Thermal Conductivity of Sustainable Earthen Materials Stabilized by Natural and Bio-Based Polymers: An Experimental and Statistical Analysis

Abstract

1. Introduction

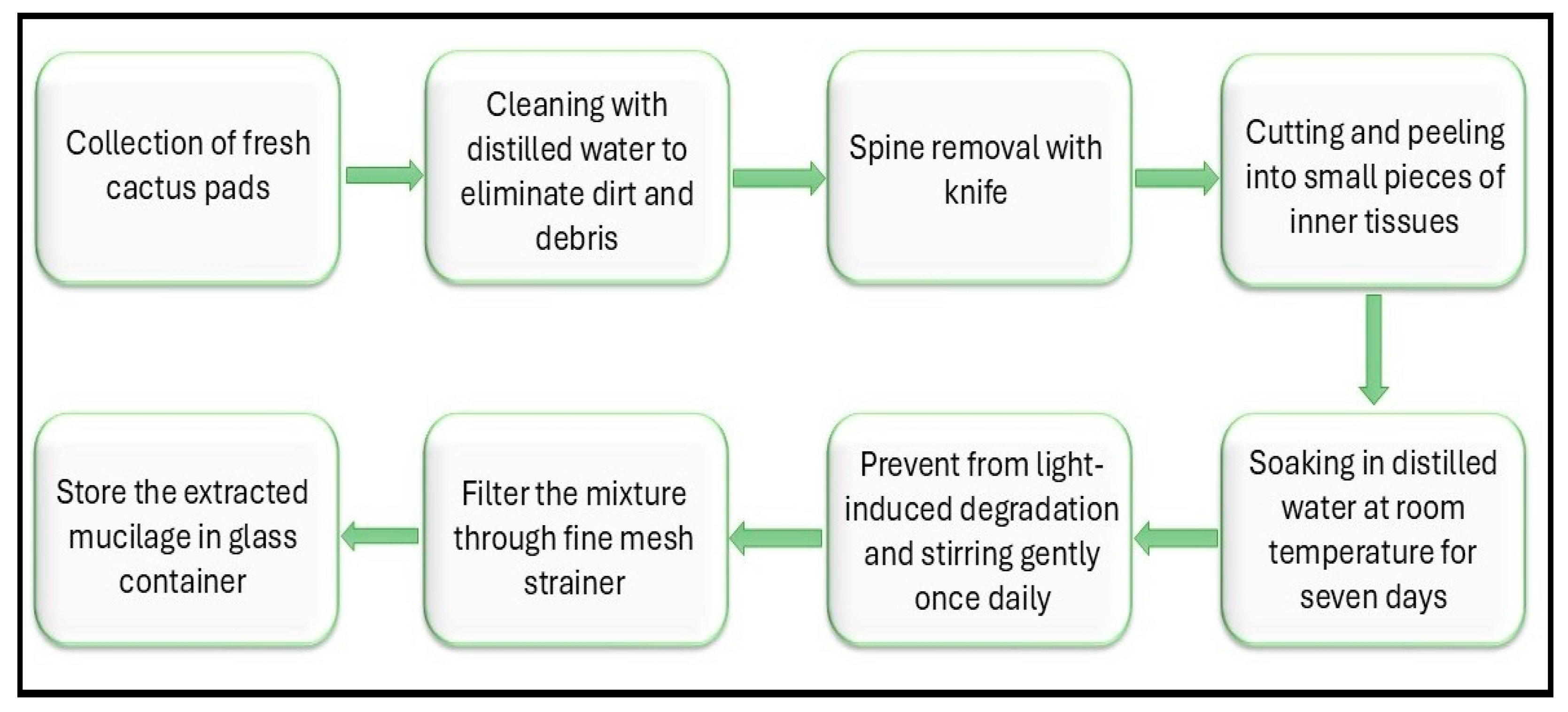

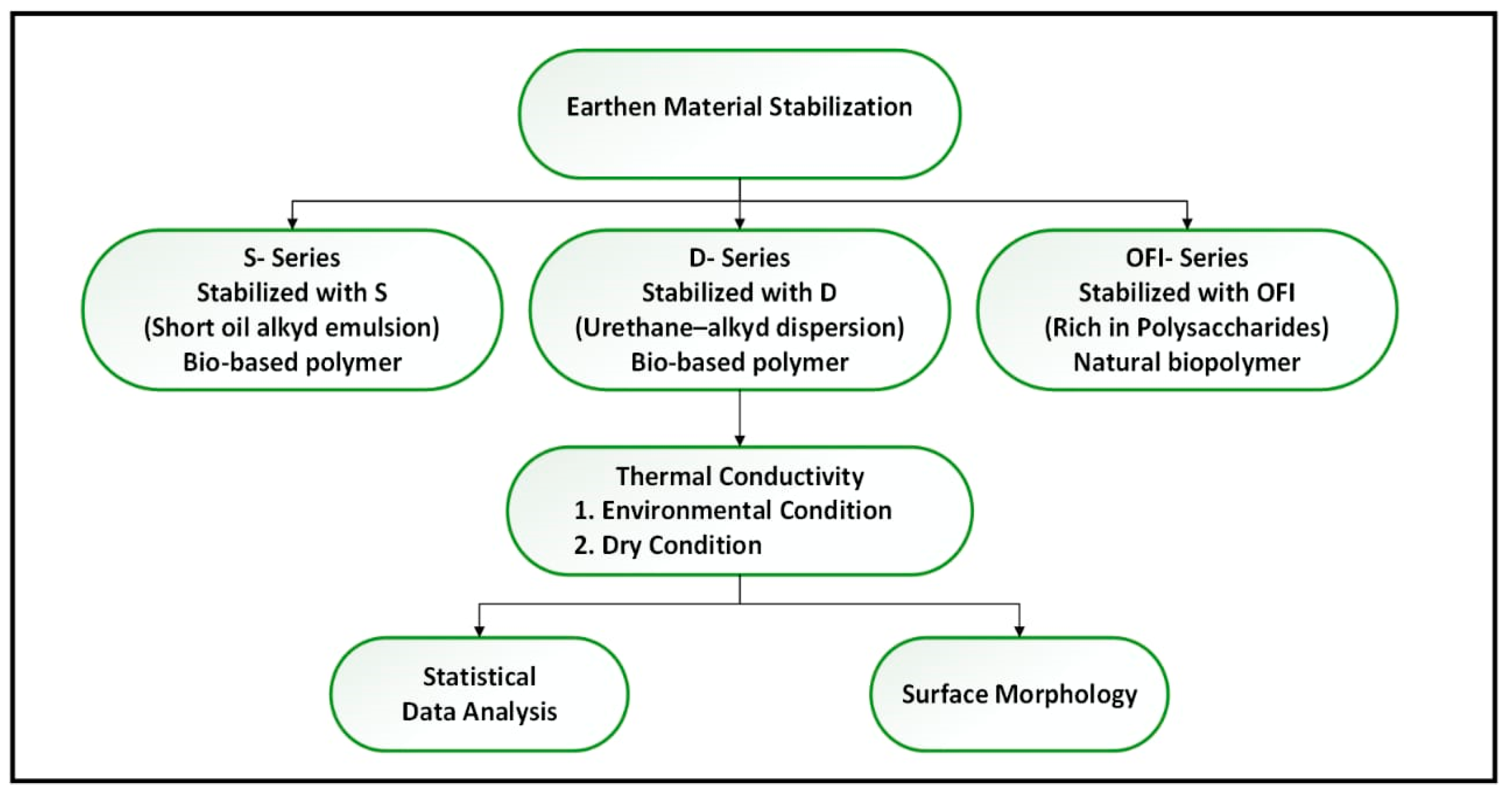

2. Materials and Methods

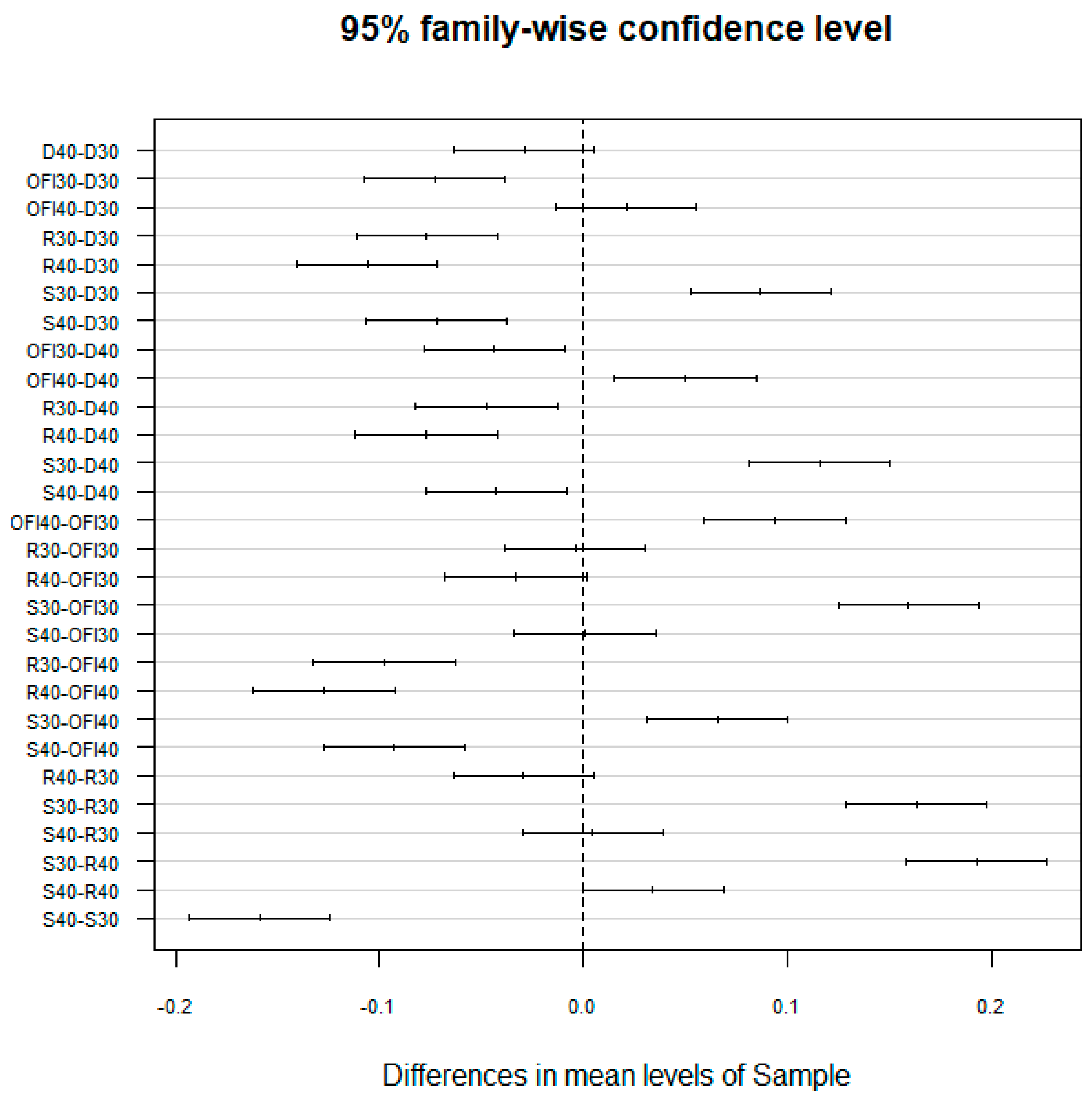

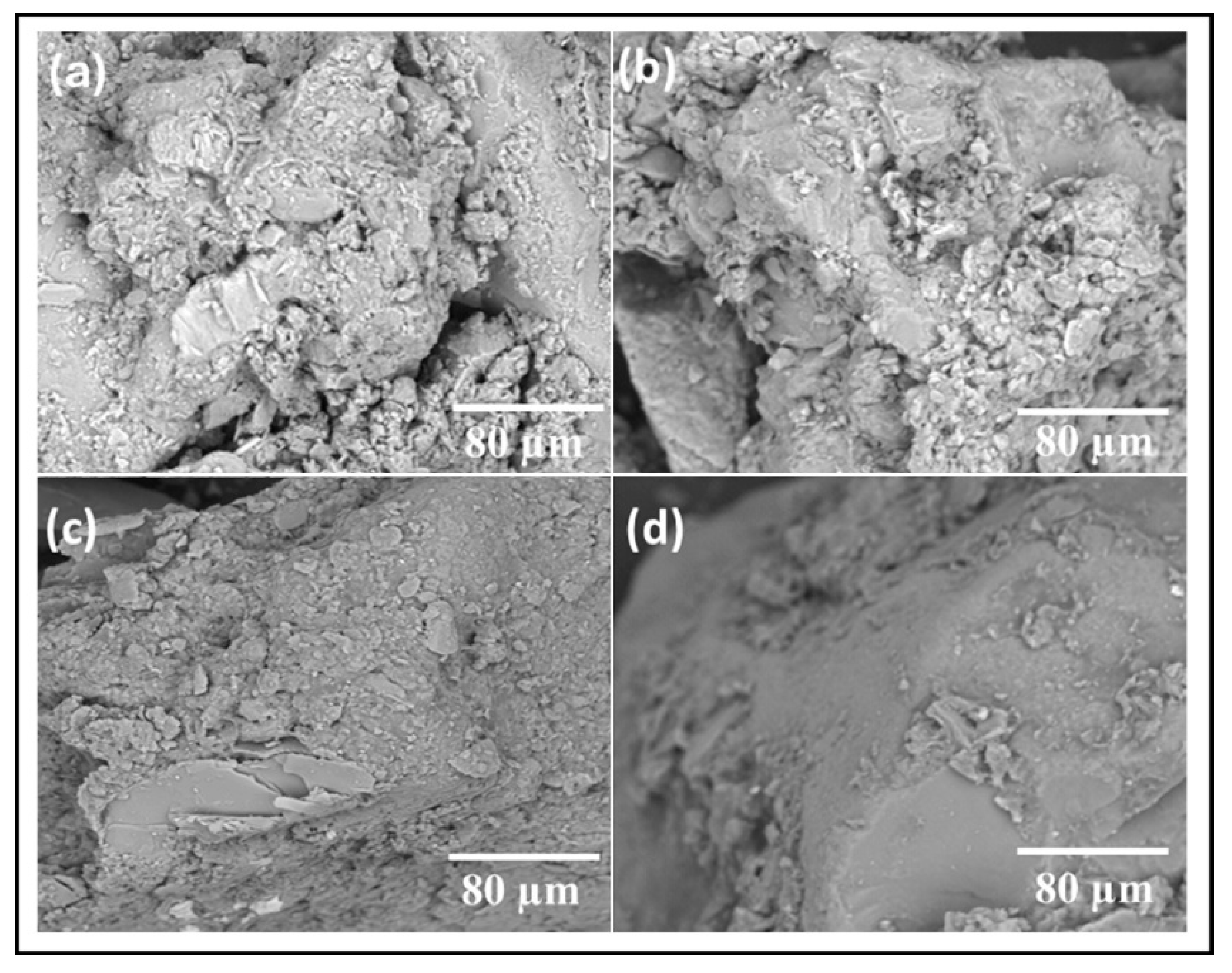

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- The findings are not correlated.

- The findings within each category are derived from a normal distribution.

- Population variations within each category are equal.

- ANOVA is a widely used advanced analytical technique in both academic research and financial studies, frequently cited for its ability to assess differences across multiple groups or categories.

ANOVA Methodology

| Origin of Variance | Sum of Squares (SS) | Freedom Degrees (Df) | Mean Square (MS) | F-Statistics | Above F Tail Area |

|---|---|---|---|---|---|

| Between groups | SSC | K-1 | MSC | MSC/MSE | p-Value |

| Within groups | SSE | N-k | MSE | ||

| Total | SST | N-1 |

- Means,

- Degrees of freedom (df) Within.

- Mean Square (MS) Within,

- Number per treatment/group

References

- Bui, Q.-B.; Morel, J.-C.; Hans, S.; Walker, P. Effect of Moisture Content on the Mechanical Characteristics of Rammed Earth. Constr. Build. Mater. 2014, 54, 163–169. [Google Scholar] [CrossRef]

- Ilman, B.; Balkis, A.P. Sustainable Biopolymer Stabilized Earthen: Utilization of Chitosan Biopolymer on Mechanical, Durability, and Microstructural Properties. J. Build. Eng. 2023, 76, 107220. [Google Scholar] [CrossRef]

- Gallipoli, D.; Bruno, A.W.; Perlot, C.; Mendes, J. A Geotechnical Perspective of Raw Earth Building. Acta Geotech. 2017, 12, 463–478. [Google Scholar] [CrossRef]

- Fitzmaurice, R. Manual on Stabilized Soil Construction for Housing; United Nations, Technical Assistance Programme: New York, NY, USA, 1958. [Google Scholar]

- Lax, C. Life Cycle Assessment of Rammed Earth; Univeristy of Bath: Bath, UK, 2010. [Google Scholar]

- Gong, N.; Zhu, M.; Zhang, Y.; Su, P.; Zhong, M.; Mu, C. The Content Optimization of Supplementary Cementitious Materials in Coral Sand-Seawater Cement Mortar: A Focus on Mechanical Properties and Transportation Costs. Constr. Build. Mater. 2024, 432, 136022. [Google Scholar] [CrossRef]

- Marmier, A. Decarbonisation Options for the Cement Industry; IGEM: Derby, UK, 2023. [Google Scholar]

- Jittin, V.; Bahurudeen, A. Production of Cleaner Binders by Reusing Agricultural By-Products: An Approach towards Zero Cement Concrete for Sustainable Future Infrastructure. J. Clean. Prod. 2024, 451, 141990. [Google Scholar] [CrossRef]

- Wojtacha-Rychter, K.; Kucharski, P.; Smolinski, A. Conventional and Alternative Sources of Thermal Energy in the Production of Cement—An Impact on CO2 Emission. Energies 2021, 14, 1539. [Google Scholar] [CrossRef]

- Mokhtar, A.; Nasooti, M. A Decision Support Tool for Cement Industry to Select Energy Efficiency Measures. Energy Strategy Rev. 2020, 28, 100458. [Google Scholar] [CrossRef]

- Habert, G. Assessing the Environmental Impact of Conventional and ‘Green’ Cement Production. In Eco-Efficient Construction and Building Materials; Elsevier: Amsterdam, Netherlands, 2014; pp. 199–238. [Google Scholar]

- Cappai, M.; Shoukat, R.; Pilia, L.; Ricciu, R.; Lai, D.; Marongiu, G.; Pia, G. Thermal Properties of Eco-Friendly Earthen Materials Stabilized with Bio-Based Polymers: Experimental Data and Modeling Procedure for Improving Mix-Design. Materials 2024, 17, 1035. [Google Scholar] [CrossRef]

- Association, C.T.E.C. Cementing the European Green Deal, Reaching Climate Neutrality along the Cement and Concrete Value Chain by 2050; The European Cement Association: Brussels, Belgium, 2020. [Google Scholar]

- Jwaida, Z.; Dulaimi, A.; Mashaan, N.; Mydin, M.A.O. Geopolymers: The Green Alternative to Traditional Materials for Engineering Applications. Infrastructures 2023, 8, 98. [Google Scholar] [CrossRef]

- Coppola, L.; Bellezze, T.; Belli, A.; Bignozzi, M.C.; Bolzoni, F.; Brenna, A.; Cabrini, M.; Candamano, S.; Cappai, M.; Caputo, D.; et al. Binders Alternative to Portland Cement and Waste Management for Sustainable Construction—Part 1. J. Appl. Biomater. Funct. Mater. 2018, 16, 186–202. [Google Scholar] [CrossRef]

- Madirisha, M.M.; Dada, O.R.; Ikotun, B.D. Chemical Fundamentals of Geopolymers in Sustainable Construction. Mater. Today Sustain. 2024, 27, 100842. [Google Scholar] [CrossRef]

- Coppola, L.; Bellezze, T.; Belli, A.; Bignozzi, M.C.; Bolzoni, F.; Brenna, A.; Cabrini, M.; Candamano, S.; Cappai, M.; Caputo, D.; et al. Binders Alternative to Portland Cement and Waste Management for Sustainable Construction—Part 2. J. Appl. Biomater. Funct. Mater. 2018, 16, 207–221. [Google Scholar] [CrossRef] [PubMed]

- Bumanis, G.; Vitola, L.; Pundiene, I.; Sinka, M.; Bajare, D. Gypsum, Geopolymers, and Starch—Alternative Binders for Bio-Based Building Materials: A Review and Life-Cycle Assessment. Sustainability 2020, 12, 5666. [Google Scholar] [CrossRef]

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; Cochran Hameen, E. Life Cycle Assessment (LCA) of Natural vs Conventional Building Assemblies. Renew. Sustain. Energy Rev. 2021, 144, 110951. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Inés Fernández, A. Low Carbon and Low Embodied Energy Materials in Buildings: A Review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Alcorn, A. Embodied Energy and CO Coefficients for NZ Building Materials; The Centre for Building Performance Research: Wellington, New Zealand, 2003. [Google Scholar]

- Asdrubali, F.; Grazieschi, G.; Roncone, M.; Thiebat, F.; Carbonaro, C. Sustainability of Building Materials: Embodied Energy and Embodied Carbon of Masonry. Energies 2023, 16, 1846. [Google Scholar] [CrossRef]

- Röhlen, U.; Ziegert, C. Earth Building Practice: Planning-Design-Building; Beuth Verlag: Berlin, Deutschland, 2011; ISBN 3410217371. [Google Scholar]

- Petcu, C.; Dobrescu, C.F.; Dragomir, C.S.; Ciobanu, A.A.; Lăzărescu, A.V.; Hegyi, A. Thermophysical Characteristics of Clay for Efficient Rammed Earth Wall Construction. Materials 2023, 16, 6015. [Google Scholar] [CrossRef]

- Wolterbeek, T.K.T.; Hangx, S.J.T. The Thermal Properties of Set Portland Cements—A Literature Review in the Context of CO2 Injection Well Integrity. Int. J. Greenh. Gas Control. 2023, 126, 103909. [Google Scholar] [CrossRef]

- Al-Radhi, Y.; Roy, K.; Liang, H.; Ghosh, K.; Clifton, G.C.; Lim, J.B.P. Thermal Performance of Different Construction Materials Used in New Zealand Dwellings Comparatively to International Practice—A Systematic Literature Review. J. Build. Eng. 2023, 72, 106346. [Google Scholar] [CrossRef]

- Kubiś, M.; Pietrak, K.; Cieślikiewicz, Ł.; Furmański, P.; Wasik, M.; Seredyński, M.; Wiśniewski, T.S.; Łapka, P. On the Anisotropy of Thermal Conductivity in Ceramic Bricks. J. Build. Eng. 2020, 31, 101418. [Google Scholar] [CrossRef]

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; Hameen, E.C. Integrating Earthen Building Materials and Methods into Mainstream Construction Using Environmental Performance Assessment and Building Policy. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 12139. [Google Scholar] [CrossRef]

- Costa-Carrapiço, I.; González, J.N.; Raslan, R.; Sánchez-Guevara, C.; Redondas Marrero, M.D. Understanding Thermal Comfort in Vernacular Dwellings in Alentejo, Portugal: A Mixed-Methods Adaptive Comfort Approach. Build. Environ. 2022, 217, 109084. [Google Scholar] [CrossRef]

- Ben-Alon, L.; Rempel, A.R. Thermal Comfort and Passive Survivability in Earthen Buildings. Build. Environ. 2023, 238, 110339. [Google Scholar] [CrossRef]

- Tushar, Q.; Zhang, G.; Bhuiyan, M.A.; Navaratnam, S.; Giustozzi, F.; Hou, L. Retrofit of Building Façade Using Precast Sandwich Panel: An Integrated Thermal and Environmental Assessment on BIM-Based LCA. Buildings 2022, 12, 2098. [Google Scholar] [CrossRef]

- Rempel, A.R.; Rempel, A.W. Intrinsic Evaporative Cooling by Hygroscopic Earth Materials. Geosciences 2016, 6, 38. [Google Scholar] [CrossRef]

- Cappai, M.; Delogu, F.; Pozzi-Escot, D.; Pacheco Neyra, G.; Meloni, P.; Pia, G. Degradation Phenomena of Templo Pintado Painted Plasters. Constr. Build. Mater. 2023, 392, 131839. [Google Scholar] [CrossRef]

- Cappai, M.; Casnedi, L.; Carcangiu, G.; Delogu, F.; Pozzi-Escot, D.; Pacheco Neyra, G.; Pia, G.; Meloni, P. Weathering of Earth-Painted Surfaces: Environmental Monitoring and Artificial Aging. Constr. Build. Mater. 2022, 344, 128193. [Google Scholar] [CrossRef]

- Jiang, M.; Jiang, B.; Lu, R.; Chun, L.; Xu, H.; Yi, G. Thermal and Humidity Performance Test of Rammed-Earth Dwellings in Northwest Sichuan during Summer and Winter. Materials 2023, 16, 6283. [Google Scholar] [CrossRef]

- Wiehle, P.; Simon, S.; Baier, J.; Dennin, L. Influence of Relative Humidity on the Strength and Stiffness of Unstabilised Earth Blocks and Earth Masonry Mortar. Constr. Build. Mater. 2022, 342, 128026. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Jaquin, P.A.; Morel, J.-C. Weathering the Storm: A Framework to Assess the Resistance of Earthen Structures to Water Damage. Constr. Build. Mater. 2020, 242, 118098. [Google Scholar] [CrossRef]

- Nakamatsu, J.; Kim, S.; Ayarza, J.; Ramírez, E.; Elgegren, M.; Aguilar, R. Eco-Friendly Modification of Earthen Construction with Carrageenan: Water Durability and Mechanical Assessment. Constr. Build. Mater. 2017, 139, 193–202. [Google Scholar] [CrossRef]

- Alhaik, G.; Ferreira, M.; Dubois, V.; Wirquin, E.; Tilloy, S.; Monflier, E.; Aouad, G. Enhance the Rheological and Mechanical Properties of Clayey Materials by Adding Starches. Constr. Build. Mater. 2017, 139, 602–610. [Google Scholar] [CrossRef]

- van Damme, H.; Houben, H. Should Raw Earth Be Improved? An Environmental Assessment. In Proceedings of the Terra, Lyon, France, 11–14 July 2016; CRAterre: Lyon, France, 2016; pp. 180–182. [Google Scholar]

- Shoukat, R.; Cappai, M.; Pia, G.; Pilia, L. An Updated Review: Opuntia Ficus Indica (OFI) Chemistry and Its Diverse Applictions. Appl. Sci. 2023, 13, 7724. [Google Scholar] [CrossRef]

- Park, S.-S.; Lee, J.-S.; Yoon, K.-B.; Woo, S.-W.; Lee, D.-E. Application of an Acrylic Polymer and Epoxy Emulsion to Red Clay and Sand. Polymers 2021, 13, 3410. [Google Scholar] [CrossRef]

- Nima, L.; Suksun, H.; Meehan, C.L.; Zaimi, A.M.M.; Tahir, M.M.; Tonnizam, M.E. Improvement of Problematic Soils with Biopolymer—An Environmentally Friendly Soil Stabilizer. J. Mater. Civ. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Kulkarni Vishakha, S.; Butte Kishor, D.; Rathod Sudha, S. Natural Polymers–A Comprehensive Review. Int. J. Res. Pharm. Biomed. Sci. 2012, 3, 1597–1613. [Google Scholar]

- Lahalih, S.M.; Ahmed, N. Effect of New Soil Stabilizers on the Compressive Strength of Dune Sand. Constr. Build. Mater. 1998, 12, 321–328. [Google Scholar] [CrossRef]

- Striani, R.; Cappai, M.; Casnedi, L.; Esposito Corcione, C.; Pia, G. Coating’s Influence on Wind Erosion of Porous Stones Used in the Cultural Heritage of Southern Italy: Surface Characterisation and Resistance. Case Stud. Constr. Mater. 2022, 17, e01501. [Google Scholar] [CrossRef]

- Majumder, A.; Losito, M.; Paramasivam, S.; Kumar, A.; Gatto, G. Buoys for marine weather data monitoring and LoRaWAN communication. Ocean. Eng. 2024, 313, 119521. [Google Scholar] [CrossRef]

- Soldo, A.; Miletic, M. Durability against Wetting-Drying Cycles of Sustainable Biopolymer-Treated Soil. Polymers 2022, 14, 4247. [Google Scholar] [CrossRef]

- Tourtelot, J.; Bourgès, A.; Keita, E. Influence of Biopolymers on the Mechanical Behavior of Earth-Based Building Materials. Recent. Prog. Mater. 2021, 3, 031. [Google Scholar] [CrossRef]

- Kariyawasam, K.K.G.K.D.; Jayasinghe, C. Cement Stabilized Rammed Earth as a Sustainable Construction Material. Constr. Build. Mater. 2016, 105, 519–527. [Google Scholar] [CrossRef]

- Cappai, M.; Pia, G. Sustainable earthen plasters: Surface resistance enhancement via thermal treatments. J. Build. Eng. 2025, 108, 112867. [Google Scholar] [CrossRef]

- Rieppi Godoy, A.S.; Peisino, L.E.; Rolón, G.; Raggiotti, B.B. Firing the wall: A novel way to protect earth buildings. Constr. Build. Mater. 2024, 445, 137878. [Google Scholar] [CrossRef]

- Stochino, F.; Majumder, A.; Frattolillo, A.; Valdes, M.; Martinelli, E. Jute fiber reinforcement for masonry walls: Integrating structural strength and thermal insulation in sustainable upgrades. J. Build. Eng. 2025, 104, 112210. [Google Scholar] [CrossRef]

- Taib, M.N.A.M.; Antov, P.; Savov, V.; Fatriasari, W.; Madyaratri, E.W.; Wirawan, R.; Osvaldová, L.M.; Hua, L.S.; Ghani, M.A.A.; Al Edrus, S.S.A.O.; et al. Current Progress of Biopolymer-Based Flame Retardant. Polym. Degrad. Stab. 2022, 205, 110153. [Google Scholar] [CrossRef]

- Getahun, M.J.; Kassie, B.B.; Alemu, T.S. Recent Advances in Biopolymer Synthesis, Properties, & Commercial Applications: A Review. Process Biochem. 2024, 145, 261–287. [Google Scholar] [CrossRef]

- Patel, D.K.; Jung, E.; Priya, S.; Won, S.-Y.; Han, S.S. Recent Advances in Biopolymer-Based Hydrogels and Their Potential Biomedical Applications. Carbohydr. Polym. 2024, 323, 121408. [Google Scholar] [CrossRef]

- Shoukat, R.; Cappai, M.; Pia, G.; Pilia, L. Rice Starch Chemistry, Functional Properties, and Industrial Applications: A Review. Polymers 2025, 17, 110. [Google Scholar] [CrossRef]

- Caillol, S. Special Issue “Natural Polymers and Biopolymers II”. Molecules 2021, 26, 112. [Google Scholar] [CrossRef]

- Losini, A.E.; Grillet, A.C.; Bellotto, M.; Woloszyn, M.; Dotelli, G. Natural Additives and Biopolymers for Raw Earth Construction Stabilization—A Review. Constr. Build. Mater. 2021, 304, 124507. [Google Scholar] [CrossRef]

- Muguda, S.; Lucas, G.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Bruno, A.W.; Gallipoli, D. Durability and Hygroscopic Behaviour of Biopolymer Stabilised Earthen Construction Materials. Constr. Build. Mater. 2020, 259, 119725. [Google Scholar] [CrossRef]

- de Souza, J.M.; Ramos Filho, R.E.B.; Duarte, J.B.; da Silva, V.M.; do Rêgo, S.R.; de Figueiredo Lopes Lucena, L.; Acchar, W. Mechanical and Durability Properties of Compressed Stabilized Earth Brick Produced with Cassava Wastewater. J. Build. Eng. 2021, 44, 103290. [Google Scholar] [CrossRef]

- Muguda, S.; Booth, S.J.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Bruno, A.W.; Gallipoli, D. Preliminary Study on Use of Biopolymers in Earthen Construction. In Proceedings of the 7th International conference on unsaturated SoilsAt: The Hong Kong University of Science and Technology, Hong Kong, China, 3–8 August 2018; Volume 8, pp. 1–2. [Google Scholar]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.-C. Effects of Xanthan Gum Biopolymer on Soil Strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Karak, N. Biopolymers for Paints and Surface Coatings. In Biopolymers and Biotech Admixtures for Eco-Efficient Construction Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 333–368. [Google Scholar]

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. Bio-Based Building Skin; Springer Nature: Berlin, Germany, 2019; ISBN 9811337470. [Google Scholar]

- Noreen, A.; Zia, K.M.; Zuber, M.; Tabasum, S.; Zahoor, A.F. Bio-Based Polyurethane: An Efficient and Environment Friendly Coating Systems: A Review. Prog. Org. Coat. 2016, 91, 25–32. [Google Scholar] [CrossRef]

- Ren, X.; Meng, L.; Soucek, M. Environmentally Friendly Coatings. In Biobased and Environmental Benign Coatings; John Wiley & Sons, Ltd.: Oxford, UK, 2016; pp. 183–223. ISBN 9781119185055. [Google Scholar]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 0470053046. [Google Scholar]

- ISO 8301:1991; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. ISO: Geneva, Switzerland, 1991.

- Venables, W.N.; Smith, D.M. An Introduction to R: Notes on R: A Programming Environment for Data Analysis and Graphics, version 4.4.2. 2024. Available online: https://cran.r-project.org/doc/manuals/R-intro.pdf (accessed on 31 October 2024).

- Záleská, M.; Pavlíková, A.; Pivák, A.; Lauermannová, A.-M.; Jankovský, O.; Pavlík, Z. Lightweight Vapor-Permeable Plasters for Building Repair Detailed Experimental Analysis of the Functional Properties. Materials 2021, 14, 2613. [Google Scholar] [CrossRef]

- Aleksandrova, O.; Zhmykhova, T.; Värnik, R.; Viira, A.-H. The One-Way Analysis of Variance of Heat-Storage Materials Used in Building of Poultry Houses. Processes 2023, 11, 104. [Google Scholar] [CrossRef]

- Choungara, T.; Ghrieb, A.; Abadou, Y.; Bustamante, R. A Statistical Approach for Green Conversion of the Amorphous E-Waste into Glassy Refractory Mortar Subjected to High Temperature. Int. J. Thermophys. 2023, 44, 44. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley & Sons, Incorporated: Hoboken, NJ, USA, 2012; ISBN 9781118214718. [Google Scholar]

- Field, A. Discovering Statistics Using IBM SPSS Statistics; Sage Publications limited: Thousand Oaks, CA, USA, 2024; ISBN 1529668700. [Google Scholar]

- Aczel, A.D. Complete Business Statistics; Irwin. Inc.: Boston, MA, USA, 1989. [Google Scholar]

- Fisher, R.A. Statistical Methods for Research Workers, 4th ed.; revised and enlarged; Oliver and Boyd: Edinburgh, UK; London, UK, 1932; pp. xiv + 307. [Google Scholar]

- Rafter, J.A.; Abell, M.L.; Braselton, J.P. Multiple Comparison Methods for Means. Siam Rev. 2002, 44, 259–278. [Google Scholar] [CrossRef]

| Samples | Kav(W/m·K) (Environmental Condition) | Kav(W/m·K) (Dry Condition) | |

|---|---|---|---|

| R-30 | 0.267 ± 0.024 | [12] | 0.252 ± 0.011 |

| R-40 | 0.239 ± 0.015 | [12] | 0.225 ± 0.011 |

| S-30 | 0.451 ± 0.034 | [12] | 0.418 ± 0.013 |

| S-40 | 0.266 ± 0.014 | [12] | 0.260 ± 0.011 |

| D-30 | 0.347 ± 0.021 | [12] | 0.327 ± 0.016 |

| D-40 | 0.322 ± 0.025 | [12] | 0.302 ± 0.014 |

| OFI-30 | 0.271 ± 0.013 | 0.259 ± 0.012 | |

| OFI-40 | 0.365 ± 0.016 | 0.353 ± 0.013 | |

| Origin of Variance | SS | df | MS | F | p-Value |

|---|---|---|---|---|---|

| Between groups | 0.12637 | 7 | 0.018053 | 73.83 | 0 |

| Within groups | 0.00391 | 16 | 0.000245 | ||

| Total | 0.13028 | 23 | 0.018298 |

| Origin of Variance | SS | df | MS | F | p-Value |

|---|---|---|---|---|---|

| Between groups | 0.08615 | 7 | 0.01231 | 82.25 | 0 |

| Within groups | 0.00239 | 16 | 0.00015 | ||

| Total | 0.08854 | 23 | 0.01246 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shoukat, R.; Cappai, M.; Pia, G.; Kubaszek, T.; Ricciu, R.; Kolek, Ł.; Pilia, L. Thermal Conductivity of Sustainable Earthen Materials Stabilized by Natural and Bio-Based Polymers: An Experimental and Statistical Analysis. Energies 2025, 18, 3144. https://doi.org/10.3390/en18123144

Shoukat R, Cappai M, Pia G, Kubaszek T, Ricciu R, Kolek Ł, Pilia L. Thermal Conductivity of Sustainable Earthen Materials Stabilized by Natural and Bio-Based Polymers: An Experimental and Statistical Analysis. Energies. 2025; 18(12):3144. https://doi.org/10.3390/en18123144

Chicago/Turabian StyleShoukat, Rizwan, Marta Cappai, Giorgio Pia, Tadeusz Kubaszek, Roberto Ricciu, Łukasz Kolek, and Luca Pilia. 2025. "Thermal Conductivity of Sustainable Earthen Materials Stabilized by Natural and Bio-Based Polymers: An Experimental and Statistical Analysis" Energies 18, no. 12: 3144. https://doi.org/10.3390/en18123144

APA StyleShoukat, R., Cappai, M., Pia, G., Kubaszek, T., Ricciu, R., Kolek, Ł., & Pilia, L. (2025). Thermal Conductivity of Sustainable Earthen Materials Stabilized by Natural and Bio-Based Polymers: An Experimental and Statistical Analysis. Energies, 18(12), 3144. https://doi.org/10.3390/en18123144