Sensitivity Analysis of a Hybrid PV-WT Hydrogen Production System via an Electrolyzer and Fuel Cell Using TRNSYS in Coastal Regions: A Case Study in Perth, Australia

Abstract

1. Introduction

- Developing a TRNSYS model for hybrid PV-WT hydrogen production in the coastal climate conditions of Perth, Australia;

- Conducting dynamic hourly simulations for a full-year 4E performance analysis;

- Evaluating monthly electricity/hydrogen potential and system efficiency;

- Providing practical insights to guide future system designs.

2. Methodology and System Design

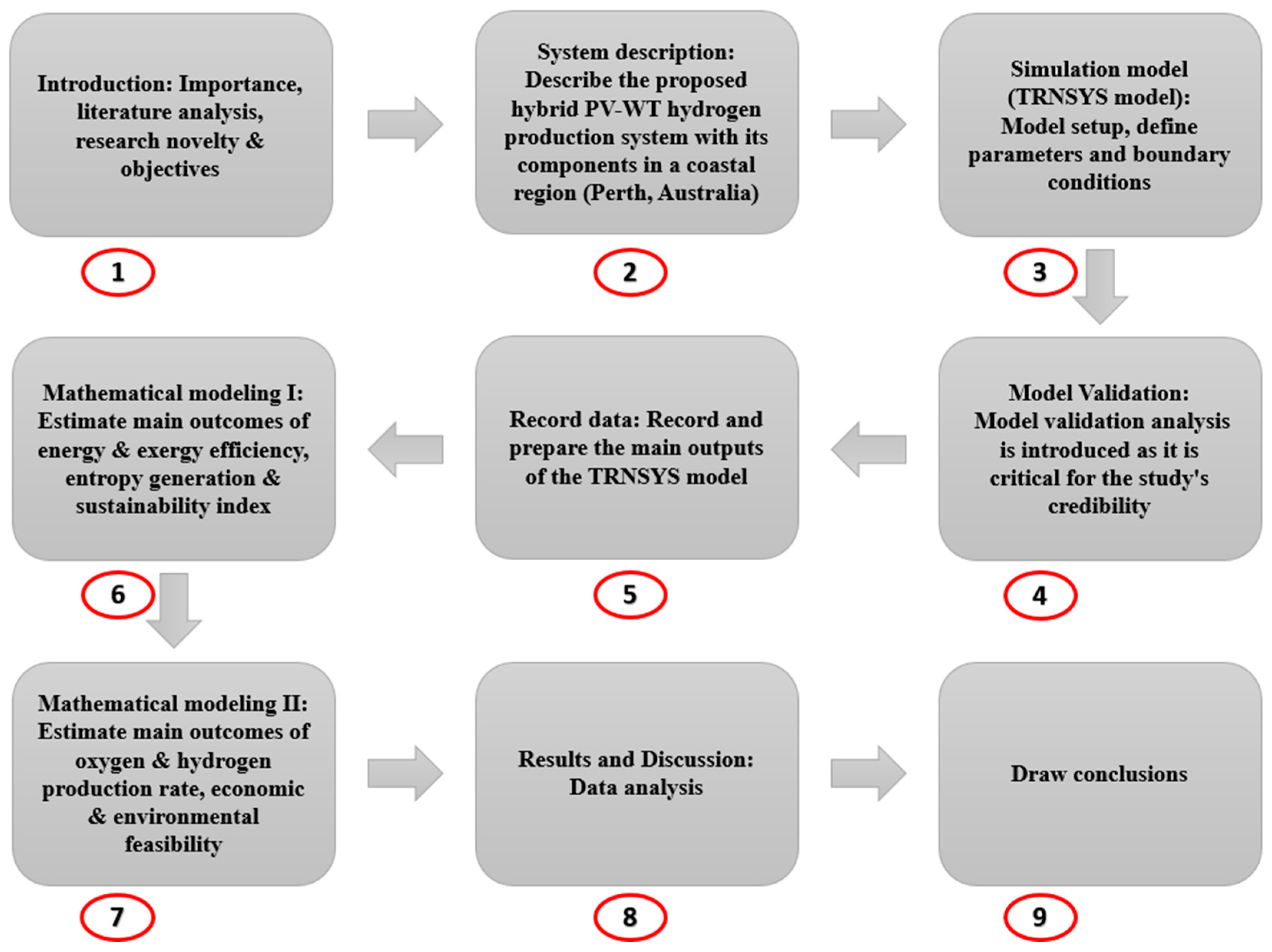

2.1. Research Methodology

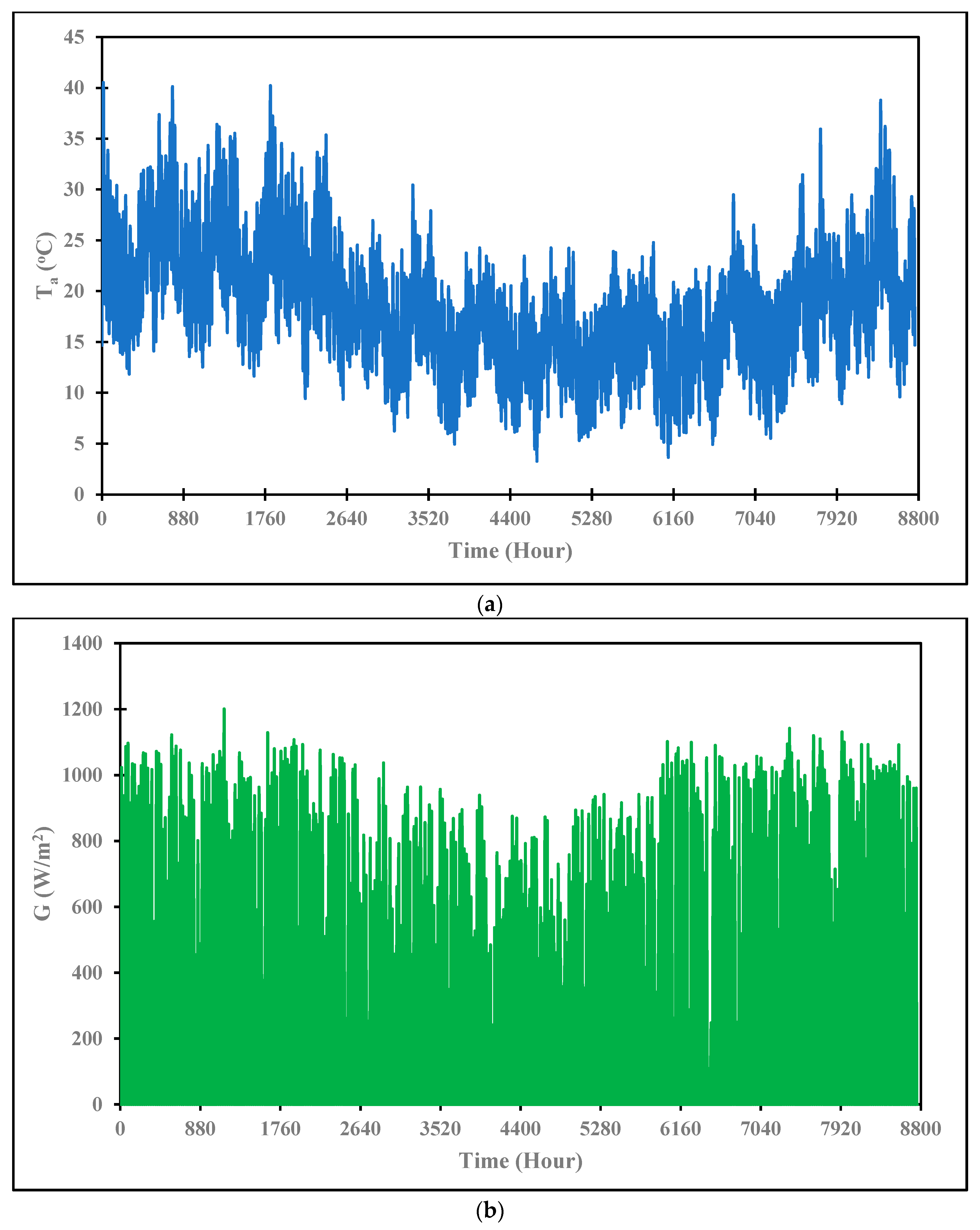

2.2. The Environmental Conditions of the Study Area

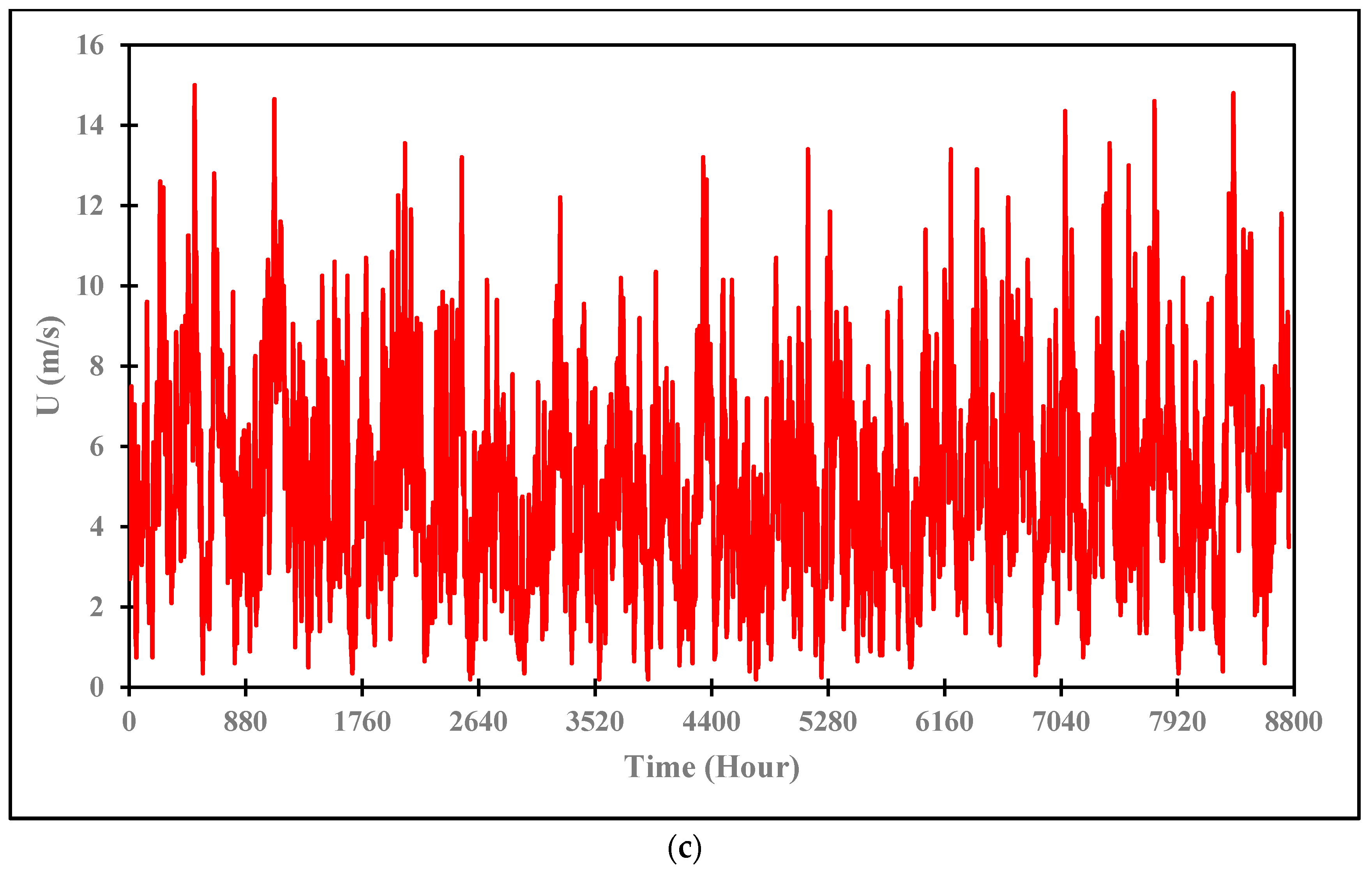

2.3. System Description

2.4. TRNSYS Model

3. Performance Analysis

3.1. Thermodynamic Analysis

3.1.1. Photovoltaic (PV) Panel Performance

3.1.2. Wind Turbine (WT) Performance

3.1.3. Electrolyzer (ELE) Performance

3.1.4. Alkaline Fuel Cell (AFC) Performance

3.1.5. Overall Efficiency

3.2. Economic and Environmental Analysis

3.2.1. Economic Analysis

3.2.2. Environmental Assessment

3.3. Model Assumptions

- The system operates under transient conditions, with hourly simulations conducted over a year using TRNSYS. Subsystems respond to dynamic operational and environmental changes based on hourly data [19].

- Although the quantity of hydrogen and oxygen generated was determined, the economic analysis was only conducted on the amount of hydrogen produced [46].

- The project lifetime is considered to be 20 years [36].

- A standard atmospheric pressure of 1 bar and a reference ambient temperature of 25 °C were considered [12].

- Water exergy is not included in the electrolyzer’s exergy analysis, and oxygen exergy is disregarded [33].

- Hydrogen is considered an ideal gas [33].

- The parametric cost assessment excludes the financial considerations of hydrogen storage and transportation.

- Physical and chemical exergy analyses of the WT, ELE, and AFC are considered.

- There are no losses or leaks from the hydrogen storage tank [33].

- The hydrogen tank volume is considered constant at 50 m3, since the effect of tank volume scalability is not taken into account in this research.

4. Results and Discussion

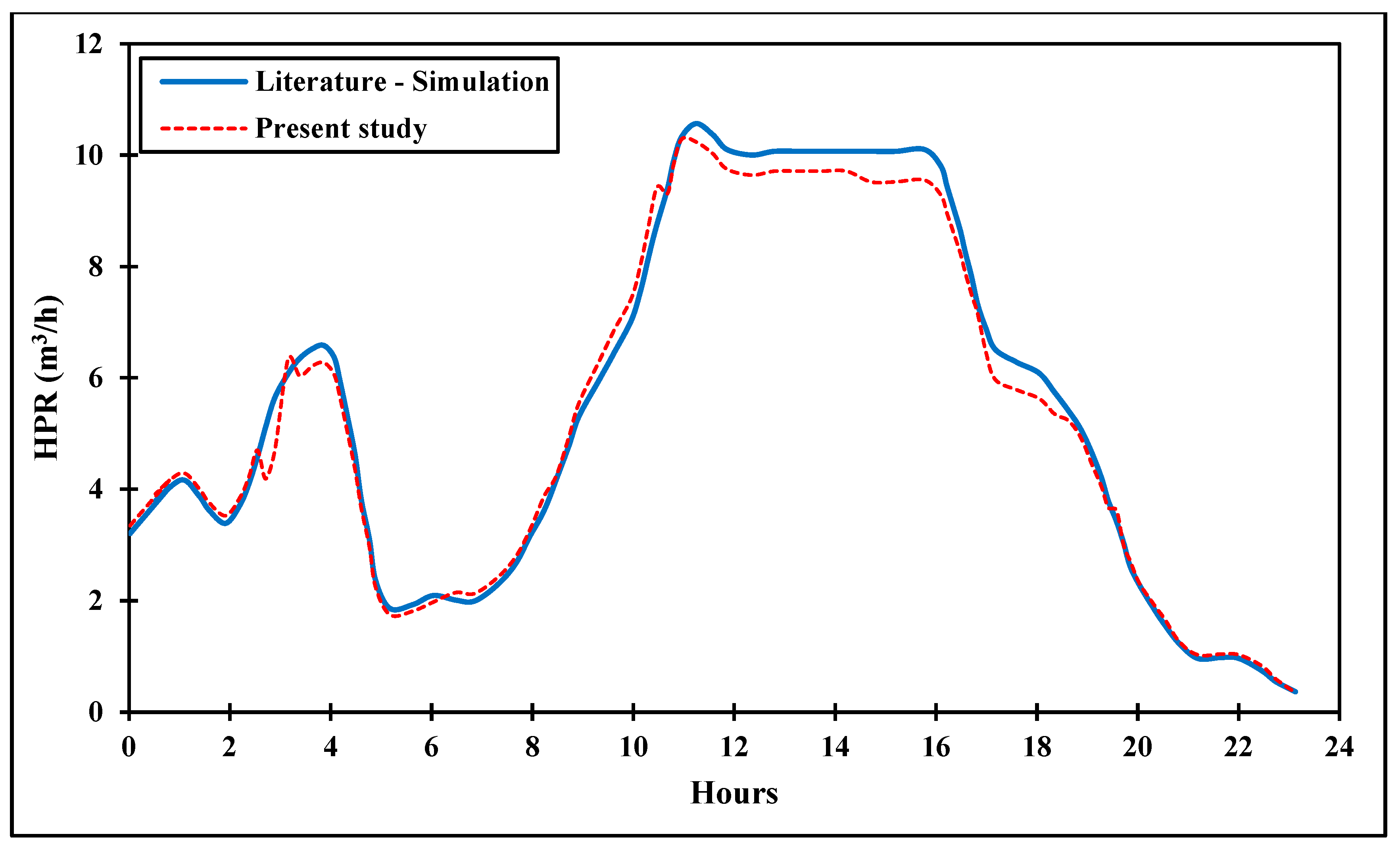

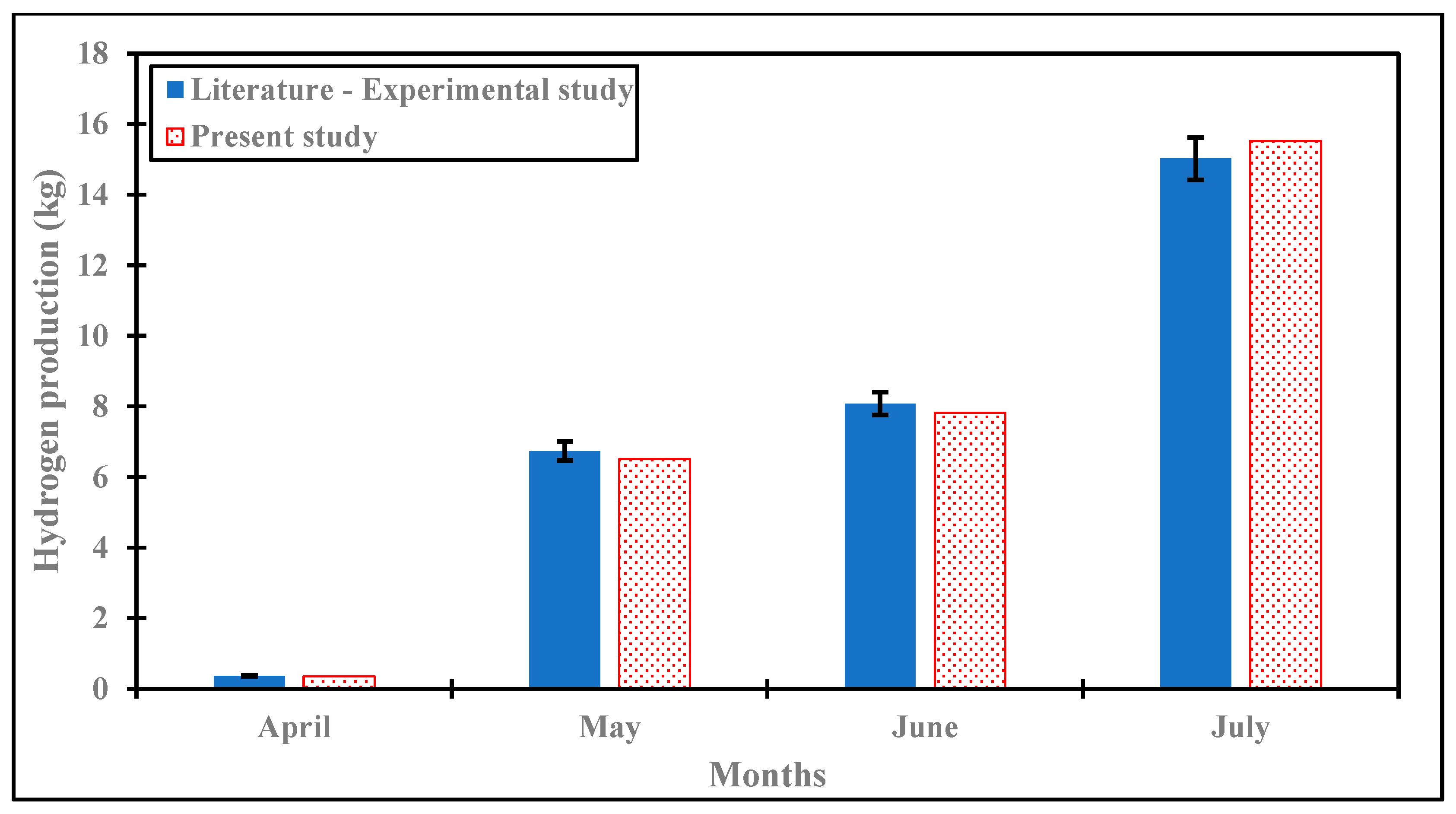

4.1. Validation Model

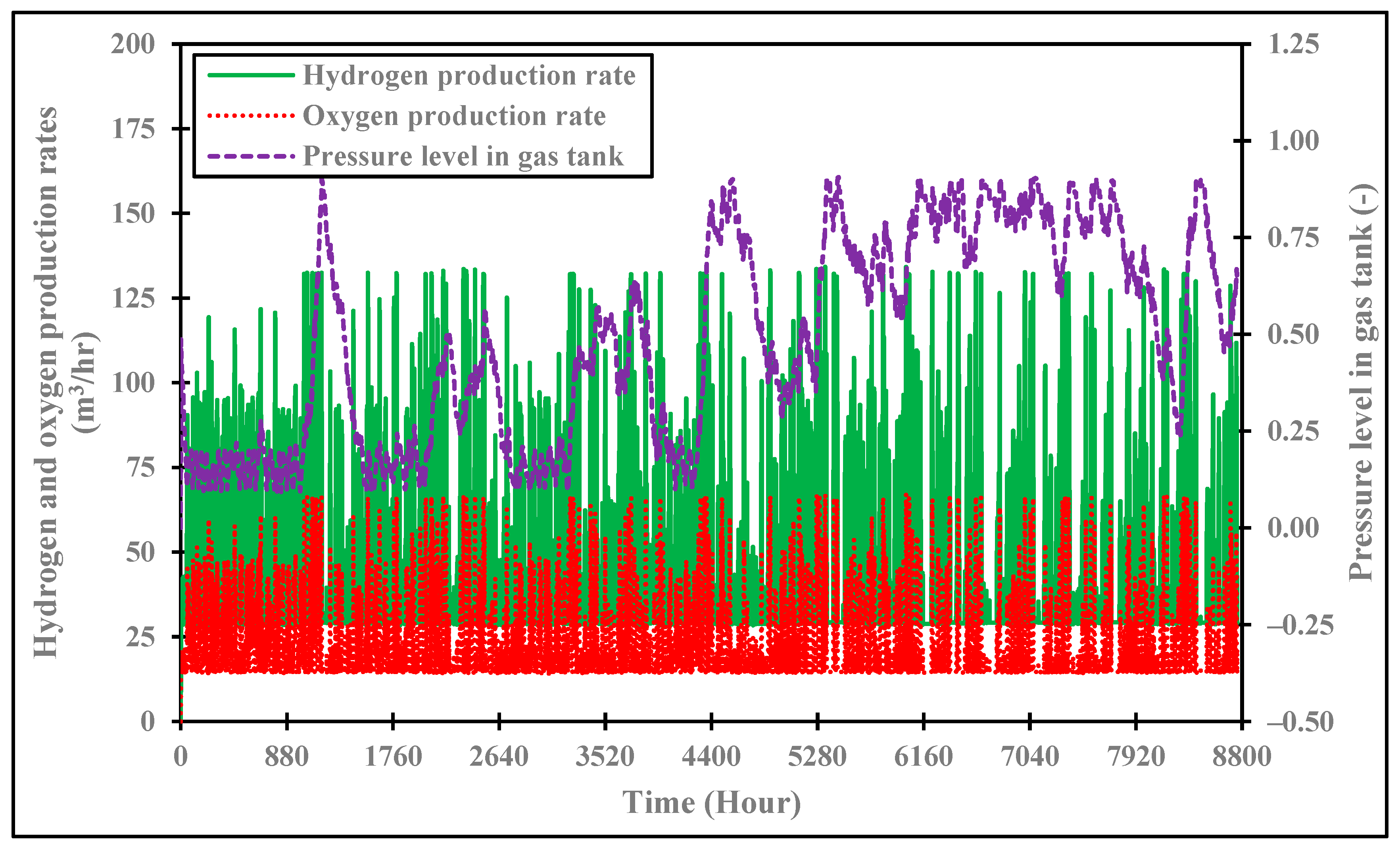

4.2. Hydrogen Production

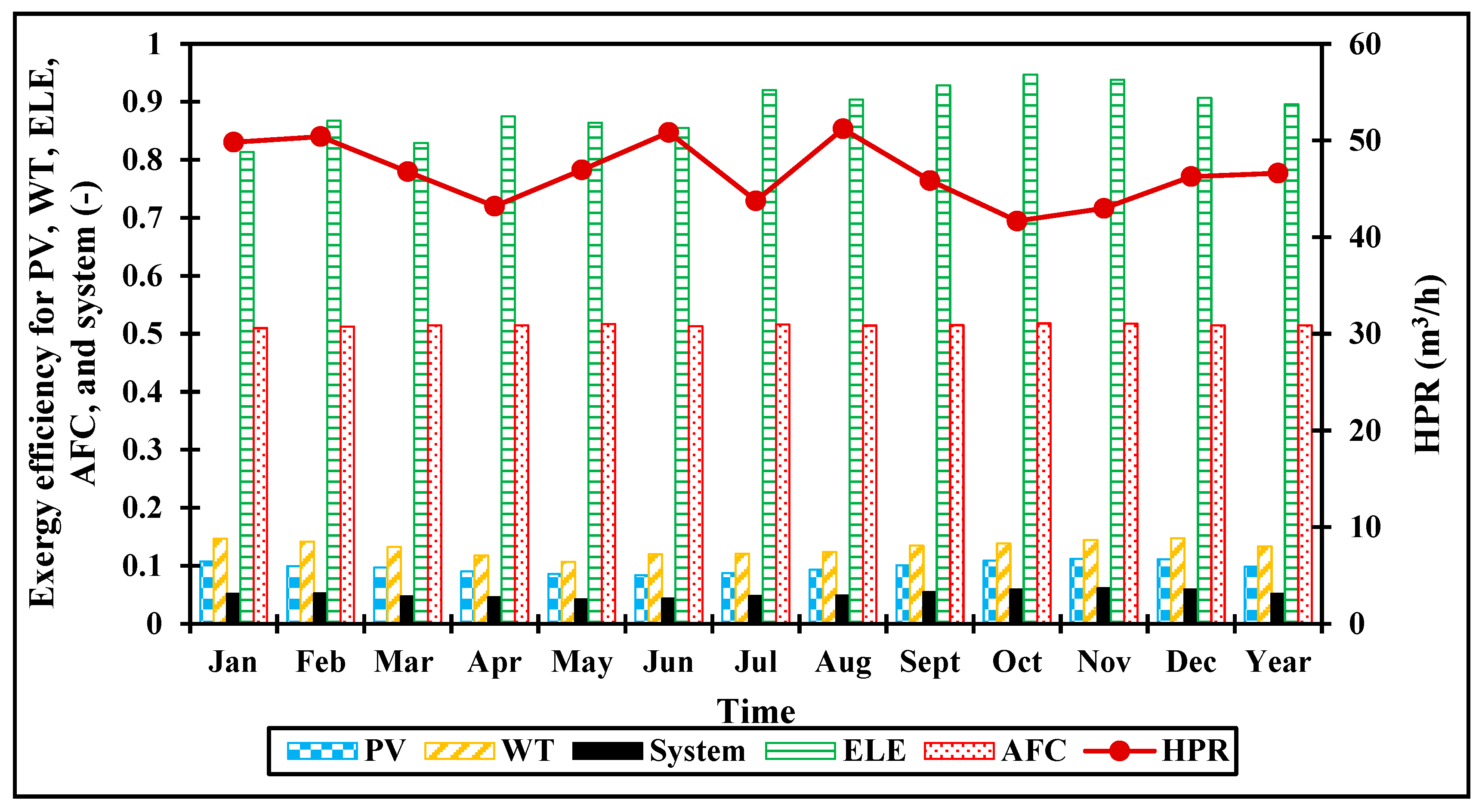

4.3. Energy and Exergy Efficiencies

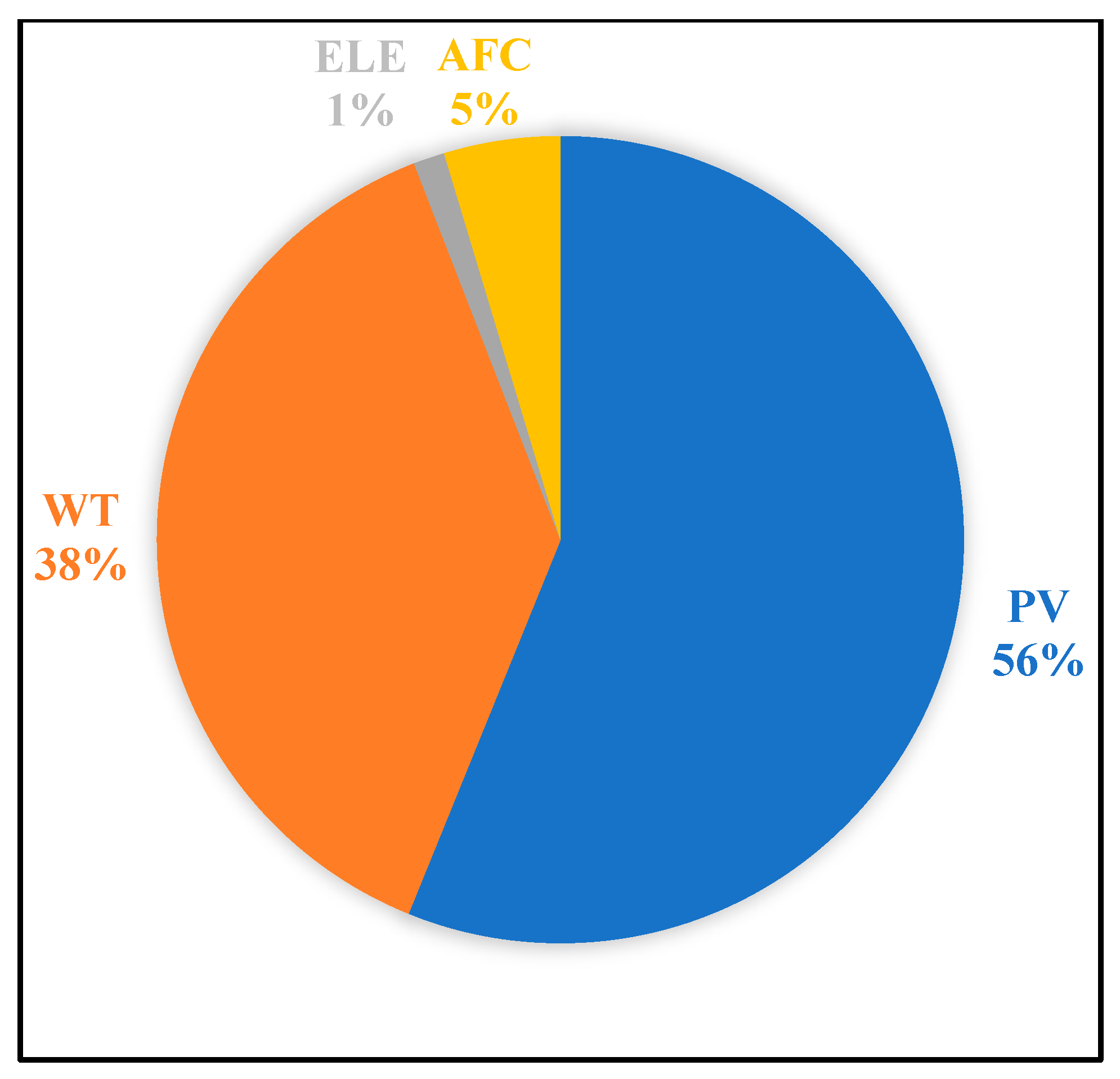

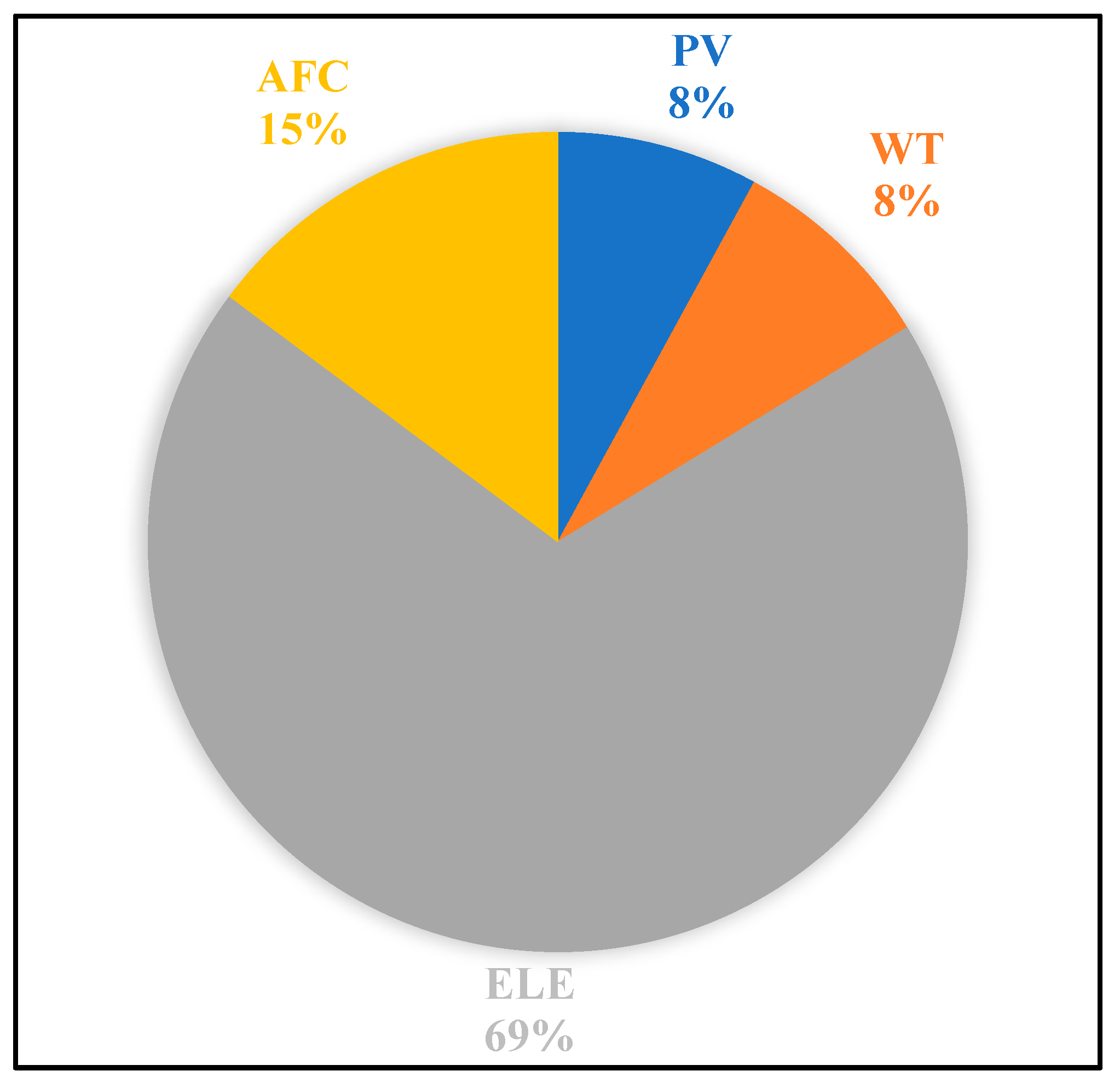

4.4. Entropy Generation and Sustainability Index

4.5. Economic and Environmental Results

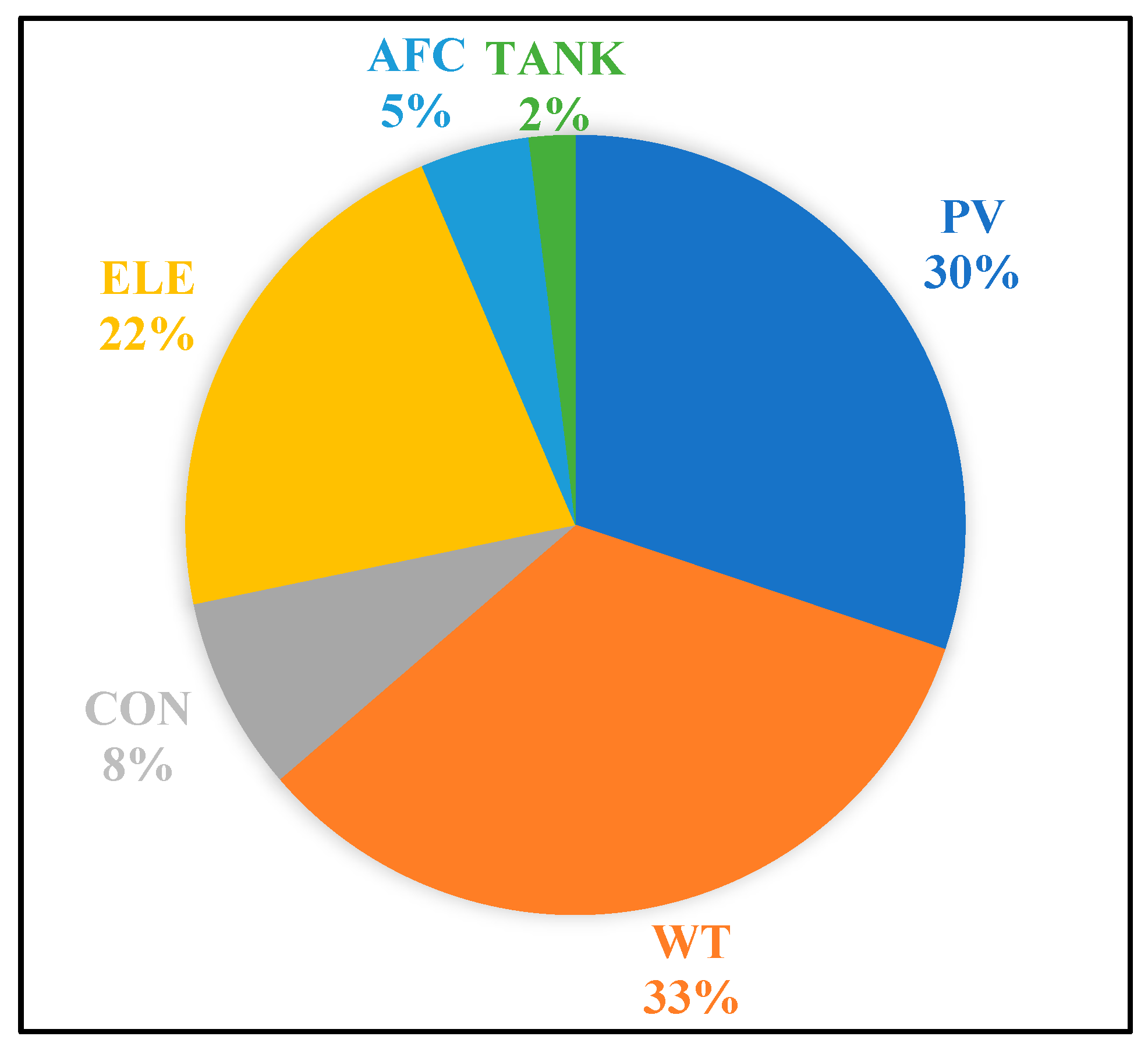

4.5.1. Economic Results

4.5.2. Environmental Assessment Results

5. Limitations and Future Research Directions

- Investigate developments in energy storage, the technique of electrolysis, and smart grid integration to improve system dependability and efficiency.

- The design and functioning of the system could be optimized by carrying out comprehensive assessments of other renewable resources that are accessible, such as solar, wind, tidal, and geothermal.

- Researchers are developing sophisticated economic models and scenario studies to assess the prospective cost sustainability of producing hydrogen from renewable sources.

- Assessing hybrid renewable-based hydrogen production integration with battery capacity and hydrogen storage sizing through parametric analysis is recommended.

- Incorporating the costs associated with hydrogen storage and transportation is recommended.

- The current analysis of CO2 reduction is limited to operational phases. The environmental assessment should be enhanced by incorporating the impacts associated with manufacturing and decommissioning processes.

- Some performance indicators of the AFC and ELE, such as current density, temperature, and pressure, can be thoroughly examined.

- The AFC’s efficiency is highly sensitive to temperature, load changes, and hydrogen supply. To maintain stability and performance under dynamic conditions, robust control strategies, real-time monitoring, and adaptive parameter adjustments are essential.

- It is advised to use machine learning and optimization techniques to facilitate renewable resource-powered hydrogen systems.

- It is advised that the performance of hybrid PV-WT hydrogen production systems be investigated concerning further configurations and design criteria.

6. Conclusions

- The findings indicate that the system performance is substantially sensitive to changes in the ambient conditions over a year. The studied hybrid PV-WT hydrogen production system annually generates 1898.426 MWh of renewable electricity, corresponding to 252.7 metric tons of hydrogen under Perth’s conditions.

- As expected, the ELE has the highest exergy efficiency, at 89.6%, and non-dimensional sustainability, at 69%, compared to the other system subcomponents. This emphasizes that exergy efficiency increases when sustainability increases.

- Solar PV panels have the highest entropy generation, at 56.14%, compared to the other system subcomponents, amounting to approximately 3.49 kW/K.

- The overall output of electrical power generation on a daily average basis is 110.761 kW from the solar PV panels and 105.954 kW from the WT. The energy and exergy efficiency on a daily average basis are 9.2% and 9.8% for solar PV panels and 41.2% and 13.3% for the WT, respectively.

- It has been observed that the overall daily average over a year for the whole system is 7.3% for energy efficiency, 5.2% for exergy efficiency, 6.22 kW/K for entropy generation, and 1.055 for sustainability index.

- Enhancing the efficiency of renewable energy resources (solar PV panels and WT) should be prioritized to minimize the system’s overall entropy generation.

- Additionally, this analysis reveals that the average yearly value of the levelized cost of energy (LCOE) is 0.102 USD/kWh, the levelized cost of hydrogen (LCOH) is 4.94 USD/kg, and the energy payback time (EPBT) is 5.61 years.

- The current findings demonstrate the economic benefits of installing this hybrid hydrogen production system in Perth, Australia, and other locations with similar climates, particularly those with comparatively high wind energy alongside solar energy.

- The results indicate that the annual CO2 emissions, net CO2 mitigation, and carbon credit gained are 1087.73 tons/year, 55777.13 tons, and USD 808768.4, respectively.

- Hybrid PV-WT renewable resources improve overall system efficiency and enable uninterrupted, ongoing operation. Such systems are suitable in remote, coastal, and arid areas.

Funding

Data Availability Statement

Conflicts of Interest

References

- Hachim, D.M.; Al-Manea, A.; Al-Rbaihat, R.; Abed, Q.A.; Sadiq, M.; Homod, R.Z.; Alahmer, A. Enhancing the Performance of Photovoltaic Solar Cells Using a Hybrid Cooling Technique of Thermoelectric Generator and Heat Sink. J. Sol. Energy Eng. 2025, 147, 021011. [Google Scholar] [CrossRef]

- Alrbai, M.; Al-Dahidi, S.; Alahmer, H.; Al-Ghussain, L.; Al-Rbaihat, R.; Hayajneh, H.; Alahmer, A. Integration and Optimization of a Waste Heat Driven Organic Rankine Cycle for Power Generation in Wastewater Treatment Plants. Energy 2024, 308, 132829. [Google Scholar] [CrossRef]

- Jabbar, H.A.; Alwan, K.J.; Hachim, D.M.; Al-Manea, A.; Al-Rbaihat, R.; Alahmer, A. Comparative Assessment of Thermal Oils and Water as Working Fluids in Parabolic Trough Collectors for Enhanced Solar Power Generation. Eng. Res. Express 2024, 6, 035514. [Google Scholar] [CrossRef]

- Alahmer, A.; Wang, X.; Al-Rbaihat, R.; Amanul Alam, K.C.; Saha, B.B. Performance Evaluation of a Solar Adsorption Chiller under Different Climatic Conditions. Appl. Energy 2016, 175, 293–304. [Google Scholar] [CrossRef]

- Al-Rbaihat, R.; Alahmer, H.; Al-Manea, A.; Altork, Y.; Alrbai, M.; Alahmer, A. Maximizing Efficiency in Solar Ammonia-Water Absorption Refrigeration Cycles: Exergy Analysis, Concentration Impact, and Advanced Optimization with GBRT Machine Learning and FHO Optimizer. Int. J. Refrig. 2024, 161, 31–50. [Google Scholar] [CrossRef]

- Alrbai, M.; Alahmer, H.; Alahmer, A.; Al-Rbaihat, R.; Aldalow, A.; Al-Dahidi, S.; Hayajneh, H. Retrofitting Conventional Chilled-Water System to a Solar-Assisted Absorption Cooling System: Modeling, Polynomial Regression, and Grasshopper Optimization. J. Energy Storage 2023, 65, 107276. [Google Scholar] [CrossRef]

- Kuterbekov, K.; Kabyshev, A.; Bekmyrza, K.; Kubenova, M. Energy, Exergy and Thermo-Economics Analyses of Hybrid Solar, Steam Turbine and Biomass Gasification System for Hydrogen Production by Polymer Membrane Electrolyzer. Int. J. Thermofluids 2024, 21, 100556. [Google Scholar] [CrossRef]

- Ahmed, I.H.; Alakoul, K.A.; Al-Manea, A.; Wetaify, A.R.H.; Saleh, K.; Al-Rbaihat, R.; Alahmer, A. An Overview of Hydrogen Production Techniques: Challenges and Limiting Factors in Achieving Wide-Scale Productivity. AIP Conf. Proc. 2024, 3051, 050003. [Google Scholar]

- Wang, M.; Yang, W.; Zhu, W.; Yang, Y.; Meng, P.; Huang, Y.; Lin, W.; Xie, C.; You, L.; Xiong, L. Hysteresis Energy Management and Optimization of Transportation Energy System Considering Dynamic Electricity Price. Energy Convers. Manag. 2025, 327, 119574. [Google Scholar] [CrossRef]

- Akpasi, S.O.; Smarte Anekwe, I.M.; Tetteh, E.K.; Amune, U.O.; Mustapha, S.I.; Kiambi, S.L. Hydrogen as a Clean Energy Carrier: Advancements, Challenges, and Its Role in a Sustainable Energy Future. Clean Energy 2025, 9, 52–88. [Google Scholar] [CrossRef]

- Osman, A.I.; Mehta, N.; Elgarahy, A.M.; Hefny, M.; Al-Hinai, A.; Al-Muhtaseb, A.H.; Rooney, D.W. Hydrogen Production, Storage, Utilisation and Environmental Impacts: A Review. Environ. Chem. Lett. 2022, 20, 153–188. [Google Scholar] [CrossRef]

- Rezaei, M.; Naghdi-Khozani, N.; Jafari, N. Wind Energy Utilization for Hydrogen Production in an Underdeveloped Country: An Economic Investigation. Renew. Energy 2020, 147, 1044–1057. [Google Scholar] [CrossRef]

- Nasser, M.; Megahed, T.F.; Ookawara, S.; Hassan, H. Performance Evaluation of PV Panels/Wind Turbines Hybrid System for Green Hydrogen Generation and Storage: Energy, Exergy, Economic, and Enviroeconomic. Energy Convers. Manag. 2022, 267, 115870. [Google Scholar] [CrossRef]

- Sopian, K.; Ibrahim, M.Z.; Wan Daud, W.R.; Othman, M.Y.; Yatim, B.; Amin, N. Performance of a PV-Wind Hybrid System for Hydrogen Production. Renew. Energy 2009, 34, 1973–1978. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Soudan, B.; Mahmoud, M.S.; Sayed, E.T.; AlMallahi, M.N.; Inayat, A.; Al Radi, M.; Olabi, A.G. Progress of Artificial Neural Networks Applications in Hydrogen Production. Chem. Eng. Res. Des. 2022, 182, 66–86. [Google Scholar] [CrossRef]

- Wilberforce, T.; Olabi, A.G.; Imran, M.; Sayed, E.T.; Abdelkareem, M.A. System Modelling and Performance Assessment of Green Hydrogen Production by Integrating Proton Exchange Membrane Electrolyser with Wind Turbine. Int. J. Hydrogen Energy 2023, 48, 12089–12111. [Google Scholar] [CrossRef]

- Sharma, S.; Agarwal, S.; Jain, A. Significance of Hydrogen as Economic and Environmentally Friendly Fuel. Energies 2021, 14, 7389. [Google Scholar] [CrossRef]

- Rezk, H.; Olabi, A.G.; Abdelkareem, M.A.; Alahmer, A.; Sayed, E.T. Maximizing Green Hydrogen Production from Water Electrocatalysis: Modeling and Optimization. J. Mar. Sci. Eng. 2023, 11, 617. [Google Scholar] [CrossRef]

- Seck, G.S.; Hache, E.; Sabathier, J.; Guedes, F.; Reigstad, G.A.; Straus, J.; Wolfgang, O.; Ouassou, J.A.; Askeland, M.; Hjorth, I. Hydrogen and the Decarbonization of the Energy System in Europe in 2050: A Detailed Model-Based Analysis. Renew. Sustain. Energy Rev. 2022, 167, 112779. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, J.; Feng, L. Transient Analysis of a Green Hydrogen Production and Storage System Using Alkaline Electrolyzer. Fuel 2022, 324, 124752. [Google Scholar] [CrossRef]

- Karacavus, B.; Aydın, K. Hydrogen Production and Storage Analysis of a System by Using TRNSYS. Int. J. Hydrogen Energy 2020, 45, 34608–34619. [Google Scholar] [CrossRef]

- Topriska, E.; Kolokotroni, M.; Dehouche, Z.; Novieto, D.T.; Wilson, E.A. The Potential to Generate Solar Hydrogen for Cooking Applications: Case Studies of Ghana, Jamaica and Indonesia. Renew. Energy 2016, 95, 495–509. [Google Scholar] [CrossRef]

- Pal, P.; Mukherjee, V. Off-Grid Solar Photovoltaic/Hydrogen Fuel Cell System for Renewable Energy Generation: An Investigation Based on Techno-Economic Feasibility Assessment for the Application of End-User Load Demand in North-East India. Renew. Sustain. Energy Rev. 2021, 149, 111421. [Google Scholar] [CrossRef]

- Joshi, A.S.; Dincer, I.; Reddy, B. V Solar Hydrogen Production: A Comparative Performance Assessment. Int. J. Hydrogen Energy 2011, 36, 11246–11257. [Google Scholar] [CrossRef]

- Dincer, I.; Joshi, A.S. Solar Based Hydrogen Production Systems; Springer: New York, NY, USA, 2013; Volume 553. [Google Scholar]

- Ratib, M.K.; Muttaqi, K.M.; Islam, M.R.; Sutanto, D.; Agalgaonkar, A.P. Large-Scale Production of Green Hydrogen from Solar Energy in Australia: Operation and Control of a Multi-Unit PEM Electrolyser System. Int. J. Hydrogen Energy 2025, 98, 873–886. [Google Scholar] [CrossRef]

- Mostafaeipour, A.; Khayyami, M.; Sedaghat, A.; Mohammadi, K.; Shamshirband, S.; Sehati, M.-A.; Gorakifard, E. Evaluating the Wind Energy Potential for Hydrogen Production: A Case Study. Int. J. Hydrogen Energy 2016, 41, 6200–6210. [Google Scholar] [CrossRef]

- Honnery, D.; Moriarty, P. Estimating Global Hydrogen Production from Wind. Int. J. Hydrogen Energy 2009, 34, 727–736. [Google Scholar] [CrossRef]

- Genç, M.S.; Çelik, M.; Karasu, İ. A Review on Wind Energy and Wind–Hydrogen Production in Turkey: A Case Study of Hydrogen Production via Electrolysis System Supplied by Wind Energy Conversion System in Central Anatolian Turkey. Renew. Sustain. Energy Rev. 2012, 16, 6631–6646. [Google Scholar] [CrossRef]

- Olateju, B.; Kumar, A.; Secanell, M. A Techno-Economic Assessment of Large Scale Wind-Hydrogen Production with Energy Storage in Western Canada. Int. J. Hydrogen Energy 2016, 41, 8755–8776. [Google Scholar] [CrossRef]

- Rezaei-Shouroki, M.; Mostafaeipour, A.; Qolipour, M. Prioritizing of Wind Farm Locations for Hydrogen Production: A Case Study. Int. J. Hydrogen Energy 2017, 42, 9500–9510. [Google Scholar] [CrossRef]

- Liponi, A.; Frate, G.F.; Baccioli, A.; Ferrari, L.; Desideri, U. Impact of Wind Speed Distribution and Management Strategy on Hydrogen Production from Wind Energy. Energy 2022, 256, 124636. [Google Scholar] [CrossRef]

- Akyuz, E.; Oktay, Z.; Dincer, I. Performance Investigation of Hydrogen Production from a Hybrid Wind-PV System. Int. J. Hydrogen Energy 2012, 37, 16623–16630. [Google Scholar] [CrossRef]

- Kalinci, Y.; Dincer, I.; Hepbasli, A. Energy and Exergy Analyses of a Hybrid Hydrogen Energy System: A Case Study for Bozcaada. Int. J. Hydrogen Energy 2017, 42, 2492–2503. [Google Scholar] [CrossRef]

- Rezaei, M.; Khalilpour, K.R.; Mohamed, M.A. Co-Production of Electricity and Hydrogen from Wind: A Comprehensive Scenario-Based Techno-Economic Analysis. Int. J. Hydrogen Energy 2021, 46, 18242–18256. [Google Scholar] [CrossRef]

- Al-Ghussain, L.; Ahmad, A.D.; Abubaker, A.M.; Hassan, M.A. Exploring the Feasibility of Green Hydrogen Production Using Excess Energy from a Country-Scale 100% Solar-Wind Renewable Energy System. Int. J. Hydrogen Energy 2022, 47, 21613–21633. [Google Scholar] [CrossRef]

- Elminshawy, N.A.S.; Diab, S.; Yassen, Y.E.S.; Elbaksawi, O. An Energy-Economic Analysis of a Hybrid PV/Wind/Battery Energy-Driven Hydrogen Generation System in Rural Regions of Egypt. J. Energy Storage 2024, 80, 110256. [Google Scholar] [CrossRef]

- Tian, C.; Tan, Q.; Fang, G.; Wen, X. Hydrogen Production to Combat Power Surpluses in Hybrid Hydro–Wind–Photovoltaic Power Systems. Appl. Energy 2024, 371, 123627. [Google Scholar] [CrossRef]

- Benghanem, M.; Mellit, A.; Almohamadi, H.; Haddad, S.; Chettibi, N.; Alanazi, A.M.; Dasalla, D.; Alzahrani, A. Hydrogen Production Methods Based on Solar and Wind Energy: A Review. Energies 2023, 16, 757. [Google Scholar] [CrossRef]

- Bhandari, B.; Lee, K.-T.; Lee, C.S.; Song, C.-K.; Maskey, R.K.; Ahn, S.-H. A Novel Off-Grid Hybrid Power System Comprised of Solar Photovoltaic, Wind, and Hydro Energy Sources. Appl. Energy 2014, 133, 236–242. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Islam, M.S.; Taura, U.H.; Barhoumi, E.M.; Mansir, I.B.; Das, B.K.; Ali Sulaiman, M.M.B.; Agyekum, E.B.; Bahadur, I. A Techno-Economic Analysis of Renewable Hybrid Energy Systems for Hydrogen Production at Refueling Stations. Int. J. Hydrogen Energy 2024, 78, 68–82. [Google Scholar] [CrossRef]

- Nasser, M.; Megahed, T.F.; Ookawara, S.; Hassan, H. Techno-Economic Assessment of Clean Hydrogen Production and Storage Using Hybrid Renewable Energy System of PV/Wind under Different Climatic Conditions. Sustain. Energy Technol. Assess. 2022, 52, 102195. [Google Scholar] [CrossRef]

- Ishaq, H.; Dincer, I. Comparative Assessment of Renewable Energy-Based Hydrogen Production Methods. Renew. Sustain. Energy Rev. 2021, 135, 110192. [Google Scholar] [CrossRef]

- Al-Mahmodi, M.; Ayadi, O.; Wang, Y.; Al-Halhouli, A. Sensitivity-Based Techno-Economic Assessment Approach for Electrolyzer Integration with Hybrid Photovoltaic-Wind Plants for Green Hydrogen Production. Int. J. Hydrogen Energy 2025, 97, 904–919. [Google Scholar] [CrossRef]

- Wei, D.; Zhang, L.; Alotaibi, A.A.; Fang, J.; Alshahri, A.H.; Almitani, K.H. Transient Simulation and Comparative Assessment of a Hydrogen Production and Storage System with Solar and Wind Energy Using TRNSYS. Int. J. Hydrogen Energy 2022, 47, 26646–26653. [Google Scholar] [CrossRef]

- Saleem, M.S.; Abas, N.; Kalair, A.R.; Rauf, S.; Haider, A.; Tahir, M.S.; Sagir, M. Design and Optimization of Hybrid Solar-Hydrogen Generation System Using TRNSYS. Int. J. Hydrogen Energy 2020, 45, 15814–15830. [Google Scholar] [CrossRef]

- TRNSYS User Manual: TRNSYS 17 a TRaN Sient SYstem Simulation Program. In TRNSYS Laboratory. Volume 4 Mathematical Reference; Solar Energy Laboratory, University of Wisconsin-Madison: Madison, WI, USA, 2009; Volume 4, pp. 1–486.

- Caliskan, H.; Dincer, I.; Hepbasli, A. Energy, Exergy and Sustainability Analyses of Hybrid Renewable Energy Based Hydrogen and Electricity Production and Storage Systems: Modeling and Case Study. Appl. Therm. Eng. 2013, 61, 784–798. [Google Scholar] [CrossRef]

- Mahdi, Z.M.; Al-Shamani, A.N.; Al-Manea, A.; Al-zurfi, H.A.; Al-Rbaihat, R.; Sopian, K.; Alahmer, A. Enhancing Photovoltaic Thermal (PVT) Performance with Hybrid Solar Collector Using Phase Change Material, Porous Media, and Nanofluid. Sol. Energy 2024, 283, 112983. [Google Scholar] [CrossRef]

- Guo, J.; Wu, Z.; Zhang, F.; Yu, H.; Qian, C. Theoretical Studies on a Dual-Function System Integrating Solar Heating and Radiative Cooling for Year-Round Energy Saving. Sol. Energy 2025, 288, 113293. [Google Scholar] [CrossRef]

- Ehyaei, M.A.; Ahmadi, A.; Rosen, M.A. Energy, Exergy, Economic and Advanced and Extended Exergy Analyses of a Wind Turbine. Energy Convers. Manag. 2019, 183, 369–381. [Google Scholar] [CrossRef]

- Ozden, E.; Tari, I. Energy–Exergy and Economic Analyses of a Hybrid Solar–Hydrogen Renewable Energy System in Ankara, Turkey. Appl. Therm. Eng. 2016, 99, 169–178. [Google Scholar] [CrossRef]

- Montazerinejad, H.; Fakhimi, E.; Ghandehariun, S.; Ahmadi, P. Advanced Exergy Analysis of a PEM Fuel Cell with Hydrogen Energy Storage Integrated with Organic Rankine Cycle for Electricity Generation. Sustain. Energy Technol. Assess. 2022, 51, 101885. [Google Scholar] [CrossRef]

- Calderón, M.; Calderón, A.J.; Ramiro, A.; González, J.F.; González, I. Evaluation of a Hybrid Photovoltaic-Wind System with Hydrogen Storage Performance Using Exergy Analysis. Int. J. Hydrogen Energy 2011, 36, 5751–5762. [Google Scholar] [CrossRef]

- Liu, G.; Qin, Y.; Yin, Y.; Bian, X.; Kuang, C. Thermodynamic Modeling and Exergy Analysis of Proton Exchange Membrane Fuel Cell Power System. Int. J. Hydrogen Energy 2020, 45, 29799–29811. [Google Scholar] [CrossRef]

- Praveenkumar, S.; Agyekum, E.B.; Alwan, N.T.; Qasim, M.A.; Velkin, V.I.; Shcheklein, S.E. Experimental Assessment of Thermoelectric Cooling on the Efficiency of PV Module. Int. J. Renew. Energy Res. 2022, 12, 1670–1681. [Google Scholar] [CrossRef]

- Bhandari, R.; Shah, R.R. Hydrogen as Energy Carrier: Techno-Economic Assessment of Decentralized Hydrogen Production in Germany. Renew. Energy 2021, 177, 915–931. [Google Scholar] [CrossRef]

- Tyagi, P.K.; Kumar, R. Performance Enhancement of Nanofluid-Based Photovoltaic/Thermal System with a Novel Finned Multi-Block Container of Phase Change Material in the Summer Season of Northern India. J. Energy Storage 2024, 90, 111733. [Google Scholar] [CrossRef]

- Turkdogan, S. Design and Optimization of a Solely Renewable Based Hybrid Energy System for Residential Electrical Load and Fuel Cell Electric Vehicle. Eng. Sci. Technol. Int. J. 2021, 24, 397–404. [Google Scholar] [CrossRef]

- Al-Sharafi, A.; Al-Buraiki, A.S.; Al-Sulaiman, F.; Antar, M.A. Hydrogen Refueling Stations Powered by Hybrid PV/Wind Renewable Energy Systems: Techno-Socio-Economic Assessment. Energy Convers. Manag. X 2024, 22, 100584. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Solar PV panels | |

| Type | Mono-crystalline (HiKu7 Mono PERC) |

| PV power | 650 W |

| PV surface area | 4.279 m2 |

| Short-circuit current (SCI) at reference conditions | 17.16 A |

| Open-circuit voltage (OCV) at reference conditions | 37.9 V |

| Temperature coefficient in the short-circuit current | 0.05 A/°C |

| Temperature coefficient in the open-circuit voltage | −0.26 V/°C |

| The number of modules in series | 5 |

| The number of modules in parallel | 154 |

| Module cells wired in series | 144 |

| Wind turbine (WT) | |

| Type | Raum Energy 3.5 kW Wind Turbine |

| Turbine power | 3500 W |

| Energy production (at 5.0 m/s average wind speed) | 500 kWh/month |

| Swept area | 12.6 m2 |

| Blade diameter | 4 m |

| Tower height to nacelle | 14.5 m |

| Start-up wind speed | 2.8 m/s |

| Braking wind speed | 22 m/s |

| Rated wind speed | 11 m/s |

| Number of turbines | 143 |

| Parameter | Value |

|---|---|

| Advanced alkaline electrolyzer (ELE) | |

| Electrode surface area | 0.25 m2 |

| Maximum allowable current density per stack | 680 mA/cm2 |

| Number of cells in series per stack | 70 |

| Number of stacks in parallel per unit | 3 |

| Minimum allowable cell voltage | 1.4 V |

| Working pressure | 7 bars |

| Working temperature | 80 °C |

| Maximum allowable operating temperature | 85 °C |

| Alkaline fuel cell (AFC) | |

| Electrode surface area | 100 cm2 |

| Number of fuel cell modules in series per stack | 64 |

| Number of stacks in parallel per fuel cell unit | 12 |

| Working temperature | 70 °C |

| Open-circuit voltage | 5.6 V |

| Minimum cell voltage limit | 0.4 V |

| Parameter | Value |

|---|---|

| Actual volume of the hydrogen tank | 50 m3 |

| Maximum allowable pressure | 200 bar |

| Initial pressure level | 0.5 |

| Molar weight of gas | 2.016 g/mol |

| Critical pressure of gas | 12.9 |

| Parameter | Present Study [Perth, Australia] | Nasser et al. [13] [Alexandria, Egypt] | Relative Error (%) |

|---|---|---|---|

| Annual electricity generation (MWh) | 107.1 | 108.4 | 1.20 |

| Overall energy efficiency (%) | 15.97 | 16.42 | 2.74 |

| Overall exergy efficiency (%) | 12.49 | 12.76 | 2.12 |

| Hydrogen production per year (kg) | 1891 | 1912 | 1.10 |

| Average LCOE (USD/kWh) | 0.172 | 0.178 | 3.37 |

| Average LCOH (USD/kg) | 4.13 | 4.19 | 1.43 |

| Average EPBT (years) | 10.15 | 10.43 | 2.68 |

| CO2 emission reduction (tons) | 681.7 | 689.4 | 1.12 |

| Time | OCV (V) | SCI (A) | V (V) | I (A) | (kW) | (kW) | (-) | (kW) | (kW) | (-) | EGPV (kW/K) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Jan | 114.902 | 847.766 | 73.597 | 838.919 | 128.045 | 1273.010 | 0.101 | 128.045 | 1188.530 | 0.108 | 3.574 |

| Feb | 104.667 | 819.832 | 65.428 | 810.469 | 122.566 | 1319.865 | 0.093 | 122.566 | 1232.049 | 0.099 | 3.732 |

| Mar | 102.439 | 806.477 | 64.140 | 798.598 | 122.013 | 1344.355 | 0.091 | 122.013 | 1255.193 | 0.097 | 3.825 |

| Apr | 95.815 | 607.716 | 58.312 | 603.404 | 95.279 | 1130.813 | 0.084 | 95.279 | 1056.776 | 0.090 | 3.286 |

| May | 91.666 | 544.513 | 54.417 | 541.920 | 88.317 | 1095.750 | 0.081 | 88.317 | 1024.613 | 0.086 | 3.228 |

| Jun | 89.169 | 490.795 | 51.433 | 489.077 | 81.922 | 1044.266 | 0.078 | 81.922 | 977.034 | 0.084 | 3.111 |

| Jul | 93.711 | 471.546 | 54.723 | 469.900 | 78.858 | 964.409 | 0.082 | 78.858 | 902.467 | 0.087 | 2.869 |

| Aug | 98.488 | 597.136 | 55.484 | 595.536 | 101.469 | 1163.404 | 0.087 | 101.469 | 1088.709 | 0.093 | 3.441 |

| Sept | 106.447 | 693.869 | 60.156 | 692.127 | 118.701 | 1257.378 | 0.094 | 118.701 | 1176.629 | 0.101 | 3.684 |

| Oct | 115.351 | 751.870 | 67.391 | 749.054 | 125.623 | 1235.444 | 0.102 | 125.623 | 1155.579 | 0.109 | 3.563 |

| Nov | 118.161 | 831.562 | 70.000 | 827.218 | 134.586 | 1286.784 | 0.105 | 134.586 | 1202.824 | 0.112 | 3.660 |

| Dec | 117.520 | 851.335 | 71.905 | 844.656 | 132.495 | 1277.872 | 0.104 | 132.495 | 1193.744 | 0.111 | 3.605 |

| Year | 104.028 | 692.868 | 62.249 | 688.406 | 110.761 | 1207.295 | 0.092 | 110.761 | 1128.549 | 0.098 | 3.493 |

| Time | U (m/s) | (kW) | (kW) | (-) | (kJ/kg) | (kJ/kg) | (kJ/kg) | (kW) | (kW) | (-) | EGWT (kW/K) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Jan | 5.800 | 140.838 | 354.094 | 0.398 | 15.627 | 83.899 | 14.950 | 140.838 | 960.237 | 0.147 | 2.761 |

| Feb | 5.598 | 129.193 | 322.615 | 0.400 | 14.806 | 83.924 | 13.926 | 129.193 | 912.004 | 0.142 | 2.633 |

| Mar | 5.201 | 108.526 | 264.177 | 0.411 | 12.975 | 83.887 | 12.023 | 108.526 | 819.035 | 0.133 | 2.398 |

| Apr | 4.590 | 80.902 | 192.954 | 0.419 | 10.473 | 83.846 | 9.364 | 80.902 | 688.273 | 0.118 | 2.076 |

| May | 4.195 | 65.175 | 153.596 | 0.424 | 8.863 | 83.826 | 7.823 | 65.175 | 609.853 | 0.107 | 1.878 |

| Jun | 4.592 | 82.283 | 193.719 | 0.425 | 10.394 | 83.770 | 9.372 | 82.283 | 687.603 | 0.120 | 2.104 |

| Jul | 4.611 | 83.401 | 194.736 | 0.428 | 10.463 | 83.755 | 9.450 | 83.401 | 691.353 | 0.121 | 2.118 |

| Aug | 4.691 | 87.373 | 204.706 | 0.427 | 10.756 | 83.761 | 9.782 | 87.373 | 707.650 | 0.123 | 2.162 |

| Sept | 5.100 | 107.141 | 252.419 | 0.424 | 12.433 | 83.774 | 11.558 | 107.141 | 794.796 | 0.135 | 2.395 |

| Oct | 5.294 | 115.989 | 279.827 | 0.415 | 13.230 | 83.784 | 12.457 | 115.989 | 838.165 | 0.138 | 2.498 |

| Nov | 5.594 | 131.099 | 321.387 | 0.408 | 14.617 | 83.807 | 13.910 | 131.099 | 908.887 | 0.144 | 2.665 |

| Dec | 5.796 | 141.053 | 353.147 | 0.399 | 15.518 | 83.841 | 14.930 | 141.053 | 958.009 | 0.147 | 2.775 |

| Year | 5.086 | 105.954 | 256.932 | 0.412 | 12.628 | 83.826 | 11.495 | 105.954 | 793.975 | 0.133 | 2.361 |

| Time | (kW) | (kW) | (kW) | (-) | (-) | EGsystem (kW/K) | SIsystem (-) | HPRsystem (m3/h) | HP (ton) |

|---|---|---|---|---|---|---|---|---|---|

| Jan | 128.045 | 140.838 | 268.883 | 0.080 | 0.052 | 6.809 | 1.055 | 49.829 | 93.544 |

| Feb | 122.566 | 129.193 | 251.759 | 0.075 | 0.052 | 6.775 | 1.055 | 50.413 | 185.919 |

| Mar | 122.013 | 108.526 | 230.539 | 0.071 | 0.047 | 6.633 | 1.050 | 46.781 | 108.631 |

| Apr | 95.279 | 80.902 | 176.180 | 0.066 | 0.045 | 5.735 | 1.048 | 43.194 | 169.841 |

| May | 88.317 | 65.175 | 153.492 | 0.061 | 0.042 | 5.483 | 1.044 | 46.960 | 172.400 |

| Jun | 81.922 | 82.283 | 164.205 | 0.065 | 0.043 | 5.641 | 1.045 | 50.840 | 167.542 |

| Jul | 78.858 | 83.401 | 162.259 | 0.070 | 0.048 | 5.325 | 1.051 | 43.759 | 318.397 |

| Aug | 101.469 | 87.373 | 188.843 | 0.068 | 0.049 | 5.983 | 1.051 | 51.216 | 339.983 |

| Sept | 118.701 | 107.141 | 225.842 | 0.074 | 0.055 | 6.422 | 1.058 | 45.859 | 378.862 |

| Oct | 125.623 | 115.989 | 241.613 | 0.080 | 0.059 | 6.362 | 1.063 | 41.675 | 413.787 |

| Nov | 134.586 | 131.099 | 265.685 | 0.082 | 0.061 | 6.632 | 1.065 | 42.984 | 381.130 |

| Dec | 132.495 | 141.053 | 273.548 | 0.083 | 0.059 | 6.736 | 1.063 | 46.262 | 302.400 |

| Year | 110.761 | 105.954 | 216.715 | 0.073 | 0.052 | 6.221 | 1.055 | 46.627 | 252.703 |

| Capital Cost | Cost per Unit |

|---|---|

| PV panels | 900 USD/kW |

| Wind turbines (WTs) | 1000 USD/kW |

| Converter (CON) | 600 USD/kW |

| Advanced alkaline electrolyzer (ELE) | 930 USD/kW |

| Alkaline fuel cell (AFC) | 450 USD/kW |

| Hydrogen storage tank | 570 USD/kg |

| Parameters | Outcome |

|---|---|

| Lifetime (n) | 20 years |

| parameter | 0.93 |

| Capital recovery factor (CRF) | 10.76% |

| Annual operation and maintenance cost () | USD 29,830 |

| Constant escalation levelized factor ( | 1.08% |

| Operation and maintenance levelized cost | USD 32,295.12 |

| Total investment cost () | USD 1,491,500 |

| Investment levelized cost | USD 160,488 |

| Embodied energy ( | 10,653,571.43 kWh |

| Annual energy for 365 days | 1,898,426.11 kWh |

| Levelized cost of energy (LCOE) for 365 days | 0.102 USD/kWh |

| Energy payback time (EPBT) | 5.61 year |

| Levelized cost of hydrogen (LCOH) for 365 days | 4.94 USD/kg |

| Reference (Year) | Region | Key Economic Indicators | |||

|---|---|---|---|---|---|

| Average LCOE (USD/kWh) | Average LCOH (USD/kg) | Average EPBT (Year) | Hydrogen Production (kg/kWh) | ||

| S. Turkdogan [59] (2021) | Ayvalık, Turkey | 0.685 | 6.85 | - | 46.40 |

| Nasser et al. [13] (2022) | Alexandria, Egypt | 0.178 | 4.19 | 10.43 | 56.69 |

| Elminshawy et al. [37] (2024) | Egypt | - | 2.22 | - | 15.23 |

| Okonkwo et al. [41] (2024) | Muscat, Oman | 0.0158 | 0.401 | - | - |

| Al-Sharafi et al. [60] (2024) | Saudi Arabia | - | 9.70 | - | - |

| Al-Mahmodi et al. [44] (2025) | Maan, Jordan | - | 3.97 | - | - |

| Present study (2025) | Perth, Australia | 0.102 | 4.94 | 5.61 | 7.51 |

| Parameters | Outcome |

|---|---|

| Embodied energy ( | 10,653,571.43 kWh |

| Annual energy for 365 days | 1,898,426.11 kWh |

| CO2 emission | 1087.73 tons/year |

| Net CO2 mitigation | 55,777.13 tons |

| Carbon credit gained | USD 808,768.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Rbaihat, R. Sensitivity Analysis of a Hybrid PV-WT Hydrogen Production System via an Electrolyzer and Fuel Cell Using TRNSYS in Coastal Regions: A Case Study in Perth, Australia. Energies 2025, 18, 3108. https://doi.org/10.3390/en18123108

Al-Rbaihat R. Sensitivity Analysis of a Hybrid PV-WT Hydrogen Production System via an Electrolyzer and Fuel Cell Using TRNSYS in Coastal Regions: A Case Study in Perth, Australia. Energies. 2025; 18(12):3108. https://doi.org/10.3390/en18123108

Chicago/Turabian StyleAl-Rbaihat, Raed. 2025. "Sensitivity Analysis of a Hybrid PV-WT Hydrogen Production System via an Electrolyzer and Fuel Cell Using TRNSYS in Coastal Regions: A Case Study in Perth, Australia" Energies 18, no. 12: 3108. https://doi.org/10.3390/en18123108

APA StyleAl-Rbaihat, R. (2025). Sensitivity Analysis of a Hybrid PV-WT Hydrogen Production System via an Electrolyzer and Fuel Cell Using TRNSYS in Coastal Regions: A Case Study in Perth, Australia. Energies, 18(12), 3108. https://doi.org/10.3390/en18123108