained by system states, demonstrating particular efficacy in resolving finite time domain optimization challenges [113]. Compared to conventional methods, PMP is widely recognized as an appealing solution owing to its relatively low computational complexity and rapid execution speed. The Hamiltonian function can be expressed as follows:

where λ is a costate; L is the instantaneous cost; and the λ dimension is the same as x.

Zhou et al. [114] investigated the energy distribution of tractors across entire operational conditions by comparing the PMP strategy with the TC and PFC strategies under transportation scenarios. The results demonstrated a reduction in fuel consumption per 100 km by 32.91% and 26.10%, respectively. Zhang et al. [115] developed a coupled dynamic model for parallel tractors during rotary tillage and plowing operations, formulating an energy management strategy based on PMP. This approach led to a decrease in equivalent fuel consumption by 10.44% and 11.20% under the respective working conditions. Stefano et al. [116] considered the prolonged operational nature of agricultural vehicles and heavy machinery, which often operate continuously for several hours around specific constant points. They proposed an energy management strategy within the PMP framework, achieving near-global optimal performance in real-world agricultural driving cycles.

PMP can be integrated with other optimization methodologies to develop enhanced strategies with superior efficiency. In [117], PMP was combined with DP to establish a DP-PMP optimization framework. This framework facilitates a comparative analysis of three EVT powertrains across 15 distinct driving conditions. It incorporates a two-tier formulation: the lower tier addresses the static optimization problem related to component operation in combined driving modes, while the upper tier focuses on minimizing the Hamiltonian value. This study concludes with an evaluation of fuel economy improvements under various conditions. A comparative analysis between DP-PMP and DP is presented in Table 3.

Table 3.

Comparison between DP-PMP and DP.

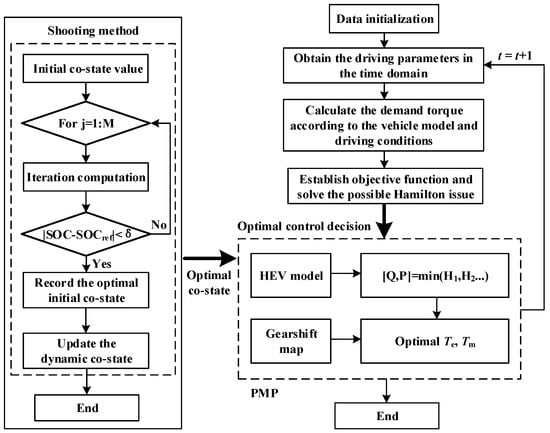

Zhang et al. [118] investigated the influence of battery aging and employed DP to derive a shift schedule aimed at minimizing frequent gear changes in the vehicle. Building upon these findings, this study utilized the PMP and ECMS frameworks to analyze the effects of torque distribution and battery lifespan, respectively. The proposed control-oriented model highlights the efficacy of DP as a benchmark strategy within a unified framework, with PMP exhibiting a marginal deviation of approximately 2% in fuel economy compared to DP. The implementation flowchart of PMP is depicted in Figure 6.

Figure 6.

The PMP implementation flowchart in [118].

Model Predictive Control

MPC represents a specialized control strategy adept at addressing nonlinear and highly constrained problems. At each sampling instant, MPC derives the current control action by solving a finite time domain open loop optimal control problem. This approach necessitates the construction of a predictive model capable of capturing the system’s dynamic behavior, with predicted values being refined through feedback correction. MPC employs a rolling finite time domain optimization strategy, ensuring that computations remain within a feasible range defined by a predetermined moving horizon along the reference trajectory. Fundamentally, MPC resolves an open loop optimal control problem [119]. While the underlying concept is model-agnostic, its implementation is inherently model-specific. Presently, MPC finds extensive application in domains such as power electronics [120], aerospace, and autonomous driving [121,122,123], primarily serving industrial control and process automation purposes.

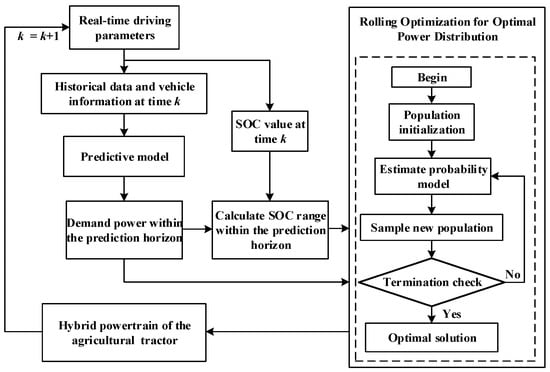

Zhao et al. [124] integrated DP with MPC, utilizing DP to determine the global SOC trajectory for tractors under various typical operating conditions. This trajectory was then employed as a power constraint within the MPC framework. Hardware-in-the-loop (HIL) testing demonstrated reductions in fuel consumption by 7.97%, 13.06%, and 11.03% during plowing, rotary plowing, and transportation tasks, respectively. In [125], the energy flow control was formulated as a discrete nonlinear optimization problem, addressed through short-term speed prediction and the estimation of distribution algorithm, resulting in significant fuel savings under periodic driving cycles. The overarching MPC framework is illustrated in Figure 7. Guo et al. [126] proposed a dual-layer MPC framework, where the outer layer employs the Krylov subspace method to resolve optimal time-varying problems, while the inner layer handles torque distribution and gear shifting, thereby enhancing computational efficiency. In [127], the reference of the low-level controller for the diesel generator set was incorporated into the MPC actions, with Pareto frontier analysis facilitating power distribution among the available energy sources. Gonzalo et al. [128] compared the impacts of battery health (SOH), battery temperature, fuel economy, and engine performance in a series hybrid tractor against conventional rule-based (RB) control, achieving a 7.2% reduction in fuel consumption, aligning with the methodology of [129]. Additionally, ref. [130] implemented multi-objective MPC as a supplementary energy management strategy to meet the dual requirements of fuel efficiency and speed tracking for hybrid tractors.

Figure 7.

Framework of the proposed strategy in [125].

3.3. Energy Management Strategies Based on Learning

Traditional energy management strategies often rely on empirical knowledge and predefined rules. While these approaches can achieve energy-saving objectives to some extent, their efficiency and adaptability are limited in complex and dynamic environments. With the rapid advancements in artificial intelligence (AI) and machine learning (ML) technologies, learning-based energy management strategies have emerged as an innovative solution. These strategies leverage historical data, real-time monitoring information, and environmental variations to identify effective patterns and rules, enabling self-optimization and continuous adjustment. Such approaches are capable of addressing complex and dynamic energy demands while also offering the flexibility to respond to diverse management requirements under conditions of high uncertainty. The incorporation of machine learning, deep learning, and related technologies has endowed energy management systems with enhanced adaptive and forecasting capabilities, unlocking significant potential in optimizing energy scheduling and load forecasting.

Learning-based control strategies have emerged as a prominent area of interest in vehicle control research, yet their application in hybrid tractor control strategies remains underexplored. Liu et al. [131] introduced a model free online reinforcement learning (RL) control strategy (DYNA-H) for plug-in hybrid electric vehicles (PHEVs), accompanied by the development of a dynamic model. The simulation results demonstrated significant enhancements in fuel economy and computational efficiency compared to the traditional Q-learning and Dyna algorithms. In reference [132], a deep deterministic policy gradient (DDPG) framework incorporating hierarchical rewards was proposed for a dual-layer energy management strategy. This framework operates at the learning layer and dynamically adapts to vehicle operating patterns. By utilizing dual reward functions to address distinct subobjectives, the DDPG agents achieved the comprehensive and in-depth exploration of optimal strategies. Zhou et al. [133] constructed a vehicle power model and a Markov probability transition model, employing a Q-learning-based reinforcement learning strategy to optimize fuel efficiency. The results indicated a notable improvement in fuel economy over conventional PID-based methods. Su et al. [134] integrated adaptive cruise control (ACC) with energy management strategies, embedding the multi-agent DDPG algorithm into a heuristic training framework, which accelerated convergence speed by 48.59%. Although these advanced strategies have not yet been applied to hybrid tractor energy management, their conceptual frameworks have significantly influenced the trajectory of future developments. With appropriate modifications, these strategies hold the potential to adapt to the complex operational environments of tractors, thereby advancing the progress of green agricultural machinery.

In conclusion, a comprehensive summary of research on energy management strategies for hybrid tractors is presented in tabular form, meticulously categorizing and delineating the classifications and characteristics of various strategies. Each strategy is associated with corresponding references, enabling researchers and engineers in the field to efficiently identify and align with their specific requirements, thereby facilitating the selection of appropriate research directions. The comparison of energy management strategies for hybrid tractors is shown in Table 4.

Table 4.

Comparison table of energy management strategies for hybrid tractors.

4. Future Development Trend

This paper provides a comprehensive review of the current research landscape in energy management for hybrid tractors, highlighting the maturity of various technologies employed in related domains. Presently, the drive to develop competitive products that align with modern market demands has intensified the need for elevated quality standards in the design and development of hybrid tractors. Beyond existing methodologies, it is imperative to integrate advancements in state-of-the-art technologies to explore innovative pathways. This section further examines prospective directions for the evolution of hybrid tractor technologies.

4.1. The Application of Intelligent Technology

In recent years, the integration of artificial intelligence (AI) and machine learning technologies has become increasingly prevalent across various sectors. Hybrid electric vehicles, akin to hybrid tractors, represent one of the most widely adopted modes of transportation, with intelligent technologies being extensively implemented. However, the development and optimization of these technologies often necessitate substantial data and computational resources. The intricate and dynamic operational environments of hybrid tractors impose additional requirements for energy management strategies that are both highly responsive and reliable. Meeting stringent response times poses significant challenges, particularly in applications demanding high real-time performance, such as scenarios involving heavy loads or precise operational scheduling. Within the agricultural sector, the adoption of new technologies tends to be slower due to the entrenched reliance on traditional methods that are perceived as mature and operable. Farmers and agricultural equipment providers typically favor technologies that have demonstrated long-term stability and reliability. Consequently, the future application of intelligent technologies in hybrid tractors holds the potential to significantly enhance agricultural productivity. The advancement of automation and intelligence in agricultural machinery also serves as an indicator of a nation’s growing comprehensive strength and technological progress.

4.2. Upgrading the Optimization Target

At present, research on agricultural machinery is still dominated by fuel economy, aiming to reduce energy consumption and emissions. However, due to its special working conditions and system complexity, hybrid tractors urgently need to introduce more comprehensive optimization objectives. Under operation conditions such as farming and traction with drastic load fluctuations, frequent sudden changes in power demand will occur. Therefore, aspects such as dynamic response performance and battery power distribution need to be taken into consideration. Meanwhile, agricultural machinery operates for a long time, and the importance of the full lifecycle cost of batteries requires that the health status of batteries be included in the control. In the domain of hybrid electric vehicles, numerous researchers have begun to explore multi-objective optimization or hierarchical optimization approaches, often incorporating additional objectives through the use of weight coefficients. Looking ahead, the field of hybrid tractors also warrants more comprehensive research on integrated optimization problems, addressing a broader range of performance criteria and advancing the potential for holistic improvements.

4.3. Deep Integration of Energy Management and Agricultural Operational Needs

With the advancement of precision agriculture, the energy management systems of hybrid tractors are expected to become increasingly integrated with the specific operational requirements of agricultural activities. For instance, based on factors such as crop type, soil conditions, and operational mode, the energy management system can dynamically adjust power output modes to ensure that the tractor operates efficiently across varying environments while simultaneously minimizing energy waste. Furthermore, the energy management system could be linked to agricultural environmental monitoring systems, allowing for the adaptation of energy usage strategies based on real-time environmental data, including parameters such as climate and soil moisture, thereby enabling “localized” energy optimization. Concurrently, as agricultural intelligence continues to evolve, the energy management system of hybrid tractors will integrate seamlessly with other agricultural machinery, such as seed drills and sprinkler irrigation systems, as well as intelligent agricultural systems. Through a unified control platform, energy management will be dynamically adjusted in alignment with the overall operational plan and schedule of the farm, ensuring the optimal allocation of energy resources across the entire agricultural operation.

5. Conclusions

With regard to tractors, as one of the most important pieces of agricultural equipment, in order to respond to the call of national policies and laws and regulations, the needs of vehicle transformation and upgrading cannot be ignored. The energy management strategy, as one of the three core issues of the vehicle control system, has received extensive attention from academia and industry. This paper makes a comprehensive and detailed analysis of all the aspects of the hybrid tractor, introduces the hybrid configuration, focuses on the application of different EMSs in the tractor, and compares their advantages and disadvantages. This paper introduces the most commonly used EMS classification from three aspects, rules, optimization, and learning, and discusses the research status through a literature review.

Rule-based strategies have become the first choice in current engineering practices due to their simplicity, reliability, and strong real-time performance. However, the optimization-based strategy has high computational complexity, is sensitive to the accuracy of working condition prediction, and requires the installation of high-performance on-board computing units. With the future integration of precision agriculture and the improvement in agricultural digitalization levels, learning-based strategies with autonomous learning capabilities will become the long-term evolution direction of EMSs. Despite significant advancements in energy management research, substantial gaps remain within the context of current technological progress. Future research directions will focus on the seamless integration of automation, intelligence, and systematization technologies, aiming to propel hybrid tractor technology toward new horizons.

Author Contributions

Conceptualization, Y.Y.; formal analysis, Y.W.; methodology, R.W.; writing—original draft preparation, Y.Y. and Z.D.; supervision, X.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by the Suzhou Key Industry Technology Innovation—Prospective Application Research Project (Grant No. SYG202128), and the Major Projects of Natural Science Research in Colleges and Universities in Jiangsu (Grant No. 24KJA460009) and Qing Lan Project.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rasool, G.; Guo, X.; Wang, Z.; Chen, S.; Ullah, I.; Ali, M.U.; Saifullah, M. Effect of Fertigation Levels on Water Consumption, Soil Total Nitrogen, and Growth Parameters of Brassica Chinensis under Straw Burial. Commun. Soil. Sci. Plant Anal. 2021, 52, 32–44. [Google Scholar] [CrossRef]

- Liu, J.; Xia, C.; Jiang, D.; Sun, Y. Development and Testing of the Power Transmission System of a Crawler Electric Tractor for Greenhouses. Appl. Eng. Agric. 2020, 36, 797–805. [Google Scholar] [CrossRef]

- Li, G.; Nazir, M.M.; Zulfiqar, F.; Siddique, K.H.; Iqbal, B.; Du, D. Harnessing soil carbon sequestration to address climate change challenges in agriculture. Soil. Tillage Res. 2024, 237, 105959. [Google Scholar] [CrossRef]

- Scolaro, E.; Beligoj, M.; Estevez, M.P.; Alberti, L.; Renzi, M.; Mattetti, M. Electrification of Agricultural Machinery: A Review. IEEE Access 2021, 9, 164520–164541. [Google Scholar] [CrossRef]

- Xiao, L.; Liu, J.; Ge, J. Dynamic game in agriculture and industry cross-sectoral water pollution governance in developing countries. Agric. Water Manag. 2021, 243, 106417. [Google Scholar] [CrossRef]

- Puška, A.; Nedeljković, M.; Šarkoćević, Ž.; Golubović, Z.; Ristić, V.; Stojanović, I. Evaluation of Agricultural Machinery Using Multi-Criteria Analysis Methods. Sustainability 2022, 14, 8675. [Google Scholar] [CrossRef]

- Lončarević, Š.; Ilinčić, P.; Šagi, G.; Lulić, Z. Development of a Spatial Tier 2 Emission Inventory for Agricultural Tractors by Combining Two Large-Scale Datasets. Sustainability 2023, 15, 13020. [Google Scholar] [CrossRef]

- Zhang, B.; Bai, T.; Wu, G.; Wang, H.; Zhu, Q.; Zhang, G.; Meng, Z.; Wen, C. Fatigue Analysis of Shovel Body Based on Tractor Subsoiling Operation Measured Data. Agriculture 2024, 14, 1604. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Z.; Ding, S.; Xia, J.; Xing, G. Adaptive disturbance observer-based fixed time nonsingular terminal sliding mode control for path-tracking of unmanned agricultural tractors. Biosyst. Eng. 2024, 246, 96–109. [Google Scholar] [CrossRef]

- Ji, K.; Li, Y.; Liang, Z.; Liu, Y.; Cheng, J.; Wang, H.; Zhu, R.; Xia, S.; Zheng, G. Device and Method Suitable for Matching and Adjusting Reel Speed and Forward Speed of Multi-Crop Harvesting. Agriculture 2022, 12, 213. [Google Scholar] [CrossRef]

- Zhu, Z.; Yang, Y.; Wang, D.; Cai, Y.; Lai, L. Energy Saving Performance of Agricultural Tractor Equipped with Mechanic-Electronic-Hydraulic Powertrain System. Agriculture 2022, 12, 436. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, Y.; Fu, S.; Feng, K.; Han, X.; Hu, Y.; Zhu, Q.; Wei, X. Analysis of Vibration Characteristics of Tractor–Rotary Cultivator Combination Based on Time Domain and Frequency Domain. Agriculture 2024, 14, 1139. [Google Scholar] [CrossRef]

- Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- Jiangyi, H.; Fan, W. Design And Testing of a Small Orchard Tractor Driven By a Power Battery. Eng. Agric. 2023, 43, e20220195. [Google Scholar] [CrossRef]

- Liu, J.; Xia, C.; Jiang, D.; Shang, G.; Han, J.; Sun, Y.; Ye, M. Determination and Application of Maximum Efficiency Curve of Crawler Electric Tractor Motors. Math. Probl. Eng. 2021, 2021, 1310926. [Google Scholar] [CrossRef]

- Jiang, H.; Lin, C. Research on a Method to Measure and Calculate Tillage Resistance of Tractor Mounted Plough. AMA-Agric. Mech. Asia Afr. Lat. A 2020, 50, 38–43. [Google Scholar]

- Troncon, D.; Alberti, L. Case of Study of the Electrification of a Tractor: Electric Motor Performance Requirements and Design. Energies 2020, 13, 2197. [Google Scholar] [CrossRef]

- Zheng, S.; Zhu, X.; Xu, L.; Zhu, T.; Wu, D. Comparative Analysis and Multi-Objective Optimization of Hybrid Permanent Magnet Motors Considering Different Saliency Characteristics. IEEE Trans. Appl. Supercond. 2021, 31, 5205205. [Google Scholar] [CrossRef]

- Magaril, E. Improvement of the environmental and operational characteristics of vehicles through decreasing the motor fuel density. Environ. Sci. Pollut. Res. 2016, 23, 6793–6802. [Google Scholar] [CrossRef]

- Talaat, M.; Arafa, I.; Metwally, H. Advanced automation system for charging electric vehicles based on machine vision and finite element method. IET Electr. Power Appl. 2020, 14, 2616–2623. [Google Scholar] [CrossRef]

- Rajashekara, K. Present Status and Future Trends in Electric Vehicle Propulsion Technologies. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 3–10. [Google Scholar] [CrossRef]

- Jia, C.; Ding, C.; Chen, W. Research on the Diffusion Model of Electric Vehicle Quantity Considering Individual Choice. Energies 2023, 16, 5423. [Google Scholar] [CrossRef]

- Beltrami, D.; Iora, P.; Tribioli, L.; Uberti, S. Electrification of Compact Off-Highway Vehicles—Overview of the Current State of the Art and Trends. Energies 2021, 14, 5565. [Google Scholar] [CrossRef]

- Liu, C.; Gao, N.; Cai, X.; Li, R. Differentiation Power Control of Modules in Second-Life Battery Energy Storage System Based on Cascaded H-Bridge Converter. IEEE Trans. Power Electron. 2019, 35, 6609–6624. [Google Scholar] [CrossRef]

- Damiani, L.; Repetto, M.; Prato, A.P. Improvement of powertrain efficiency through energy breakdown analysis. Appl. Energy 2014, 121, 252–263. [Google Scholar] [CrossRef]

- Liu, X.; Wan, Y.; Dong, Z.; He, M.; Zhou, Q.; Tse, C.K. Buck–Boost–Buck-Type Single-Switch Multistring Resonant LED Driver with High Power Factor and Passive Current Balancing. IEEE Trans. Power Electron. 2019, 35, 5132–5143. [Google Scholar] [CrossRef]

- Li, Y.; Liu, M.; Wang, Y.; Xu, L.; Lei, S. Energy Management Optimization and Validation of a Hydrogen Fuel Cell-Powered Agricultural Tractor Based on Hierarchical Dynamic Programming. IEEE Access 2024, 12, 21382–21401. [Google Scholar] [CrossRef]

- Hipp, E.; Kerschl, S.; Pflanz, T.; Gruber, C. Hydrogen Supplied ICEs and Fuel Cells for Commercial Vehicles. Fuel Cells 2003, 3, 133–140. [Google Scholar] [CrossRef]

- Falahi, M.; Chou, H.-M.; Ehsani, M.; Xie, L.; Butler-Purry, K.L. Potential Power Quality Benefits of Electric Vehicles. IEEE Trans. Sustain. Energy 2013, 4, 1016–1023. [Google Scholar] [CrossRef]

- Situ, L. Electric Vehicle Development: The Past, Present & Future. In Proceedings of the presented at the 2009 3RD International Conference on Power Electronics Systems And Applications: Electric Vehicle And Green Energy, Hong Kong, China, 20–22 May 2009. [Google Scholar]

- Stanislav, F.; Dmitry, I.; Lev, M.; Sergey, B.; Alexander, B. Complete Traction Electric Equipment Sets of Electro-Mechanical Drive Trains for Tractors. In Proceedings of the IEEE Region 8 SIBIRCON-2010, Irkutsk Listvyanka, Russia, 11–15 July 2010. [Google Scholar]

- Xi, Z.Q.; Zhou, Z.L.; Li, Y. Fuzzy control strategy of powershift transmission of tractor. Appl. Mech. Mater. 2013, 241, 1959–1963. [Google Scholar] [CrossRef]

- Tian, X.; Cai, Y.; Sun, X.; Zhu, Z. Collaborative optimization of fuel economy and battery life for plug-in hybrid electric buses considering traffic condition. J. Energy Storage 2024, 90, 111928. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, L.; Zhou, Y.; Pan, B.; Wang, R.; Wang, L.; Yan, X. Energy management strategies for fuel cell hybrid electric vehicles: Classification, comparison, and outlook. Energy Convers. Manag. 2022, 270, 116179. [Google Scholar] [CrossRef]

- Zhang, X.; Mi, C.C.; Masrur, A.; Daniszewski, D. Wavelet-transform-based power management of hybrid vehicles with multiple on-board energy sources including fuel cell, battery and ultracapacitor. J. Power Sources 2008, 185, 1533–1543. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V.; Somà, A. Comparative Analysis of Hybrid Electric Architectures for Specialized Agricultural Tractors. Energies 2022, 15, 1944. [Google Scholar] [CrossRef]

- Zhu, Z.; Sheng, J.; Zhang, H.; Wang, D.; Chen, L. Optimization and Analysis of Clutch Switching Timing for Hybrid Tractors Equipped with Hydraulic Mechanical Combined Transmission. Appl. Sci. 2024, 14, 4914. [Google Scholar] [CrossRef]

- Zhu, Z.; Lai, L.; Sun, X.; Chen, L.; Cai, Y. Design and Analysis of a Novel Mechanic- Electronic-Hydraulic Powertrain System for Agriculture Tractors. IEEE Access 2021, 9, 153811–153823. [Google Scholar] [CrossRef]

- Ducusin, M.; Gargies, S.; Berhanu, B.; Mi, C. Modeling of a Series Hybrid Electric High-Mobility Multipurpose Wheeled Vehicle. IEEE Trans. Veh. Technol. 2007, 56, 557–565. [Google Scholar] [CrossRef]

- Vinot, E.; Trigui, R.; Cheng, Y.; Espanet, C.; Bouscayrol, A.; Reinbold, V. Improvement of an EVT-Based HEV Using Dynamic Programming. IEEE Trans. Veh. Technol. 2014, 63, 40–50. [Google Scholar] [CrossRef]

- Fajri, P.; Ferdowsi, M.; Lotfi, N.; Landers, R. Development of an Educational Small-Scale Hybrid Electric Vehicle (HEV) Setup. IEEE Intell. Transp. Syst. Mag. 2016, 8, 8–21. [Google Scholar] [CrossRef]

- Luo, C.; Shen, Z.; Evangelou, S.; Xiong, G.; Wang, F.-Y. The combination of two control strategies for series hybrid electric vehicles. IEEE/CAA J. Autom. Sin. 2019, 6, 596–608. [Google Scholar] [CrossRef]

- Gao, Y.; Ehsani, M. Parametric design of the traction motor and energy storage for series hybrid off-road and military vehicles. IEEE Trans. Power Electron. 2006, 21, 749–755. [Google Scholar] [CrossRef]

- Kumar, A.; Thakura, P.R. ADVISOR-Based Performance Analysis of a Hybrid Electric Vehicle and Comparison with a Conventional Vehicle. IETE J. Res. 2023, 69, 753–761. [Google Scholar] [CrossRef]

- Harmon, F.G.; Frank, A.A.; Joshi, S.S. The control of a parallel hybrid-electric propulsion system for a small unmanned aerial vehicle using a CMAC neural network. Neural Netw. 2005, 18, 772–780. [Google Scholar] [CrossRef]

- Cao, Y.; Yao, M.; Sun, X. An Overview of Modelling and Energy Management Strategies for Hybrid Electric Vehicles. Appl. Sci. 2023, 13, 5947. [Google Scholar] [CrossRef]

- Enang, W.; Bannister, C. Modelling and control of hybrid electric vehicles (A comprehensive review). Renew. Sustain. Energy Rev. 2017, 74, 1210–1239. [Google Scholar] [CrossRef]

- Ehsani, M.; Gao, Y.; Miller, J.M. Hybrid Electric Vehicles: Architecture and Motor Drives. Proc. IEEE 2007, 95, 719–728. [Google Scholar] [CrossRef]

- Borhan, H.A.; Vahidi, A.; Phillips, A.M.; Kuang, M.L.; Kolmanovsky, I.V. Predictive Energy Management of a Power-Split Hybrid Electric Vehicle. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10 July 2009; pp. 1–9. [Google Scholar]

- Munsi, M.S.; Chaoui, H. Energy Management Systems for Electric Vehicles: A Comprehensive Review of Technologies and Trends. IEEE Access 2024, 12, 60385–60403. [Google Scholar] [CrossRef]

- Rind, S.J.; Ren, Y.; Hu, Y.; Wang, J.; Jiang, L. Configurations and Control of Traction Motors for Electric Vehicles: A Review. Chin. J. Electr. Eng. 2017, 3, 1–17. [Google Scholar] [CrossRef]

- Tran, D.-D.; Vafaeipour, M.; El Baghdadi, M.; Barrero, R.; Van Mierlo, J.; Hegazy, O. Thorough state-of-the-art analysis of electric and hybrid vehicle powertrains: Topologies and integrated energy management strategies. Renew. Sustain. Energy Rev. 2020, 119, 109596. [Google Scholar] [CrossRef]

- Wei, C.; Sun, X.; Chen, Y.; Zang, L.; Bai, S. Comparison of architecture and adaptive energy management strategy for plug-in hybrid electric logistics vehicle. Energy 2021, 230, 120858. [Google Scholar] [CrossRef]

- Shi, Z.; Sun, X.; Lei, G.; Yang, Z.; Guo, Y.; Zhu, J. Analysis and Optimization of Radial Force of Permanent-Magnet Synchronous Hub Motors. IEEE Trans. Magn. 2020, 56, 7508804. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, Y.; Liu, K.; Wang, G.; Song, Y.; Chakrabarti, P. Shifting quality analysis of unmanned tractor equipped with series hydro-mechanical transmission. Trans. Can. Soc. Mech. Eng. 2024, 48, 221–237. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V. Numerical Performance Investigation of a Hybrid eCVT Specialized Agricultural Tractor. Appl. Sci. 2022, 12, 2438. [Google Scholar] [CrossRef]

- Li, X.; Liu, M.; Xu, L.; Zhang, M.; Yan, X. Design and Test of Tractor Serial Hydraulic and Mechanical Hybrid Transmission System. Trans. Chin. Soc. Agric. Mach. 2022, 53, 406–413. [Google Scholar]

- Nino-Baron, C.E.; Tariq, A.R.; Zhu, G.; Strangas, E.G. Trajectory Optimization for the Engine–Generator Operation of a Series Hybrid Electric Vehicle. IEEE Trans. Veh. Technol. 2011, 60, 2438–2447. [Google Scholar] [CrossRef]

- Corno, M.; Roselli, F.; Savaresi, S.M. Bilateral Control of SeNZA—A Series Hybrid Electric Bicycle. IEEE Trans. Control. Syst. Technol. 2017, 25, 864–874. [Google Scholar] [CrossRef]

- Hofman, T.Z. Framework for Combined Control and Design Optimization of Hybrid Vehicle Propulsion Systems. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2007. [Google Scholar]

- Zhu, Z.; Chai, X.; Xu, L.; Quan, L.; Yuan, C.; Tian, S. Design and performance of a distributed electric drive system for a series hybrid electric combine harvester. Biosyst. Eng. 2023, 236, 160–174. [Google Scholar] [CrossRef]

- Lee, D.-H.; Kim, Y.-J.; Choi, C.-H.; Chung, S.-O.; Inoue, E.; Okayasu, T. Development of a Parallel Hybrid System for Agricultural Tractors. J. Fac. Agric. Kyushu Univ. 2017, 62, 137–144. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Łyp-Wrońska, K.; Gdowska, K.; Paciolla, F. Sustainability Evaluation of Hybrid Agriculture-Tractor Powertrains. Sustainability 2024, 16, 1184. [Google Scholar] [CrossRef]

- Li, H.; Song, Z.H.; Xie, B. Plowing Performance Simulation and Analysis for Hybrid Electric Tractor. Appl. Mech. Mater. 2013, 365–366, 505–511. [Google Scholar] [CrossRef]

- Kim, Y.J.; Song, B.; Kim, J. Load torque estimation for a parallel hybrid agricultural tractor in field operations. Int. J. Precis. Eng. Manuf. 2013, 14, 1865–1868. [Google Scholar] [CrossRef]

- Linares, P.; Méndez, V.; Catalán, H. Design parameters for continuously variable power-split transmissions using planetaries with 3 active shafts. J. Terramechanics 2010, 47, 323–335. [Google Scholar] [CrossRef]

- Savaresi, S.M.; Taroni, F.; Prevedi, F.; Bittanti, S. On the design and tuning of the controllers in a power-split continuously variable transmission for agricultural tractors. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2003, 217, 745–759. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, Y.; Song, Y.; Xue, L.; Chen, X. Optimizing the fuel economy of hydrostatic power-split system in continuously variable tractor transmission. Heliyon 2023, 9, e15915. [Google Scholar] [CrossRef]

- Goswami, G.; Jaiswal, S.; Nutakor, C.; Sopanen, J. Co-Simulation Platform for Simulating Heavy Mobile Machinery With Hydraulic Actuators and Various Hybrid Electric Powertrains. IEEE Access 2022, 10, 105770–105785. [Google Scholar] [CrossRef]

- Cong, C.; Guangqiao, C.; Jinlong, Z.; Jianping, H. Dynamic Monitoring Of Harvester Working Progress Based On Traveling Trajectory And Header Status. Eng. Agric. 2023, 43, e20220196. [Google Scholar] [CrossRef]

- Han, J.; Yan, X.; Tang, H. Method of controlling tillage depth for agricultural tractors considering engine load characteristics. Biosyst. Eng. 2023, 227, 95–106. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, H.; Liu, S.; Lu, D.; Tang, Y. Development of Structure and Control System of Self-Propelled Small Green Vegetables Combine Harvester. J. Agric. Sci. Technol. 2023, 25, 1045–1058. [Google Scholar]

- Cordiner, S.; Galeani, S.; Mecocci, F.; Mulone, V.; Zaccarian, L. Torque Setpoint Tracking for Parallel Hybrid Electric Vehicles Using Dynamic Input Allocation. IEEE Trans. Control. Syst. Technol. 2014, 22, 2007–2015. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Guo, Q. Varying-Domain Optimal Management Strategy for Parallel Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2014, 63, 603–616. [Google Scholar] [CrossRef]

- Tian, X.; Cai, Y.; Sun, X.; Zhu, Z.; Xu, Y. An adaptive ECMS with driving style recognition for energy optimization of parallel hybrid electric buses. Energy 2019, 189, 116151. [Google Scholar] [CrossRef]

- Mohebbi, M.; Charkhgard, M.; Farrokhi, M. Optimal Neuro-Fuzzy Control of Parallel Hybrid Electric Vehicles. In Proceedings of the 2005 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 7 September 2005. [Google Scholar]

- Boyali, A.; Demirci, M.; Acarman, T.; Guvenc, L.; Tur, O.; Ucarol, H.; Kiray, B.; Ozatay, E. Modeling and Control of a Four Wheel Drive Parallel Hybrid Electric Vehicle. In Proceedings of the 2006 IEEE Conference on Computer Aided Control System Design, 2006 IEEE International Conference on Control Applications, 2006 IEEE International Symposium on Intelligent Control, Munich, Germany, 4–6 October 2006; pp. 155–162. [Google Scholar]

- Sun, X.; Dong, Z.; Jin, Z.; Tian, X. System-Level Energy Management Optimization Based on External Information for Power-Split Hybrid Electric Buses. IEEE Trans. Ind. Electron. 2024, 71, 14449–14459. [Google Scholar] [CrossRef]

- Jia, C.; Qiao, W.; Qu, L. Modeling and Control of Hybrid Electric Vehicles: A Case Study for Agricultural Tractors. In Proceedings of the 2018 IEEE Vehicle Power and Propulsion Conference (VPPC), Chicago, IL, USA, 27–30 August 2018; pp. 1–6. [Google Scholar]

- Vu, N.-L.; Messier, P.; Nguyễn, B.-H.; Vo-Duy, T.; Trovão, J.P.F.; Desrochers, A.; Rodrigues, A. Energy-optimization design and management strategy for hybrid electric non-road mobile machinery: A case study of snowblower. Energy 2023, 284, 129249. [Google Scholar] [CrossRef]

- Lee, H.-S.; Kim, J.-S.; Park, Y.-I.; Cha, S.-W. Rule-based power distribution in the power train of a parallel hybrid tractor for fuel savings. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 231–237. [Google Scholar] [CrossRef]

- Lombardi, S.; Di Ilio, G.; Tribioli, L.; Jannelli, E. Optimal design of an adaptive energy management strategy for a fuel cell tractor operating in ports. Appl. Energy 2023, 352, 121917. [Google Scholar] [CrossRef]

- Choi, S.; Song, B.; Kim, Y. Torque Assist Strategy for Hybrid Agricultural Tractor with Consideration of Field Operations. Trans. Korean Soc. Mech. Eng. A 2014, 38, 593–600. [Google Scholar] [CrossRef]

- Kang, H.; Jung, D.; Kim, M.; Min, K. Study of Energy Management Strategy Considering Various Working Modes of Plug-in Hybrid Electric Tractor. Trans. Korean Soc. Mech. Eng. B 2013, 37, 181–186. [Google Scholar] [CrossRef]

- Xu, W.; Liu, M.; Xu, L.; Zhang, S. Energy Management Strategy of Hydrogen Fuel Cell/Battery/Ultracapacitor Hybrid Tractor Based on Efficiency Optimization. Appl. Sci. 2023, 13, 151. [Google Scholar] [CrossRef]

- Chen, J.; Ning, X.; Li, Y.; Yang, G.; Wu, P.; Chen, S. A Fuzzy Control Strategy for the Forward Speed of a Combine Harvester Based on KDD. Appl. Eng. Agric. 2017, 33, 15–22. [Google Scholar] [CrossRef]

- Diba, F.; Esmailzadeh, E. Development of hybrid electric heavy-duty truck with self-propelled trailer. Int. J. Heavy Veh. Syst. 2018, 25, 203–222. [Google Scholar] [CrossRef]

- Yang, H.; Sun, Y.; Xia, C.; Zhang, H. Research on Energy Management Strategy of Fuel Cell Electric Tractor Based on Multi-Algorithm Fusion and Optimization. Energies 2022, 15, 6389. [Google Scholar] [CrossRef]

- Zhu, Z.; Sheng, J.; Zhang, H.; Wang, D.; Chen, L. Optimization of Mode-Switching Quality of Hybrid Tractor Equipped with HMCVT. Appl. Sci. 2024, 14, 6288. [Google Scholar] [CrossRef]

- Ghobadpour, A.; Mousazadeh, H.; Kelouwani, S.; Zioui, N.; Kandidayeni, M.; Boulon, L. An intelligent energy management strategy for an off-road plug-in hybrid electric tractor based on farm operation recognition. IET Electr. Syst. Transp. 2021, 11, 333–347. [Google Scholar] [CrossRef]

- Zhang, R.; Tao, J.; Zhou, H. Fuzzy Optimal Energy Management for Fuel Cell and Supercapacitor Systems Using Neural Network Based Driving Pattern Recognition. IEEE Trans. Fuzzy Syst. 2019, 27, 45–57. [Google Scholar] [CrossRef]

- Tian, X.; He, R.; Sun, X.; Cai, Y.; Xu, Y. An ANFIS-Based ECMS for Energy Optimization of Parallel Hybrid Electric Bus. IEEE Trans. Veh. Technol. 2020, 69, 1473–1483. [Google Scholar] [CrossRef]

- Bellman, R.E. Dynamic Programming; Princeton University Press: Princeton, NJ, USA, 1957. [Google Scholar]

- Cui, L.; Mao, H.; Xue, X.; Ding, S.; Qiao, B. Design optimization and test for a pendulum suspension of the crop sprayer boom in dynamic conditions based on a six DOF motion simulator. Int. J. Agric. Biol. Eng. 2018, 11, 76–85. [Google Scholar] [CrossRef]

- Yuan, L.-M.; Cai, J.-R.; Sun, L.; Han, E.; Ernest, T. Nondestructive Measurement of Soluble Solids Content in Apples by a Portable Fruit Analyzer. Food Anal. Methods 2016, 9, 785–794. [Google Scholar] [CrossRef]

- Zhu, Y.; Zou, X.; Shen, T.; Shi, J.; Zhao, J.; Holmes, M.; Li, G. Determination of total acid content and moisture content during solid-state fermentation processes using hyperspectral imaging. J. Food Eng. 2016, 174, 75–84. [Google Scholar] [CrossRef]

- Zhang, H.D.; Shi, D.H.; Cai, Y.F.; Zhou, W.Q.; Yang, H.T. Research on Transmission Efficiency Oriented Predictive Control of Power Split Hybrid Electric Vehicle. Math. Probl. Eng. 2020, 2020, 7024740. [Google Scholar]

- Zhang, K.; Deng, X.; Lu, Z.; Wang, T. Research on the Energy Management Strategy of a Hybrid Tractor OS-ECVT Based on a Dynamic Programming Algorithm. Agriculture 2024, 14, 1658. [Google Scholar] [CrossRef]

- Schmid, R.; Buerger, J.; Bajcinca, N. Energy management for series-production plug-in-hybrid electric vehicles based on predictive DP-PMP. Auto 2021, 69, 52–64. [Google Scholar] [CrossRef]

- Chen, J.; He, H.; Wang, Y.X.; Quan, S.; Zhang, Z.; Wei, Z.; Han, R. Research on Energy Management Strategy for Fuel Cell Hybrid Electric Vehicles Based on Improved Dynamic Programming and Air Supply Optimization. Energy 2024, 300, 131567. [Google Scholar] [CrossRef]

- Dong, H.; Zhao, L.; Zhou, H.; Li, H. Hierarchical Optimization Based on Deep Reinforcement Learning for Connected Fuel Cell Hybrid Vehicles through Signalized Intersections. Processes 2023, 11, 2689. [Google Scholar] [CrossRef]

- Li, W.; Wang, C.; Pei, H.; Xu, C.; Lin, G.; Deng, J.; Jiang, D.; Huang, Y. An Improved Energy Management Strategy of Diesel-Electric Hybrid Propulsion System Based on FNN-DP Strategy. Electronics 2023, 12, 486. [Google Scholar] [CrossRef]

- Shen, Z.; Luo, C.; Dong, X.; Lu, W.; Lv, Y.; Xiong, G.; Wang, F.-Y. Two-Level Energy Control Strategy Based on ADP and A-ECMS for Series Hybrid Electric Vehicles. IEEE Trans. Intell. Transp. Syst. 2022, 23, 13178–13189. [Google Scholar] [CrossRef]

- Sun, X.; Cao, Y.; Jin, Z.; Tian, X.; Xue, M. An Adaptive ECMS Based on Traffic Information for Plug-in Hybrid Electric Buses. IEEE Trans. Ind. Electron. 2022, 70, 9248–9259. [Google Scholar] [CrossRef]

- Sun, X.; Xue, M.; Cai, Y.; Tian, X.; Jin, Z.; Chen, L. Adaptive ECMS Based on EF Optimization by Model Predictive Control for Plug-In Hybrid Electric Buses. IEEE Trans. Transp. Electrif. 2022, 9, 2153–2163. [Google Scholar] [CrossRef]

- Sun, X.; Jin, Z.; Xue, M.; Tian, X. Adaptive ECMS With Gear Shift Control by Grey Wolf Optimization Algorithm and Neural Network for Plug-In Hybrid Electric Buses. IEEE Trans. Ind. Electron. 2024, 71, 667–677. [Google Scholar] [CrossRef]