Abstract

Buildings are major energy consumers, accounting for a significant portion of global energy consumption. Integrating hydrogen systems, electrolyzers, accumulation, and fuel cells is proposed as a clean and efficient energy alternative to mitigate this impact and move toward a more sustainable future. This paper presents a systematic procedure for incorporating these technologies into buildings, considering building engineers, and stakeholders. First, an in-depth analysis of buildings’ main energy consumption parameters is conducted, identifying areas of energy need with the most significant optimization potential. Next, a detailed review of the various opportunities for hydrogen applications in buildings is conducted, evaluating their advantages and limitations. Performing a scientific review to find and understand the requirements of building engineers and the stakeholders has given notions of integration that emphasize the needs. As a result of the review process and identifying the needs to integrate hydrogen into buildings, a flowchart is proposed to facilitate decision-making regarding integrating hydrogen systems into buildings. This flowchart is accompanied by a matrix of variables that considers the defined requirements, allowing for combining the most suitable solution for each case. The results of this research contribute to advancing the adoption of hydrogen technologies in buildings, thus promoting the transition to a more sustainable and resilient energy model.

1. Introduction

The global temperature increase poses a critical challenge that requires coordinated action at both individual and collective levels. The European Union’s 2030 Climate Target Plan sets an ambitious goal to reduce greenhouse gas emissions by at least 55% by 2030 [1]. With these emission reduction targets, countries, regions, cities, and businesses actively pursue carbon neutrality goals [2]. A key to these efforts is improving energy efficiency, particularly in the building sector, which demands intensified intervention [1].

According to the European Commission, approximately 75% of existing buildings in the EU are energy inefficient [3]. Notably, 85% of the building stock was constructed before 2001, and 85–95% of these buildings are expected to remain operational by 2050. Researchers have long focused on developing classification systems, strategies, and methodologies for retrofitting these buildings, either partially or comprehensively. Multi-Criteria Decision-Making Problems (MCDMP) emerge as a commonly employed strategic approach [4,5,6,7,8,9,10].

The building sector is responsible for roughly 40% of total energy consumption globally, as reported by the United Nations Environment Program (UNEP) [11]. It is essential to focus on buildings by initiating energy retrofits and incorporating energy efficiency measures into standard building maintenance [12]. Property owners, therefore, play a role in implementing improvements that reduce energy consumption and enhance sustainability [3]. The primary strategies to tackle energy consumption involve reducing energy use [9,10,12,13] and integrating low-carbon technologies [14,15,16,17].

In recent years, a well-known yet underutilized technology in the building sector—hydrogen—has gained increasing attention for its potential to enhance energy systems. Recent studies highlight H2 as a promising resource for decarbonizing buildings’ heating needs [18,19]. A study anticipates that H2 could fulfill most of the United Kingdom’s heat demand by 2050 [20]. Hydrogen’s potential for decarbonization extends to the EU economy [3], which is currently fostering the development of a clean H2 strategy [19]. This strategy uses renewable sources to produce hydrogen through electrolyzers, facilitating fossil fuel reduction [19] and enhanced sustainability.

Since free hydrogen is scarce, the concept of a “hydrogen economy” is built upon the extraction of hydrogen from various sources and its diverse applications within the energy sector [21]. Beyond direct uses, hydrogen is increasingly viewed as a resilient and sustainable energy source of the future [22]. It offers a solution to long-term challenges in storing electricity generated from renewable sources [23]. Also, hydrogen’s versatility in production methods and energy applications underpins its role as an energy carrier [24].

It is well established that integrating H2 into the current power grid could significantly enhance renewable energy penetration [25]. As renewable energy sources constitute a larger share of the grid, buildings’ energy dependency on non-renewable electricity would decrease [25]. H2 can serve as a clean energy source in energy applications to meet buildings’ electricity demands [26].

A recent analysis by the International Energy Agency (IEA) projects that the cost of producing H2 from renewable electricity may decline by up to 30% by 2030, driven by decreasing renewable energy costs and the scaling up H2 production [25]. Strong evidence suggests that H2 technology may follow a cost and performance improvement trajectory similar to photovoltaic (PV), solar panels, and battery storage technologies [27,28].

Based on the current state of technology development, this article aims to identify the requirements for integrating hydrogen (H2) into buildings. Bibliographic references indicate that further technological advancements in architecture are essential to facilitate H2 installation [29]. These technological advancements can be interpreted as cost-effective methodologies and supportive policies, which are required [30] to maximize H2’s potential in reducing carbon dioxide (CO2) emissions [22] and enhancing the efficiency of renewable energy installations in buildings [31]. Moreover, initial scientific research revealed a need for documented guidelines to address this integration gap, which the article is going to focus on.

Two agents are proposed to articulate the process of integrating H2 into buildings. The requirements of these agents align with the article’s objective and contribute to technological advancements in H2 and architecture. These hypothesized requirements reflect the motivation behind this work, which stems from discussions during a project that aims to integrate an H2 system into a building in northern Spain.

The research team considers building engineering and stakeholder agents’ relevant parameters to develop a documented guideline. Building engineer requirements, which determine the space’s materials, location, and characteristics, are essential for adequately integrating any element into a building. Stakeholder requirements can be evaluated, as Si et al. [9] describe, highlighting the vital role that these agents play in any building implementation or project. Furthermore, the criteria set by stakeholders are crucial for developing and executing any project.

These building engineers’ and stakeholders’ requirements, identified as parameters, have formed the development of an initial tool for consulting the requirements for integrating H2 systems in architecture through already published knowledge. This resource provides a foundational reference point to facilitate efforts in H2 system integration within buildings. Determining these parameters ensures that the method followed is reproducible, regardless of each parameter’s development stage.

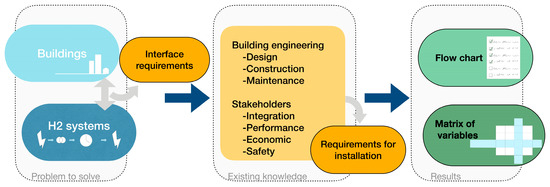

As a summary of this first section, as shown in the graphical abstract (Figure 1), an initial identification of the deficiencies of existing buildings and a study of the advancement of H2 systems are conducted, and a problem is detected: the lack of information, methodologies, and regulations that describe how to integrate H2 systems into buildings. This article aims to identify the key requirements for incorporating H2 into buildings, considering both building engineering and stakeholder perspectives. This investigation, motivated by a real-world project in northern Spain, seeks to develop a foundational tool—a flowchart and a matrix—based on existing knowledge to facilitate the integration of H2 systems in architecture.

Figure 1.

Graphical abstract of the article where the problem to solve, the existing knowledge, and results are presented.

2. Methods—Classification of Knowledge

To address the need for integration guidelines, the selected requirements—building engineer and stakeholder requirements—were determined to meet the system’s needs. Hence, a literature review was conducted to find information related to the identified parameters.

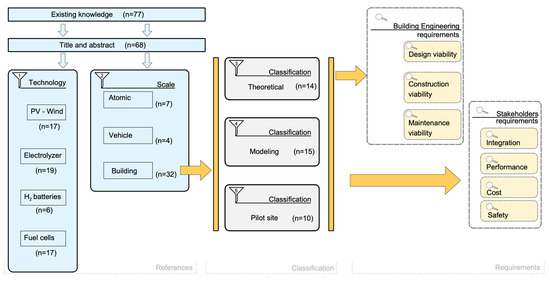

Figure 2 presents a workflow diagram of the literature review that has been classified. On the left side, the outcomes of the scientific literature are illustrated, with a list of general groupings in blue, followed by an initial classification in grey of the articles that have installed H2 systems in buildings. On the right side, in orange, are the subsequent defined requirements—building engineering requirements and stakeholder needs—categorized into design viability, construction viability, and maintenance viability on one side and integration, performance, cost, and safety on the other. The scientific literature will define the matrix of variables.

Figure 2.

Workflow of the methodology in progress. From left to right: in blue, the existing knowledge; in grey, the classification of articles; in orange, requirements to be responded to; building engineering requirements, stakeholder requirements.

Seventy-seven articles have defined the scientific literature. Technology and scale differentiation have accurately developed an initial grouping of the knowledge. Identifying the technology used can provide an overview of the installations. Regarding scale application, seven articles focus on the atomic scale application, four on the vehicle scale application, and thirty-two on the building scale application.

Based on this grouping, the analysis focuses on the building scale application, so the development is limited to this area. Articles on building-scale application are classified into three different categories to identify the approaches of the articles and find responses to the defined requirements. At the time, nearly half of the articles classified under the building scale focus on simulations (15), followed by theoretical articles (14). The group of studies developing pilot sites (10 articles) represents the smallest subset of results. These categories will organize and answer building engineer and stakeholder requirements.

2.1. Building Engineering Requirements

The system’s requirements must be considered when integrating external elements into a building. Therefore, the life cycle of a project is related to the building engineers’ requirements. The life-cycle requirements are naturally segmented into three phases according to their needs.

- The first phase is related to design viability. This is the phase when the technical material aspects of the system, including components, connections, spatial requirements, and controls, are determined. The objective is to optimize and customize the system.

- The second phase is related to construction viability. In this phase, the space is materialized, including determining location, scale, dimensions, operations, and requirements.

- The final phase concerns the maintenance viability of the building services. This is a delicate phase for the building owners, as the more innovative the systems, the more uncertainties they raise regarding their performance, reliability, and costs. This phase encompasses the work to be carried out, including startup, shutdown, and response times, as well as the periodic repair and replacement of components.

Having defined the three parameters (design, construction, and maintenance), we comprehensively analyze the knowledge associated with each classification (theoretical, modeling, and pilot site). This enables us to group knowledge on comparable scales, facilitating subsequent analysis.

Referring to the knowledge found related to the theoretical classification articles, the following is highlighted (see Table A1): Design aspects were mentioned in more than half of the articles (85%) and included the presence of notions about initial decision-making [32,33], scale and dimension [34,35], and form of work [36,37]. Most articles complemented H2 with PV, wind power, and fuel cells (FCs). Regarding construction, 28% of the authors focused on developing it. The schema of the principle and work mode addresses this topic [38,39,40,41], with the articles concentrating on results [36,42,43,44,45] or a description of its operation [45,46,47]. Just 7% of the articles assessed the maintenance work involved in an H2 installation.

Articles related to modeling explain that using models or modeling in the working process seems relevant since 46.5% of the results included this aspect (see Table A2). For some authors, the modeling process is used as a device [46,48], while for others, it results from the work [43,49,50,51]. Comparing and assessing its impact and technical value is applicable in both cases. Regarding the variables analyzed, 50% of the results considered the design factor. In comparison, 50% of the articles also focused on and described the construction process, while 62% of the results focused on the maintenance factor.

Referring to the last classification, pilot sites, (see Table A3), most of them used modeling to predict performance or behavior [39,40,45,46,49,52,53], principally MATLAB Simulink, TRNSYS 18, and HOMER Energy. The authors agreed on the technical feasibility of H2 and the need for economic [39,45] and legal development [23,52]. It is remarkable how little importance the authors attached to security aspects despite these affecting the safety of operations. Security was addressed in only 40% of the articles focusing on the design factor. Some examples of design considerations include the following: pumped H2 systems as a better option than batteries [54]; deploying H2-based building vehicles (proton-exchange membrane fuel cells—PEMFC) enhances regional energy flexibility and reduces the reliance on fossil fuels [49]. On the other hand, 70% of the articles considered construction-related concepts. In addition to requiring a large amount of space, the articles noted that sites also need to be close to a source of renewable energy production [40].

Moreover, selected sites should offer opportunities for H2 implementation for energy storage, transportation, and stationary applications [23], even though there are better strategies than using H2 for batteries due to the high energy losses [55]. Nevertheless, using this surplus electricity effectively requires alignment with the energy consumption [46]. However, even if global efficiency is still low, it is estimated that the period between 2023 and 2031 will see a reduction in costs, the flexibility to work in different contexts, and the ability to couple different consumptions [52]. Yet, these production systems can reduce emissions by approximately 250 t CO2/year [39]. It is estimated that three small FCs could cover most of the end-use energy demands of six homes by networking homes and systems [54]. The presence of maintenance aspects was more significant than the previous results, at 70%. Maintenance of electrolyzers is crucial, as their intermittent operations can cause a drop in efficiency of up to 50% [39]. Compressors must be installed to ensure maximum space efficiency, thereby prolonging the profitability of this solution [40]. Any technical issues encountered can be successfully resolved, thus improving system efficiency and cost-effectiveness [23]. With anticipated trends in cost reduction and reduced emissions, this technology is expected to play a critical role in advanced energy management systems in 2023–2031 [53].

2.2. Stakeholders’ Requirements

In this context, the following requirements were determined and analyzed according to the steps outlined by Si et al. [9]. On the one hand, integrating H2 into buildings was considered, alongside energy performance and the installation of complementary equipment. The economic costs were also evaluated, and finally, the safety and security measures for using and designing H2 systems were examined.

Finding information related to stakeholders was complex. In addition, the information found in publications was scarce. It can be deduced that the research developed, not being executable in a building within a regulatory framework, impacts the stakeholders’ requirements.

Regarding the integration requirement, references were found to respond to industrial demands, not urban areas or inside buildings; the requirements followed to integrate the H2 system are mechanical components [56], materials, and connections. On the other hand, word integration is also used to combine the work modes of the system elements [45,49,53].

Existing knowledge has focused on the system’s performance, primarily through predictive models [50] and analyses of energy needs [31]. The study of performance is related to building energy use, which is aligned with energy, production, and storage [31,32,39].

The following lines are developed regarding the economic costs of the H2 system found in the references. Despite the predicted reduction in production costs [57], “the more popular the technology becomes, the more competitive prices will be”. Articles focus on studying fuel costs [40,58] and the cost of building the system [39,45,52,53].

The requirement referring to safety in H2 establishes political and regulatory frameworks, which often have to be adapted to the specific demands of H2 [23]. Over 100 years of safe H2 production, transportation, and use have shown that it poses no more risk than natural gas or gasoline [45]. H2 is understood to be as hazardous as other fuels [59]. H2 safety engineering (H2SE) is crucial for the success of the H2 economy and its public acceptance. This procedure consists of three main steps: qualitative design review, quantitative safety analysis, and trial safety design [60]. Large-scale island-based projects such as Utsira and BIG HIT are being carried out in controlled environments to prioritize safety [56]. In addition, to address public resistance, they have made special efforts to organize information campaigns to secure support from local entities and authorities [23]. To prevent incidents in H2 facilities that might pose safety risks [61], Lawrence Livermore National Laboratory contributes to safe H2 operations by developing instructional materials [62].

Additionally, H2 safety problems have been efficiently controlled in the industry for many years. However, safety analyses are needed for transportation and residential fuel markets [63]. The first step in this process is to establish political and regulatory frameworks, which often have to be adapted to the specific demands of H2 [23].

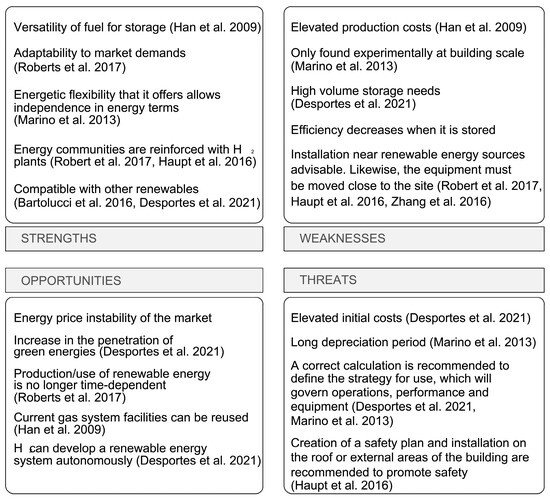

Figure 3 presents a SWOT analysis based on the results obtained. An outstanding strength of H2 is its versatility and adaptability to market demands, whether in production, storage or as fuel [33,34]. This characteristic adapts well to the energy needs of buildings, where it can strengthen energy communities [34,35], taking advantage of its compatibility with renewable energies [36]. Also, H2 offers opportunities such as increasing green energy penetration [37] and adding stability to the electricity market.

Figure 3.

SWOT of using H2 in buildings, based on the research analysis [33,34,35,36,37,38,39].

This SWOT analysis must take into account the overall issue of regulation. Similar to what is happening with the rapid development and implementation of electric vehicles and the problems associated with underground parking [64], the use of the production, accumulation, and use system in buildings, at least in Europe, is deregulated, but this is not the case for industrial buildings. In any case, the lack of specific regulations may affect what is presented here, since their development can create new opportunities for development, but also threats, if certain developments are limited. Strengths arise from having a specific regulatory framework, and a major weakness in development if it is not consolidated homogeneously across different countries.

On the other hand, installing H2 systems presents weaknesses related to their location near renewable energy sources [35,38] and the large amount of space required for storage [37]. In addition, high initial costs represent a limitation [37], as does the need for precise calculations to define an appropriate usage strategy [37,39].

The SWOT analysis of H2 in buildings allowed us to focus on these systems’ challenges, such as reducing the elevated initial cost and depreciation through policies, and shortcomings such as the high storage volume needed and the installation’s efficiency. As soon as H2 is treated like any other technology, research on costs, pilot sites, location, design, and safety must continue.

3. Flowchart and Matrix of Variables

Based on the knowledge found, the following information is deduced after considering the design, construction, and maintenance requirements, as well as integration, performance, economics, and safety.

The system must be organized with a clear objective to ensure design viability. Communication with the building and organization system hinges on this. Full automation will allow for addressing possible errors and switching control on and off to manage costs. Referring to construction viability, the system needs to be scalable, regardless of its location within the building. Therefore, it is recommended that the area where it is located be large enough for the installation to be extended and for staff to work comfortably. Although the safety of existing installations has been proven, it is essential to highlight the need for natural cross-ventilation and coolers or boilers, depending on the weather and exposure to external agents. Regarding maintenance viability, technicians must be trained to operate the system according to programming, interpret alarms, and perform maintenance work. Therefore, viewing the system in real time and comparing the data with historical data is necessary to adjust values within safe parameters.

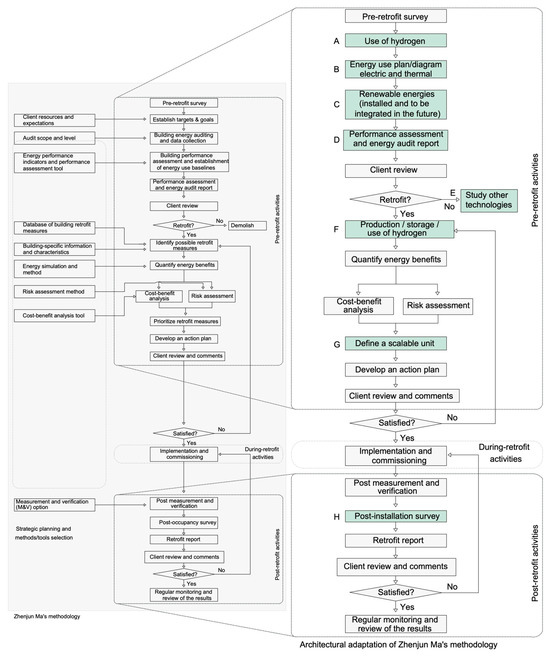

After analyzing existing knowledge, the need for a precise sequence of steps is deduced as a recommended guide to follow in the process. Therefore, given the diversity of data and insights into the status and procedures for incorporating H2 into projects and daily practices, it is essential to refer to Zhenjun Ma’s methodology [10]. Zhenjun Ma’s work, which provides a multi-criteria guide for comparison and classification in retrofitting processes, can be adapted to this context through architectural adaptation. This adaptation contributes to the structured approach to integrating H2 systems. The main change during the methodology’s interpretation is modifying the base goal. The methodology changes from an open hypothesis to a determinate one: integrating an H2 system into buildings. These changes are graphed in green, emphasizing the importance of first steps.

Based on the information on integrating H2 systems, a flowchart, Figure 4, is developed. The tool consolidates the findings of this study into a practical framework that facilitates the process of integrating H2 into buildings in the pre-retrofit, during-retrofit, and post-retrofit phase. The capacity to address and foresee future inquiries facilitates a holistic approach to the installation. Similarly, pre-determining task assignments for skilled individuals optimizes the work process.

Figure 4.

Architectural adaptation of Zhenjun Ma’s methodology for H2 implementation in buildings in the right side column.

The interpretation of the methodology creates a flowchart of recommended checks for integrating H2 into buildings. Moreover, the flowchart provides a series of questions, maintaining a linear process, to help ensure that ideas stay clear and focused at each stage for building engineers and stakeholders involved in integrating H2 into buildings. Initially, the questions posed are oriented to the required usage, complementarity, and system performance related to building engineers. In the last steps, the focus is on measurements, reports, and surveys related to stakeholders.

As mentioned, the first phase of the flowchart corresponds to pre-retrofit activities related to building engineers, except A and B, where stakeholders should be involved too. Tasks that need to be developed are associated with defining the strategy, design, and unit, and consist in the following:

A: Use of hydrogen. The goal is to use hydrogen. Even if the work-mode and the product form will be determined at a later stage, it is important to identify the possibility of using hydrogen. It also needs to be determined whether it will be produced, accumulated, used, or/and bought, depending on the final object.

B: Energy use plan/diagram: electric and thermal. Determination of the object of using H2 in relation to the building energy requirement. Moreover, the components of the hydrogen system have to be identified. Depending on the efficiency required and energy demands of the building, the system will be used as a backup, electrical, or thermal source, depending on the efficiency needed, if any, and the building’s energy demands.

C: Renewable energies (installed and to be integrated in the future). Combining renewable energies with hydrogen systems allows for increased versatility and closes the loop of a green energy system. Its integration can be initially gradual, as defined by the system module.

D: Performance assessment and energy audit report. After developing a hypothetical response to the challenges facing hydrogen, including its operation, the building, and its potential connection to renewable energies, its energy feasibility is assessed. The assessment and the report demonstrate the technical viability of the system.

E: Studying other technologies. Given the specific requirements, we may need to explore alternative renewable technologies beyond hydrogen. The final object might be electrical efficiency, so the results obtained could not be enough.

F: Production/storage/use of hydrogen. Once the technical specifications have been established, the optimal hydrogen system type is defined, considering production, storage, utilization, and hydrogen procurement. This step allows us to adjust and identify the scale of the system.

G: Defining a scalable unit. A phased approach with small-scale modules is recommended, allowing for gradual implementation and potential future expansion. For example, the module can be 50% of the total requirement.

Furthermore, stakeholders need to supervise the post-retrofit activities, task H. These agents will oversee the installation’s lifecycle and the system’s correct work mode.

H: Post-installation survey. Once the system is operational and data is collected, verifying that its performance aligns with the original design is necessary. Additionally, this includes overseeing that maintenance tasks are being carried out correctly and that the system is operating according to the defined requirements (verification of programming).

As outlined in the flowchart, we combine the requirements of building engineers and stakeholders to create a shared understanding and a collaborative framework. This approach addresses the need for increased coordination between these actors, who traditionally work independently, to ensure a successful H2 system installation.

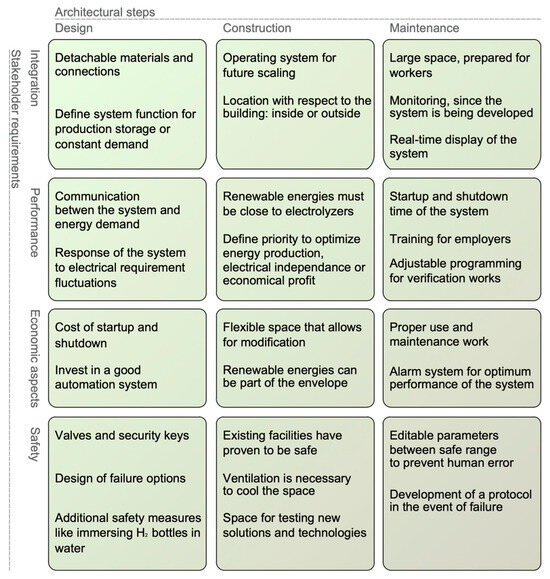

Integrating stakeholder requirements and architectural processes allows for the grouping and organization of information. Furthermore, by refining the results under the criteria of the research team, which is in constant contact with companies and manufacturers [26], the first variable matrix is developed, which is, to our knowledge, a reference for the integration of H2 systems into buildings; see Figure 5. Thus, the table serves as a promising tool for integrating H2 into buildings and disseminating the needs and considerations to be addressed according to the requirements of each particular case.

Figure 5.

Matrix of architecture and stakeholders’ variables to implement H2 in buildings.

The matrix comprises three columns (building lifecycle steps) and four rows (stakeholder perspectives). The columns identify design, construction, and maintenance aspects. The rows develop integration, performance, economic factors, and safety-related requirements. The matrix includes significant findings and results of the applied methodology. Additionally, it was noted that comparing and finding sufficient information becomes increasingly challenging as projects move into the maintenance and safety phases.

Thanks to the development of the flowchart and the matrix of variables, the lack of information on integrating H2 systems into buildings is solved. Thus, determining key steps and concepts for integrating H2 into buildings provides stakeholders and building engineers with an initial reference that was previously unavailable.

On the one hand, it is of great interest to assess the specific impact that integrating an H2 system into buildings and other large consumers would have. However, aspects such as the effect on the power grid, building energy performance, and system responsiveness still require further study. For this reason, the flowchart and the matrix of variables are designed to be flexible, allowing modifications and increases in the number of parameters and agents involved.

Conversely, experience limited to a pilot site restricts the available information regarding maintenance, safety, and economic costs. Consequently, these aspects should be considered the first approximation of the requirements. As case study publications increase, the proposed guidelines can be enriched, validated, and expanded.

The integration of H2 into buildings represents a novel technology that faces entry challenges in the current market. Therefore, both administrations and owners must be aware of this and collaborate to encourage the inclusion of these innovative solutions in the future of construction.

4. Discussion

The reference analysis reveals a need for more pilot experiences compared to studies focused on calculations and simulations. These studies’ initial hypotheses emphasize the relationship between H2 systems and renewable energy sources, underscoring their complementary role. In other words, while the number of pilot projects is limited, integrating renewable energies will remain crucial in H2 system designs.

Furthermore, the need for policies and regulations directly impacts the implementation and execution of pilot projects. A sufficient number of these sites is essential to develop and assess the technical requirements of H2 systems for integration purposes. Implemented solutions must comply with Equipment for potentially explosive atmospheres (ATEX) certifications, which significantly affect installation costs. The EU should develop a standard for “Implementation of unusual technologies in buildings” or equivalent. The regulatory framework can also be extended to implement other results, with safety always being the top priority.

At the School of Architecture of the University of Navarra in Pamplona, Spain, the implementation of a H2 system is underway.

It is considered relevant to note that the supplier company has a thorough knowledge of the operation of the H2 system. However, it does not have specific recommendations for integrating into buildings. It is limited to complying with current regulations, which may restrict its ability to adapt to the project’s requirements.

The flowchart application allowed the following points to be determined as the project was being developed. This allowed the considerations and their consequences to be identified from the beginning.

A: Use of hydrogen. The implementation of a hydrogen system is a strategic commitment; the definition of the form is going to be developed in the following steps.

B: Energy use plan/diagram—electric and thermal. The system must be able to meet electrical demand in the event of a power outage in the building, even if it is temporary.

C: Renewables (already installed and will be integrated in the future). Energy contribution from PV panels is integrated into the system. As the H2 system expands, the PV panel will increase proportionally.

D: Performance assessment and energy audit report. Thanks to the H2 produced during the week, it is feasible to disconnect the building on Saturdays.

E: Study other technologies. It is not evaluated because the retrofit continues.

F: Production/storage/use of hydrogen. The final decision is to install a complete system (production, storage, and use of H2). In this way, the system can be evaluated as a whole.

G: Define a scalable unit. The selected module is a 2.5 kW cell with a small-scale available industrial electrolyzer.

Unfortunately, the flowchart application has been halted at the pre-retrofit activities stage due to administrative issues related to stakeholders, specifically the additional economic cost of complying with ATEX-certified products. Consequently, the project is drafted and evaluated and is awaiting installation to execute and assess post-retrofit activities.

On the other hand, applying the variable matrix has verified and guided issues to be considered during the design process. The development of this project involves a diverse range of agents from different sectors, such as H2 supplier companies, stakeholders, maintenance staff, building engineers, and electric suppliers. Additionally, part of the team responsible already has experience with similar installations, albeit on a smaller scale (CIFP San Jorge) [65].

The application of the matrix of variables has been essential for defining and highlighting the different necessities between all the agents involved:

Design

- Implementation of detachable materials and connections. Same metric and material.

- Definition of the system for storage and determinate production. Permanent H2 production and FC work scheduled only on Saturdays.

- Create a communication protocol. Connect to the general control system.

- Establish the role of the system on electrical consumption. The system covers the electrical needs on Saturdays.

- Invest in an automation system. Design a complete automation system.

- Design of failure option. Establish a series of alarms.

Construction

- Provision for possible future scaling. Ensure the adaptability of the equipment to meet larger requirements.

- Location of the system—consider placement outside the building.

- Integration of PV elements into the building envelope.

- Prioritize H2 production.

- Determine ventilation flow. Design window and fans.

Maintenance

- Provision of space for workers.

- Implement a monitoring system. Design a local visor of the systems.

- Training for employees.

- Determination of safe parameters. Investigate the safe operational range.

- Assess use and maintenance needs. Cleaning and control.

- Design alarms to ensure optimum performance.

The assurance that the different sections will be completed by building engineers and stakeholders, with the support of the supplier company, has provided peace of mind at this stage of the project. However, highlighting the need to establish a common language to facilitate integration has been essential. This task is complex, as it first requires unifying the needs of all involved and setting clear priorities. Nevertheless, interdisciplinary collaboration is crucial to ensuring a successful integration aligned with the project’s objectives.

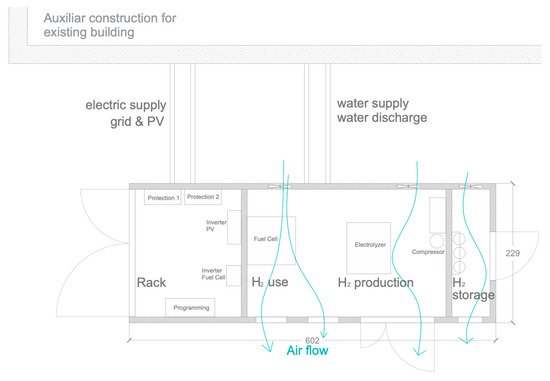

The final system, designed but not executed, includes the production of H2, the storage of H2, and the electrical production with renewable H2. The installation consists of a 40 kW PV plant, a storage system, and two fuel cells with a total capacity of 5 kW. Its goal is to supply the building with electricity on Saturdays. This way, locally produced electricity ensures the building’s independence (Figure 6).

Figure 6.

Plan to install an H2 system at the School of Architecture of Pamplona. The system will be installed between the chillers’ auxiliary and prominent buildings, ensuring a safe space to study technology. The installation aims to supply electricity to the main buildings on Saturdays, ensuring temporary electrical independence.

5. Conclusions

Developing interface requirements for building integration with H2 systems is necessary. This article seeks to identify relevant information about building engineers’ and stakeholders’ requirements within the existing knowledge base. Based on the two sets of requirements and parameters, the goal is to propose tools to facilitate and guide the integration of H2 systems into buildings.

Integrating H2 into buildings presents a significant opportunity to reduce carbon footprints and enhance the sustainability of major energy consumers like buildings. Research in this field is advancing the adoption of hydrogen technologies in the building sector, supporting the transition to a more sustainable and resilient energy model. However, the analyses of building energy consumption and assessments of H2 system opportunities reveal a notable lack of published studies on its integration in this context. The absence of detailed regulatory frameworks generates uncertainty and confines H2 system implementations to pilot buildings, delaying widespread integration.

A flowchart and a variable matrix have been developed as supportive tools to architects, building engineers, mechanical engineers, and electrical engineers, to address and guide them into the challenge of integrating H2 systems in buildings. These resources are designed to be applied across different stages, from integrating single components to implementing a H2 system, from design to maintenance.

The first tool is a flowchart of recommended questions and verification steps. Based on an adaptation of Zhenjun et al.’s protocol, it is tailored to address the specific requirements of integrating H2 systems into buildings by establishing a systematic sequence of actions linked to building engineers or stakeholders. This flowchart follows the conventional design, calculation, and installation phases, guiding decision-making and strategic planning. The questions focus on implementing H2, system compatibility, and performance, proceeding to final evaluations that include measurements, reports, and surveys.

The second tool is a variable matrix that combines building engineering requirements with stakeholder needs. This matrix evaluates and contrasts essential concepts, addressing design, construction, and maintenance considerations, as well as integration, performance, economic factors, and safety. The resulting framework guides technical considerations tailored to both groups’ priorities.

In conclusion, the proposed flowchart and variable matrix offer a foundational approach to integrating H2 systems into buildings. However, further maintenance, cost, and safety research are essential, as these aspects cannot be fully addressed without a regulatory framework supporting implementation beyond pilot projects. Given the innovative nature of H2 technology, collaboration between regulatory bodies and building owners is critical to encouraging its adoption and promoting a more sustainable future in the building sector.

Author Contributions

Methodology, S.D.-O. and C.M.-G.; Investigation, S.D.-O.; Data curation, C.M.-G. and A.Z.-R.; Writing—original draft, S.D.-O.; Writing—review & editing, C.M.-G. and A.Z.-R.; Objective determination, Supervision, M.A.; Project administration, C.M.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

PhD fellowship by Cátedra Fundación Saltoki received by Sara Dorregaray-Oyaregui.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ATEX | Equipment for potentially explosive atmospheres |

| CHHP | Combined heat, hydrogen, and power |

| CHP | Combined heat and power |

| CO2 | Carbon Dioxide |

| DDPG | Deep Deterministic Policy Gradient |

| FC | Fuel Cell |

| GBRS/GNRS | Green building/neighborhood rating systems |

| GHG | Greenhouse gas |

| H2 | Hydrogen |

| IEA | International Energy Agency |

| kW | Kilowatts |

| MCDMP | Multi-Criteria Decision-Making Problems |

| PEMFC | Proton-exchange membrane fuel cells |

| PV | Photovoltaic |

| t | Tone |

Appendix A

Appendix A.1

Table A1.

The search results were filtered by theoretical articles, where the main focus of the studies is highlighted according to the three viability types.

Table A1.

The search results were filtered by theoretical articles, where the main focus of the studies is highlighted according to the three viability types.

| Reference | Technology | Data/Method | Design | Construction | Maintenance |

|---|---|---|---|---|---|

| Holappa, 2020 [44] | Carbon capture and storage (CCS) | assessed levels achievable | Materials | - | |

| Zhu et al., 2020 [35] | - | nine different criteria | Infrastructure | Location | - |

| Desportes et al., 2021 [31] | PV, battery and H2 batteries | DDPG αep Algorithm to Learn the Policy | Performance | - | - |

| AlHashmi et al., 2021 [41] | Battery and H2 storage | TOPSIS method | Energy economy | - | |

| Han et al., 2009 [33] | FCs | combined heat and power (CHP) and combined heat, hydrogen, and power (CHHP) | Efficiency | - | - |

| Boretti 2024 [22] | Renewables | GHG | Integration | - | |

| Li et al., 2021 [36] | Combined cooling, heat and power (CCHP) system | life cycle cost | Work mode | Cost comparison | |

| Zhang et al., 2022 [34] | Biomass and public grid | polygeneration system | Work mode | - | - |

| Madurai Elavarasan et al., 2022 [32] | Renewables | digitalization | Strategies | - | |

| Sung et al., 2011 [66] | PV and FCs | integrated energy-saving system | Integration | Location | - |

| Apostoleris et al., 2021 [67] | Application-oriented concentrator PV | CPV “Toolbox” | PV tracking | - | - |

| Zhang et al., 2022 [37] | PV, wind energy | green building/neighborhood rating systems (GBRSs/GNRS) | Energy storage | ||

| Cherrad, 2019 [68] | Gas-cooled reactors | adsorbed mass of hydrogen, Bernuilli and flow loss | Work mode |

Appendix A.2

Table A2.

The search results were filtered by modeling, with the corresponding viability type studied.

Table A2.

The search results were filtered by modeling, with the corresponding viability type studied.

| Reference | Technology | Program (s) | Design | Construction | Maintenance |

|---|---|---|---|---|---|

| Murray et al., 2018 [38] | Battery, thermal storage and H2 storage | CESAR (no info at the article) | Work mode | Equipment, storage | |

| Marino et al., 2013 [45] | PV, wind power, electrolyzer and FCs | POVSOL https://valentin-software.com/produkte/pvsol-premium/ (accessed on 3 June 2020). | Work mode, efficiency | Economic cost | |

| Hedström et al., 2004 [40] | FC system, PV, FC array, electrolyzer, biogas burner, and storage tank | MATLAB Simulink | Equipment and location | Fuel cost | |

| Marino et al., 2012 [39] | PV, H2 storage and FCs | POVSOL Expert, Valentine Energy Software, Berlin, 2012 | Equipment | Sustainability and economic cost | |

| Kuwahara et al., 2022 [46] | Geothermal and solar | BEST Building Energy Simulation Tool (BEST). Available online: https://www.ibec.or.jp/best/ (accessed on 3 June 2020). | Equipment | ||

| Roberts et al., 2017 [53] | Pumped H2 storage | HOMER Computer software. Vers. Legacy. N.p., n.d. https://www.homerenergy.com/ (accessed on 3 June 2020). | Work mode | Economic cost | |

| Bartolucci et al., 2021 [50] | PV, proton exchange membrane (PEM), electrolyzer, and heat pump | MILP (Mixed Integer Linear Programming) | Equipment | Efficiency | |

| Joshua et al., 2024 [69] | PV, electrolyzer | MATLAB Simulink | Work mode | Scalability | |

| Dong et al., 2022 [43] | PV, solar thermal collectors, wind power, electrolyzer, tank, FC CHP, absorption chiller | ILOG CPLEX MATLAB | Hydrogen cost | ||

| Fan Hong et al., 2023 [70] | PV, wind, battery, and FCs | MATLAB (no info at the article) | Work mode | ||

| Calise et al., 2017 [42] | FCs, PV thermal collector, electrolyzer, and single-stage lithium bromide (LiBr/ H2O) | TRNSYS Solar energy laboratory, TRNSYS. A transient system simulation program University of Wisconsin, Madison (2006) | Equipment | Pay-back | |

| He et al., 2021 [49] | FCs | TRNSYS 18 and Python | Work mode | - | FC degradation |

| Pedamallu et al., 2016 [71] | PV, wind power, batteries | BUENAS (Bottom-Up Energy Analysis System) | Equipment | ||

| Lamagna et al., 2021 [52] | PV and storage | MATLAB ConfigDym built by Sylfen | Integration | Economic cost | |

| He et al., 2021 [48] | PV, H2 vehicles, H2 stations and H2 pipelines | TRNSYS 18 | Management | ||

| Liu et al., 2022 [51] | Energy communities integrated with H2 vehicles and battery vehicles | TRNSYS 18 | Work mode |

Appendix A.3

Table A3.

Pilot site classification of the filtered search with the articles’ topic.

Table A3.

Pilot site classification of the filtered search with the articles’ topic.

| Reference | Technology | Location | Design | Construction | Maintenance |

|---|---|---|---|---|---|

| Hedström et al., 2004 [40] | FC, PV, electrolyzer, H2 storage, biogas, heat exchangers and accumulator tank | GlashusETT, Stockholm Sweden | Equipment and location | Fuel cost | |

| Marino et al., 2012 [39] | PV, H2 storage and FCs | ARPACAL Reggio Calabria | Equipment | Sustainability and economic cost | |

| Marino et al., 2013 [45] | PV, wind power, electrolyzer, and FCs | ARPACAL Reggio Calabria | Work mode, efficiency | Economic cost | |

| Masi et al., 2024 [29] | PV and FCs | Benevento | Equipment | ||

| Kuwahara et al., 2022 [46] | Geothermal and solar for heating and air conditioningf | Ibaraki Prefecture, Japan | Equipment | ||

| Aki et al., 2012 [54] | FCs and accumulator tank | Osaka | System | Equipment | |

| Roberts et al., 2017 [53] | Pumped H2 storage | Lake Sammamish, WA, | Work mode | Economic cost | |

| He et al., 2021 [49] | FCs, H2 cars. | House in San Francisco | Work mode | FC degradation | |

| Widera, 2019 [23] | Wind power and electrolyzer | Utsira and Orkney archipelago | Equipment and location | Technical issues | |

| Lamagna et al., 2021 [52] | PV and storage | Procida Naples | Integration | Economic cost |

References

- European Commission. Communication from the Commission to the European Parliament, The Council, the European Economic and Social Committee and the Committee of the Regions A Renovation Wave for Europe-Greening Our Buildings, Creating Jobs, Improving Lives. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A52012DC0673 (accessed on 11 October 2024).

- Unfccc, Adoption of the Paris Agreement. 2016. Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 11 October 2024).

- European Commission. 2020. Available online: https://energy.ec.europa.eu/system/files/2020-07/hydrogen_strategy_0.pdf (accessed on 11 October 2024).

- Ibn-Mohammed, T.; Greenough, R.; Taylor, S.; Ozawa-Meida, L.; Acquaye, A. A decision support framework for evaluation of environmentally and economically optimal retrofit of non-domestic buildings. In Sustainability in Energy and Buildings. Smart Innovation, Systems and Technologies; Hakansson, A., Höjer, M., Howlett, R., Jain, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; De Masi, R.F.; De’Rossi, F.; Vanoli, G.P. Energy retrofit of an educational building in the ancient center of Benevento. Feasibility study of energy savings and respect of the historical value. Energy Build. 2015, 95, 172–183. [Google Scholar] [CrossRef]

- Karmellos, M.; Kiprakis, A.; Mavrotas, G. A multi-objective approach for optimal prioritization of energy efficiency measures in buildings: Model, software and case studies. Appl. Energy 2015, 139, 131–150. [Google Scholar] [CrossRef]

- Roberti, F.; Exner, D.; Troi, A. Energy consumption and indoor comfort in historic refurbished and non-refurbished buildings in south tyrol: An open database. In Smart and Sustainable Planning for Cities and Regions. SSPCR 2017. Green Energy and Technology; Bisello, A., Vettorato, D., Laconte, P., Costa, S., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Pombo, O.; Rivela, B.; Neila, J. The challenge of sustainable building renovation: Assessment of current criteria and future outlook. J. Clean. Prod. 2016, 123, 88–100. [Google Scholar] [CrossRef]

- Si, J.; Marjanovic-Halburd, L.; Nasiri, F.; Bell, S. Assessment of building-integrated green technologies: A review and case study on applications of Multi-Criteria Decision Making (MCDM) method. Sustain. Cities Soc. 2016, 27, 106–115. [Google Scholar] [CrossRef]

- Ma, Z.; Cooper, P.; Daly, D.; Ledo, L. Existing building retrofits: Methodology and state-of-the-art. Energy Build. 2012, 55, 889–902. [Google Scholar] [CrossRef]

- UN Environment. Global Environment GEO-6 Healthy Planet, Healthy People; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Economidou, M.; Todeschi, V.; Bertoldi, P.; D’Agostino, D.; Zangheri, P.; Castellazzi, L. Review of 50 years of EU energy efficiency policies for buildings. Energy Build. 2020, 225, 110322. [Google Scholar] [CrossRef]

- Toosi, H.A.; Lavagna, M.; Leonforte, F.; Del Pero, C.; Aste, N. Life Cycle Sustainability Assessment in Building Energy Retrofitting; A Review. Sustain. Cities Soc. 2020, 60, 102248. [Google Scholar] [CrossRef]

- Yang, L.; Yan, H.; Lam, J.C. Thermal comfort and building energy consumption implications–A review. Appl. Energy 2014, 115, 164–173. [Google Scholar] [CrossRef]

- Zuazua-Ros, A.; Martín-Gómez, C.; Bermejo-Busto, J.; Vidaurre-Arbizu, M.; Baquero, E.; Miranda, R. Thermal energy performance in working-spaces from biomorphic models: The tuna case in an office building. Build. Simul. 2016, 9, 347–357. [Google Scholar] [CrossRef]

- Sicignano, E.; Di Ruocco, G.; Melella, R. Mitigation strategies for reduction of embodied energy and carbon, in the construction systems of contemporary quality architecture. Sustainability 2019, 11, 3806. [Google Scholar] [CrossRef]

- Sugar, L.; Kennedy, C. A low carbon infrastructure plan for Toronto, Canada. Can. J. Civ. Eng. 2013, 40, 86–96. [Google Scholar] [CrossRef]

- Neto, L.S.A.; de Souza, L.R.; Muniz, P.B.V.; Câmara, J.C.C. Use of Hydrogen as Energy Source: A Literature Review. J. Bioeng. Technol. Health 2022, 5, 60–64. [Google Scholar] [CrossRef]

- Akyüz, E.S.; Telli, E.; Farsak, M. Hydrogen generation electrolyzers: Paving the way for sustainable energy. Int. J. Hydrogen Energy 2024, 81, 1338–1362. [Google Scholar] [CrossRef]

- Hart, D.; Howes, J.; Lehner, F.; Dodds, P.; Hughes, N.; Fais, B. Scenarios for Deployment of Hydrogen in Contributing to Meeting Carbon Budgets and the 2050 Target; E4tech: London, UK, 2015. [Google Scholar]

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrogen Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Boretti, A.; Pollet, B.G. Hydrogen economy: Paving the path to a sustainable, low-carbon future. Int. J. Hydrogen Energy 2024, 93, 307–319. [Google Scholar] [CrossRef]

- Widera, B. Renewable hydrogen as an energy storage solution. E3S Web Conf. 2019, 116, 00097. [Google Scholar] [CrossRef]

- Turkdogan, S. Design and optimization of a solely renewable based hybrid energy system for residential electrical load and fuel cell electric vehicle. Eng. Sci. Technol. Int. J. 2021, 24, 397–404. [Google Scholar] [CrossRef]

- IEA. The Future of Hydrogen, The Future of Hydrogen; OECD: Paris, France, 2019. [Google Scholar] [CrossRef]

- Dorregaray-Oyaregui, S.; Martín-Gómez, C.; Aguado, M. Installation of fuel cells in building in use: Technical, regulatory, and economic feasibility. Energy Convers. Manag. 2024, 22, 100536. [Google Scholar] [CrossRef]

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef]

- Repsol. Repsol will Invest €2.549 Billion to Boost Renewable Hydrogen; Repsol: Madrid, Spain, 2021; pp. 1–6. [Google Scholar]

- De Masi, R.F.; Festa, V.; Penchini, D.; Ruggiero, S.; Tariello, F.; Vanoli, G.P.; Zinno, A. State of art of hydrogen utilization for building sector and set-up with preliminary experimental results of 1 kWel solid oxide fuel cell installed in a nearly zero energy house. Energy 2024, 302, 131810. [Google Scholar] [CrossRef]

- European Commission. A Hydrogen Strategy for a Climate Neutral Europe The Path Towards a European Hydrogen Eco-System Step by Step; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Desportes, L.; Fijalkow, I.; Andry, P. Deep Reinforcement Learning for Hybrid Energy Storage Systems: Balancing Lead and Hydrogen Storage. Energies 2021, 14, 4706. [Google Scholar] [CrossRef]

- Elavarasan, R.M.; Pugazhendhi, R.; Irfan, M.; Mihet-Popa, L.; Khan, I.A.; Campana, P.E. State-of-the-art sustainable approaches for deeper decarbonization in Europe–An endowment to climate neutral vision. Renew. Sustain. Energy Rev. 2022, 159, 112204. [Google Scholar] [CrossRef]

- Han, J.; Elgowainy, A.; Wang, M. Fuel-Cycle Analysis of Fuel Cells for Combined Heat, Hydrogen, and Power Generation. In Volume 6: Emerging Technologies: Alternative Energy Systems; Energy Systems: Analysis, Thermodynamics and Sustainability; ASMEDC: Lake Buena Vista, FL, USA, 2009; pp. 367–375. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, R.; Zeng, R.; Zhu, R.; Kong, X.; He, Y.; Li, H. Integrated performance optimization of a biomass-based hybrid hydrogen/thermal energy storage system for building and hydrogen vehicles. Renew. Energy 2022, 187, 801–818. [Google Scholar] [CrossRef]

- Zhu, L.; Hu, L.; Yüksel, S.; Dinçer, H.; Karakuş, H.; Ubay, G.G. Analysis of Strategic Directions in Sustainable Hydrogen Investment Decisions. Sustainability 2020, 12, 4581. [Google Scholar] [CrossRef]

- Li, N.; Zhao, X.; Shi, X.; Pei, Z.; Mu, H.; Taghizadeh-Hesary, F. Integrated energy systems with CCHP and hydrogen supply: A new outlet for curtailed wind power. Appl. Energy 2021, 303, 117619. [Google Scholar] [CrossRef]

- Zhang, S.; Ocłoń, P.; Klemeš, J.J.; Michorczyk, P.; Pielichowska, K.; Pielichowski, K. Renewable energy systems for building heating, cooling and electricity production with thermal energy storage. Renew. Sustain. Energy Rev. 2022, 165, 112560. [Google Scholar] [CrossRef]

- Murray, P.; Orehounig, K.; Grosspietsch, D.; Carmeliet, J. A comparison of storage systems in neighbourhood decentralized energy system applications from 2015 to 2050. Appl. Energy 2018, 231, 1285–1306. [Google Scholar] [CrossRef]

- Marino, C.; Nucara, A.; Pietrafesa, M.; Pudano, A.; Tripodi, M. Energetic, economic and environmental sustainability of integrated techniques for energy production in buildings using hydrogen as storage system. Renew. Energy Power Qual. 2012, 1, 1240–1244. [Google Scholar] [CrossRef]

- Hedström, L.; Wallmark, C.; Alvfors, P.; Rissanen, M.; Stridh, B.; Ekman, J. Description and modelling of the solar–hydrogen–biogas-fuel cell system in GlashusEtt. J. Power Sources 2004, 131, 340–350. [Google Scholar] [CrossRef]

- AlHashmi, M.; Chhipi-Shrestha, G.; Nahiduzzaman, K.M.; Hewage, K.; Sadiq, R. Framework for Developing a Low-Carbon Energy Demand in Residential Buildings Using Community-Government Partnership: An Application in Saudi Arabia. Energies 2021, 14, 4954. [Google Scholar] [CrossRef]

- Calise, F.; Figaj, R.D.; Massarotti, N.; Mauro, A.; Vanoli, L. Polygeneration system based on PEMFC, CPVT and electrolyzer: Dynamic simulation and energetic and economic analysis. Appl. Energy 2017, 192, 530–542. [Google Scholar] [CrossRef]

- Dong, X.; Wu, J.; Xu, Z.; Liu, K.; Guan, X. Optimal coordination of hydrogen-based integrated energy systems with combination of hydrogen and water storage. Appl. Energy 2022, 308, 118274. [Google Scholar] [CrossRef]

- Holappa, L. A General Vision for Reduction of Energy Consumption and CO2 Emissions from the Steel Industry. Metals 2020, 10, 1117. [Google Scholar] [CrossRef]

- Marino, C.; Nucara, A.; Pietrafesa, M.; Pudano, A. An energy self-sufficient public building using integrated renewable sources and hydrogen storage. Energy 2013, 57, 95–105. [Google Scholar] [CrossRef]

- Kuwahara, R.; Kim, H.; Sato, H. Evaluation of Zero-Energy Building and Use of Renewable Energy in Renovated Buildings: A Case Study in Japan. Buildings 2022, 12, 561. [Google Scholar] [CrossRef]

- Starkov, S.O.; Lavrenkov, Y.N. Application of spiking neural networks for modeling the process of high-temperature hydrogen production in systems with gas-cooled reactors. Izv. Wysshikh Uchebnykh Zawedeniy Yad. Energ. 2019, 2019, 143–154. [Google Scholar] [CrossRef]

- He, Y.; Zhou, Y.; Yuan, J.; Liu, Z.; Wang, Z.; Zhang, G. Transformation towards a carbon-neutral residential community with hydrogen economy and advanced energy management strategies. Energy Convers. Manag. 2021, 249, 114834. [Google Scholar] [CrossRef]

- He, Y.; Zhou, Y.; Wang, Z.; Liu, J.; Liu, Z.; Zhang, G. Quantification on fuel cell degradation and techno-economic analysis of a hydrogen-based grid-interactive residential energy sharing network with fuel-cell-powered vehicles. Appl. Energy 2021, 303, 117444. [Google Scholar] [CrossRef]

- Bartolucci, L.; Cordiner, S.; Mulone, V.; Pasquale, S. Hydrogen based Multi Energy Systems: Assessment of the marginal utility of increasing hydrogen penetration on system performances. Int. J. Hydrogen Energy 2021, 46, 38588–38602. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Y.; Yang, H.; Wu, H. Uncertainty energy planning of net-zero energy communities with peer-to-peer energy trading and green vehicle storage considering climate changes by 2050 with machine learning methods. Appl. Energy 2022, 321, 119394. [Google Scholar] [CrossRef]

- Lamagna, M.; Nastasi, B.; Groppi, D.; Rozain, C.; Manfren, M.; Garcia, D.A. Techno-economic assessment of reversible Solid Oxide Cell integration to renewable energy systems at building and district scale. Energy Convers. Manag. 2021, 35, 113993. [Google Scholar] [CrossRef]

- Roberts, T.; Cai, H. Hybrid Renewable Energy System Model Analysis: Pumped Hydrogen Storage Compared to Battery-Bank Storage Systems. In AEI 2017; American Society of Civil Engineers: Reston, VA, USA, 2017; pp. 184–203. [Google Scholar] [CrossRef]

- Aki, H.; Taniguchi, Y.; Tamura, I.; Kegasa, A.; Hayakawa, H.; Ishikawa, Y.; Yamamoto, S.; Sugimoto, I. Fuel cells and energy networks of electricity, heat, and hydrogen: A demonstration in hydrogen-fueled apartments. Int. J. Hydrogen Energy 2012, 37, 1204–1213. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- F.H.A. Community EnergyScotland, Calvera, BIG HIT. 2020. Available online: https://www.bighit.eu/about (accessed on 14 June 2024).

- IEA. Key World Energy Statistics 2021, IEA. 2020. Available online: https://www.iea.org/reports/key-world-energy-statistics-2021 (accessed on 14 June 2024).

- Zheng, D.; Yu, L.; Wang, L.; Tao, J. A screening methodology for building multiple energy retrofit measures package considering economic and risk aspects. J. Clean. Prod. 2019, 208, 1587–1602. [Google Scholar] [CrossRef]

- Ricci, M.; Newsholme, G.; Bellaby, P.; Flynn, R. Hydrogen: Too dangerous to base our future upon? Inst. Chem. Eng. Symp. Ser. 2006, 2006, 42–60. [Google Scholar]

- Saffers, J.B.; Molkov, V.V. Hydrogen safety engineering framework and elementary design safety tools. Int. J. Hydrogen Energy 2014, 39, 6268–6285. [Google Scholar] [CrossRef]

- Mirza, N.R.; Degenkolbe, S.; Witt, W. Analysis of hydrogen incidents to support risk assessment. Int. J. Hydrogen Energy 2011, 36, 12068–12077. [Google Scholar] [CrossRef]

- Aceves, S.M.; Espinosa-Loza, F.; Petitpas, G.; Ross, T.O.; Switzer, V.A. Hydrogen safety training for laboratory researchers and technical personnel. Int. J. Hydrogen Energy 2012, 37, 17497–17501. [Google Scholar] [CrossRef]

- Najjar, Y.S.H. Hydrogen safety: The road toward green technology. Int. J. Hydrogen Energy 2013, 38, 10716–10728. [Google Scholar] [CrossRef]

- Tohir, M.Z.M.; Martín-Gómez, C. Electric vehicle fire risk assessment framework using Fault Tree Analysis. Open Res. Eur. 2023, 3, 178. [Google Scholar] [CrossRef]

- CIFP San Jorge. El Hidrógeno Verde, el Nuevo Combustible en la Capacitación de Especialistas en Energías Renovables en la FP Vasca. Available online: https://www.Fpsanturtzilh.Eus/2023/02/24/El-Hidrogeno-Verde-El-Nuevo-Combustible-En-La-Capacitacion-de-Especialistas-En-Energias-Renovables-En-La-Fp-Vasca/ (accessed on 18 July 2024).

- Sung, W.P.; Ou, W.S.; Chang, J.M.; Kuan, Y.D. Studies on an Integrated Energy-Saving System Combining Architectural Energy-Saving Features and Renewable Energy in Taiwan. Adv. Mat. Res. 2011, 250–253, 3271–3274. [Google Scholar] [CrossRef]

- Apostoleris, H.; Stefancich, M.; Chiesa, M. The CPV “Toolbox”: New Approaches to Maximizing Solar Resource Utilization with Application-Oriented Concentrator Photovoltaics. Energies 2021, 14, 795. [Google Scholar] [CrossRef]

- Cherrad, N. Pumping of hydrogen by free heating for buildings supply from a safe storage bed. Therm. Sci. Eng. Prog. 2019, 13, 100370. [Google Scholar] [CrossRef]

- Joshua, S.R.; Yeon, A.N.; Park, S.; Kwon, K. Solar–Hydrogen Storage System: Architecture and Integration Design of University Energy Management Systems. Appl. Sci. 2024, 14, 4376. [Google Scholar] [CrossRef]

- Fan, H.; Wang, L.; Xing, M.; Tian, S.; Yu, W. Coordinated Scheduling of Multiple Buildings with Electric-Hydrogen Complementary Considering Frequency Stability Constraints. J. Shanghai Jiao Tong Univ. 2023, 57, 1559–1570. [Google Scholar] [CrossRef]

- Pedamallu, L.R.T.; Singh, V.K.; Gomes, A.P.F. Quantitative Assessment of Advanced Energy Efficiency Retrofitting for Hospitals in India. In Proceedings of the ASME 2016 10th International Conference on Energy Sustainability, ES 2016, Collocated with the ASME 2016 Power Conference and the ASME 2016 14th International Conference on Fuel Cell Science, Engineering and Technology, Charlotte, NC, USA, 26–30 June 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).