Reinjection of Produced Water into Formations in Unconventional Gas Reservoirs

Abstract

1. Introduction

2. Overview of Produced-Water Treatment in Gas Fields

2.1. Produced Water in Gas Fields

2.2. Methods for Treating Produced Water in Gas Fields

2.2.1. Reinjection into Formations

2.2.2. Compliant Discharge After Meeting Regulatory Standards

2.2.3. Resource Utilization

- 1.

- Internal reuse

- 2.

- External reuse

- 3.

- Recycling of Valuable Components

2.3. Applications of Produced-Water Reinjection in Gas Fields

3. Research on the Reinjection of Produced Water into Formations in Gas Fields

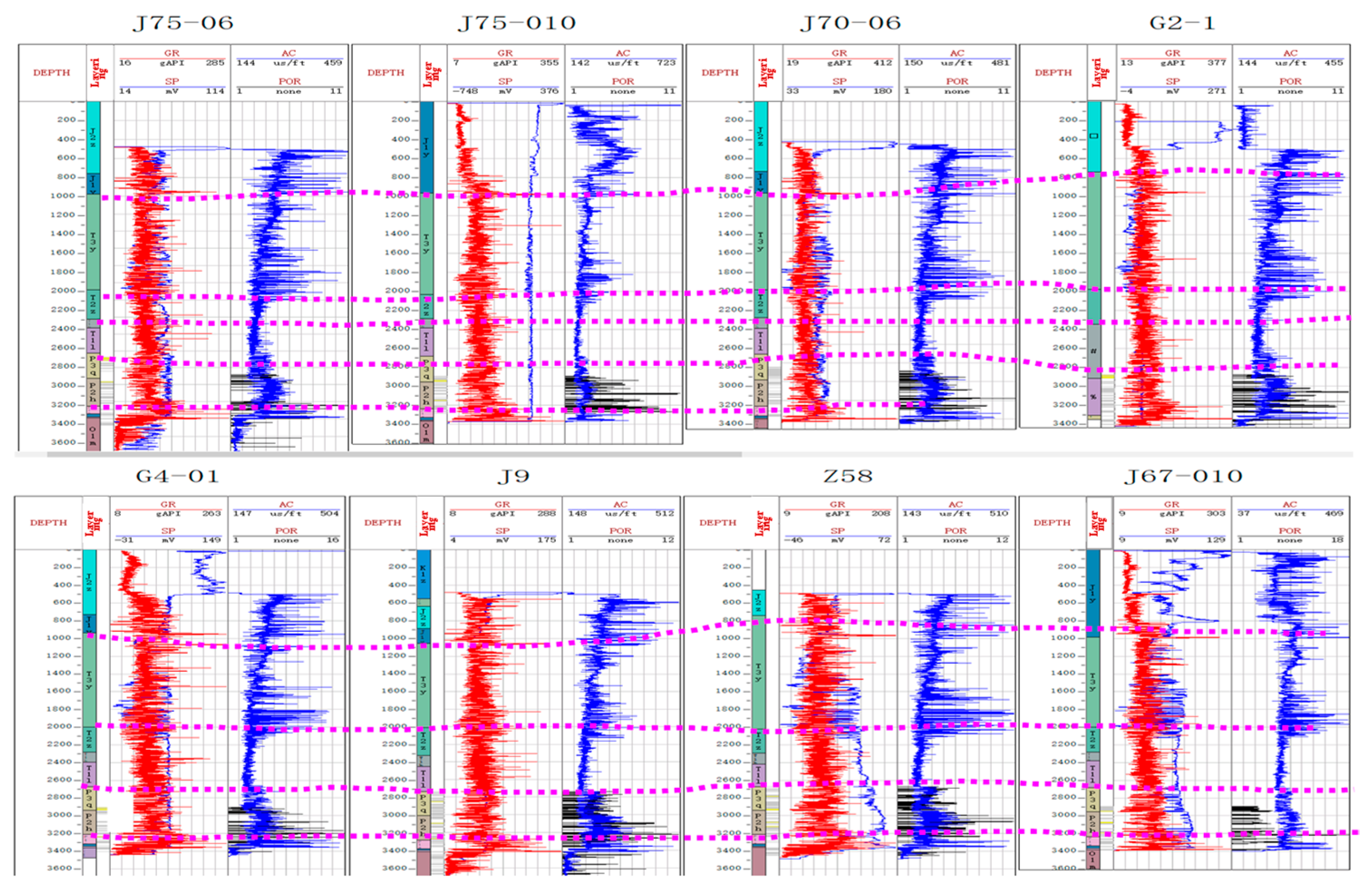

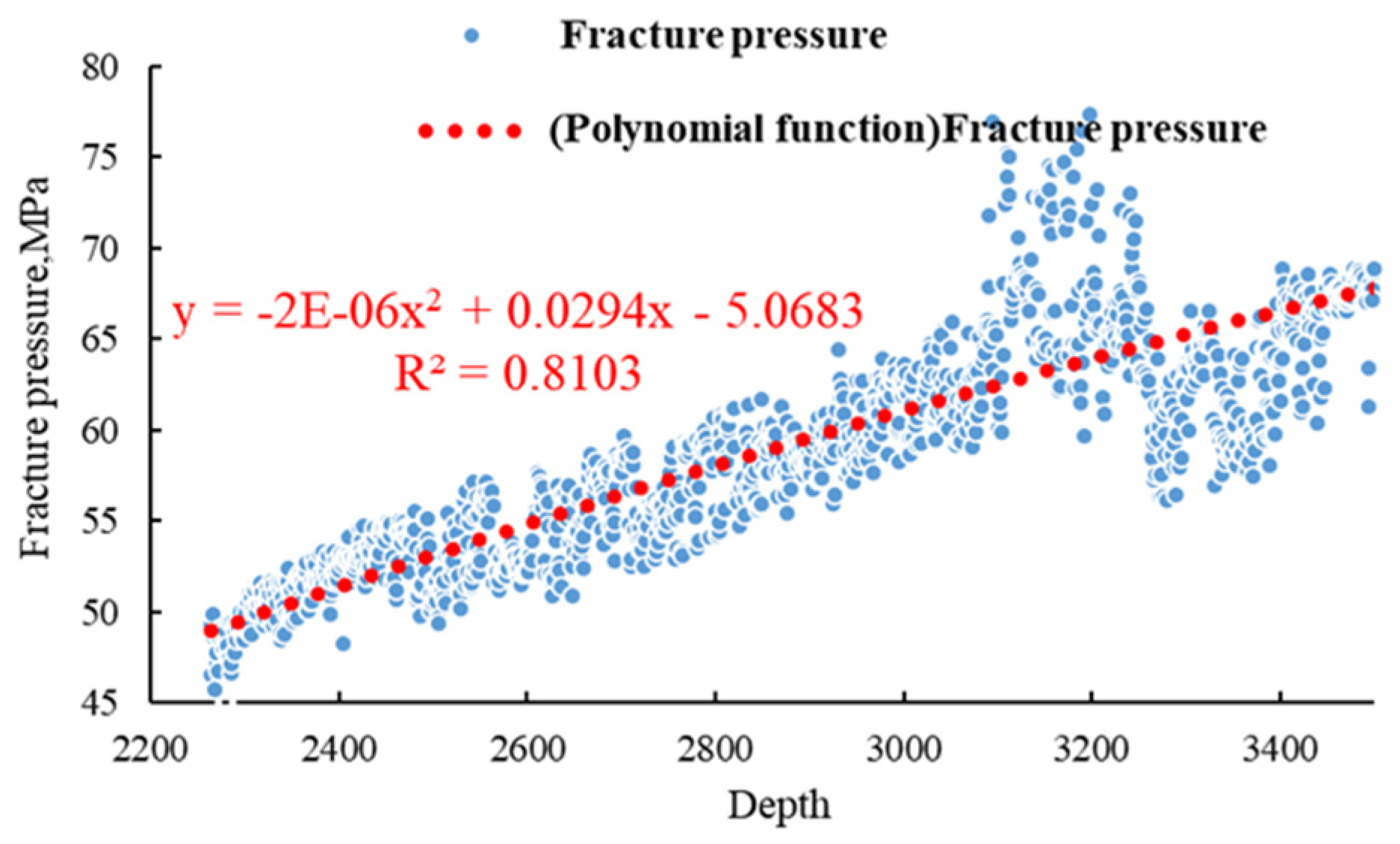

3.1. Criteria for Reinjection Layer Selection

3.2. Formation Selection Analysis for Produced-Water Reinjection

4. Numerical Simulation of Produced-Water Reinjection in Gas Fields

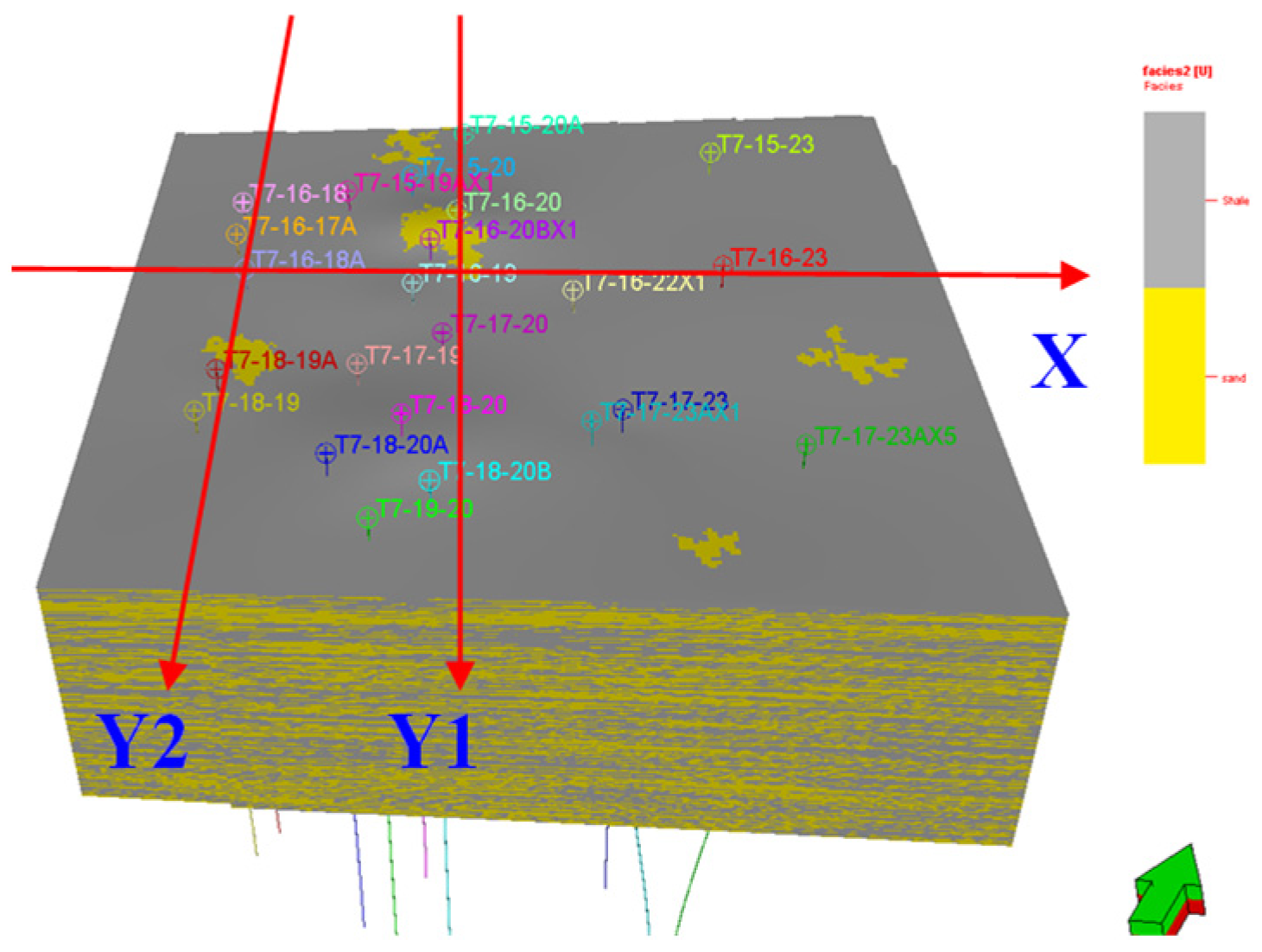

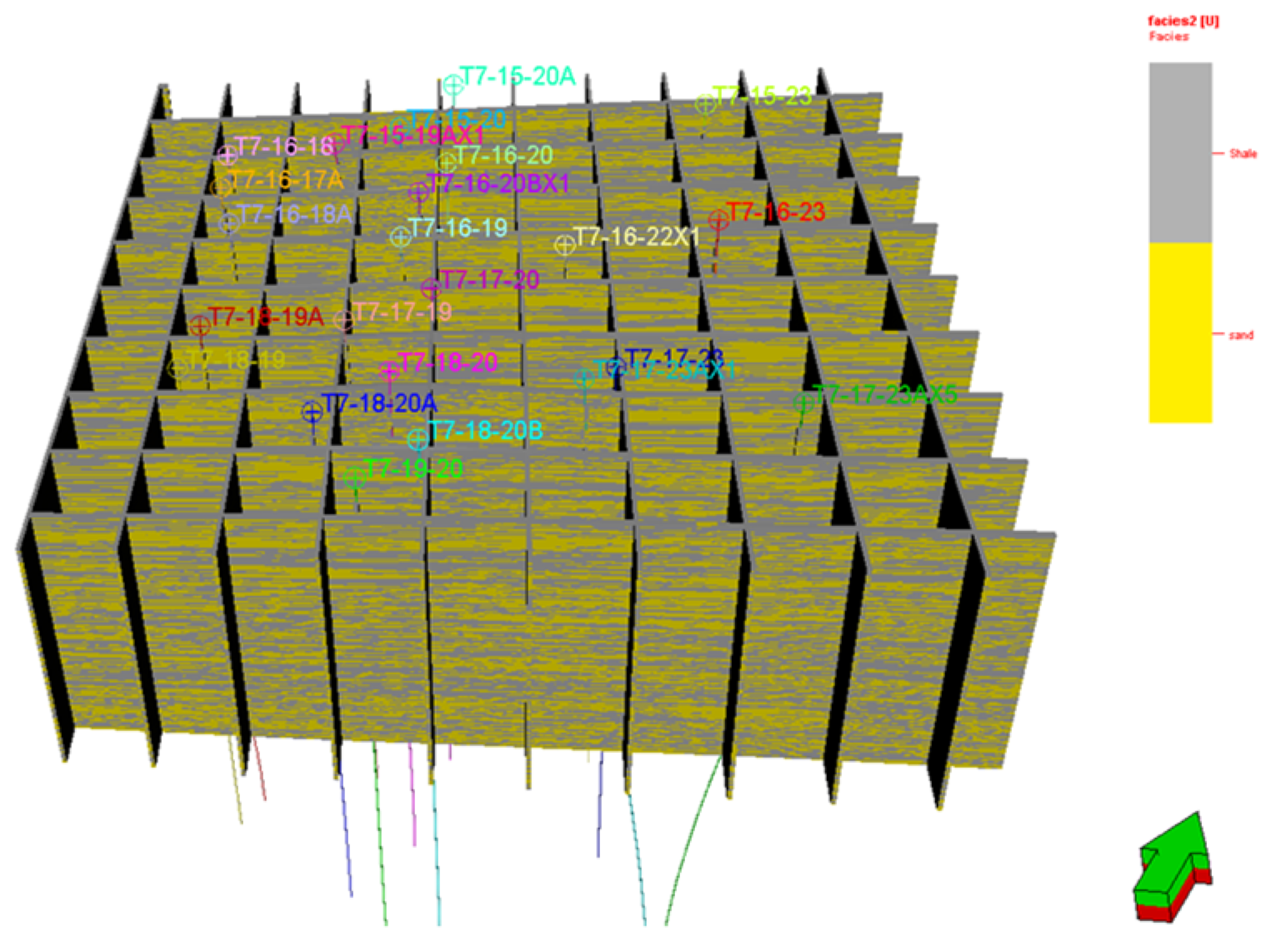

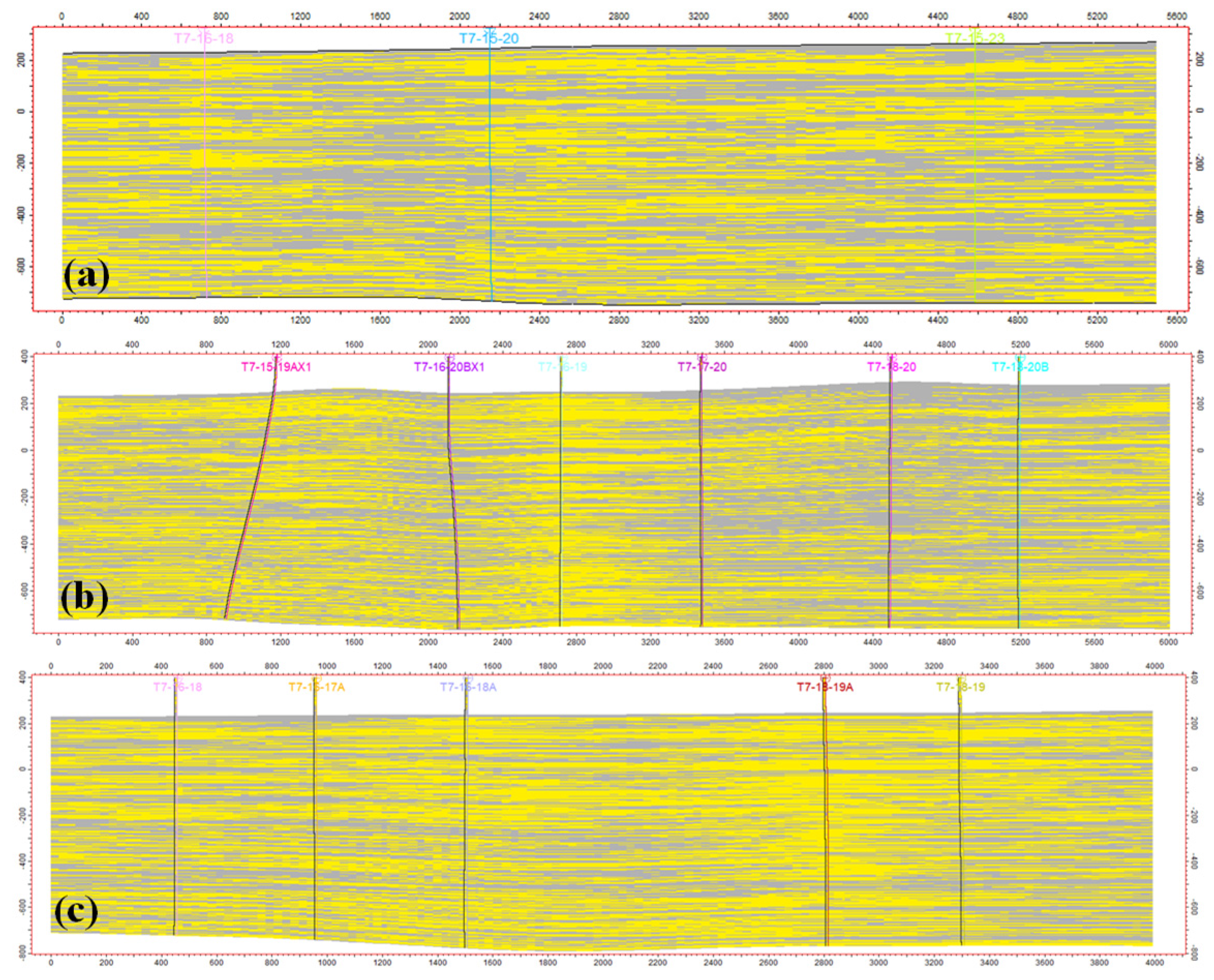

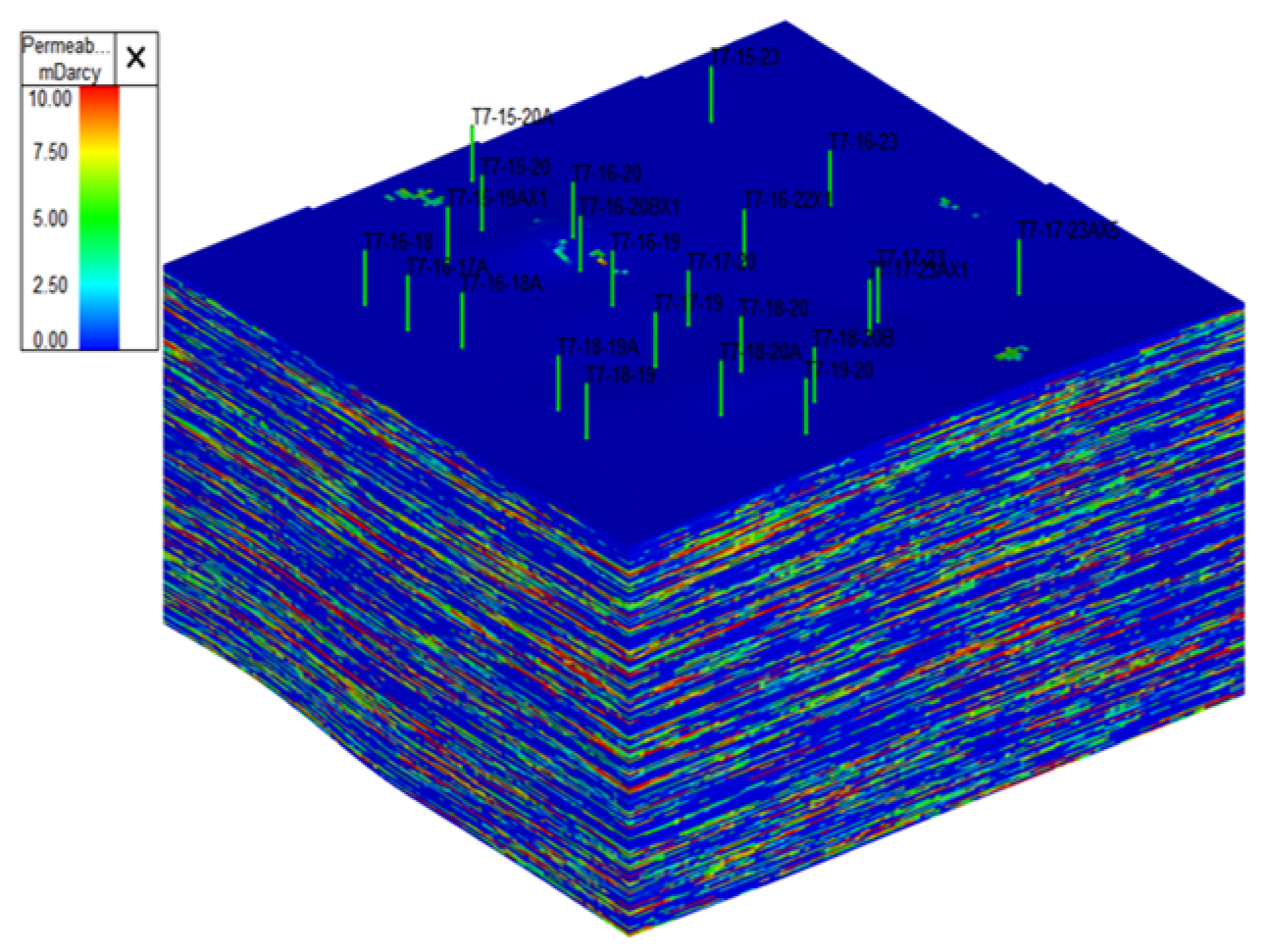

4.1. Three-Dimensional Geological Model

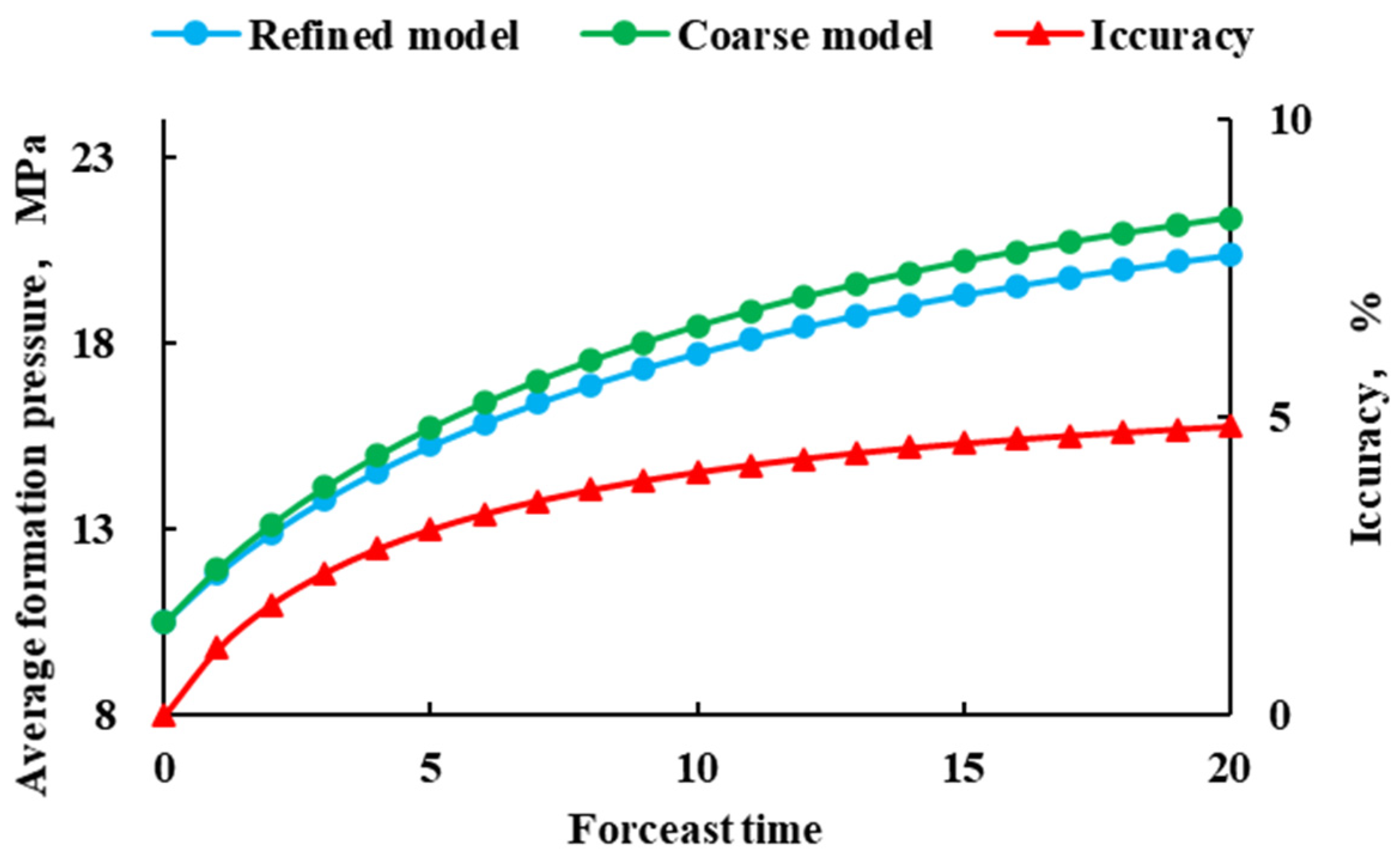

4.2. Three-Dimensional Numerical Modeling

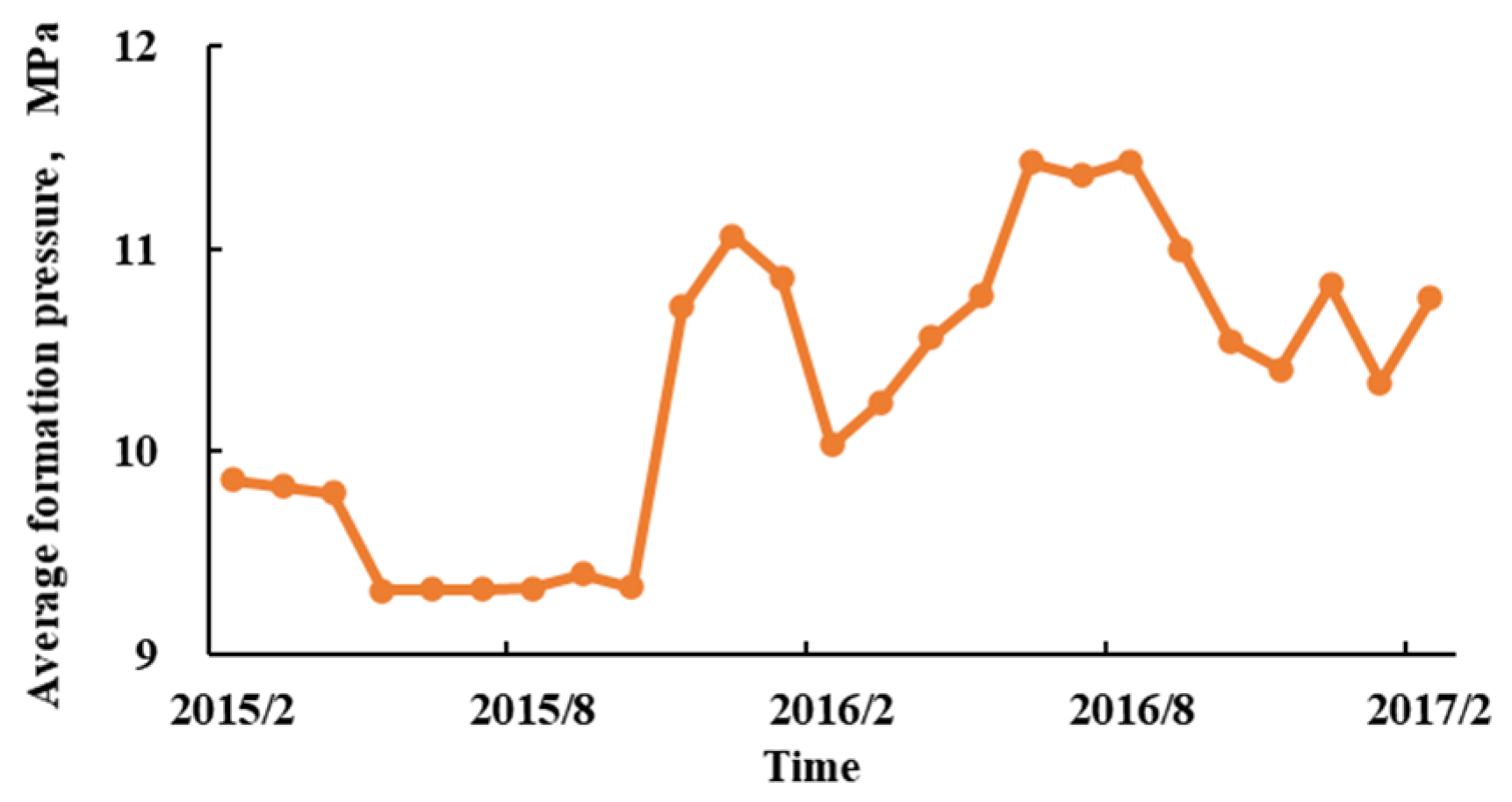

4.3. Extracted Water Reinjection Simulation Program

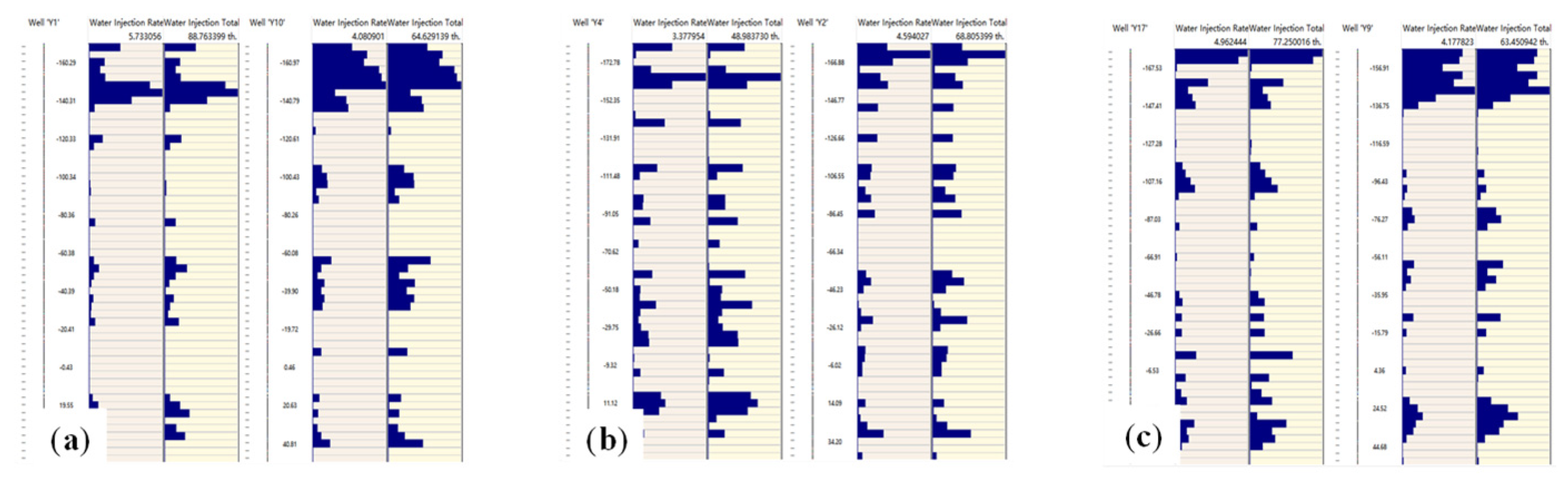

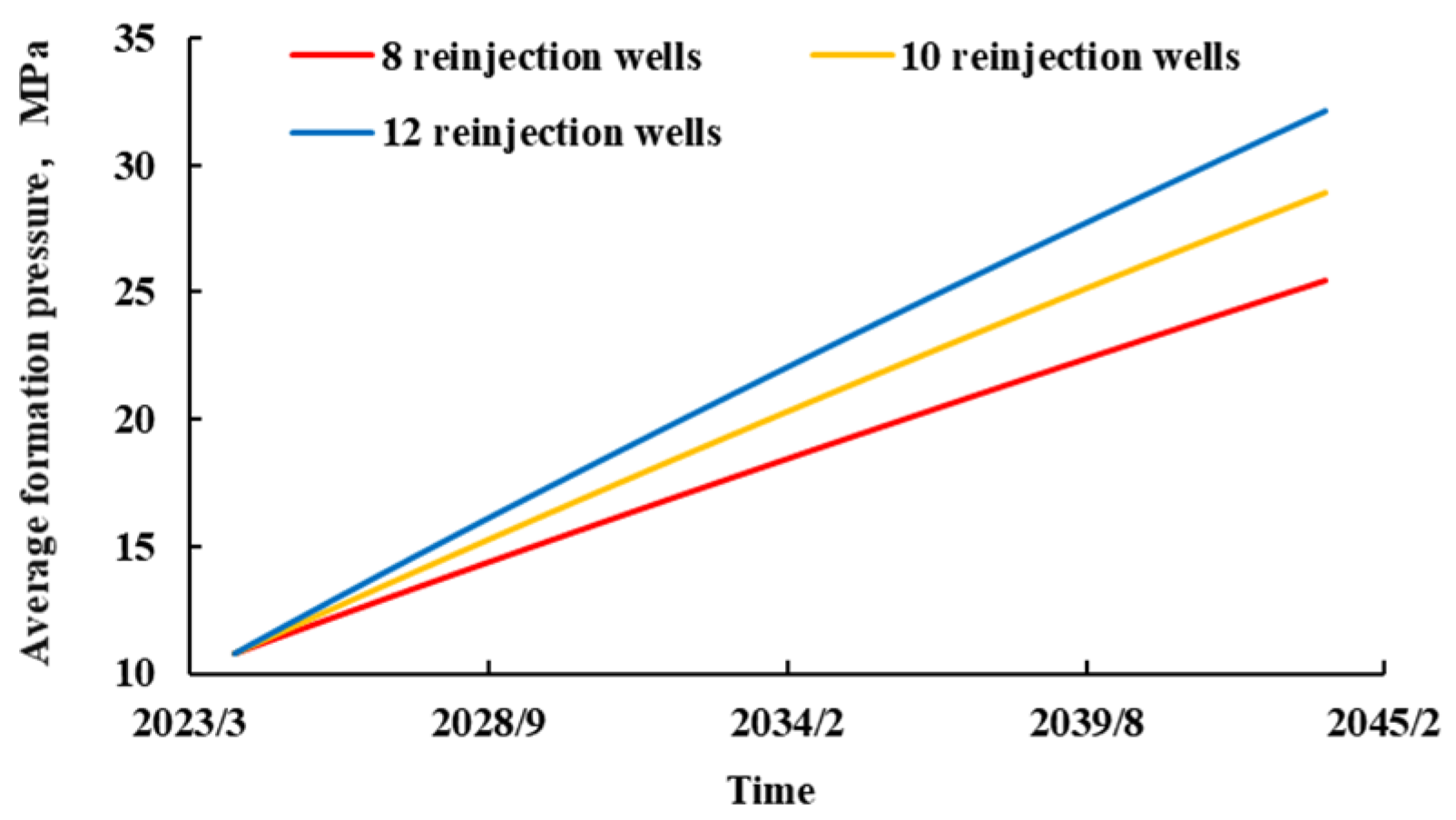

4.3.1. Preferred Number of Wells in Group A

4.3.2. Group B Daily Injection Volume Preference

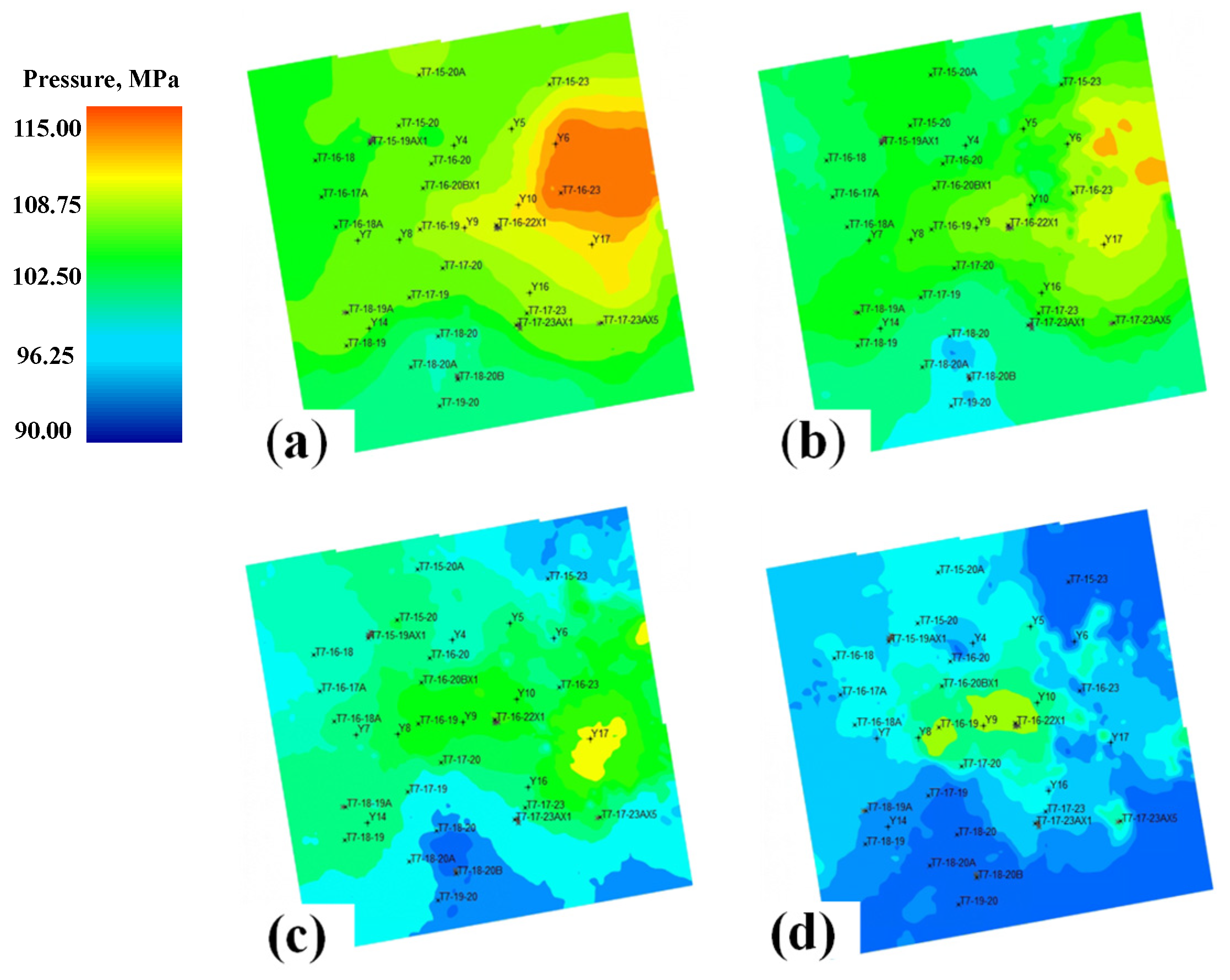

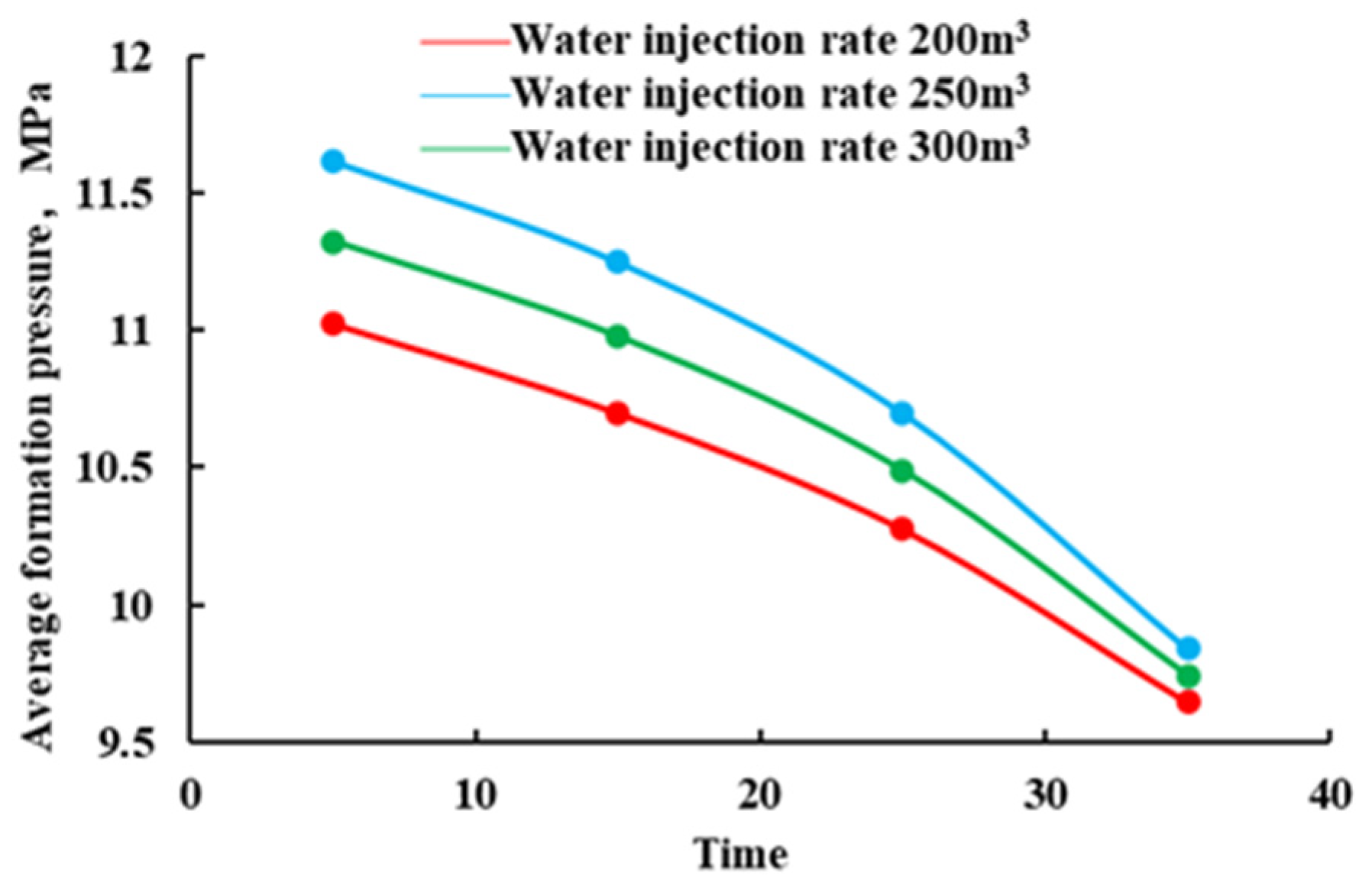

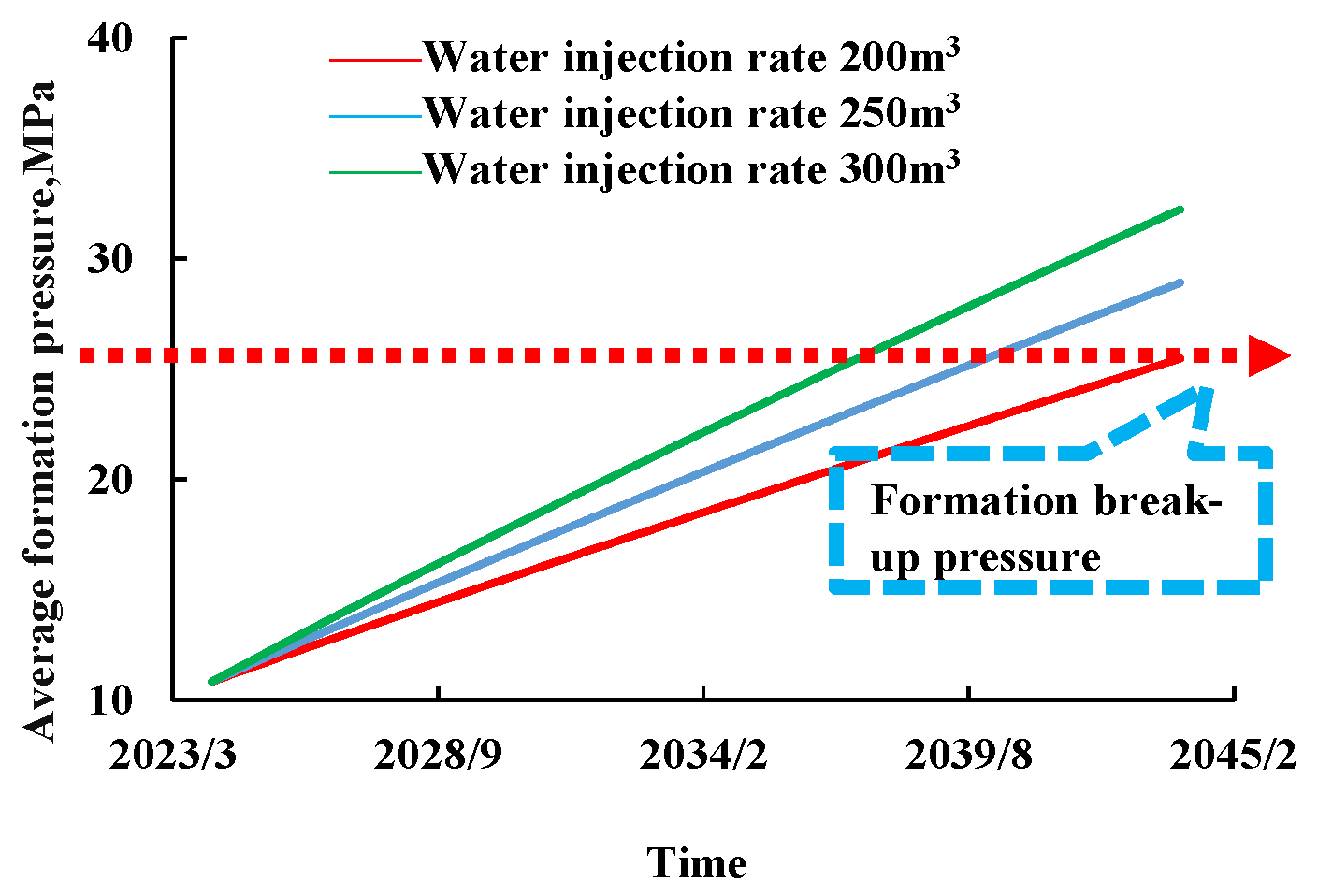

- Pressure distribution in the overlying strata

- 2.

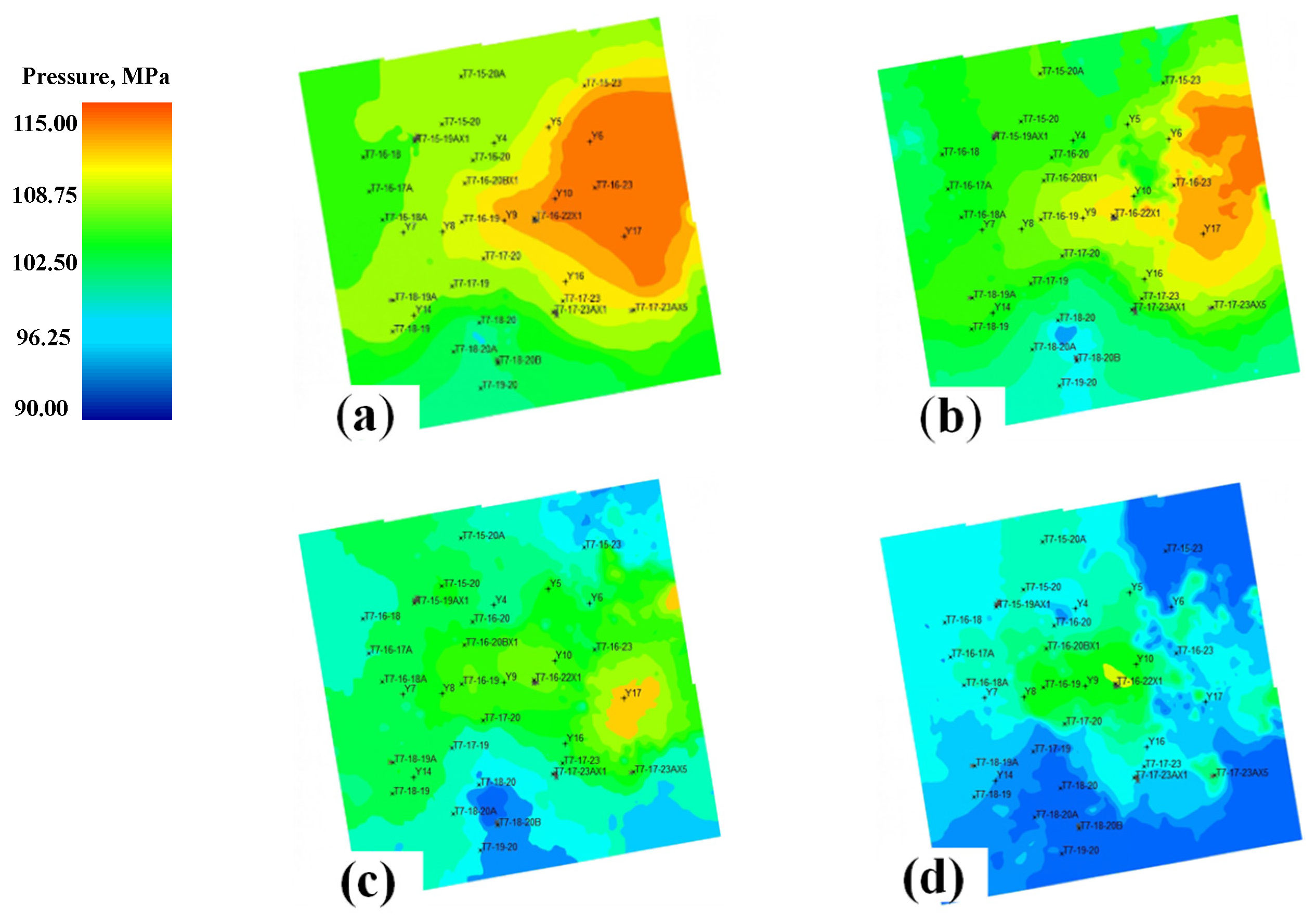

- Stratigraphic Pressure Distribution in the Reinjection Layer

- 3.

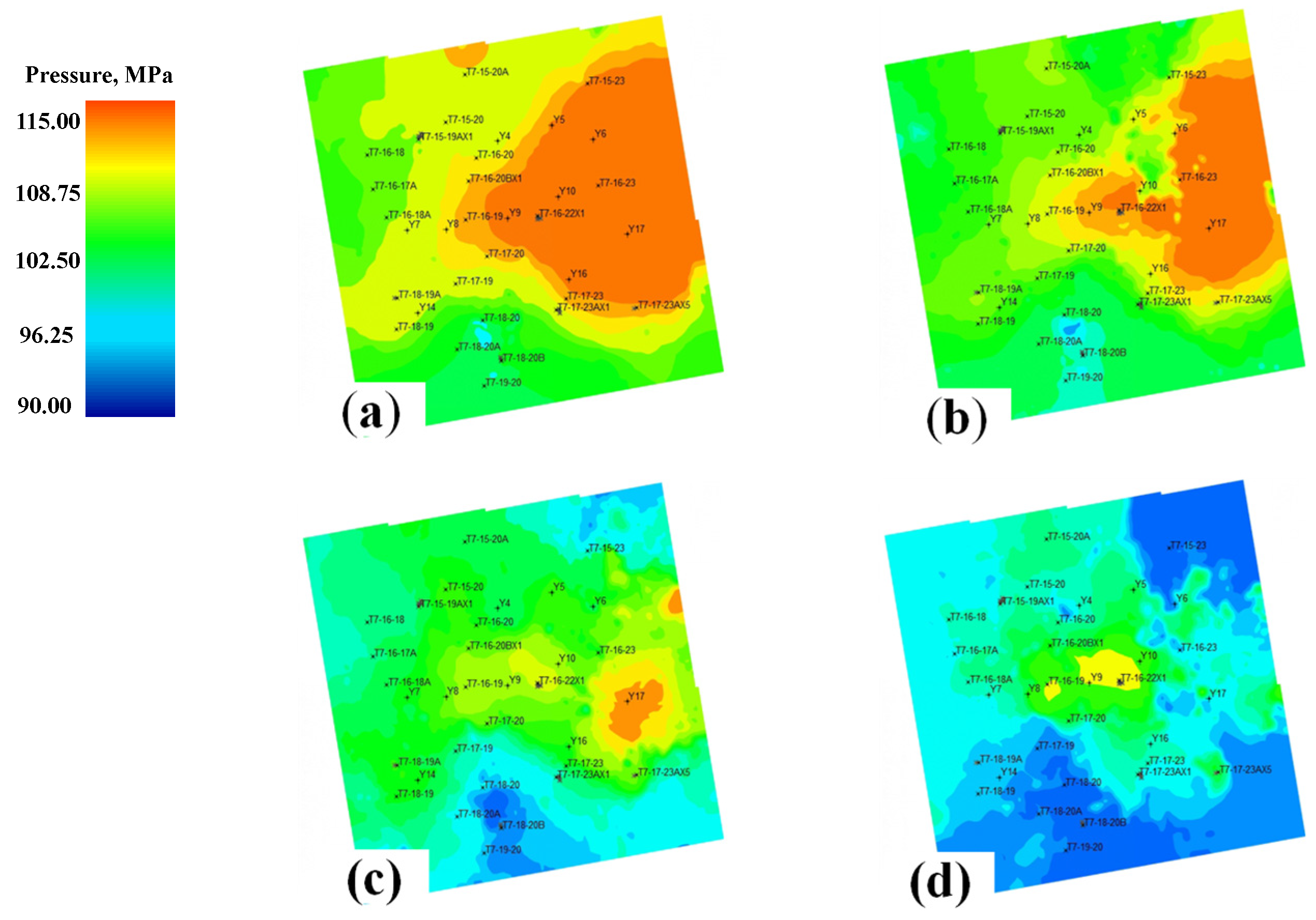

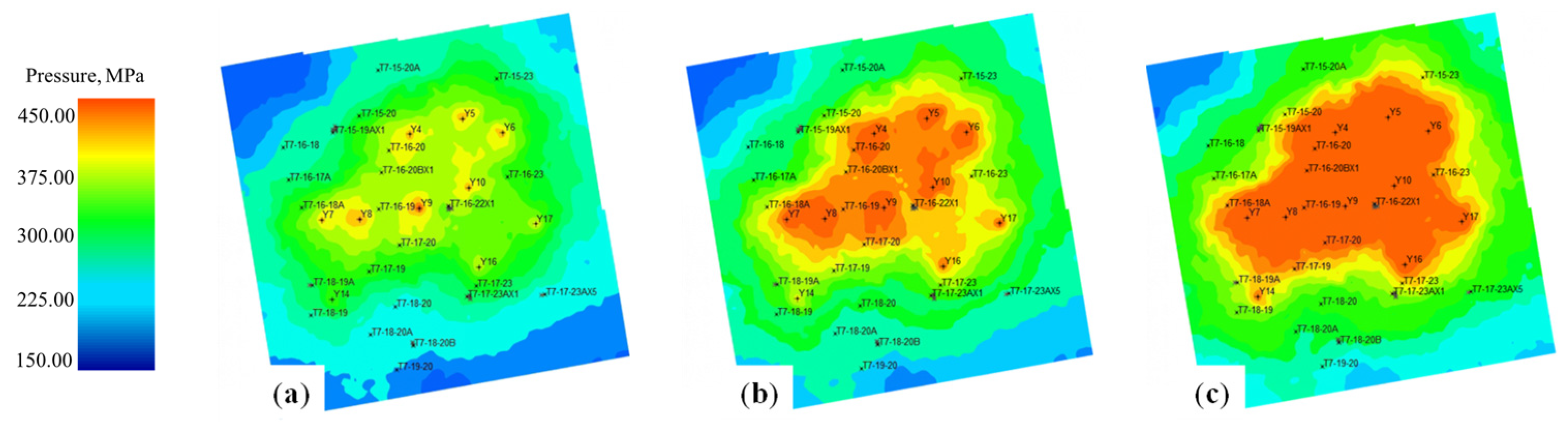

- Reinjection water extent

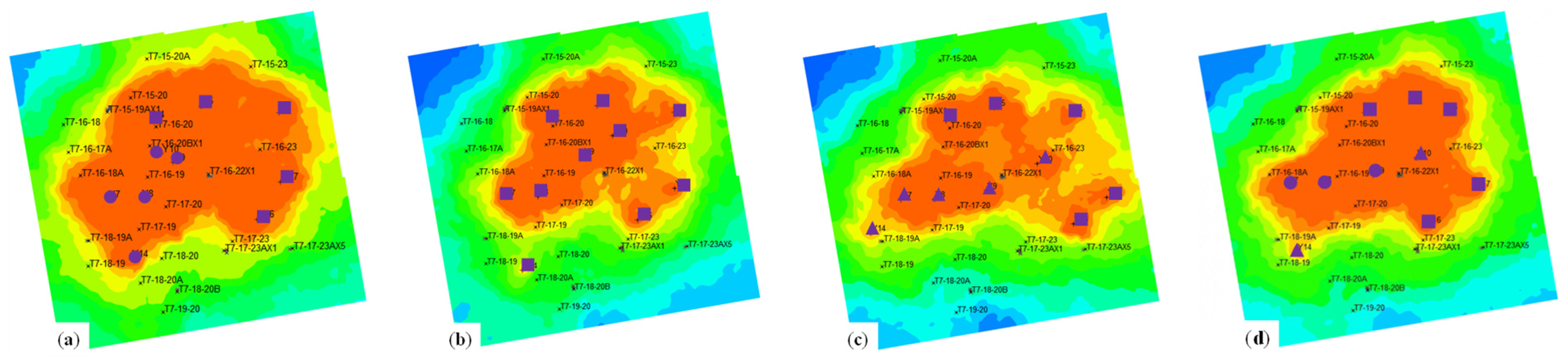

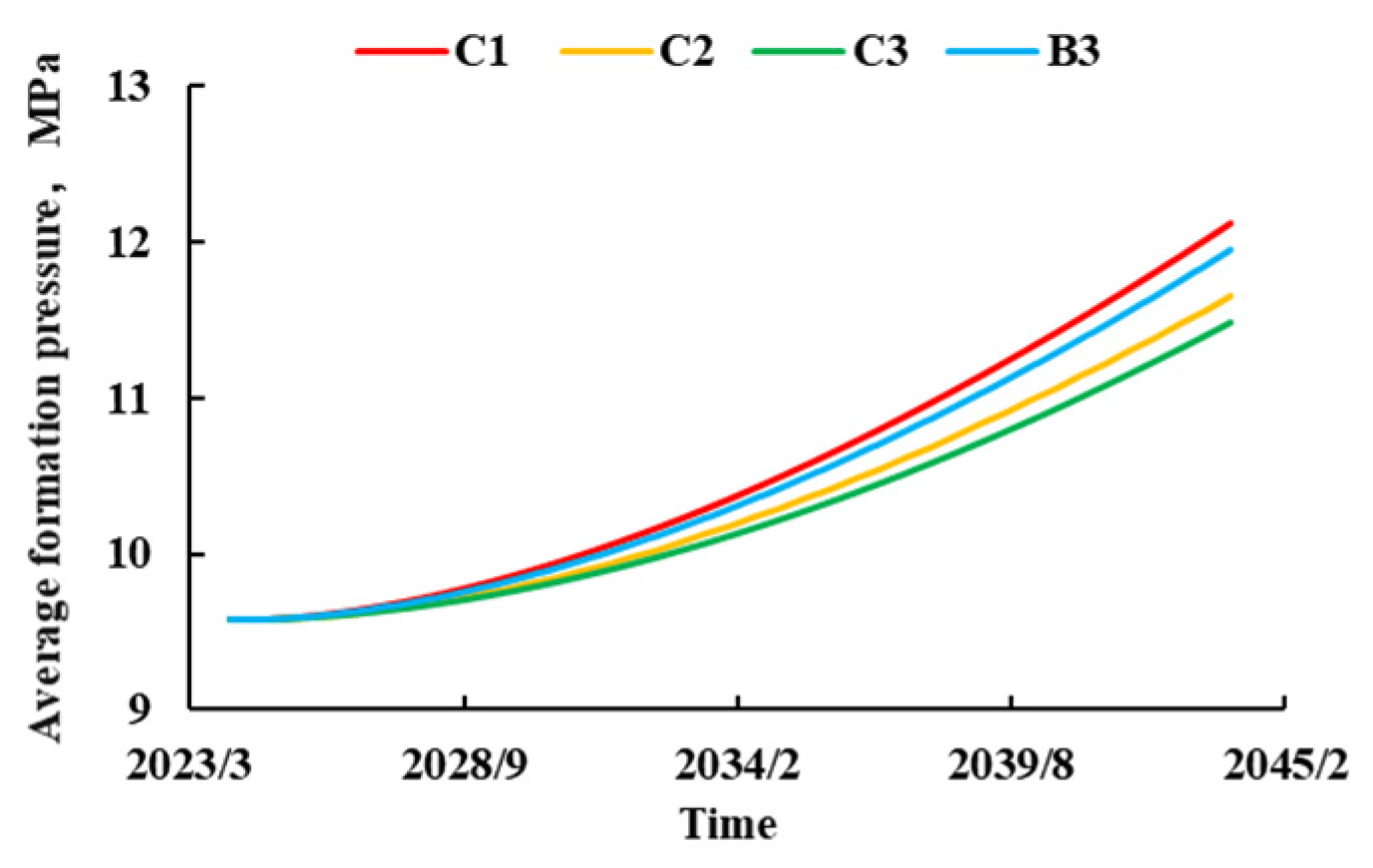

4.3.3. Group C Stratigraphic Inhomogeneity Study

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, C.; Xiu, C.; Guo, D.; Song, Q.; Wu, B.; Zhang, K. Research progresses on environmental risk in reinjection of unconventional gas produced water. Environ. Prot. Chem. Ind. 2020, 40, 15–20. [Google Scholar]

- Jia, C.; Hu, J.; Sepehrnoori, K. Numerical studies of unstable fingering flow in a water-oil system. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 22–25 April 2024. [Google Scholar]

- Yang, S.; Wang, Q.; Zhang, K.; Chen, H.; Liu, S.; Cai, M.; Wang, Y. Key challenges and countermeasures for treatment and disposal of gas field produced water in China. Ind. Water Treat. 2024, 44, 13–20. [Google Scholar]

- Lin, J.; Li, S.; Jiang, C.; Xu, G.; Wu, L.; Wang, N.; Yang, H.; Wang, J. Research on key technologies for treating produced water of gas field. Petrochem. Ind. Appl. 2024, 43, 49–53. [Google Scholar]

- Liu, J.; Che, J.; Du, K.; Zhang, Q.; Meng, H.; Guo, X.; Luo, H.; Wu, H. Optimization and application of sewage treatment agents in gas field. Chem. Eng. 2024, 52, 29–33. [Google Scholar]

- Liu, D.; Cai, Y.; Feng, Z.; Zhang, Q.; Hu, L.; Li, S. Feasibility study on geothermal dolomite reservoir reinjection with surface water in Tianjin, China. Water 2024, 16, 3144. [Google Scholar] [CrossRef]

- Alrekabi, A.; Adhab, S.A.; Aljubouri, H.; Saad, H.F.A. Formation damage modeling for unfiltered produced water reinjection in north-rumaila oil field. Pet. Chem. 2024, 64, 875–882. [Google Scholar] [CrossRef]

- Xia, T.; Feng, Q.; Wang, A.; Shu, Q.; Zhang, Y.; Sun, Y. A numerical study of particle migration in porous media during produced water reinjection. ASME. J. Energy Resour. Technol. 2022, 144, 073002. [Google Scholar] [CrossRef]

- Wang, J. Corrosion mechanism and prevention technology of water injection pipeline column in puguang gas field. China Pet. Chem. Stand. Qual. 2022, 42, 38–39+42. [Google Scholar]

- Zhang, D. Causes and countermeasures of wellbore corrosion in gas field sewage reinjection wells. China Pet. Chem. Stand. Qual. 2020, 40, 41–42. [Google Scholar]

- Wang, R.; Chen, Z.; Zhao, F.; You, J.; Jiang, F.; Bai, H.; Zhang, R. Prediction of limit water injection capacity of sewage injection wells in Yulin gas field. Environ. Prot. Oil Gas Fields 2023, 33, 20–26. [Google Scholar]

- He, K.; Weng, B.; Jiao, Y.; Wu, X.; Lin, Q.; Hu, X. Application of Hall plot in environmental risk prevention and control of gas field water reinjection. Chem. Eng. Oil Gas 2023, 52, 122–125+129. [Google Scholar]

- Liu, Q.; Lu, K.; Wu, R. Evaluation and Index Prediction of sewage reinjection capability in water drive gas reservoir. Environ. Prot. Oil Gas Fields 2022, 32, 33–37. [Google Scholar]

- Bao, B.; Wang, W. Process design and efficiency enhancement of natural gas produced water treatment technologies. China Pet. Chem. Stand. Qual. 2025, 45, 184–186. [Google Scholar]

- Huang, Y.; Lei, H.; Na, J.; Yuan, Y.; Tian, H. Investigations of the impact of geothermal water reinjection on water-rock interaction through laboratory experiments and numerical simulations. Appl. Geochem. 2024, 175, 106180. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, H.; Lv, G.; Wu, F.; Xiao, P.; Zhu, M.; Zhao, C.; Liu, Q. Synergistic effects of mixed microorganisms on the corrosion of X65 carbon steel in actual reinjection water. J. Environ. Chem. Eng. 2024, 12, 114015. [Google Scholar] [CrossRef]

- Yu, C.; Cheng, K.; Huang, Z.; Huang, Z.; Li, J.; Hu, J.; Yang, D.; Li, R. Experimental study on reinjection enhancement of sandstone with radial wells. Geothermics 2024, 120, 102972. [Google Scholar] [CrossRef]

- Guo, X.; Yang, C.; Chen, W.; Li, X.; Liu, K. Research progress on inverse demulsifiers and flocculants for oil-bearing produced water from unconventional gas fields. Environ. Prot. Chem. Ind. 2023, 43, 304–313. [Google Scholar]

- Hu, Z.; Liu, C.; Li, X.; Liu, K.; Chen, W. Status of disposal methods and treatment technology of produced water from unconventional gas fields in China. Environ. Prot. Chem. Ind. 2024, 44, 11–20. [Google Scholar]

- Silva, T.L.S.; Morales-Torres, S.; Castro-Silva, S.; Figueiredo, J.L.; Silva, A.M.T. An overview on exploration and environmental impact of unconventional gas sources and treatment options for produced water. J. Environ. Manag. 2017, 200, 511–529. [Google Scholar] [CrossRef]

- Si, L. Study on selecting layers for reinjection of highly saline produced water from unconventional gas fields. Sci. Technol. Innov. 2025, 5, 113–116. [Google Scholar]

- Abdelhamid, C.; Latrach, A.; Rabiei, M.; Venugopal, K. Produced water treatment technologies: A review. Energies 2025, 18, 63. [Google Scholar] [CrossRef]

- Gangwar, A.; Rawat, S.; Rautela, A.; Yadav, I.; Singh, A.; Kumar, S. Current advances in produced water treatment technologies: A perspective of techno-economic analysis and life cycle assessment. Environ. Dev. Sustain. 2024, prepublish. [Google Scholar] [CrossRef]

- Sanchez-Rosario, R.; Hildenbrand, Z.L. Produced water treatment and valorization: A techno-economical review. Energies 2022, 15, 4619. [Google Scholar] [CrossRef]

- Ma, M.; Zhang, X.; Chen, Z. Research progress on treatment technologies of gas field produced water. Environ. Prot. Chem. Ind. 2023, 43, 285–291. [Google Scholar]

- Guo, F.; Wang, Y.; Shang, F.; Fang, L.; Zhang, X. Comparison and optimization of the permeability upscaling methods: A case study on Libra Oilfield in Brazil. Petroleum Geol. Oilfield Dev. Daqing 2019, 38, 58–66. [Google Scholar]

- Zhao, B. Discussion on the influence of grid coarsening on reservoir numerical simulation. In Proceedings of the 2017 International Conference on Oil and Gas Field Exploration and Development (IFEDC 2017), Chengdu, China, 21–22 September 2017; Daqing Oil Production Plant Fourth Geological Brigade: Daqing, China, 2017; pp. 990–995. [Google Scholar]

- Liu, Z. Influence of mesh coarsening on results of reservoir numerical simulation. Petrochem. Ind. Technol. 2017, 24, 149. [Google Scholar]

- Liu, Z.; Gu, J. Analysis of the effect of mesh coarsening on the results of numerical simulation calculations. J. Oil Gas Technol. 2015, 37, 44–46. [Google Scholar]

- Miao, W.; Gu, J.; Wu, G.; Lv, N.; Yu, B. Study on the Heterogeneity of the Reservoir in Block B, HUAQING Oilfield and Its Water-injecting Opening Effects. Inn. Mong. Petrochem. Ind. 2020, 46, 102–104. [Google Scholar]

- Dong, L.; Zhong, P.; Zhang, Q.; Wang, M.; Dong, W.; Wang, Y.; Yang, C. Experimental Investigation on Layer Subdivision Water Injection in Multilayer Heterogeneous Reservoirs. ACS Omega 2023, 8, 43546–43555. [Google Scholar] [CrossRef]

| Nations | Oil and Gas Fields | Water Reinjection Technology/Processes | Key Challenges |

|---|---|---|---|

| China | Changqing Oilfield | Hierarchical treatment process, digital monitoring, layered reinjection | Complex water quality, low permeability of reservoirs, high inhomogeneity |

| Daqing Oilfield | Pretreatment and advanced treatment technology, downhole oil–water cyclone separation, same-well injection and production, skid-mounted chemical equipment | Serious equipment corrosion, high viscosity of produced water, the difficulty of separating oil and water. | |

| Xinjiang Oilfield | Graded treatment, in situ separation and reinjection technology, CO2 synergistic sequestration | Complex water quality, limited processing capacity of existing reinjection systems, harsh reinjection conditions | |

| United States | Permian Basin | Graded physical separation, great-depth-boron treatment, deep geological sequestration, CO2 collaborative storage | The large volume of fracture recharge water, complex geological structures, regulations and public pressure |

| United Kingdom | Clair Ridge | Low mineralization water drive technology, sand control and microseismic monitoring technology, deep geological storage technology | Fracture development in reservoirs, engineering risks, the greater energy consumption of reverse osmosis systems |

| Canada | Surmont | Evaporation pond and advanced oxidation technology, coupled bio-membrane treatment technology, steam-assisted gravity drainage reinjection technology | The difficulty of treating high levels of salt and organic matter, cold-climate influence, low reservoir permeability, the demand for high-pressure injection |

| Saudi Arabia | Shaybah | High-temperature membrane separation and air floatation-coupling technology, deep saltwater layer reinjection technology, CO2 synergistic storage | Processes are affected by high temperatures in the summer; there is a risk of high salt and high silicon scaling |

| Modeling Parameters | Unit | Numerical Value |

|---|---|---|

| Number of grids | number | 123 × 120 × 250 |

| Grid size in the x-direction | m | 50 |

| Grid size in the x-direction | m | 50 |

| Grid size in the x-direction | m | 4 |

| Porosity | f | 0–0.29 |

| Permeability | mD | 0–30 |

| Area of study area | km2 | 36 |

| Ground pressure coefficient | MPa/m | 8.95 × 10−3 |

| Rock compression factor | MPa−1 | 4 × 10−4 |

| Viscosity of water | mPa·s | 0.6 |

| Density of water | g/cm3 | 1.0203 |

| Compression factor of water | MPa−1 | 5 × 10−5 |

| Volume factor of water | / | 1.007 |

| Program Number | Number of Wells Injected | ||

|---|---|---|---|

| Er > 0.7 | 0.5 > Er > 0.7 | Er < 0.5 | |

| C1 | 5 | 5 | 0 |

| C2 | 0 | 10 | 0 |

| C3 | 0 | 50 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, H.; Zheng, P.; Yue, P.; Mu, Y. Reinjection of Produced Water into Formations in Unconventional Gas Reservoirs. Energies 2025, 18, 3149. https://doi.org/10.3390/en18123149

Xing H, Zheng P, Yue P, Mu Y. Reinjection of Produced Water into Formations in Unconventional Gas Reservoirs. Energies. 2025; 18(12):3149. https://doi.org/10.3390/en18123149

Chicago/Turabian StyleXing, Haosen, Peng Zheng, Ping Yue, and Yu Mu. 2025. "Reinjection of Produced Water into Formations in Unconventional Gas Reservoirs" Energies 18, no. 12: 3149. https://doi.org/10.3390/en18123149

APA StyleXing, H., Zheng, P., Yue, P., & Mu, Y. (2025). Reinjection of Produced Water into Formations in Unconventional Gas Reservoirs. Energies, 18(12), 3149. https://doi.org/10.3390/en18123149